Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Connection seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

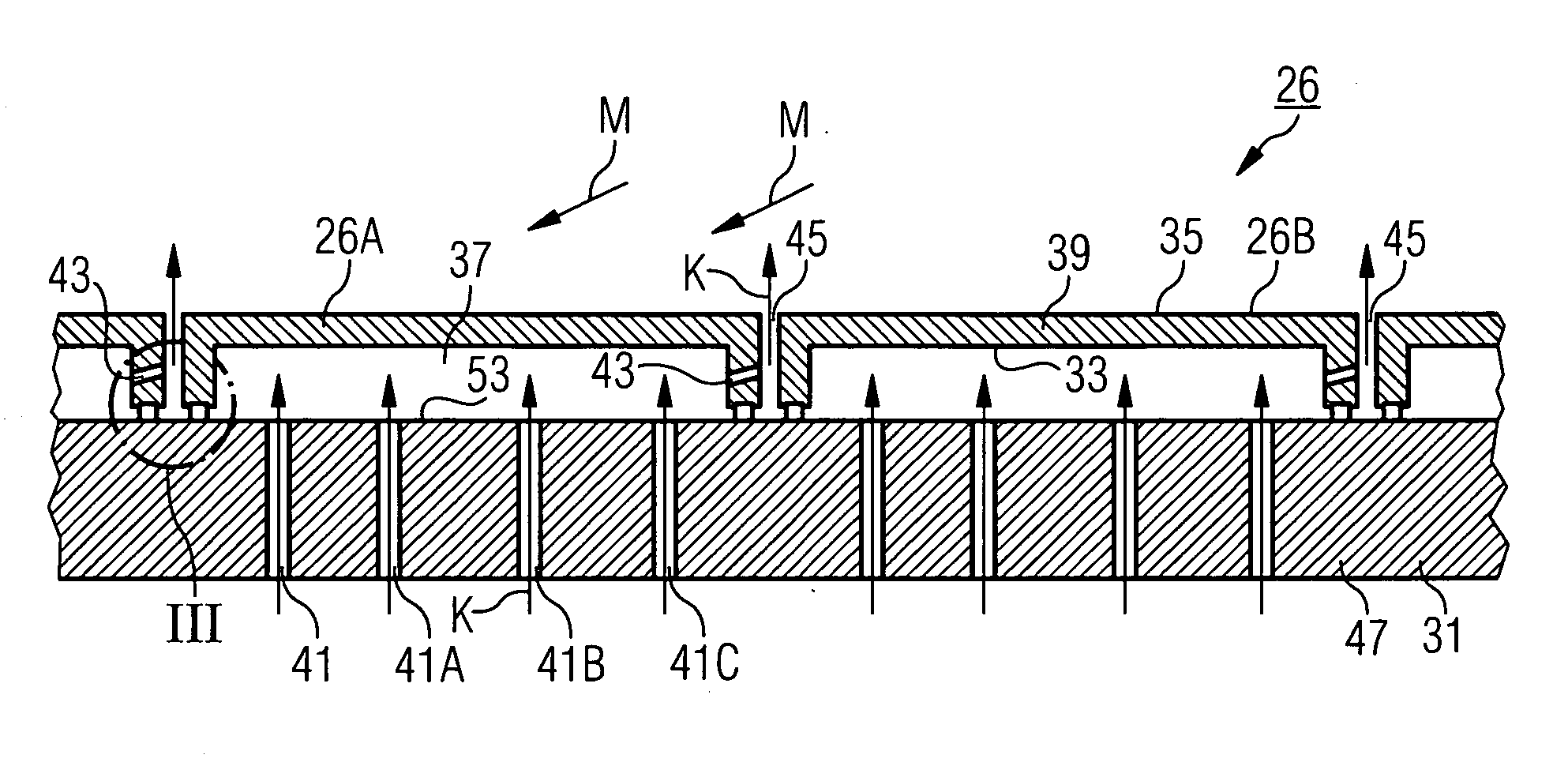

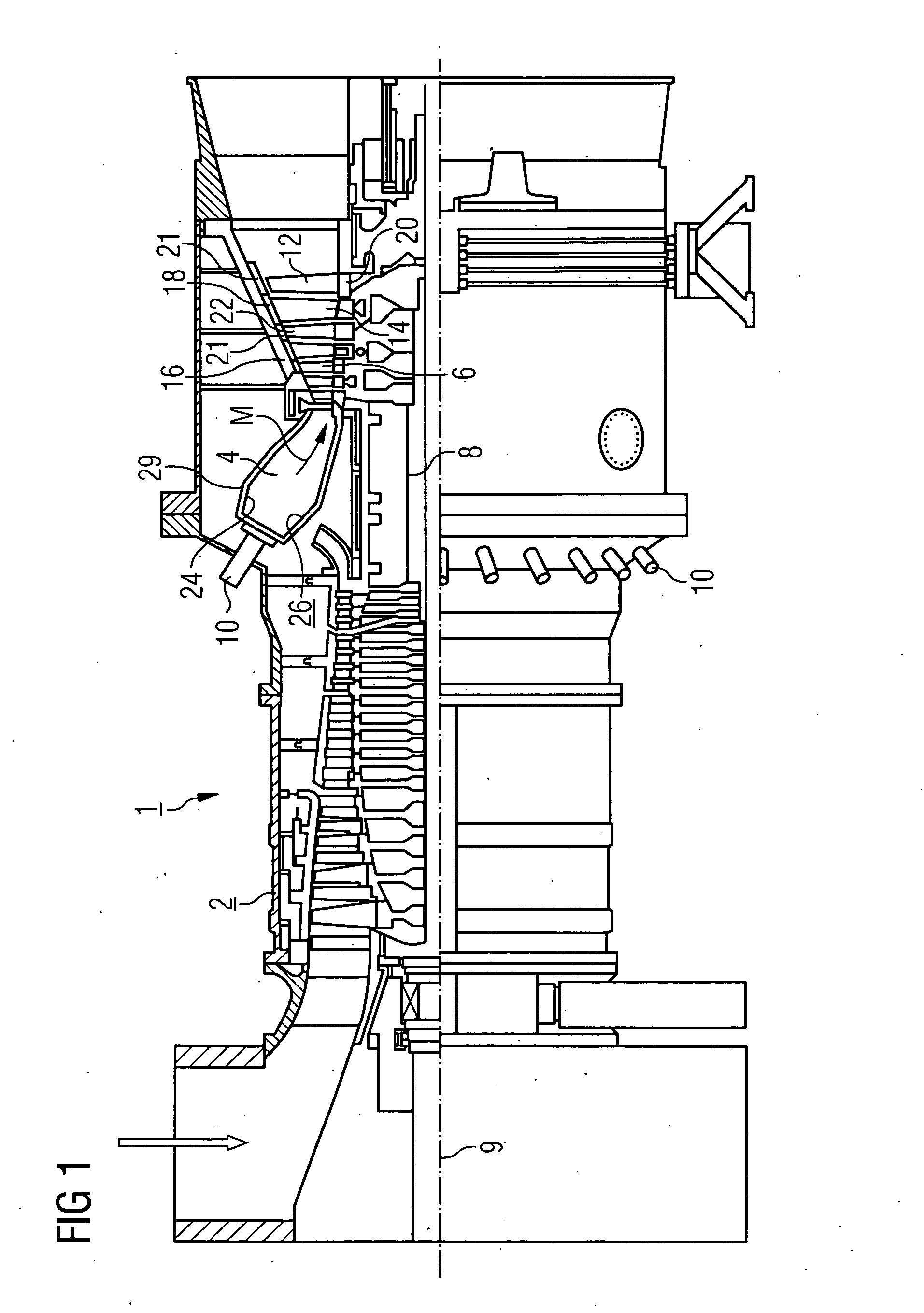

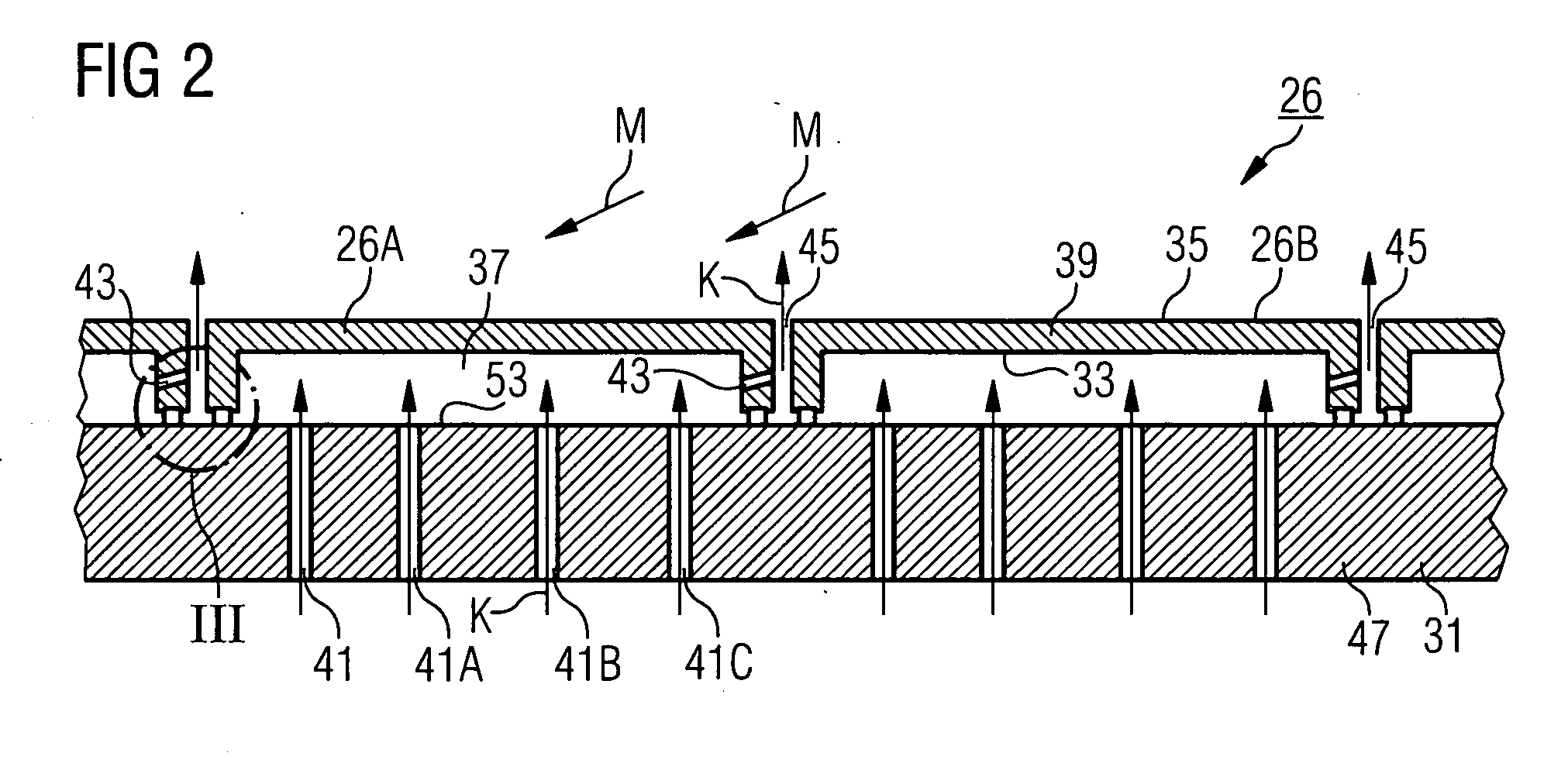

Heat Shield Arrangement for a Component Guiding a Hot Gas in Particular for a Combustion Chamber in a Gas Turbine

InactiveUS20090077974A1Reduce consumptionEffectively measureContinuous combustion chamberTurbine/propulsion engine coolingInterior spaceCombustion chamber

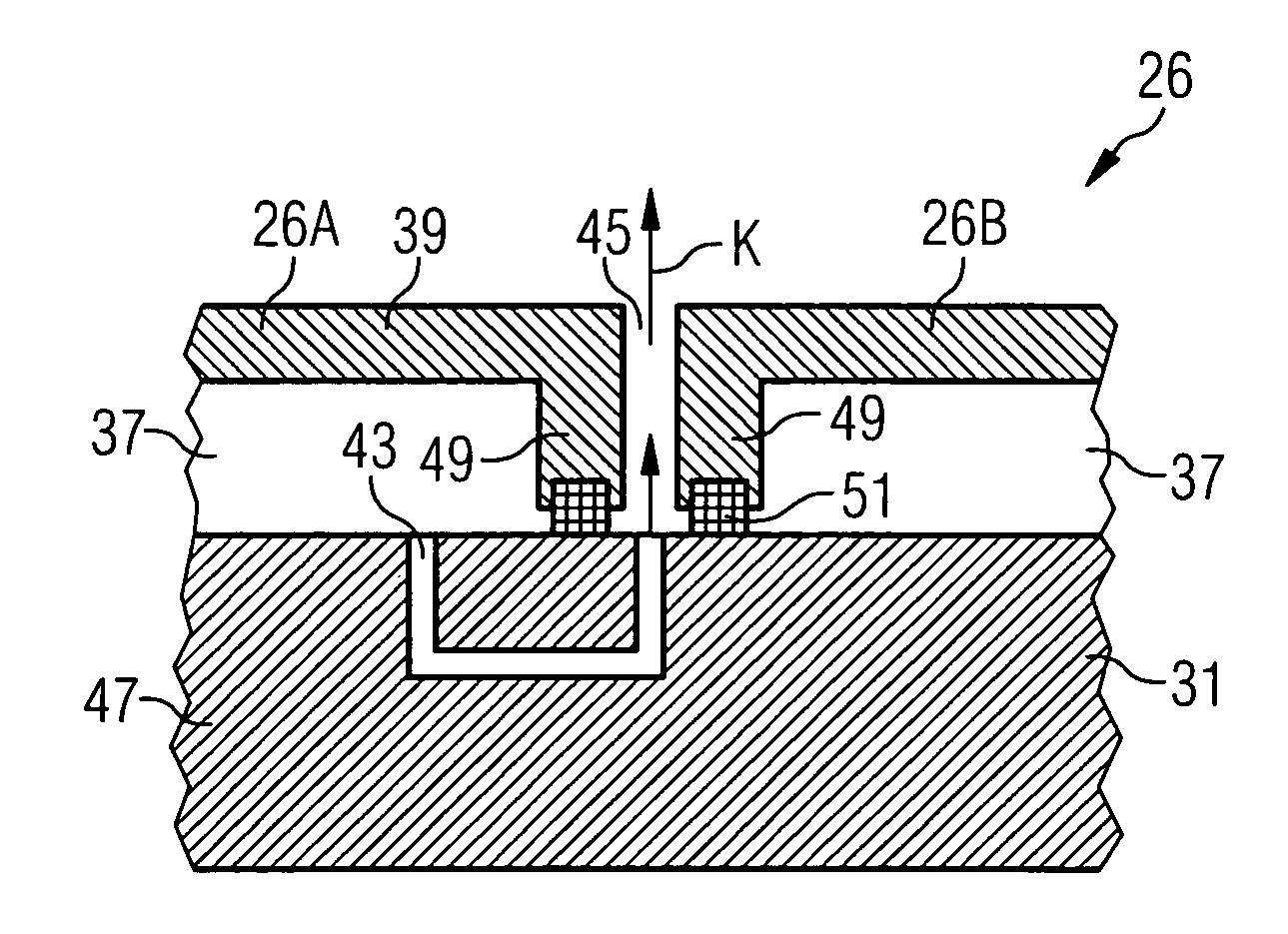

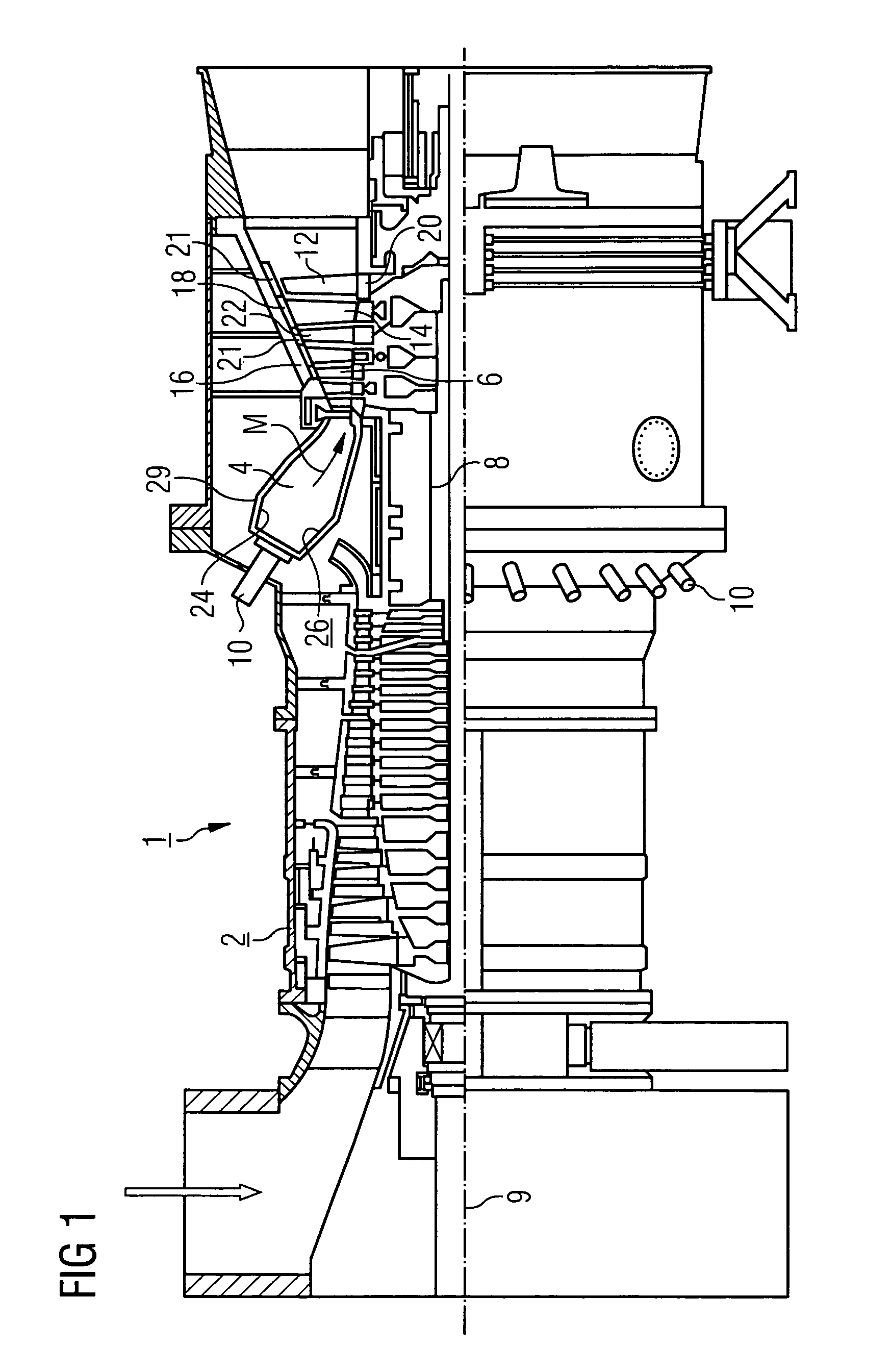

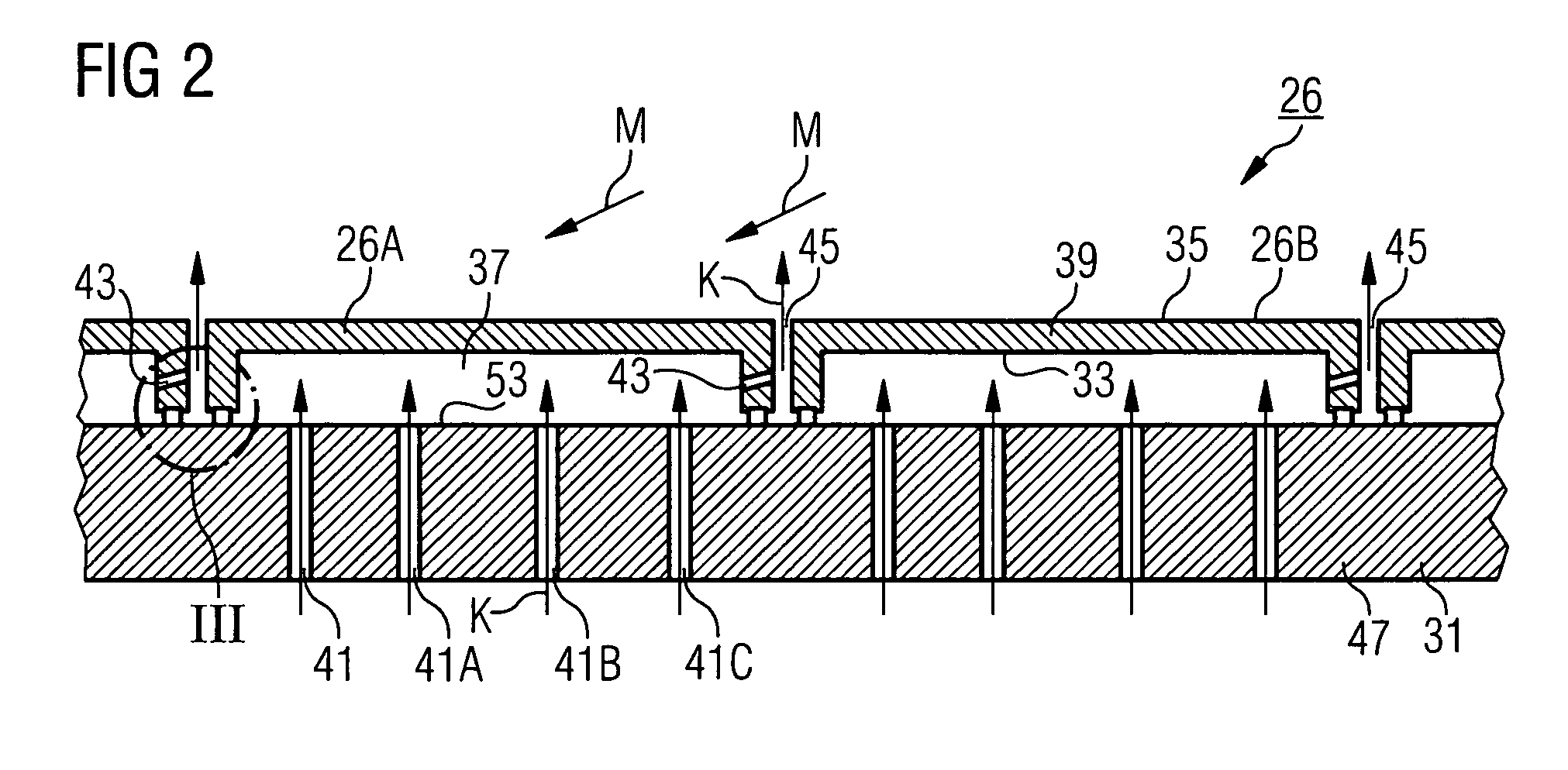

The invention relates to a heat shield arrangement for a hot gas (m)-guiding component, which comprises a number of heat shield elements arranged side-by-side on a supporting structure while leaving a gap there between. A heat shield element can be mounted on the supporting structure whereby forming an interior space which is delimited in areas by a hot gas wall to be cooled, with an inlet channel for admitting a coolant into the interior space. According to the invention, a coolant discharge channel is provided for the controlled discharge of coolant from the interior space and, from the interior space, leads into the gap. Coolant can be saved and efficiently used by the specific coolant discharge via the coolant discharge channel, and reduction in pollutant emissions can also be achieved. The heat shield arrangement is particularly suited for linking a combustion chamber of a gas turbine.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

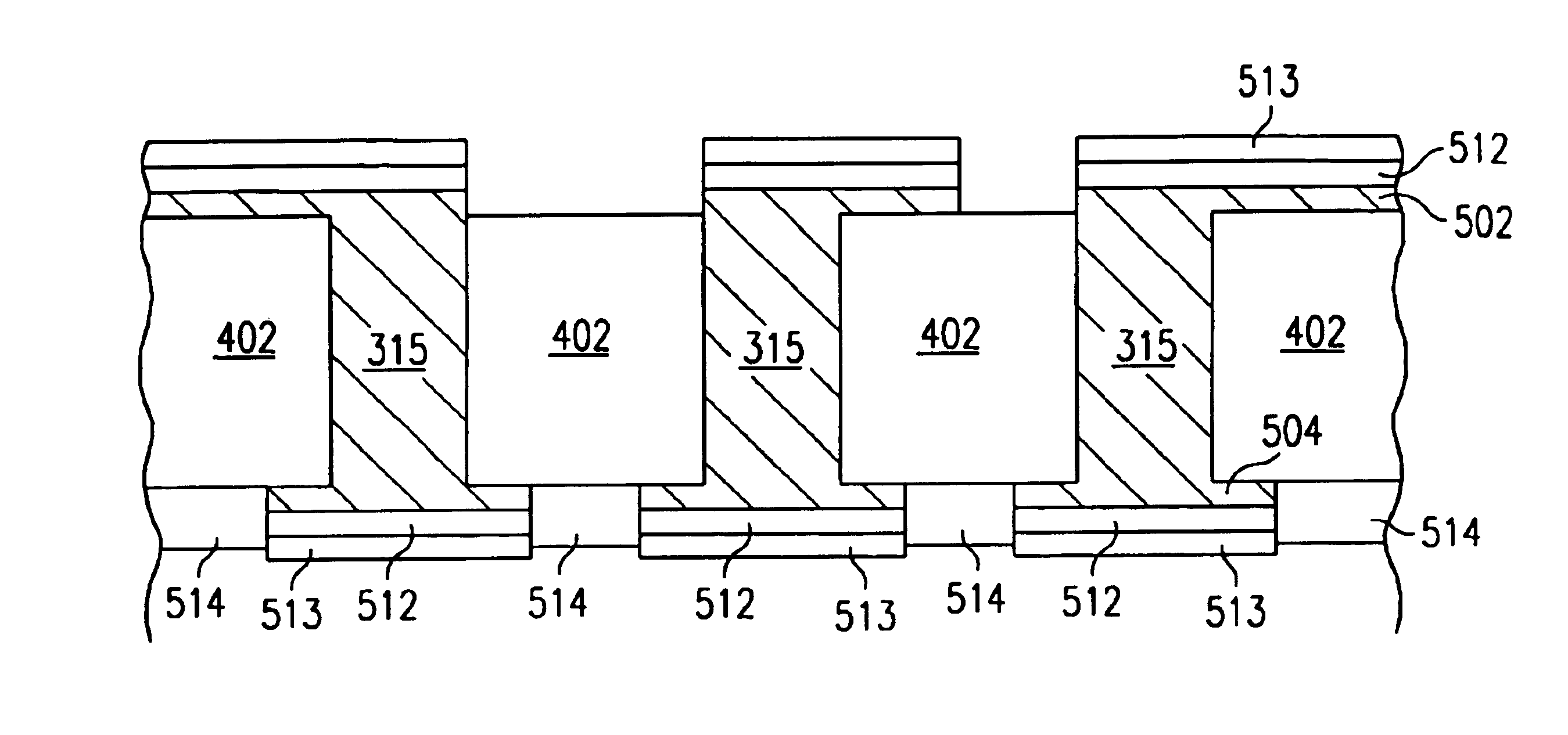

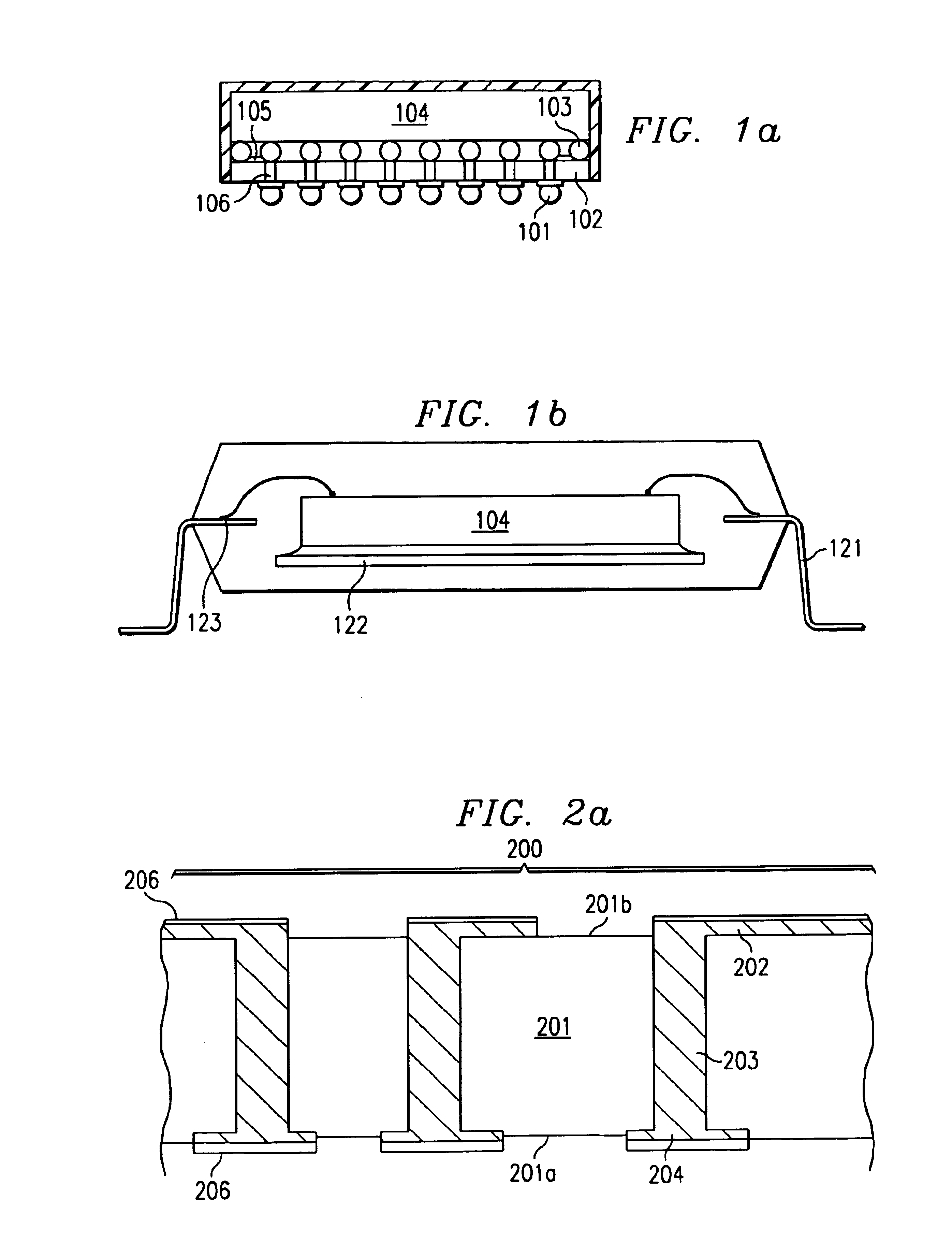

Method of fabricating flexible circuits for integrated circuit interconnections

InactiveUS6915566B2Increases conductor thicknessConnection sealPrinted circuit assemblingLine/current collector detailsIntegrated circuit interconnectFlexible circuits

A method for the fabrication of a double-sided electrical interconnection flexible circuit (200) particularly useful as a substrate for an area array integrated circuit package. A copper matrix with studs (203) is pressed through a dielectric film (201) having a copper layer on the opposite surface, thereby forming an intermediate structure for a flex circuit with self-aligned solid copper vias in a one step process. The contacts are reinforced by plating both surfaces with a layer of copper, and conventional processes are used to complete the circuit patterning.

