Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Eliminate cavities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

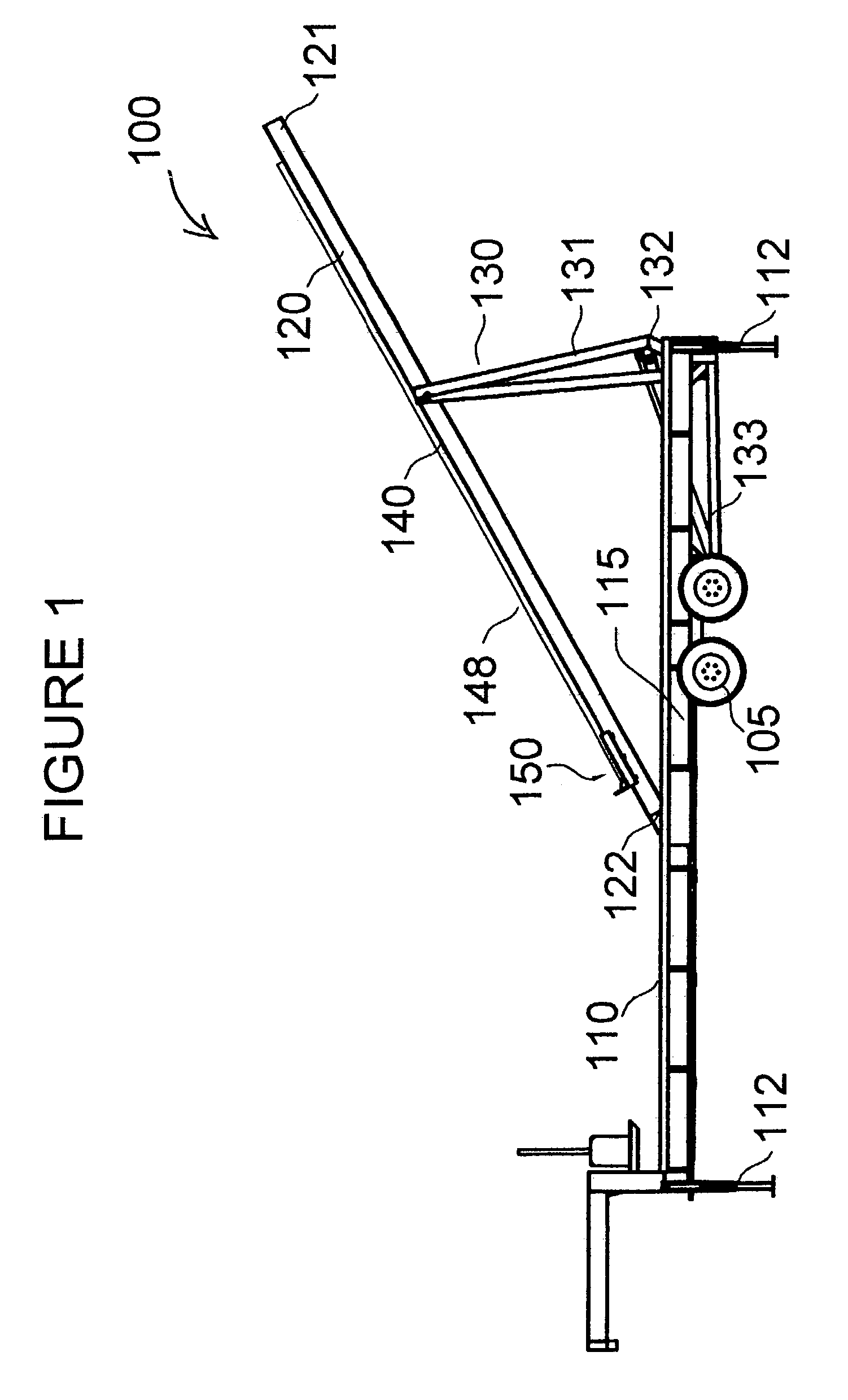

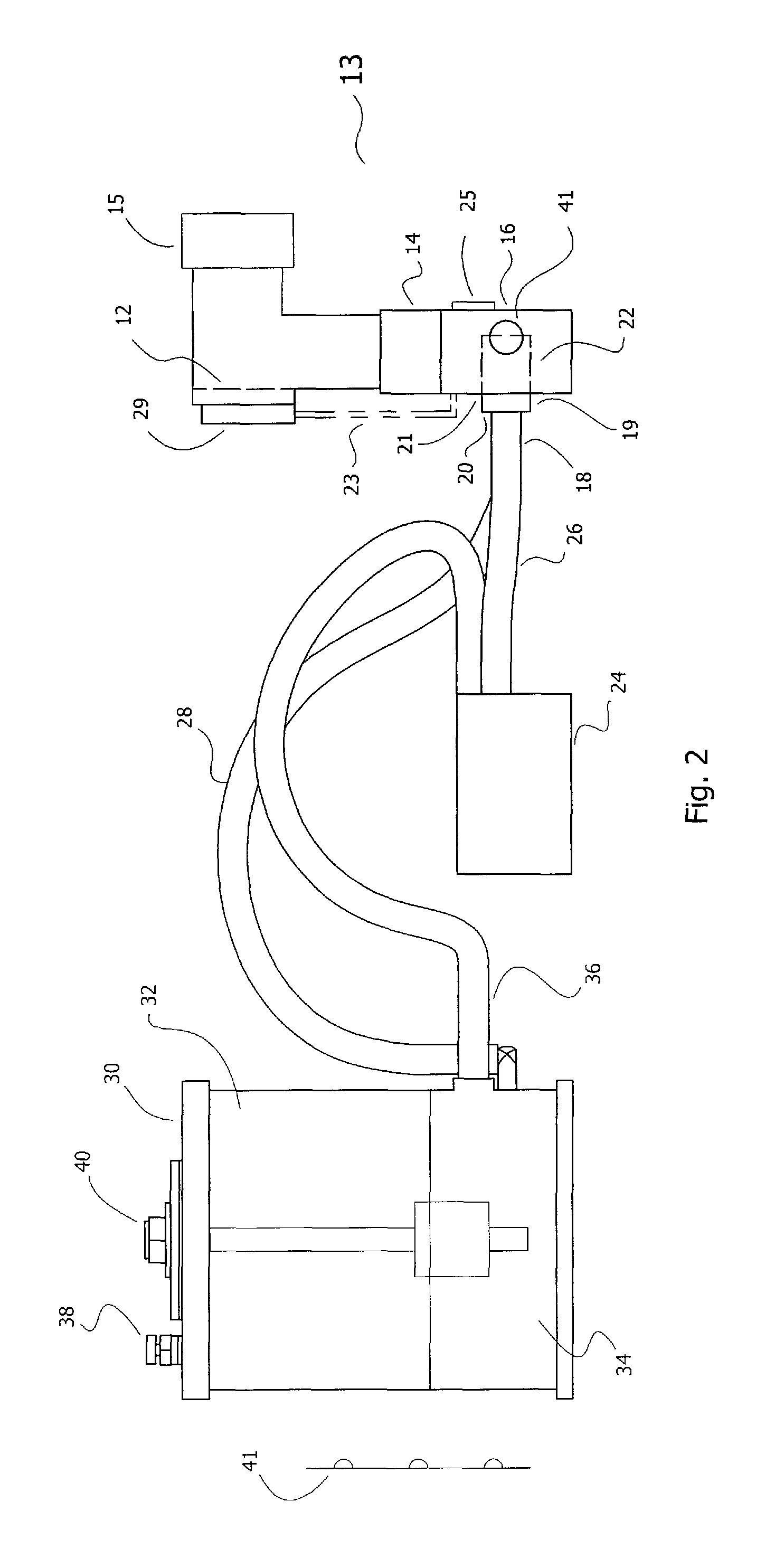

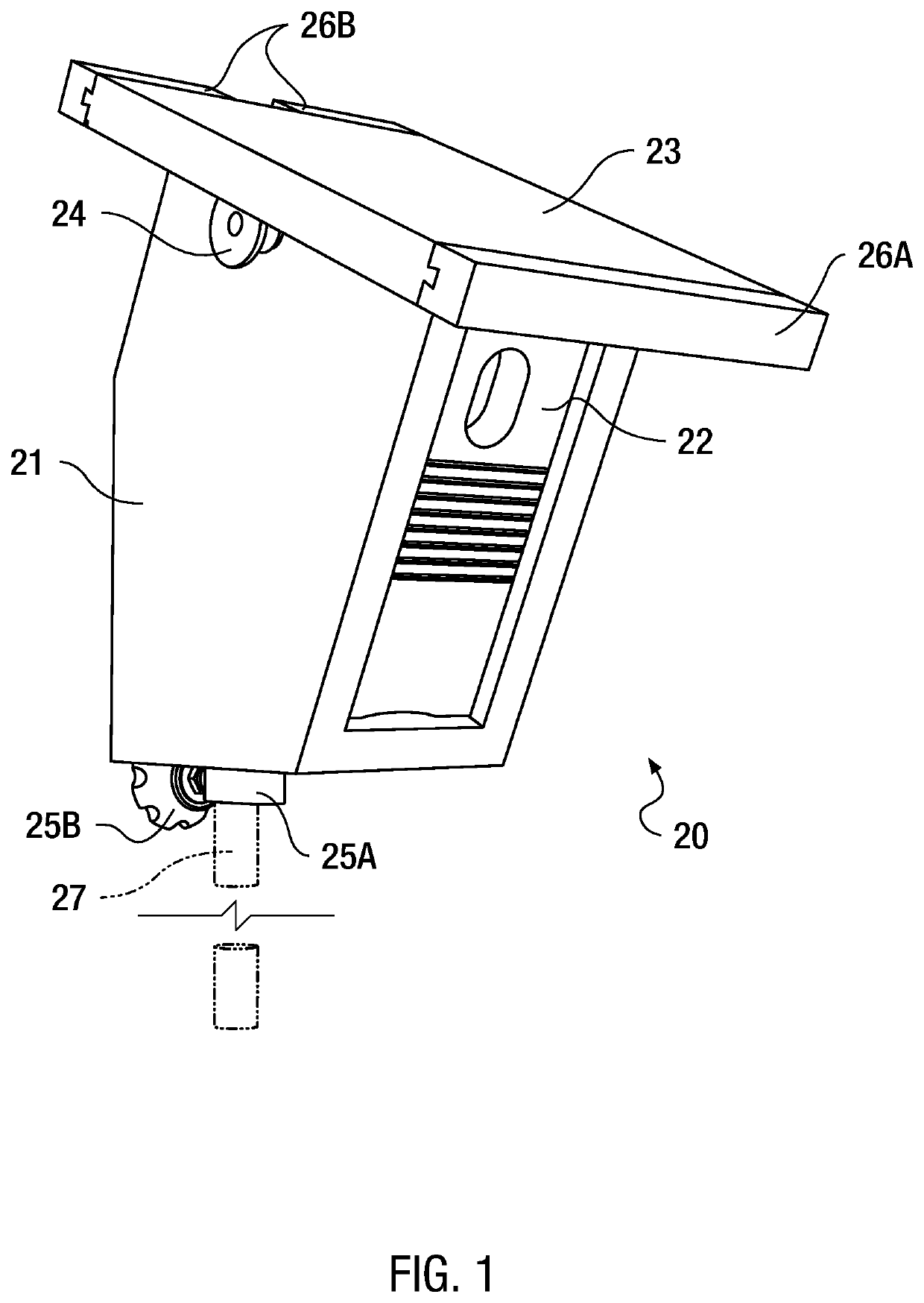

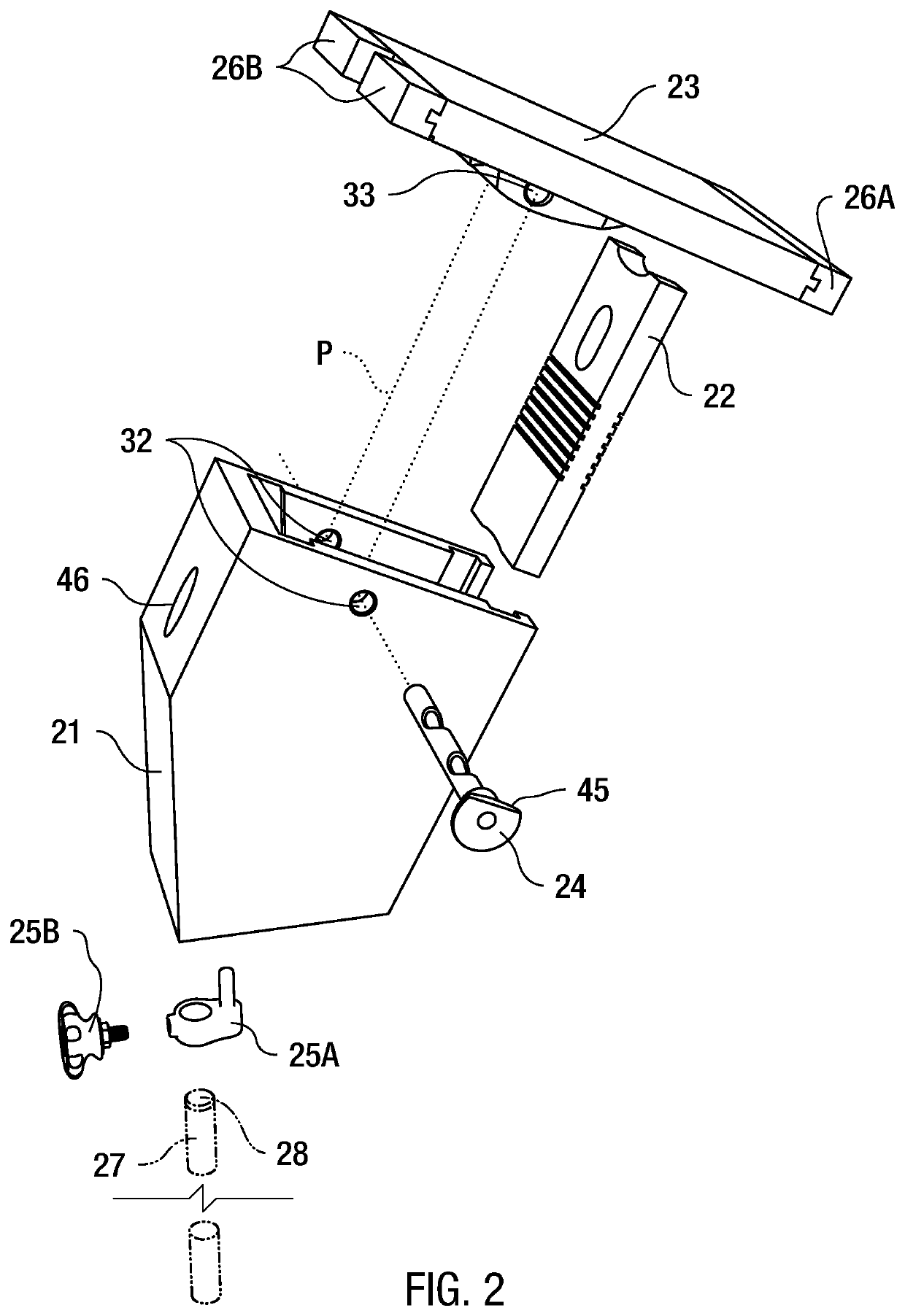

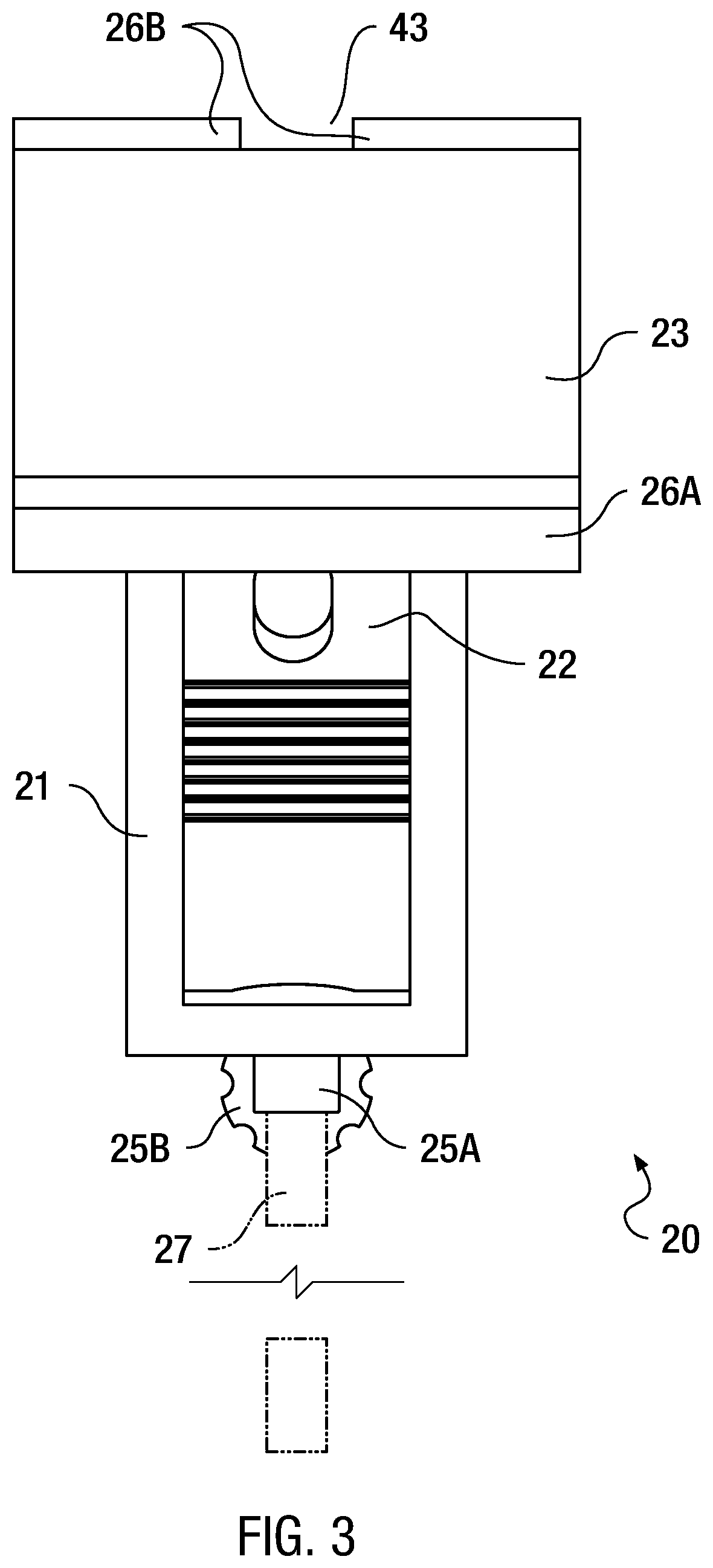

Pipe handling apparatus for presenting sections of pipe to a derrick work floor having a high-speed carriage assembly

ActiveUS7021880B2Assisted movementReduce frictionDrilling rodsLoading/unloadingEngineeringCantilever

A pipe handling apparatus for raising and lowering pipe to and from a raised derrick work floor. The apparatus comprises a longitudinally-extending base, with a longitudinally-extending cavity therein. An elongate, longitudinally-extending boom member is provided, which is adapted for raising out of and nestable positioning in such cavity. The boom member has a longitudinally-extending trough therein on an upperside surface thereof, adapted to receive at least one section of pipe. At least one arm member is coupled to the boom member for raising a proximal end of such boom member. A carriage member, slidably coupled to the boom member, is moveable longitudinally along the boom in the trough. The carriage member is adapted to engage and slidably transport one end of the pipe along the trough. Motive means are provided to permit powered movement of the carriage member along the boom.

Owner:FORUM US

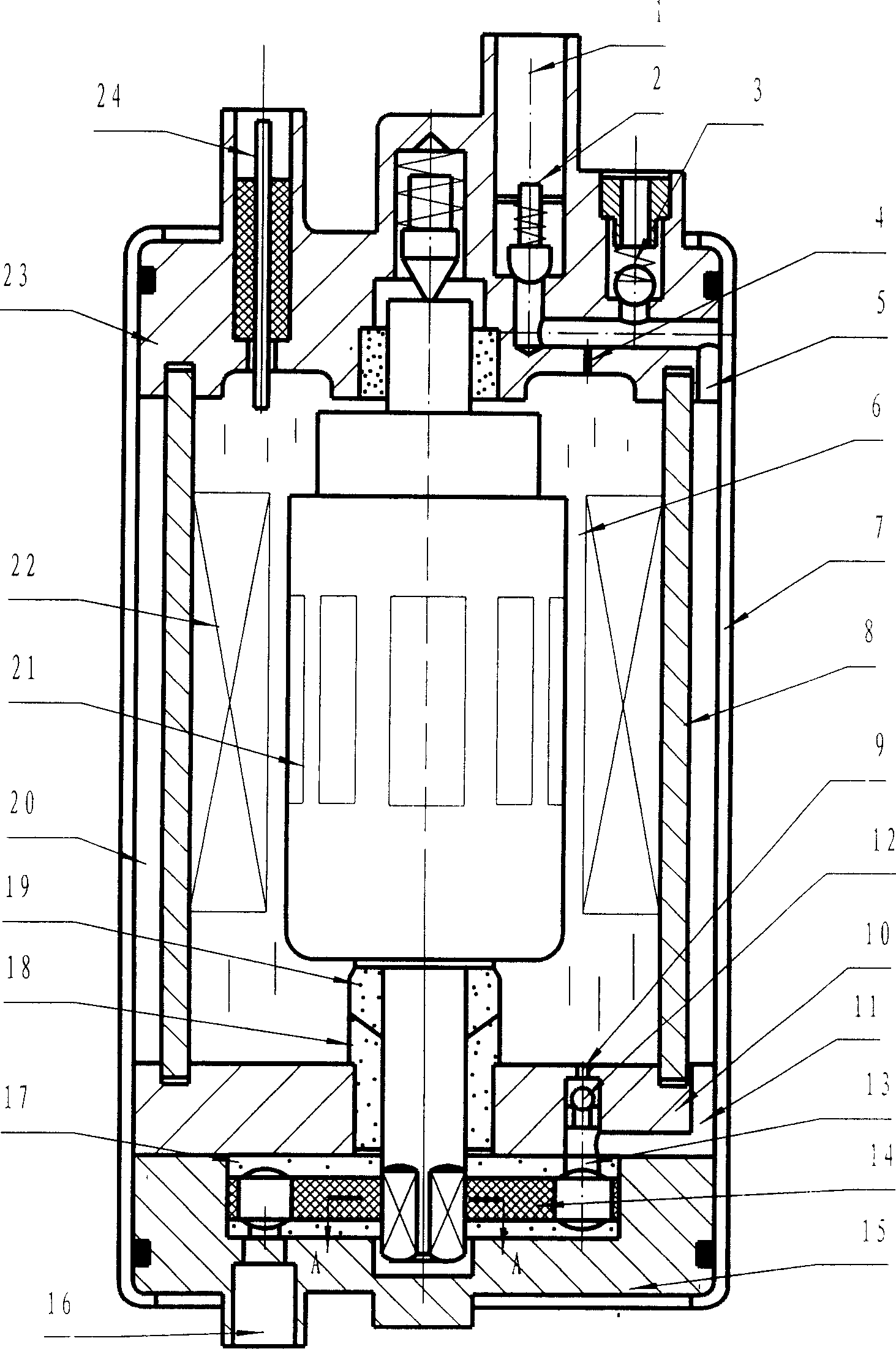

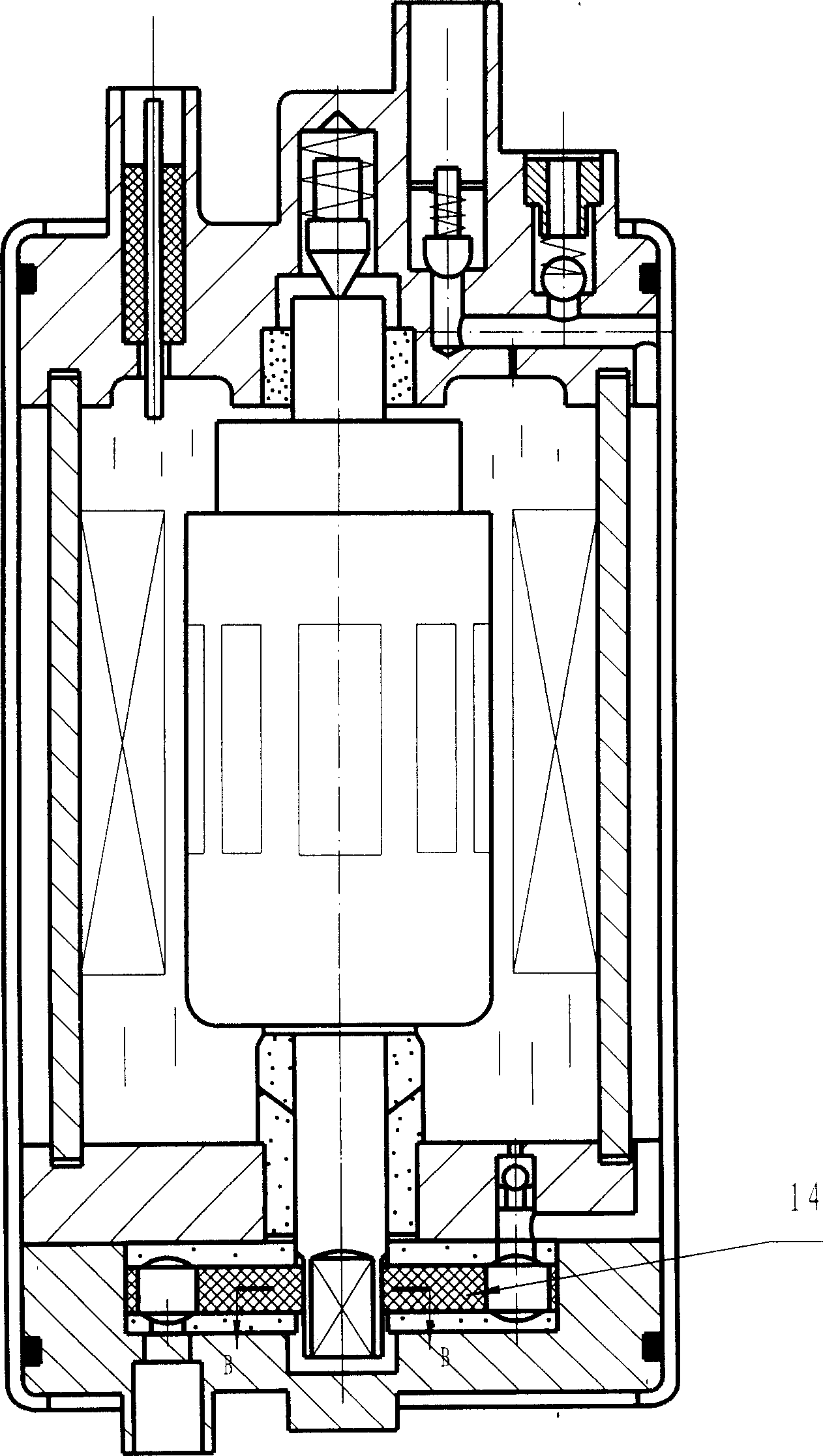

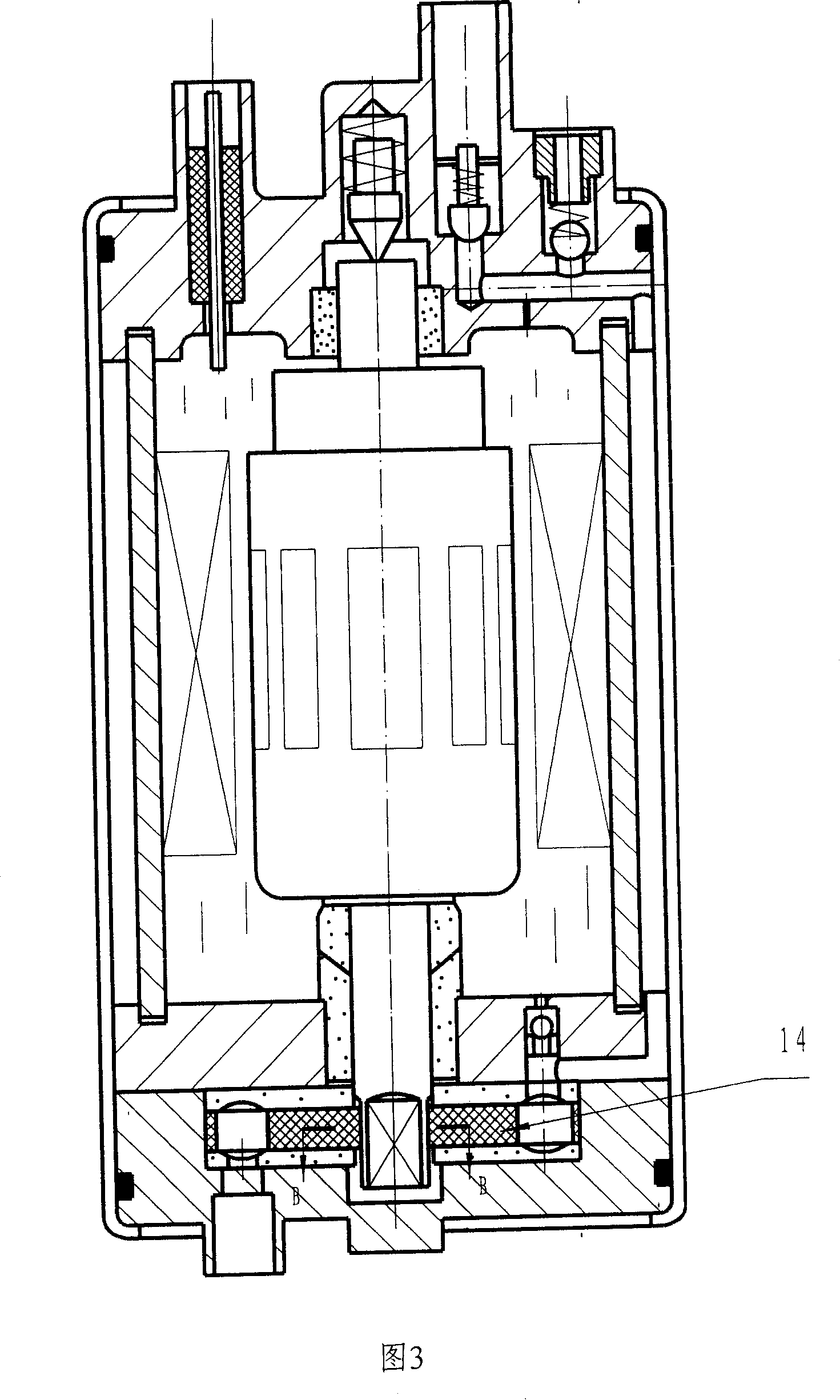

Electric fuel pump suitable for fuel containing alcohol

The electric fuel oil pump suitable for fuel containing alcohol has a shell, an inner casing inside the shell to constitute together with the shell one cavity serving as the main fuel oil conveying flow channel, and a motor set inside the inner casing and with gap among its parts serving as the secondary fuel oil conveying flow channel. While over 80 % of the fuel oil is conveyed through the main fuel oil conveying flow channel, the rest flows through the secondary fuel oil conveying flow channel to lubricate and clean the inside parts and cool the rotor and the stator, so as to raise the work efficiency of the motor. There are one non-return valve set at fuel inlet hole inside the secondary fuel oil conveying flow channel and one conic friction pair at the lower bearing on the end of the vane wheel to further raise the operation reliability and safety.

