Diaphragm Damper Device, Holding Member Therefor, And Production Method For Diaphragm Damper Device

一种保持部件、阻尼器的技术,应用在弹簧/减振器制造、燃料喷射装置、减振器等方向,能够解决制造装置复杂大型化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

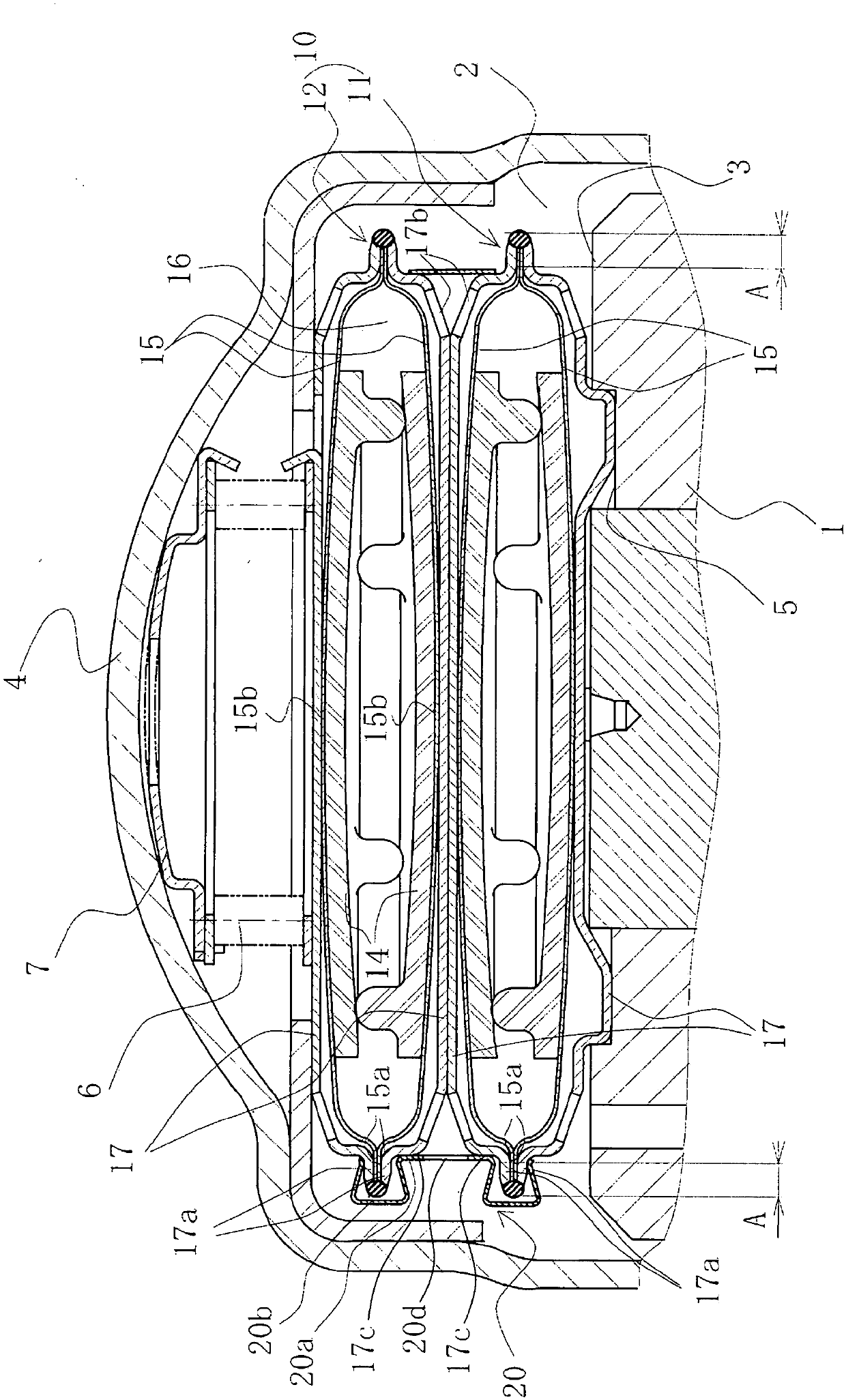

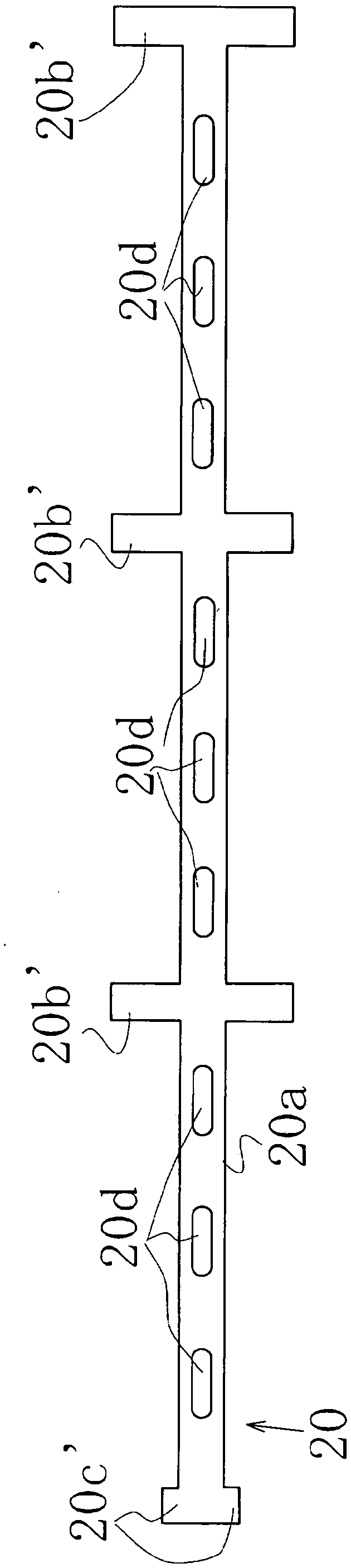

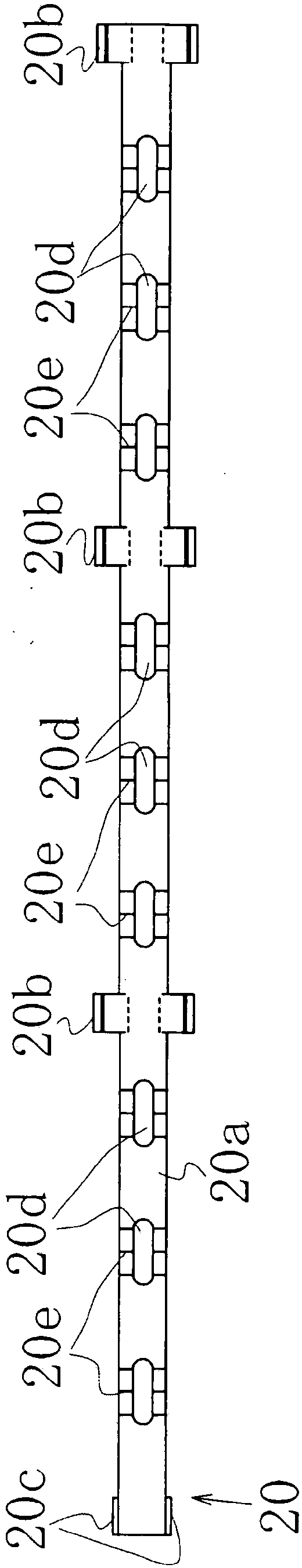

[0037] refer to Figure 1 to Figure 5 , the diaphragm damper device 10 and the holding member 20 provided in the diaphragm damper device 10 according to Embodiment 1 of the present invention will be described.

[0038] figure 1 The illustrated diaphragm damper device 10 is used in a high-pressure pump that pressurizes fuel supplied from a fuel tank and pressurizes it toward an injector by reciprocating a plunger.

[0039]The high-pressure pump has a fuel chamber 2 that can accommodate fuel supplied from the outside, and pressurizes and discharges the fuel by repeating the "suction process", "quantity adjustment process" and "pressurization process". When the plunger descends, it sucks fuel from the fuel chamber 2 to the pressurized chamber. When the plunger rises, part of the fuel in the pressurized chamber returns to the fuel chamber 2 in the "adjustment process". After the suction valve is closed, the "pressurization process" Fuel is pressurized as the plug rises further....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com