Auxiliary welding equipment for box type steel component and machining process of auxiliary welding equipment

A technology of auxiliary equipment and section steel, applied in welding/cutting auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems of low processing efficiency, difficult to guarantee product quality, easy to produce deviation, etc., to improve processing efficiency and improve position accuracy. degree, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

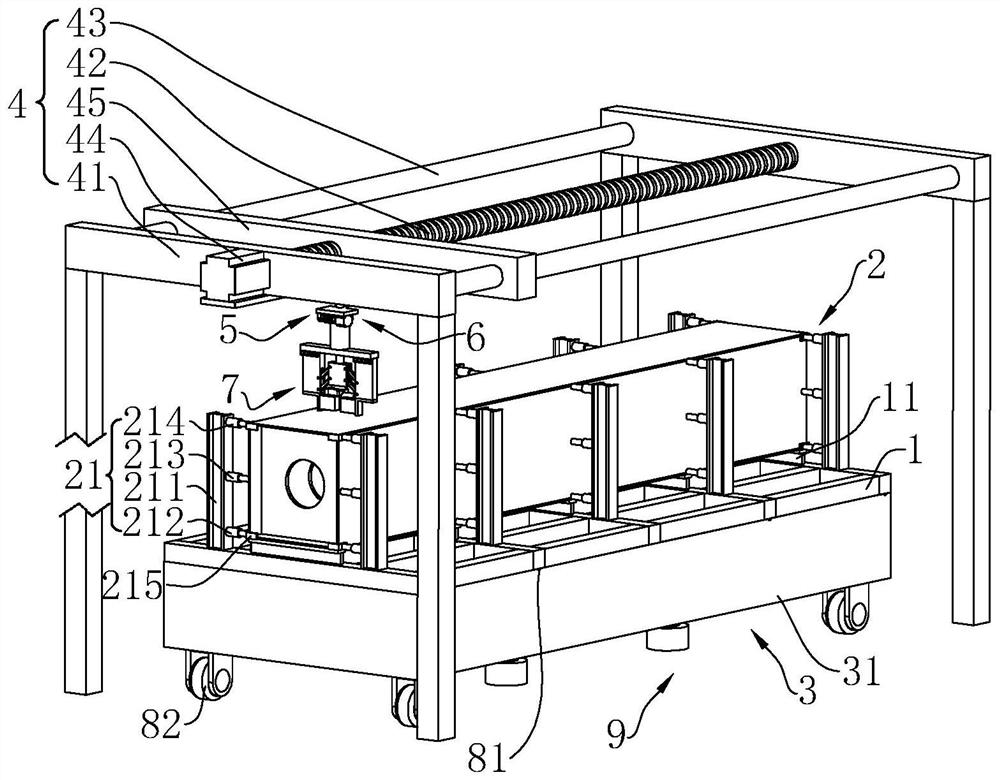

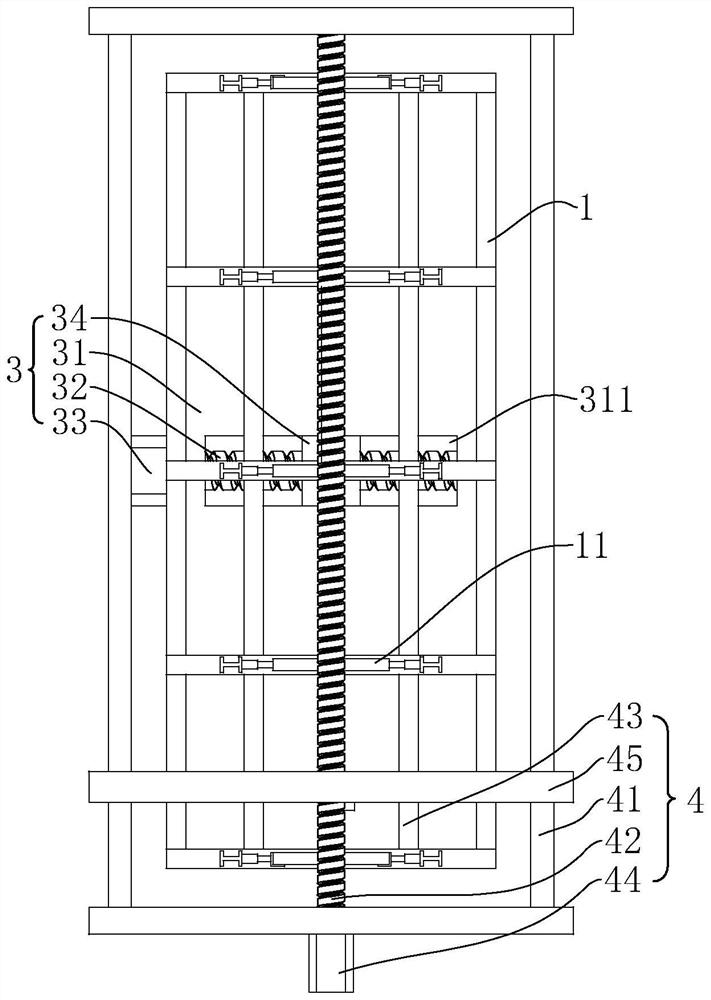

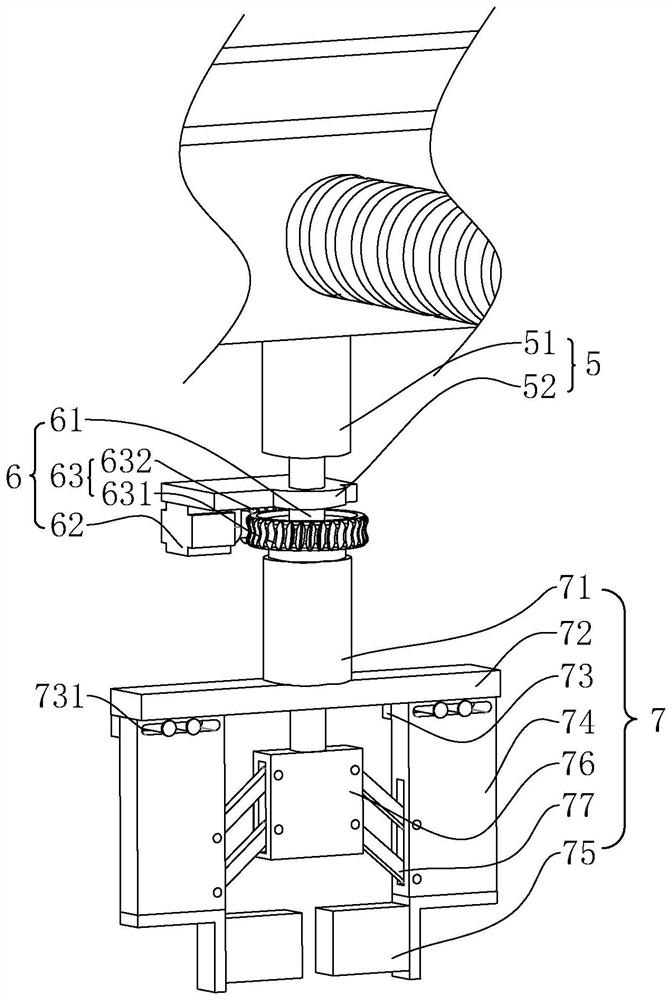

[0068] A welding auxiliary equipment for box-shaped steel members, referring to figure 1 , including a tire frame 1, a main body positioning device, a welding support device and a control system. The main body positioning device is arranged on the tire frame 1, and the main body positioning device is used for positioning the bottom plate and the top plate. The welding support device temporarily fixes the partition and side plates during welding. The control system is used to control the main body positioning device and the welding support device. The control system is a programmable logic controller.

[0069] The tire frame 1 is a rectangular frame, and the top of the tire frame 1 is fixedly connected with a plurality of support plates 11 at intervals along its length direction. Width, when the box-shaped steel member is welded, the bottom plate is first placed on a plurality of support plates 11 .

[0070] The main body positioning device includes two sets of positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com