Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Avoid magnetic flux leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

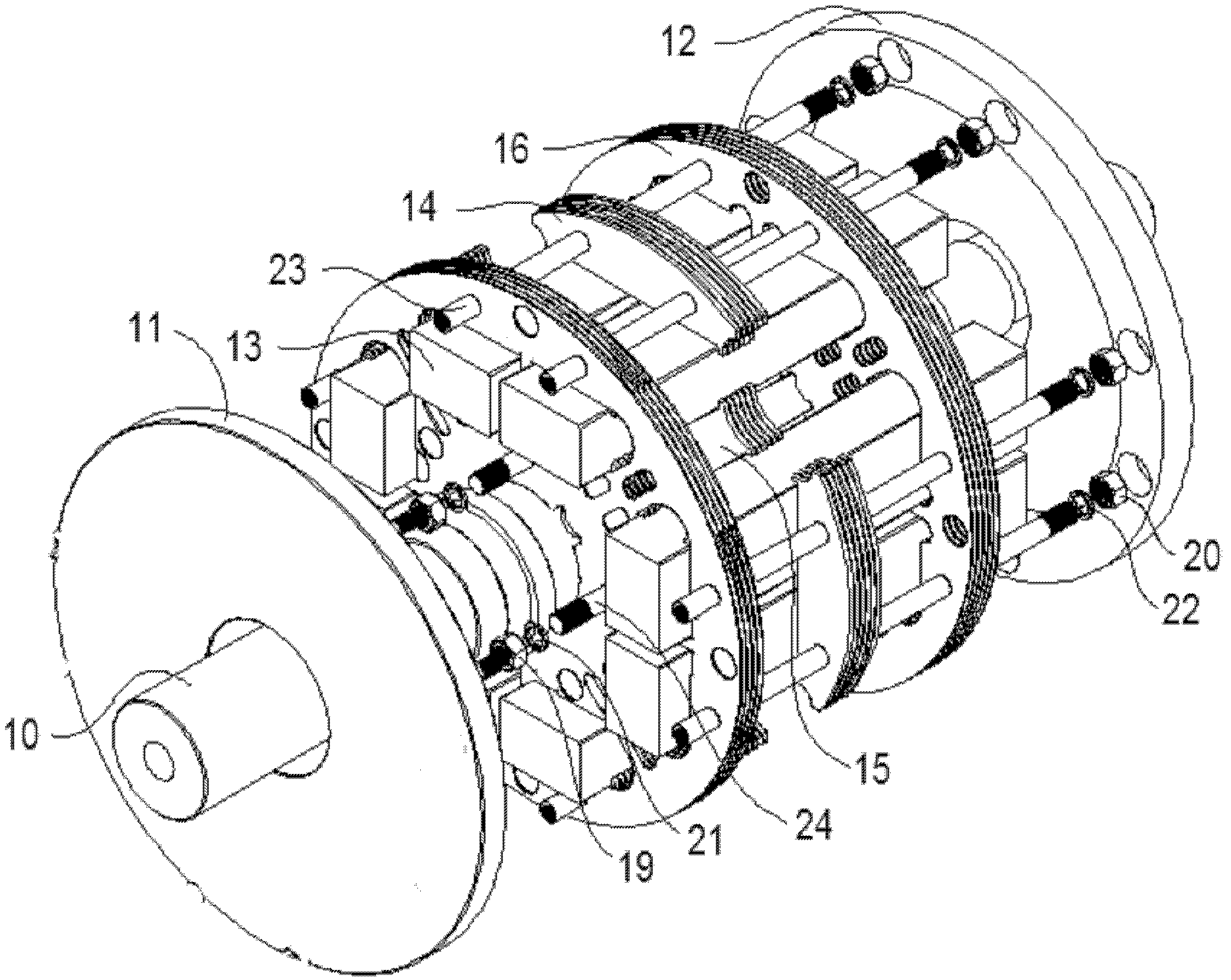

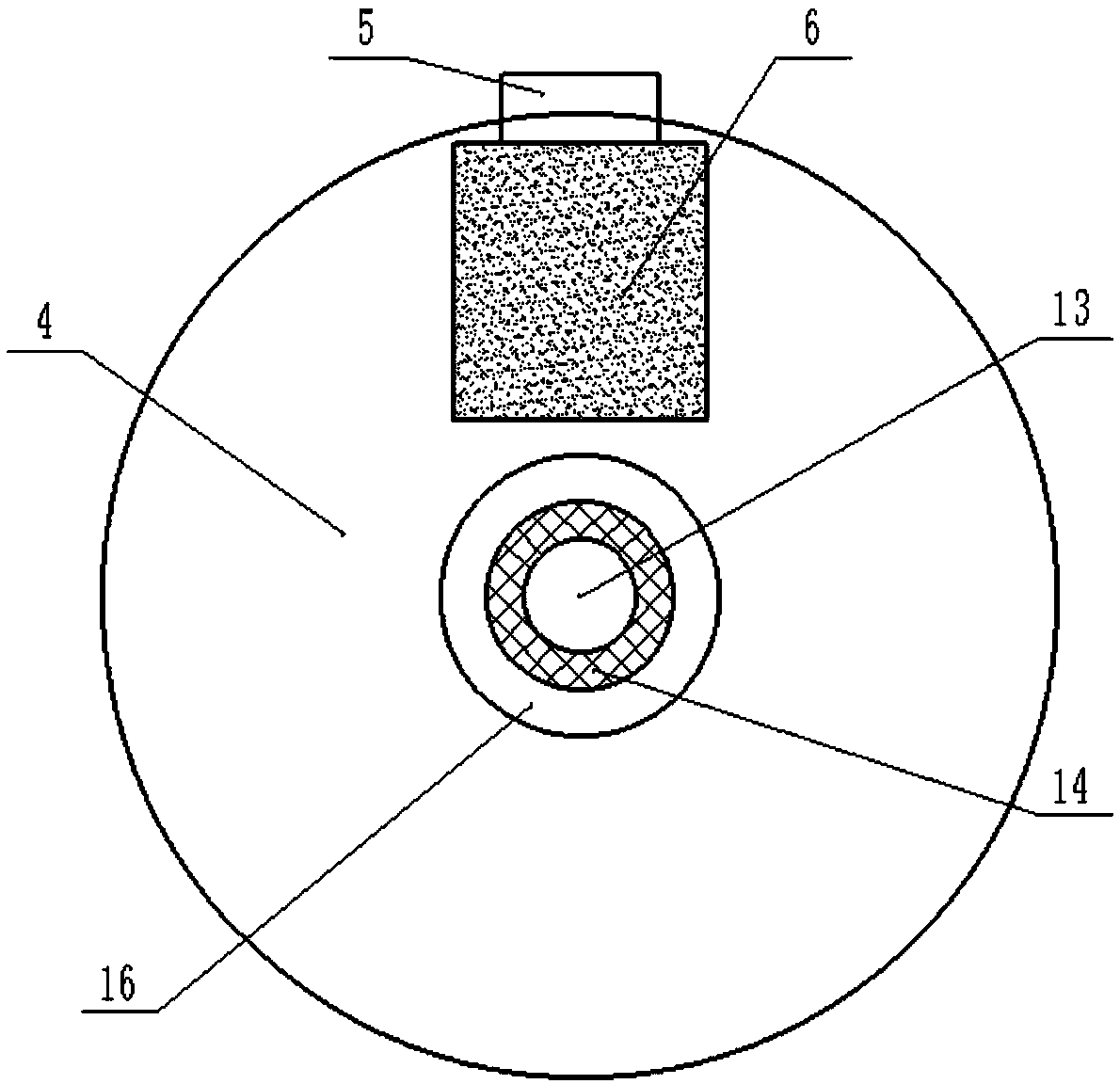

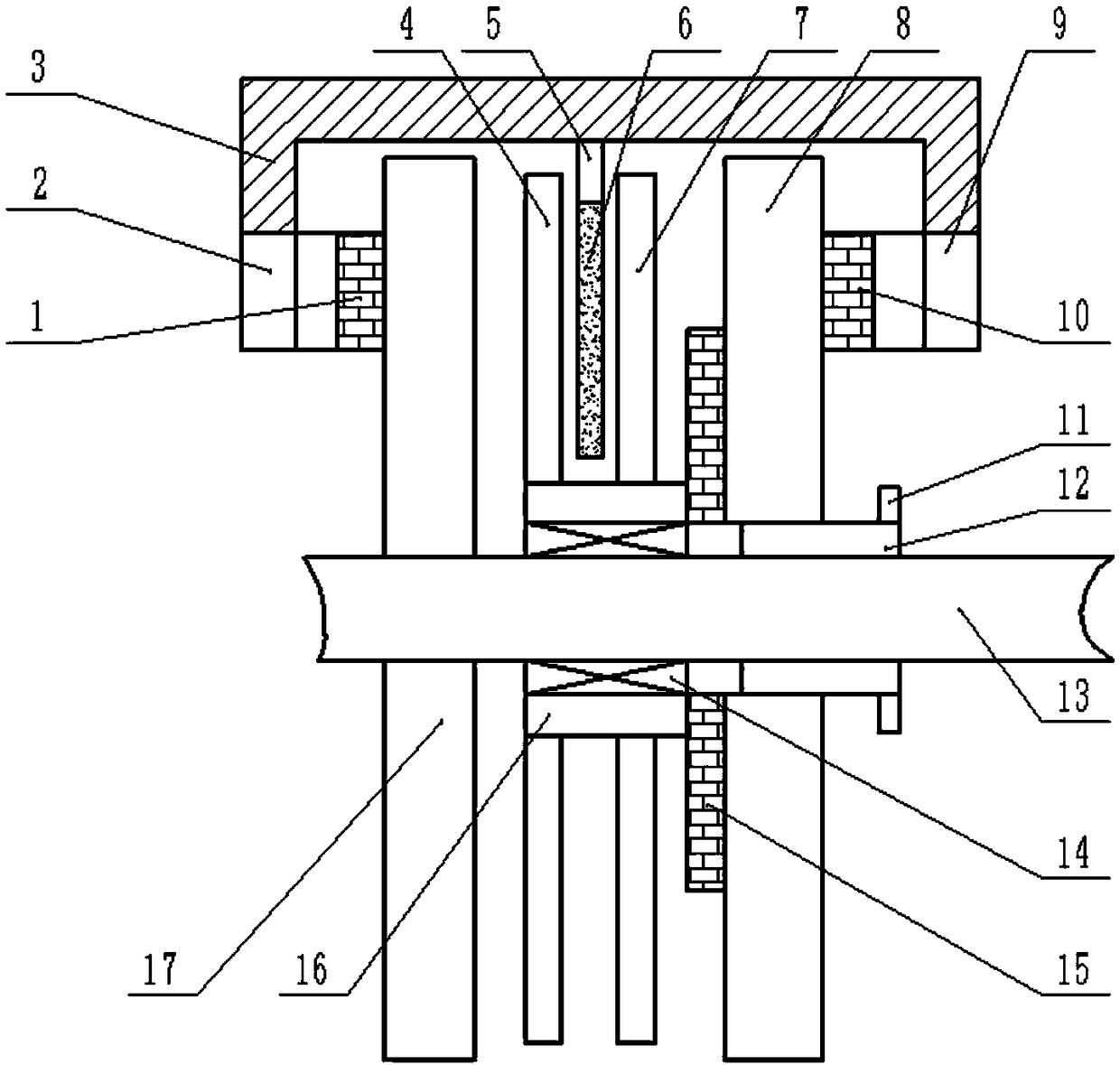

Novel intelligent vibration reduction electric wheel

InactiveCN104827886ARealization of intelligent vibration reductionAchieve vibration damping effectBraking element arrangementsMotor depositionVibration controlClosed loop

The invention relates to a novel intelligent vibration reduction electric wheel. According to the requirement for the limited space of a hub, a hub motor, a brake, an intelligent vibration reduction system assembly and the like are designed, and all the designed subsystems are integrated in the limited space of the hub. A vehicle body is used as a target system, and a controllable closed loop system can be formed by combining the novel intelligent vibration reduction electric wheel. The novel intelligent vibration reduction electric wheel mainly comprises an independent suspension support, a symmetrical up-down unequal length swing arm, an MR damper, a spiral spring, a controller, an acceleration and displacement sensor, a wheel spindle, a hub motor, a brake assembly, a hub and a tire part. The acceleration and displacement sensor is used for collecting the accelerated speed of the vehicle body and dynamic displacement signals of a suspension, the accelerated speed of the vehicle body and the dynamic displacement signals of the suspension are transmitted to the controller in real time, a four-channel electric vehicle vibration control strategy is adopted, a variable domain fuzzy control algorithm is used, a control instruction is output to the MR damper to give out electric current change signals, the MR damper is used as an actuator to regulate damping force in real time, and therefore the intelligent damping effect of an electric vehicle can be achieved on urban roads.

Owner:CHINA THREE GORGES UNIV

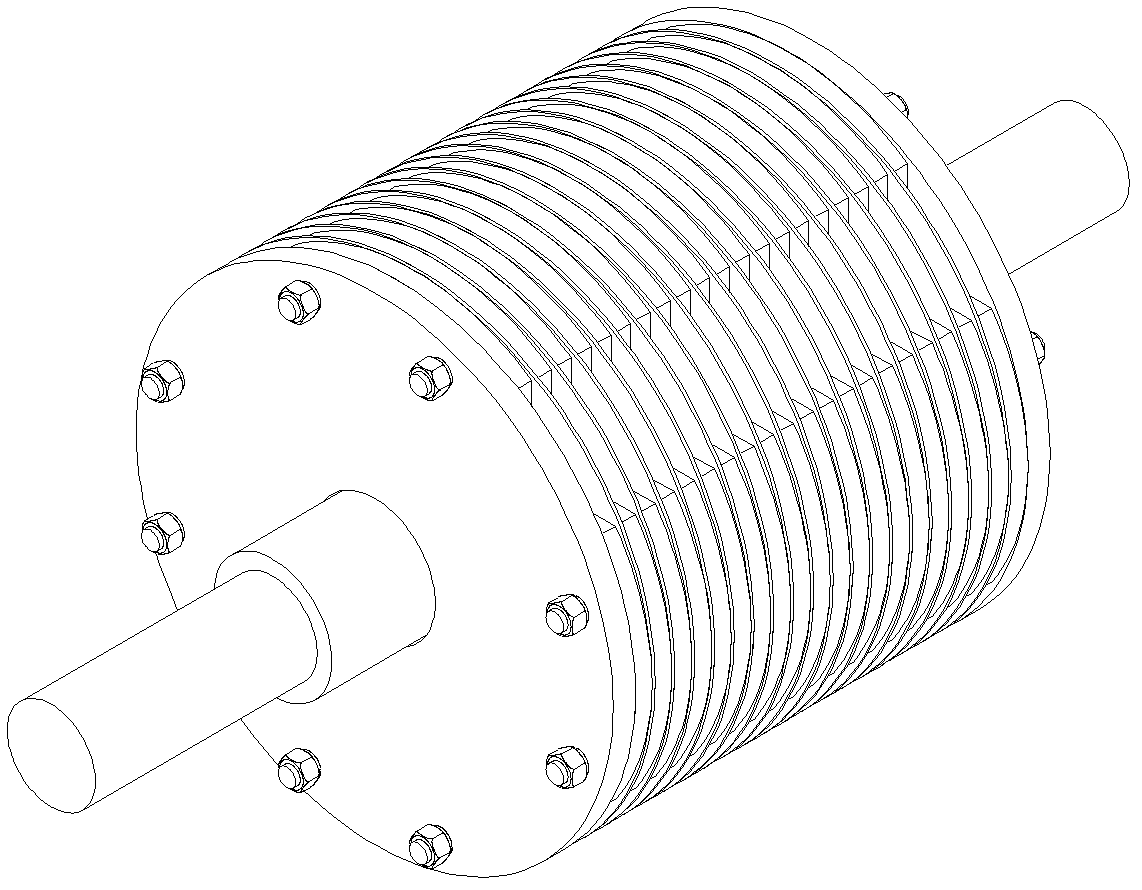

Sectional rotor structure for permanent magnet synchronous motor

ActiveCN102545435ANot easy to breakExtended service lifeMagnetic circuit rotating partsEngineeringPermanent magnet synchronous motor

A sectional rotor structure for a permanent magnet synchronous motor comprises a rotating shaft, a rotor core, permanent magnets, rotor pole shoes, a front end-plate and a rear end-plate, wherein a plurality of rotor baffles are arranged between the two end-plates; the rotor pole shoes are independent of one another and axially distributed at intervals together with the rotor baffles; the rotor baffles divide axially a rotor into a plurality of rotor units; two end surfaces of the rotor pole shoes in each rotor unit are respectively clung to the end surfaces of the adjacent rotor baffles; the rotor pole shoes in each rotor unit correspond to the permanent magnets; through holes allowing the permanent magnets to penetrate are formed on the rotor baffles; pole shoe draw-in bolts penetrate the front end-plate, the rotor pole shoes, the rotor baffles and the rear end-plate and axially lock the rotor pole shoes and the rotor baffles, which are arranged between the front and the rear end-plates; and the corners of the through holes of the rotor baffles are in arc transition, and clearances are kept between the permanent magnets and the permanent-magnet through holes on the rotor baffles. The sectional rotor structure for the permanent magnet synchronous motor has the advantages of high mechanical strength and suitability for motors rotating at high speed.

