Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Does not affect positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

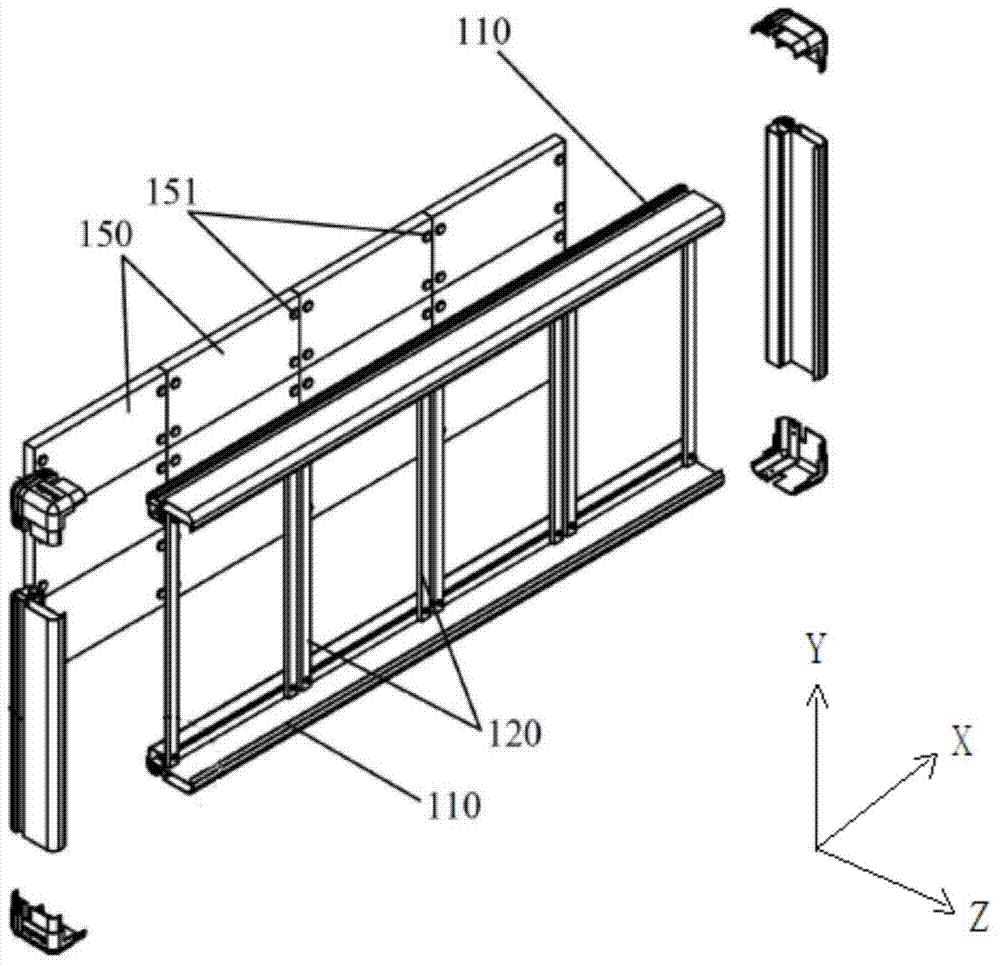

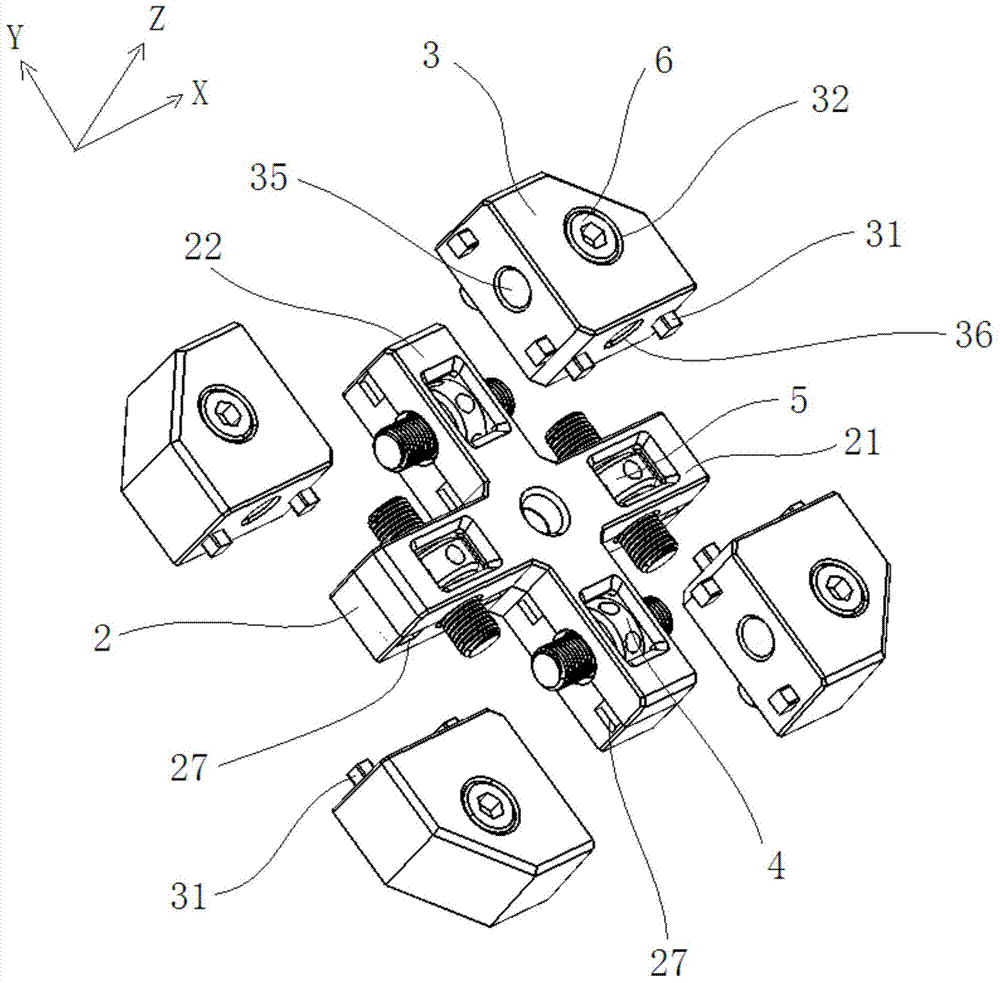

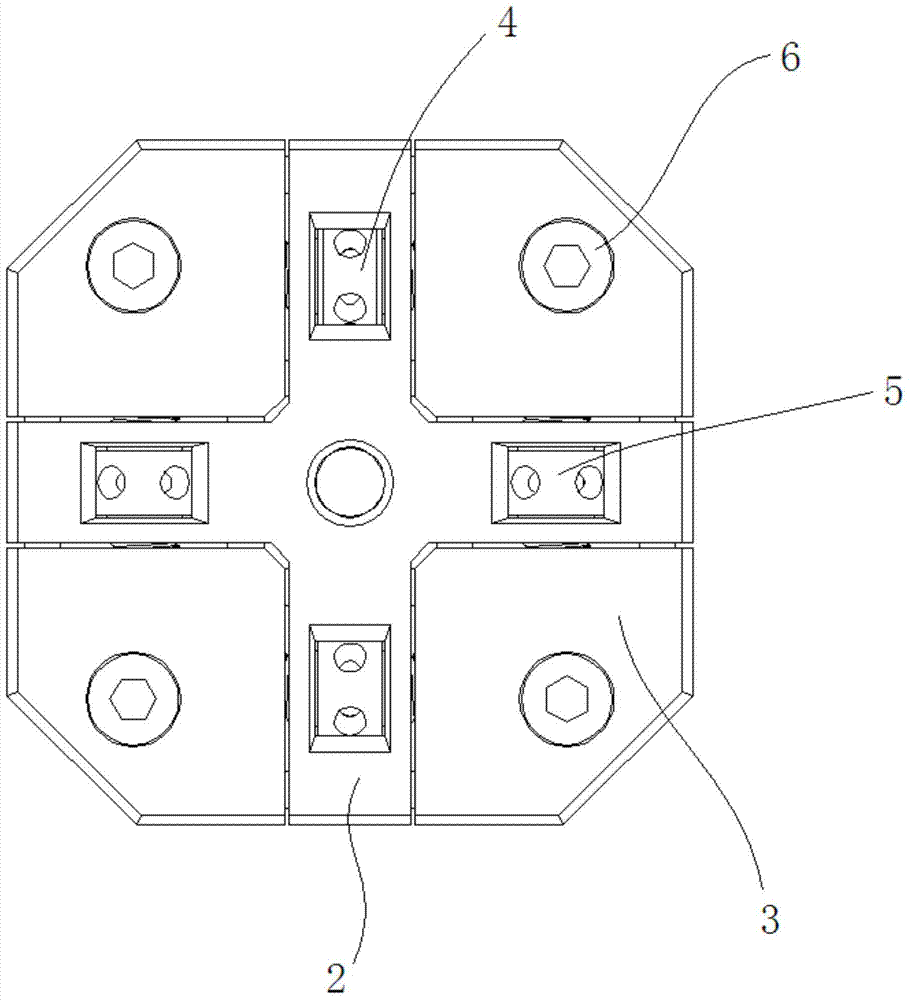

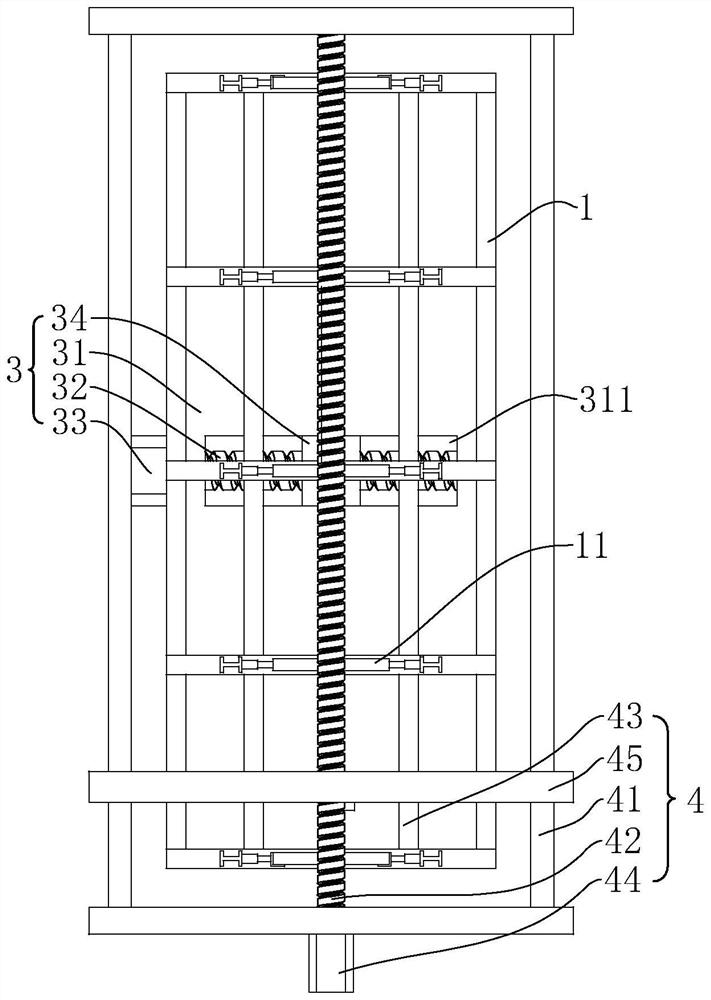

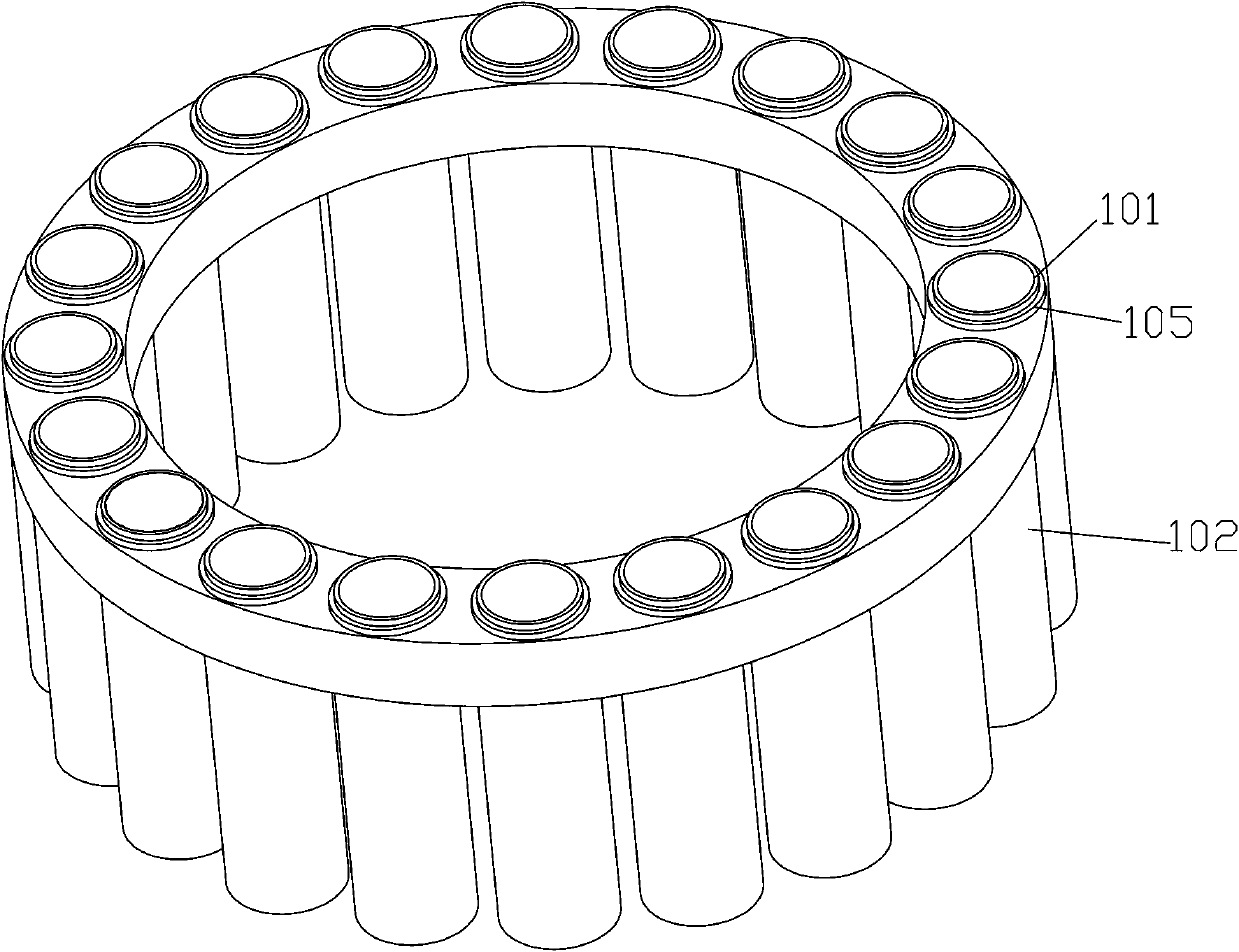

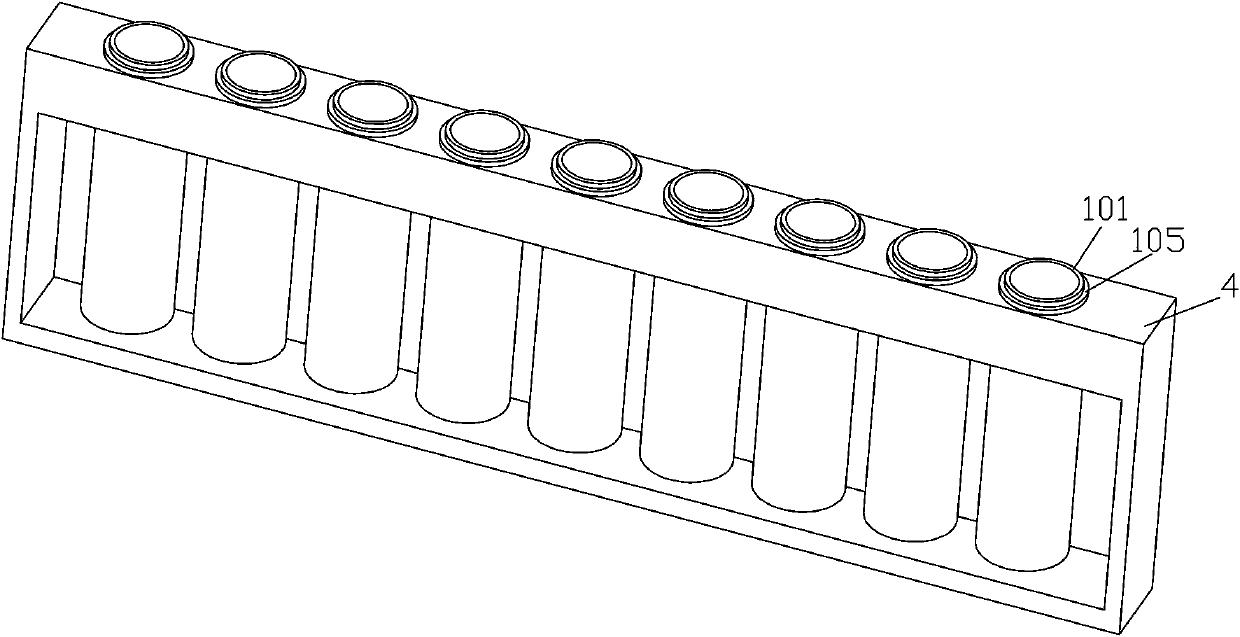

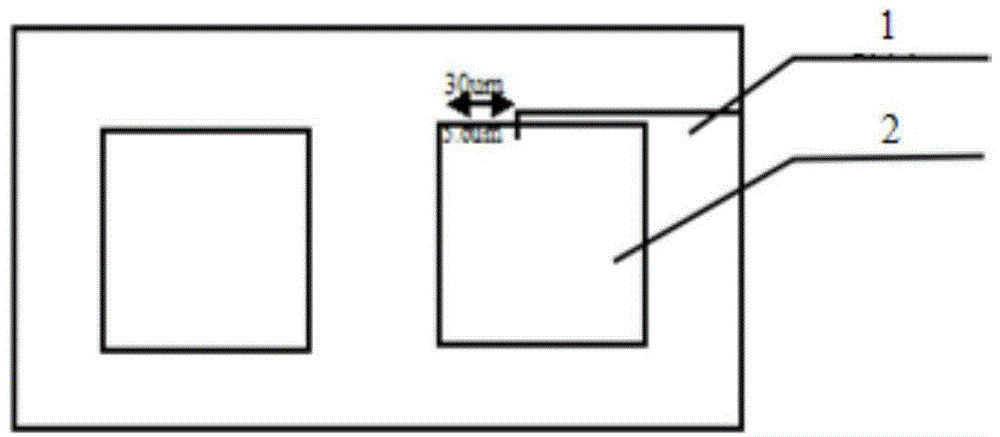

LED module installing mechanism

ActiveCN104723074AEasy to adjustSave adjustment timeCasings/cabinets/drawers detailsPrintingLED displayEngineering

The invention discloses an LED module installing mechanism. The LED module installing mechanism comprises a fixed rack (2), a gap adjusting mechanism on the fixed rack (2), and at least two moving blocks (3) movably connected with the fixed rack (2). LED modules (100) are arranged on the moving blocks (3). The two ends of the gap adjusting mechanism are connected with the moving blocks (3) respectively. By adjusting the moving block (3) on the two sides to move away or get close to each other, a gap between the LED modules (100) arranged on the moving blocks (3) is adjusted. The invention belongs to the technical field of LED modules and LED display screens. According to the LED module installing mechanism, the technical problems in the prior art that the method for adjusting the planar gap between the LED modules is complex and unstable, and the adjustment on the planeness which is perpendicular to the planar direction of the LED modules is unable to achieve are solved. The LED module installing mechanism is particularly applicable to adjusting the planeness perpendicular to the direction of the LED modules and the planar gap between the LED modules, the adjusting operation is simple, and the adjusting effect is stable.

