Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Easy welding work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

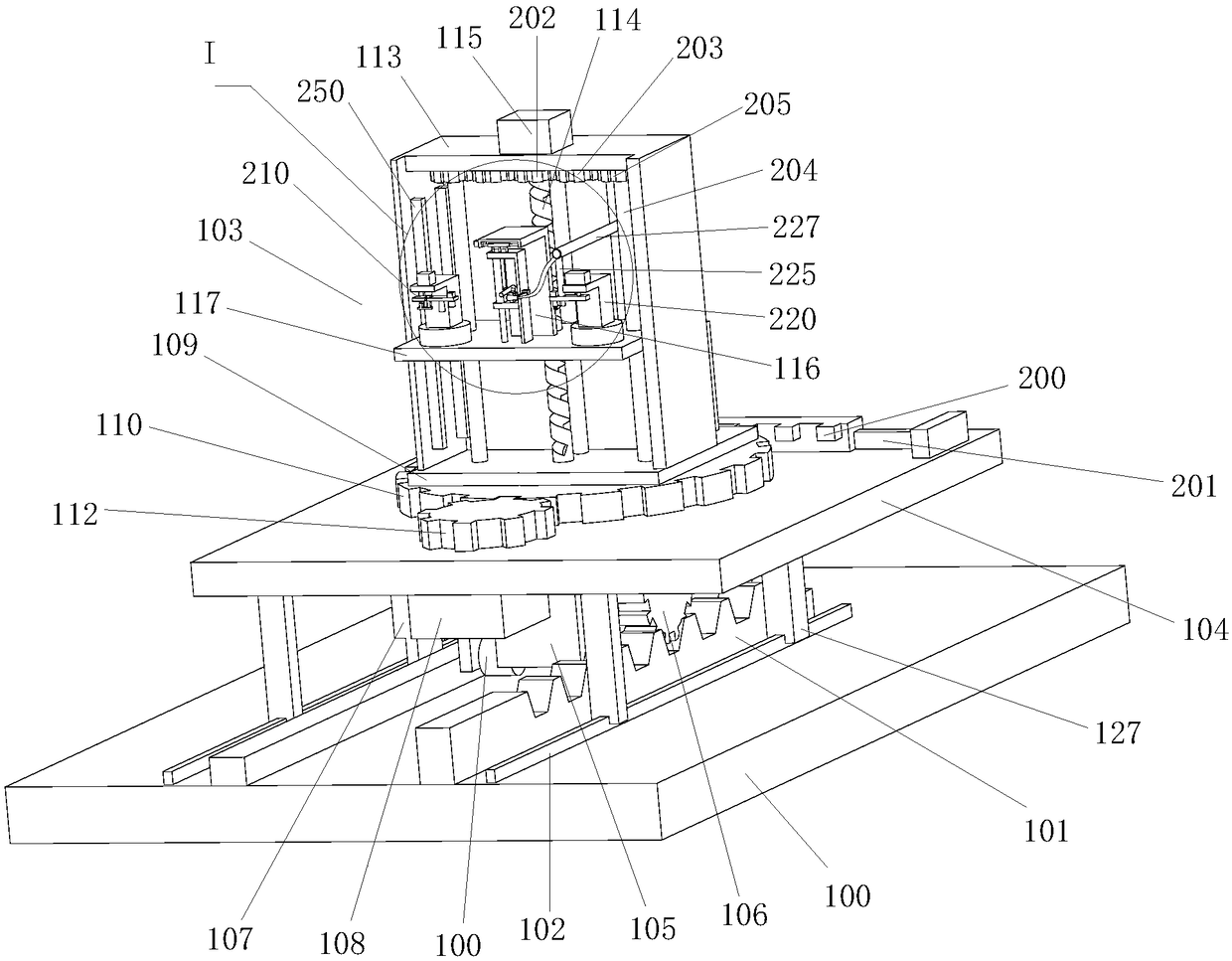

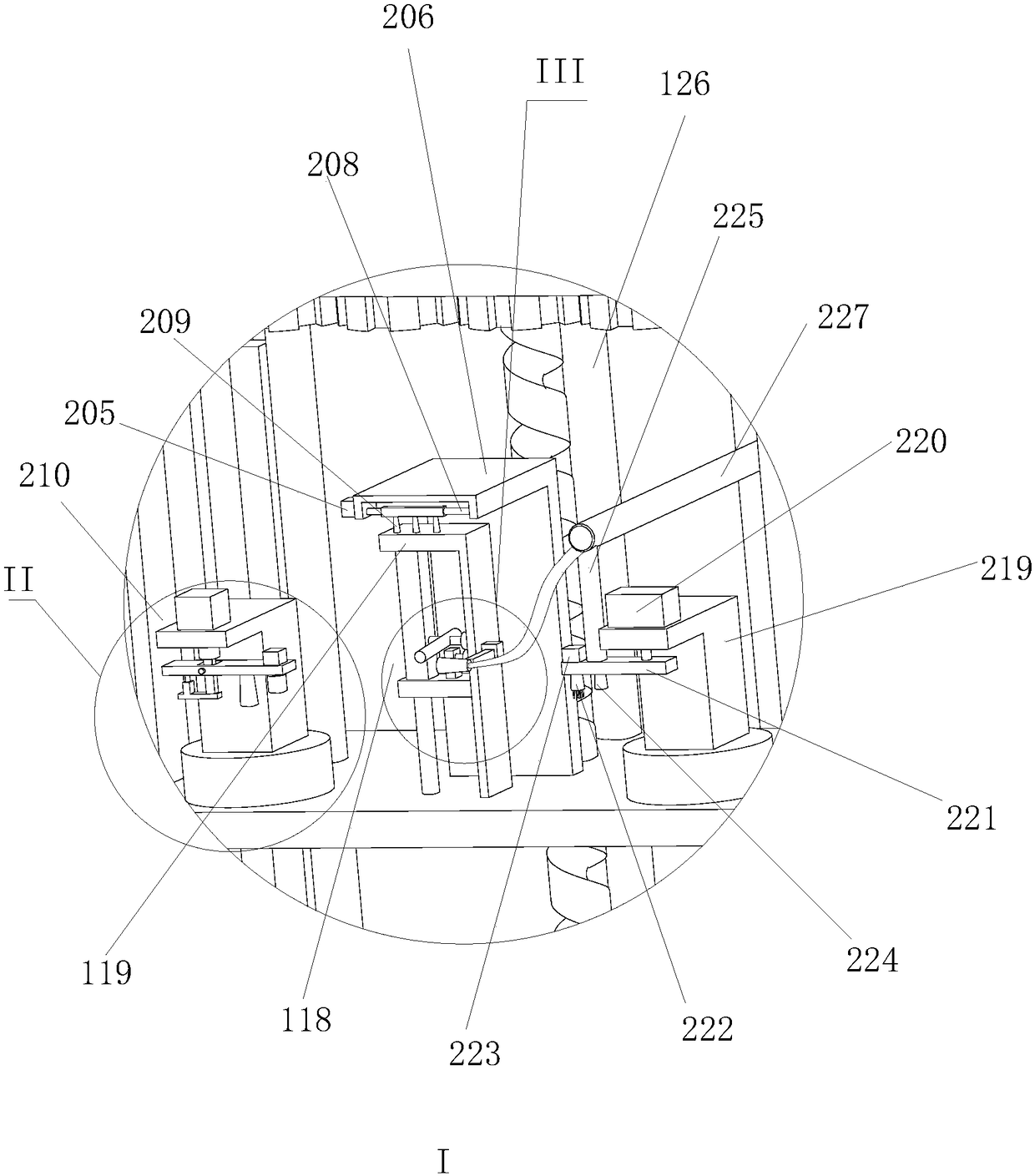

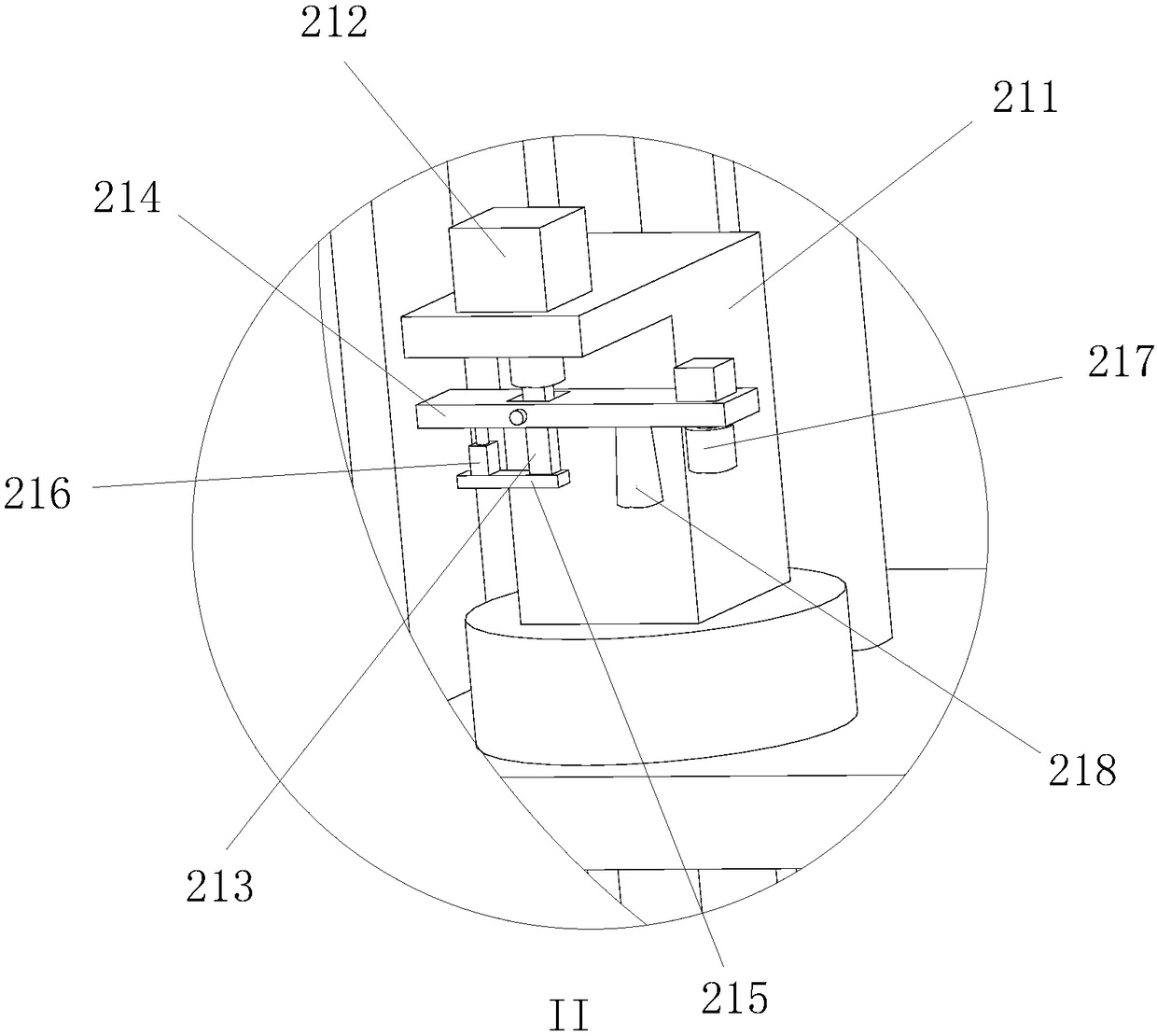

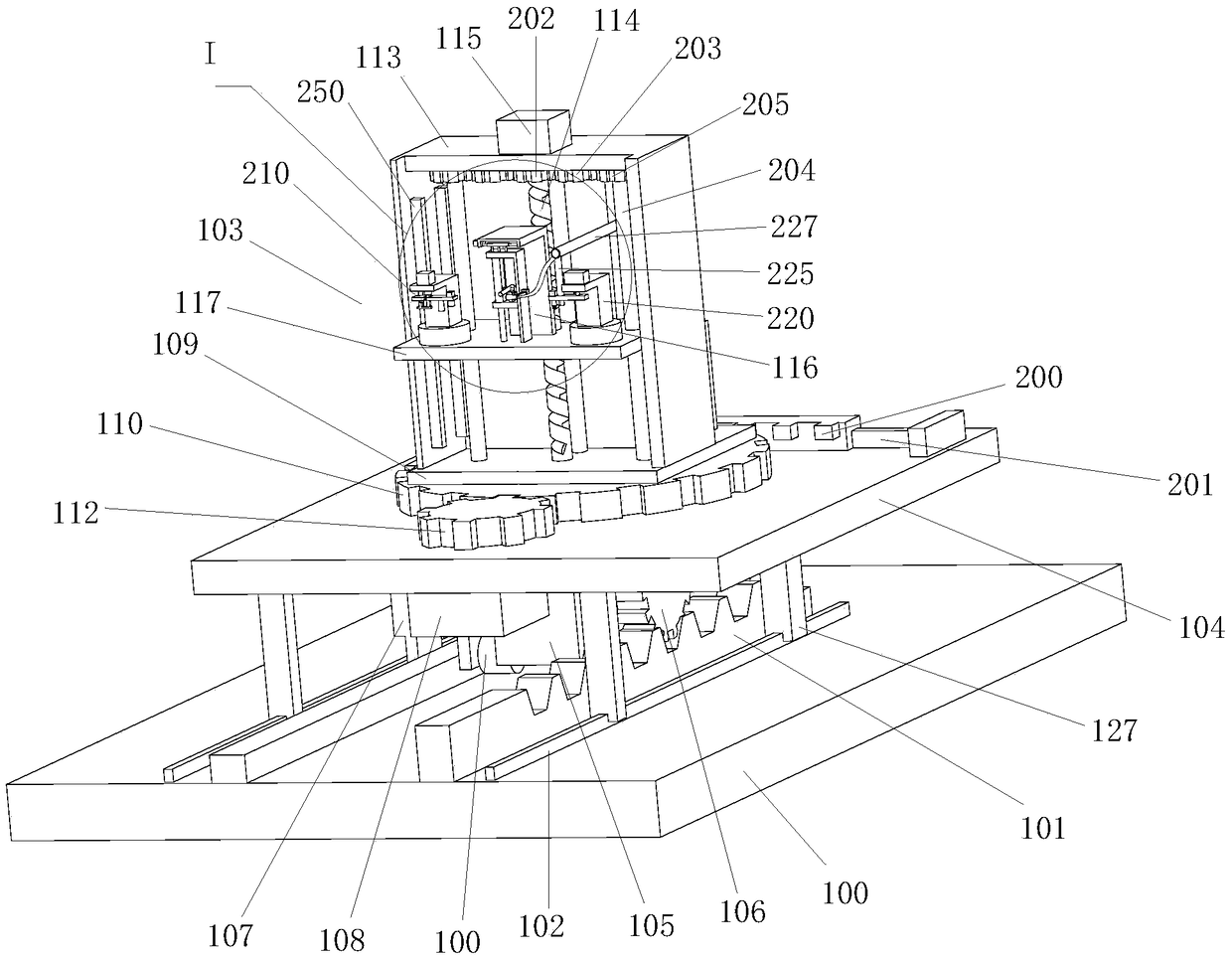

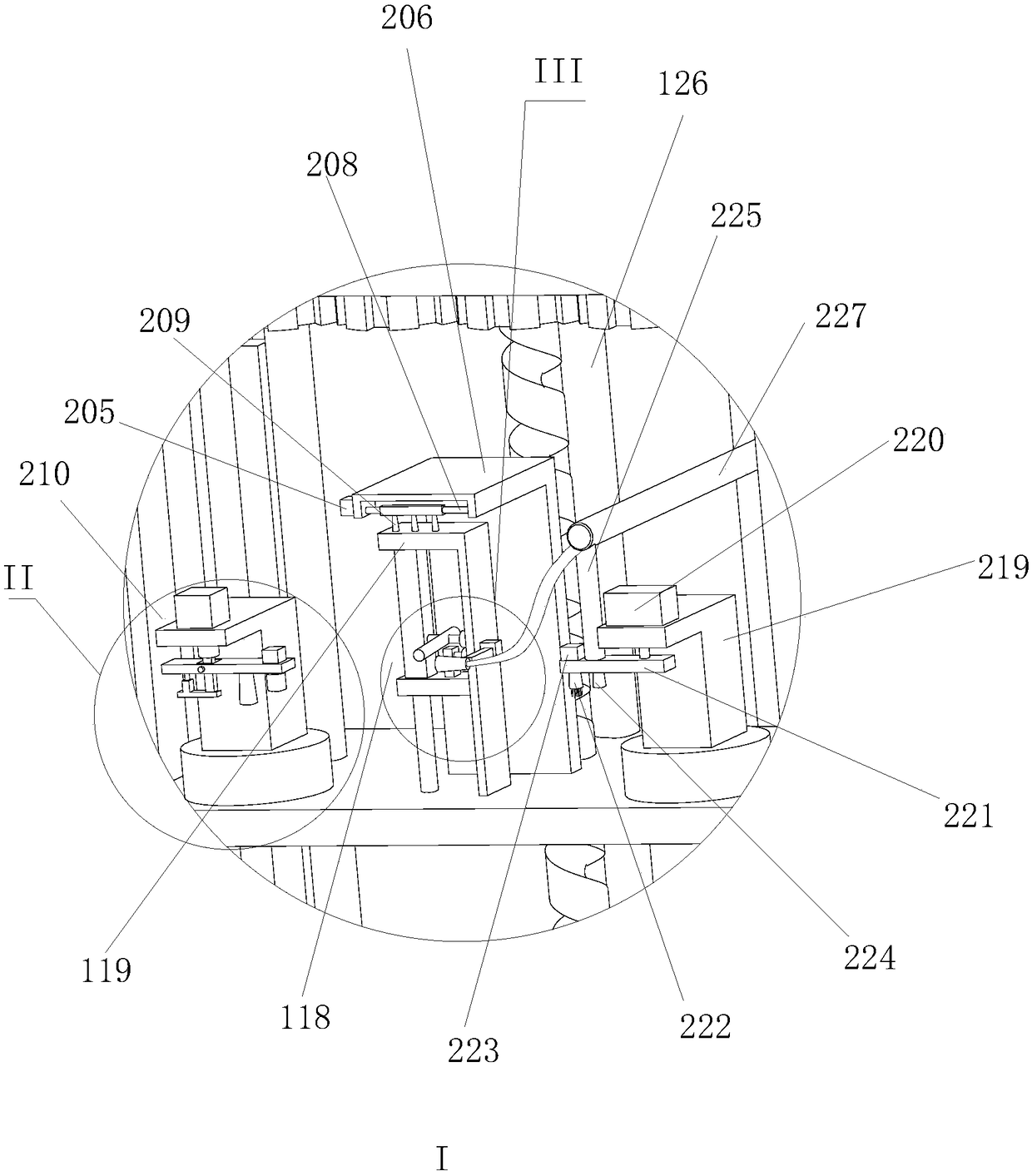

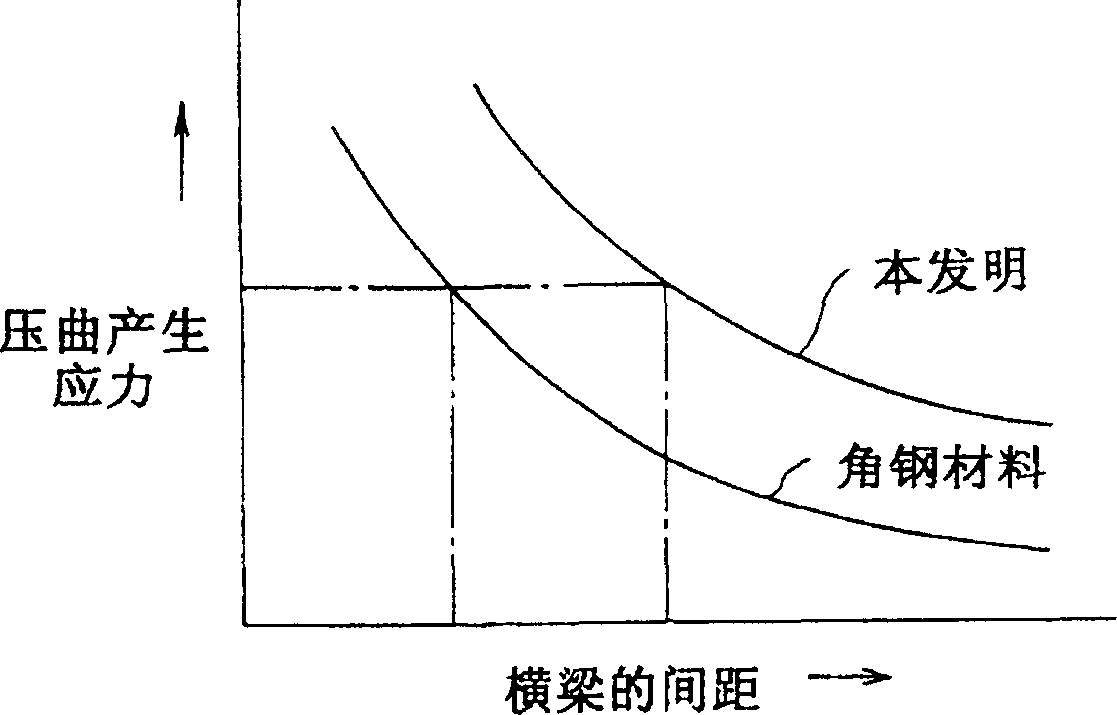

Multifunctional industrial robot for intelligent manufacturing automatic production line

ActiveCN108436343AGuaranteed rotational freedomIncrease freedomProgramme-controlled manipulatorWelding/cutting auxillary devicesInterference fitProduction line

