Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Avoid insufficient combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air volume self-adaptive gas water heater control system

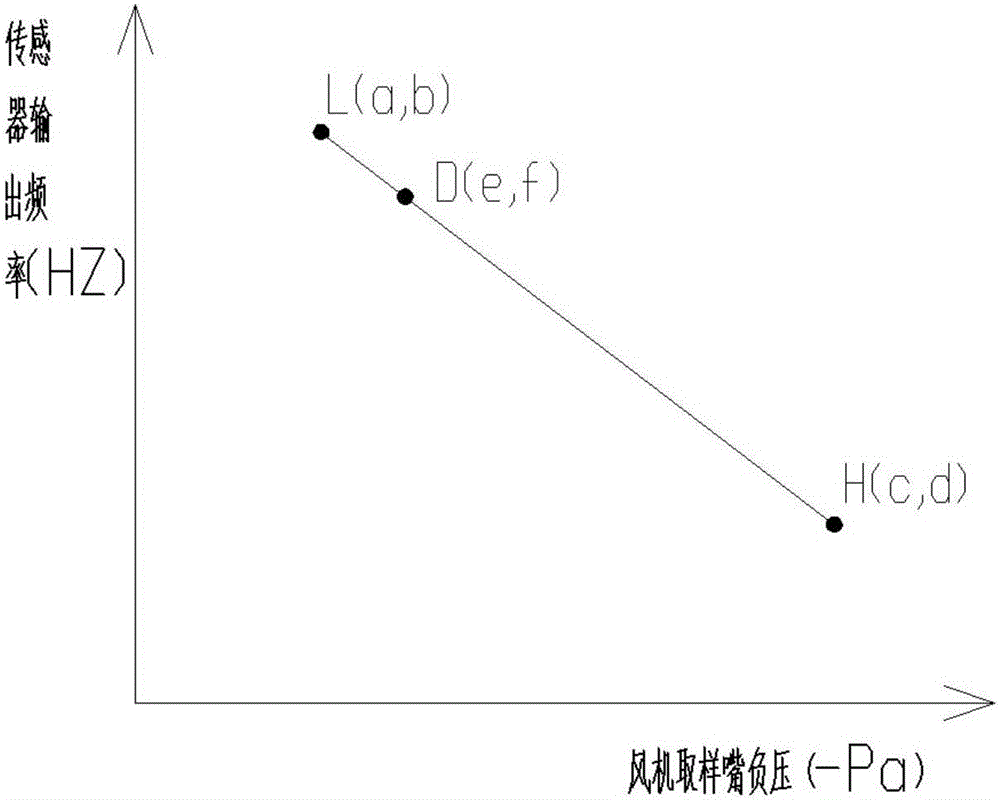

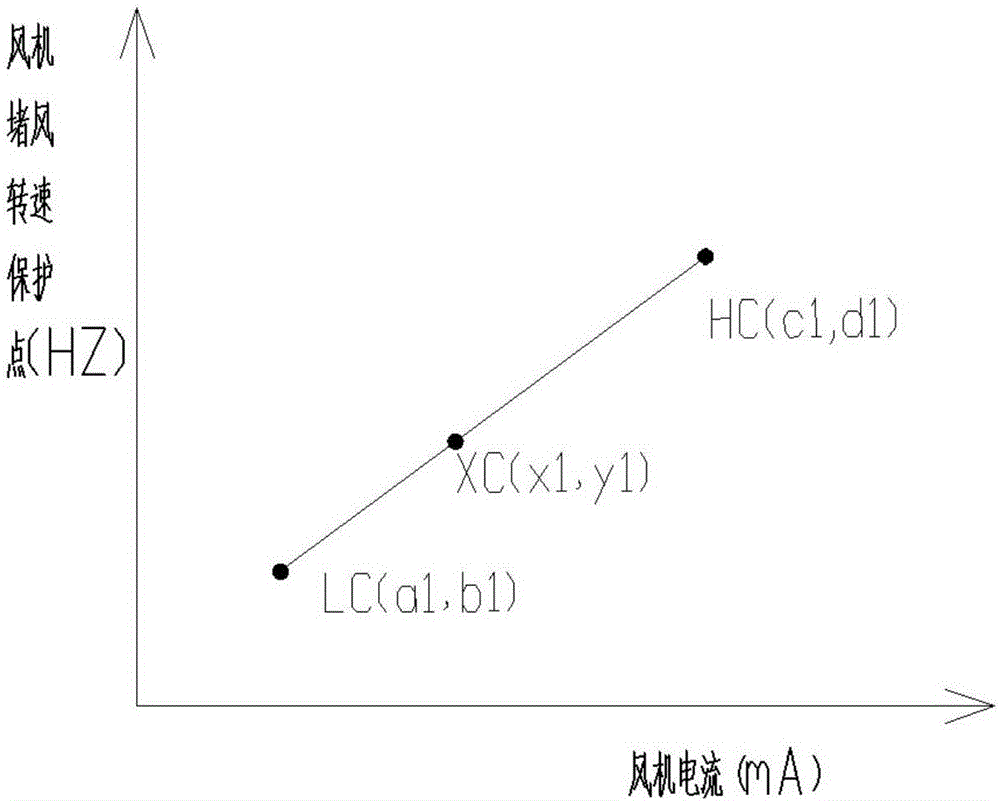

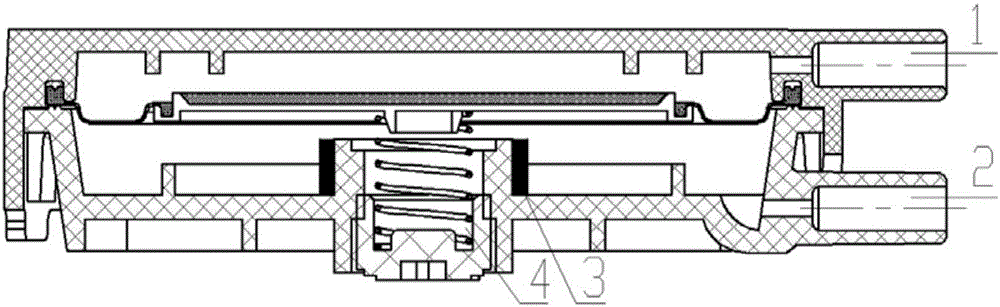

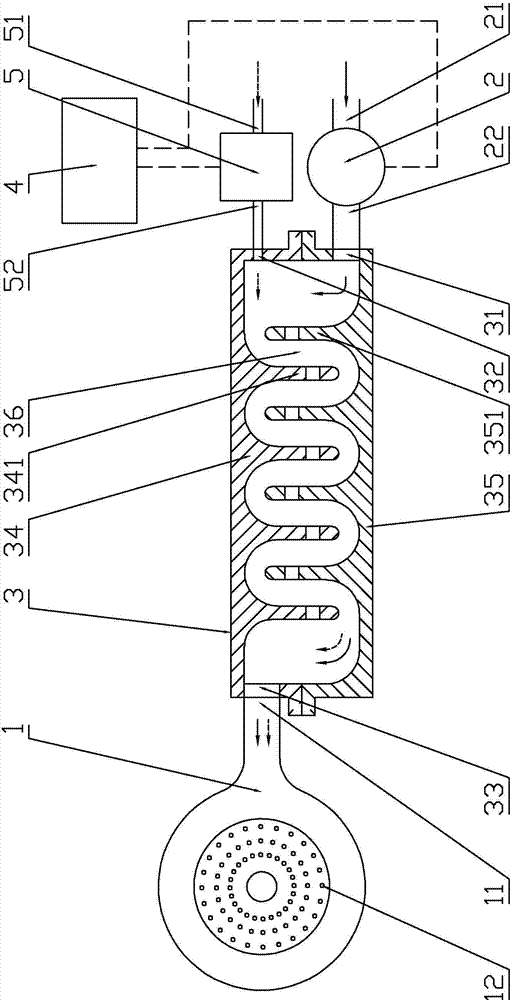

The invention discloses an air volume self-adaptive gas water heater control system which is characterized by comprising a main controller and an air pressure sensor connected with the main controller. By means of the main controller, all thermal loads of a gas water heater can correspond to output frequency of the air pressure sensor in a one-to-one mode; when the gas water heater is in a certain thermal load state, the main controller can change fan current to enable the output frequency of the air pressure sensor to be kept at a corresponding value all the time. According to the air volume self-adaptive gas water heater control system disclosed by the invention, a rotation speed of a fan is controlled according to frequency signals, the burning insufficiency phenomenon caused by factors of smoke exhaust block, altitude difference and the like is completely avoided, and adaptation, safety and high efficientibility of the gas water heater are wholly improved; when a low-cost motor is replaced in later, whether property and technical parameters of a replaced motor are completely identical with those of the low-cost motor need not be taken into consideration, and great convenience is brought to engineering design and after sale.

Owner:GUANGDONG MACRO GAS APPLIANCE

Household gas stove

ActiveCN103292325AWell mixedHomomixerDomestic stoves or rangesGaseous fuel burnerProcess engineeringGas cooking stove

A household gas stove comprises a combustor and a fan, wherein a gas inlet and a gas outlet are formed in the combustor, and an air inlet and an air outlet are formed on the fan. The household gas stove is mainly characterized by further comprising a mixer, a controller and a gas proportional valve, wherein a gas inlet and a gas outlet are formed in the gas proportional valve, a mixed gas outlet in the mixer is communicated with the gas inlet on the combustor, the gas outlet in the gas proportional valve and the air outlet in the fan are communicated with the mixer, the gas proportional valve, the fan and the controller are electrically connected, and the gas proportional valve and the fan enable proportion of gas and air in the mixed gas to be in a proportion for thorough burning under control of the controller. The household gas stove has the advantages of enabling the gas and the air to be mixed evenly and further enabling the gas to be fully burnt.