Owner:GLUX VISUAL EFFECTS TECH (SHENZHEN) CO LTD

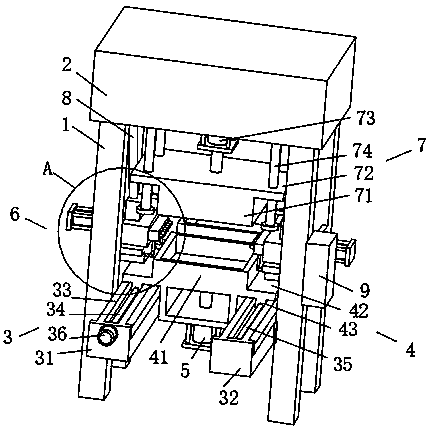

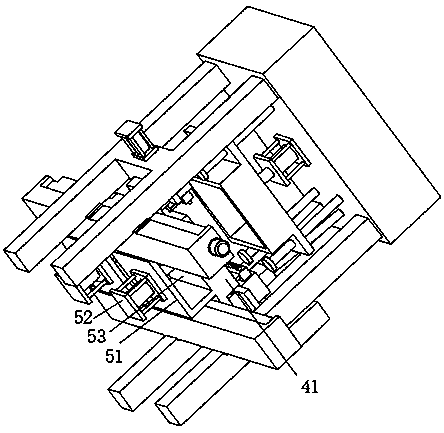

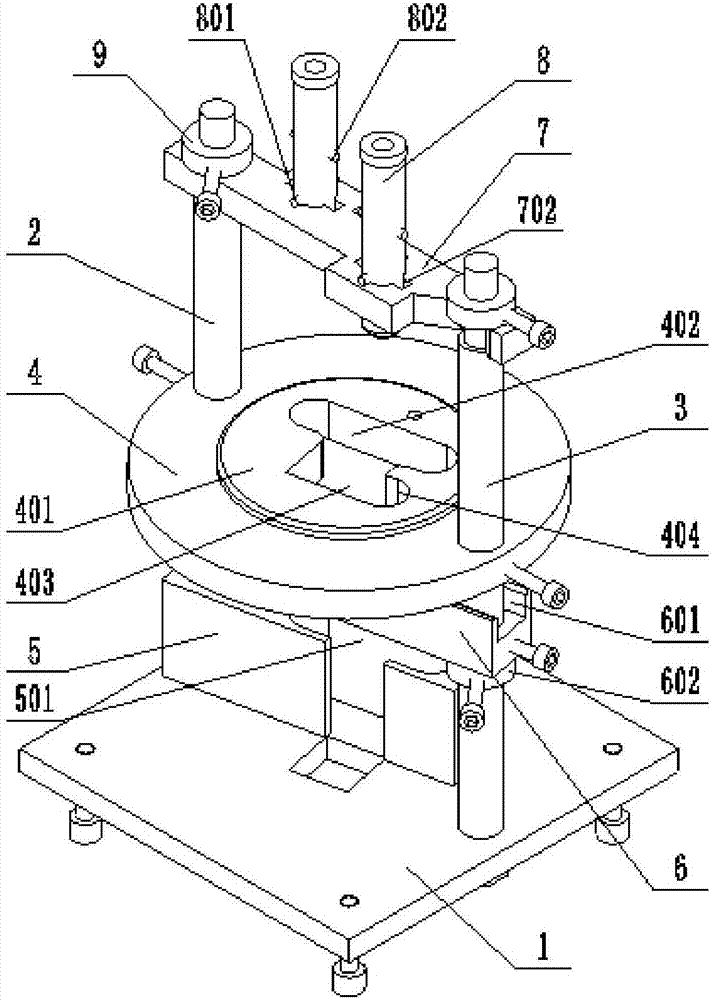

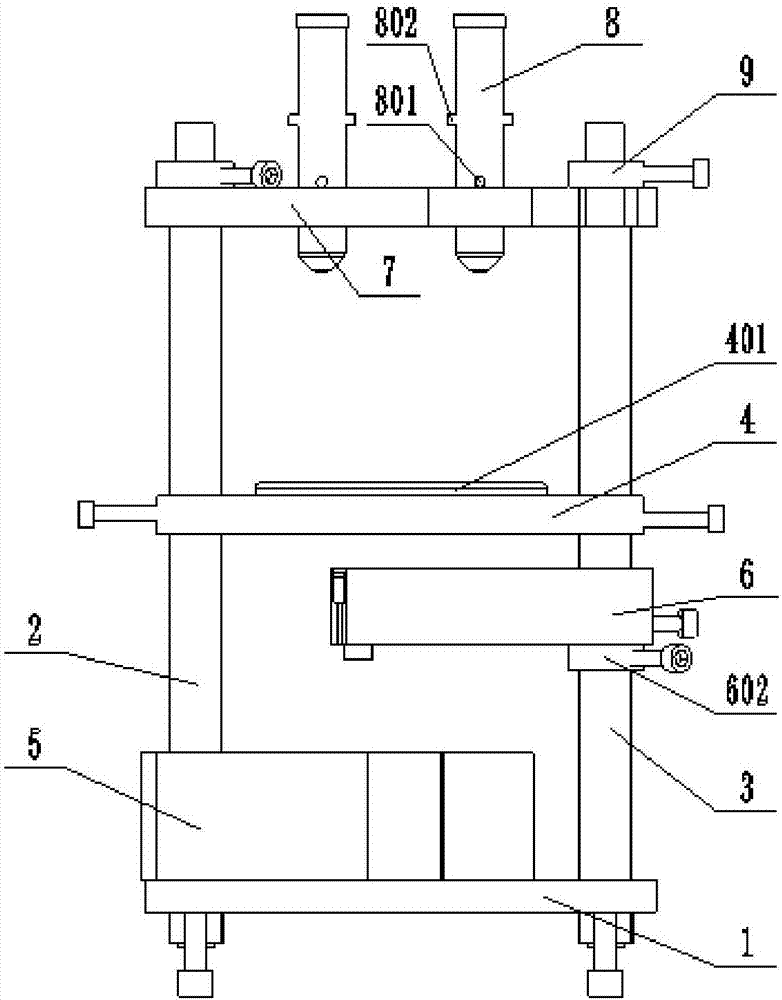

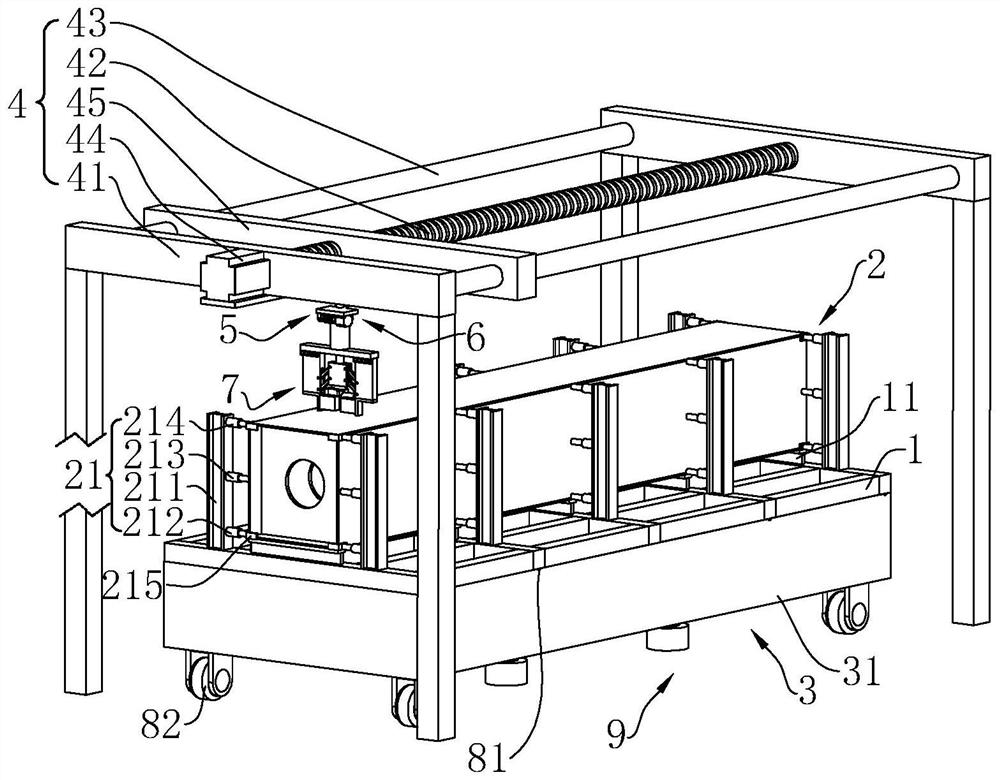

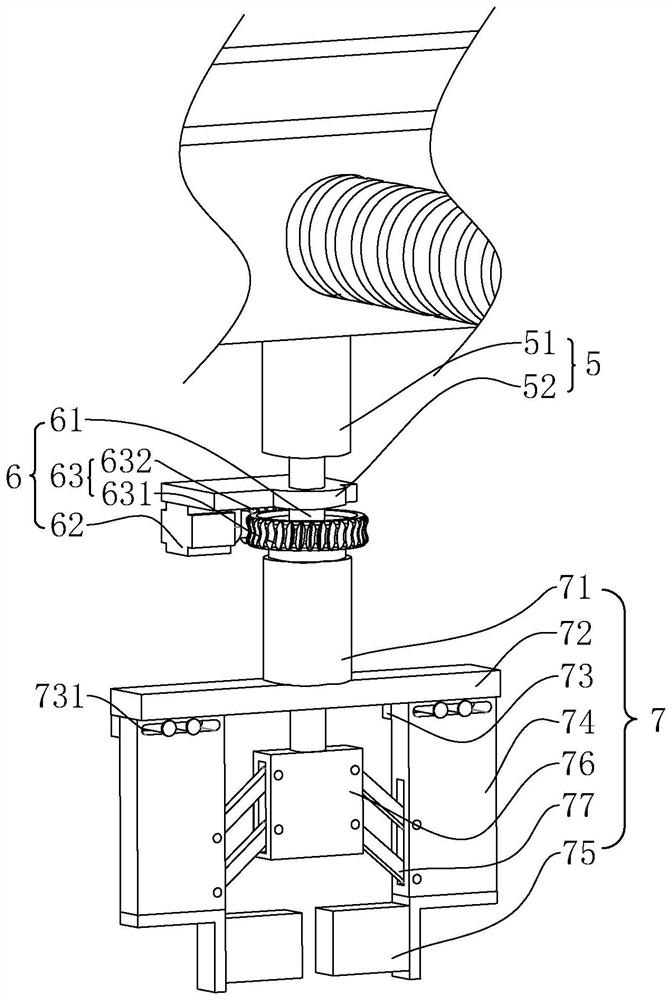

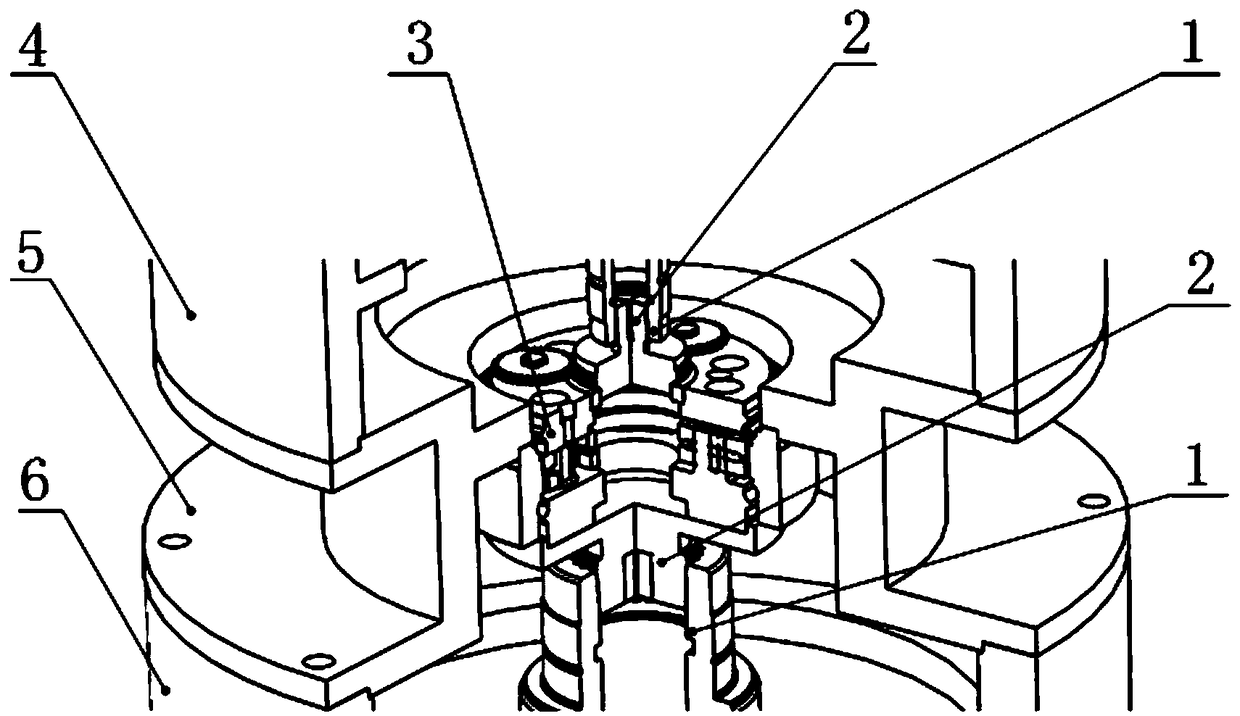

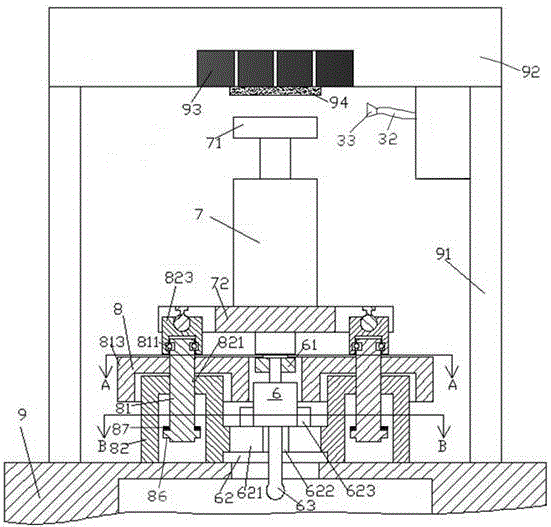

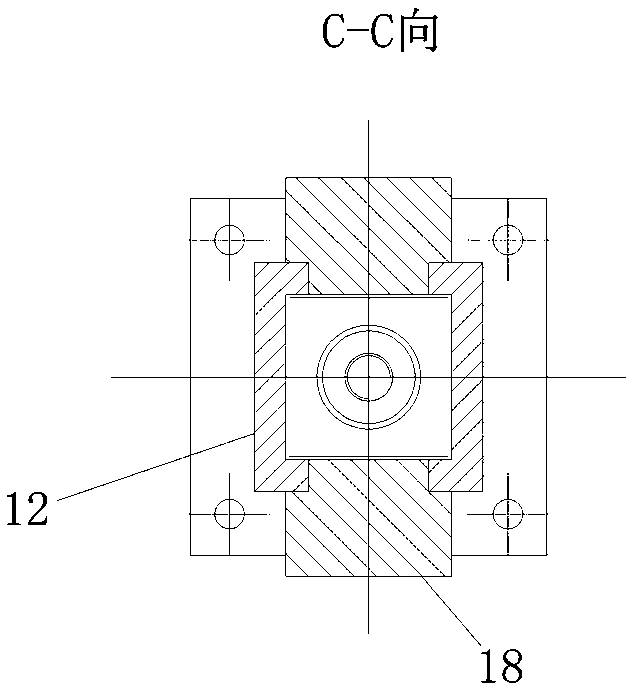

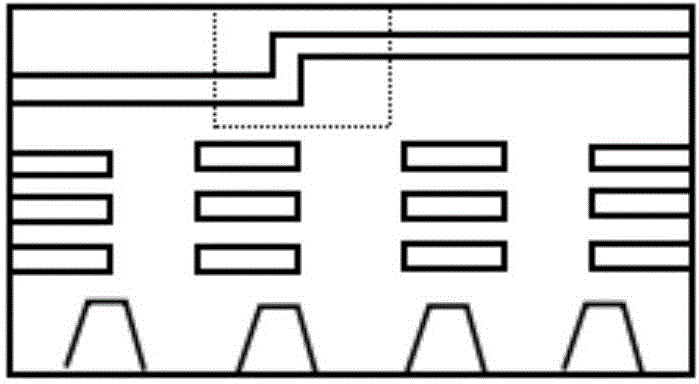

Constant temperature type double-station hot core box core shooting machine

ActiveCN109773139ANovel structural designMeet production needsMoulding machine componentsMoulding machinesTransfer mechanismEngineering

The invention discloses a constant temperature type double-station hot core box core shooting machine, and belongs to the technical field of core shooting machines. The constant temperature type double-station hot core box core shooting machine comprises a supporting frame and a sand storage box, wherein the sand storage box is installed at the top end of the supporting frame. The constant temperature type double-station hot core box core shooting machine further comprises a position transfer mechanism, lower core box assemblies, a core ejection mechanism, sand shooting mechanisms, an upper core box assembly, a connecting pipeline and a PLC control box. The position transfer mechanism is installed between the left side inner wall and the right side inner wall of the supporting frame. The two lower core box assemblies are arranged, and the core ejection mechanism is fixedly installed at the bottoms of the lower core box assemblies. The two sand shooting mechanisms are arranged and located above the lower core box assemblies. The upper core box assembly is fixedly installed at the bottom of the sand storage box, and the PLC control box is installed on one side wall of the supportingframe. The purpose that replacement of core boxes and the sand casting work can be accomplished under the condition that the whole working process does not need to be stopped is achieved, the production efficiency is improved, and utilization is more flexible; precoated sand in sand shooting assemblies is located in the environment with the constant temperature, and therefore the quality of a moldcore product is guaranteed, the manufacturing cost is low, and maintenance is convenient.