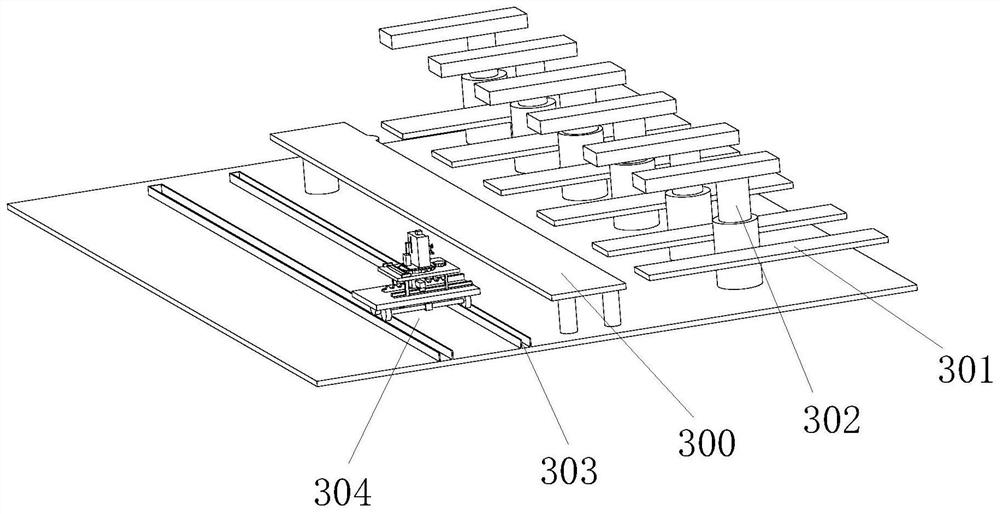

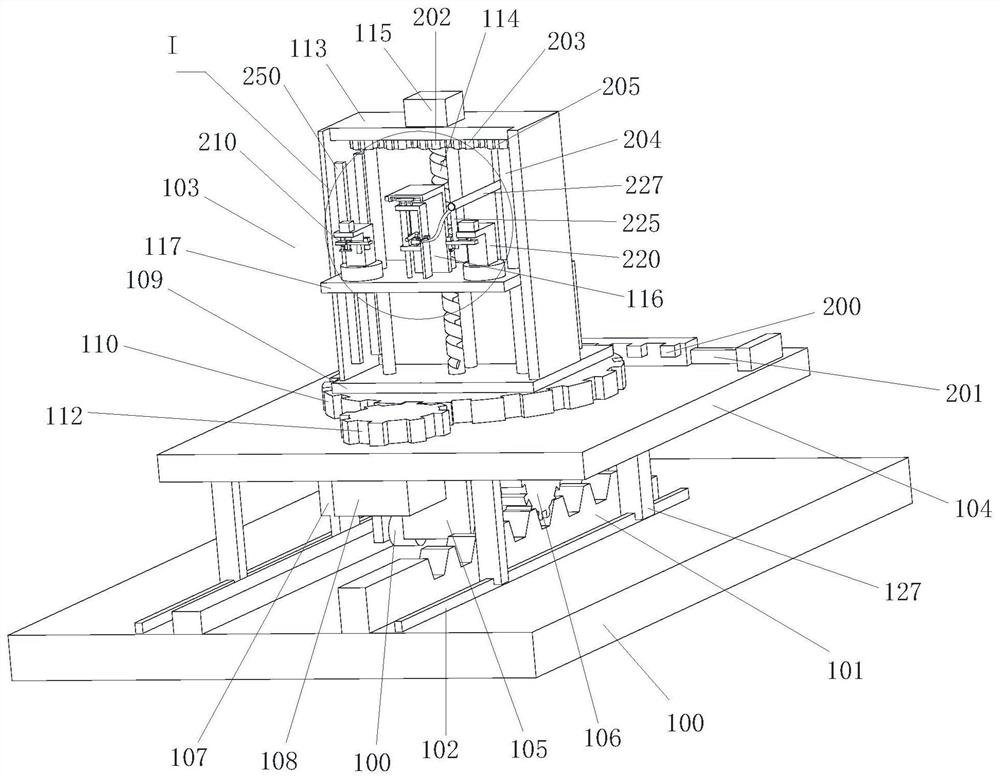

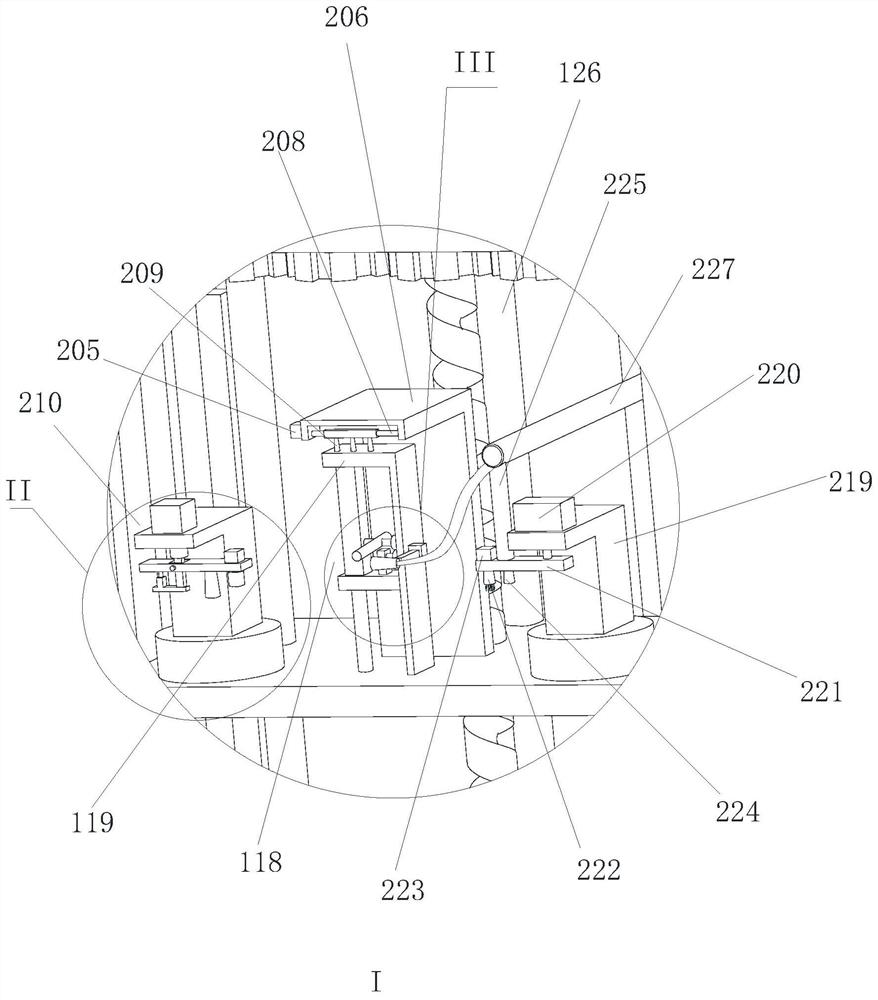

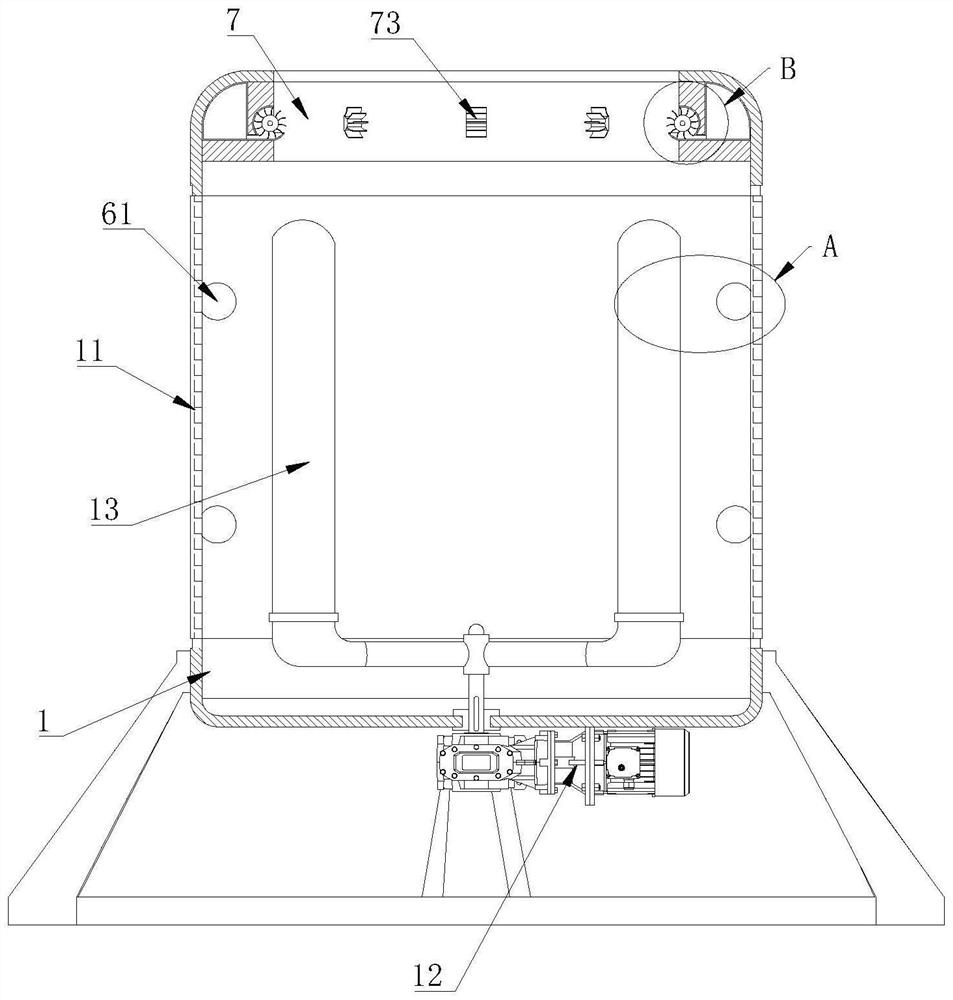

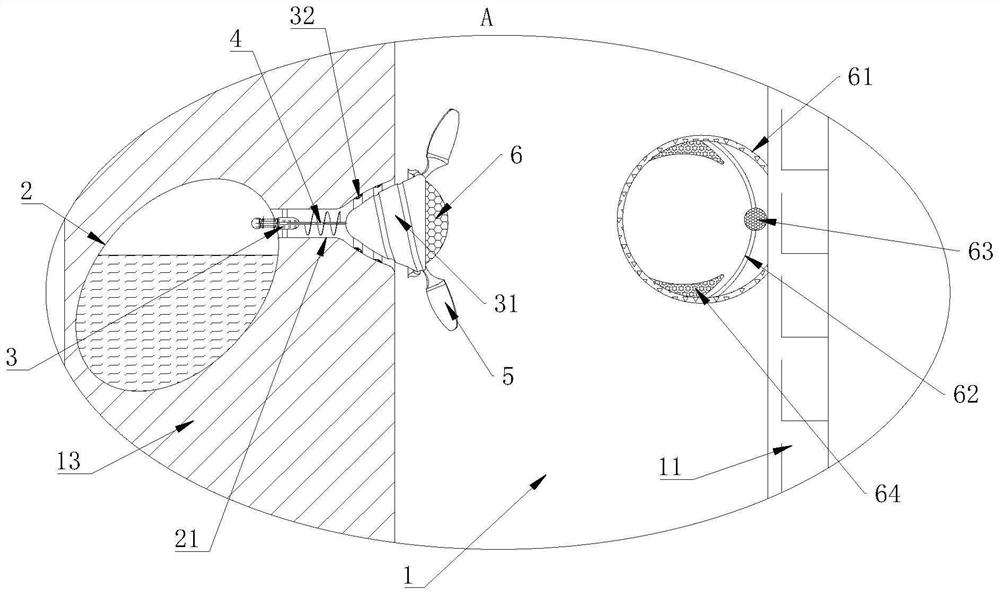

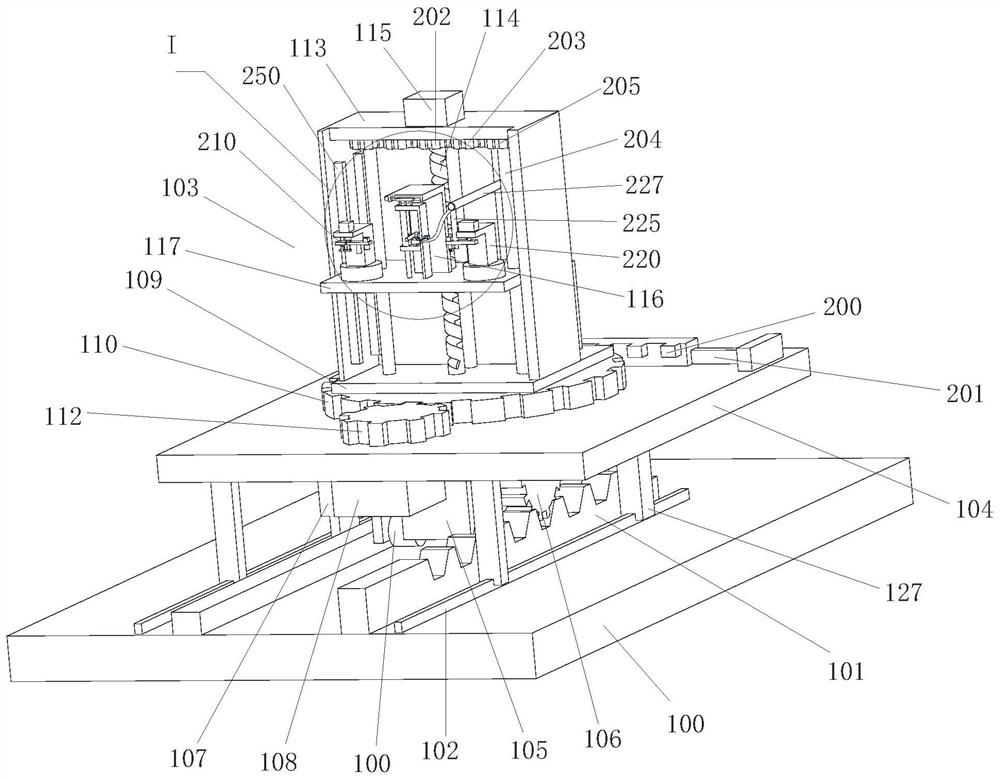

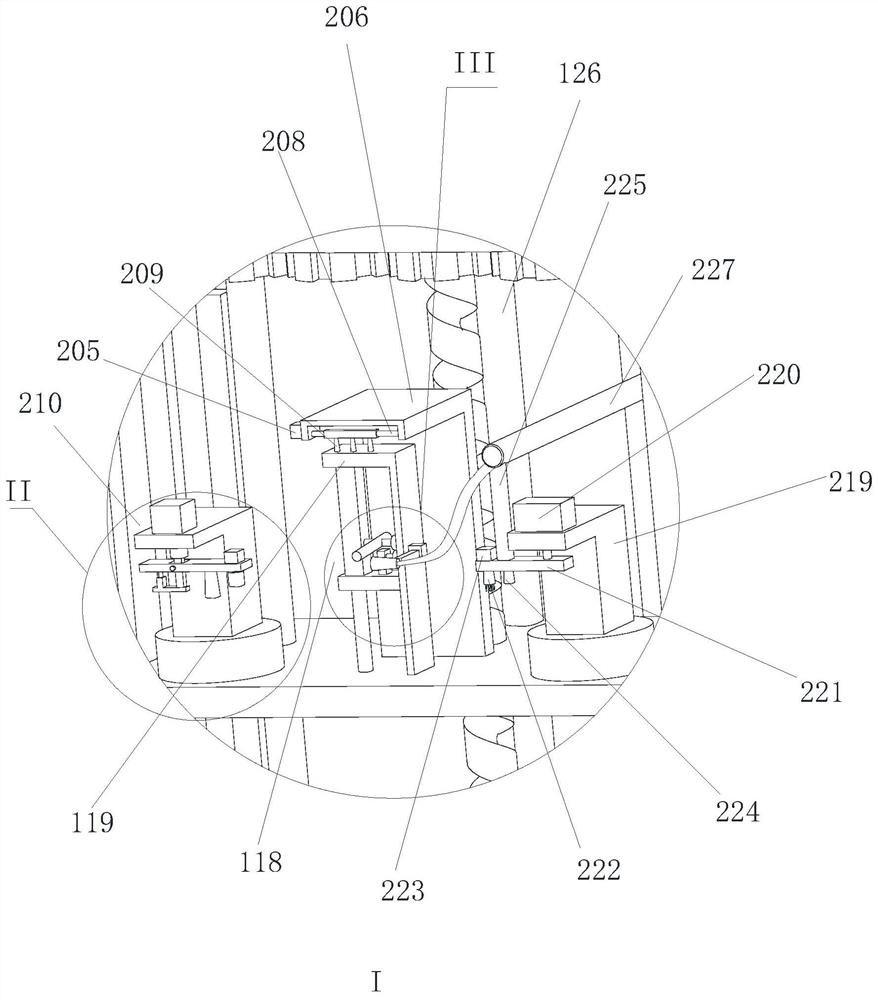

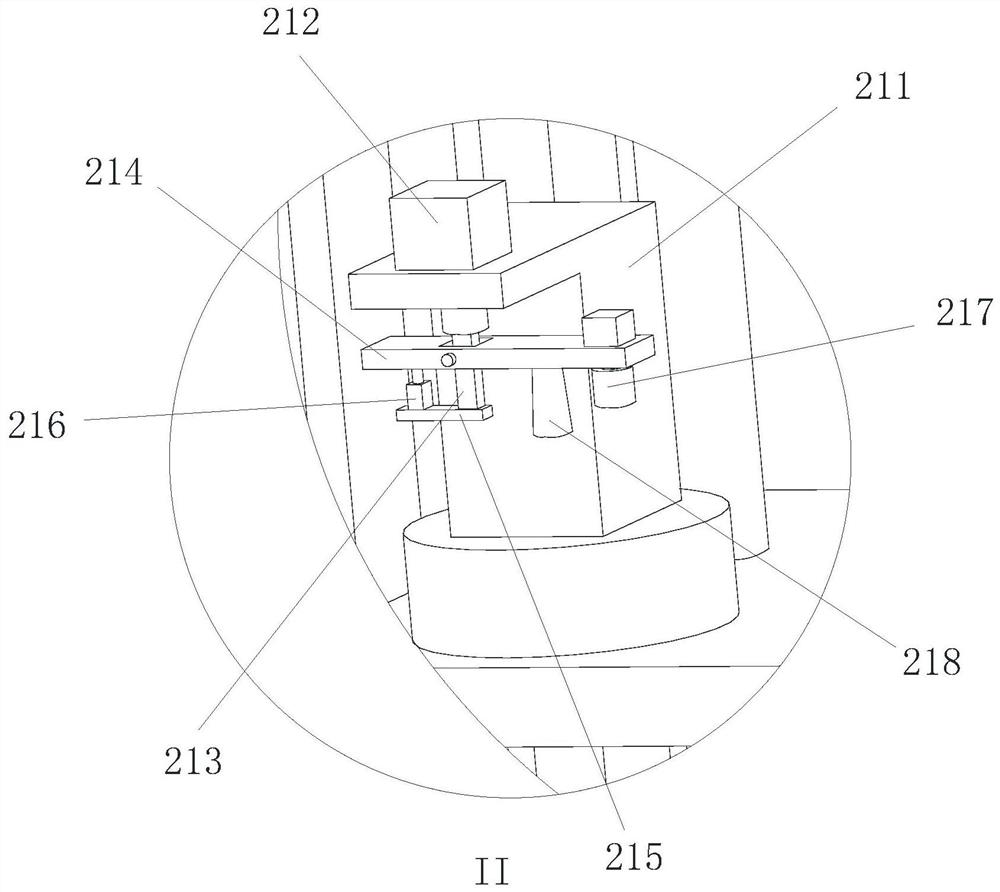

The invention relates to the field of robot equipment, and discloses a multifunctional industrial robot for an intelligent manufacturing automatic production line. The multifunctional industrial robotcomprises a bottom plate, wherein a welding manipulator is fixed to the bottom plate, and a small wheel unit is arranged on the lower portion of the bottom plate; the welding manipulator which linearly moves along a first guide rail group is arranged on a first rack and the first guide rail group, the welding manipulator comprises a welding platform, supporting legs are arranged under the weldingplatform, and the supporting legs are slidably arranged on the first guide rail group; a first gear is coaxially connected to an output shaft of a first motor, the first gear is meshed with the firstrack, an installing rod is arranged on one side of the first motor, a supporting wheel is arranged at the bottom of the installing rod, and the supporting wheel makes rolling contact with the bottomplate; and a rotating disc is installed on a welding platform, the rotating disc is sleeved with a gear ring, the inner side of the gear ring is in interference fit with the outer side face of the rotating disc, and a second gear is meshed with the gear ring. The multifunctional industrial robot for the intelligent manufacturing automatic production line has the advantages of being wide in application range, low in cost, accurate in transmission control and the like.

Owner:聊城锐利机械设备有限公司

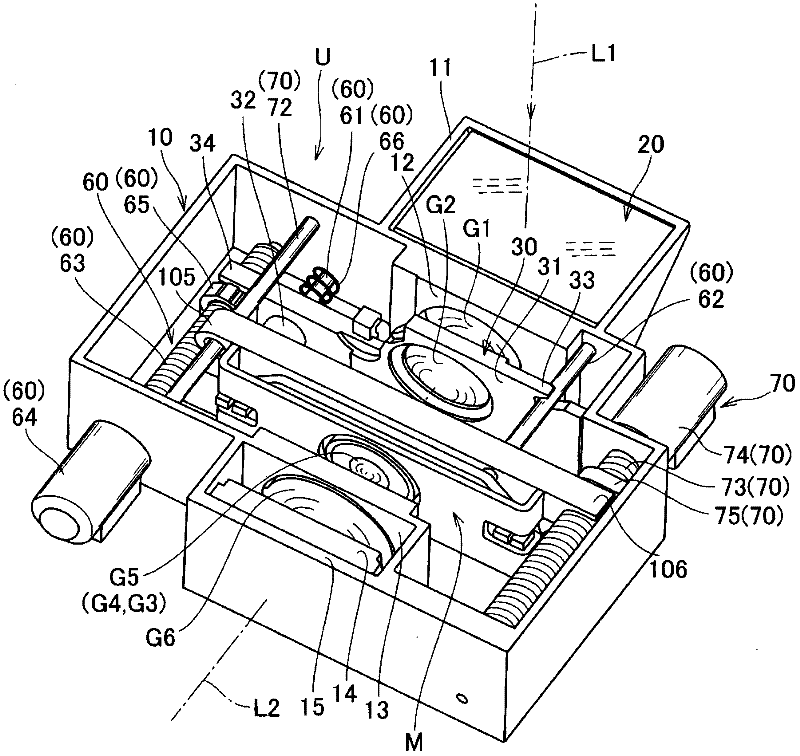

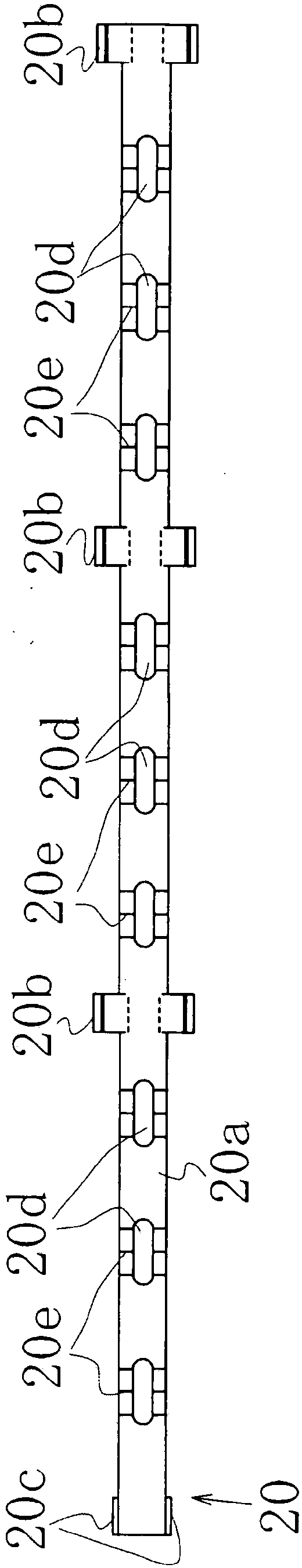

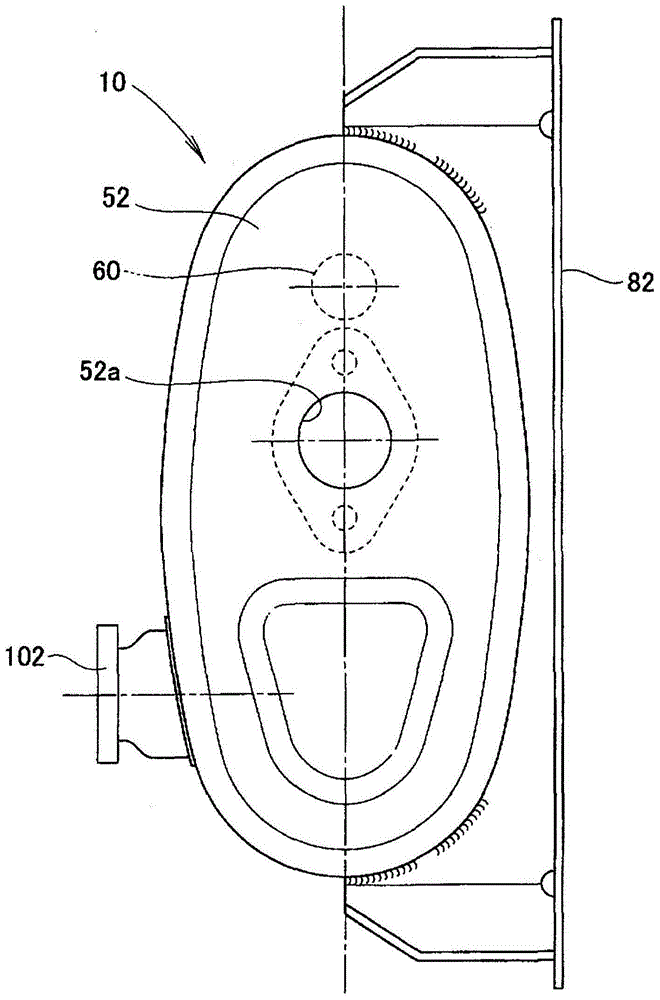

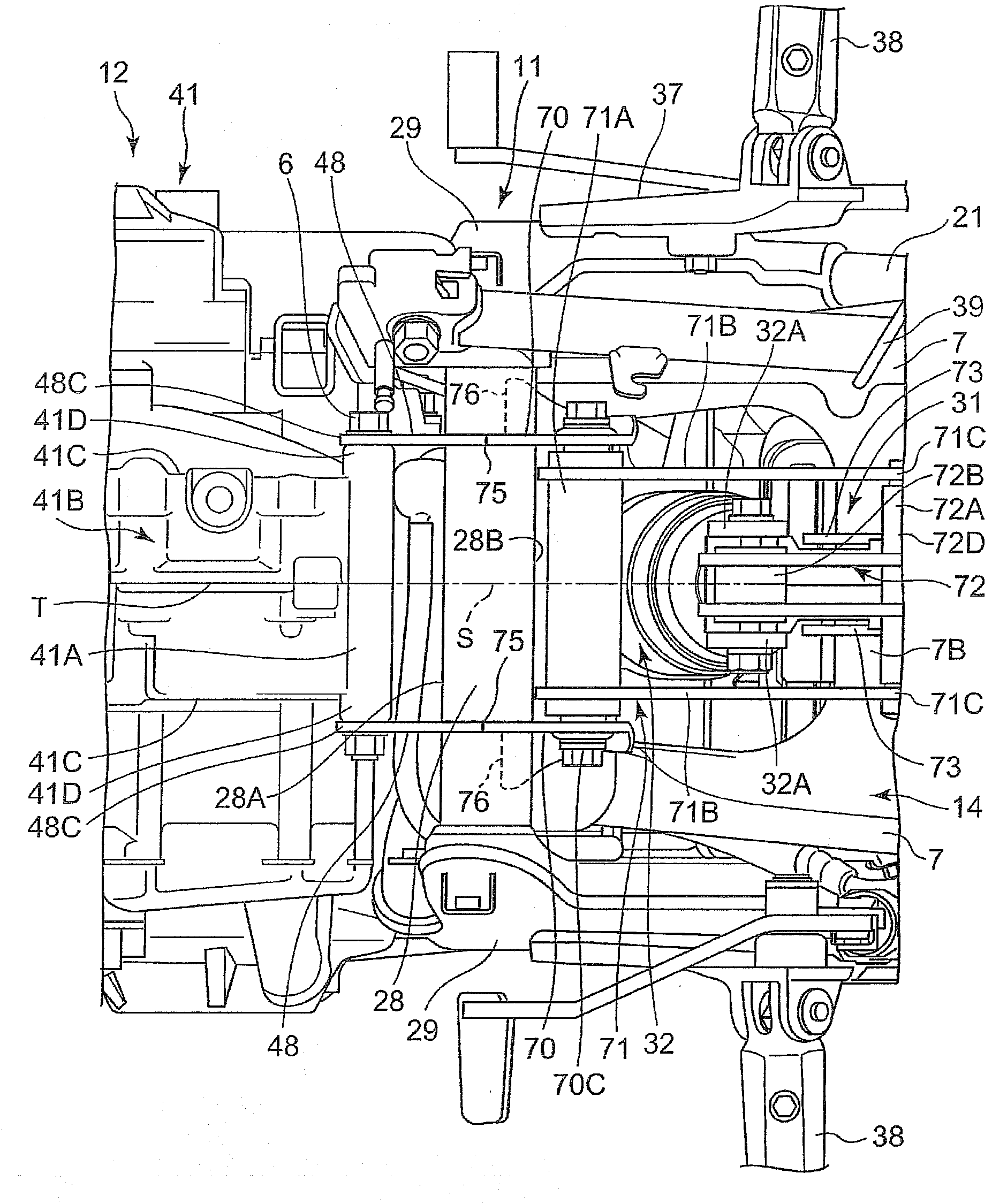

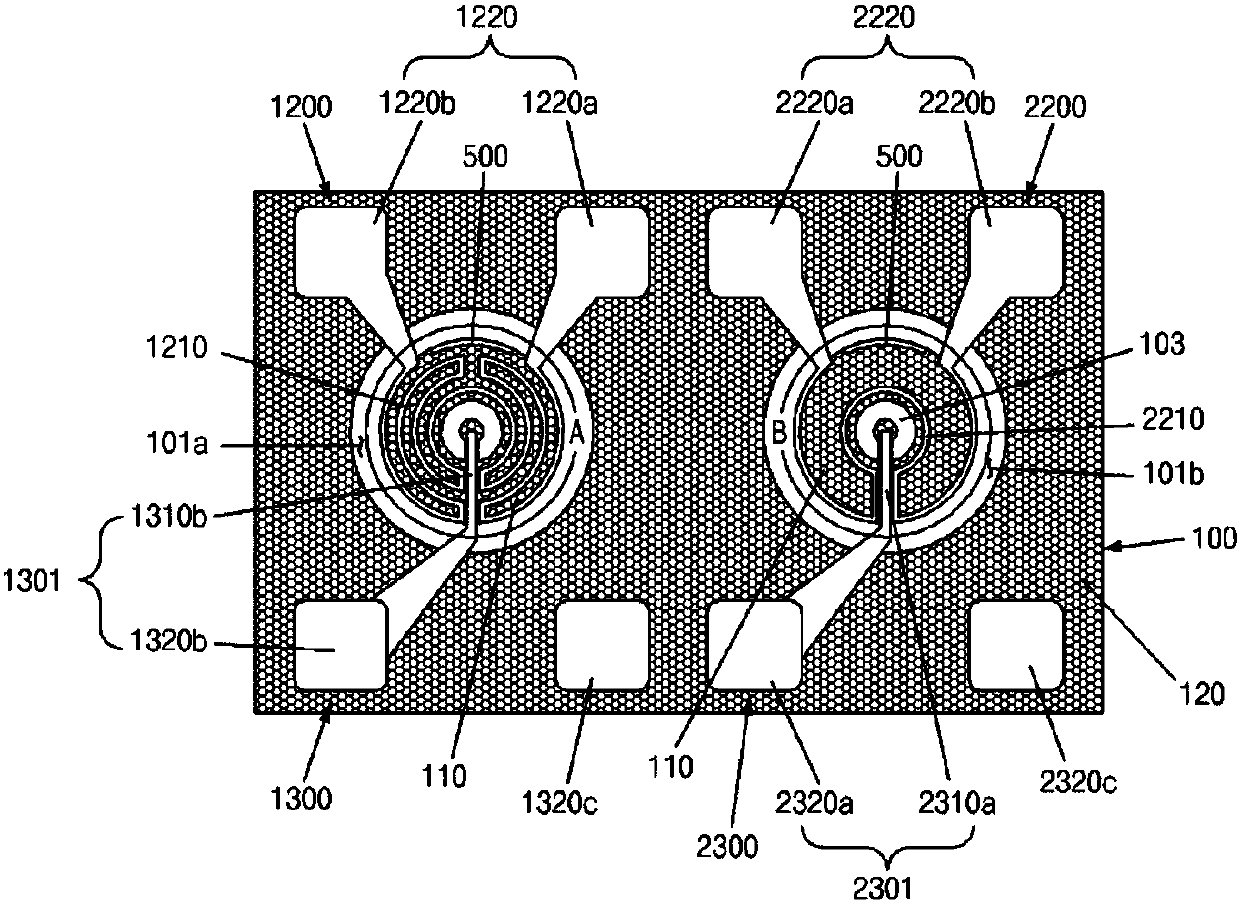

Image blur correction device, imaging lens unit, and camera unit

InactiveCN102165367ASimple structureEasy welding workTelevision system detailsPrintersOptical axisEngineering

An image blur correction device comprises: a flat plate-like base (100) having an opening section (101) open in an optical axis direction; a flat plate-like movable holding member (110) for holding a lens and supported so as to be movable within a plane perpendicular to the optical axis of the lens; a first drive mechanism (130) including a first magnet and a first coil to drive the movable holding member in a first direction perpendicular to the optical axis; a second drive mechanism (140) including a second magnet and a second coil to drive the movable holding member in a second direction perpendicular to the optical axis; and detecting means (170, 180) for detecting the position of the movable holding member. The movable holding member is movably supported located adjacent to a base. The first drive mechanism and the second drive mechanism are arranged at positions line-symmetrical with respect to a first straight line (S1) perpendicular to the optical axis of the lens. The configuration allows the device to be reduced in size and thickness and can highly accurately correct a shift of the optical axis of the lens due to hand shaking.