Owner:GUANGDONG VANWARD ELECTRIC

All-in-one ceramic heating member and preparation technology thereof

ActiveCN104860683AAvoid insufficient combustionTo achieve the purpose of heating airManufacturing technologyRaw material

The invention relates to the technical field of ceramic heating member preparation technologies and especially relates to an all-in-one ceramic heating member and a preparation technology thereof. The all-in-one ceramic heating member comprises 50-95% of a ceramic raw material and 5-50% of a heating raw material. The ceramic raw material comprises 50-95% of Si3N4, 0.1-10% of MgO, 0.1-5% of Y2O3, 0.1-5% of Al2O3, 0.1-5% of SiO2, 0.1-5% of La2O3 and 0.1-5% of BN. The heating raw material comprises one or two of MoSi2 and TiC. The preparation technology comprises material blending, ball milling, drainage, molding, pre-sintering, sintering, polishing processing and electrode connection. The preparation technology has simple processes, is conducive to continuous production, has high production efficiency and a low production cost, and is conducive to large-scale production. The ceramic heating member has a long service life, stable power and high heating efficiency.

Owner:广东国研新材料有限公司

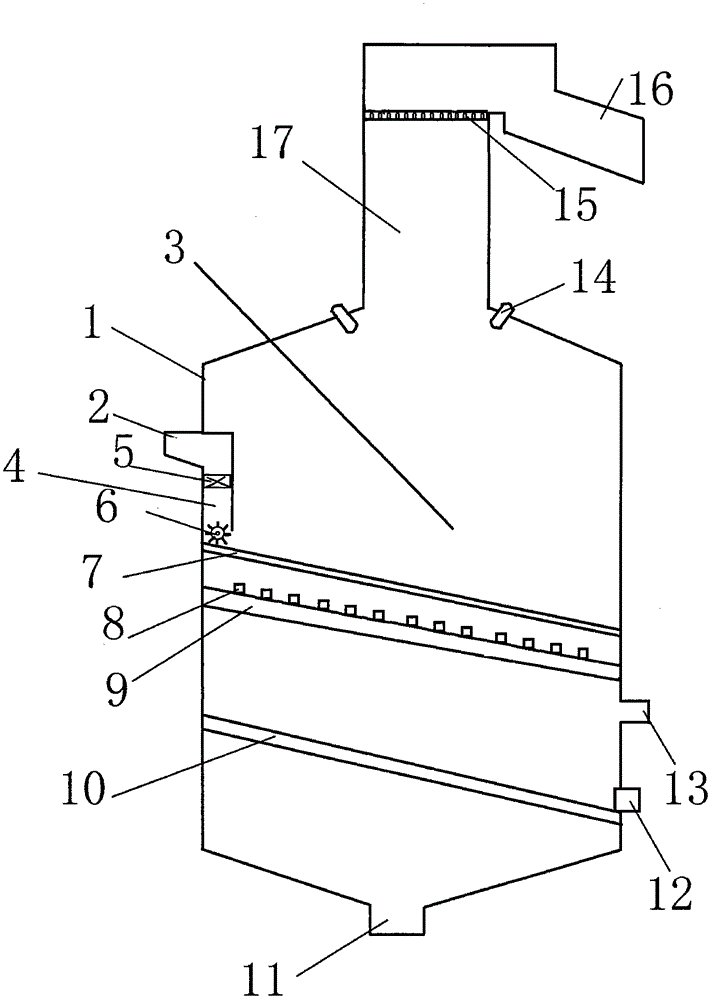

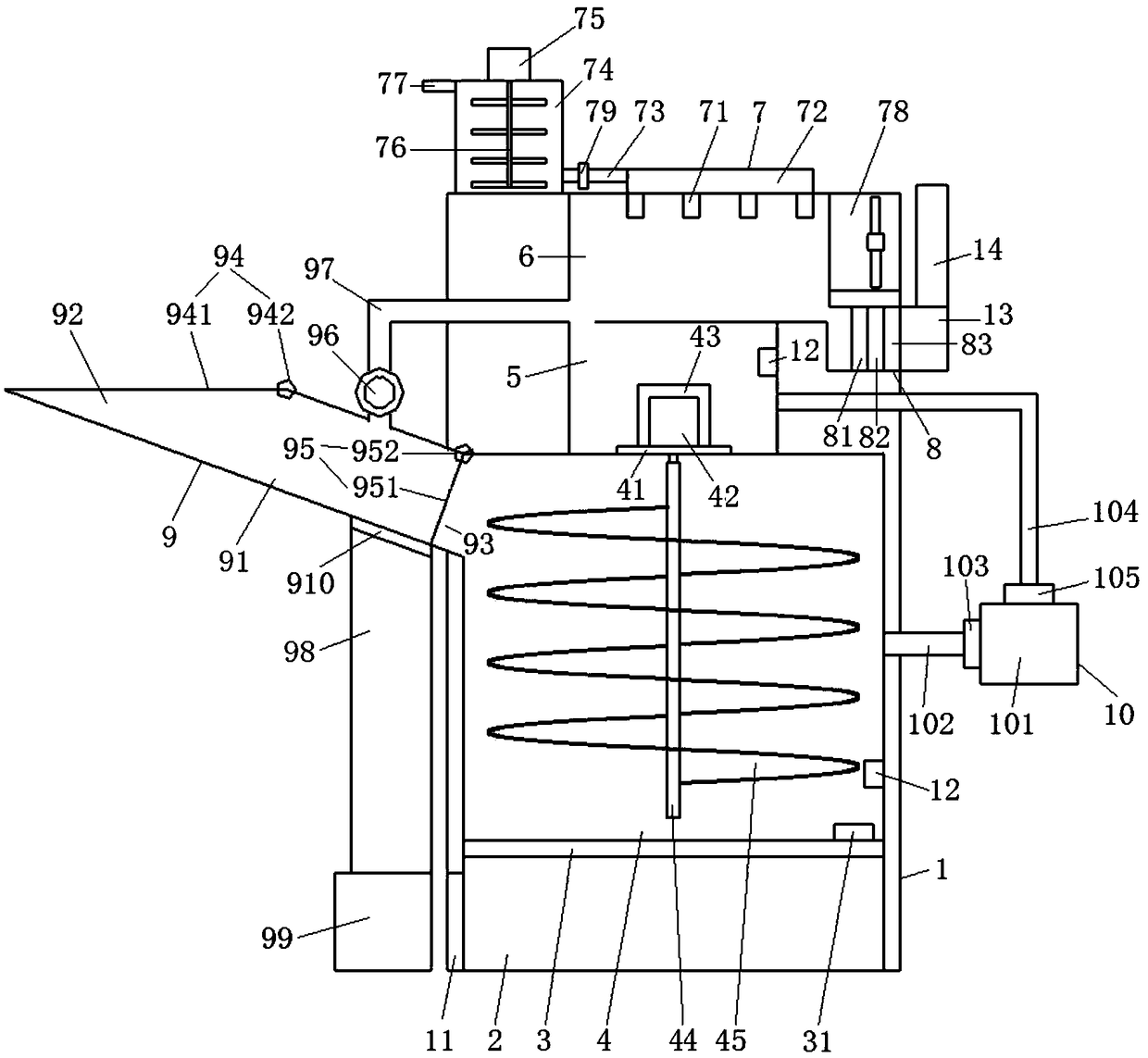

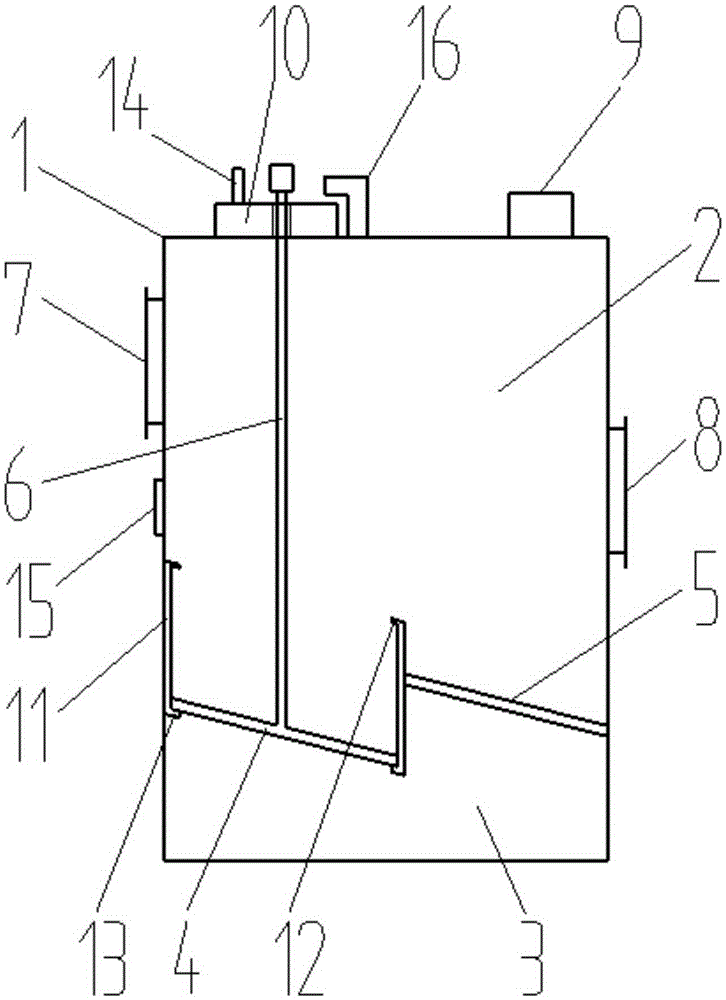

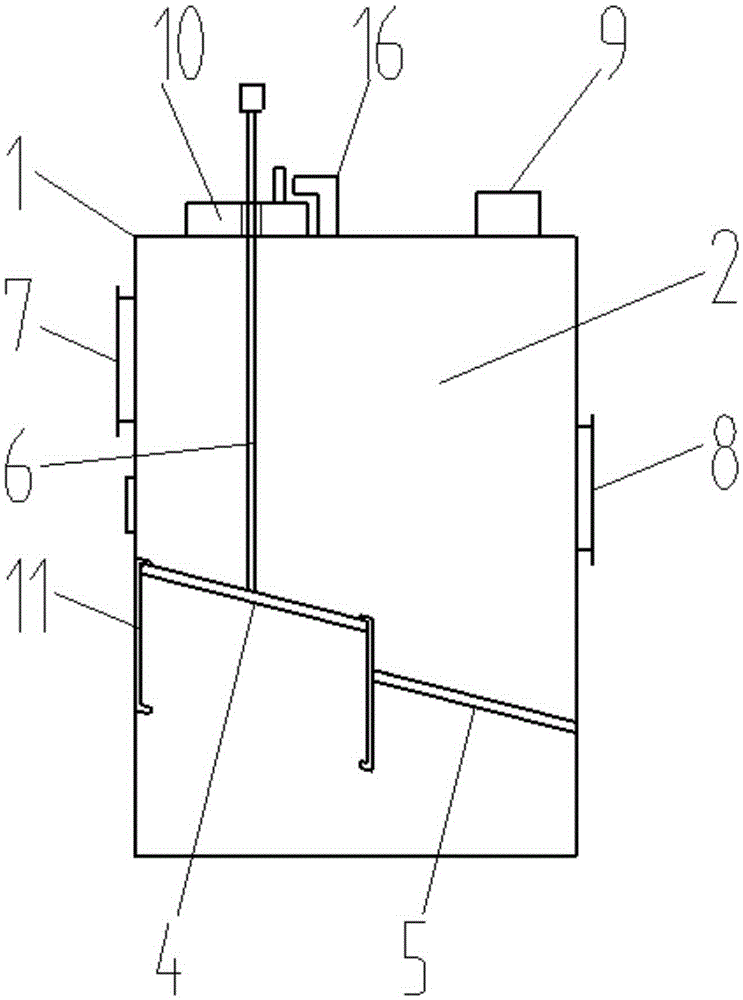

Wind power blade waste pyrolysis incinerator and control method thereof

The invention discloses a wind power blade waste pyrolysis incinerator and a control method thereof. The wind power blade waste pyrolysis incinerator comprises an incinerator body; a cooling pipe is arranged at the exterior of the incinerator body; an opening is formed in the top of the incinerator body; a smoke vent communicating with the outside is formed in the upper end of the incinerator body; an ash discharge chute furnace is arranged at the bottom of the incinerator body; a working cavity is formed in the incinerator body; an electric control feed door, a spiral agitator, a gas supply and distributing device and an isolation hood are arranged in the incinerator body; the electric control feed door and the spiral agitator are driven by motors correspondingly; the electric control feed door is arranged between a drying zone and a pyrolysis zone; a plurality of through holes are formed in the electric control feed door; the spiral agitator is located in the pyrolysis zone and the combustion zone; the gas supply and distributing device is arranged at the bottom of a combustion zone, is connected with a spiral bearing and can rotate in the incinerator body; and the isolation hoodis arranged on the inner side of the gas supply device and is used for isolating the gas supply device and a wind power blade material. Wind power blade waste can be pyrolyzed and burnt fully, and pollution is reduced.

Owner:上海博士高环保成套工程有限公司

Efficient garbage combustion furnace

InactiveCN104930519AAvoid direct influxAvoid direct influx situationsIncinerator apparatusCombustion chamberSlag

The invention discloses an efficient garbage combustion furnace. The efficient garbage combustion furnace comprises a furnace body, a garbage feeding port, a conveying pipe, a combustion net, a fire grate, a vibration screen mesh, an ash discharging port, a slag discharging port, a blower nozzle, secondary air supply nozzles and an exhaust chimney. The garbage feeding port is formed in one side of the furnace body, a primary combustion chamber is arranged above the combustion net, the fire grate is arranged below the combustion net in parallel with the combustion net, a plurality of combustion nozzles are arranged on the fire grate, the blower nozzle is formed below the fire grate, the ash discharging port is formed in the bottom end of the