Owner:ZHEJIANG UNIV

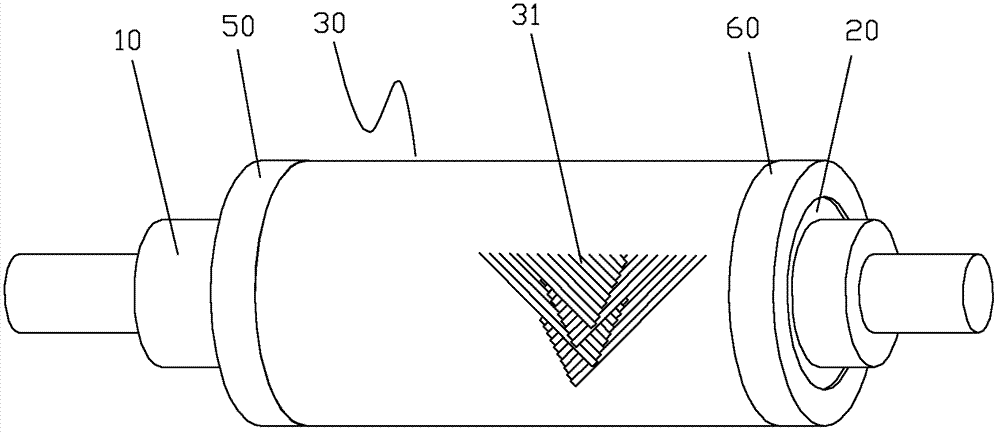

Motor permanent magnet fixing structure, motor permanent magnet fixing method and motor comprising the structure

InactiveCN103368300AReduce thicknessReduce gapMagnetic circuit rotating partsManufacturing stator/rotor bodiesFiber bundleProtection layer

The invention provides a motor permanent magnet fixing structure, a motor permanent magnet fixing method and a motor comprising the structure. The motor permanent magnet fixing structure comprises a rotor iron core, a permanent magnet and a composite material layer, wherein the permanent magnet is covered on the outer surface of the rotor iron core, and the composite material layer comprises expanding fiber bundles arranged around the outer surface of the permanent magnet. The fixing method comprises the steps of: step 1, sizing and expanding fiber bundles to form expanding fiber bundles; step 2, winding a plurality of expanding fiber bundles on the outer surface of the permanent magnet to form a fiber pre-forming body; and step 3, forming a composite material layer on the fiber pre-forming body by using a resin film infusion molding process. According to the motor permanent magnet fixing structure, the motor permanent magnet fixing method and the motor comprising the structure, the problem in the prior art that a gap between the permanent magnet and a stator winding is too large to cause magnetic flux leakage as the thickness of a protection layer for protecting the permanent magnet is too great can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

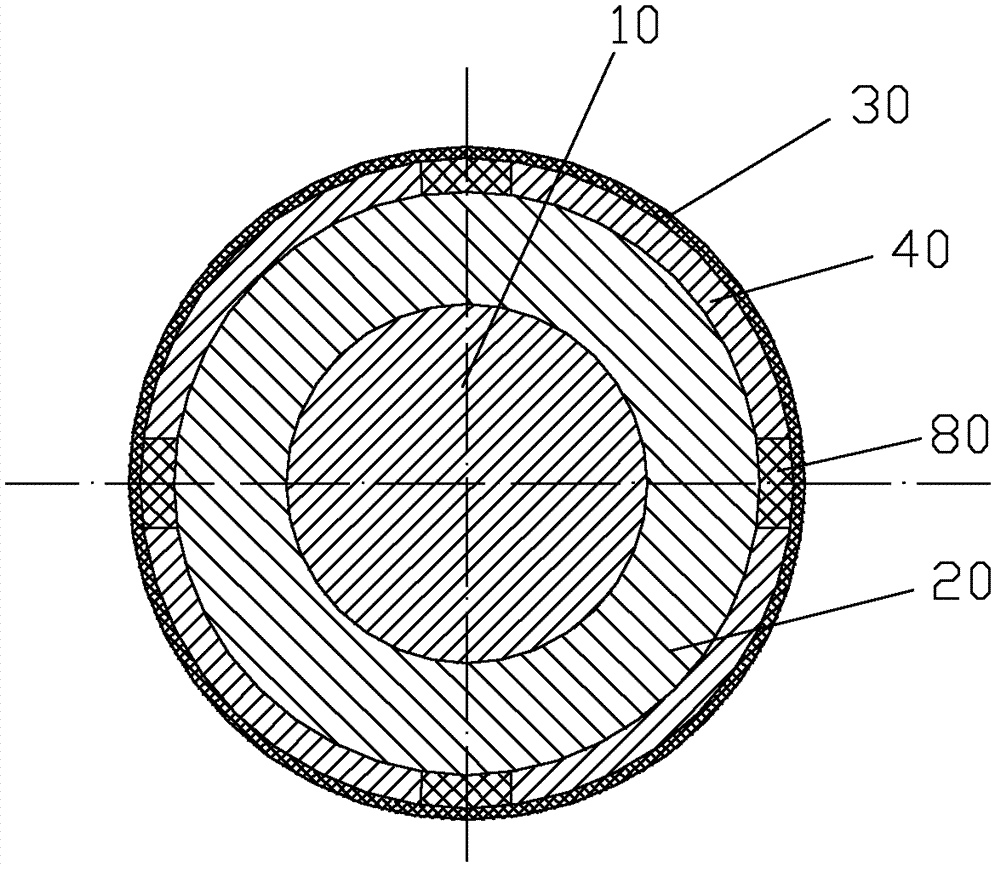

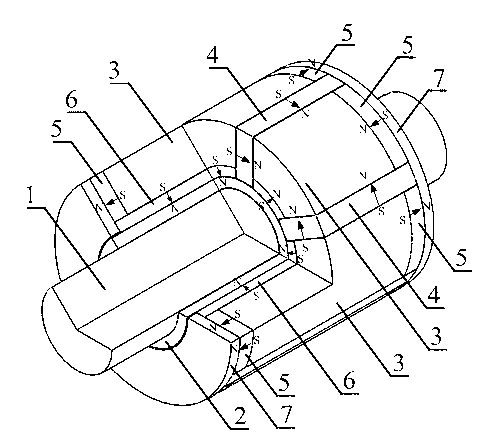

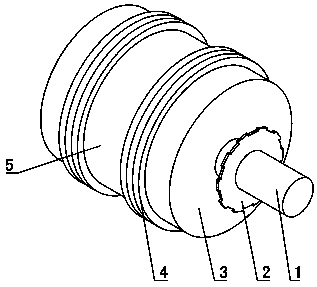

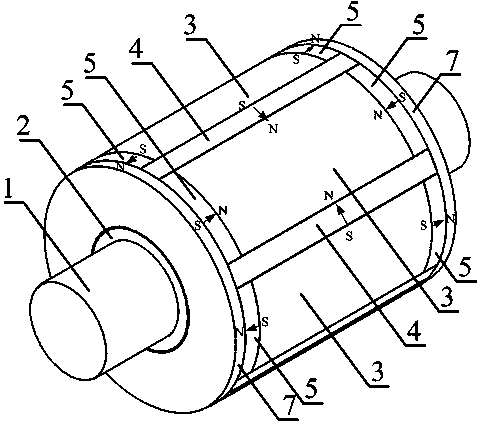

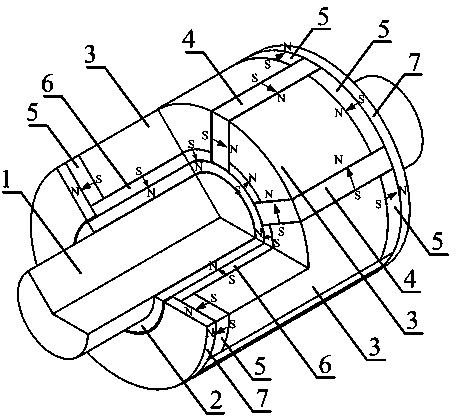

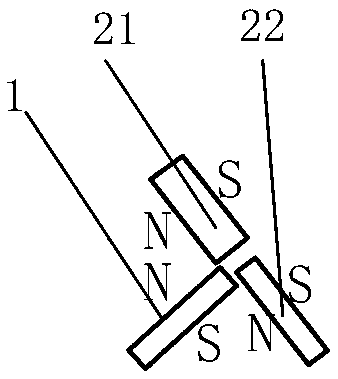

Composite permanent-magnet rotor for permanent-magnet motor and manufacturing method thereof

InactiveCN102761210AIncrease profitAvoid magnetic flux leakageMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorMagnetic poles

The invention discloses a composite permanent-magnet rotor for a permanent-magnet motor and a manufacturing method thereof. According to the invention, firstly, a magnetically-conductive shaft sleeve made from a magnetically-conductive material is sleeved on a rotor shaft; then, rotor cores are made into sectors, and the sectorial rotor cores are evenly distributed, mounted and fixed on the magnetically-conductive shaft sleeve; the other five surfaces of each sectorial rotor core mounted and fixed on the magnetically-conductive shaft sleeve except the upper end surface in the shape of a circular arc are all pasted and surrounded by permanent-magnet blocks made from magnetically-conductive materials, and each permanent-magnet block has the same polarity as the magnetic pole of the faying surface of each sectorial rotor core; the sectorial rotor cores and the permanent-magnet blocks are clamped and fixed on the magnetically-conductive shaft sleeve through annular end pressing plates fixed at both ends of the magnetically-conductive shaft sleeve; and the annular end pressing plates are made from magnetically-conductive materials. The composite permanent-magnet rotor has the advantages of compact structure, low flux leakage at axial end parts, high utilization rate of magnetic efficiency of permanent magnets, strong immunity from interference, stable working performance, high rotor strength, long service life and the like.

Owner:LINQUAN AEROSPACE MOTOR CO LTD

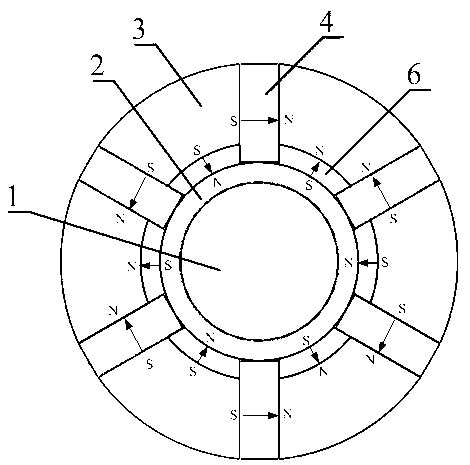

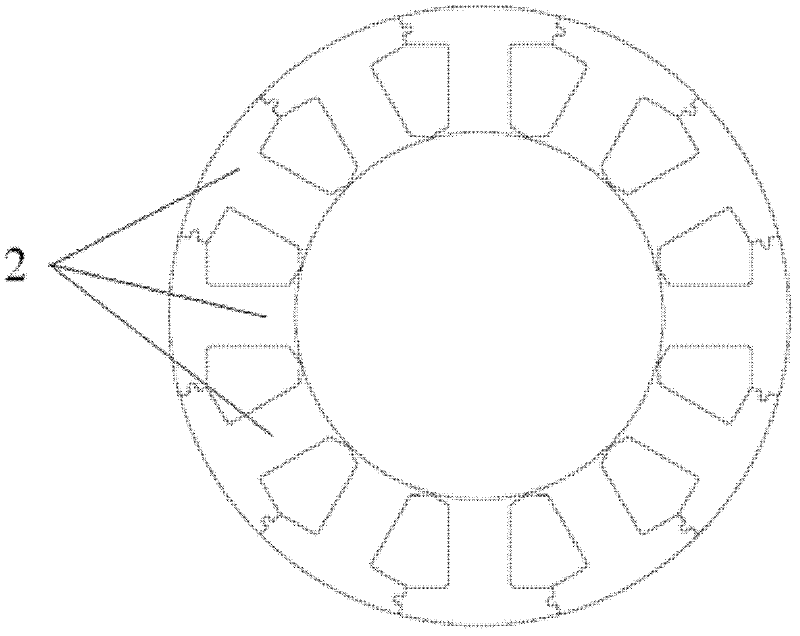

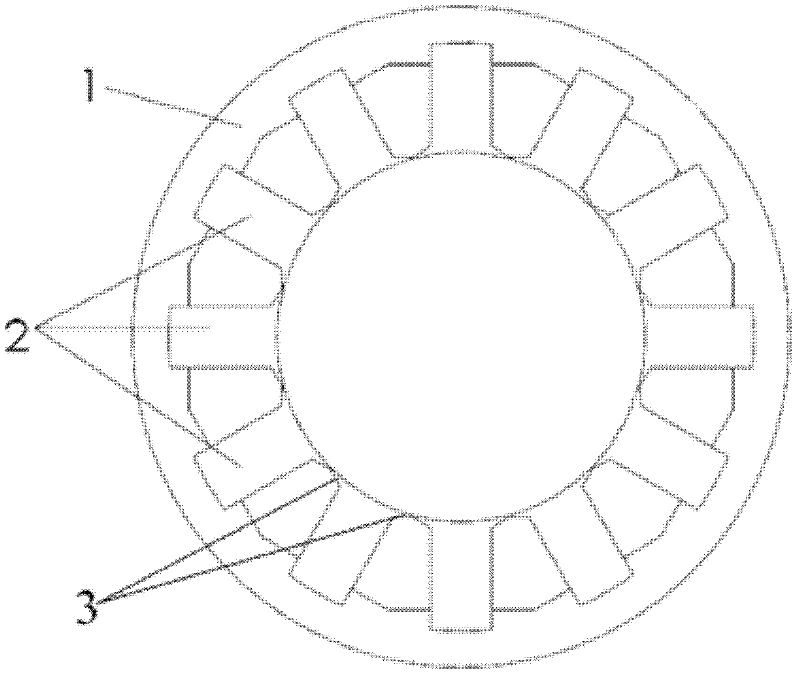

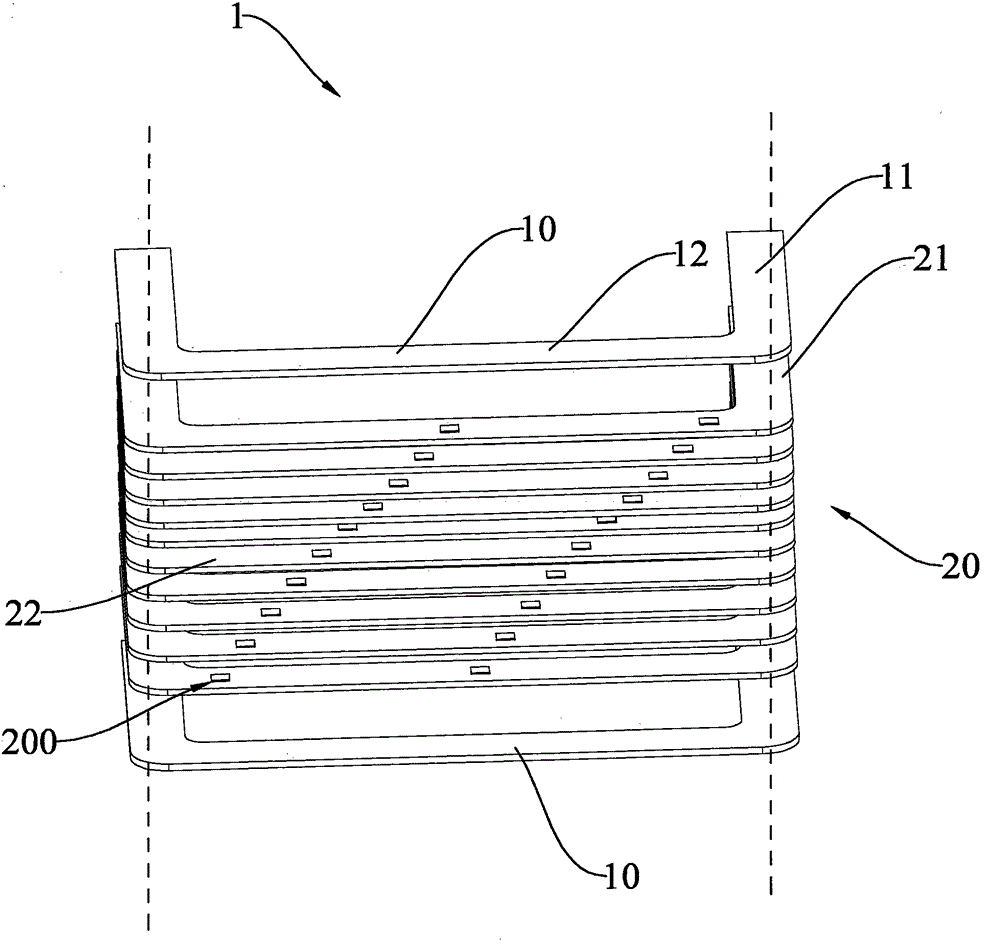

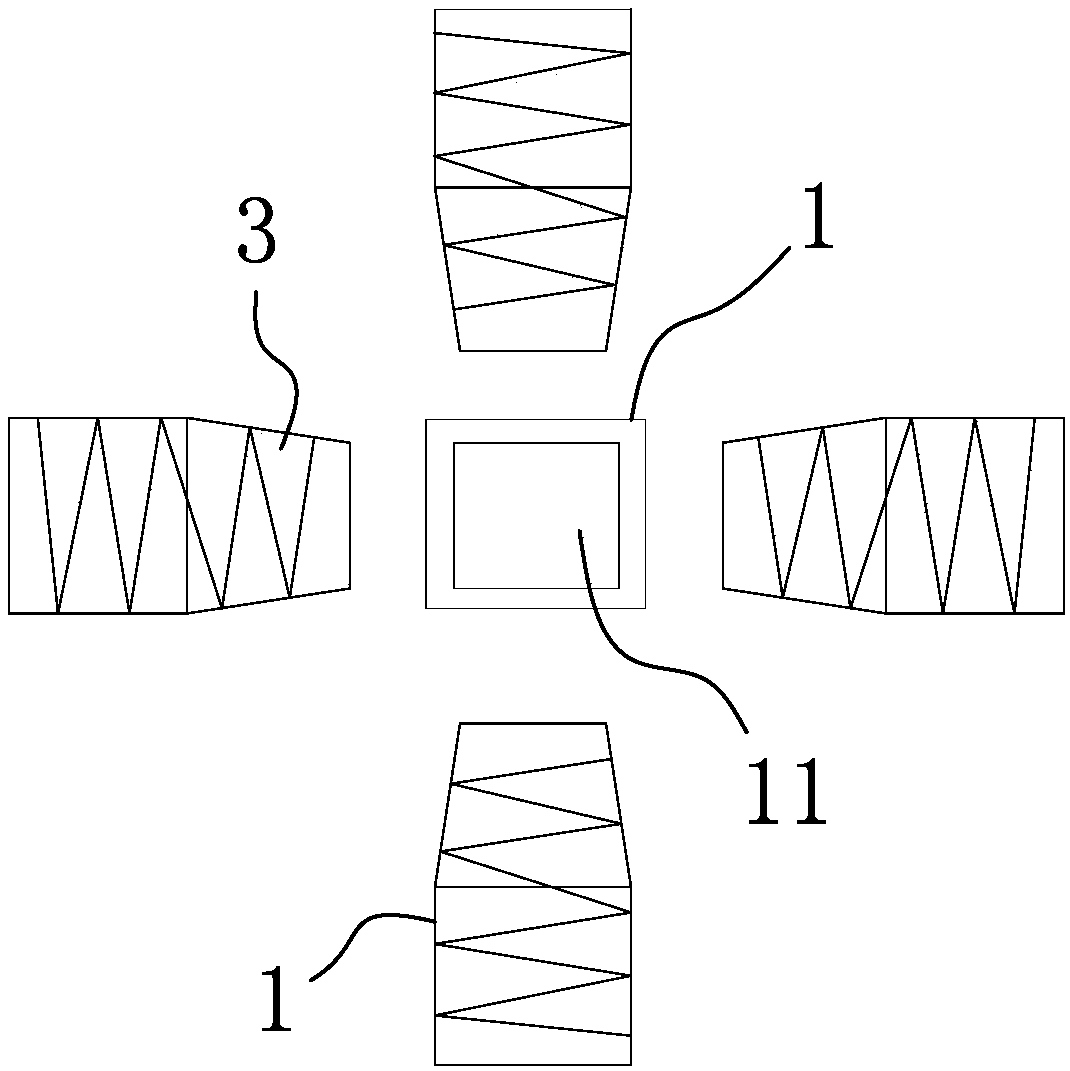

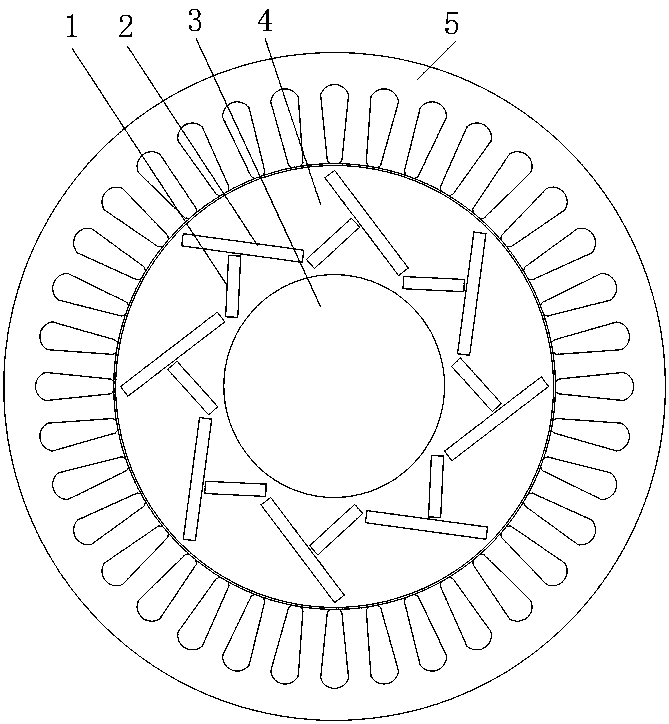

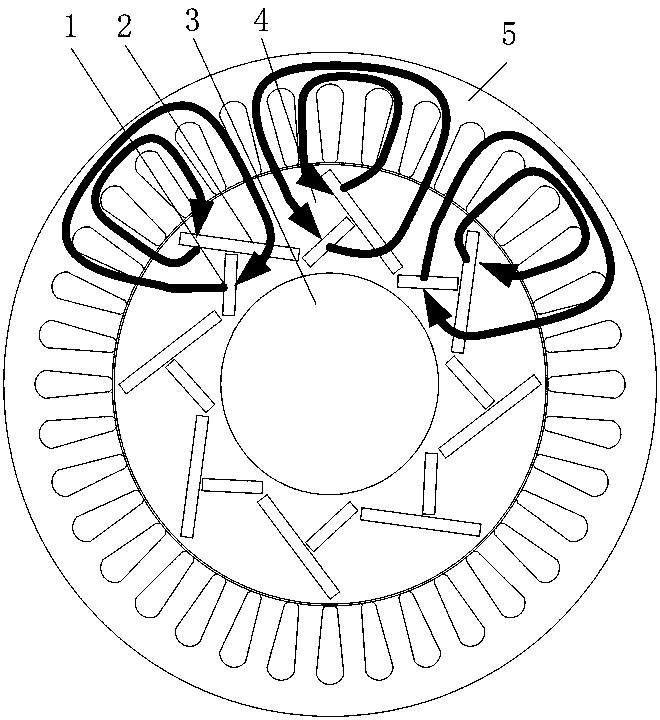

Laminate structure of stator iron core of motor

InactiveCN102340190AGuaranteed coaxialityGuaranteed uniformityMagnetic circuit stationary partsNew energyConductor Coil

