Automatic tape winding technology based on multiple actions and application method

A multi-action, tape-winding technology, applied in the parts of the strapping machine, paper/cardboard containers, containers, etc., can solve the problems of chaotic processes, low degree of automation, and speed up the automation process of tape-winding process, so as to speed up the automation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with drawings and embodiments.

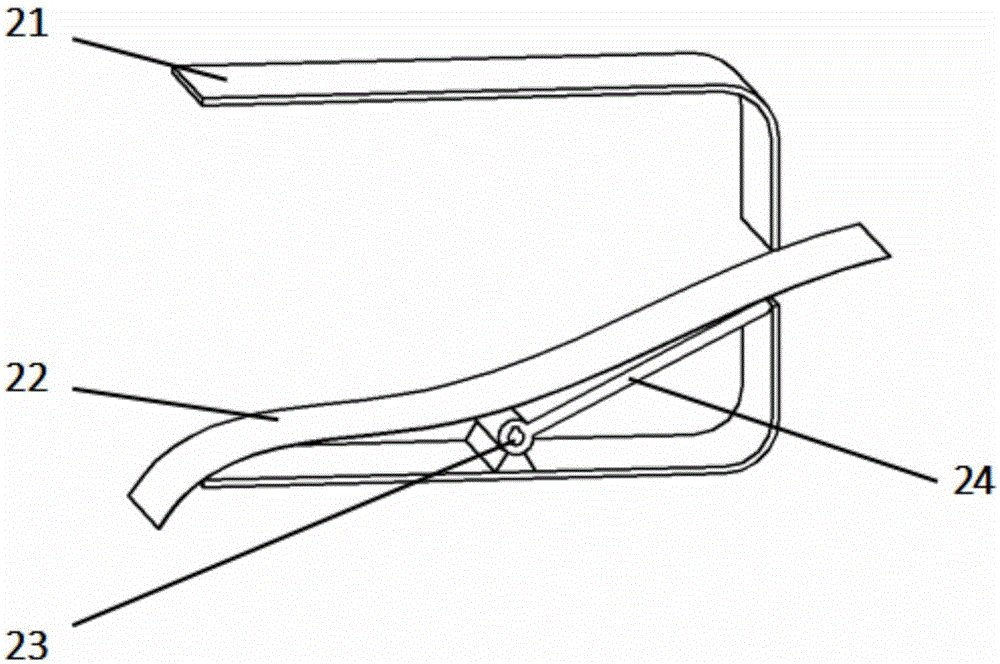

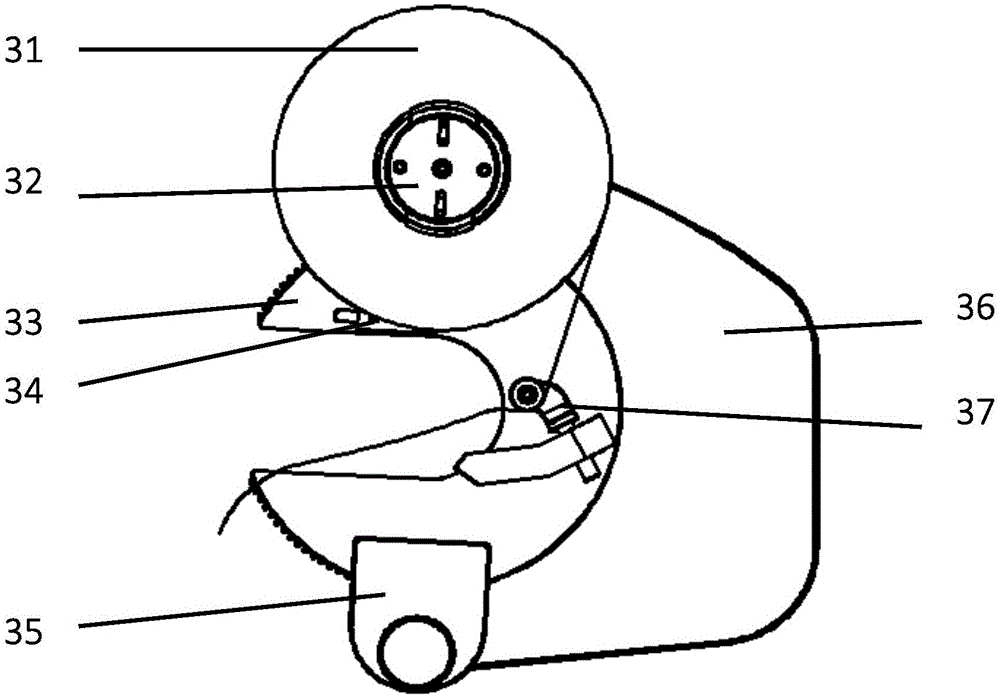

[0039] Such as Figure 1-4 As shown, based on the multi-action automatic tape winding process, the tape winding (tape wrapping, rubber wrapping) process is decomposed into four actions according to the automation feasibility during the multi-action, which are respectively the action of winding the wire, the action of sticking the tape, Winding action, cutting action.

[0040]The wire gathering action is an action of passing the messy and scattered wire bundles through the wire gathering mechanism to make the wire bundles more regular and orderly.

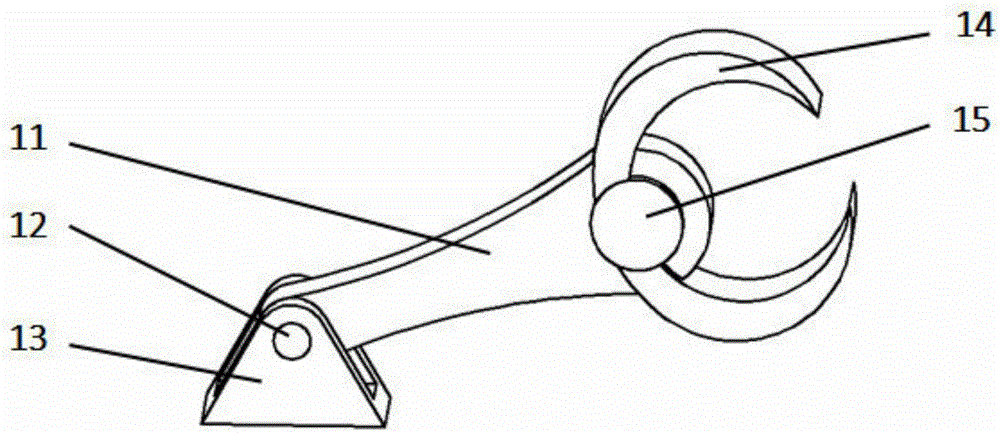

[0041] Such as figure 1 As shown, the winding mechanism includes a connecting rod 11, a connecting shaft 12, a winding fixing device 13, a winding device 14, and a winding power drive device 15; one end of the connecting rod 11 is fixed on the winding fixing device 13 through the connecting shaft 2 , and the connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com