furnace body, the vibration screen mesh is obliquely formed above the ash discharging port, the slag discharging port is formed in the lowermost portion of the vibration screen mesh, the secondary combustion chamber is arranged above the primary combustion chamber, the secondary air supply nozzles are arranged on the two sides of the bottom of the secondary combustion chamber, and a filter screen is arranged on the top of the secondary combustion chamber which is communicated with the exhaust chimney. The efficient garbage combustion furnace is high in work efficiency, combustion is thorough, harmful gas and particles entering atmosphere are reduced, environmental pollution is avoided, ash collected by the ash discharging port can serve as fertilizer, and cyclic utilization of resources is achieved.

Owner:施婷婷

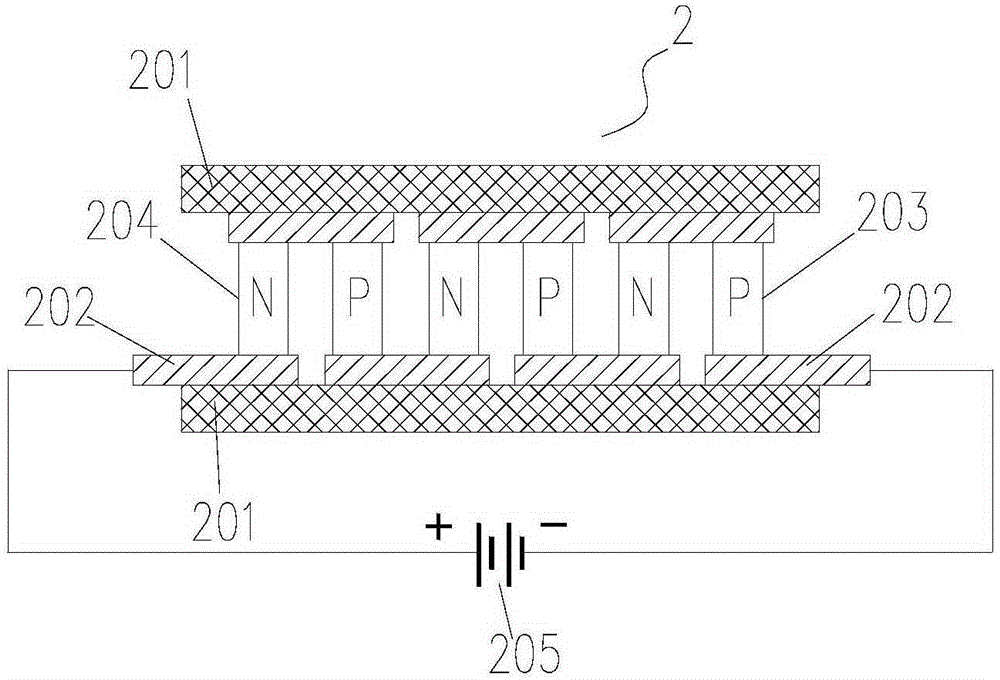

Vehicle and intake air temperature management controller, system and method

ActiveCN106704015AImprove reliabilityExtended service lifeElectrical controlInternal combustion piston enginesState of artCombustion

The invention discloses a vehicle and intake air temperature management controller, system and method. According to the method, whether intake air of a vehicle is heated or cooled is judged according to the intake air temperature of an engine in combination with the intake air temperature of an intercooler. According to the vehicle and intake air temperature management controller, system and method, the Peltier effect is innovatively used, in cooperation with a temperature management device, the electronics principle is used, and the controllable temperature management system is provided; the intake air temperature is controlled through the intelligent logic, and the intake air system performance is improved greatly; the problems of insufficient combustion, carbon deposition of the engine, increase of the fuel consumption and the like caused by the too high or too low intake air temperature are solved, the operating reliability of the engine is improved, and the service life of the engine is prolonged; meanwhile, the vehicle maintenance cost brought by the similar problems is lowered; and the problems, needed to be solved in the prior art, of vehicles, especially the truck industry are solved.

Owner:BEIQI FOTON MOTOR CO LTD

Methanol fuel gasification stove

InactiveCN104121608AAvoid insufficient combustionImprove burnout rateDomestic stoves or rangesLiquid heating fuelProcess engineeringDirect heating

The invention discloses a methanol fuel gasification stove which comprises an ignition device, a heating device, a gas distributing chamber, a gas producing chamber, a fuel tube, a pressurizing tube, a gas feeding pipe and a methanol storage device. Because the heating device is arranged in the gas distributing chamber, a liquid methanol fuel in the gas producing chamber is directly heated into a gas state by the heating device, the liquid methanol fuel is pre-heated so that the problem of insufficient combustion caused by direct heating of liquid methanol is prevented, and the burn-off rate is increased. Because the gaseous methanol fuel is supplied to the gas distributing chamber through the gas feeding pipe, the methanol fuel can directly enter the gas distributing chamber after being gasified, and the use of an air blower or a pressure container is reduced to a certain extent. Because the gas producing chamber is further connected with the pressurizing pipe, and the gaseous methanol fuel is conveyed to the methanol storage device through the pressurizing pipe to gradually fill a space occupied by the outflowing liquid methanol fuel and then extrude remained liquid methanol fuel to continuously flow into the fuel tube, so that the self circulation of combustion is further realized.