Owner:COPAL CO LTD

Laser device with pendulous press roller

Owner:LEISTER TECHNOLOGIES

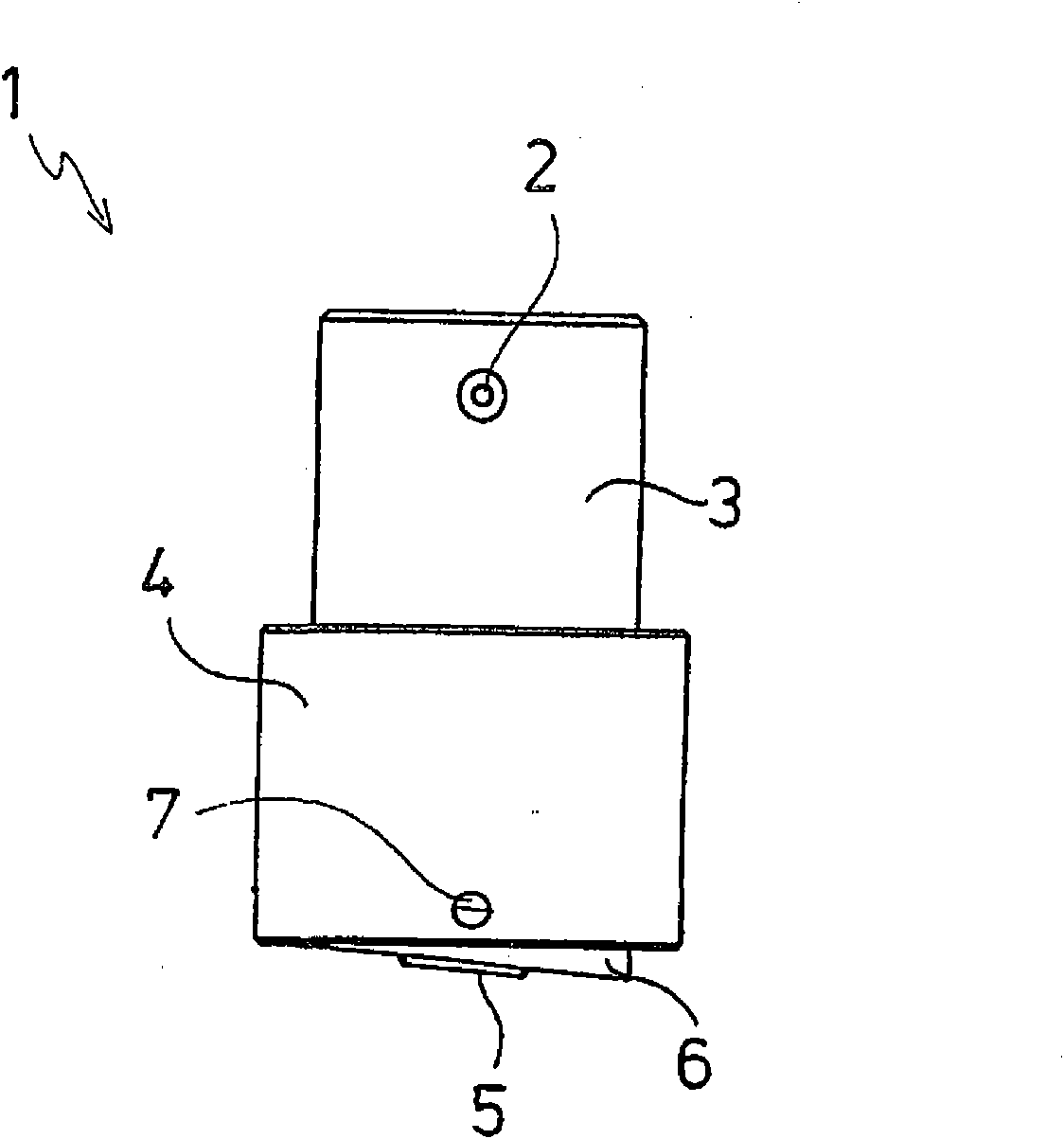

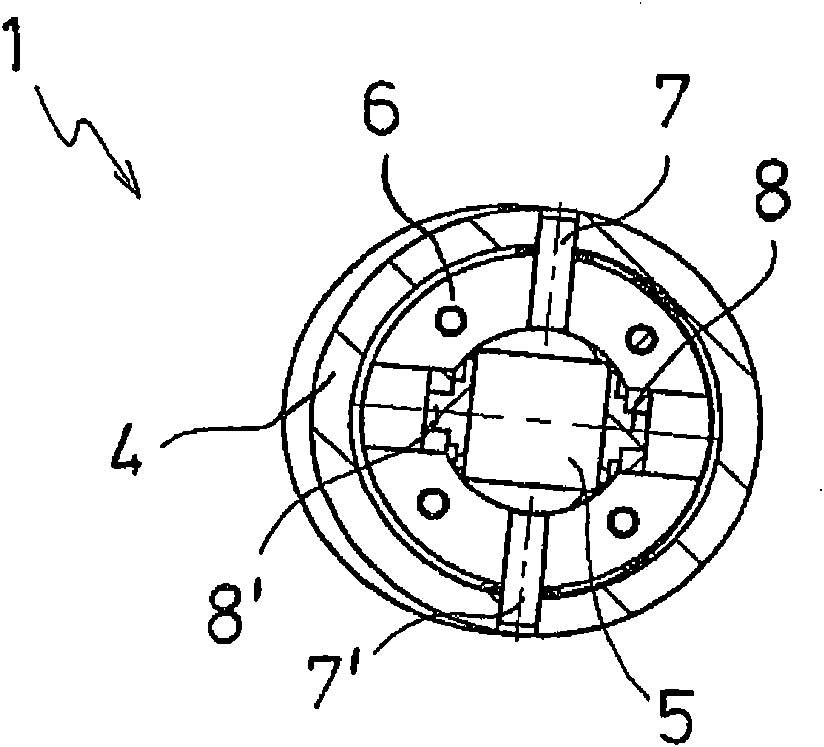

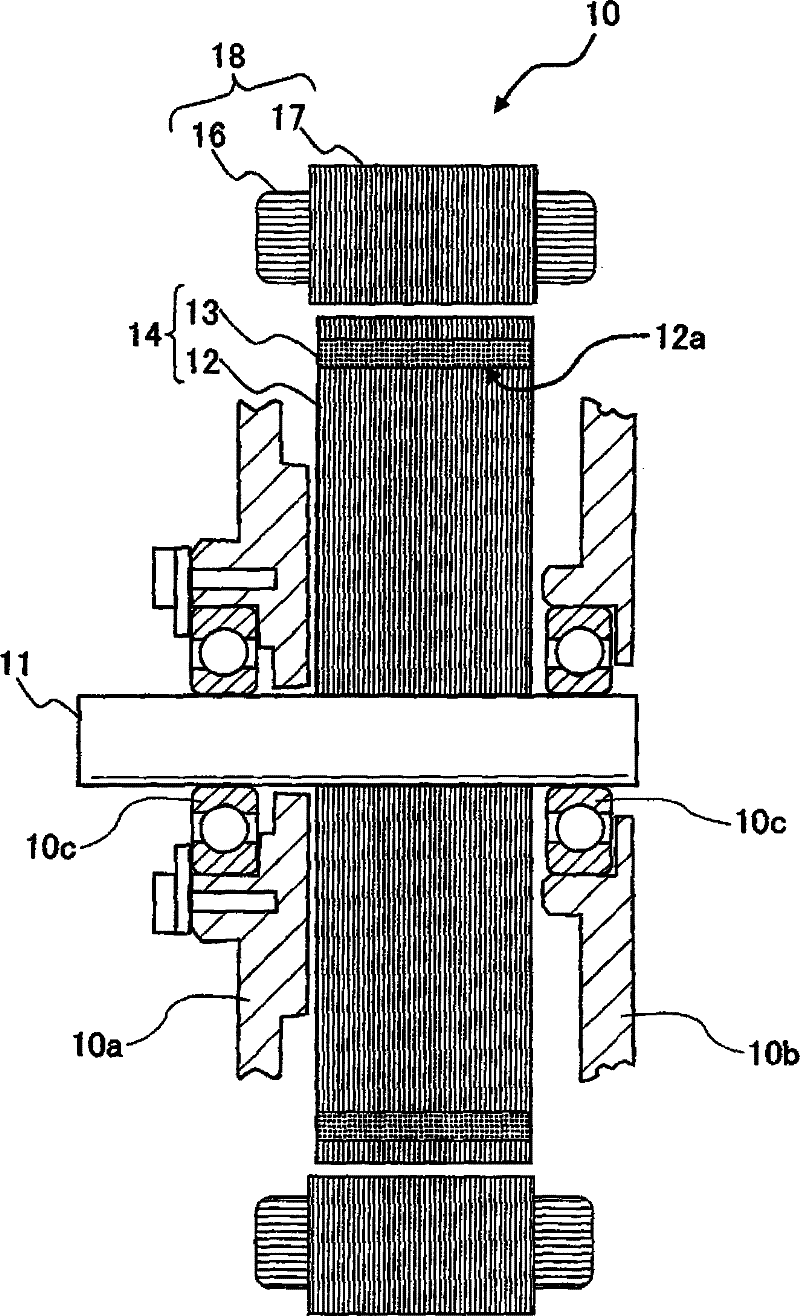

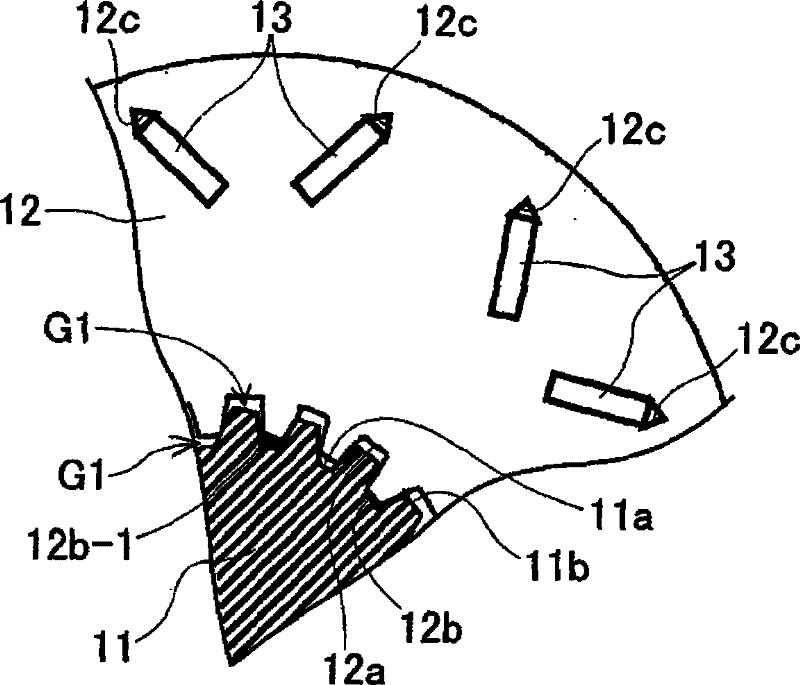

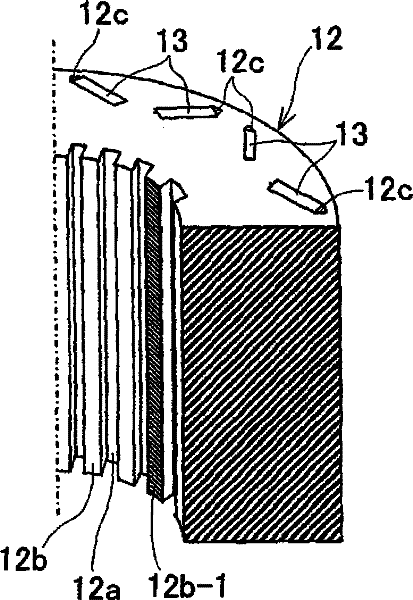

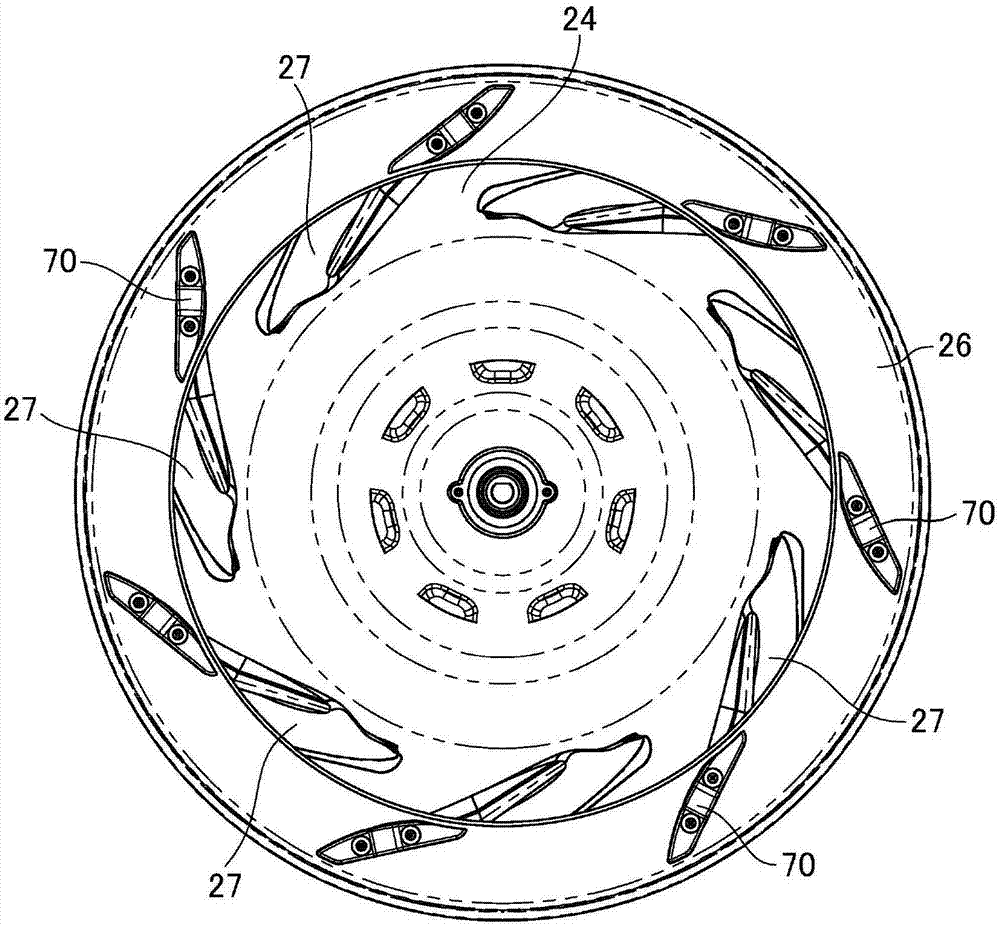

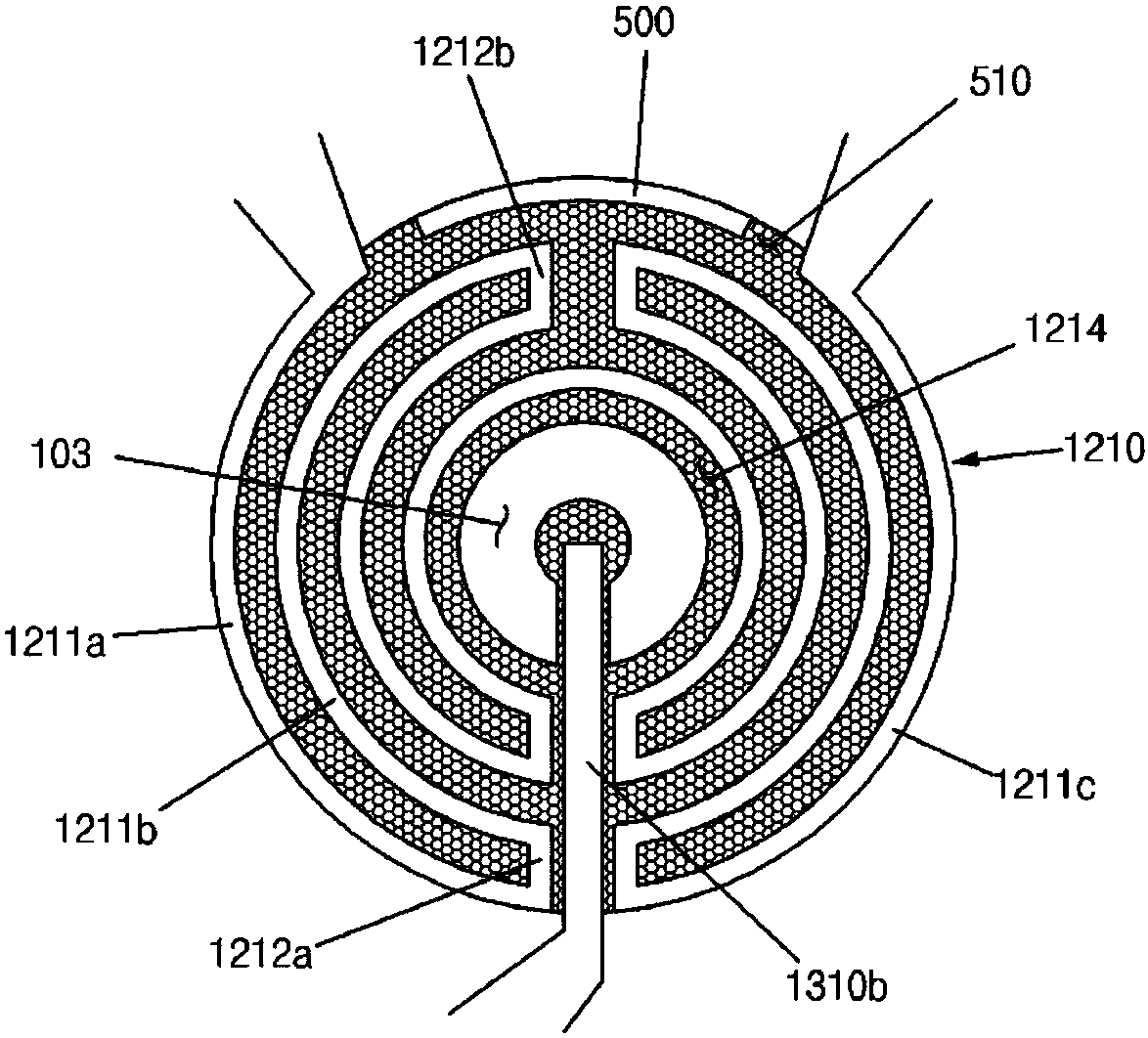

Rotor core and method of fastening rotor core and rotary shaft

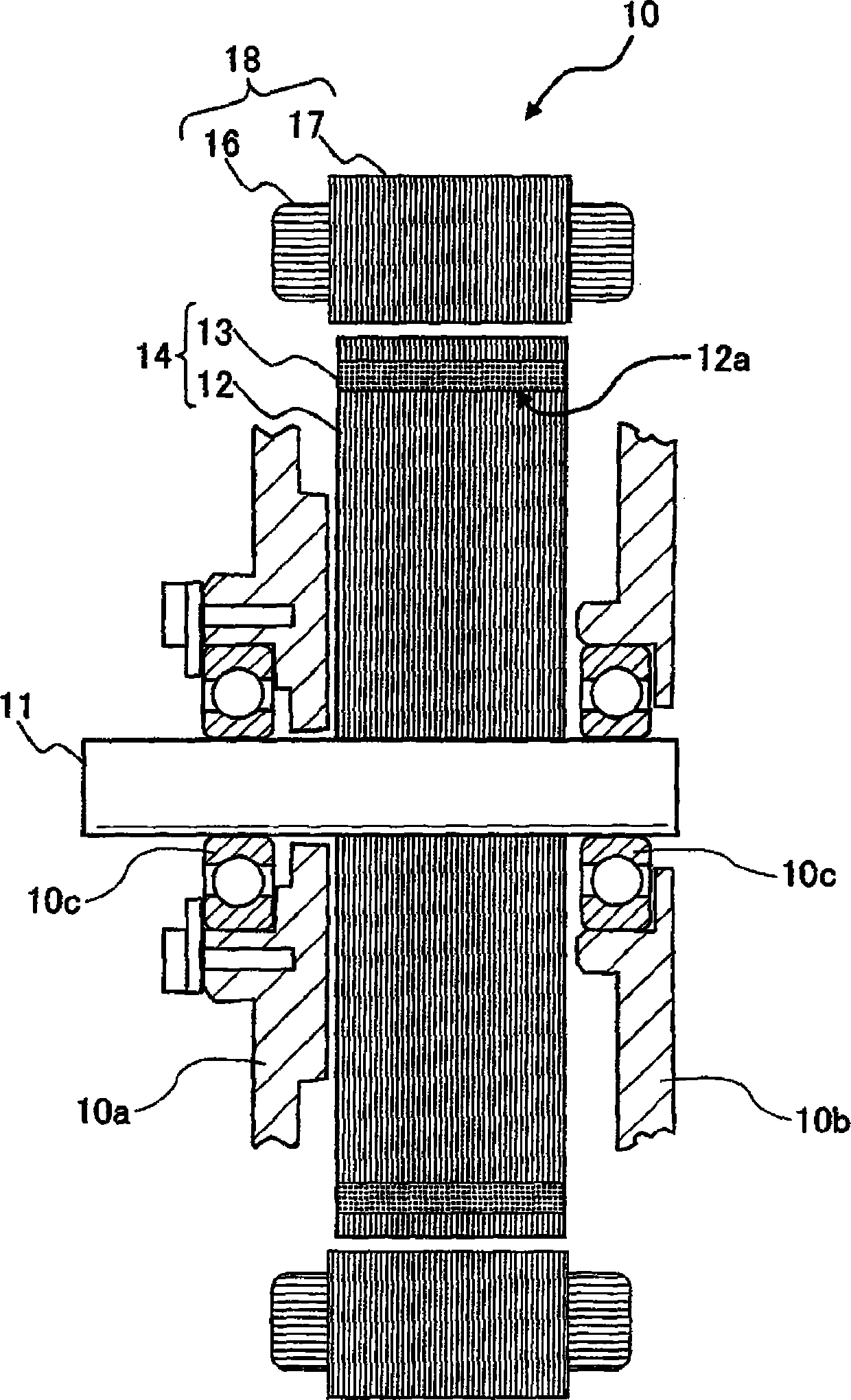

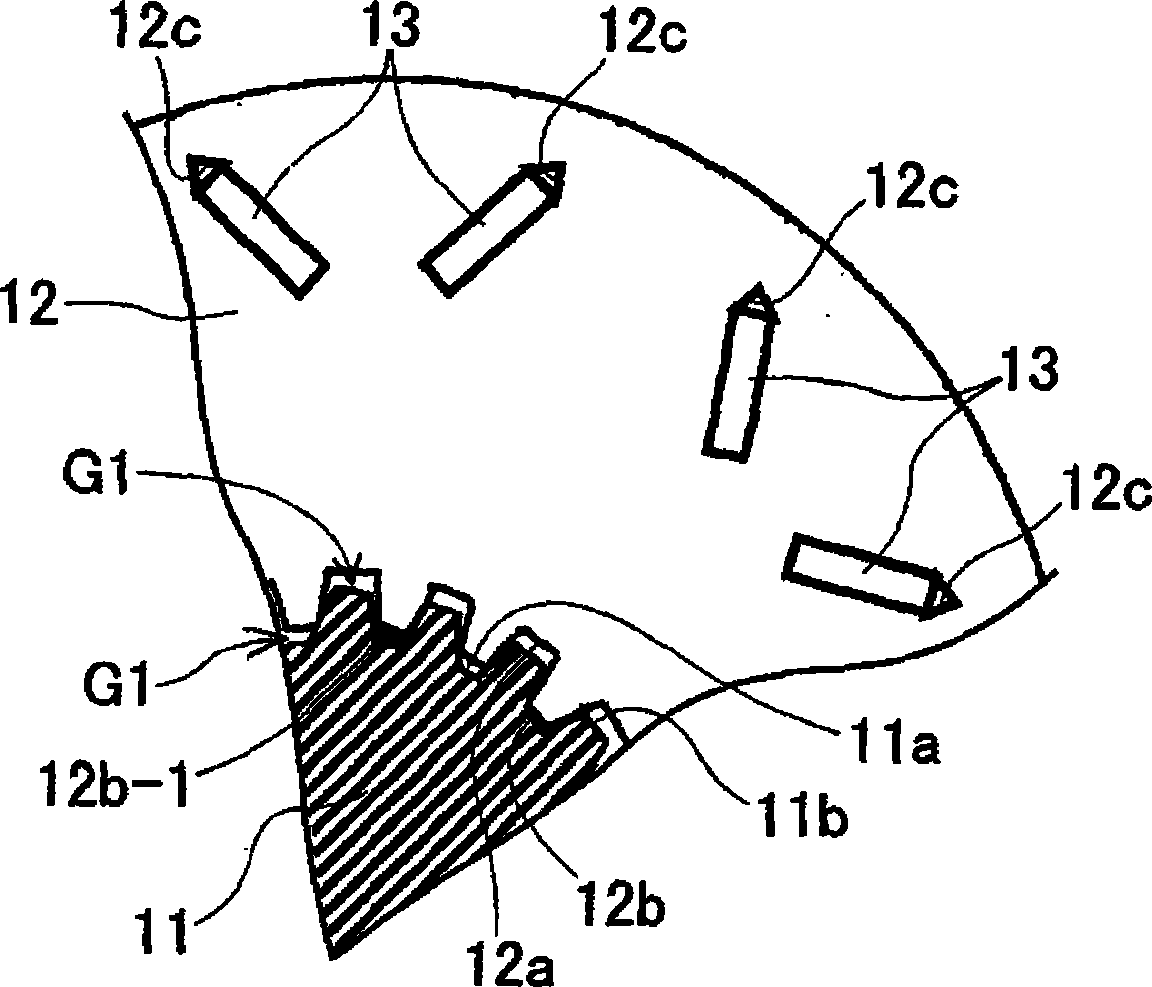

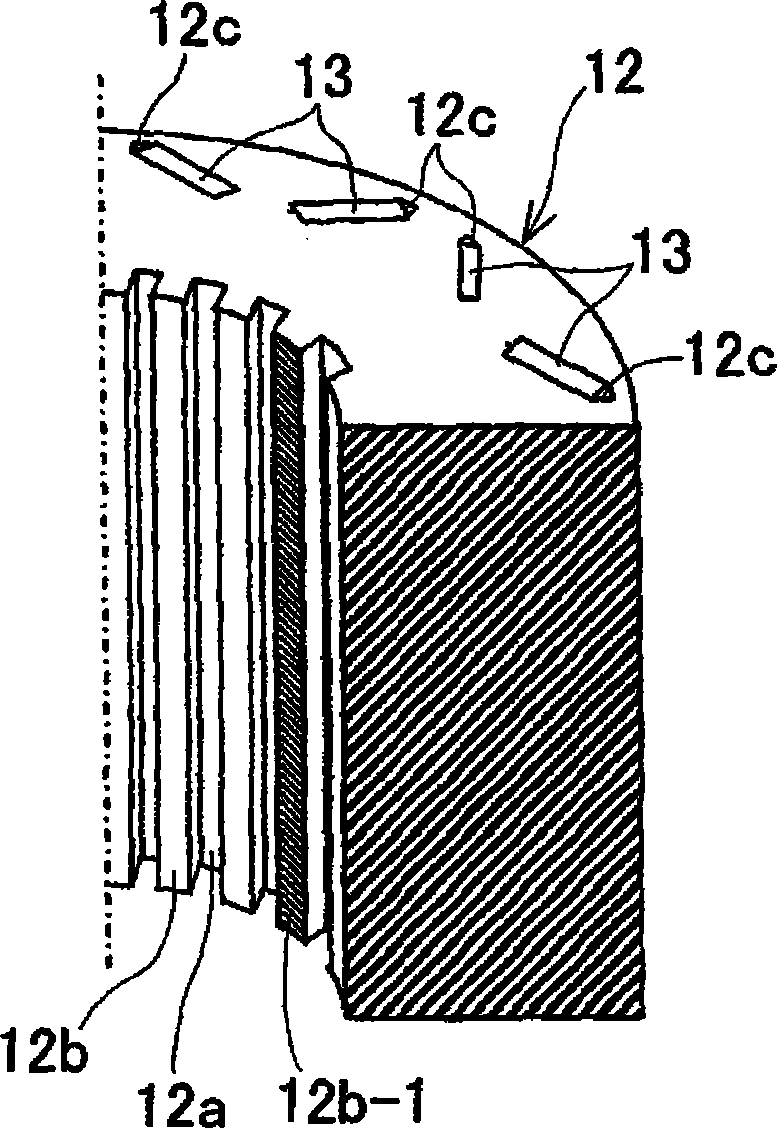

ActiveCN102244429AProperly fastenedAvoid axial deformationMagnetic circuit rotating partsElectric machinesEngineeringMechanical engineering

The invention provides a rotor core and a method of fastening the rotor core and a rotary shaft. The method of fastening the rotor core having no end plate and composed of laminated steel plates, and the rotary shaft by means of thermal insert can prevent the rotor core from being axially deformed due to the thermal insert load. The rotor core (12) is formed by axially laminating a plurality of circular-ring-shaped steel plates having through holes embedded in the shaft (11). A first groove (12a) and a first projecting bar (12b) are alternately formed on circumferential direction of the rotor core (12) inner peripheral surface where the through holes are formed. The first groove (12a) is recessed towards the outer radial direction and axially extends. The first projecting bar (12b) projects towards the inner radial direction and axially extends. A welding part (12b-1) for combining axially adjacent steel plates together is equipped on the projecting end face of the first projecting bar (12b). The welding part (12b-1) is continuously equipped from one axial end to the other axial end.