The invention discloses a laminate structure of a stator iron core of a motor, which relates to the field of the motors and aims at solving the problems of the large harmonic wave and the high noise of the motors and the bad concentricity and the bad axiality of a stator. The laminate structure of the stator iron core of the motor is formed by splicing a stator yoke part (1) and a plurality of stator teeth (2); the stator yoke part (1) is annular; the stator teeth (2) are formed into a whole made of one material; the inner edges of the stator teeth (2) are round; the outer ends of the stator teeth (2) are embedded at the annular inner side of the stator yoke part (1) to form one stator iron core laminate; and a plurality of the stator iron core laminates are laminated to form a whole stator iron core. Preferably, the single stator tooth (2) is T-shaped, and two sides of the inner end of the single stator tooth are provided with flanks (3). By using the laminate structure of the stator iron core of the motor, a combined closed slot structure needed by a centralized winding is easy to achieve; the integral concentricity and the axiality of a stator laminate and the precision of an inner circle and an outer circle are guaranteed; the efficiency of the motor is improved; the harmonic wave is small; the noise is low; and the consistency of products is good. The laminate structure of the stator iron core of the motor is applicable to various motors, in particular to the motors used by new-energy-source automobiles.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

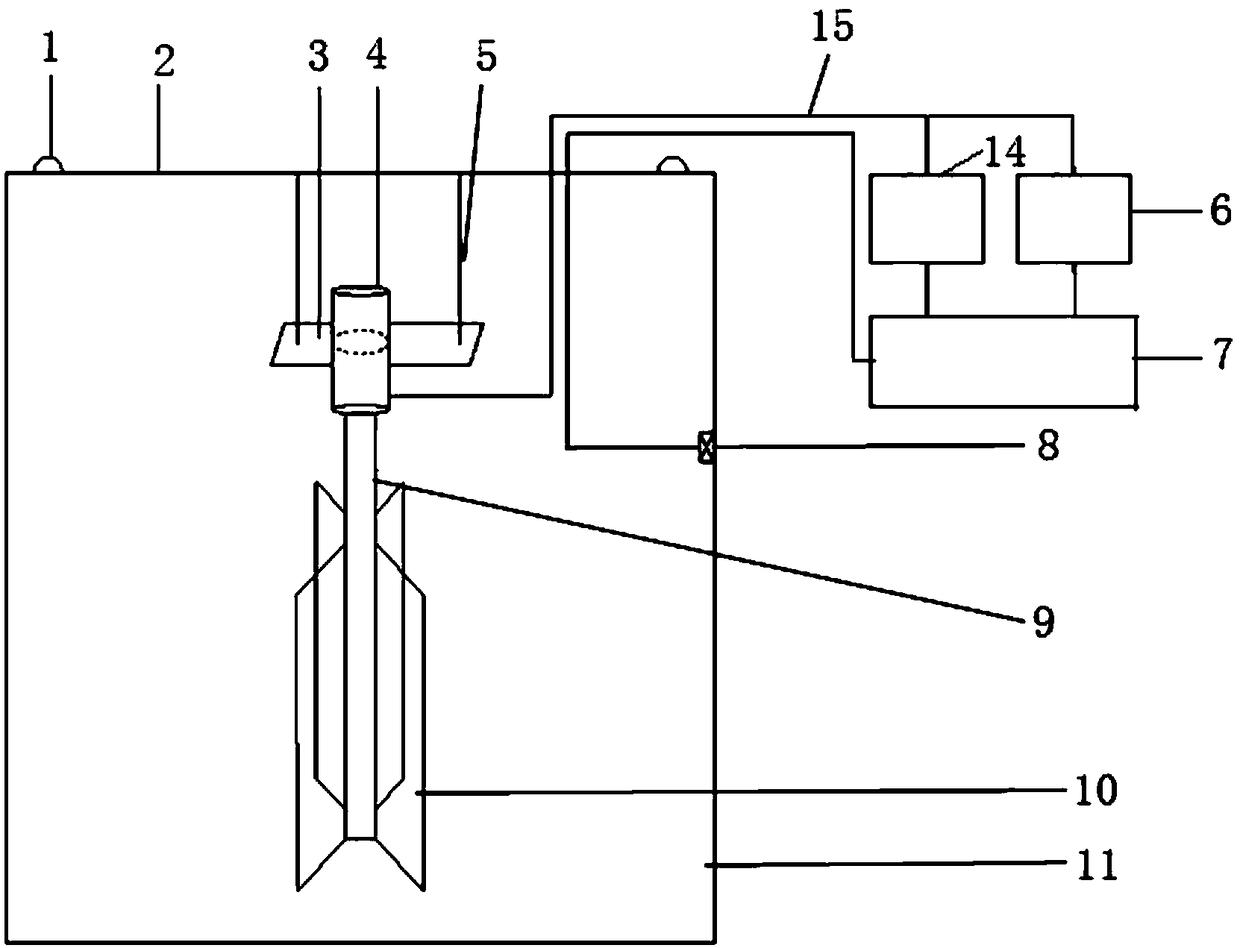

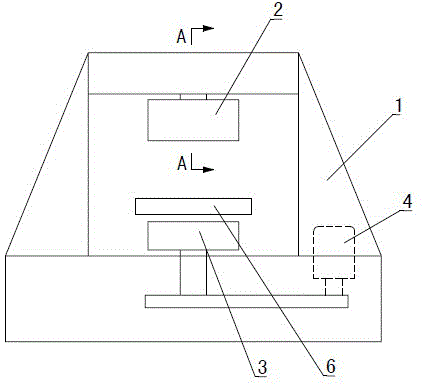

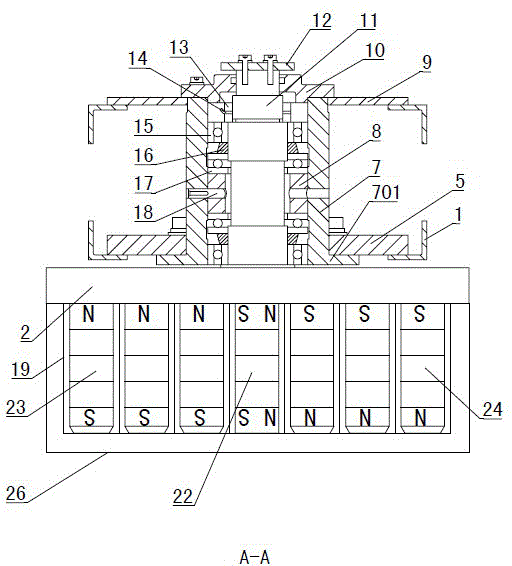

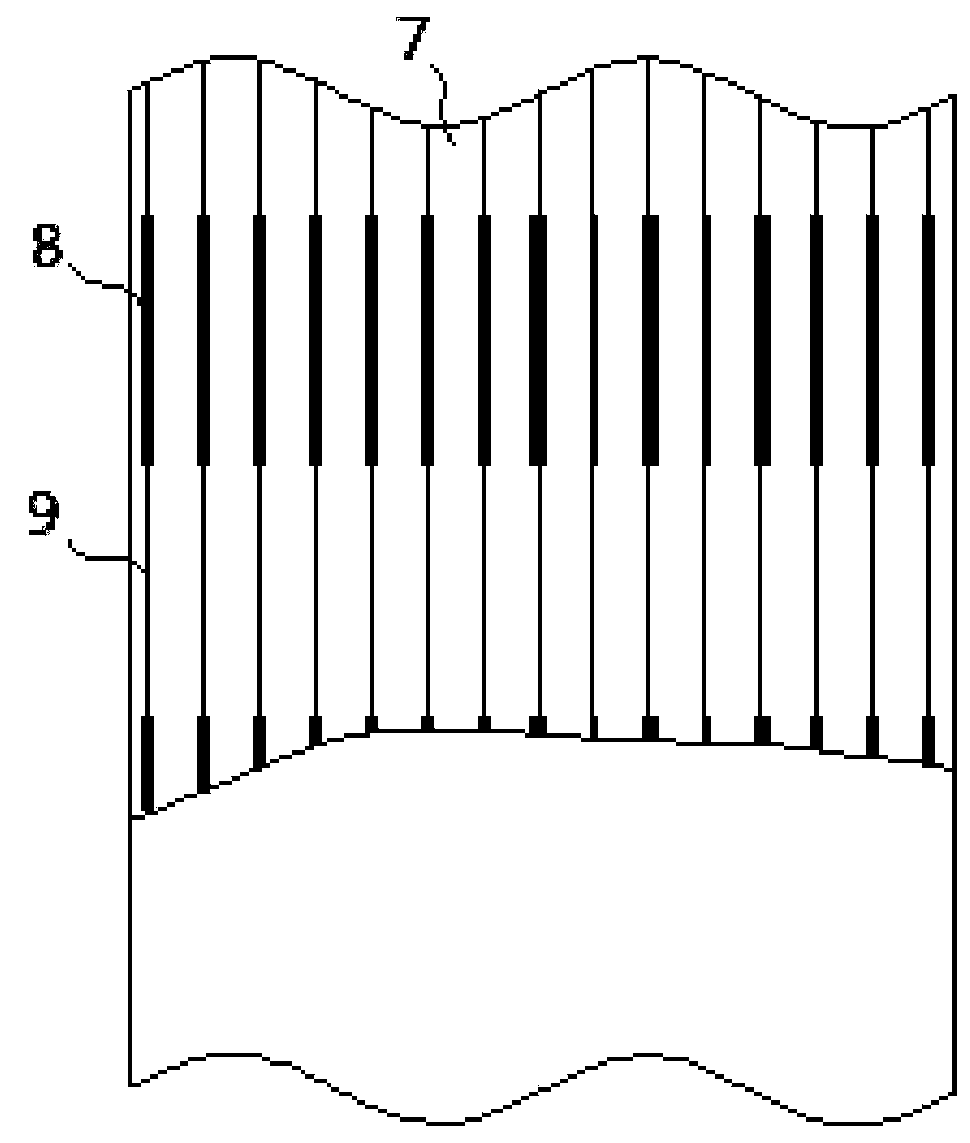

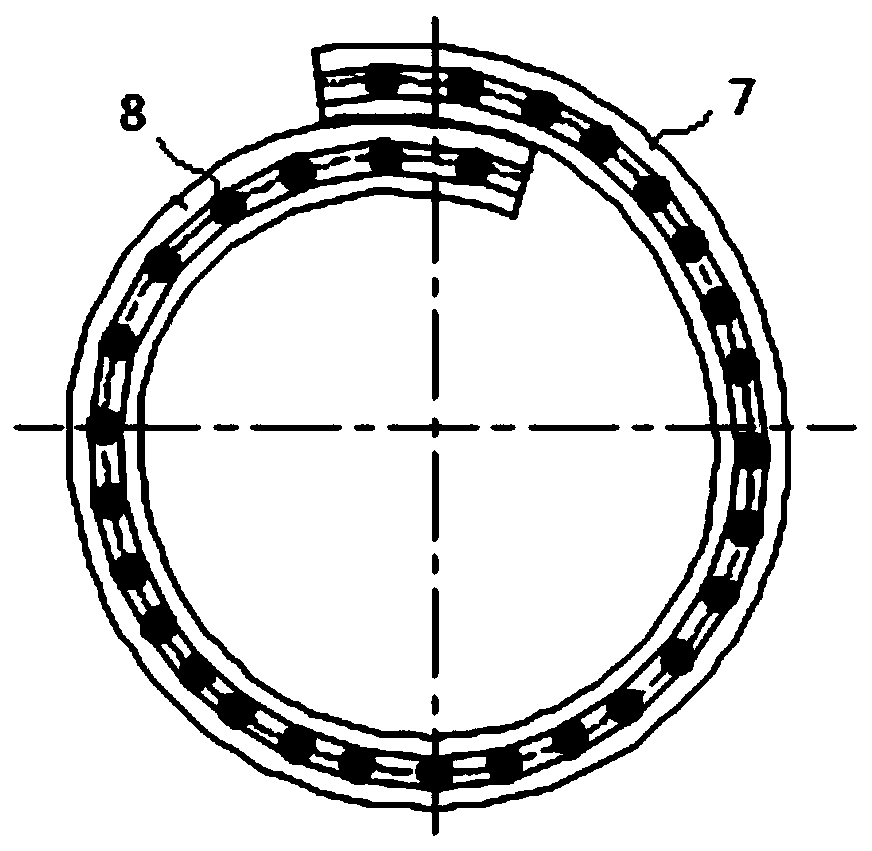

Deep sea foundation electromagnetic induction space positioning and direction finding device for supergravity centrifuge

PendingCN108426572AMaster comprehensiveStructural solutionNavigation by terrestrial meansUsing reradiationMagnetic sourceEngineering

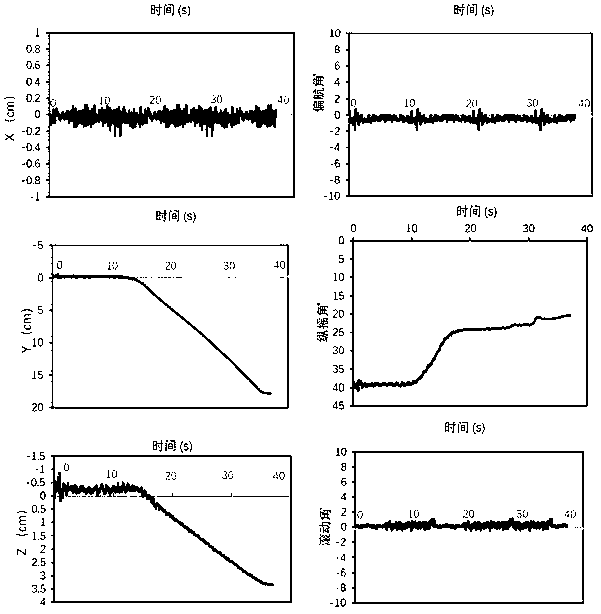

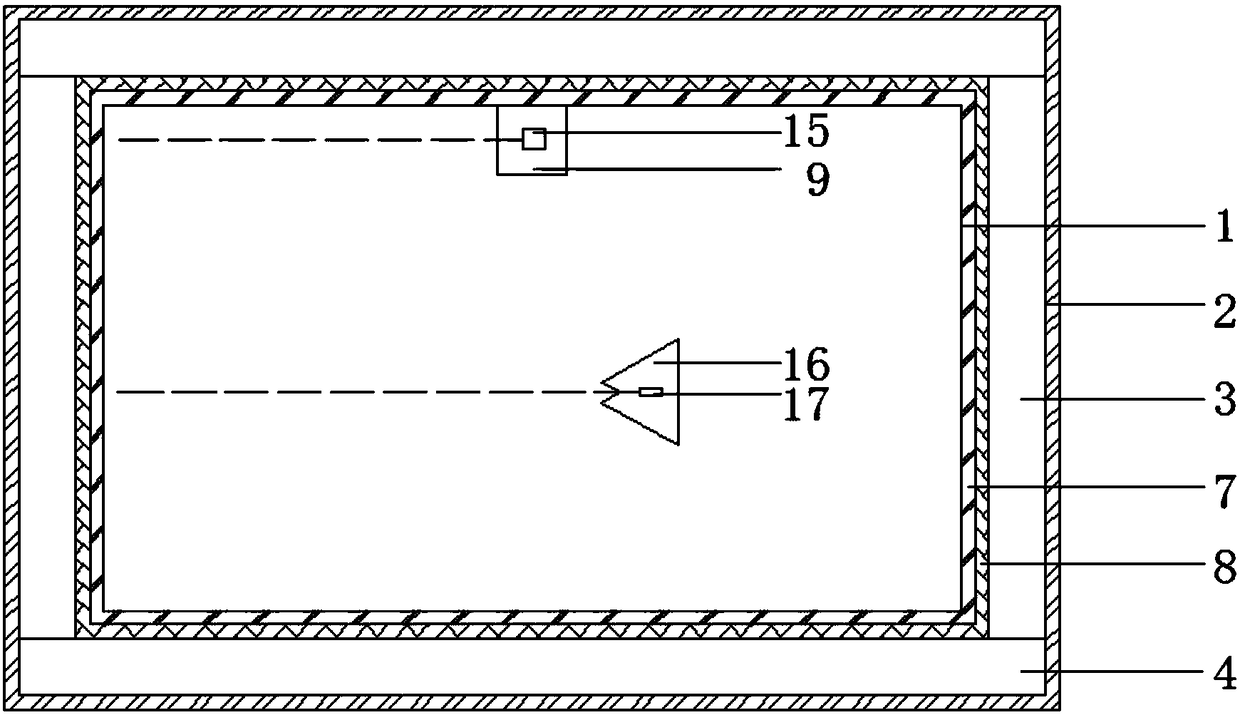

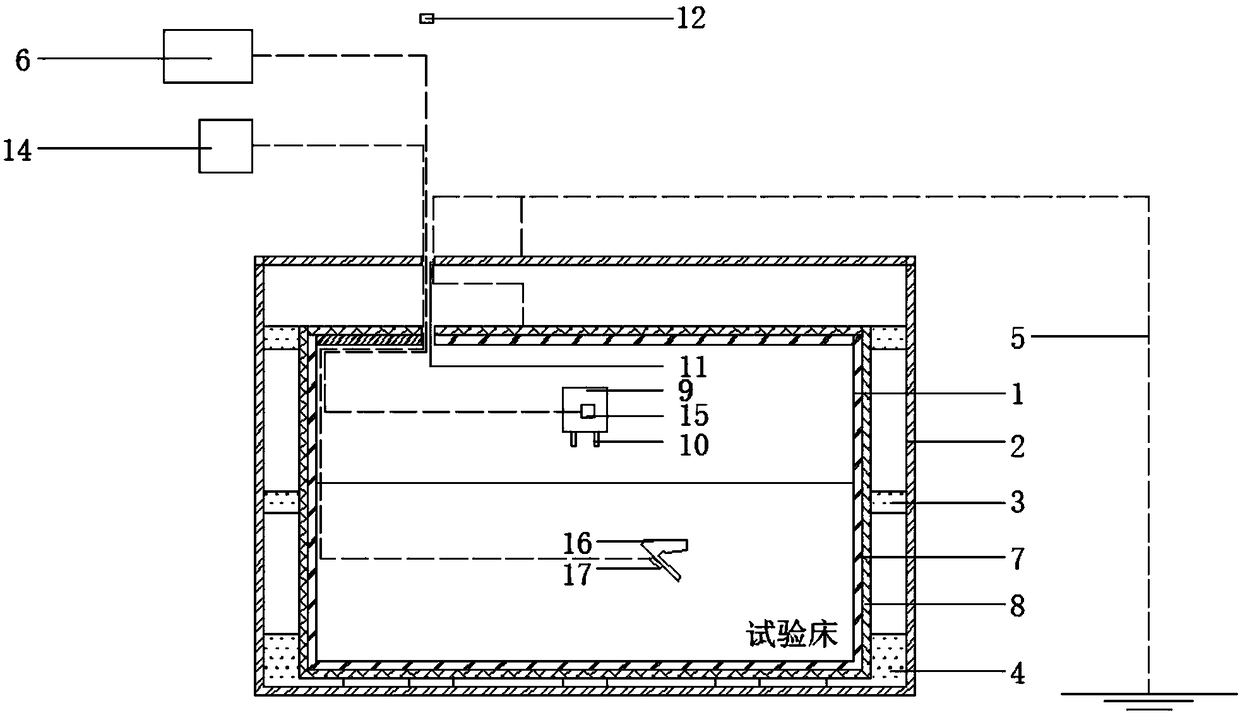

The invention discloses a deep sea foundation electromagnetic induction space positioning and direction finding device for a supergravity centrifuge. The device comprises a shielding box located inside and a model box located outside, wherein the shielding box is fixed in the model box through supports and cushion blocks, a magnetic source support is fixed on the inner side wall of the shielding box, a magnetic source is fixedly arranged on the magnetic source support, the shielding box is filled with an experimental soil mass, a deep sea foundation is arranged in the experimental soil mass and can move freely in the experimental soil mass of the shielding box, and a tracker is fixed on the deep sea foundation; the shielding box and the model box are grounded through grounding wires, the tracker is connected with an equipment independent power supply outside the model box through a power line, and the tracker is connected with a data collecting and processing system outside the model box through a data line. The device is used for shielding low-frequency interfering magnetic field produced during operation of the centrifuge and accurately tracking the position and attitude information of a structure in a centrifuge deep sea foundation experiment, the accuracy of magnetic induction tracking equipment is improved, and the motion information of the deep sea foundation is detectedcontinuously in real time.

