Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

145results about How to "Constant load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

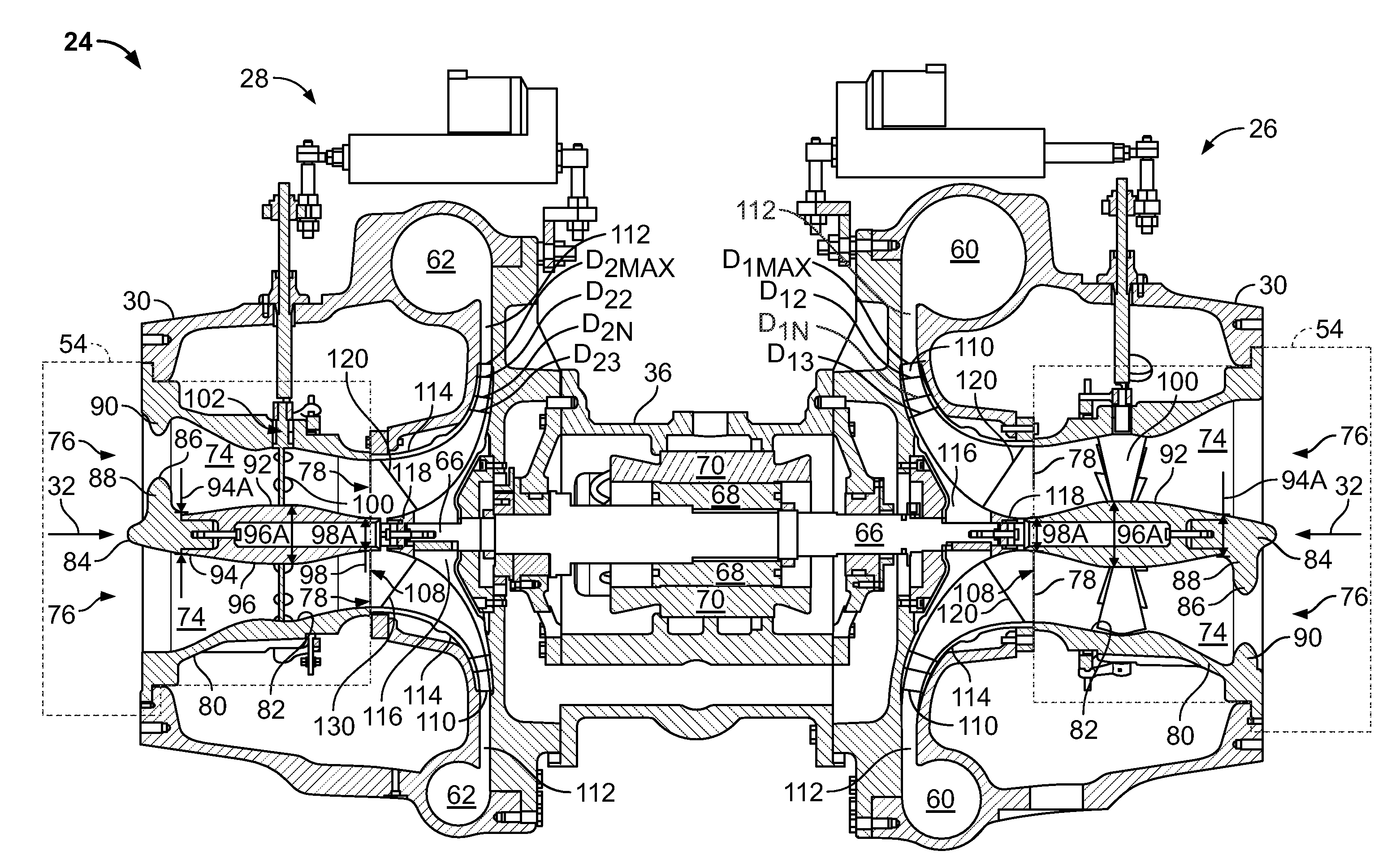

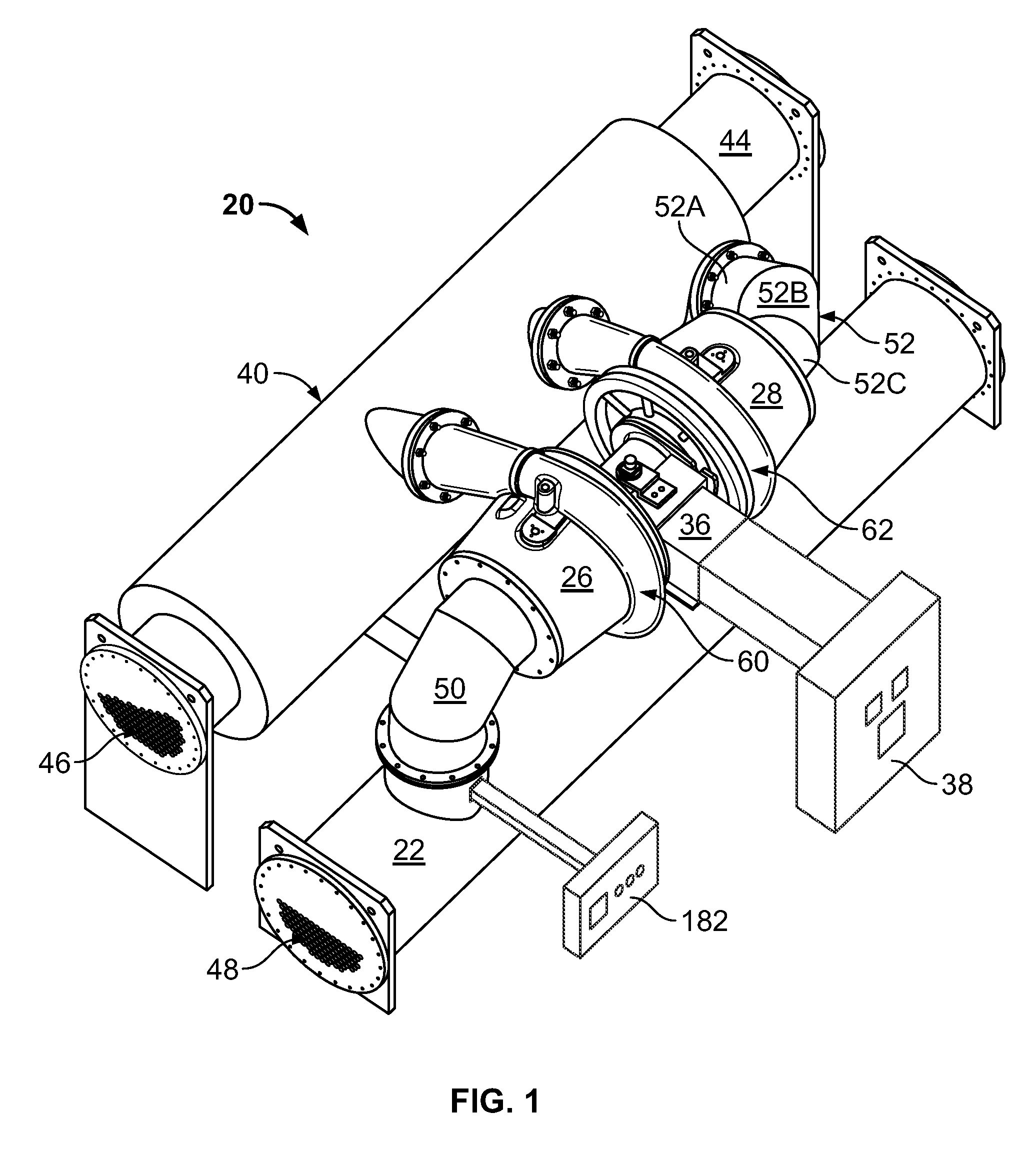

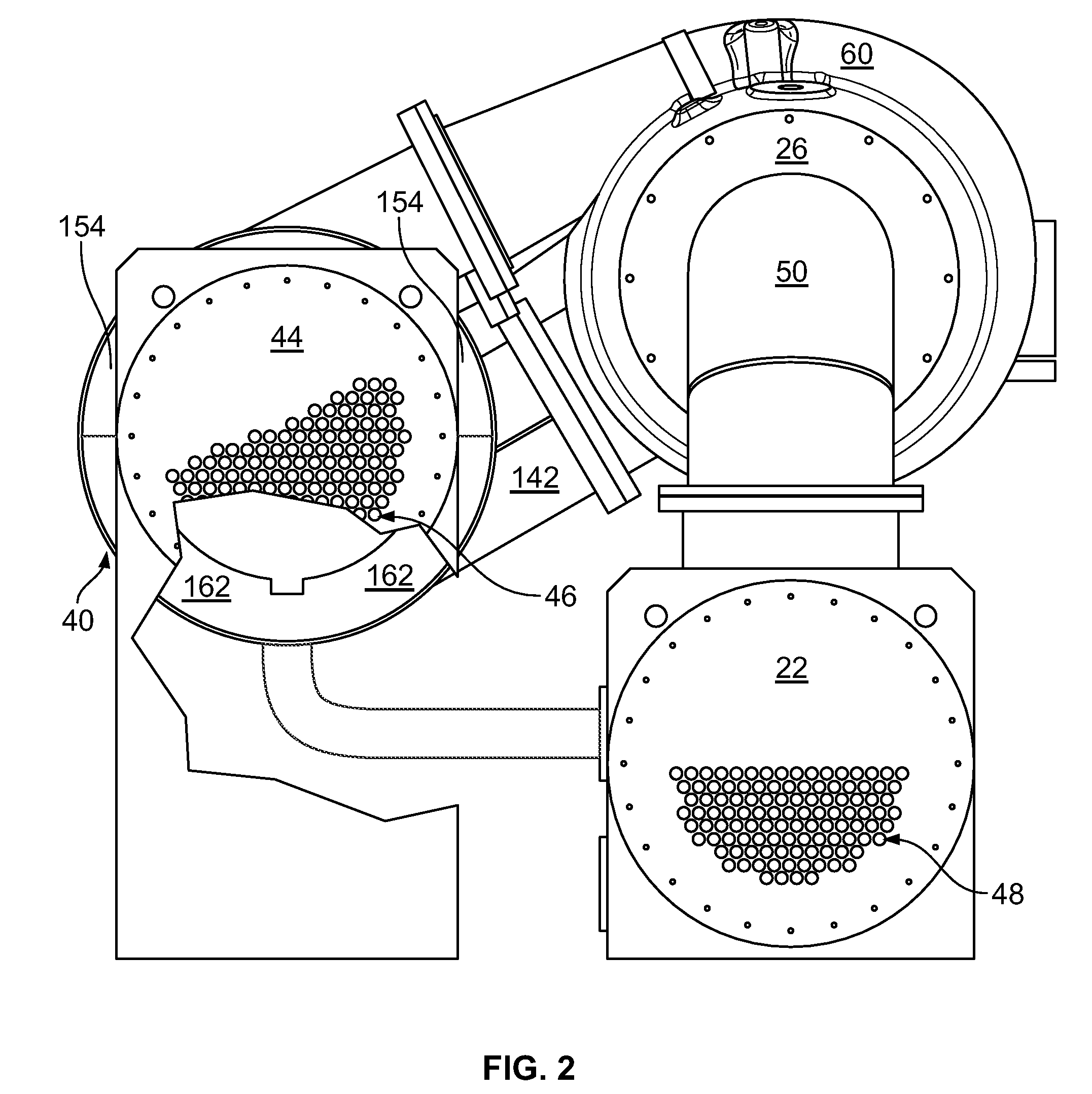

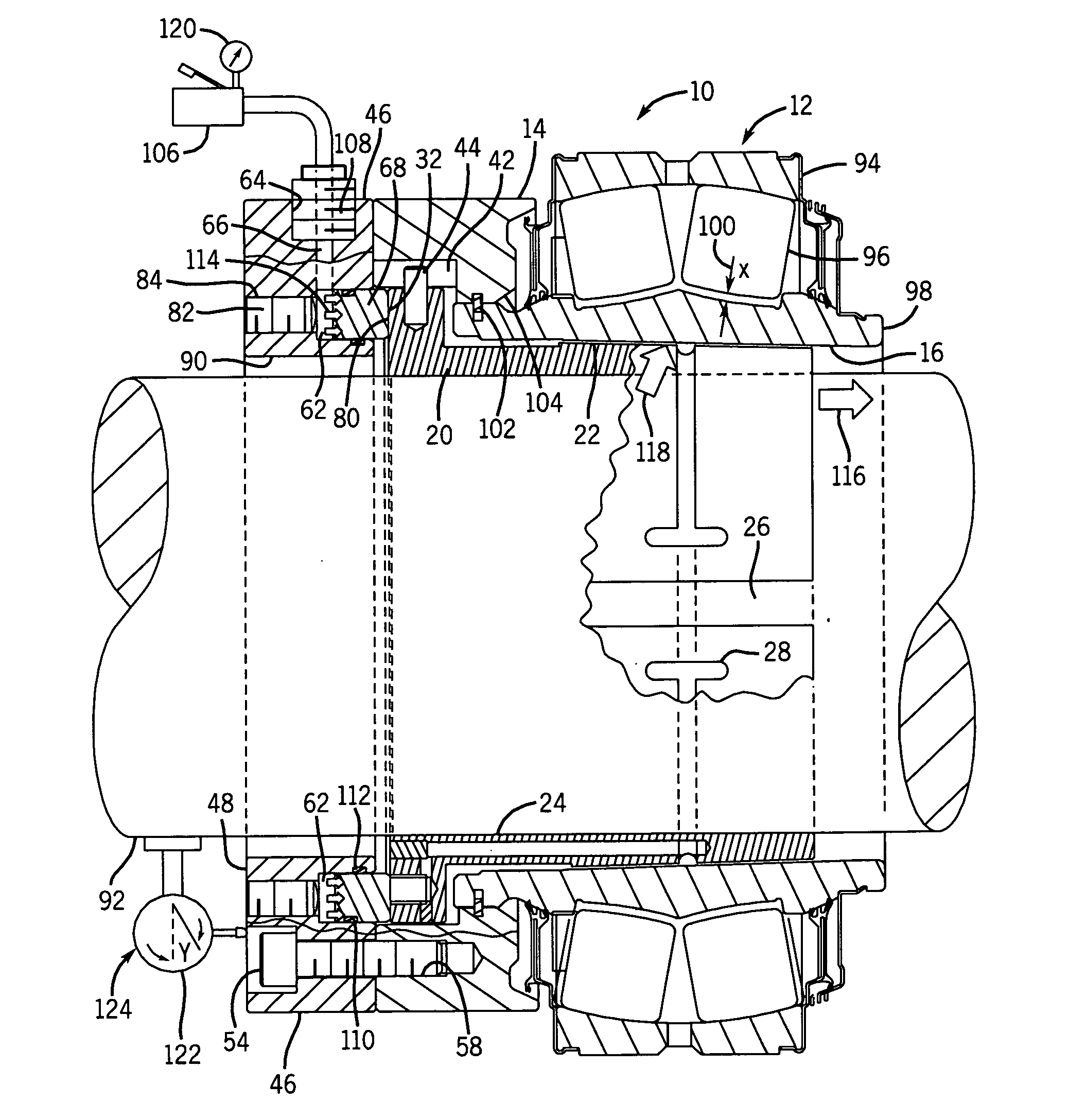

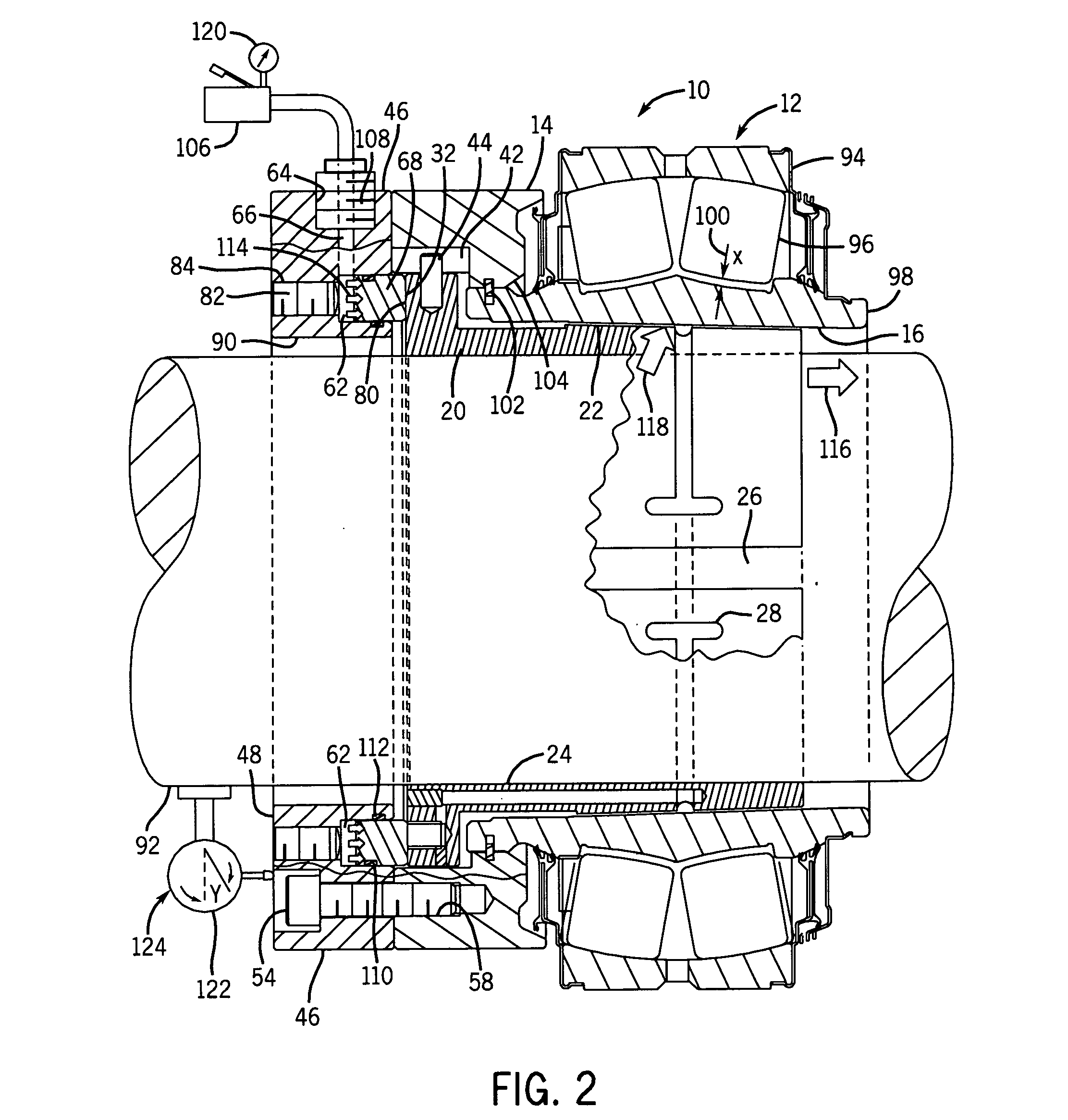

Centrifugal compressor assembly and method

ActiveUS20090205360A1High energy densityImprove performancePump componentsRotary non-positive displacement pumpsConstant angleHigh energy