Owner:TEXAS INSTR INC

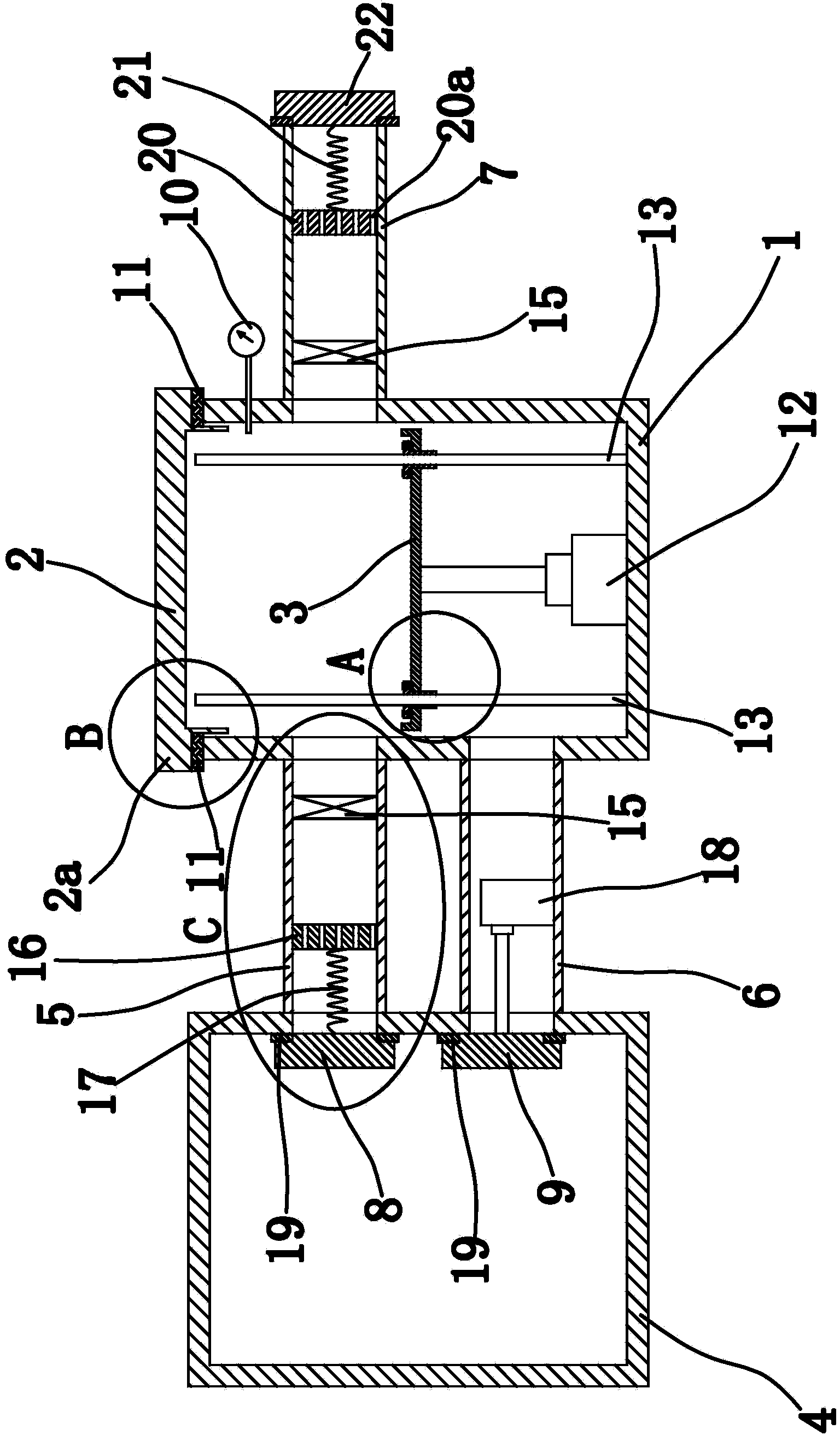

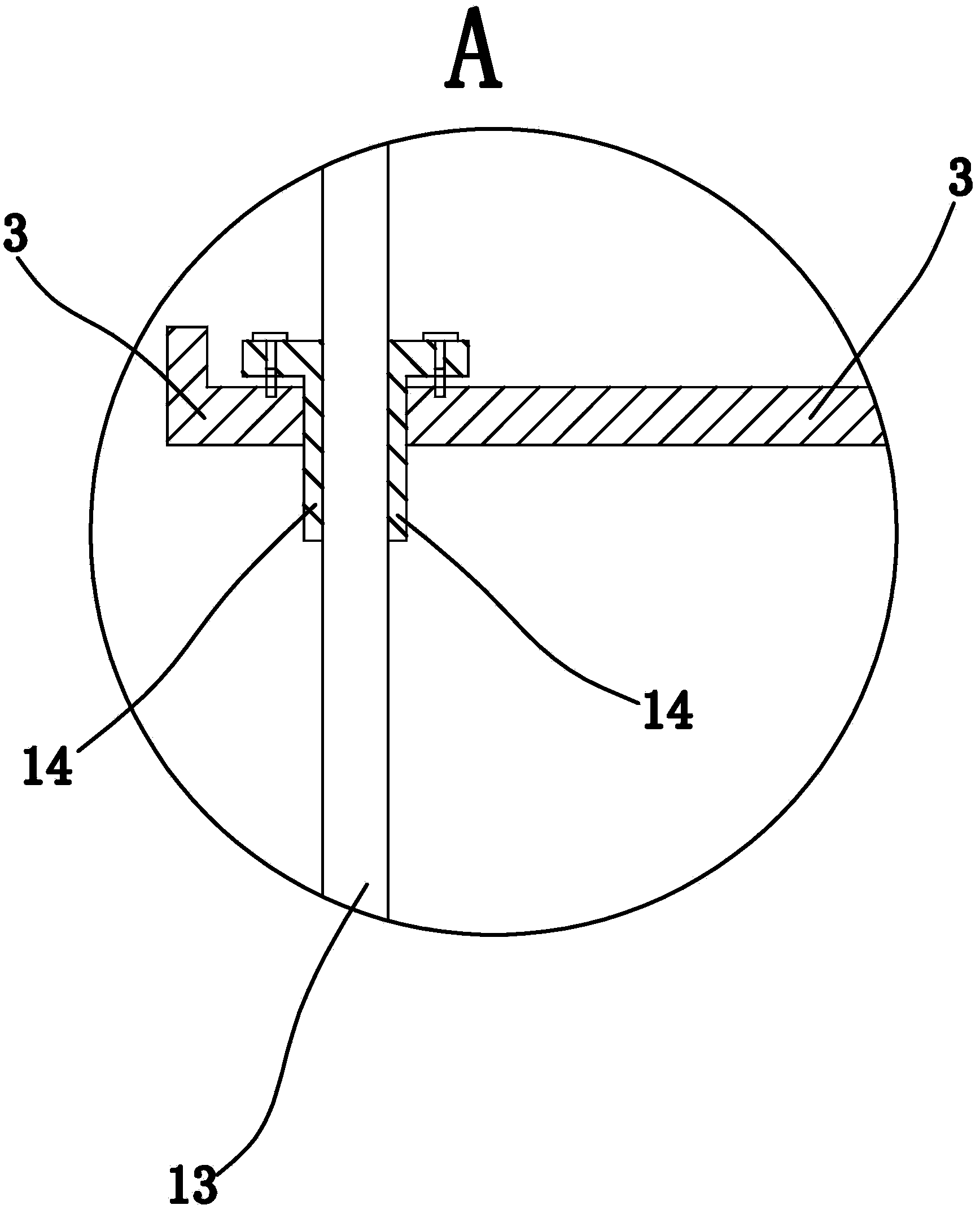

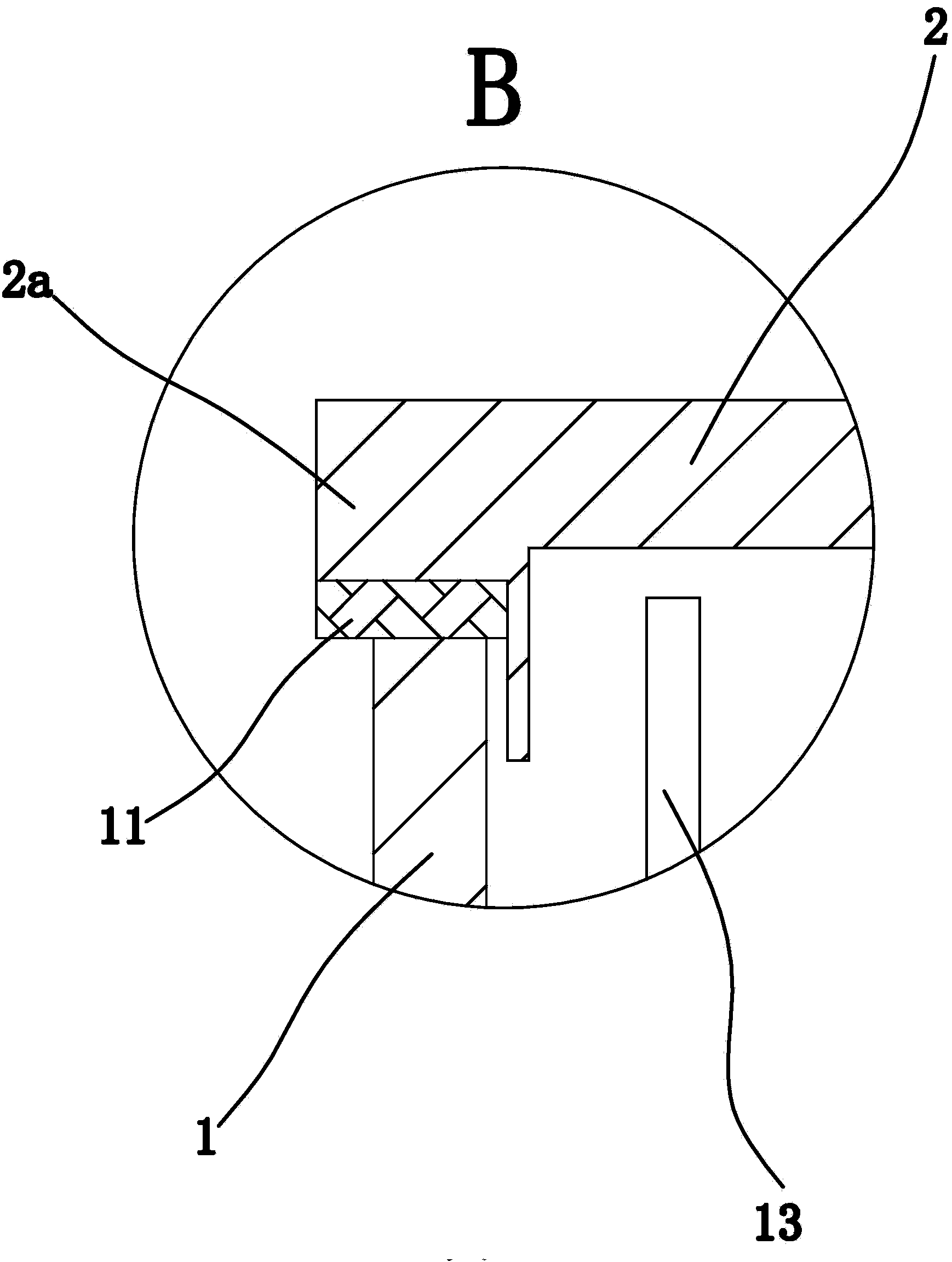

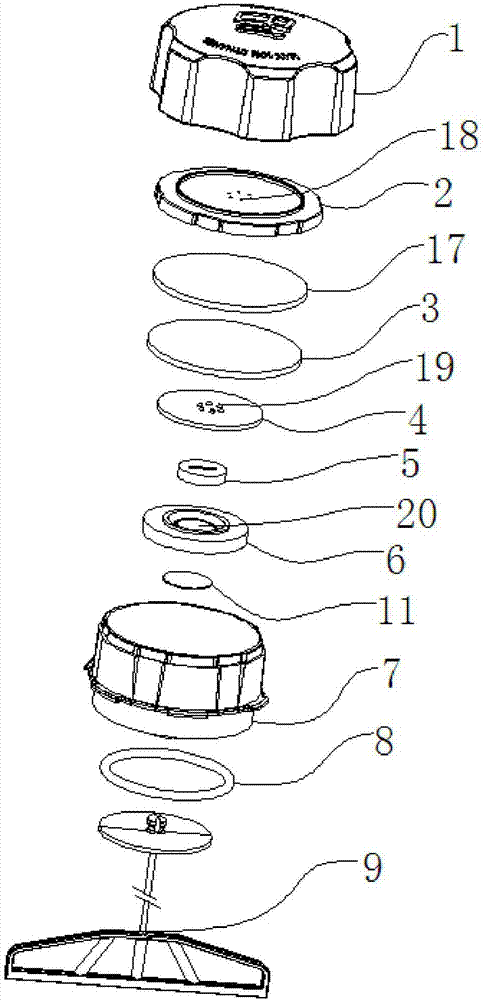

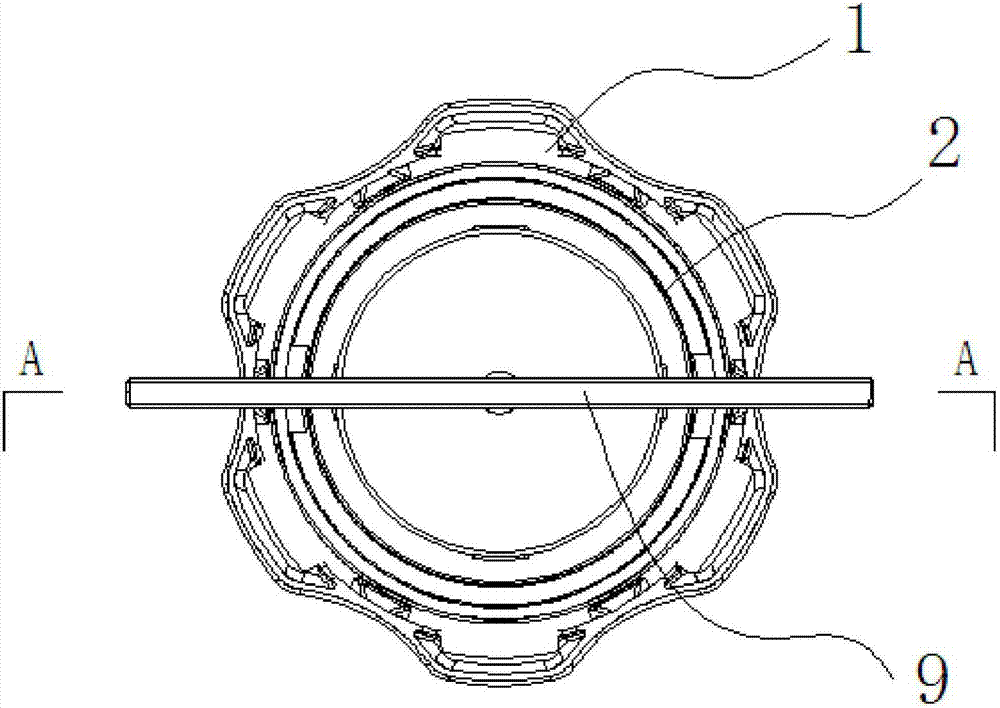

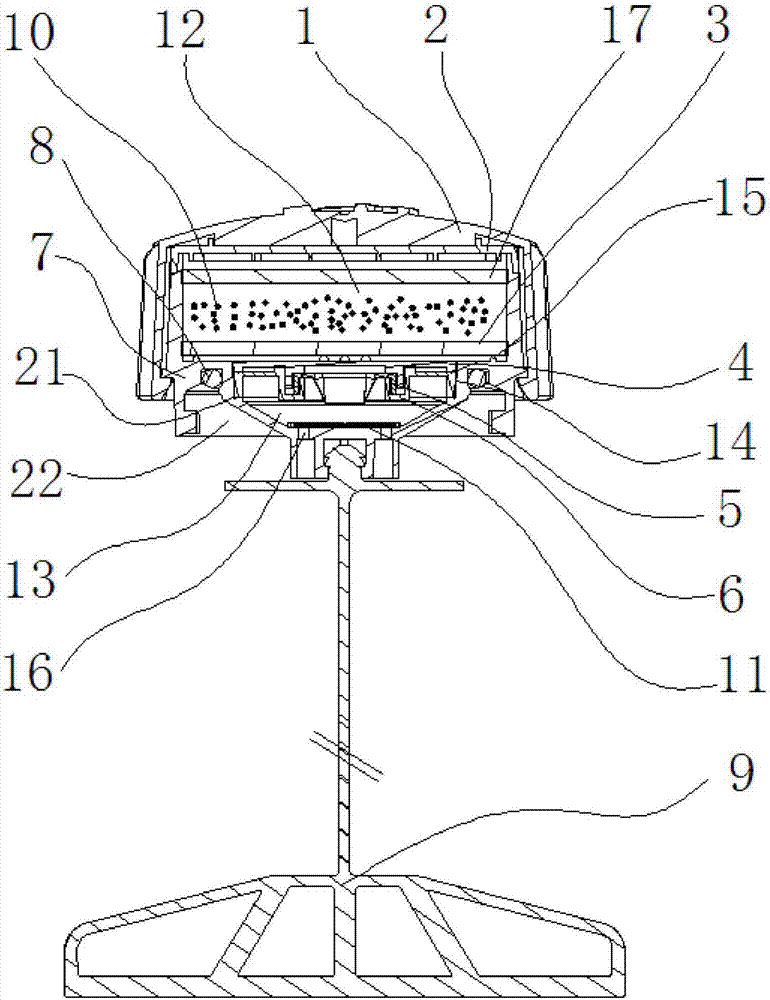

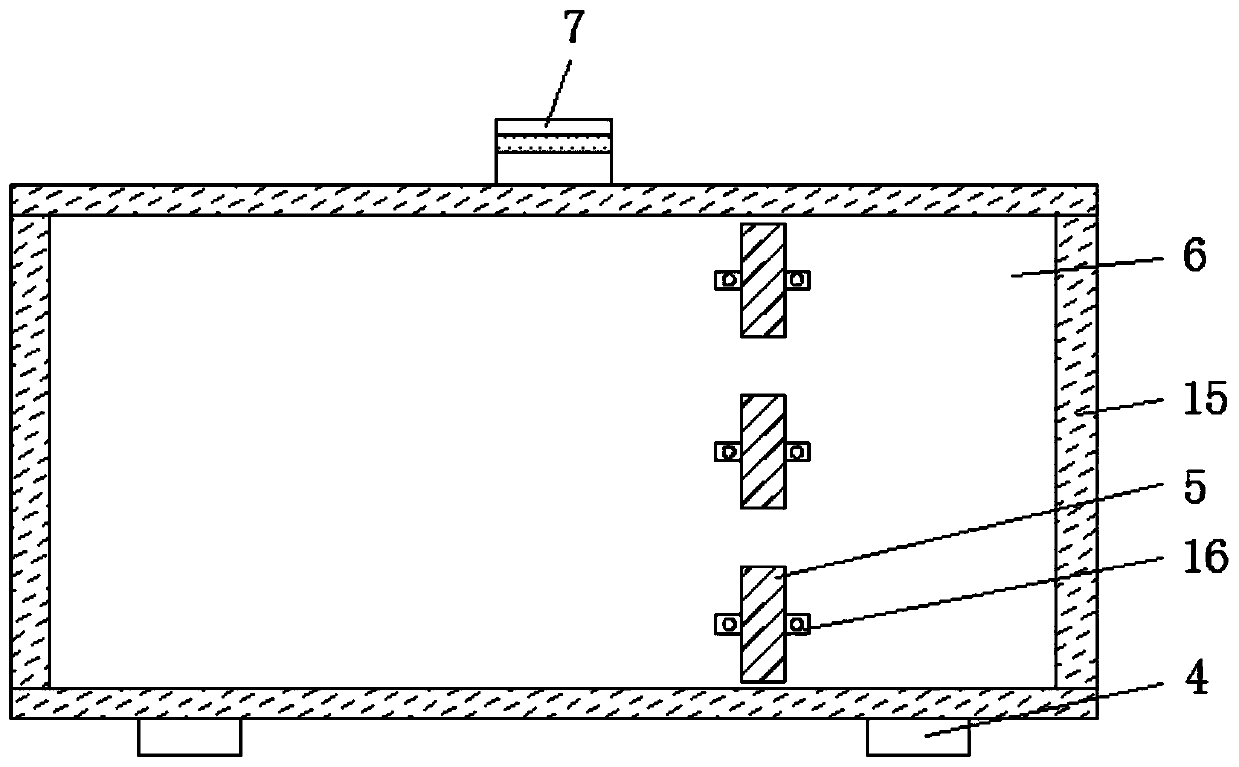

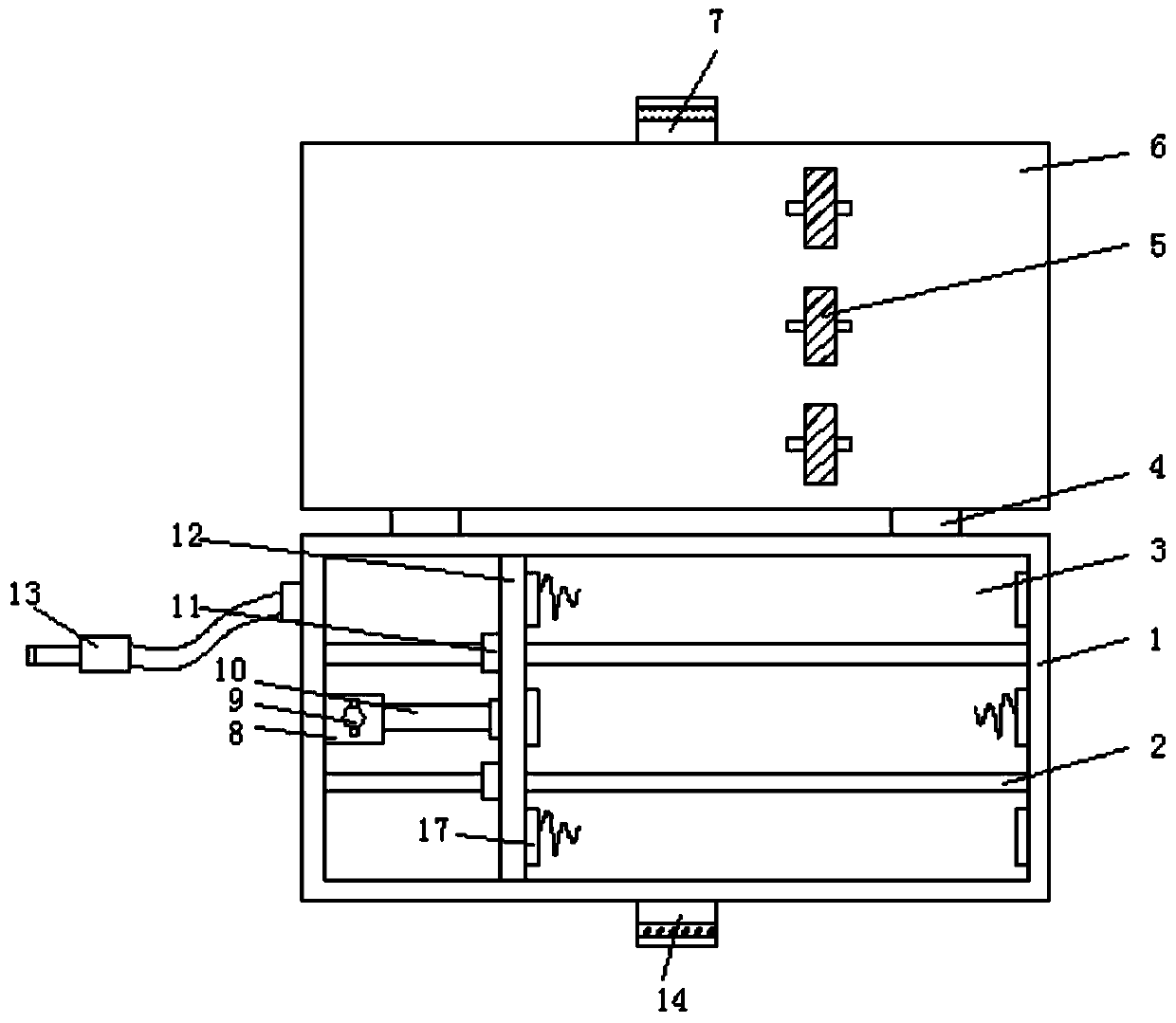

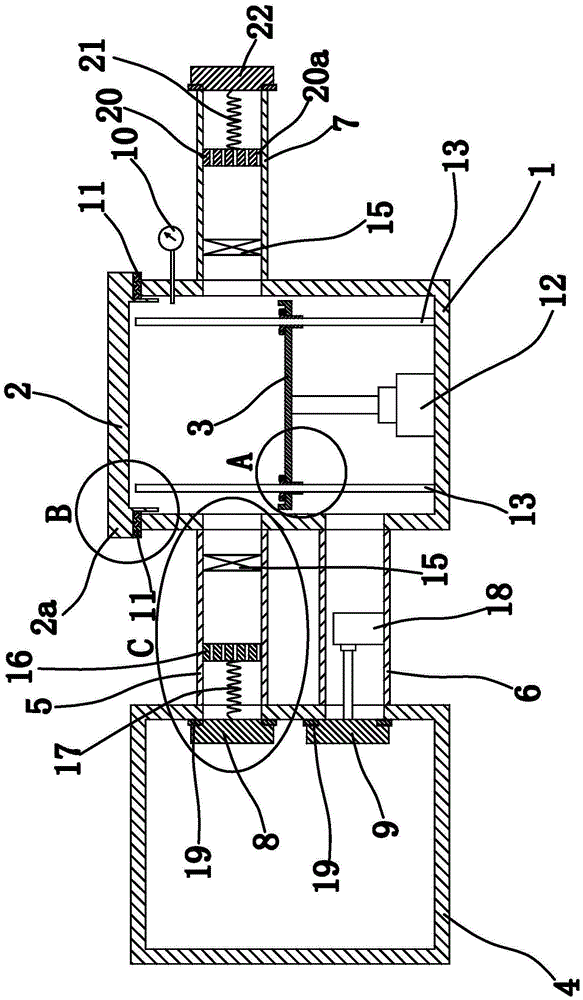

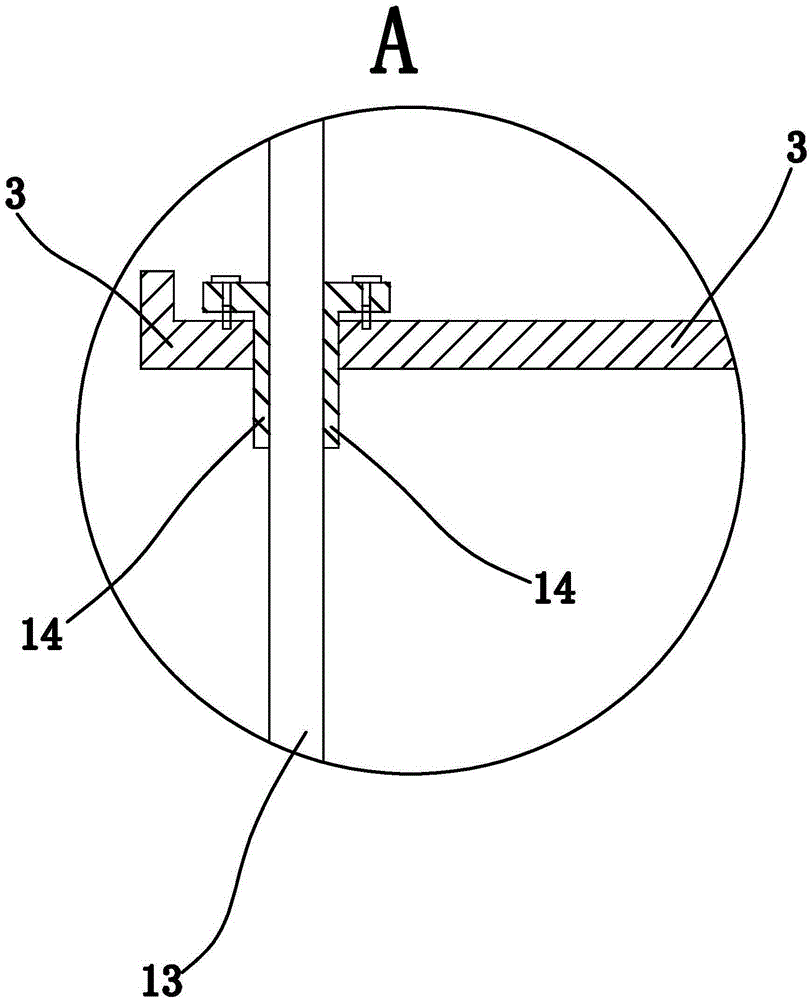

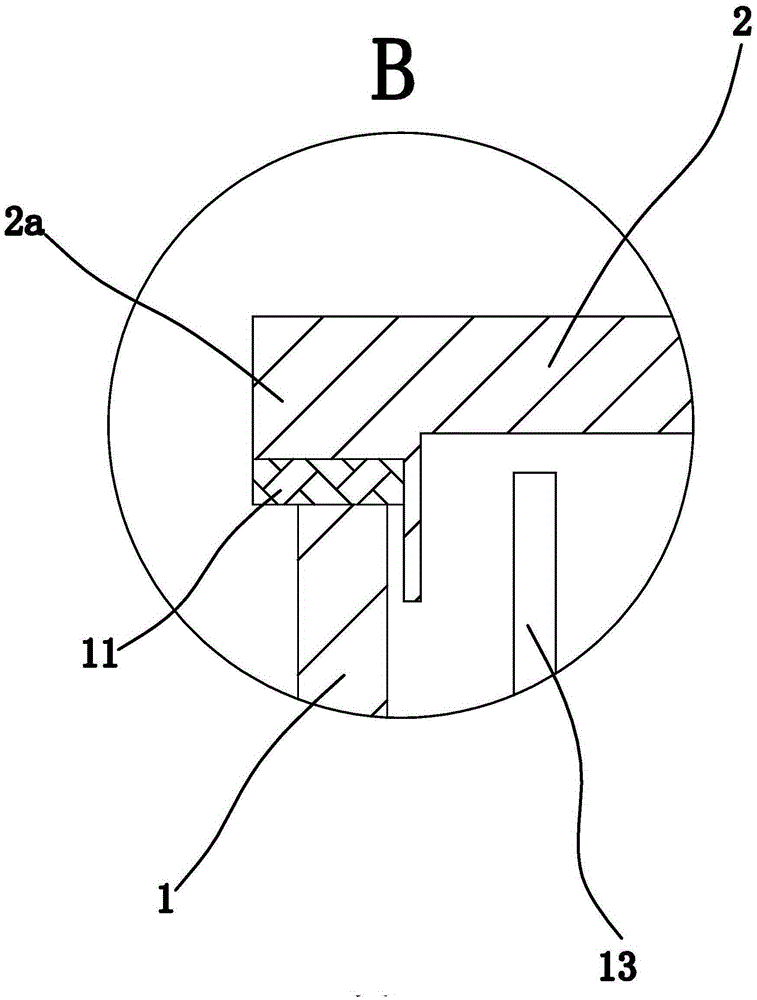

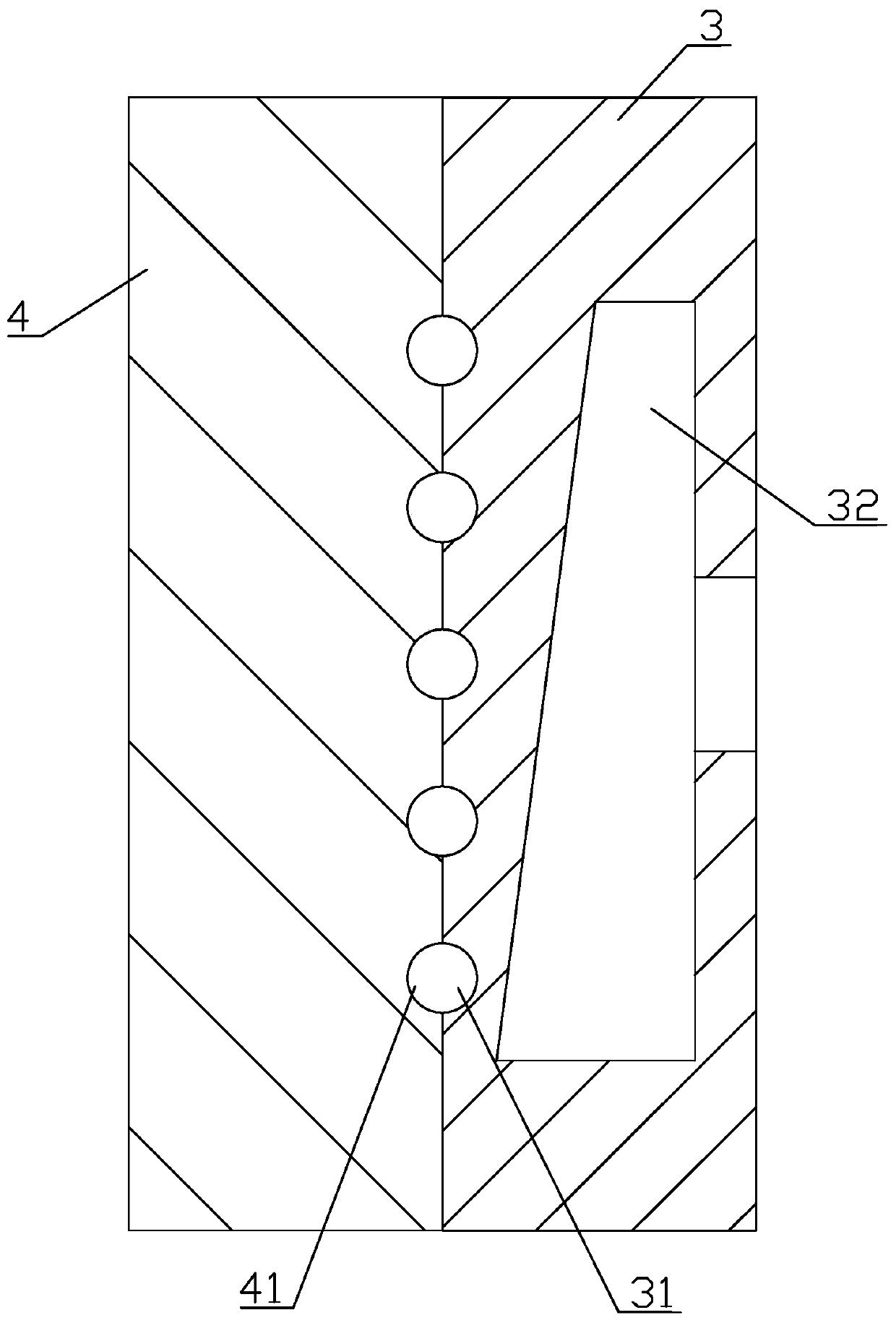

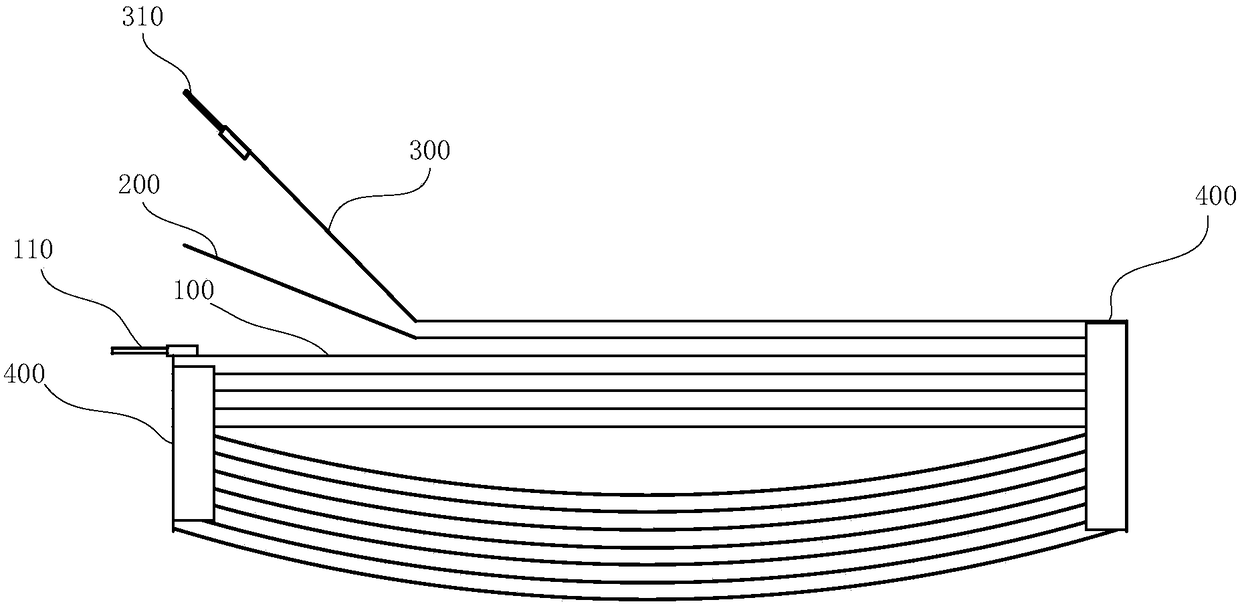

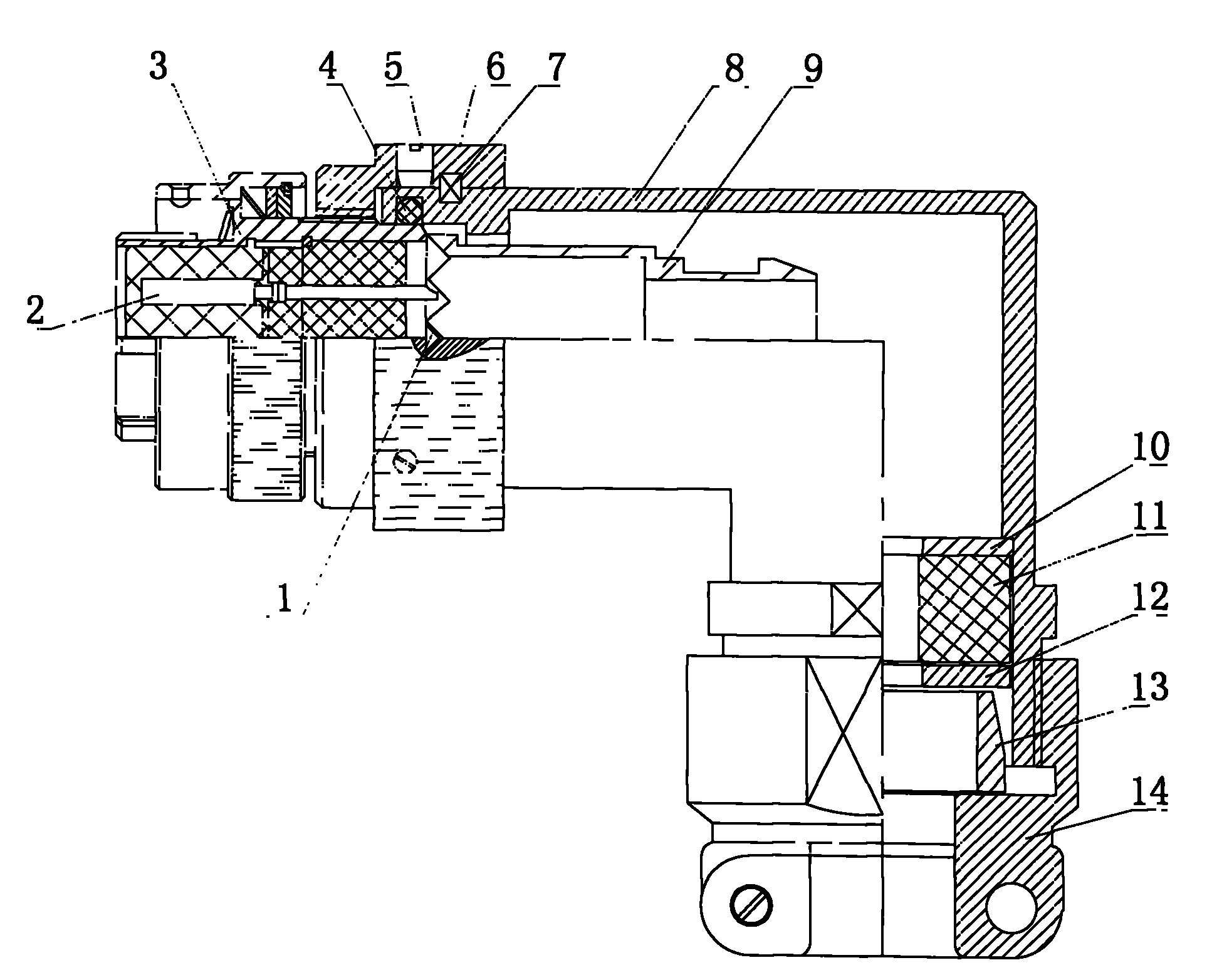

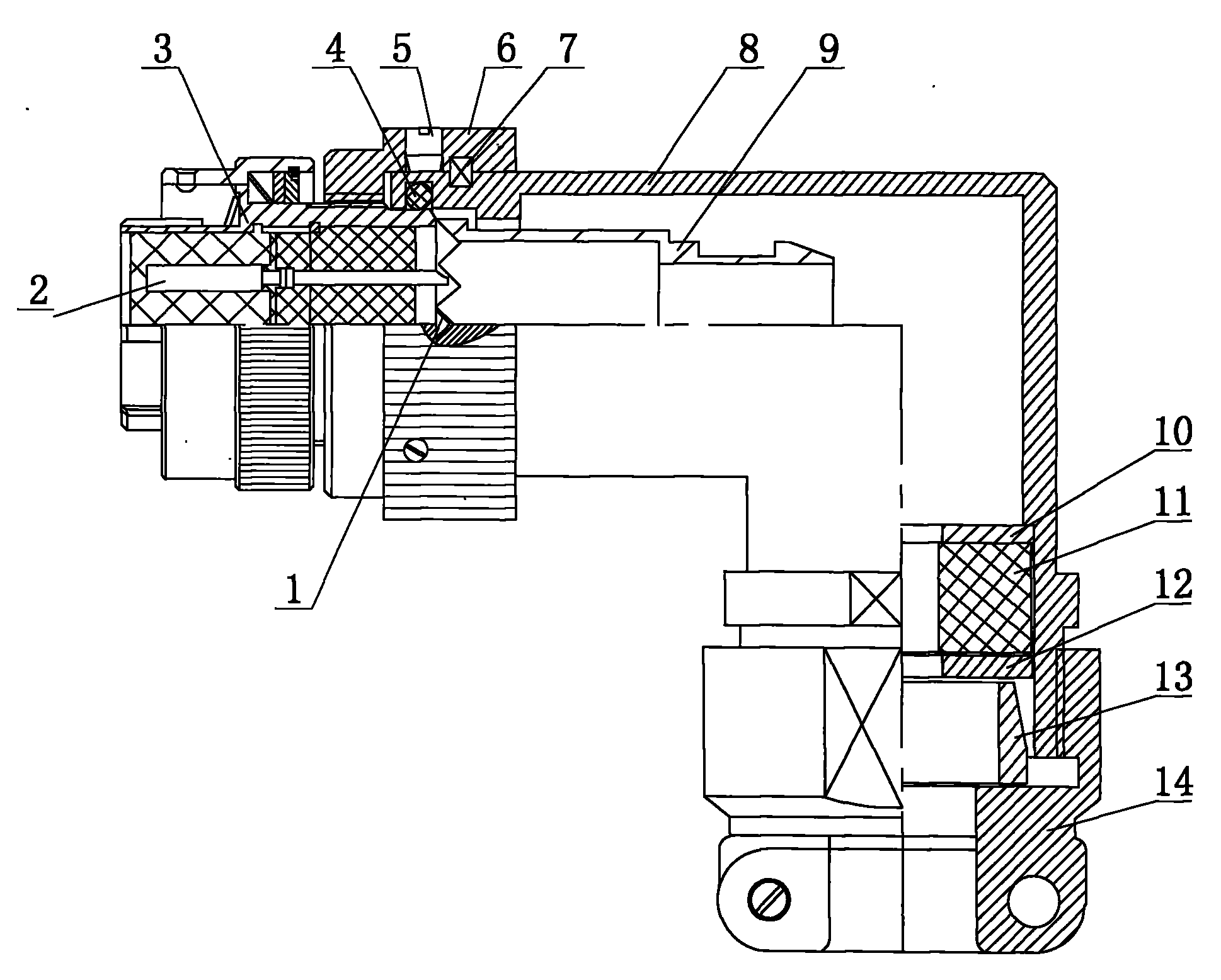

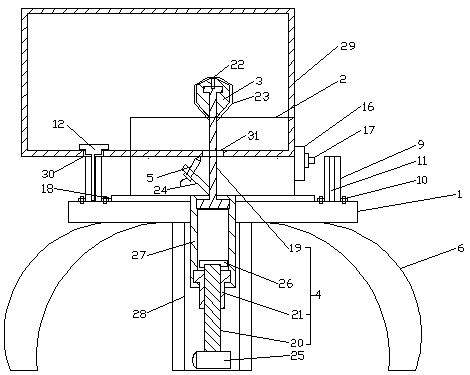

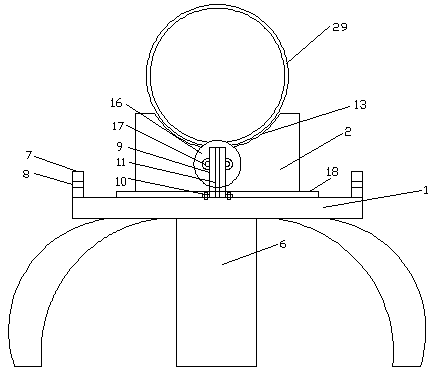

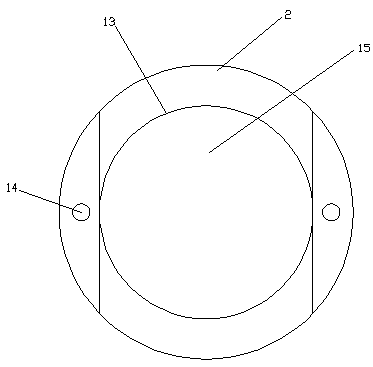

Biogas digester

ActiveCN104293655AReduce leakageReduce lossesGas production bioreactorsWaste based fuelSlagEngineering

The invention provides a biogas digester which is used for solving the problem that waste of biogas is easily caused in the slag removal process in the conventional biogas digester. The biogas digester comprises a gas storage tank and a digester body in which a fermentation disc is arranged, wherein the top of the digester body is connected with a sealing cover; a lifting device which can drive the fermentation disc to translate up and down is arranged at the bottom of the fermentation disc; a gas inlet pipe and a gas outlet pipe are arranged between the gas storage tank and the digester body; a gas suction piece I is arranged in the gas inlet pipe; a sealing plate I and a sealing plate II are arranged in the gas storage tank; an elastic piece through which the sealing plate I has the tendency of sealing the gas inlet pipe is connected to the sealing plate I; a cylinder I through which the sealing plate II seals or opens the gas outlet pipe is connected to the sealing plate II; an exhaust pipe and a pressure gage are connected to the digester body; a gas suction piece II is arranged in the exhaust pipe; a sealing plate III is arranged at the end face of the exhaust pipe; and a spring I through which the sealing plate III has the tendency of sealing the exhaust pipe is arranged between the gas suction piece II and the sealing plate III. The biogas digester disclosed by the invention has the advantages that waste of biogas is avoided during slag removal.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Heat shield arrangement for a component guiding a hot gas in particular for a combustion chamber in a gas turbine

InactiveUS7849694B2Manufactured lowUsed economicallyContinuous combustion chamberTurbine/propulsion engine coolingInterior spaceCombustion chamber

The invention relates to a heat shield arrangement for a hot gas (m)-guiding component, which comprises a number of heat shield elements arranged side-by-side on a supporting structure while leaving a gap there between. A heat shield element can be mounted on the supporting structure whereby forming an interior space which is delimited in areas by a hot gas wall to be cooled, with an inlet channel for admitting a coolant into the interior space. According to the invention, a coolant discharge channel is provided for the controlled discharge of coolant from the interior space and, from the interior space, leads into the gap. Coolant can be saved and efficiently used by the specific coolant discharge via the coolant discharge channel, and reduction in pollutant emissions can also be achieved. The heat shield arrangement is particularly suited for linking a combustion chamber of a gas turbine.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