Owner:曹宝军 +1

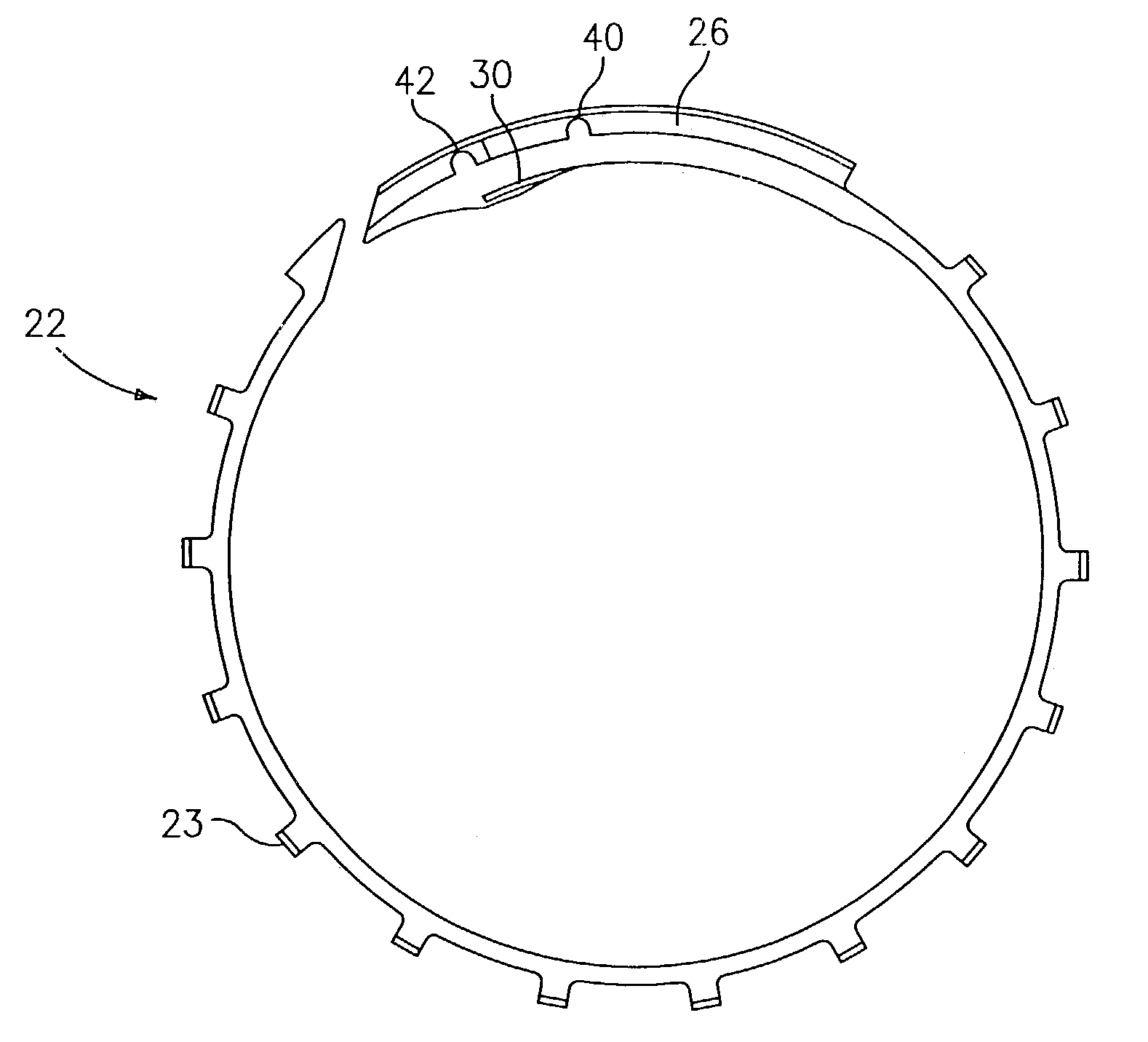

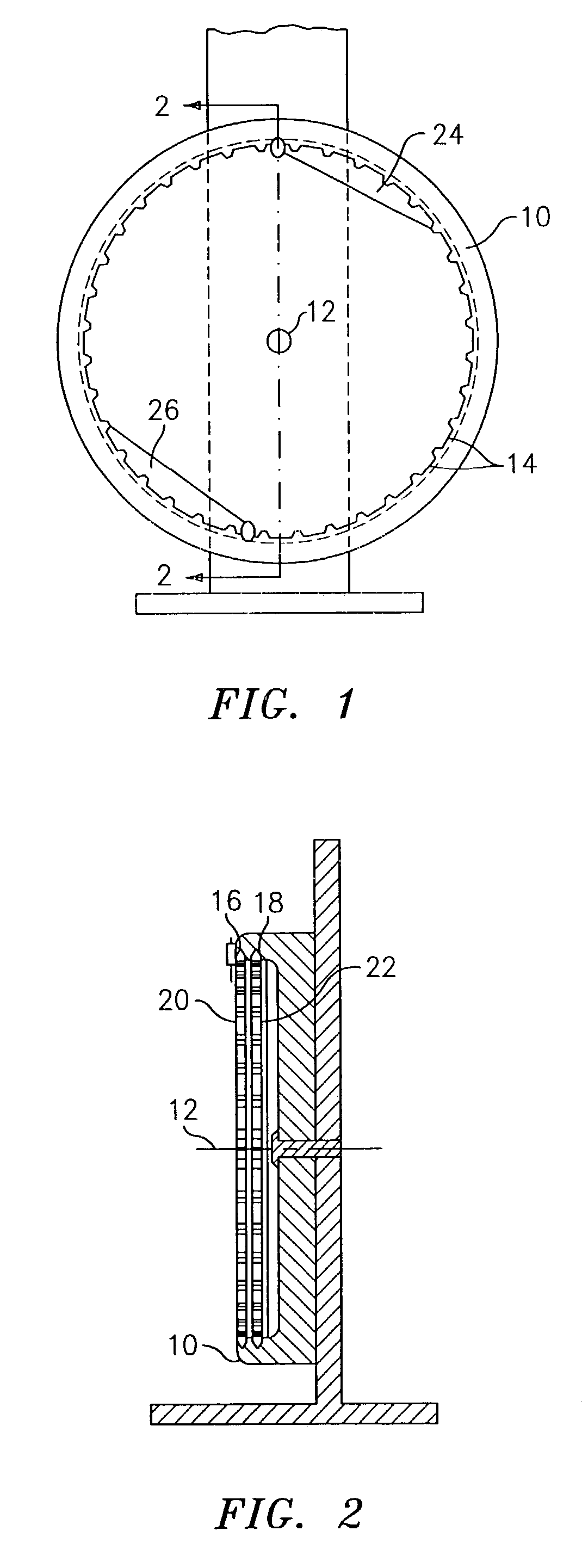

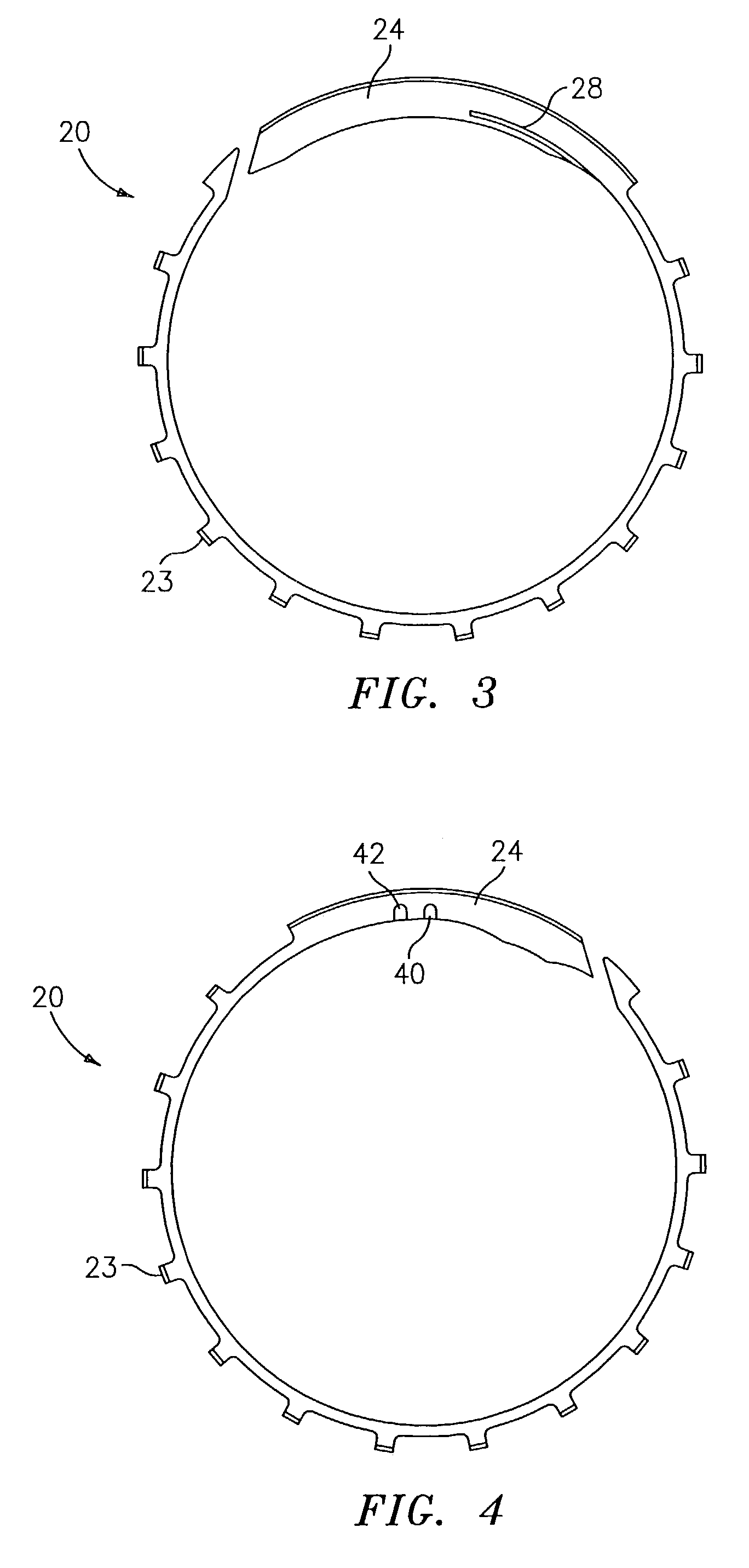

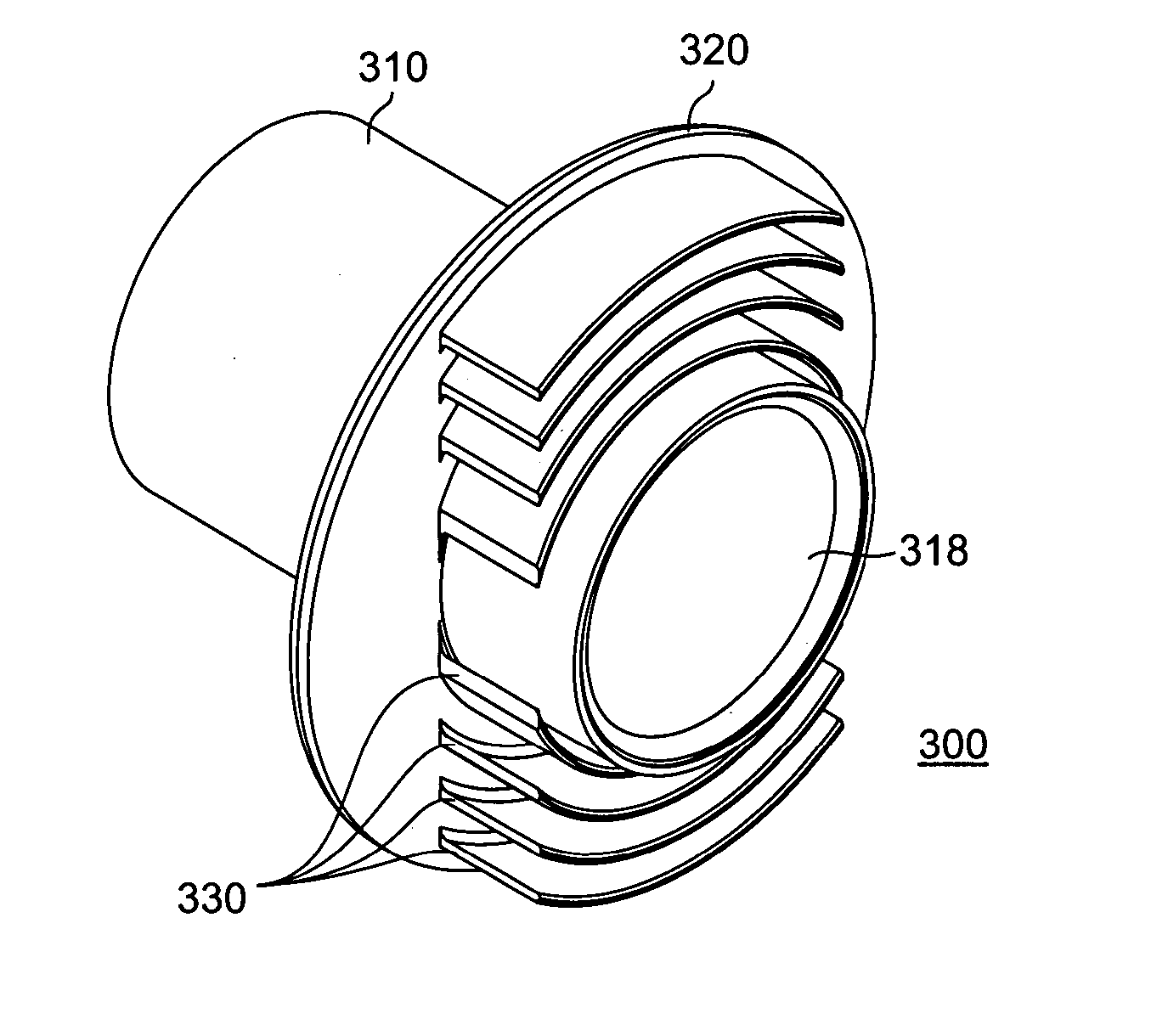

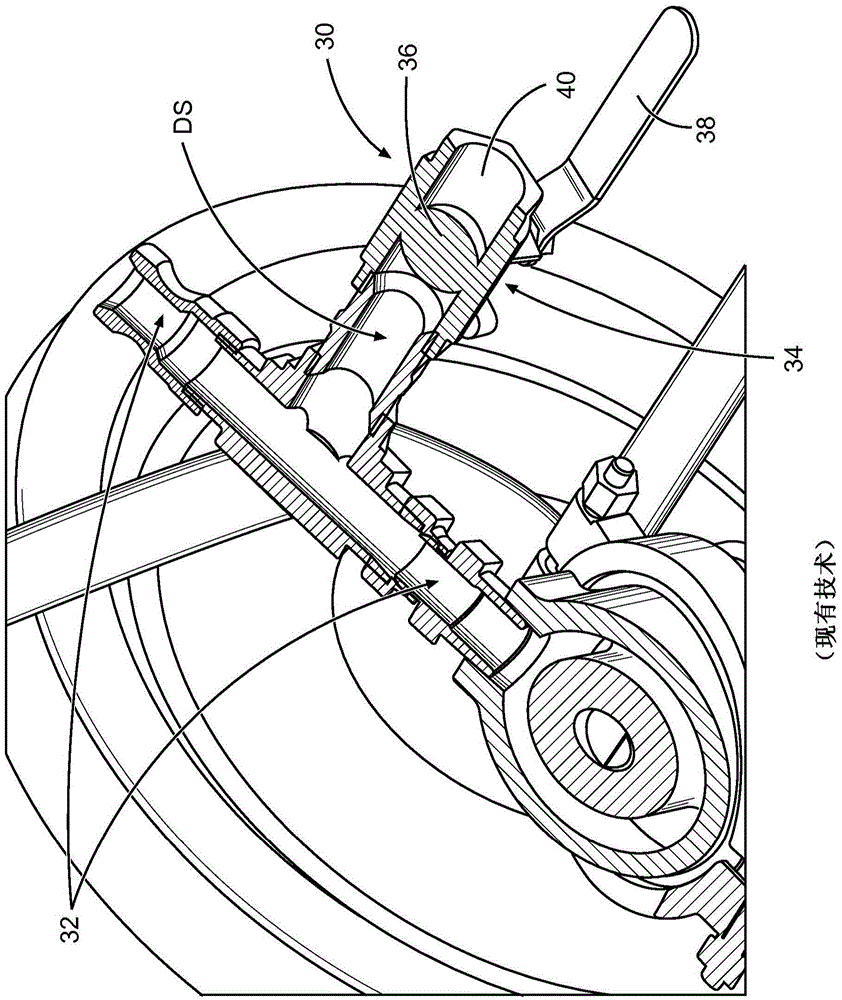

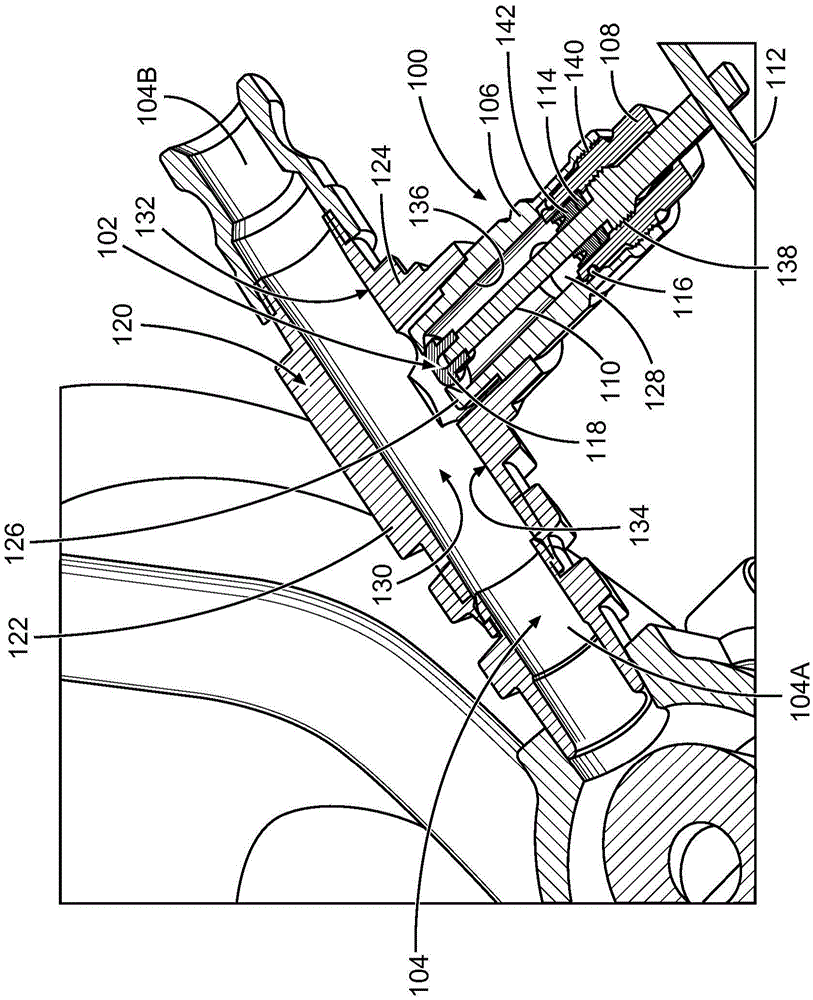

Rotor balancing system for turbomachinery

InactiveUS8122785B2Reduce the impactReduce impactInertia force compensationPropellersWindageTurbomachinery

The present invention relates to an improved rotor balancing system which allows for fine tune onsite adjustment for turbomachinery. The rotor balancing system comprises a rotor element having a row of locating slots and a device for reducing windage effects caused by the locating slots and protruding anti-rotation pins. In a preferred embodiment, the device for reducing windage effects comprises at least one balancing ring which partially or fully covers the locating slots and internal slots for engaging and disengaging that does not protrude outbound of the ring. Each balancing ring is preferably provided with two integrally formed anti-rotation members for engaging the locating slots. Each balancing ring is also preferably provided with a slot in a weighted portion of the ring for receiving a tool for positioning the balancing ring in a desired position. A method for positioning the balancing ring on a rotor element using the slot and the tool is also described herein.

Owner:RAYTHEON TECH CORP

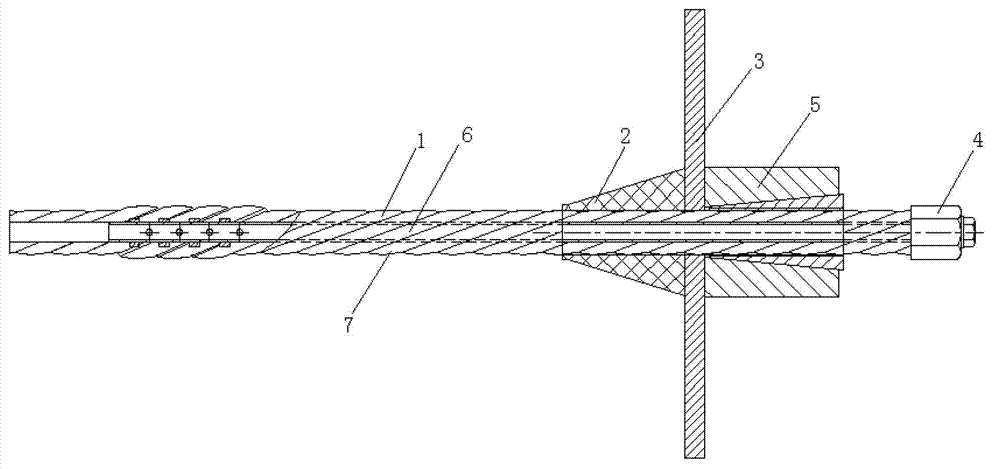

Pre-stress spiral rib hollow grouting anchor rope

The invention discloses a pre-stress spiral rib hollow grouting anchor rope which comprises an anchor rope body which stretches into a rock-soil drilling hole; the anchor rope body is formed by weaving and twisting a plurality of high-strength spiral rib pres-stress steel wires; a rope tool is fixedly connected with the rear end of the anchor rope body; a grouting core tube penetrates through the anchor rope body and the anchor tool; a support disc is sleeved on the anchor tool; a locking nut is screwed on the anchor tool at the rear end of the support disc; the locking nut props against the rear end face of the support disc; and a slurry stopping plug which aligns with the rock-soil drilling hole is sleeved at the rear end of the anchor rope body. According to the grouting anchor rope, by increasing the grouting pressure, while being filled into the drilling hole so as to realize the overall-length anchoring, slurry spreads into the rock fractures around the drilling hole at the same time, so that the bonding and curing functions to the surrounding rock are achieved, and the deep hole anchoring grouting is realized.