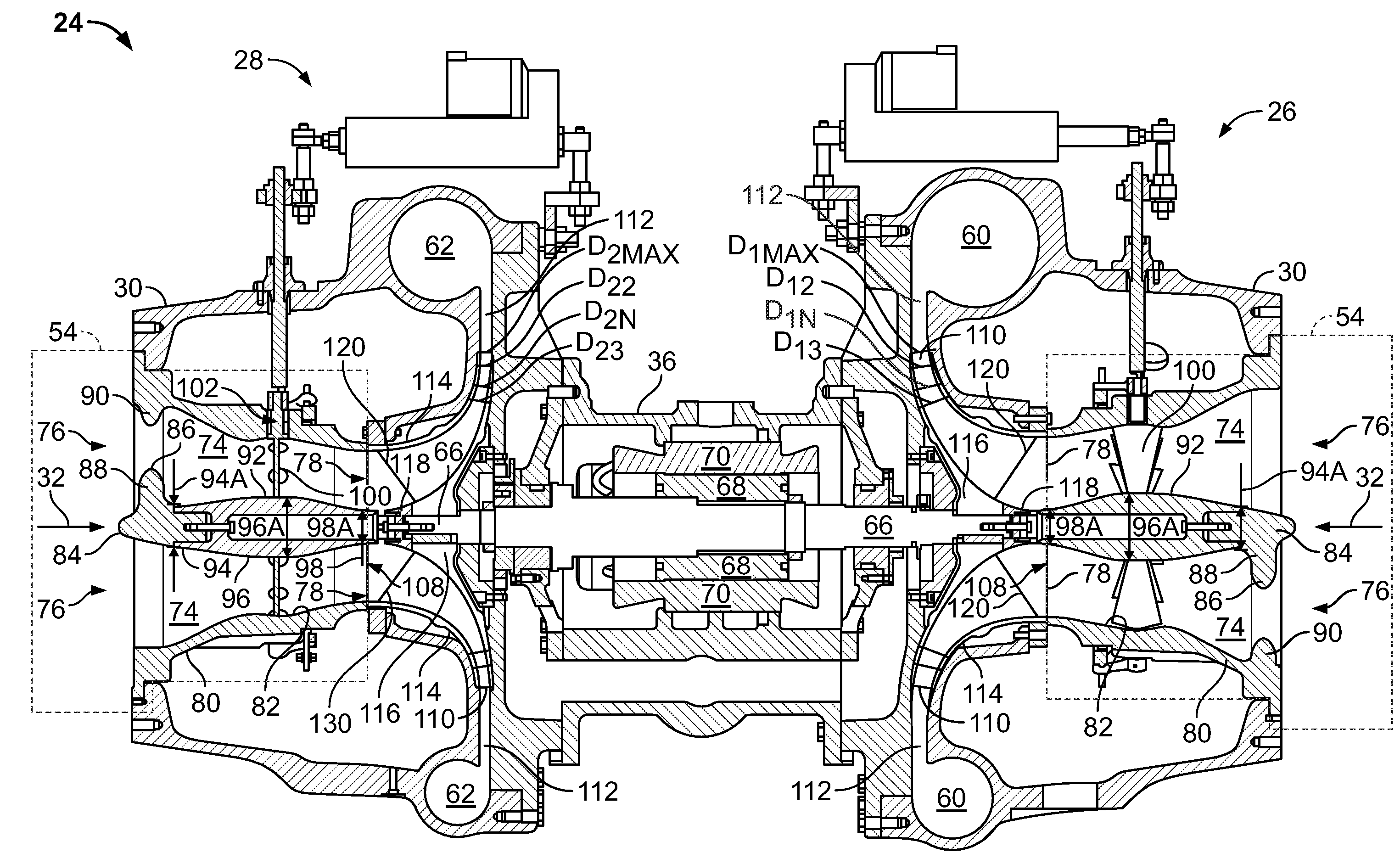

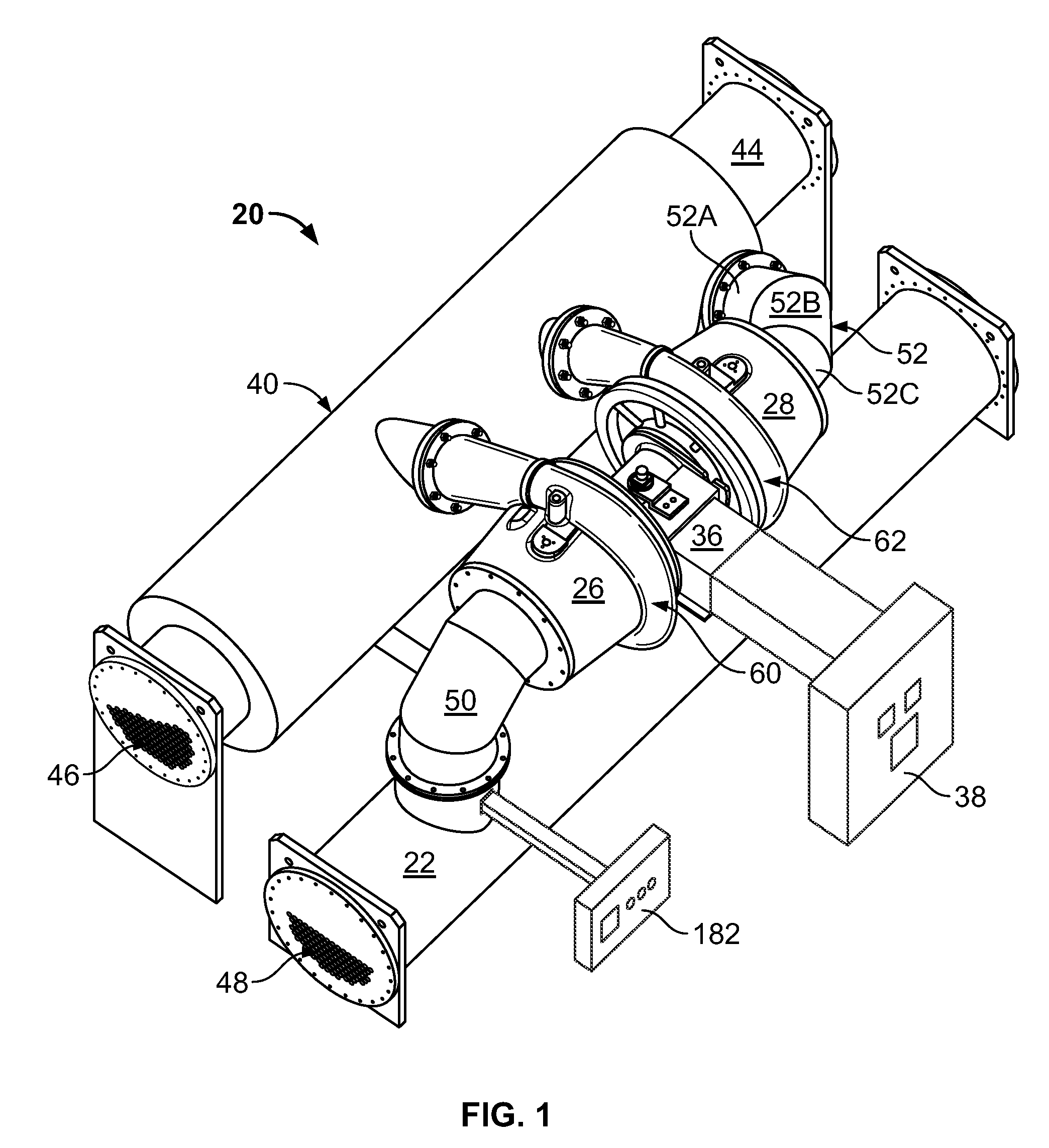

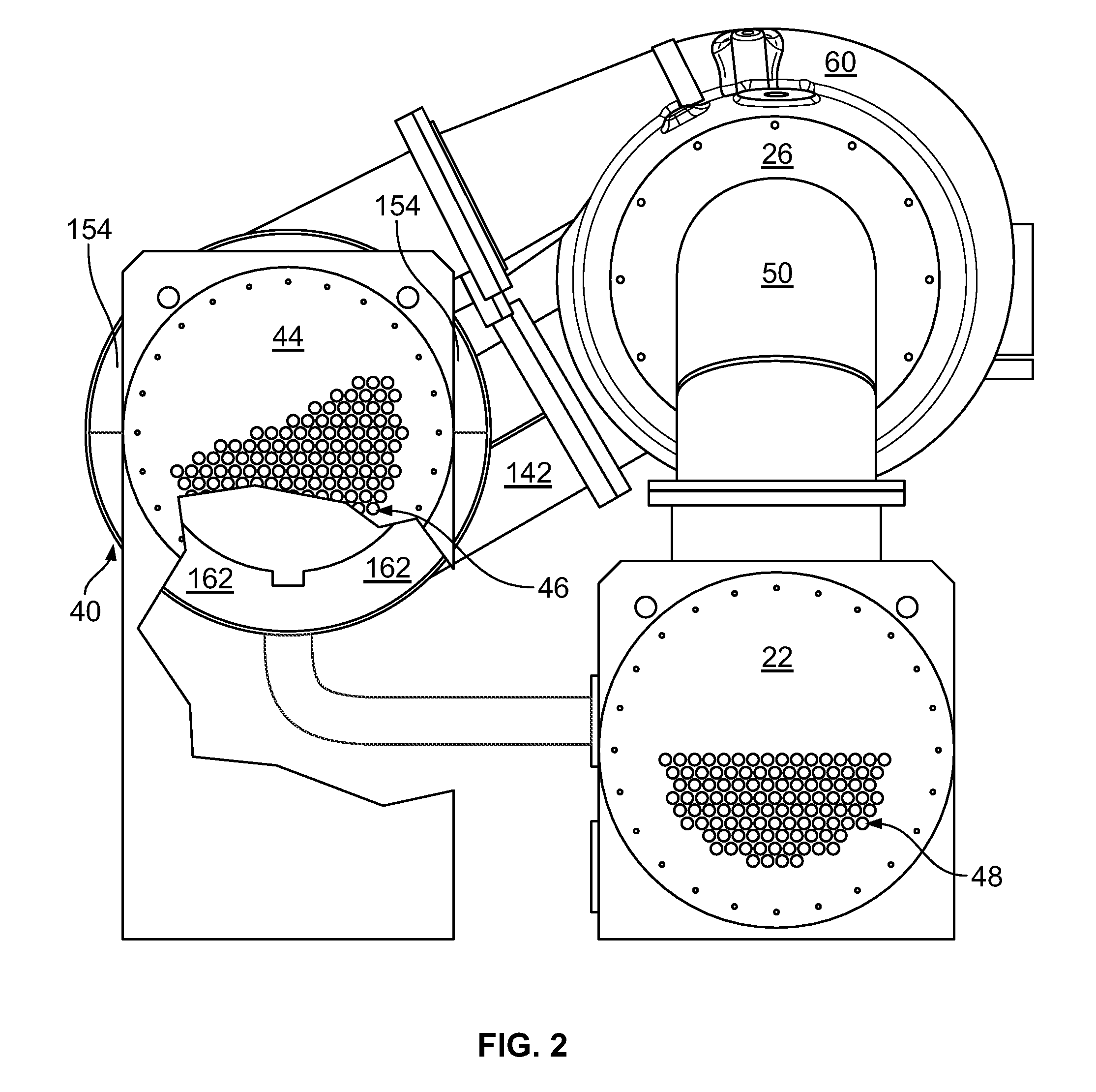

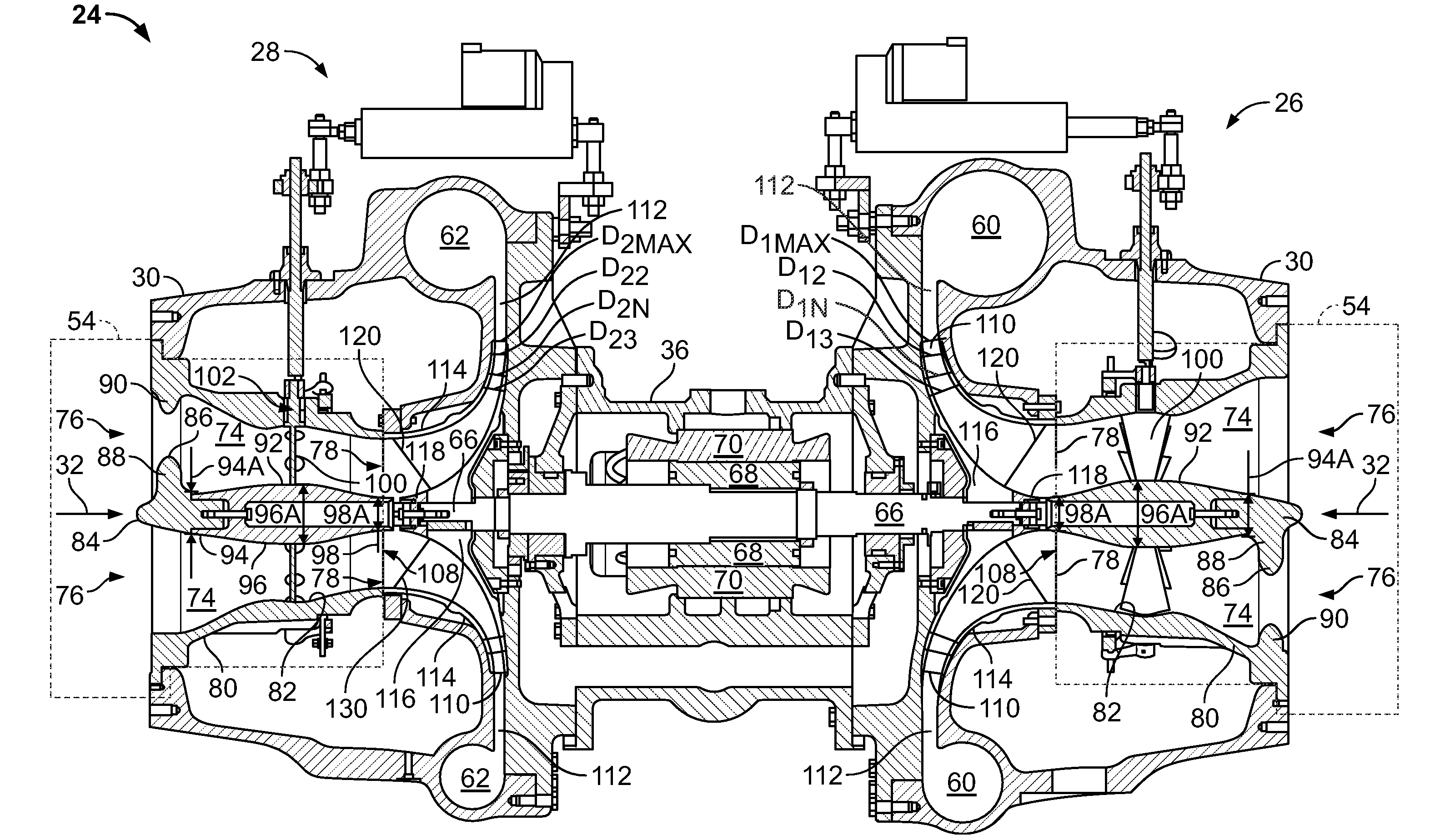

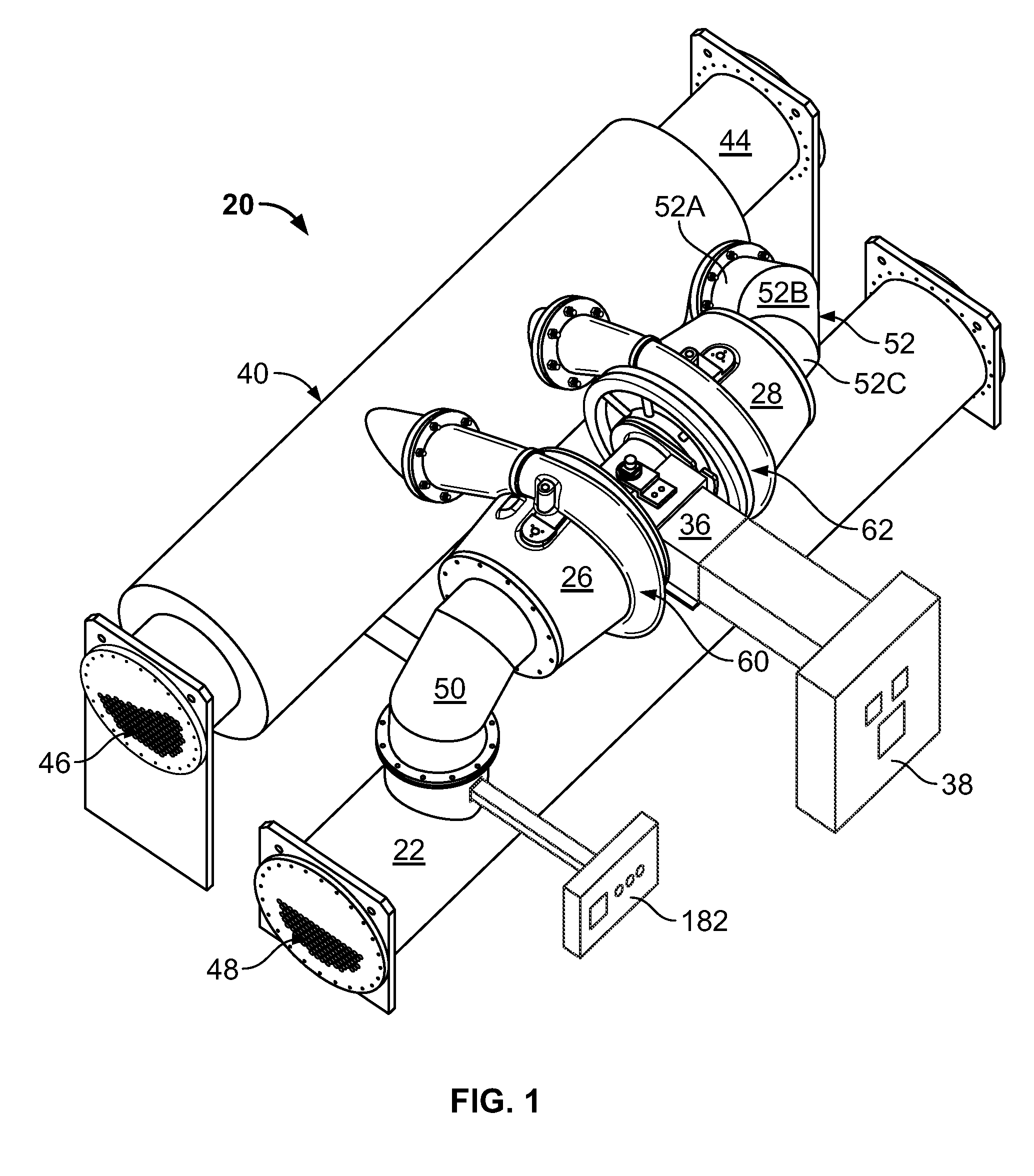

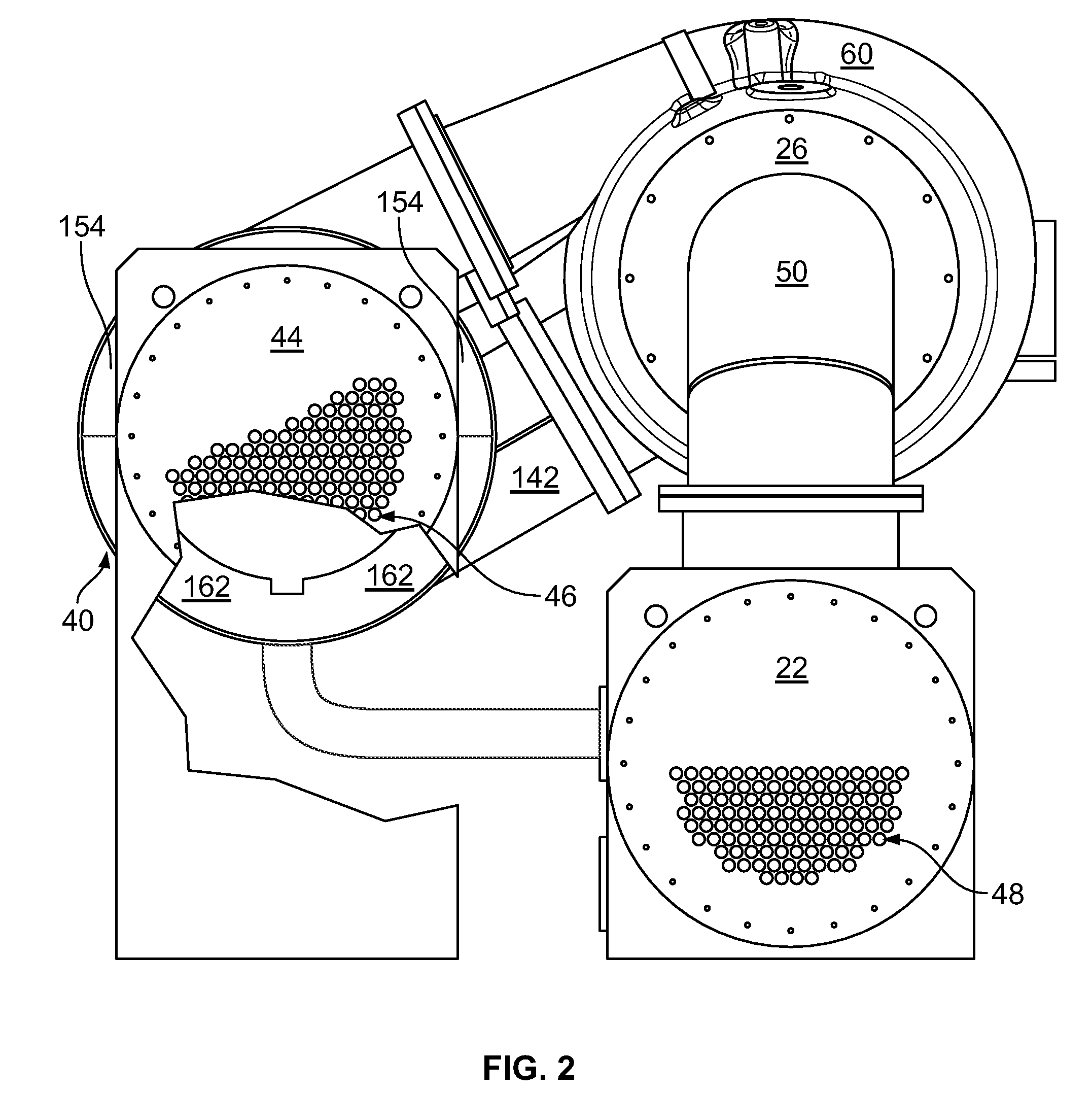

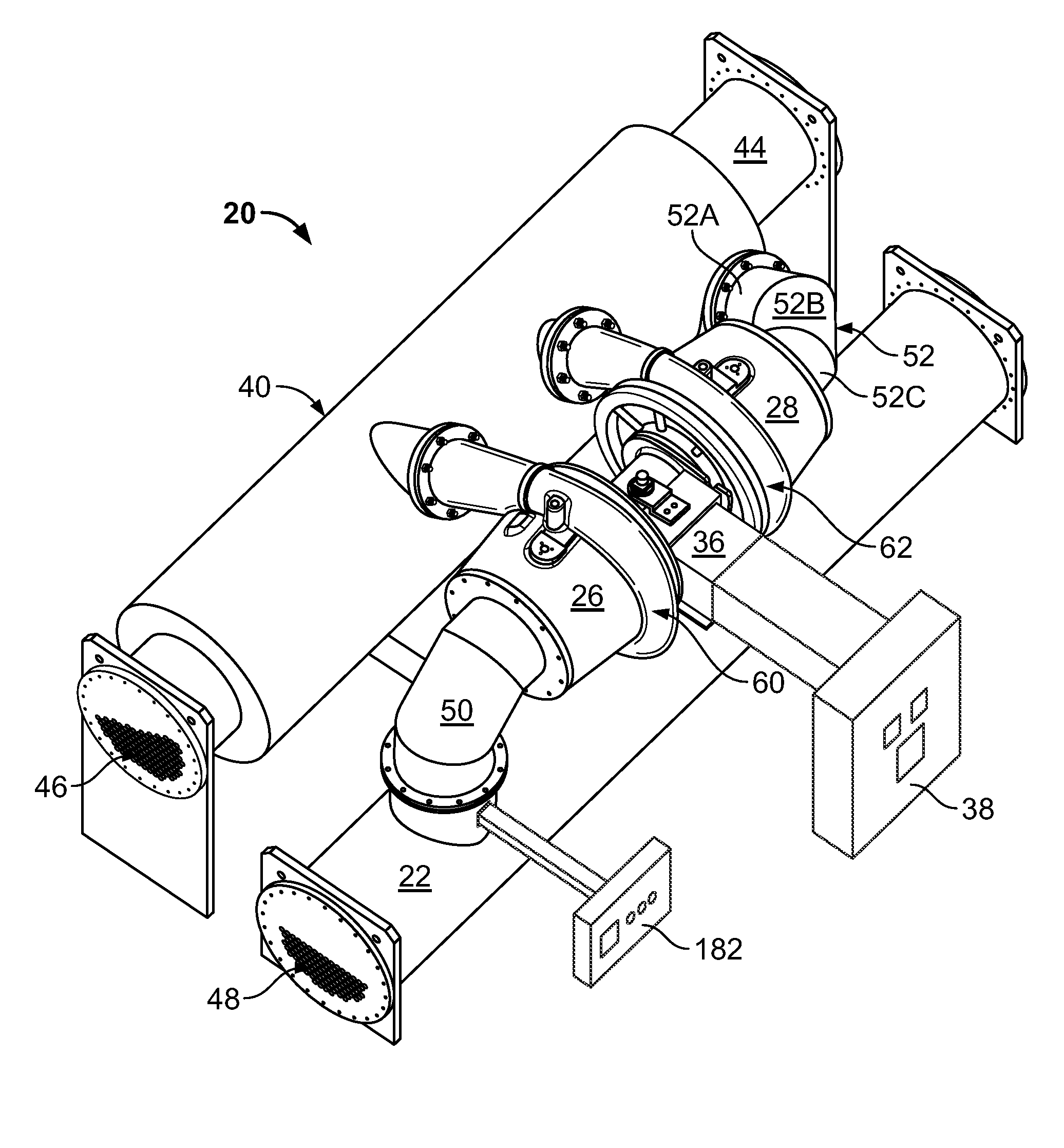

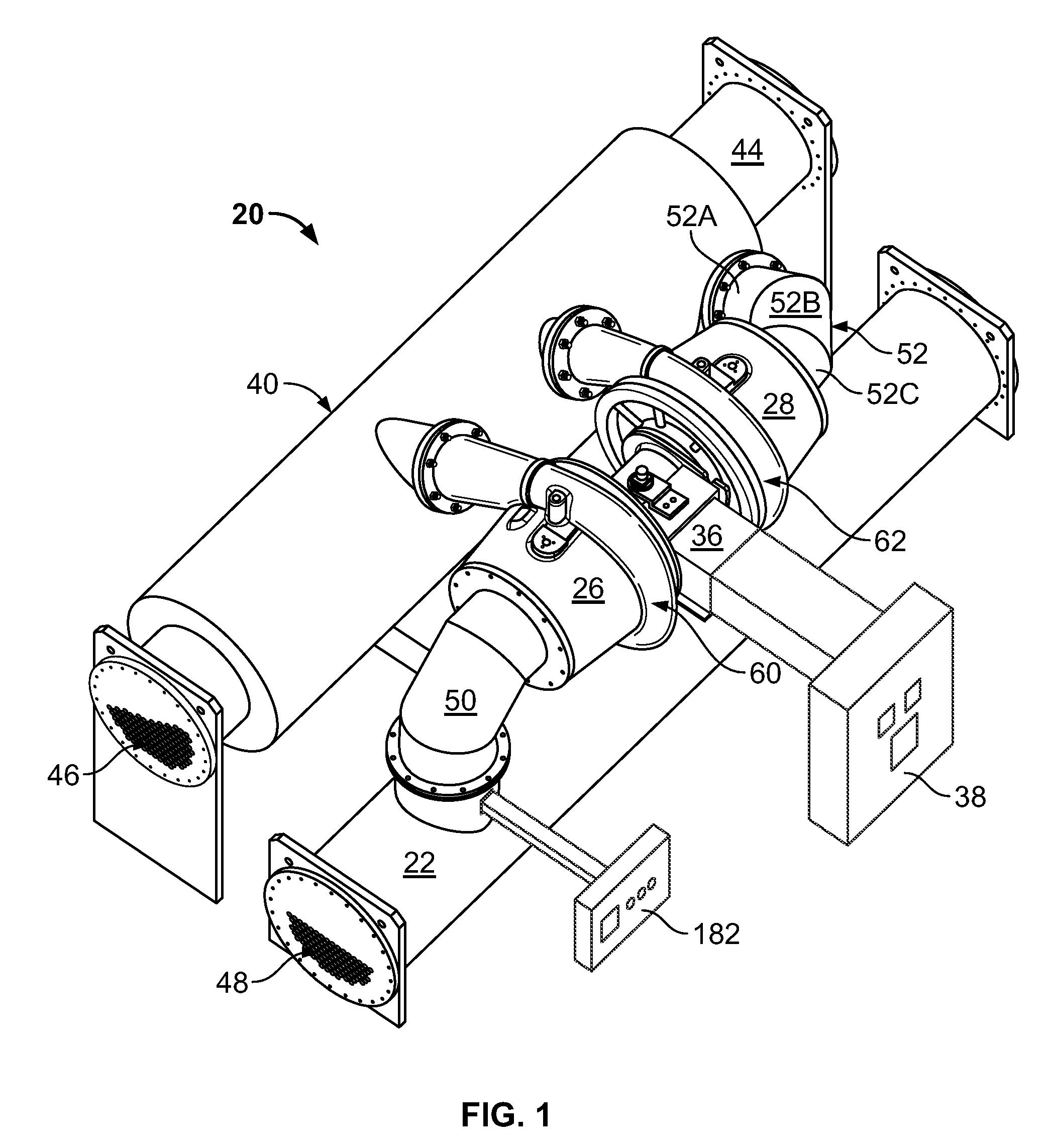

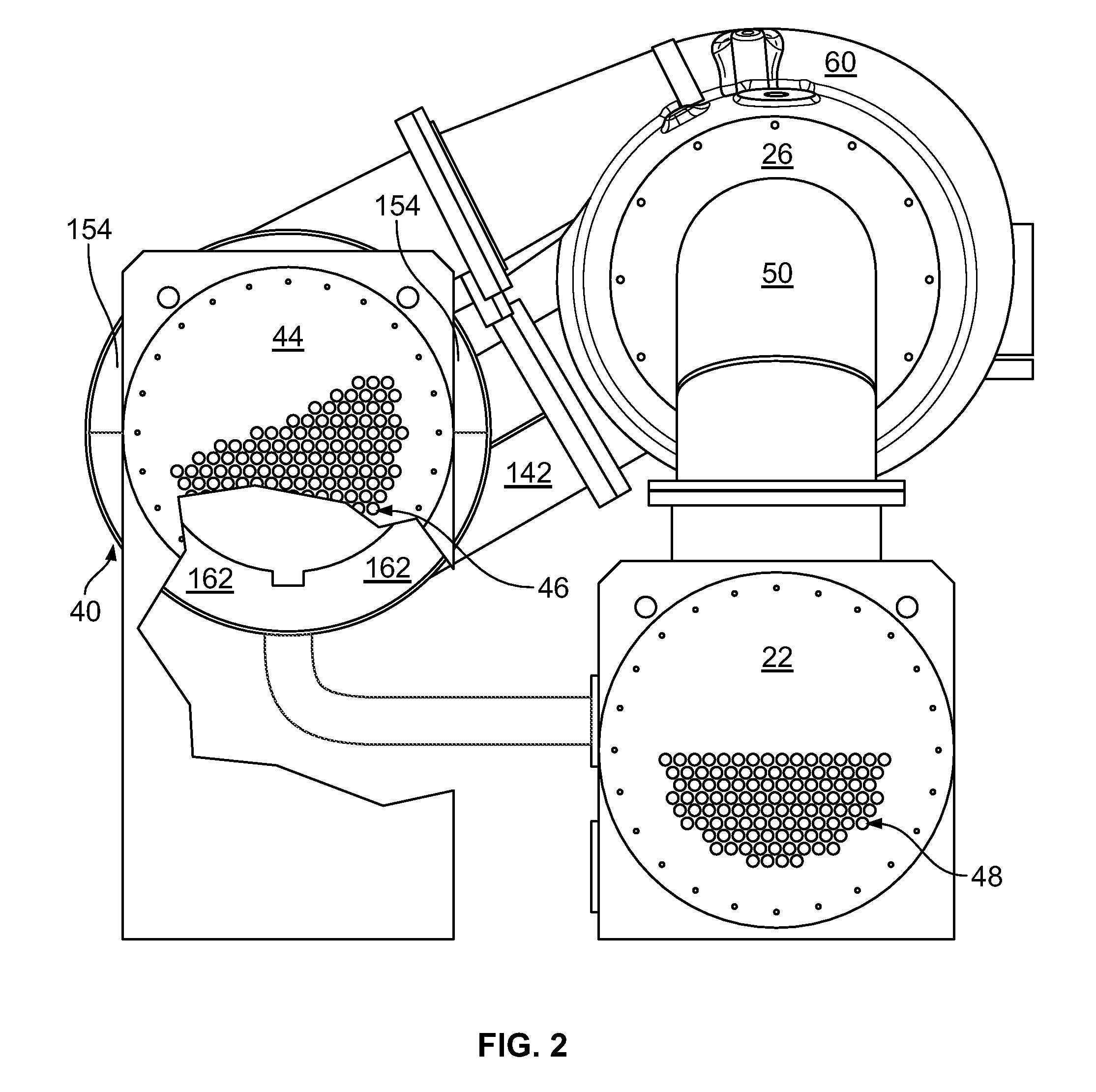

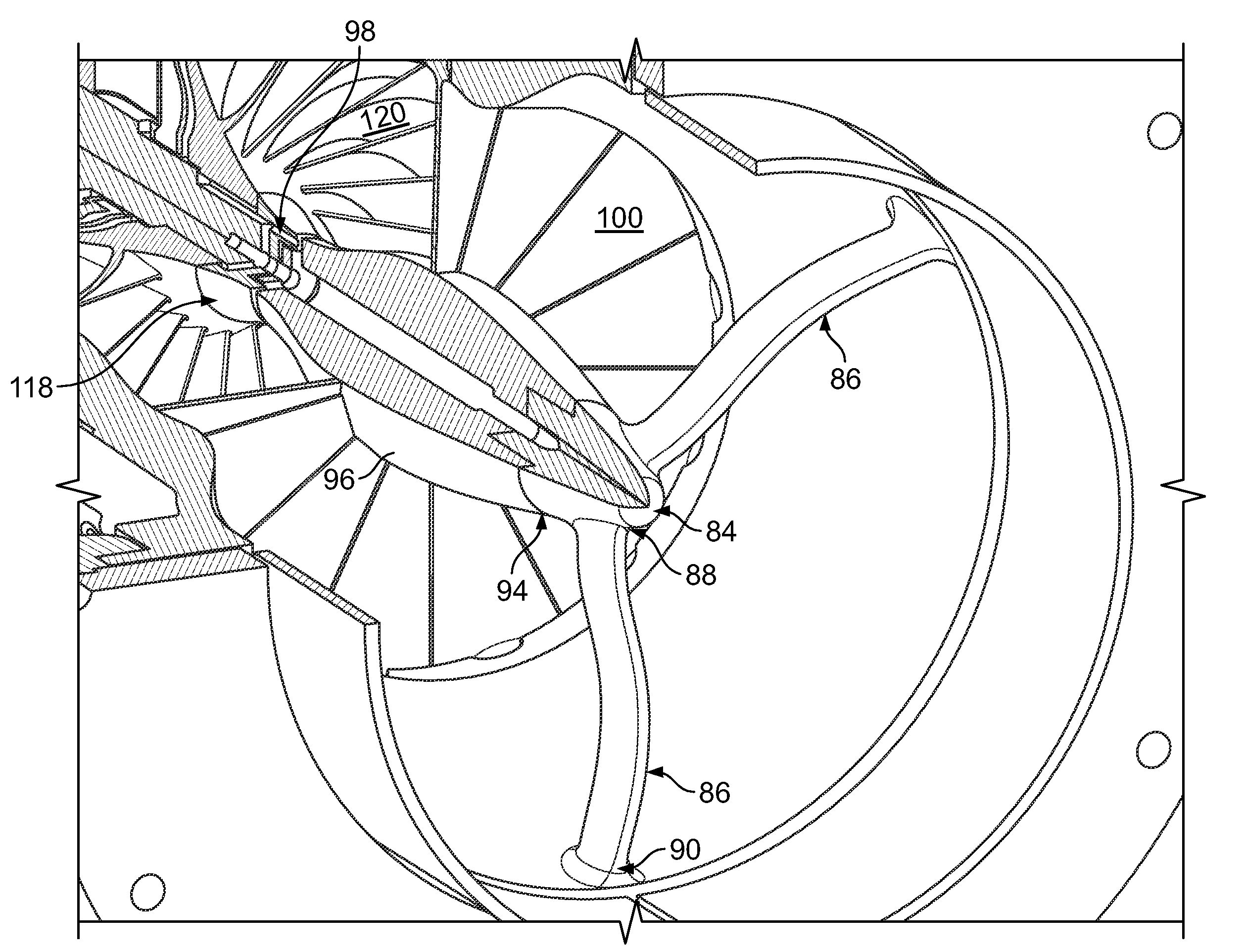

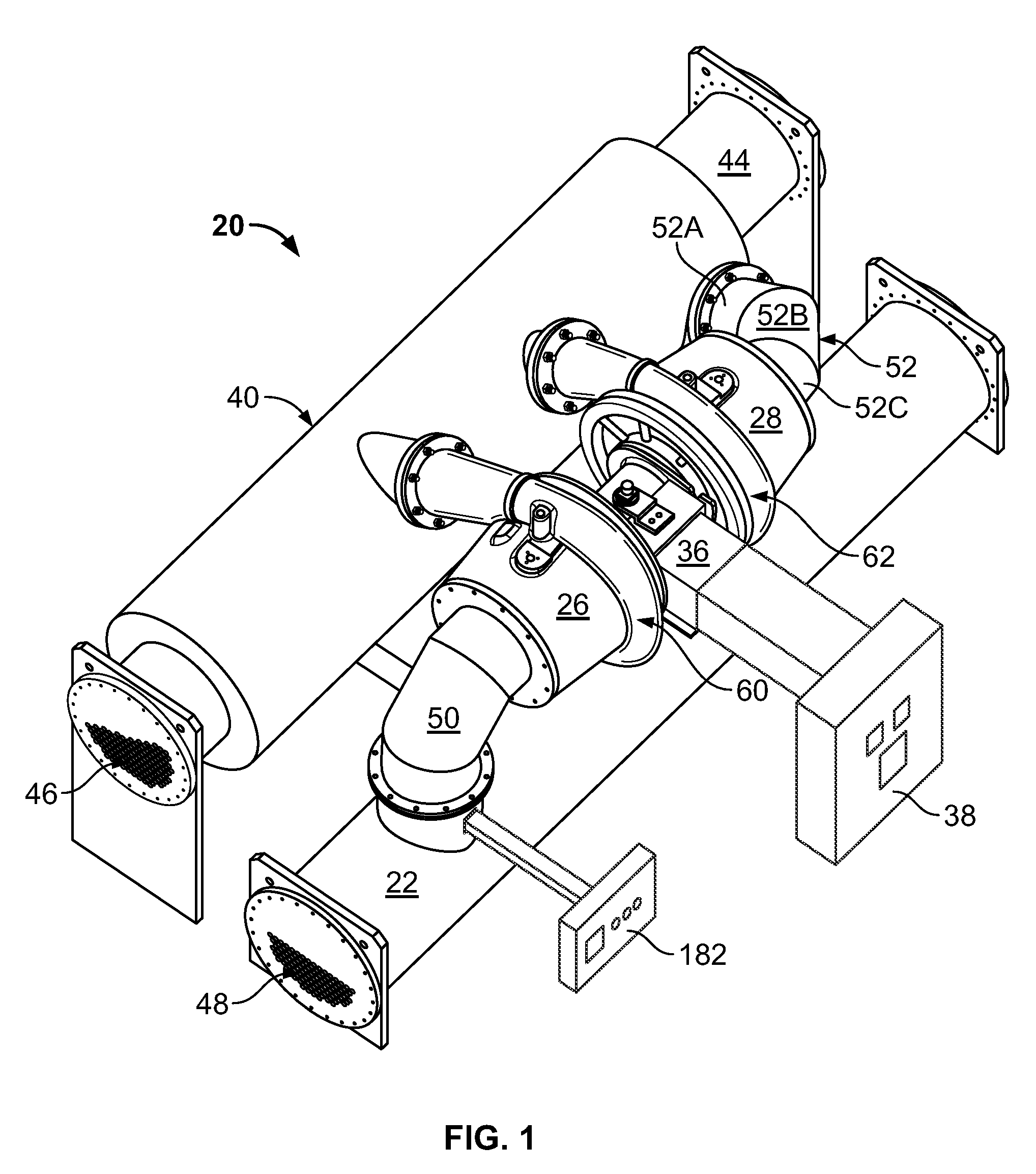

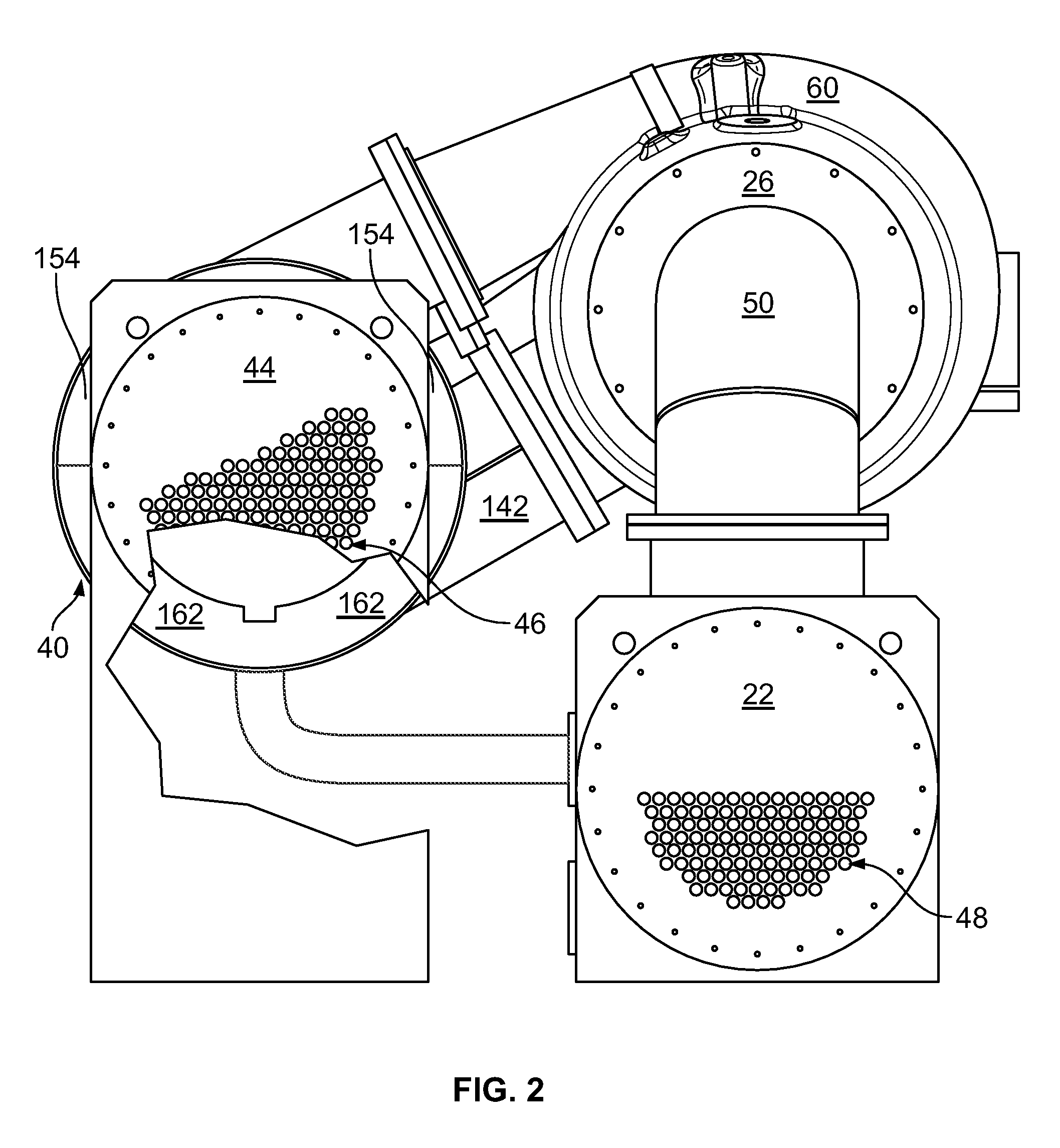

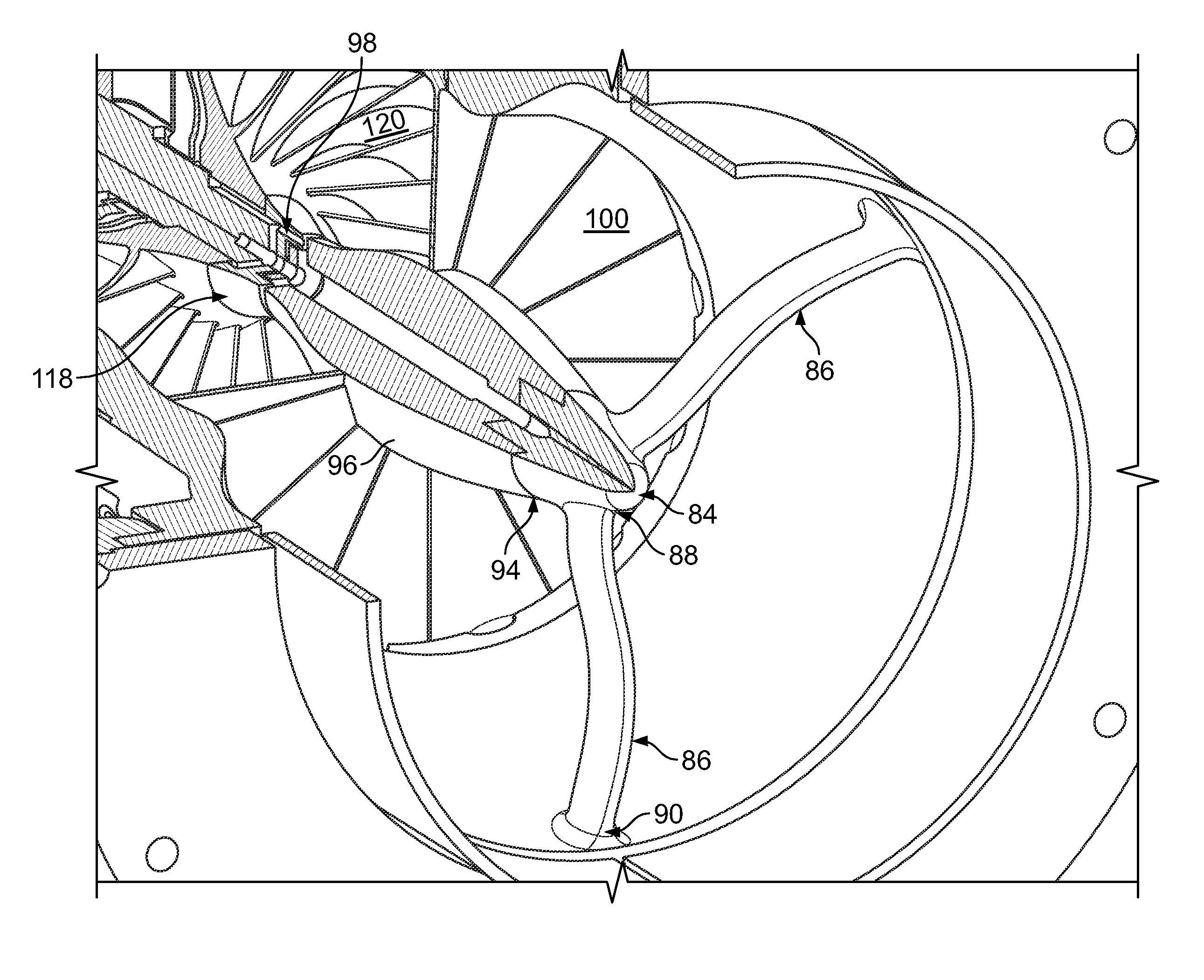

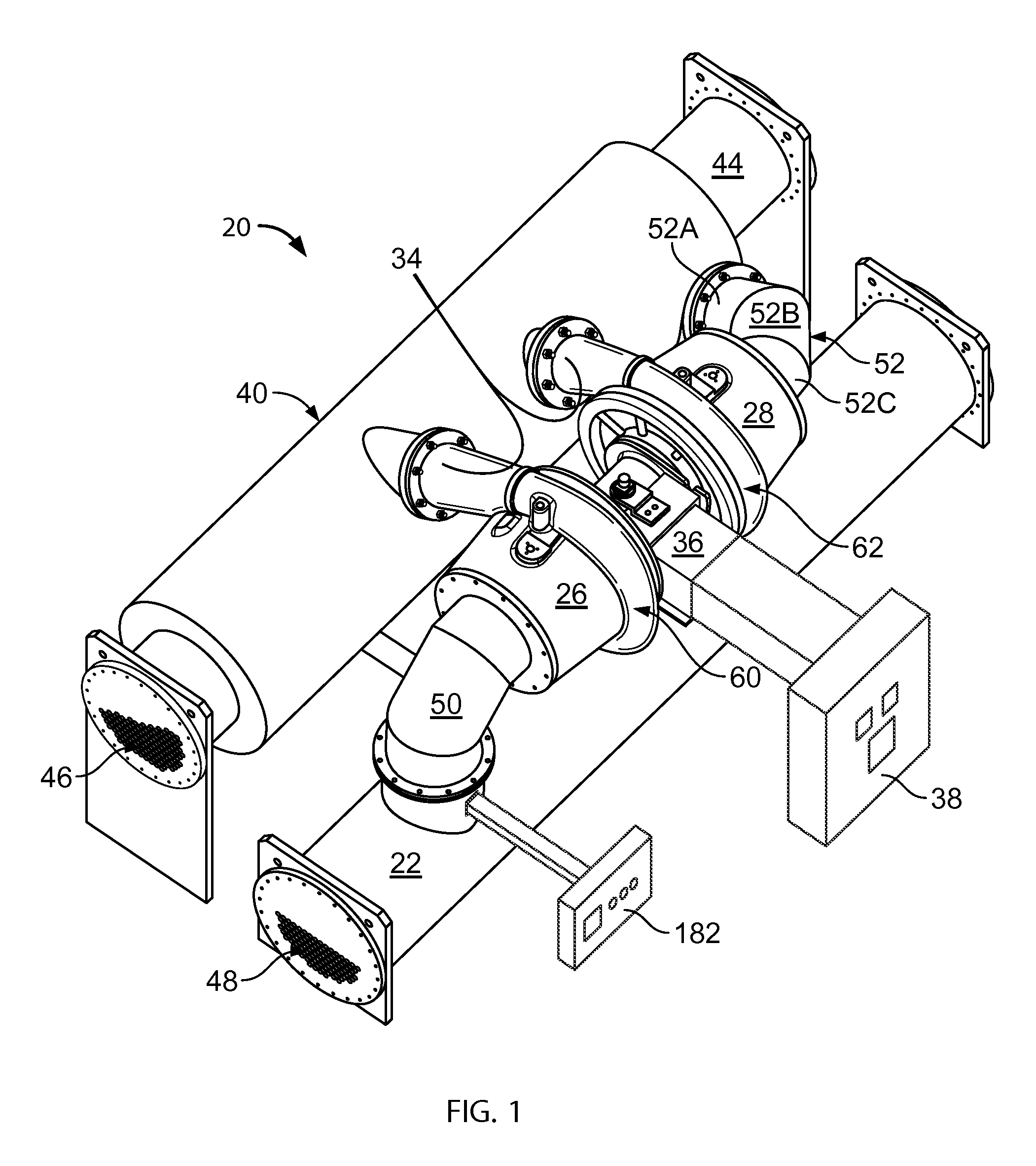

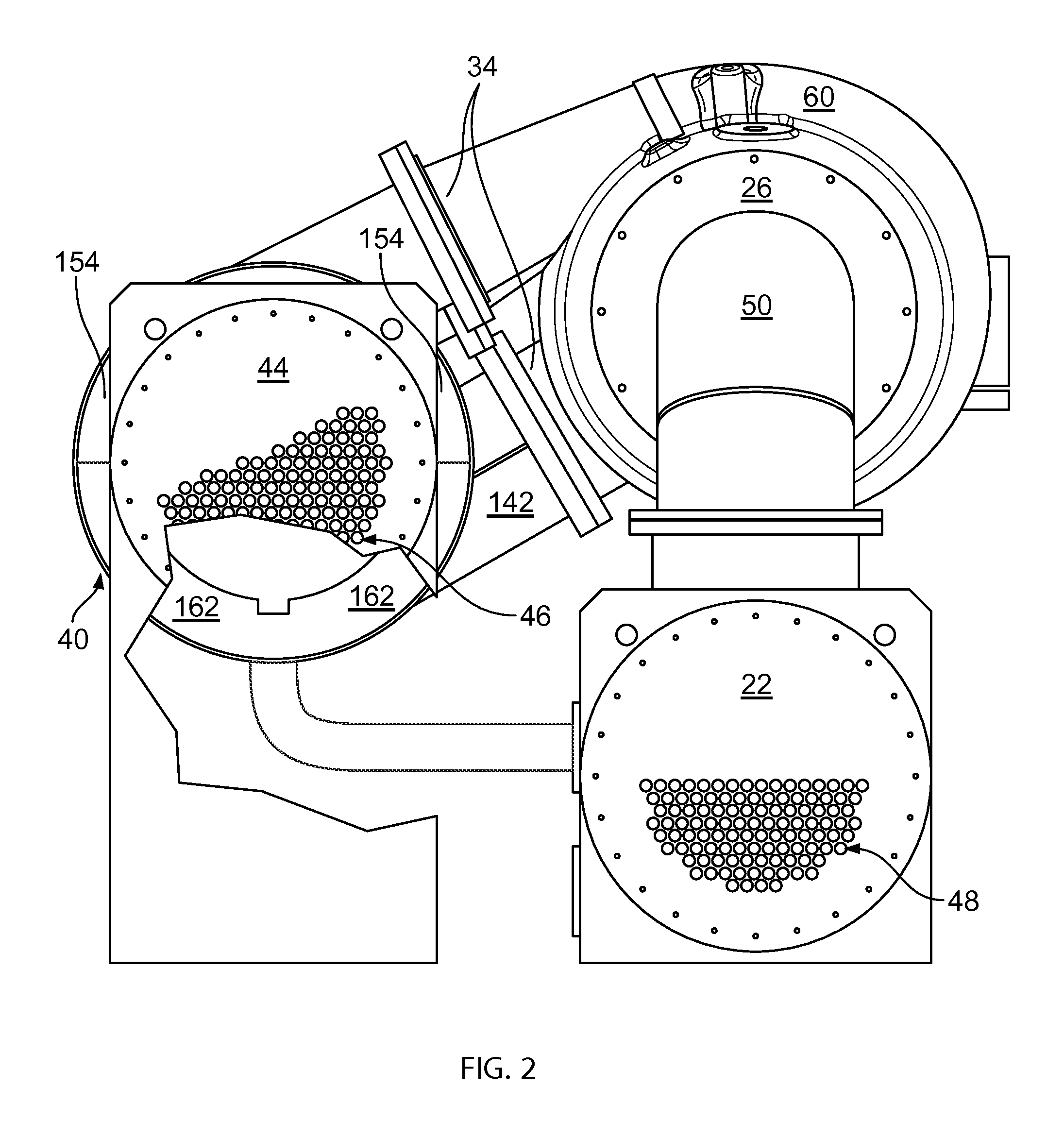

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS7856834B2Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

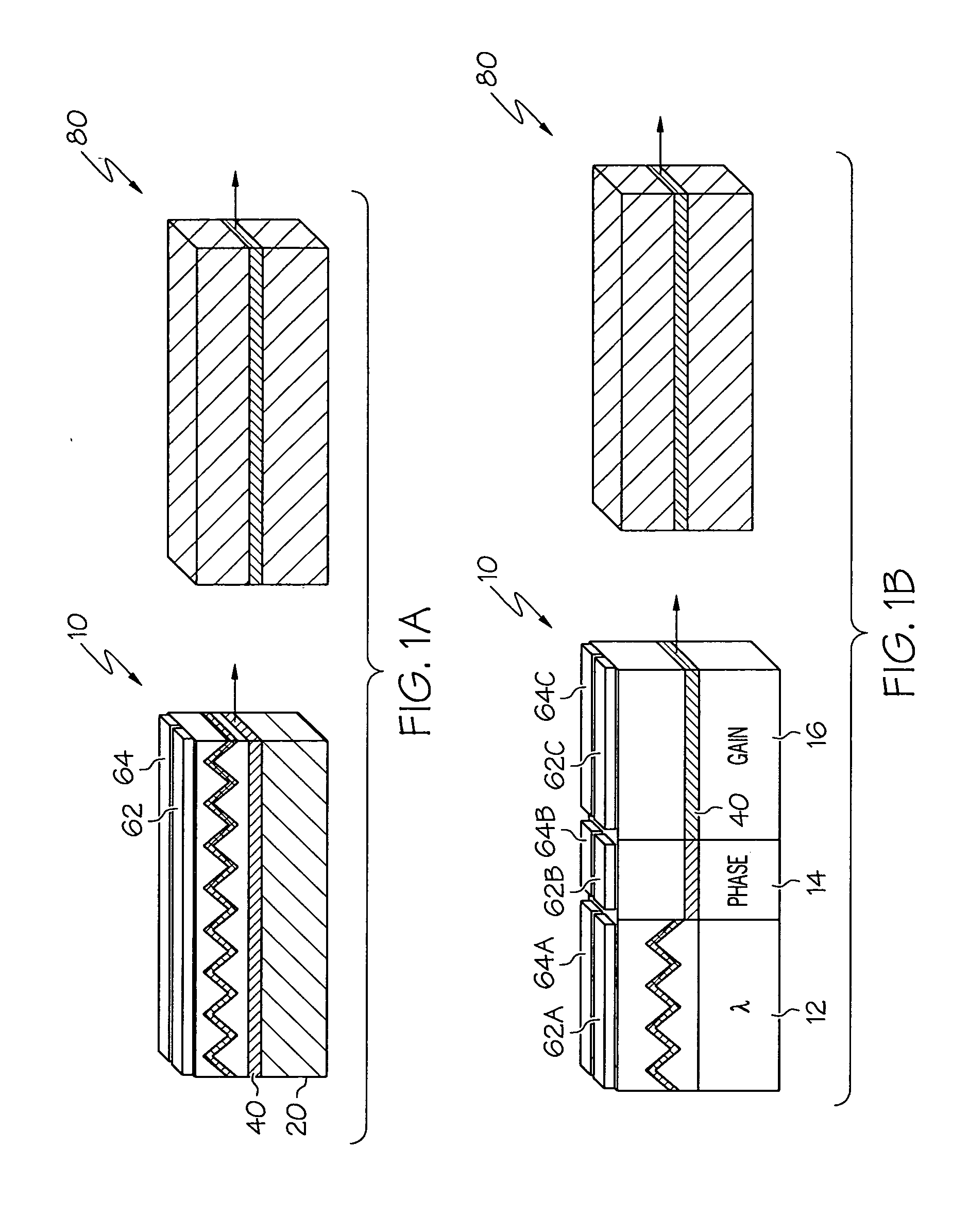

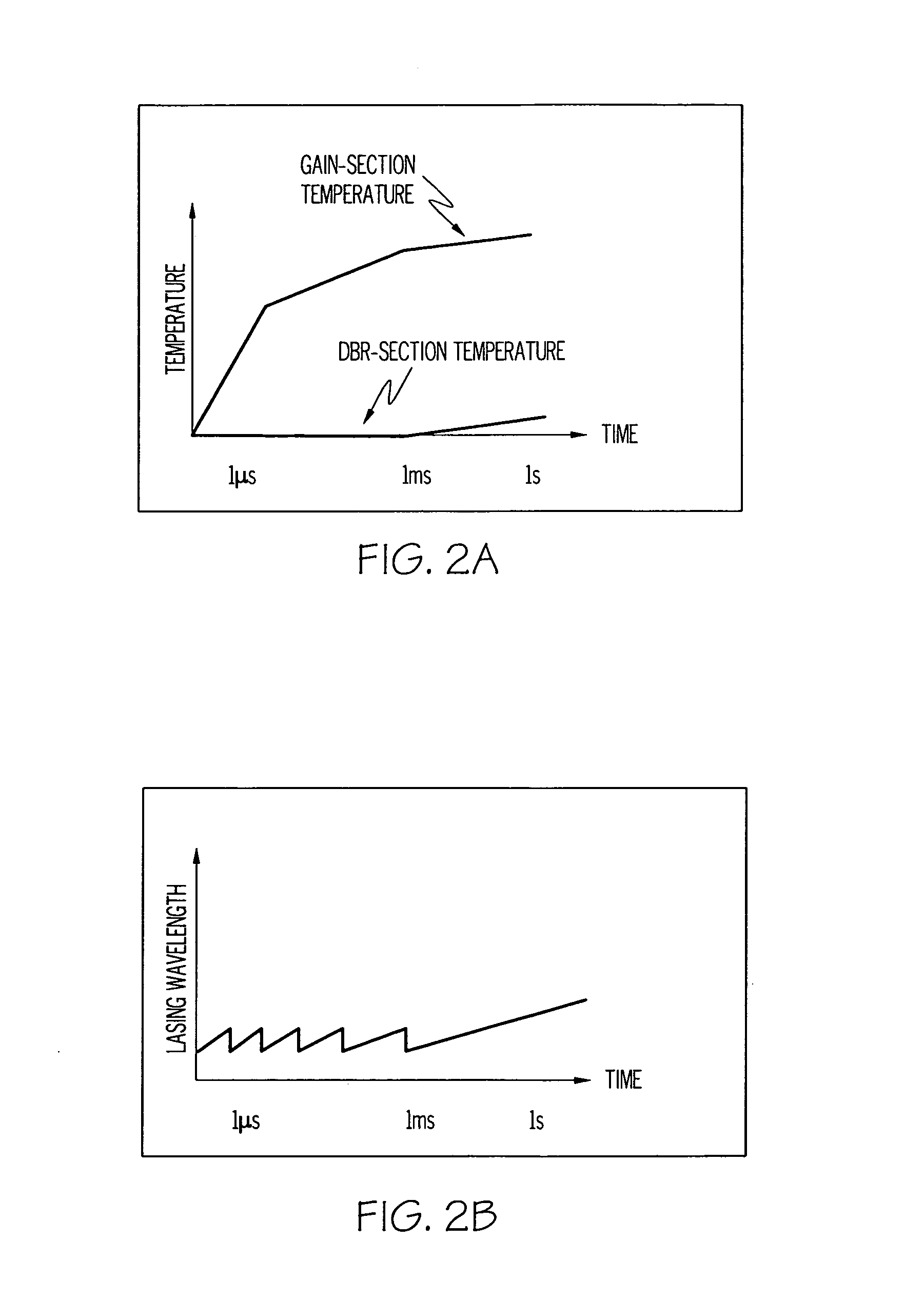

Thermal compensation in semiconductor lasers

InactiveUS20080063016A1High output powerWithout excessive noiseOptical wave guidanceLaser cooling arrangementsDriving currentHarmonic

The present invention relates to methods for modulating a semiconductor laser and wavelength matching to a wavelength converter using monolithic micro-heaters integrated in the semiconductor laser. The present invention also relates to wavelength matching and stabilization in