Cover or deck structure for marine vessel

A technology for covers and ships, applied in the direction of hull deck, ship construction, ship hatches/hatches, etc., can solve the problems of increased buckling strength improvement, increased manufacturing costs, increased welding hours, etc., to achieve buckling strength Improvement, simplification of welding work, and the effect of increasing the arrangement pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

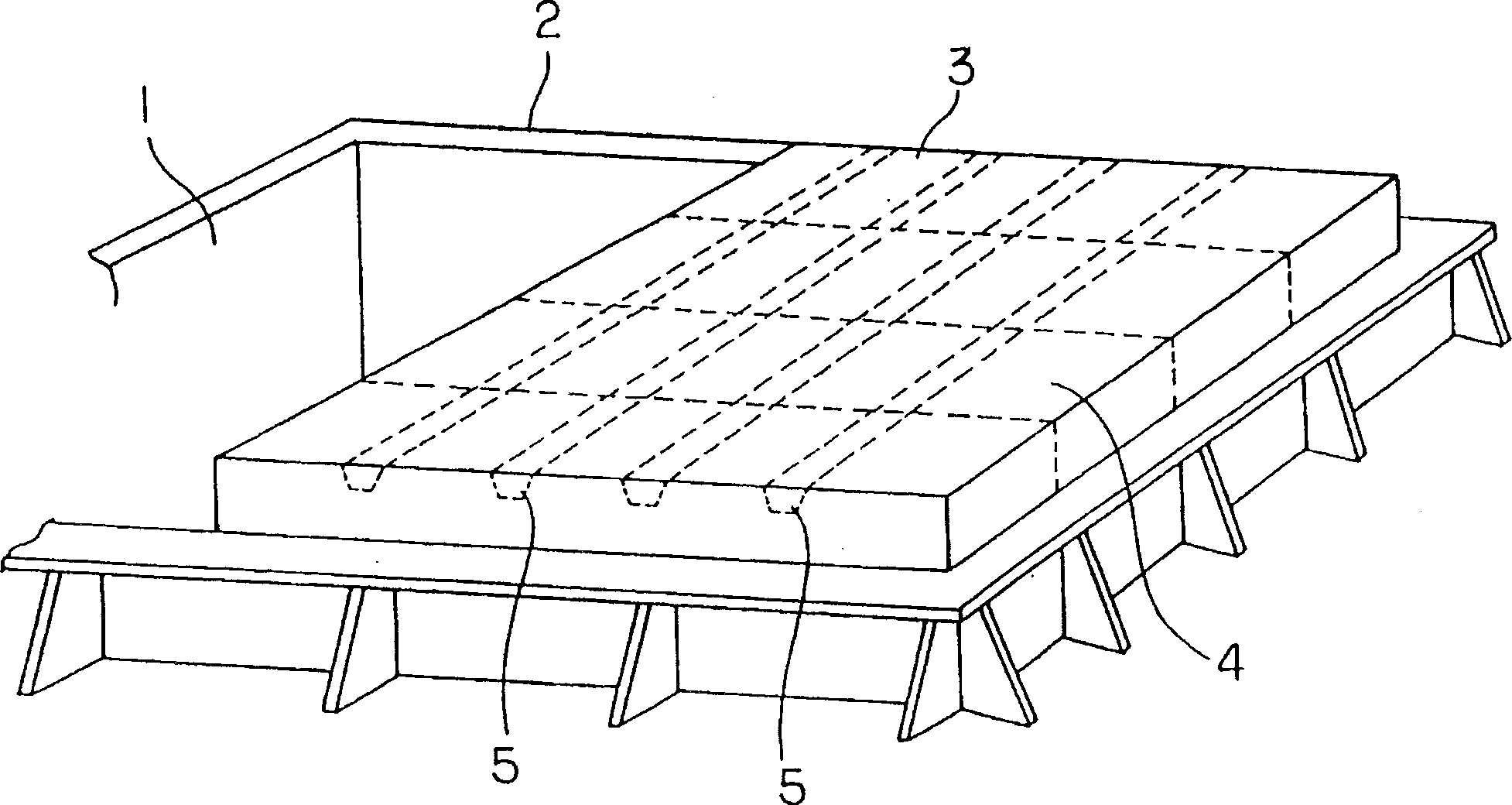

[0016] Hereinafter, an embodiment in which the present invention is applied to a hatch cover will be described with reference to the drawings.

[0017] In Fig. 1, 1 is a hatch opening, and a hatch cover 3 for opening and closing the opening 1 is provided on the peripheral edge 2 thereof. The hatch cover 3 is composed of, for example, a pair of covers, and side rolling types and pontoon types are known.