Owner:LIYANG WANSHENG CASTING

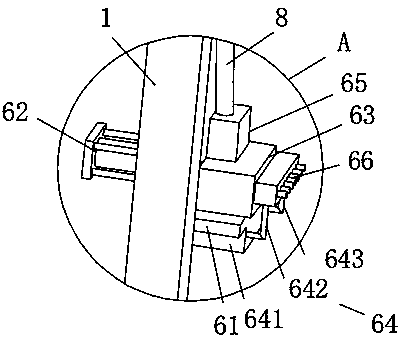

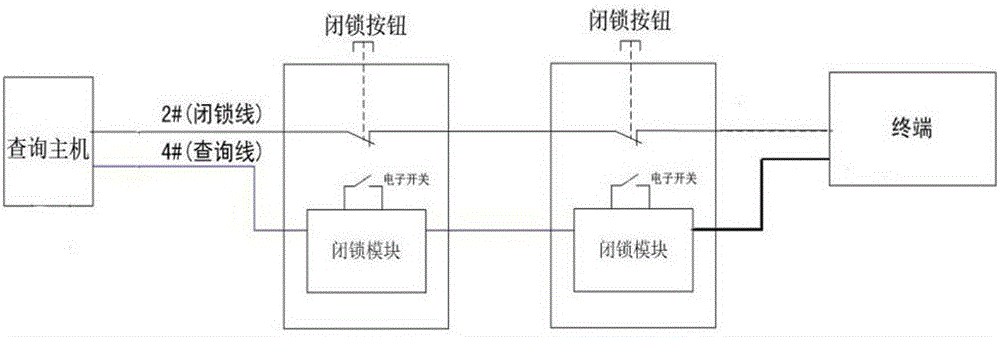

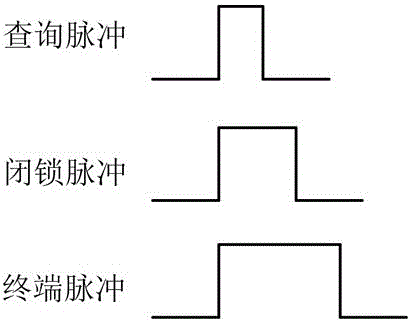

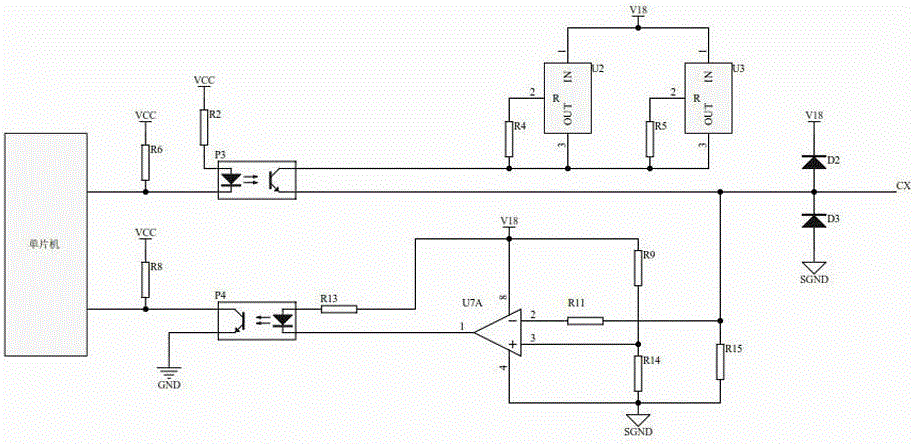

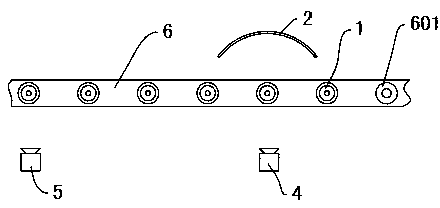

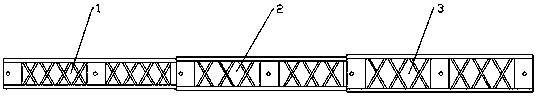

Mine belt protective system along-line shutting query method

ActiveCN106553878ADoes not affect positioningSimple structureConveyorsControl devices for conveyorsRemote controlComputer module

The invention relates to a mine belt protective system along-line shutting query method. The mine belt protective system along-line shutting query method comprises a query host, a plurality of along-line shutting modules and a terminal module. The query method includes the steps that the query host sends a query signal, the along-line shutting modules and the terminal module process the query signal and replies the query signal, and the query host then processes the replied signal to achieve remote fault location, remote input and remote control. The mine belt protective system along-line shutting query method has the beneficial effects that remote fault location and along-line shutting can be achieved without address coding for along-line shutting, and replacement without influencing positioning positions can be achieved; and the structure is simple, operation is convenient, normal communication can be carried out by sequentially connecting equipment with cables, debugging and allocation are not needed, installation debugging and allocation are greatly simplified, the fault rate is reduced, and the working efficiency is improved.

Owner:山东开创电气有限公司

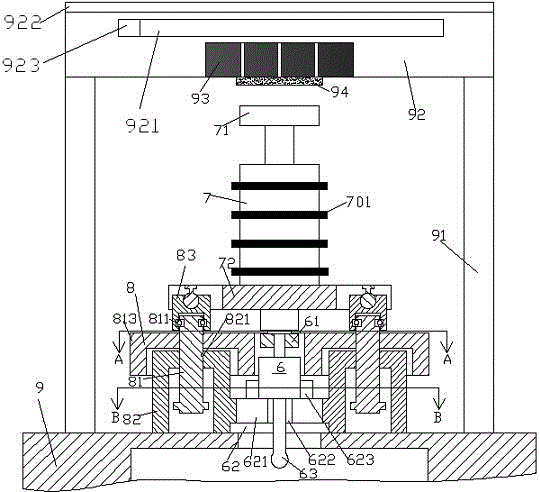

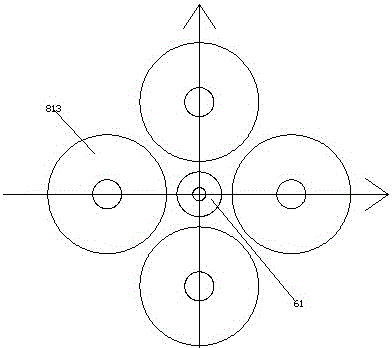

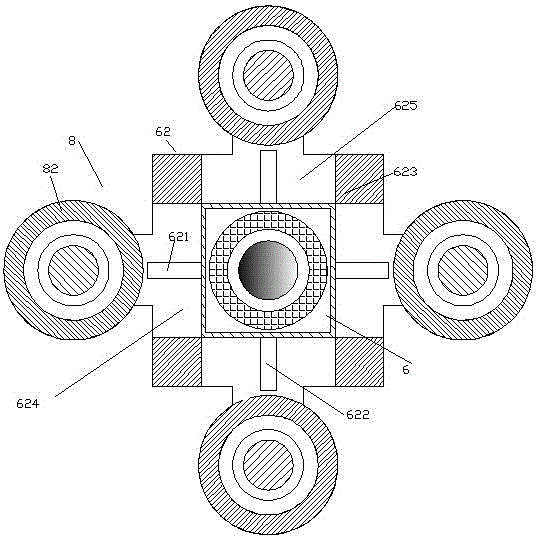

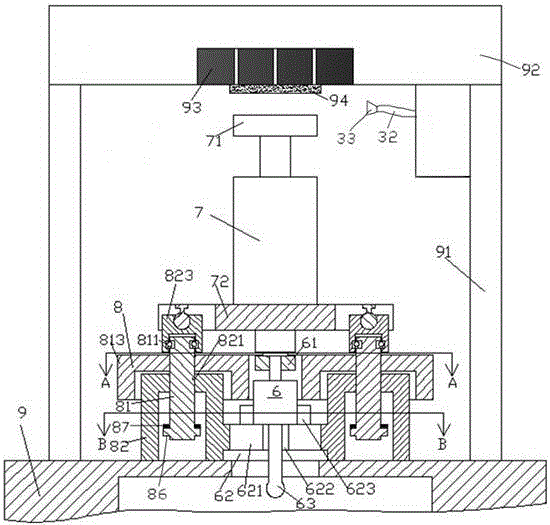

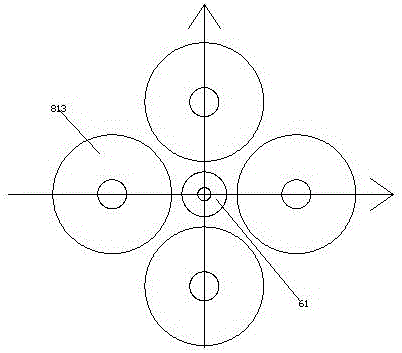

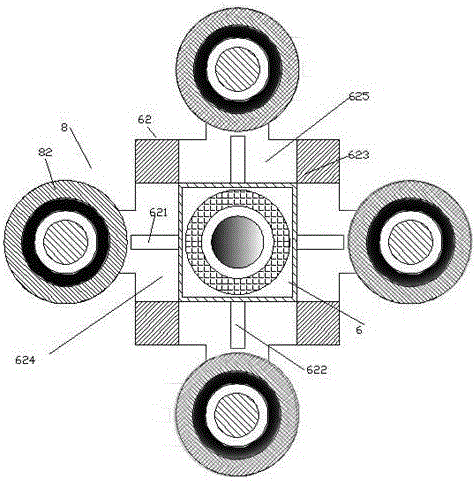

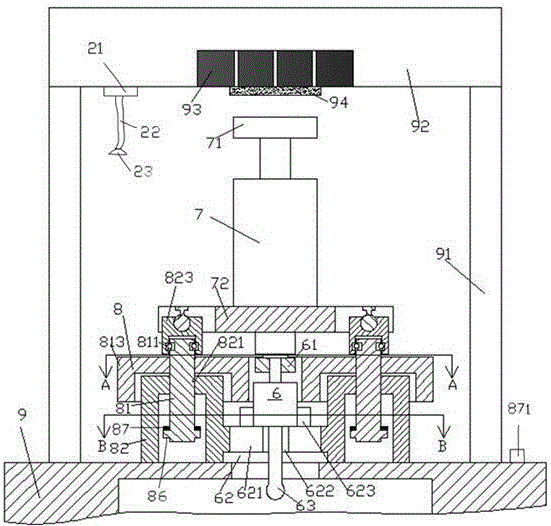

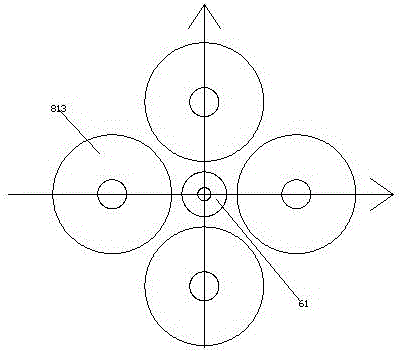

Energy-saving and environment-friendly grinding device

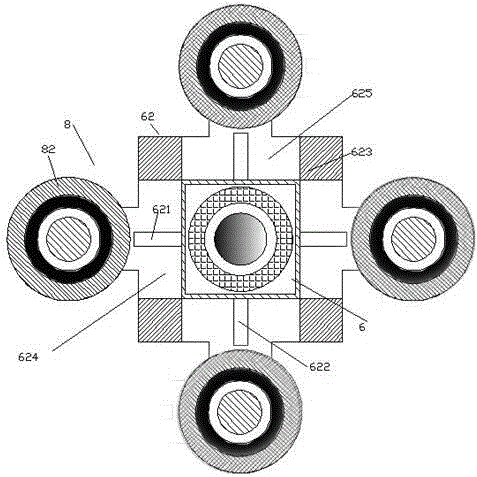

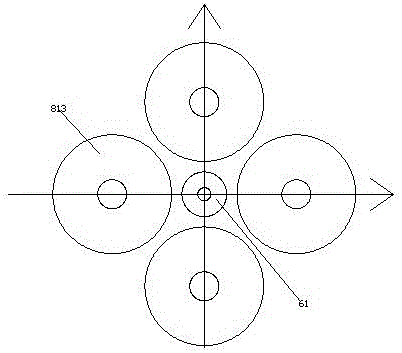

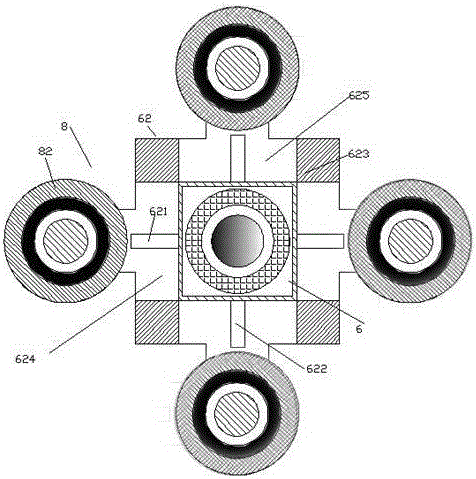

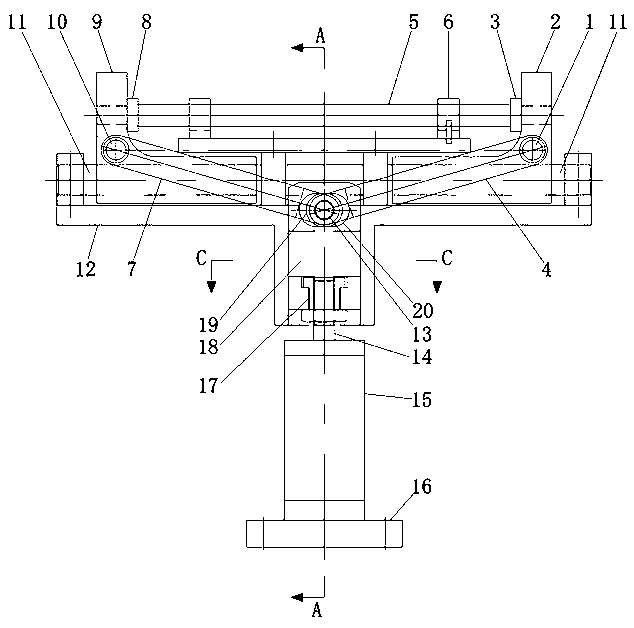

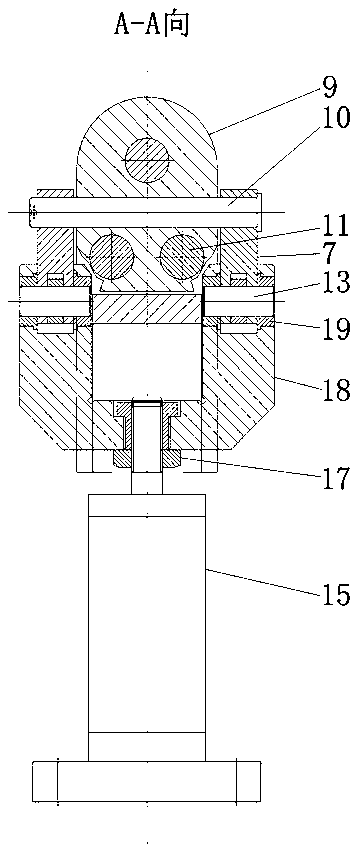

InactiveCN105965336AAvoid burnsSave energyGrinding drivesGrinding work supportsTransverse axisEngineering

An energy-saving and environment-friendly grinding device, comprising a base (9) and a workpiece fixing table (92) supported above the base (9) by a column (91), the workpiece fixing table (92) A workpiece holding device (93) is provided on the lower side to hold the workpiece (94) on the lower side of the workpiece holding device (93), and the upper side of the base (9) is fixedly arranged on the Four inclination adjustment devices (8) below the workpiece fixing table (92), the four inclination adjustment devices (8) are evenly distributed in the circumferential direction so that two of them are located in the direction of the horizontal axis and the other two are located in the direction of the vertical axis axis direction.