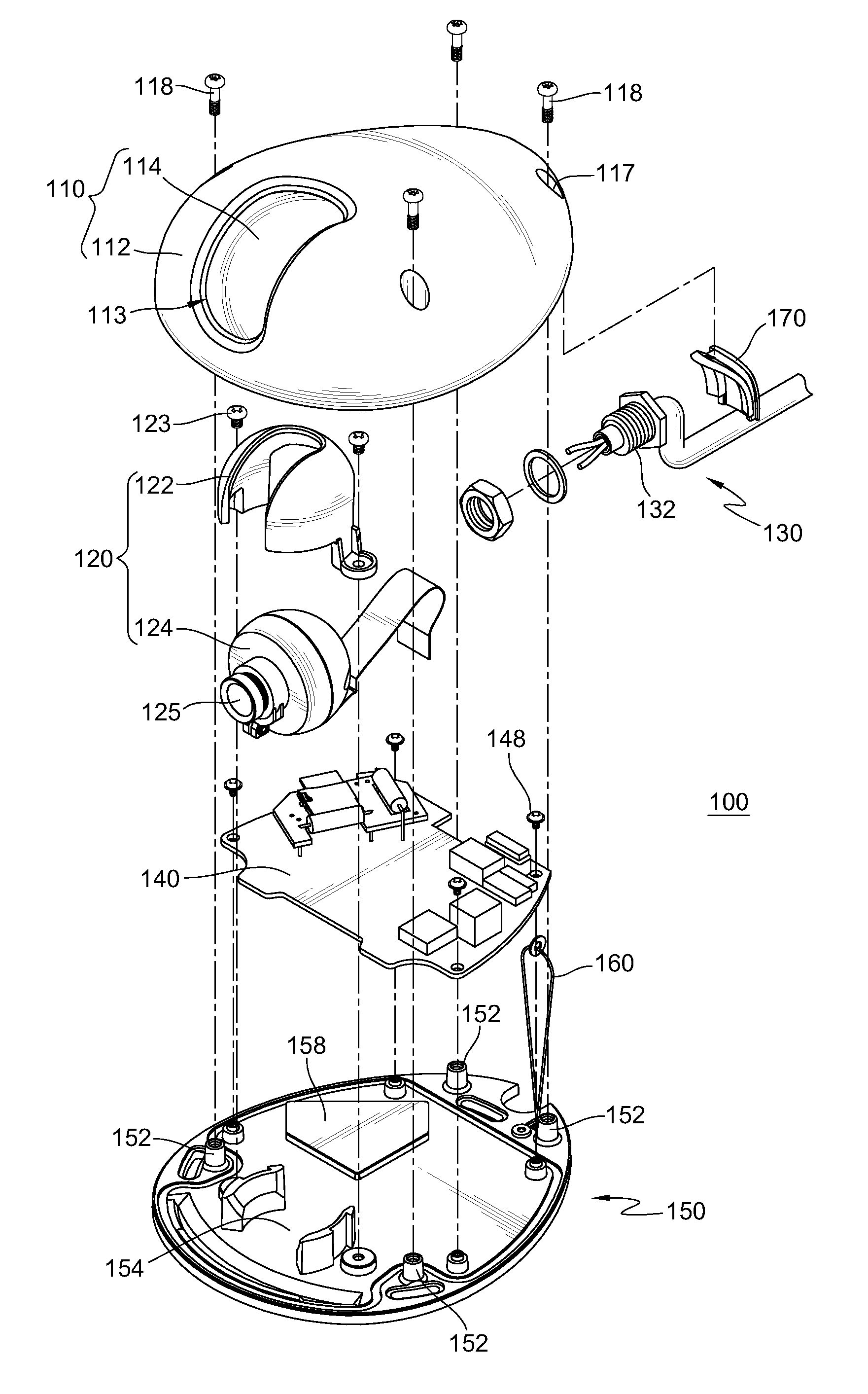

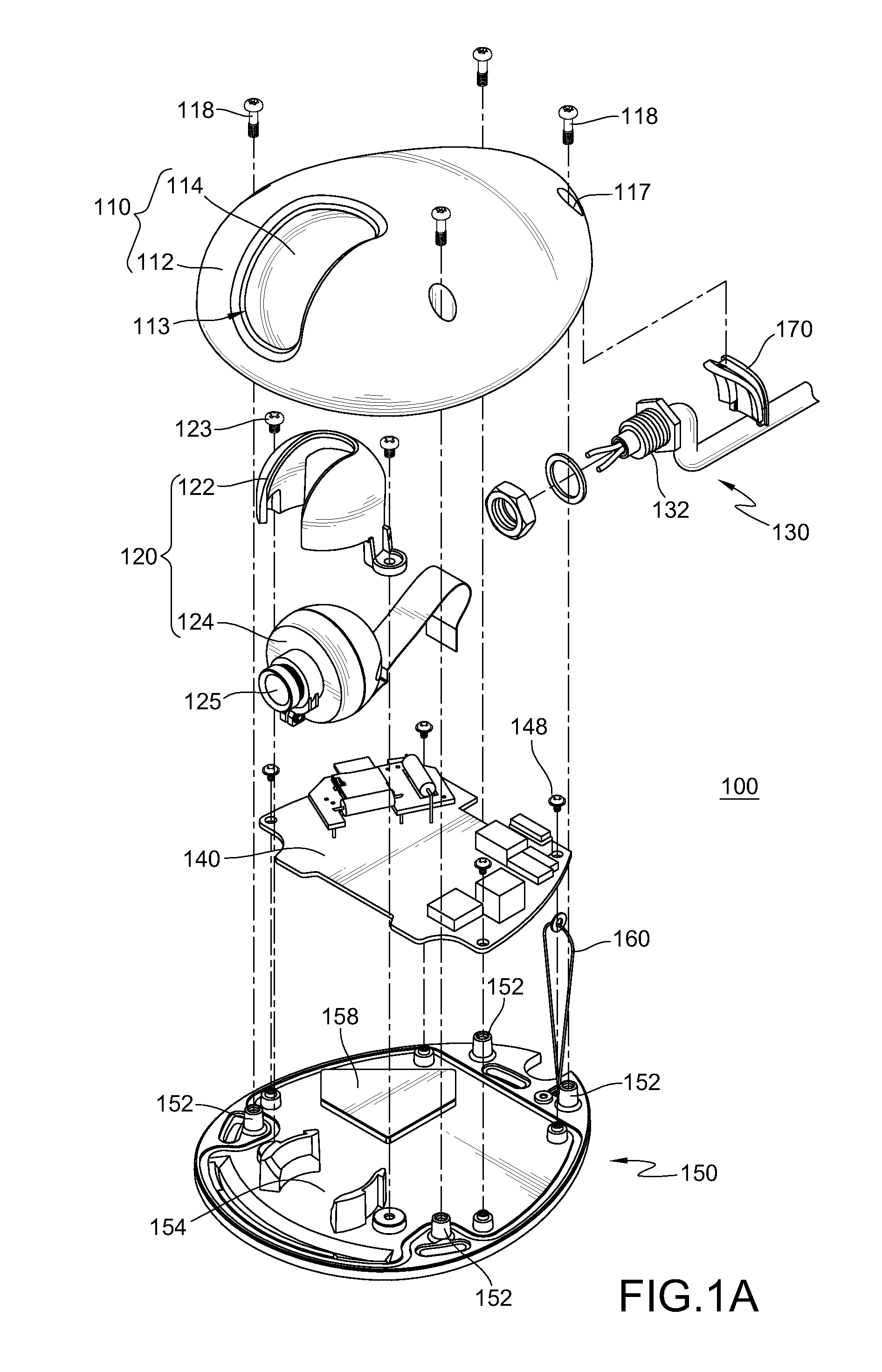

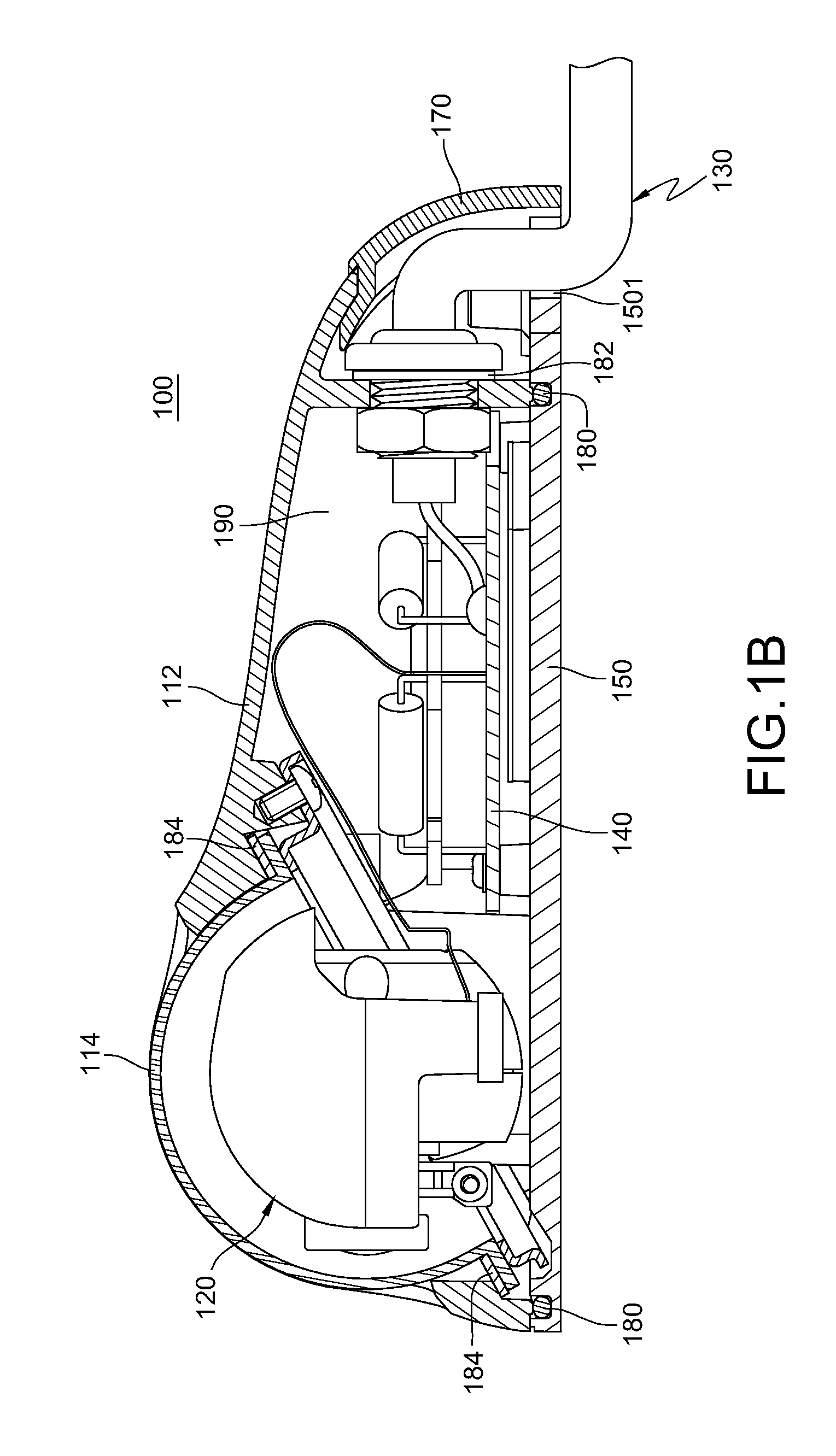

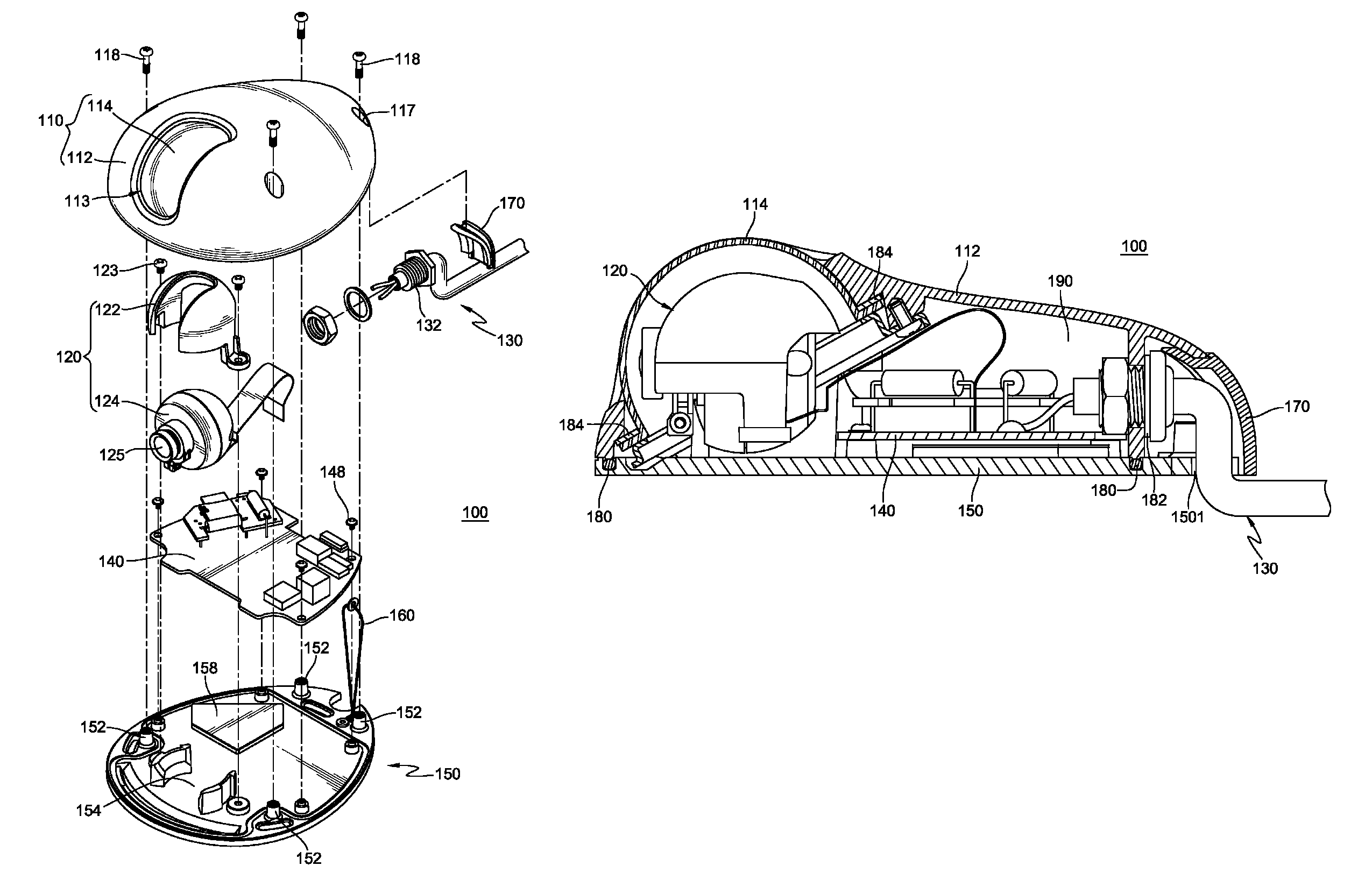

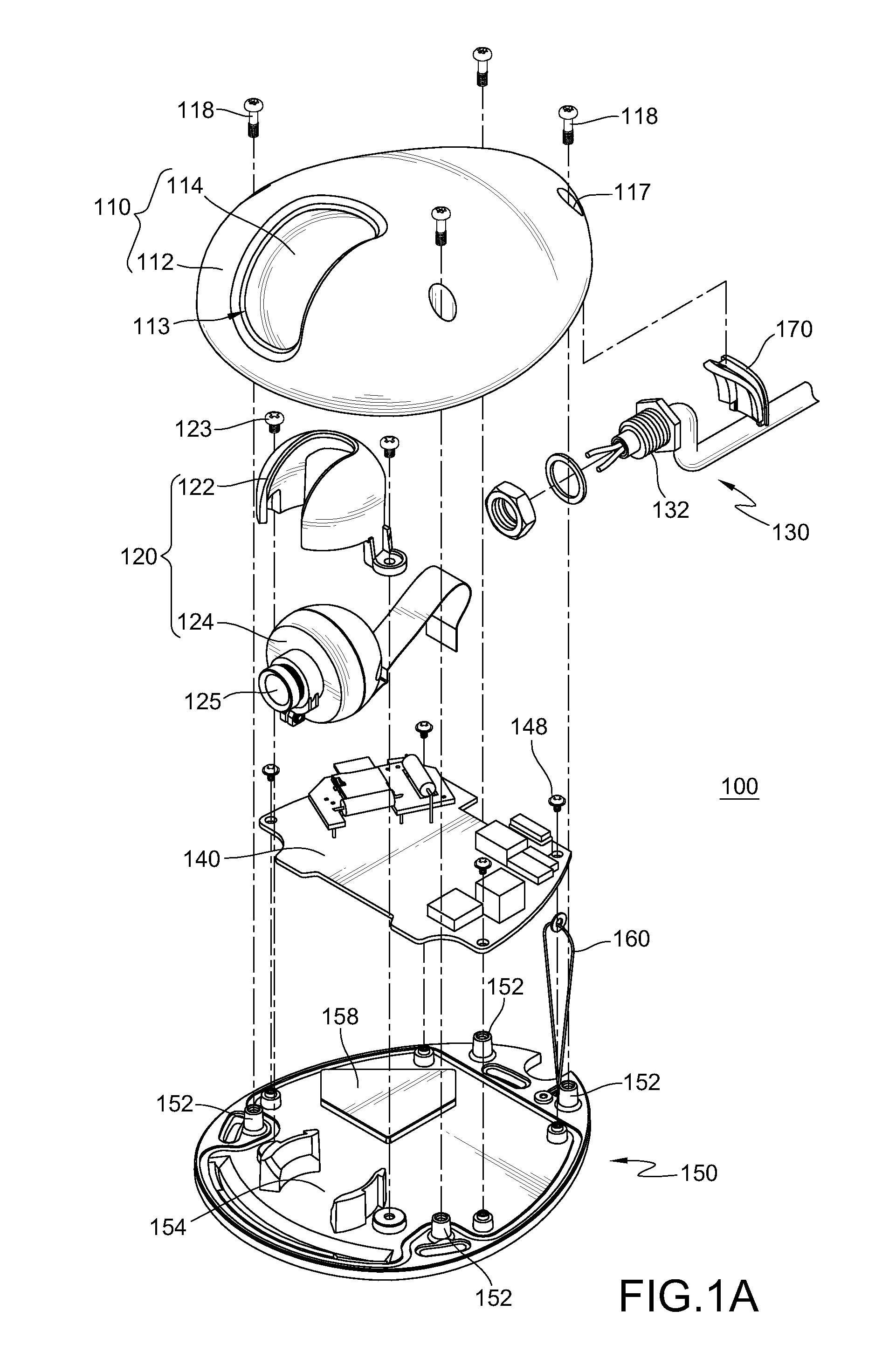

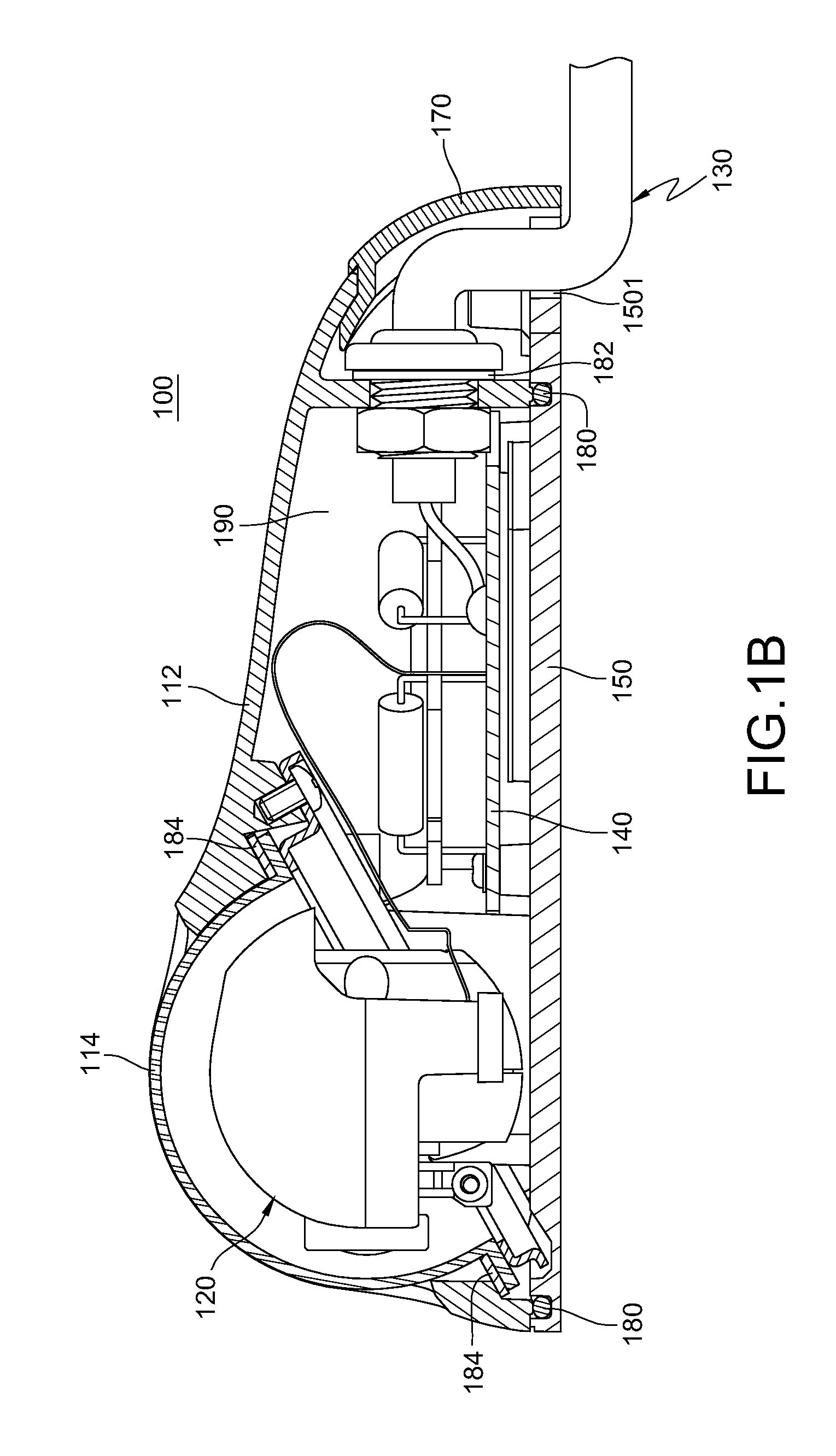

Photographic device

ActiveUS20120008935A1Easily damagedLow photograph qualityBurglar alarmCamera body detailsEngineeringSignal lines

A photographic device includes an upper cover component, a lens module, a signal line set, a circuit board, and a lower cover. The upper cover component comprises an upper casing having a through hole and a transparent mask. The transparent mask is fastened under the through hole and exposed by it and does not protrude from an outer surface of the upper casing. The lens module has a photographic lens facing the mask. The signal line set has a fixing end fastened to one end of the upper casing. The circuit board is electrically connected to the lens module and the signal line set. The lower cover and the upper casing are joined and enclose the lens module and the circuit board. As the transparent mask does not protrude from the outer surface of the upper casing, cracks of the transparent mask caused by a foreign object can be prevented.