Owner:ZHEJIANG UNIV

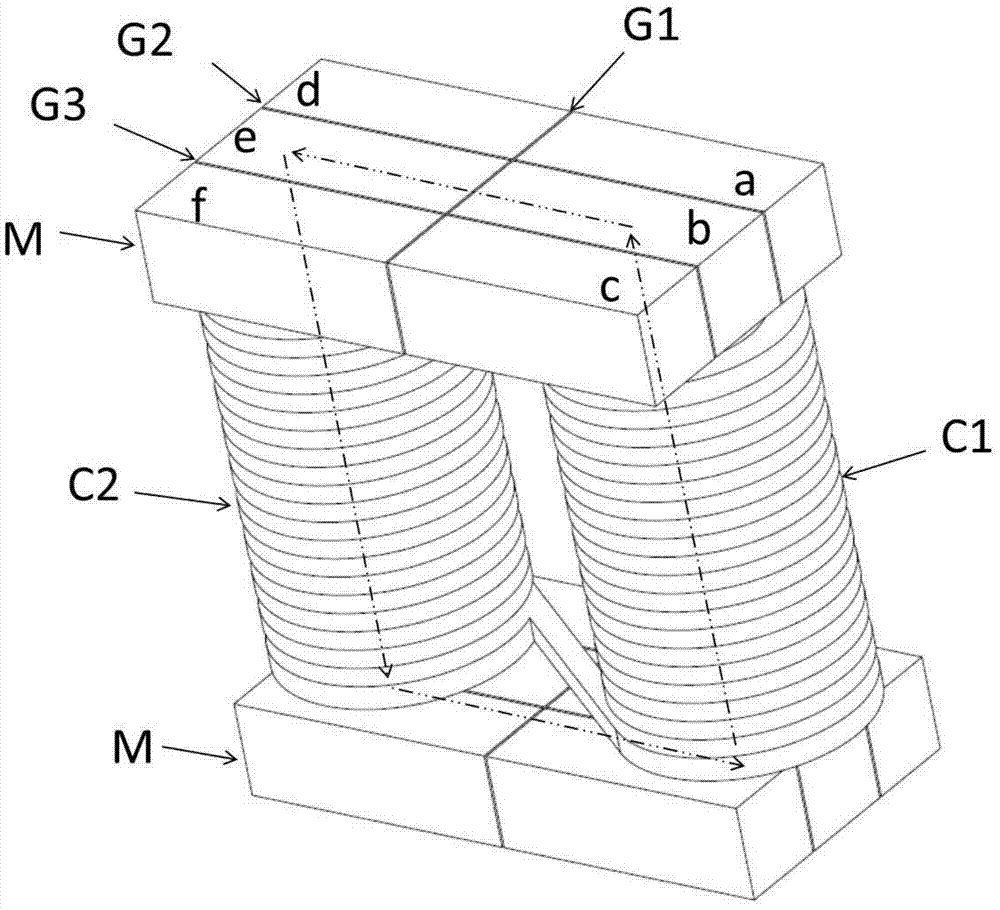

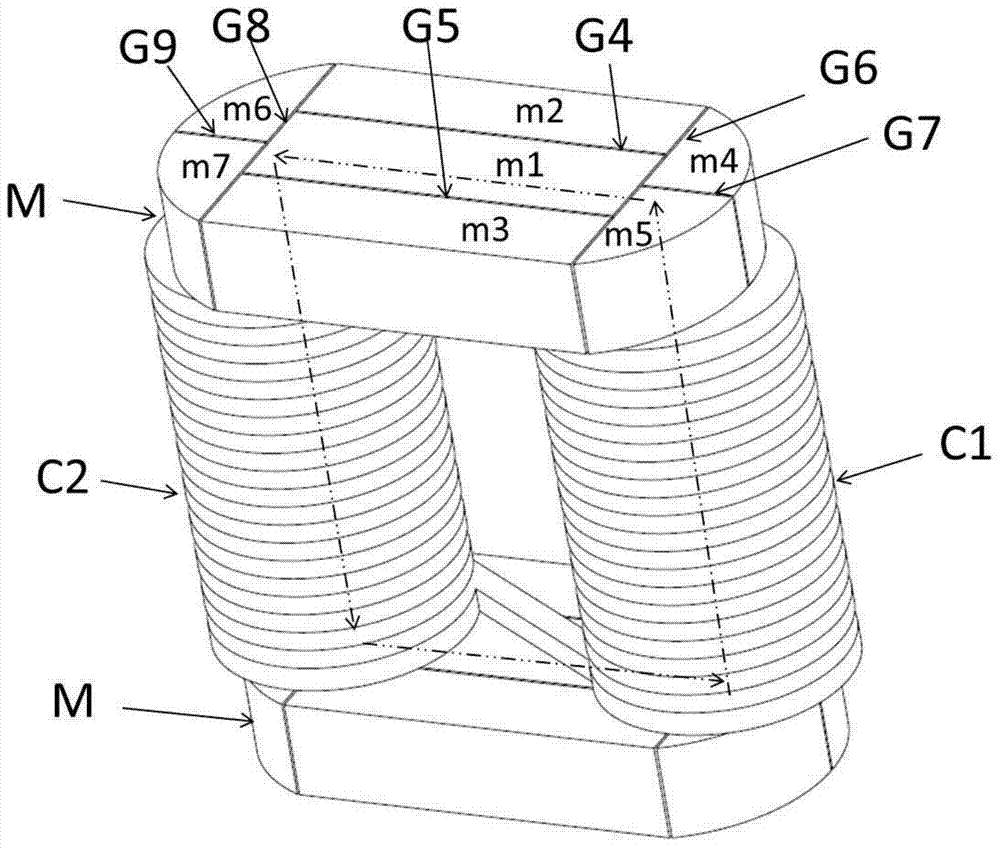

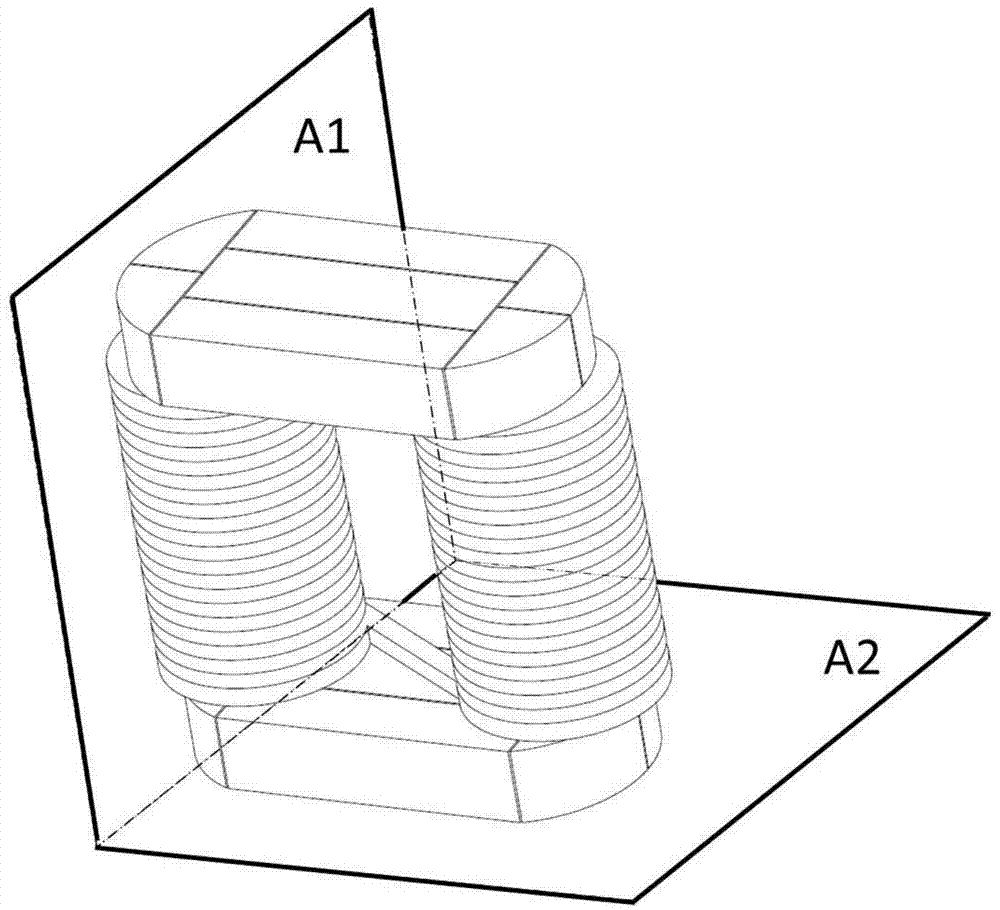

Integrated inductor

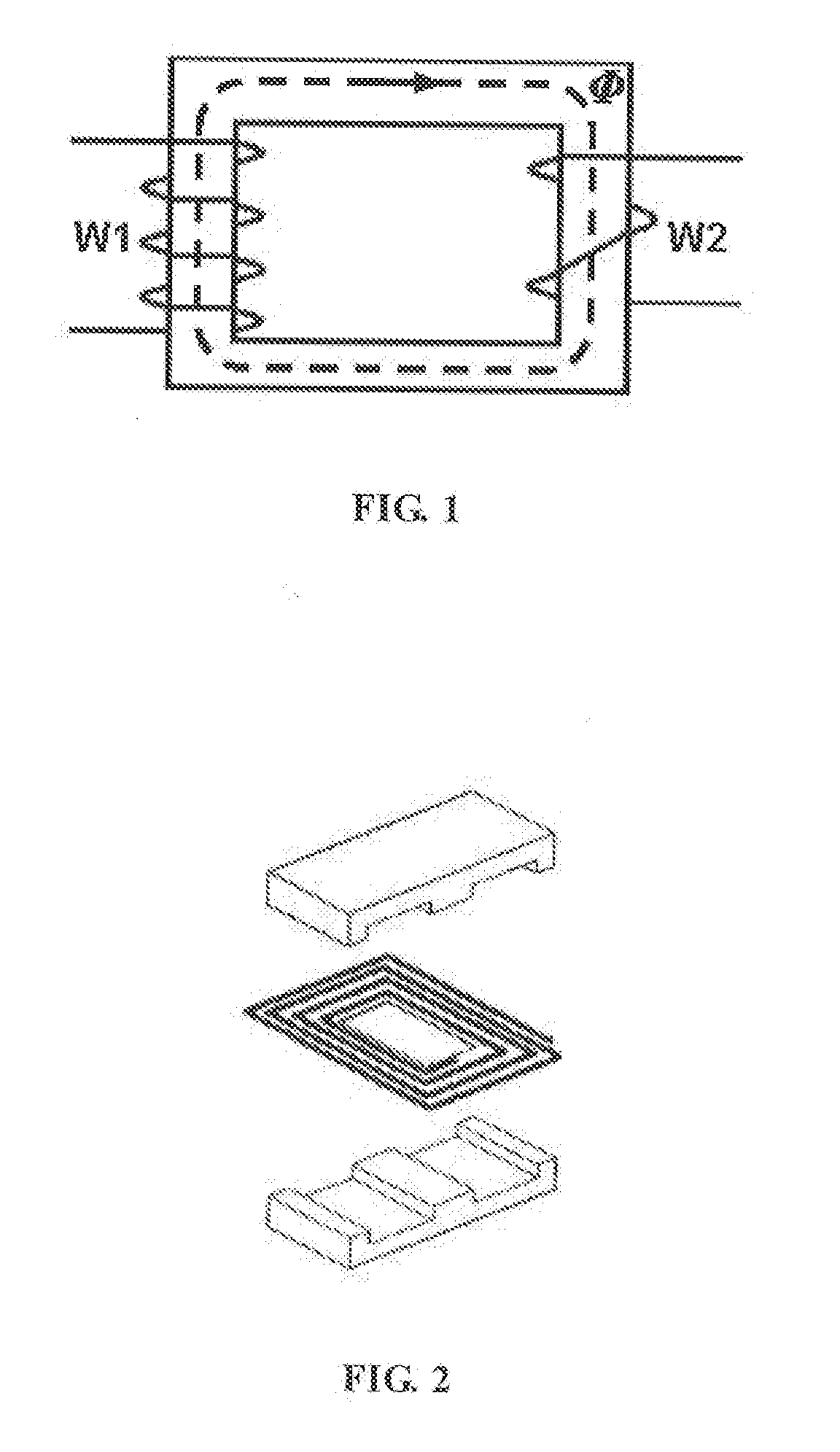

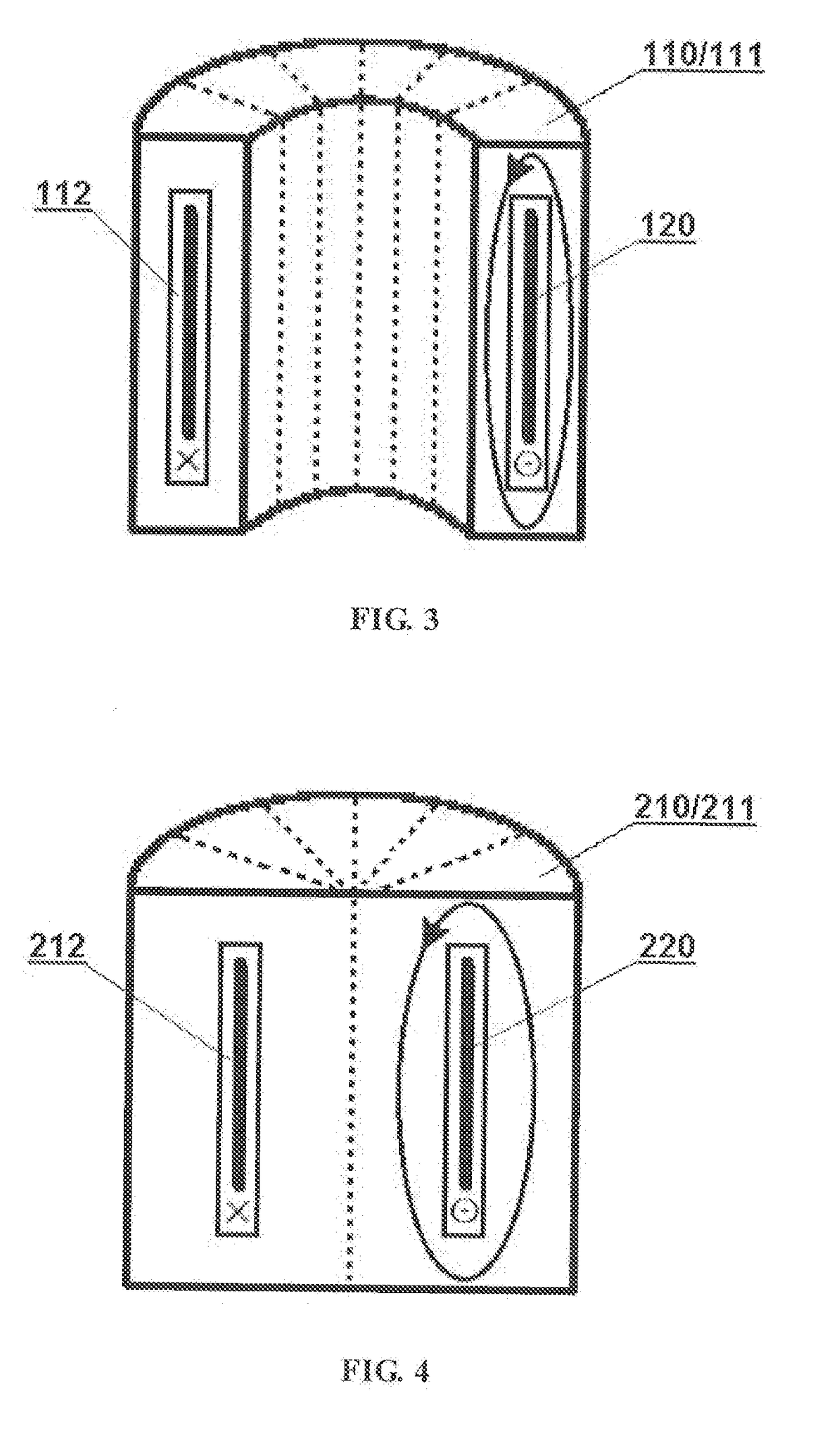

ActiveCN104715886AAvoid intersectionIntersect lessTransformers/inductances magnetic coresCores/yokesInductorElectrical and Electronics engineering

An integrated inductor comprises a first winding (C1) and a second winding (C2); a first internal magnetic core in the first winding (C1) and a second internal magnetic core in the second winding (C2); and at least one external magnetic core (M) outside the first winding (C1) and the second winding (C2), used for being connected to end portions of the first and second internal magnetic cores to form a magnetic path, the external magnetic core (M) being formed by multiple sub-magnetic cores joint with each other; the magnetic conductivity of at least one sub-magnetic core of the multiple sub-magnetic cores is greater than the magnetic conductivity of other sub-magnetic cores, and the at least one sub-magnetic core at least covers a part of end surfaces of the first internal magnetic core and the second internal magnetic core. The integrated inductor can alleviate the phenomenon of flux leakage, and can reduce costs of the magnetic cores.

Owner:EATON INTELLIGENT POWER LTD

A permanent magnet double disc brake and a braking method thereof

ActiveCN108895096AExtended service lifeReduce wearAxially engaging brakesBrake actuating mechanismsFriction reductionCalipers

The invention discloses a permanent magnet double disc brake and a braking method thereof, comprises an inner brake disc, an outer brake disc, a connecting shaft, a sliding gear, a bearing, a permanent magnet ring, a double-disc brake caliper, a permanent magnet connecting block and a permanent magnet brake assembly, wherein the permanent magnet brake assembly is arranged between the outer brake disc and the inner brake disc and comprises a permanent magnet, a first rotor disc, a second rotor disc, a rotor connecting sleeve and an intermediate friction plate. A permanent magnet double disc brake can provide two braking modes under the working state: a pure friction braking mode and a compound braking mode of friction braking and permanent magnet braking. Through the axial movement of the inner brake disc, the interruption and connection of the power transmission are realized, and the magnetic flux leakage phenomenon of the existing permanent magnet retarder on the market is avoided. The utility model has the advantages of no additional permanent magnet braking operation control mechanism, both permanent magnet auxiliary braking energy-saving, effective reduction of friction disc wear and large braking torque of the double-disc brake, and good heat dissipation performance.

Owner:JIANGSU UNIV

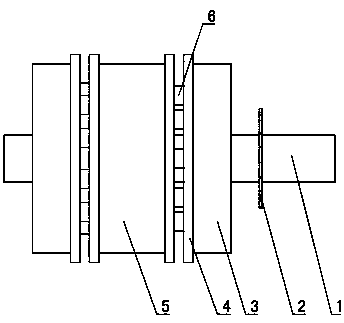

Pneumatic clutch controlling permanent magnetic retarder

InactiveCN101295912AHigh torqueFast responsePermanent-magnet clutches/brakesDynamo-electric brake controlBrake torqueStator

The invention provides a pneumatic clutch control type permanent magnetism retarder, which relates to a permanent magnetism retarder which comprises a stator and a rotor, wherein, the stator comprises a stator frame, a magnet support, a magnet external holder, a permanent magnet; the rotor comprises a rotor disk and a flange, and the rotor disk and the flange are connected by a clutch device which has the same axis with the rotor disk; the permanent magnet is fixed on the magnet support. Under the normal driving state of a vehicle, the rotor disk does not rotate, does not generate eddy current which hinders the movement of a transmission shaft and does not generate heat. When speed is need to be lowered, the pneumatic clutch starts to work and the rotor disk rotates to realize speed slowing. By utilizing the pneumatic clutch to carry out control, the rotor does not rotate under non-working sate; therefore, the invention has the advantages of requiring no degaussing, no reverse braking torque when in no braking state, energy-saving, large torque moment, high reaction speed, compact structure, safety and long service life.

