Tool holder

A tool holder and tool technology, applied in the direction of manufacturing tools, metal processing, tool holder accessories, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

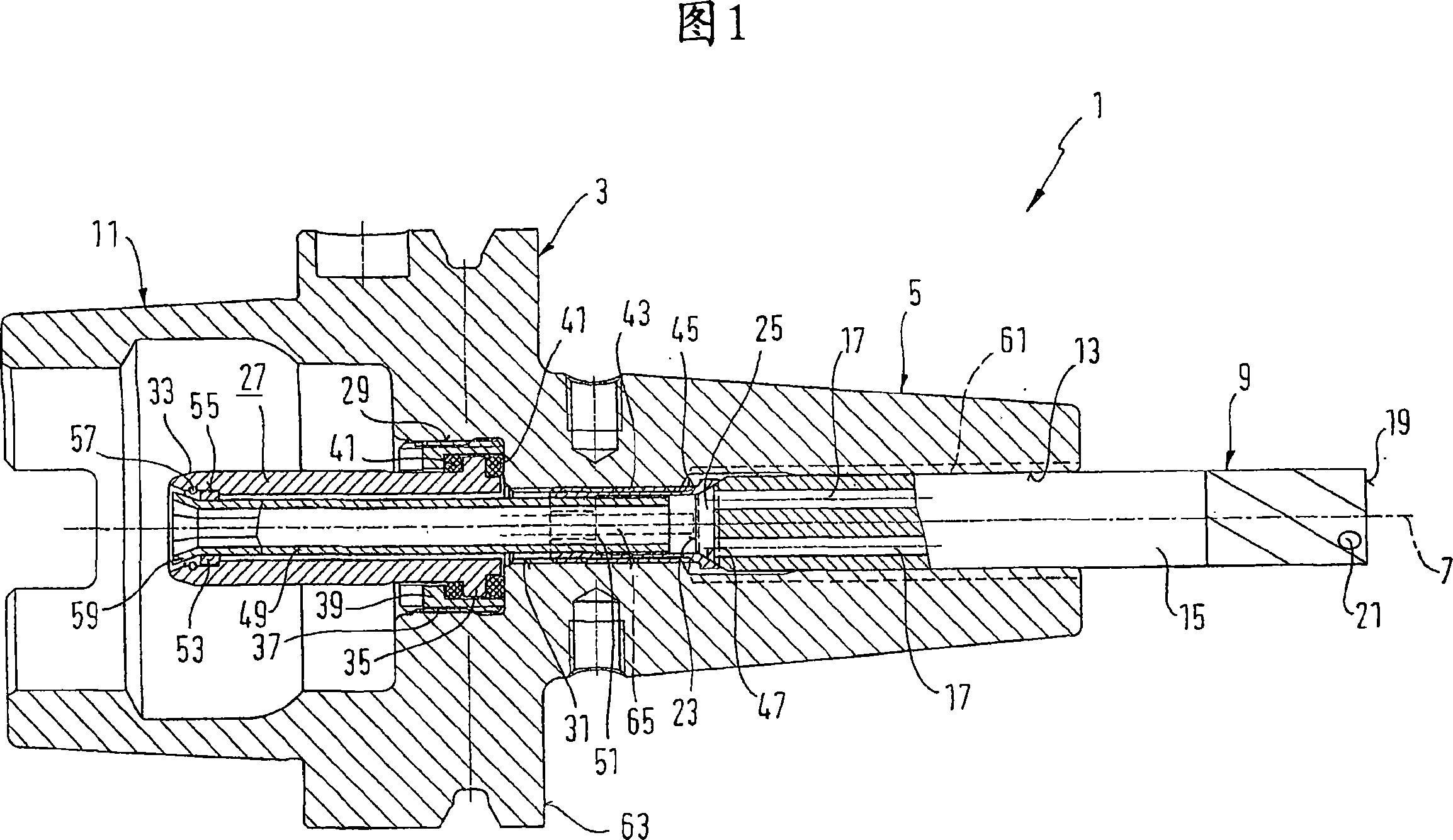

[0042] Fig. 1 shows a tool clamp of the shrinking chuck type, which is usually an integral clamp body 3, which has a sleeve-shaped tool mounting section 5 at one end of the clamp body 3 in the axial direction, which is used to rotate around a rotation axis 7 Ground-driven tools 9, such as milling cutters or drills, and at the axially opposite ends there is a joint section 11 here in the form of a hollow rod joint for resistance to the rotary drive shaft of the machine tool not shown in detail here. Twisted joints. The mounting section 5 has a mounting hole 13 concentric with the axis of rotation 7, which can be thermally expanded by means of an induction coil, especially by induction heating, so the tool 9 can be loosely inserted into the mounting hole 13 or taken out of the mounting hole with its handle 15. After the installation section 5 is cooled, the tool handle 15 is press-fitted and fixed.

[0043] There are a plurality of extensions in the tool 9, where two axial channels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com