Owner:VIVOTEK INC

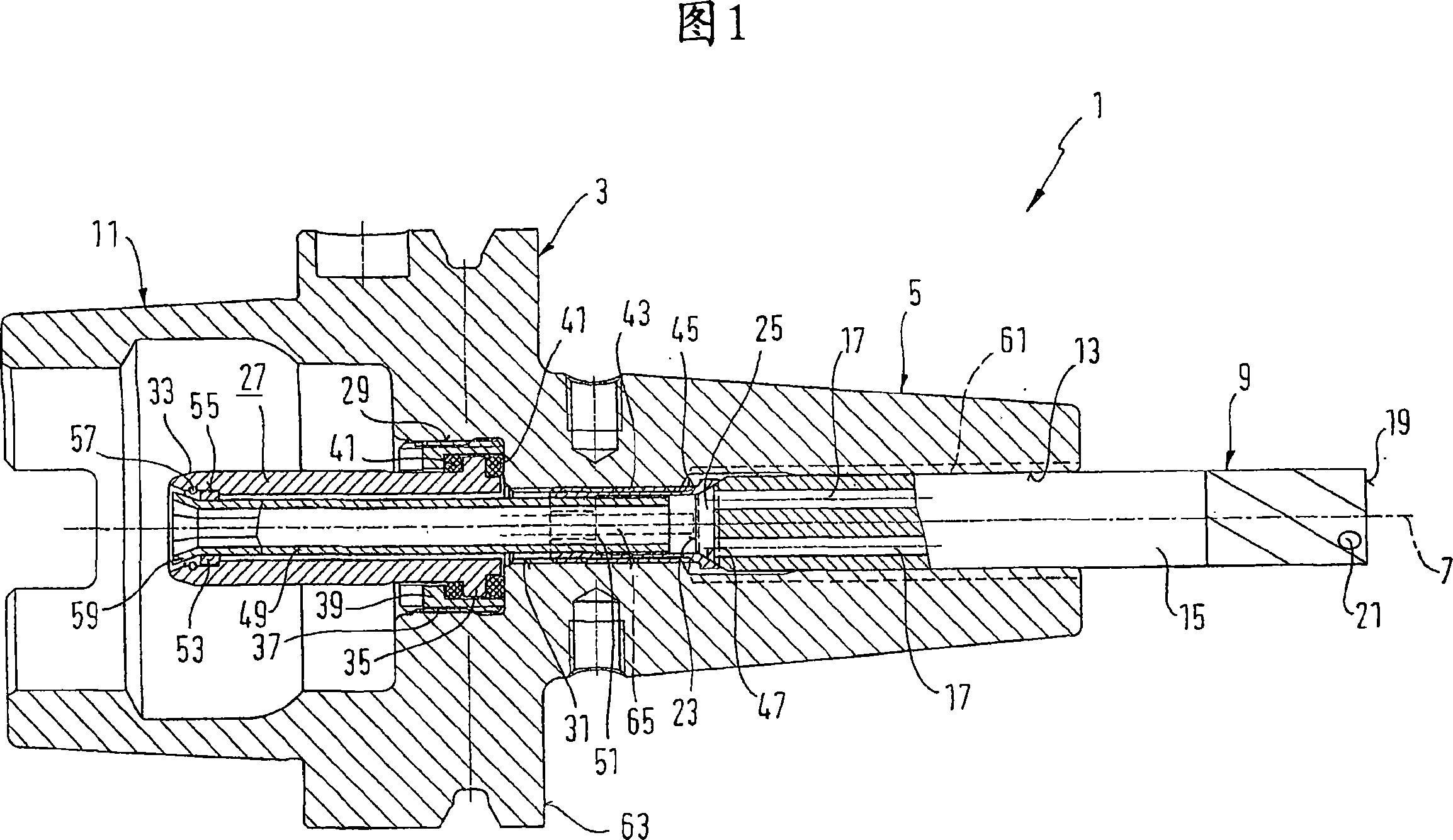

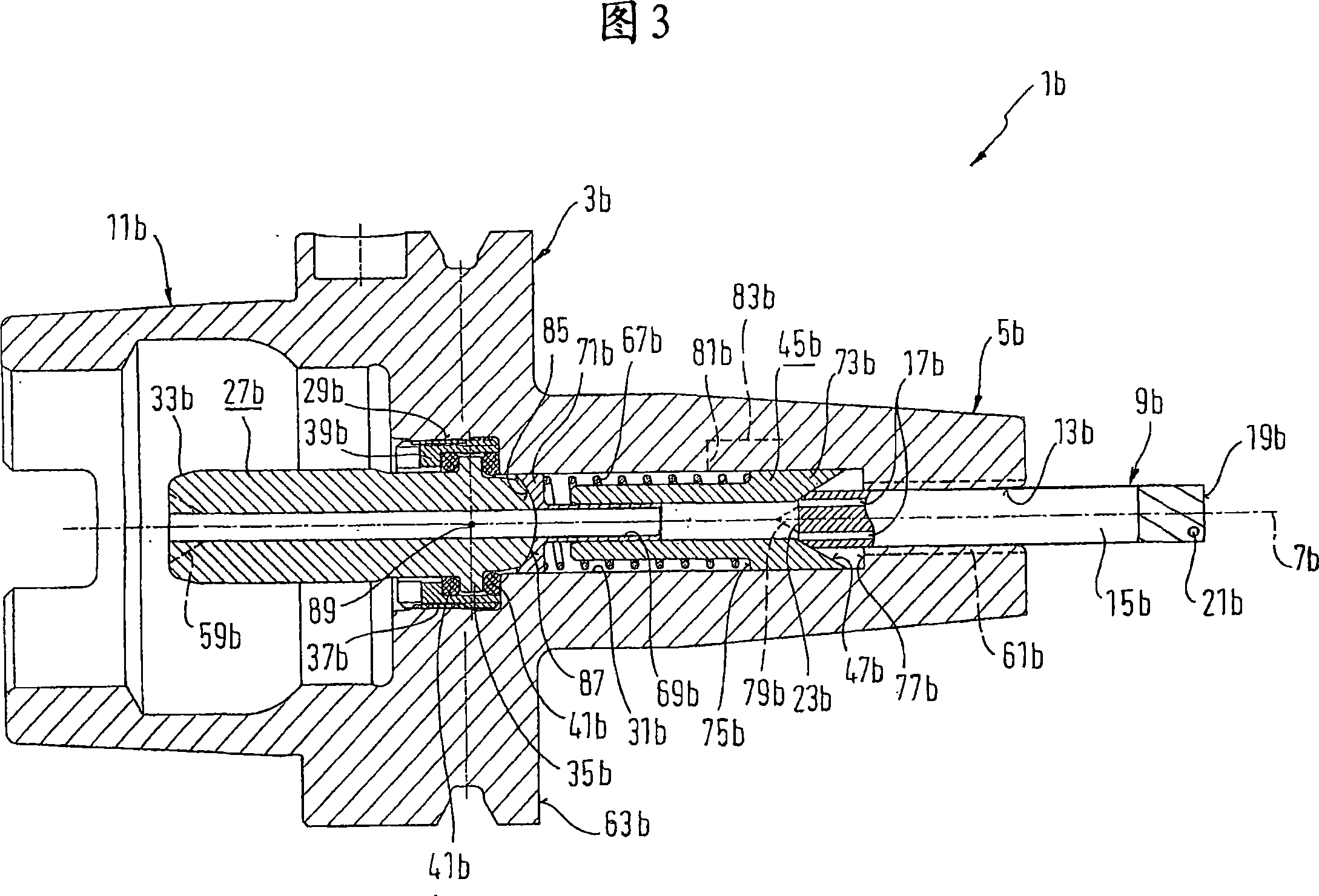

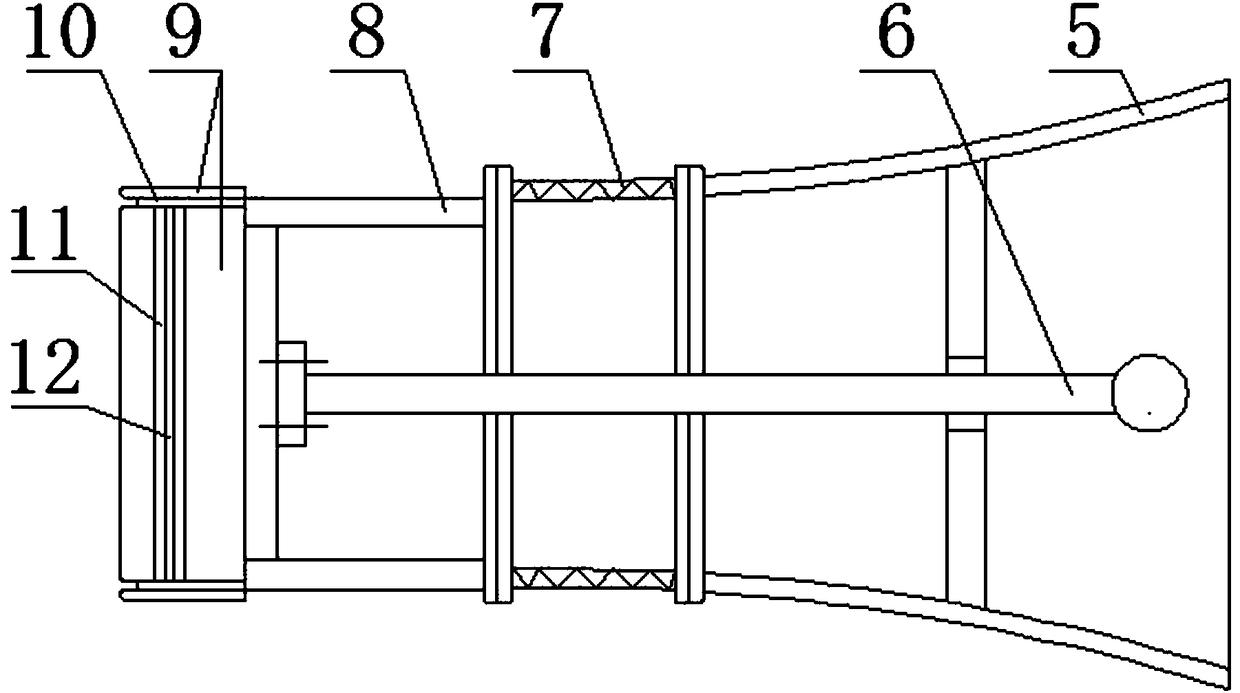

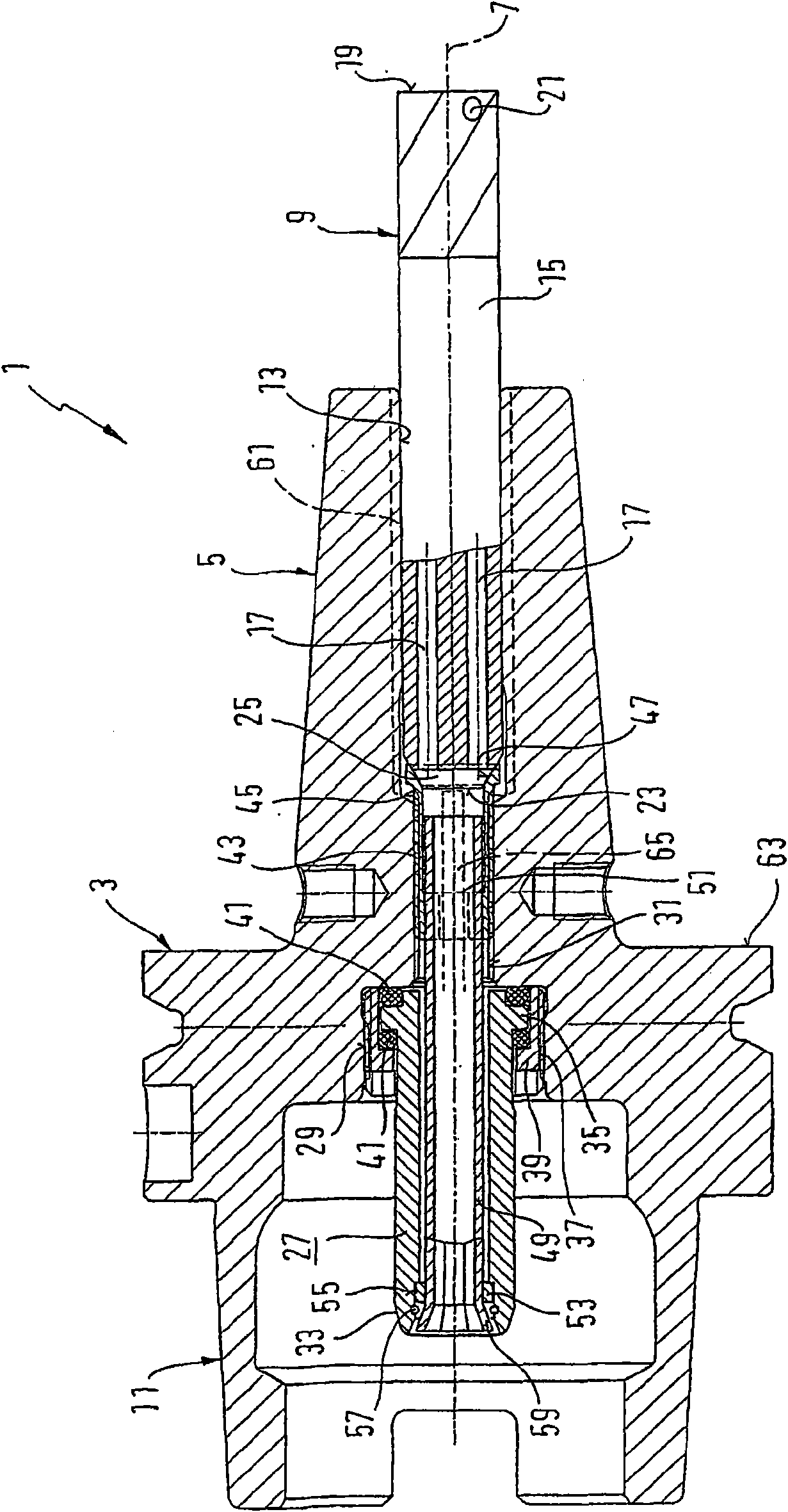

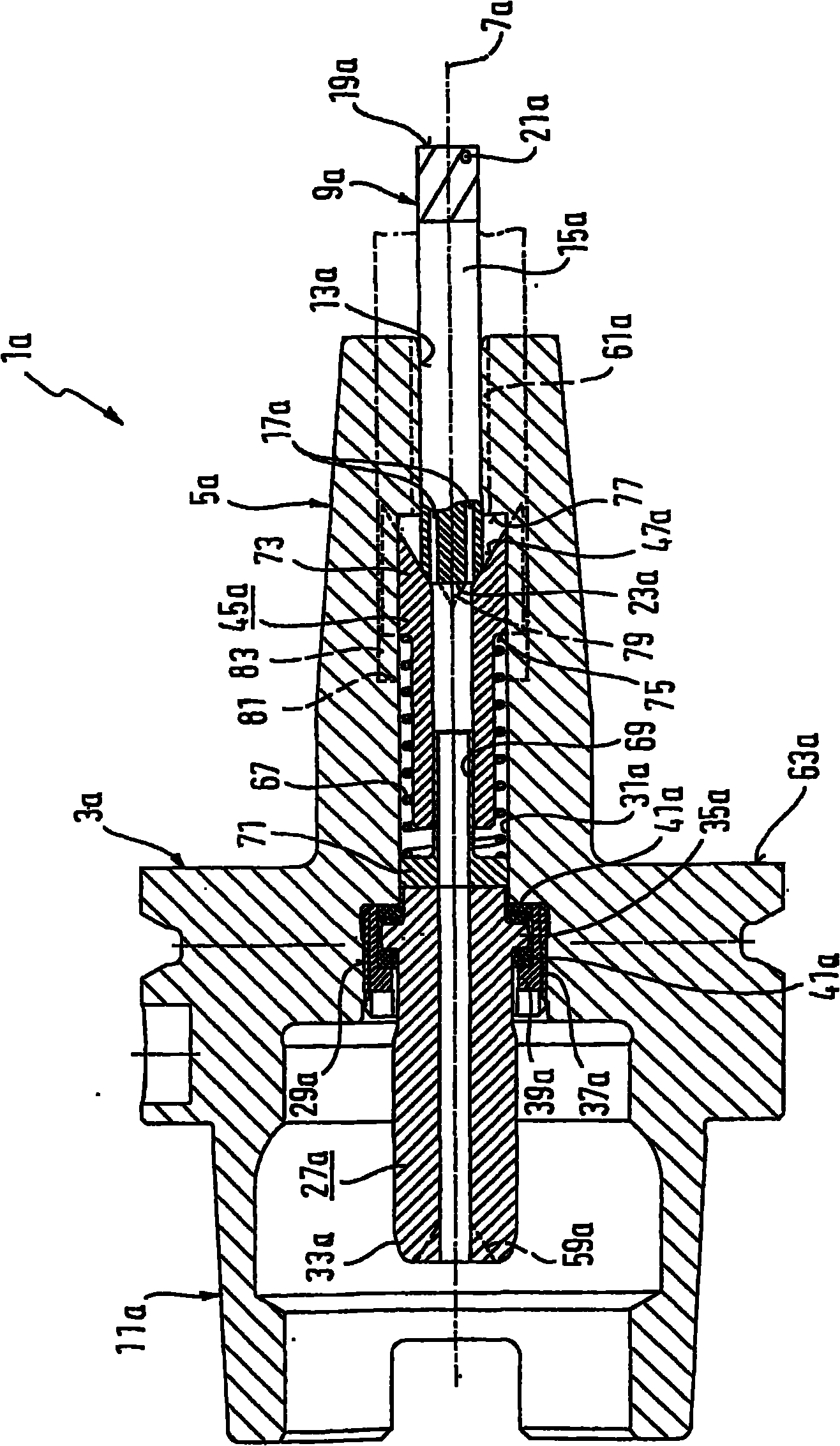

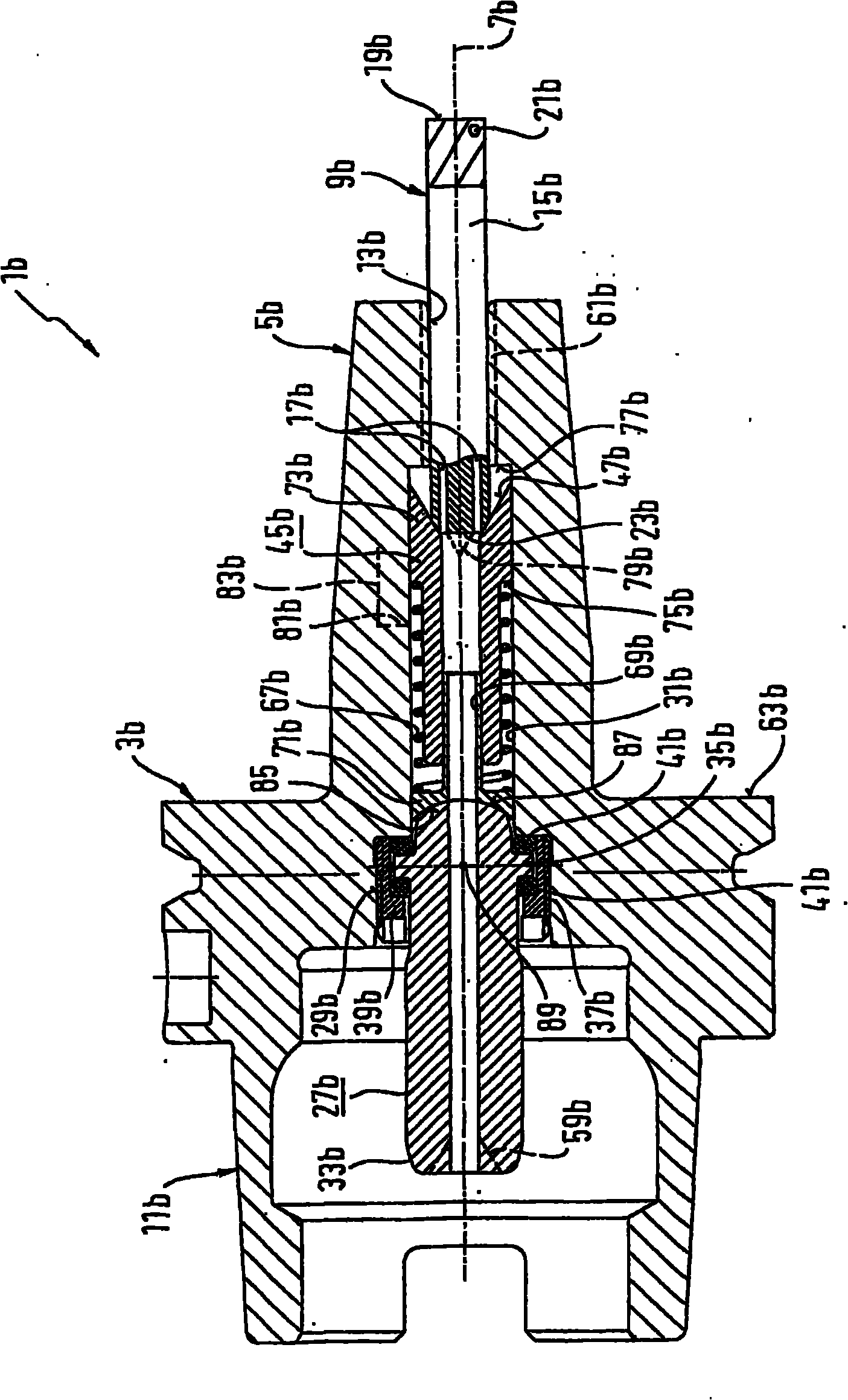

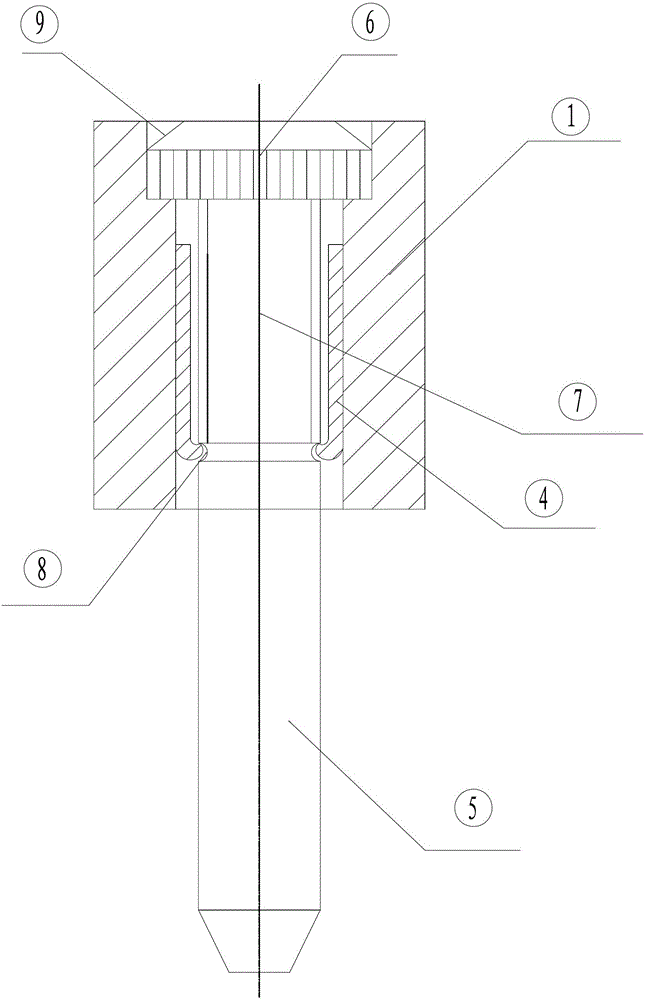

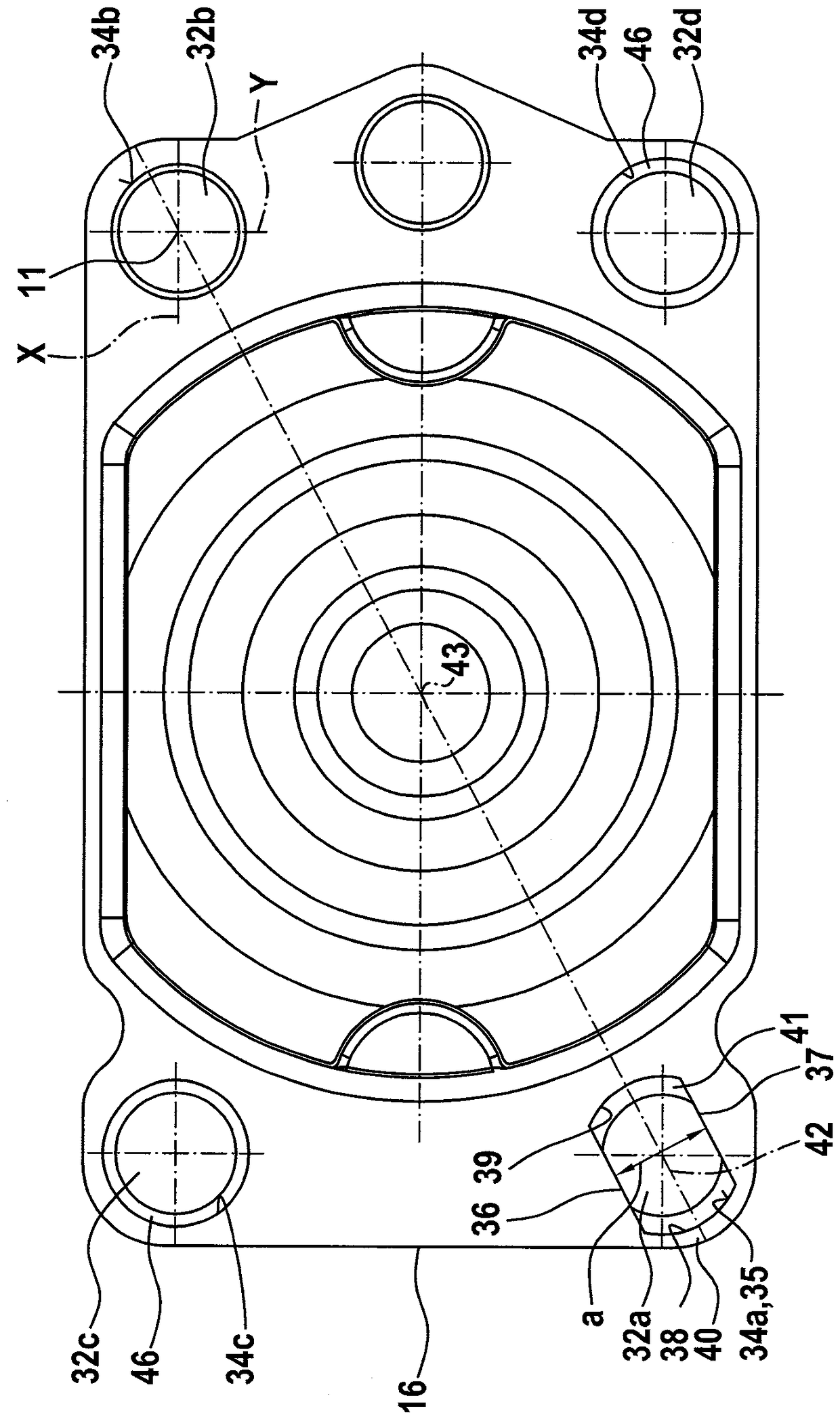

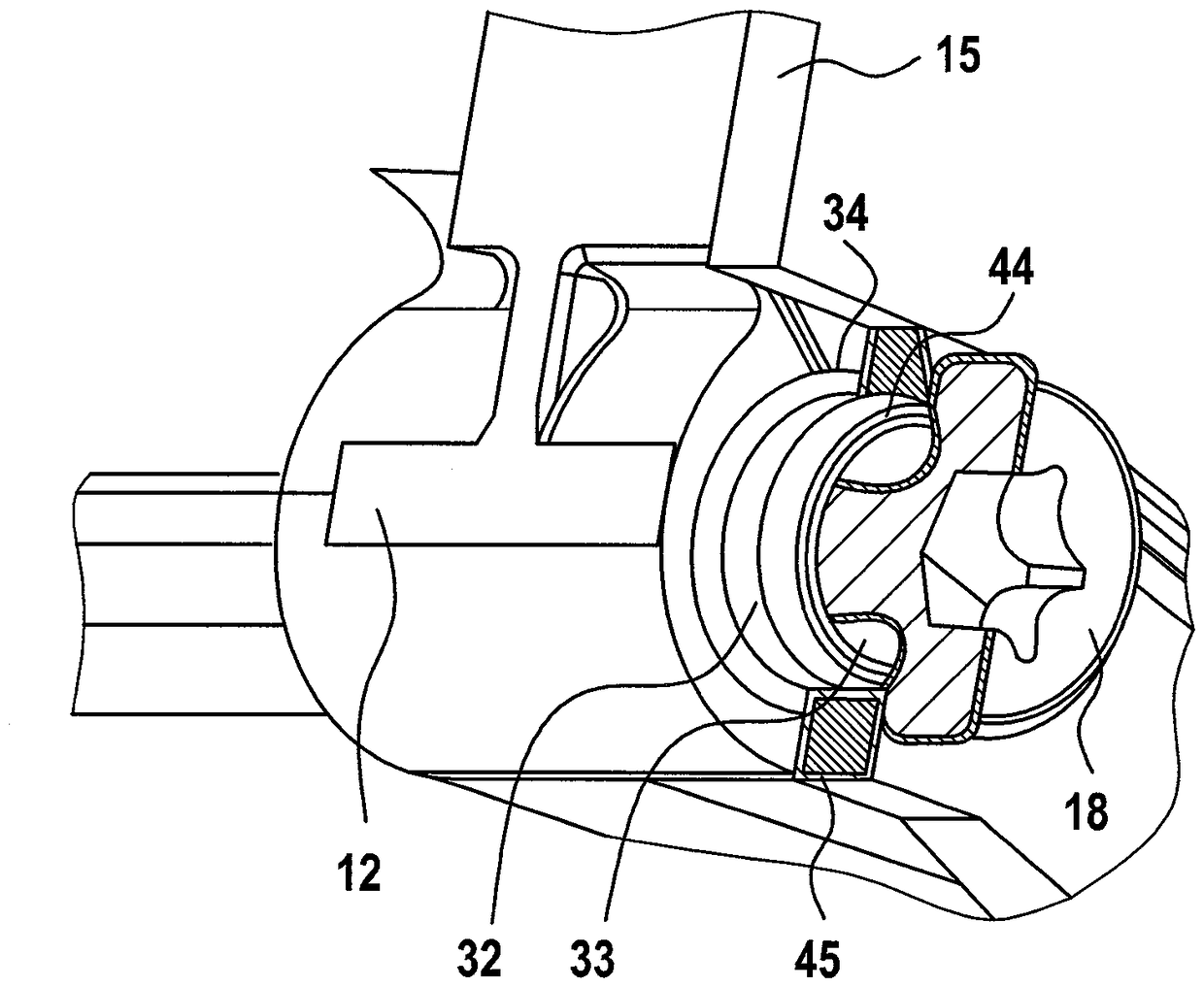

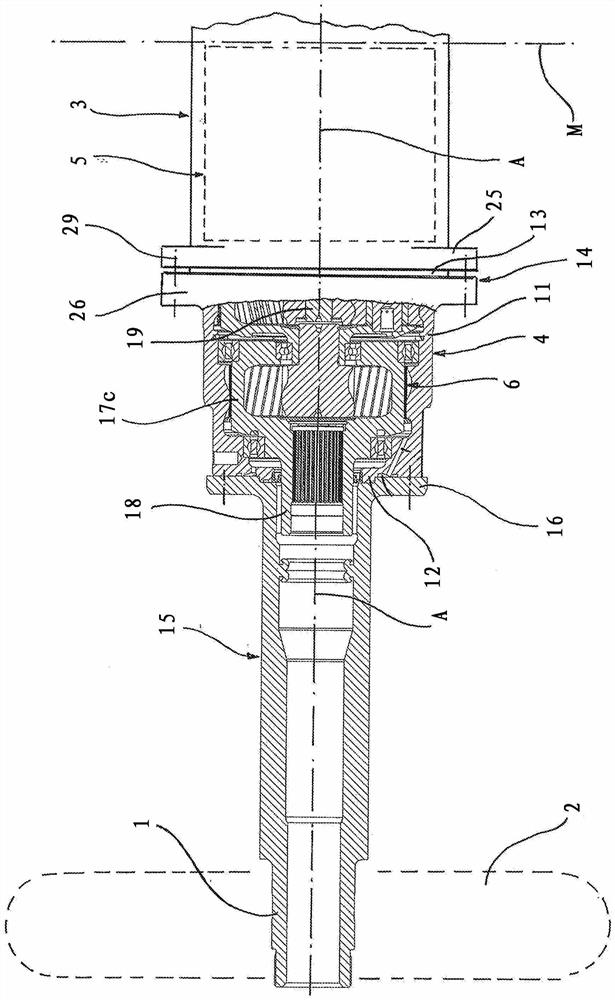

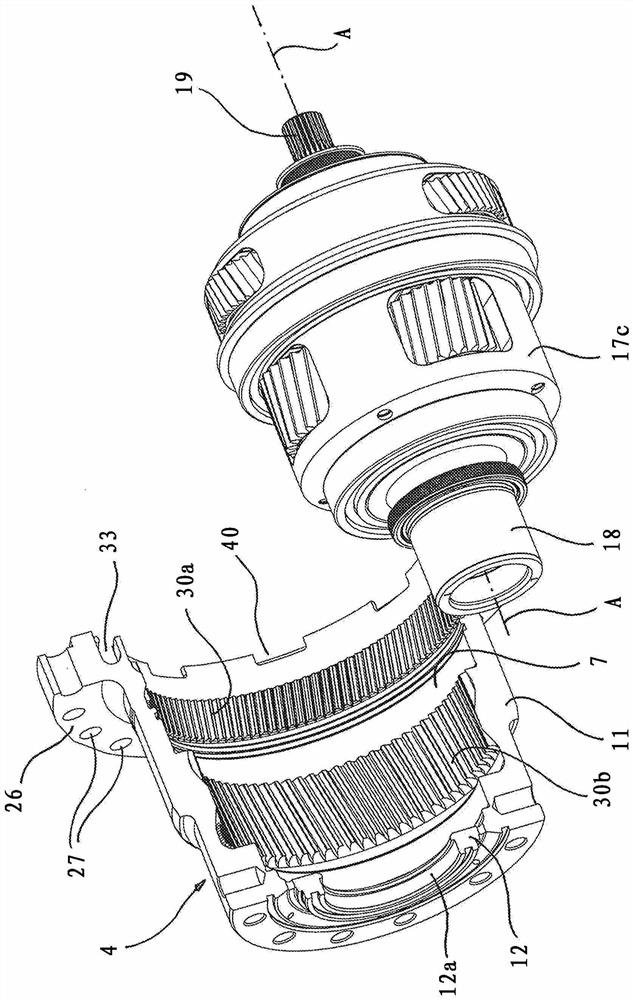

Tool holder

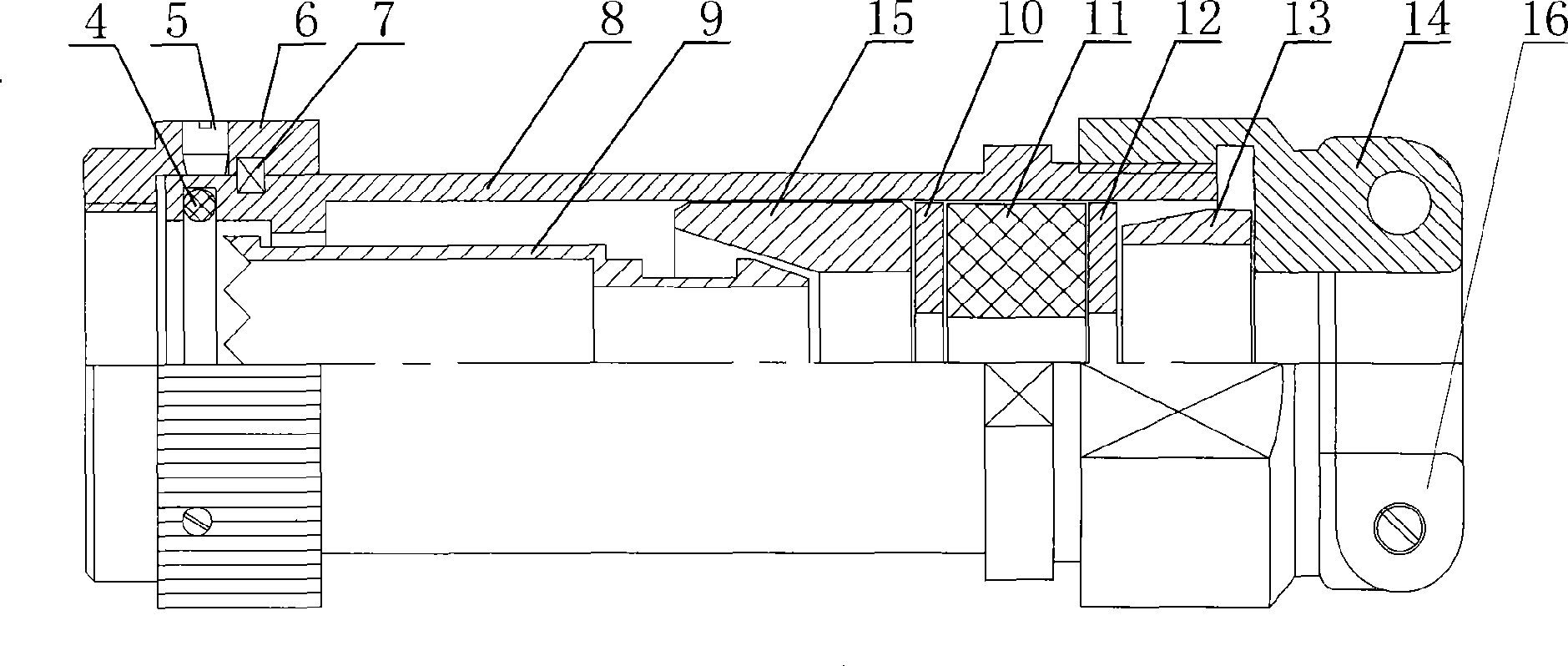

InactiveCN101119821AAvoid formingReduce torqueSleeve/socket jointsMeasurement/indication equipmentsFluid couplingLubrication

The aim of the invention is to improve the guiding of a lubricant through a tool holder in a small quantity lubrication system. According to the invention, a tool holder (1) comprises, in the maintaining body thereof (3), an axially displaceable stop sleeve (45) which is mounted in a through opening (31) which is connected to the receiving opening (13) for a tool shaft (15) and a stop surface (47) which is adjacent to the front end (23) of the tool shaft (15). Said stop sleeve (45) is screwed into an inner thread (43) of the through opening (31) and is coupled in a rotationally fixed manner, but in an axially displaceable manner, to a control tube (49) which engages in said stop sleeve (45) in an axial manner. Said control tube (49) is mounted in an axially fixed manner to the side thereof, but in a rotatable manner to the fluid coupling (27). A lubricant can be guided over the blades of the tool (9) by means of the fluid coupling (27), the control tube (49), the stop sleeve (45) and channels (17). Said tool holder (1 ) enables the fluid to be guided in an essentially calm manner to the tool, even in small amounts, and simplifies the longitudinal pre-adjustment of the tool unit / tool holder unit.

Owner:FRANZ HAIMER MASCHINENBAU KG

Photographic device

ActiveUS8382386B2Easily damagedLow photograph qualityBurglar alarmCamera body detailsCamera lensForeign object

Owner:VIVOTEK INC

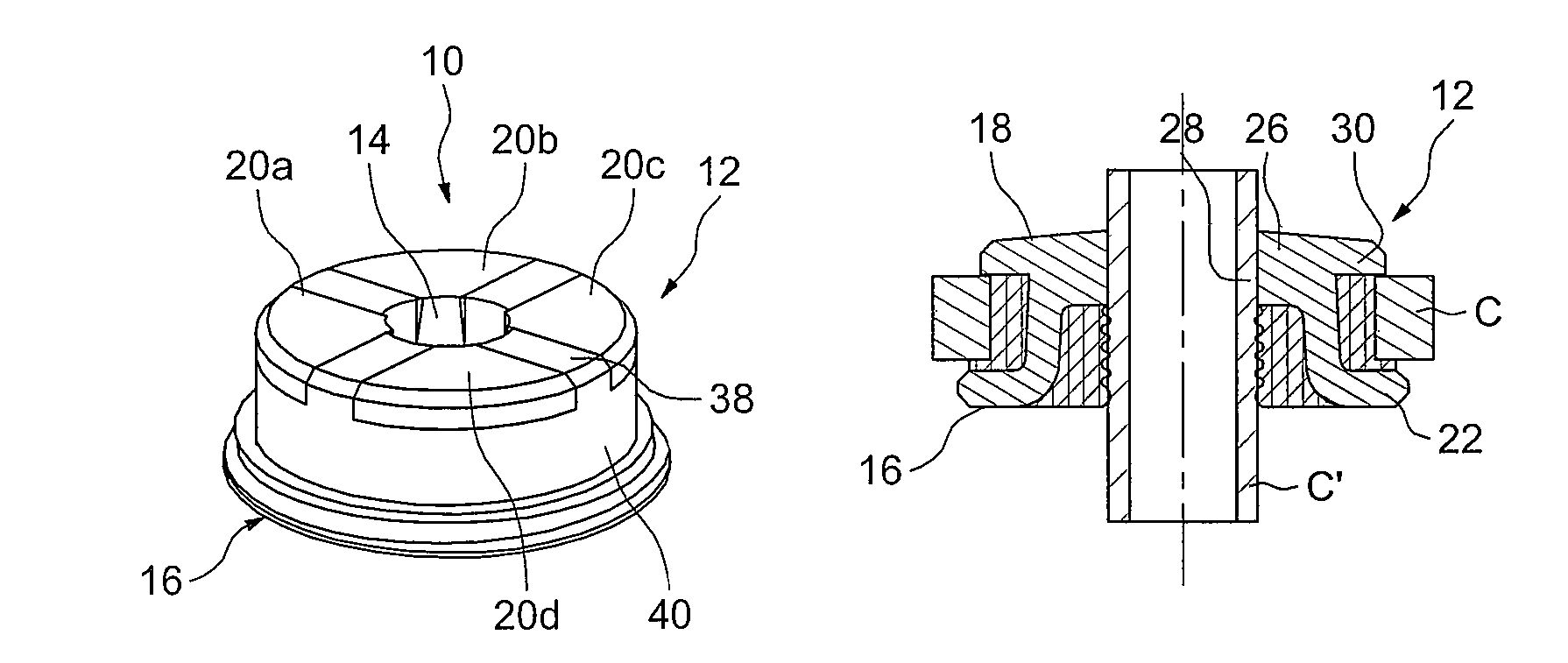

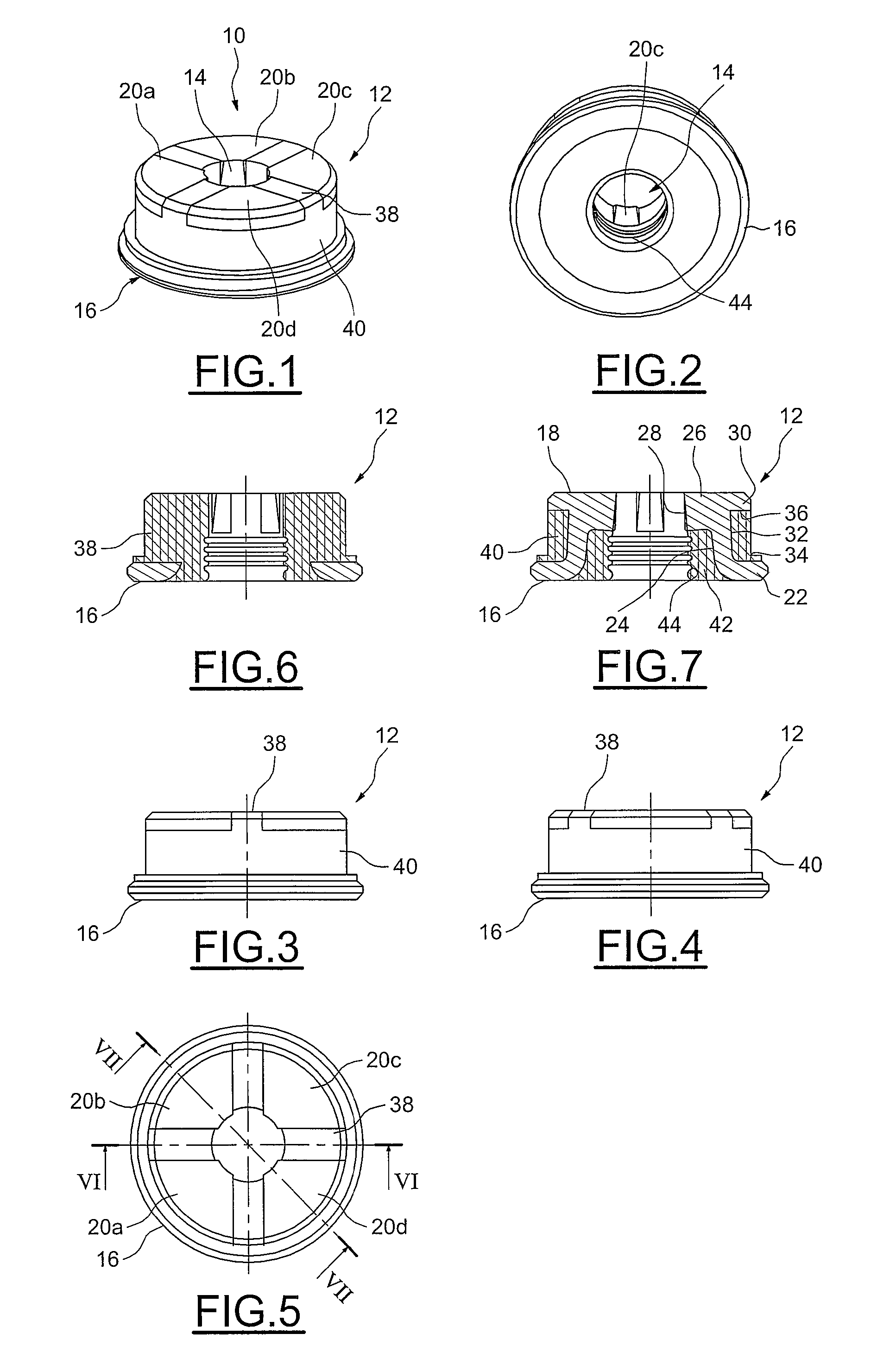

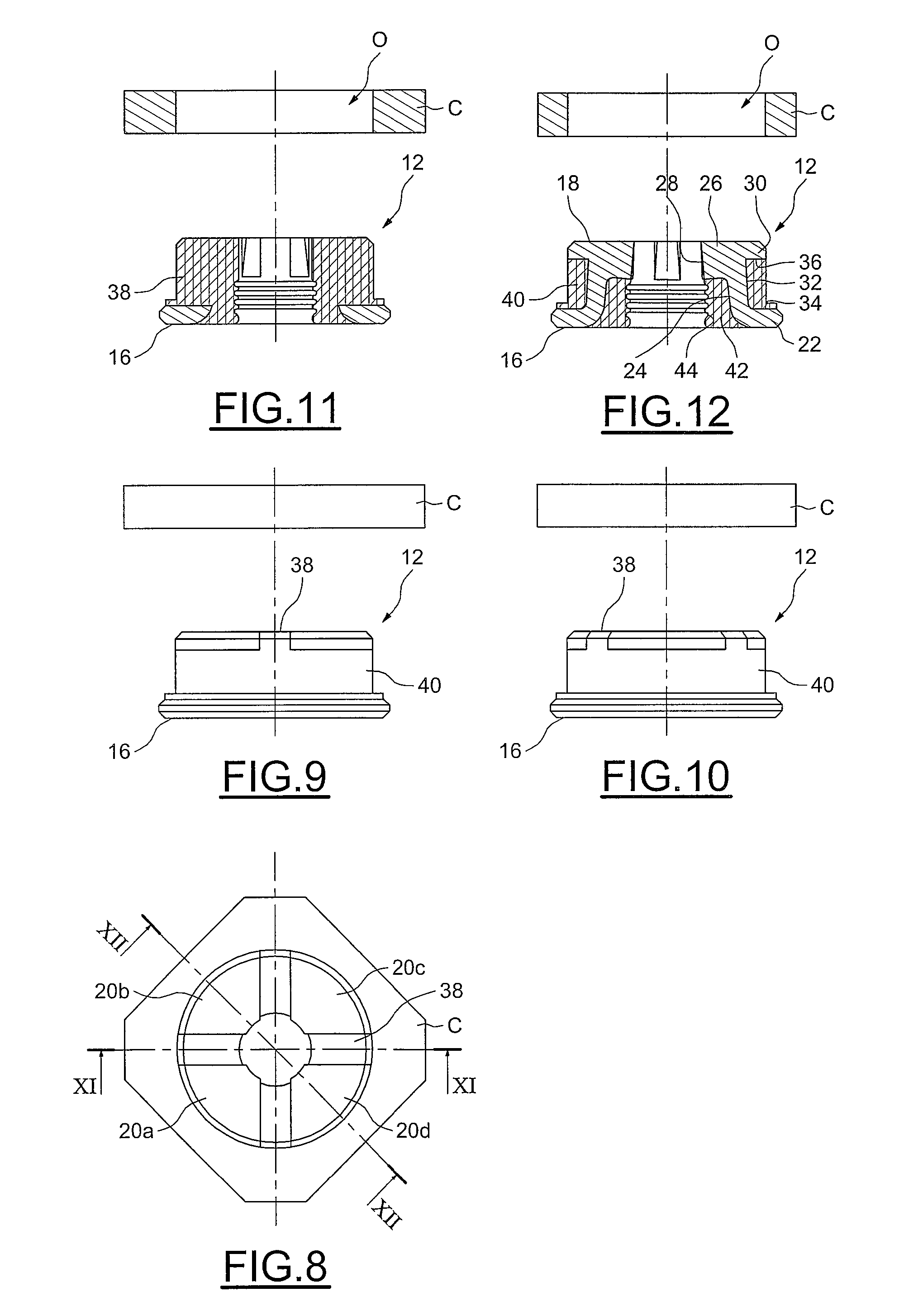

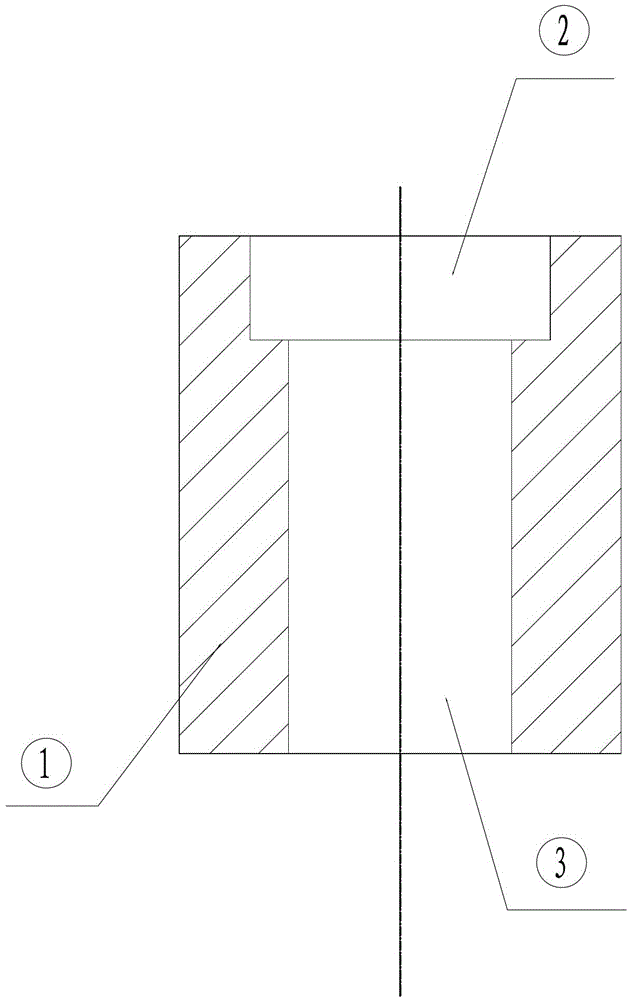

Device for the sealed retention of a pipe, method for the sealed mounting of a pipe through a partition wall and use of such a device for the sealed penetration of a partition wall of an aircraft tank