Owner:DENSO CORP

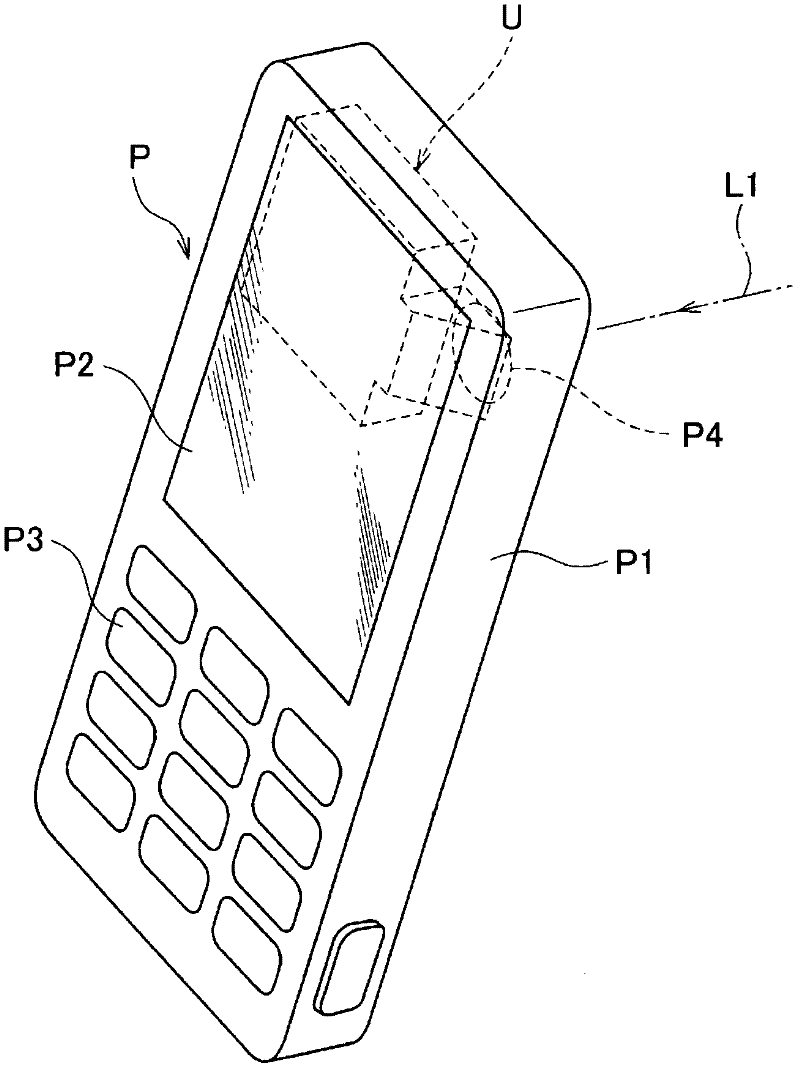

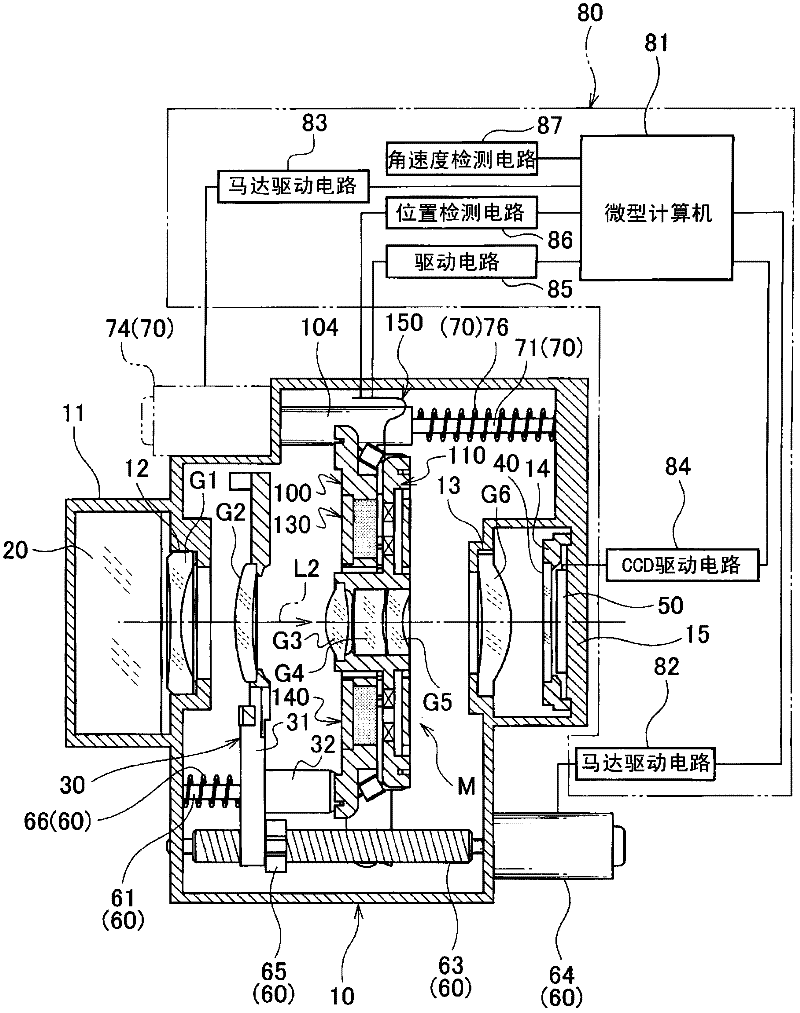

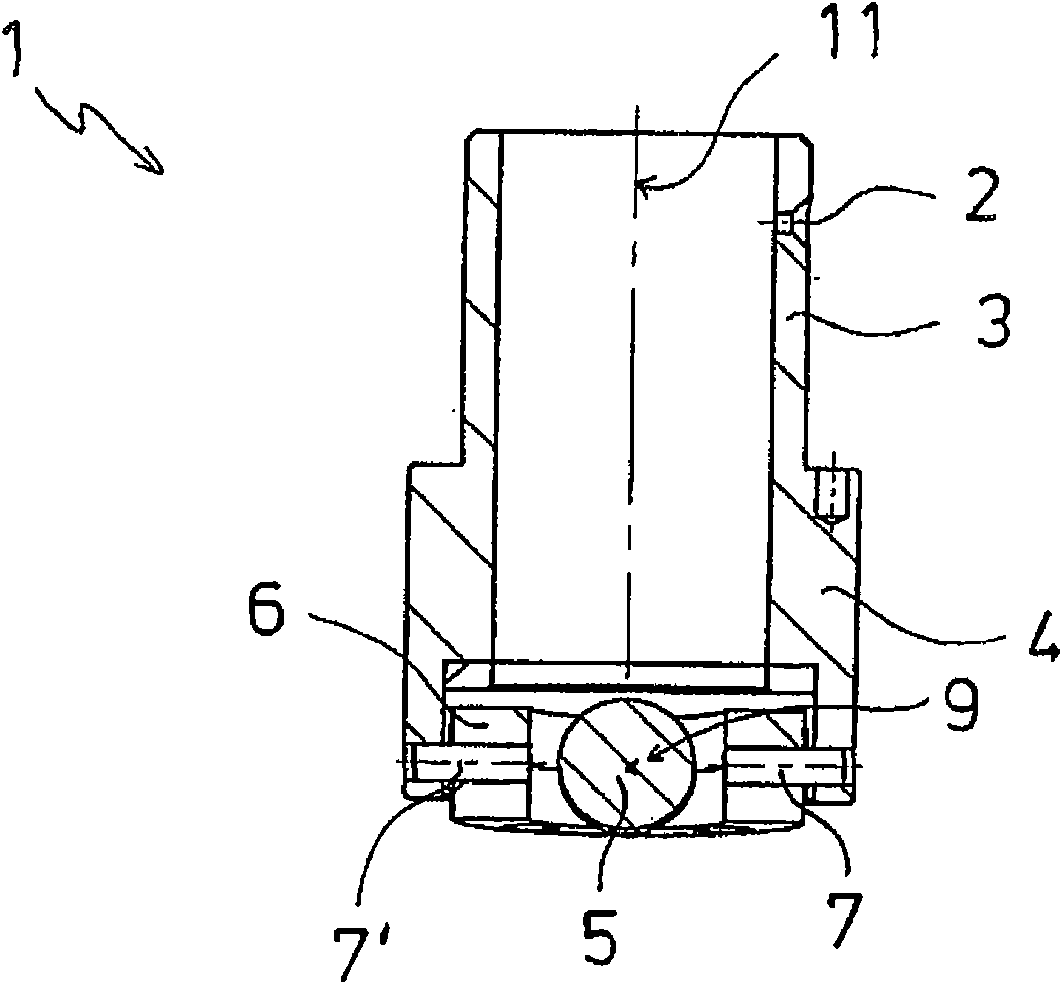

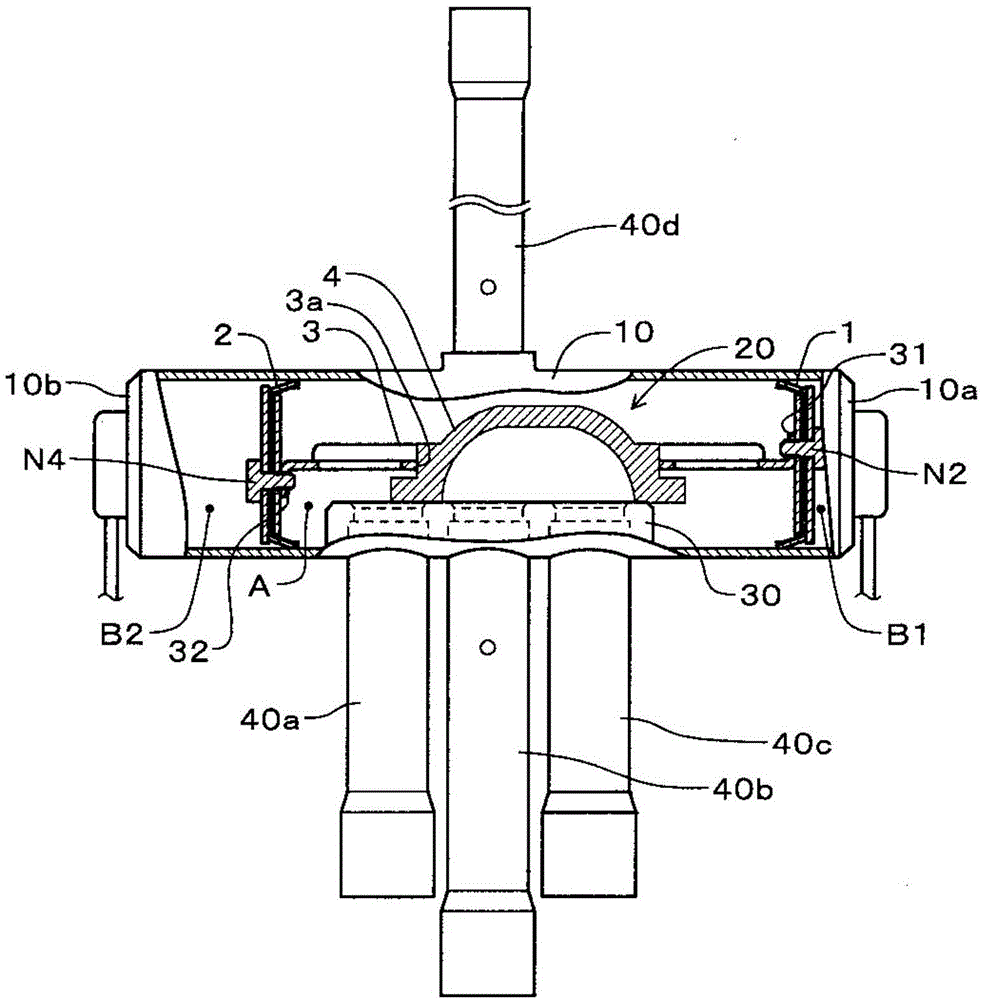

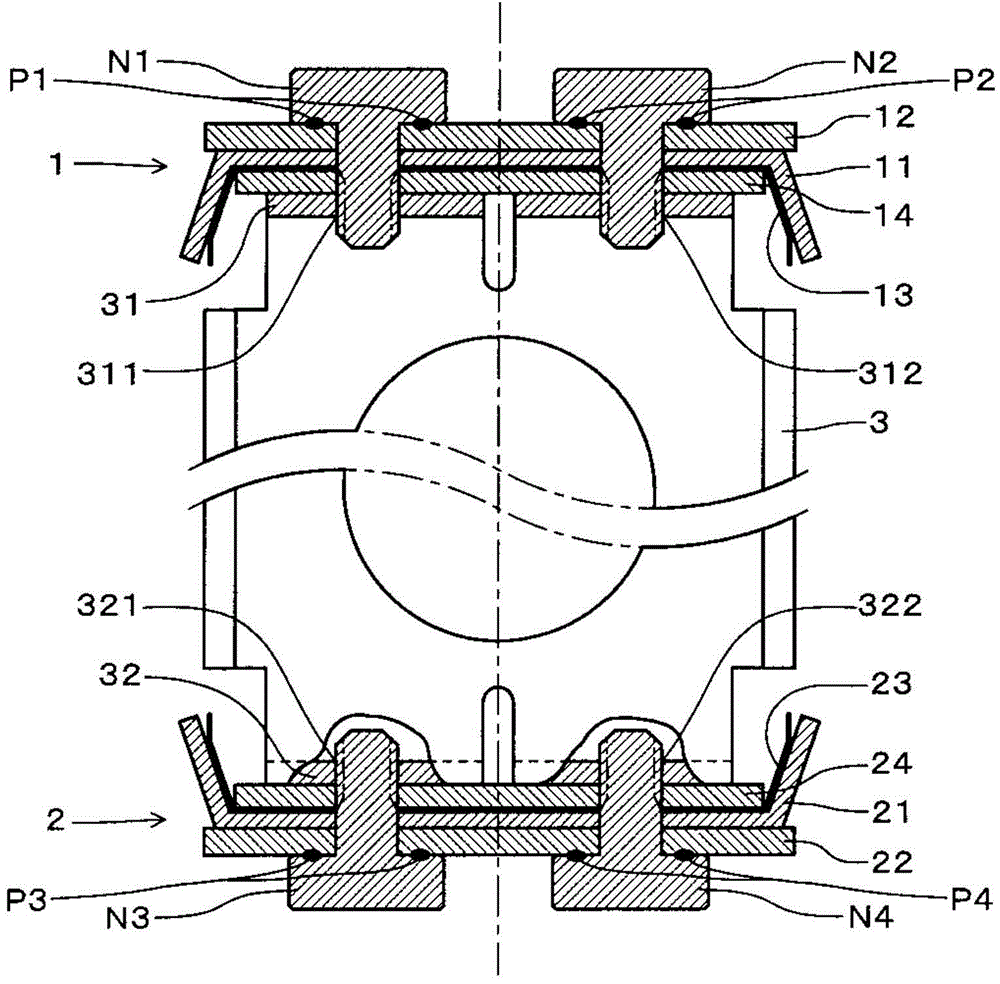

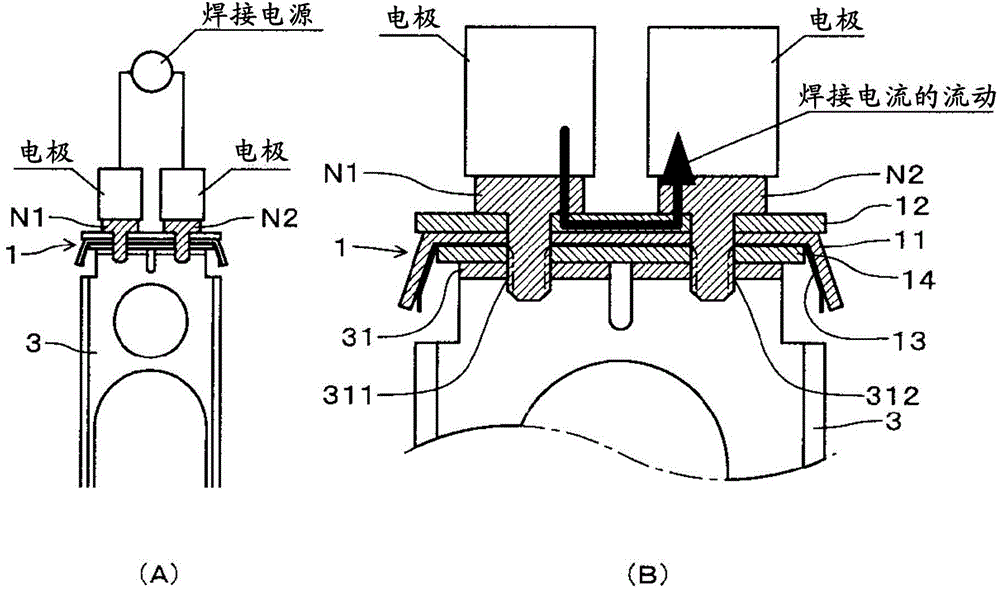

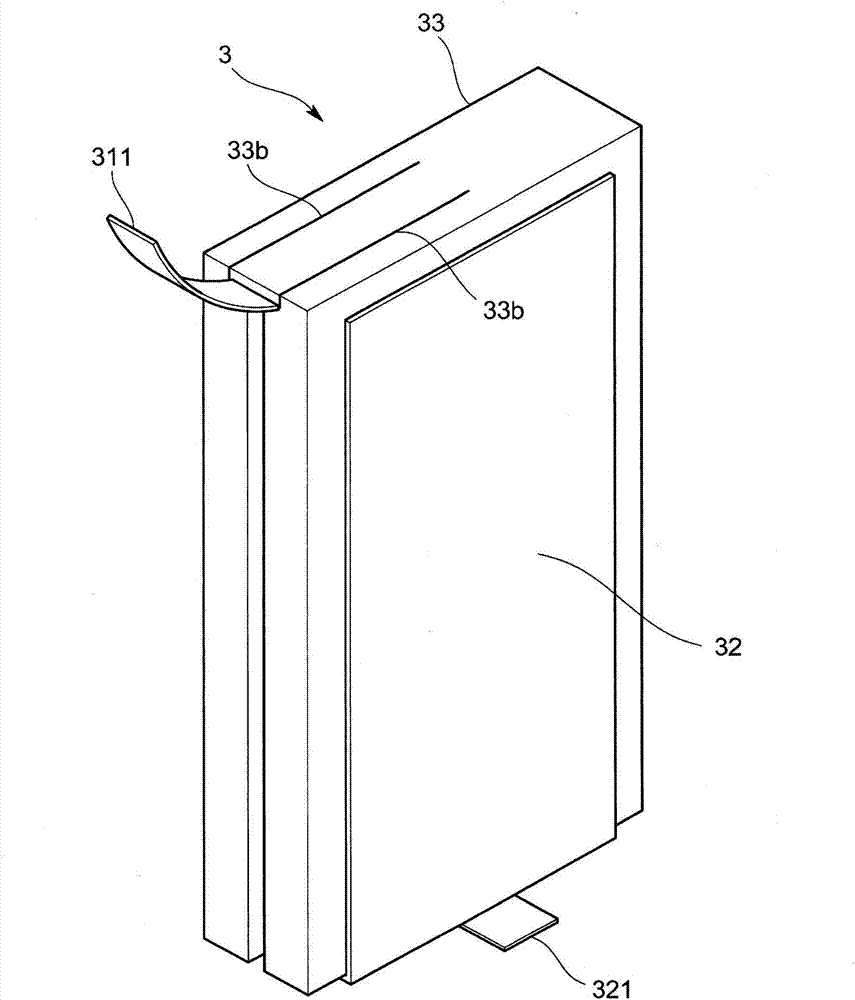

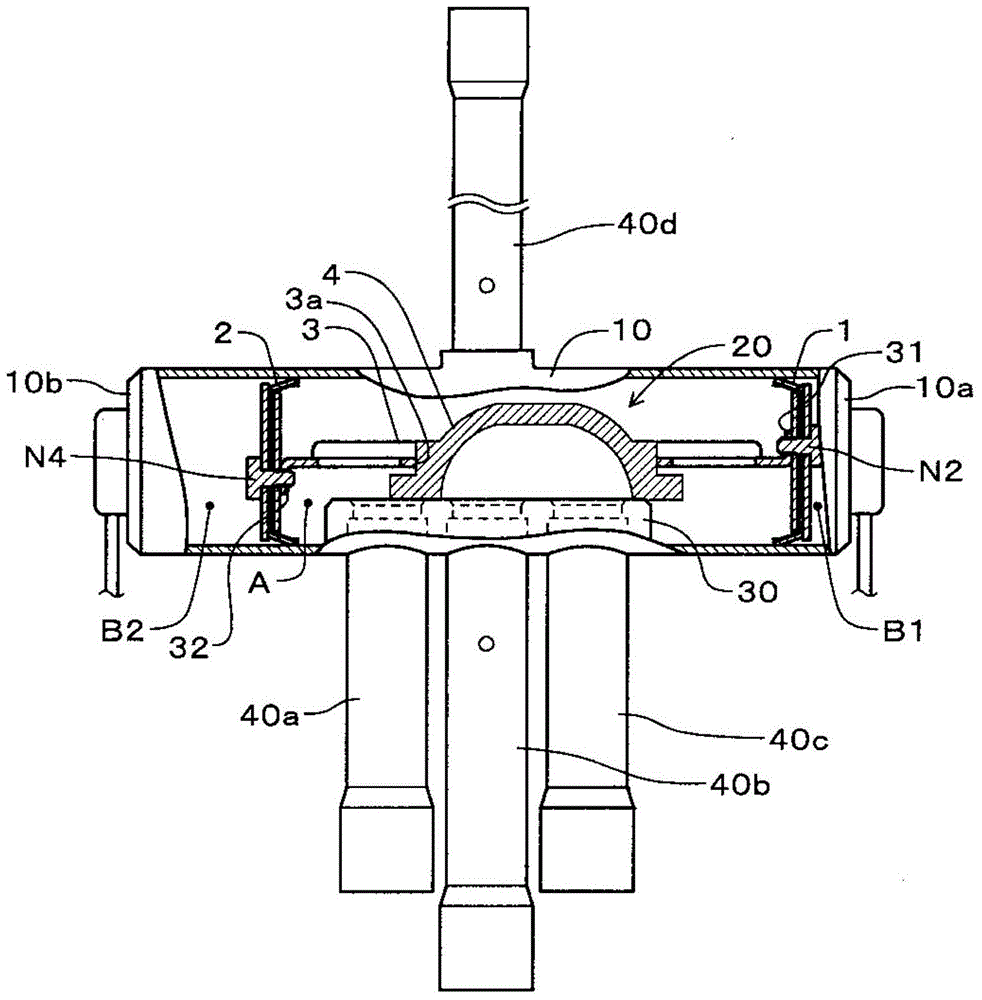

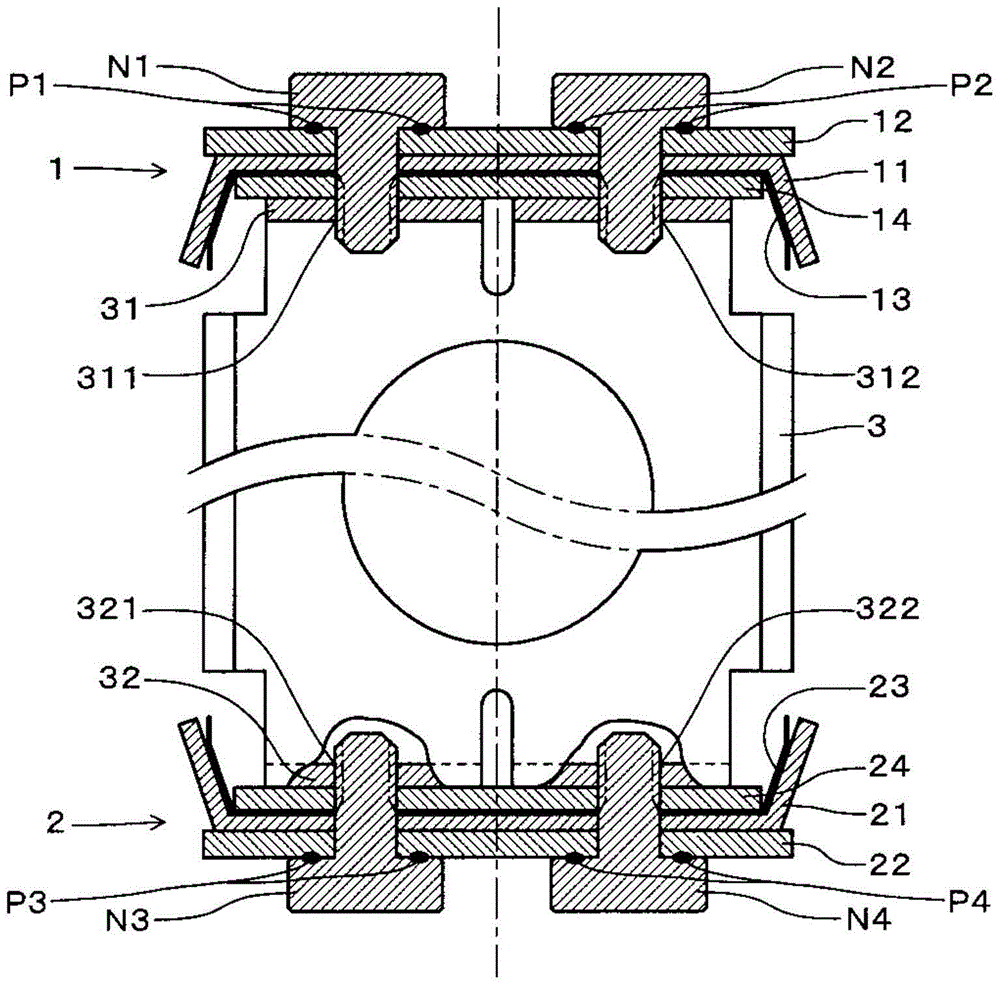

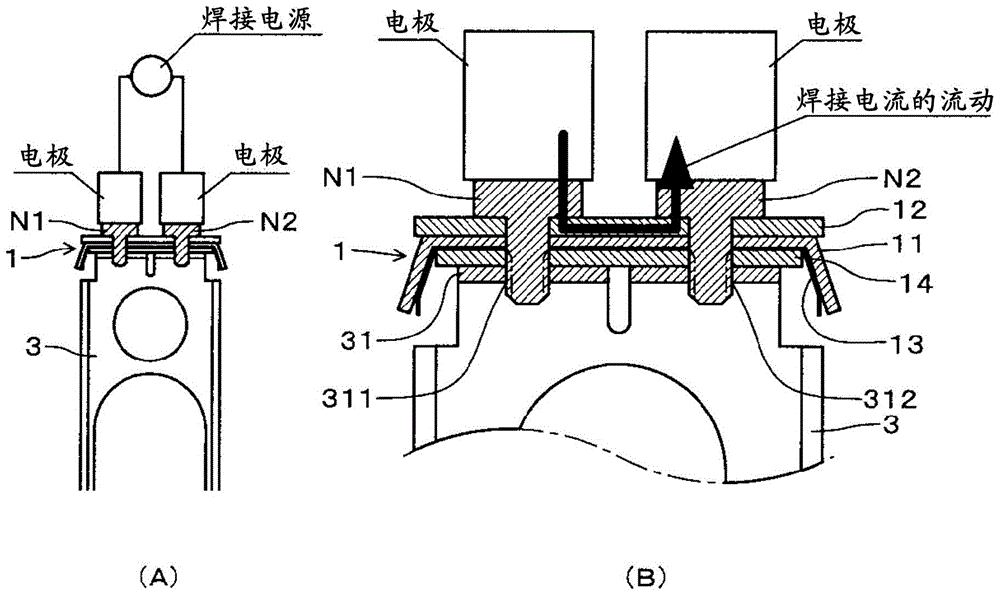

Four-way switching valve and method for welding fixing screws of four-way switching valve

InactiveCN104344013APrevent looseningEasy to assembleMultiple way valvesResistance welding apparatusElectrical resistance and conductanceEngineering

A four-way switching valve accommodates a piston valve in a valve casing. The piston valve is formed by first and second pistons (1, 2), a connecting fitting and a valve body (4). The piston (1) is formed by a pad (11), a guide plate (12), a tooth spring (13) and a reinforcing plate (14). The piston (2) is formed by a pad (21), a guide plate (22), a tooth spring (23) and a reinforcing plate (24). The piston (1) is fixed to a vertical plate (31) of the connecting fitting via fixing screws (N1, N2). The piston (2) is fixed to a vertical plate (32) of the connecting fitting via fixing screws (N3, N4). Fusing layers (P1, P2) generated by resistance welding are formed at a position where the fixing screw (N1) is abutted with the guide plate (12) and a position where the fixing screw (N2) is abutted with the guide plate (12). Fusing layers (P3, P4) generated by resistance welding are formed at a position where the fixing screw (N3) is abutted with the guide plate (22) and a position where the fixing screw (N4) is abutted with the guide plate (22).

Owner:SAGINOMIYA SEISAKUSHO INC

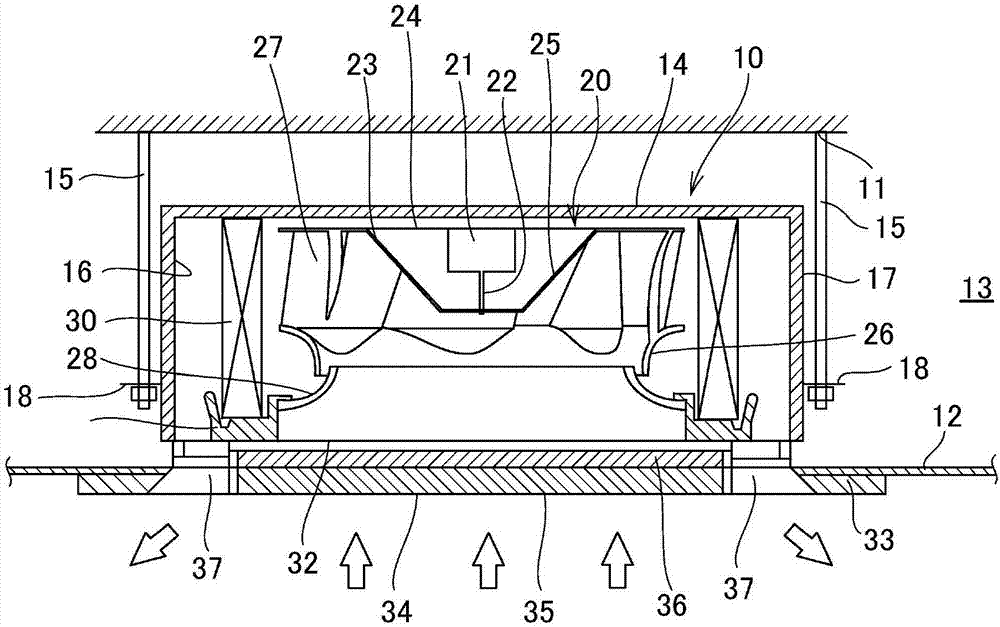

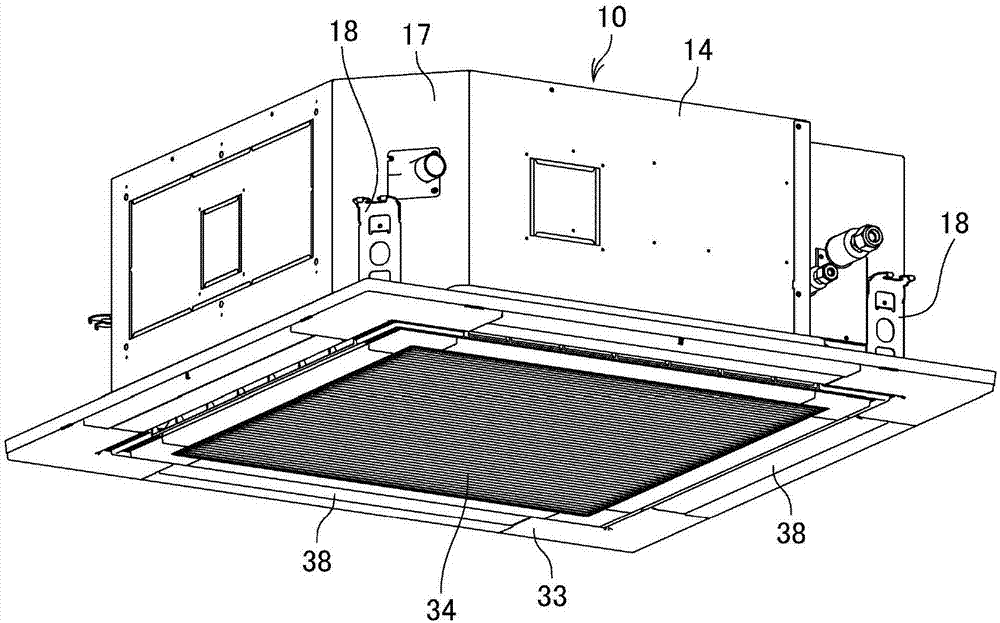

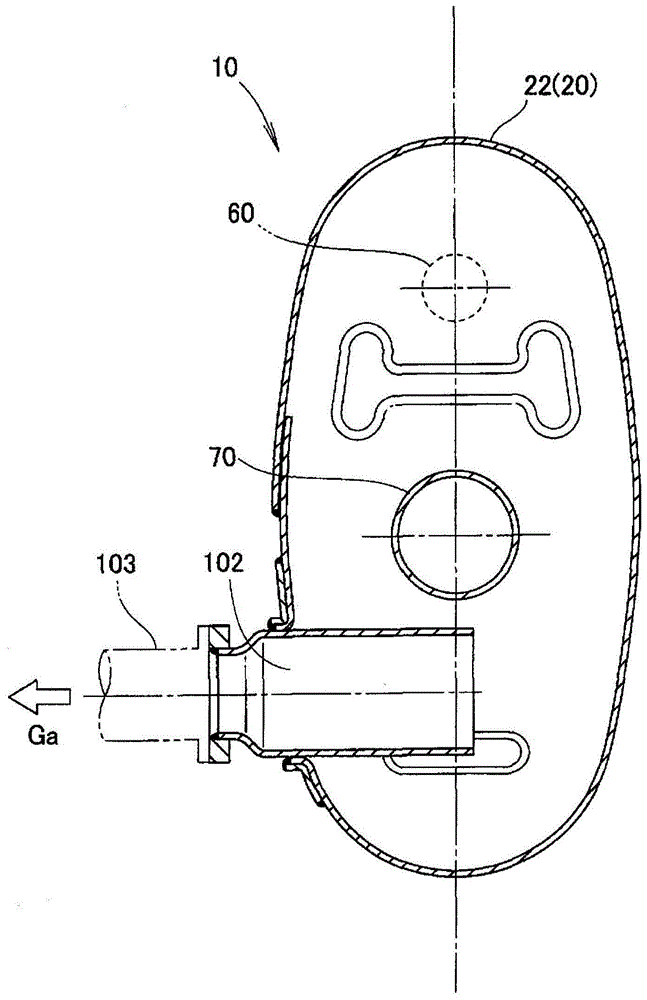

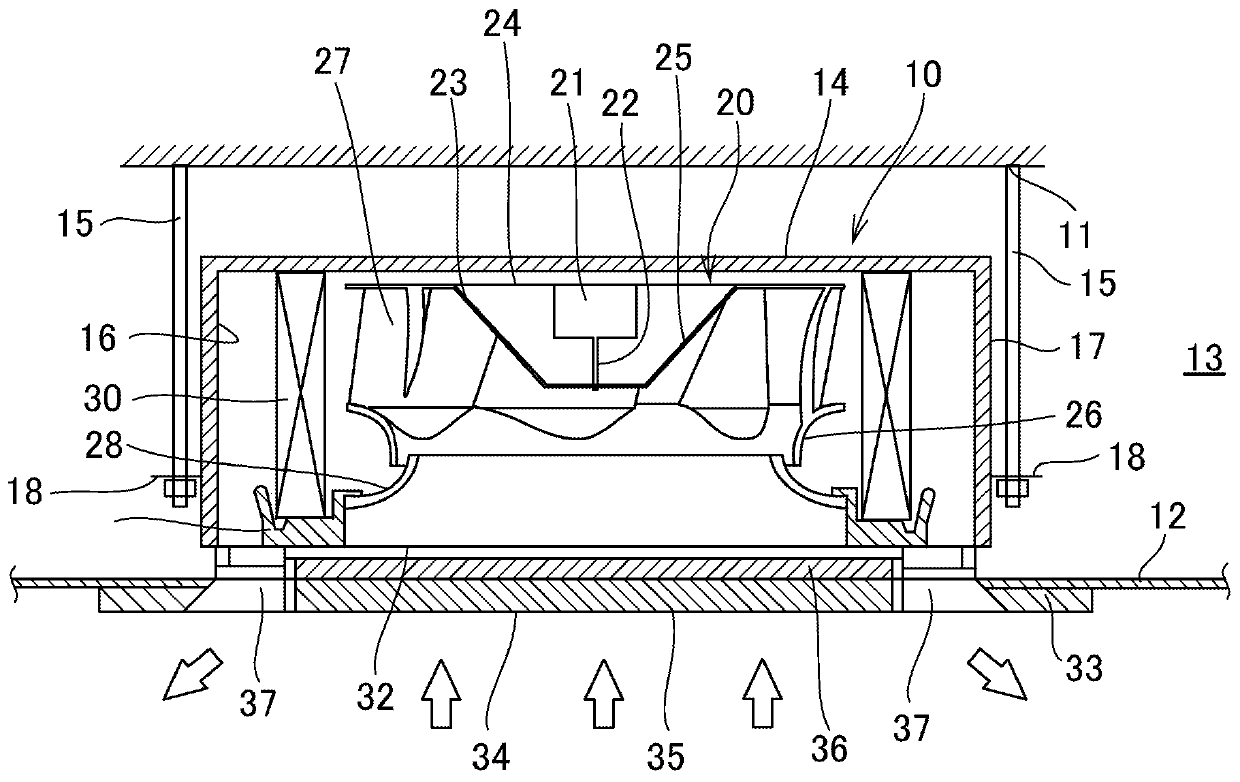

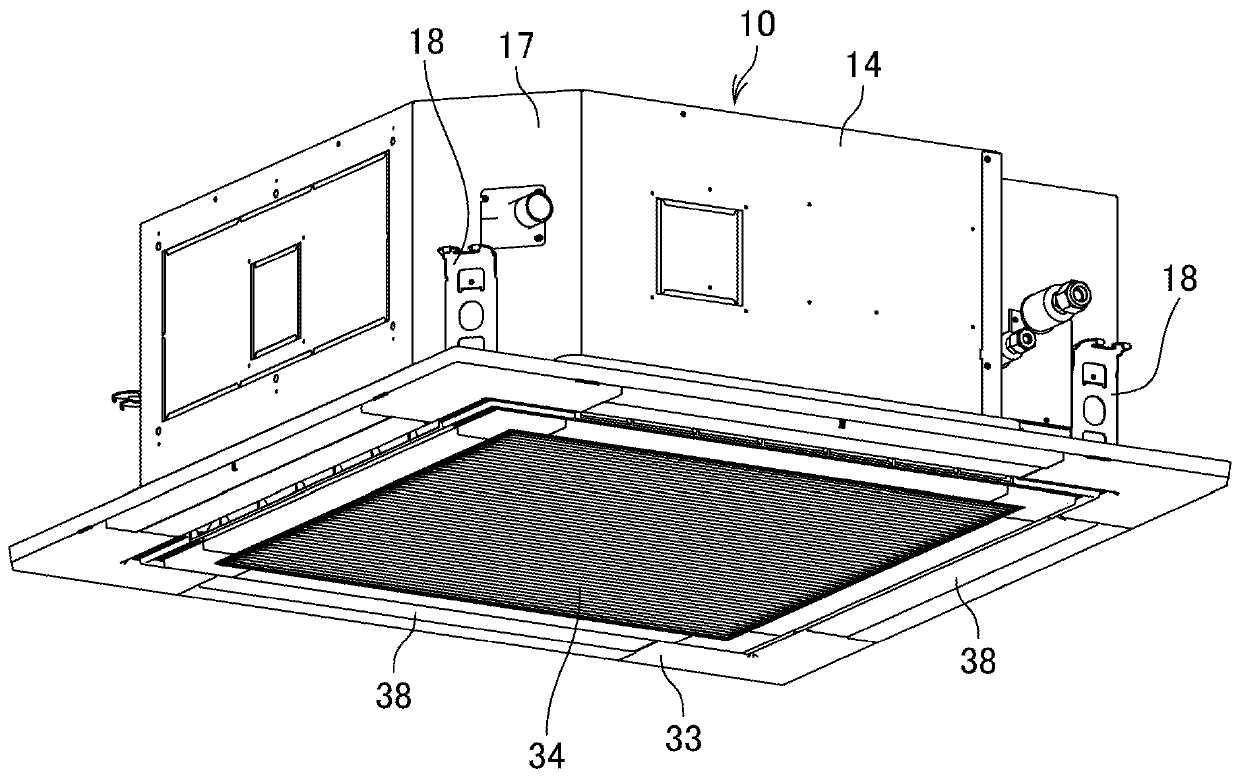

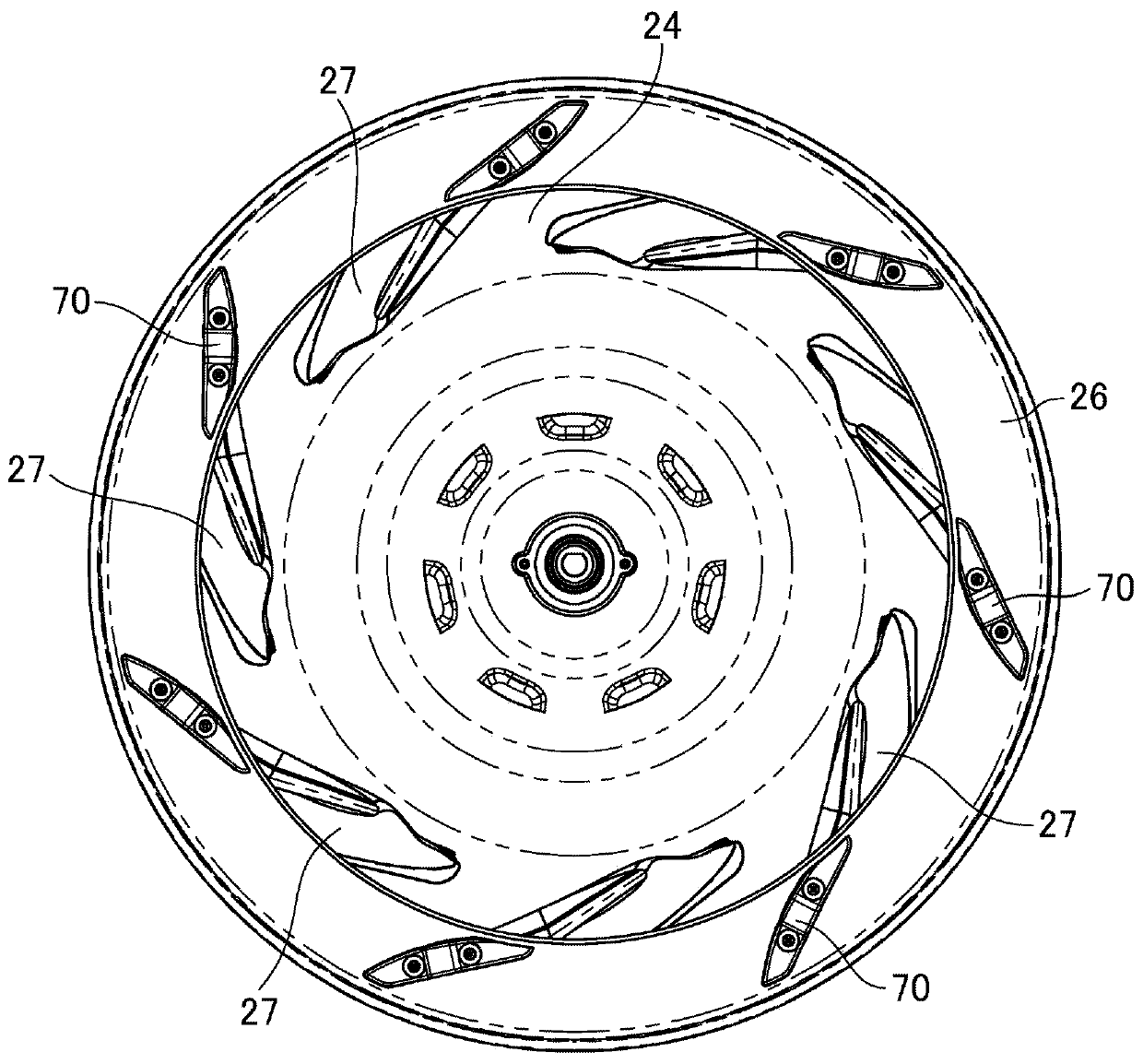

Turbofan

ActiveCN106949076AStable supportEasy welding workPump componentsPump installationsEngineeringTurbofan

The invention provides a turbofan which can stably support a blade part and can easily perform welding operation. The turbofan comprises a mainboard (24), a cover (26) and a plurality of blade parts (27), wherein blade parts (27) comprise flange portions (45), the flange portions (45) are welded to the mainboard (24), so that the blade parts (27) are jointed to the mainboard (24).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

