Two-way floating force-increasing clamping mechanism for high-pressure sealing

A clamping mechanism and high-pressure sealing technology, used in workpiece clamping devices, manufacturing tools, etc., can solve the problems of large space occupation, large air consumption, influence, etc., and achieve the effect of compact structure and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

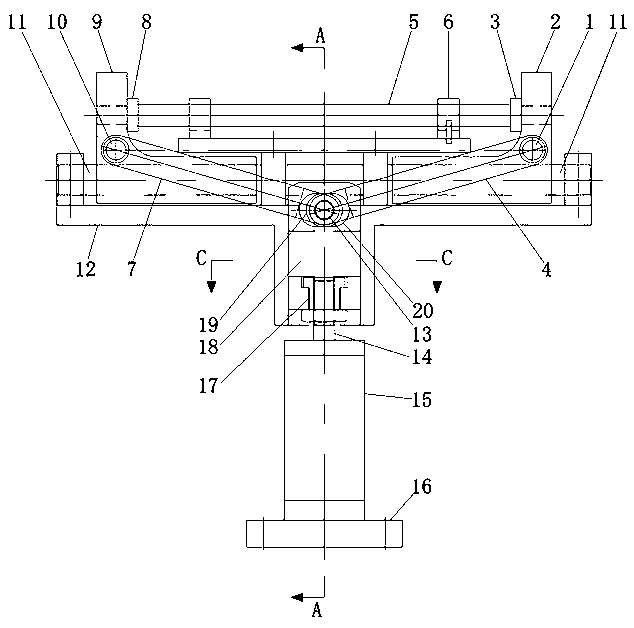

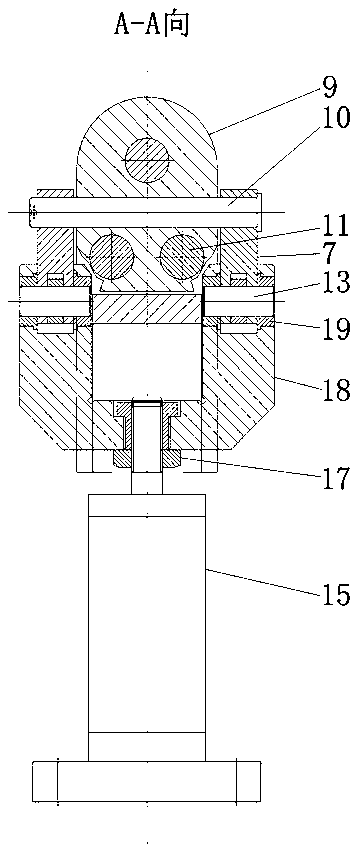

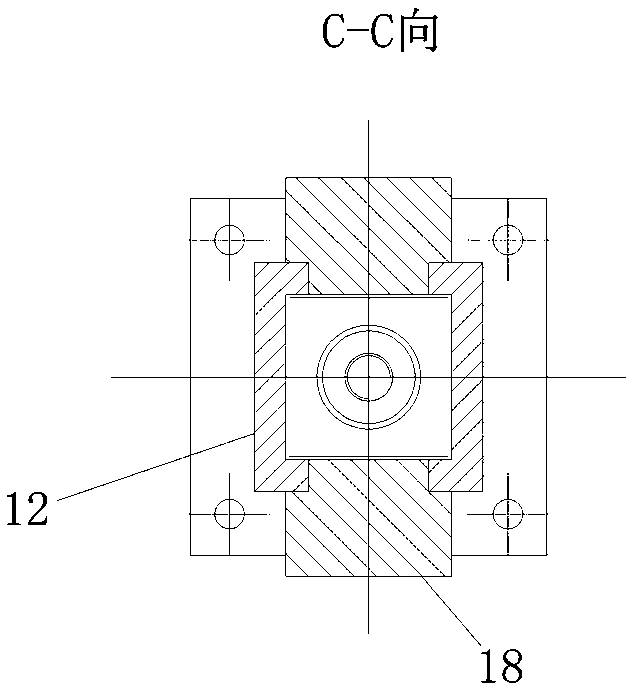

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] Such as Figure 1-5 As shown, a bidirectional floating booster clamping mechanism for high pressure sealing includes a base 12, a large cylinder 15 located below the base 12, a push-pull block 18 connected to the upper end of the piston rod 14 of the large cylinder 15, and a push-pull block 18 arranged on the base 12. The positioning tool 6 in the middle of the upper end and the left slider indenter 9 and the right slider indenter 2 that are slidably arranged on the base 12 facing each other, the left slider indenter 9 and the right slider indenter 2 are located on the positioning tool 6 The left and right sealing pads 8 and 3 are respectively arranged on the left and right sides of the workpiece position, and the push-pull block 18 is arranged in the chute at the bottom of the base 12, and the middle part of the push-pull block 18 is hinged with the left conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com