Owner:晋江市晋美日用品有限公司

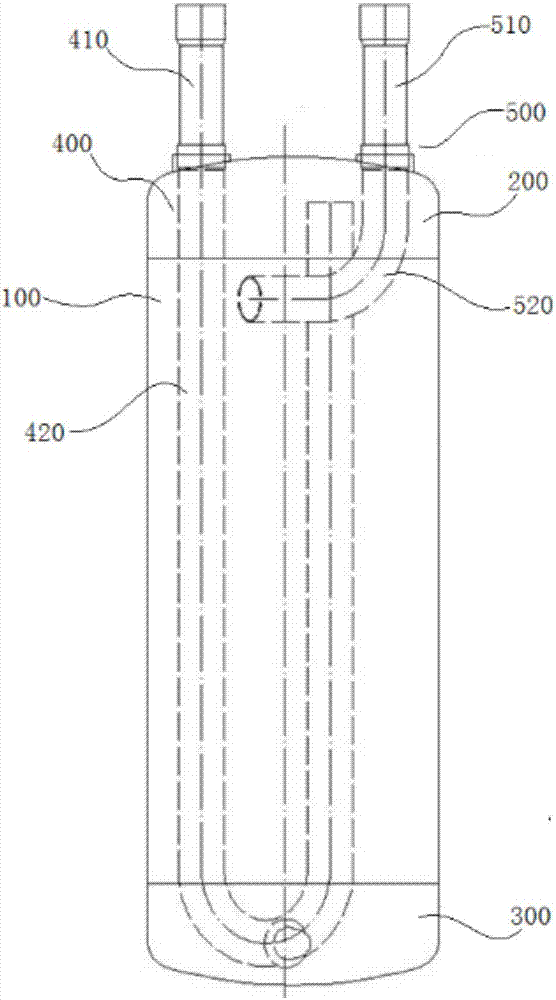

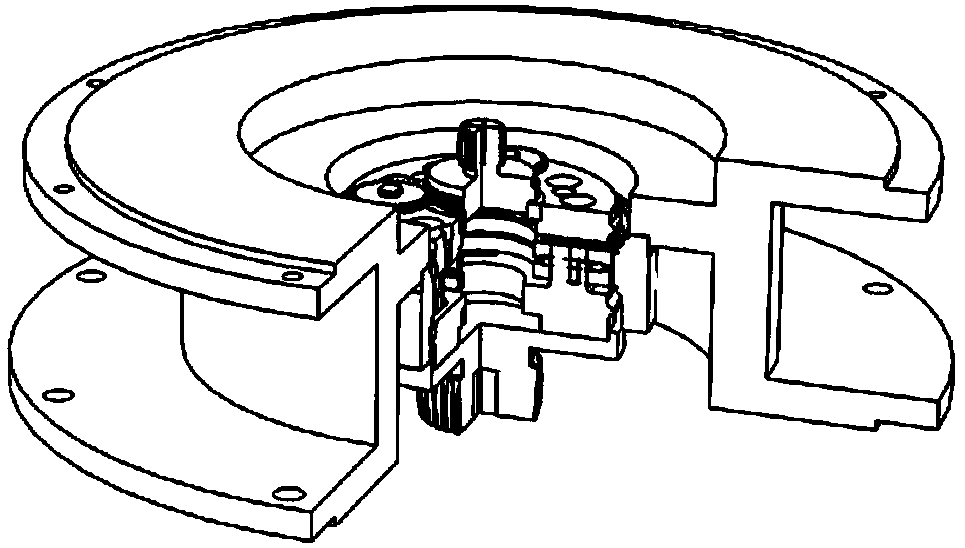

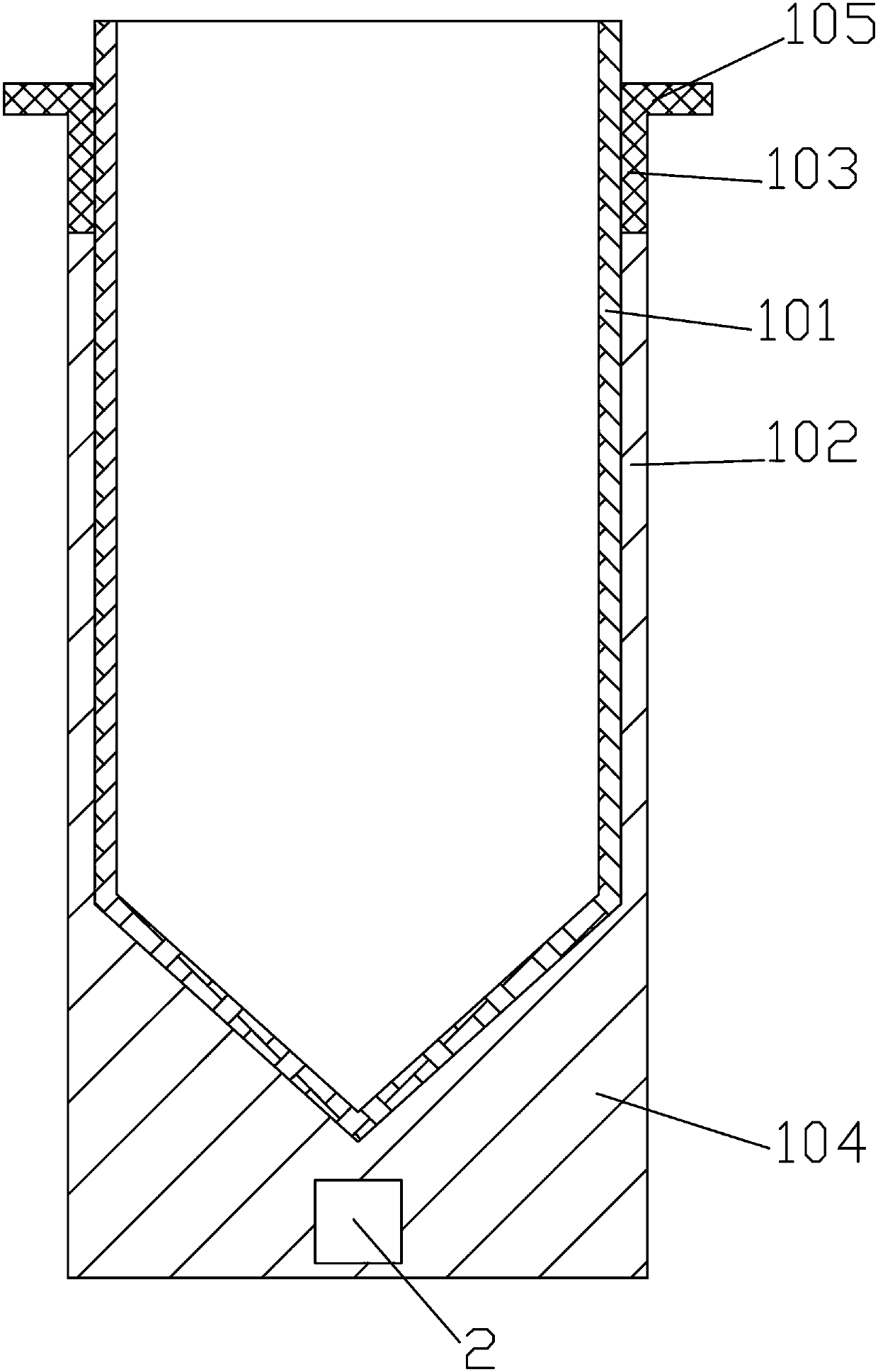

Gas-liquid separator welding fixture and application method thereof

ActiveCN107363465AHigh precision positioningPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesPhysicsVapor–liquid separator

The invention discloses a gas-liquid separator welding fixture and an application method thereof, and belongs to the field of fixtures. The fixture comprises a bottom plate, a guide positioning disc, a limiting baffle and a support plate, wherein two upright posts are arranged on the bottom plate; the guide positioning disc is arranged on the two uprights in a sleeving way, and a first kidney-shaped hole and a positioning hole which penetrate through the upper and lower surfaces are formed in the guide positioning disc; the limiting baffle and the support plate are both positioned below the guide positioning disc; a second kidney-shaped hole corresponding to the first kidney-shaped hole is formed in the limiting baffle; a positioning slot corresponding to the positioning hole is formed in the upper surface of the support plate; a protection gas pipe seat is mounted above the guide positioning disc; two protection gas pipes are fixed, and correspond to the first kidney-shaped hole and the positioning hole respectively. The fixture disclosed by the invention can finish welding of a gas-liquid separator with high efficiency and high precision; moreover, oxidation caused by high temperature of welding can be avoided, and acid pickling after welding is omitted. The application method disclosed by the invention can be used for positioning a gas inlet pipe, a gas outlet pipe and an upper end cover with high efficiency and high precision to finish welding of the gas-liquid separator.

Owner:ANHUI ZHONGHUI REFRIGERATION

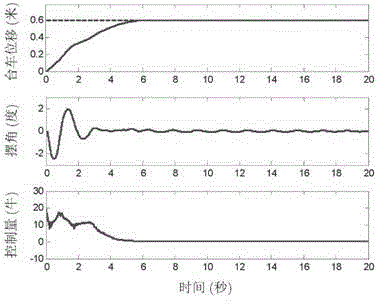

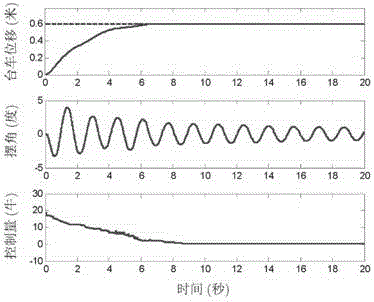

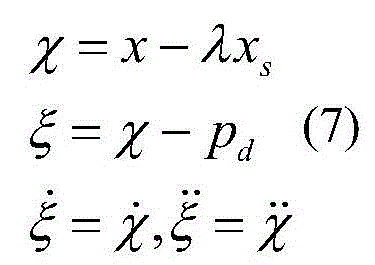

Adjusting and control method of swing resistance enhanced bridge-type crane

ActiveCN104129712ADoes not affect positioningImprove anti-swing effectLoad-engaging elementsBridge typeControl objective

An adjusting and control method of a swing resistance enhanced bridge-type carne comprises the following steps: step one, constructing an error signal; step two, determining a control target; step three, determining a control discipline; and step four, realizing the control method. The method can greatly improve the trolley transportation speed and effectively eliminate the swing of loads, thus improves the work efficiency and safety of the whole system, and has a very important practical application meaning.

Owner:扬州祥帆重工科技有限公司

Grinding equipment capable of manually adjusting inclined angle

InactiveCN106181626AThe structure of the device is stableReliable useGrinding carriagesGrinding drivesTransverse axisEngineering

The invention discloses grinding equipment capable of manually adjusting an inclined angle. The grinding equipment comprises a base (9), and a workpiece fixed table (92) supported above the base (9) through a stand column (91); a workpiece holding device (93) is arranged on the lower side surface of the workpiece fixed table (92) for keeping a workpiece (94) on the lower side surface of the workpiece holding device (93); and four inclined angle adjusting devices (8) are fixed below the workpiece fixed table (92) on the upper side surface of the base (9), and are uniformly distributed in the peripheral direction, so that two opposite inclined angle adjusting devices (8) are positioned in the transverse axis direction, and other two opposite inclined angle adjusting devices (8) are positioned in the longitudinal axis direction.

Owner:郑世浦

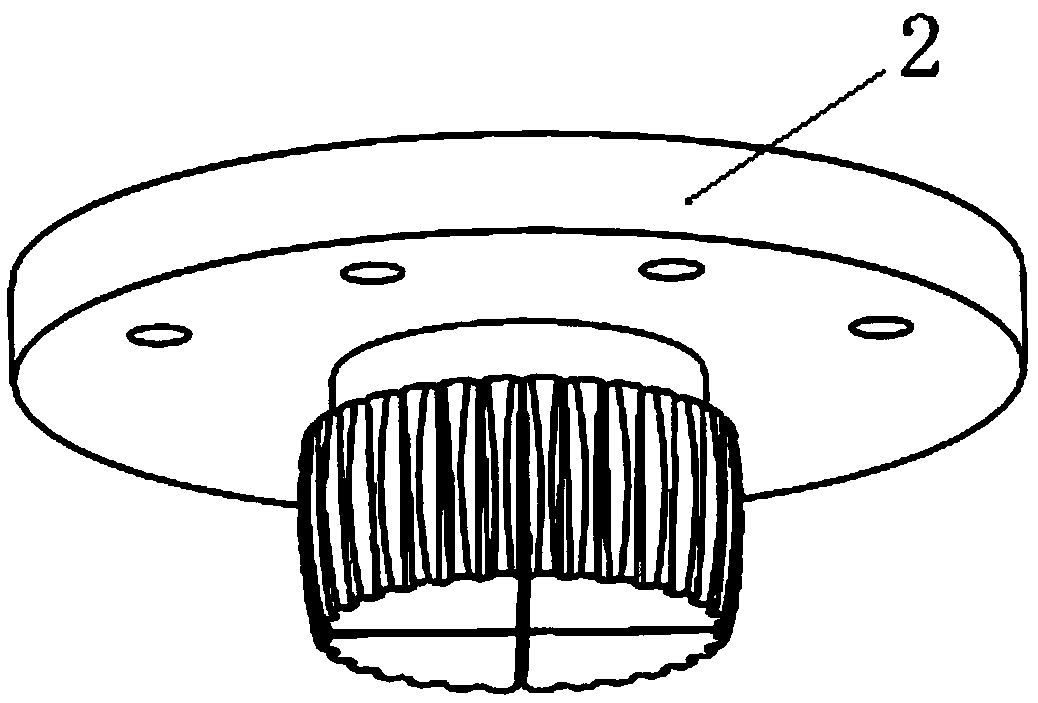

Composite structure of radiator fan and molding method thereof

ActiveCN102062111ACombined positioning accuracy improvementReduce fit errorPump installationsCooling/ventilation/heating modificationsStatorComputer fan

The invention discloses a composite structure of a radiator fan and a molding method thereof. The composite structure of the radiator fan is characterized by comprising a base plate, a stator insertion seat positioning part, a stator group, a plastic combined seat part, an axle center and a rotor blade group, wherein the base plate comprises an attached surface and a stator assembly surface; the stator insertion seat positioning part is arranged in the center of the stator assembly surface; the stator group comprises silicon steel sheets, coils and a plastic insulating frame seat; the plastic combined seat part is integrally formed on the stator group, and can be inserted, connected and matched with the stator insertion seat positioning part; the axle center is connected to the plastic combined seat part, and has a root fixedly connected to the center of the plastic combined seat part; and the rotor blade group comprises a hub, blades, a shaft sleeve, a bearing component and magnetic rings. The axle center is integrally assembled on the plastic structure of the stator group, and a composite design is adopted between the stator group and the base plate, so precise positioning between the axle shaft and the silicon steel sheets and coils of the stator group can be easily realized by the planning design of an extrusion mould. Therefore, the composite structure of the radiator fan can achieve great improvements in combination and position correction accuracy, is smoother to run and has the advantages of effectively reducing noises, along with practicability and progressiveness.

Owner:SUZHOU FORCECON ELECTRIC

Auxiliary welding equipment for box type steel component and machining process of auxiliary welding equipment

ActiveCN114043150AGuarantee product qualityImprove location accuracyWelding/cutting auxillary devicesAuxillary welding devicesControl systemProgrammable logic controller

The invention discloses auxiliary welding equipment for a box type steel component and a machining process of the auxiliary welding equipment, and relates to the technical field of steel structure machining. The auxiliary welding equipment for the box type steel component comprises a jig frame and further comprises a main body positioning device, a welding supporting device and a control system; the main body positioning device is used for fixing and positioning a bottom plate and a top plate; the welding supporting device is used for temporarily fixing and positioning partition plates and side plates; and the control system is a programmable logic controller and is electrically connected with the positioning device and the welding supporting device. In the auxiliary welding equipment, the design positions of all parts of the box-type steel component are programmed in the control system, then the main body positioning device and the welding supporting device are controlled to work through the control system, and all the parts of the box-type steel component are positioned, so that the position accuracy of all the parts of the box-type steel component is improved, and the product quality of the box type steel component is ensured; and the processing efficiency is greatly improved.

Owner:北钢建设集团股份有限公司

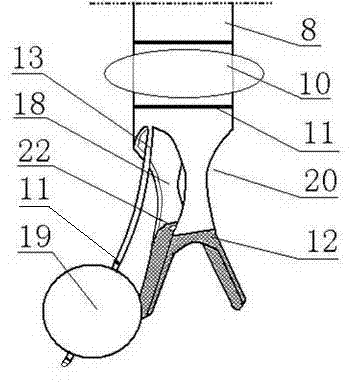

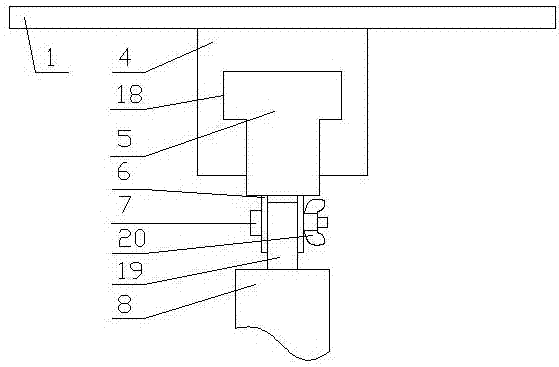

One-lung ventilation integrated device of single-cavity trachea catheter and bronchus blocking device

The invention relates to a one-lung ventilation integrated device of a single-cavity trachea catheter and a bronchus blocking device, belonging to medical apparatuses. The one-lung ventilation integrated device comprises a Y-shaped tee joint connected with the single-cavity trachea catheter, wherein a catheter bag is arranged at the front end of the single-cavity trachea catheter, an unaffected-side bronchus opening and an affected-side bronchus opening are arranged on a left side and a right side in the front of the catheter bag, a tip end of the catheter bag is provided with a V-shaped bulge clamp, a bronchus blocking system and the single-cavity trachea catheter are integrated, the front end of a blocking pipe penetrates out from an upper edge of the affected-side bronchus opening and is out of shape in the wall of a catheter body upwards, a blocking bag is arranged at the front end of the blocking pipe, the tail end of the blocking pipe penetrates out from an affected-side root of the catheter body and is connected with a bidirectional blocking pipe switch, and an elastic guide wire special for dredging the blocking pipe is arranged at the tail end of the blocking pipe. The one-lung ventilation integrated device of the single-cavity trachea catheter and the bronchus blocking device, disclosed by the invention, has a simple structure and reasonable design and integrates various advantages of a traditional one-lung ventilation device so as to provide clinic with a novel one-lung ventilation device having the advantages of convenience for operation, exactness in location and flexibility for conversion of one-lung ventilation and double-lung ventilation, and makes an affected lung better keep a static collapse state.