Owner:深圳华琰科技有限公司

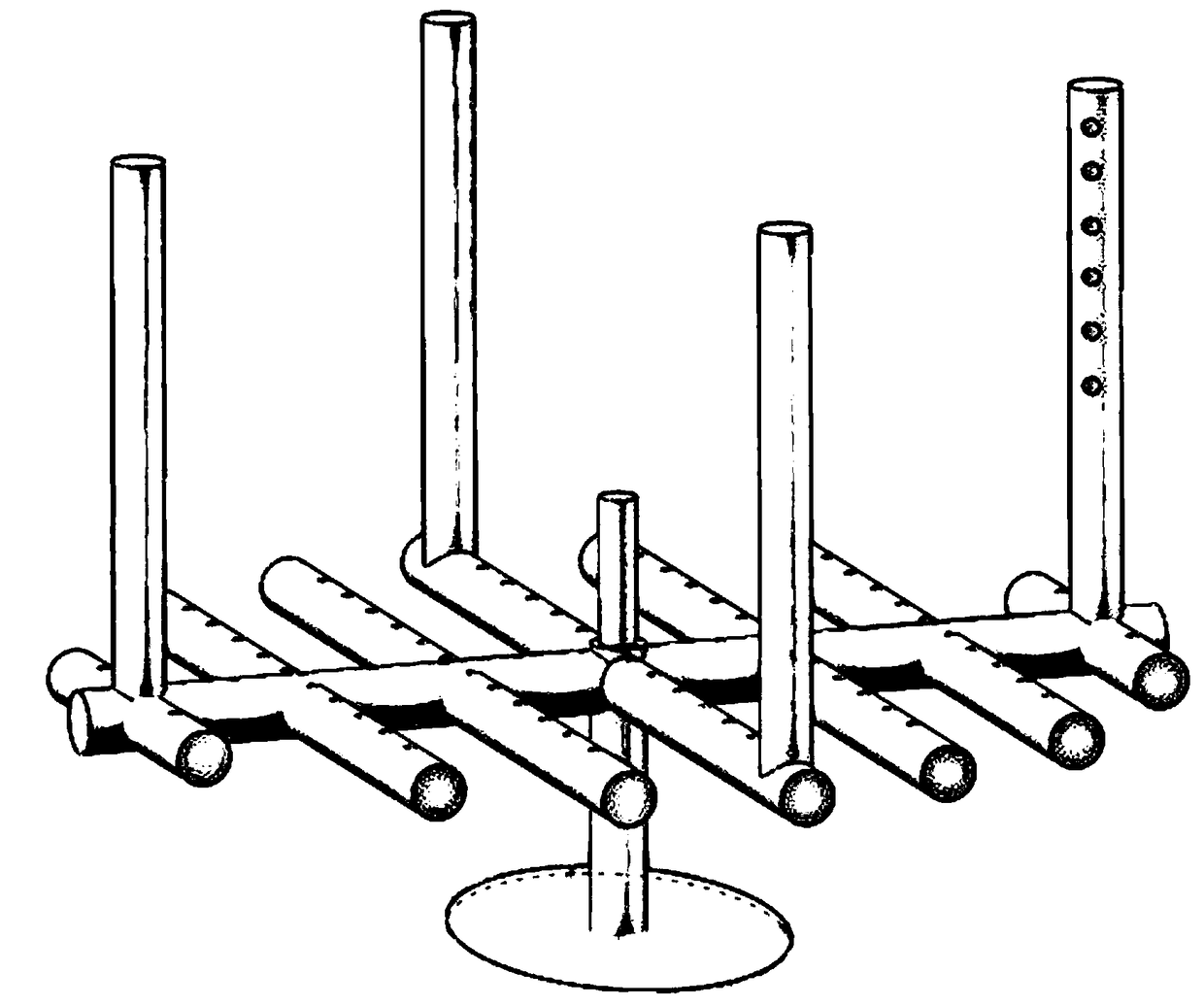

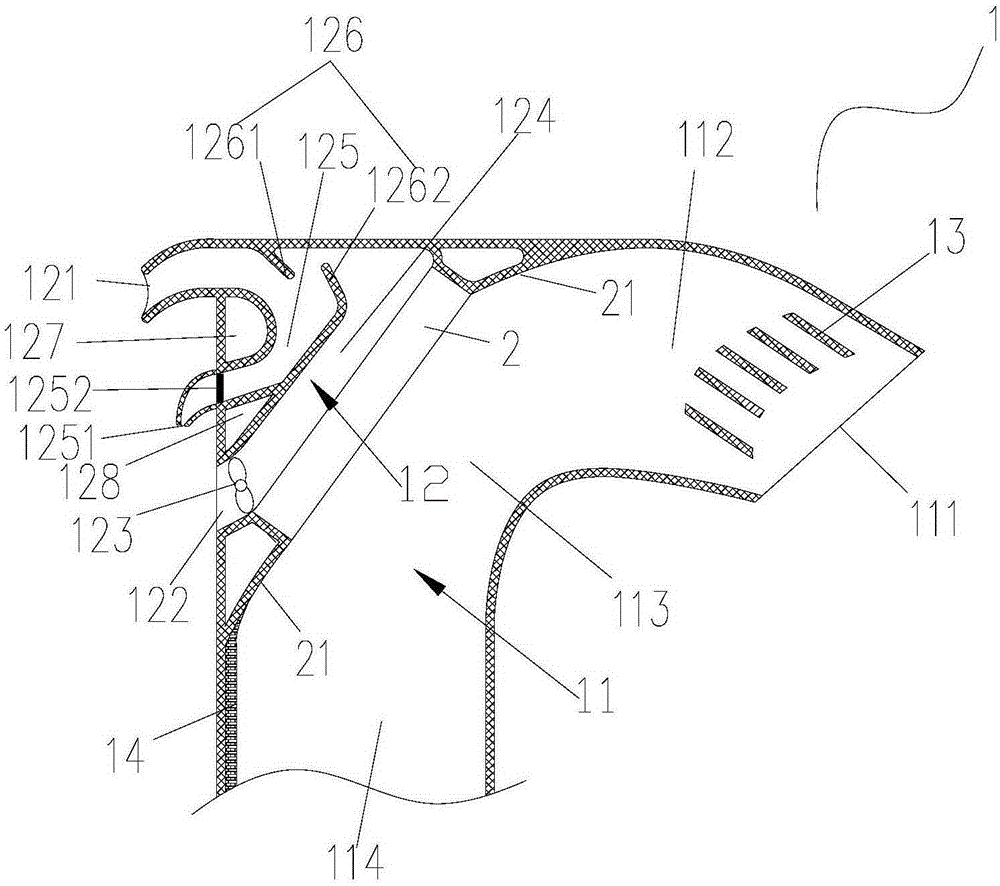

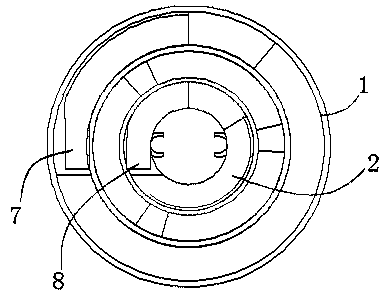

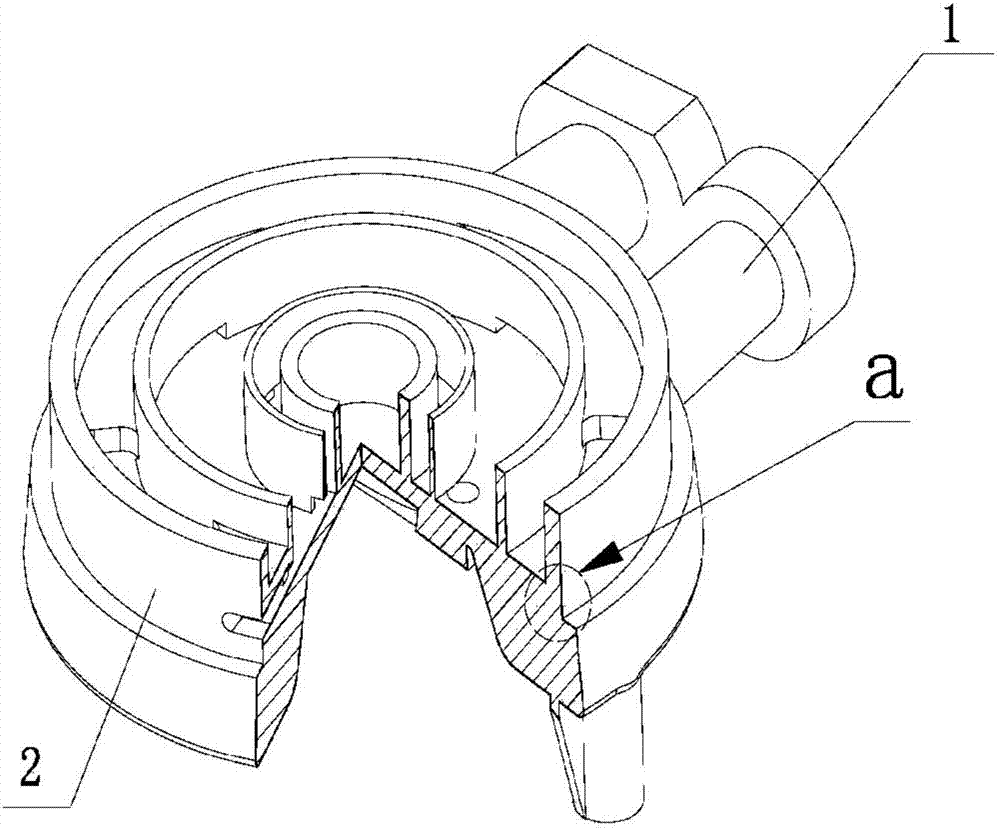

Combustor of gas stove

ActiveCN109737404AEvenly distributedAvoid insufficient combustionDomestic stoves or rangesGaseous fuel burnerAirflowEngineering

The invention discloses a combustor of a gas stove, and relates to the technical field of combustors. The combustor comprises an outer ring, a positioning column, an outer ring air inlet injection pipe mechanism and a center air inlet injection pipe mechanism; an inner ring is arranged on the inner side of the outer ring, the inner ring is connected with the outer ring through a linking block, andthe outer ring air inlet injection pipe mechanism is arranged at the bottom of the outer ring. The combustor has the beneficial effects that according to the combustor of the gas stove, through a center mixing cavity and an outer ring mixing cavity, inner arcs of the center mixing cavity and the outer ring mixing cavity are distributed from deep to shallow, through the center mixing cavity and the outer ring mixing cavity, it is ensured that the air flow can be stable during mixing and free of buffer, combustion flames are evenly distributed, the two mixing cavities are formed in the bottom of the outer ring, when the device carries out combustion work, complete upper air inlet combustion is achieved, comprehensive oxygen supplementing is achieved, and the phenomenon that due to long-timecombustion of the combustor, due to insufficient oxygen supplementing, combustion insufficiency of red fire, yellow flames, black smoke and the like is caused is avoided.