ActiveUS8690161B2Avoid deformationConnection sealSleeve/socket jointsFluid pressure sealed jointsEngineering

This device for the sealed retention of a pipe for the sealed penetration of a partition wall by the pipe comprises a body equipped with a sealed axial passage for the pipe and with a peripheral region for the sealed mounting of the device in an orifice made in the partition wall. The body comprises a set of rigid retaining sectors each comprising a bearing shoe for the pipe, and a sealing material positioned between the sectors to delimit the said sealed passage, and around the said sectors in the said peripheral region of the body via which region it is mounted on the partition wall.

Owner:AMPHENOL AIR LB

Carbon tank oil tank cover

PendingCN107143440ANo gapAvoid enteringGas treatmentNon-fuel substance addition to fuelFuel oilCarburetor

The invention relates to the technical field of carbon tank equipment, in particular to a carbon tank oil tank cover. The carbon tank oil tank cover comprises an oil tank outer cover and an oil tank inner cover, a filling cavity is formed in the middle of the oil tank inner cover, an upper port of the filling cavity is wrapped with the oil tank outer cover, a volume cavity is formed in the bottom of the oil tank inner cover, an upper ventilation cover is arranged at the upper end of the volume cavity, an air guiding gap is formed between the side wall of the upper ventilation cover and the inner wall of the volume cavity, a lower breathing plate is arranged at the bottom of the filling cavity, a welding ring is arranged between the lower breathing plate and the bottom of the filling cavity, a port in the upper end of the volume cavity is formed in the inner side of the welding ring, the lower surface of the lower breathing plate is fixedly connected with the filling cavity through the welding ring, and an air inlet and exhaust hole is formed in the bottom face of the volume cavity. The phenomenon that oil suction padding enters the volume cavity from the gap between the filling cavity and the lower breathing plate so as to enter the oil tank is avoided, the phenomena that the oil suction padding pollutes fuel oil in the oil tank, and the blocks a carburetor are avoided, and the oil tank cover is more environment-friendly and safer.