Owner:张海山

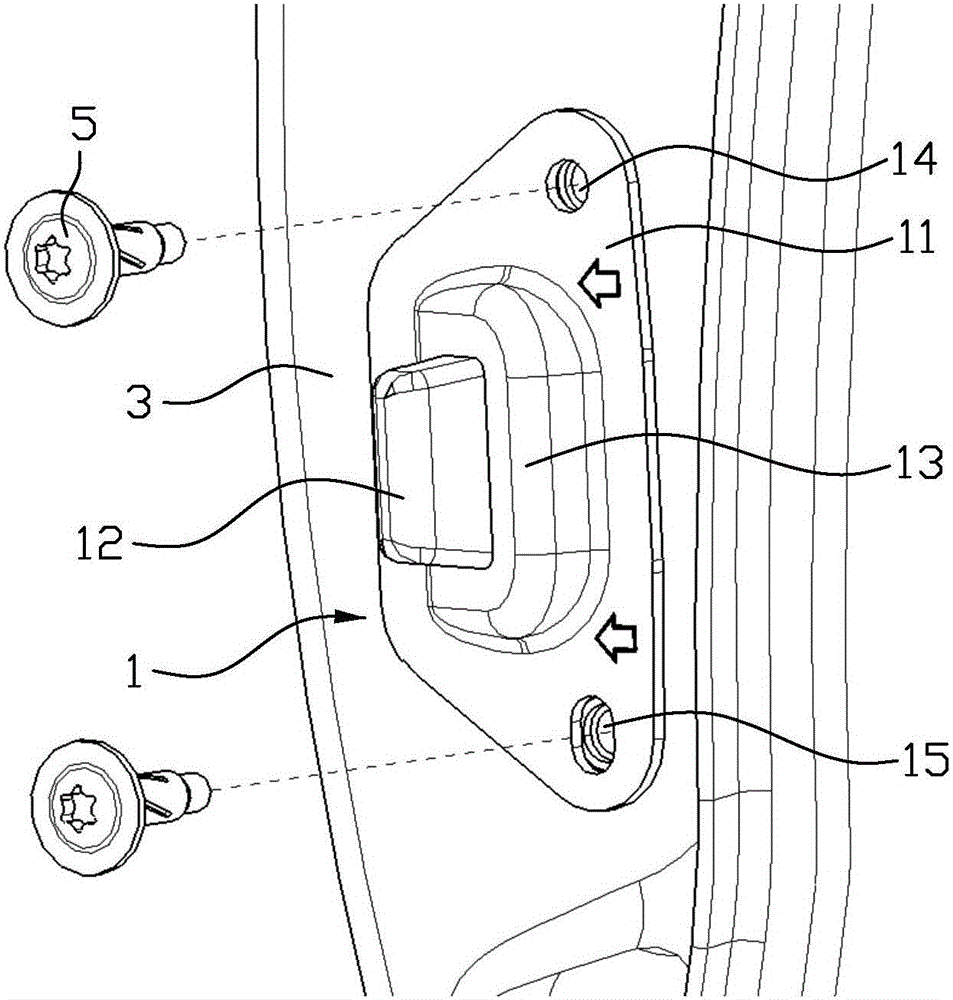

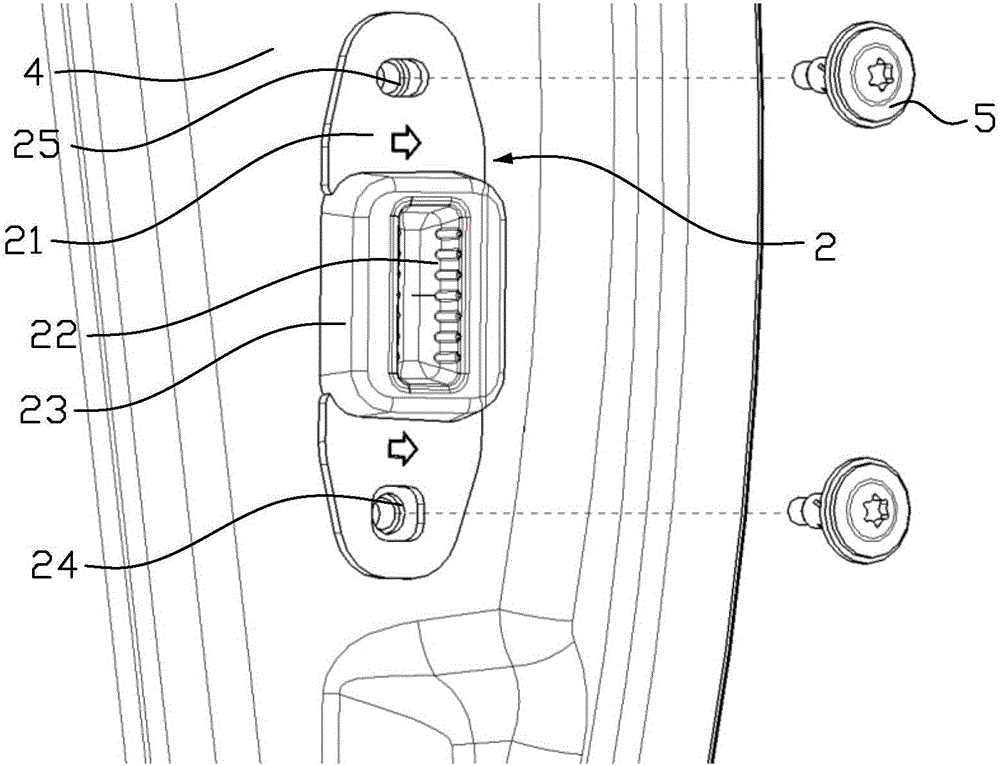

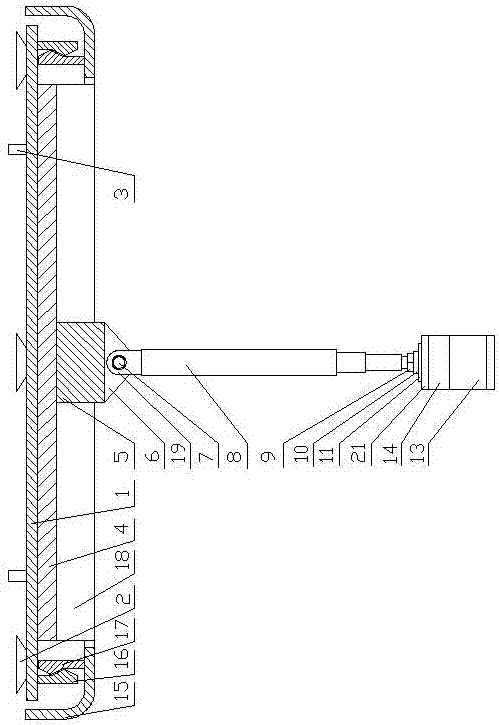

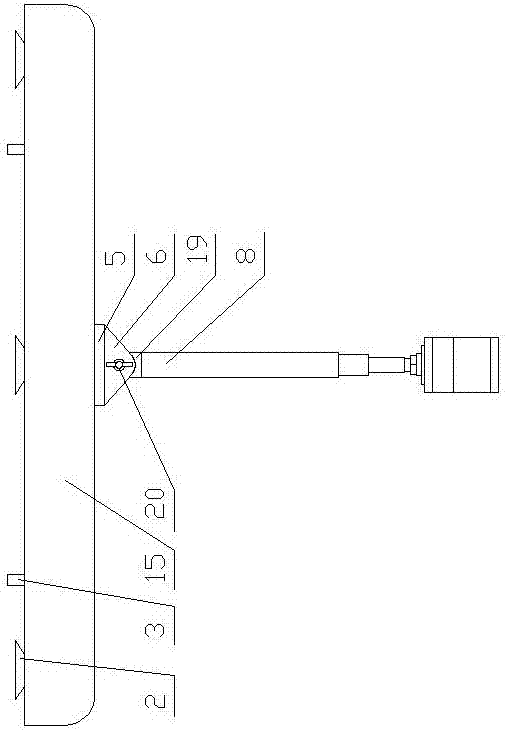

Limit block assembly of automobile slide door, and assembling method thereof

InactiveCN106499275ADoes not affect positioningWith buffer functionBuilding braking devicesWing fastenersEngineeringMechanical engineering

The invention provides a limit block assembly of an automobile slide door. The limit block assembly comprises a limit block convex block and a limit block concave block, wherein the limit block convex block is fastened on the automobile slide door; and the limit block concave block can be pre-tensioned on an automobile B-pillar and is capable of being extruded by the limit block convex block to slide under a closing force of the slide door, adaptively clamped with the limit block convex block after the slide door is closed, and finally tightly fixed on the automobile B-pillar. The invention further provides an assembling method of the limit block assembly of the automobile slide door. The assembling method comprises the following steps: fastening the limit block convex block on the automobile slide door; pre-tensioning the limit block concave block on the automobile B-pillar; closing the slide door, and enabling the limit block concave block to be extruded by the limit block convex block to slide and adaptively clamped with the limit block convex block; and fastening the limit block concave block on the automobile B-pillar. In conclusion, the adaptive clamping between the limit block concave block and the limit block convex block can be realized through the limit block assembly of the automobile slide door, which is provided by the invention; and moreover, the limit block concave block and the limit block convex block have a buffering function and do not influence location of the slide door.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Vehicle-used mobile phone navigation dedicated support

ActiveCN107249059AAdjust orientationHeight adjustableVehicle componentsTelephone set constructionsMobile navigationEngineering

The invention discloses a vehicle-used mobile phone navigation dedicated support comprising an installing plate. A set of suction discs are installed on the bottom part of the installing plate. A set of fixing bolts are arranged on the installing plate in a penetrating way. The upper part of the installing plate is provided with a track which is slidably matched with a slide block. A connecting base is arranged on the slide block. The connecting base is matched with one end of a telescopic rod through a connecting screw rod. The other end of the telescopic rod is connected with a nut in a screwed way. The nut is matched with a limiting base through a damping bearing. The limiting base is detachably connected with a lower clamp plate through a bolt. The lower clamp plate is slidably matched with an upper clamp base. A decoration cap is arranged on the installing plate in a buckling way. The vehicle-used mobile phone navigation dedicated support can be arranged on the vehicle ceiling position above the driving seat so that the requirement for hanging the mobile phone can be met for the driver, the hanging position of the mobile phone can be flexibly adjusted, the dangerous situation caused by the fact that the driver cannot watch the road head in case of watching navigation can be avoided and the driving safety can be enhanced.

Owner:浙江中超新材料股份有限公司

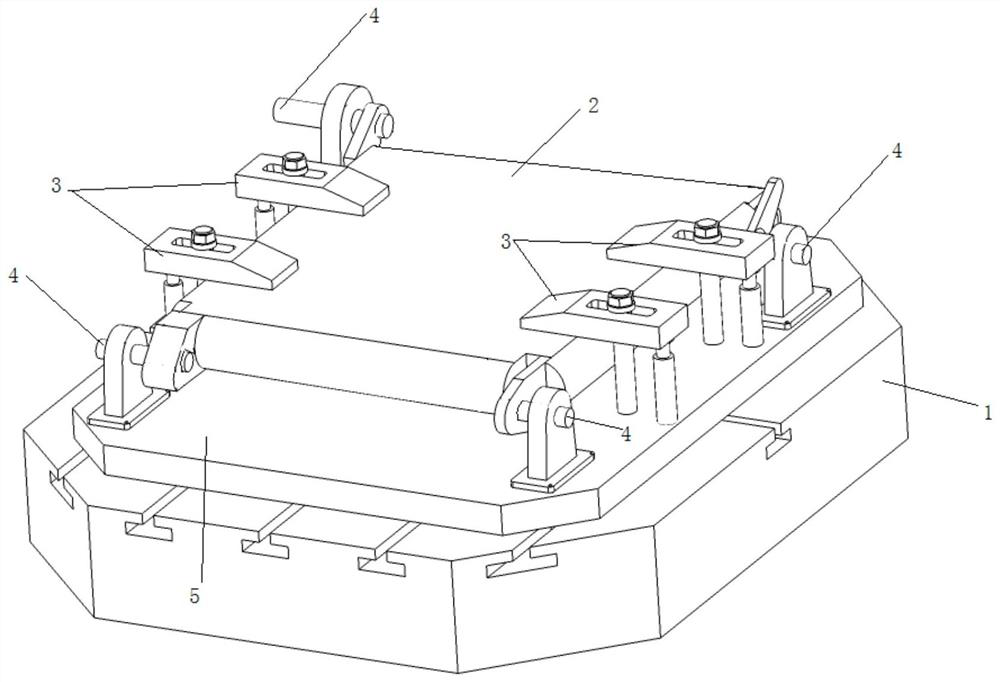

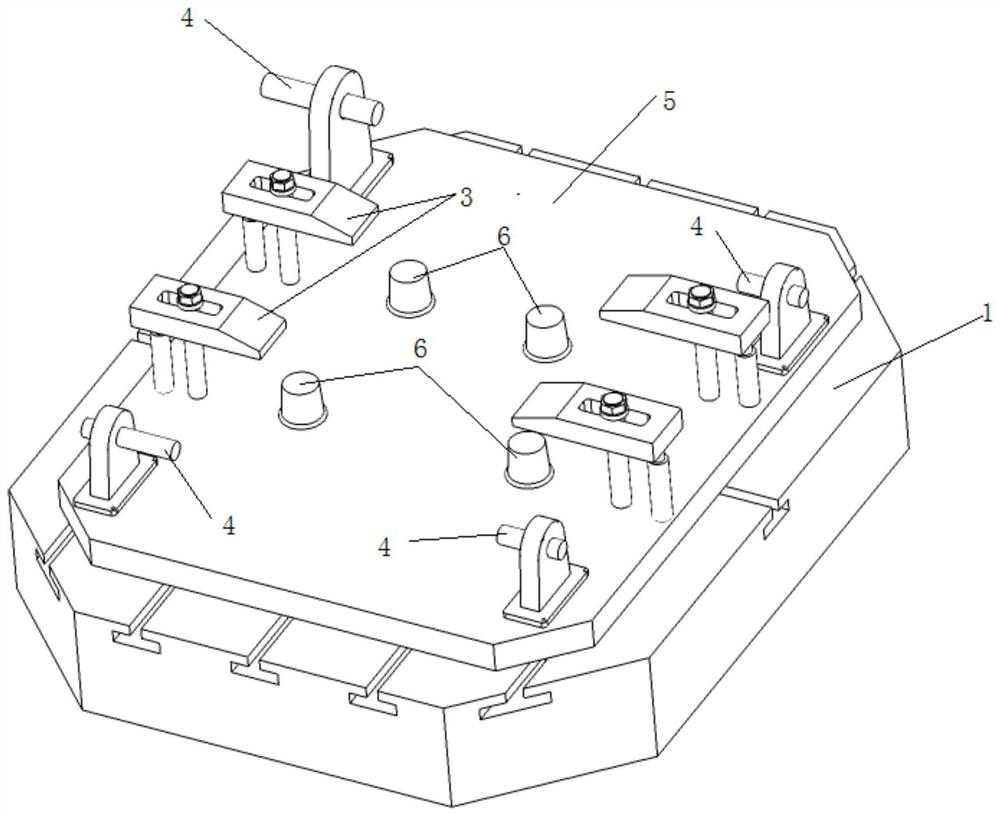

Special-shaped part machining method, fixture and fixture design method

ActiveCN111702521ARapid positioningShort production cyclePositioning apparatusMetal-working holdersManufacturing qualityManufacturing engineering

The invention provides a five-axis milling integrated positioning machining method capable of achieving special-shaped part space multi-location-degree control requirements, a fixture and a fixture design method. According to the positioning method, the machining element of a workpiece is determined by the fixture at first to position the workpiece, then, the direction of the fixture is adjusted through the position of the workpiece so that the workpiece can be clamped by existing surfaces of the workpiece, and clamping operation is completed at a time. According to the invention, the existingmachining idea that a workpiece is positioned and clamped onto a workbench through unstable surfaces at first, then, the direction of a fixture is gradually adjusted through a measuring tool or simulation machining mode to adjust the workpiece to align machining elements is broken through. In the existing machining method, because the workpiece is a complex structure body, an operator can often align the machining position by adjusting the fixture repeatedly, positioning is accurate and convenient after the method and the fixture of the invention are adopted, clamping is stable and reliable,adjusting is convenient, the working efficiency is high, and the product manufacturing quality is stable.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

Deformable outer cone drum-shaped gapless spline structure

PendingCN109356944AWith deformation elasticityRealize gapless contactYielding couplingDrive shaftTorque transmission

The invention discloses a deformable outer cone drum-shaped gapless spline structure for connecting an input shaft of a speed reducer to be detected with a high-speed end transmission shaft of a speedreducer detector, and connecting an output shaft of the speed reducer to be detected with a low-speed end transmission shaft of the speed reducer detector. The spline structure comprises a connectingshaft and a matching hole, wherein the connecting shaft is connected on the input shaft / the output shaft of the speed reducer to be detected; the matching hole is connected on the transmission shaftsof the high-speed end / the low-speed end of the speed reducer detector; and the connecting shaft is an involute outer spline, the matching hole is an involute internal spline, and the connecting shaftand the matching hole are connected through the involute outer spline and the involute inner spline which are matched with each other, thereby achieving large-torque transmission. According to the deformable outer cone drum-shaped gapless spline structure, rapid gapless connection and transmission of a separable shafting can be ensured, large torque transmission is realized, a certain coaxial error is tolerated, and the positioning of a fixed outer shell is not affected.

