Cylindrical battery and manufacturing method thereof

A cylindrical battery, cylindrical technology, applied in secondary battery manufacturing, cylindrical shell battery/battery, secondary battery, etc., can solve the problems of current collection efficiency deviation, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] One embodiment of the cylindrical battery of the present invention will be described below with reference to the drawings.

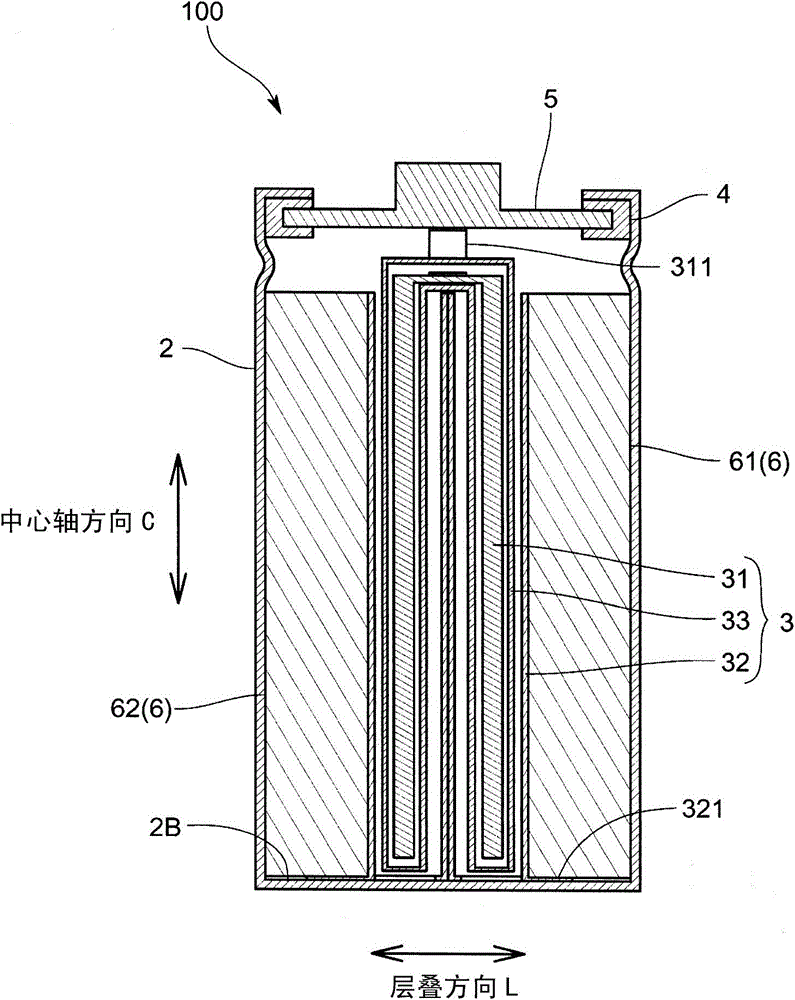

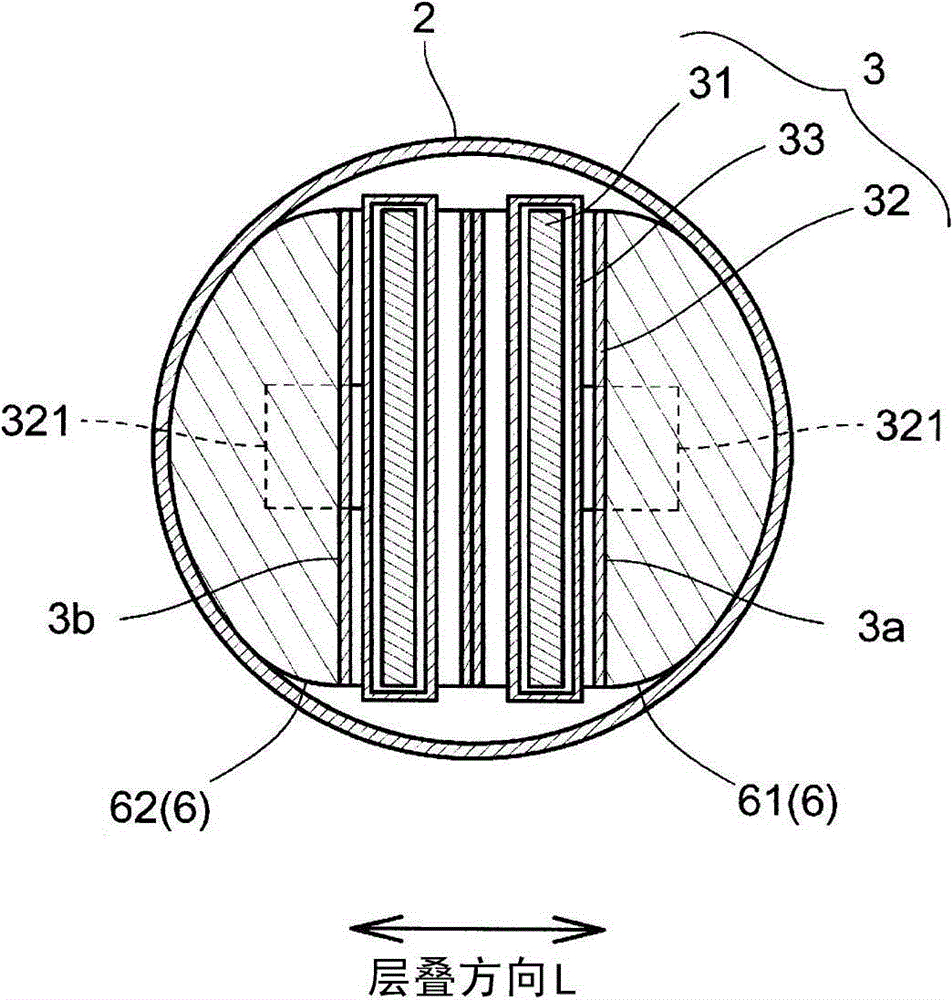

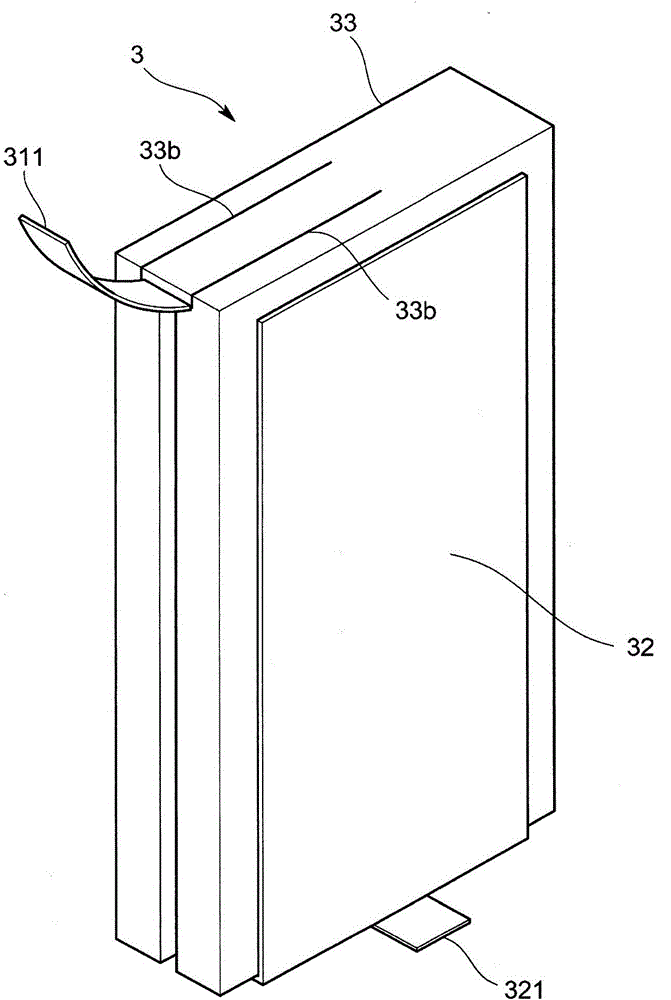

[0069] The cylindrical battery 100 of the present embodiment is, for example, an alkaline storage battery such as a nickel-cadmium storage battery or a nickel-hydrogen storage battery. Specifically, it can be, for example, a low-capacity type with a capacity of 1800mAh or less for a single 3 or 650mAh or less for a single 4, such as figure 1 as well as figure 2 As shown, it has: a bottomed cylindrical metal battery case 2; disposed in the battery case 2, a substantially rectangular parallelepiped electrode group composed of a positive electrode plate 31, a negative electrode plate 32, and a separator 33 3.

[0070] The battery case 2 is a bottomed cylinder that has been nickel-plated, such as figure 1 As shown, the upper opening is sealed by the sealing body 5 through the insulator 4 . In addition, the current collector terminal 311 protrudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com