Owner:佛山市宇煜五金有限公司

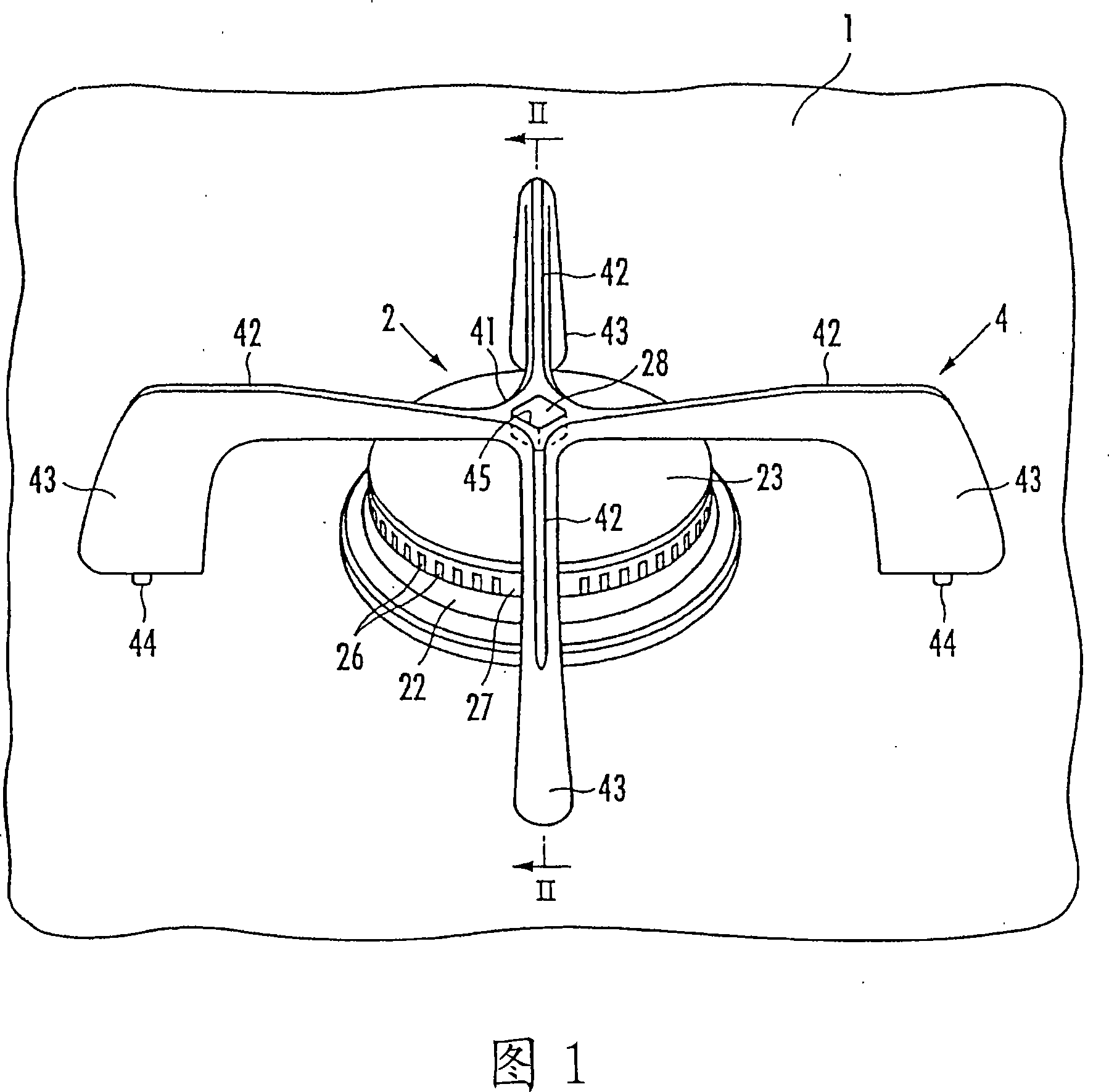

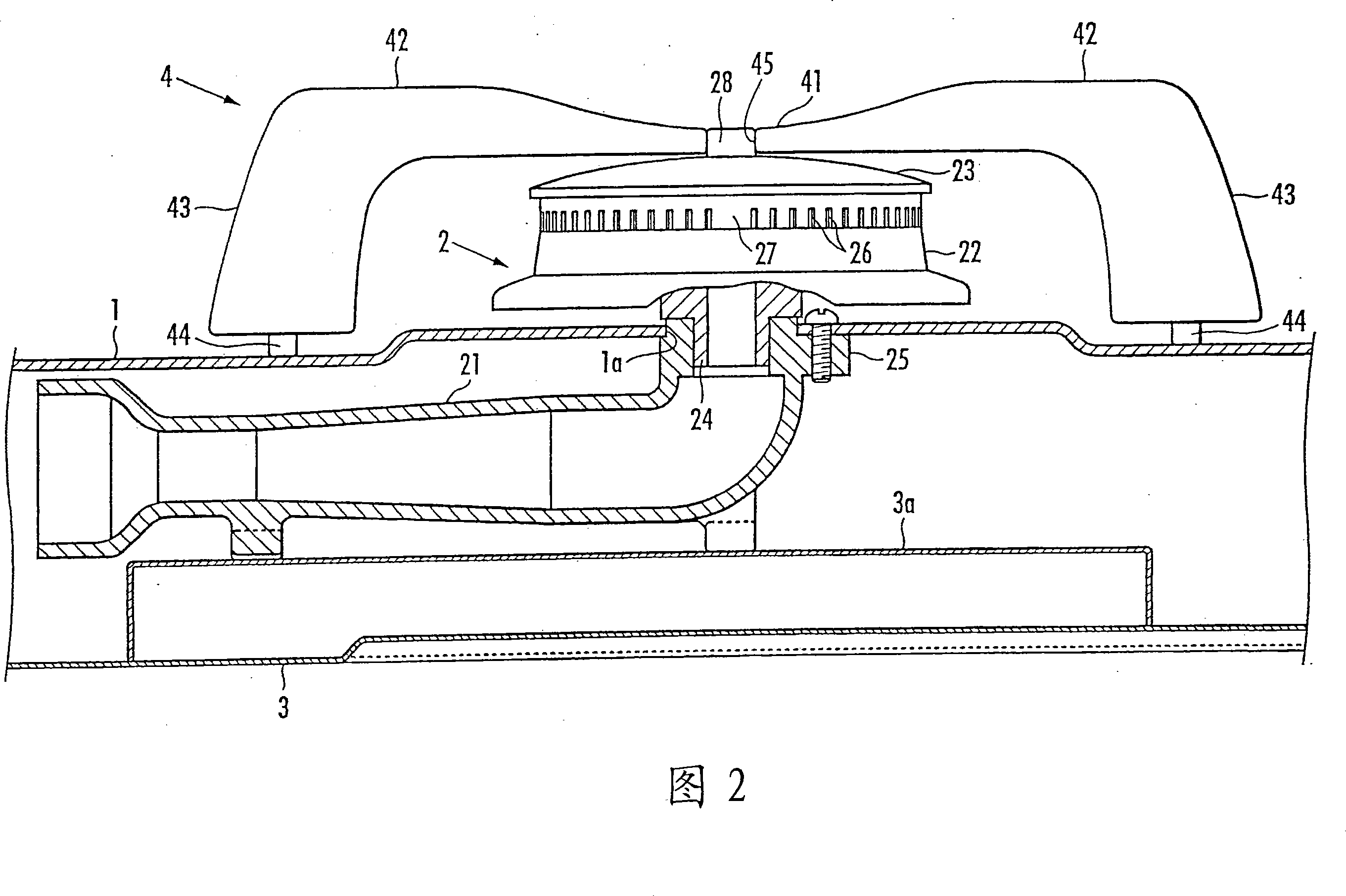

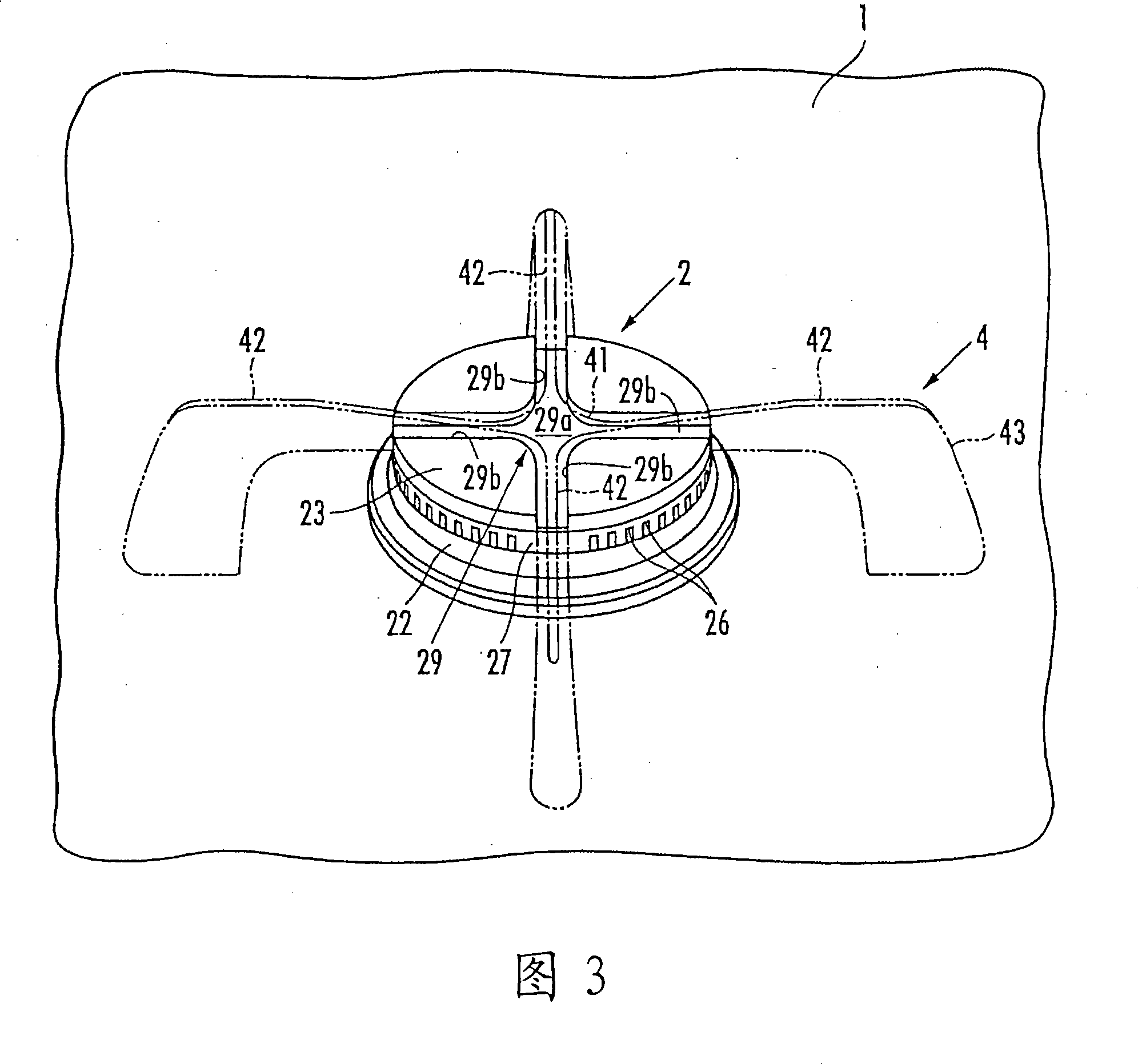

Combustion gas kitchen range

InactiveCN101187478AAvoid insufficient combustionDomestic stoves or rangesLighting and heating apparatusCombustorEngineering

The invention provides a fuel gas stove which is provided with a burner (2) extruded to the top of a faceplate (1) and a bracket (4) arranged at the faceplate, directly confirming the position of the bracket corresponding to the burner. The bracket (4) is provided with a central connecting part (41) at the top of the burner and a plurality of bracket claws (42) extending to the radial outside of the central connecting part. The central connecting part of the bracket (4) forms a positioning hole (45) penetrating up and down and the top of the burner is provided with a heave (28) embedded in the positioning hole. The cross section shape of the embossment and the positioning hole is that the embossment (28) can be embedded in the positioning hole (45) only when the bracket (4) is located at the standard phase position of the same position of a fireless hole (27) of the bracket claw (42) and the burner (2).

Owner:RINNAI CORP

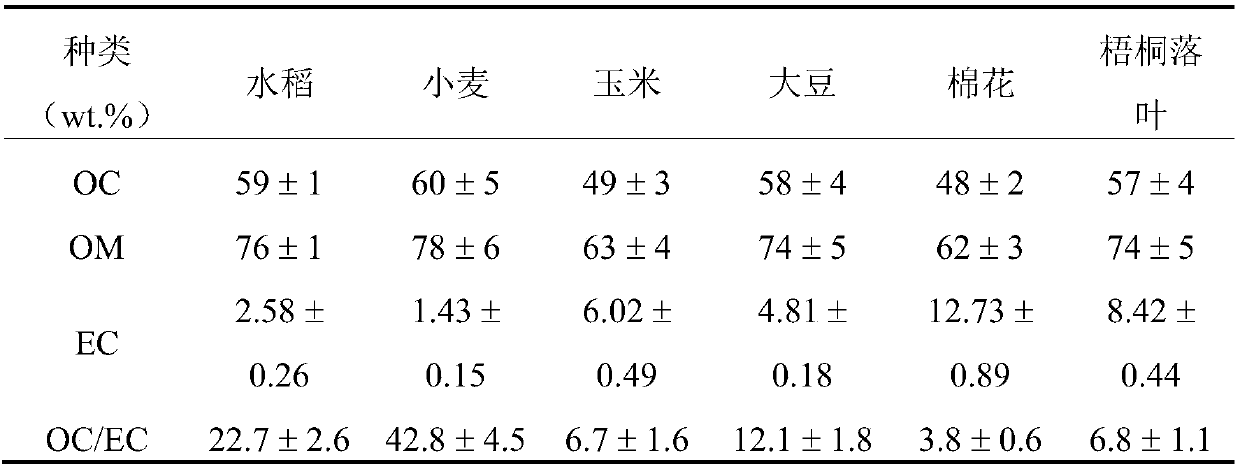

Granular biomass fuel and preparation method thereof

The invention discloses a granular biomass fuel which comprises a biomass raw material and an additive, wherein the additive is calcium carbonate, magnesium carbonate or a mixture of calcium carbonate and magnesium carbonate; and the weight of the additive is 0.1%-1.8% of that of the biomass raw material. According to the granular biomass fuel disclosed by the invention, acidic volatile gas can be prevented from volatilizing into atmosphere; the problems of environmental pollution caused by the acidic volatile gas and insufficient combustion of the granular biomass fuel are solved; and the combustion efficiency of the granular biomass fuel is improved.

Owner:海聚高分子材料科技(广州)有限公司 +2

Efficient and environment-friendly garbage incinerator

InactiveCN109357264ASpray evenlyAvoid pollutionEmission preventionIncinerator apparatusCombustion chamberSulfur

The invention discloses an efficient and environment-friendly garbage incinerator. The garbage incinerator comprises a furnace body and a controller, wherein a waste chamber, a furnace grate, a hearth, a secondary combustion chamber and a flue gas treatment chamber are sequentially arranged in the furnace body from bottom to top; the furnace grate is fixedly connected to the inner wall of the furnace body, an ignition assembly is arranged on the furnace grate, and a flue gas treatment assembly is arranged above the flue gas treatment chamber; a filter assembly is arranged on one side of the flue gas treatment chamber, one end of the filter assembly penetrates through the outside of the furnace body and is in communication with a first fan, and the first fan is connected to a smoke discharge pipe; a feeding device is arranged on one side of the furnace body, the feeding device penetrates through the furnace body to the interior of the hearth, and one side, away from the feeding device,of the furnace body is further provided with an air inlet assembly; and the air inlet assembly is correspondingly in communication with the interior of the hearth and the interior of the secondary combustion chamber, and a discharging port is formed in the position, corresponding to the waste chamber, of the furnace body; and a discharging door is arranged on the discharging port, the dischargingdoor is hinged to the furnace body, and the feeding device and the air inlet assembly are electrically connected to the controller. According to the garbage incinerator, the sulfur removal effect is effectively improved, and the generation amount of toxic and harmful smoke can be reduced.