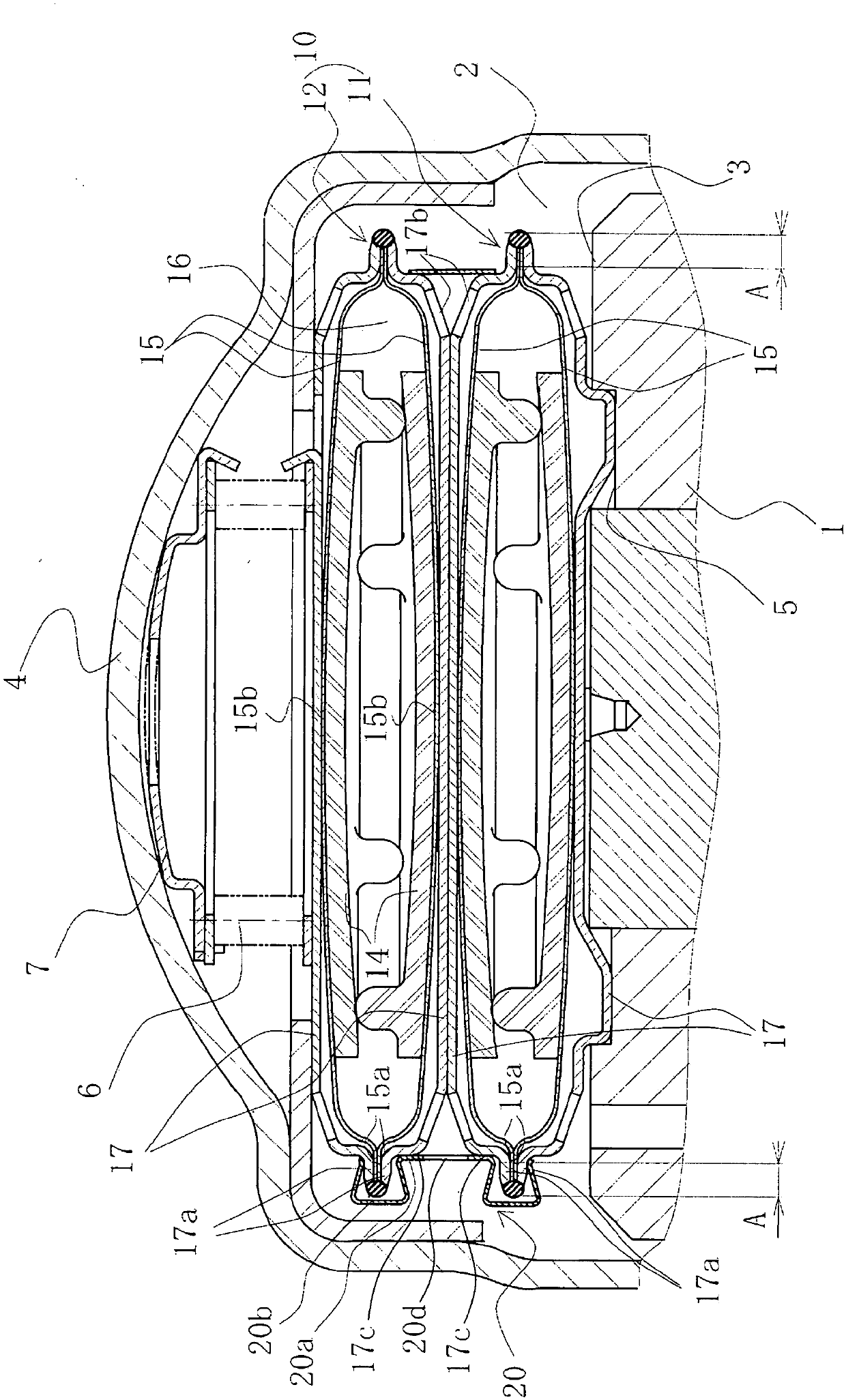

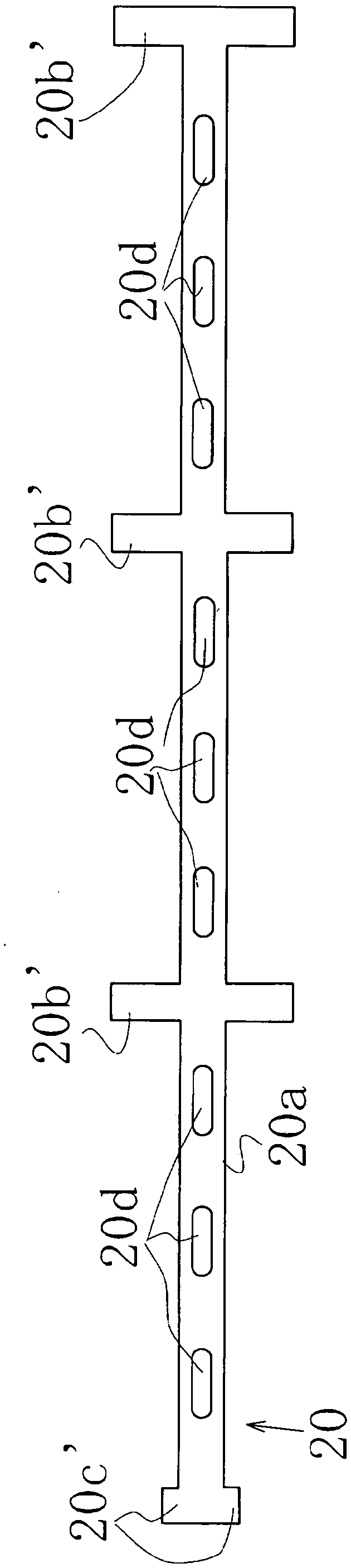

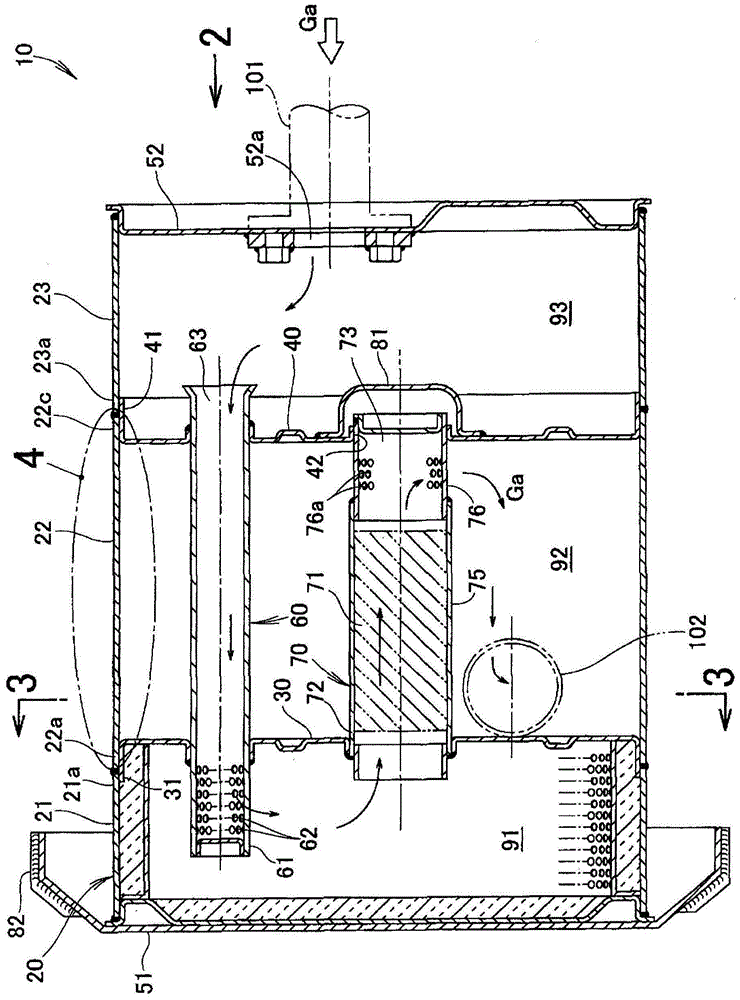

Diaphragm Damper Device, Holding Member Therefor, And Production Method For Diaphragm Damper Device

ActiveCN107709821AAvoid complicationsEasy welding workSpringsMachines/enginesEngineeringShock absorber

A holding member for a diaphragm damper device comprising a plurality of diaphragm dampers is formed from an elastic material and comprises: a band section to which the side perimeter of the pluralityof diaphragm dampers can be elastically fastened; and hook sections provided on both sides of the band section. The hook sections elastically sandwich each of the plurality of diaphragm dampers thathave been arranged overlapping.

Owner:EAGLE INDS

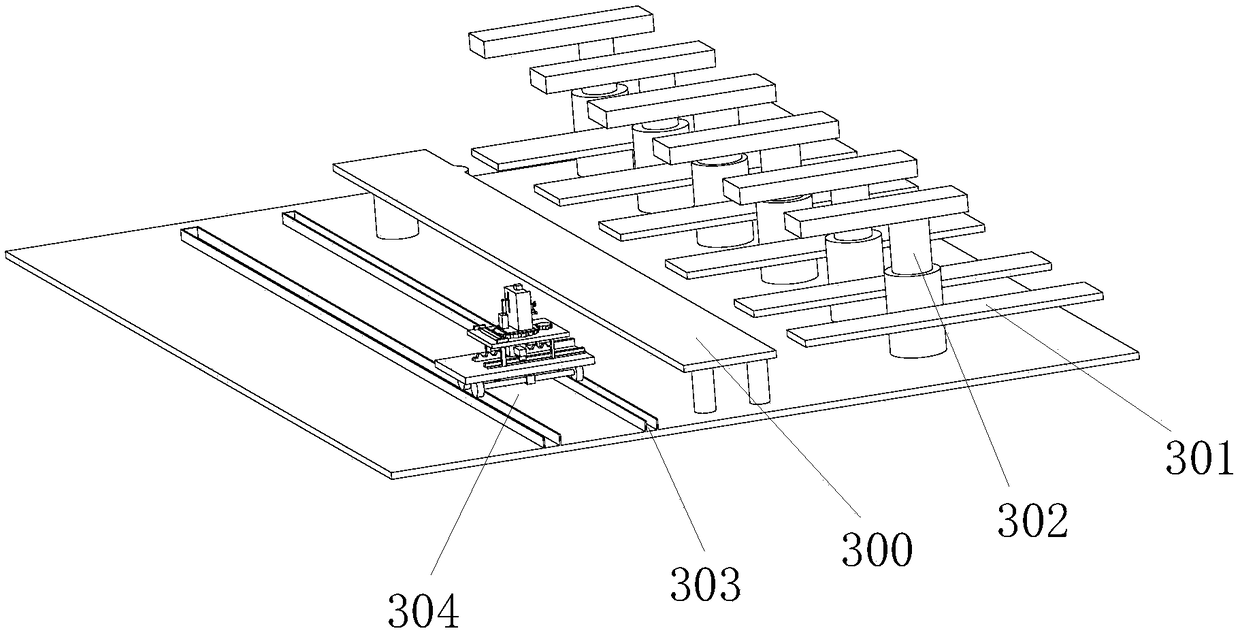

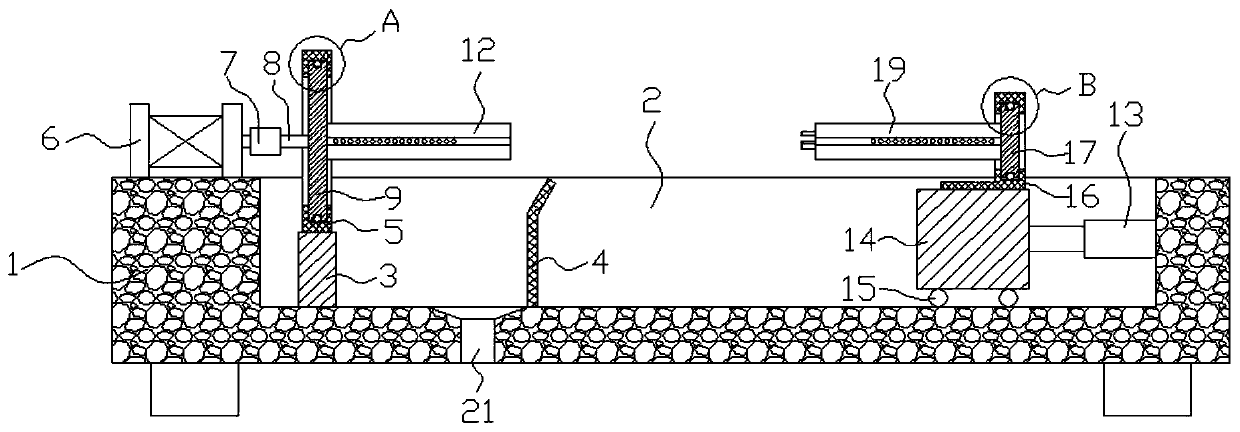

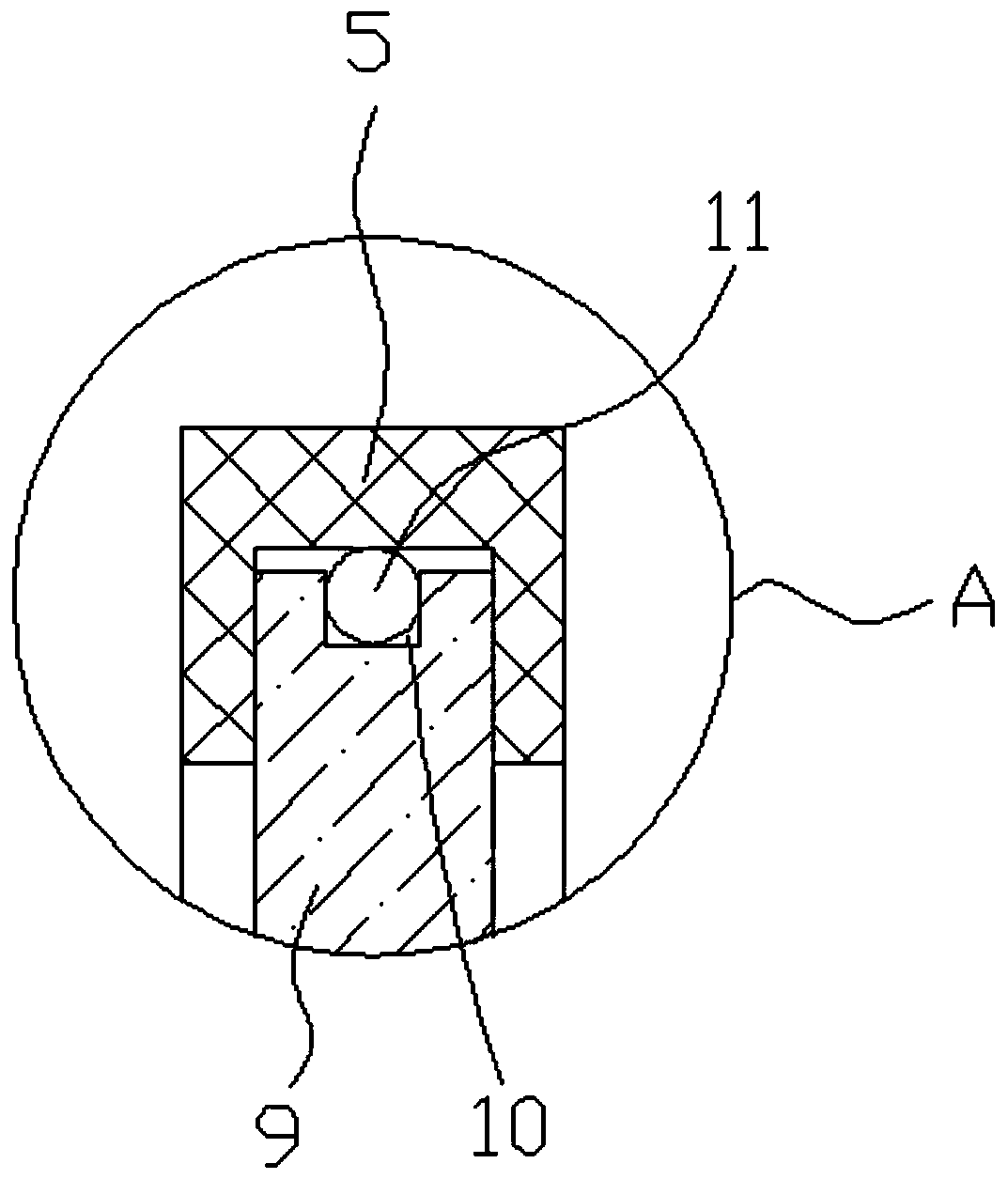

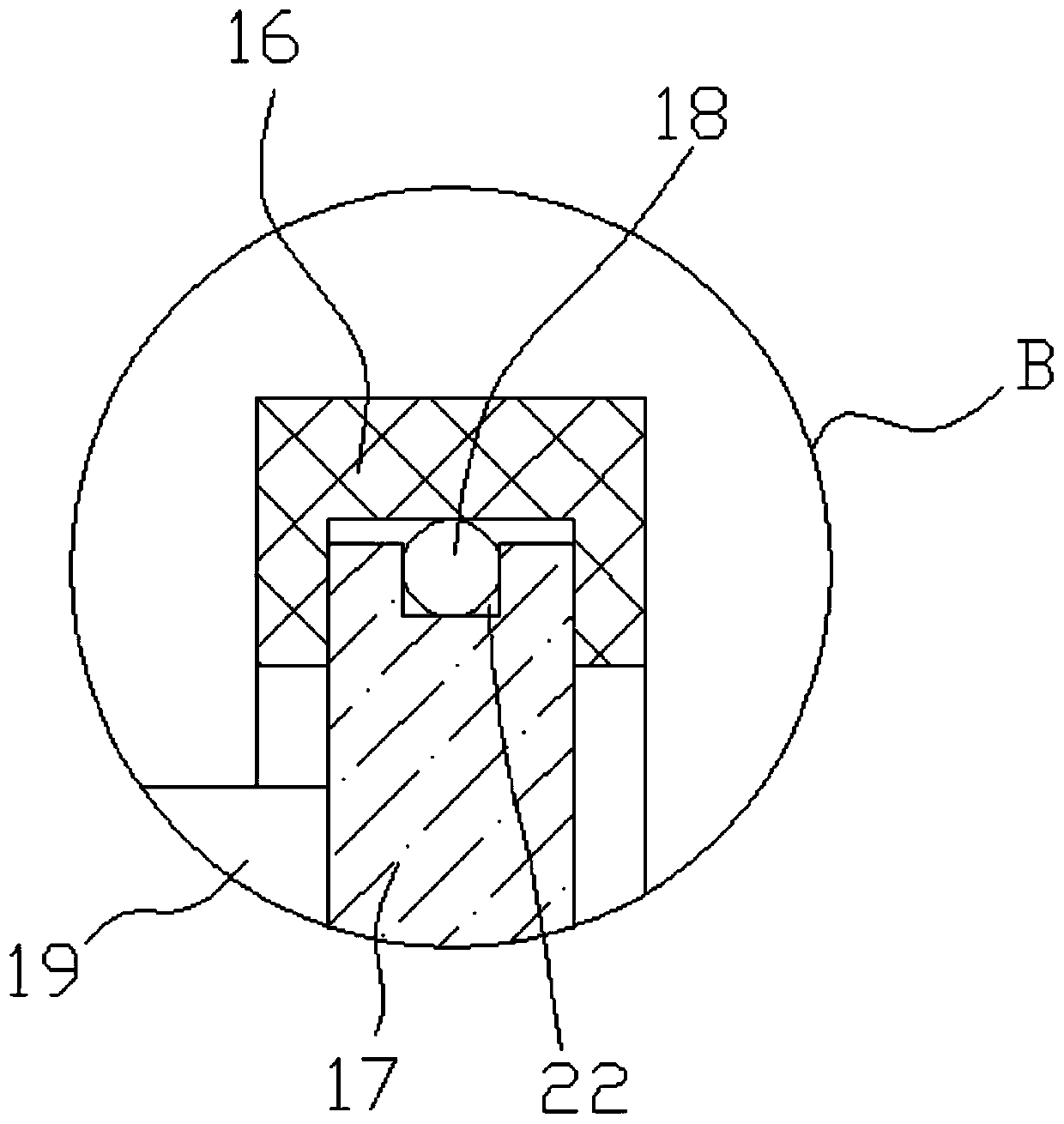

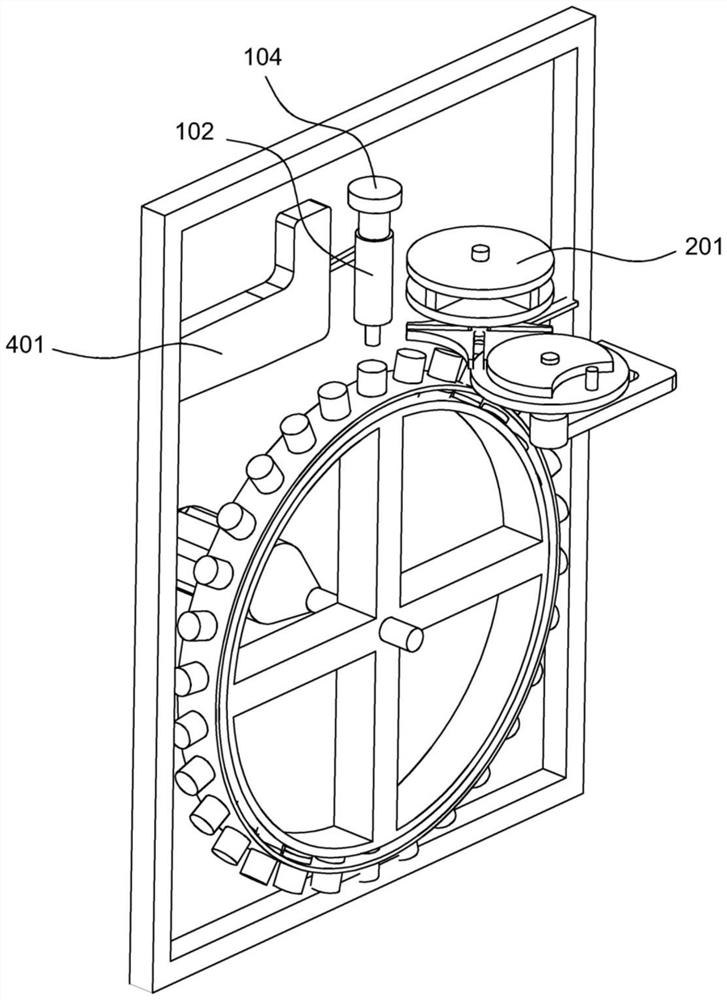

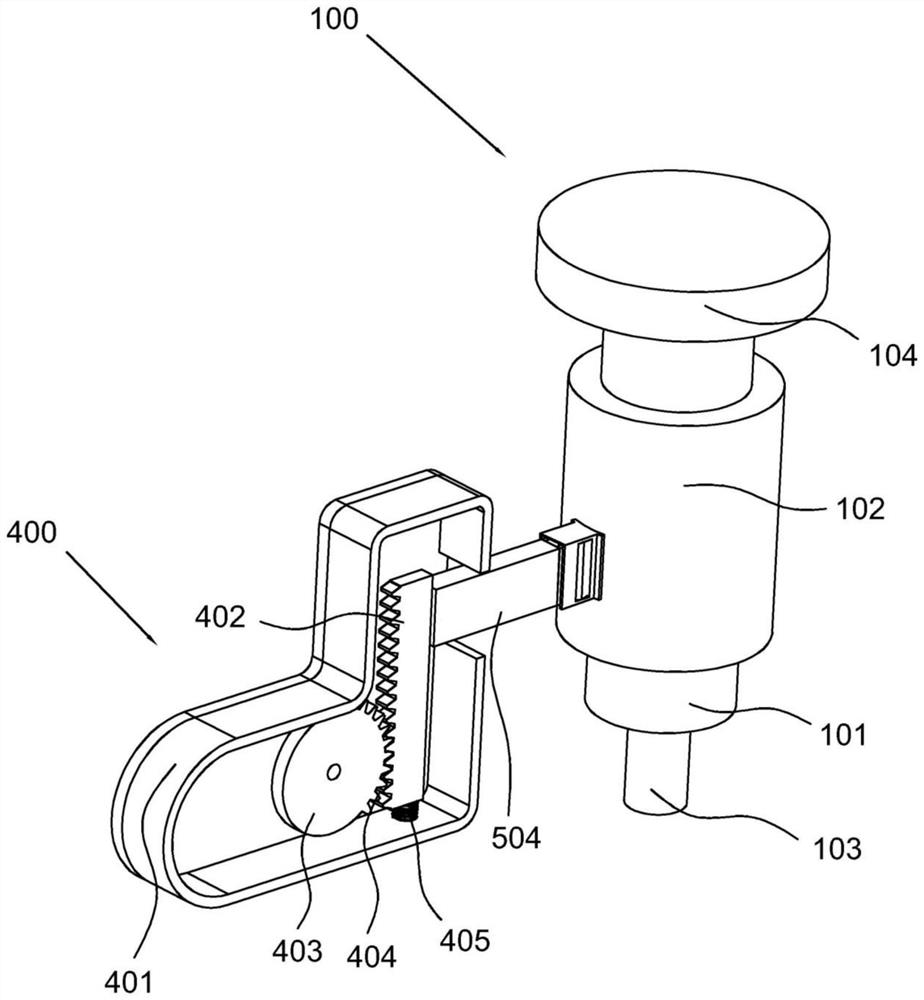

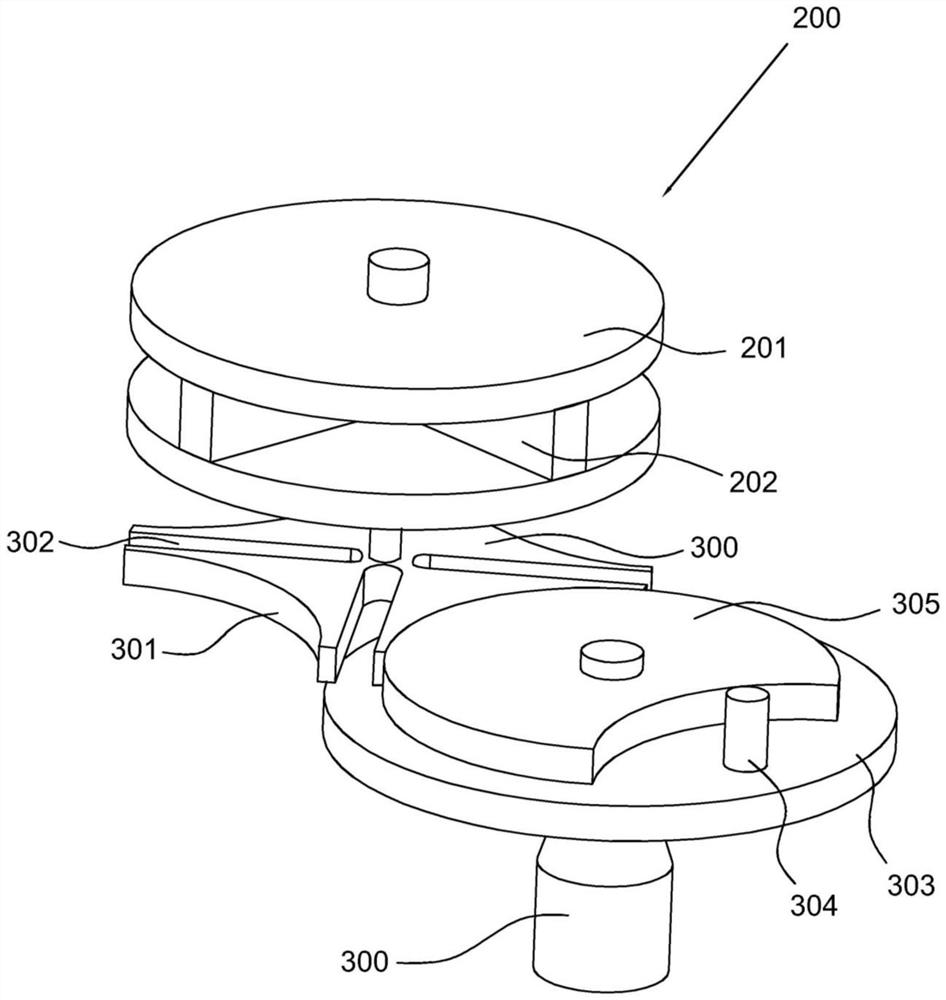

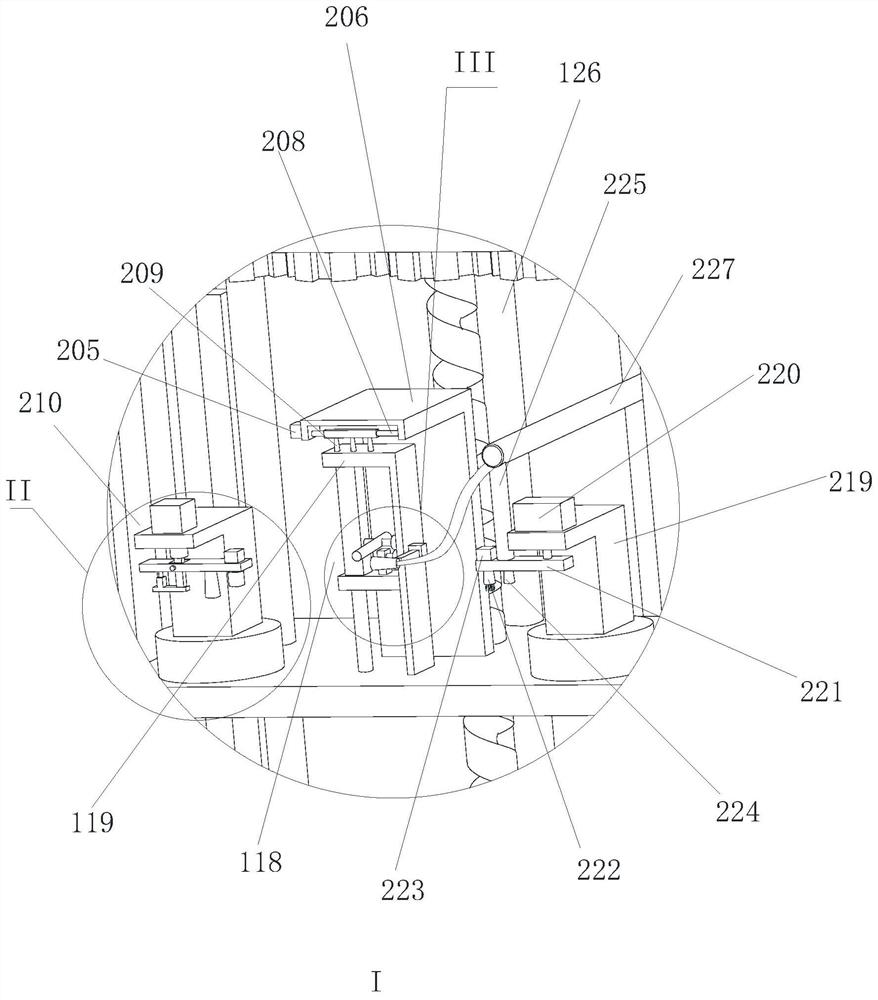

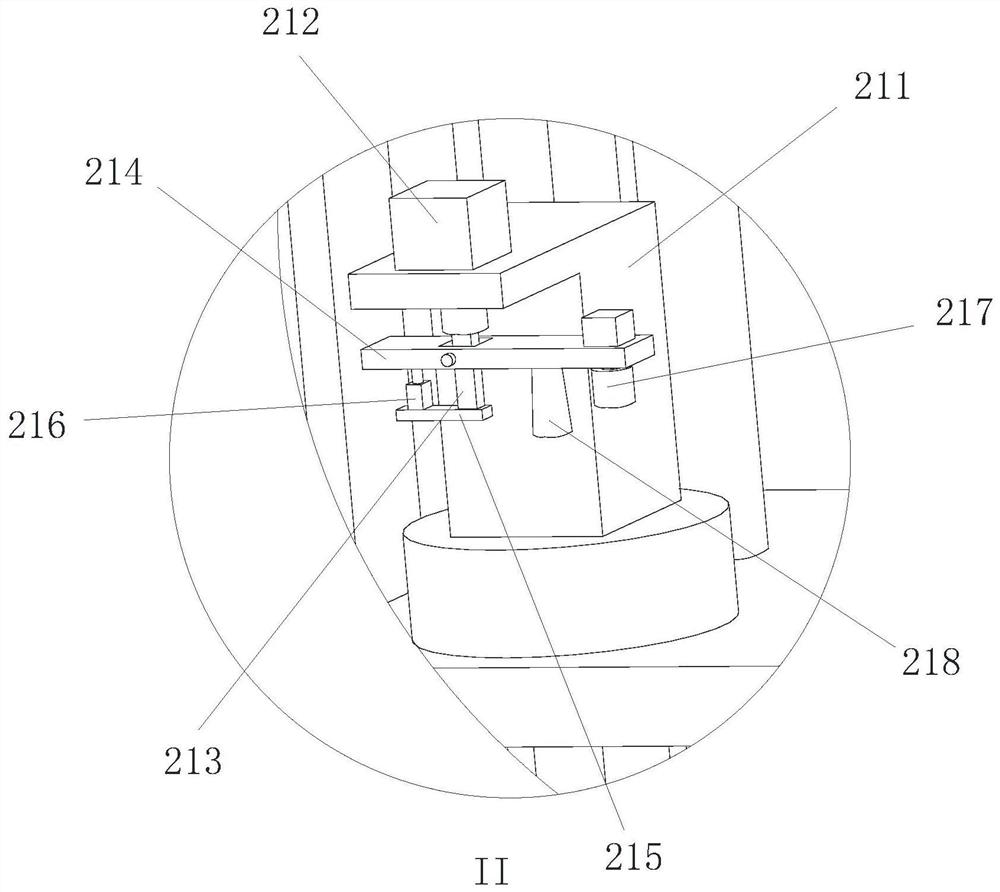

Automatic production and assembly system based on intelligent industrial robot

ActiveCN109014667AGuaranteed reliabilityGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesInterference fitEngineering

The invention relates to the field of robot equipment, and discloses an automatic production and assembly system based on an intelligent industrial robot. The automatic production and assembly systemcomprises a bottom plate, wherein a welding manipulator is fixedly arranged on the bottom plate, and a small wheel set is arranged below the bottom plate; the welding manipulator which linearly movesalong a first guide rail group is arranged on a first rack and the first guide rail group, the welding manipulator comprises a welding platform, supporting legs are arranged below the welding platform, the supporting legs are arranged on the first guide rail group in a sliding mode, an output shaft of a first motor is coaxially connected with a first gear, the first gear and the first rack mesh with each other, a mounting rod is arranged on one side of the first motor, a supporting wheel is arranged at the bottom of the mounting rod, and the supporting wheel is in rolling contact with the bottom plate; a rotating disc is installed on the welding platform, a gear ring is arranged outside the rotating disc in a sleeving mode, the inner side surface of the gear ring is in interference fit with the outer side surface of the rotating disc, and the gear ring meshes with a second gear. The automatic production and assembly system has the advantages of being wide in application range, low in cost, accurate in transmission control and the like.