Owner:CHONGQING BAIKE DINGYU TECH CO LTD

Unmanned aerial vehicle battery box

InactiveCN110021724AMove preciselyNot easy to shiftPower plant constructionCell component detailsWear resistantEngineering

Owner:芜湖市极星航空科技有限公司

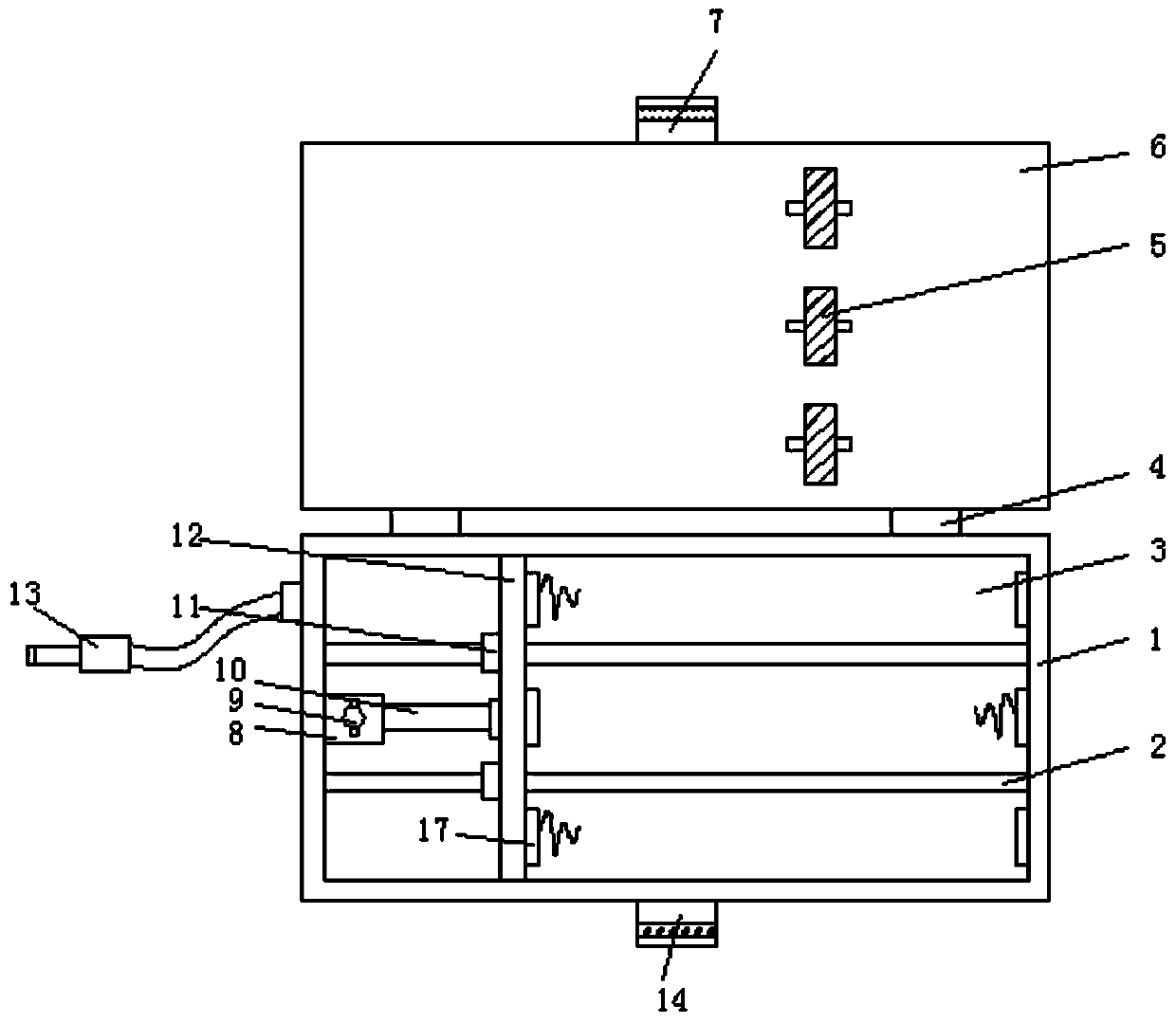

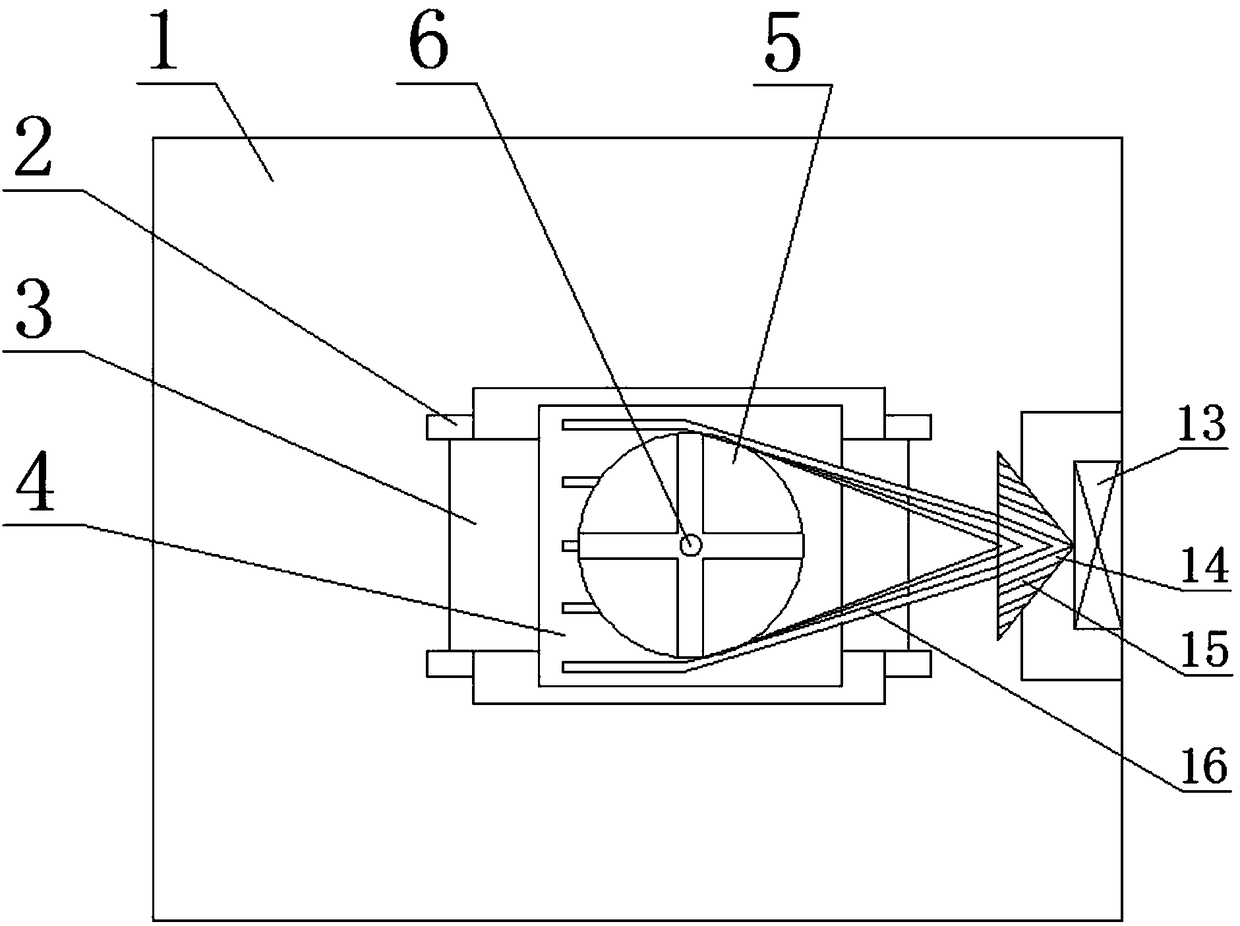

High-performance processing system with self-adjusting function

InactiveCN108268106AGuaranteed Sealed ButtGuaranteed cooling effectDigital processing power distributionHandling systemMotherboard

The invention belongs to the technical field of processing systems and discloses a high-performance processing system with a self-adjusting function, which is used for solving the problems that CPUs (central processing units) in existing processing systems have poor heat dissipation effect and hot air flow in boxes have poor heat dissipation effect due to non-uniform blowing. The system comprisesa box, wherein a CPU is mounted on a mainboard in the box body, a cooling fan is mounted on the CPU, a guiding cover is mounted on the side wall of the box, a cooling fan is mounted on the other sidewall of the box, the guiding cover and the cooling fan are mounted on two adjacent side walls, a plurality of heat dissipating through holes are formed in the side wall which is opposite to the side wall where the cooling fan is mounted, first sliding chutes are horizontally formed in the box, a sliding frame is nested in the first sliding chutes, a second sliding chute in the vertical direction is formed in the sliding frame, a slider is nested in the second sliding chute, and a first gas guide cylinder is connected to the slider and connected with a second gas guide cylinder through a telescopic pipe.

Owner:河南趣读信息科技有限公司

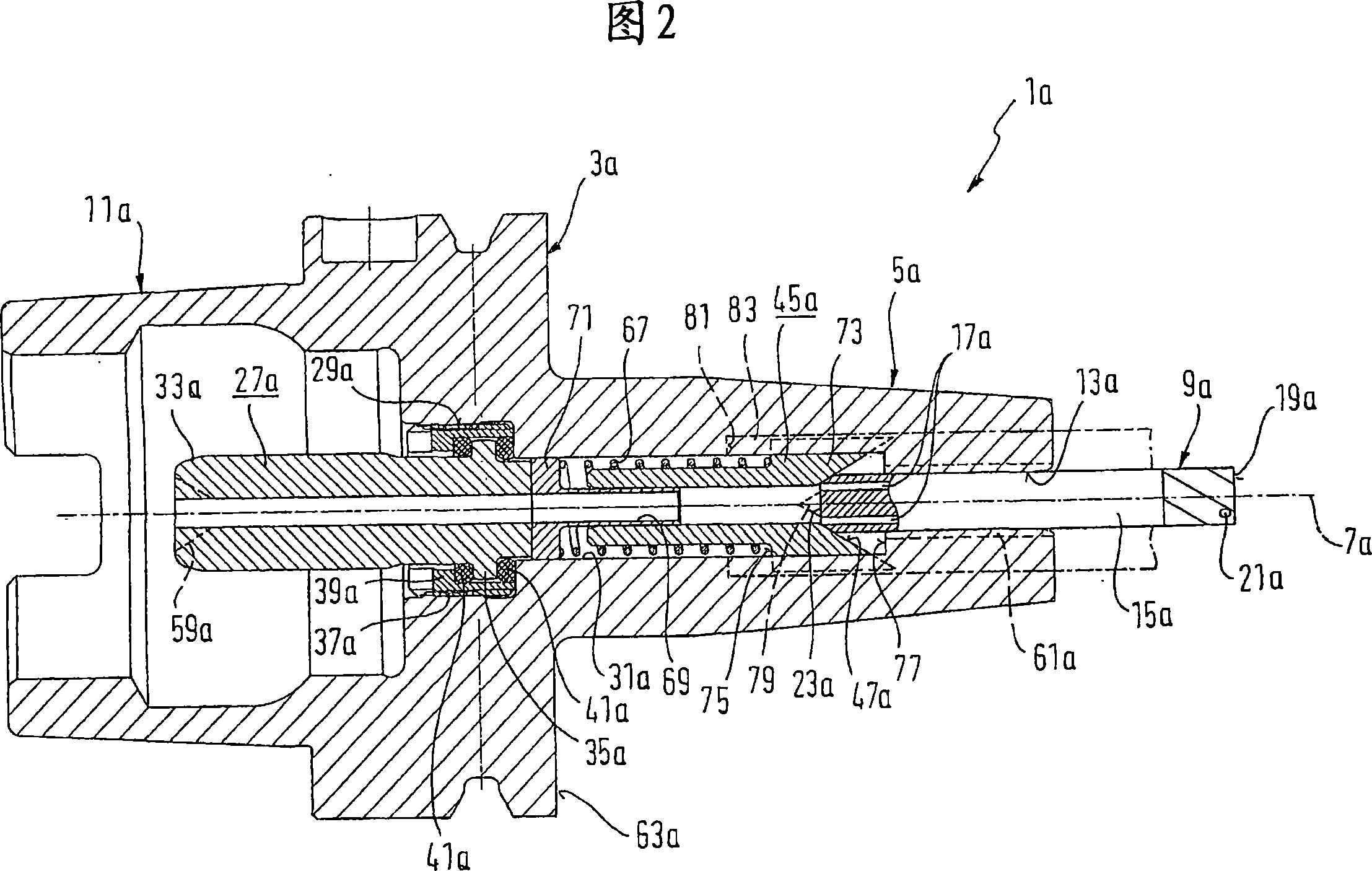

Tool holder

InactiveCN101797651AConnection sealSleeve/socket jointsMeasurement/indication equipmentsLubricationLubricant

The present invention relates to a tool holder. The aim of the utility model is to improve the guiding of lubricant in a system with small lubricant amount through the tool holder. Thus the invention provides the tool holder (1) which comprises an axially displaceable stop sleeve (45) in a through opening (31) which is connected to the receiving opening ( 13 ) for a tool shaft ( 15 ) in a holder body (3). The stop sleeve abuts against an end (23) of a tool shaft (15) through a stop surface (47). The invention requests that: the stop sleeve (45a, b, d-i) comprises a spring (67a,b,d-i) which pretighens the stop surface (47a, b, d-i) to the end (23a, b, d-i) of the tool shaft (15a, b, d-i). The tool holder (1) can feed the lubrication fluid to the tool (9) basically without eddy at a state with small lubrication amount, and simplifies the length pre-adjustment of the tool-tool holder assembly.

Owner:FRANZ HAIMER MASCHINENBAU KG

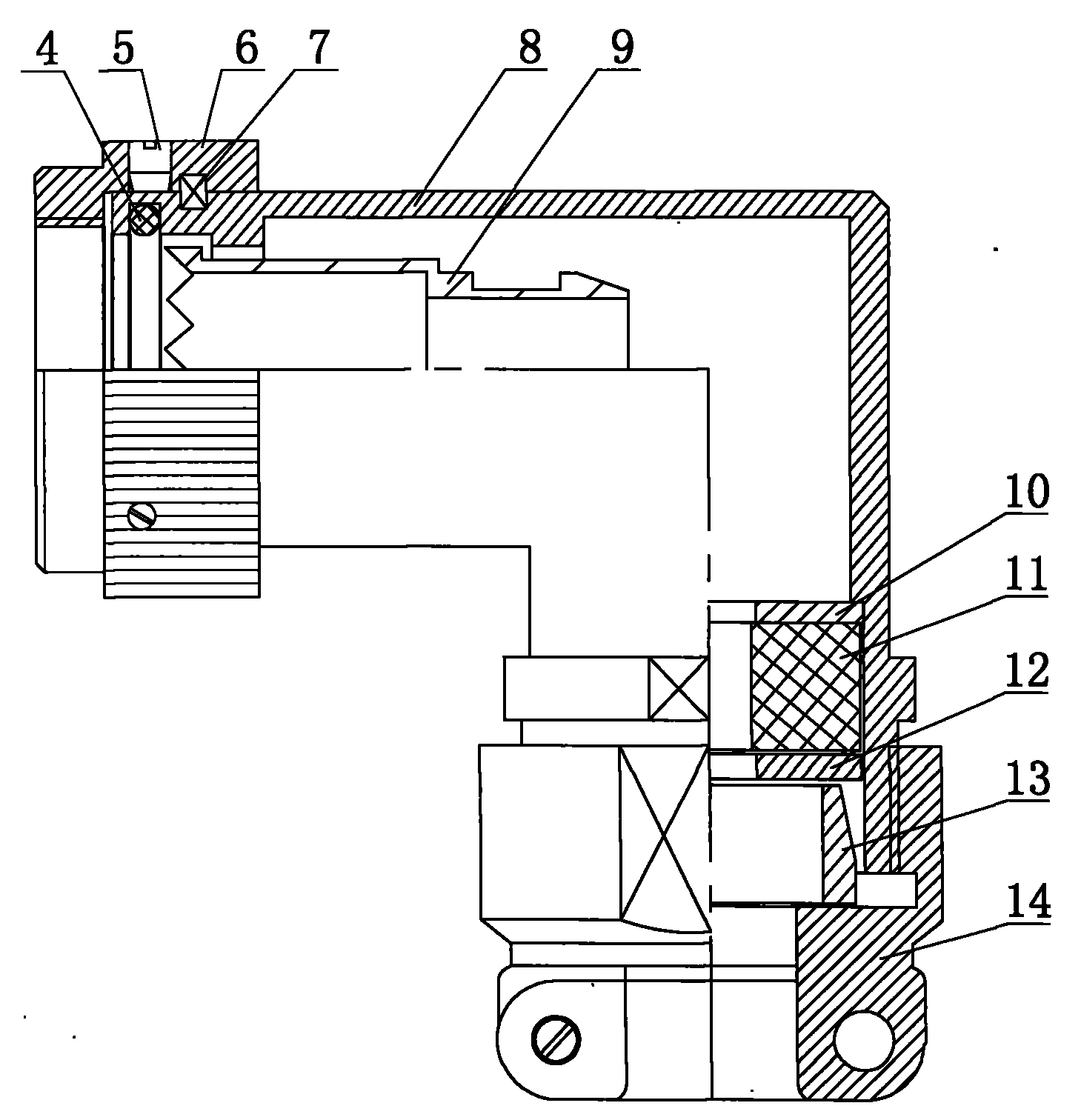

Explosive-proof straight travel electric actuator

InactiveCN104235470ACause damageRealize power outputOperating means/releasing devices for valvesSemi automaticActuator

The invention provides an explosive-proof straight travel electric actuator, capable of solving the problem that the traditional electric actuator cannot be switched back and forth between manual operation and electric operation. The explosive-proof straight travel electric actuator comprises a shell; a valve rod, a motor, a manual shaft, a worm, a worm wheel, a manual bevel gear, a clutch pawl and a switching handle, wherein the manual shaft is meshed with the manual bevel gear; a clutch pawl sleeve is linked with the valve rod, and the clutch pawl can be driven to rotate by the manual bevel gear; a compression spring I is arranged between the clutch pawl and the manual bevel gear; the worm wheel is linked with the valve rod and is driven by the motor; a clutch rack is arranged between the worm wheel and the clutch pawl; one end of the clutch rack is hinged with a safety pin; the switching handle is provided with a shifting block and a volute spiral spring; a back-up block is hinged in the shell; a compression spring II is arranged between the shifting block and the back-up block; the upper end of the shifting block is provided with a lobe abutting on the other end of the clutch rack and the upper end of the back-up block. The explosive-proof straight travel electric actuator has the advantages of manual semi-automatic switching operation and electric semi-automatic switching operation.

Owner:ZHEJIANG JINGJIE IND

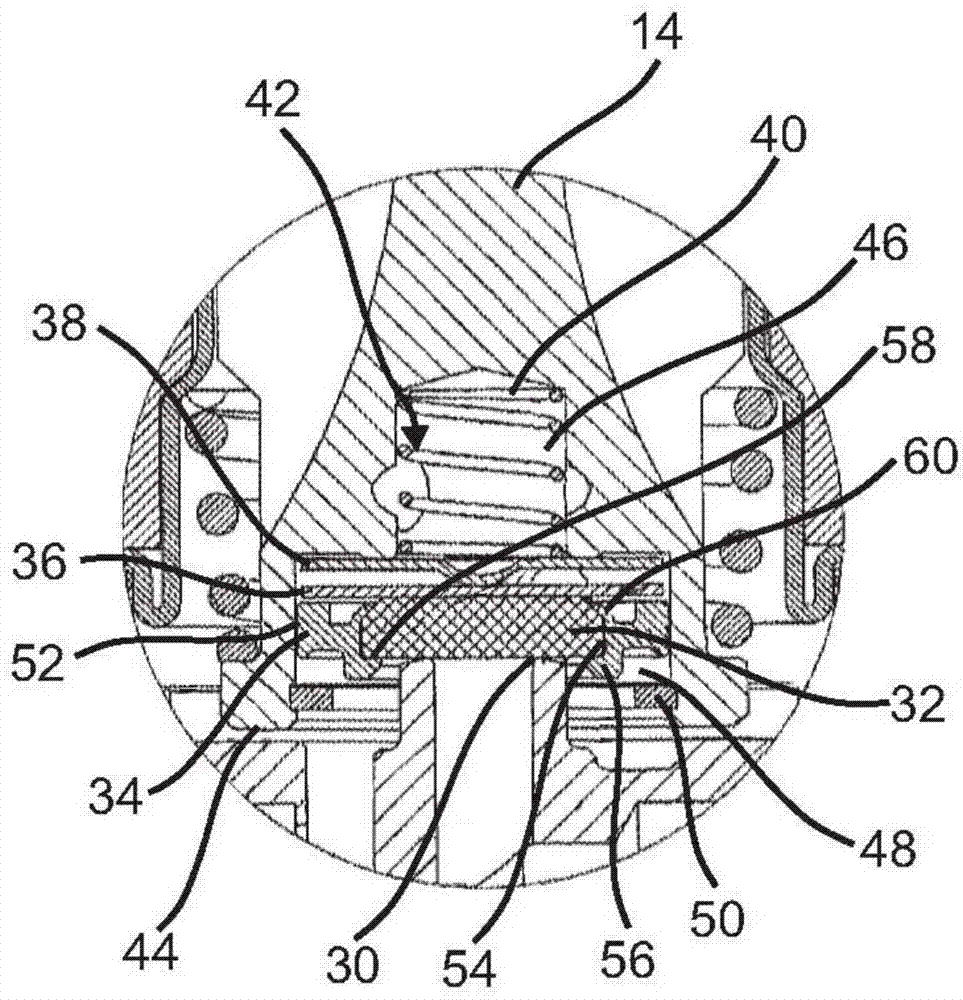

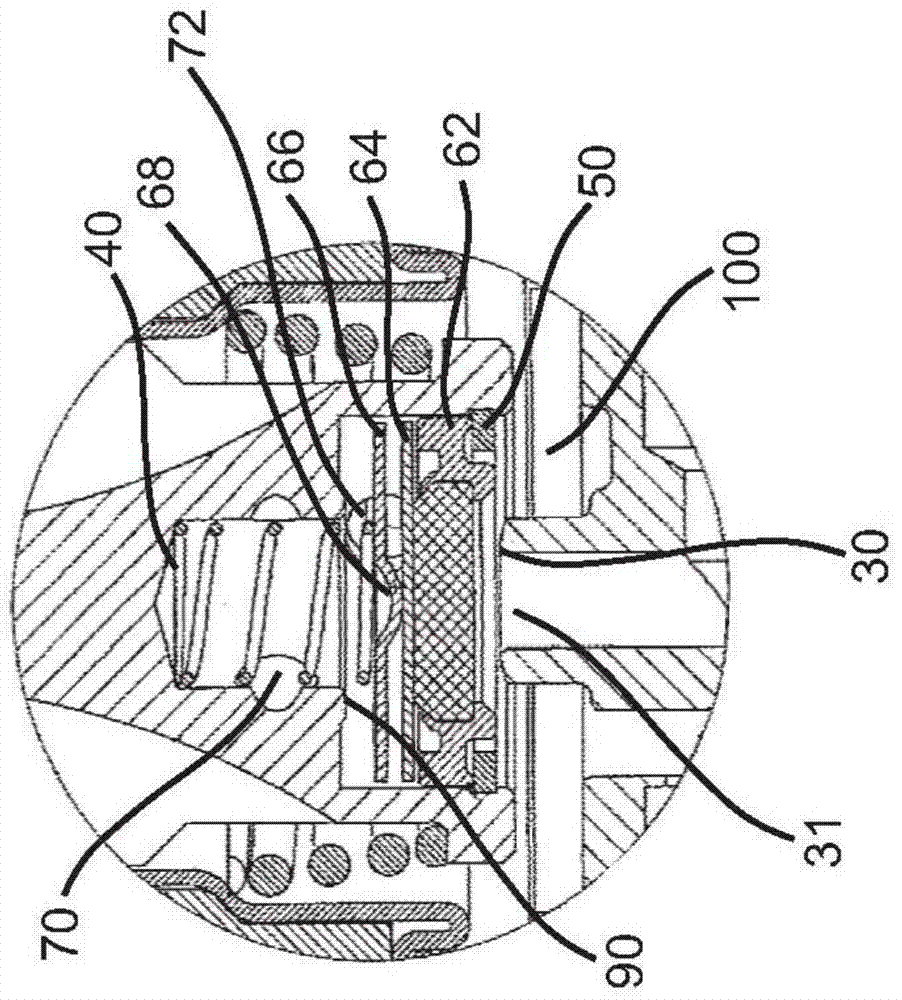

Sealing system for a solenoid valve and solenoid valve

ActiveCN103711921AReduce adhesionReduce contact surfaceOperating means/releasing devices for valvesLift valveSolenoid valveEngineering

A sealing system for a solenoid valve is provided for accommodation in a recess in an actuating element movable by a coil. The recess proceeds from an end face of the actuating element close to a valve seat. The actuating element is movably mounted in a solenoid valve and designed to clear or close the valve seat (30). A sealing disk and a spring element biasing the sealing disk are provided, wherein the spring element is arranged on the end face facing away from the valve seat centered with respect to the sealing disk and exerts a force on the sealing disk in direction of the valve seat. The sealing disk is axially shiftably guided in the actuating element. A solenoid valve itself includes such sealing system.

Owner:BURKERT WERKE

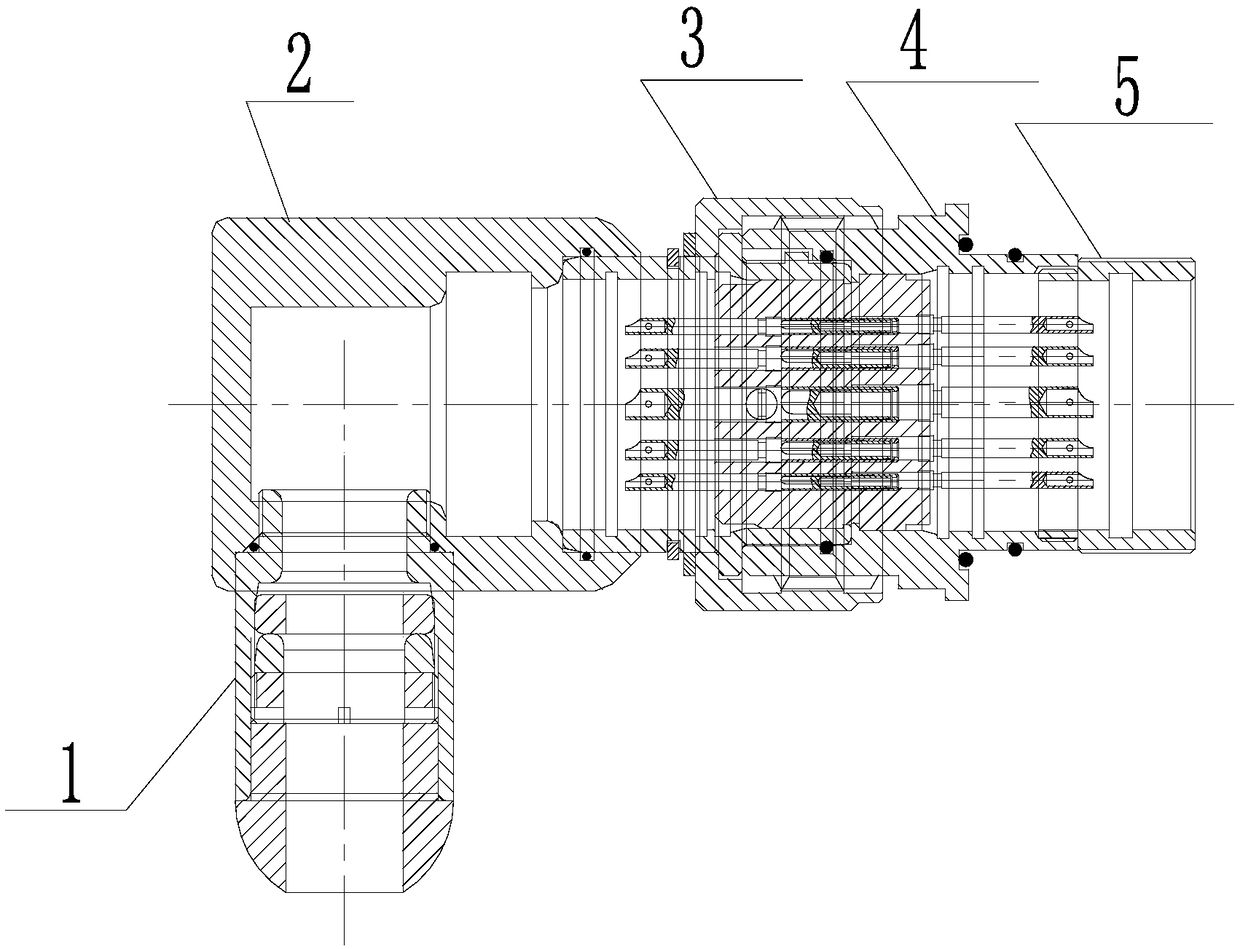

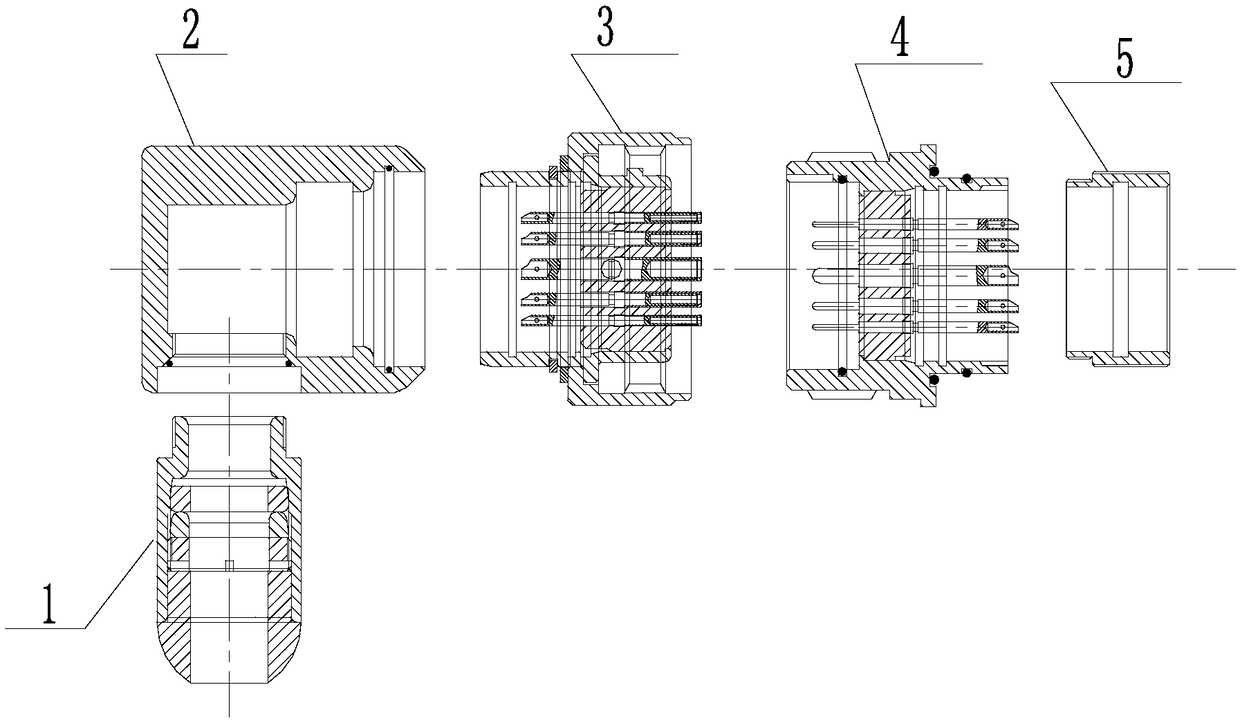

Metal shell watertight connector

PendingCN109346880AReasonable structureEasy to install and connectCouplings bases/casesTwo-part coupling devicesEngineeringCorrosion

The invention provides a metal shell watertight connector. The metal shell watertight connector comprises a wire protecting sleeve assembly, a wire protecting barrel assembly, a female joint insertingassembly, a pin inserting assembly and a pin inserting reinforcing assembly, wherein the wire protecting barrel assembly is of a hollow barrel structure with a closed left end and an opened right end, and a mounting through hole is formed in the outer side wall of the hollow barrel structure; the wire protecting sleeve assembly is arranged in the mounting through hole; the right end of the wire protecting barrel assembly is connected with the female joint inserting assembly; the female joint inserting assembly is connected with the pin inserting component; and the pin inserting assembly is connected with the pin inserting reinforcing assembly. The metal shell watertight connector is reasonable in structure, convenient to install and connect, waterproof and reliable, and the underwater operation of the water depth of 0-6000 meters can be met; and in addition, the metal shell watertight connector is resistant to acid and alkali and corrosion, not aged easily, long in service life, capable of filling up the blank of a domestic deep water watertight connector, and has relatively high economic value and scientific research value.

