Deformable outer cone drum-shaped gapless spline structure

A gapless, involute external spline technology, applied to elastic couplings, mechanical equipment, couplings, etc., can solve problems such as inability to quickly replace, difficulty in ensuring coaxiality, and angle measurement errors of reducers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

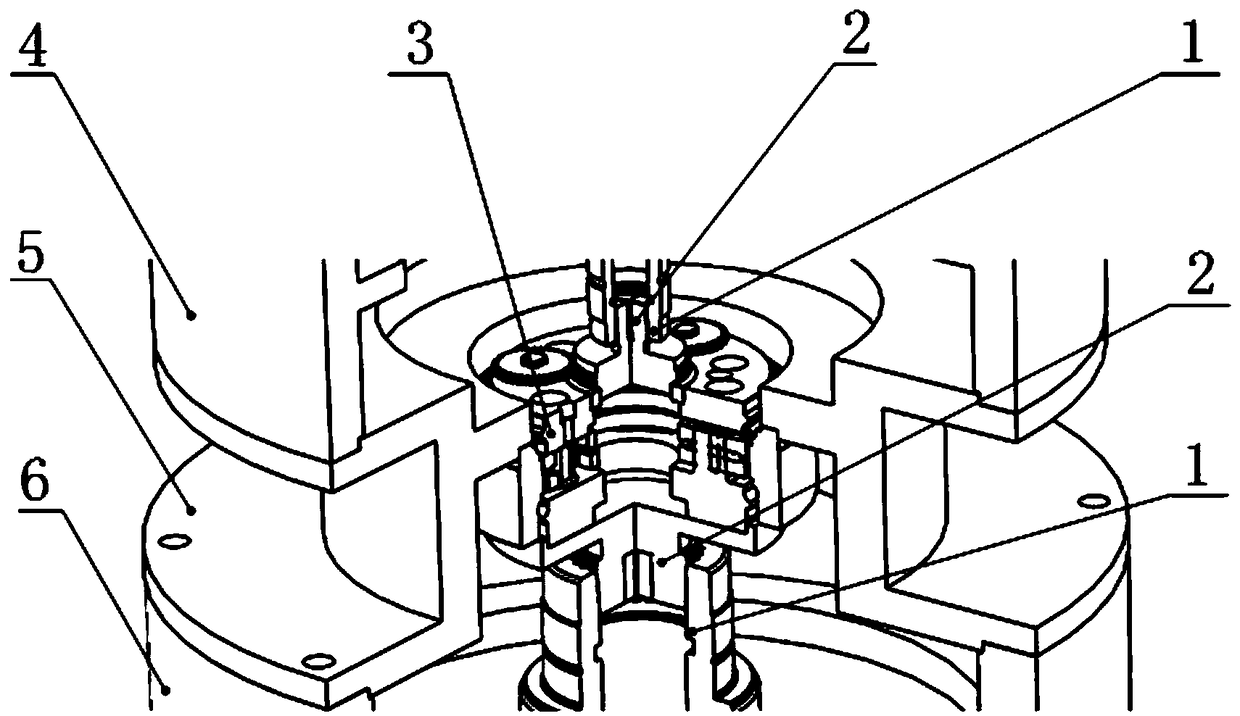

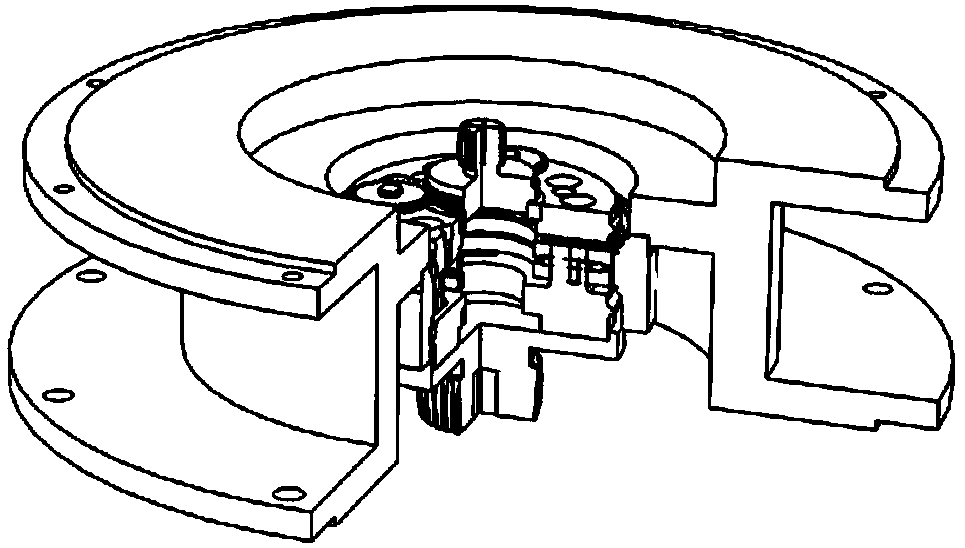

[0016] as attached Figure 1 to Figure 4 As shown, a deformable outer cone drum-shaped gapless spline structure is applied to the connection between the input shaft of the tested reducer 3 and the