Owner:TIANJIN UNIV

Method for storing and locating selected content on web page

InactiveCN104090947ADoes not affect positioningIntelligent positioningNatural language data processingSpecial data processing applicationsComputer terminalUniform resource locator

The invention discloses a method for storing and locating selected content on a web page. According to the method, a root node of a main body of the web page is used as a reference node, the offset of the initial position and the end position of the content selected by a user is worked out, and the web page url, the reference node, the selected content, the offset of the initial position of the selected content and the offset of the end position of the selected content are used as locating information to be stored in a server; when the selected content needs to reappear, the locating information is obtained from the server, and the selected content is located in a new web page according to the locating information; when locating fails, locating can be conducted again according to the total number of times of appearance of the selected content in the web page and the sequence of the appearance times. The method for storing and locating selected content on the web page is high in adaptability and the method is accurate and stable no matter whether the method is applied to a computer or a mobile terminal.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

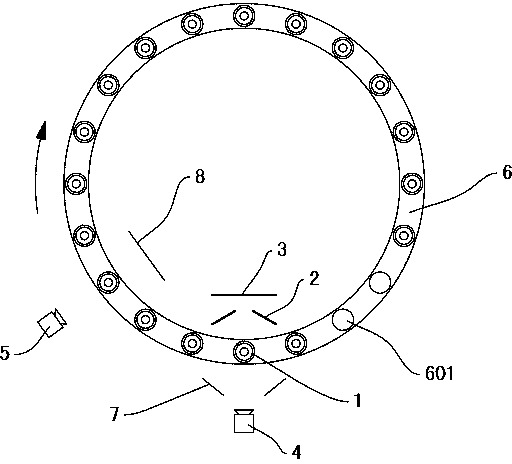

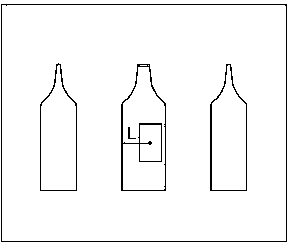

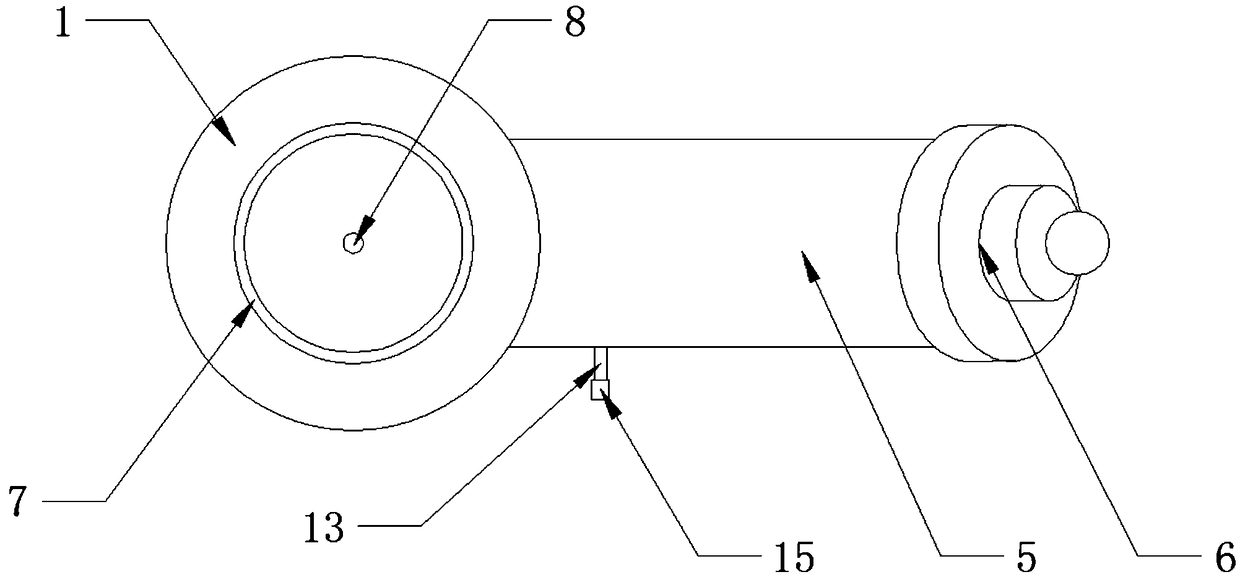

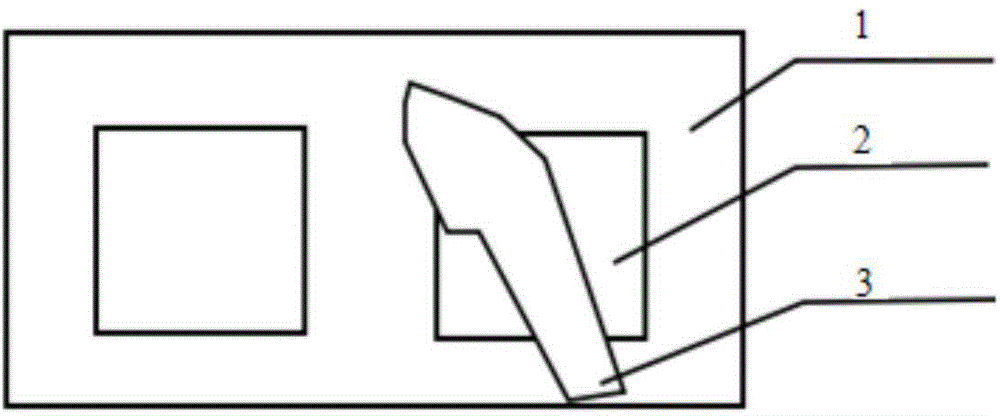

Container labeling position adjustment system and method for labeling container

InactiveCN104071403AReduce in quantityLow costLabelling machinesLabelling short rigid containersComputer visionMirror image

The invention relates to a container labeling position adjustment system and a method for labeling a container, and particularly relates to a device and a method for accurately labeling the surface of the container. Two reflective mirrors (2) are fixed on the other side of a transmission device (6), which is opposite to a first camera (4), the first camera (4) and the two reflective mirrors (2) respectively correspond to a range of 120 degrees on the circumference of the container (1), mirror images of the container (1) in the reflective mirrors (2) are positioned in an imaging range of the first camera (4), and an image of the whole surface of the container (1) can be collected by the first camera (4), so as to determine the position of a designator. The method for labeling the container comprises the following steps: calibrating the first camera (4) and a second camera (5) first, then performing coarse positioning by utilizing an image shot by the first camera (4), and finally, performing fine positioning by utilizing the second camera (5), so that one side of the designator of the container (1) and a to-be-pasted label are accurately positioned. The method has the advantages of low cost, high detection efficiency and the like.

Owner:北京创想智控科技有限公司

Grinding device capable of manually controlling grinding angle

InactiveCN106181625ADoes not affect positioningStable structureGrinding carriagesGrinding drivesHorizontal axisMechanical engineering

The invention discloses a grinding device capable of manually controlling a grinding angle. The grinding device comprises a pedestal (9) and a workpiece fixing table (92) which is supported above the pedestal (9) through stand columns (91); a workpiece holding device (93) is arranged on the lower side surface of the workpiece fixing table (92) for holding workpieces (94) on the lower side surface of the workpiece holding device (93); four inclination angle regulating devices (8) below the workpiece fixing table (92) are fixedly arranged on the upper side surface of the pedestal (9); and the four inclination angle regulating devices (8) are uniformly distributed in the circumferential direction, so that two inclination angle regulating devices are oppositely arranged in the horizontal-axis direction, and the other two inclination angle regulating devices are oppositely arranged in the longitudinal-axis direction.

Owner:郑世浦

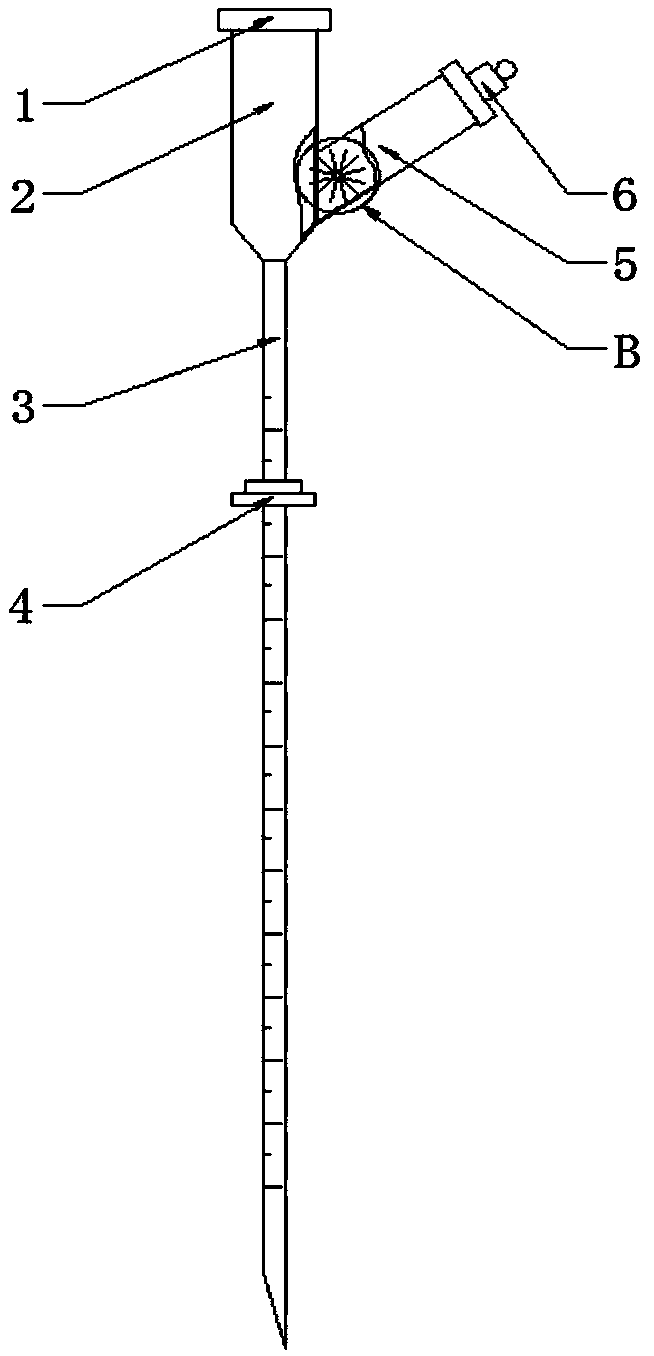

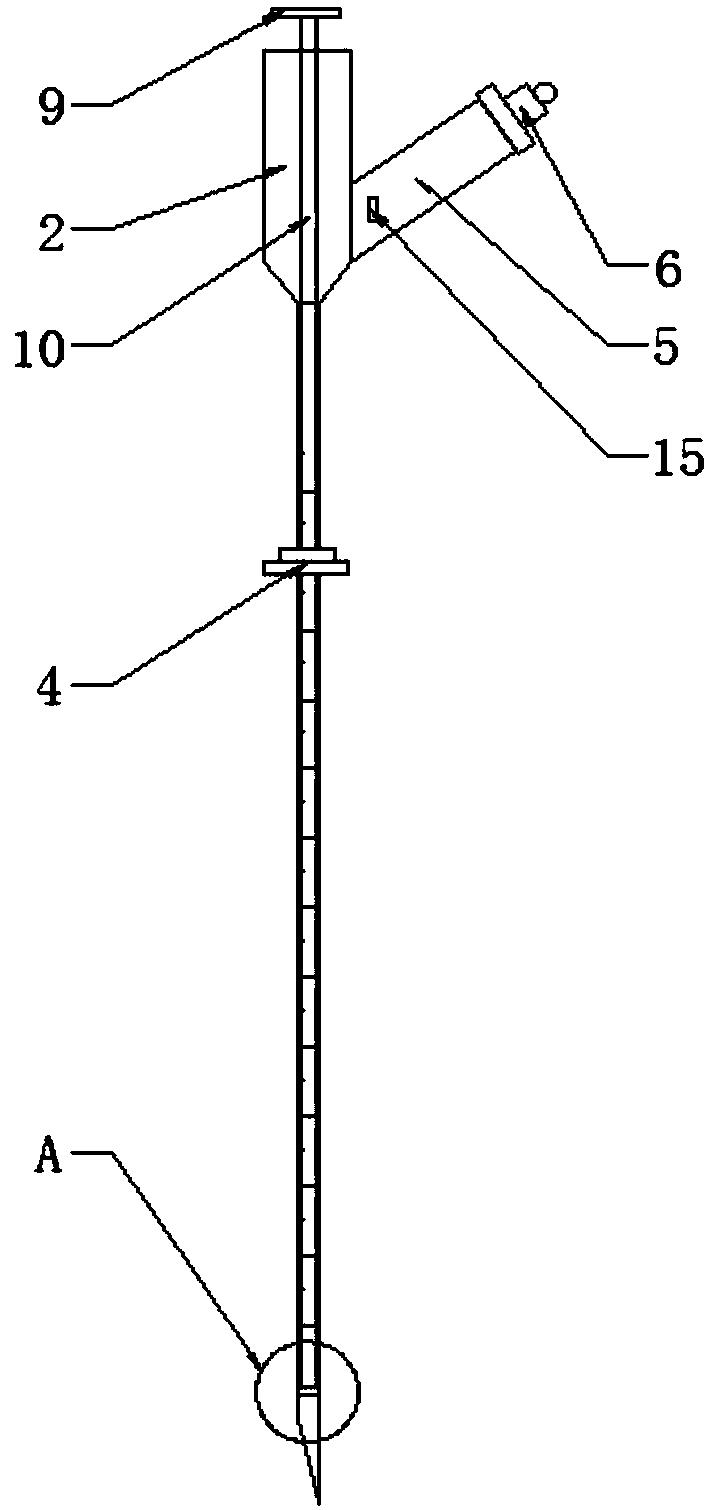

Limit device for improving axial accuracy of particle implanting needle

PendingCN109173085AHigh precisionProtect human healthX-ray/gamma-ray/particle-irradiation therapyAngular deviationBiomedical engineering

The invention belongs to the technical field of particle implantation, and discloses a limit device for improving axial accuracy of a particle implanting needle. The limit device comprises a positioning cap, a main lumen tube and a needle tube. One end of the main lumen tube is detachably connected with a positioning cap, the other end of the main lumen tube is communicate with a needle tube, andthe positioning cap is connected with a positioning assembly at one end away from the main lumen tube, and the outside of the needle tube is provided with a scale mark. As the limiting device for improving axial accuracy of a particle implanting needle sets the positioning assembly, the positioning assembly can not only detect the angular deviation of the implantation needle, but also detect the axial accuracy of the implantation needle, so as to ensure that each particle can be implanted into a predetermined area.

Owner:成都真实维度科技有限公司 +1

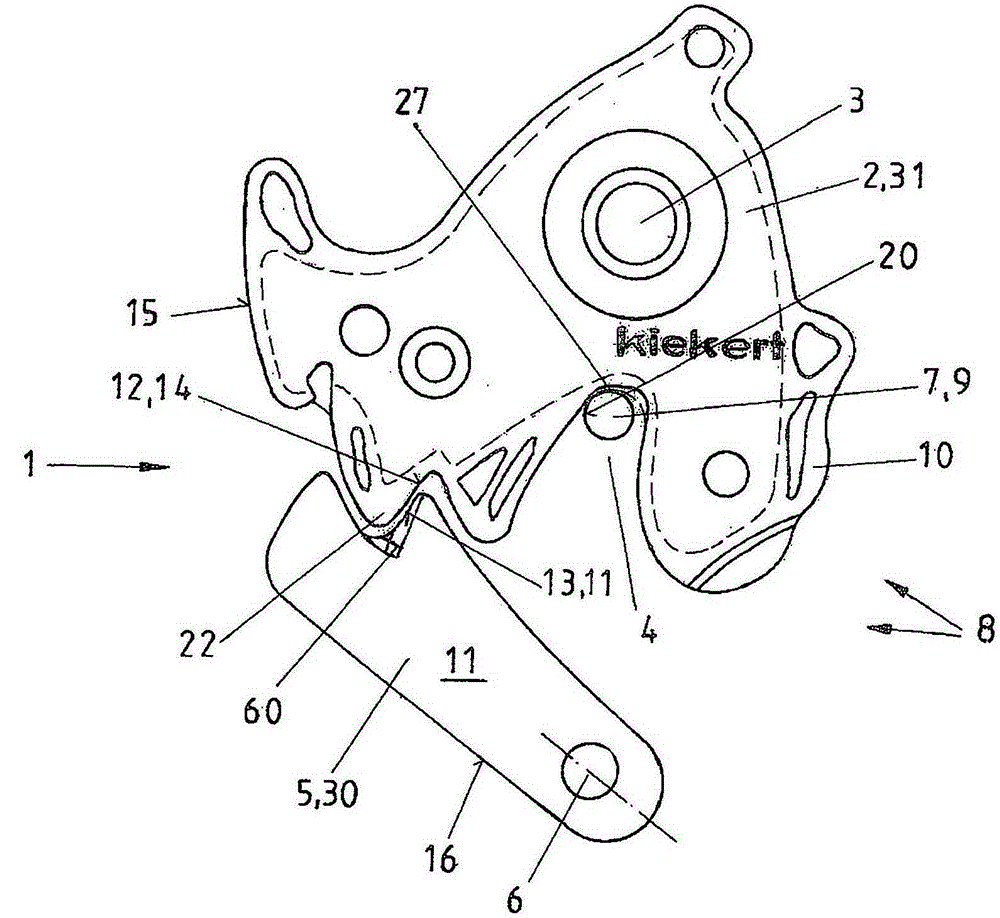

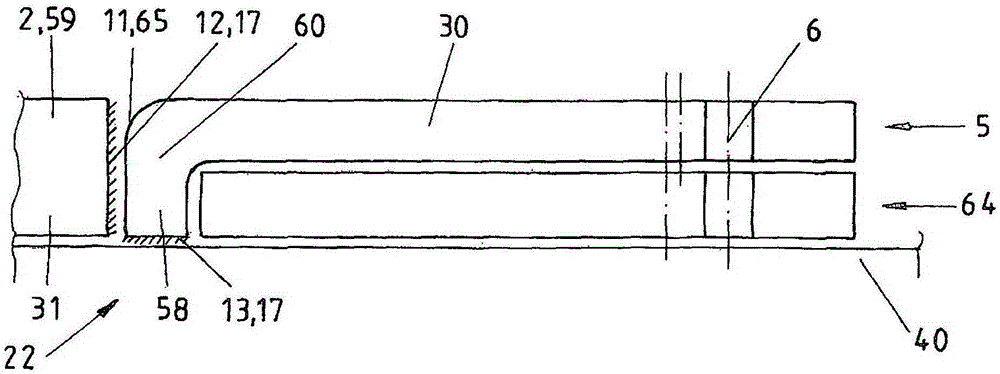

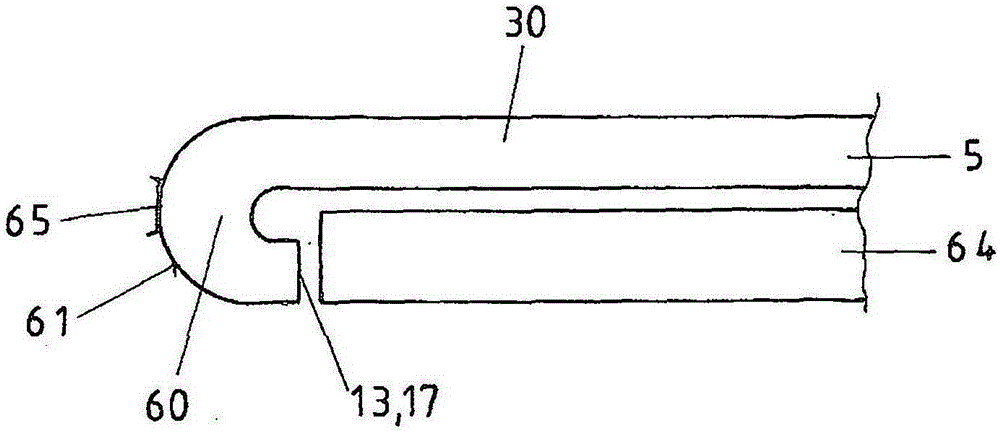

Method for producing motor vehicle door locks with a rolling surface as a locking part contour

ActiveCN105189895AThe locking surface is reducedReduce areaNoise-prevention/anti-rattling lockingMetal-working apparatusVertical edgeEngineering

The invention relates to a method for producing motor vehicle door locks with the locking parts: a rotary latch and a pawl. Said latch and the pawl are stamped from rolled sheet metal defining vertical or approximately vertical edges with corresponding latch surfaces on the rotary latch and the pawl, and subsequently are provided with a covering whilst maintaining the catch surfaces. After stamping, the locking parts are bent in the region of the main latch and / or another latch resulting in the formation a contour which is void of stamped channels, and are then inserted into the lock housing box.