Owner:河南省乾憬光电科技有限公司

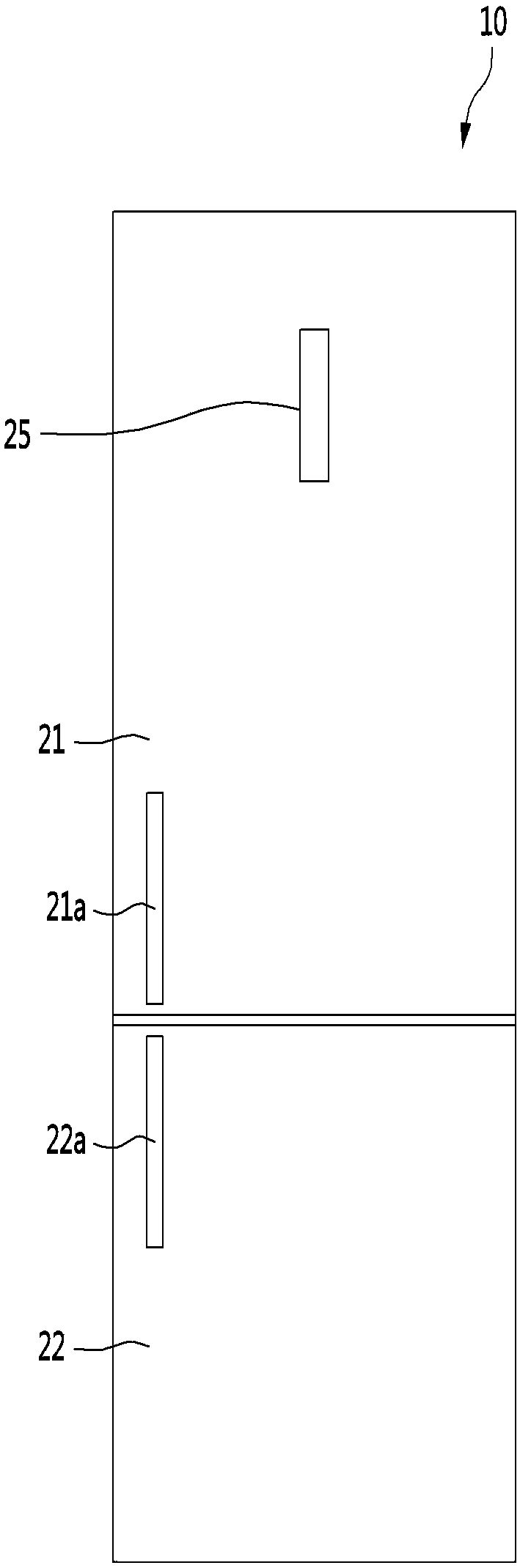

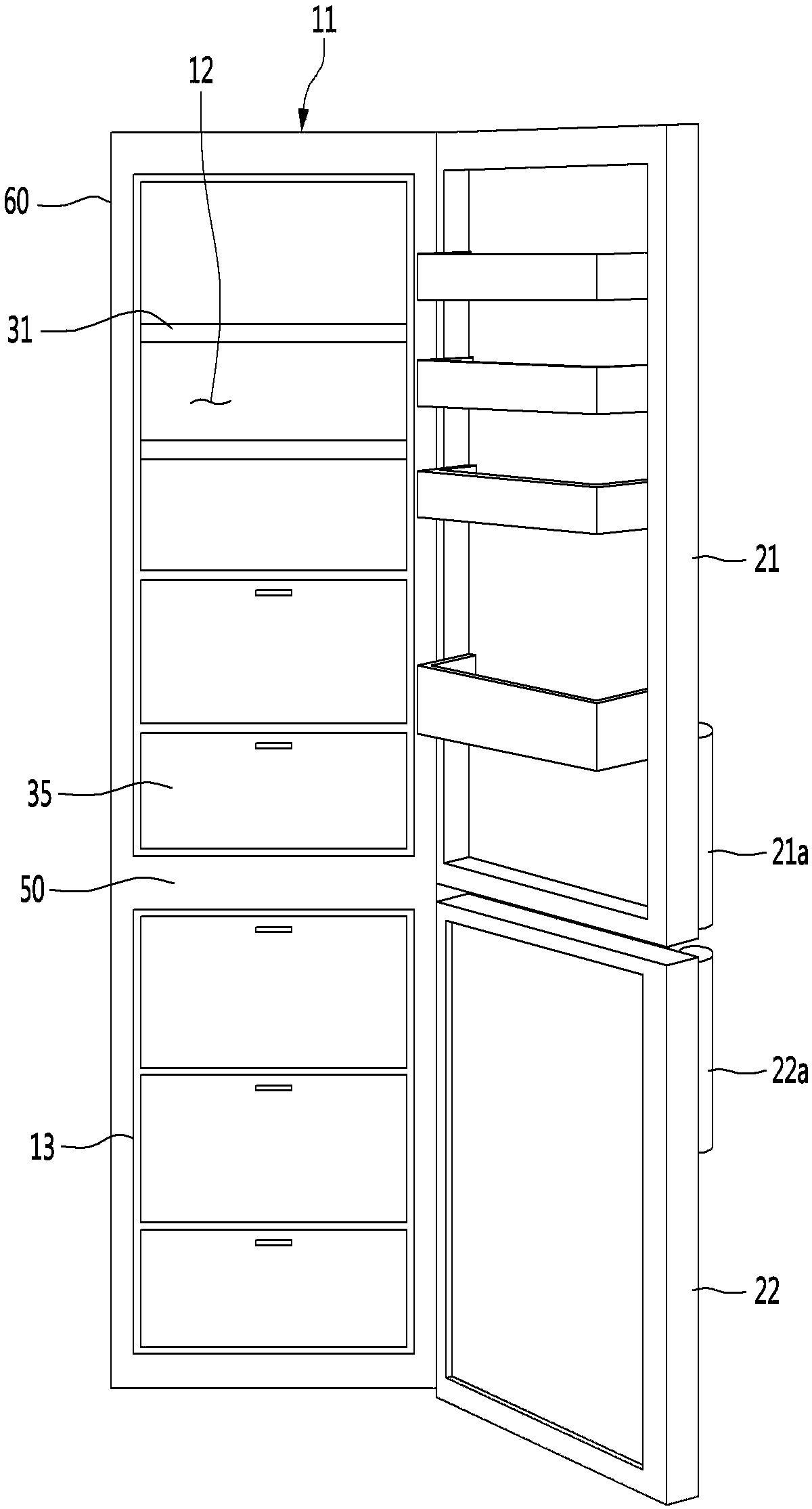

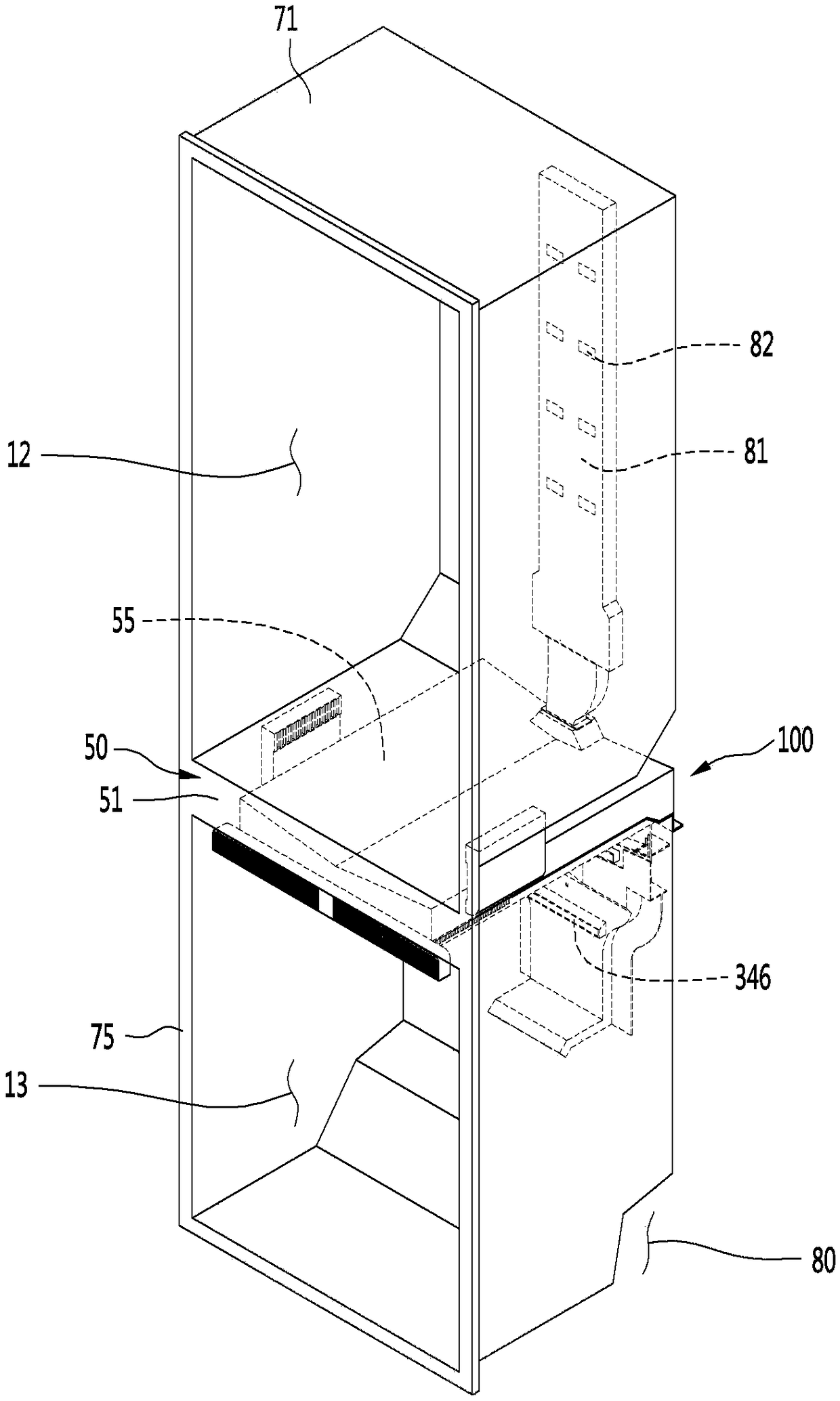

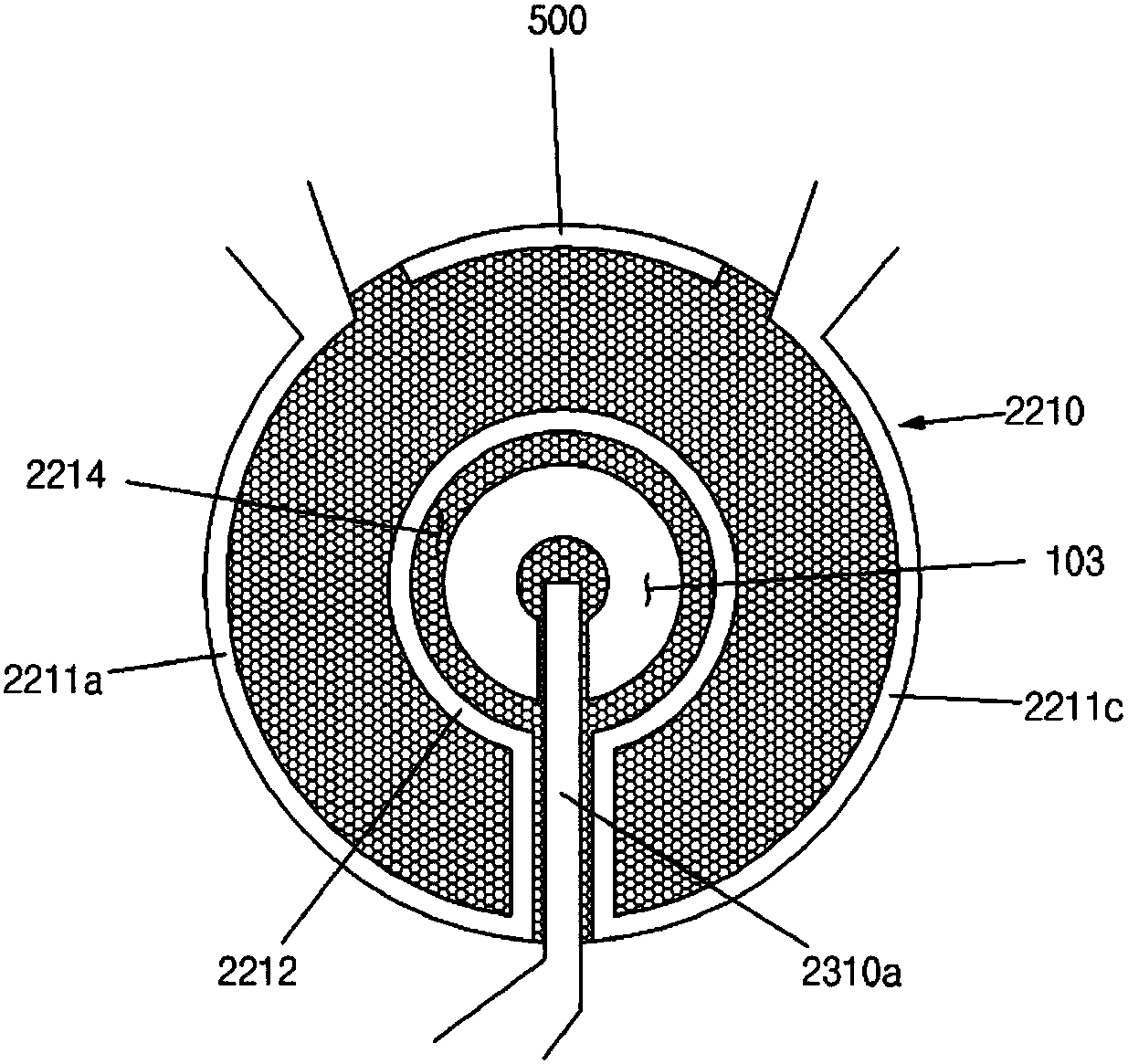

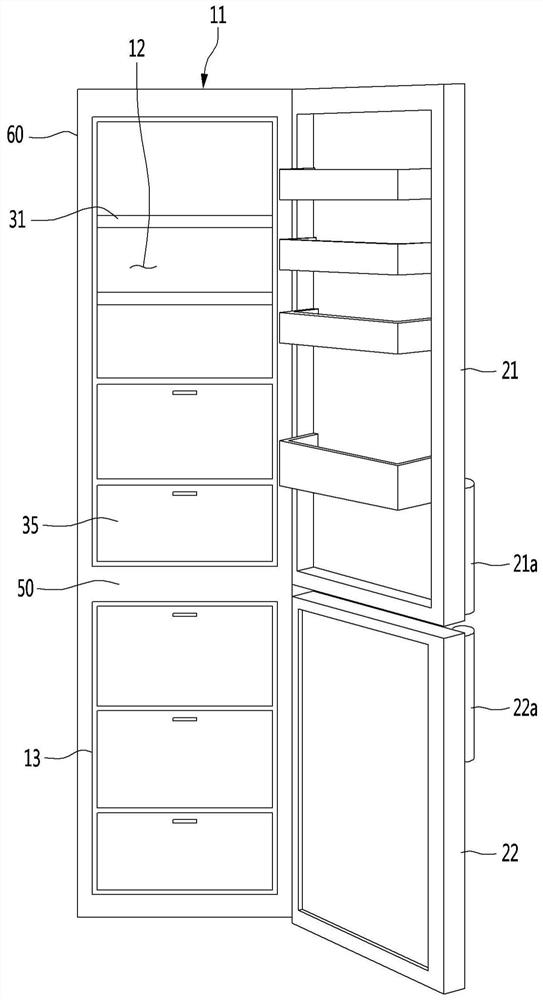

Refrigerator

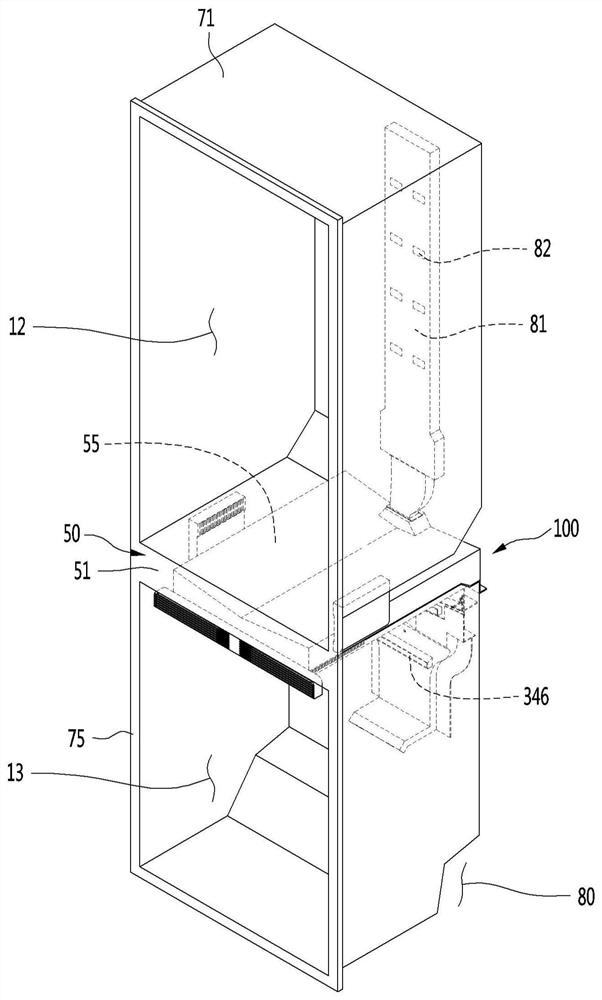

ActiveCN108571852AIncreased internal storage spaceIncrease pull distanceDomestic refrigeratorsEvaporators/condensersRefrigerated temperatureEvaporator

A refrigerator is provided. The refrigerator may include an evaporator installed inside an evaporator case, a water tray provided below the evaporator and configured to collect water, a grill cover provided at a rear side of the evaporator case and configured to accommodate a blower fan, and a tray support provided in the grill cover to support the water tray so that an inner storage space of therefrigerator may increase, a withdrawal distance of a drawer provided in the refrigerator may increase, and a storage capacity of the refrigerator may be improved.