laser sources in general, without regard to whether the laser is modulated or whether second harmonic generation is utilized in the laser source. According to one embodiment of the present invention, a method of compensating for thermally induced patterning effects in a semiconductor laser is provided where the laser's heating element driving current IH is set to a relatively high magnitude when the laser's driving current ID is at a relatively low magnitude. Additional embodiments are disclosed and claimed.

Owner:CORNING INC

Paintball loader systems

InactiveUS20080236558A1Reduce loadImprove loading speedAmmunition loadingCompressed gas gunsMicrocontrollerSystems design

A paintball loader system designed to efficiently deliver paintballs to a paintball gun. The drive mechanism is a screw-type design comprising a resilient auger. A microcontroller is programmed to automatically adjust the rotation of the auger based on data from multiple sensor points within the loader. The auger is mounted such that both rotational axial movements are enabled during operation. The axial movement of the auger is used to maintain a constant force on the paintballs awaiting loading within the paintball gun.

Owner:BOSCH JOHN P MR

Centrifugal compressor assembly and method

ActiveUS8037713B2Improve performanceReduce physical sizePump componentsRotary non-positive displacement pumpsMixed flowHigh energy

Owner:TRANE INT INC

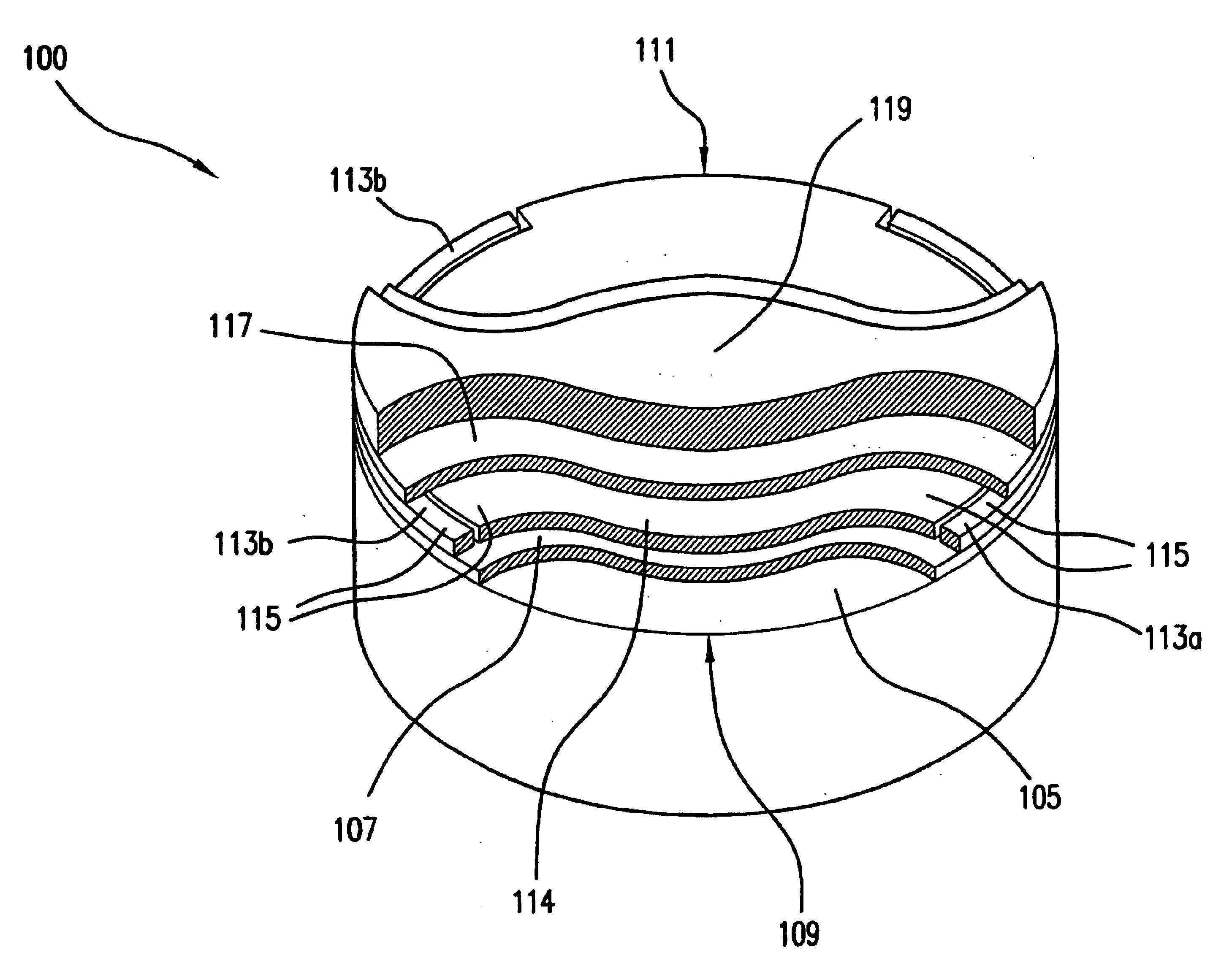

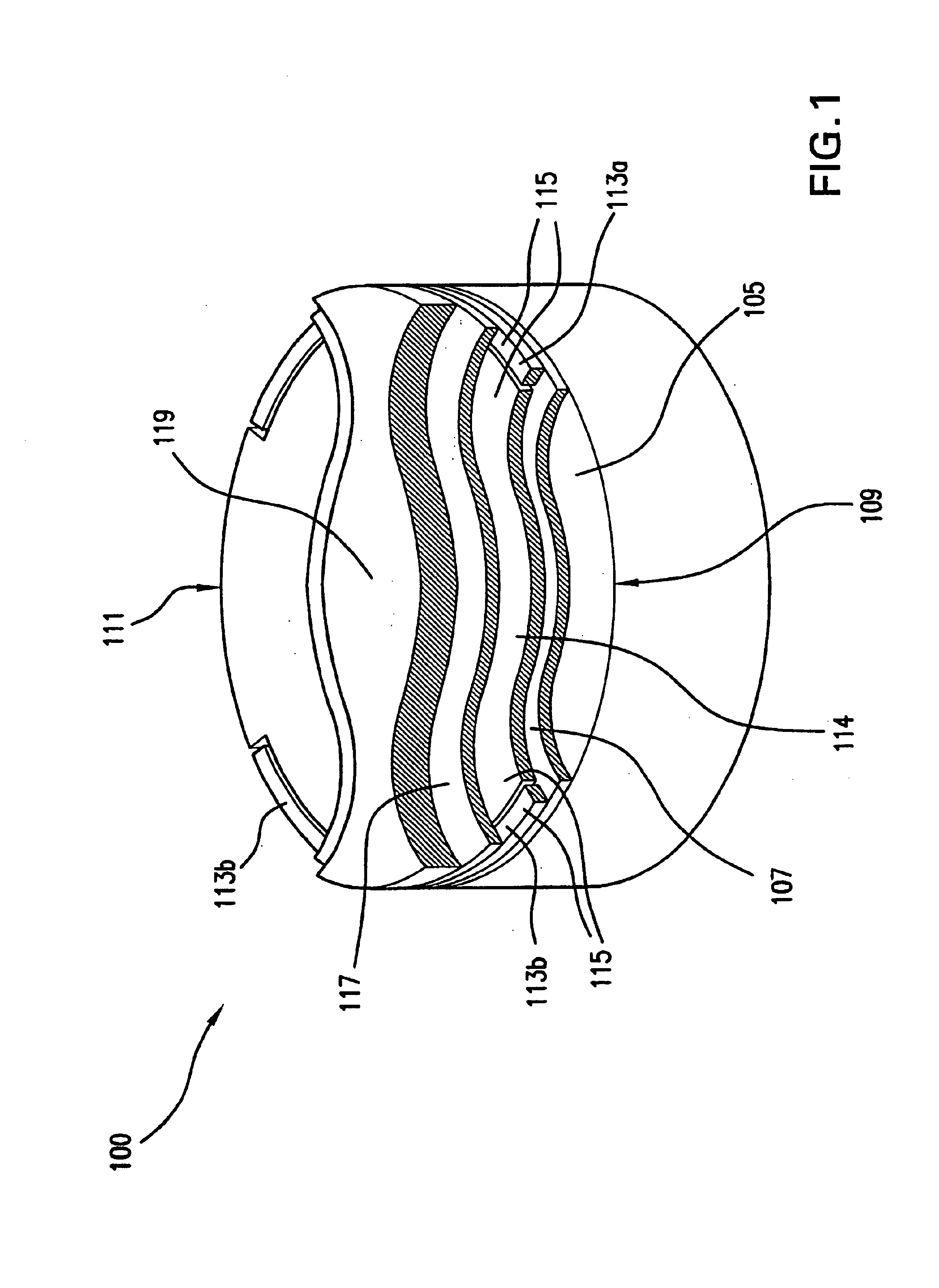

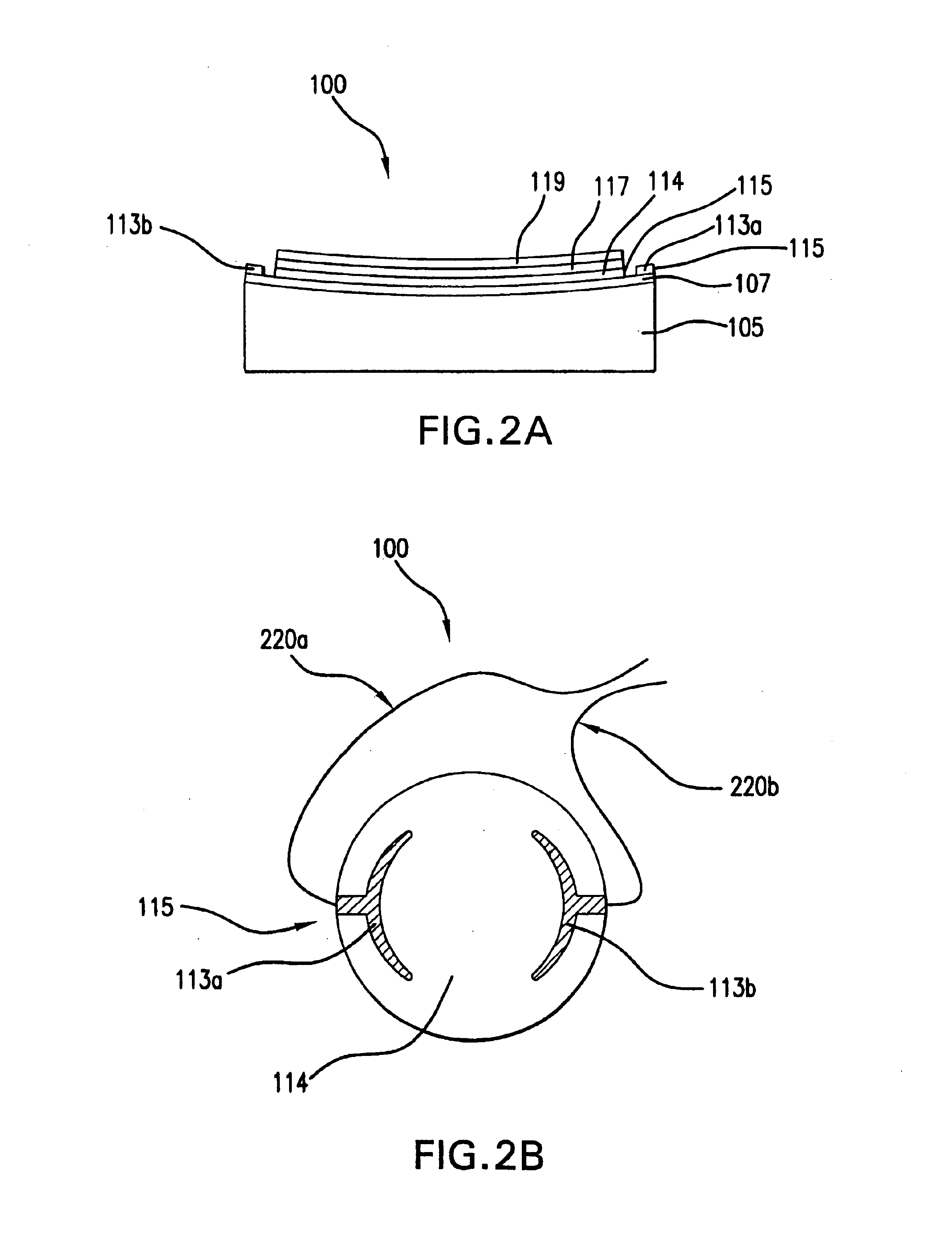

Implant for Deploying Bone Graft Material and Methods Thereof

InactiveUS20100042216A1Easy to integrateAvoid fore-and-aft and lateral bendingSpinal implantsBone growthVertebra

Invertebral implants are provided for carrying bone graft material and extruding the bone graft material between the implant and the adjacent vertebral bodies. The implants include first and second implant extrusion members shiftable relative to one another between a pre-implantation configuration having an enlarged cavity for receiving bone graft material therein and an implantation configuration having a smaller cavity. As the first and second implant extrusion members shift during implantation to the implantation configuration bone graft material is extruded from the cavity and into gaps or spaces between the upper and lower vertebral engaging surfaces of the implant and the adjacent vertebral bodies. After extrusion the bone graft material is subjected to spinal loading and stress to encourage strong bone growth therethrough.

