Cross plate type viscosity measuring device and measuring method for magnetorheological fluid

A liquid viscosity, measuring device technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of complex structure of the testing device, inconvenient operation, measurement error of magnetic flux leakage, etc., achieve simple structure, convenient operation, and prevent magnetic flux leakage The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

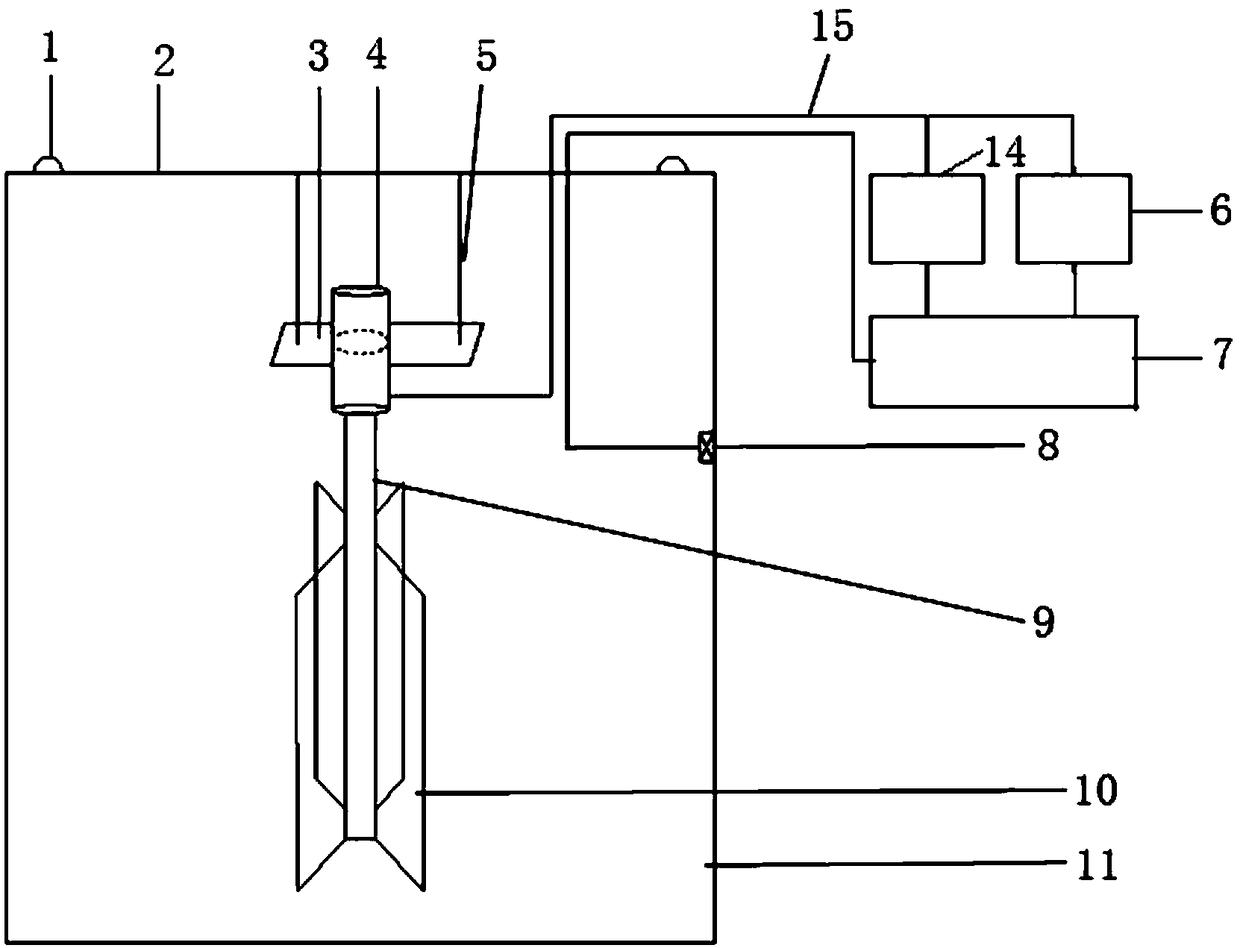

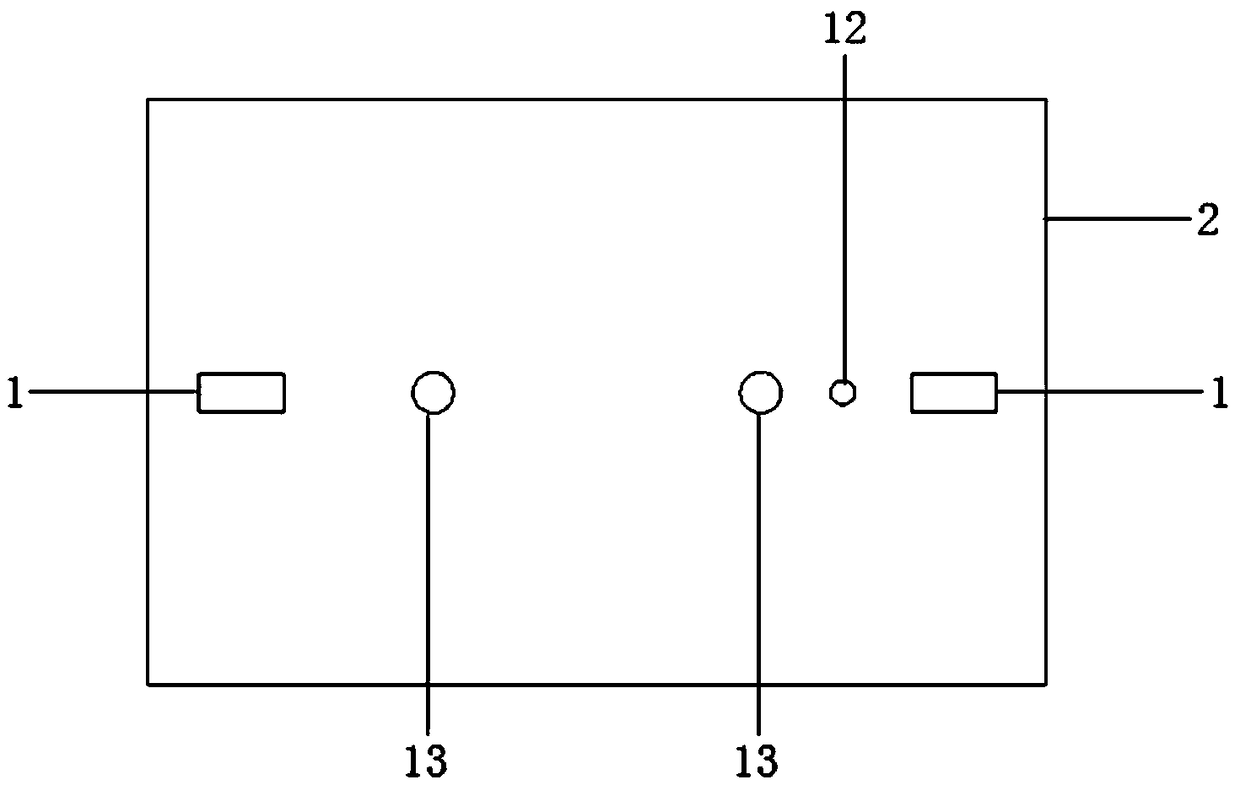

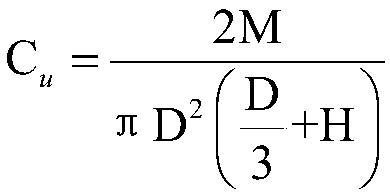

[0025] Such as figure 1 As shown, a cross-plate type magnetorheological fluid viscosity measuring device of the present invention includes: a magnetorheological fluid working cylinder 11 with a cylinder head 2, a cross plate head 10, a shaft rod 9, a numerically controlled motor 4, and a temperature sensor 8 , fixed support frame 3, torque tester 14, rotational speed sensor 6 and data acquisition control system 7. The magnetorheological fluid working cylinder 11 is used to contain the magnetorheological fluid to be tested. The cross plate head 10 is connected with the numerical control motor 4 through the shaft 9 , and the numerical control motor 4 is fixed on the cylinder head 2 through the fixed support plate 3 . The amount of magnetorheological liquid in the cylinder needs to exceed the level of the upper end of the cross plate head 10 to ensure that the cross plate head 10 is completely submerged in the magnetorheological liquid to be tested. The temperature sensor 8 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com