Vibration and abrasion test bench

A vibration wear and test bench technology, which is used in the application of repetitive force/pulsation force to test material strength and test wear resistance. It can solve the problems of inability to test vibration and wear, and achieve the effect of good mechanism expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

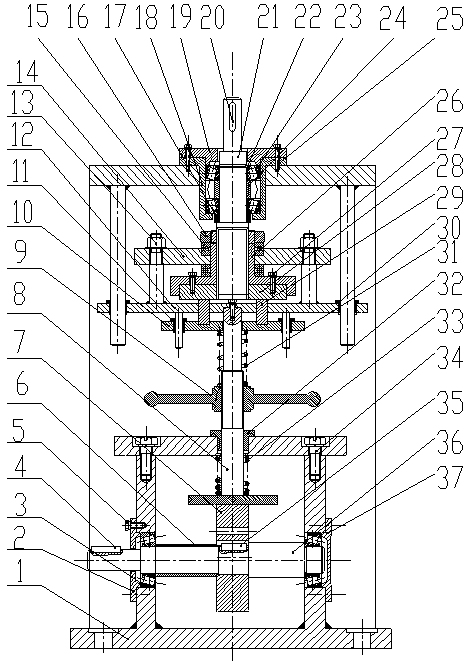

[0012] Such as figure 1 As shown, the vibration wear test bench of the present invention includes a box body 1, a left end cover 2, a bearing 3, a key 4, a screw 5, a jacket 6, an eccentric wheel 7, a push rod 8, a turntable 9, a sample plate 10, a guide Sleeve 11, guide table 12, nut 13, cover plate 14, thrust ball bearing 15, round nut 16, bearing jacket 17, sleeve cup 18, bearing cover 19, rotating shaft transmission key 20, rotating shaft 21, shaft retaining ring 22. Tapered roller bearing 23, support sleeve 24, screw 25, fixture 26, fixing bolt 27, standard sample 28, sample to be tested 29, first guide sleeve 30, loading spring 31, second guide sleeve 32, Compression spring 33, outer hexagon screw 34, transmission key 35, vibration shaft 36, right end cover 37.

[0013] The electromagnetic speed regulating motor is connected with the vibration s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com