Owner:扬州市洪泉实业有限公司

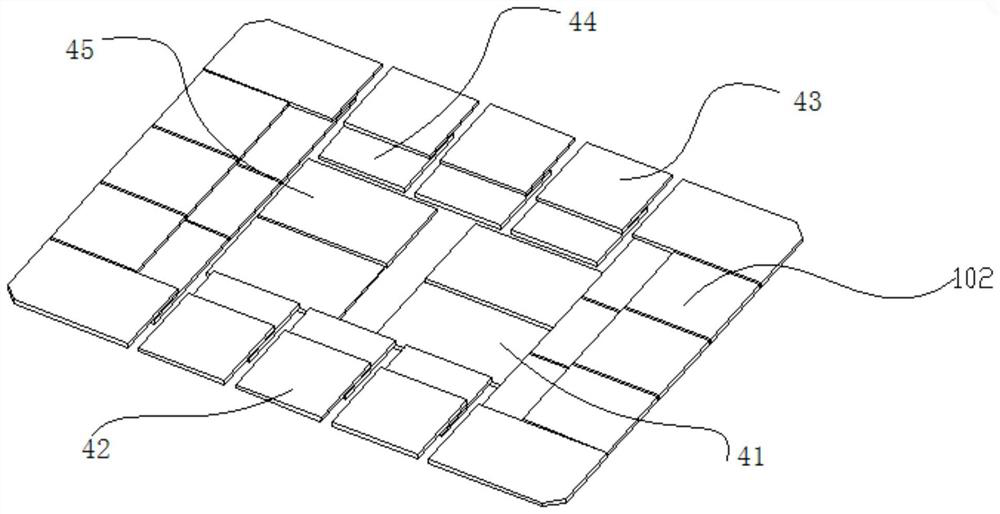

Transmitting assembly and charging assembly structure for wireless charging of electric automobile

PendingCN112002532AHigh magnetic permeabilityReduce power consumptionTransformers/inductances coolingCharging stationsFerrite layerTransmitter coil

The invention discloses a transmitting assembly for wireless charging of an electric automobile. The transmitting assembly comprises a non-metal shell, a transmitting coil, a transmitting magnetic core and a metal shell that are sequentially assembled from top to bottom. The transmitting magnetic core comprises at least two ferrite layers which are stacked in a staggered mode. Each ferrite layer is formed by splicing a plurality of ferrites; the ferrite layer corresponding to the periphery of the transmitting coil is close to the transmitting coil; the rest ferrite layers are sequentially arranged in a retracting manner corresponding to the central position of the transmitting coil and are gradually far away from transmitting coil. The invention further discloses a charging assembly for wireless charging of the electric automobile, wherein the charging assembly comprises the transmitting assembly and the receiving assembly which are arranged in parallel, the problem that a transmittingmagnetic field is uneven in distribution is solved, magnetic saturation is inhibited, and the wireless charging efficiency is improved.

Owner:上海万暨电子科技有限公司

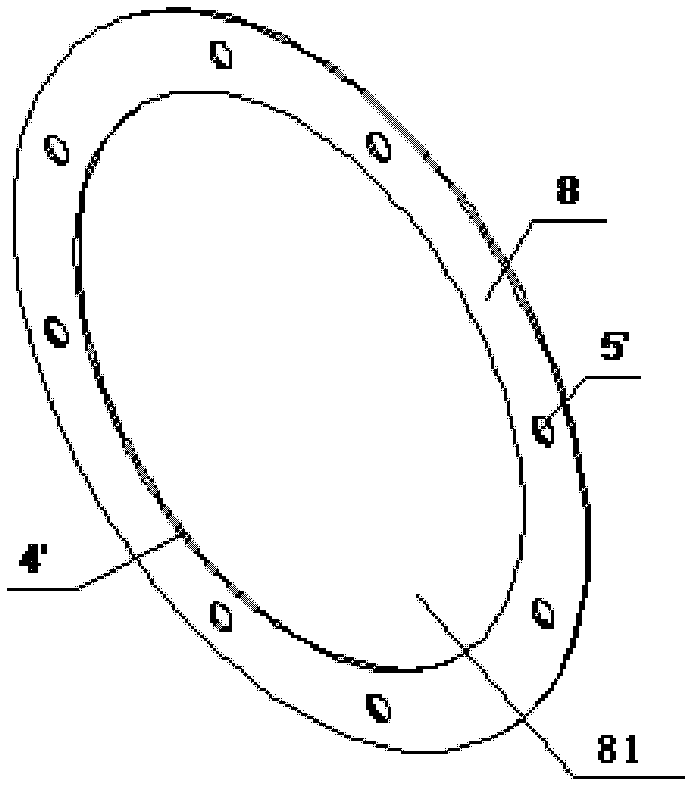

Method for machining magnetic yoke applicable to electromagnetic clutch

InactiveCN103352933AExtended service lifeEasy to useMagnetically actuated clutchesCores/yokesPunchingElectromagnetic clutch

The invention provides a method for machining a magnetic yoke applicable to an electromagnetic clutch. The magnetic yoke applicable to the electromagnetic clutch comprises an outer circular ring (1), an inner circular ring (2), a bottom pad (3) and a connecting hole (4), and is characterized in that the outer circular ring (1), the inner circular ring (2) and the bottom pad (3) are formed by once punching; the connecting hole (4) is formed in the outer circular ring (1). The magnetic yoke applicable to the electromagnetic clutch is made of a cylindrical steel cake material by a metal through once punching, so that the rigidity of the magnetic yoke is greatly enhanced, internal pores can not be formed, magnetic leakage in the working process of the electromagnetic clutch is effectively avoided, the working efficiency is improved, the service life of the electromagnetic clutch is prolonged, and the electromagnetic clutch is simple in structure and convenient to implement.

Owner:卢国孝

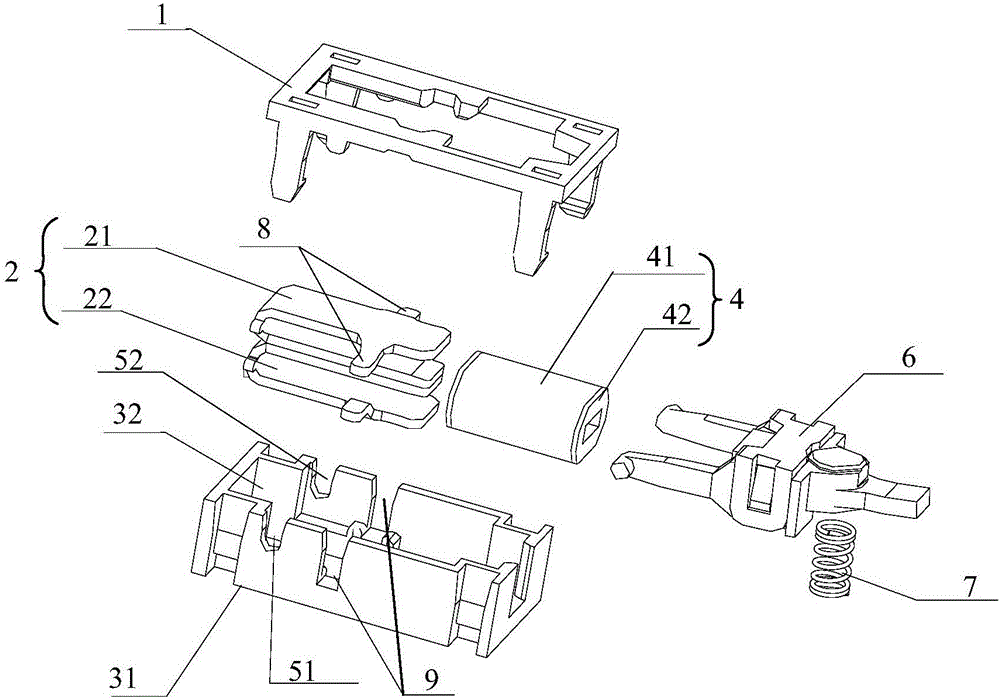

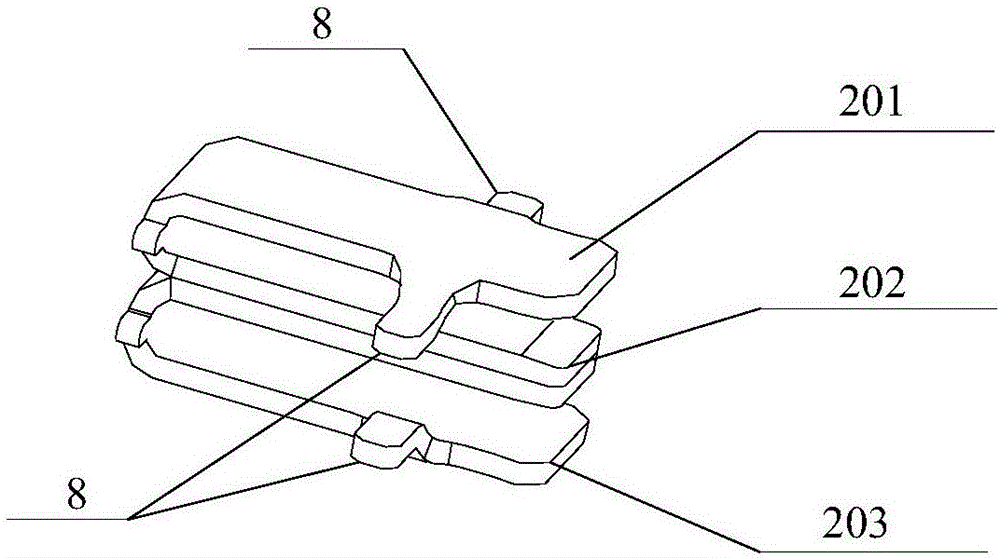

Self-generating device and wireless switch

ActiveCN106712441ARealize the function of power generationIncrease power generation functionDynamo-electric machinesEngineeringWireless

The invention discloses a self-generating and a wireless switch, relates to the technical field of wireless switches, and solves a problem that a self-generating device in the prior art is not sufficient in power generation. The device comprises a pedestal and a magnetic field generation unit disposed on the pedestal. The magnetic field generation unit comprises an E-shaped iron core, a hollow coil assembly, and a magnetic conduction contact. The E-shaped iron core comprises a basic body, a first stretch-out body, a central stretch-out body and a second stretch-out body, wherein the first stretch-out body, the central stretch-out body and the second stretch-out body are disposed on the basic body. The hollow coil assembly sleeves the central stretch-out body, and the length of the central stretch-out body in the Z-axis direction is less than the length of the first stretch-out body in the Z-axis direction and the length of the second stretch-out body in the Z-axis direction. The device is used for the wireless switch.

Owner:NINGBO BULL ELECTRIC CO LTD

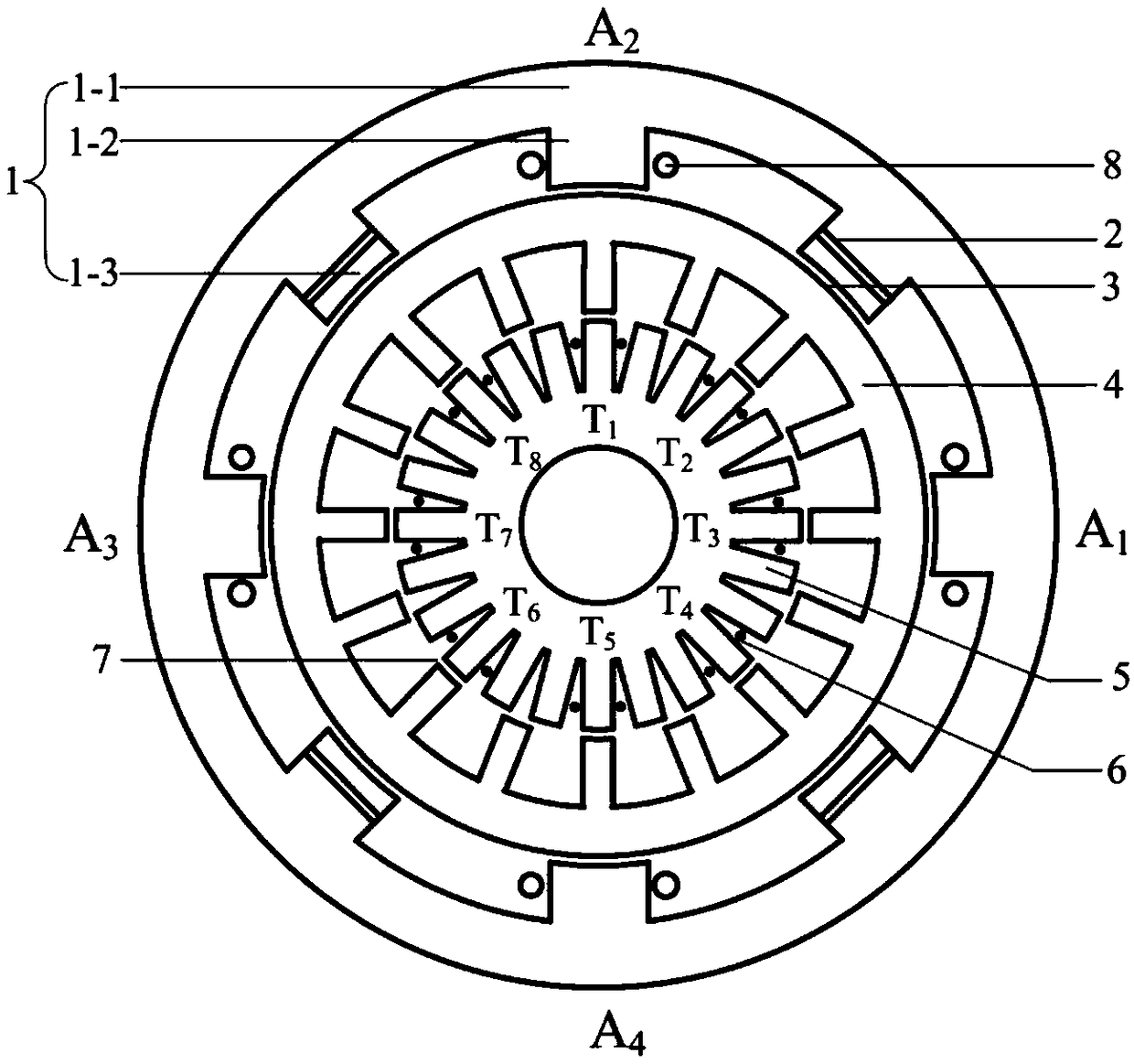

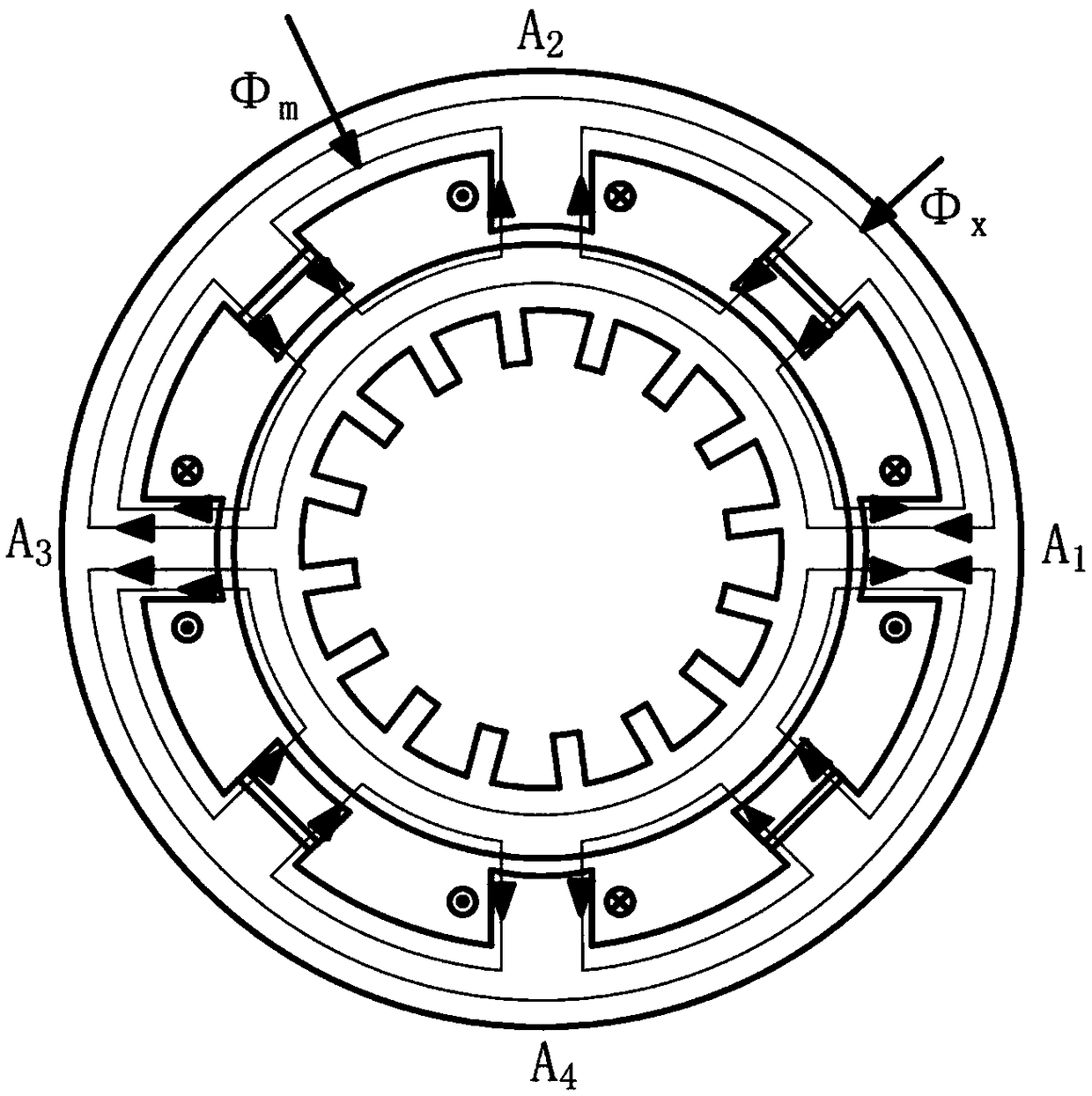

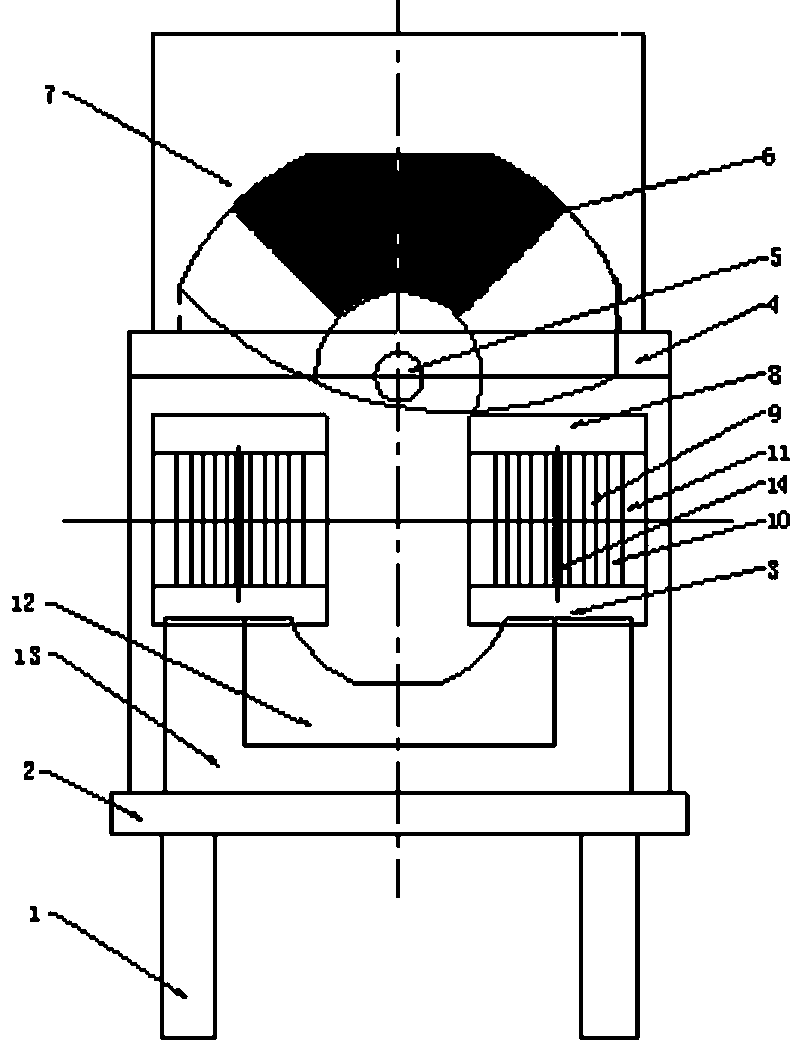

Dual-stator hybrid excitation magnetic suspension switched reluctance machine

ActiveCN108880152AGood suspensionHigh densityMagnetic circuit stationary partsMagnetic holding devicesElectric machineThree-phase

The invention discloses a dual-stator hybrid excitation magnetic suspension switched reluctance machine. The dual-stator hybrid excitation magnetic suspension switched reluctance machine comprises a 24-pole inner stator, a 16-pole rotor and an 8-pole hybrid outer stator, wherein the inner stator, the rotor and the hybrid outer stator are sequentially and coaxially sleeved from inside to outside, the hybrid outer stator comprises eight symmetrically-distributed salient poles and four sheet-shaped permanent magnets, the radial widths of the permanent magnets are equal to the widths of tooth poles of the outer stator, the permanent magnets employ a radial magnetizing mode, the permanent magnets and a suspension winding on the outer stator jointly act to generate a suspension force, a three-phase 24 / 16 outer rotor SRM structure is arranged in the motor, and the dual-stator hybrid excitation magnetic suspension switched reluctance machine has the advantage of conventional SRM, is relativelysmall in stepping angle, relatively small in torque ripple and relatively high in control accuracy; windings on tooth poles of the inner stator are used for providing torque are independent to a suspension magnetic field, and the problem of coupling between the torque and the suspension is solved; and meanwhile, the axial length is relatively small, the permanent magnets are used for providing bias magnetic flux, so that the power consumption is relatively low, the motor running efficiency is improved, and the excitation mode of the torque winding is not unique.