Owner:ANHI SHENGYUN HEAVY MACHINERY CO LTD

Device for preventing locking by mistake for financial service equipment

ActiveCN109611865ASolve the problem of clumpingGuaranteed loosenessIncinerator apparatusElectrical and Electronics engineering

The invention discloses a device for preventing locking by mistake for financial service equipment. The device comprises a handle, a safe box lock tongue, a lock stopping door strip, a spring piece, acoded lock and a pickproof door strip, wherein the spring piece is installed under the safe box lock tongue; the pickproof door strip is welded to a corresponding position in a safe box; the handle,the safe box lock tongue, the lock stopping door strip, the spring piece and the coded lock are all installed on a box door of the safe box; the lock stopping door strip is installed under the safe box lock tongue and is connected with the spring piece; the safe box lock tongue is installed on the inner side of the box door of the safe box and has a preset distance from the inner side of the box door; and the upper end and the lower end of the safe box lock tongue are slidably connected with an upper limiting block and a lower limiting block which are installed on the box door. According to the device for preventing locking by mistake for the financial service equipment, the left moving position and the right moving position of the safe box lock tongue can be restricted automatically through the action of a combination of the lock stopping door strip and the spring piece and the pickproof door strip, and a function of preventing locking by mistake is realized.

Owner:甸石(上海)环保科技有限公司

Method for preventing coking of circular fluidization bed boiler

ActiveCN110107890AImprove combustion efficiencyImprove classification performanceSievingFluidized bed combustionCombustionPrimary screening

The invention discloses a method for preventing coking of a circular fluidization bed boiler, and belongs to the technical field of circular fluidization bed boilers. The method for preventing cokingof the circular fluidization bed boiler comprises the following steps that coal as fired enters a pretreatment device; the coal as fired is subjected to coarse crushing, primary screening, drying, fine crushing, secondary screening and the like; the fine crushed coal is subjected to screening by a secondary vibration screen, and the particle size of the coal is between 0 and 1 mm after screening;the coal as fired is charged; high-melting-point material powder is jetted into a furnace hearth by a jetting device; the boiler is cleaned after halting cooling; by adopting the method, coal of different particle sizes is conveyed into the circular fluidization bed boiler according to an accurate ratio; excessive moisture in the raw coal is dried; the problem of over-crushing of the coal during afine crushing process is avoided; a combustion improver which is accurately prepared is added, so that fullness of coal combustion is improved; and the occurring probability of the coking problem islowered.