Owner:淮南市顺辉锚固有限公司

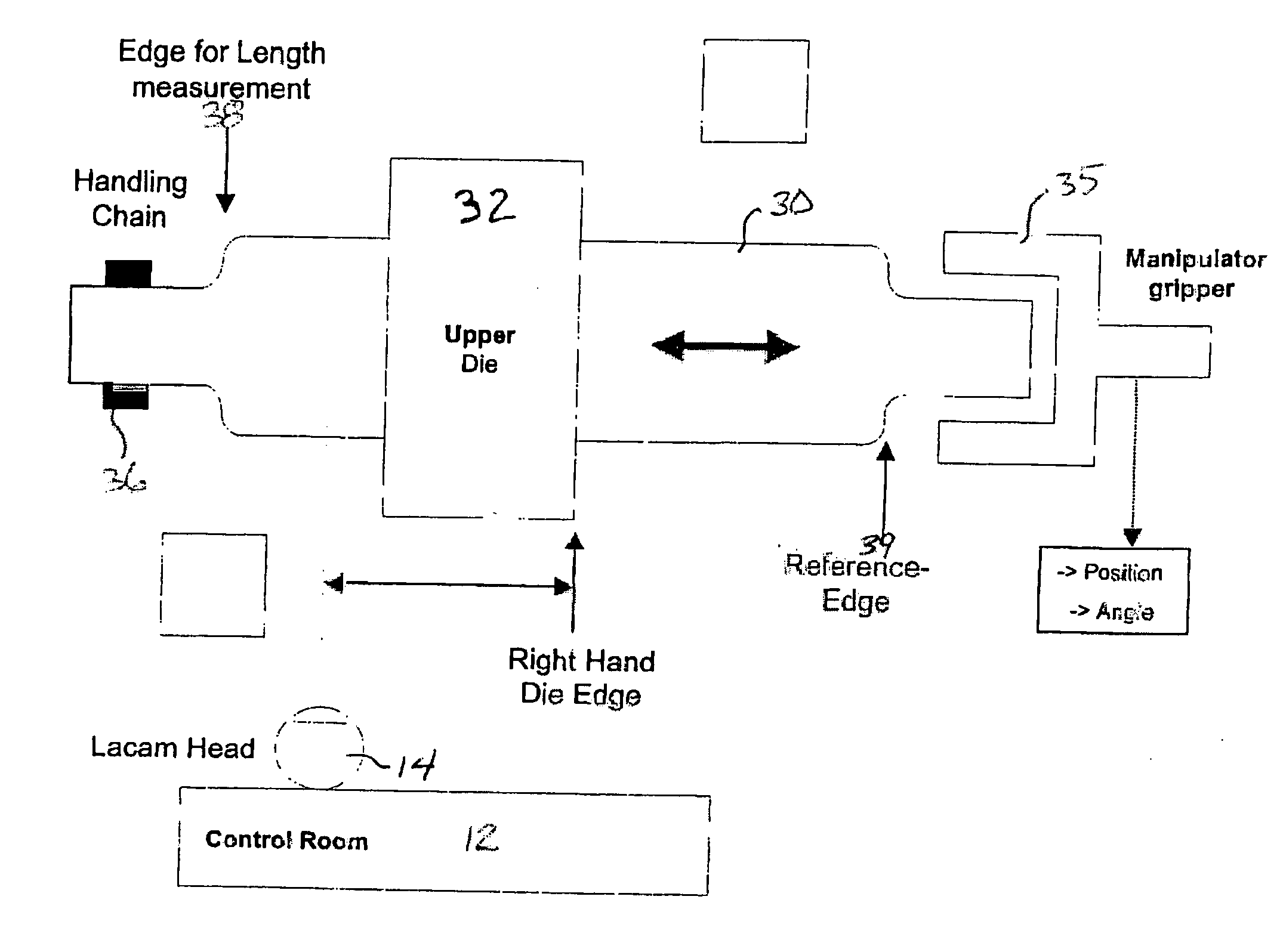

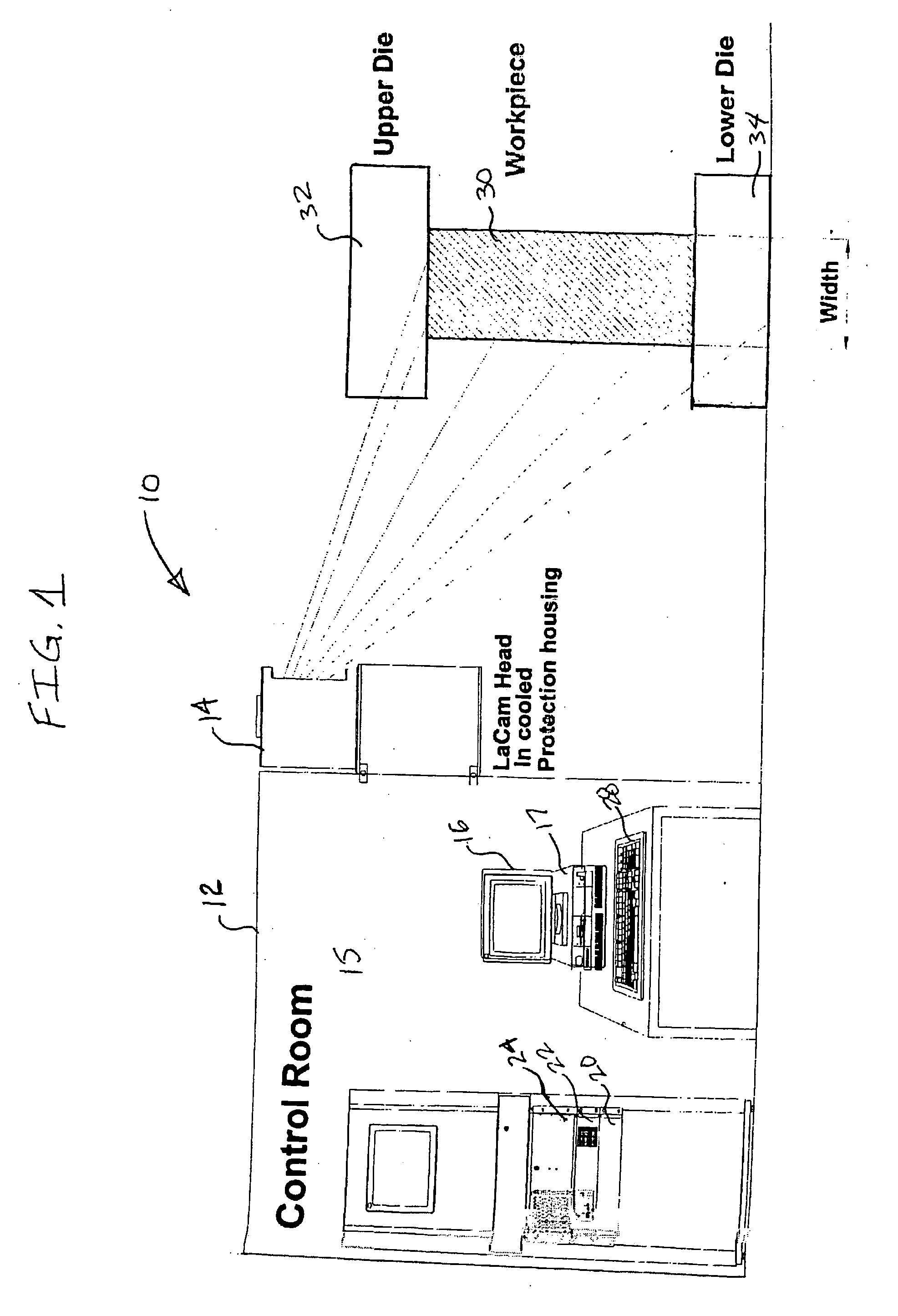

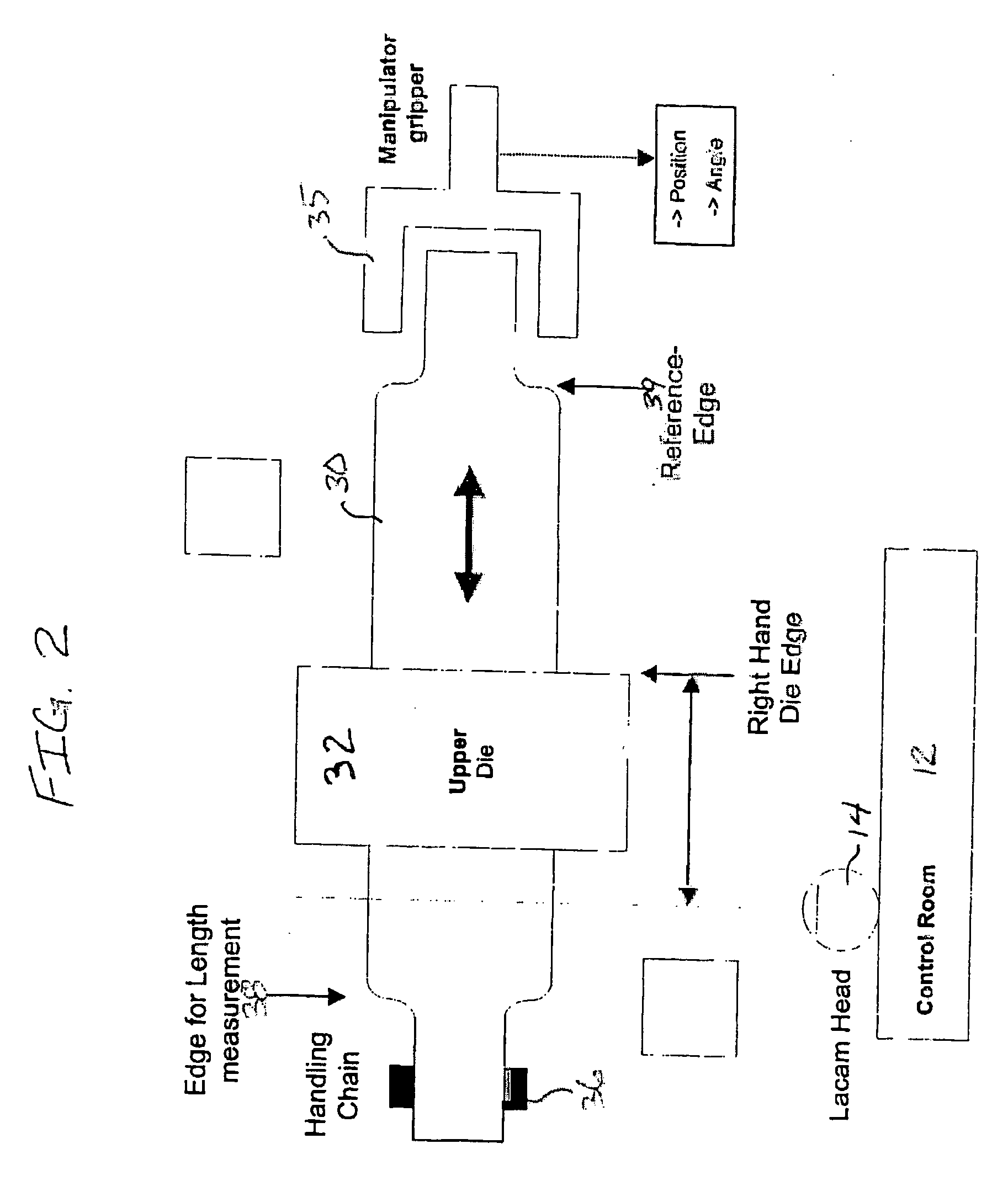

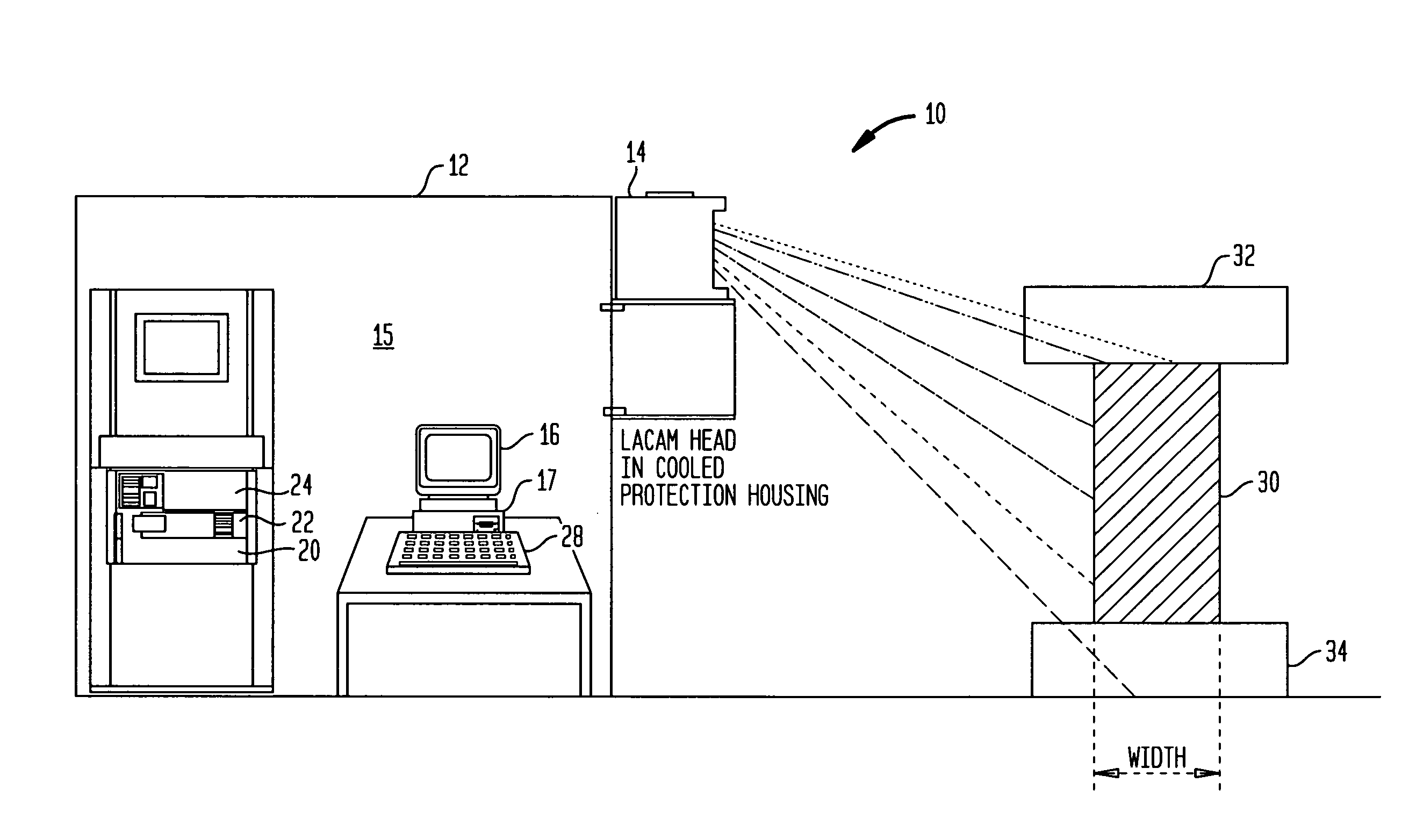

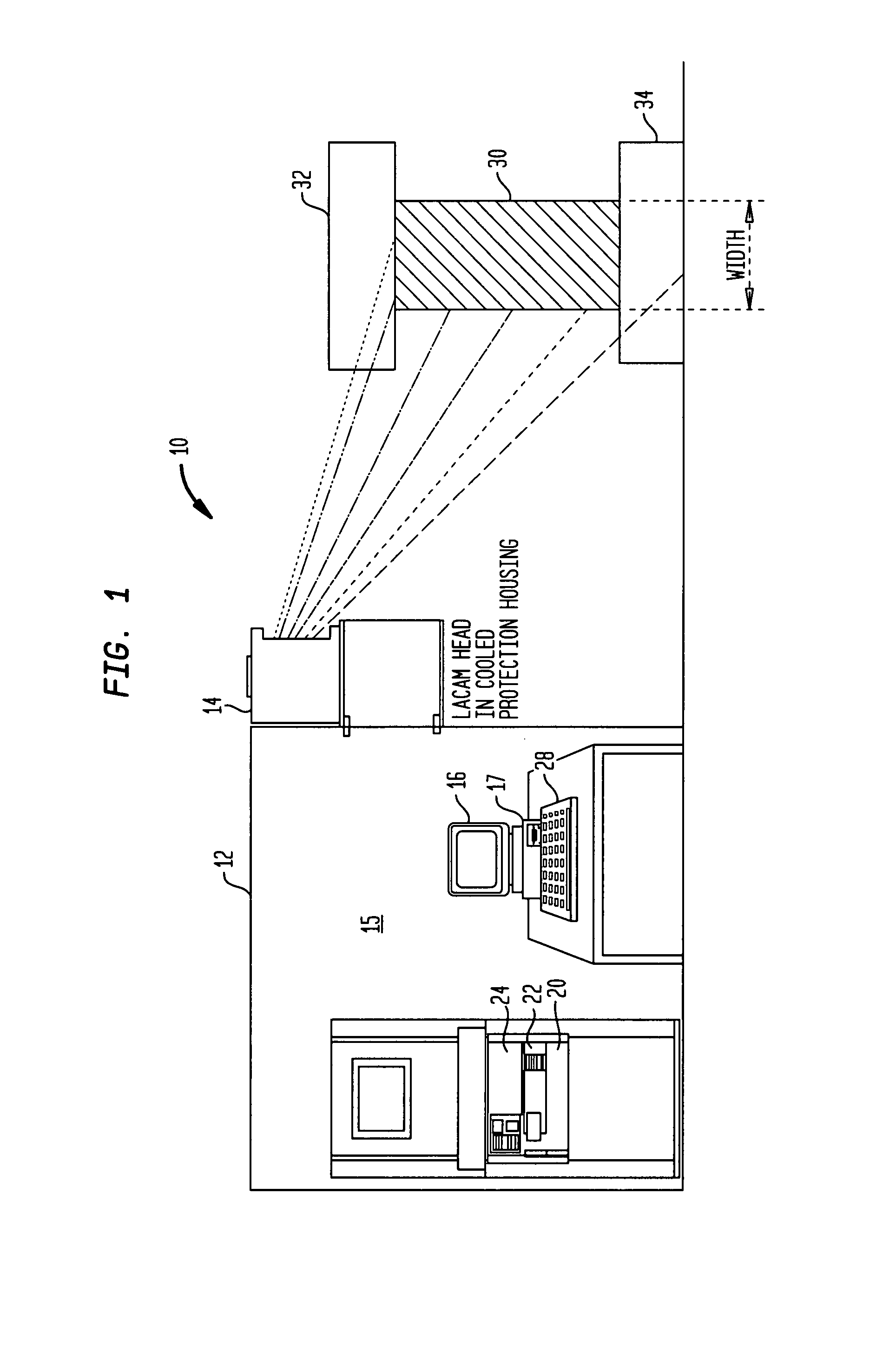

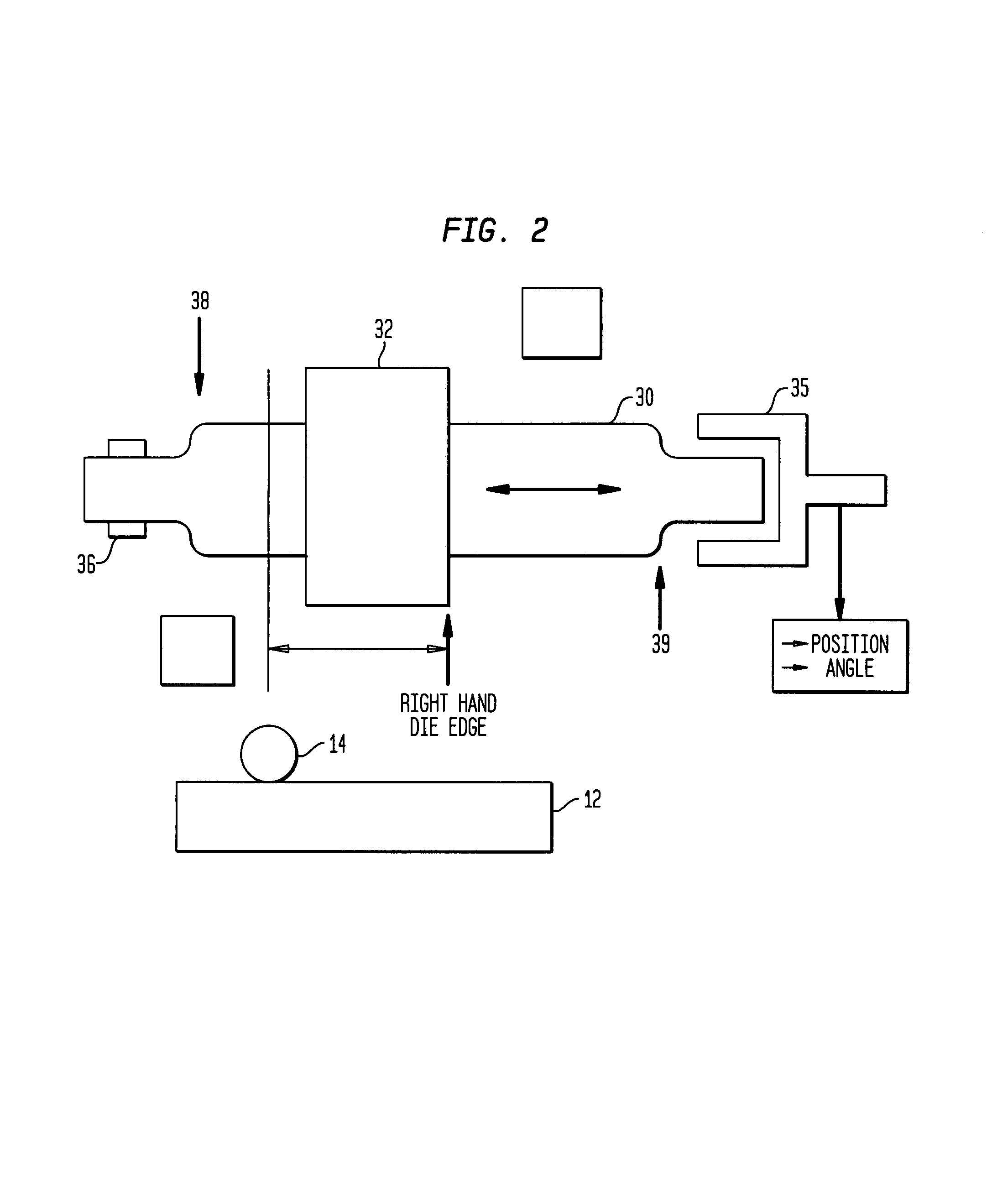

Method and apparatus for optimizing forging processes

ActiveUS20050247092A1Eliminate cavitiesStrengthen and consolidateShaping safety devicesHammer drivesEngineeringForging

A method and apparatus for optimizing the forging of a workpiece that is moved along a longitudinal axis of a forging press. The method includes detecting the relative positions of the first and second ends of the workpiece along the longitudinal axis and calculating a length of the workpiece therebetween.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

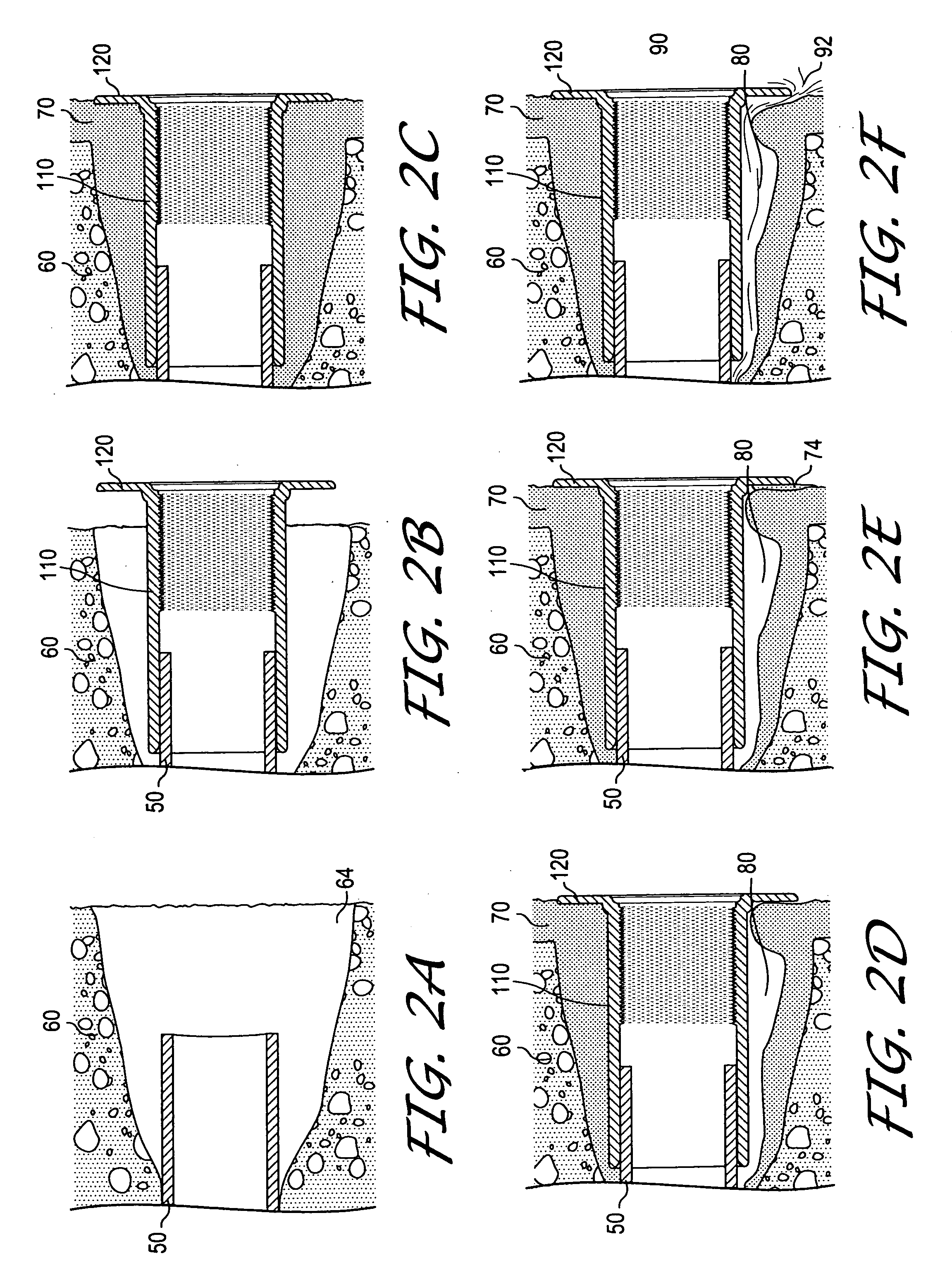

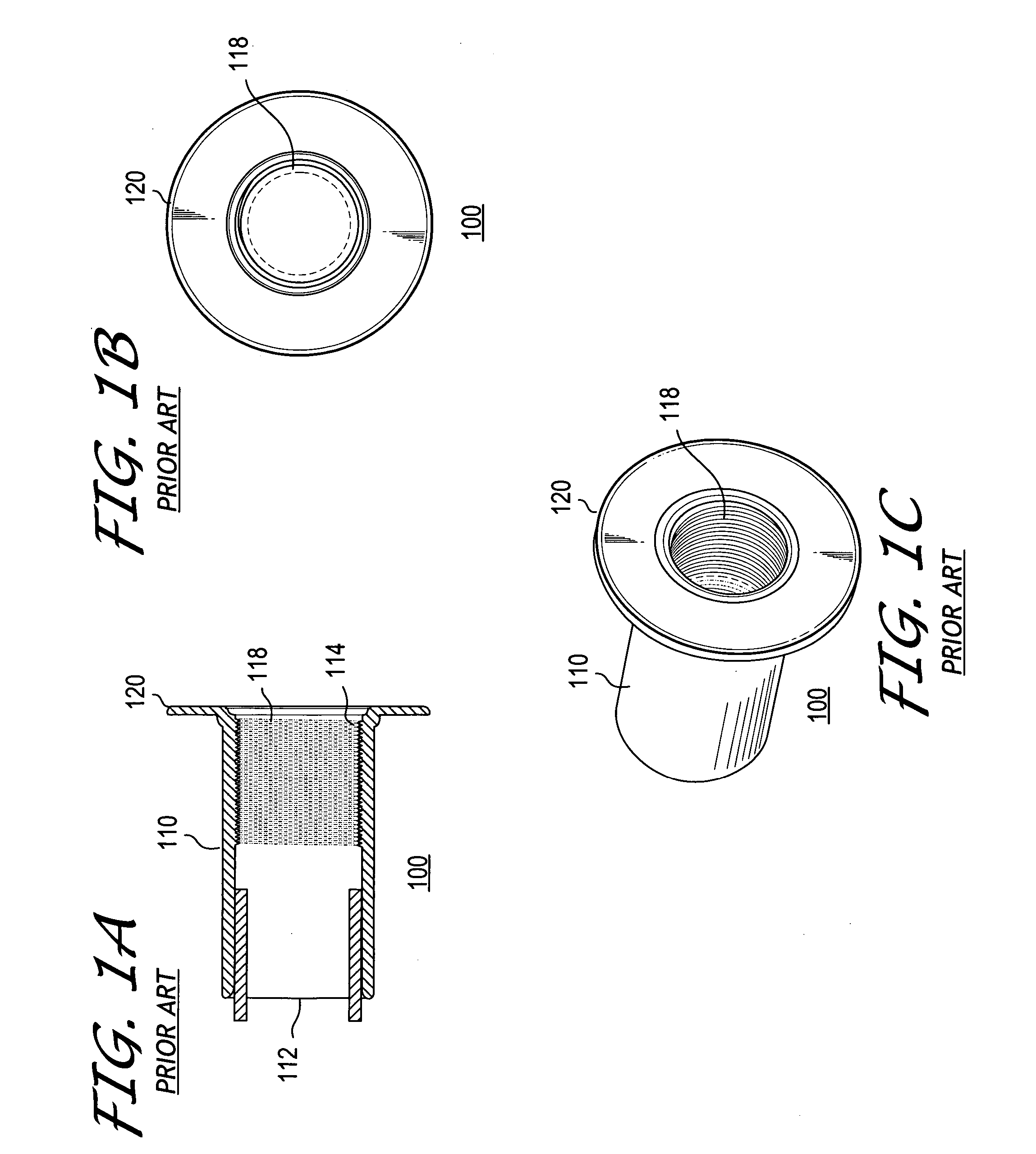

Non-leak pool fixture and method for implementing

An improved sidewall fitting is disclosed with a fitting body and one or more flanges disposed about the fitting body. Plaster catches disposed along a face of one flange and positioned approximately coextensively with the fitting body. The bodies of the plaster catches may be curvilinear-shaped, straight or concentric rings and the body portions may be of heights for aligned or off-setting configurations. The fitting is installed the plaster catches oriented directly below the body of the fitting, along a generally horizontal plane. Plaster is layered over the flange and plaster catches, and up to the opening in the fitting body. The plaster catches may be disposed along a posterior face of a flange, or simultaneously along the anterior and posterior faces. A second fitting type includes an extension surface for increased bonding with the plaster with additional surface area available for sealing with the plaster. Disposed onto the sealing surface is a leave-out strip, which protects the sealing surface during cementing. After removal of the leave-out strip, the sealing surface provides an uncontaminated surface on which a sealant may be liberally applied. Optionally, a seal may be provided on the sealing surface interposed between the leave-out strip.