Owner:JIANGSU UNIV

Transformer iron core and manufacture method thereof

ActiveCN105006351ANo magnetic interferenceAvoid magnetic flux leakageTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerMaterials science

The invention discloses a transformer iron core and a manufacture method thereof. The transformer iron core comprises a pair of external iron core sheets and multiple internal iron core sheets arranged between the external iron core sheets. Each internal iron core sheet is provided with at least one iron core groove for increasing magnetic resistance of the internal iron core sheet, the internal iron core sheets are stacked and connected between the external iron core sheets in a surface-to-surface manner, the iron core grooves are formed at preset positions of the internal iron core sheets, and the preset positions are adaptive to the ion core grooves of the internal iron core sheets and are in staggered arrangement for enclosing the iron core grooves of each layer.

Owner:浙江仁栋电气科技有限公司

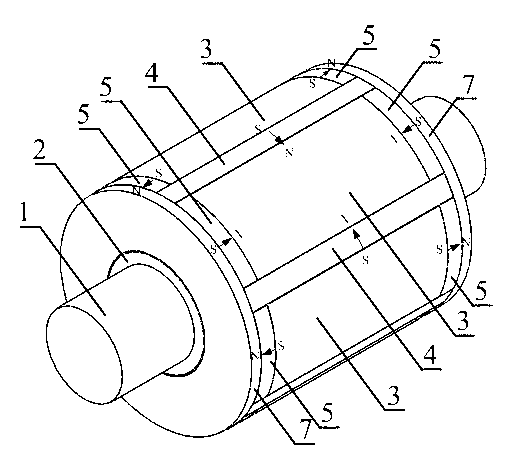

Tangential permanent magnet synchronous motor rotor structure

InactiveCN102570666AExtended service lifeOvercome centrifugal forceMagnetic circuit rotating partsPermanent magnet synchronous motorNon magnetic

A tangential permanent magnet synchronous motor rotor structure comprises a rotating shaft, magnetism isolating shaft sleeves, permanent magnets, rotor pole shoes, a left end plate and a right end plate; the permanent magnets and the rotor pole shoes are distributed at intervals along the circumferences of the magnetism isolating shaft sleeves; the permanent magnets are clung to the rotor pole shoes; a plurality of rotor partition boards made from non-magnetic materials are arranged between the two end plates; the rotor pole shoes are independent from one another; the rotor pole shoes and the rotor partition boards are distributed at intervals in the axial direction; the rotor partition boards divide a rotor into a plurality of rotor units in the axial direction; and two end surfaces of one rotor pole shoe in each rotor unit are clung to the end surfaces of adjacent rotor partition boards; through holes allowing the magnetism isolating shaft sleeves to penetrate are formed on the rotor partition boards; stretching bolts penetrate the left end plate, the rotor pole shoes, the rotor partition boards and the right end plate respectively; and the stretching bolts lock the left and the right end plates and the rotor pole shoes, the permanent magnets and the rotor partition boards between the left and the right end plates in the axial direction. The tangential permanent magnet synchronous motor rotor structure has the advantage of high mechanical strength and is applicable to high-speed rotating motors.

Owner:ZHEJIANG UNIV

Multi-track magnetic motor and control method thereof

InactiveCN107733192AHigh energy conversion rateImprove efficiencyStructural associationPermanent magnet rotorElectric machine

A multi-track magnetic motor and a control method thereof belong to the technical field of motors. It is characterized in that: the side of the rotor close to the stator (4) is provided with a plurality of installation holes, the permanent magnets (7) are embedded in the installation holes of the installation plate, and even number of permanent magnets (7) are arranged in a ring and evenly spaced, phase The polarities of the adjacent permanent magnets (7) are oppositely set; the stator (4) is provided with a plurality of coils arranged in a ring and evenly spaced, the number of coils on the stator (4) and the permanent magnet on the rotor matched with it (7) are equal in number. This multi-track magneto makes full use of the exciting magnetic field of the permanent magnet. The rotor is made of magnetically conductive material, which avoids the occurrence of magnetic flux leakage and improves the energy conversion rate of the motor. The efficiency of the motor is high. The rotor rotates synchronously with the permanent magnet. The occurrence of the phenomenon of cutting the magnetic induction line is avoided; the excitation magnetic field of the permanent magnet fully utilized by the control method of the multi-track magneto motor has no dead angle, and the motor can be started by using a small current.

Owner:蔡晓青

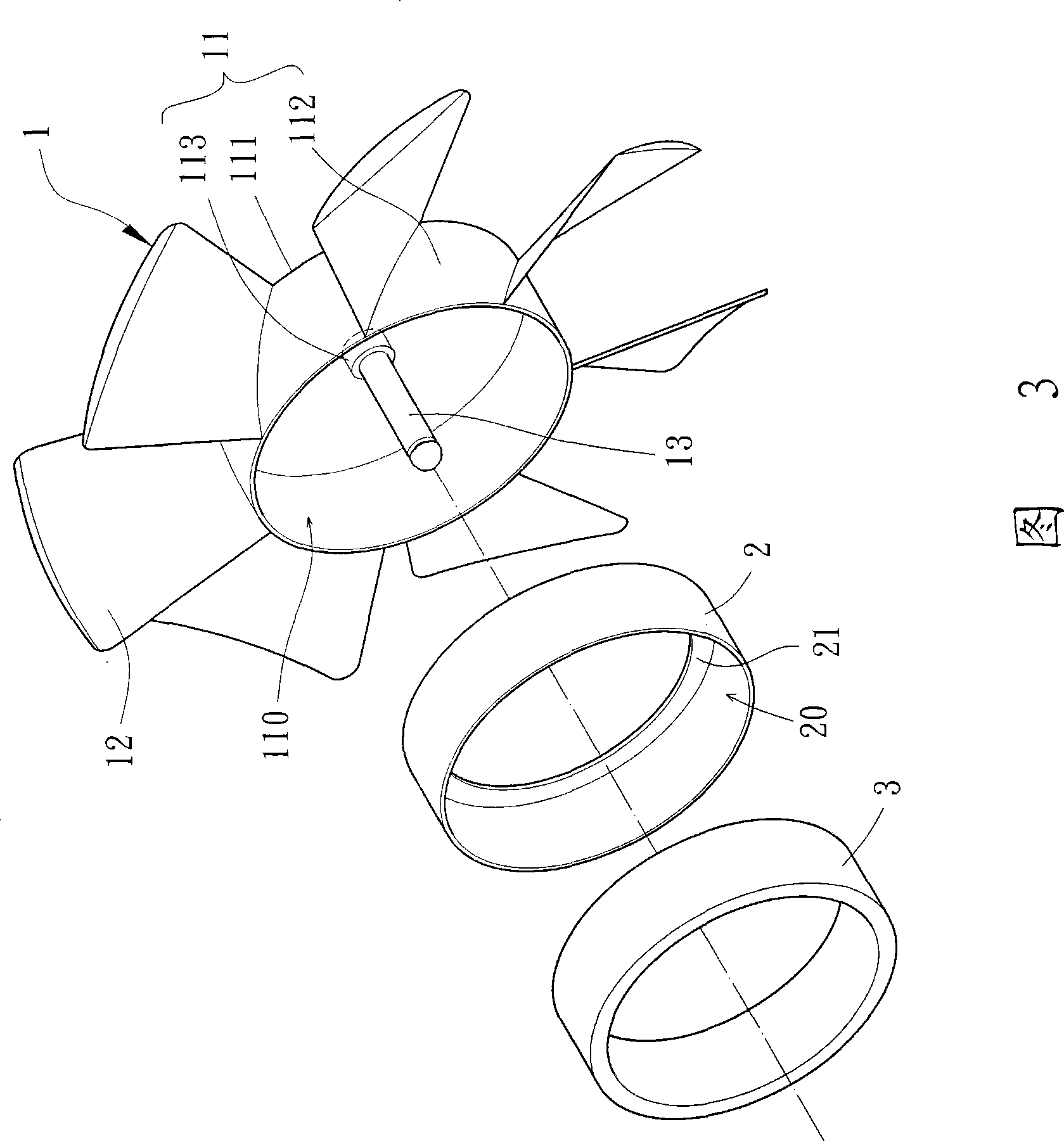

Fan impeller

InactiveCN101377208AImprove overall structural strengthReduce overall weightPump componentsPumpsImpellerInterior space

The present invention relates to a fan wheel, which comprises a hub, a plurality of fan blades and an annular metal body, and wherein, the fan blades are connected with the outer circumferential surface of the hub. The hub is provided with a top cover part, an annular wall part and a shaft lever base; wherein, the annular wall part is axially bent from the periphery of the top cover part; the top cover part and the annular wall part jointly round an interior space; and the shaft lever base is arranged at an axial position on the hub and positioned in the interior space. Moreover, the thickness of the annular wall part is less than the thickness of the top cover part, so that the annular metal body can be easily correspondingly and tightly assembled in the interior space.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

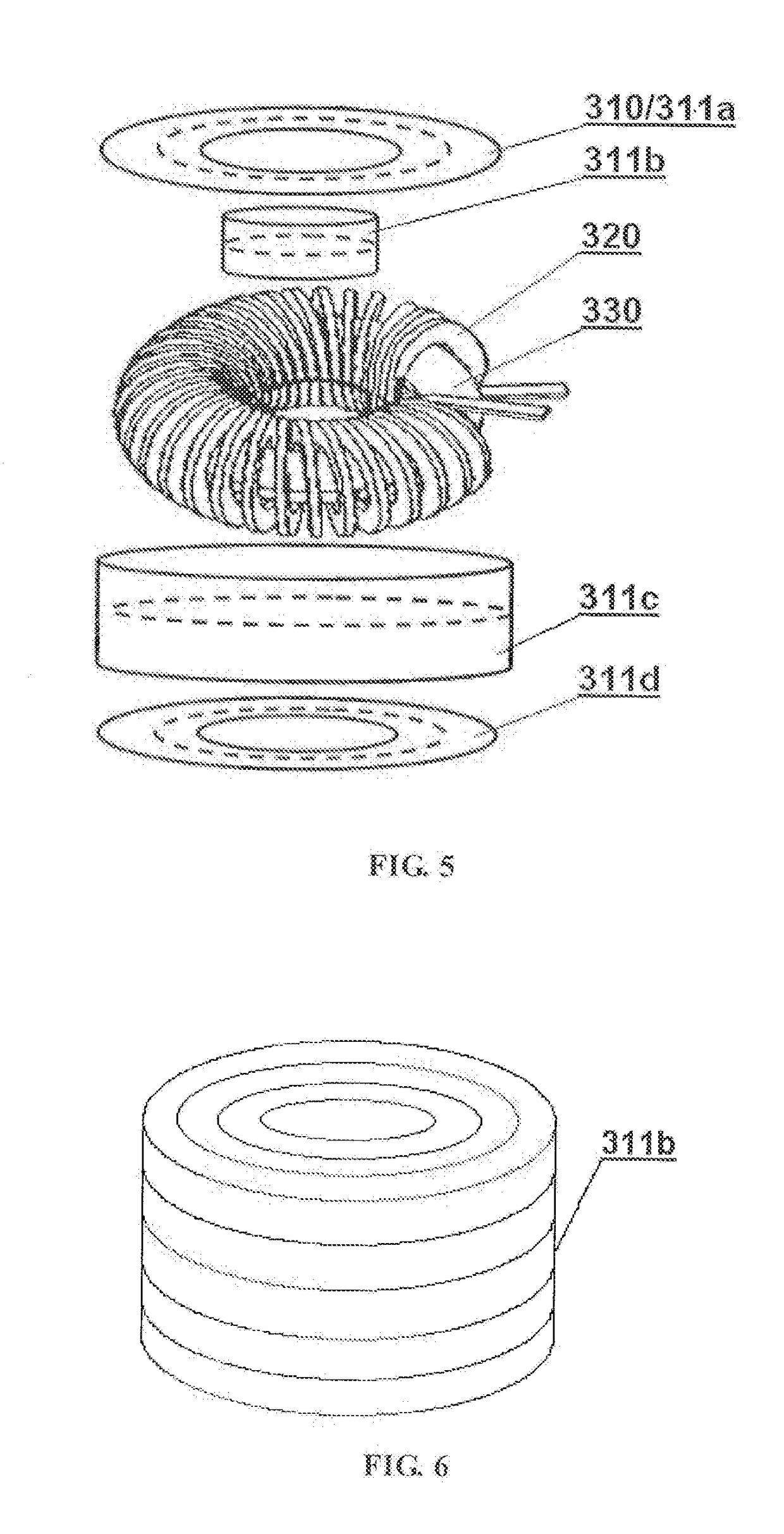

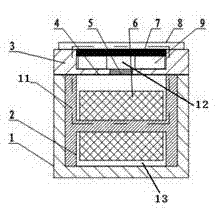

Electromagnetic induction device and method for manufacturing same

InactiveUS20190057807A1Avoid magnetic flux leakageReduce magnetic resistanceTransformers/inductances casingsTransformers/inductances coils/windings/connectionsMagnetic fluxElectromagnetic induction

Disclosed are an electromagnetic induction device and a method for manufacturing the same. The device comprises a magnetic cover (110) and at least one set of coils (120). The magnetic cover (110) consists of two or more magnetic units (111), and a closed magnetic flux loop can be formed within each magnetic unit (111). The magnetic units (111) are joined together to form a substantially closed integrated body having at least one cavity (112) therein, and dividing surfaces between the magnetic units (111) are disposed substantially along the magnetic flux loop without interrupting the magnetic flux loop. The coils (120) are placed in the cavity (112) formed by the magnetic cover (110), electrodes of the coils (120) are led out of the magnetic cover (110), and the magnetic flux loop in the magnetic cover (110) is formed after energization of the coils (120). The electromagnetic induction device of the present invention can substantially close coils, preventing magnetic flux leakage to a maximum extent. Further, since dividing surfaces between magnetic units are disposed along a magnetic flux loop, no air gap is generated in the magnetic flux loop, thereby effectively decreasing magnetic resistance.

Owner:BOLYMEDIA HLDG

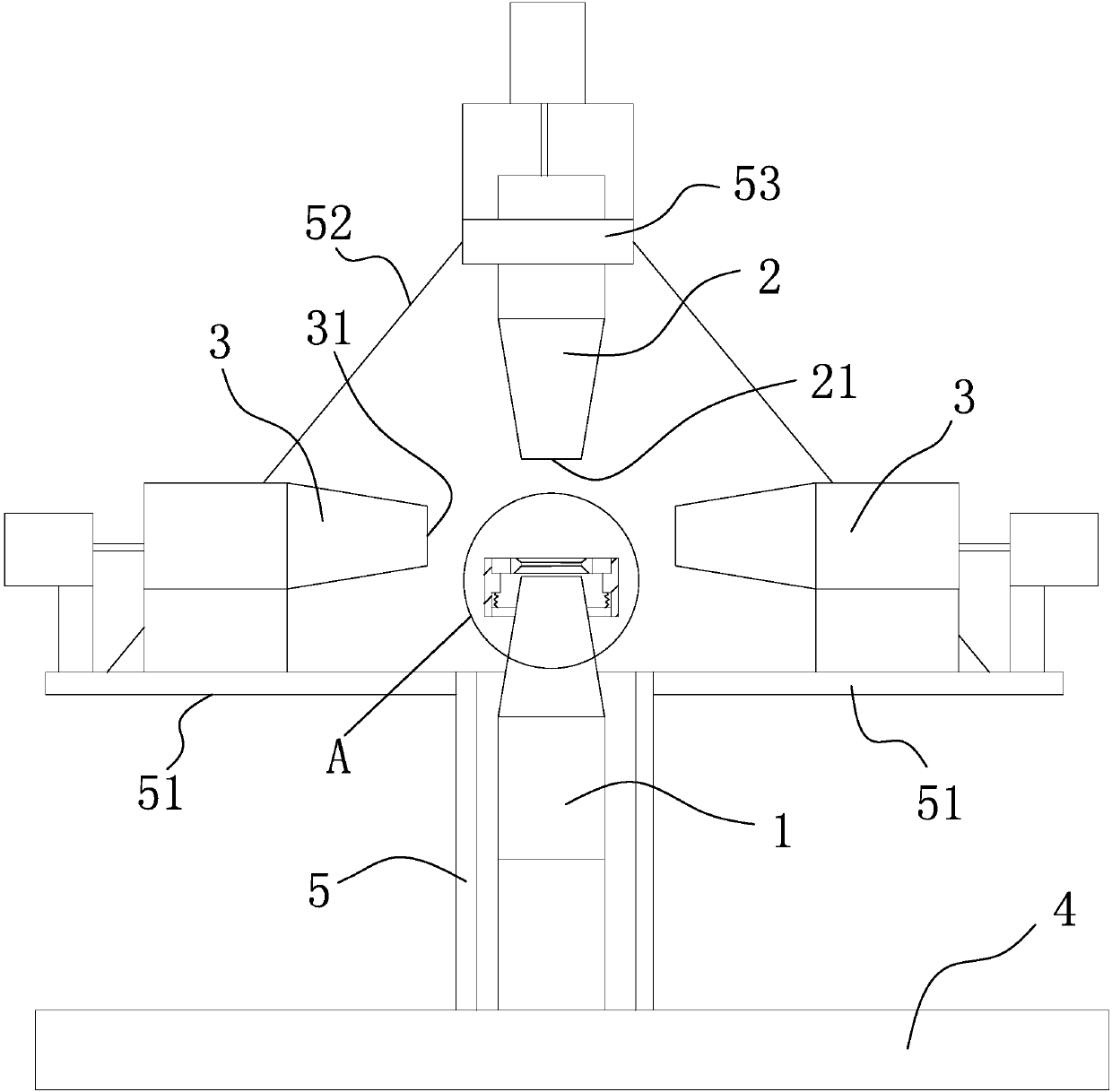

Magnetizing device and magnetizing method for six-sided magnetic suspension body

ActiveCN107910156AIncrease the magnetization strengthImprove magnetization efficiencyMagnetic bodiesAccelerometry techniqueMagnetization

The invention belongs to the technical field of accelerometers, particularly relates to a magnetizing device and magnetizing method for a six-sided magnetic suspension body and aims at solving the problem of unreasonable design in the prior art. The magnetizing device for the six-sided magnetic suspension body comprises a vertically arranged lower magnetizing head, an upper magnetizing head located above the lower magnetizing head, and four lateral surface magnetizing heads which are distributed along the circumference and are horizontally arranged, wherein the lateral surface magnetizing heads are located between the lower magnetizing head and the upper magnetizing head; a first magnetizing contact plane is arranged at the upper end of the lower magnetizing head; a second magnetizing contact plane parallel to the first magnetizing contact plane is arranged at the lower end of the upper magnetizing head; and a vertically arranged third magnetizing contact plane is arranged at the innerend of each lateral surface magnetizing head. The magnetizing device and the magnetizing method have the advantages that the method is simple, and simultaneous magnetization of six sides can be completed once, so that the magnetization efficiency can be improved.

