Rivet type bolt

A bolt and rivet technology, applied in rivets and other directions, can solve the problems that bolts cannot meet various occasions, seal connection loads, etc., and achieve the effect of simple structure, fast connection and improved resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

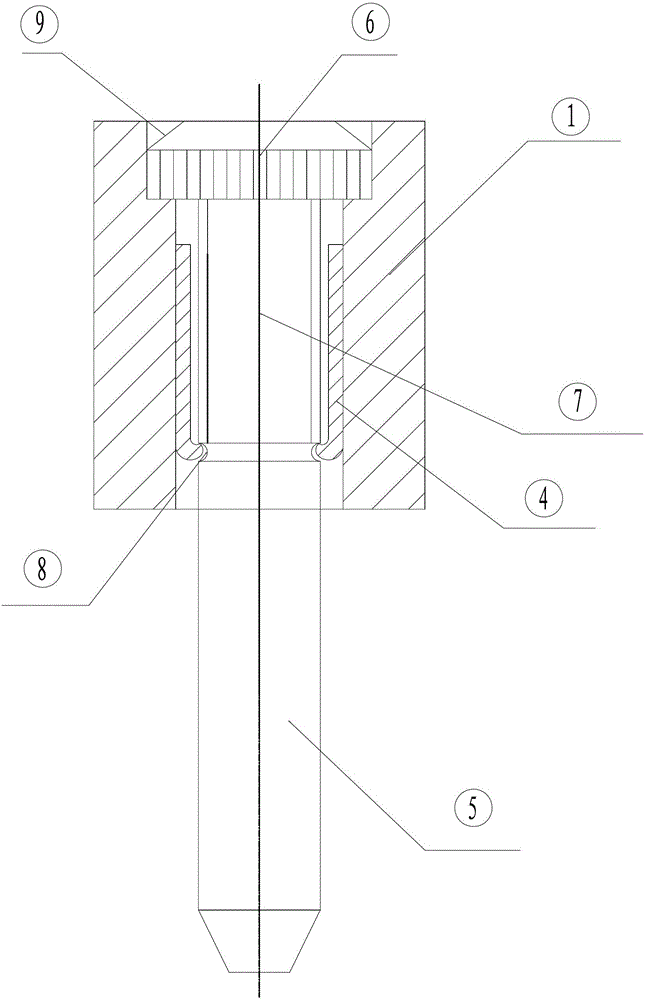

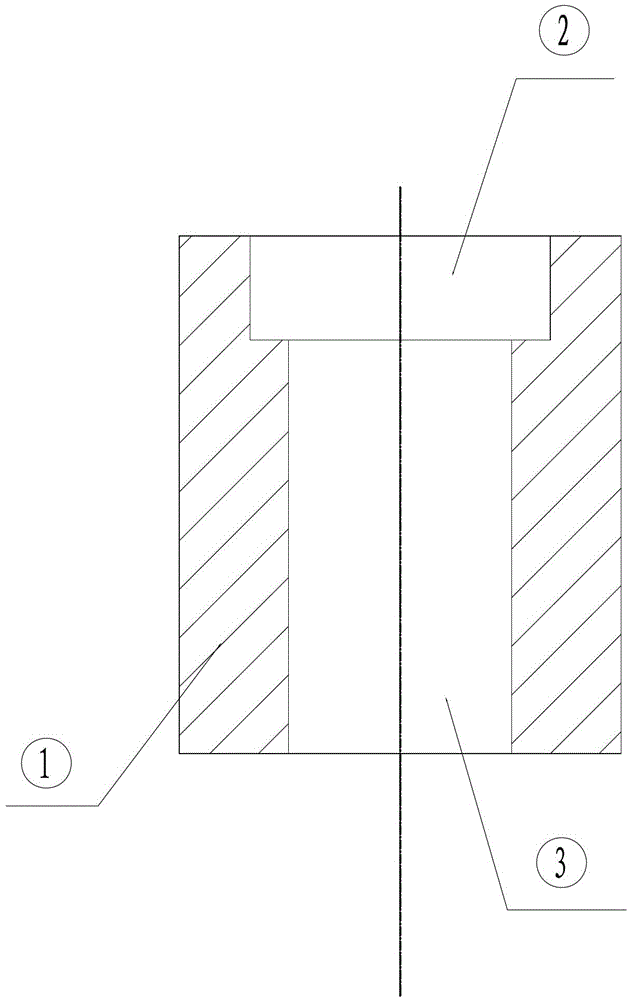

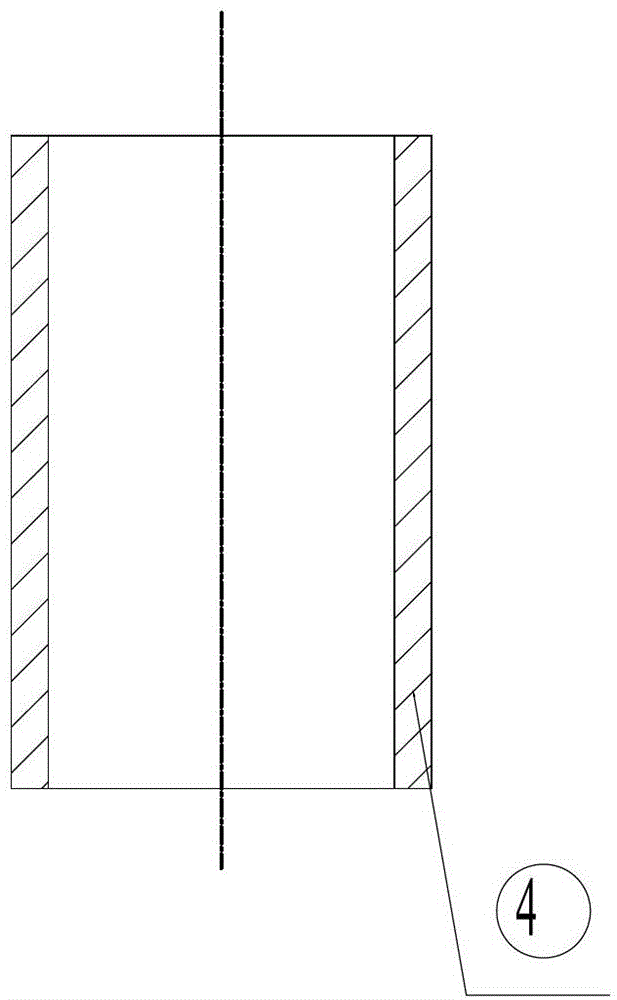

[0019] like Figure 1~4 As shown, the present invention is a rivet type bolt, comprising a nail body 1 and a nail core 5, the nail body 1 is provided with a counterbore 2 and a through hole 3 coaxial therewith, and the diameter of the counterbore 2 is larger than that of the through hole 3 diameter, the nail core 5 runs through the through hole 3 and the nail head 6 at the upper end of the nail core 5 is clamped on the boss formed by the counterbore 2 and the through hole 3, and the lower end of the nail head 6 is connected to the nail mandrel rod 10, so A fracture groove 8 is set on the nail mandrel 10, and the fracture groove 8 divides the nail mandrel 10 into upper and lower parts, the upper end is provided with a screw 7, and the lower end is a polished rod; the screw 7 is covered with a protective cover 4, so The lower end of the protective sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com