Owner:YEAGER BRYAN KEITH +1

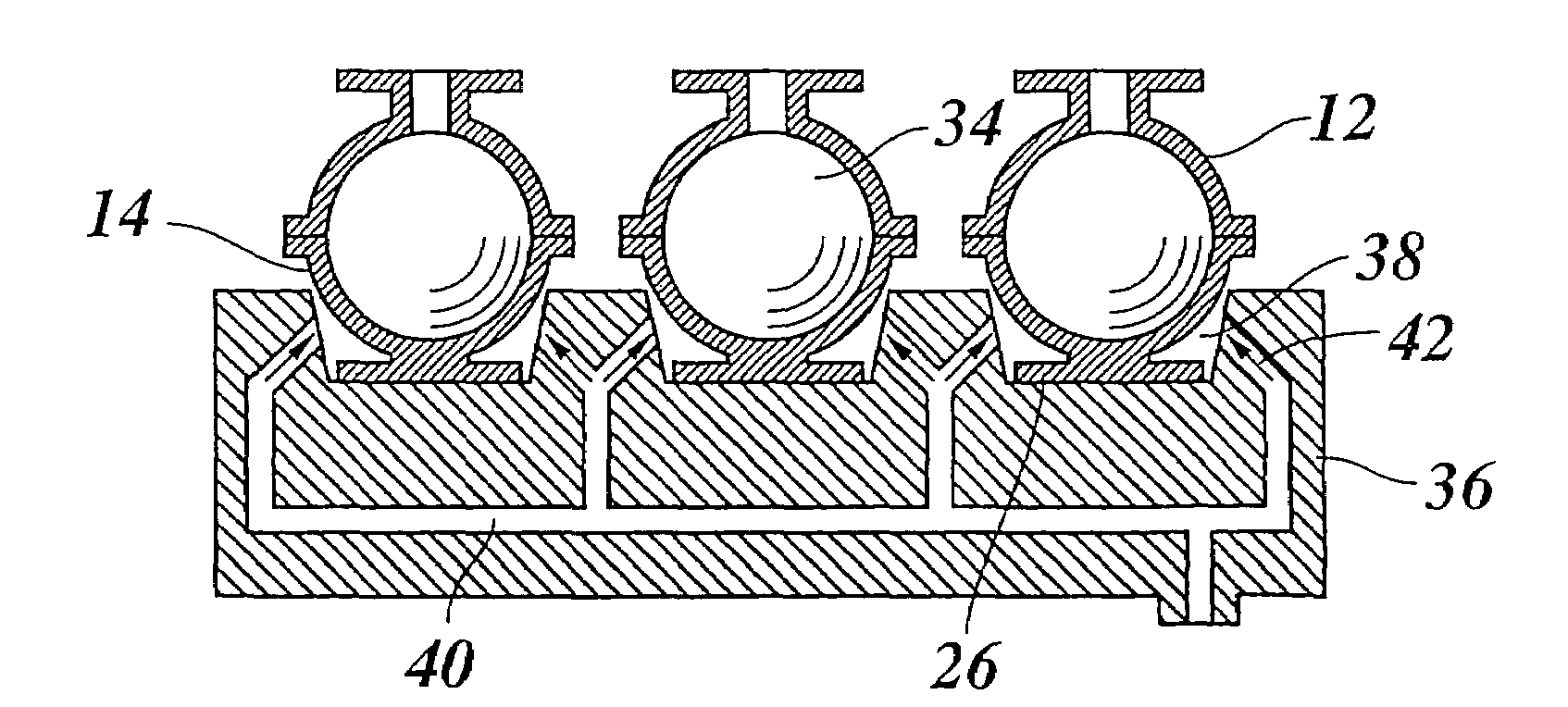

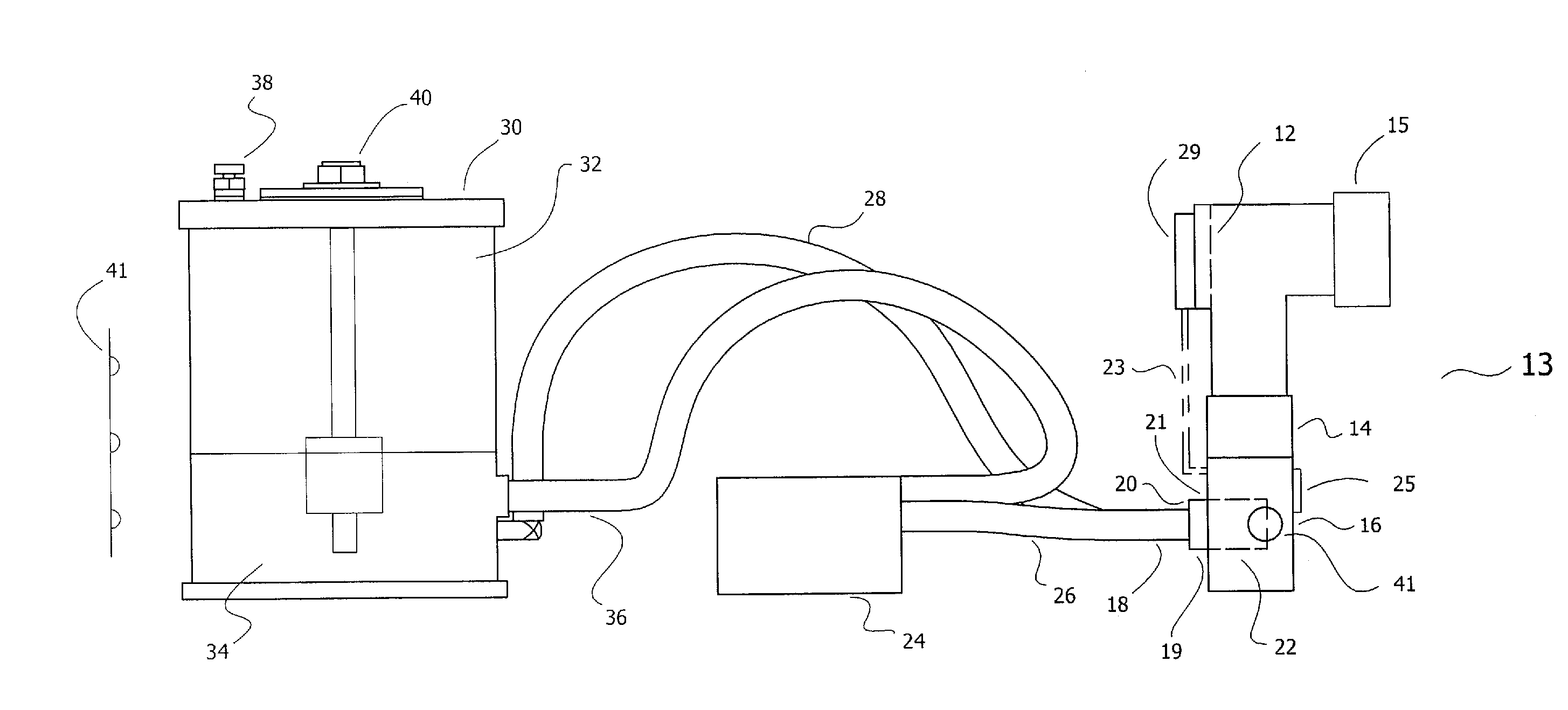

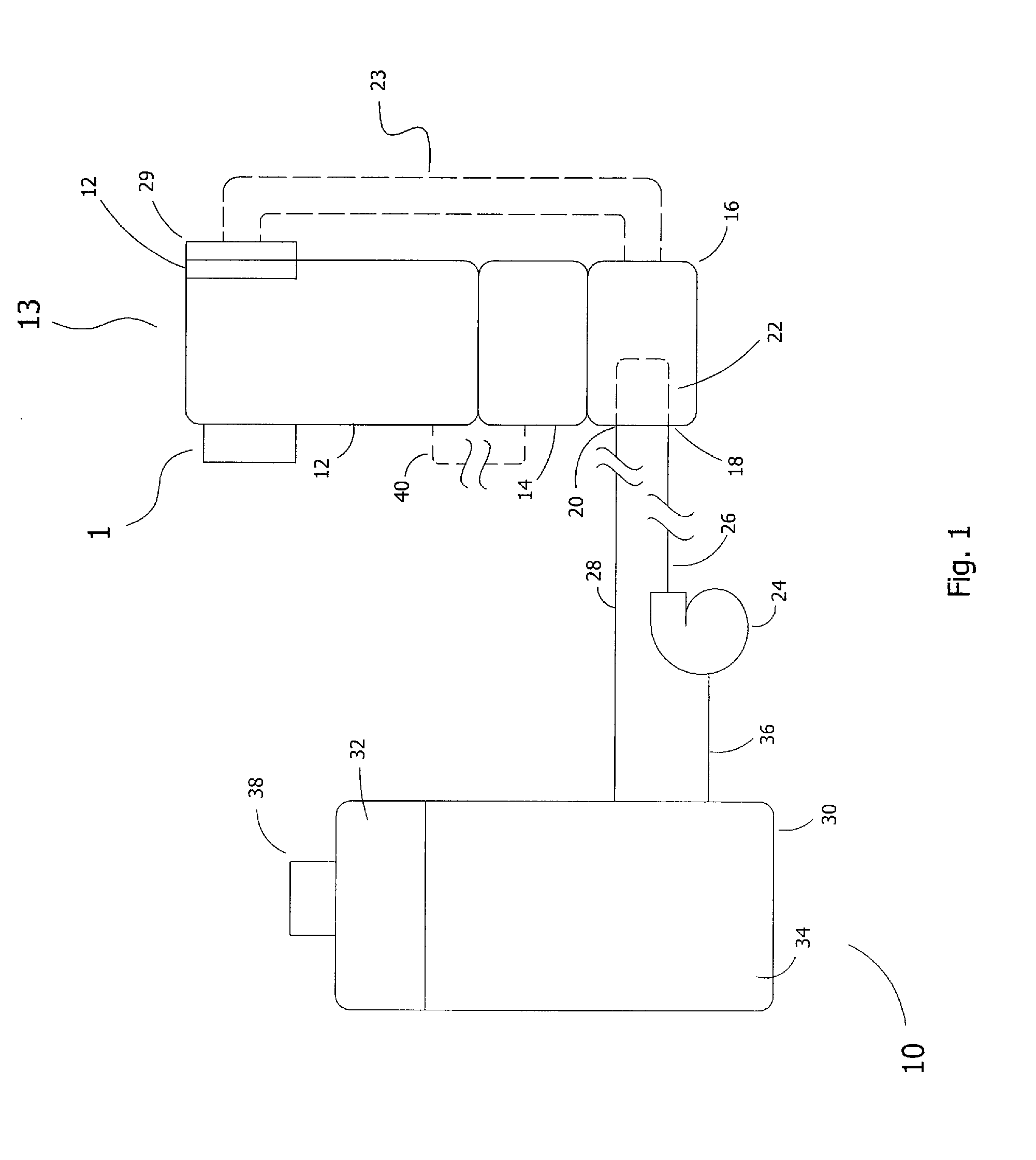

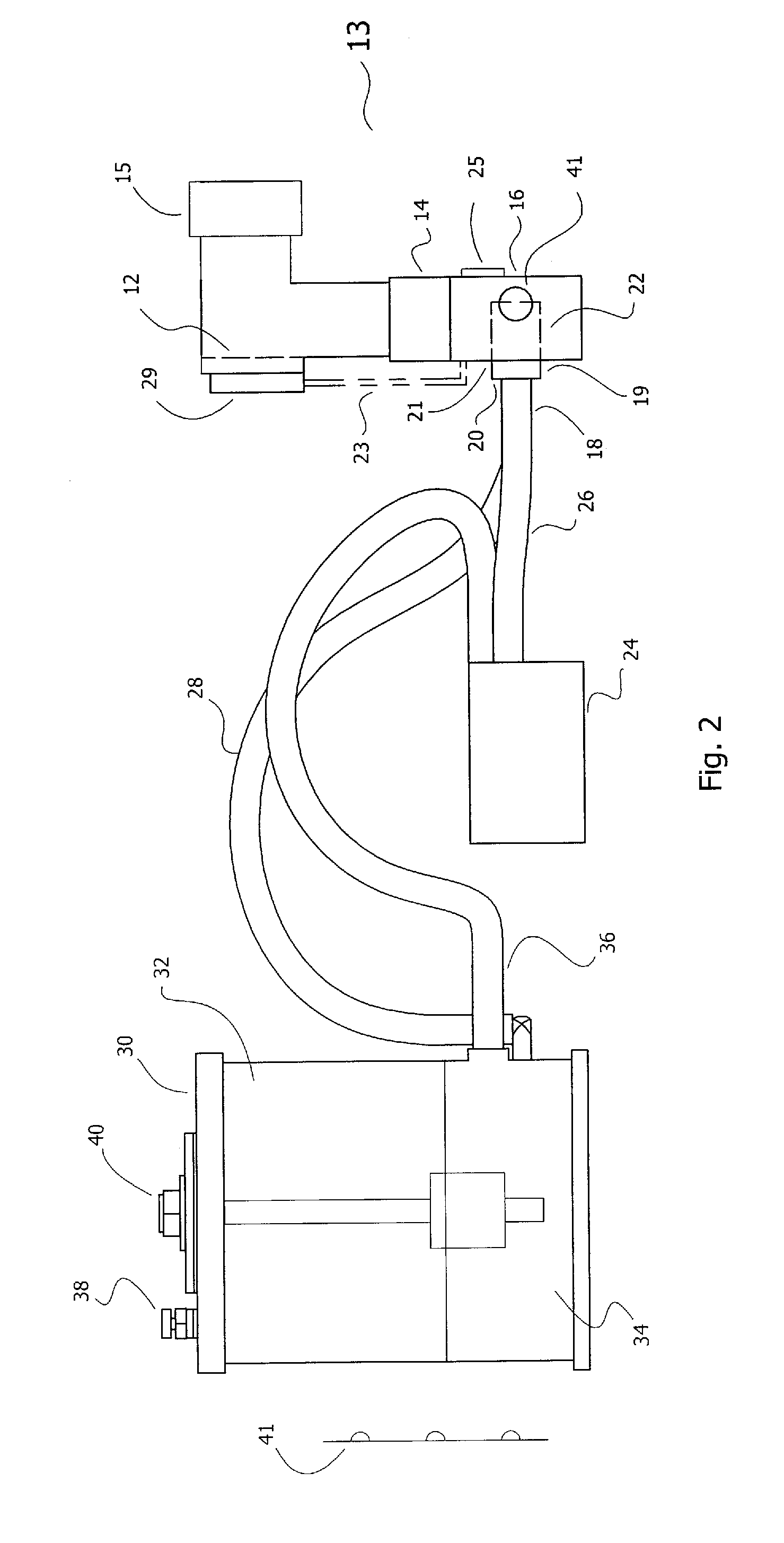

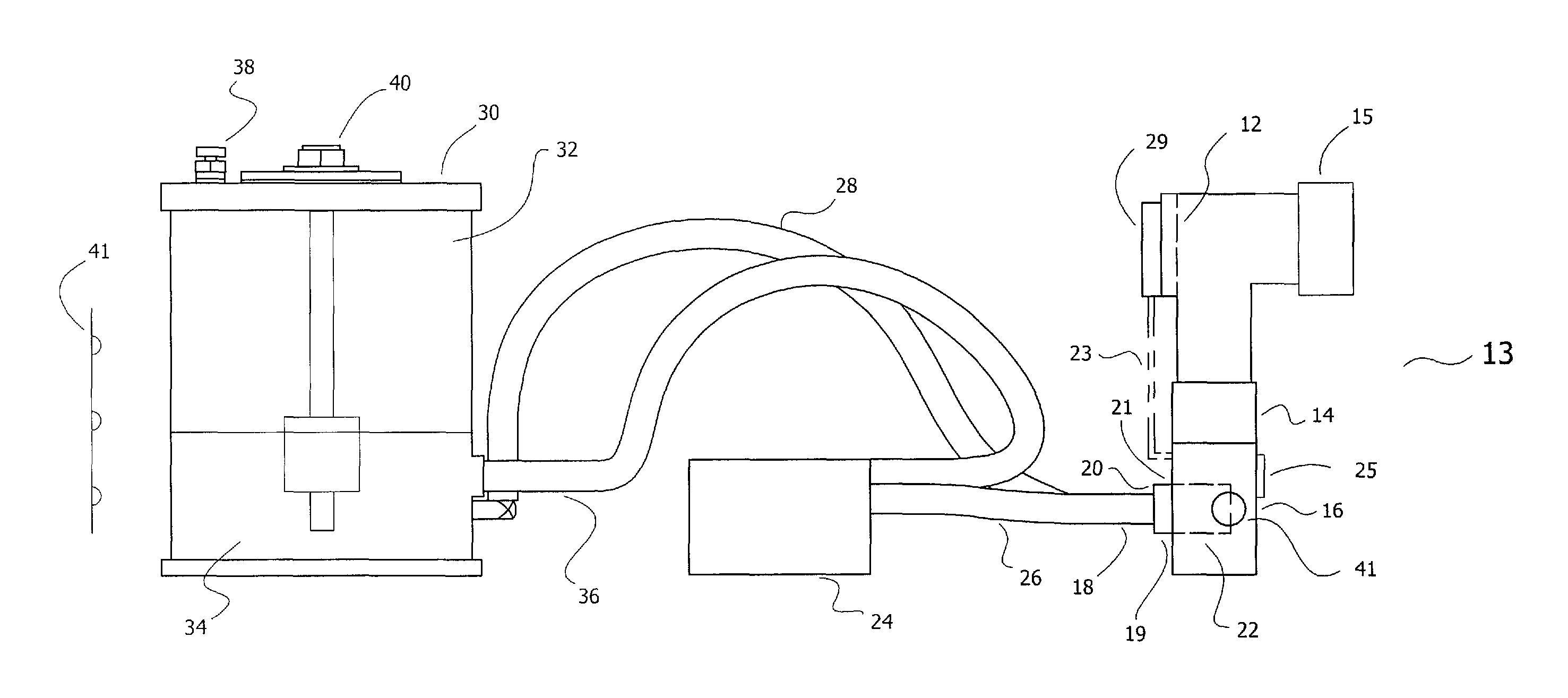

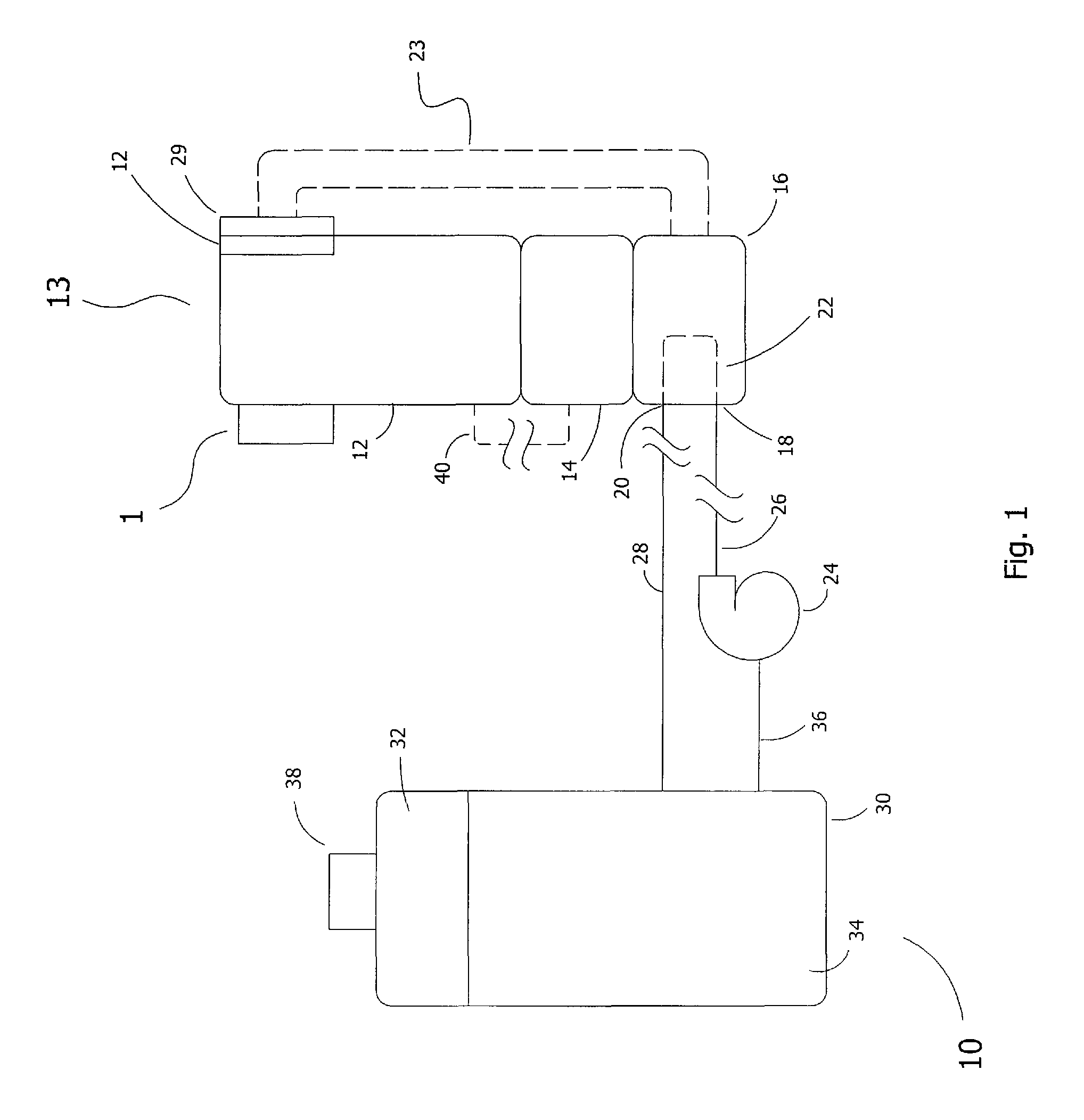

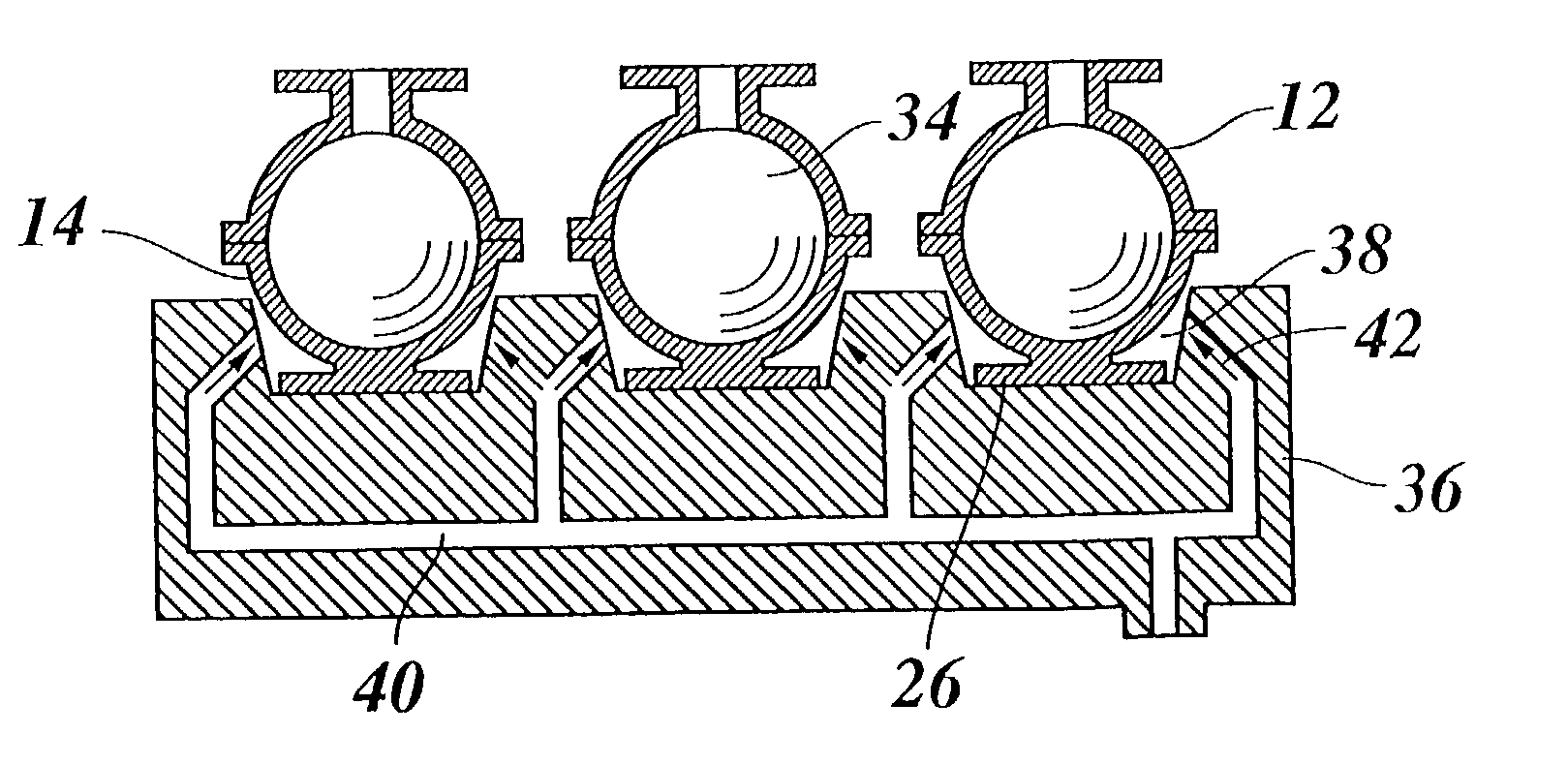

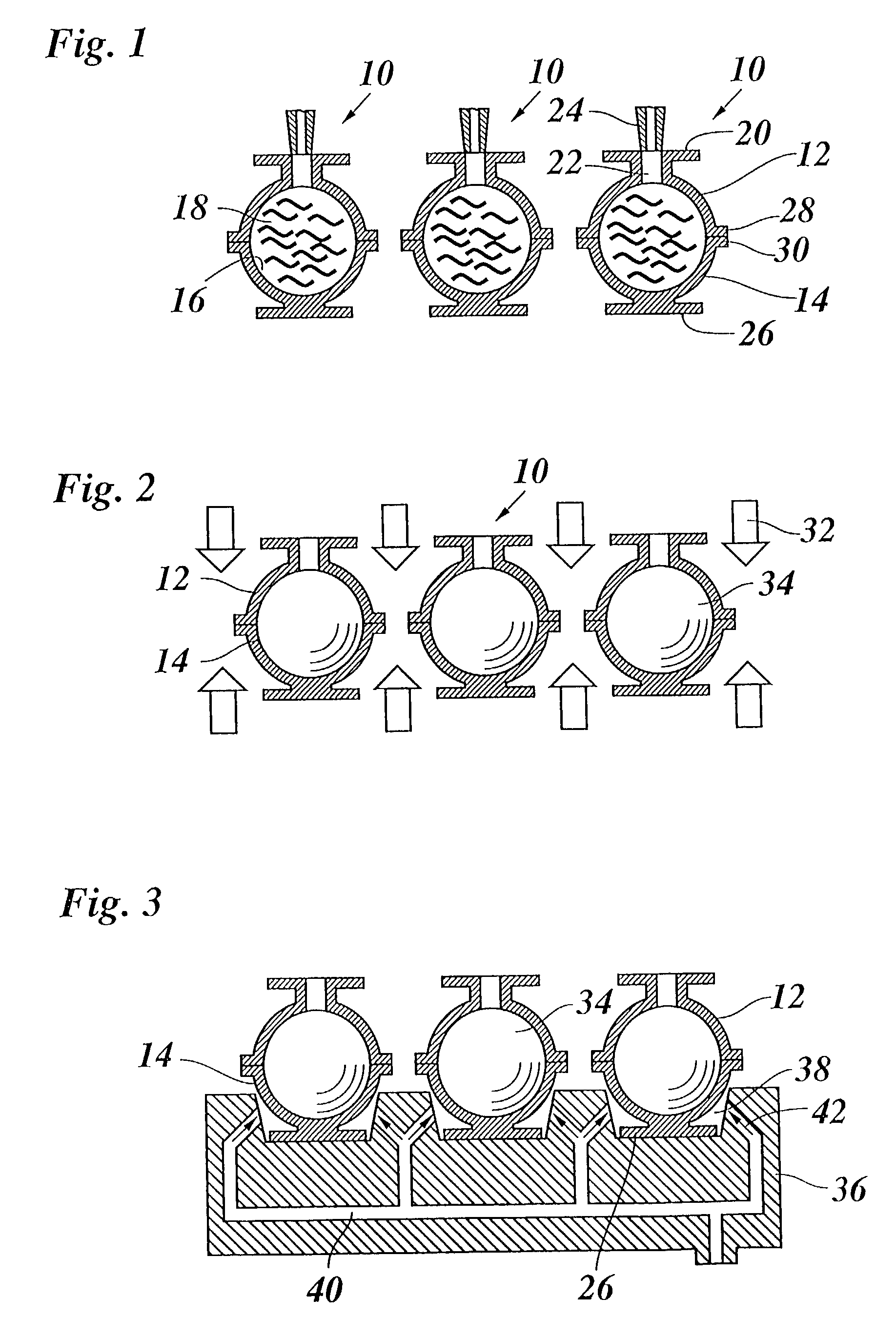

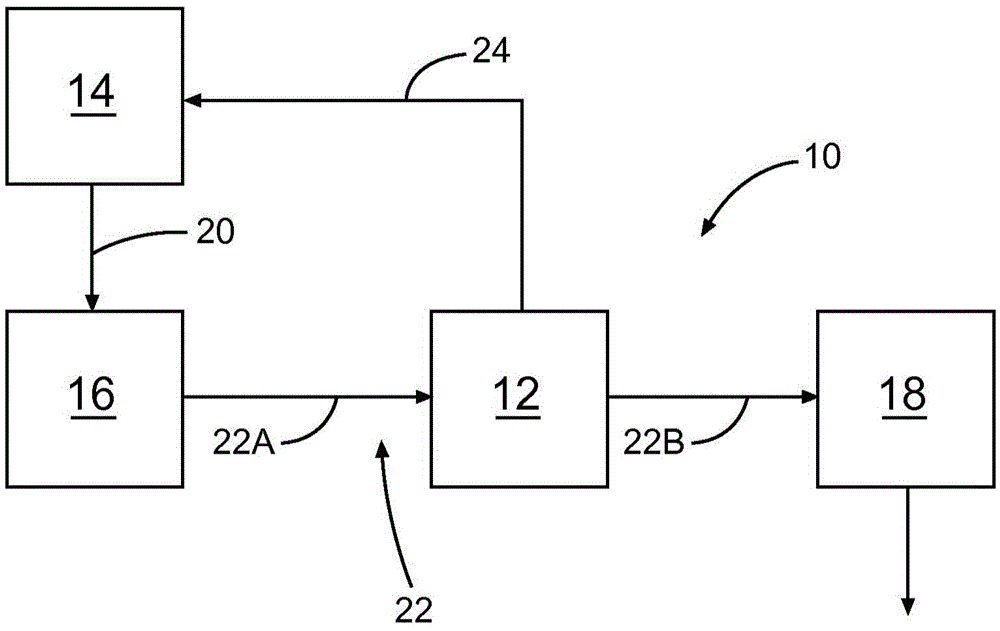

Liquid cooled video projector

ActiveUS20130293852A1Eliminate cavitiesMagnetic measurementsProjectorsMotor driveLiquid cooling system

Disclosed is a liquid cooling system for use with MRI positioned video projectors to dissipate heat from the projector light source through liquid cooling. The system includes a heat sink body for mounting to the projector light source, the heat sink body constructed of a material to transfer heat away from the projector light. A remotely mounted motor-driven pump provides fluid circulation, the pump is constructed and / or mounted so as to not to be effected by the MRI magnetic field. The pump is coupled to the heat sink block by use of flexible tubing that is constructed and arranged to provide heat transfer to the environment thereby maintaining the projector light source temperature at a reduced level. A liquid reservoir is fluidly coupled to the pump intake for use in maintaining liquid levels at an optimum position.