Owner:ZIBO QILIN GUIHE THERMOELECTRIC

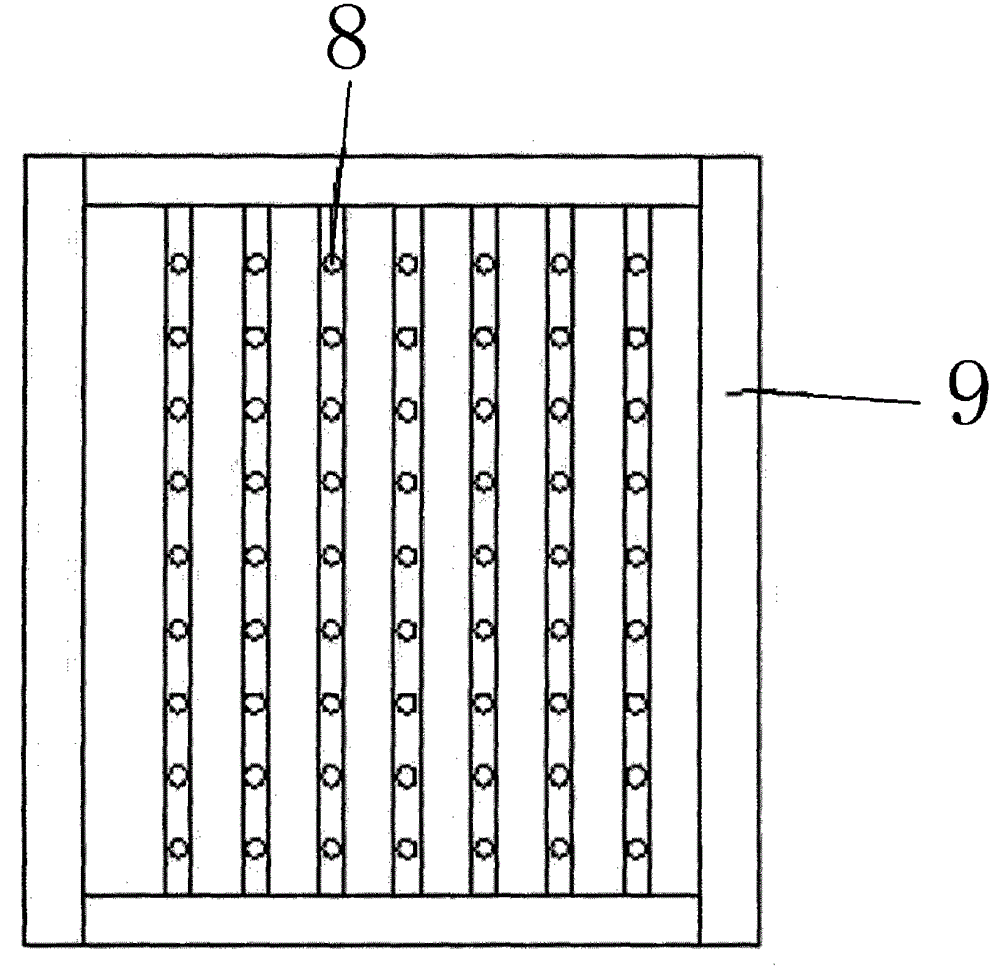

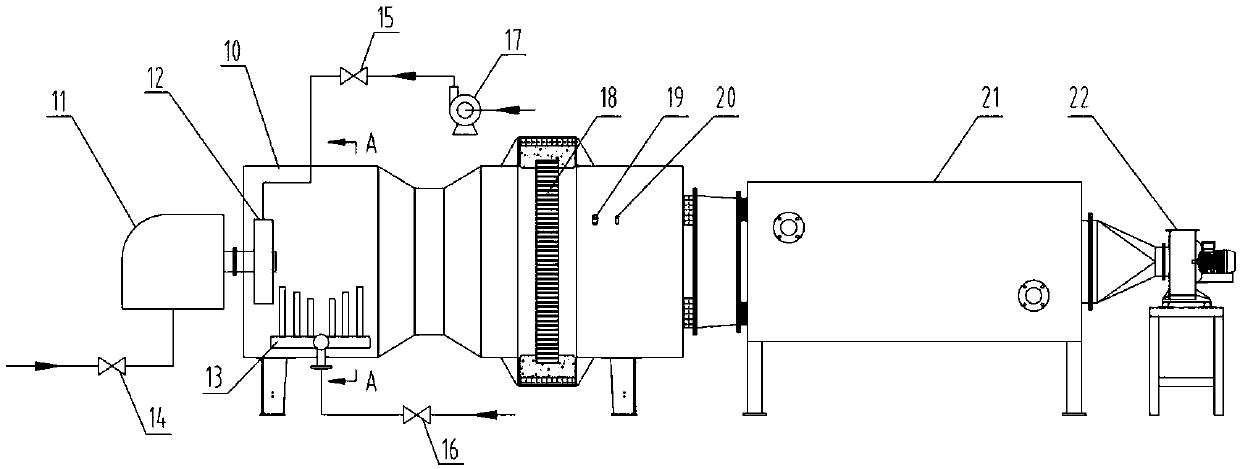

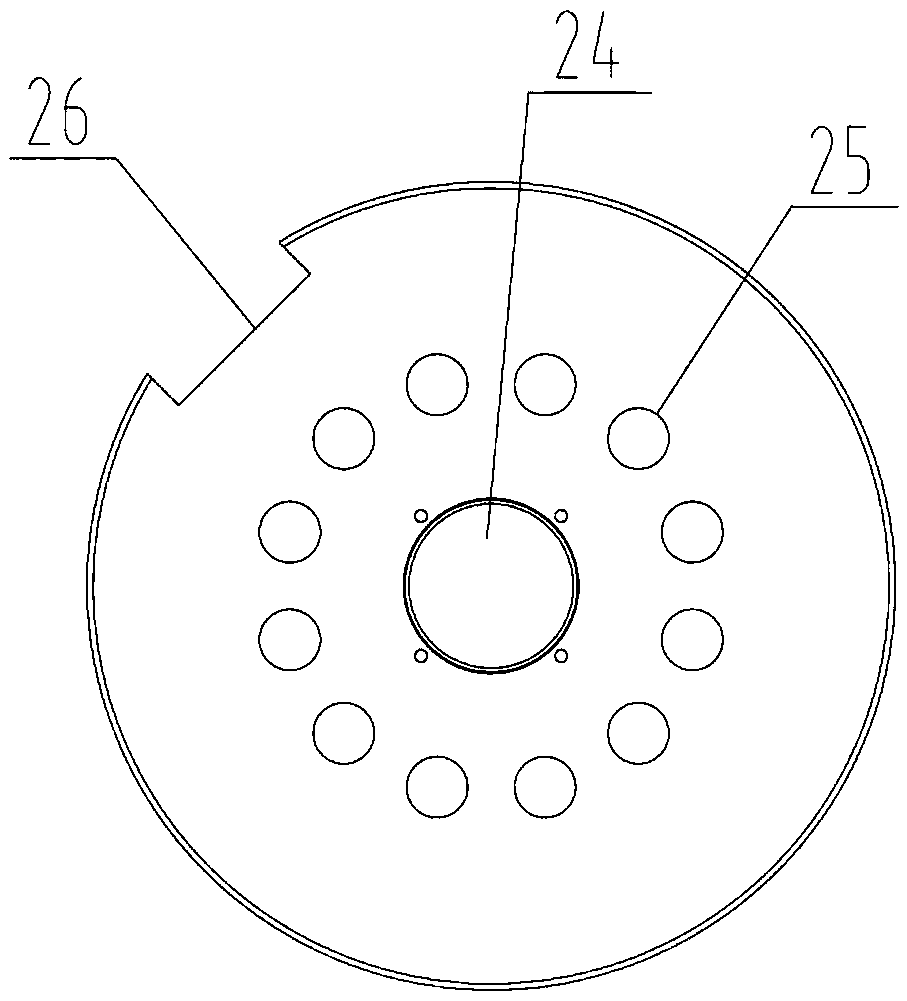

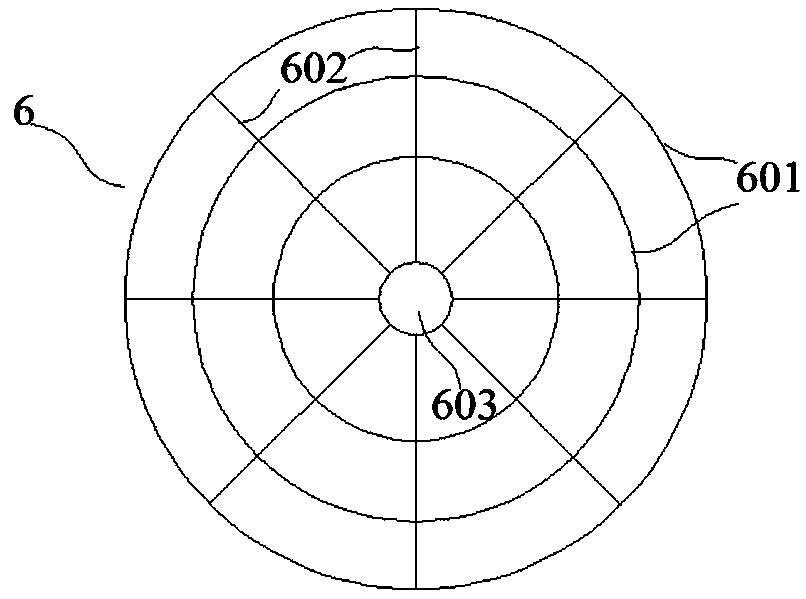

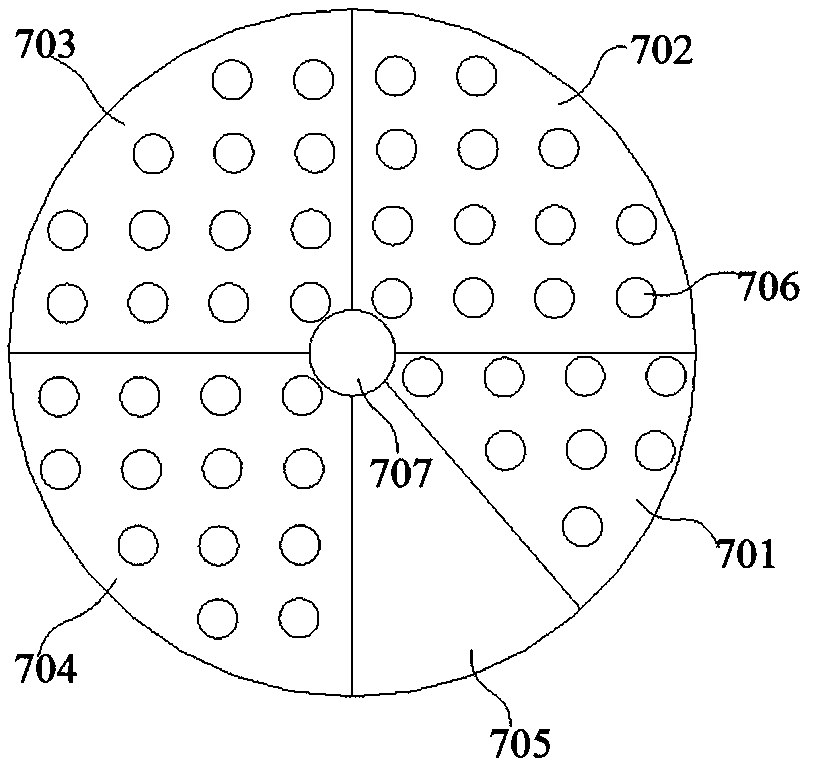

High-purity waste ammonia gas incinerating furnace, system and technology

ActiveCN109595568AReduce NOX generationKeep the oven warmIncinerator apparatusNitric oxideProcess engineering