Owner:PIONEER SURGICAL TECH INC

Centrifugal compressor assembly and method

ActiveUS20090208331A1Improve performanceReduce physical sizeEngine manufacturePump componentsMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

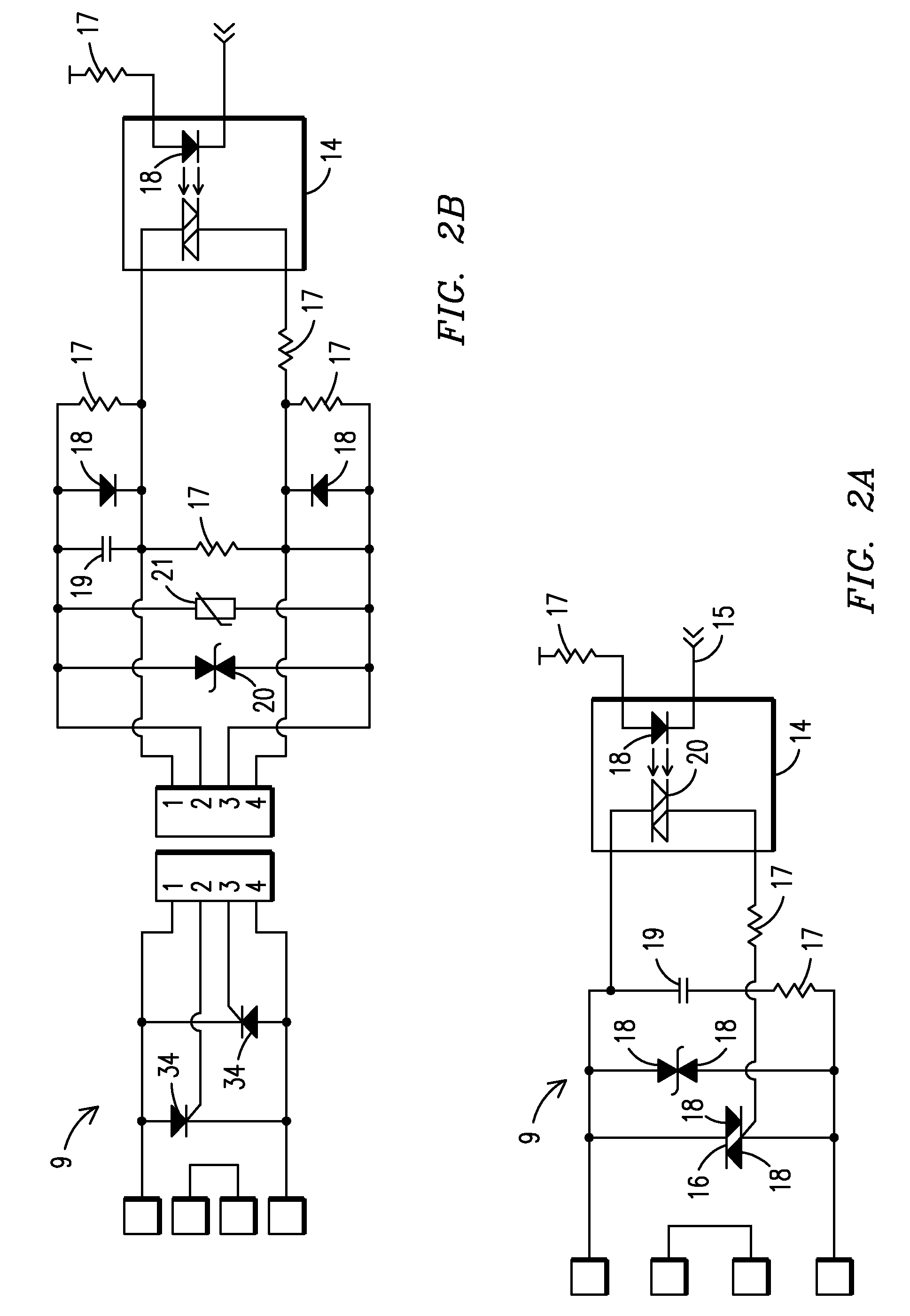

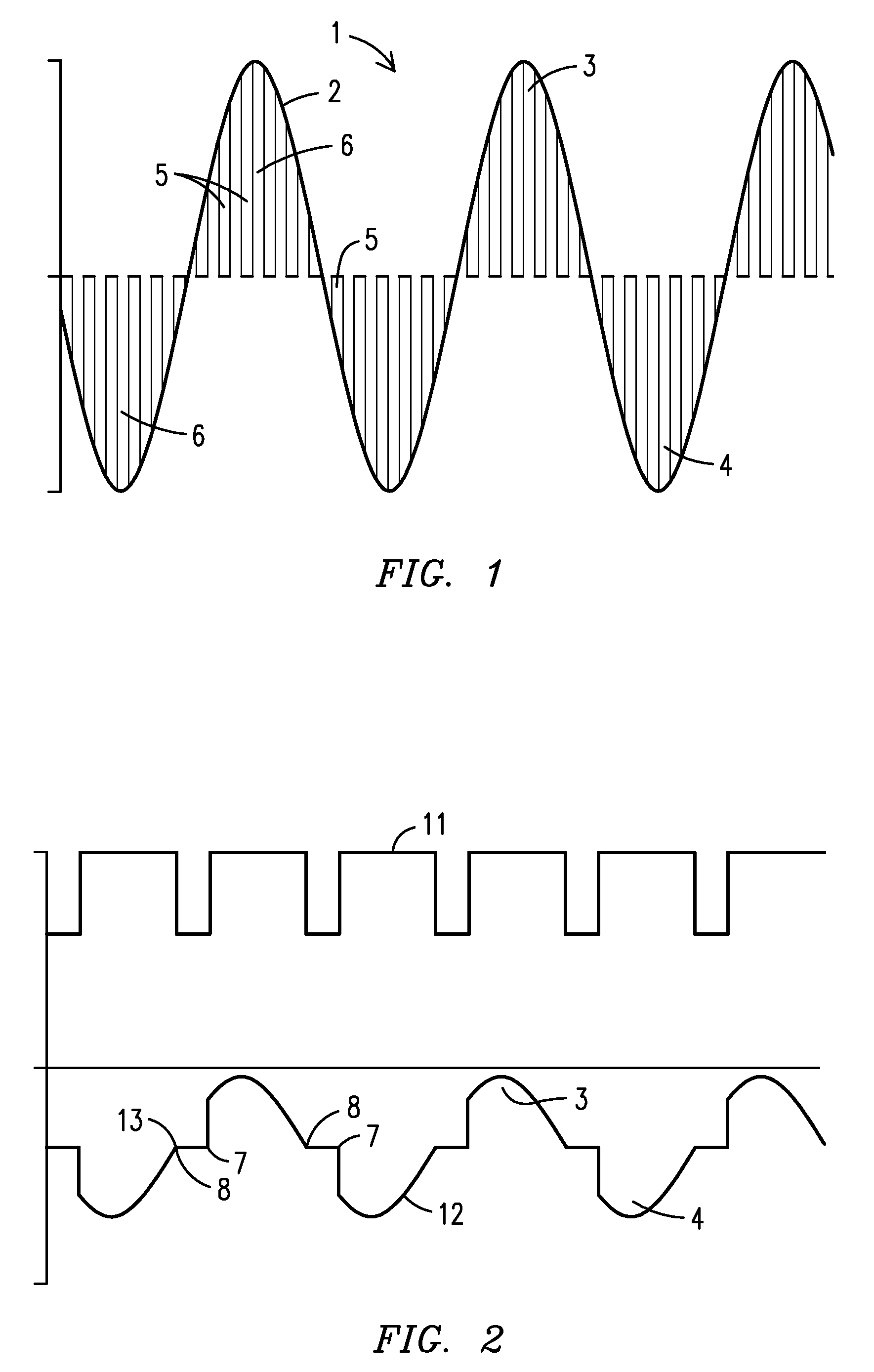

System and method for providing constant loading in ac power applications

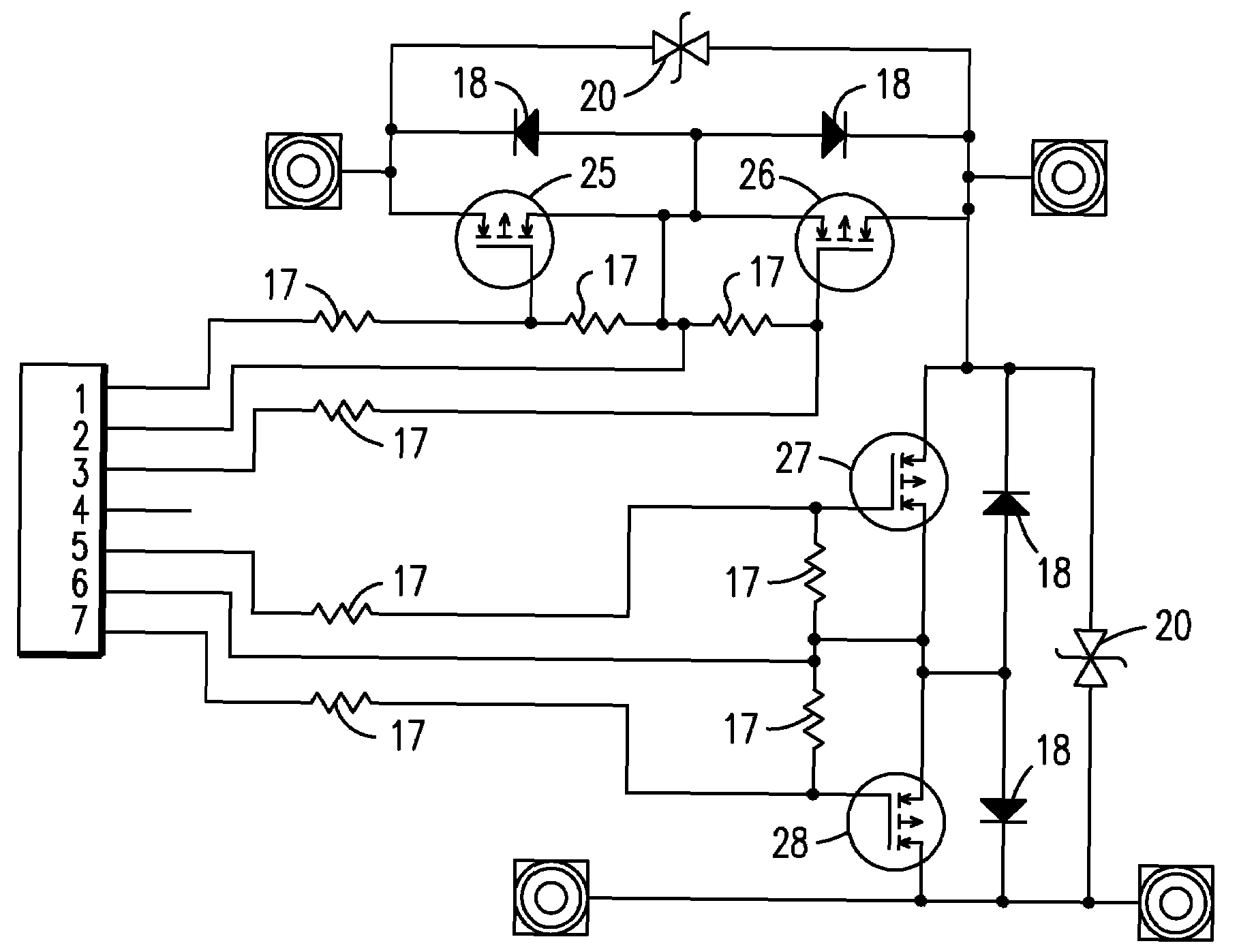

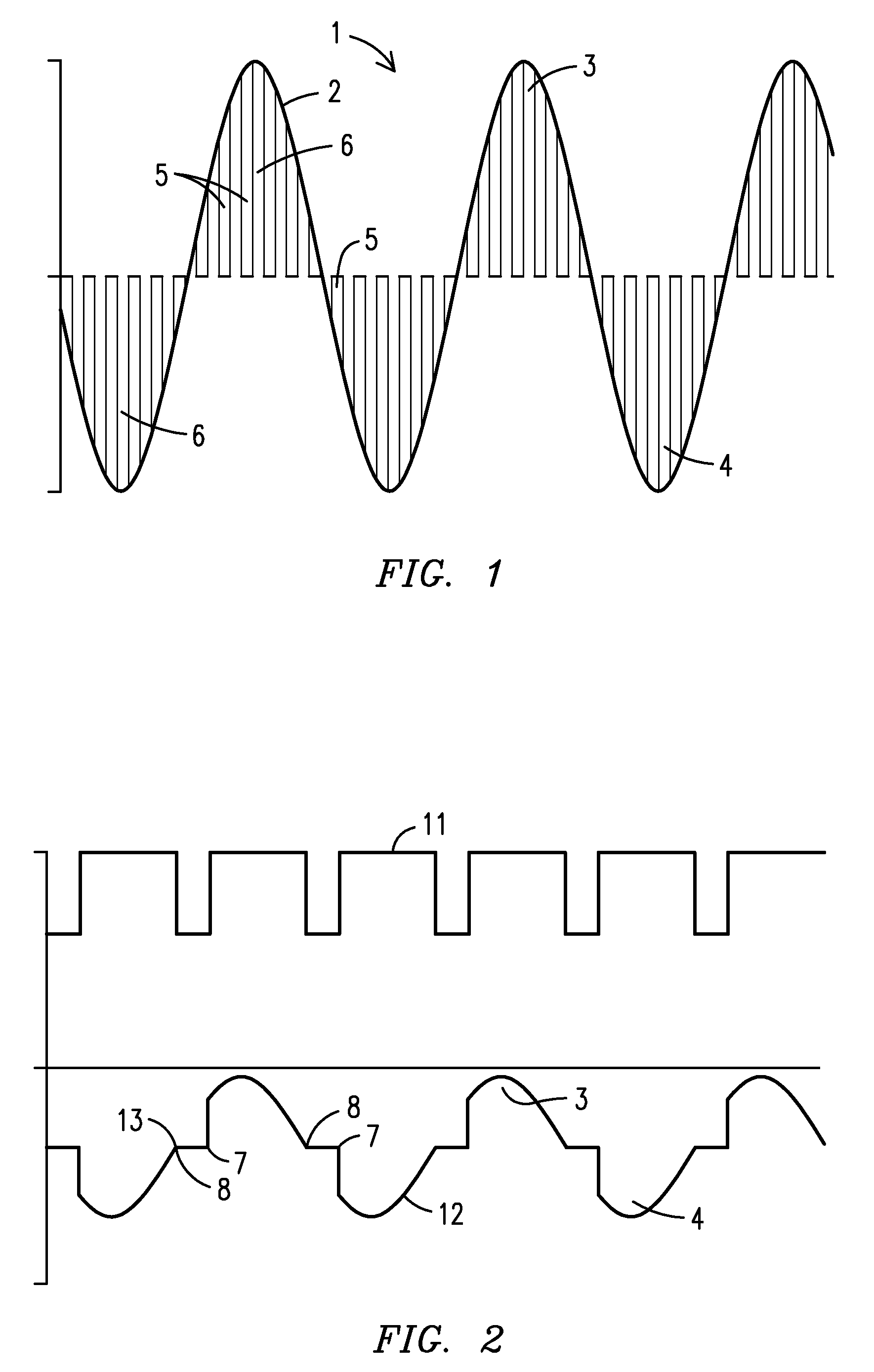

ActiveUS20090200981A1Constant loadApply evenlySingle-phase induction motor startersSynchronous motors startersEngineeringField-effect transistor

A system and method for providing constant loading in AC power applications wherein at least one turn-on point (7) of at least one half cycle of a modulating sine wave (2) is determined; at least one turn-off point (8) of said at least one half cycle of a modulating sine wave (2) is determined; and at least one slice (5) located between said at least one turn-on point (7) and said at least one turn-off point (8) is removed. The slices (5) may be removed by utilizing triode alternating current switches, silicone controlled rectifiers, insulated gate bipolar transistors or field effect transistors.

Owner:THE POWERWISE GRP

Centrifugal compressor assembly and method

ActiveUS20090205362A1Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Systems and methods for detecting refrigerant leaks in cooling systems

ActiveUS20100300129A1Constant loadDetection of fluid at leakage pointEvaporators/condensersEngineeringRefrigerant

A method of detecting loss of refrigerant within a cooling system of the type having a condenser, a refrigerant receiver in fluid communication with the condenser, a sensor configured to detect a level of refrigerant within the receiver, an evaporator in fluid communication with the receiver, and a pump or compressor in fluid communication with the evaporator and the condenser, includes establishing a baseline measurement of refrigerant mass contained in the receiver with the sensor during certain power loads applied to the cooling system, monitoring a mass of refrigerant in the receiver with the sensor at a certain power load applied to the cooling system, and identifying whether the monitored mass of refrigerant is less than the baseline measurement of refrigerant mass over a predetermined period of time. Systems for detecting loss of refrigerant are further disclosed.

Owner:SCHNEIDER ELECTRIC IT CORP

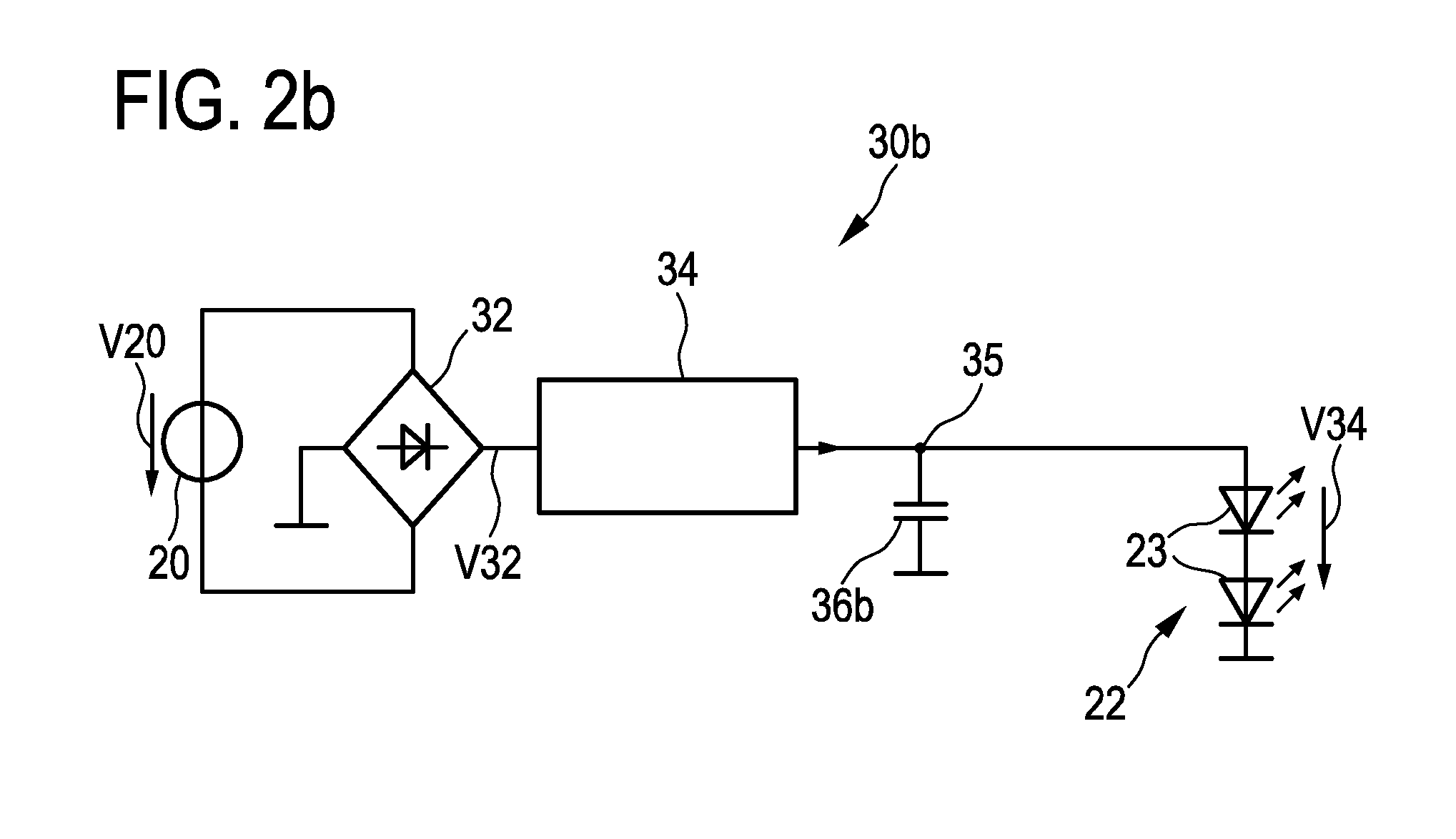

Dc-dc driver device having input and output filters, for driving a load, in particular an LED unit