Owner:KIEKERT AG

Grinding equipment with grinding angle capable of being adjusted manually

InactiveCN106181627ADoes not affect positioningStable structureGrinding carriagesGrinding drivesTransverse axisEngineering

The invention provides grinding equipment with the grinding angle capable of being adjusted manually. The grinding equipment comprises a base (9) and a workpiece fixing table (92) supported above the base (9) through stand columns (91). A workpiece retaining device (93) is arranged on the lower side face of the workpiece fixing table (92), and used for retaining a workpiece (94) onto the lower side face of the workpiece retaining device (93). Four inclination angle adjustment devices (8) below the workpiece fixing table (92) are fixedly arranged on the upper side face of the base (9), and the four inclination angle adjustment devices (8) are evenly distributed in the circumferential direction, so that two opposite inclination angle adjustment devices (8) are located in the transverse axis direction, and the other two opposite inclination angle adjustment devices (8) are located in the longitudinal axis direction.

Owner:郑世浦

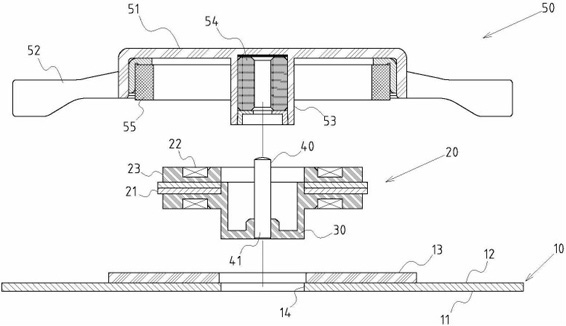

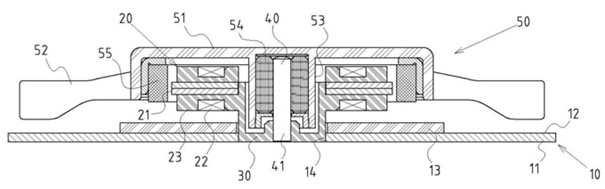

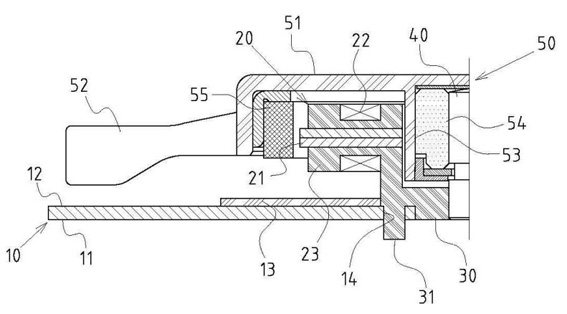

Two-way floating force-increasing clamping mechanism for high-pressure sealing

PendingCN111390789ASatisfy high sealing force requirementsDoes not affect positioningWork holdersEngineeringPiston rod

The invention provides a two-way floating force-increasing clamping mechanism for high-pressure sealing. The mechanism comprises a base, a large air cylinder located below the base, a push-pull blockconnected with the upper end of a piston rod of the large air cylinder, a positioning tooling arranged in the middle of the upper end of the base as well as a left slider press head and a right sliderpress head which are directly opposite to each other and arranged on the base in a sliding manner, a left sealing gasket and a right sealing gasket are arranged on the left side and the right side, located in the workpiece positions of the positioning tooling, of the left slider press head and the right slider press head respectively, the push-pull block is arranged in a sliding groove formed inthe lower part of the base, a left connecting rod and a right connecting rod are hinged to the middle of the push-pull block through central drive pins, the left connecting rod is hinged with the leftslider press head through a left drive pin, and the right connecting rod is hinged with the right slider press head through a right drive pin. The mechanism is compact in structure and occupies smallspace; by adoption of the force-increasing principle, a relatively large blocking force requirement of ports of a to-be-detected workpiece can be met by one air cylinder; and clamping force of the ports on two sides of the to-be-detected workpiece can be balanced adaptively, and the positioning of the workpiece cannot be affected by the clamping force.

Owner:尊道(上海)自动化设备有限公司

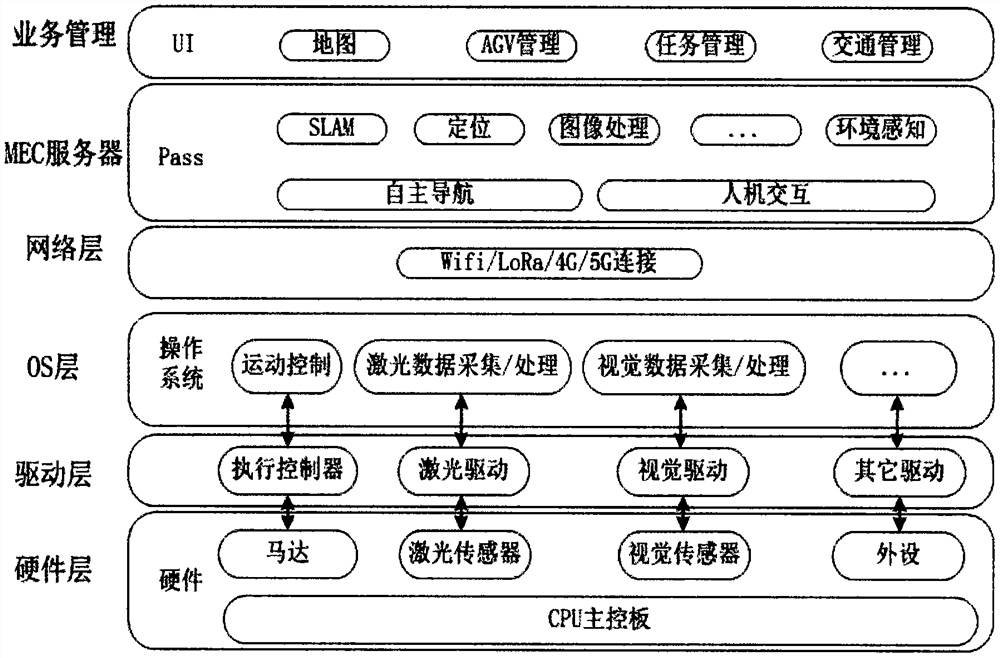

Clouded AGV application system of 5G smart factory

InactiveCN112731914AHigh degree of intelligenceIncrease production capacityNavigation instrumentsElectromagnetic wave reradiationSmart factoryEdge computing

A clouded AGV application system of a 5G smart factory is a clouded AGV application solution of the 5G smart factory, and a clouded AGV moves modules needing complex computing power requirements such as positioning, navigation, image recognition and environmental perception operated by an AGV upper computer upwards to a 5G edge computing server so as to meet the increasing computing power requirements of the AGV. Meanwhile, modules with higher requirements on real-time performance such as motion control and emergency obstacle avoidance are still retained in the AGV body to meet the requirements on safety and the like. Equivalently, a brain is added to the AGV at the cloud end, and besides original complex calculation of the AGV, expansion of various AI capacities becomes possible. A plurality of cloud AGVs can form a flexible production carrying system, and the operation route can be adjusted in time along with the adjustment of the production process flow, so that the production flexibility and the competitiveness of enterprises are greatly improved.

Owner:苏州景灏达机器人技术有限公司

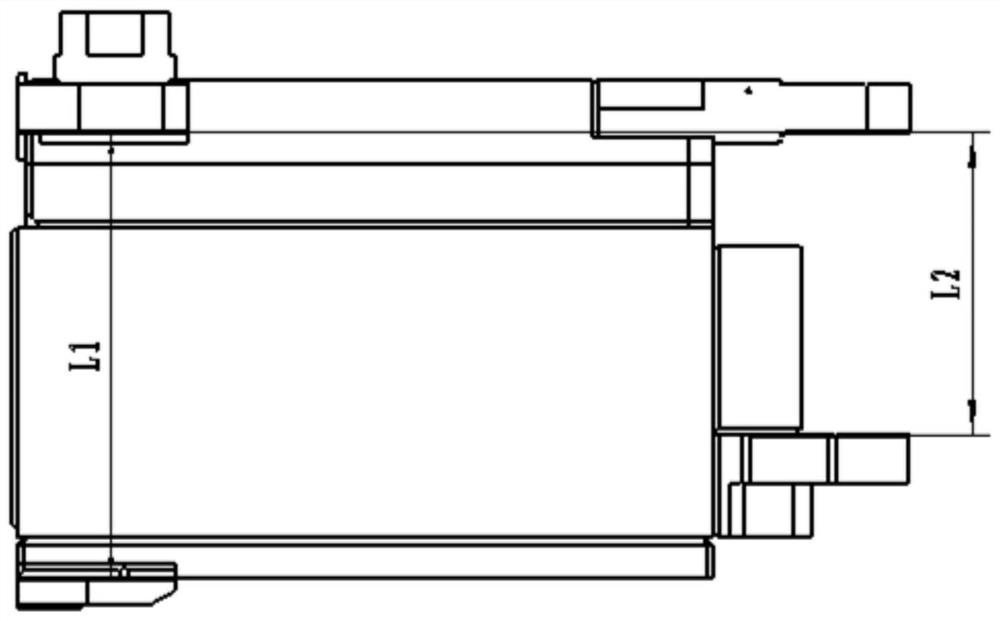

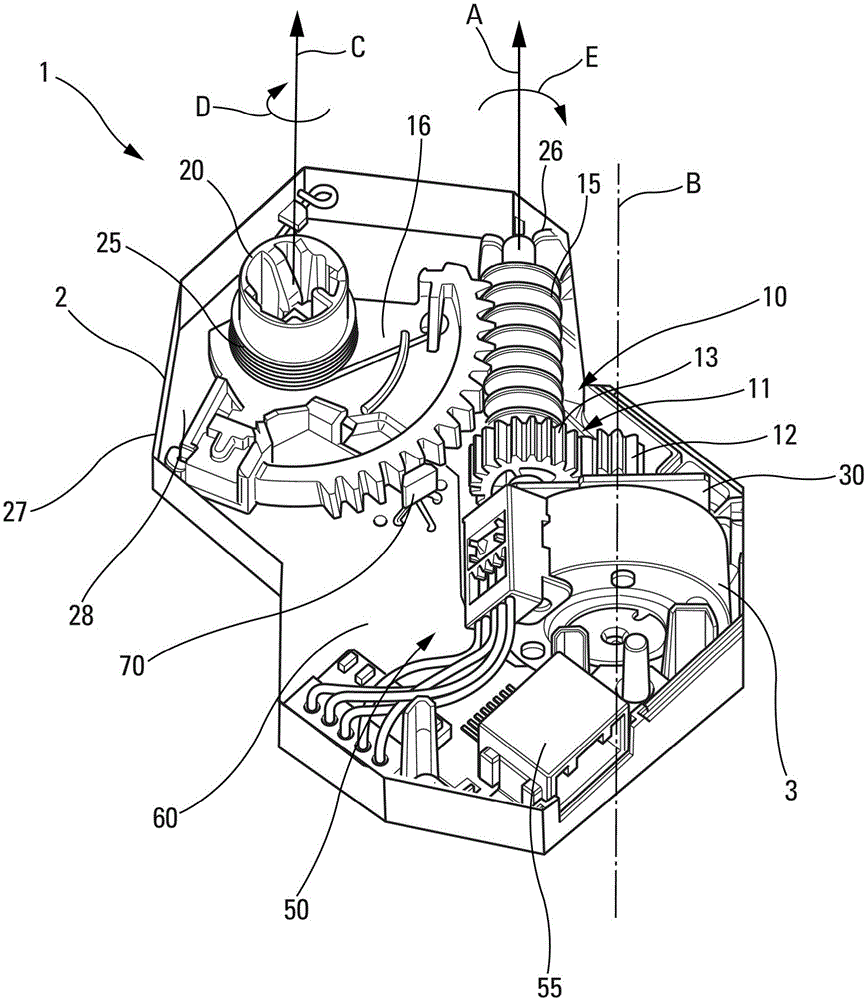

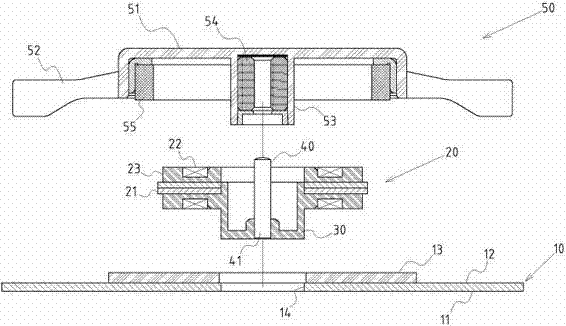

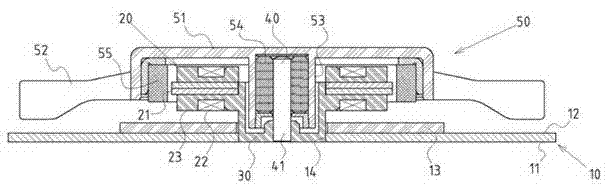

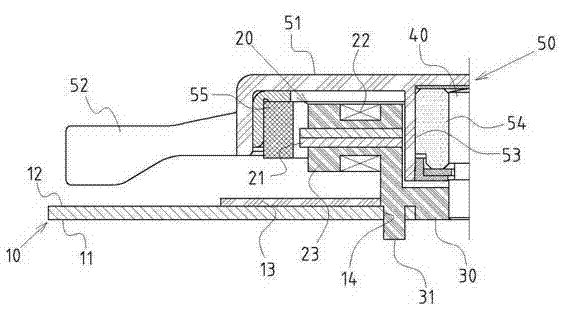

Actuator for rendering at least one optical element movable

ActiveCN105305717APrecise positioningAchieving performance levelsOptical signallingMechanical energy handlingAxial pressureEngineering

The invention relates to an electric actuator (1) to render optical elements movable. The electrical actuator generally has a motor (3), a mechanical transmission assembly (10) having an endless screw (15), a support element of the endless screw (15), a drive mechanism (20), and a return mechanism (25). The motor (3) is configured to drive the mechanical transmission assembly (10) and the mechanical transmission assembly (10) is configured to drive the drive mechanism (20), wherein the return mechanism (25) exerts an axial pressure against the endless screw (15) in such a way as to press the endless screw (15) against the support element. The disclosure also relates to an assembly having a movable optical element and an electric actuator (1) of the movable optical element as described above.

Owner:AML SYST

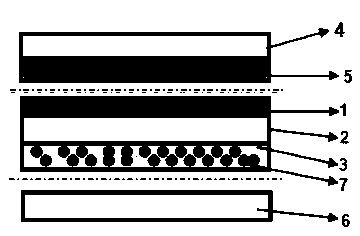

Antistatic three-layer scratch resistant protective pasting film

ActiveCN103407223AHigh transparencyImprove yieldTelephone set constructionsMetal layered productsTectorial membraneSilver particles

The invention discloses an antistatic three-layer scratch resistant protective pasting film. With a three-layer structure, the protective film includes a protective layer, a use layer and a release layer that are stacked together in order. The use layer includes a first optical PET film, a hardened coating and a first organosilicon pressure-sensitive adhesive. The first organosilicon pressure-sensitive adhesive contains 50-200nm nanoscale silver particles. According to the invention, the antistatic three-layer scratch resistant protective pasting film can be applied in protective pasting films of mobile phones. The adding of nano-silver particles into the organosilicon pressure-sensitive adhesive in the use layer ensures high transparency of the protective pasting film (greater than 90%). Meanwhile, with an antistatic function, the protective pasting film cannot absorb dust or occur self-adsorption and affect positioning during pasting, and cannot generate touch screen failure after pasting, thus being able to improve the pasting yield rate of terminal users.

Owner:YIDONG ELECTRONICS CHANGSHU

Suspension mechanical mixing device and mixer adopting same

PendingCN107560924ALow costReduce complexityPreparing sample for investigationEngineeringMixing effect

The invention relates to the technical field of liquid mixing, and particularly relates to a suspension mechanical mixing device. The device comprises an oscillation mixing device, wherein the oscillation mixing device comprises an oscillation tube for placing a mixing tube, and the inner wall of the oscillation tube is matched with the outer wall of the mixing tube. The device is characterized inthat a flexible tissue connected with an external bracket is arranged at the upper part of the oscillation tube; one or more vibration mechanism is arranged at the bottom of the inner cavity of the oscillation tube. The device can be used for quickly and effectively realizing uniform distribution of suspensions, such as a sample or reaction reagent, for a long time, and has the advantages of simple structure, low cost, good uniform mixing effect, no occurrence of pollution carrying, low failure rate and the like.

