Minimum cavity relief valve

A pressure reducing valve and valve seat technology, applied in the field of pressure reducing valves, can solve problems such as blockage and agglomeration, valve inoperability, and valve uselessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In this specification, references to "one embodiment" or "an embodiment" or "an example" or "example" in this specification are not intended to necessarily refer to the same embodiment or example; however, such embodiments are not mutually exclusive unless otherwise stated or otherwise apparent to one of ordinary skill in the art having the benefit of this disclosure. Accordingly, various combinations and / or integrations of the embodiments and examples described herein may be included, as well as other embodiments and examples defined within the scope of all claims based on this disclosure and all legal equivalents of such claims.

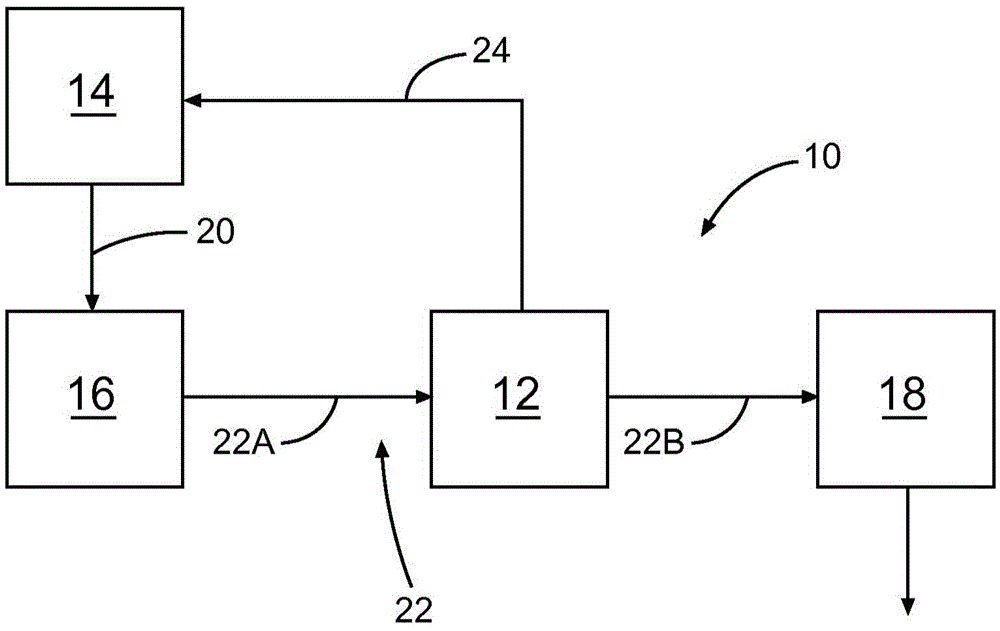

[0011] figure 1 is a schematic diagram of a pumping and injection system 10 in which a minimum cavity pressure reducing valve 12 according to the present invention may be used. System 10 includes container 14 , pump 16 and sparging mechanism 18 . Container 14 includes a hopper or other similar vessel into which material is held for pumping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com