Owner:AVOTEC

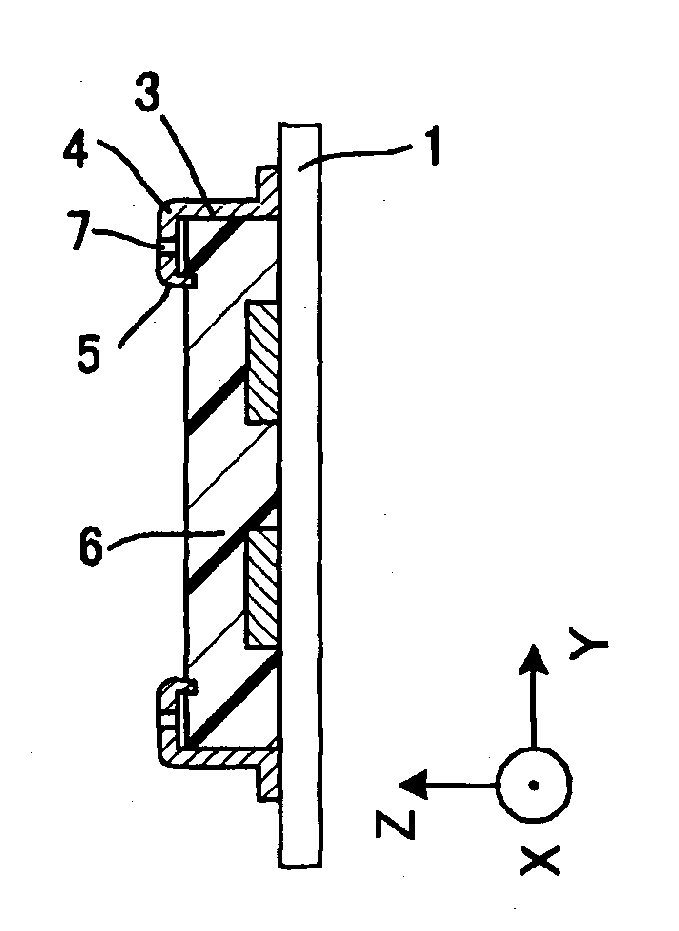

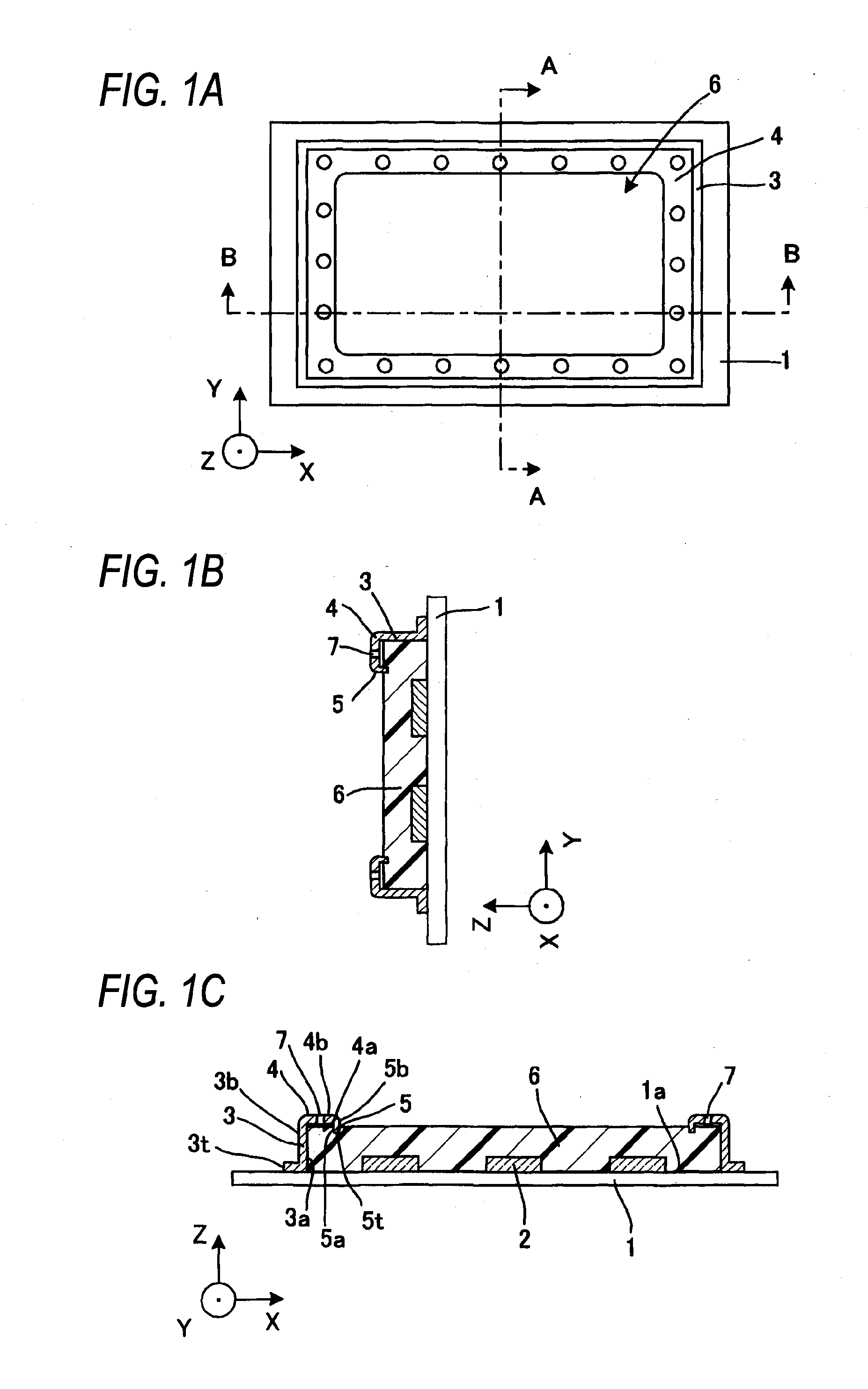

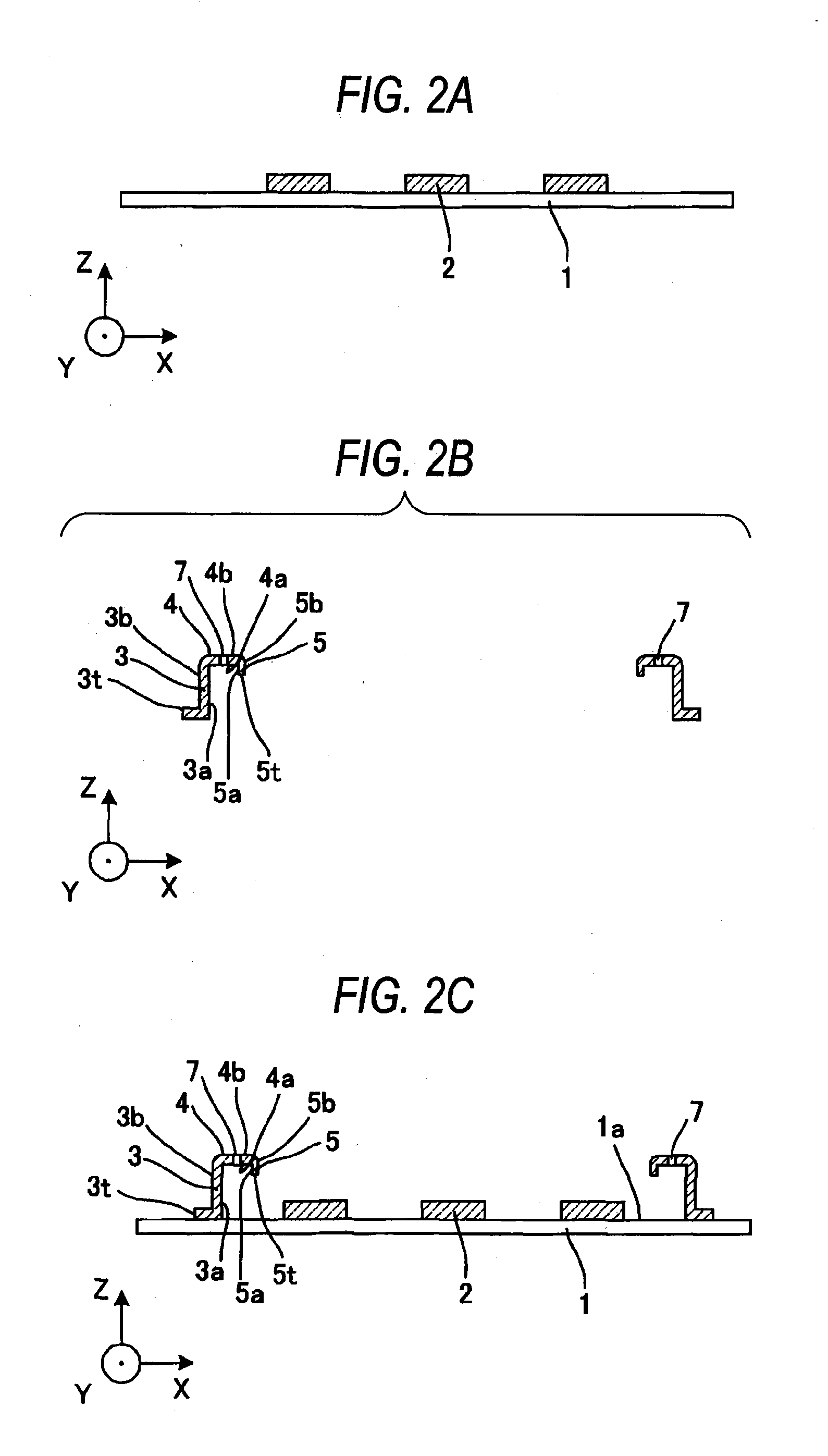

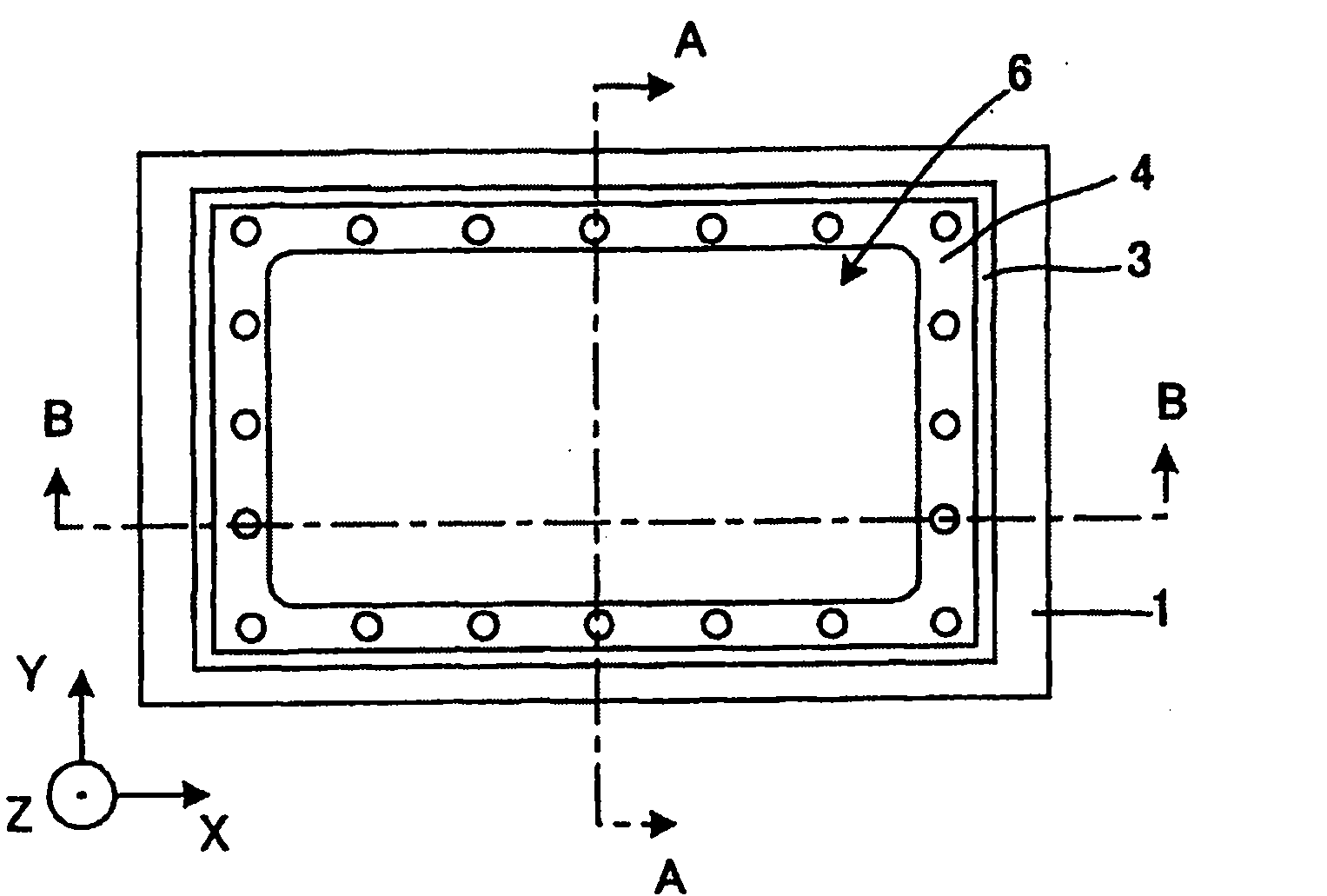

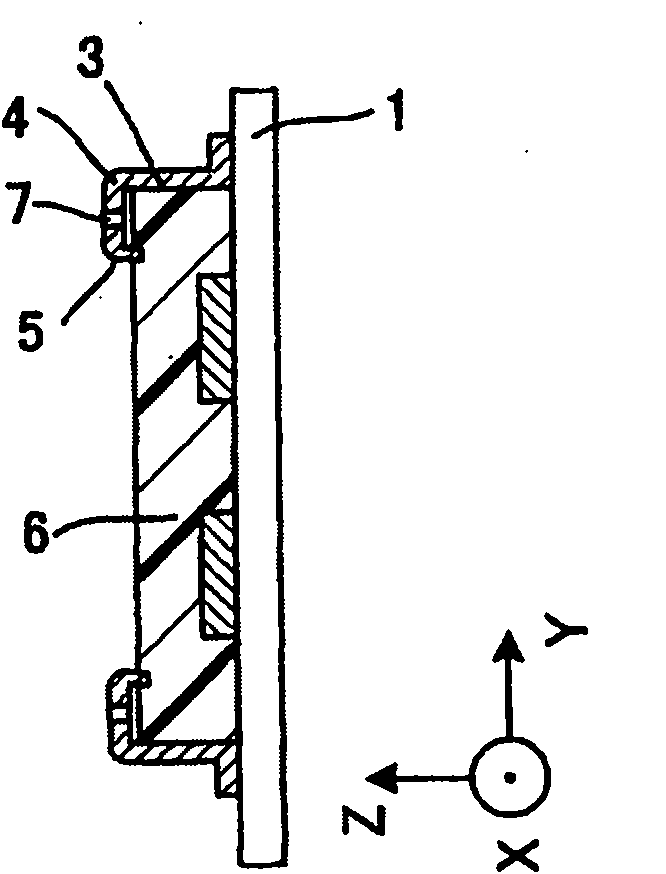

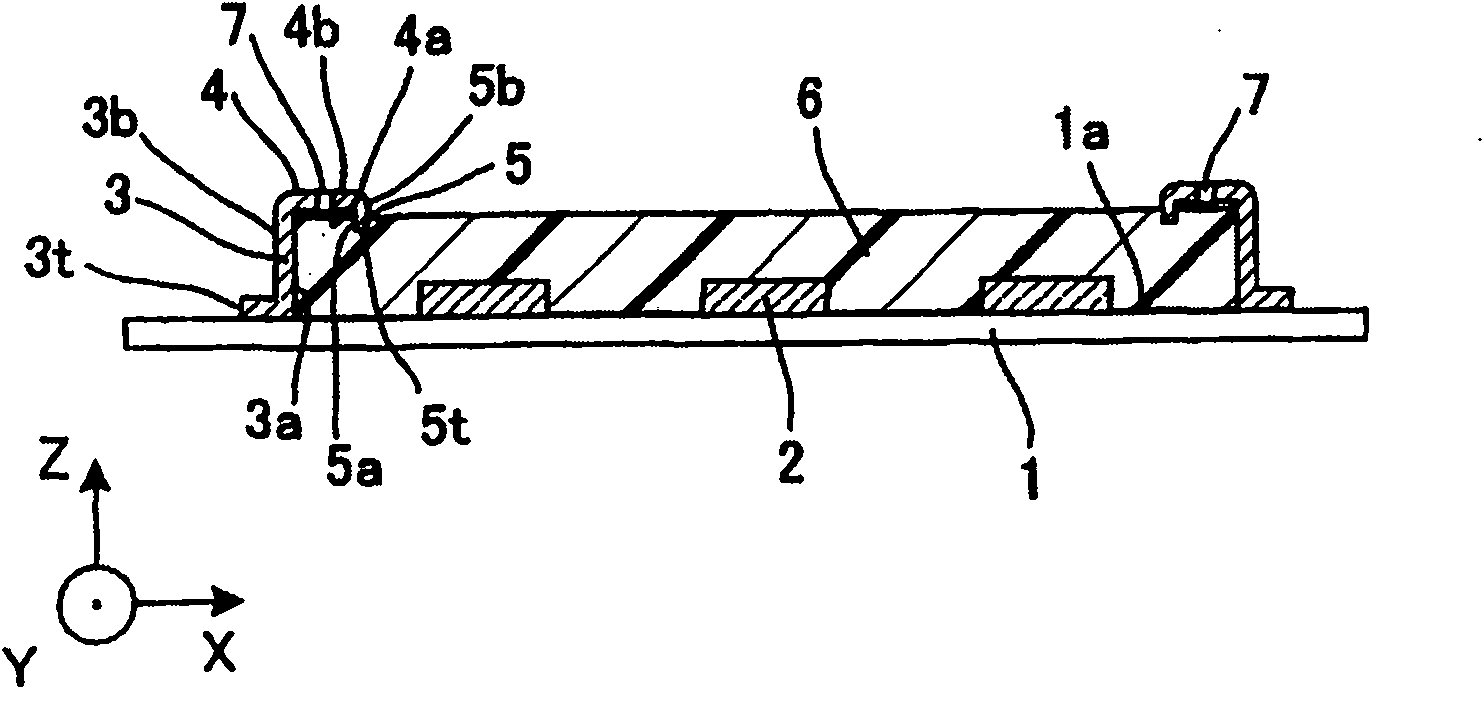

Circuit module and electronic equipment using the circuit module

InactiveUS20100271788A1High strengthEliminate cavitiesPrinted circuit aspectsPrinted circuit manufactureEngineeringHigh intensity

Owner:PANASONIC CORP

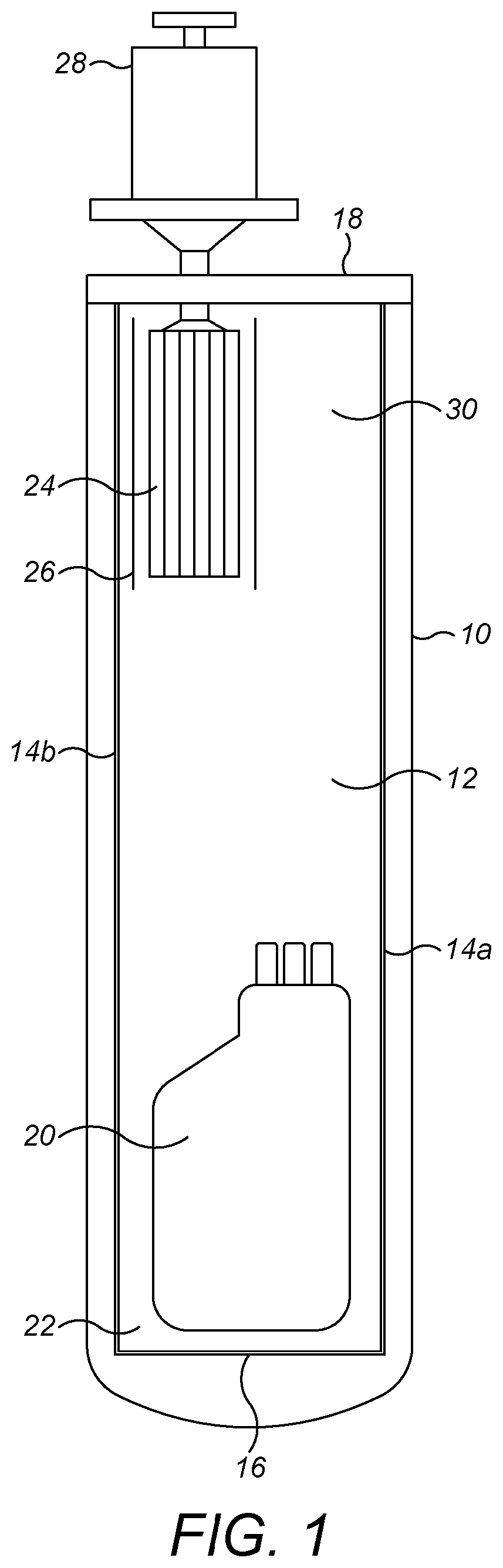

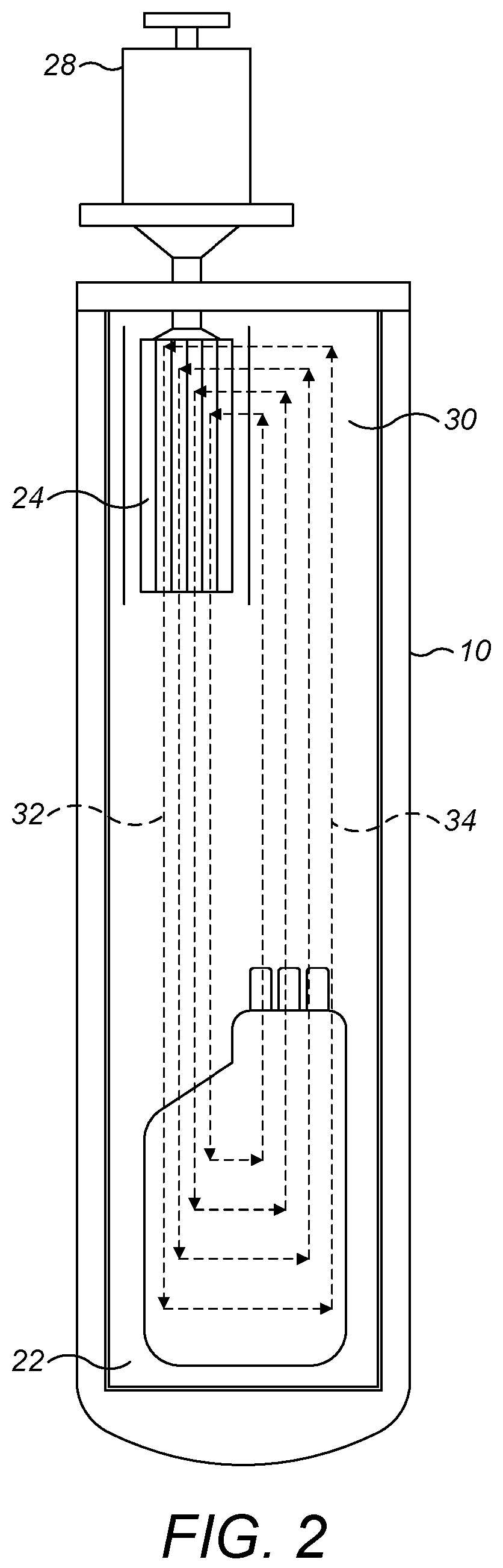

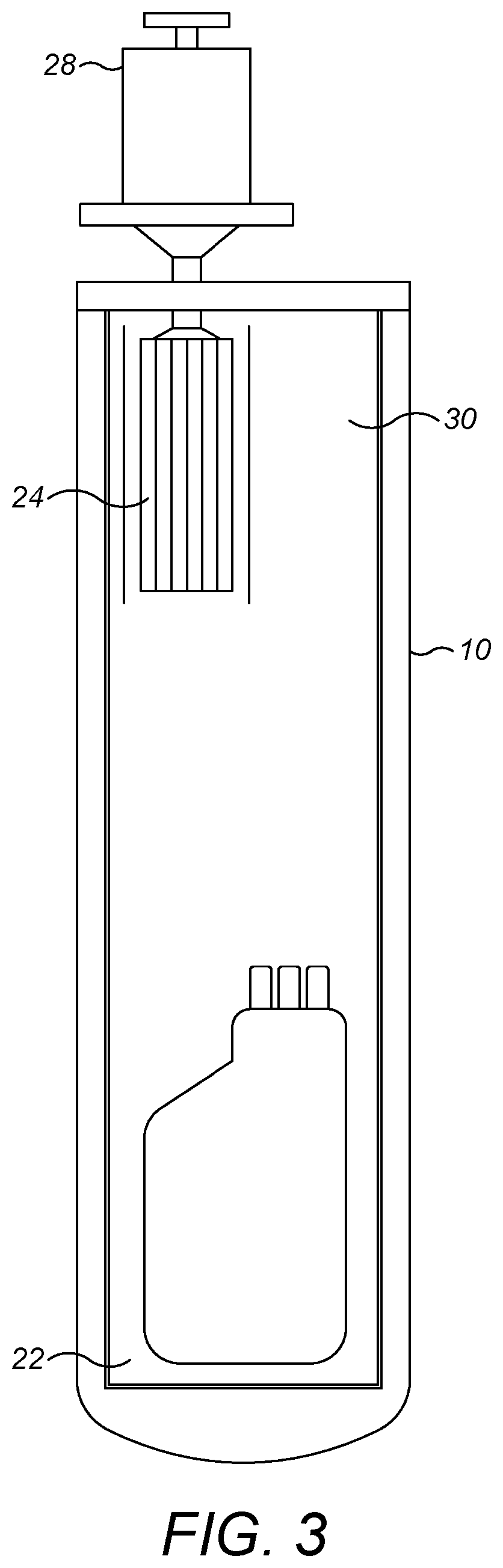

Shipping Container

ActiveUS20200085036A1Low costCooling can be acceleratedCompression machinesDead animal preservationCryopreservationIndustrial engineering

The present invention relates to a shipping container for cryopreserved biological samples in which a cryopreserved sample can be maintained on arrival at its destination for a period of time, for example several months.

Owner:ASYMPTOTE

Liquid cooled video projector

ActiveUS8985780B2Eliminate cavitiesLighting heating/cooling arrangementsProjectorsMotor driveLiquid cooling system

Owner:AVOTEC

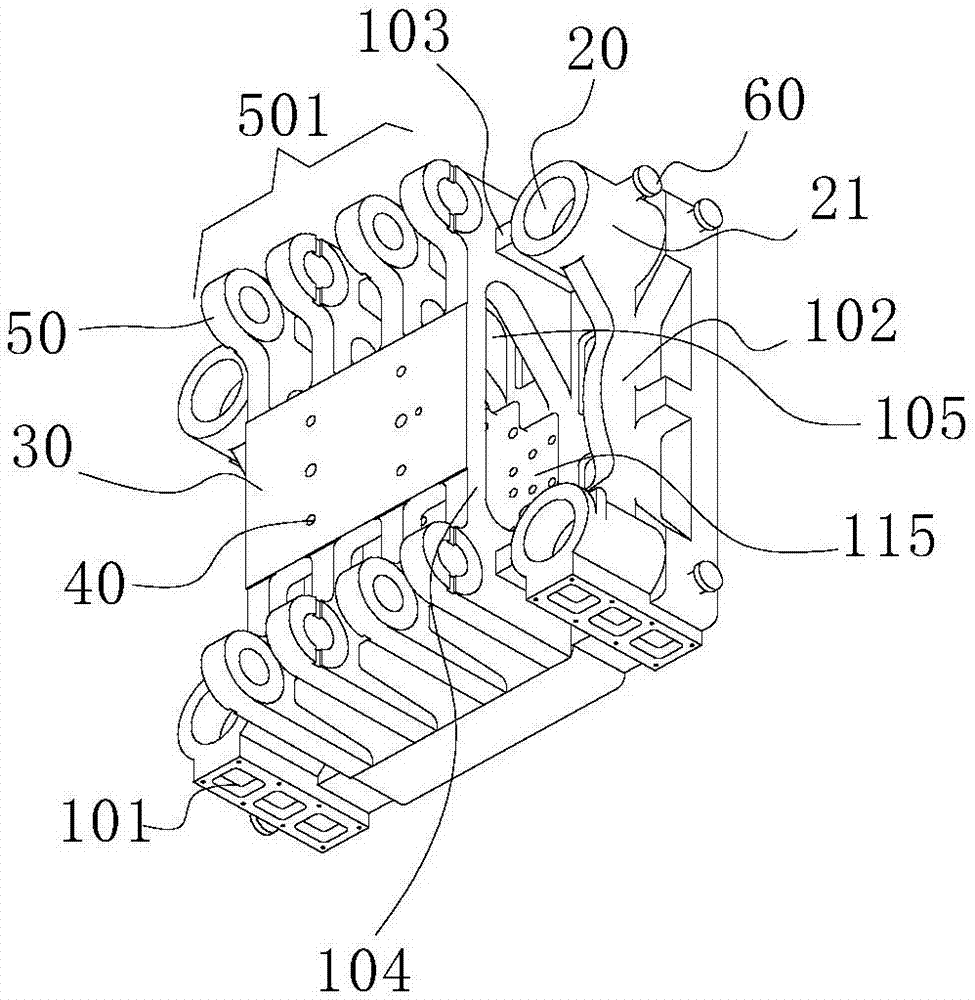

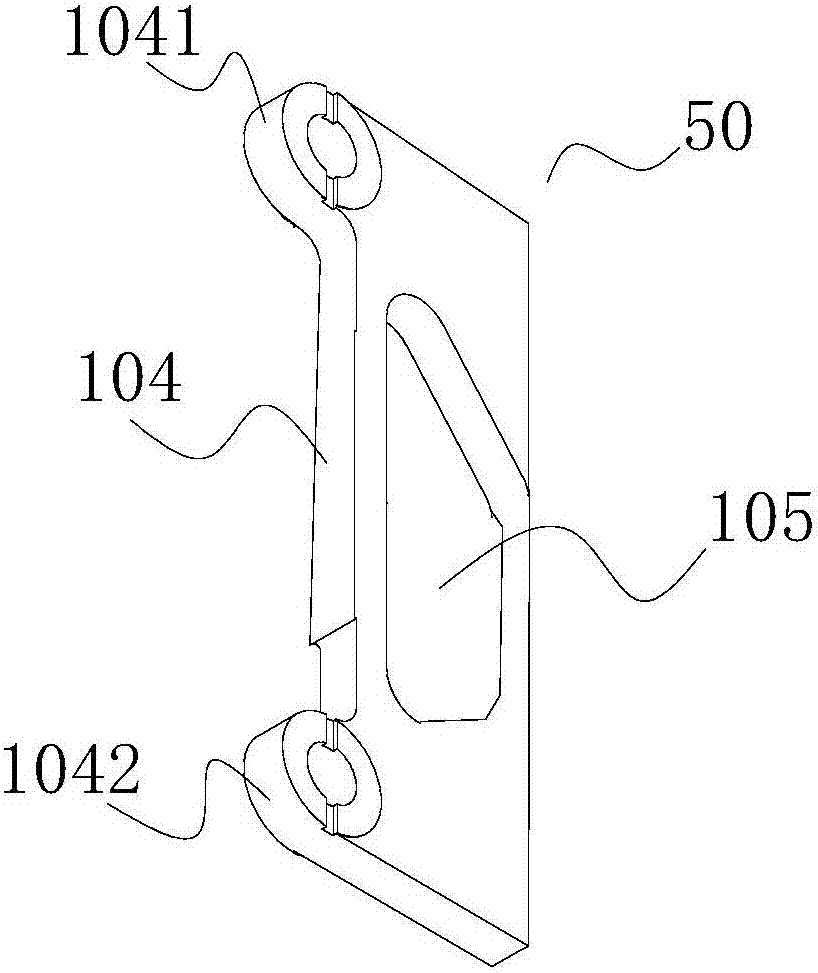

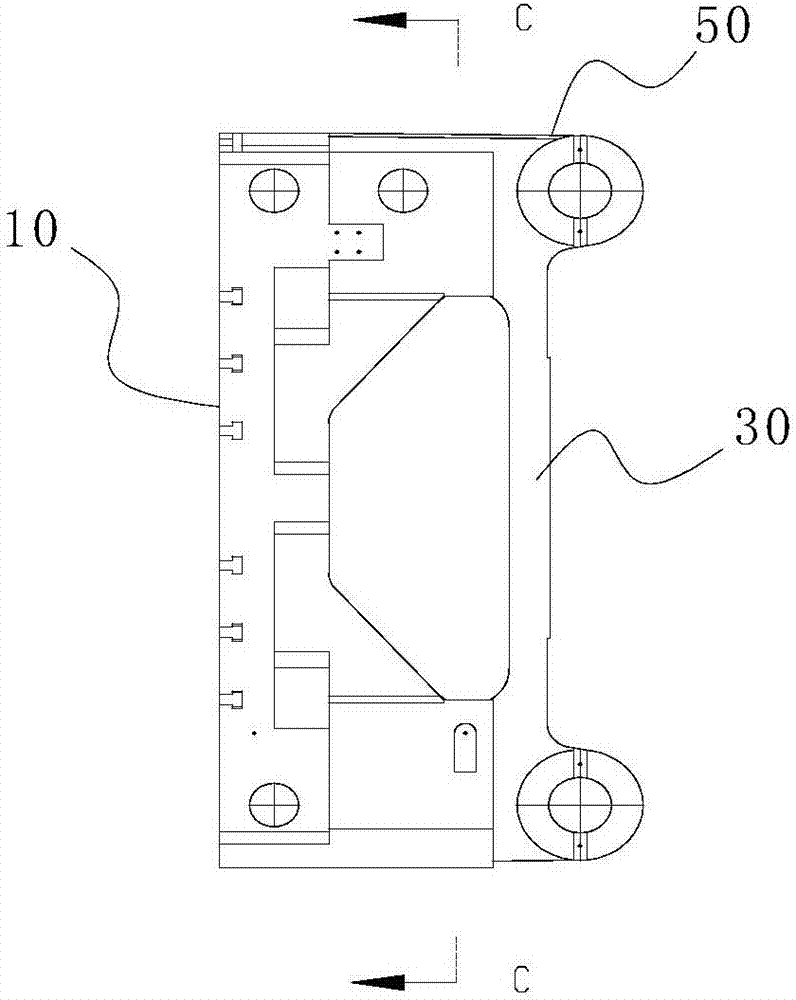

Moving die plate of injection molding machine and injection molding machine

The invention discloses a moving die plate of an injection molding machine and the injection molding machine. The moving die plate of the injection molding machine comprises a die block base body, a guide cylinder provided with a guide column hole, an ejecting mechanism mounting plate and mechanically reamed connecting bases, wherein the guide cylinder and the mechanically reamed connecting bases are separately arranged on the die block base body, the mechanically reamed connecting bases are arranged in pairs, and a first reinforcing rib plate is connected between each pair of mechanically reamed connecting bases; the ejecting mechanism mounting plate is arranged on the first reinforcing rib plates; and the mechanically reamed connecting bases are directly connected to the die block base body, and no gaps are arranged between the mechanically reamed connecting bases and the die block base body, so that the mechanically reamed connecting bases cannot easily deform or crack when subjected to tensile force or pressure. Therefore, the strength and the rigidity of the mechanically reamed connecting bases can be increased; and at the same time, by adopting reasonable mechanism design, used materials are reduced, and the weight of the moving die plate is reduced, so that the moving die plate is more flexible in running and more convenient to machine.