high-speed end transmission shaft of the reducer tester, and the connection between the output shaft of the tested reducer 3 and the reducer. The connection of the drive shaft at the low speed end of the instrument detector. The adapter 5 connected to the fixed casing of the tested reducer 3 is pressed against the cylinder body 4 at the high-speed end and the cylinder body 6 at the low-speed end through the positioning of the seams.

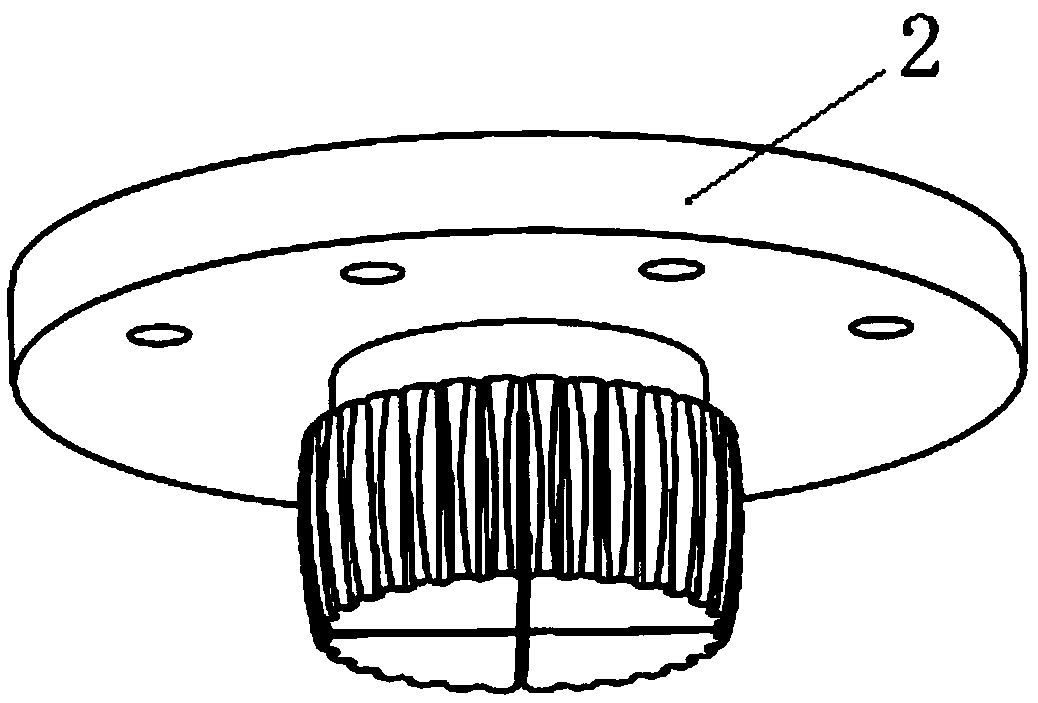

[0017] The deformable outer cone drum-shaped gapless spline structure of the present invention includes a connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com