Owner:徐州新南湖科技有限公司

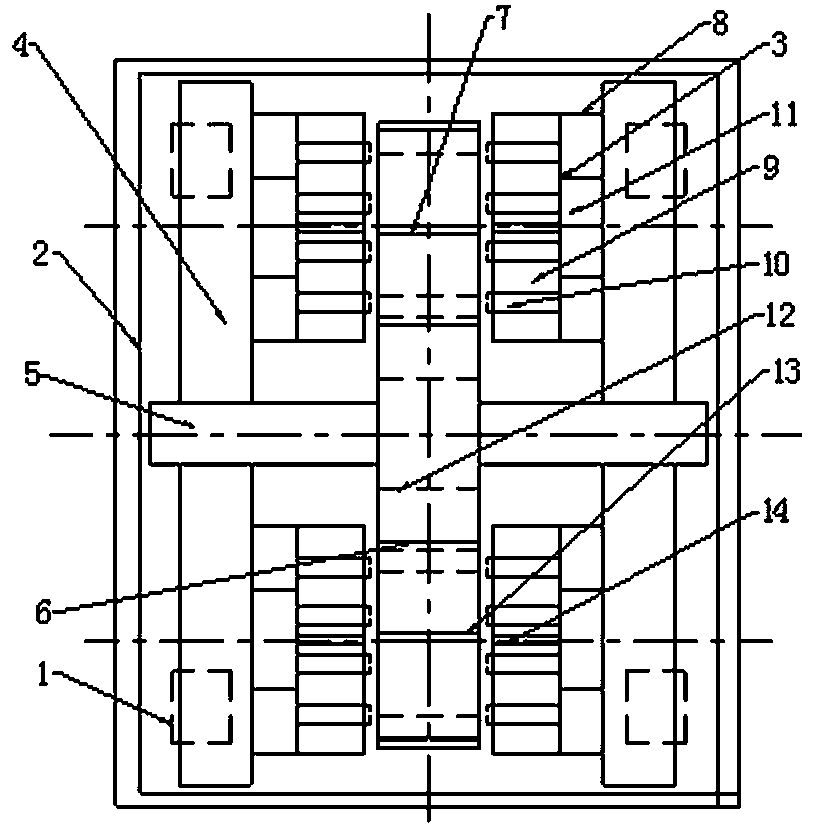

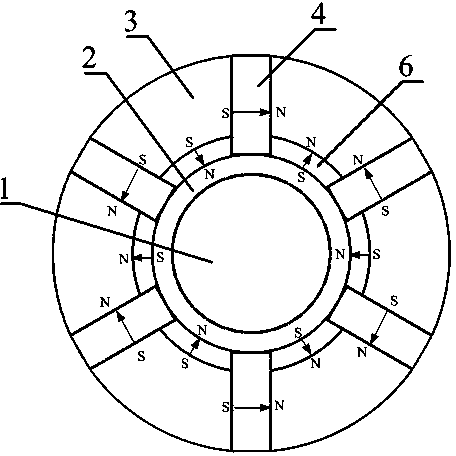

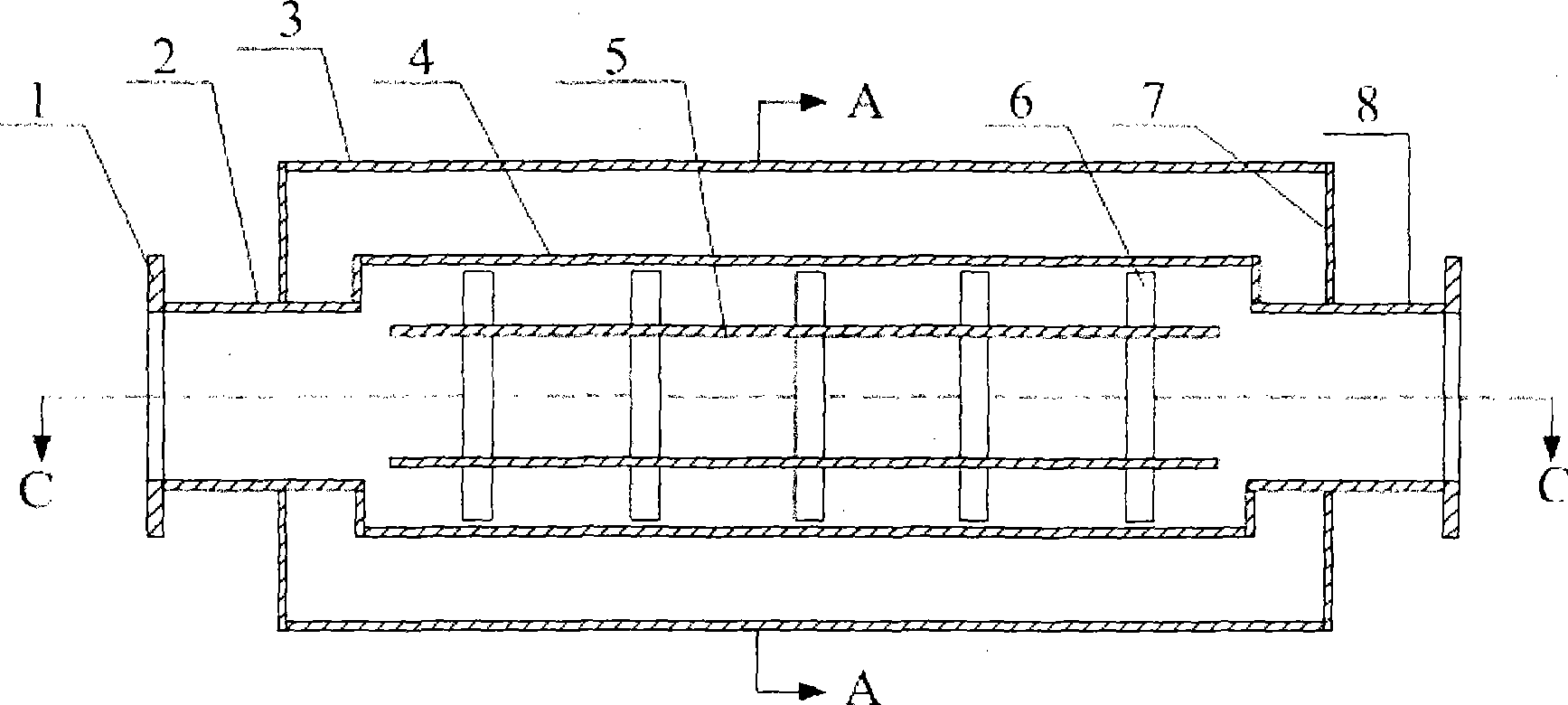

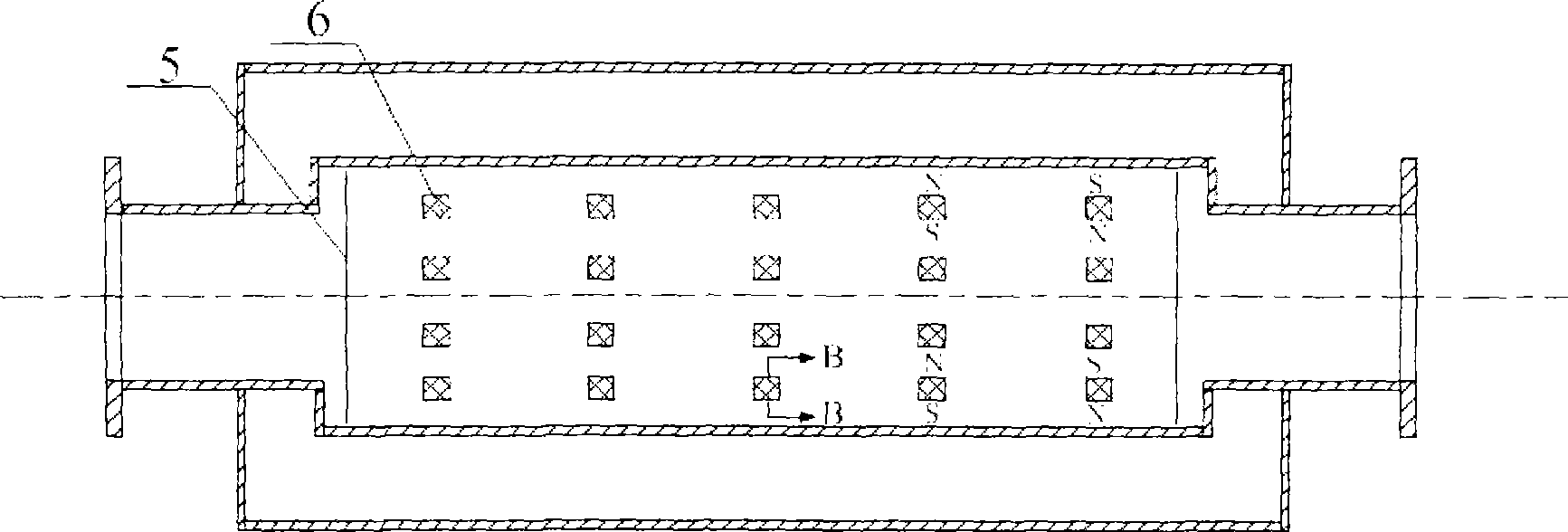

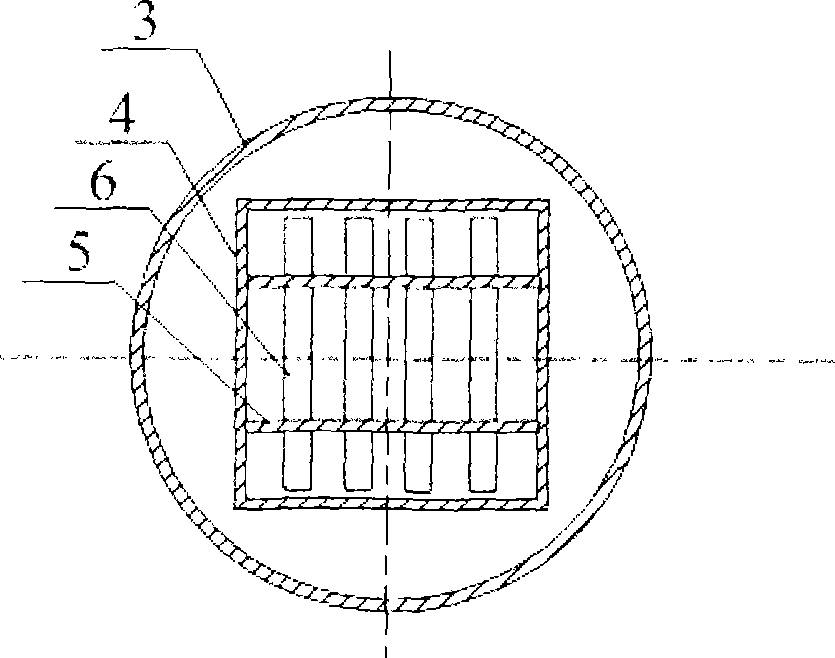

Continuous halving double-antipodal-type magnetic system permanent magnet high-gradient strong magnetic separation device

ActiveCN107855213AIncrease sorting spaceIncrease throughputHigh gradient magnetic separatorsMagnetic polesMagnetic separation

The invention discloses a continuous halving double-antipodal-type magnetic system permanent magnet high-gradient strong magnetic separation device. A rotating shaft is used as the center of the device, and the mode of symmetrically arranging magnet yokes of the same magnetic system is adopted to form complete machine front-back symmetrical magnetic poles of the antipodal-type structure. The radial center plane of a magnetism gathering medium barrel is used as a symmetry plane to form left-right halving-type symmetrical magnetic poles of the antipodal-type structure. The structural style of apolygon magnetism gathering medium barrel is adopted in the magnetism gathering medium barrel, and an inner cavity of the magnetism gathering medium barrel is divided into four regions with the same area symmetrically at the two sides of a perpendicular bisector of the magnetism gathering medium barrel in the length direction. Magnetism gathering media are symmetrically installed in the regions atthe two ends of the inner cavity of the magnetism gathering medium barrel, and the adjacent regions at the two sides of the perpendicular bisector refer to magnetism gathering medium-free regions. Square permanent magnets are adopted as the magnetic poles, and five-face square extrusion soft iron materials at the upper side, the lower side, the left side, the right side and the tail portion serveas the magnetic poles. The square soft iron materials are further used as magnetic pole guide magnetic force lines. The square soft iron magnetic poles with the five faces being extruded are symmetrically arranged to form the antipodal-type structure.

Owner:河北地质大学

A kind of semi-hard magnetic material and preparation method thereof

The invention relates to a semi-hard magnetic material, which contains iron, nickel, boron and silicon, and the mass percentages of each element are 55-65%, 22-32%, 1-8% and 1-8% respectively. A method for preparing a semi-hard magnetic material: 1) putting iron, nickel, boron, and silicon into a steelmaking furnace, the mass percentages of iron, nickel, boron, and silicon being 55-65%, 22-32%, 1-8%, 1-8%, steelmaking temperature 2700-3200°C, smelting for 1.5-2.5 hours, tapping temperature 2000-2500°C; 2) Spraying the molten alloy obtained in step 1), the speed of the spraying roller 700-900 rpm, spray molten alloy on the circumferential surface of the high-speed rotating belt spray roller, protected by argon, until the alloy on the surface of the roller is solidified to form an alloy sheet, and the alloy sheet is removed from the surface of the roller. The semi-hard magnetic material prepared by the method of the invention has high material utilization rate and low cost.

Owner:江苏科晶智能科技股份有限公司

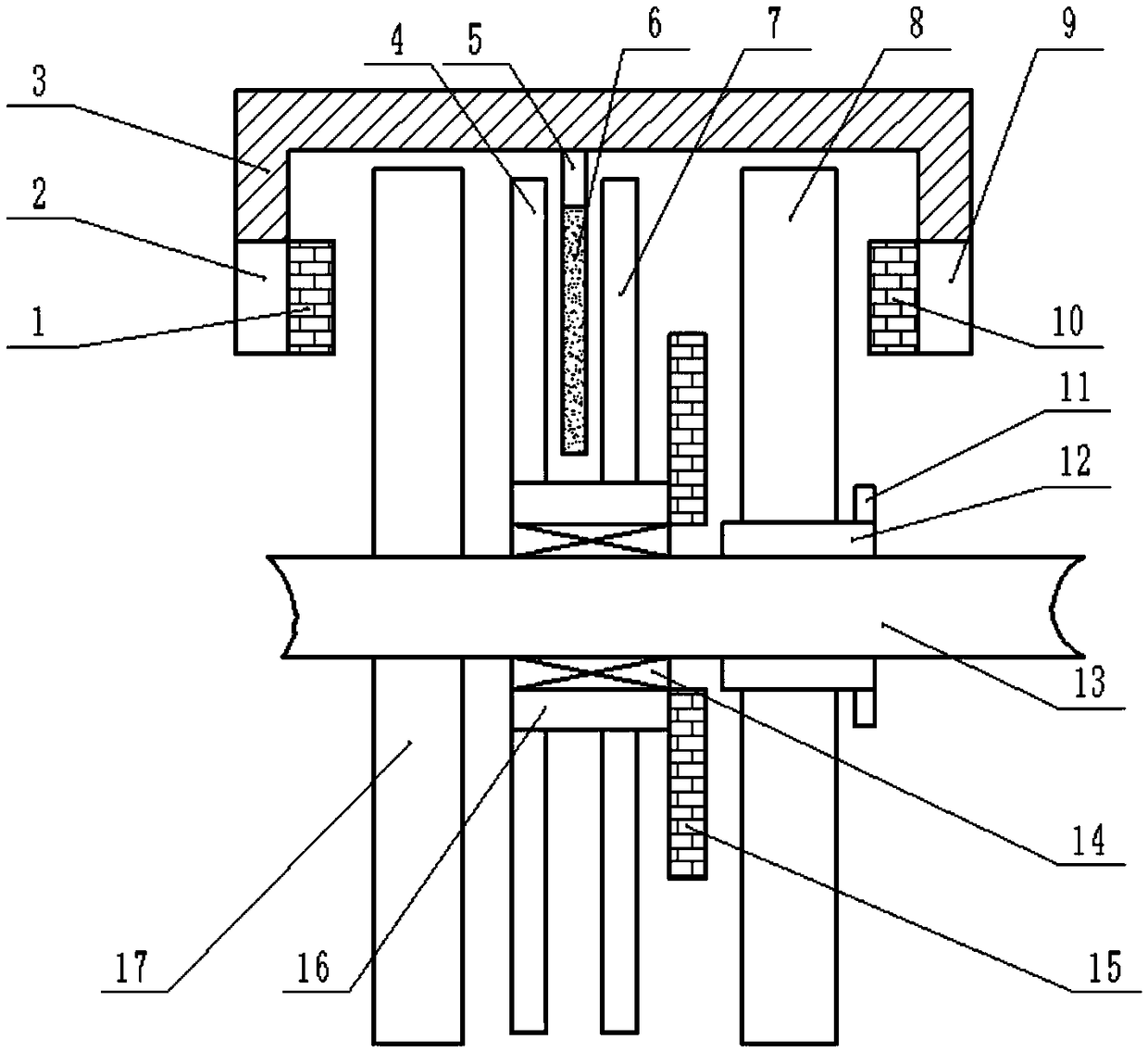

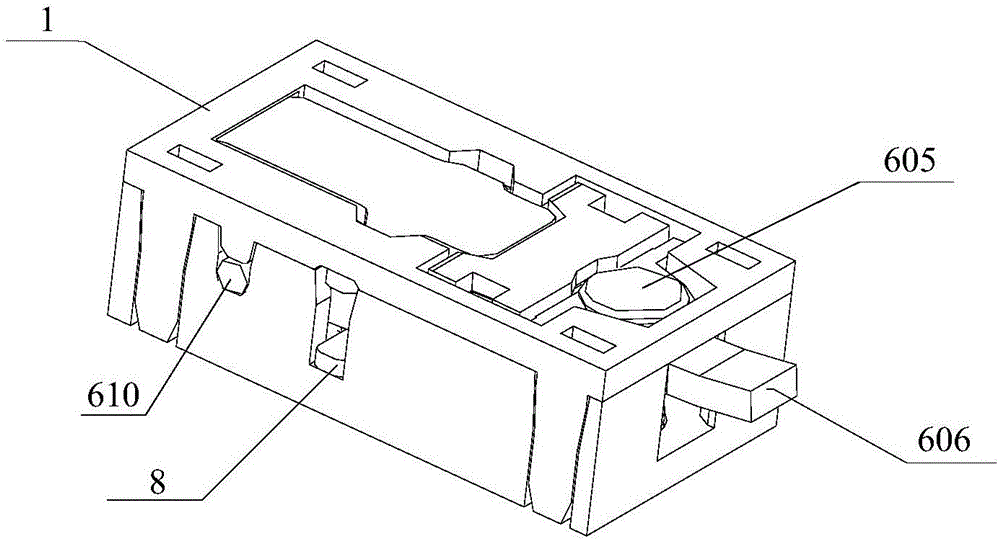

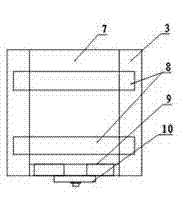

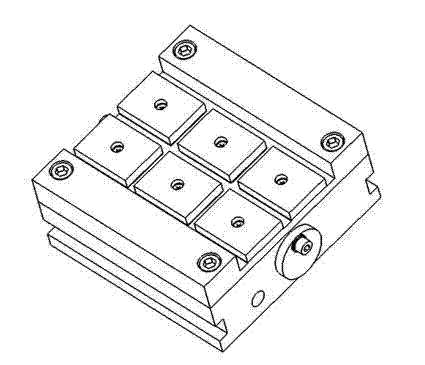

Active clamping mechanism for hole forming of non-magnetic member

InactiveCN102267057AQuick clampingRapid positioningPositioning apparatusMetal-working holdersNon magneticAirplane