Owner:孔治

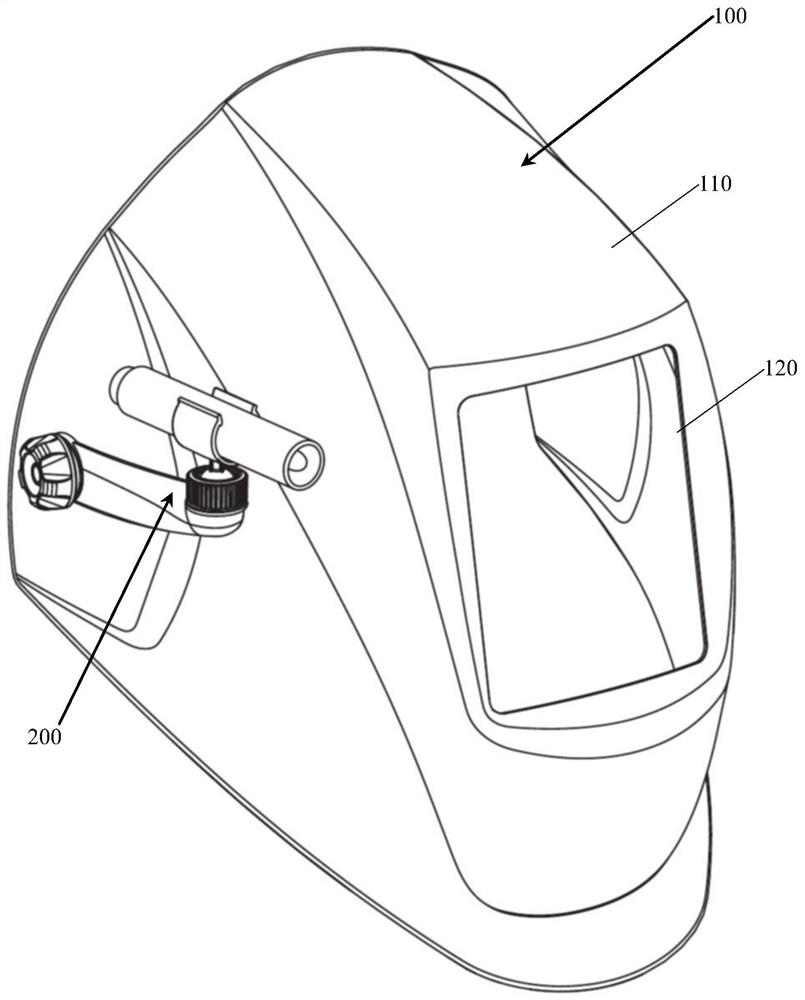

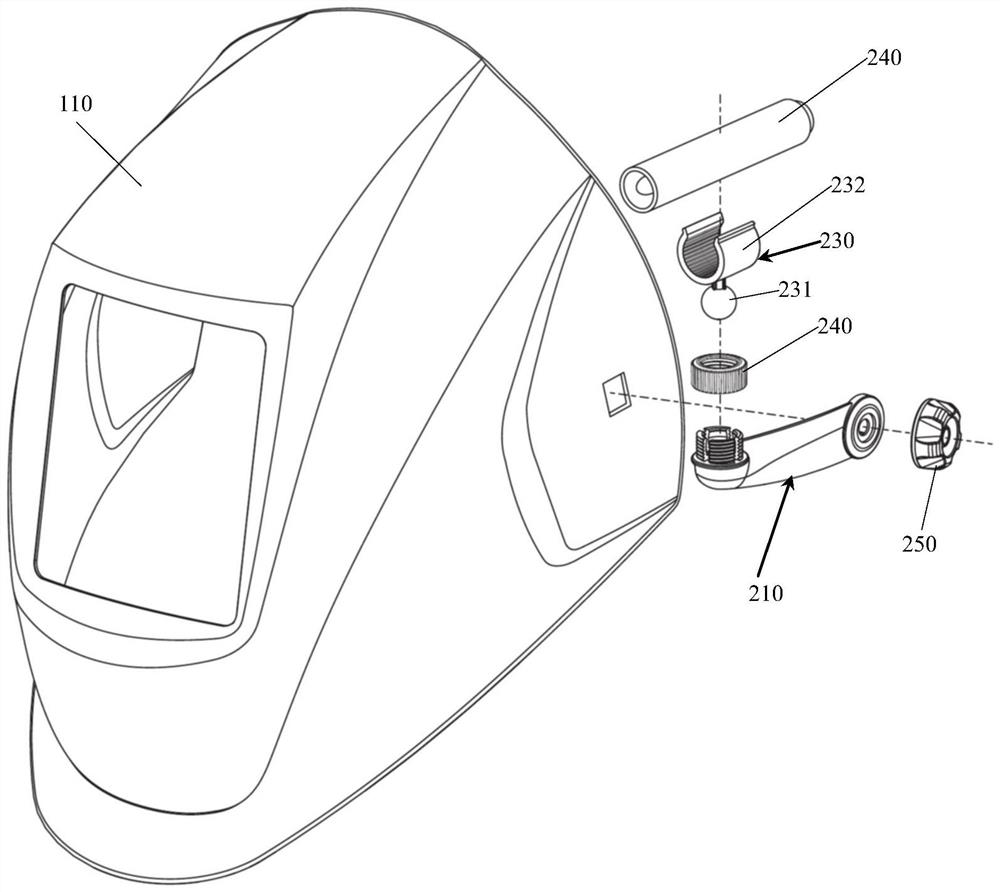

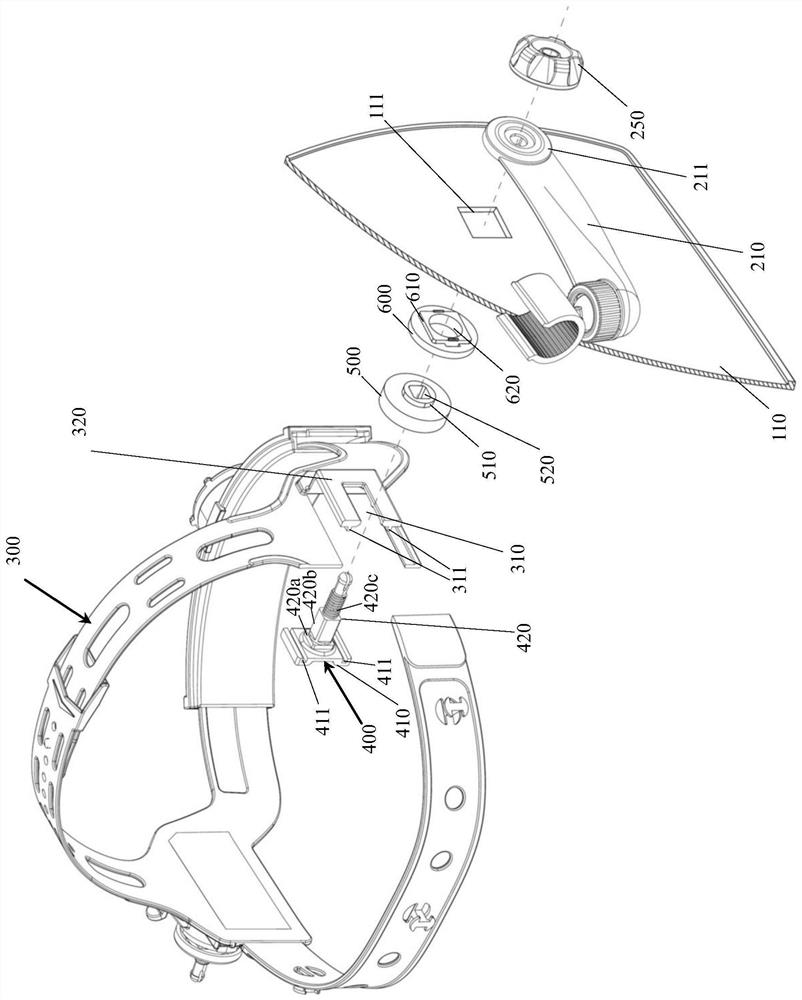

Welding mask assembly and lamp assembly thereof

PendingCN113367889AEasy to upgradeObserve stabilityLighting elementsEye-masksRotational axisEngineering

The invention discloses a welding mask assembly which comprises a head band structure (300), a welding mask (100) which is provided with a shell (110) and a lamp assembly (200) which comprises an installation part (400), a lamp holder (210) and a lamp (240) detachably installed on the lamp holder (210), the installation part (400) is installed on the head band structure (300) in a non-rotating mode, the shell (110) is connected to the installation part (400) in a rotating mode around the rotating axis limited by the installation part (400), the lamp holder (210) is detachably connected to the installation part (400) in a non-rotatable manner, and at least one part of the shell (110) is located between the head band structure (300) and the lamp holder (210) and can rotate relative to the installation part (400).

Owner:泰克曼(南京)安全防护设备有限公司

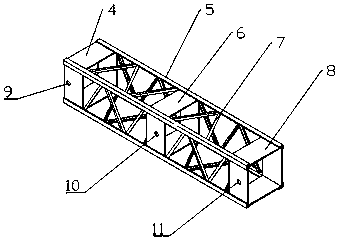

Plate enhanced telescopic truss arm structure

InactiveCN108190764AImprove stabilityImprove reliabilityCranesStructural engineeringUltimate tensile strength

The invention provides a plate enhanced telescopic truss arm structure, and relates to the field of engineering machinery. The plate enhanced telescopic truss arm structure is characterized in that plates are welded in a truss structure, so that a crane telescopic arm structure for enhancing the truss structure is formed. The plate enhanced telescopic truss arm structure can be utilized in severalsections of telescopic arms of the topmost end of an all-terrain crane and conventional combined sub arms of the all-terrain crane and a crawler crane, the plates are welded in the truss structure, the advantage that the effect of wind load on the truss structure is small is reserved, strength of the root part of the sub arm of the crane can be strengthened, the arm rising condition of the craneis improved, and the problem that the truss telescopic arm needs to be disassembled and assembled at any time and cannot quickly extend and retract is solved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Composite structure of radiator fan and molding method thereof

ActiveCN102062111BReduce fit errorDoes not affect positioningPump installationsCooling/ventilation/heating modificationsEngineeringMechanical engineering

The invention discloses a composite structure of a radiator fan and a molding method thereof. The composite structure of the radiator fan is characterized by comprising a base plate, a stator insertion seat positioning part, a stator group, a plastic combined seat part, an axle center and a rotor blade group, wherein the base plate comprises an attached surface and a stator assembly surface; the stator insertion seat positioning part is arranged in the center of the stator assembly surface; the stator group comprises silicon steel sheets, coils and a plastic insulating frame seat; the plasticcombined seat part is integrally formed on the stator group, and can be inserted, connected and matched with the stator insertion seat positioning part; the axle center is connected to the plastic combined seat part, and has a root fixedly connected to the center of the plastic combined seat part; and the rotor blade group comprises a hub, blades, a shaft sleeve, a bearing component and magnetic rings. The axle center is integrally assembled on the plastic structure of the stator group, and a composite design is adopted between the stator group and the base plate, so precise positioning between the axle shaft and the silicon steel sheets and coils of the stator group can be easily realized by the planning design of an extrusion mould. Therefore, the composite structure of the radiator fancan achieve great improvements in combination and position correction accuracy, is smoother to run and has the advantages of effectively reducing noises, along with practicability and progressiveness.

Owner:SUZHOU FORCECON ELECTRIC

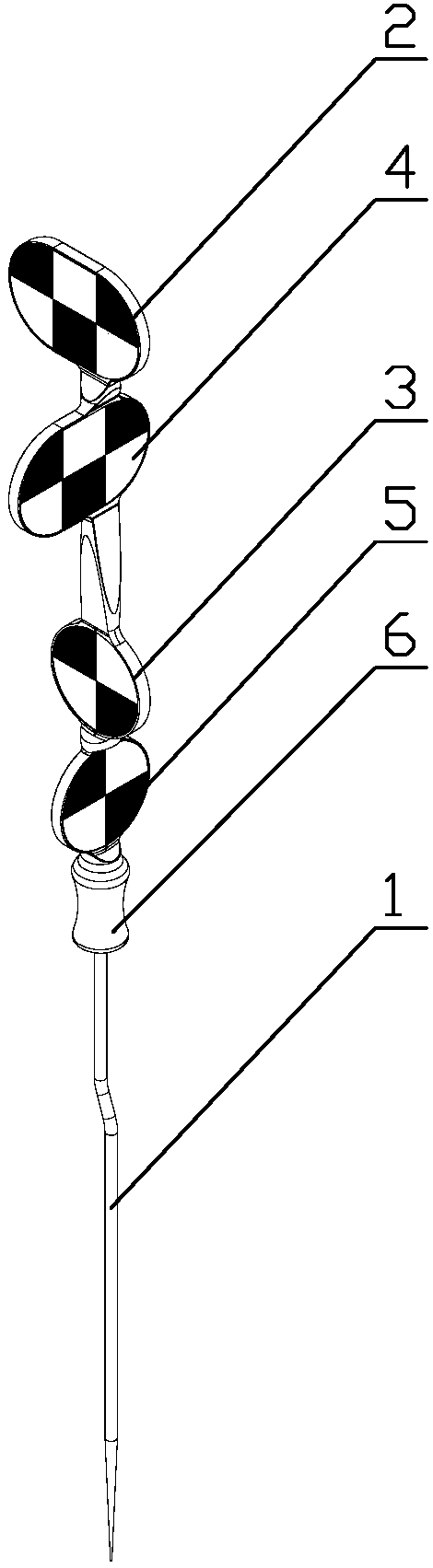

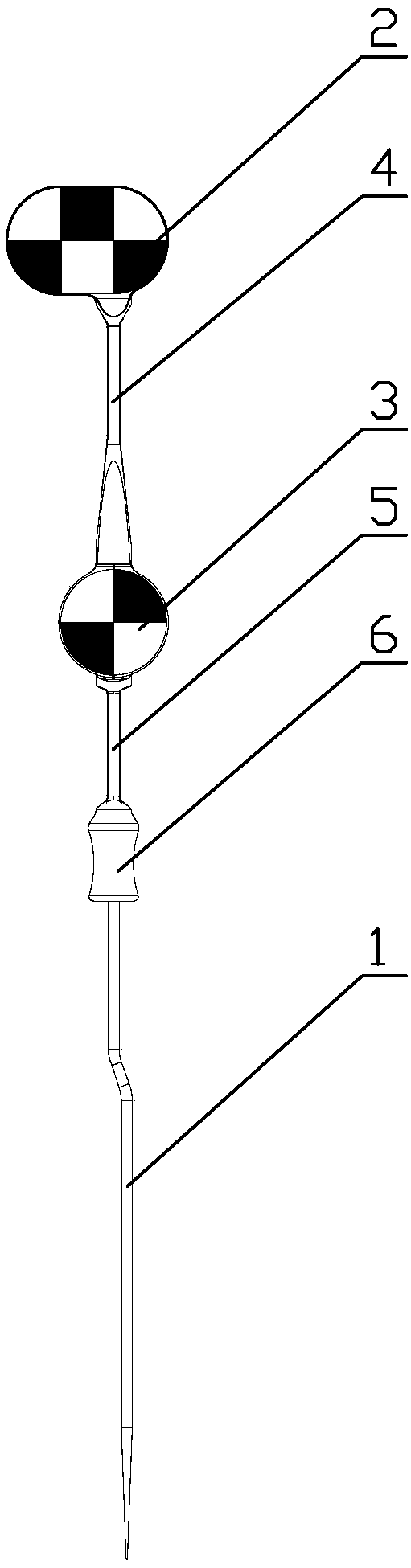

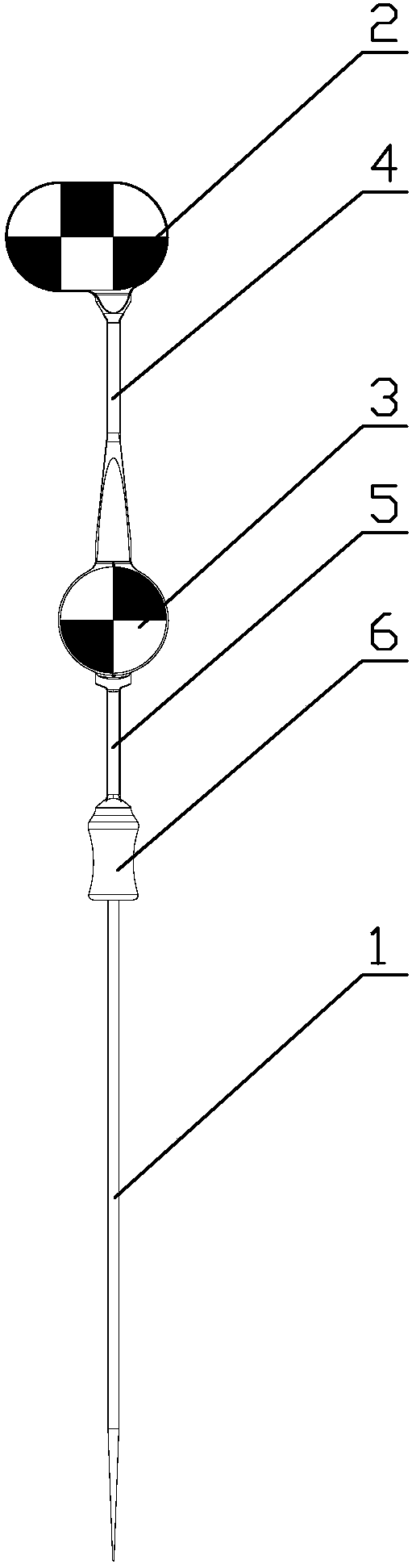

Surgical navigation probe, surgical navigation device and navigation method

InactiveCN108451655AAccurate judgmentReduce riskSurgical navigation systemsComputer-aided planning/modellingRadiologyDisplay device

The invention relates to a surgical navigation probe, comprising a shank and a positioning component connected to the same. The positioning component includes an upper positioning block and a second positioning block on a same plane; the surface of each of the upper and lower positioning blocks is provided with a positioning grid in mesh form; the adjacent positioning grids have great color differences of filling colors; intersections of the four adjacent positioning grids; the upper positioning block is provided with two positioning points; the lower positioning block is provided with a positioning point; the two positioning points of the upper positioning block and one positioning point of the lower positioning block form a main positioning face. The invention also provides a surgical navigation device, comprising two high-definition cameras, a processor and a display. Accurate navigation can be provided, accurate judgment can be ensured for a disease part, and incision area is decreased.

Owner:GUANGZHOU QIANMU ELECTRONICS CO LTD

Method for removing welding spots

InactiveCN104465421AAvoid damageRealize secondary useSolid-state devicesSoldering apparatusMetalIndustrial engineering

The invention discloses a method for removing welding spots. The method comprises the steps that firstly, a metal line connected to a welding pad through the welding spots is removed; secondly, a chip with the metal line removed is fixed to a sample platform of a probe station; thirdly, the probe tip of a probe is used for pushing the root of the welding spots so as to disengage the welding spots from the welding pad completely; lastly, the disengaged welding spots are removed from the chip. According to the method, a manual grinding method is not adopted, the welding pad and a to-be-analyzed structure cannot be abraded, physical positioning and following analyzing are not affected, and the success rate of manufactured samples is increased; the welding spots are removed through the probe, the chip cannot be contaminated, the operation process is safe and simple, and the sample manufacturing time is shortened; the old probe in the sample platform of the probe station serves as a tool, cost is hardly produced, and secondary using of the waste resource is achieved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com