Upper prefabricated member-lower prefabricated member butting structure and upper prefabricated member-lower prefabricated member combination face grouting method

A technology of prefabricated parts and joint surfaces, applied to building components, building structures, walls, etc., can solve problems affecting structural safety, cavities appearing on the joint surface of upper and lower floors, and air cannot be discharged, so as to ensure safety and eliminate cavities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

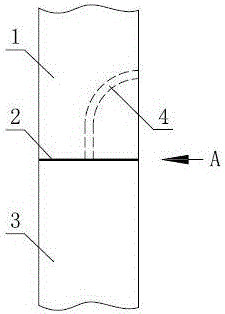

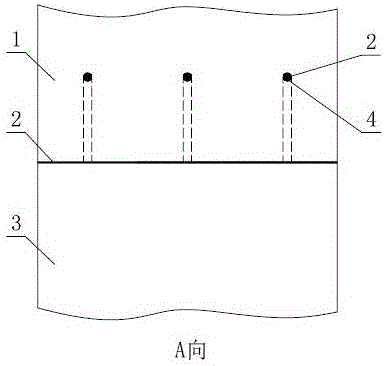

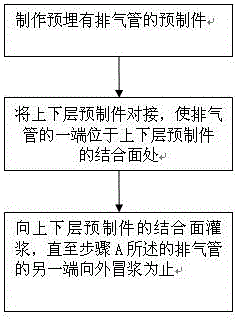

[0021] as attached figure 1 , 2 As shown, the butt joint structure of the upper and lower prefabricated parts in this embodiment includes two prefabricated parts that are connected to the upper and lower layers, that is, the upper prefabricated part 1 and the lower prefabricated part 3, and the joint surfaces of the upper and lower prefabricated parts are filled with grouting . At least one preform, that is, the upper preform 1 is provided with an exhaust channel, one end of the exhaust channel extends outside the joint surface of the preform, and the other end of the exhaust channel extends outside the other surfaces of the preform. The preferred exhaust channel in this embodiment is the built-in exhaust pipe 4 or exhaust groove. During the actual pouring process, the exhaust pipe 4 has been pre-buried in the upper prefabricated part 1 . When the concrete 2 is poured into the joint surface of the upper prefabricated part 1 and the lower prefabricated part 3, the gas in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com