The invention provides an active clamping mechanism for hole forming of a non-magnetic member and belongs to the technical field of the active clamping mechanism. The active clamping mechanism mainly comprises a base body, an H-shaped magnetic core, coils, a horizontal panel, a group cushion block, a positioning stop block and an iron pressing strip. By adopting a novel winding mode, a non-magnetic connecting member can be quickly clamped, positioned and disassembled; and by adoption of the group cushion block, the active clamping mechanism can be quickly adjusted and can protect a tool and aclamp from being damaged in the process of hole forming operation. The active clamping mechanism is simple and compact in structure and convenient to adjust and disassemble, and can meet requirementsfor accurate hole forming and high-efficiency clamping of the non-magnetic connecting member during the assembly of an airplane.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Composite permanent-magnet rotor for permanent-magnet motor and manufacturing method thereof

InactiveCN102761210BIncrease profitAvoid magnetic flux leakageMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorMagnetic poles

Owner:LINQUAN AEROSPACE MOTOR CO LTD

Strong magnetic sterilizing device

InactiveCN101496627AIncrease the magnetic field strengthUniform magnetic field distributionMilk preservationFood preservationLiquid mediumLiquid state

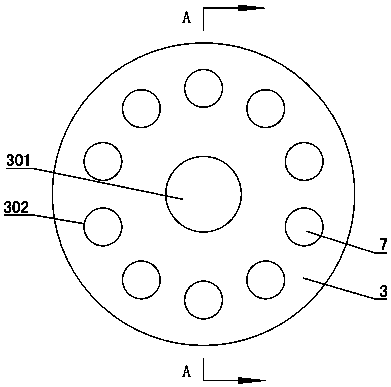

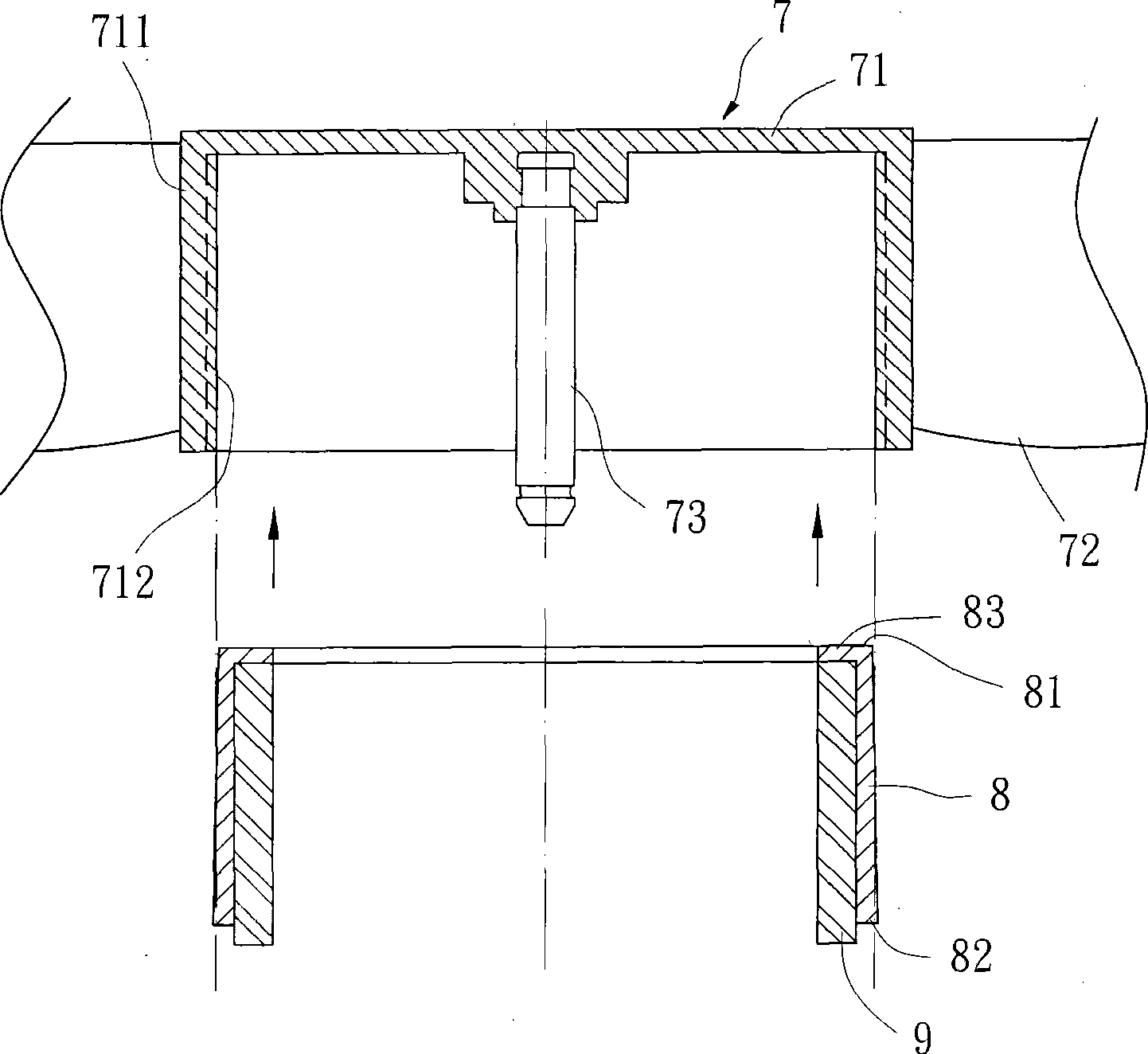

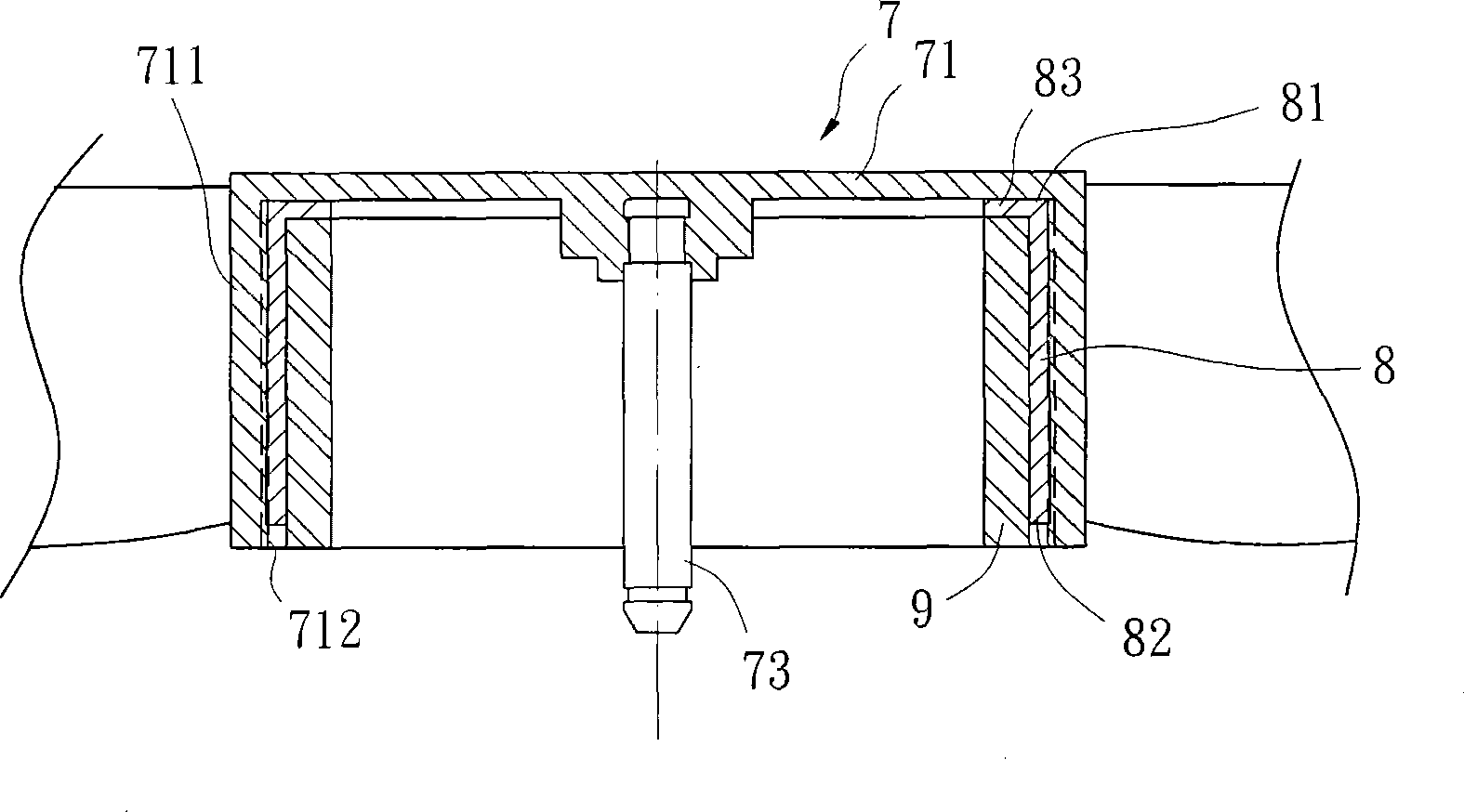

The invention discloses a high-magnetic sterilizing device. Two ends of a sterilizing cylinder are provided with connecting flanges, the outside of the sterilizing cylinder is fixedly provided with a magnetic shield cover, a positioning plate is arranged in the sterilizing cylinder, the positioning plate is distributed with positioning holes, magnetic grid tubes matched with the positioning holes are fixed on the positioning plate through the positioning holes to form multiple groups of longitudinal tandem magnetic grids, and neodymium-iron-boron magnet block sets forming high-gradient alternating magnetic circuits are placed in the magnetic grid tubes. Because the neodymium-iron-boron magnet block sets are fixed in the sterilizing cylinder through the positioning plate to form the multiple groups of the longitudinal tandem magnetic grids, the magnetic field intensity in the sterilizing cylinder is high, the magnetic field distribution is even, the sterilizing efficiency is high, and the sterilizing device achieves an internal magnetic grid type structure and cannot be influenced by caliber dimension; because the outside of the sterilizing cylinder is also provided with the magnetic shield cover, the sterilizing device can avoid the occurrence of magnetic leakage phenomena; and the sterilizing device has the characteristics of simple structure, high magnetic field intensity and good sterilizing effect, has no energy consumption or pollution, is free from maintenance, and is a novel and unique efficient liquid medium sterilizing device.

Owner:李家政

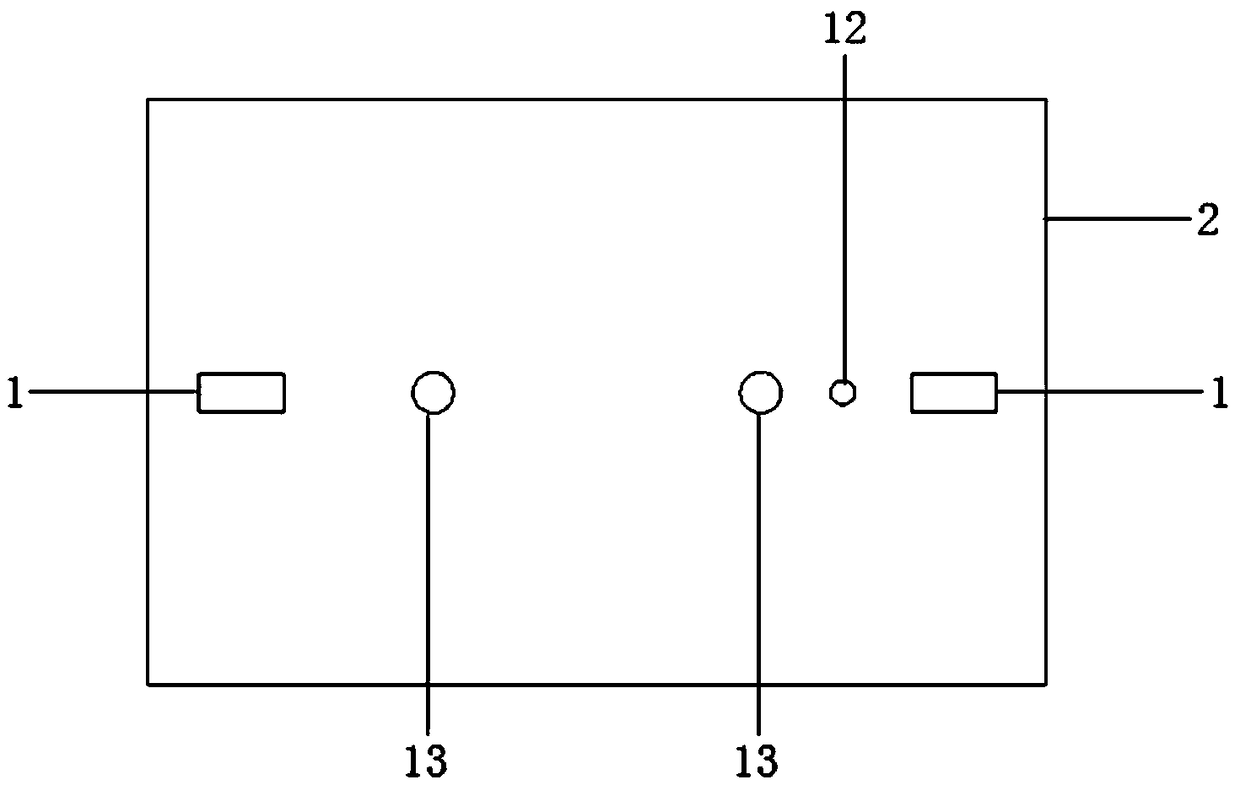

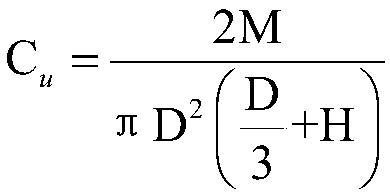

Cross plate type viscosity measuring device and measuring method for magnetorheological fluid

PendingCN109357972AHigh precisionReduce the effect of viscosityFlow propertiesMagnetic currentNumerical control

The invention relates to a cross plate type viscosity measuring device and a measuring method for magnetorheological fluid. The device comprises a magnetorheological fluid working cylinder with a cylinder cover, a cross plate head, a shaft lever, a numerical control motor, a temperature sensor, a fixed supporting plate frame, a torque tester, a rotating speed sensor and a data acquisition controlsystem; the magnetorheological fluid working cylinder is used for filling with the magnetorheological fluid to be measured, the cross plate head is connected with the numerical control motor through ashaft rod, and is completely immersed in the magnetorheological fluid to be measured, the numerical control motor is fixed on the cylinder cover through the fixed supporting plate frame, the temperature sensor is arranged on the inner wall of the inner layer of the working cylinder and connected with the data acquisition control system through wires, the torque tester and the rotation speed sensor respectively collect torque and rotating speed of the numerical control motor and send the torque and the rotating speed of the numerical control motor to the data acquisition control system. The measuring method obtains the viscosity of the magnetorheological fluid at different magnetic intensity by calculating a viscosity and shear yield strength formula. The cross plate type viscosity measuring device is simple in structure, the measuring method is convenient to operate, and measurement result is accurate.

Owner:SHENYANG JIANZHU UNIVERSITY

Electric vehicle permanent magnet synchronous driving motor

ActiveCN109391113AIncrease the magnetic field strengthIncrease output powerMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention provides an electric vehicle permanent magnet synchronous driving motor and belongs to the technical field of electric vehicles. The driving motor is an inner rotor structure and includes first permanent magnets, second permanent magnets, a nonmagnetic fixed core, a rotor core and a stator, wherein the rotor core is internally fixed to the nonmagnetic fixed core; the number of the first permanent magnets and the number of the second permanent magnets are the same and are both even numbers; the first permanent magnets and the second permanent magnets have different lengths and arein [lambda] shapes; the outer side of the rotor core has a high-strength steel hoop. Compared with the existing permanent magnet synchronous motor, the electric vehicle permanent magnet synchronous driving motor has higher magnetic field strength, larger output power, larger mechanical strength, and lower torque ripple, can utilize reluctance torque, and has better sinusoidality in the air gap flux density.

Owner:GANZHOU FORTUNE ELECTRONICS

Radial rotor structure for permanent magnet synchronous motor

ActiveCN102545434BOvercome centrifugal forceExtended service lifeMagnetic circuit rotating partsElectric machineClassical mechanics

A radial rotor structure for a permanent magnet synchronous motor comprises a rotating shaft, a rotor core, permanent magnets, rotor pole shoes, a left end-plate and a right end-plate, wherein a plurality of rotor baffles are arranged between the two end-plates; the rotor pole shoes are independent of one another and distributed at intervals together with the rotor baffles; the rotor baffles axially divide a rotor into a plurality of rotor units; two end surfaces of the rotor pole shoes in each rotor unit are respectively clung to the end surfaces of the adjacent rotor baffles; one rotor pole shoe in each rotor unit corresponds to one permanent magnet; the rotor baffles are circular ring-shaped; the rotor core and the permanent magnets penetrate the circular through holes in the rotor baffles; a plurality of supporting wing plates are uniformly distributed on the outer side surface of the rotor core and are in clearance fit with the rotor baffles; and draw-in bolts penetrate the left end-plate, the rotor pole shoes, the rotor baffles and the right end-plate and axially lock the left and the right end-plates, as well as the rotor pole shoes and the rotor baffles, which are arranged between the left and the right end-plates. The radial rotor structure for the permanent magnet synchronous motor has the advantages of high mechanical strength and suitability for motors rotating at high speed.

Owner:ZHEJIANG UNIV

Magnetic Therapy Machine

InactiveCN103656860BEasy to assembleEasy to installMagnetotherapy using variable magnetic fieldsEngineeringControl circuit

Owner:SHANDONG HEXIER MEDICAL EQUIP

Vibration Energy Harvester Based on Various Magnetic Phase Change Alloys

ActiveCN110707894BAvoid magnetic flux leakageRealize switchingDynamo-electric machinesMagnetic phaseEnergy harvester

Owner:NANJING UNIV OF SCI & TECH

Magnetic resistance type driving belt conveyor and driving control method

InactiveCN111498395ASolve slippageSolve the problem of transmission failure such as difficulty in startingConveyorsControl devices for conveyorsMagnetic reluctanceEngineering

The invention discloses a magnetic resistance type driving belt conveyor. The magnetic resistance type driving belt conveyor comprises a driving device, a conveying belt (7) and rollers (11), whereinthe conveying belt (7) is wound between the rollers (11) at two ends, the conveying belt (7) is provided with at least one set of iron cores, and the set of iron cores are distributed at intervals ina warp direction of the conveying belt (7); the driving device comprises a power supply part and a stator which are connected with each other, the stator comprises coil windings (5), the conveying belt (7) is sleeved with the coil windings (5), and the coil windings (5) are uniformly arranged in the warp direction of the conveying belt (7), and the power supply part is used for providing current for the coil windings (5); and the iron cores can drive the conveying belt (7) under the action of the coil winding (5). The invention further provides a driving control method of the magnetic resistance type driving belt conveyor. The iron cores are stressed to drive the conveying belt (7) by controlling the magnitude of current in the coil windings (5), and the problems that in the prior art, theconveying belt slides in a transmission mode, starting is difficult, and the number of power transmission components is large are solved.

Owner:福建龙净环保智能输送工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com