Owner:广东佳明机器有限公司

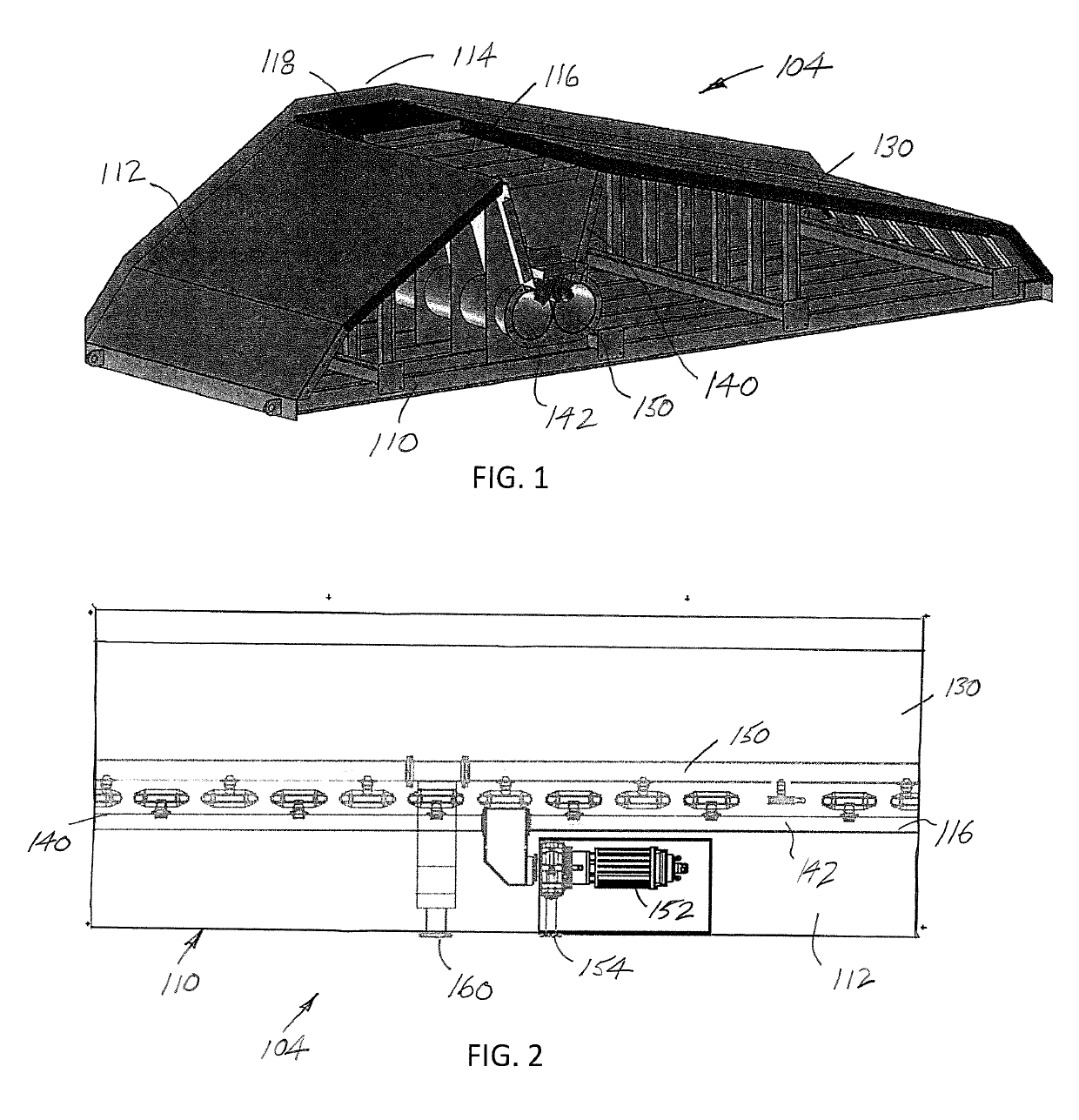

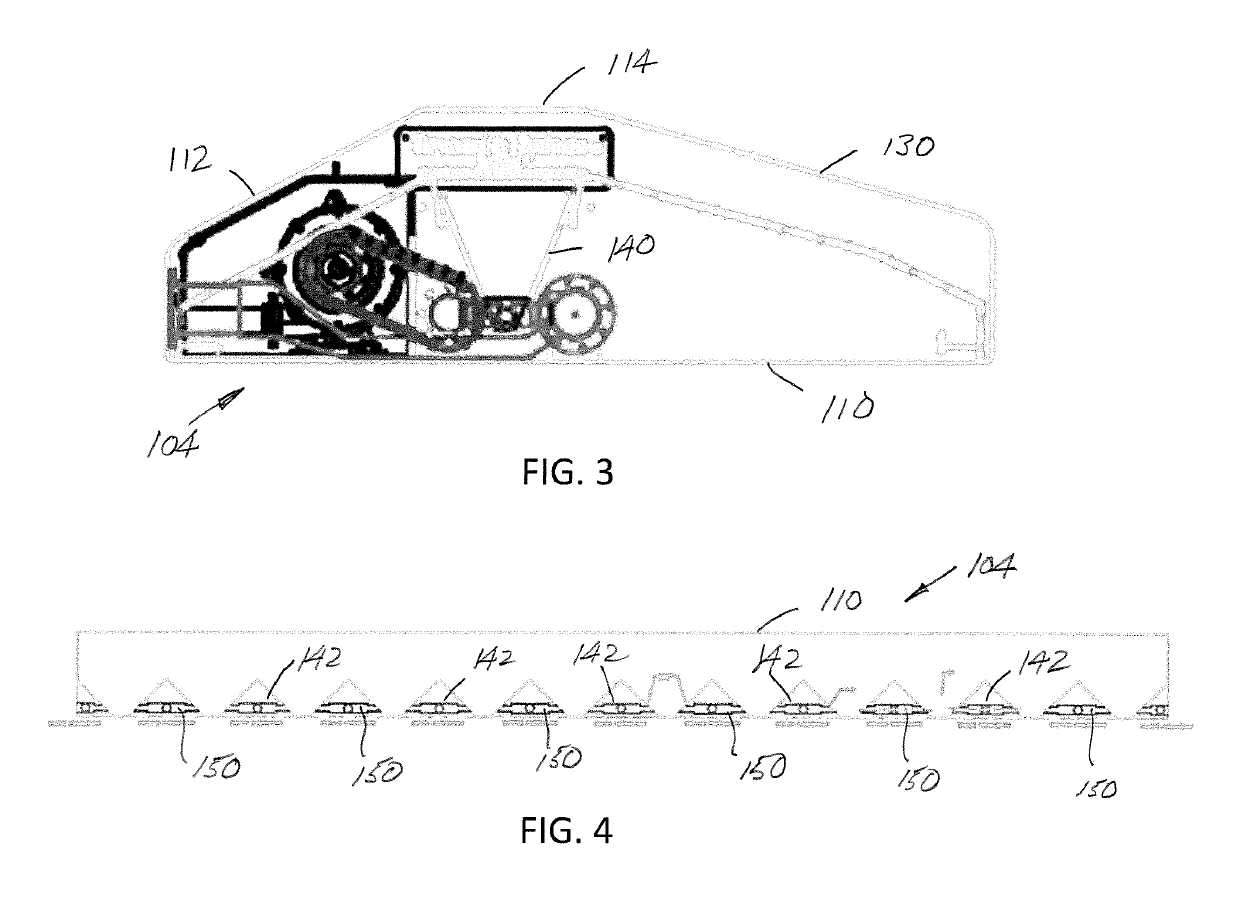

Collector with return and silt basin, bubbler and process

InactiveUS20190144317A1Simple and effective and economicalEfficient removalTransportation and packagingMixing methodsEngineeringOxygen

A collector includes one or more air / oxygen / gas introduction ports to form a bubbler that produces curtains of air / oxygen / gases into the waterway. The bubbler can be integrated into the collector, or formed as a separate component used with or without the collector. First and second pumps provide for improved removal of sediment collected in the collector cavity.

Owner:TUCKER RANDALL L

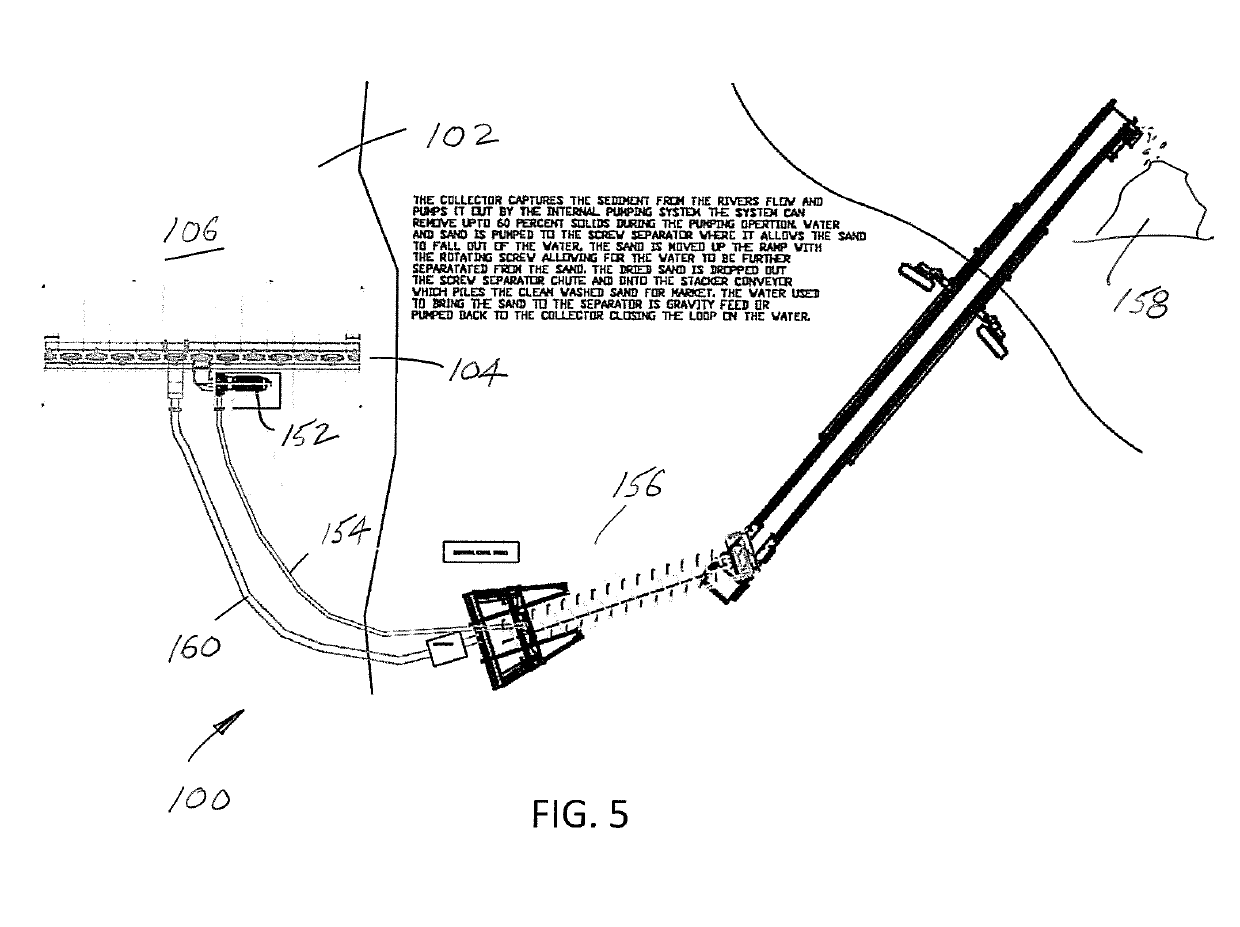

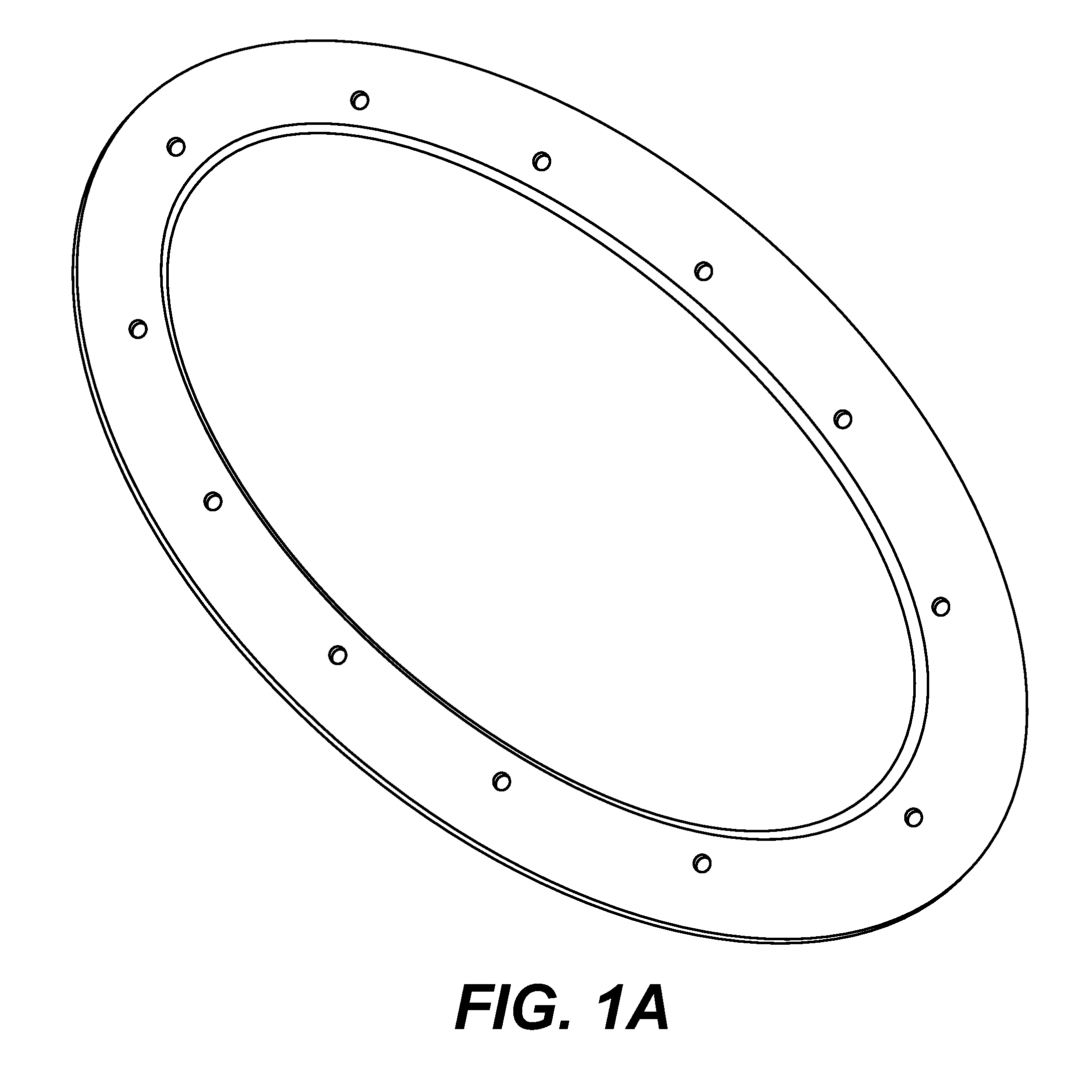

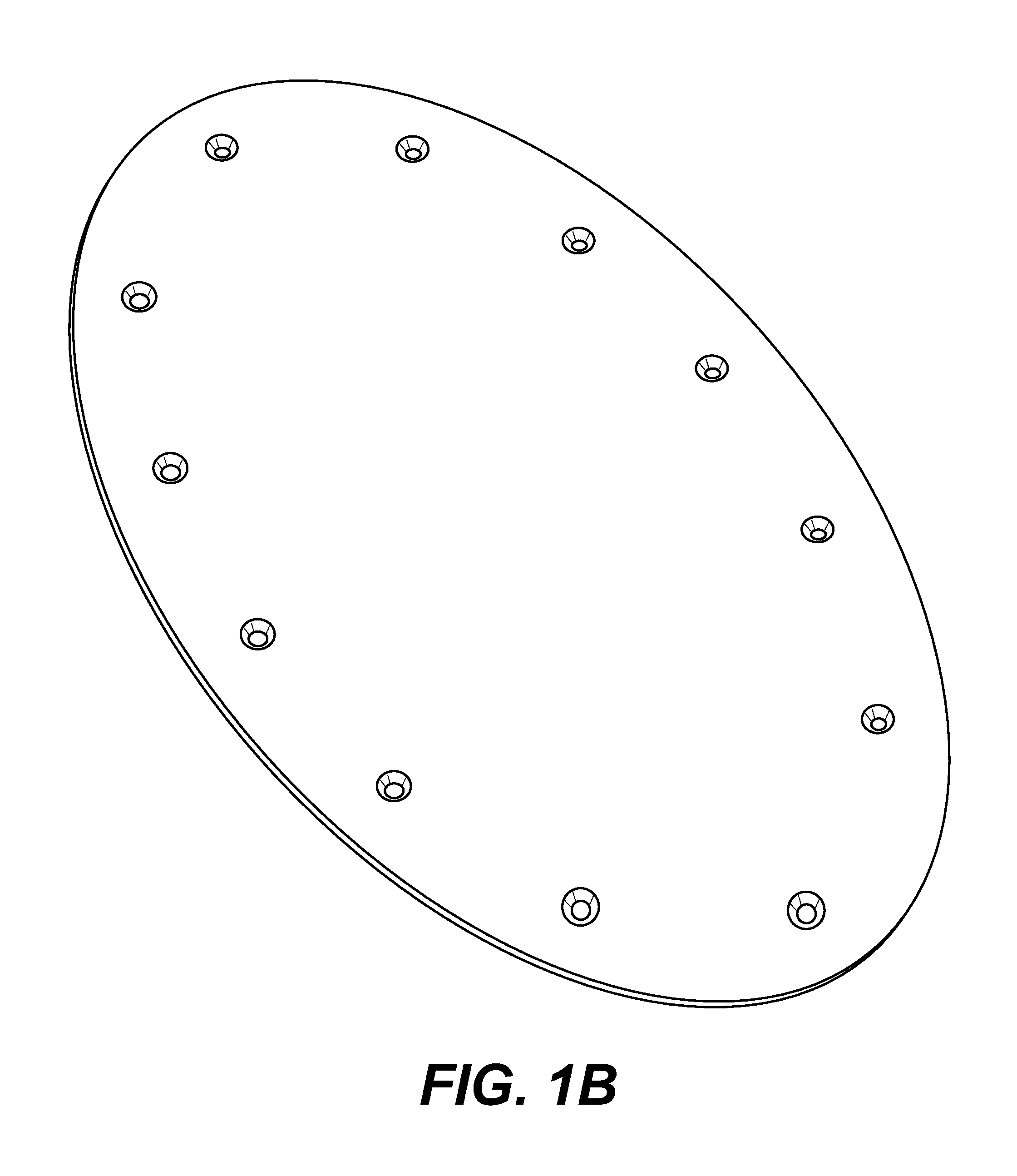

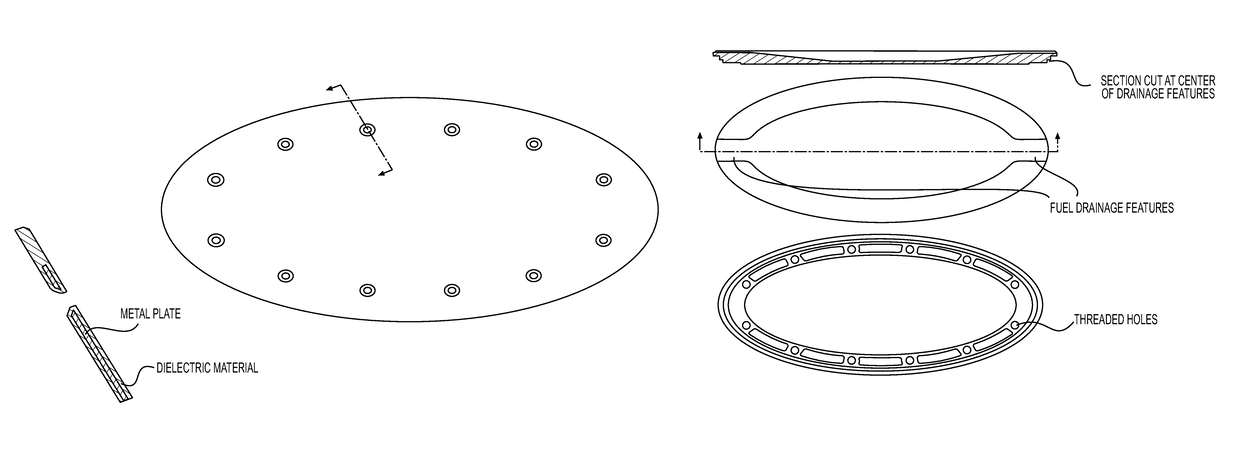

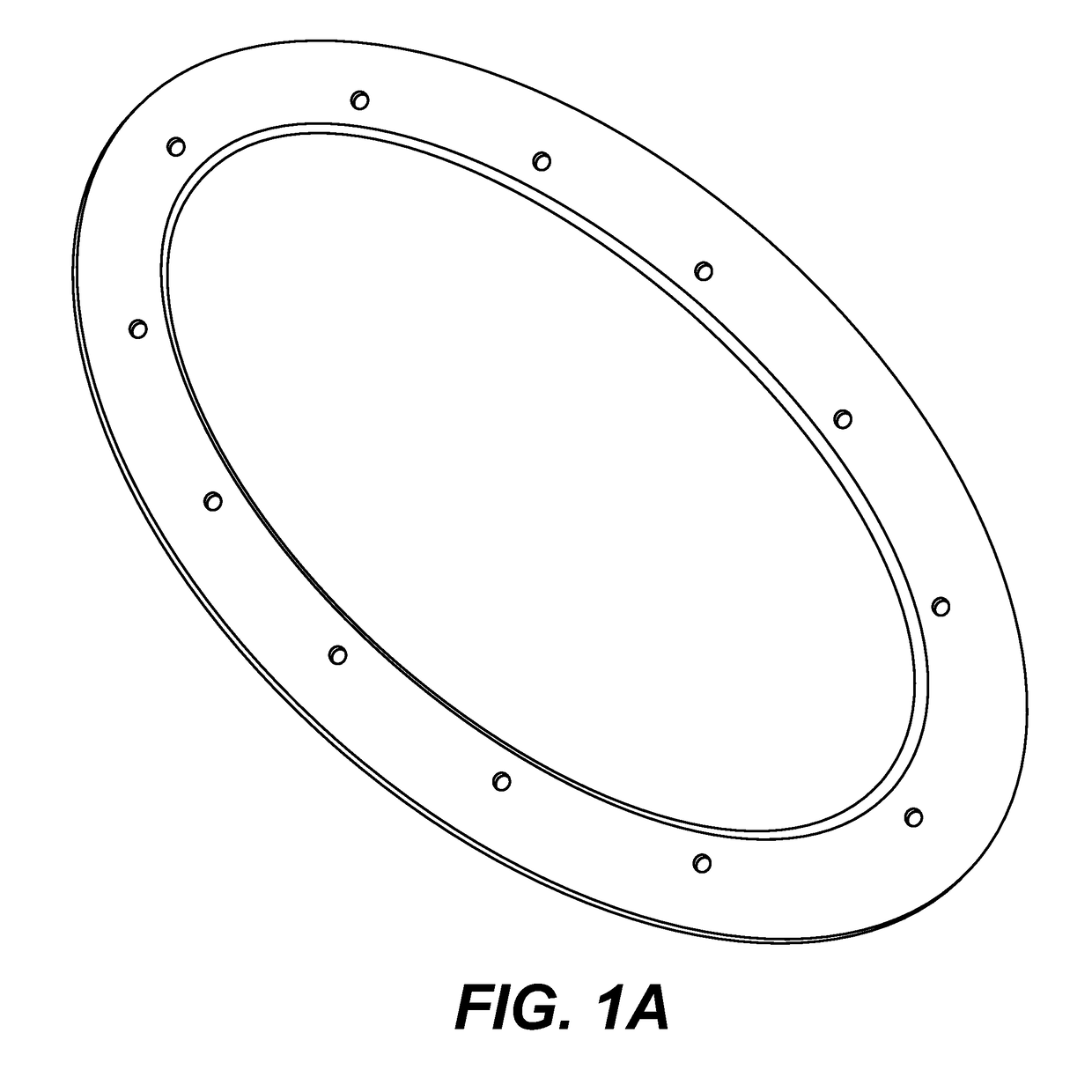

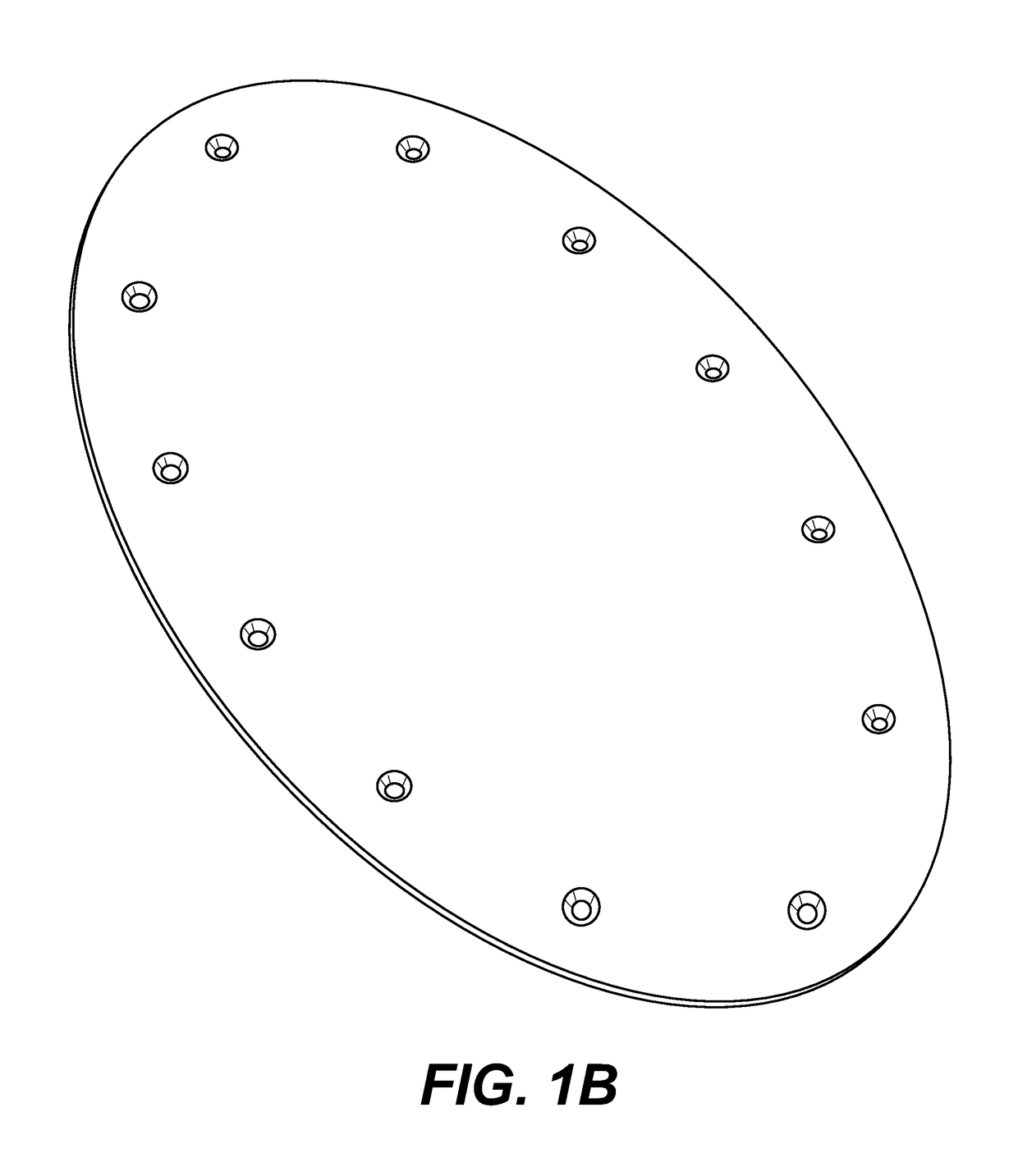

Fuel Tank Access Door Systems And Methods

ActiveUS20160001871A1Improve securityReduce maintenance costsAircraft lighting protectorsFuel tank safety measuresElectricityFuel tank