Owner:LG ELECTRONICS INC

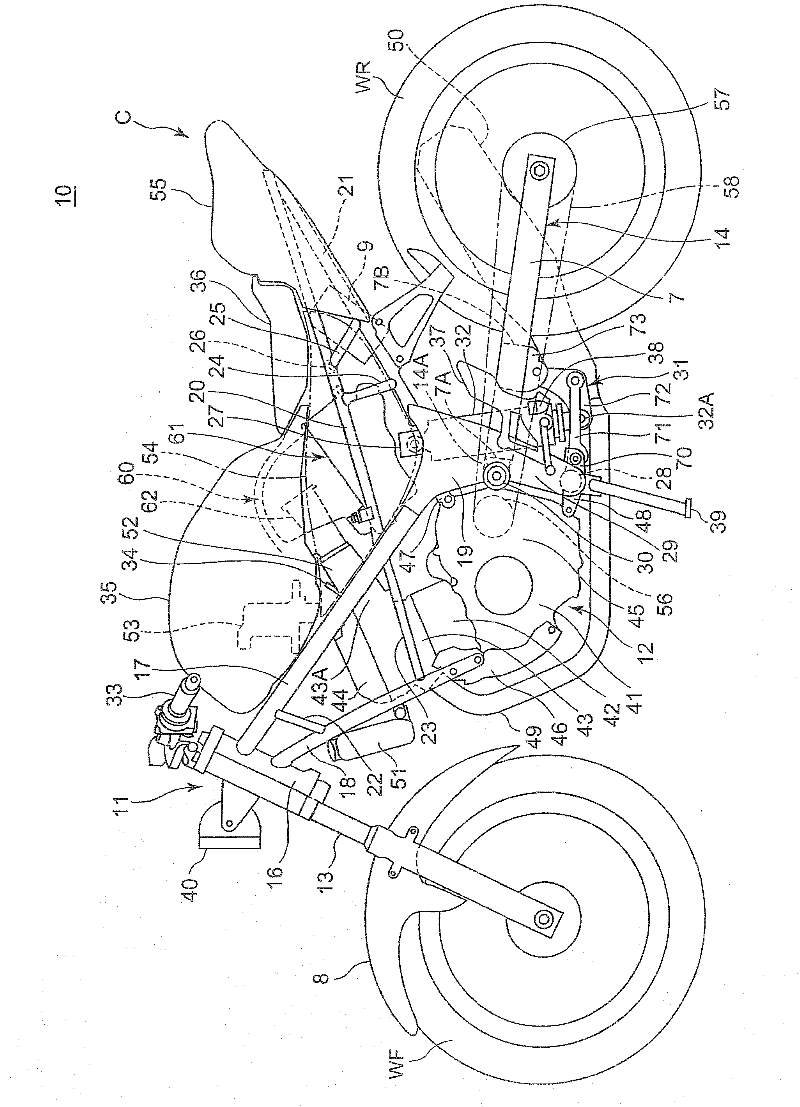

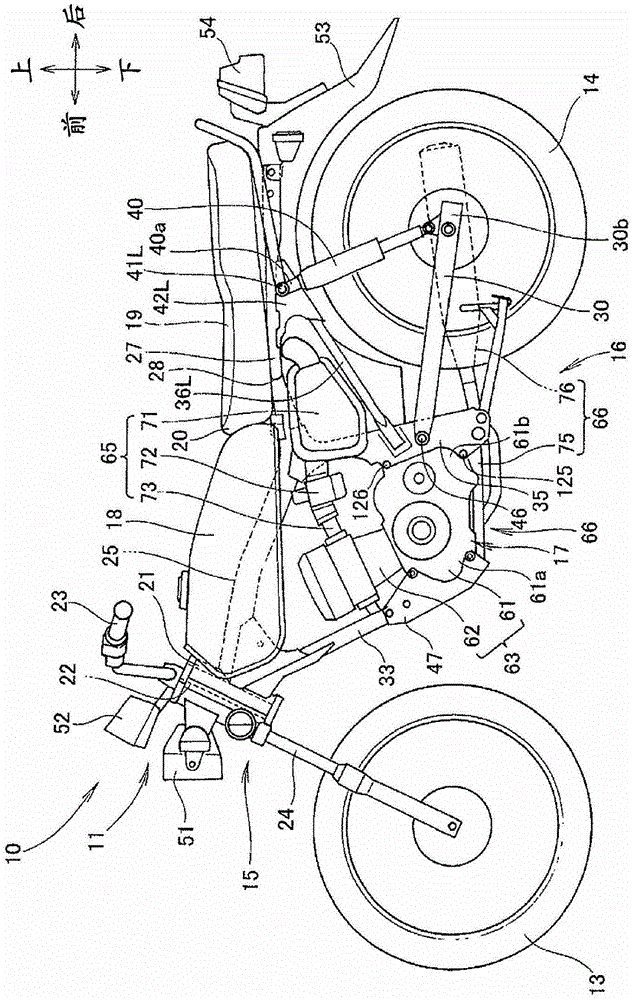

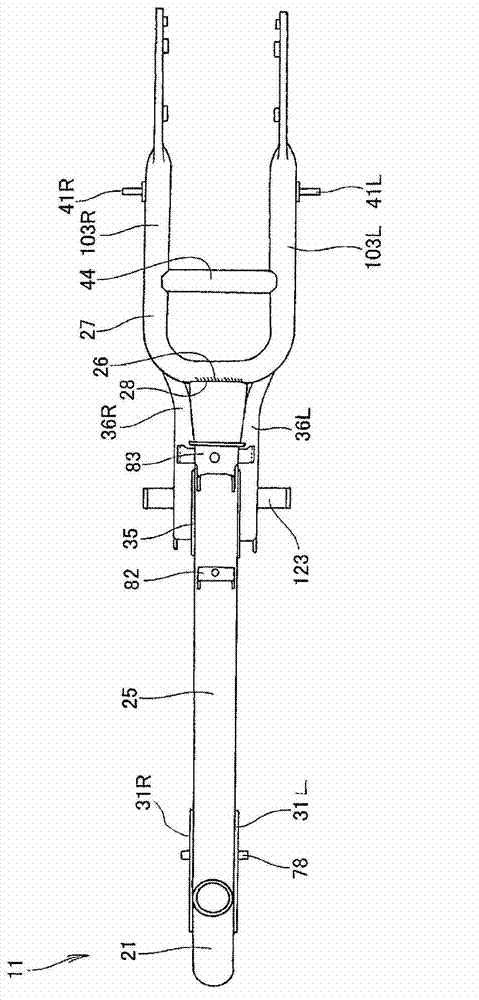

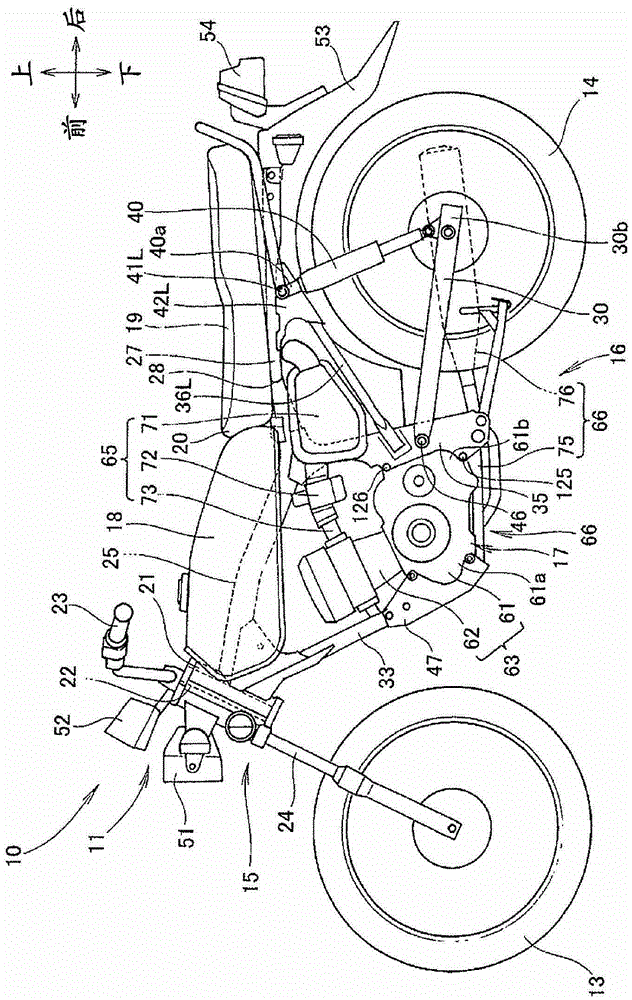

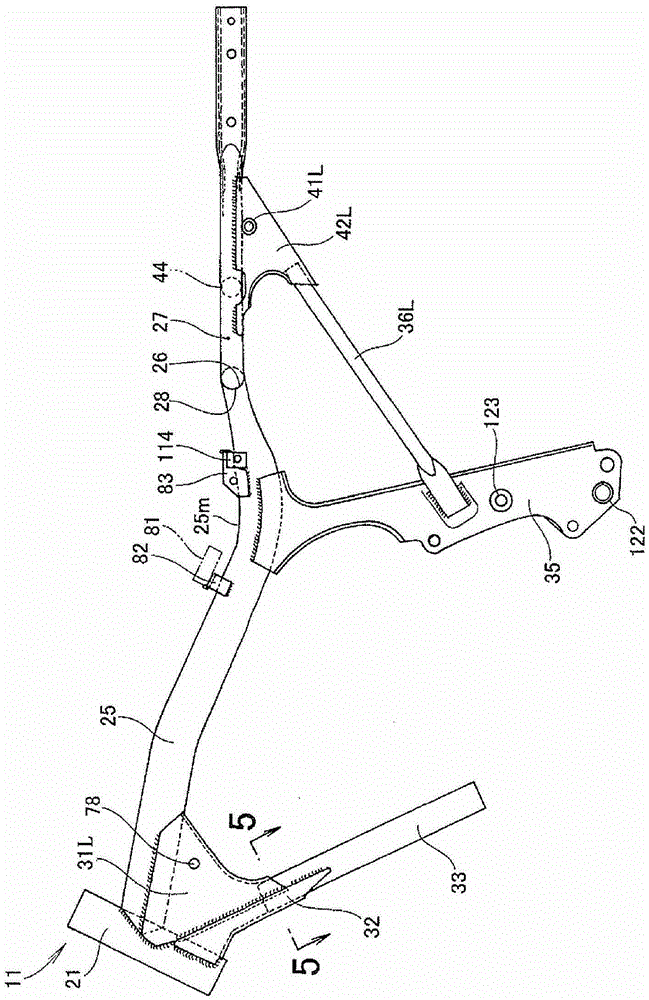

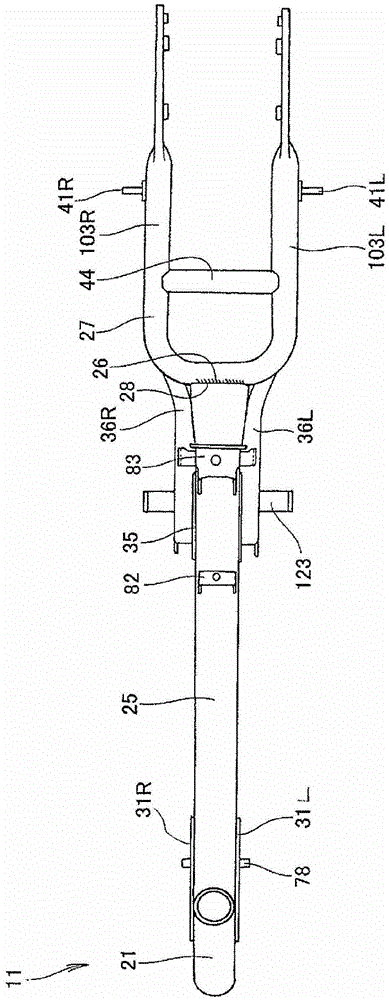

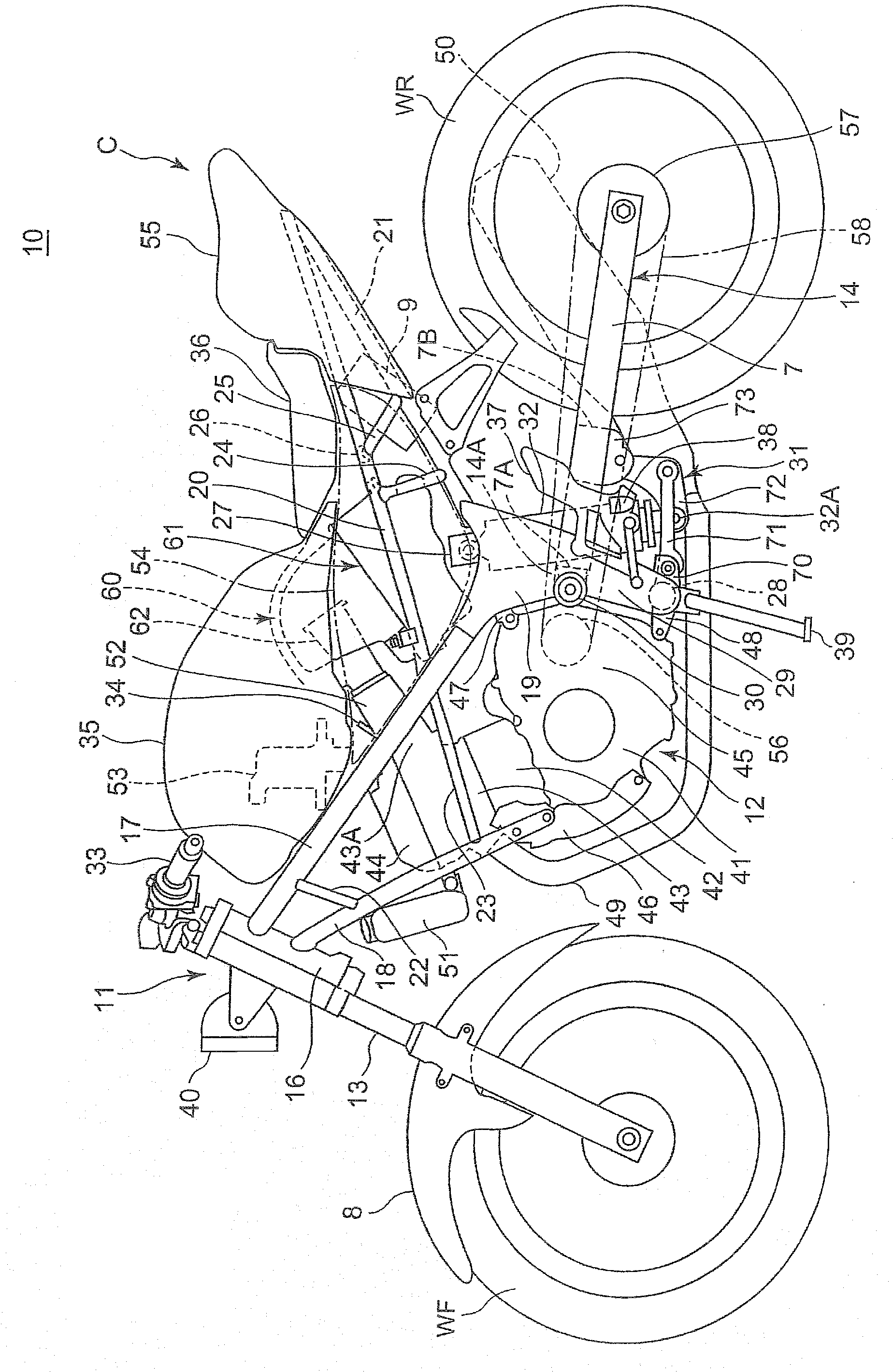

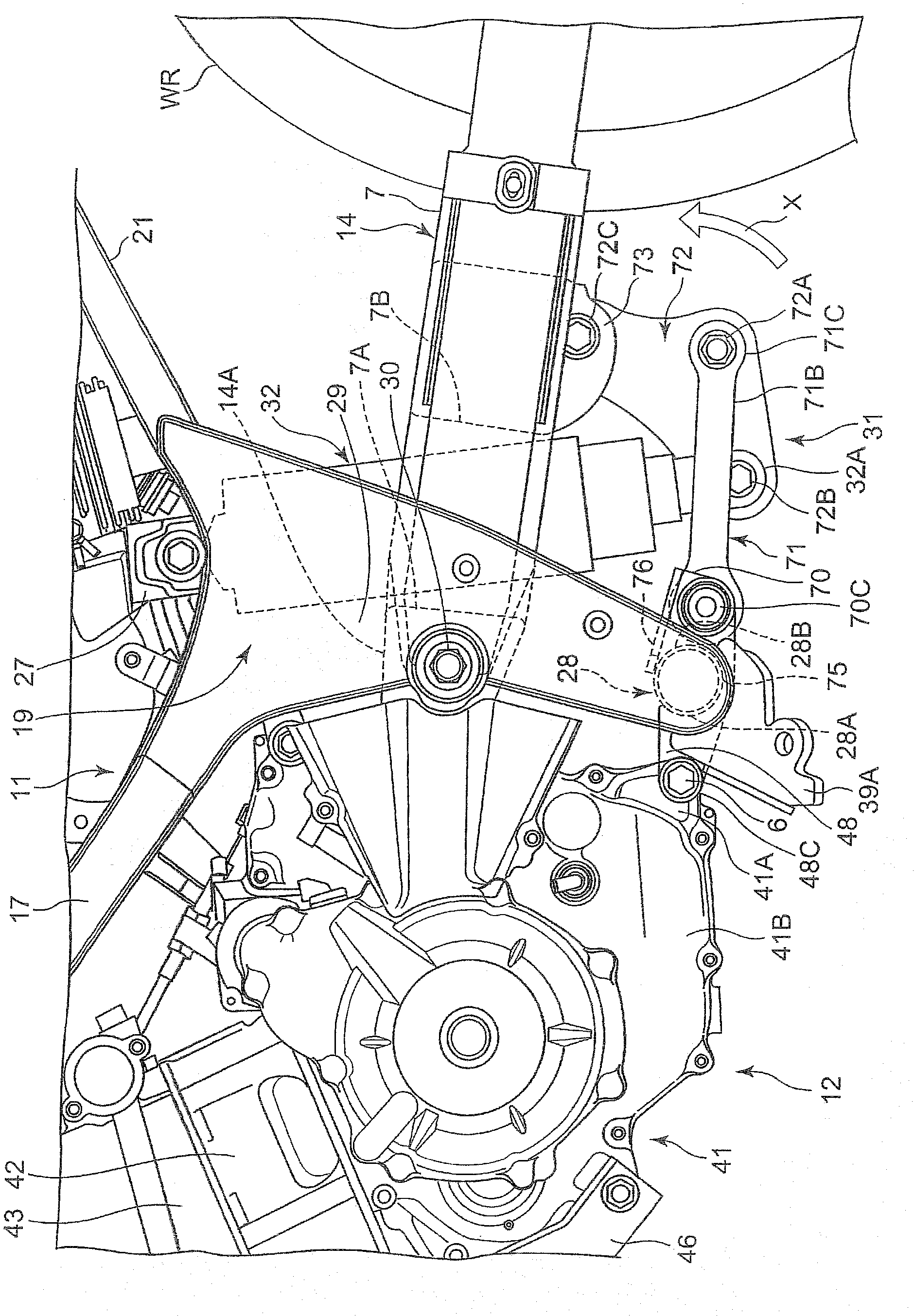

Saddled vehicle

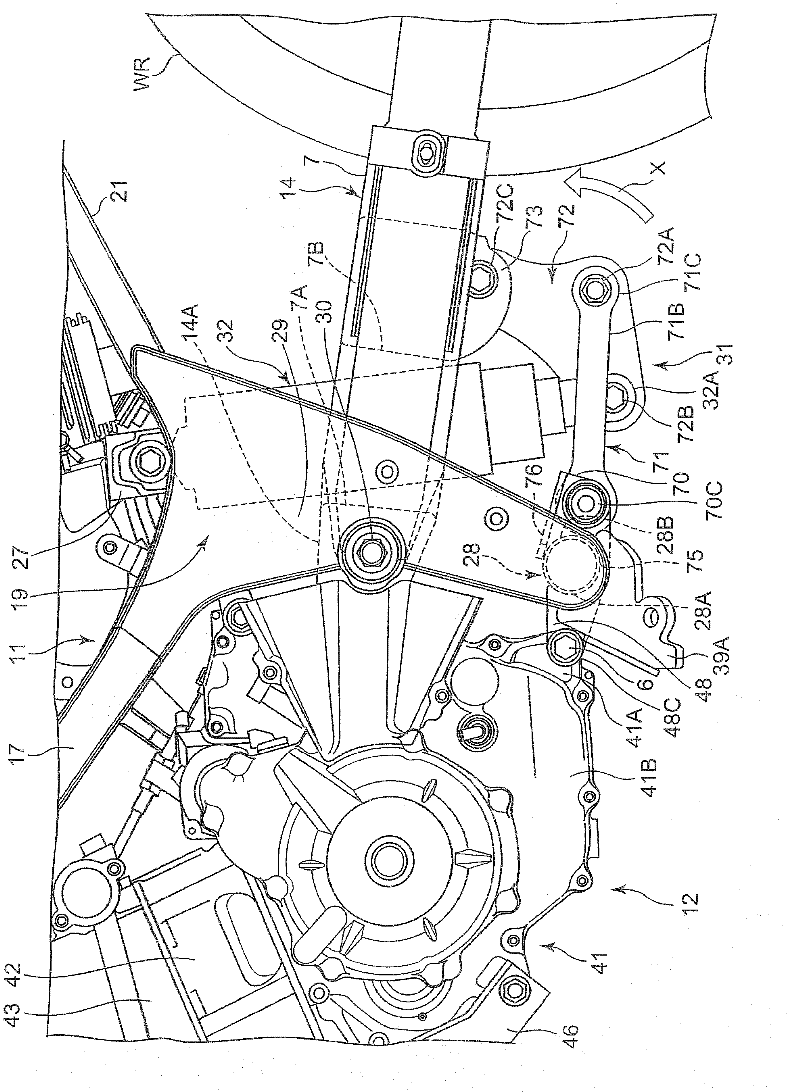

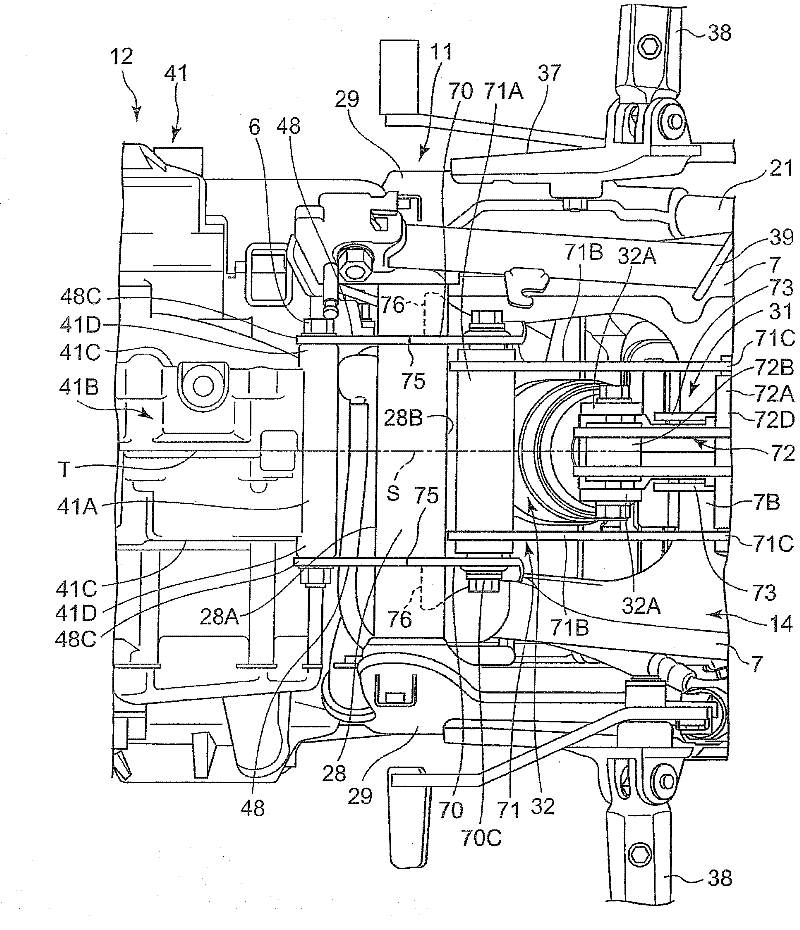

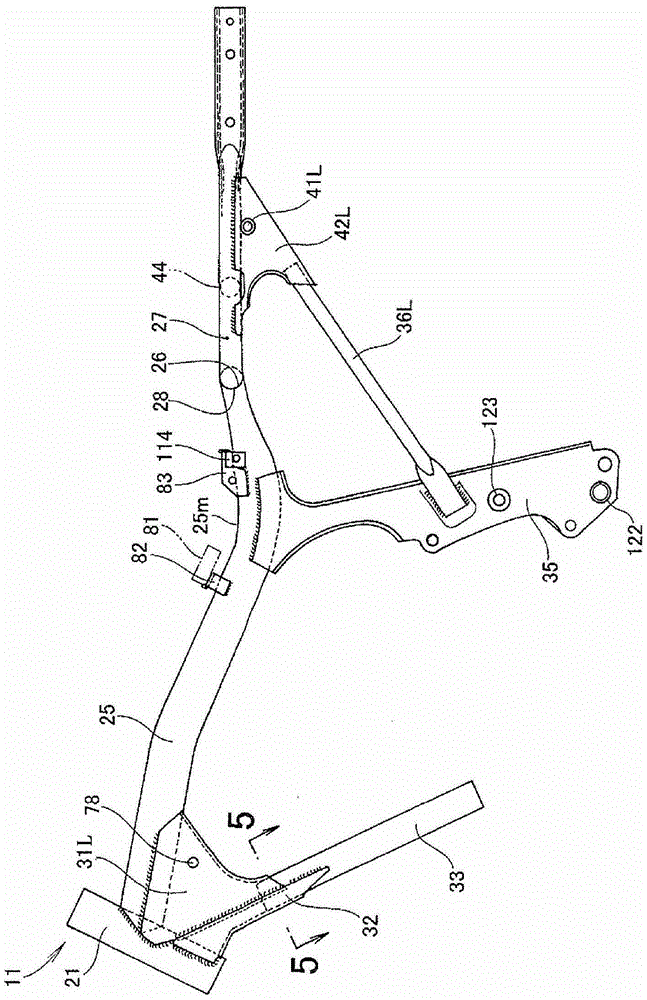

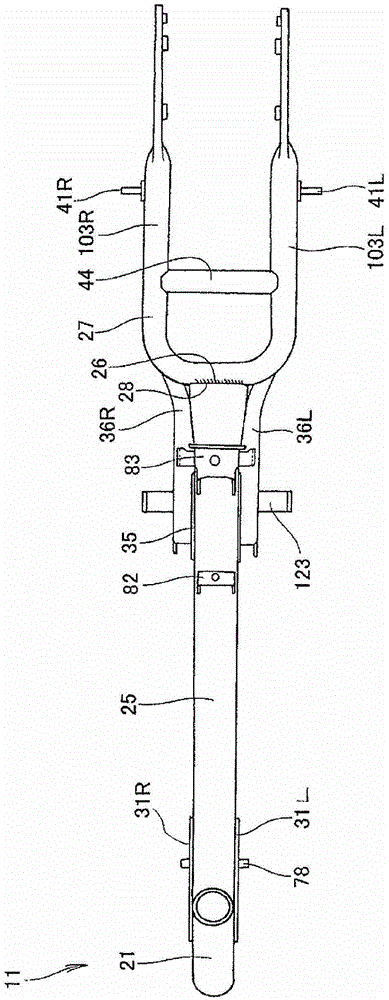

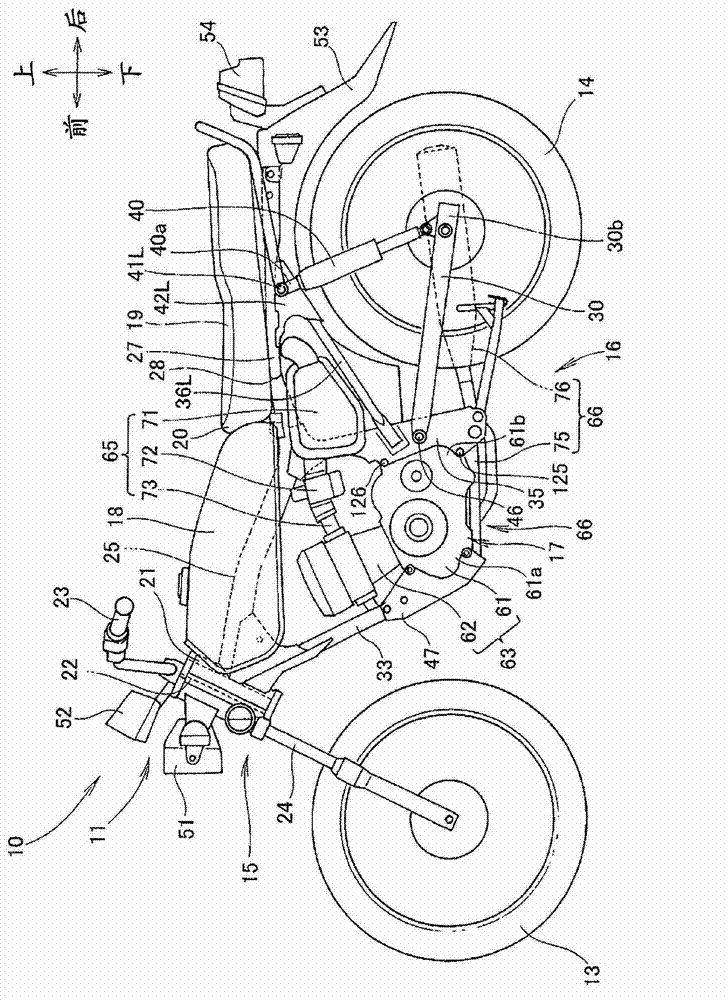

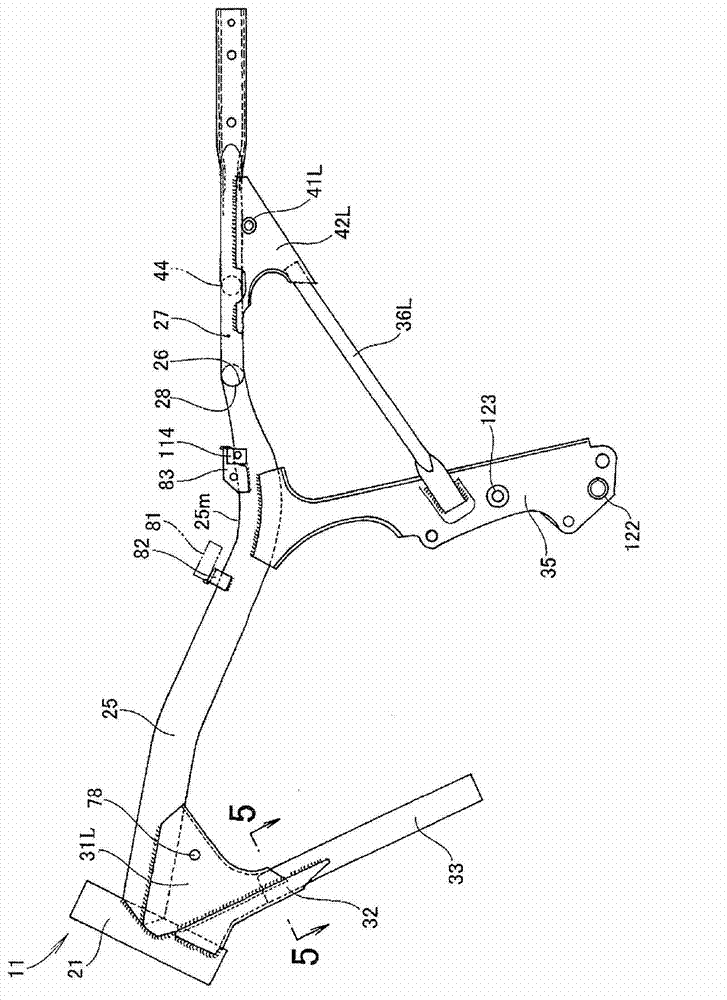

ActiveCN102481967ANo need to increase intensityThe case of loads that prevent deformationAxle suspensionsMotorcyclesVehicle frameBody frame

A saddled vehicle having a cross-member which is reduced in weight by preventing a non-uniform load from acting on the cross-member. A saddled vehicle provided with: a vehicle body frame (11) for suspending an engine (12); a swing arm (14) for pivotably suspending a rear wheel (WR); a pair of left and right pivot sections (29) for forming a part of the vehicle body frame (11) and pivotably supporting the swing arm (14); a lower cross-member (28) for connecting the pivot sections (29); a rear cushion (32) for applying an elastic force to the swing arm (14); a link mechanism (31) to which the lower end (32A) of the rear cushion (32), the swing arm (14), and the pivot sections (29) are connected; link connection stays (70) which are formed behind the lower cross-member (28) and to which the link mechanism (31) is connected; and lower hangers (48) which are formed in front of the lower cross-member (28) and to which the engine (12) is affixed. The link connection stays (70) are formed at the same position in the widthwise direction of the vehicle, and so are the lower hangers (48).

Owner:HONDA MOTOR CO LTD

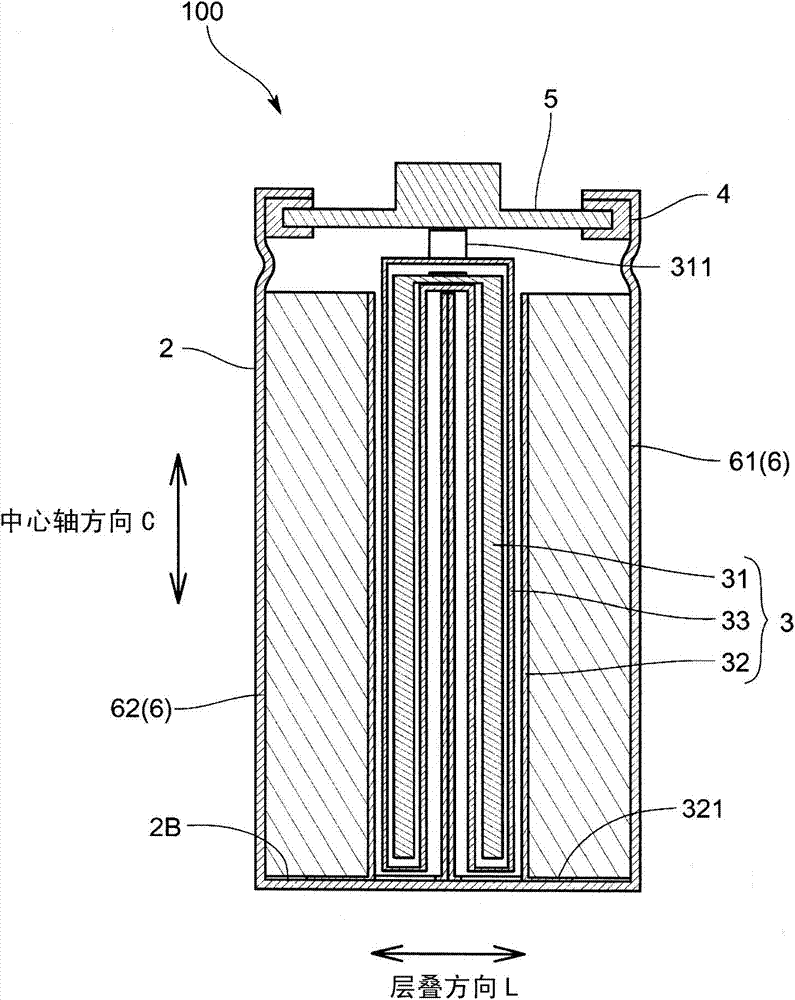

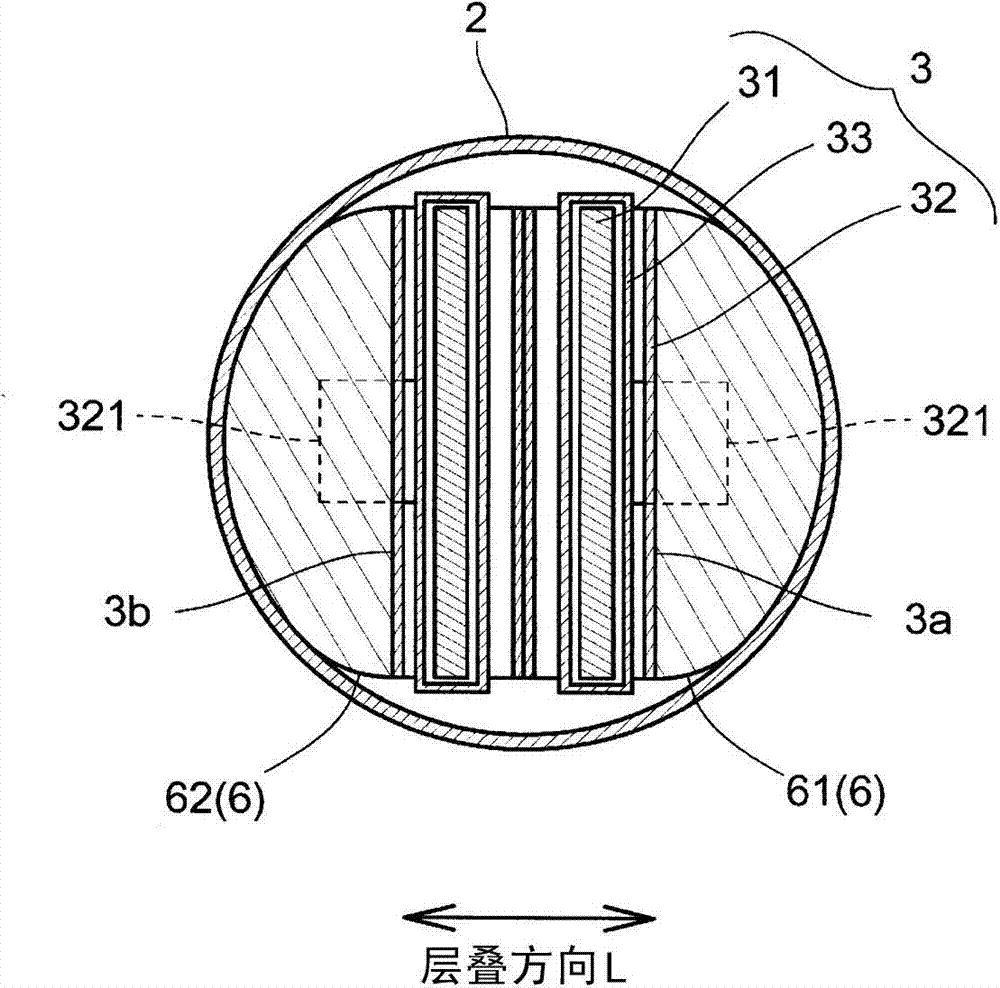

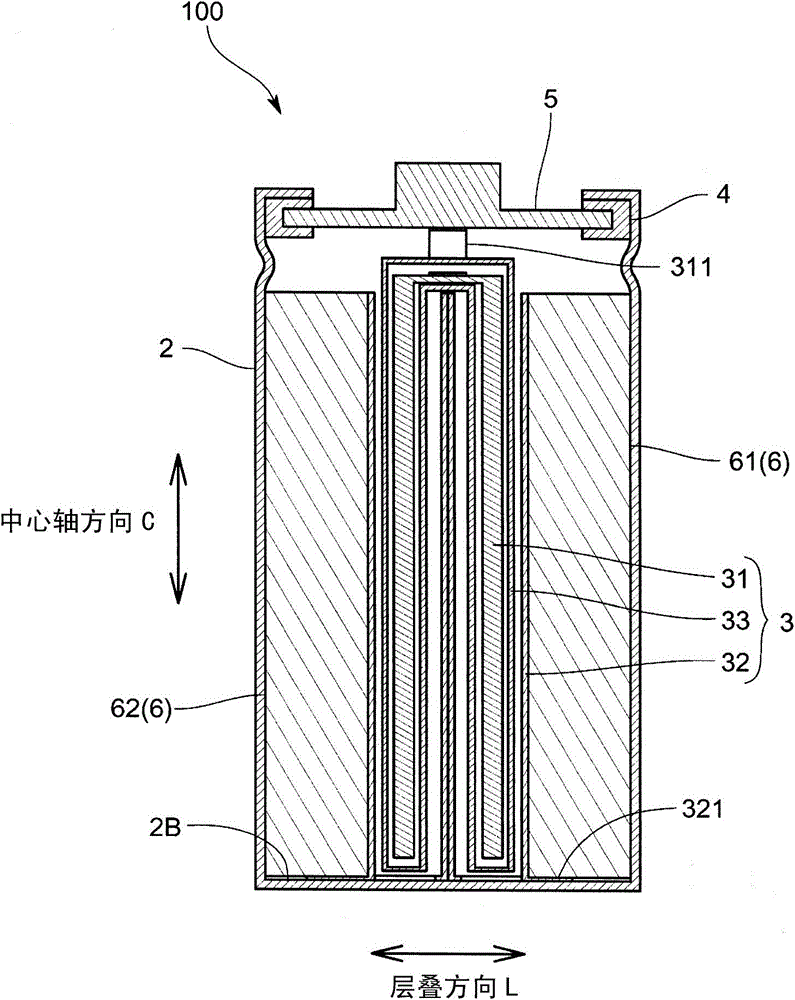

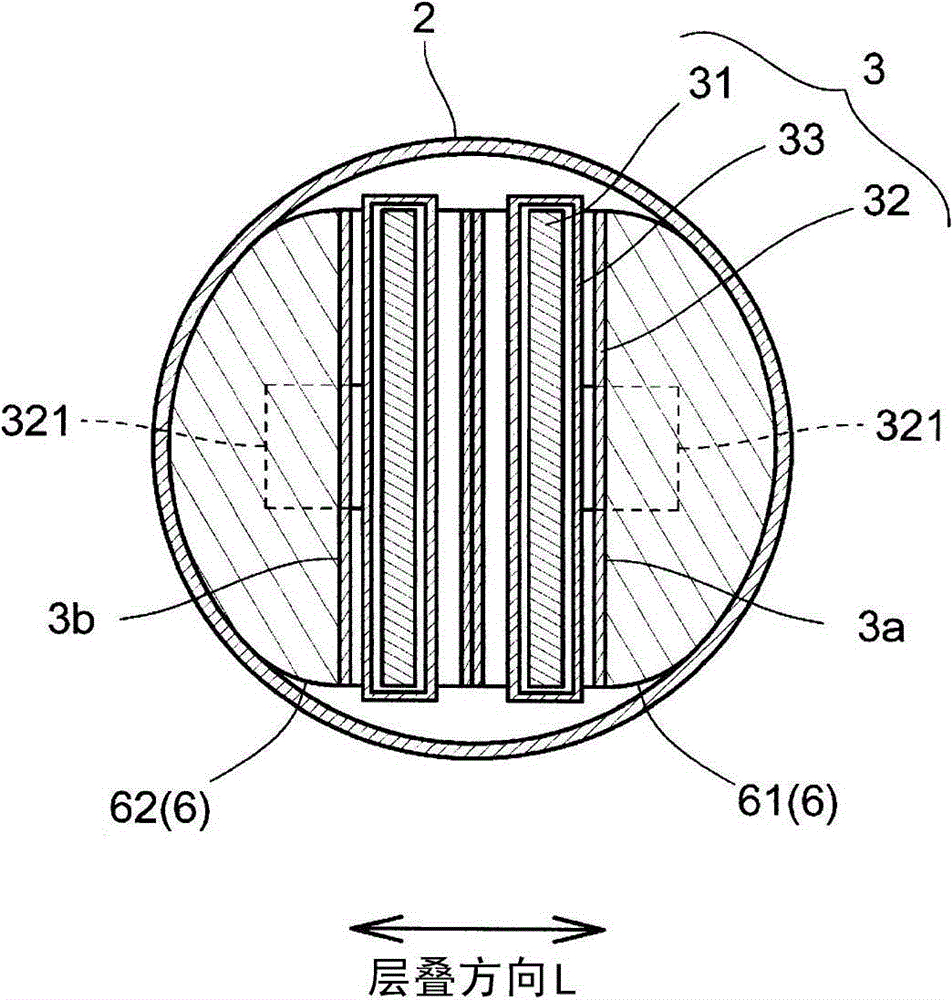

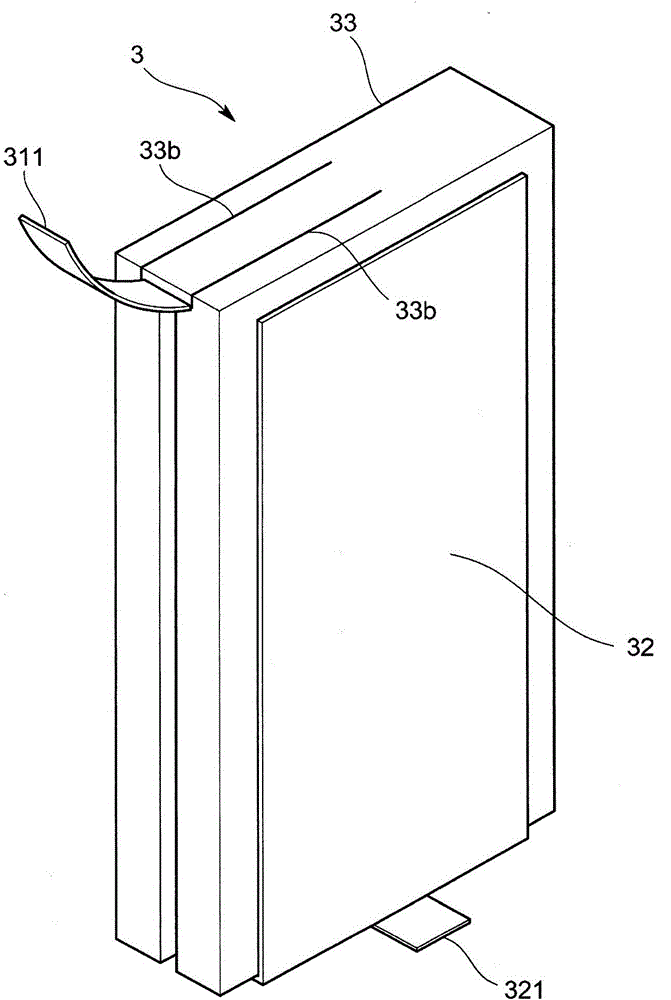

Electrode plate, stacked electrode assembly, and batteries

ActiveCN103718340AReduce in quantitySimple homeworkCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringCurrent collector

The purpose of the present invention is to prevent inconsistency in current collection efficiency by integrating current collector terminals using two active material retention sections which retain active materials, to simplify welding operations by reducing the number of current collector terminals, and to simplify the operation of stacking multiple electrode plates. Specifically, the present invention provides a stacked electrode assembly (3) including a positive plate (31), a negative plate (32) and a separator (33). The positive plate (31) is formed substantially in a U-shape such that two active material retention sections (31B) for retaining cathode active materials are arranged opposite each other, and the negative plate (32) is formed substantially in a U-shape such that two active material retention sections (32B) for retaining anode active materials are arranged opposite each other. The positive plate (31) and the negative plate (32) are stacked such that at least one active material retention section (31B) in the positive plate (31) is interposed between the two active material retention sections (32B) in the negative plate (32).

