Electric fuel pump suitable for fuel containing alcohol

An electric fuel pump, alcohol fuel technology, applied in liquid fuel engines, components of pumping devices for elastic fluids, liquid fuel feeders, etc., can solve problems such as abnormal wear, shortening service life, and causing danger , to achieve the effect of ensuring reliability and safety, improving work efficiency, and safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

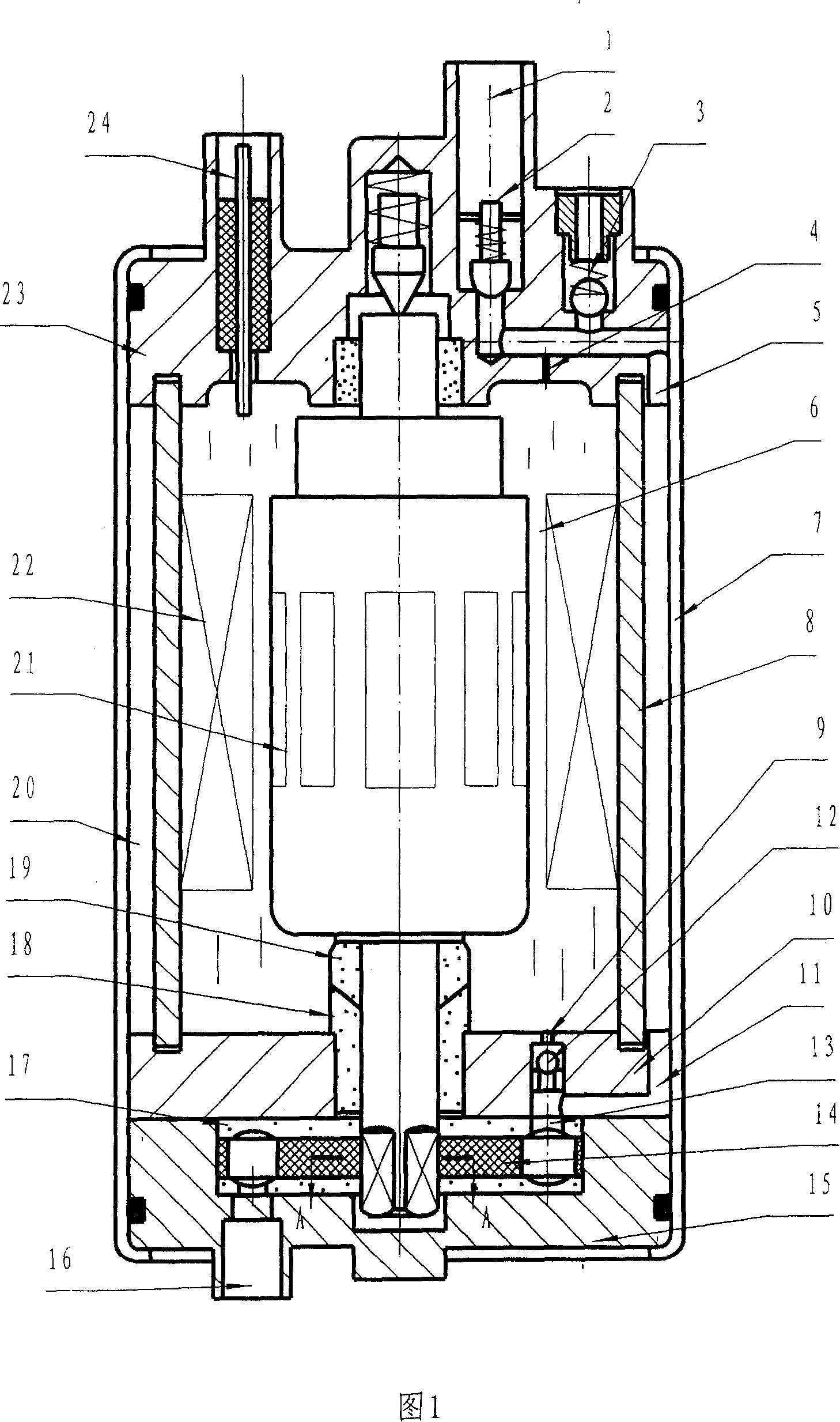

[0015] In Fig. 1 and Fig. 2, the upper and lower ends of the housing 7 are respectively provided with an upper end cover 23 and a lower end cover 15, the motor is arranged in the inner shell 8 placed in the housing 7, and the housing 7 and the inner shell 8 It constitutes the main fuel delivery flow channel 20, and the secondary fuel delivery flow channel 6 is formed by the gap between the motor stator and the rotor in the inner shell 8. The shape join method of the edge is joined. The fuel pump inlet hole 16 connected to the pump body on the lower cover 15 is a straight through hole, while the pump body oil outlet hole 13 on the lower end cover 10 communicates with the main fuel delivery channel 20 through the fuel inlet hole 11, The fuel oil inlet hole 9 communicates with the fuel secondary delivery flow channel 6, and the oil outlet hole 13 of the pump body is provided with a lower check valve 12, and the fuel pump outlet hole 1 provided on the upper end cover 23 is provide...

