Container labeling position adjustment system and method for labeling container

A technology for adjusting systems and containers, applied to labeling, labeling machines, rigid containers with short markings, etc., can solve the problems of large detection time, reduced detection efficiency, and increased costs, achieving low cost, improved detection efficiency, and reduced Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

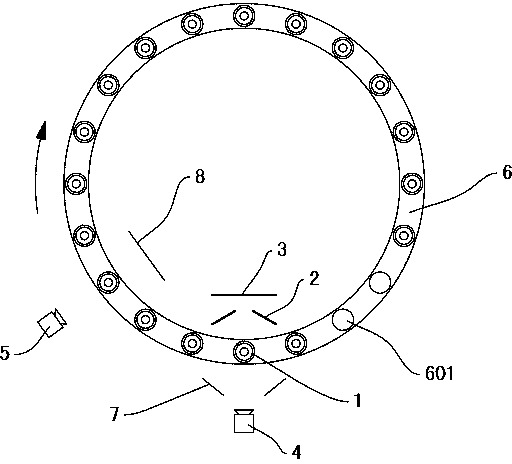

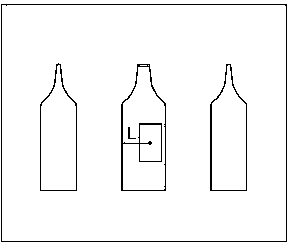

[0034] refer to figure 1 , the container labeling position adjustment system includes a transmission device 6, a container 1, a first camera 4, a second camera 5, a reflector 2 and a backlight board, the transmission device 6 is arranged in an arc shape, and the transmission device 6 is evenly spaced. a pallet 601, and place a container 1 vertically on each pallet 601. Take the container 1 as a beer bottle as an example, an identifier (not shown in the figure) is provided on the surface of the container 1, and the label should be pasted directly below the identifier. , the first camera 4 and the second camera 5 are arranged at intervals along the transmission direction of the transmission device 6, the first camera 4 and the second camera 5 are all fixed on the outside of the transmission device 6, and there are two mirrors 2, both of which are fixed on the transmission device 6, the two reflective mirrors 2 and the first camera 4 respectively correspond to the 120° range of t...

Embodiment 2

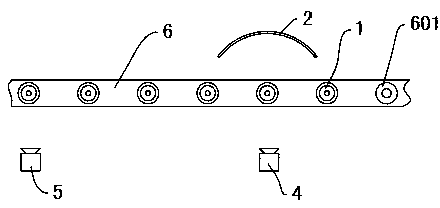

[0050] refer to image 3 , the container labeling position adjustment system includes a transmission device 6, a container 1, a first camera 4, a second camera 5 and a mirror 2, the transmission device 6 transmits the container 1 in a straight line, and the first camera 4 and the second camera 5 are separated by three A pallet 601, two reflective mirrors 2 are arc mirrors coaxial with the container 1, the two reflective mirrors 2 and the first camera 4 respectively correspond to the range of 120° of the circumference of the container 1, and the arc mirrors can effectively reduce the mirror image of the container 1 deformation to improve positioning accuracy. The two reflectors 2 can be connected to each other, which can prevent the first camera 4 from capturing the scene behind the reflector 2, which facilitates image processing and improves positioning accuracy. Other structures are with embodiment 1.

[0051] The rough positioning method described in step 3 in embodiment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com