Owner:HOUMA ECONOMIC DEV ZONE RIXIANG TECH CO LTD

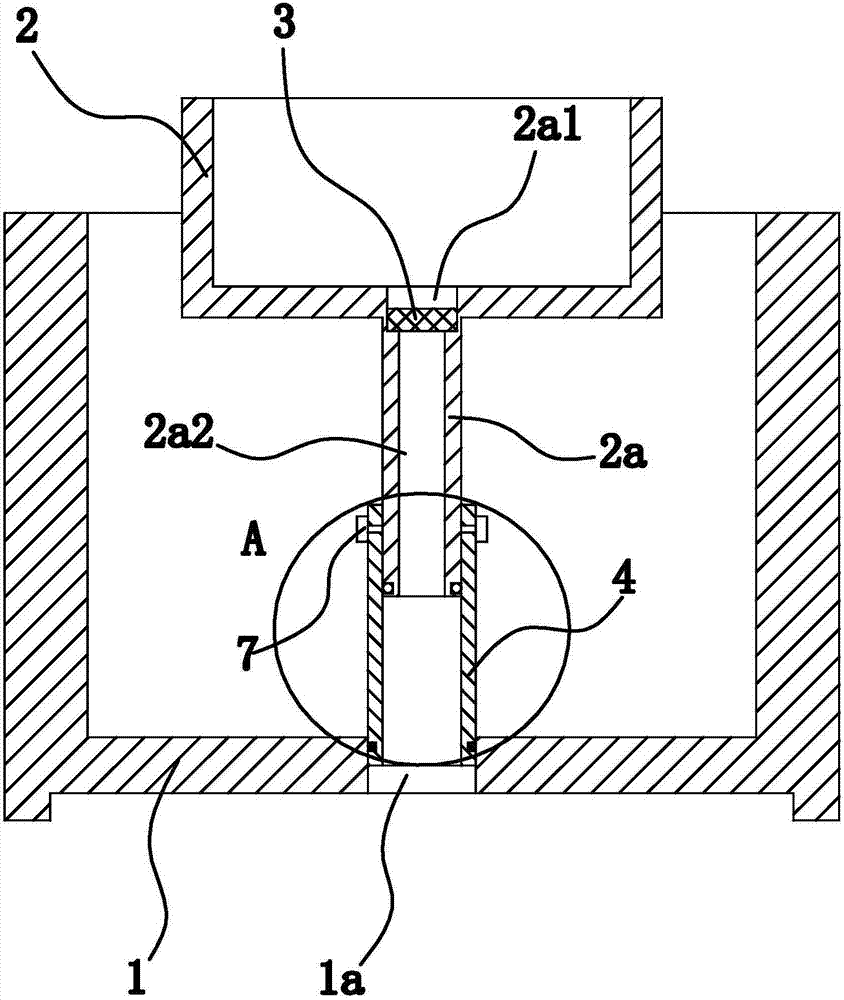

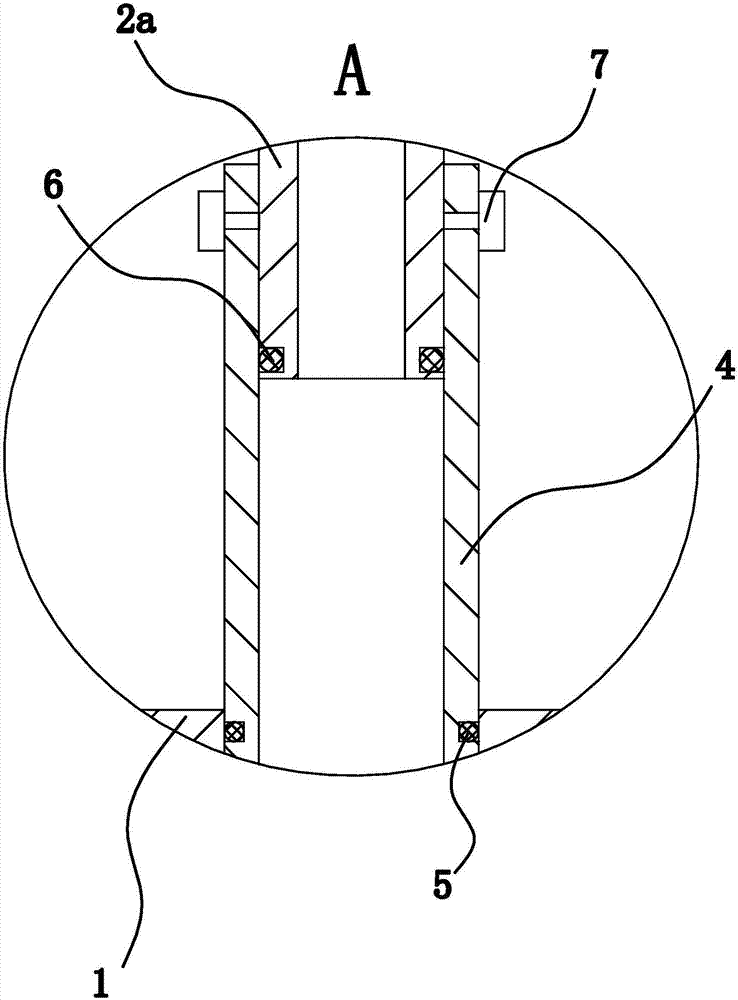

a digester

ActiveCN104293655BReduce leakageReduce lossesGas production bioreactorsWaste based fuelSlagEngineering

The invention provides a biogas digester which is used for solving the problem that waste of biogas is easily caused in the slag removal process in the conventional biogas digester. The biogas digester comprises a gas storage tank and a digester body in which a fermentation disc is arranged, wherein the top of the digester body is connected with a sealing cover; a lifting device which can drive the fermentation disc to translate up and down is arranged at the bottom of the fermentation disc; a gas inlet pipe and a gas outlet pipe are arranged between the gas storage tank and the digester body; a gas suction piece I is arranged in the gas inlet pipe; a sealing plate I and a sealing plate II are arranged in the gas storage tank; an elastic piece through which the sealing plate I has the tendency of sealing the gas inlet pipe is connected to the sealing plate I; a cylinder I through which the sealing plate II seals or opens the gas outlet pipe is connected to the sealing plate II; an exhaust pipe and a pressure gage are connected to the digester body; a gas suction piece II is arranged in the exhaust pipe; a sealing plate III is arranged at the end face of the exhaust pipe; and a spring I through which the sealing plate III has the tendency of sealing the exhaust pipe is arranged between the gas suction piece II and the sealing plate III. The biogas digester disclosed by the invention has the advantages that waste of biogas is avoided during slag removal.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Combined fish tank

InactiveCN107509679AChange distanceChange sizePisciculture and aquariaReceptacle cultivationLocking mechanismEngineering

The invention provides a combined fish tank, which belongs to the technical field of daily necessities. It solves the problem of poor practicability of the existing flower pots with fish tanks. The combined fish tank includes a tank body made of transparent glass and a flower pot vertically arranged in the tank body. The bottom of the flower pot has a cylindrically protruding water-permeable part. The filter screen of the upper cavity and the lower cavity, the upper cavity communicates with the inner cavity of the flower pot, the upper cavity and the lower cavity communicate through the mesh of the filter screen, the bottom of the cylinder body is vertically penetrated with drainage holes, and the drainage holes are vertically arranged There is a circular tube-shaped drain pipe, which is sealed and fixed with the cylinder body. The upper end of the drain pipe extends out of the drain hole, and the lower end of the permeable part is inserted into the drain pipe. There is an O-ring between the permeable part and the drain pipe to make the two connected and sealed. First, the permeable part can slide along the axial direction of the drain pipe, and a detachable locking mechanism that can limit the sliding of the permeable part is provided between the two. The combined fish tank has the advantage of high practicability.

Owner:南京卓策知识产权服务有限公司

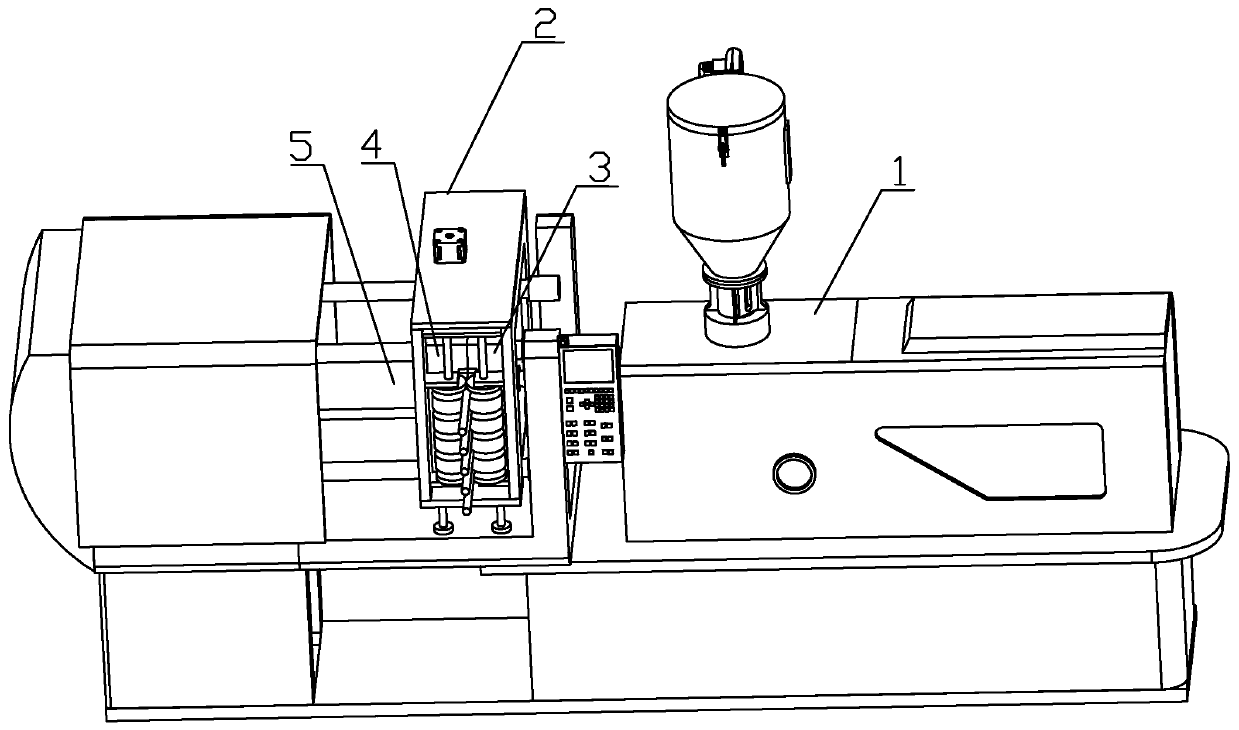

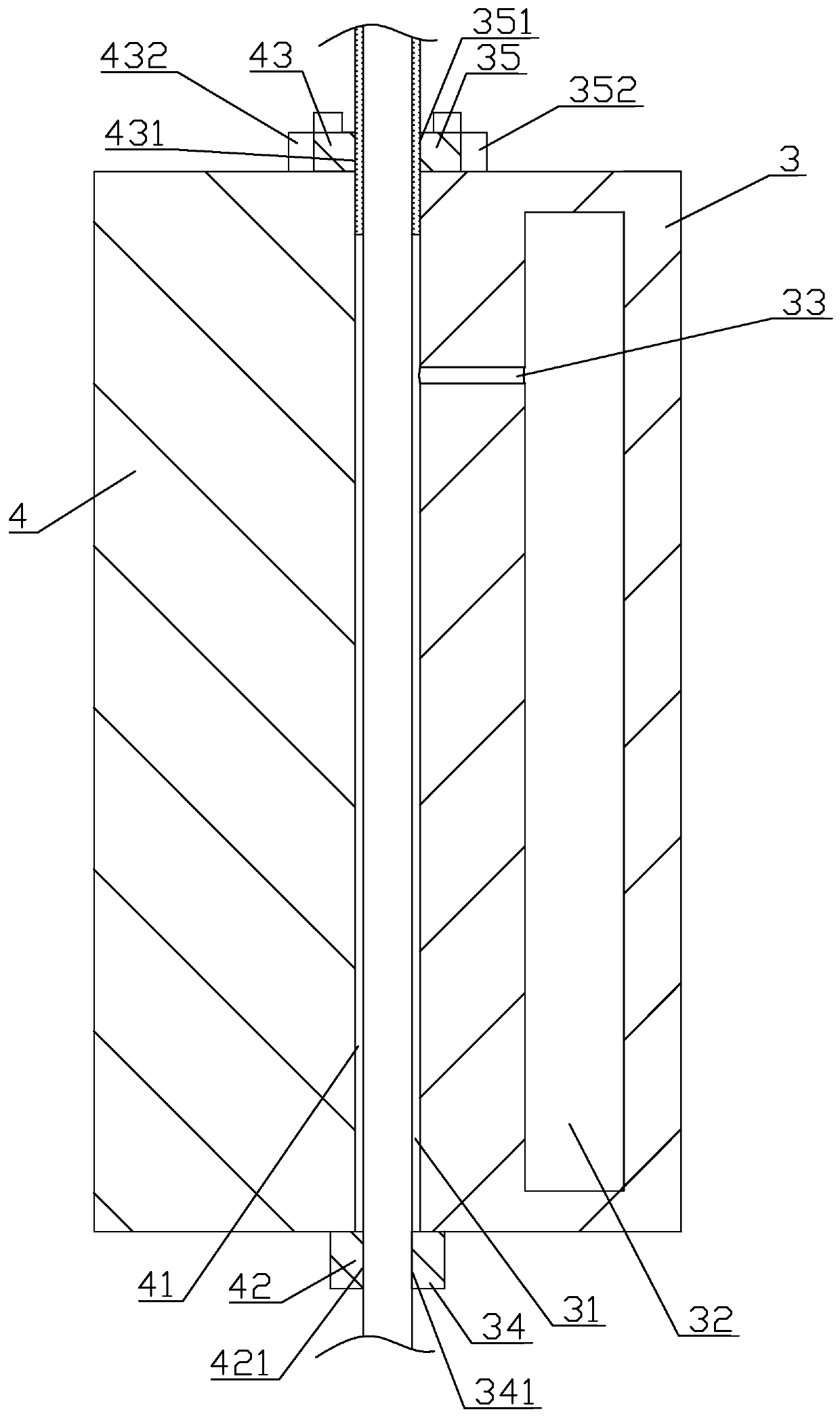

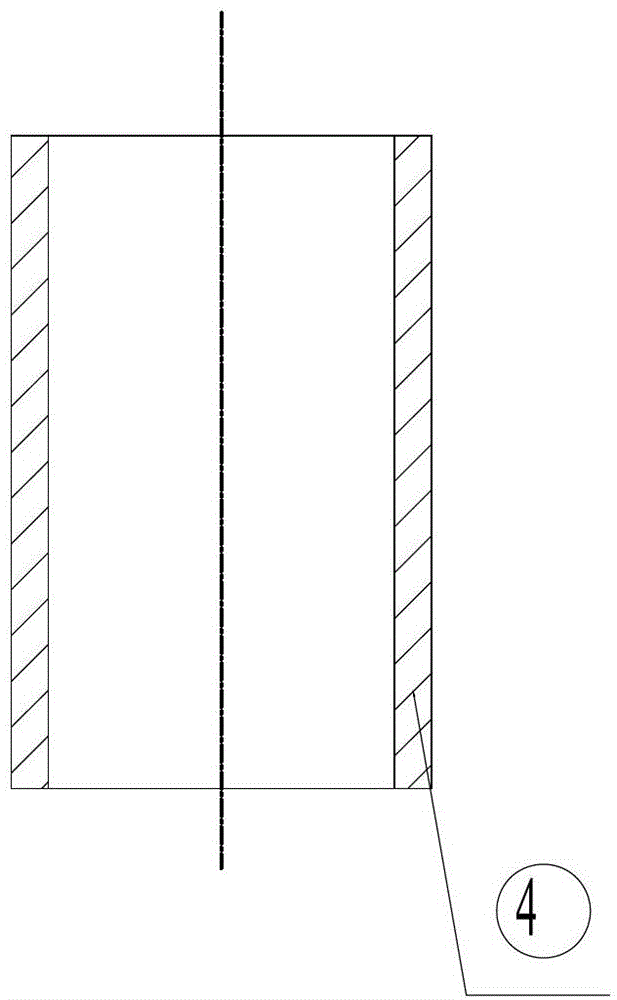

Insulation sleeve injection molding process and matching injection molding machine thereof

InactiveCN111300734AAvoid installation stepsEasy to produceInsulating conductors/cablesCopper wireProcess engineering

The invention discloses an insulation sleeve injection molding process. The insulation sleeve injection molding process includes the following steps that 1, a copper wire is straightened; 2, the copper wire is conveyed; 3, mold closing injection molding is carried out, an injection molding machine is started to make a movable mold plate and a static mold plate on the injection molding machine be closed, at the moment, the copper wire penetrates through an injection molding passage formed by the movable mold plate and the static mold plate, and then plastic raw materials are heated and injectedinto the injection molding passage by the injection molding machine; 4, equal distance transmission is conducted, the injection molding machine is started to separate the movable mold plate from thestatic mold plate, then the copper wire continues to be conveyed, so the copper wire is molded to form a section of the insulation sleeve separated from the static mold plate, and the next section ofthe copper wire enters the static mold plate; 5, the third step and the fourth step are repeated, so the rear section of the copper wire is molded to form the insulation sleeve; and 6, the wire is coiled, and in the third step, the copper wire is in sealed connection with the movable mold plate and the static mold plate to prevent molten plastic liquid flowing out of the injection molding passage.The insulation sleeve injection molding process has the following effects of improving the situation that the insulation sleeve is easily separated from the copper wire and facilitating to promote the quality of wire products.

Owner:益模钢模五金(深圳)有限公司

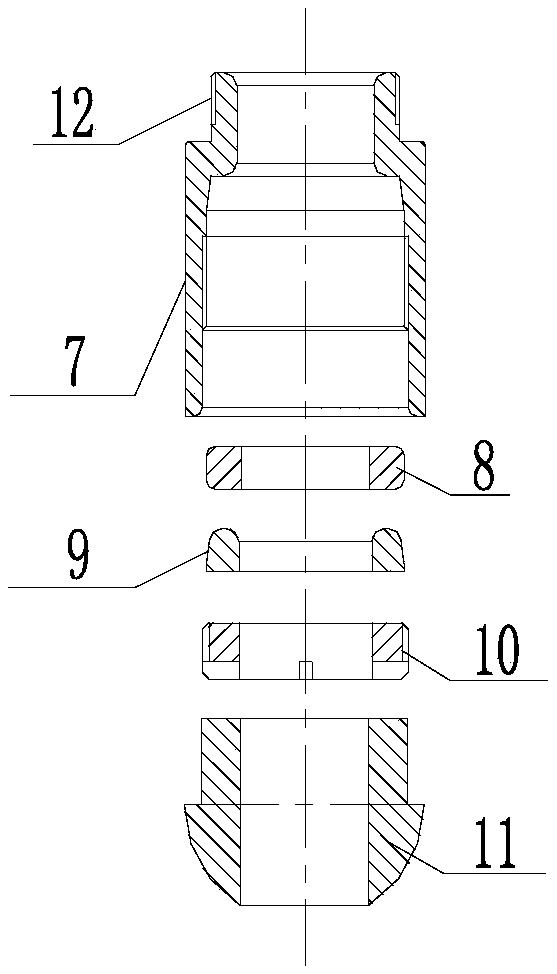

Rivet type bolt

The invention relates to a rivet type bolt, in particular to a bolt capable of being used in vibration resistance, tightness and single-face connection in automobile and aviation industry, and belongs to the technical field of fasteners. The rivet type bolt comprises a rivet body and a rivet core, wherein a counter bore and a through hole which are coaxial with the rivet body are arranged on the rivet body, the diameter of the counter bore is larger than that of the through hole, the rivet core penetrates through the through hole, and a rivet head at the upper end of the rivet core is clamped on a boss formed by the counter bore and the through hole. The rivet type bolt is characterized in that the lower end of the rivet head is connected with a rivet core rod, a fracture groove is arranged on the rivet core rod and divides the rivet core rod into an upper part and a lower part, threads are arranged at the upper end of the fracture groove, and a polish rod is arranged at the lower end of the fracture groove; and a protective sleeve is sleeved on the threads, the lower end of the protective sleeve is clamped in the fracture groove, and a chamfer is arranged at the upper end of the rivet head. The rivet type bolt is simple, compact and reasonable in structure, and firm and sealed in connection, and improves resistance to single-face and blind hole connection vibration particularly in simple operations of single-face blind hole connection.

Owner:WUXI ANSHIDA HARDWARE

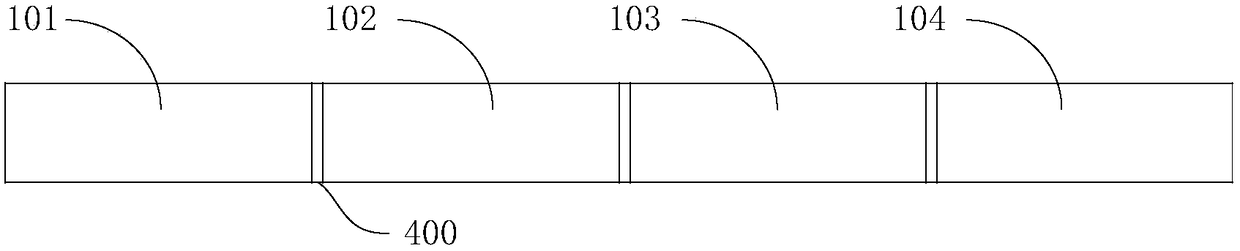

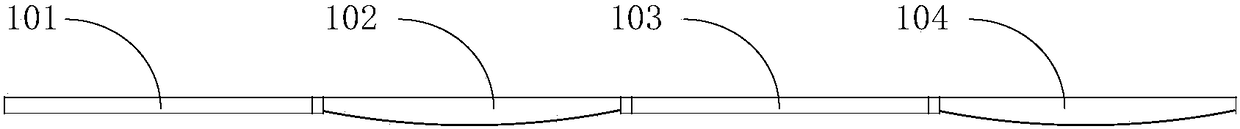

Lithium battery winding core, mobile phone battery, mobile phone and manufacturing method thereof

InactiveCN105895967BAvoid wastingConnection sealFinal product manufactureLi-accumulatorsElectrical batteryEngineering

The invention discloses a lithium battery winding core, a mobile phone battery, a mobile phone and a manufacturing method thereof, belonging to the technical field of mobile phones; the lithium battery winding core includes: a positive electrode sheet, a negative electrode sheet and a diaphragm; the diaphragm is arranged between the positive electrode sheet and the negative electrode sheet Between; the lamination of the positive electrode sheet, separator and negative electrode sheet is made into a winding core by winding. One side of the winding core is curved and the other side is flat; a mobile phone battery, including a winding core of a lithium battery. By making the lithium battery winding core into a curved surface structure, it provides a basis for the curved surface battery of the mobile phone; the mobile phone battery is made into a curved surface structure, and the connection with the curved surface of the mobile phone is more sealed, eliminating the gap as much as possible and avoiding the waste of space.

Owner:SHANGHAI GREEN ORANGE IND

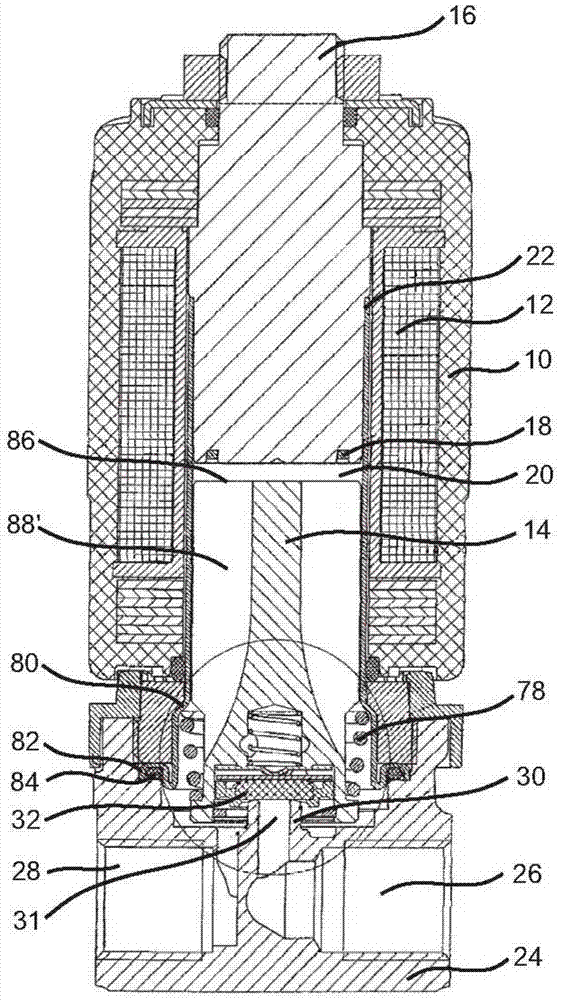

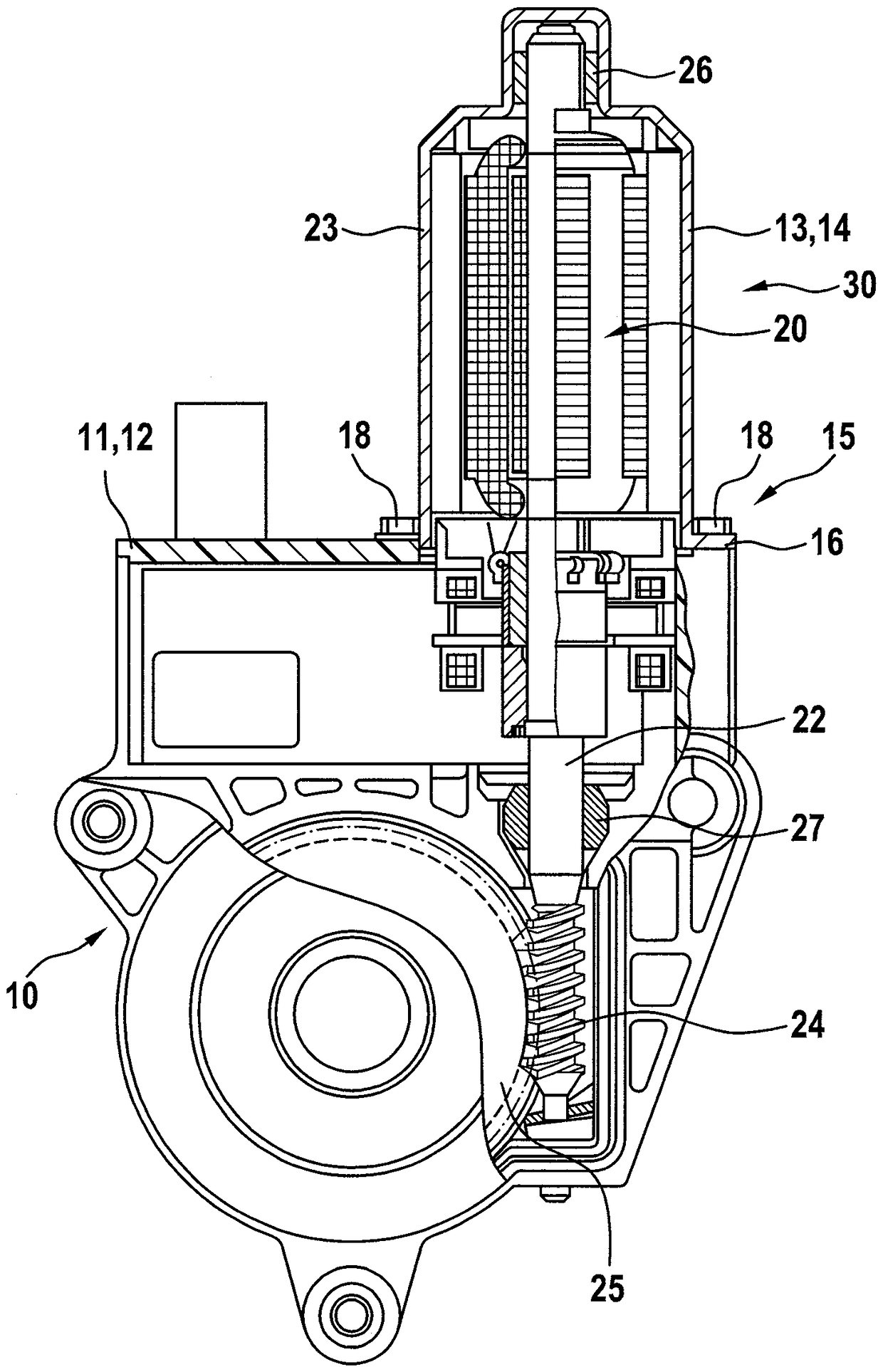

Manufacturing method and drive unit for a drive unit for a motor vehicle servo drive

InactiveCN104052190BAccurate centerEasy to makePower-operated mechanismMechanical energy handlingManufacturing technologyEngineering

The invention relates to a method for producing driving unit for motor vehicle servo driving device and the driving unit. The driving unit comprises a first housing part connected with a second housing part in a linkage area. In order to center the housing parts, the first housing parts is provided with at least two centering pins cooperating with centering openings arranged in the second housing parts. A first clearance fit is arranged in one of the centering pin and the corresponding centering opening. During determination of dimensional tolerance set of distances between the centering openings and the centering pins, a reference point related to one of the centering pins and the corresponding centering opening is selected, and the dimensional tolerance set is stared from the reference point, so least-possible second clearance fits or transition fits in manufacturing technology is configured between the centering pins and the corresponding centering openings, and the first clearance fit is configured between at least one other centering pin and the corresponding centering opening.

