Welding method of the four-way switching valve and the fixing screw of the four-way switching valve

A four-way switching valve and welding method technology, which is applied to multi-way valves, welding equipment, valve devices, etc., can solve the problems of increasing the number of parts, troublesome assembly operations, and increasing costs, and achieves easy assembly operations, easy welding operations, and easy welding. The effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

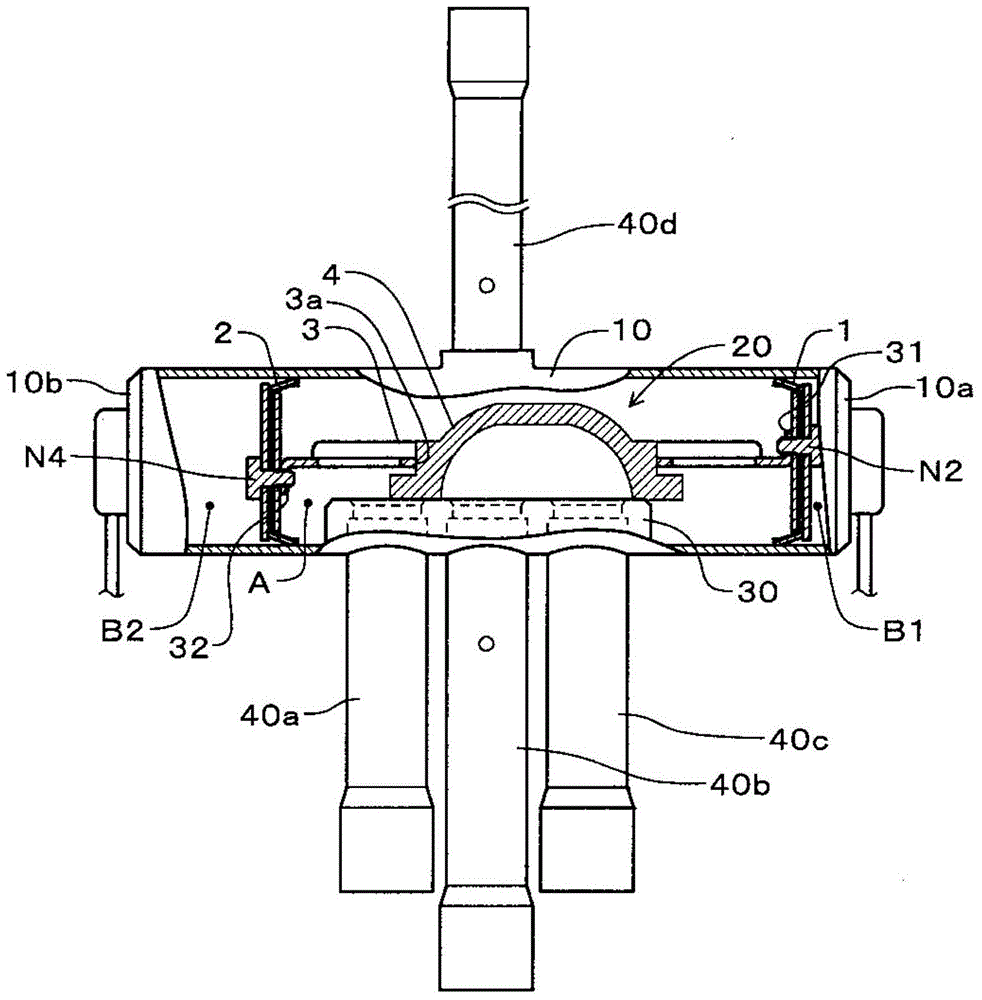

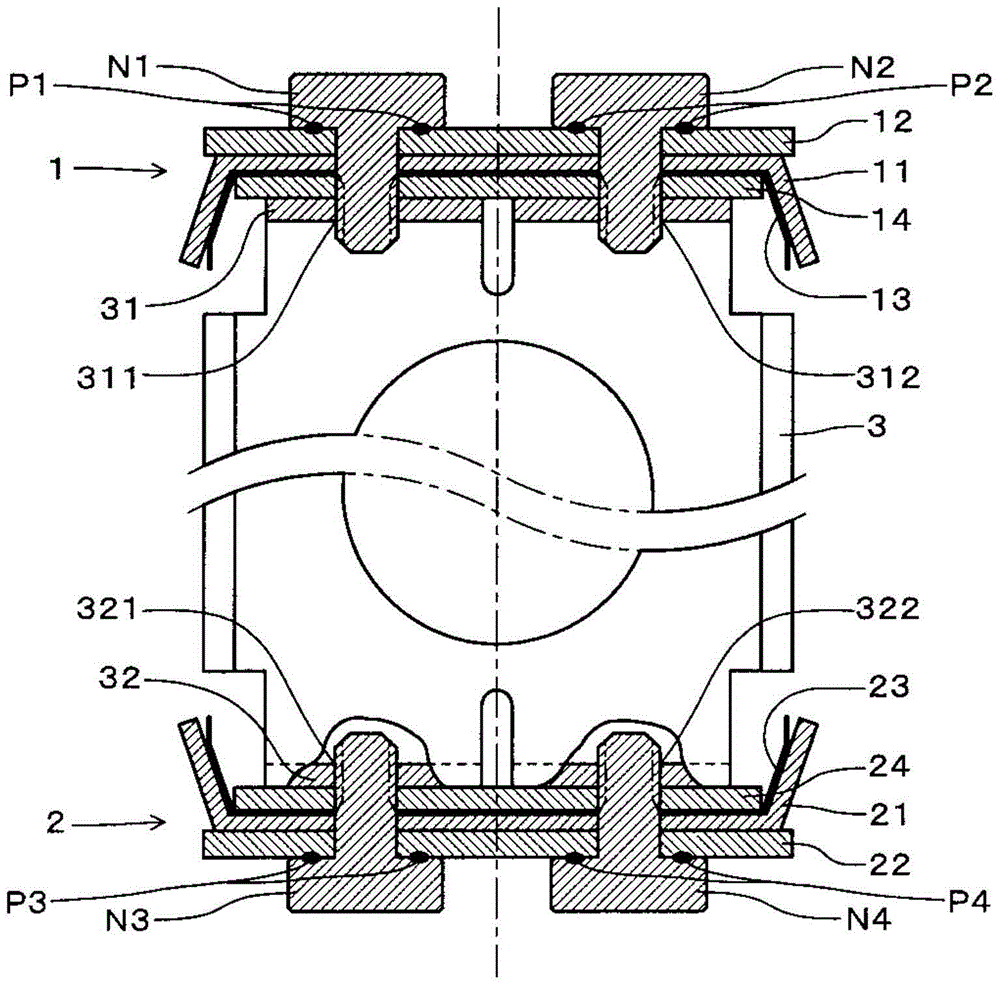

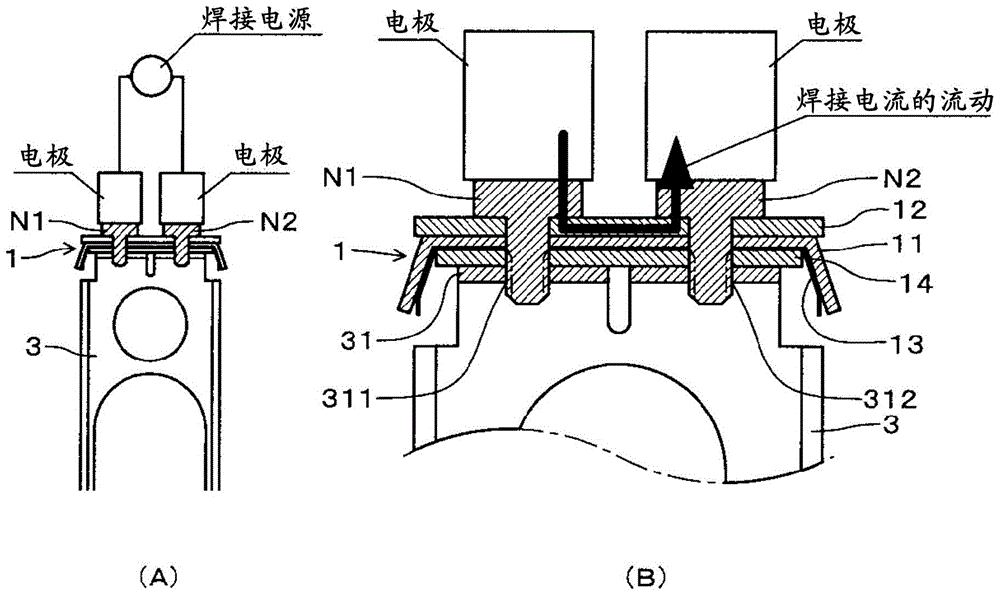

[0024] Next, embodiments of the present invention will be described. figure 1 It is a partially cutaway side view of the four-way switching valve of the embodiment. The four-way switching valve of this embodiment includes: a valve case 10 constituting a cylindrical main valve chamber A, first and second sub-valve chambers B1, B2; a piston valve 20 accommodated in the valve case 10; Valve seat 30 in valve housing 10 . The piston valve 20 is composed of a first piston 1 , a second piston 2 , a stainless steel connection fitting 3 , and a bowl-shaped valve body 4 . The first and second pistons 1 and 2 are respectively attached to both ends of the joint fitting 3 , and the valve body 4 is fitted into a fitting hole 3 a in the center of the joint fitting 3 to be held by the joint fitting 3 .

[0025] The first and second pistons 1, 2 divide the inside of the valve casing 10 into a main valve chamber A in the center and two sub-valve chambers B1, B2 on both sides thereof. The fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com