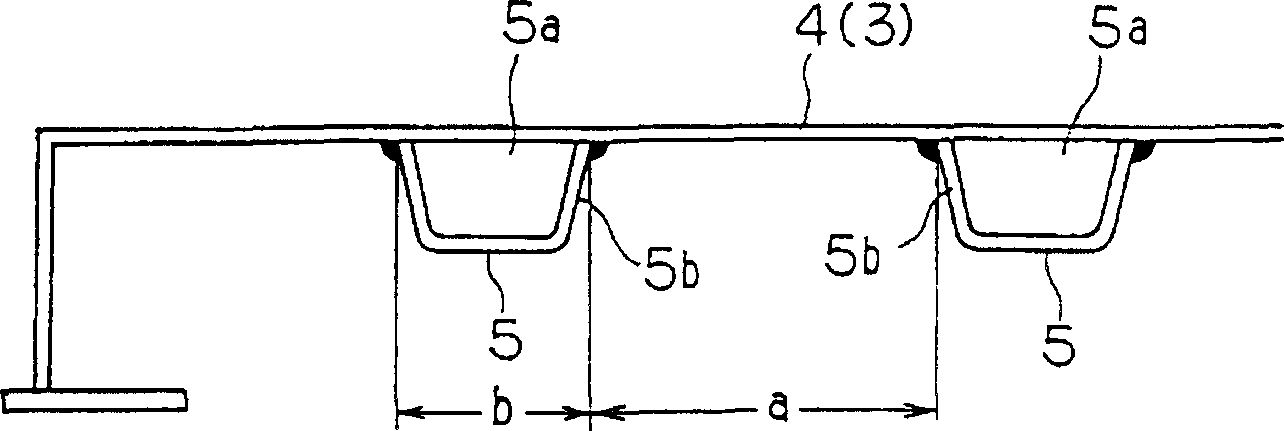

[0018] On the top plate 4 of the hatch cover 3, beams 5 having a U-shaped or V-shaped cross section are fastened parallel to each other at predetermined intervals by welding on the inner side thereof.

[0019] The U-shaped or V-shaped beam 5 is in a state where the opening surface 5a is in close contact with the top plate 4, and both legs 5b are respectively fixed by corner welding from the outside.

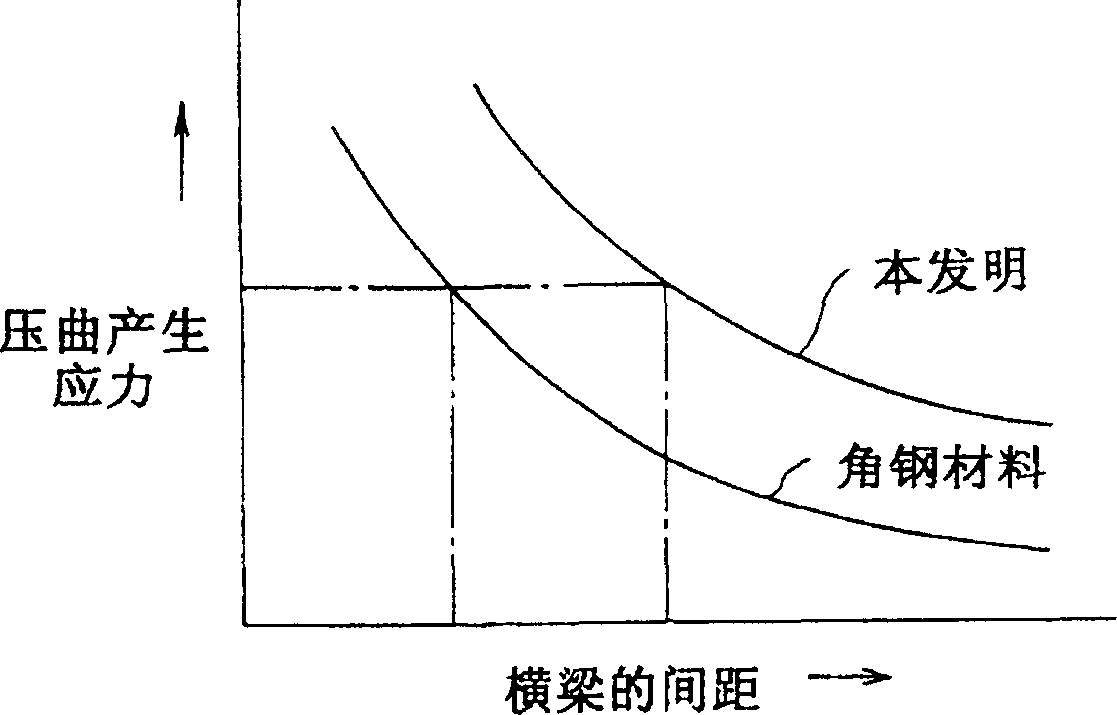

[0020] U-shaped or V-shaped beams 5, when welded on the inside of the top plate 4, form a box-shaped structure with the top plate 4, these are in order to improve the buckling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com