Owner:TEXTRON INNOVATIONS

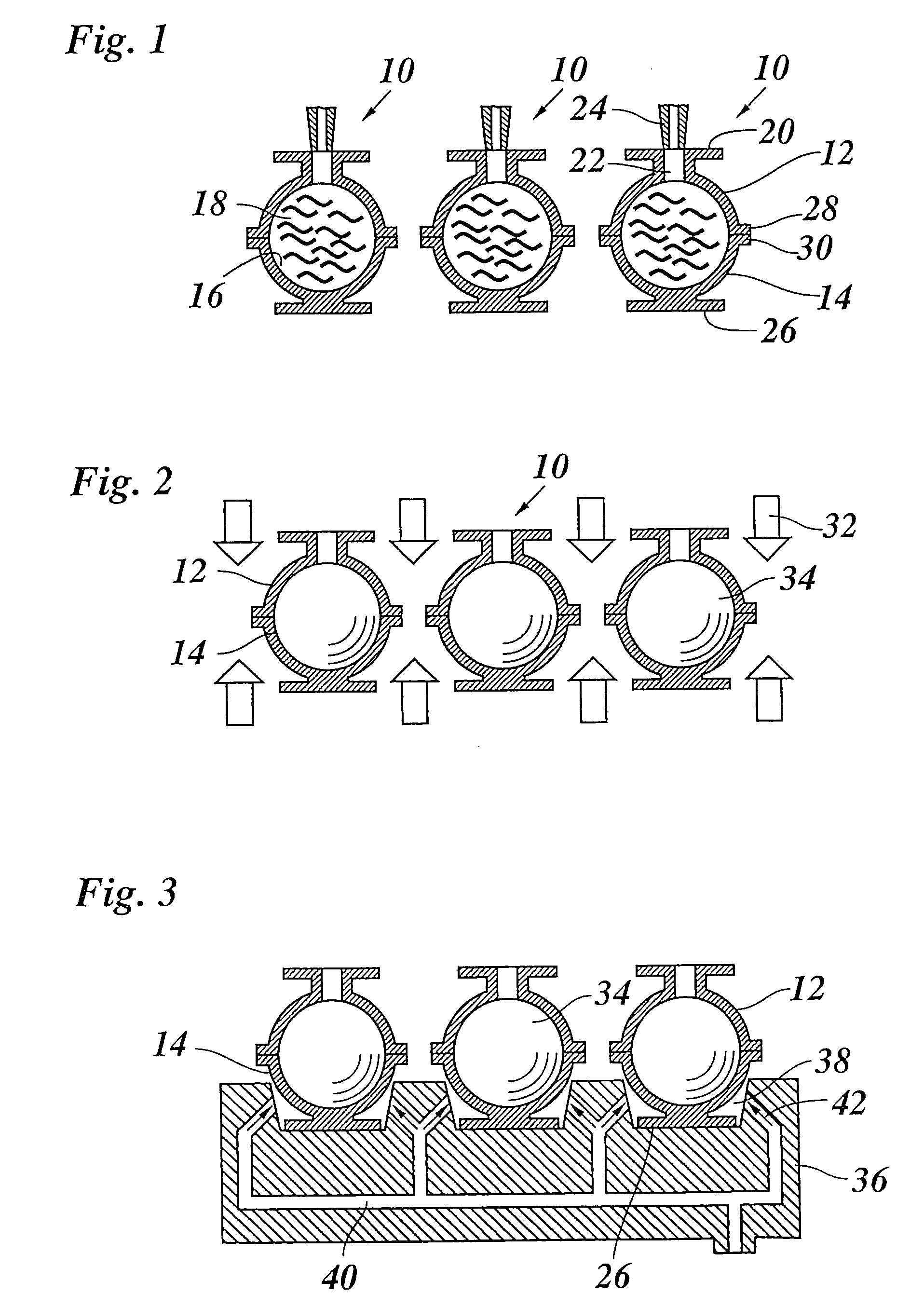

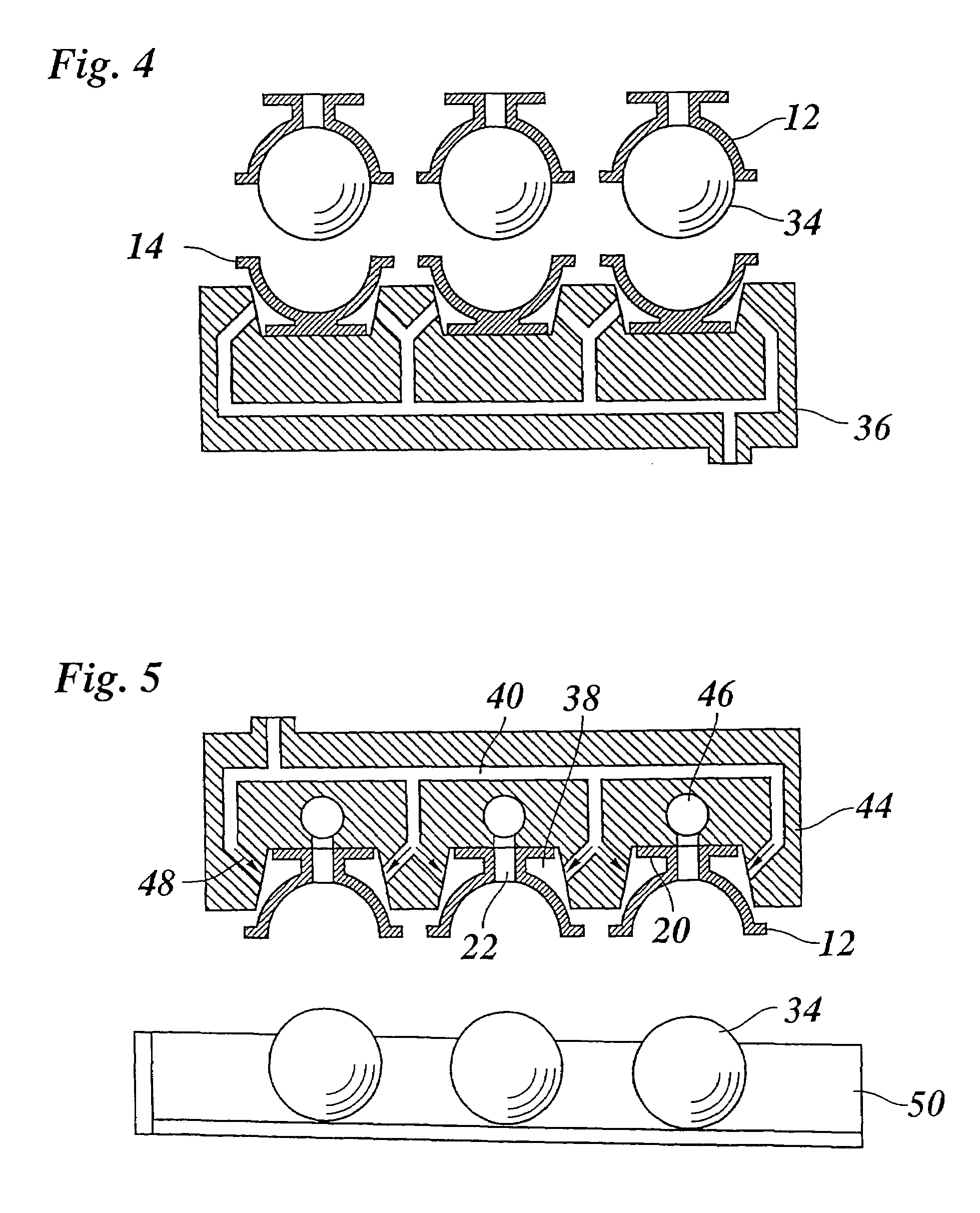

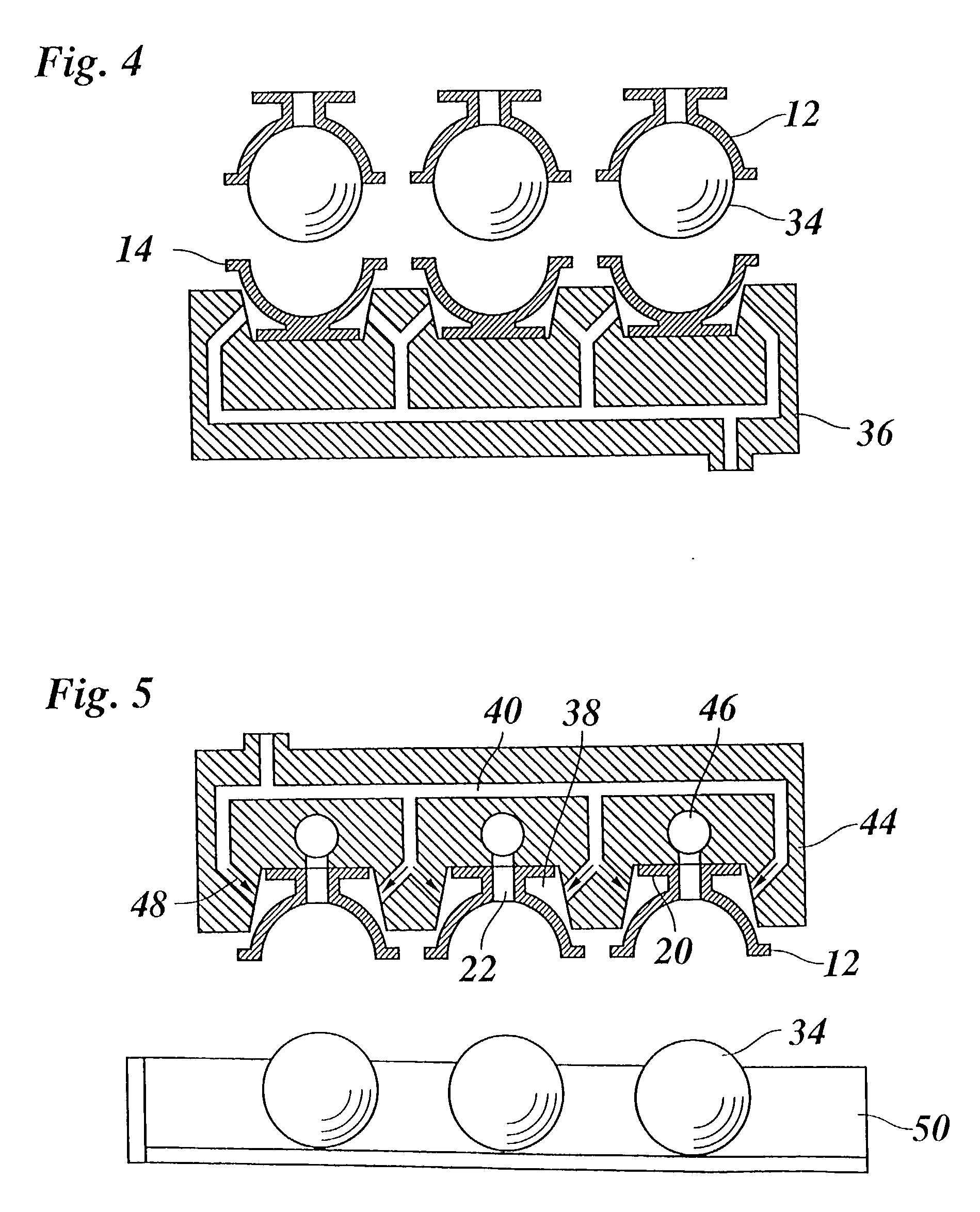

Method and device for manufacturing pellets of hot-melt ink

A method for manufacturing pellets of hot-melt ink which includes the steps of filling molten ink into a mold cavity defined by a first die and a second die of a mold, allowing the ink to cool down and solidify in the mold cavity, and heating at least one of the first and second dies for re-melting the surface of the ink pellet to facilitate its removal from the mold cavity.

Owner:OCE TECH

Method and apparatus for optimizing forging processes

ActiveUS7281402B2Eliminate cavitiesStrengthen and consolidateShaping safety devicesHammer drivesMachine pressForging

A method and apparatus for optimizing the forging of a workpiece that is moved along a longitudinal axis of a forging press. The method includes detecting the relative positions of the first and second ends of the workpiece along the longitudinal axis and calculating a length of the workpiece therebetween.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

Nest box or birdhouse

ActiveUS11363802B1Easy nesting cavity cleaningEliminate nesting cavityBird housingsAnimal scienceNest box

A nest box or birdhouse wherein a removable roof panel provides easy physical access to a nest cavity and also secures an interchangeable entrance panel in multiple positions—for both active-breeding-season use and off-season storage. All vertical enclosure components can remain in place during activity monitoring, avoiding harm to eggs or hatchlings when the nest box is opened. In the off-season-storage configuration, the enclosed nest cavity is eliminated to prevent infestation. The nest box utilizes a hollow roof-locking pin for increased ventilation. Furthermore, an adjustable-height mounting mechanism helps prevent predator attacks and allows the nest box to be accessed at safe heights during physical monitoring and maintenance.

Owner:NELSON JEFFREY TODD

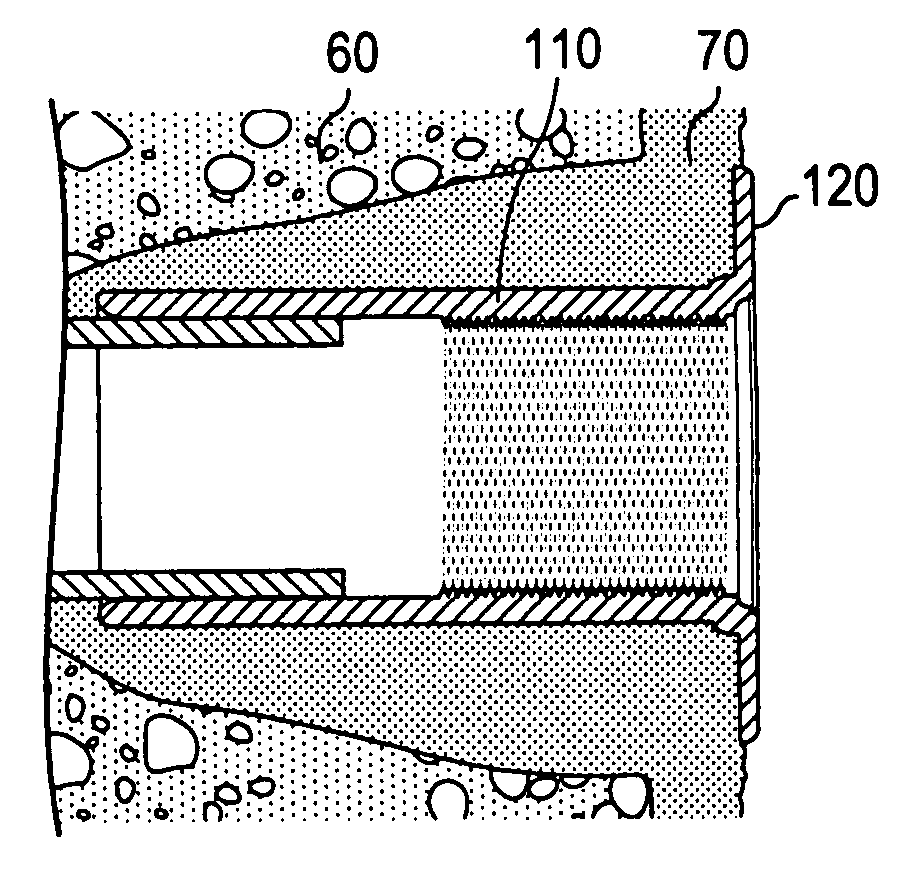

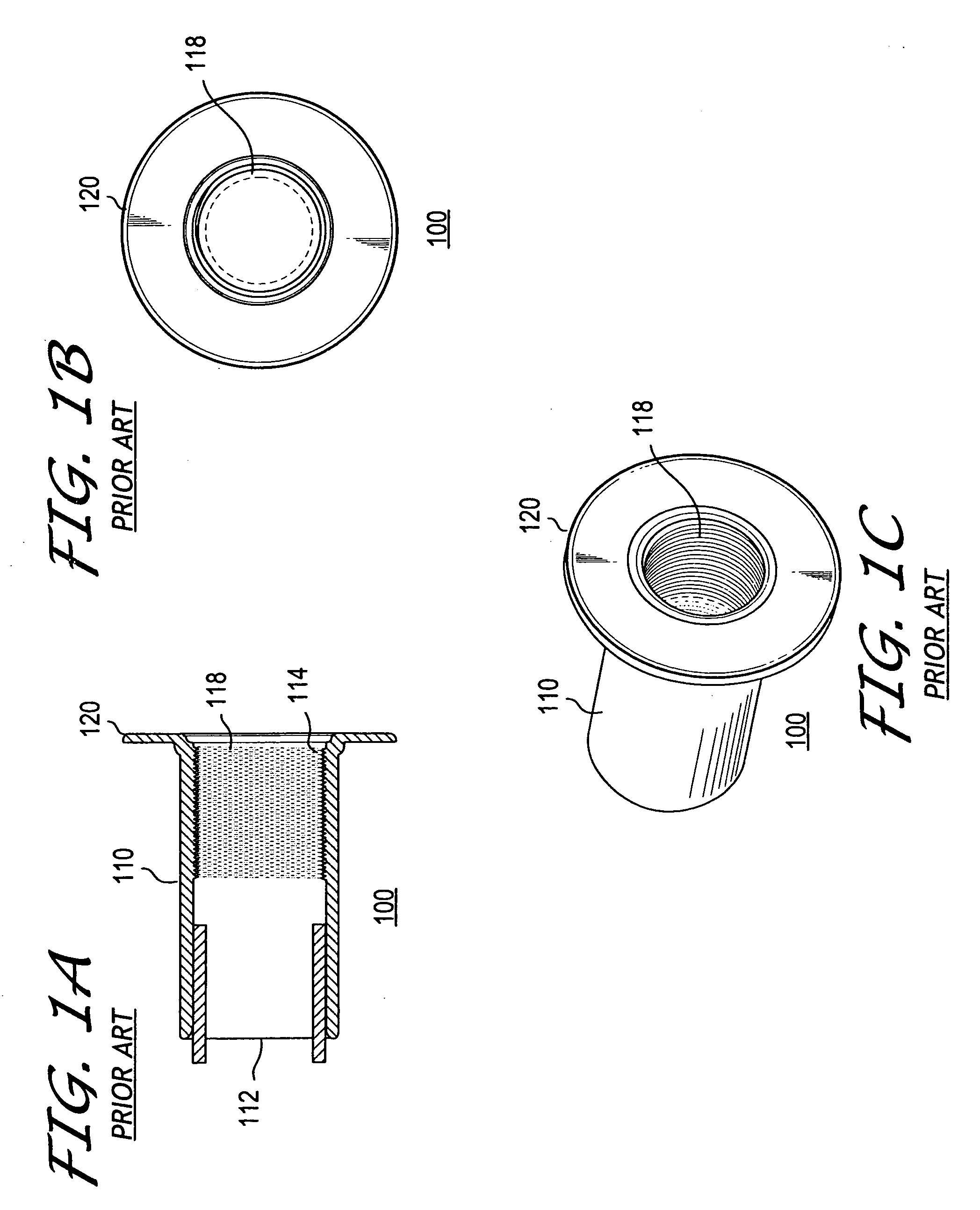

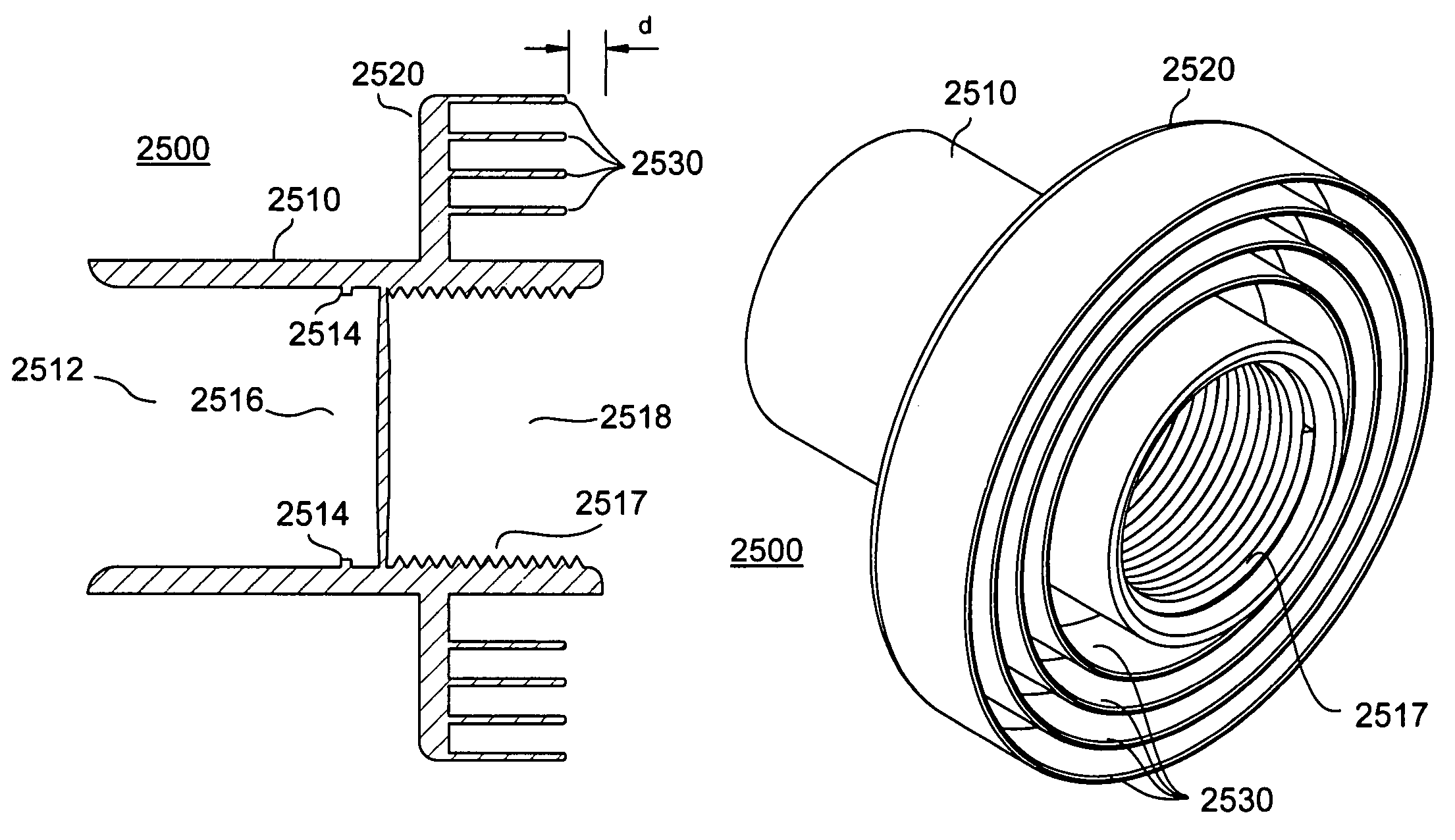

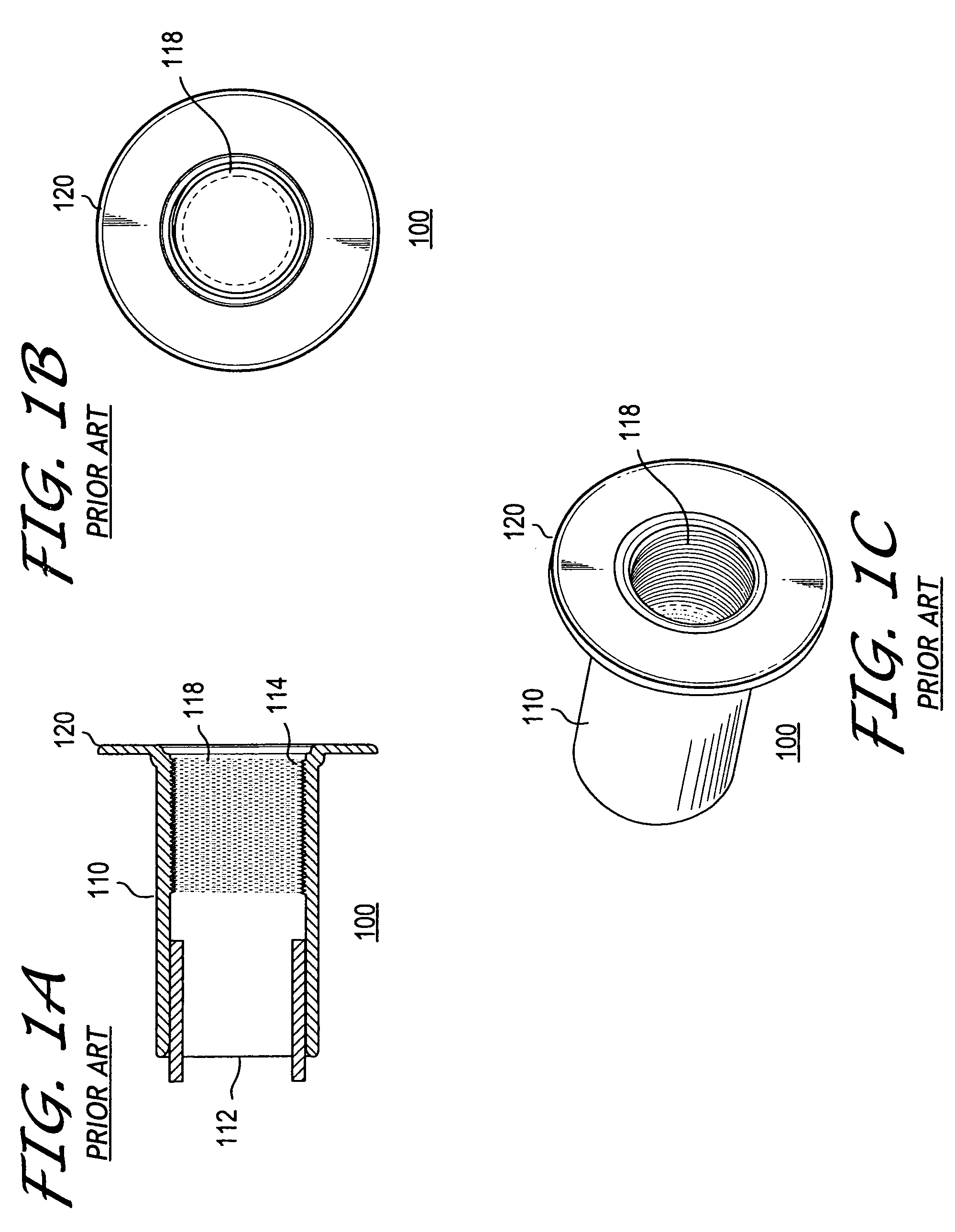

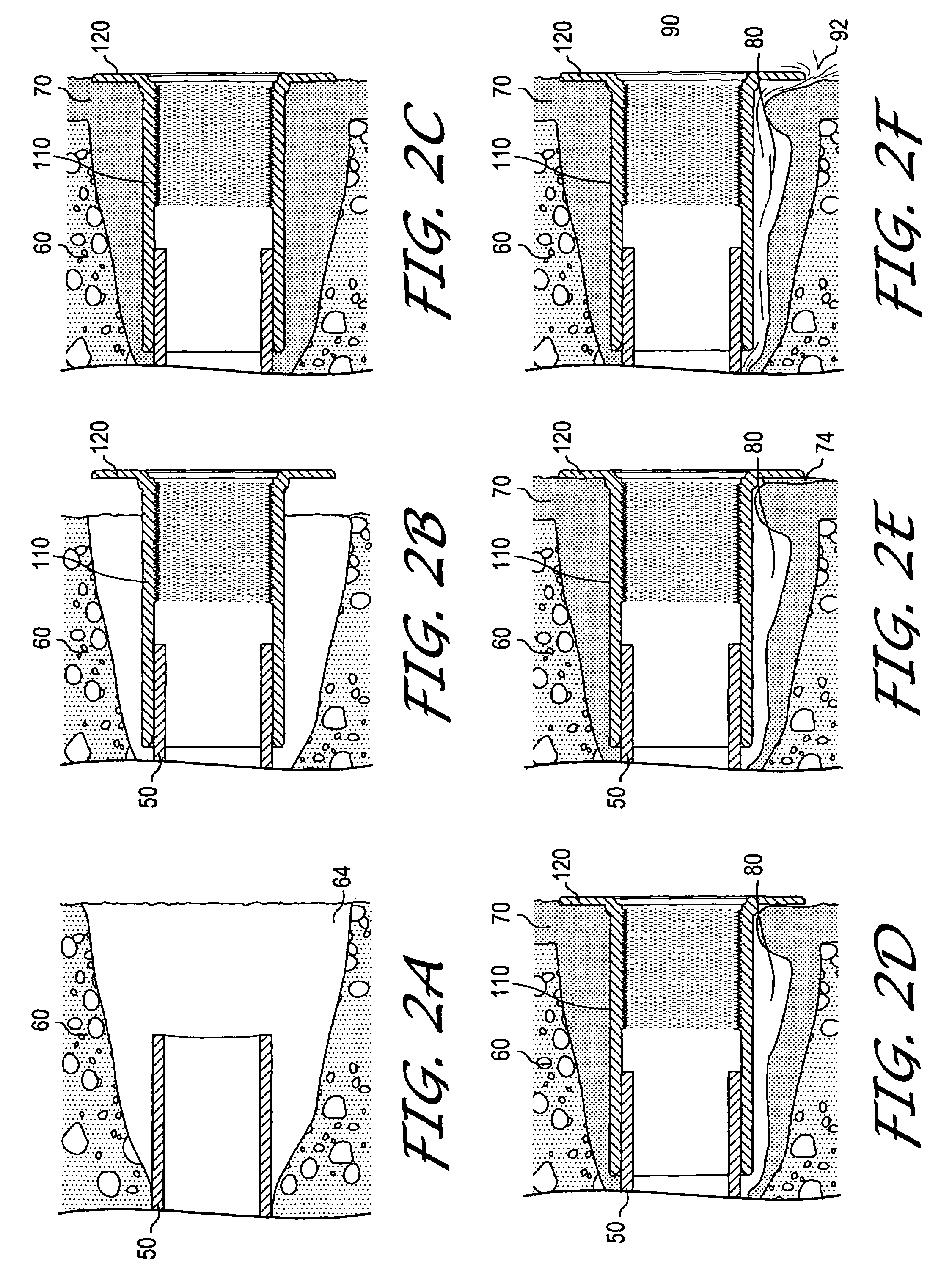

Non-leak pool fixture and method for implementing

InactiveUS20060066098A1Easy to implementPremature leakageForms/shuttering/falseworksPipe connection arrangementsEngineeringSealant

An improved sidewall fitting is disclosed with a fitting body and a flange disposed about the fitting body. Plaster catches disposed along a face of the flange and positioned approximately coextensively with the fitting body. The bodies of the plaster catches may be curvilinear-shaped or straight and the body portions may be of heights for aligned or off-setting configurations. The fitting is installed the plaster catches oriented directly below the body of the fitting, along a generally horizontal plane. Plaster is layered over the flange and plaster catches, and up to the opening in the fitting body. The plaster catches may be disposed along a posterior face of a flange, or simultaneously along the anterior and posterior faces. A second fitting type includes an extension surface for increased bonding with the plaster with additional surface area available for sealing with the plaster. Disposed onto the sealing surface is a leave-out strip, which protects the sealing surface during cementing. After removal of the leave-out strip, the sealing surface provides an uncontaminated surface on which a sealant may be liberally applied. Optionally, a seal may be provided on the sealing surface interposed between the leave-out strip.

Owner:YEAGER BRYAN KEITH +1

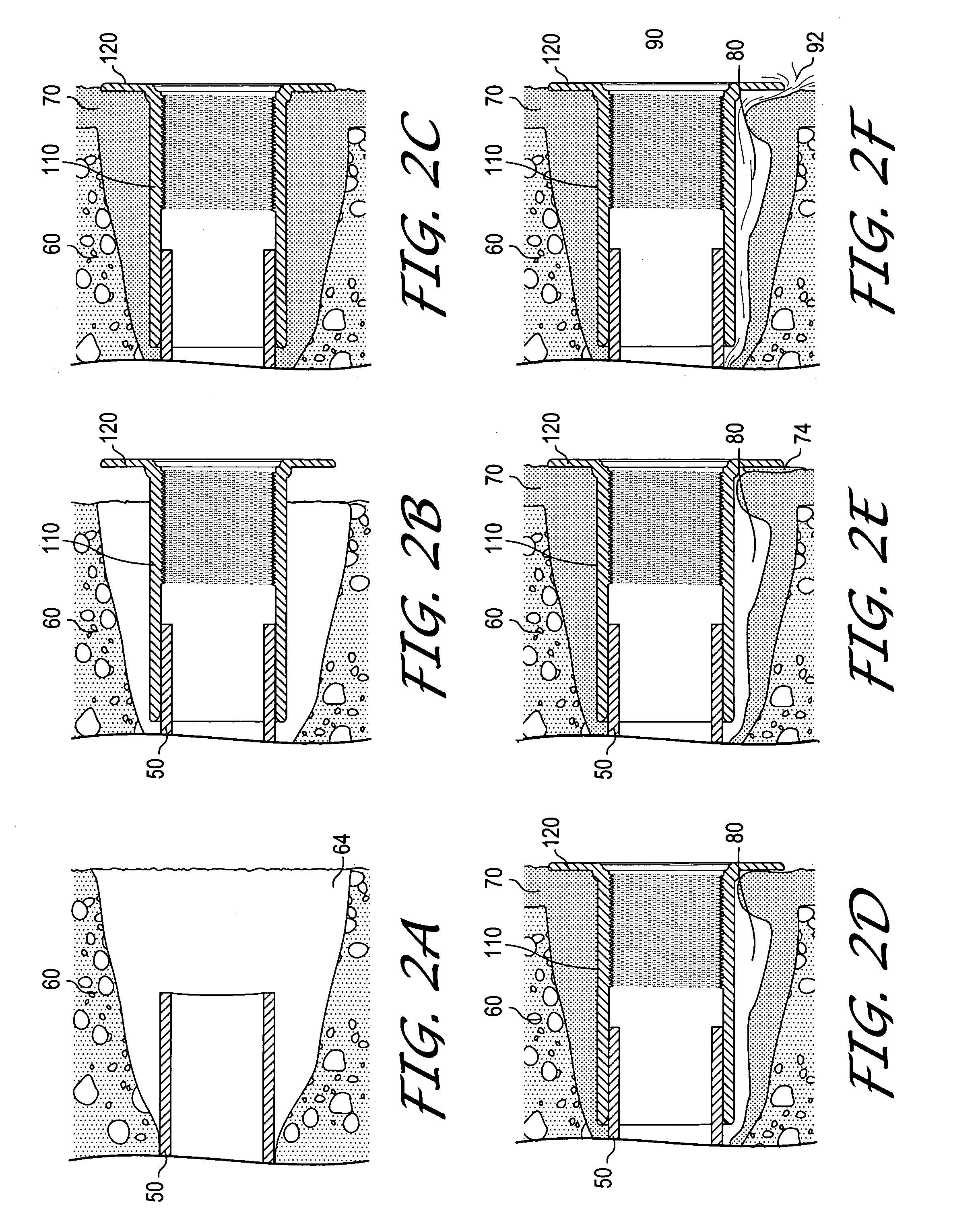

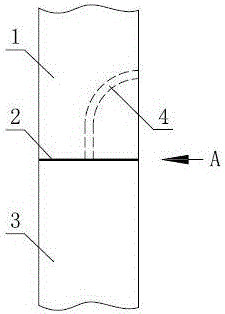

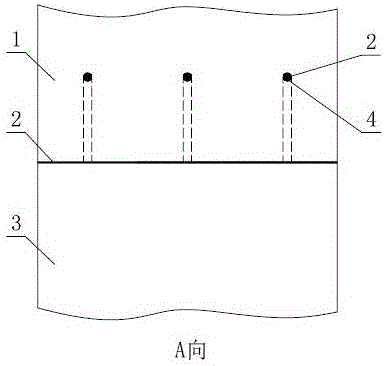

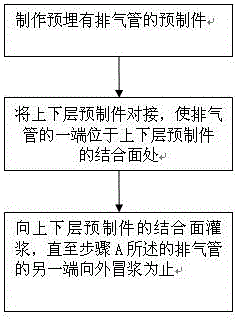

Upper prefabricated member-lower prefabricated member butting structure and upper prefabricated member-lower prefabricated member combination face grouting method

The invention provides an upper prefabricated member-lower prefabricated member butting structure and an upper prefabricated member-lower prefabricated member combination face grouting method, aiming to overcome the effect on structural safety due to the fact that failure to exhaust air in a hollow cavity leads to cavities formed in upper layer-lower layer combination faces finally when the combination faces of upper and lower shear walls and upper and lower frame columns are grouted. The upper prefabricated member-lower prefabricated member butting structure comprises an upper prefabricated member and a lower prefabricated member which are butted, the combination face of the two prefabricated members is grouted, and at least one of the prefabricated members is provided with an exhaust passage with one end extending out of the combination face of the prefabricated member and the other end extending out of other surfaces thereof. The upper prefabricated member-lower prefabricated member butting structure and the upper prefabricated member-lower prefabricated member combination face grouting method have the advantages that both structural safety and construction quality are guaranteed, and the butting structure and the grouting method are suitable for grouting of the combination face of the upper and lower prefabricated members.