ActiveUS20140125241A1Improve power factorConstant loadElectroluminescent light sourcesDc-dc conversionLow voltageInductor

The present invention relates to a driver device (50a-50f) and a corresponding method for driving a load (22), in particular an LED unit comprising one or more LEDs (23). The proposed driver device comprises power input terminals (51, 52) for receiving a rectified supply voltage (vr) from an external power supply, power output terminals (53, 54) for providing a drive voltage and / or current for driving a load (22), a half bridge unit (70) comprising a first (60) and second (61) switching element coupled in series between a high voltage node (57) and a low voltage node (58) and having a switch node (59) between said first and second switching elements, a buck-boost input filter unit (71) comprising a first inductor (Lm) and a series diode (Dm) coupled between a power input terminal (51, 52) and said half bridge unit (70), a buck output filter unit (72) comprising a second inductor (Lo, Lc) coupled between said half bridge unit (70) and a power output terminal (53, 54), an energy storage unit (73), and a control unit (64) for controlling said switching elements (60, 61).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

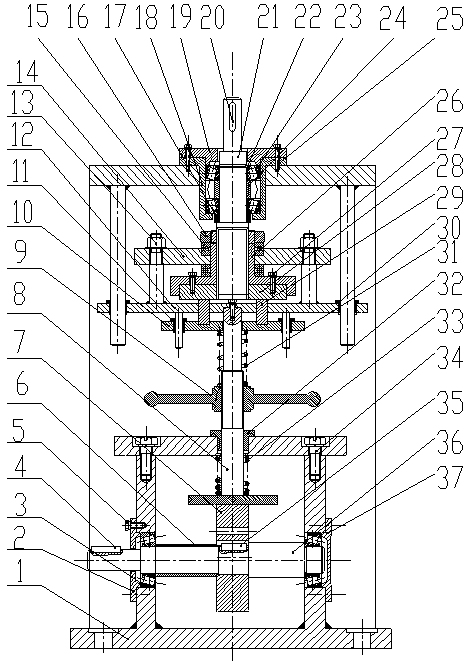

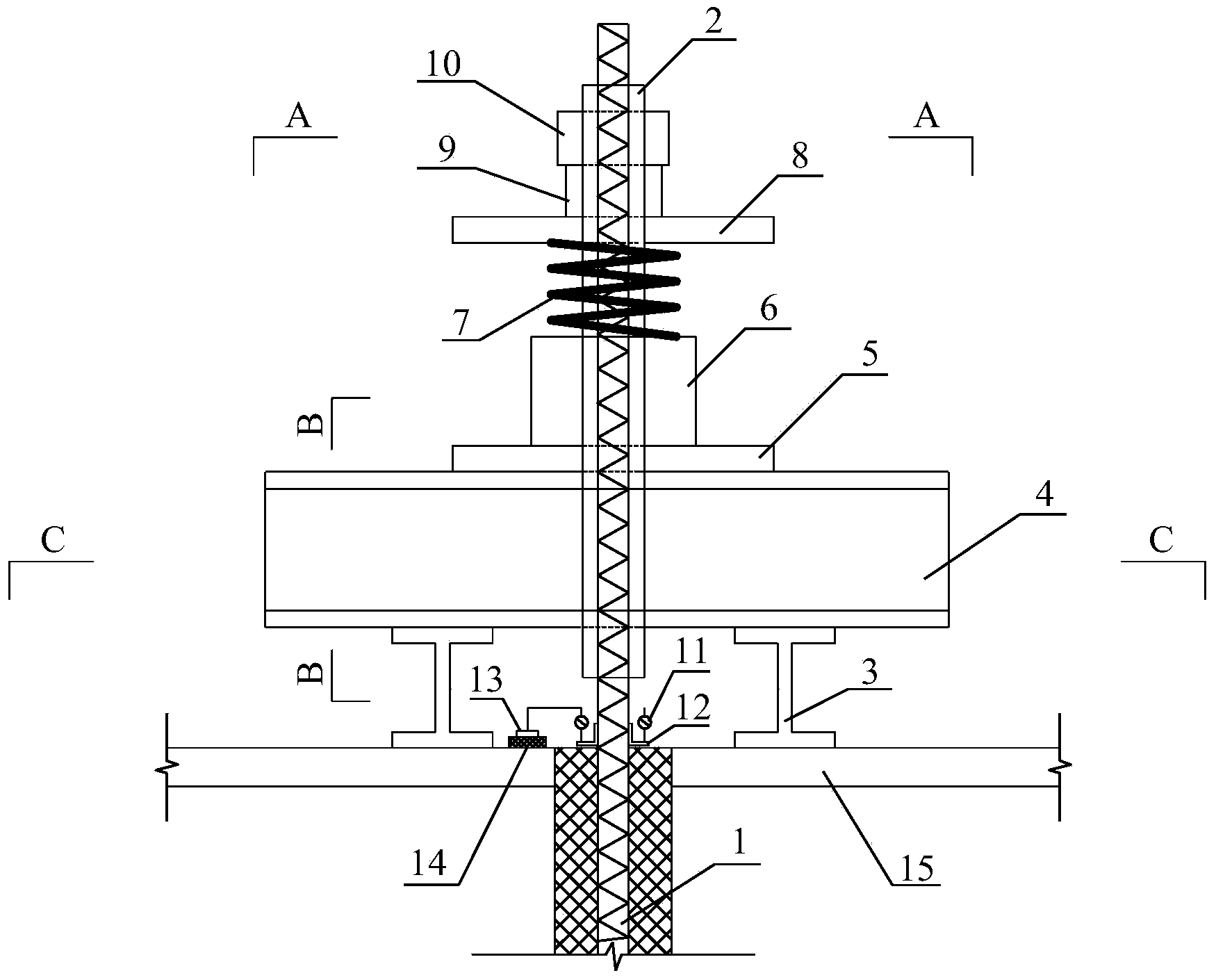

Vibration and abrasion test bench

ActiveCN103163036AStrong expandabilityRealize the vibration functionMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceEngineeringScrew thread

The invention relates to a vibration and abrasion test bench. A vibrating shaft input end is connected with an electromagnetic speed adjusting motor; the vibrating shaft is fixed at the bottom of a box body by a bearing; the center of the vibrating shaft is connected with an eccentric wheel; the eccentric wheel is matched and connected with a push rod by a pressure spring; the push rod is connected with the box body in a sliding way; the push rod is connected with a rotary disc by screw thread; a load spring is connected between the rotary disc and a sample plate; the sample plate is arranged at the top of the push rod; a top end is fixedly connected with a guide bench; the sample plate is connected with the guide bench in a sliding way; a cover plate is fixedly connected on the guide bench; a clamp is connected on the cover plate in a moveable way; the lower end of the clamp is fixedly connected with a standard sample; the top of the box body is connected with a rotary shaft; the lower end of the rotary shaft is connected with the clamp in a sliding way; and the input end of the rotary shaft is connected with the motor. The test bench disclosed by the invention can provide various compound environments with variable load, the presence of vibration, the absence of vibration and the like for studies of friction and abrasion between solids under the vibrating condition and various precise instruments can be arranged on the test bench for scientific researches. The test bench has good organization expandability.

Owner:SHANGHAI INST OF TECH

Concrete lever type tension-compression creep device provided with static pulley

InactiveCN104677745ASimple structureStable structureMaterial strength using tensile/compressive forcesConstant loadTension compression

The invention relates to a concrete lever type tension-compression creep device provided with a static pulley. The concrete lever type tension-compression creep device consists of a support device, a loading device and a test piece connecting device; the concrete lever type tension-compression creep device adopts a double-level mechanism to realize tension and compression. The concrete lever type tension-compression creep device has the beneficial technical effects that the device is simple and reliable in structure, is capable of applying a continuous and constant load onto a test piece, and is small in floor space; and two test functions including a tension test and a compression test can be provided by a set of device.

Owner:CHONGQING JIAOTONG UNIVERSITY

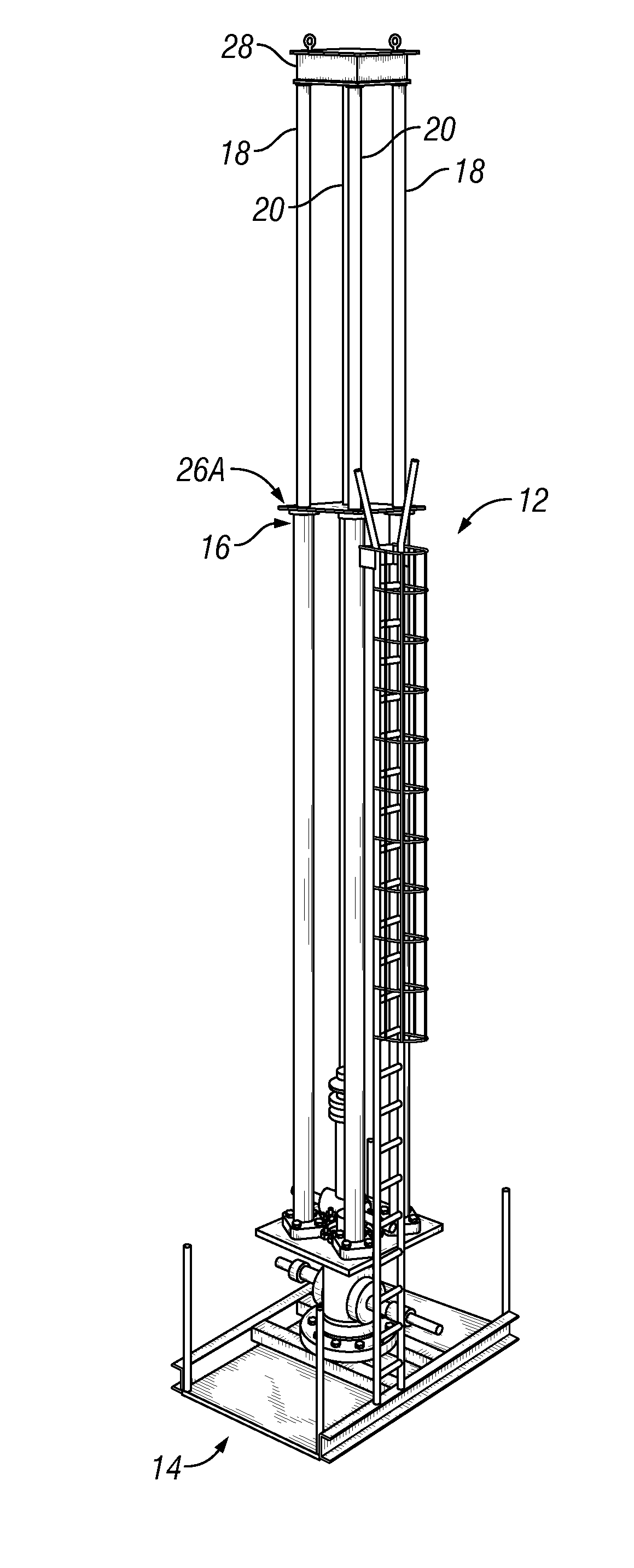

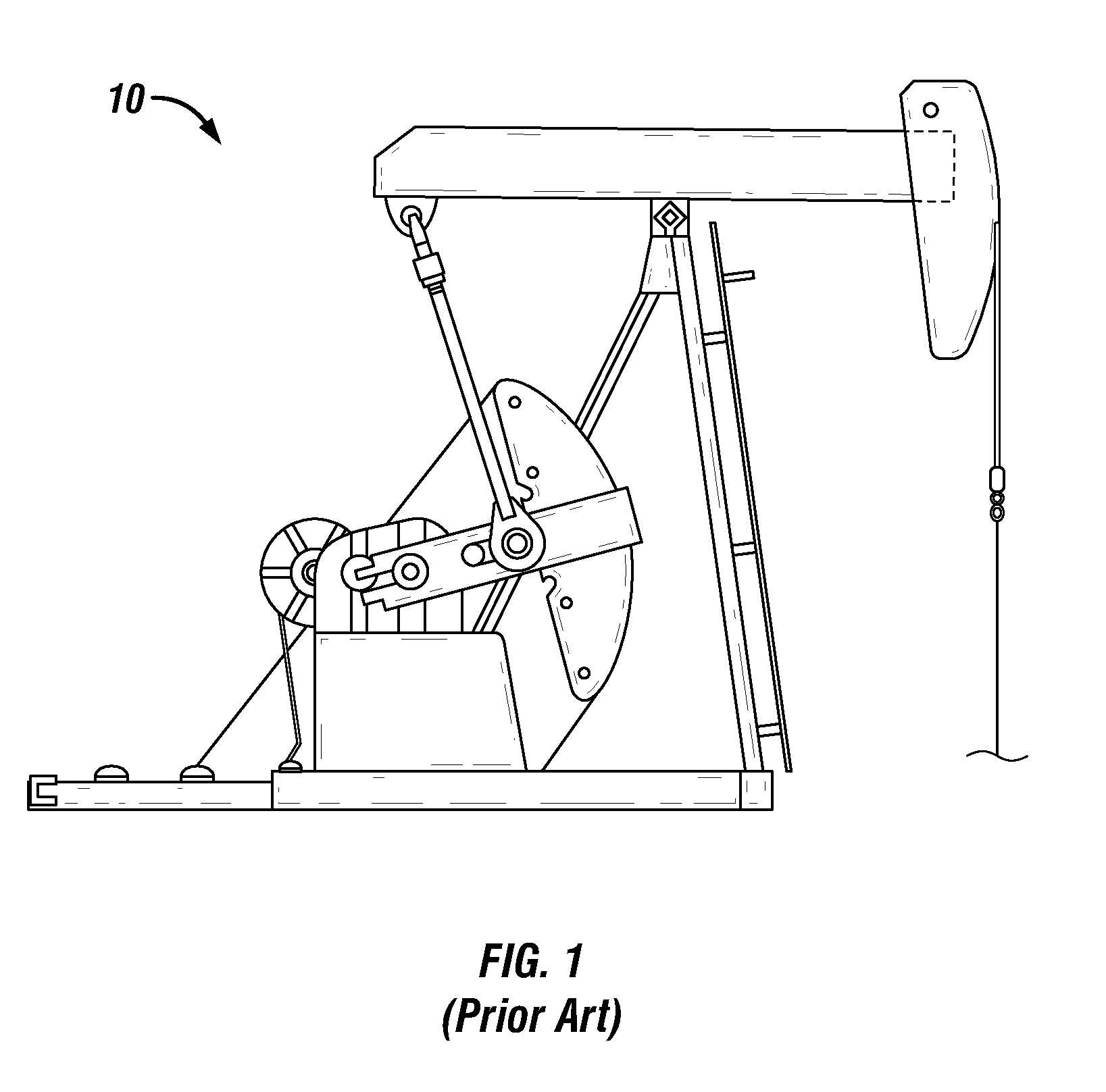

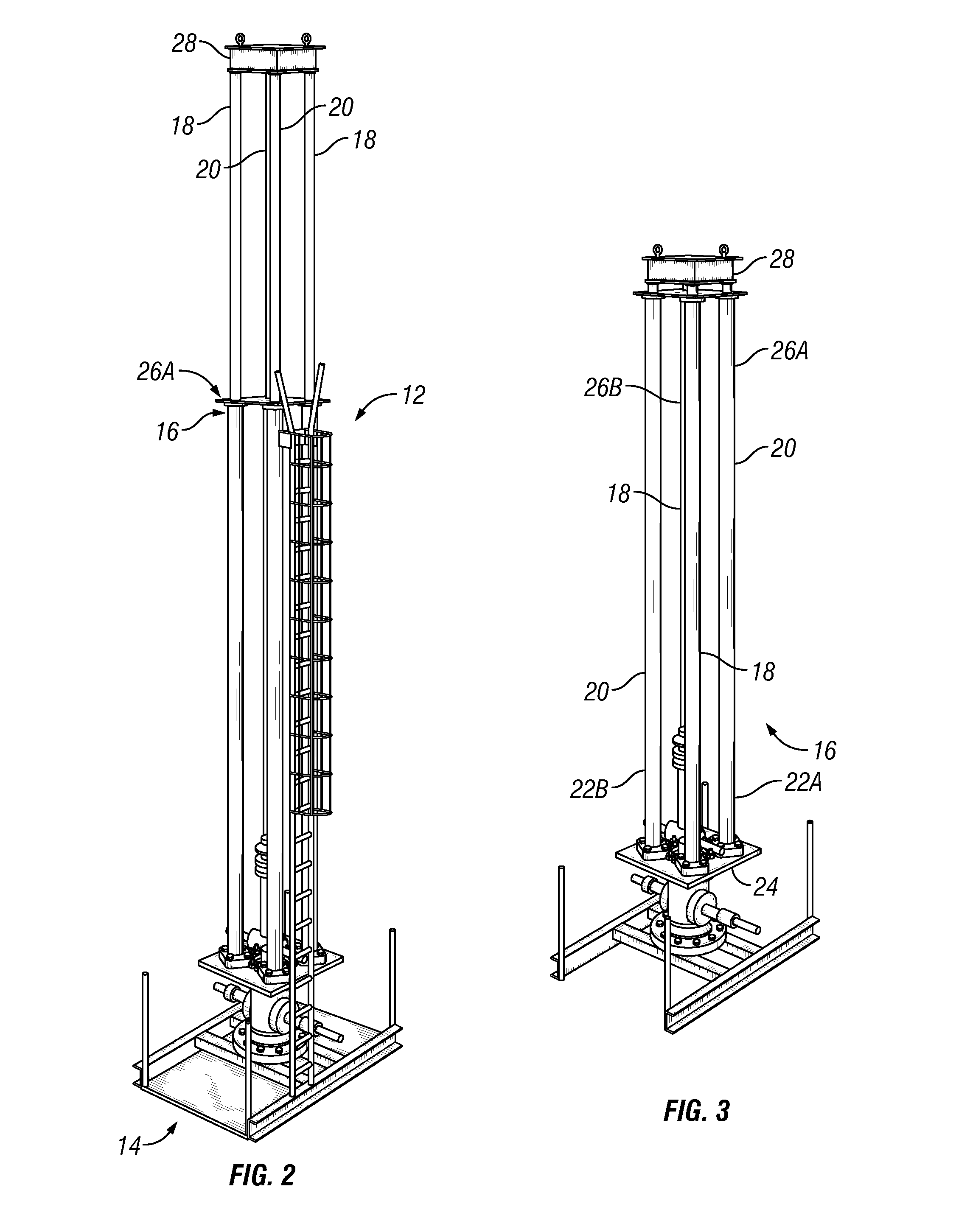

Hydraulic Oilfield Lift Pump

InactiveUS20100300679A1Reduce large load fluctuationRelieve pressureFlexible member pumpsFluid removalHydraulic cylinderSystems design

A vertically orientated hydraulically driven oilfield lift pump unit having a simplified hydraulic system. The system uses a pair of single acting hydraulic cylinders in tandem with a pair of double acting hydraulic cylinders interacting with hydraulic accumulators to provide an energy efficient, robust hydraulic system design with a minimum number of components.

Owner:NAT OILWELL VARCO LP

Method and apparatus for managing actinic intensity transients in a lithography mirror

InactiveUS6994444B2Reduce and eliminate variationReduce edge effectsMirrorsOptical filtersTemperature controlEdge effects

An apparatus and method of maintaining a time-constant heat load on a lithography mirror. The mirror includes a resistive layer formed on a substrate, contacts for coupling a power supply to the resistive layer, an insulating sublayer formed on the resistive layer, a polished layer formed on the insulating layer, and a reflective layer formed on the polished layer. The time-constant heat load on the lithography mirror is maintained by placing an additional electrical heat load on the mirror according to the actinic heat load transmitted by the mask. Maintaining the time-constant heat load can reduce or eliminate variation in image distortion that occurs as a result of changes in actinic heat load on the lithography mirror. Independent temperature control can be used to mitigate “cold-edge effect.”

Owner:ASML HLDG NV

System and method for providing constant loading in AC power applications

ActiveUS8120307B2Constant loadApply evenlySingle-phase induction motor startersSynchronous motors startersConstant loadField-effect transistor

A system and method are provided for constant loading in AC power applications where at least one turn-on point of at least one half cycle of a modulating sine wave is randomly selected; at least one turn-off point is determined; and at least one slice located between the at least one turn-on point and turn-off point is removed. The slices may be removed by utilizing insulated gate bipolar transistors or field effect transistors.

Owner:THE POWERWISE GRP

Centrifugal compressor assembly and method

ActiveUS9353765B2Improve performanceReduce physical sizeEngine manufacturePump componentsMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Comparator circuits with local ramp buffering for a column-parallel single-slope ADC

ActiveUS20160118992A1Low comparator kickbackConstant loadPower saving provisionsElectric signal transmission systemsComparators circuitsVoltage variation

A comparator circuit suitable for use in a column-parallel single-slope analog-to-digital converter comprises a comparator, an input voltage sampling switch, a sampling capacitor arranged to store a voltage which varies with an input voltage when the sampling switch is closed, and a local ramp buffer arranged to buffer a global voltage ramp applied at an input. The comparator circuit is arranged such that its output toggles when the buffered global voltage ramp exceeds the stored voltage. Both DC- and AC-coupled comparator embodiments are disclosed.