Owner:GS YUASA INT LTD

Welding device for petrochemical engineering

PendingCN110280931AEasy to weldAchieve rotationWelding/cutting auxillary devicesAuxillary welding devicesCouplingDrive shaft

The invention discloses a welding device for petrochemical engineering. The welding device for the petrochemical engineering comprises a base and a limiting device, wherein a working groove is formed in the top of the base, a fixing base and a baffle are arranged at the bottom of an inner cavity of the working groove, a left fixing ring is arranged at the top of the fixing base, a rotating motor is arranged at the top of the base, a rotating shaft is arranged on the right side of the rotating motor through a coupler, a left rotating disc is fixedly connected to the right end of the rotating shaft, a left ball is arranged between the left fixing ring and the left rotating disc, a driving shaft is arranged on the right side of the left rotating disc, an electric telescopic rod is arranged on the right side wall of the working groove, a moving trolley body is arranged on the left side of the electric telescopic rod, a right fixing ring is arranged at the top of the moving trolley body, a right rotating disc is arranged in an inner cavity of the right fixing ring, a right ball is arranged between the right fixing ring and the right rotating disc, and a driven shaft is arranged on the left side wall of the right rotating disc. According to the welding device, a pipeline can be rotated when the pipeline is welded, and the device is very suitable for welding large-diameter pipelines, and effectively reduces the operation intensity of welding personnel.

Owner:NANJING CHEM CONSTR

Engine muffler

ActiveCN104061055BImprove air tightnessEasy welding workSilencing apparatusMachines/enginesEngineeringExpansion chamber

Owner:HONDA MOTOR CO LTD

motorcycle

ActiveCN103241322BReduce in quantityIncrease the number of connecting operationsMotorcyclesEngineeringRocker arm

Owner:HONDA MOTOR CO LTD

Two-wheeled motorcycle

The invention provides a two-wheeled motorcycle which has reduced amount of parts of a motocycle frame. The two-wheeled motorcycle comprises a head pipe (21), a main frame (25), and a pivot branch frame (35); the head pipe (21) supports and rotates a steering shaft (22); the main frame (25) extends from the head pipe (21) to the back part in the front-and-back direction of the motocycle; the pivot branch frame (35) is connected with the main frame (25), supports and swings a back rocker arm (30). The main frame (25) is a single frame with a round cross section; motocycle seat guide rails (27) form a U shape or a V shape with the opening facing backwards in the front-and-back direction of the motocycle; and the motocycle seat guide rails (27) are contacted and fixedly connected with the back end of the main frame (25).

Owner:HONDA MOTOR CO LTD

motorcycle

ActiveCN103241321BGuaranteed welding lengthEasy welding workMotorcyclesEngineeringMechanical engineering

The present invention provides a two-wheel motorcycle which can disperse load bear a jointing part between a pivot frame and a main frame and maintenance appropriate deflection on each part of the motorcycle frame. The two-wheel motorcycle comprises the main frame (25) and the pivot frame (35). The main frame (25) extends from a head pipe (21) to back part in a front-and-back direction of the vehicle. The pivot frame (35) is connected with the main frame (25). Furthermore the pivot frame (35) supports a back rocker lever (30) and causes the back rocker lever to be swingable. The main frame (25) is a single frame and has a circular section. Furthermore the main frame extends to the back part of the pivot frame (35) in the front-and-back direction of the motorcycle. The pivot frame (35) is provided with a T-shaped part (90) which is approximately T-shaped when viewed from the side surface of the motorcycle. The upper part of the T-shaped part (90) contacts with the main frame (25) along a length-direction axis of the main frame (25) and is welded on the main frame (25).

Owner:HONDA MOTOR CO LTD

Roller nail recoil type nail puller for high-pressure roller mill

PendingCN112719851ASolve the problem that it is difficult to pull out and replaceImprove replacement efficiencyMetal working apparatusEngineeringStructural engineering

The invention discloses a roller nail recoil type nail puller for a high-pressure roller mill. The roller nail recoil type nail puller comprises a nail pulling assembly, a nail pulling preparation assembly and a driving assembly, wherein the nail pulling assembly comprises a nail pulling middle pipe, a sleeve arranged outside the nail pulling middle pipe in a sleeving manner, and a nail pulling shaft arranged at the end of the nail pulling middle pipe, and a stop block is arranged at the rear end of the nail pulling middle pipe; the nail pulling preparation assembly comprises a grinding head arranged at the position close to a roller nail ring, spray guns arranged at the position close to a roller nail on the roller nail ring, and gluing pieces arranged at the position close to the spray gun, and the roller nail ring is provided with a position replacement part used for driving the gluing pieces and the spray guns to select positions; and the driving assembly is arranged at the position of the nail pulling assembly.

Owner:广西钢铁集团有限公司 +1

Saddled vehicle

ActiveCN102481967BNo need to increase intensityThe case of loads that prevent deformationAxle suspensionsMotorcyclesVehicle frameEngineering

Owner:HONDA MOTOR CO LTD

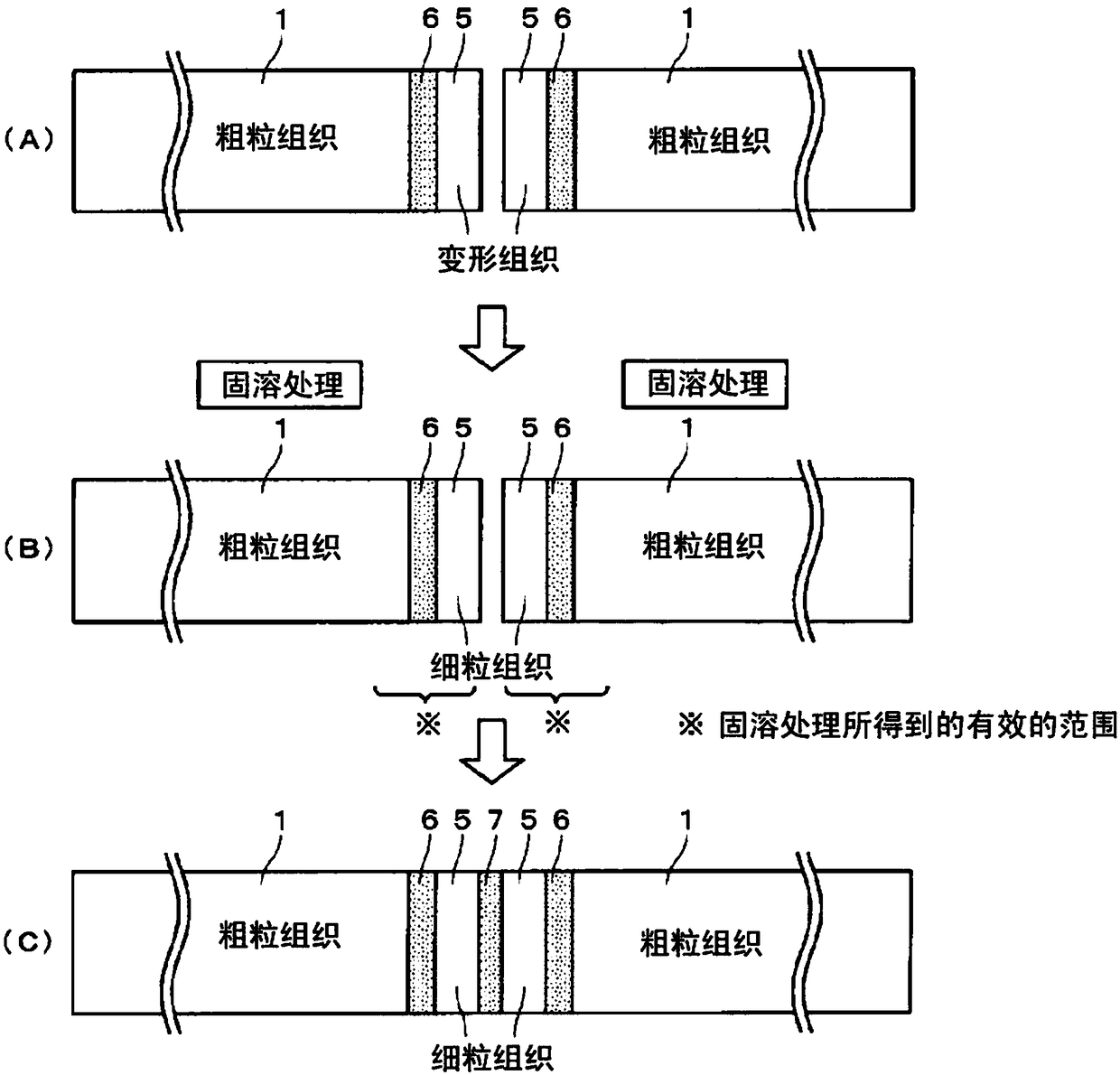

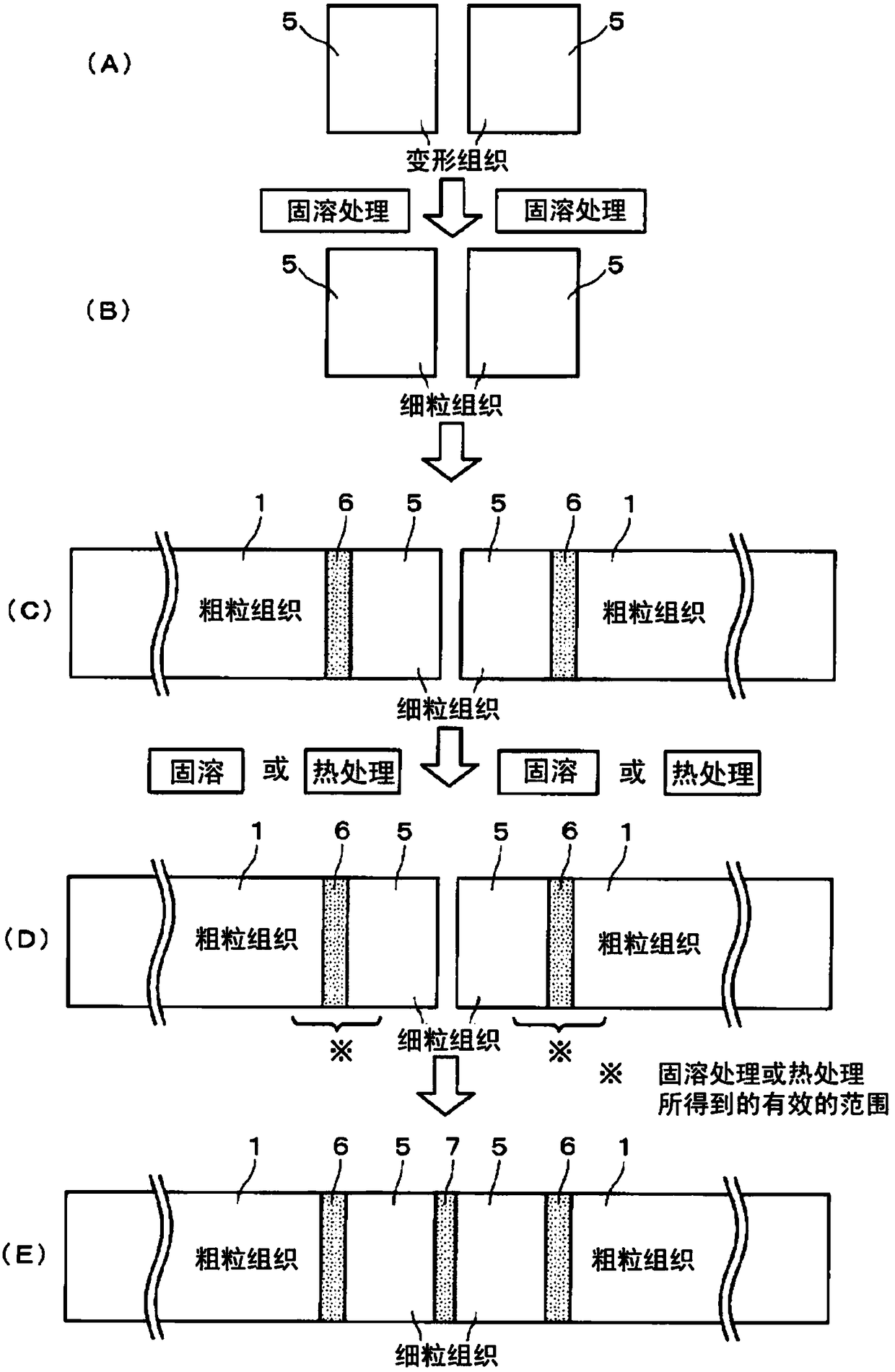

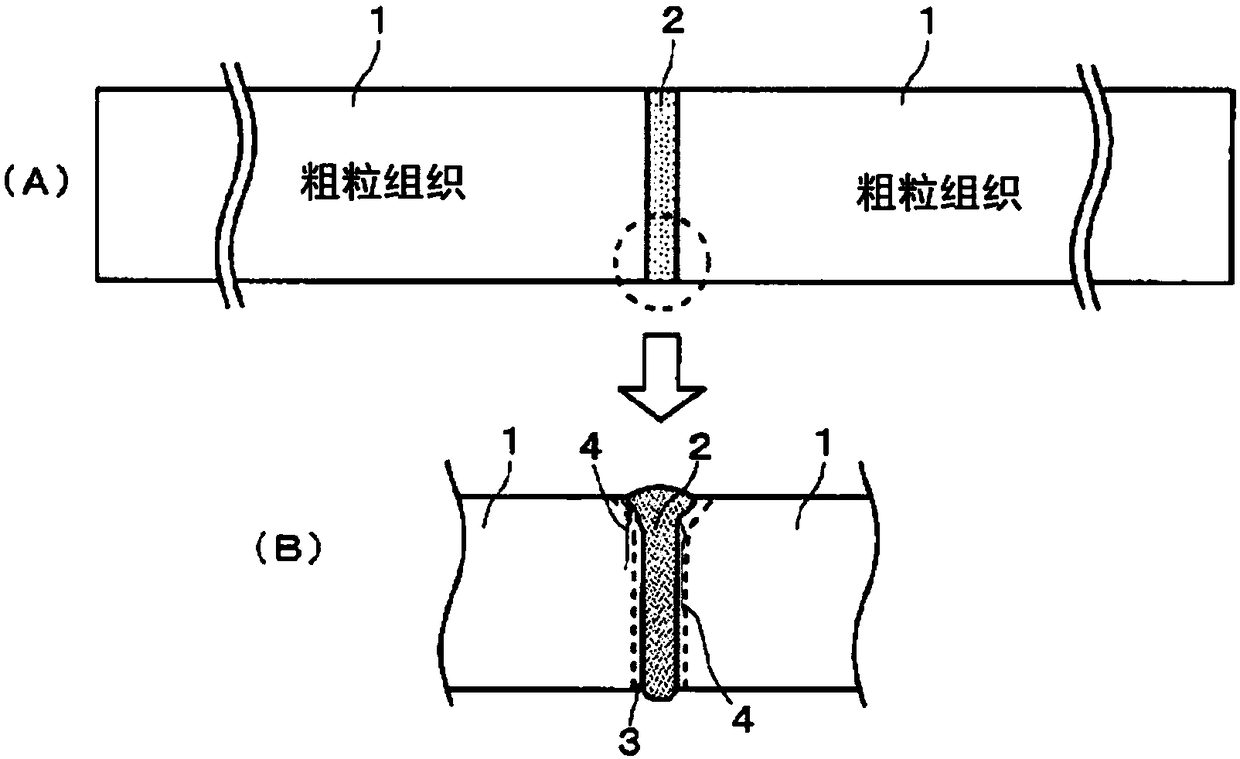

Welded joint structure of thick-walled large-diameter pipe and its welding construction method

ActiveCN105722630BPrevent reheat cracksEasy welding workArc welding apparatusPipeline systemsSolution treatmentThick wall

A pair of thick-walled large-diameter base pipes (1) constituted of an Ni-based alloy which comprises, in terms of wt%, 20-35% Cr, 0.1-10% Mo, 0.1-3% Al, 0.11-3% Ti, and Ni as the remainder and intermediate pieces constituted of the same material and having a width of about 60 mm are subjected beforehand to hot working or cold working, thereby giving a solution treatment to a range including portions to be finally welded on a site where at least a boiler has been installed. Thereafter, the intermediate pieces are finally welded to each other on the site where a boiler has been installed. With this method, it is possible to obtain a highly reliable welded-joint structure in a thick-walled large-diameter pipe.

Owner:MITSUBISHI POWER LTD

Cylindrical battery and manufacturing method thereof

ActiveCN103718340BReduce in quantitySimple homeworkFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryEngineering

Owner:GS YUASA INT LTD

Welding method of the four-way switching valve and the fixing screw of the four-way switching valve

InactiveCN104344013BPrevent looseningEasy to assembleMultiple way valvesResistance welding apparatusCouplingPiston

PROBLEM TO BE SOLVED: To provide a four-way selector valve such that a lockscrew for fixing a piston to coupling metal fittings is securely prevented from being loosened, the number of components is decreased, and trouble in manufacture is saved.SOLUTION: A piston valve is accommodated in a valve housing. The piston valve comprises first and second pistons 1 and 2, coupling metal fittings 3, and a valve body. The piston 1 comprises a packing 11, a guide plate 12, a toothed lock spring 13, and a reinforcing plate 14. The piston 2 comprises a packing 21, a guide plate 22, a toothed lock spring 23, and a reinforcing plate 24. The piston 1 is fixed to a vertical plate 31 of the coupling metal fittings 3 with lockscrews N1, N2. The piston 2 is fixed to a vertical plate 32 of the coupling metal fittings 3 with lockscrews N3, N4. Molten layers P1, P2 are formed by resistance welding at a contact place between the lockscrew N1 and the guide plate 12 and at a contact place between the lockscrew N2 and the guide plate 12. Molten layers P3, P4 are formed by resistance welding at a contact place between the lockscrew N3 and the guide plate 22 and at a contact place between the lockscrew N4 and the guide plate 22.

Owner:SAGINOMIYA SEISAKUSHO INC

Micro sensor

InactiveCN107727713AImprove measurement accuracyEasy welding workMaterial heat developmentMaterial resistanceMoisturePhysics

Disclosed is a micro sensor. Particularly, a first sensor electrode is provided on a first side of a substrate, a second sensor electrode is provided on a second side of the substrate, and the substrate is provided with an etching hole penetrating from the first side to the second side of the substrate. A sensing material provided between the first sensor electrode and the second sensor electrodeis inserted in the etching hole. When detecting gas, the micro sensor can minimize influence of moisture in air.

Owner:POINT ENG

refrigerator

ActiveCN108571852BIncreased internal storage spaceIncrease pull distanceDomestic refrigeratorsEvaporators/condensersIceboxEngineering

The invention relates to a refrigerator, comprising: an evaporator disposed inside the shell of the evaporator; a defrosting water tray disposed on the lower side of the evaporator, the defrosting water tray collects the defrosting water; a grill cover, It is arranged on the rear side of the evaporator shell, and the grill cover accommodates the blower fan; and, the tray supporting device is arranged on the grill cover, and the tray supporting device supports the defrosting water tray; so that the refrigerator The internal storage space of the refrigerator is increased, and the pull-out distance of the drawer provided in the refrigerator is increased. Therefore, the accommodating property of food can be improved.

Owner:LG ELECTRONICS INC

Rotor core and method of fastening rotor core and rotary shaft

ActiveCN102244429BAvoid deformationEasy welding workMagnetic circuit rotating partsElectric machinesEngineeringMechanical engineering

The invention provides a rotor core and a method of fastening the rotor core and a rotary shaft. The method of fastening the rotor core having no end plate and composed of laminated steel plates, and the rotary shaft by means of thermal insert can prevent the rotor core from being axially deformed due to the thermal insert load. The rotor core (12) is formed by axially laminating a plurality of circular-ring-shaped steel plates having through holes embedded in the shaft (11). A first groove (12a) and a first projecting bar (12b) are alternately formed on circumferential direction of the rotor core (12) inner peripheral surface where the through holes are formed. The first groove (12a) is recessed towards the outer radial direction and axially extends. The first projecting bar (12b) projects towards the inner radial direction and axially extends. A welding part (12b-1) for combining axially adjacent steel plates together is equipped on the projecting end face of the first projecting bar (12b). The welding part (12b-1) is continuously equipped from one axial end to the other axial end.

Owner:DENSO CORP

An automated production and assembly system based on intelligent industrial robots

ActiveCN109014667BGuaranteed reliabilityGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesInterference fitRobot hand

The invention relates to the field of robot equipment, and discloses an automatic production and assembly system based on an intelligent industrial robot, which includes a base plate, a welding manipulator is fixed on the base plate, and a small wheel set is arranged below the base plate; a first rack and a first guide rail set The welding manipulator is provided with a welding manipulator that moves linearly along the first guide rail group. The welding manipulator includes a welding platform, and a supporting leg is provided under the welding platform. The supporting leg is slidably arranged on the first guide rail group. The first gear, the first gear and the first rack are meshed with each other, one side of the first motor is provided with a mounting rod, the bottom of the mounting rod is provided with a supporting wheel, and the supporting wheel is in rolling contact with the bottom plate; a turntable is installed on the welding platform, and the turntable A gear ring is sheathed on the outside of the rotary table, the inner surface of the gear ring is in interference fit with the outer surface of the turntable, and the second gear meshes with the gear ring. The device has the advantages of wide application range, low cost, precise transmission control and the like.

Owner:河南省乾憬光电科技有限公司

High-strength automatic casting equipment for rear axle head

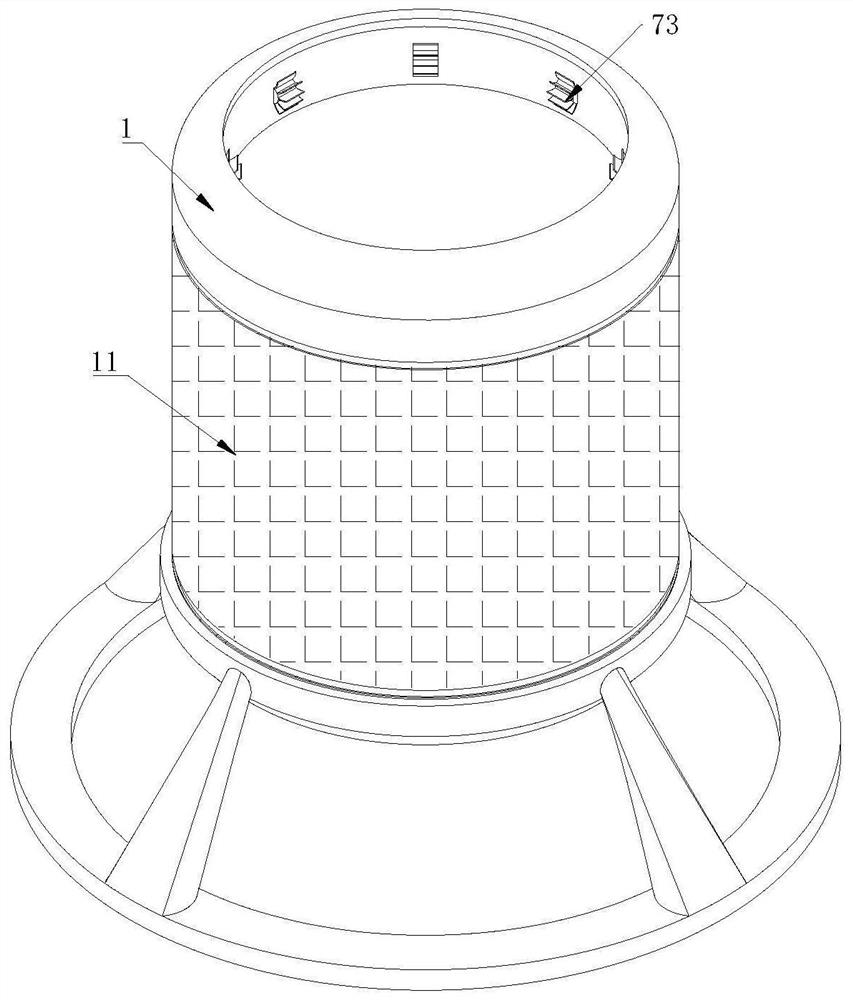

InactiveCN113351857ASpeed up the flowReduce the temperatureCasting apparatusFurnace typesElectric machineryTurbofan

The invention belongs to the technical field of axle casting, and particularly relates to high-strength automatic casting equipment for a rear axle head. The high-strength automatic casting equipment comprises a cooling bin, wherein a ventilation net is fixedly connected to the side wall of the cooling bin; a speed reduction motor is installed at the bottom of the cooling bin; the output end of the speed reduction motor penetrates through the bottom of the cooling bin and is fixedly connected with a turbofan blade; and the turbofan blade is arranged inside the cooling bin in an inverted U shape. According to the high-strength automatic casting equipment, the rear axle head is placed inside the cooling bin, then airflow inside the cooling bin is guided through the U-shaped turbofan blade, so that the airflow can uniformly flow near the rear axle head, and then all portions of the side wall of the rear axle head can be cooled at a relatively uniform speed.

Owner:徐州大泰机电科技有限公司

A multifunctional industrial robot for intelligent manufacturing automation production line

ActiveCN108436343BGuaranteed rotational freedomIncrease freedomProgramme-controlled manipulatorWelding/cutting auxillary devicesInterference fitProduction line

The invention relates to the field of robot equipment, and discloses a multifunctional industrial robot for an intelligent manufacturing automatic production line. The multifunctional industrial robotcomprises a bottom plate, wherein a welding manipulator is fixed to the bottom plate, and a small wheel unit is arranged on the lower portion of the bottom plate; the welding manipulator which linearly moves along a first guide rail group is arranged on a first rack and the first guide rail group, the welding manipulator comprises a welding platform, supporting legs are arranged under the weldingplatform, and the supporting legs are slidably arranged on the first guide rail group; a first gear is coaxially connected to an output shaft of a first motor, the first gear is meshed with the firstrack, an installing rod is arranged on one side of the first motor, a supporting wheel is arranged at the bottom of the installing rod, and the supporting wheel makes rolling contact with the bottomplate; and a rotating disc is installed on a welding platform, the rotating disc is sleeved with a gear ring, the inner side of the gear ring is in interference fit with the outer side face of the rotating disc, and a second gear is meshed with the gear ring. The multifunctional industrial robot for the intelligent manufacturing automatic production line has the advantages of being wide in application range, low in cost, accurate in transmission control and the like.

Owner:聊城锐利机械设备有限公司

turbo fan

ActiveCN106949076BStable supportEasy welding workPump componentsPump installationsEngineeringTurbofan

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

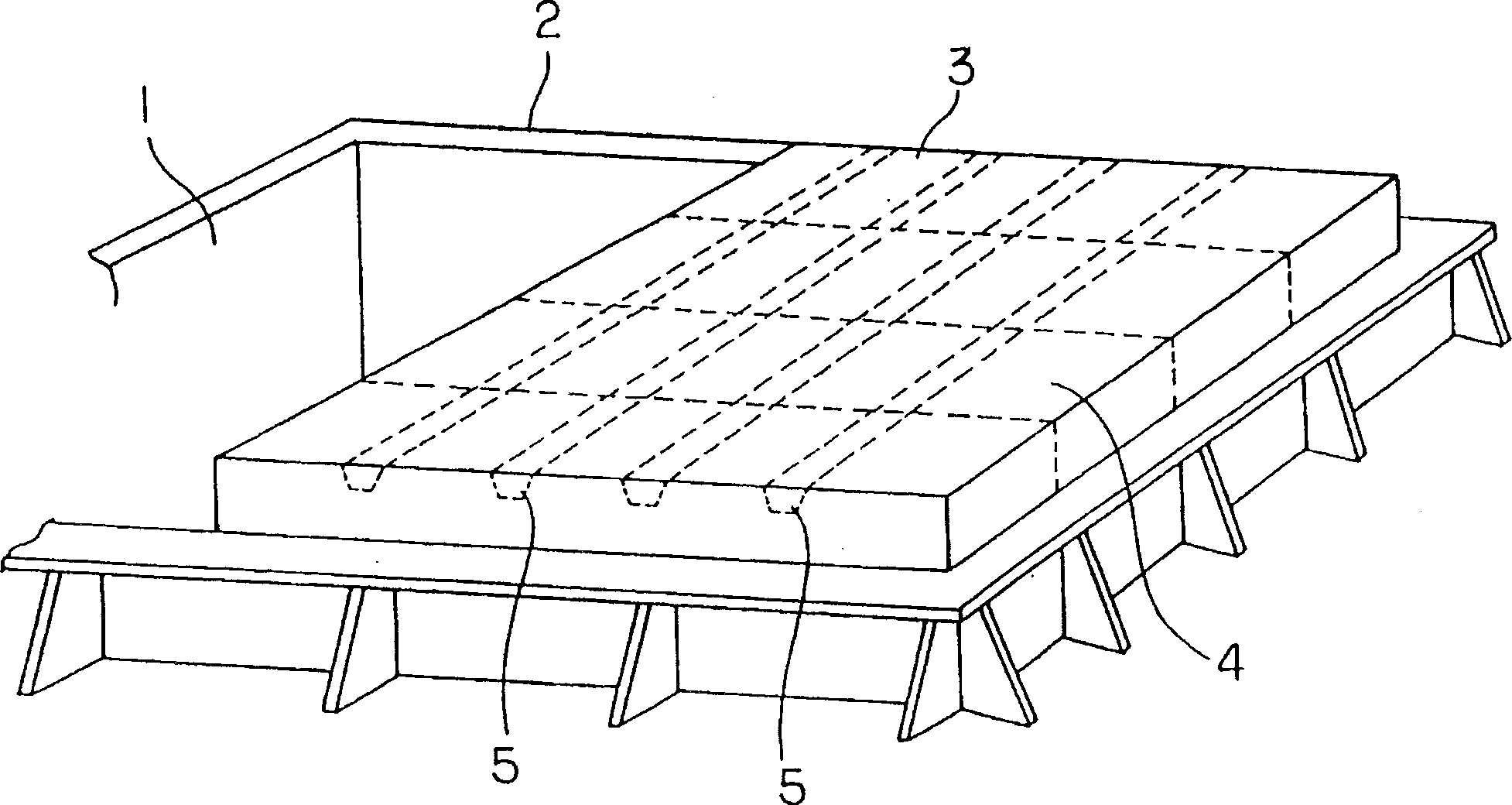

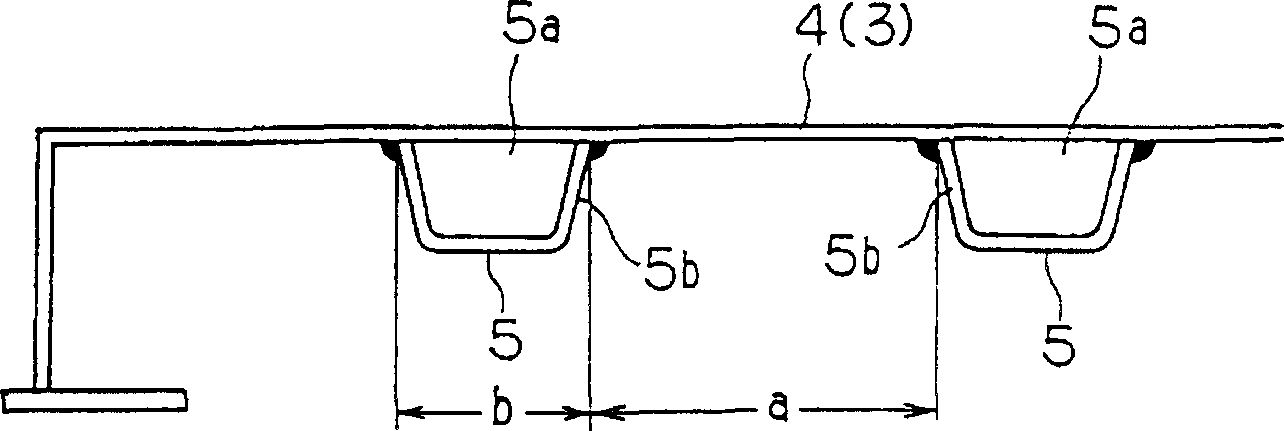

Cover or deck structure for marine vessel

InactiveCN1113773CIncreased stiffness and buckling strengthIncrease configuration spacingHull decksHull framesDistortionMarine engineering

A cover or deck structure for marine vessels. Beams (5) having a U-shaped or V-shaped cross section are welded and fixed to a back surface of a top plate (4) at predetermined intervals with opened surfaces thereof in close contact with the top plate (4). The cover or deck is enhanced in rigidity, reduced in welding distortion and improved in its workability.

Owner:萱场·马库故莱高株式会社

An automated factory that can be monitored remotely

InactiveCN108747107BMeet needsGuaranteed rotational freedomWelding/cutting auxillary devicesAuxillary welding devicesGear wheelTico Robot

Owner:安徽喜尔奇日用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com