Embodiment 2

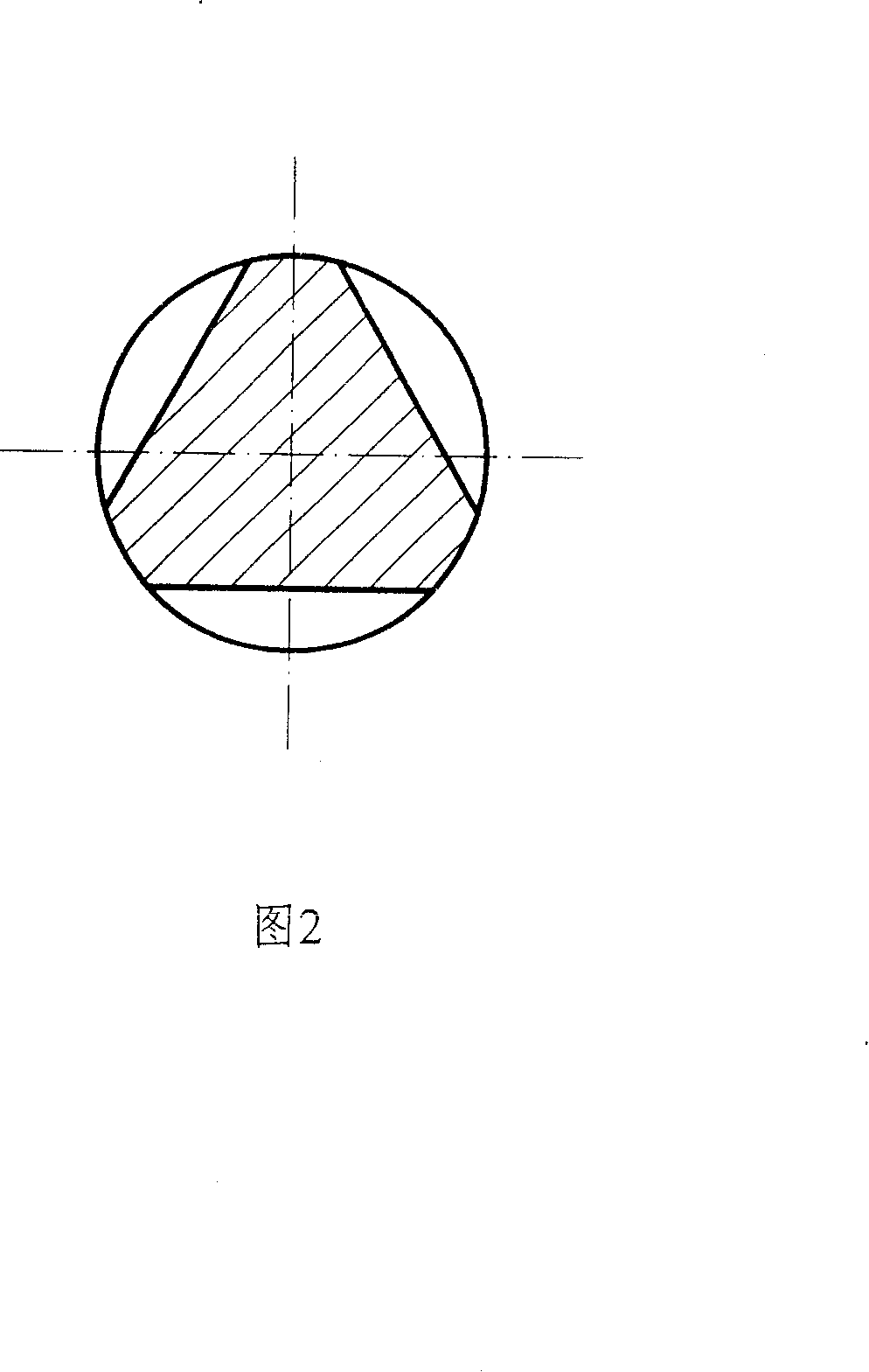

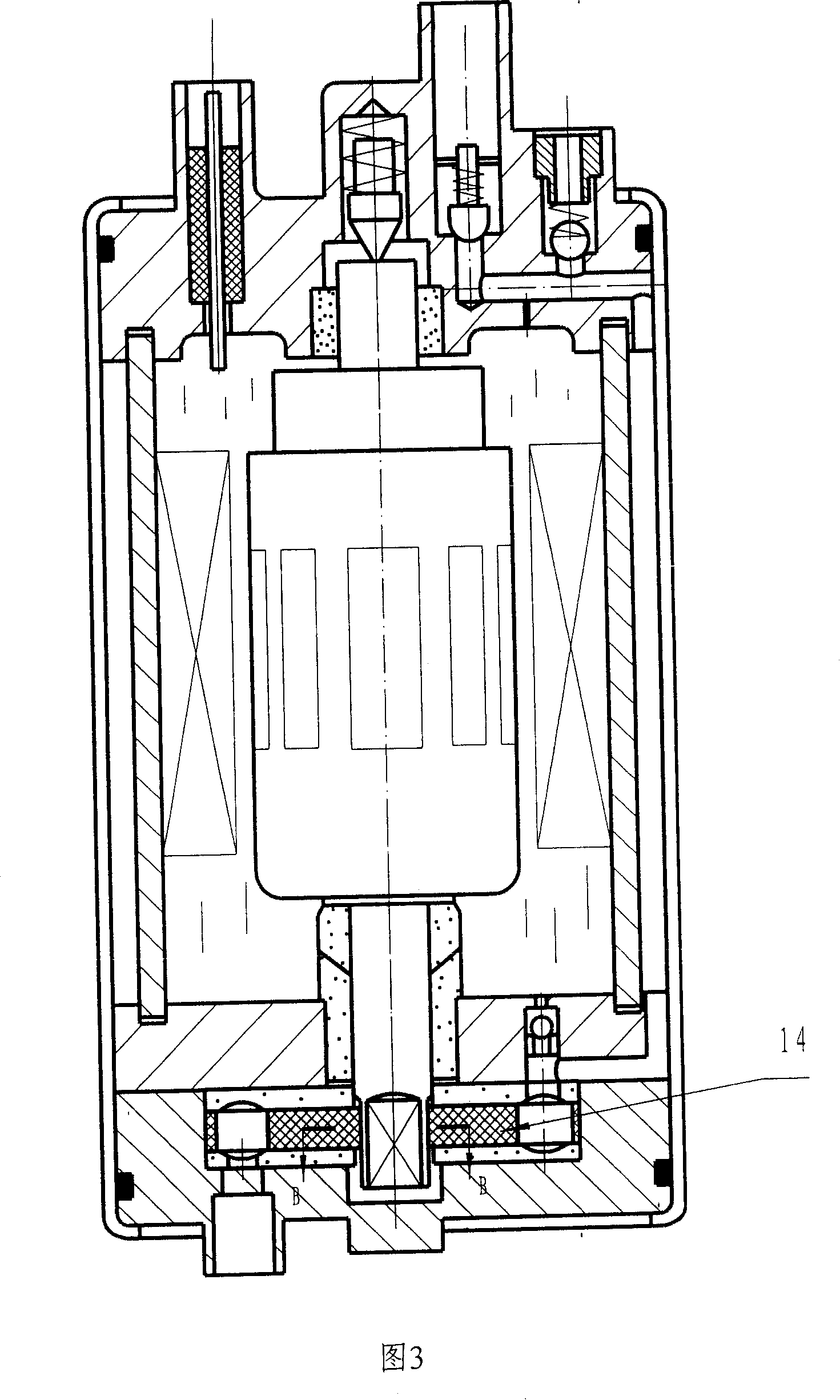

[0019] In Fig. 3 and Fig. 4, the impeller 14 in the pump body and the central axis of the motor are connected by a forming connection with four straight sides, and the rest of the structure is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com