Owner:TELEDYNE SCI & IMAGING

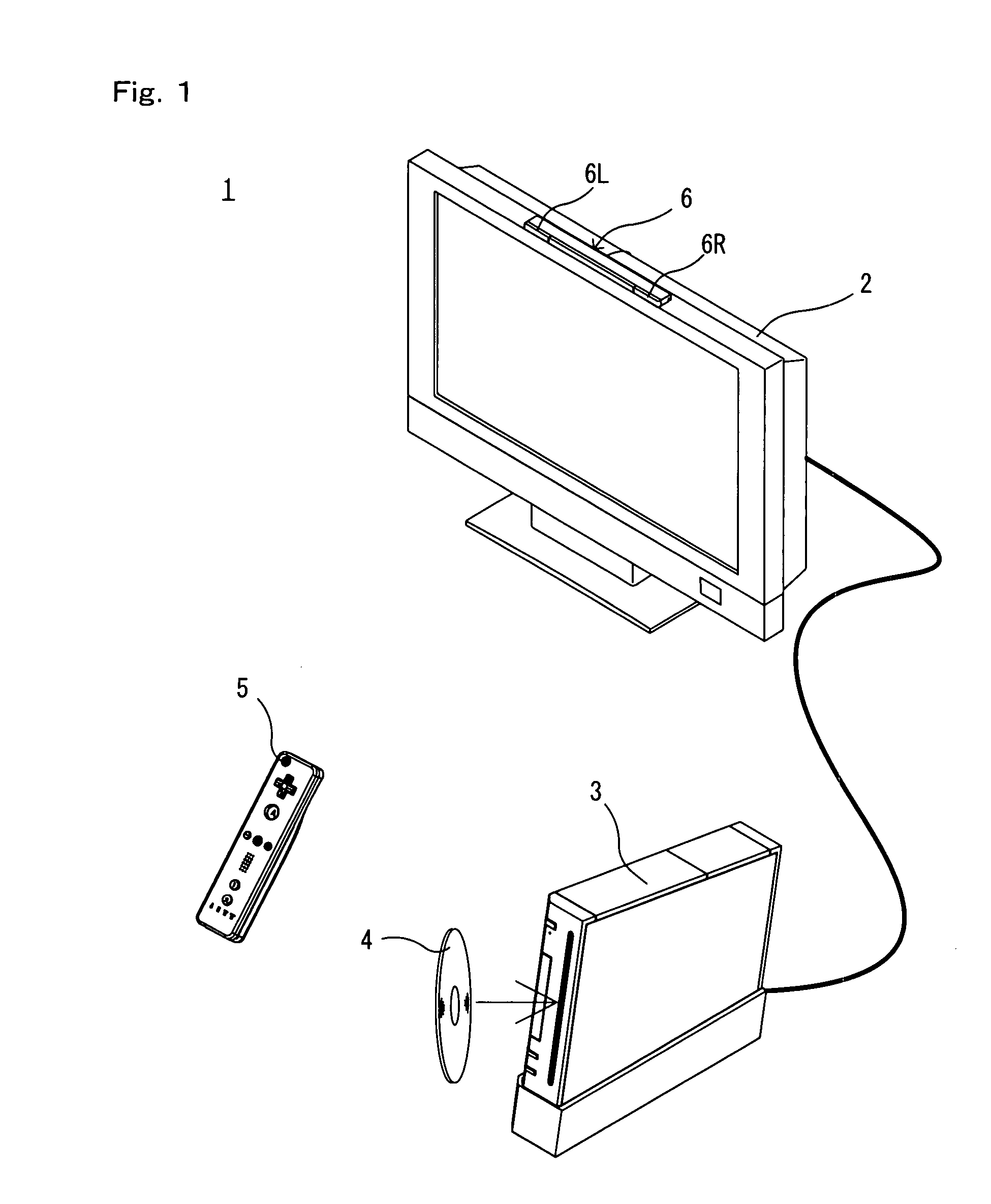

Storage medium having game program stored thereon and game apparatus

ActiveUS20090017909A1Avoid system loadConstant loadVideo gamesSpecial data processing applicationsThree-dimensional spaceInput device

The game apparatus shoots a moving object from a predetermined weapon object and moves the moving object in a three-dimensional space in a case where an input from an input device is received. At least one of the size, the shape, and the number of a contact determination area defined for the moving object is changed in accordance with a distance over which the moving object moves in the three-dimensional space. The game apparatus determines whether or not the contact determination area defined for the moving object contacts a contact determination area defined for a target object. A predetermined game process is performed when the determination result of a contact determination step is positive.

Owner:NINTENDO CO LTD

Hydraulically positioned shaft bearing attachment system and method

ActiveUS7866894B2Reduce friction lossEliminate needRoller bearingsBearing assemblyEngineeringMechanical engineering

A mounting system is disclosed for mounting a bearing assembly or other mechanical element to a shaft. The mounting system uses a tapered sleeve mechanism to secure the bearing assembly on the shaft. Specifically, a pressure loaded piston drives the sleeve from a pre-assembled position to an initial position. The initial position is determined by monitoring the pressure applied to the piston. Once the initial position has been reached, a linear indicator is used to measure the axial sleeve movement from the initial position to a final position. The system remains in place after the bearing is installed on the shaft and facilitates removal of the bearing assembly from the shaft.

Owner:DODGE INDS +1

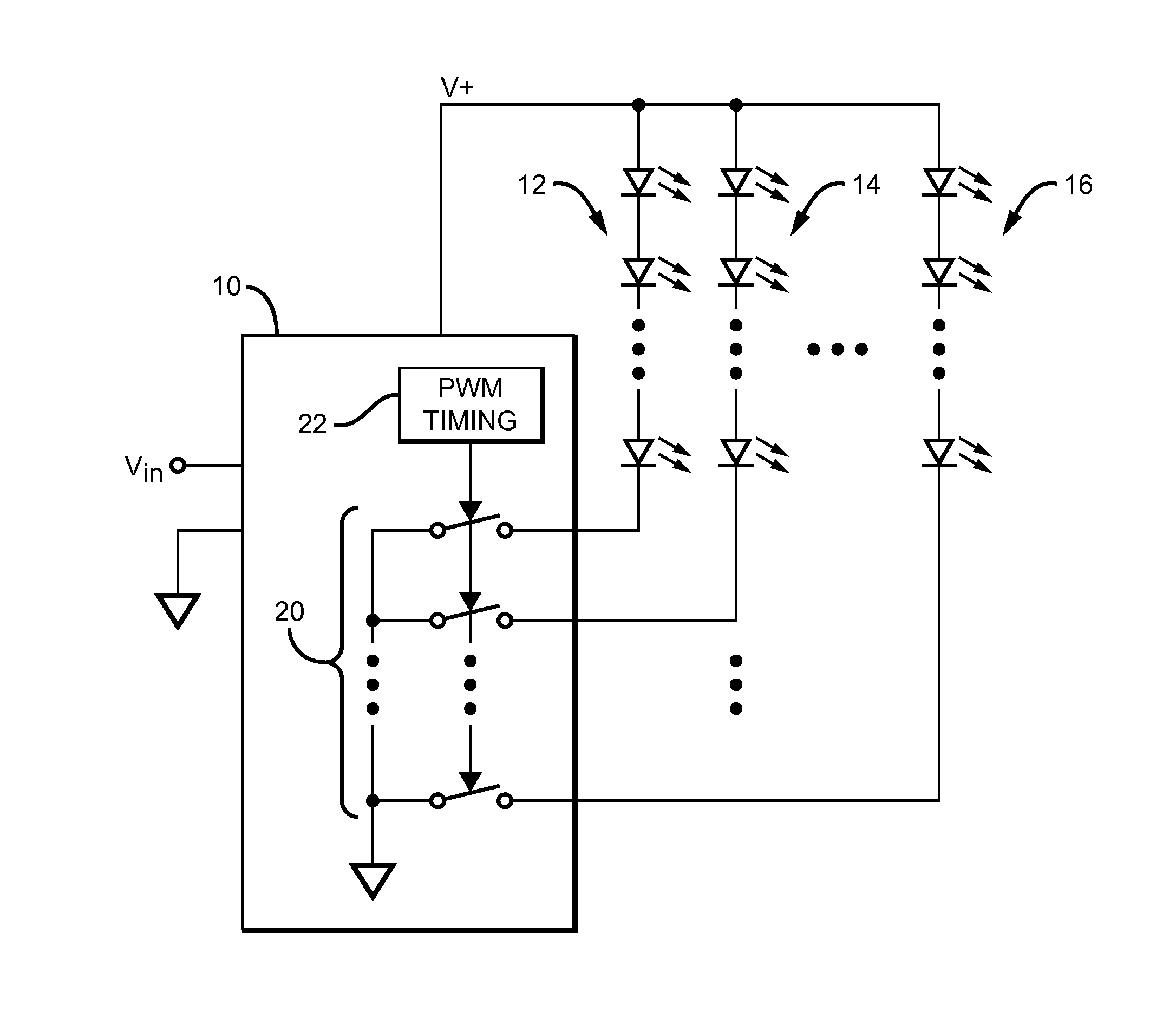

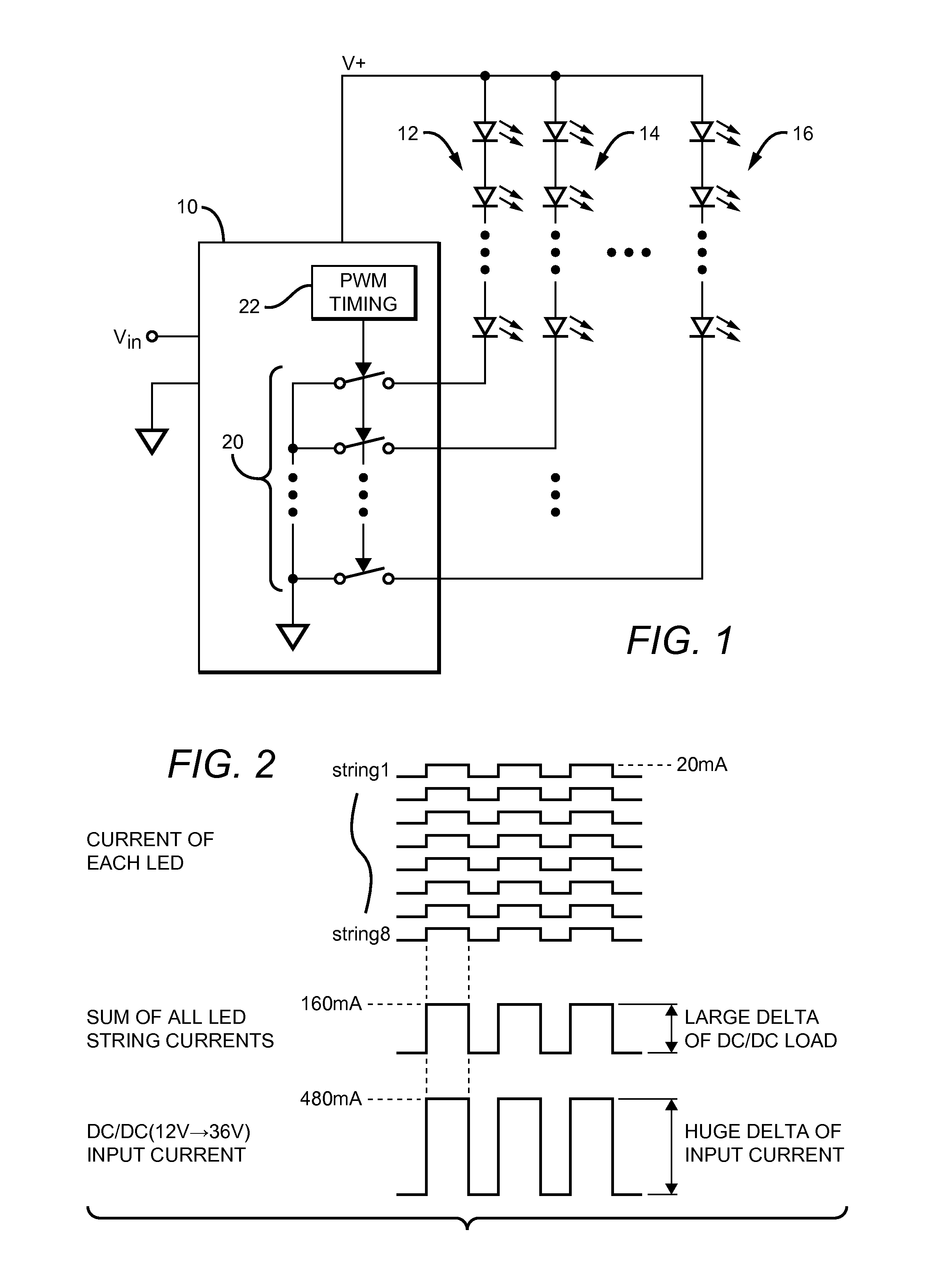

Multi-string LED driving method and system

ActiveUS20130082613A1Constant loadSpread the loadElectrical apparatusElectroluminescent light sourcesConstant loadDriver circuit

A multi-string LED driving method and system requires generating pulse-width-modulated (PWM'd) driving signals to respective LED strings to control their brightness levels, and staggering the timing of the driving signals such that the number of LED strings driven on simultaneously varies over time by no more than one LED string. The PWM'd driving signals are generated to, for example, achieve local dimming for a display device which employs a multi-string LED backlight system; the present method enables local dimming to be achieved while maintaining a relatively constant load on the drive circuit. The staggering of the timing of the PWM'd driving signals is preferably implemented by arranging the ON times of the driving signals such that they occur serially, such that the loading imposed by the LED strings is spread throughout each switching cycle.

Owner:ANALOG DEVICES INC

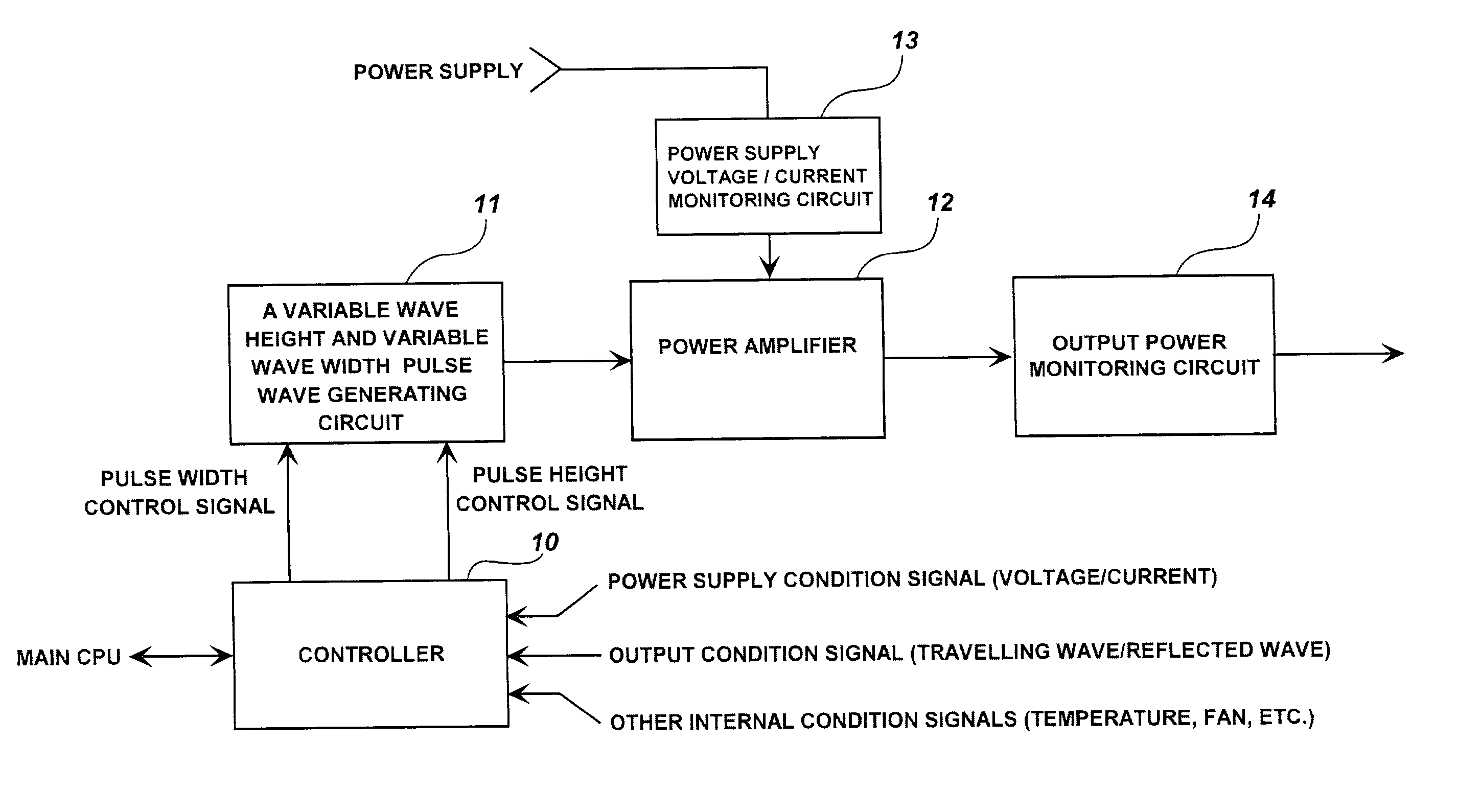

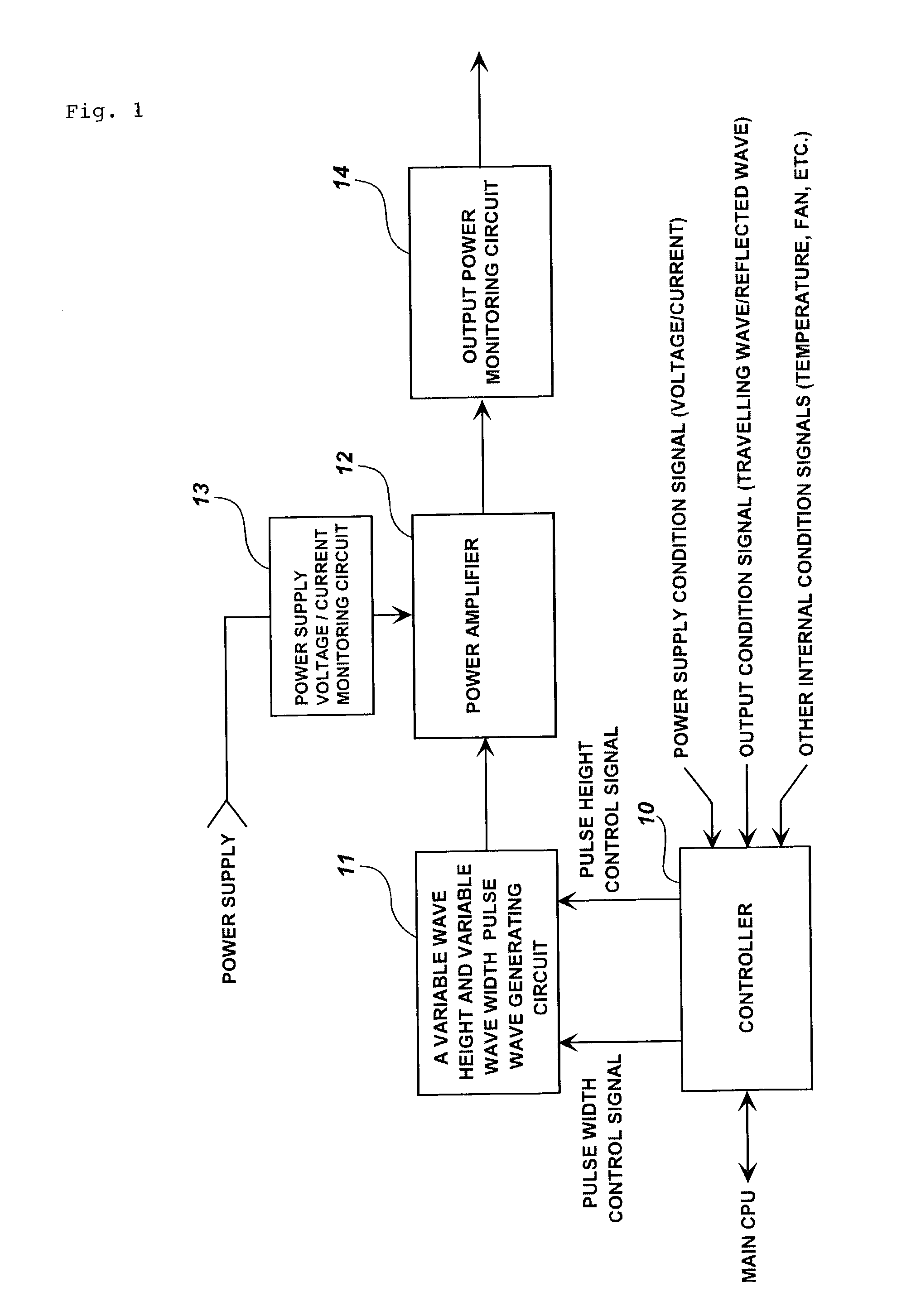

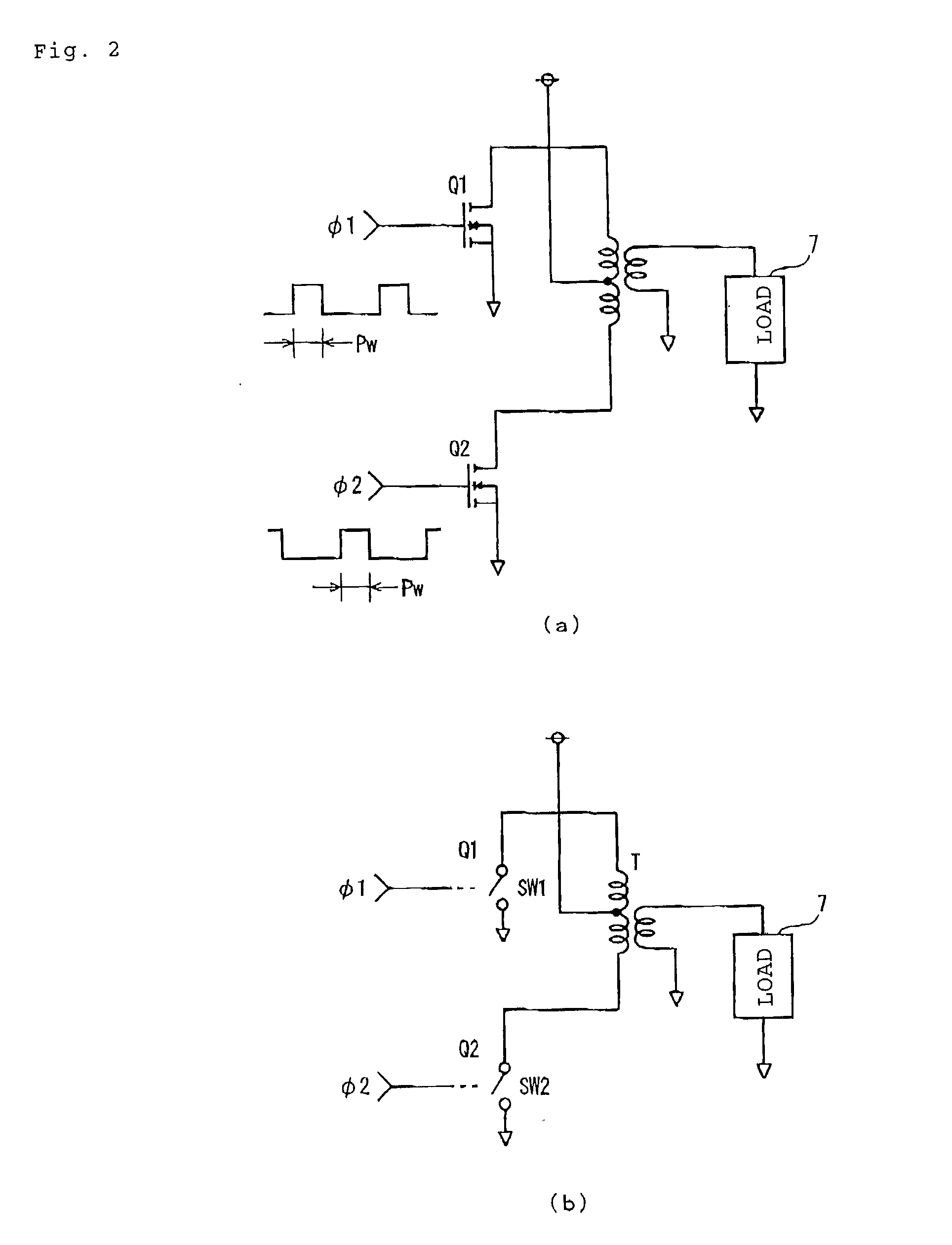

Radio frequency amplifier and method of driving the same

InactiveUS20030042977A1Not easily destroyedSimple powerPush-pull amplifiersPhase-splittersAudio power amplifierPulse height

The present invention relates to a radio frequency amplifier and a method of driving the radio frequency amplifier, and an object of the present invention is to provide a radio frequency amplifier and a method of driving the radio frequency amplifier which are excellent in the controllability at the time of a low power output while keeping the advantage of a high efficiency and give the heating generated by a power loss of such a degree that dewing generated due to over-cooling by the cooling system is not generated at the time of a low power output. The radio frequency amplifier is structured by a variable wave height and variable wave width pulse wave generating circuit 11 that generates a pulse wave (rectangular wave) having an arbitrary pulse height and pulse width, and a power amplifier 12 that is driven by the rectangular wave.