Owner:深圳市鹏城建筑集团有限公司 +1

Non-leak pool fixture and method for implementing

An improved sidewall fitting is disclosed with a fitting body and one or more flanges disposed about the fitting body. Plaster catches disposed along a face of one flange and positioned approximately coextensively with the fitting body. The bodies of the plaster catches may be curvilinear-shaped, straight or concentric rings and the body portions may be of heights for aligned or off-setting configurations. The fitting is installed the plaster catches oriented directly below the body of the fitting, along a generally horizontal plane. Plaster is layered over the flange and plaster catches, and up to the opening in the fitting body. The plaster catches may be disposed along a posterior face of a flange, or simultaneously along the anterior and posterior faces. A second fitting type includes an extension surface for increased bonding with the plaster with additional surface area available for sealing with the plaster. Disposed onto the sealing surface is a leave-out strip, which protects the sealing surface during cementing. After removal of the leave-out strip, the sealing surface provides an uncontaminated surface on which a sealant may be liberally applied. Optionally, a seal may be provided on the sealing surface interposed between the leave-out strip.

Owner:YEAGER BRYAN KEITH +1

Fuel tank access door systems and methods

ActiveUS9718533B2Improve securityReduce maintenance costsAircraft accessoriesAircraft lighting protectorsElectricityFuel tank

Owner:TEXTRON INNOVATIONS

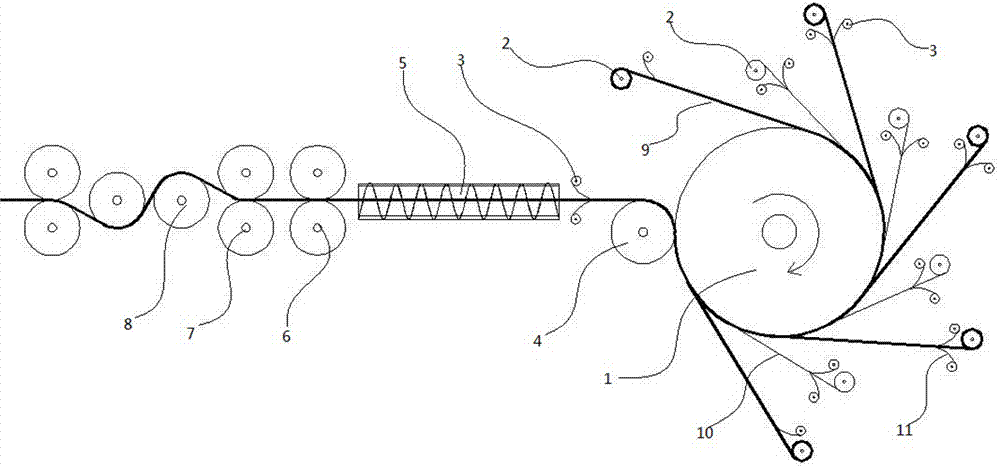

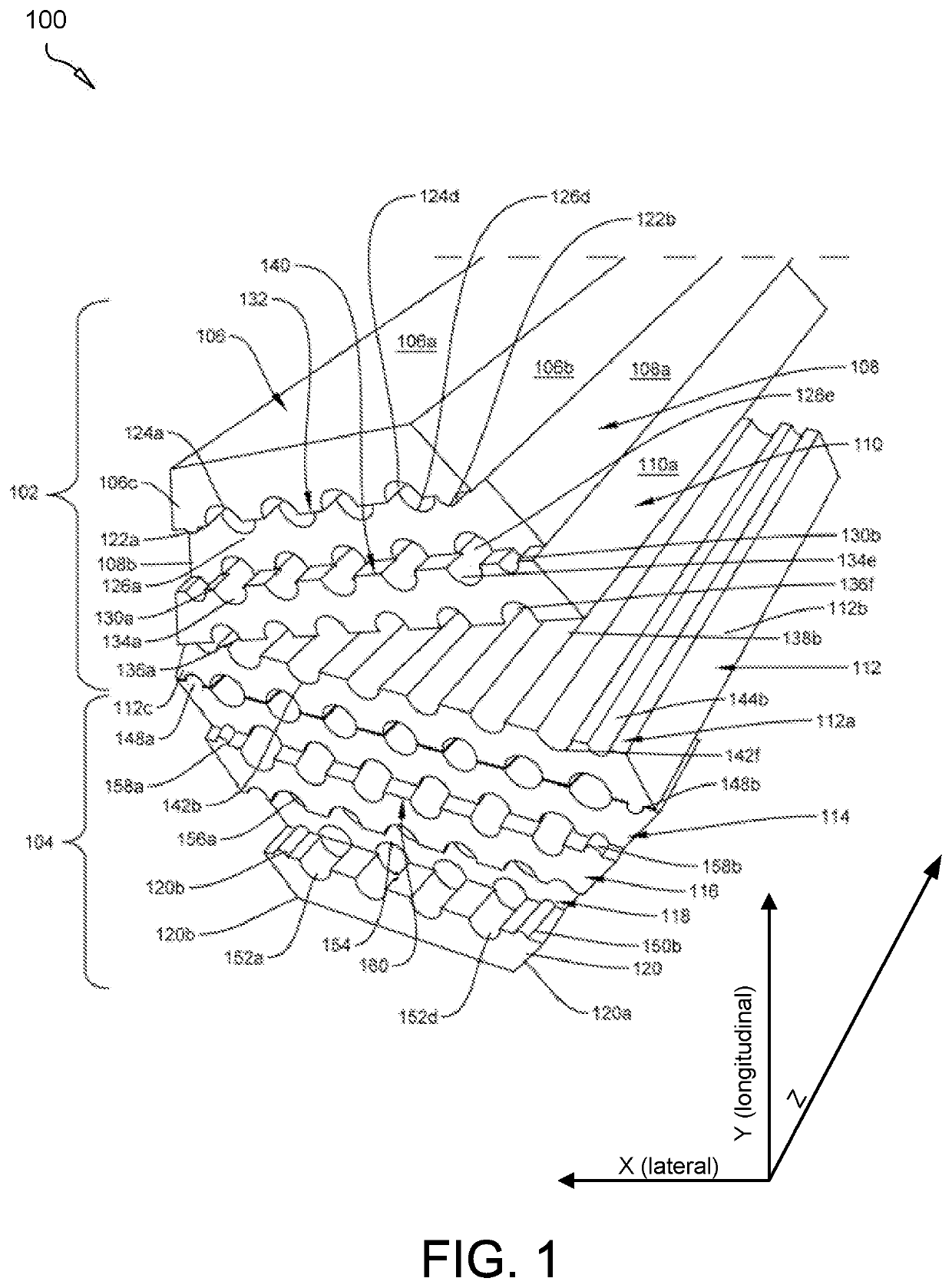

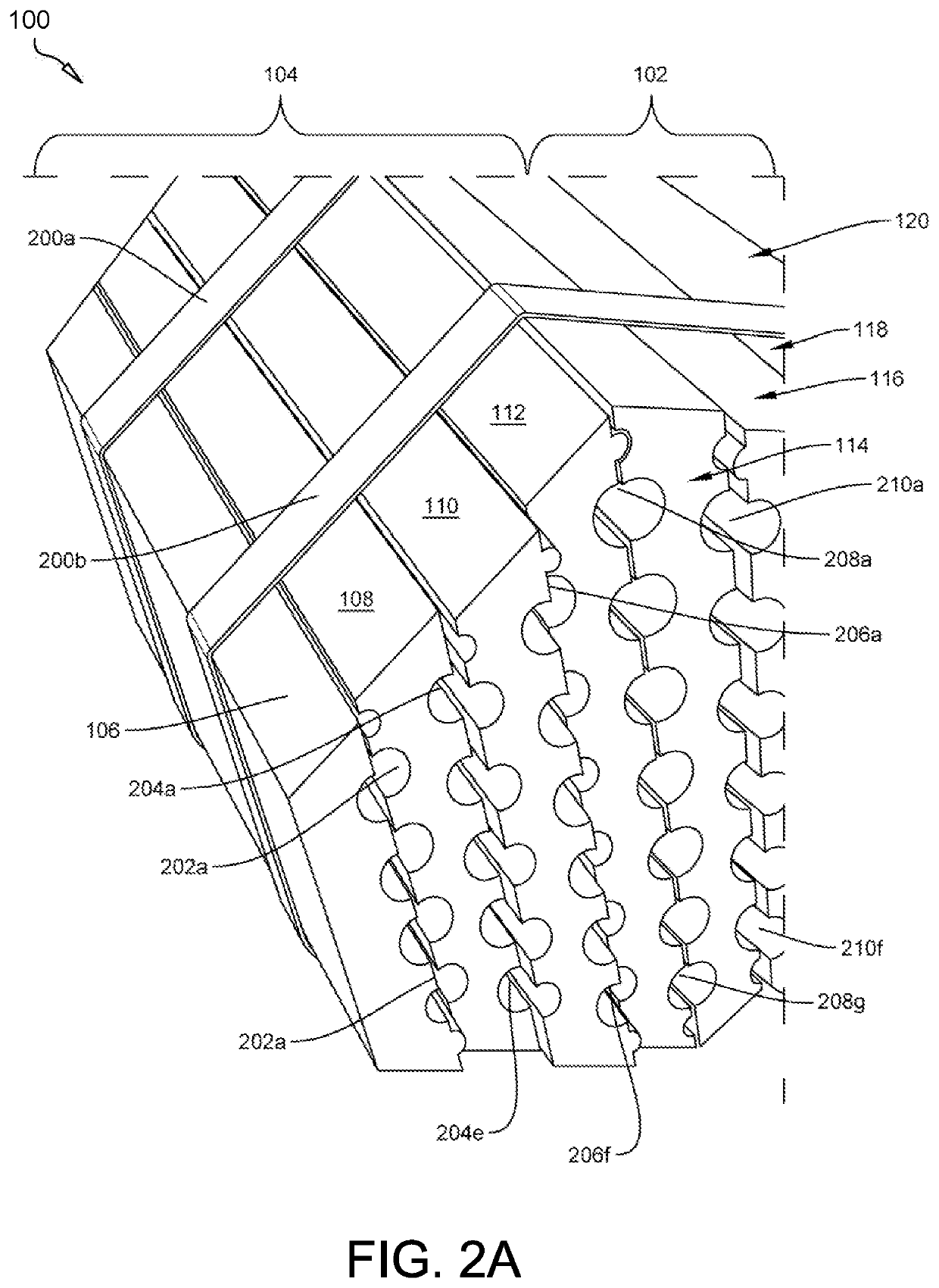

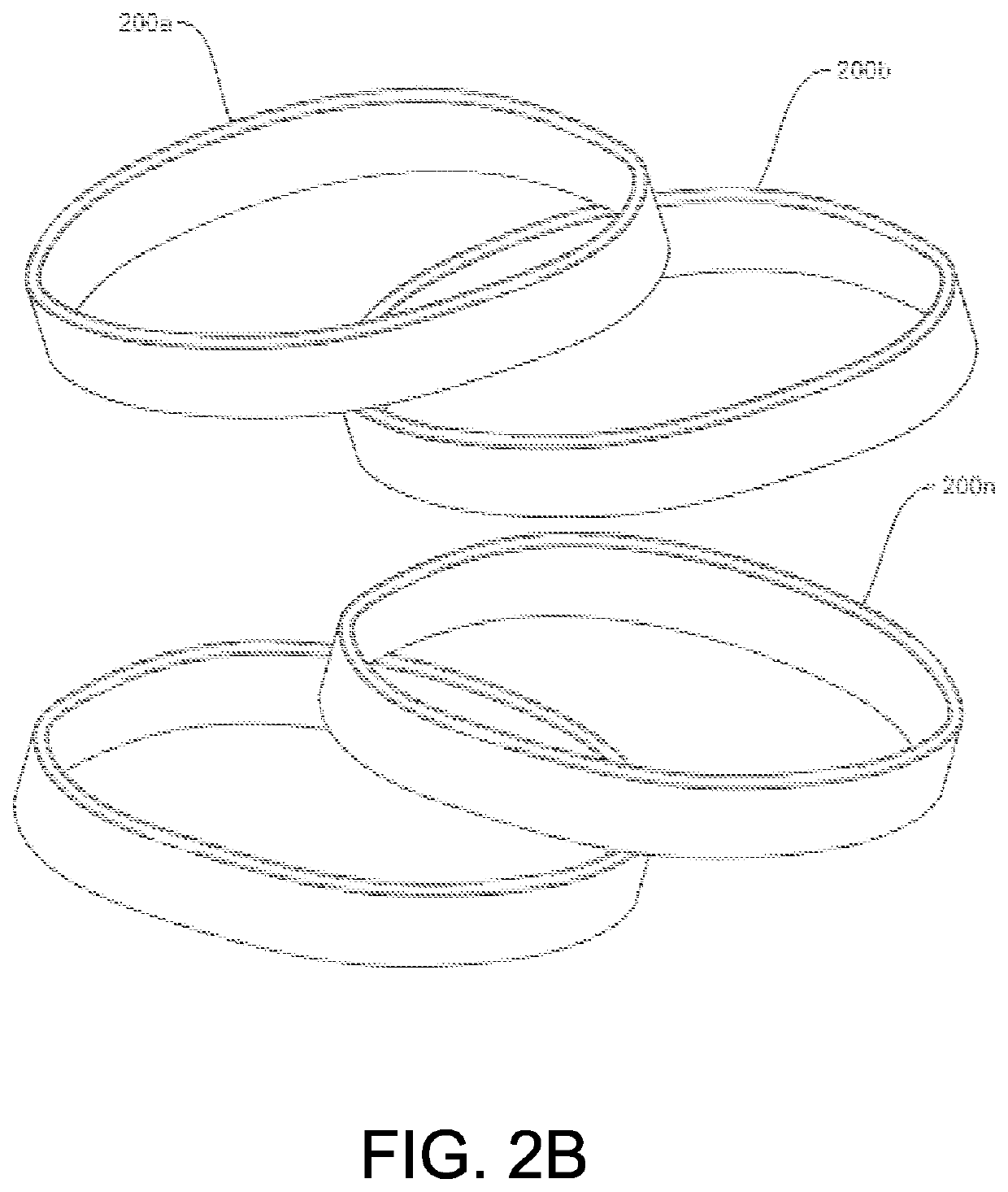

Thermoplastic carbon fiber composite material preparation production line

InactiveCN107571594ARealize overlay combinationGuaranteed intensificationLamination ancillary operationsLaminationMaterials preparationProduction line

The invention relates to a thermoplastic carbon fiber composite material preparation production line which comprise an overlapping mechanism, a hot-pressing mechanism, a leveling mechanism and a discharge mechanism which are arranged in sequence in a production line movement direction, wherein the overlapping mechanism comprises an overlapping roller and a plurality of uncoiling rollers which arearranged at the periphery of the overlapping roller in a surrounding manner; the uncoiling rollers consist of carbon fiber uncoiling rollers and resin uncoiling rollers; the carbon fiber uncoiling rollers and the resin uncoiling rollers are arranged at the periphery of the overlapping roller in an alternative surrounding manner in sequence; and the hot-pressing mechanism comprises a high-frequencysensing heater and a hot-pressing roller which is arranged at the tail end of the high-frequency sensing heater. As a plurality of uncoiling rollers are matched with the same overlapping roller, overlapping combination of multiple layers of materials is achieved, dynamic overlapping is achieved in an overlapping roller rotation manner, intensification of stations is achieved, and the overlappingspeed is also greatly increased.

Owner:FOSHAN LANRUI OUTE INFORMATION SERVICES CO LTD

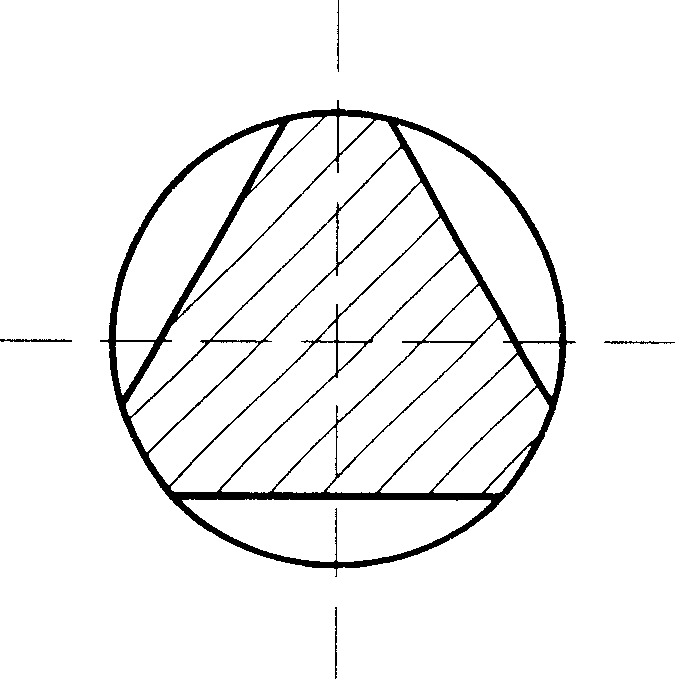

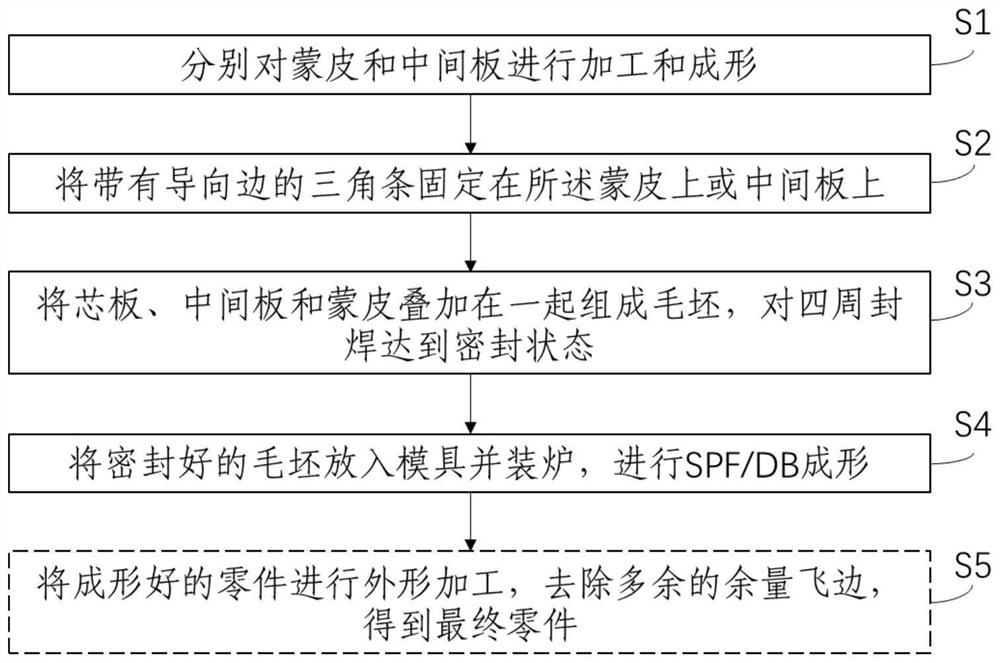

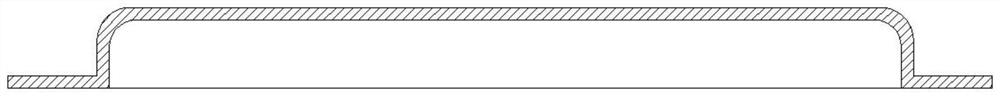

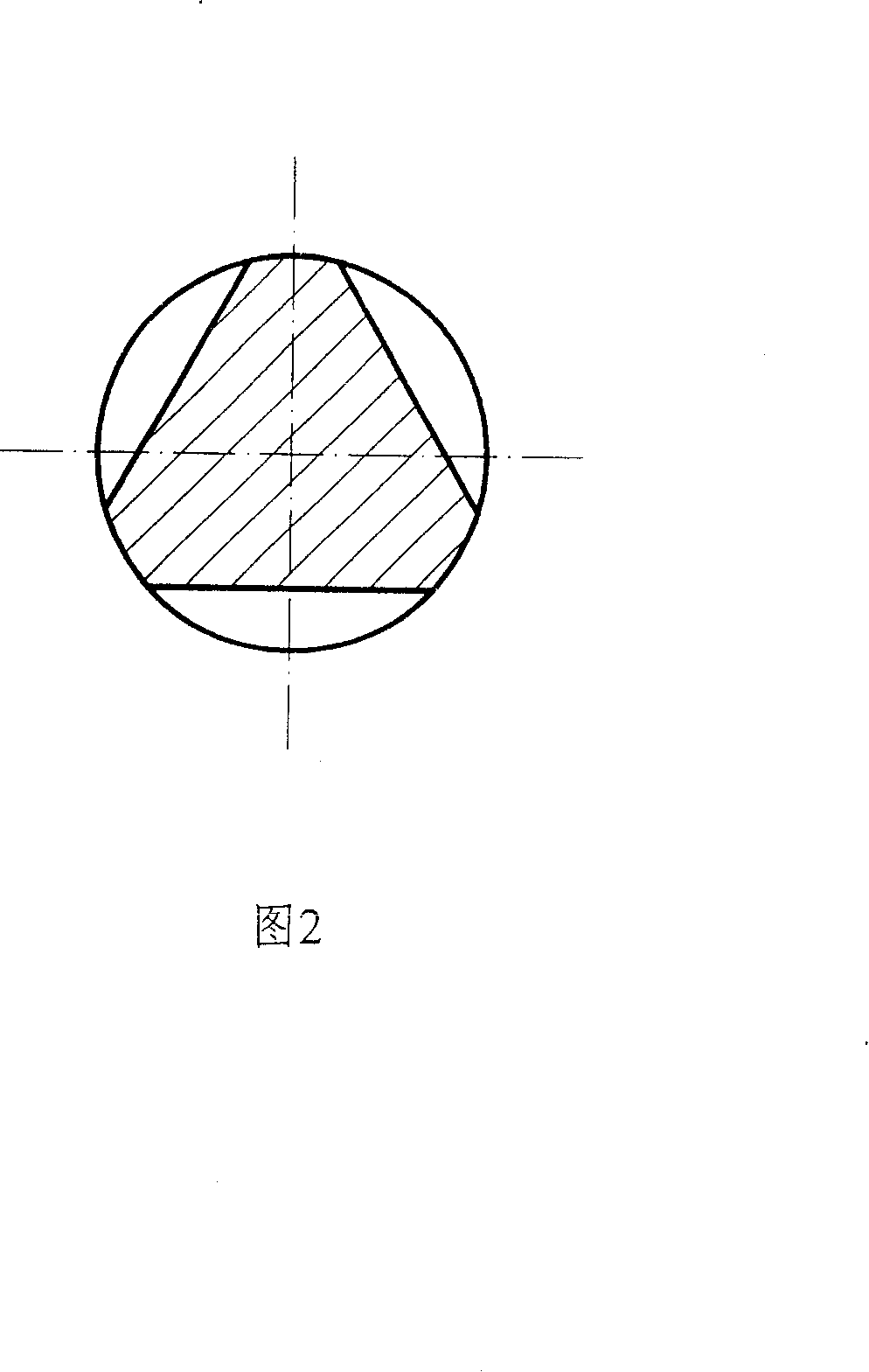

SPF/DB hollow structure forming method

PendingCN114571190AEliminate cavitiesImprove structural performanceNon-electric welding apparatusMedicineStructural engineering

The invention discloses an SPF / DB hollow structure forming method. The method comprises the steps that firstly, a skin and a middle plate are machined and formed; 2, a triangular strip with a guide edge is fixed to the skin or the middle plate; 3, the core plate, the middle plate and the skin are stacked together to form a blank, and the periphery is sealed and welded to achieve a sealed state; and 4, the sealed blank is put into a mold and charged into a furnace, and SPF / DB forming is carried out. Compared with the traditional SPF / DB technology, the technical scheme provided by the invention has the advantages that a triangular cavity is eliminated, and the structural performance and reliability are improved; and moreover, the internal and external shapes of the hollow structure can be synchronously and accurately controlled, more functions are realized, the degree of freedom of design is improved, and the rigidity, fatigue and other properties of parts are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Method for producing glass powders

InactiveUS7059153B2Avoid pollutionLow viscosityGlass blowing apparatusGlass reforming apparatusPhysical chemistryGlass particle

A powder of solid and spherical glass particles is easily manufactured by subjecting a mixed solution of a raw material oxide powder comprising a glass network-forming element, and an aqueous solution of a water-soluble compound comprising a glass-forming element other than the element of the raw material oxide powder to spray-thermal decomposition, wherein the spray-thermal decomposition temperature is set to be in a specific range according to the amount of the raw material oxide powder in the total of the amount of the raw material oxide powder and the oxide-converted amount of the water-soluble compound, as well as the average particle size of the glass powder to be manufactured.

Owner:MURATA MFG CO LTD

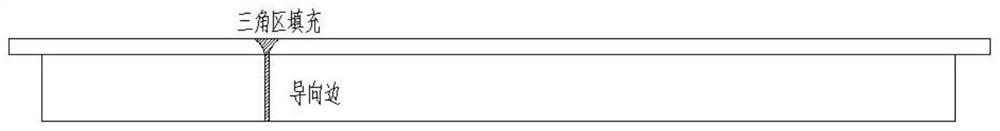

Electric fuel pump suitable for fuel containing alcohol

The electric fuel oil pump suitable for fuel containing alcohol has a shell, an inner casing inside the shell to constitute together with the shell one cavity serving as the main fuel oil conveying flow channel, and a motor set inside the inner casing and with gap among its parts serving as the secondary fuel oil conveying flow channel. While over 80 % of the fuel oil is conveyed through the main fuel oil conveying flow channel, the rest flows through the secondary fuel oil conveying flow channel to lubricate and clean the inside parts and cool the rotor and the stator, so as to raise the work efficiency of the motor. There are one non-return valve set at fuel inlet hole inside the secondary fuel oil conveying flow channel and one conic friction pair at the lower bearing on the end of the vane wheel to further raise the operation reliability and safety.

Owner:曹宝军 +1

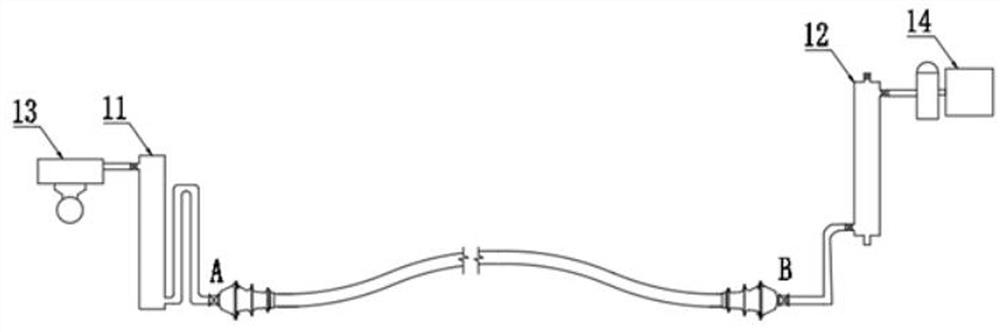

Vacuum grouting device and grouting method for prestress long distance, large diameter and multiple curvature duct

PendingCN111997369AExtend vacuum timeEasy to operateBuilding material handlingClassical mechanicsEngineering

The invention discloses a vacuum grouting device and a grouting method for a prestress long distance, large diameter and multiple curvature duct. The grouting device comprises a grouting pump and a vacuum pump. The grouting device is characterized by further comprising a slurry inlet buffer and a slurry outlet buffer. The slurry inlet buffer is arranged between the grouting pump and an entrance ofa to-be-poured duct, and the slurry outlet buffer is arranged between an outlet of the to-be-poured duct and the vacuum pump. According to the vacuum grouting device and the grouting method, as the vacuum pump works continuously in a grouting process, the slurry inlet buffer separates air in a grouting rubber tube initially, the slurry outlet buffer prolongs a vacuumizing time and the duct is kept in a vacuum state or an approximately vacuum state all the time, the duct is filled with the slurry. The vacuum grouting device is easy to operate and solves the problem of tedious steps as different grouting process methods are needed in different slurry types.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

Hexagonal nesting block for solitary tunnel nesting bees and other hymenopterans

A bee nesting block, comprising: a first arrangement having a first slab, a second slab, a third slab and a fourth slab, wherein a stacked first arrangement forms a first staggered ledge and a second staggered ledge to provide a landing surface and greater planer space as a visual cue for improved nest recognition for one or more mason bees; and a second arrangement having a fifth slab, a sixth slab, a seventh slab and an eighth slab, wherein a stacked second arrangement forms a third staggered ledge and a fourth staggered ledge to provide a landing surface for the one or more mason bees; wherein the first arrangement is stacked onto the second arrangement to form the bee nesting block having a hexagonal shape; wherein the first arrangement stacked on to the second arrangement are fastened to one another using a plurality of bands or sleeves.

Owner:CLARK KIMBALL

Circuit module, and electronic device using the module

InactiveCN101779528AHigh strengthHigh bonding strengthPrinted circuit aspectsElectrical connection printed elementsMechanical engineeringHemt circuits

Owner:PANASONIC CORP

Denture Adhesive Remover for Intraoral and Extraoral Use

InactiveUS20120237901A1Eliminate cavitiesCosmetic preparationsToilet preparationsAcetic acidDenture adhesives

Described herein are all-natural compositions and methods of using them for removing denture adhesive from both the denture apparatus and the oral cavity. The compositions comprise acetic acid and water. The invention includes wipes premoistened with a composition of the invention.

Owner:WHITE KRISTINE A +1

Minimum cavity relief valve

InactiveCN105612377AEliminate cavitiesOperating means/releasing devices for valvesEqualizing valvesEngineeringVALVE PORT

The disclosure addresses a relief valve suitable for use in systems for delivering relatively viscous fluids. The described relief valve includes a housing and a valve mechanism moveable relative to an opening into the housing to allow or prevent flow from a flow path adjacent the relief valve into and through the housing. The relief valve is configured to minimize, and in many examples, essentially eliminate, a cavity between the housing opening and the adjacent flow path. Elimination of this cavity offers significant advantages as it minimizes or eliminates a location for pumped materials to accumulate and / or cure, which can lead to impairment or disabling of the relief valve operation.

Owner:GRACO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com