Owner:ROBERT BOSCH GMBH

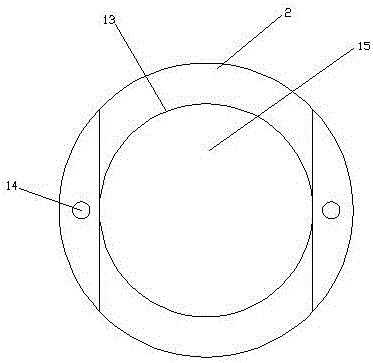

Water-proof cable tail clip for circular electric connector

The invention relates to a waterproof cable tail clamp for a circular electric connector, wherein a nut is arranged on one end of a sleeve through a shell retainer ring; an inner cavity of an opening of the sleeve is provided with an 'O'-shaped ring; a set screw is arranged on the nut; the nut is closely connected with a plug or a socket; and an inner cavity on one end of the sleeve is provided with a lining provided with a tooth opening, and an inner cavity on the other end of the sleeve is provided with a rubber gasket of which both surfaces are provided with gaskets for limitation, whereina hold-down ring is arranged on one gasket on an opening part of the sleeve, and a hold-down nut is sleeved outside the opening of the sleeve. The waterproof cable tail clamp hermetically connects the electric connector and a cable into the sleeve, has good sealing performance, is effectively waterproof and dustproof, can avoid damage of the cable due to severe bending, and is convenient to insert and maintain.

Owner:熊金生

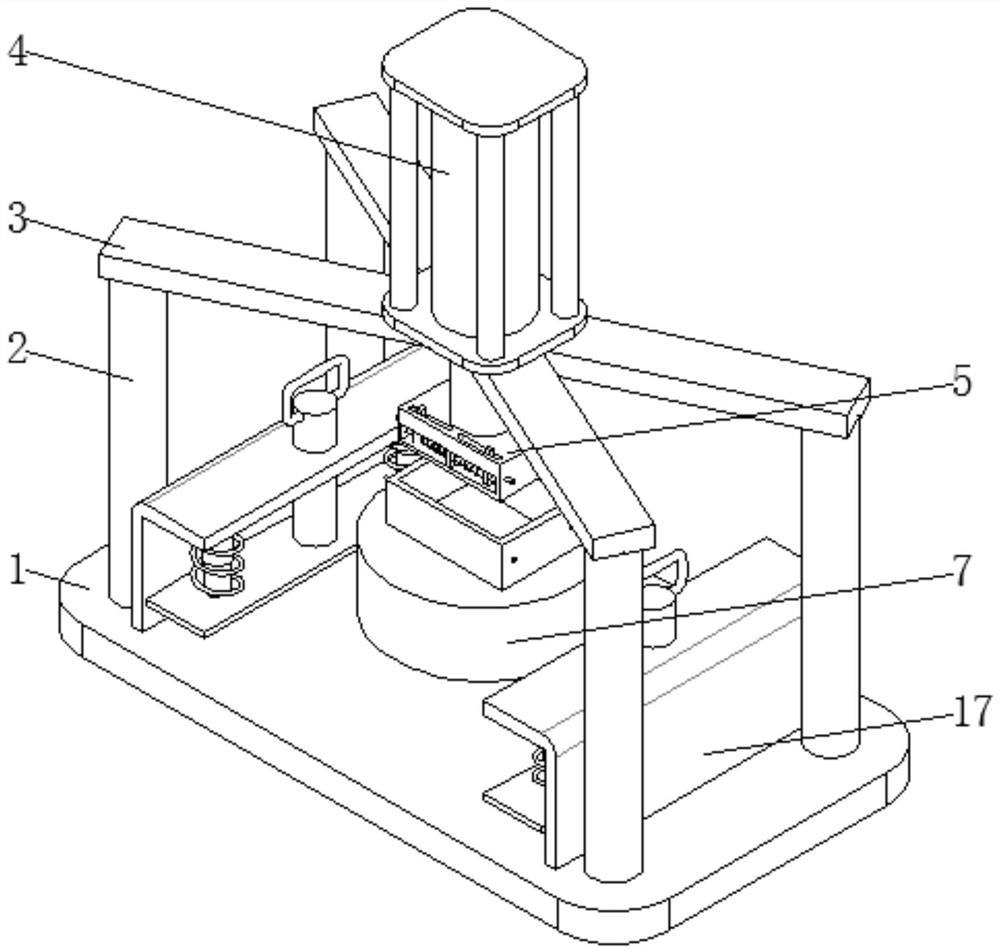

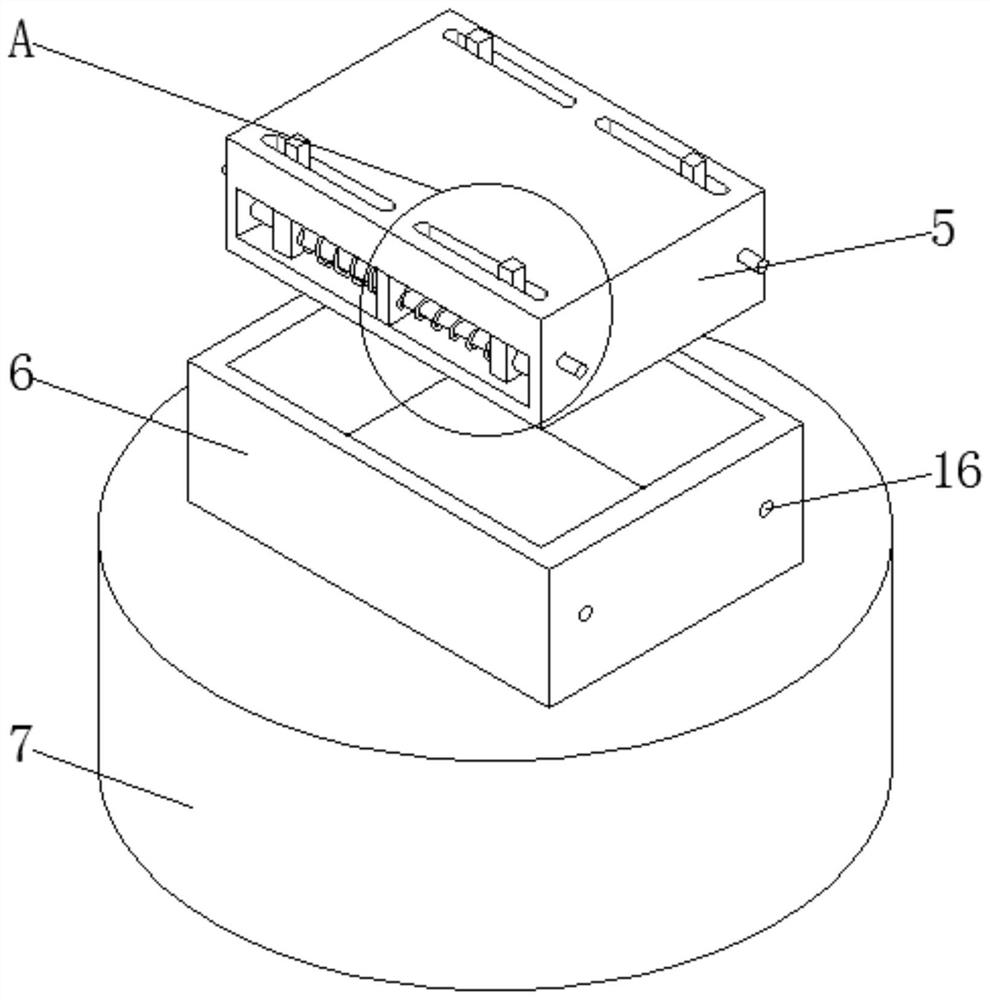

A jacking machine for high voltage transformer shell processing

ActiveCN105880344BRealize notch processingConnection sealShaping toolsMetal-working feeding devicesEngineeringInstrument transformer

The invention relates to an opening drawing machine for processing of a high-voltage instrument transformer housing. The machine comprises a worktable, a supporting platform, a drawing die, a transmission mechanism and a heating gun, wherein supporting legs are arranged at the bottom part of the worktable, and sleeves are arranged at two sides of the top part of the worktable; an arc-shaped concave port and limiting holes are formed in the top part of the supporting platform; a stopping plate is arranged on the outer wall of the supporting platform; the transmission mechanism comprises a pulling rod, a lead screw and a lead screw nut; a fastening bolt is arranged between the top part of the pulling rod and the drawing die; an anticorrosive coating is arranged at the outside of the drawing die; a drying gun bracket is arranged at the outside of the pulling rod; a baffle plate is arranged on the top part of the lead screw; a nut sleeve which is connected to the bottom part of the pulling rod is arranged at the outside of the lead screw nut. With the adoption of the machine, the high-voltage instrument transformer housing can be reliably mounted and fastened; a drawing opening is high in forming performance and high in quality, so that the connecting sealing performance and the processing efficiency of the high-voltage instrument transformer housing can be improved.

Owner:SUQIAN GENERAL MACHINERY

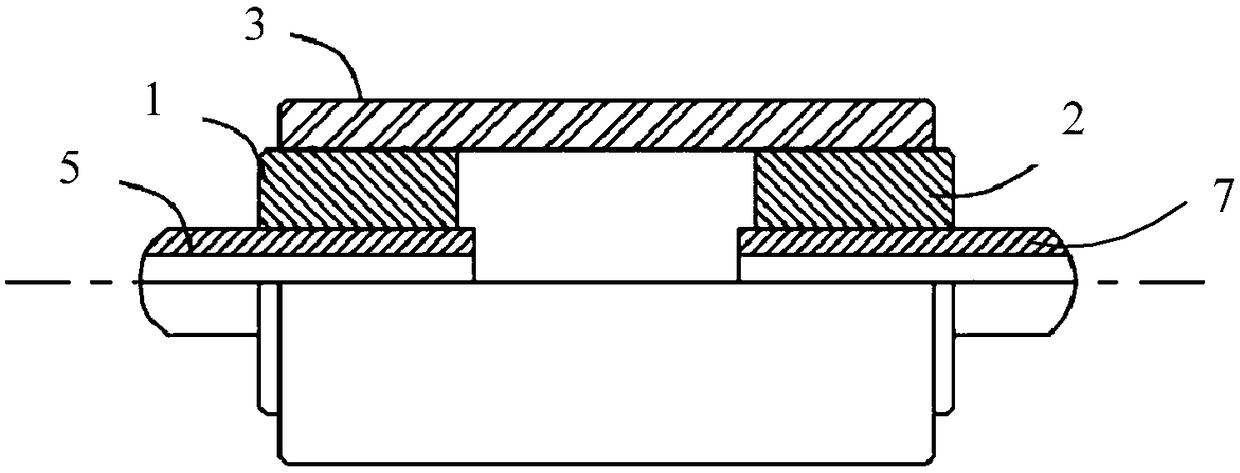

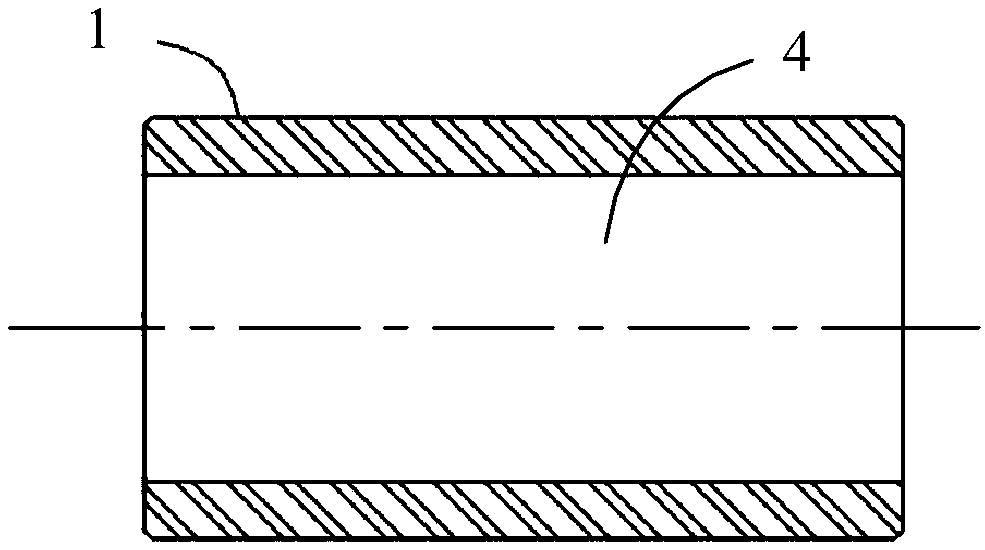

Smart Metal Seal Fittings

The invention discloses an intelligent metal seal joint. The intelligent metal seal joint comprises a first connection pipe 1, a second connection pipe 2 and a pipe-shaped connection part 3; the firstconnection pipe 1 is provided with a first through hole 4 which is used for allowing a first pipeline 5 to pass, and the first pipeline 5 is tightly connected with the first connection pipe 1; the second connection pipe 2 is provided with a second through hole 6 which is used for allowing a second pipeline 7 to pass, and the second pipeline 7 is tightly connected with the second connection pipe 2; the first connection pipe 1 is tightly connected with one end of the pipe-shaped connection part 3, the second connection pipe 2 is tightly connected with the other end of the pipe-shaped connectionpart 3, and the pipe-shaped connection part 3 is provided with a third through hole 8 which is used for allowing the first connection pipe 1 and the second connection pipe 2 to pass; the first through hole 4, the second through hole 6 and the third through hole 8 are coaxially formed; and the first connection pipe 1, the second connection pipe and the pipe-shaped connection part 3 are made of shape memory alloy, and thus, the corrosion resistance and the sealing performance of the pipe joint can be improved.

Owner:烟台浩忆生物科技有限公司

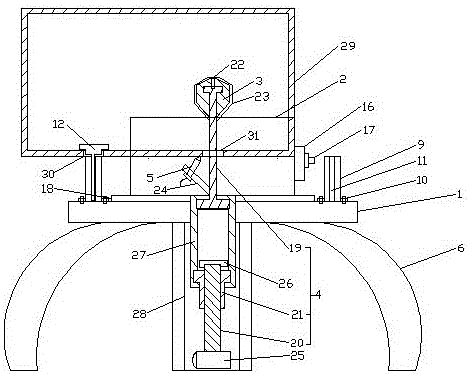

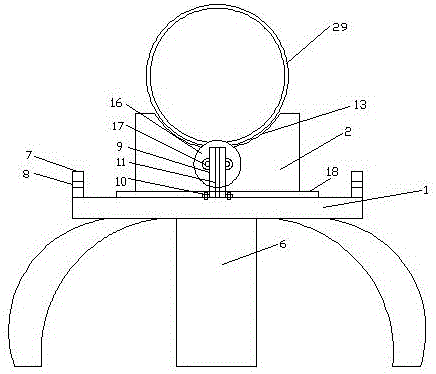

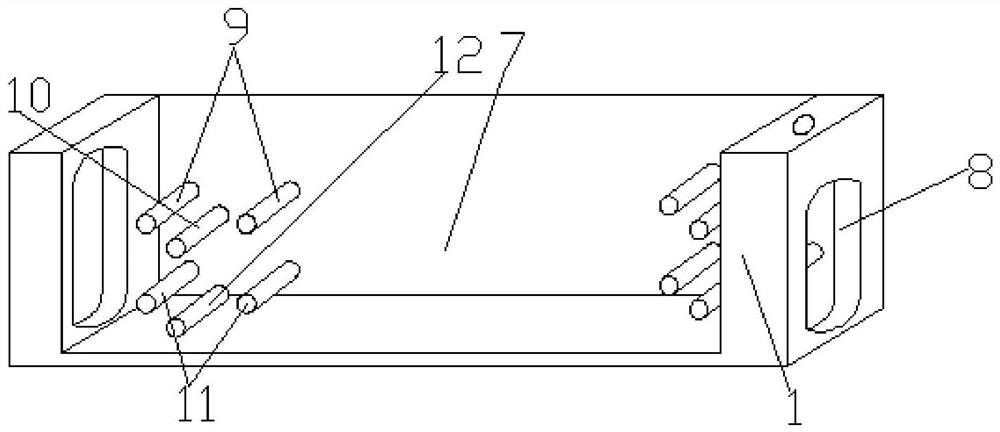

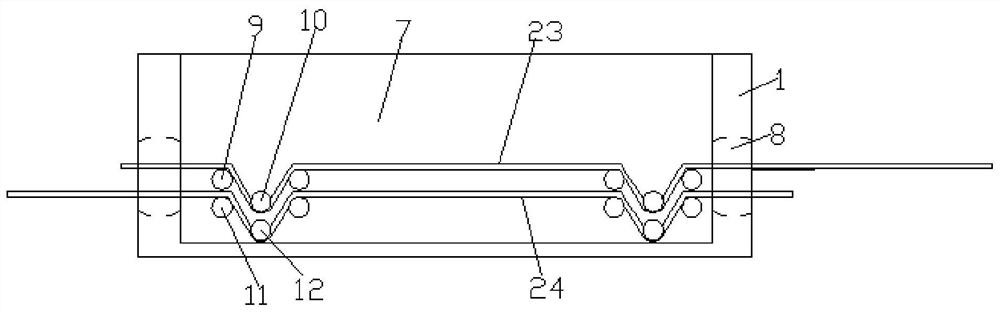

Opening drawing machine for processing of high-voltage instrument transformer housing

ActiveCN105880344ARealize notch processingConnection sealShaping toolsMetal-working feeding devicesInstrument transformerMechanical engineering

The invention relates to an opening drawing machine for processing of a high-voltage instrument transformer housing. The machine comprises a worktable, a supporting platform, a drawing die, a transmission mechanism and a heating gun, wherein supporting legs are arranged at the bottom part of the worktable, and sleeves are arranged at two sides of the top part of the worktable; an arc-shaped concave port and limiting holes are formed in the top part of the supporting platform; a stopping plate is arranged on the outer wall of the supporting platform; the transmission mechanism comprises a pulling rod, a lead screw and a lead screw nut; a fastening bolt is arranged between the top part of the pulling rod and the drawing die; an anticorrosive coating is arranged at the outside of the drawing die; a drying gun bracket is arranged at the outside of the pulling rod; a baffle plate is arranged on the top part of the lead screw; a nut sleeve which is connected to the bottom part of the pulling rod is arranged at the outside of the lead screw nut. With the adoption of the machine, the high-voltage instrument transformer housing can be reliably mounted and fastened; a drawing opening is high in forming performance and high in quality, so that the connecting sealing performance and the processing efficiency of the high-voltage instrument transformer housing can be improved.

Owner:SUQIAN GENERAL MACHINERY

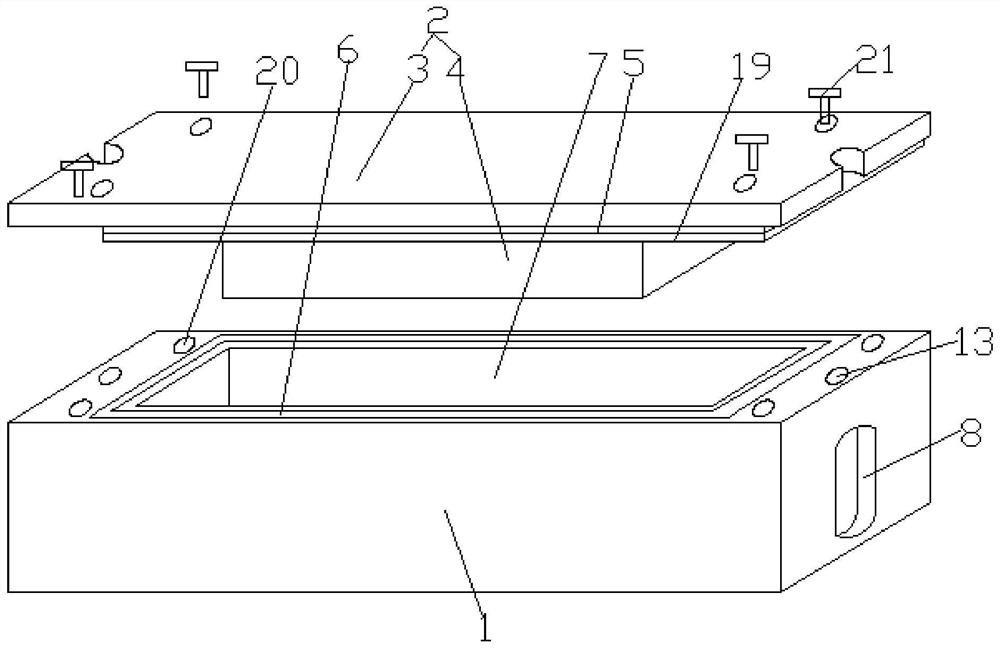

Connection protection device of flexible graphite lightning protection grounding belt

InactiveCN112201988AImprove plasticityImprove connection strengthCouplings bases/casesConnection contact member materialStructural engineeringGraphite

The invention discloses a connection protection device for a flexible graphite lightning protection grounding belt, and the device is characterized in that the device comprises an installation box, afirst graphite cable and a second graphite cable, the top of the installation box is provided with a cover plate, the cover plate comprises a top plate and a pressing plate, and the bottom end of thetop plate is fixedly provided with the pressing plate; a rectangular clamping block is arranged at the bottom end of the top plate and surrounds the outer surface of the pressing plate, a rectangularclamping groove matched with the rectangular clamping block is formed in the top of the mounting box, and a communicating cavity is formed in the mounting box. The invention has the beneficial effectsthat the rectangular clamping blocks are inserted into the rectangular clamping grooves, so the sealing performance of connection is improved; after completion, the threaded rod can be rotated, the T-shaped part at the bottom of the threaded rod rotates in the T-shaped groove, and finally the moving block is driven to descend, so the graphite cable in the through hole is extruded, and the sealingstrip is arranged, so the graphite cable penetrates through the through holes in the two ends, the through hole can be completely sealed, and the graphite cable is moved, so the connection is more sealed, and the communicating cavity is in a sealed state.

Owner:ANHUI HUAXI ELECTRIC POWER TECH CO LTD

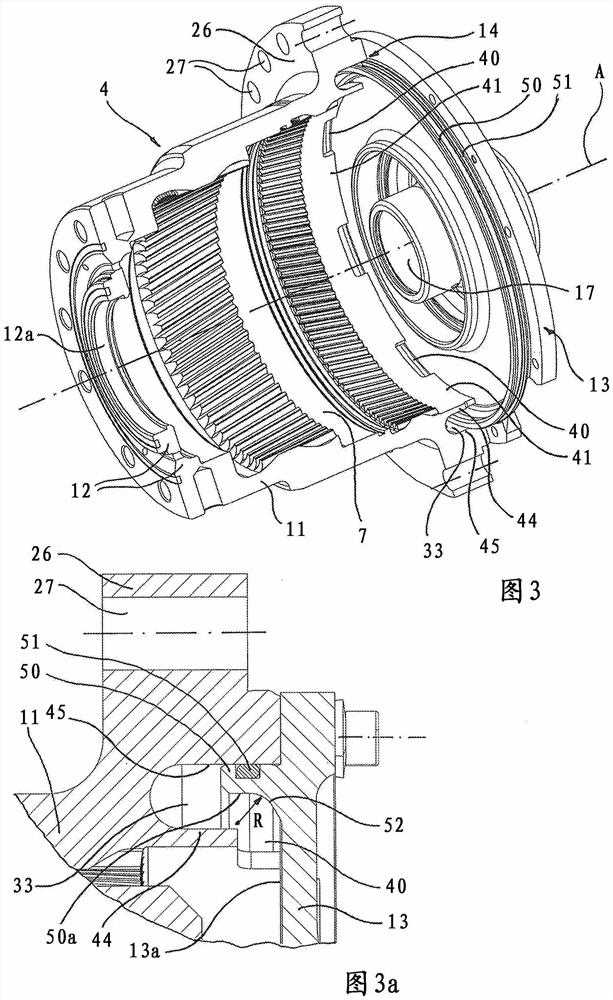

Electric drive unit for motor vehicle

PendingCN114206652AEfficient exchangePromote withdrawalElectric propulsion mountingGear lubrication/coolingElectric driveCooling fluid

The invention relates to an electric drive unit for a motor vehicle. The invention relates to an electric drive unit for a motor vehicle, comprising an electric drive (5), a transmission (6) which is arranged downstream of the electric drive (5) in the direction of a force transmission flow and which is arranged in a transmission housing (4), a device for circulating a cooling liquid in an interior (7) of the transmission housing (4), and a rotatably arranged input or output shaft (19, 18) of the transmission (6), according to the invention, the transmission housing (4) consists of a housing peripheral wall (11) annularly surrounding a central axis (A) and an end wall (13), and the end wall (13) extends radially outward from an opening (17) for the input or output shaft (19, 18) to a connecting region (14) in which the end wall (13) and the housing peripheral wall (11) are connected to each other. In order to improve the flow state by means of structural measures, in particular in the region of the transmission housing in which the coolant is discharged or withdrawn from the transmission in the region of the coolant circulation, an annular chamber (33) is provided which extends in the circumferential direction along a connecting region (14) and which is connected to the interior (7) via a separate opening (40).

Owner:BPW BERGISCHE ACHSEN KOMMANDITGES

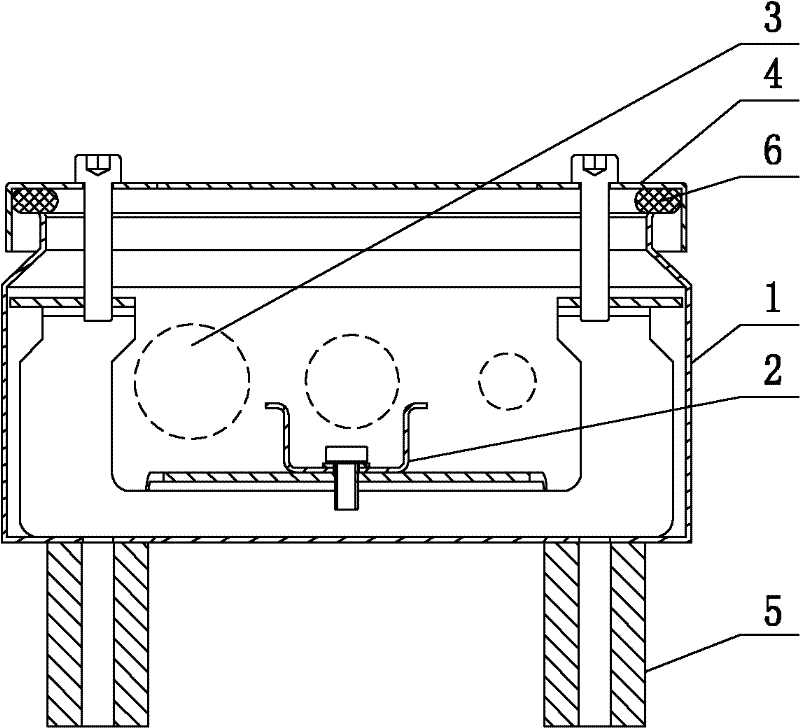

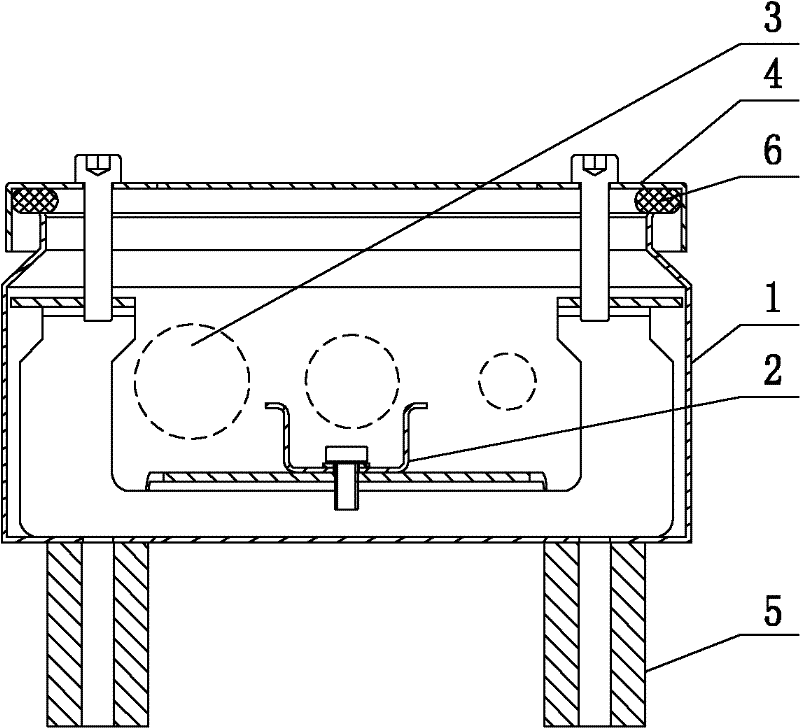

Electrical box for mortar cylinder

InactiveCN102395252AIncrease heightImprove working environmentHermetically-sealed casingsWorking environmentErosion

The invention relates to an electrical box for a mortar cylinder. The electrical box comprises a box body, and electrical components in the box body, wherein a connection hole is formed on the wall of the box body; a cover body matching with the box body is mounted at the port of the box body; and a stand is mounted at the bottom of the box body. The stand at the bottom of the electrical box for the mortar cylinder can effectively prevent mortar from being sputtered into the electrical box, thereby reducing erosion and damage to the components in the electrical box by mortar, improving working environment of the components and prolonging service life of the electrical box.

Owner:CHANGZHOU HAISHUO MACHINERY MFG

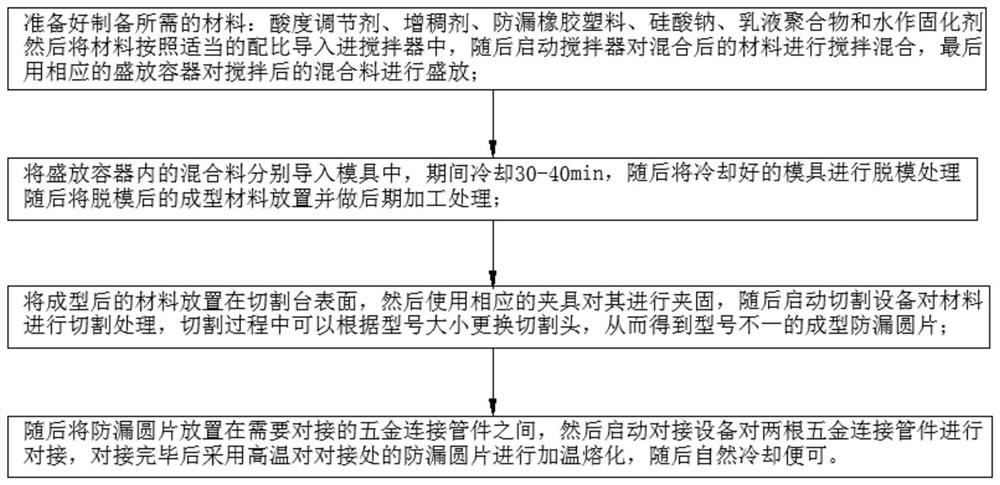

Anti-leakage method for bathroom hardware connecting piece

InactiveCN113819237AImprove leak-proof effectConnection sealEngine sealsDomestic articlesEmulsionFirming agent

The invention belongs to the technical field of anti-leakage methods, and particularly relates to an anti-leakage method for a bathroom hardware connecting piece, which comprises the following steps: S1, preparing materials required for preparation: an acidity regulator, a thickening agent, anti-leakage rubber plastic, sodium silicate, an emulsion polymer and water as a curing agent; mixing the raw materials according to a proper ratio, introducing the materials into a stirrer according to a proper ratio, starting a stirrer to stir and mix the mixed materials, and finally, containing the stirred mixture by using a corresponding container. The acidity regulator, the thickening agent, anti-leakage rubber plastic, the sodium silicate, the emulsion polymer and the water are used as curing agents to be mixed according to the proportion and manufactured into the anti-leakage wafer, so that the overall anti-leakage effect can become better, and the manufactured anti-leakage wafer can be correspondingly melted and then solidified after the hardware connecting pipe is in butt joint; and furthermore, the whole connection becomes more sealed.

Owner:广东阿普凡智能卫浴有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com