Owner:AGILENT TECH INC

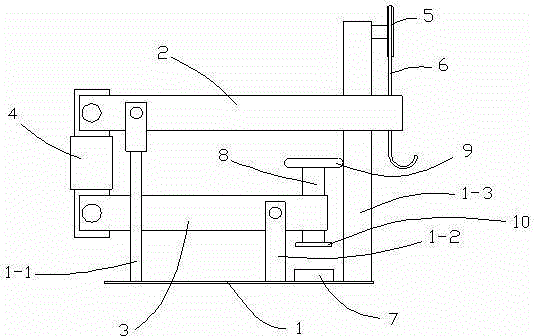

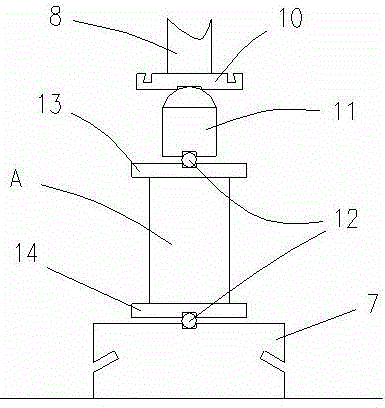

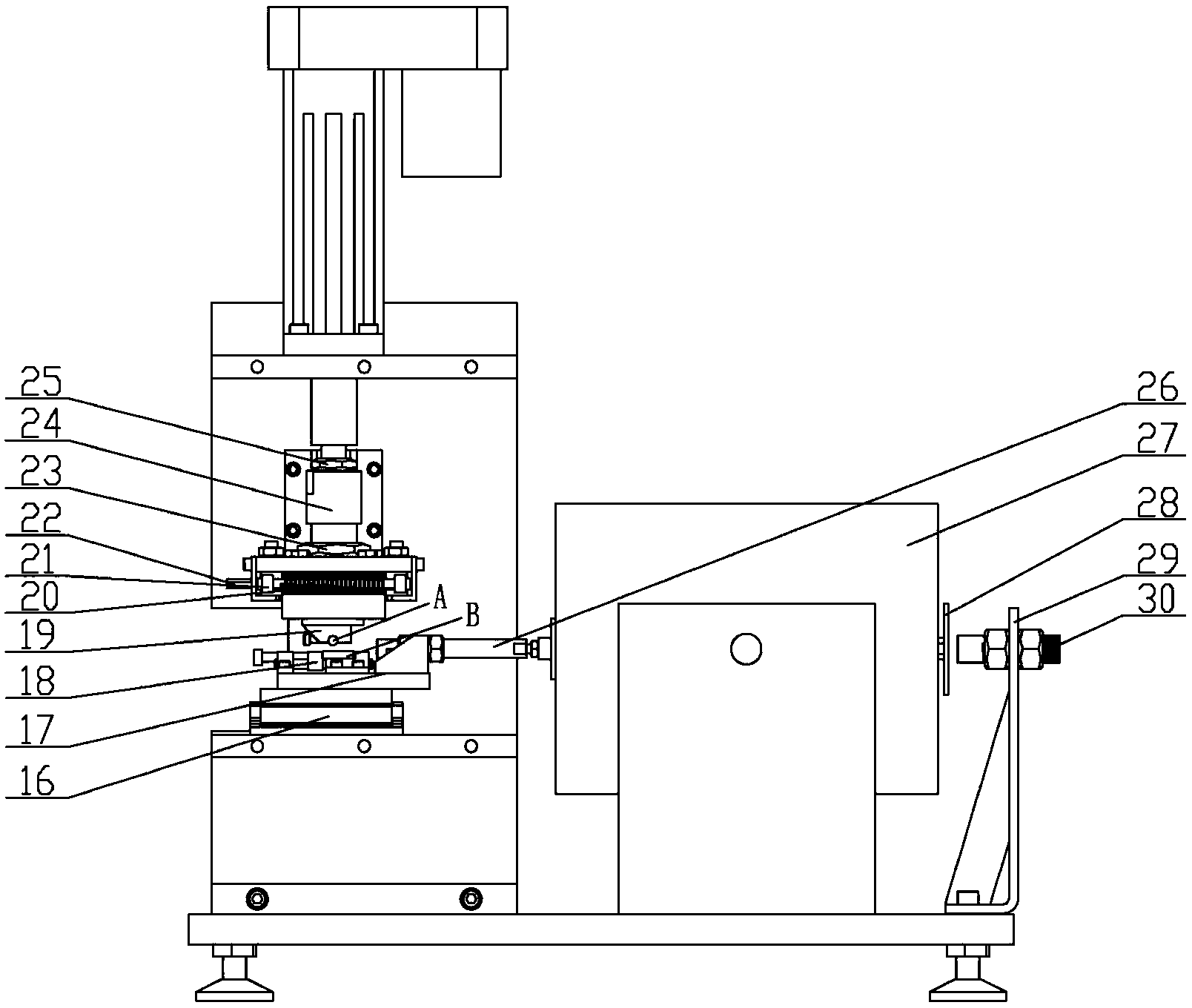

Reciprocating type micro-friction abrasion testing machine

ActiveCN103308407ALarge amplitudeIncrease amplitudeInvestigating abrasion/wear resistanceSignal conditioningDesign testing

The invention discloses a reciprocating type micro-friction abrasion testing machine and belongs to a micro-friction and abrasion testing device. The testing machine comprises a bottom plate, and a bracket, a driving device, a loading device, a positioning and clamping device and a signal conditioning and data acquisition device which are arranged on the bottom plate, wherein the bracket at least consists of two side plates which are longitudinally fixed on the bottom plate; a lower sliding rail seat and a top cylinder seat are at least arranged between the two side plates. An exciter serves as a power source, the equipment is small in size and has high driving force and wide amplitude and frequency variation range, the signal is provided by a signal generation card, multiple driving signals are provided, the frequency and the amplitude are convenient to adjust, and the testing machine is easily controlled by a computer program; meanwhile, a clamp system for a fixation test is simple in structure, reliable in clamping and convenient to mount, and tests in multiple friction pair contact forms can be realized by replacing the clamp. The designed testing machine is high in precision and convenient to operate and provides a reliable experimental instrument for research of micro abrasion.

Owner:NANJING BIO INSPIRED INTELLIGENT TECH

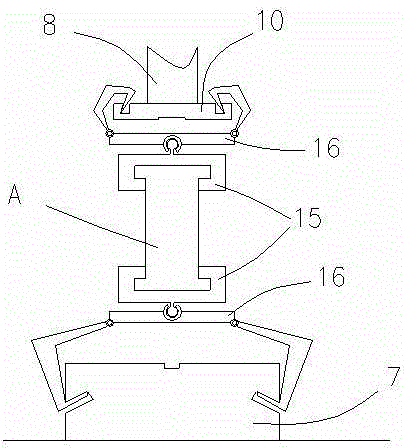

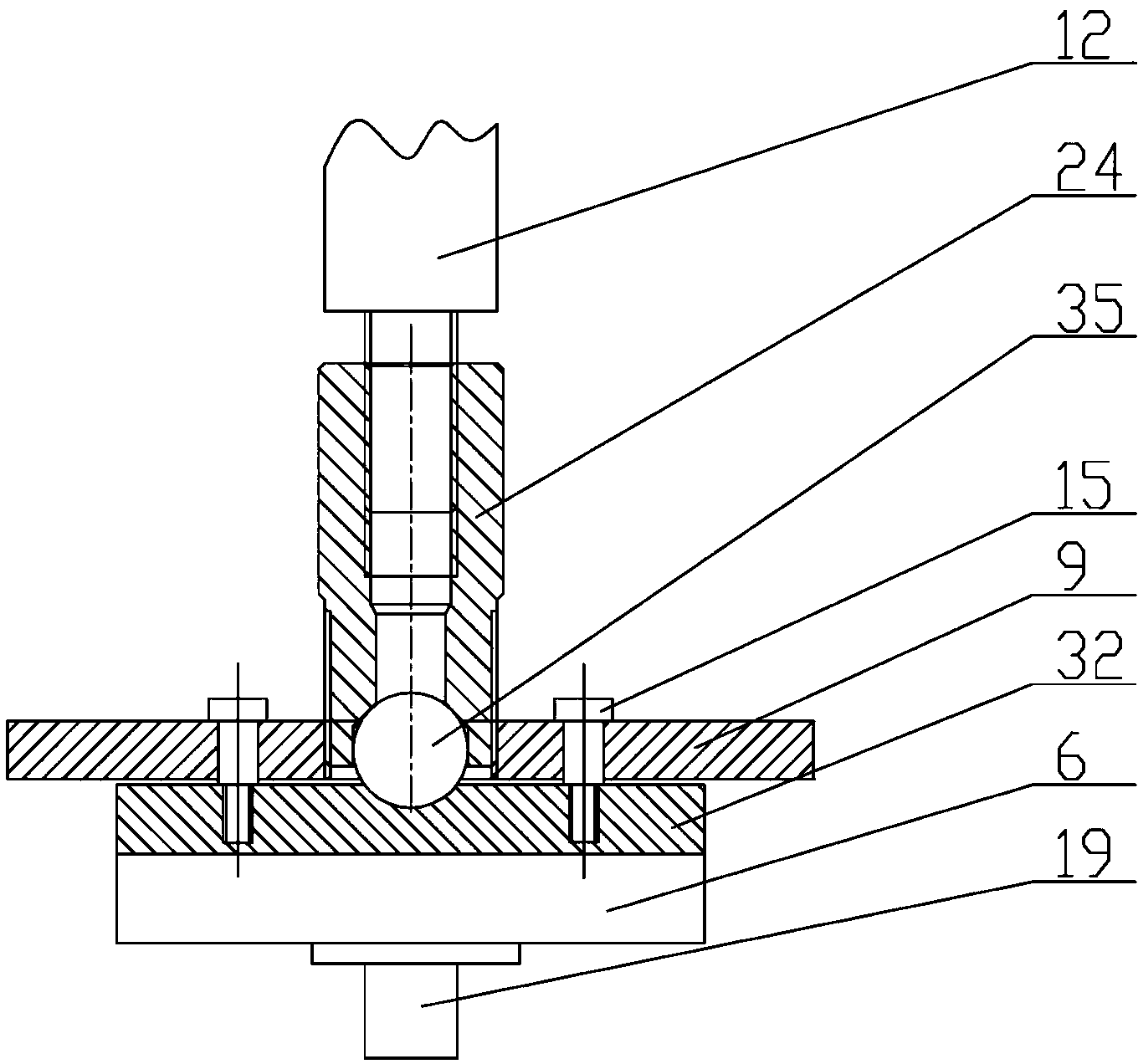

Creep test loading device for non-metal anti-floating anchor

The invention belongs to the technical field of in-situ test equipment and relates to a creep test loading device for a non-metal anti-floating anchor. An anchor body is of a solid rod-shaped structure and is bonded with a steel casing pipe. H-shaped steel is perpendicular to a concrete cushion layer and is symmetrically arranged on the two sides of the anchor body. A counterforce beam is a box-type section formed by welding two pieces of H-shaped steel. The counterforce beam is provided with a steel base plate. The steel base plate, a penetrating jack, a spring, a steel plate, an anchor cable axial force meter and an anchorage device are stacked on the counterforce beam and arranged outside the steel casing pipe in a sleeved mode. The anchorage device is welded to the outside of the steel casing pipe. A dial indicator is arranged on L-shaped organic glass in an erecting mode. The L-shaped organic glass is arranged on the interface of the concrete cushion layer and the anchor body. A magnetic indicator base of the dial indicator is arranged on a standard beam arranged on a concrete buttress. The concrete buttress is arranged on the concrete cushion layer. The creep test loading device is simple in overall structure, convenient to install, high in testing precision and high in operability.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

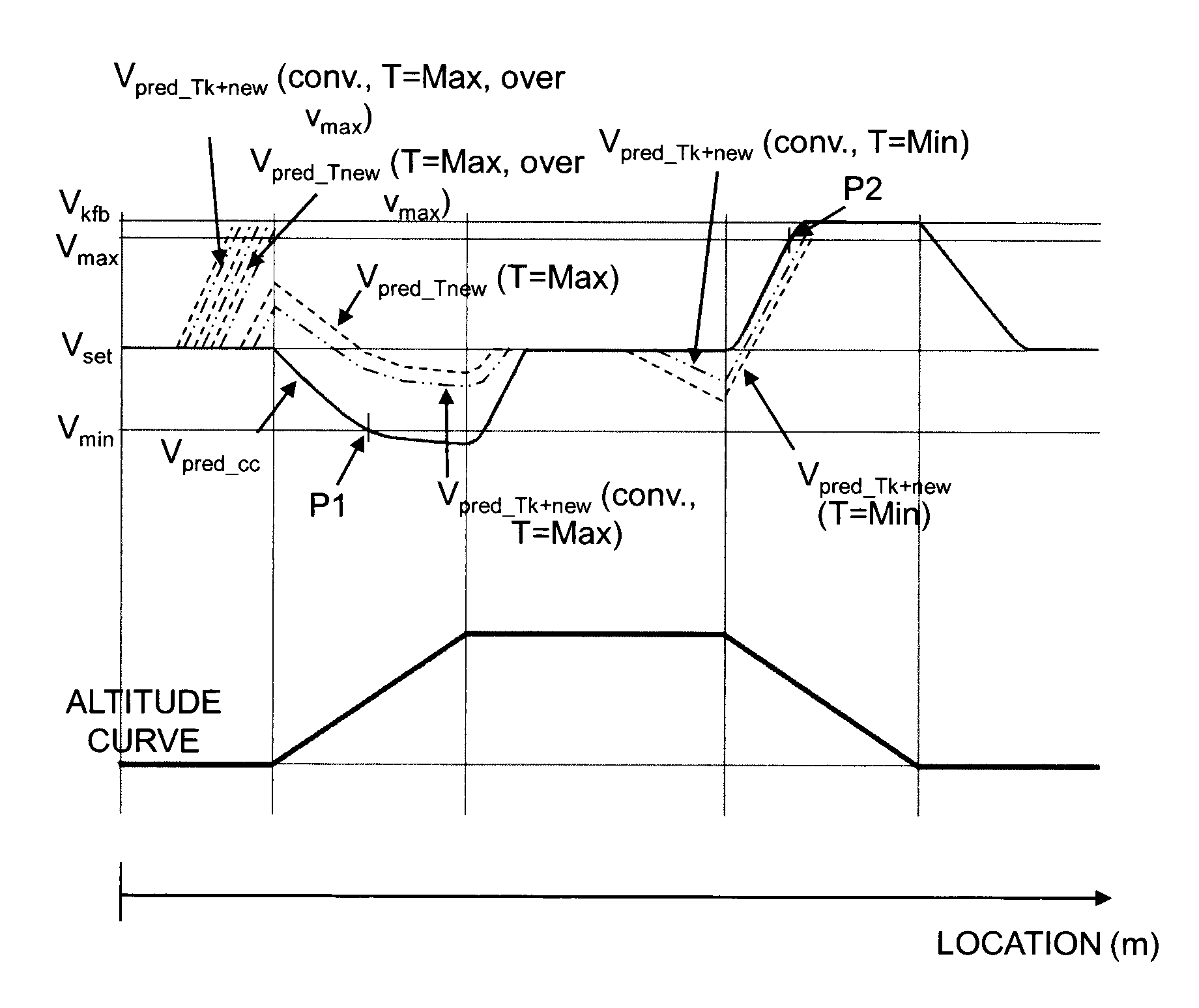

Method and module for controlling a vehicle's speed

InactiveUS20130085651A1Constant loadLow costVehicle fittingsDigital data processing detailsHorizonCruise control

A method for controlling a vehicle's speed by adopting a desired speed vset for the vehicle; determining a horizon for the intended itinerary made up of route segments, effecting the following during each of a number of simulation cycles (s) each comprising a number N of simulation steps conducted at a predetermined frequency f: first predicting the vehicle's speed vpred<sub2>—< / sub2>cc along the horizon with conventional cruise control when vset is presented as reference speed, comparing the predicted vehicle speed vpred<sub2>—< / sub2>cc in a range vmin to vmax, making a second prediction of the vehicle's speed vpred<sub2>—< / sub2>Tnew along the horizon based on the vehicle's engine torque T; determining a reference value for how the vehicle's speed is to be influenced on the basis of at least one of the comparisons and the predicted vehicle speed vpred<sub2>—< / sub2>Tnew; controlling the vehicle by the reference value. A module for the foregoing controls a vehicle's speed.

Owner:SCANIA CV AB

Hydraulically positioned shaft bearing attachment system and method

ActiveUS20080075402A1Reduce friction lossEliminate needRoller bearingsBearing assemblyEngineeringMechanical engineering

A mounting system is disclosed for mounting a bearing assembly or other mechanical element to a shaft. The mounting system uses a tapered sleeve mechanism to secure the bearing assembly on the shaft. Specifically, a pressure loaded piston drives the sleeve from a pre-assembled position to an initial position. The initial position is determined by monitoring the pressure applied to the piston. Once the initial position has been reached, a linear indicator is used to measure the axial sleeve movement from the initial position to a final position. The system remains in place after the bearing is installed on the shaft and facilitates removal of the bearing assembly from the shaft.

Owner:DODGE INDS +1

Vertically movable partition walls

ActiveUS7156142B2Simple and economical structureLoads imposed on the support structure are constantExtensible doors/windowsCurtain accessoriesStructural engineeringEngineering

A partition wall, upwardly movable into storage position and downwardly movable into vertical, down position. The wall comprises a plurality of similar trains of elongated members. The members of each train are arranged to form a single pantograph forming longitudinally aligned rows of diamonds. The trains are spaced laterally to form a wall plane and oriented so that the diamonds of the pantographs operate in a plane at a 90° angle to that wall plane. A plurality of panels are provided, each panel being secured to a pair of corresponding members in adjacent trains. The panels are secured to corresponding pairs of opposed sides of the diamonds. Means are provided to raise and lower the trains at a similar rate. The pantographs are contracted when the wall is in a storage position and the elongated when the wall is in down position. The panels form a vertical wall when the pantographs are elongated in down position.

Owner:SKYFOLD INC

Paintball loader systems

InactiveUS7966999B2Reduce loadImprove loading speedAmmunition loadingCompressed gas gunsMicrocontrollerSystems design

A paintball loader system designed to efficiently deliver paintballs to a paintball gun. The drive mechanism is a screw-type design comprising a resilient auger. A microcontroller is programmed to automatically adjust the rotation of the auger based on data from multiple sensor points within the loader. The auger is mounted such that both rotational axial movements are enabled during operation. The axial movement of the auger is used to maintain a constant force on the paintballs awaiting loading within the paintball gun.

Owner:BOSCH JOHN P MR

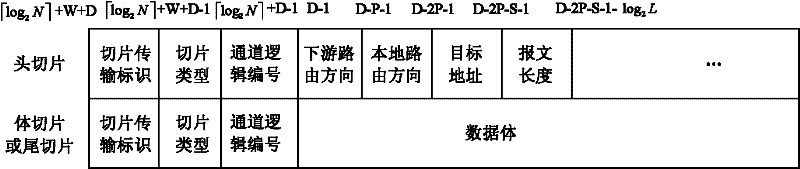

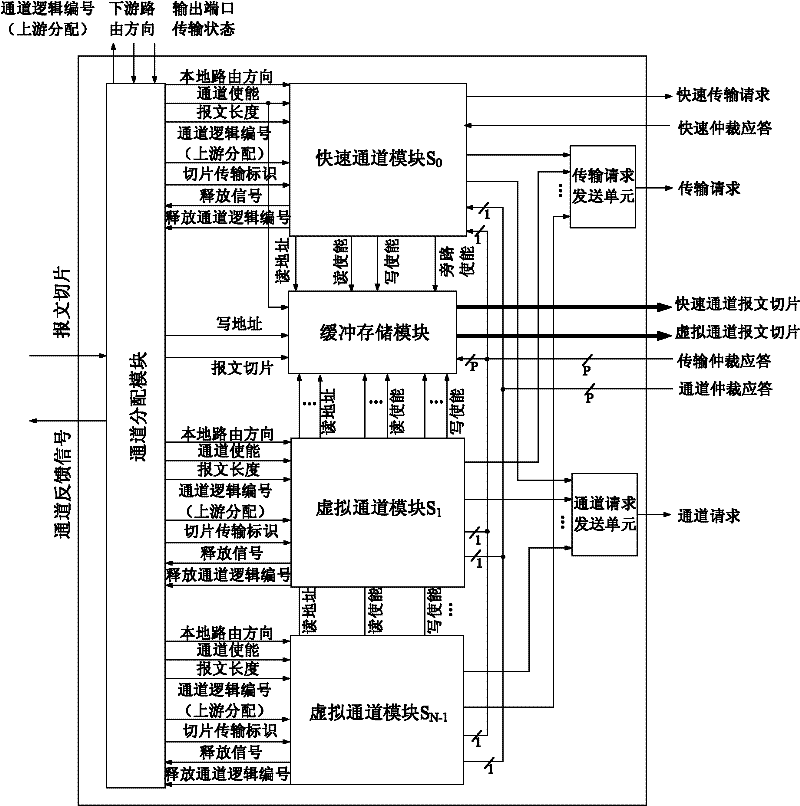

One-cycle router on chip based on quick path technology

InactiveCN102185751AReduce forwarding delayConstant loadData switching switchboardsCrossbar switchComputer module

The invention discloses a one-cycle router on chip based on a quick path technology. The one-cycle router on chip consists of P input ports, a quick arbitration module, a transmission arbitration module, a path arbitration module, an anticipating signal management module, a crossbar switch and P output ports, wherein the input port consists of a path allocation module, a buffer storage module, a quick path module, a virtual path module, a transmission request transmission unit and a path request transmission unit; the quick arbitration module consists of a first response control part and P quick arbitration parts; the path arbitration module consists of a path request distribution part, P path arbitration parts and a second response control unit; the transmission arbitration module consists of a transmission request distribution part, P transmission arbitration parts and a third response control part; and the anticipating signal management module consists of P computing storage parts and P signal driving parts. The one-cycle router on chip can realize one-cycle forwarding operations, and is applied to various routing algorithms.

Owner:NAT UNIV OF DEFENSE TECH

Method and module for controlling a vehicle's speed

InactiveUS8744718B2Constant loadLow costVehicle fittingsDigital data processing detailsHorizonCruise control

A method for controlling a vehicle's speed includes adopting a desired speed vset for the vehicle; determining by means of map data and location data a horizon for the intended itinerary which is made up of route segments with at least one characteristic for each segment; effecting the following during each of a number of simulation cycles (s) each comprising a number N of simulation steps conducted at a predetermined frequency f: making a first prediction of the vehicle's speed vpred<sub2>—< / sub2>cc along the horizon with conventional cruise control when vset is presented as reference speed, which prediction depends on the characteristics of said segment; comparing the predicted vehicle speed vpred<sub2>—< / sub2>cc with vmin and vmax, which demarcate a range within which the vehicle's speed is intended to be; making a second prediction of the vehicle's speed vpred<sub2>—< / sub2>Tnew along the horizon when the vehicle's engine torque T is a value which depends on the result of said comparison in the latest preceding simulation cycle (s−1); determining at least one reference value for how the vehicle's speed is to be influenced on the basis of at least one of said comparisons in that simulation cycle (s) and the predicted vehicle speed vpred<sub2>—< / sub2>Tnew; sending to a control system in the vehicle said at least one reference value with respect to which the vehicle is thereupon regulated. The invention comprises also a module for controlling a vehicle's speed.

Owner:SCANIA CV AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com