The invention discloses a high-purity waste ammonia gas incinerating system. A high-purity waste ammonia gas incinerating furnace, a combustion device, an ammonia gas pipeline, a combustion supportingair pipeline, a fuel pipeline, a heat exchange device, a smoke discharging draught fan and a control device are included. The high-purity waste ammonia gas incinerating furnace comprises a furnace body, a first gas inlet distribution device, a second gas inlet distribution device and a fire barrier. The first gas inlet distribution device is connected with the ammonia gas pipeline through an ammonia gas pipeline connector, and the second gas inlet distribution device is connected with the combustion supporting air pipeline through an air supplementing port. When fuel generates flames in a hearth through a flame nozzle of the combustion device, the first gas inlet distribution device is used for distributing guided-in ammonia gas on the flame peripheries for sufficient combustion, and thesecond gas inlet distribution device is used for axially spraying guided-in combustion supporting air so that an air wall can be formed on the flame peripheries. Furthermore, a corresponding high-purity waste ammonia gas incinerating furnace and a corresponding incinerating technology are disclosed. Through the high-purity waste ammonia gas incinerating system, furnace and technology, in the heating power incineration process, generation of nitric oxide can be controlled while high-purity waste ammonia gas is completely combusted.

Owner:普兰特换热设备(溧阳)有限公司

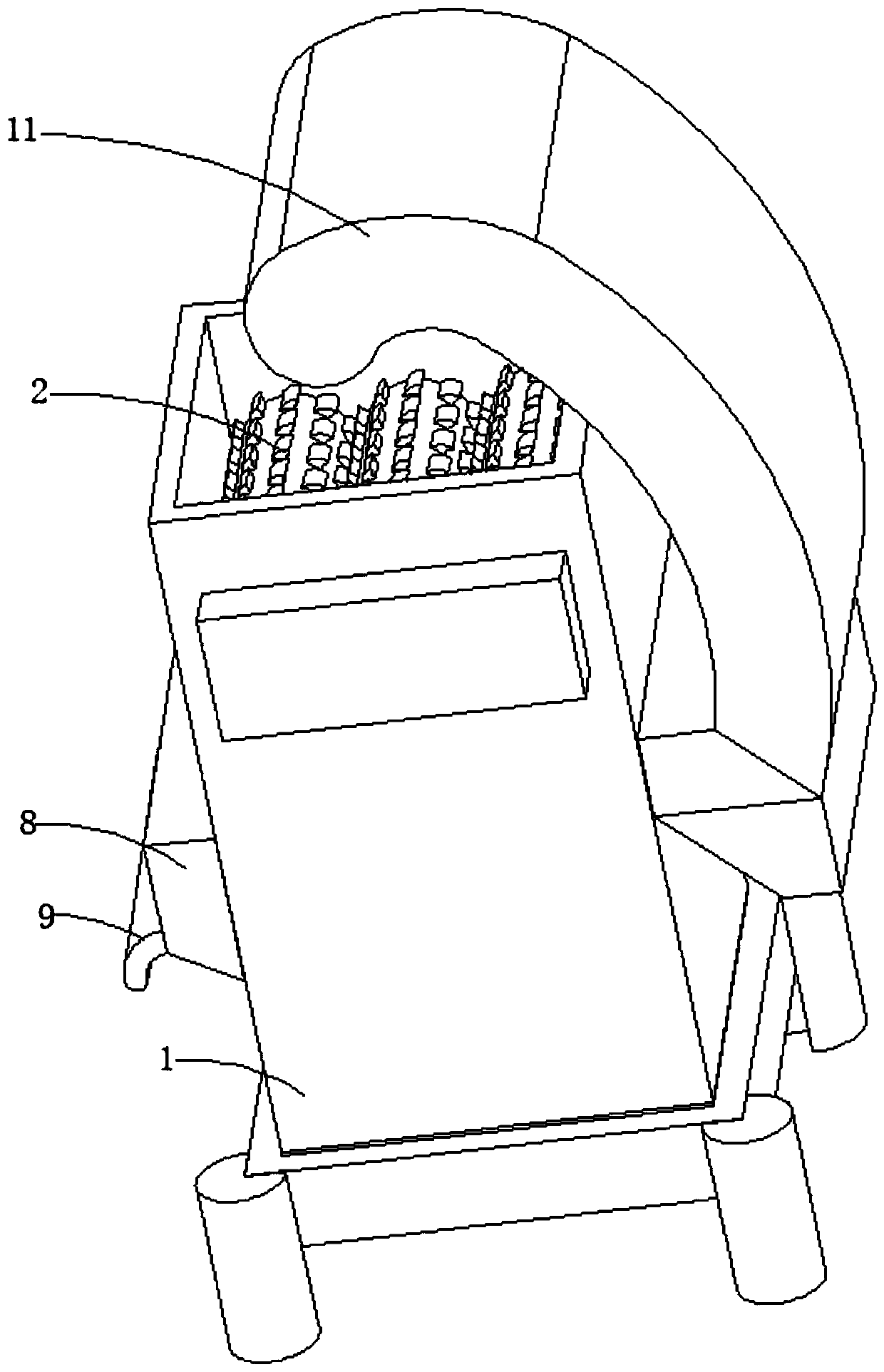

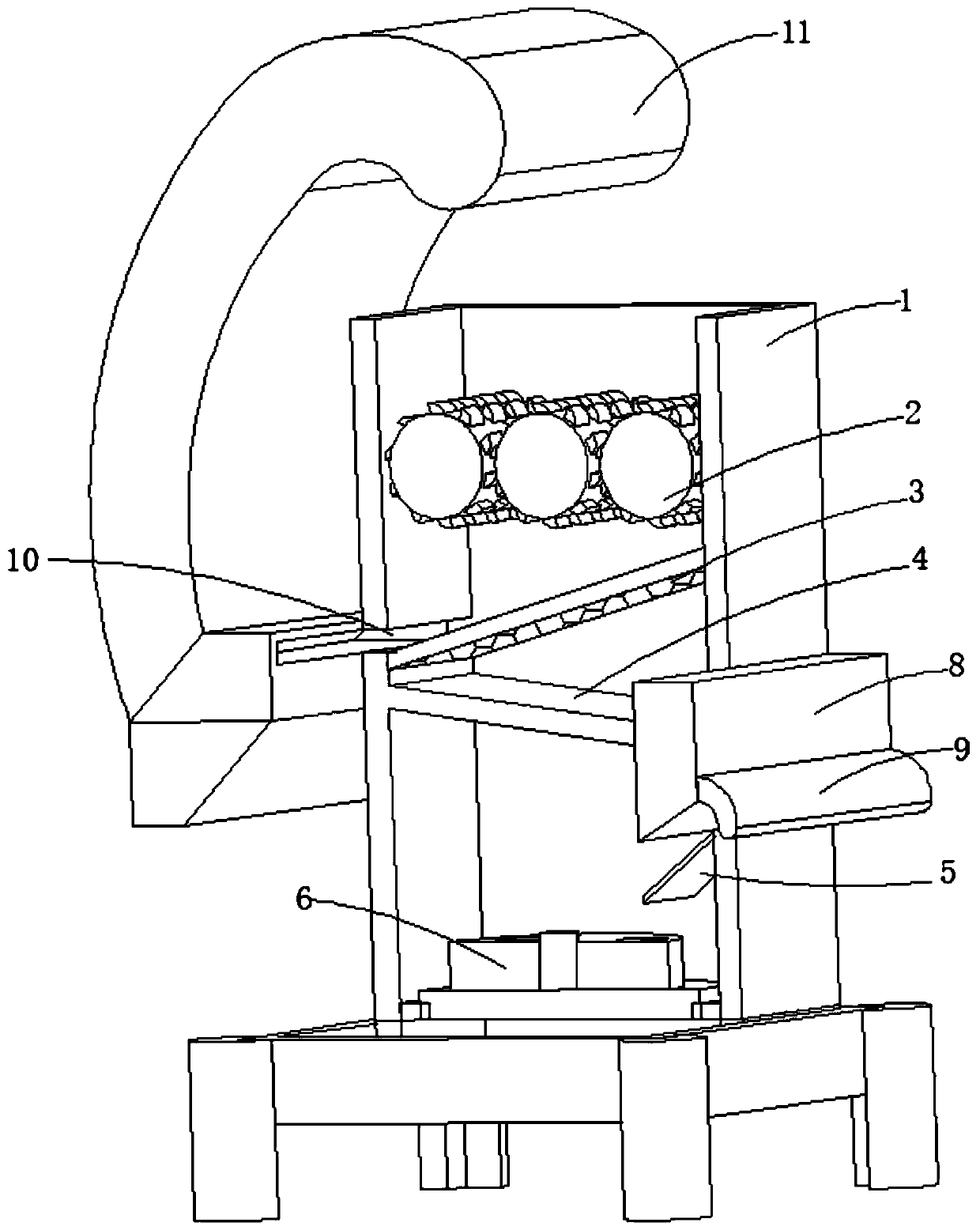

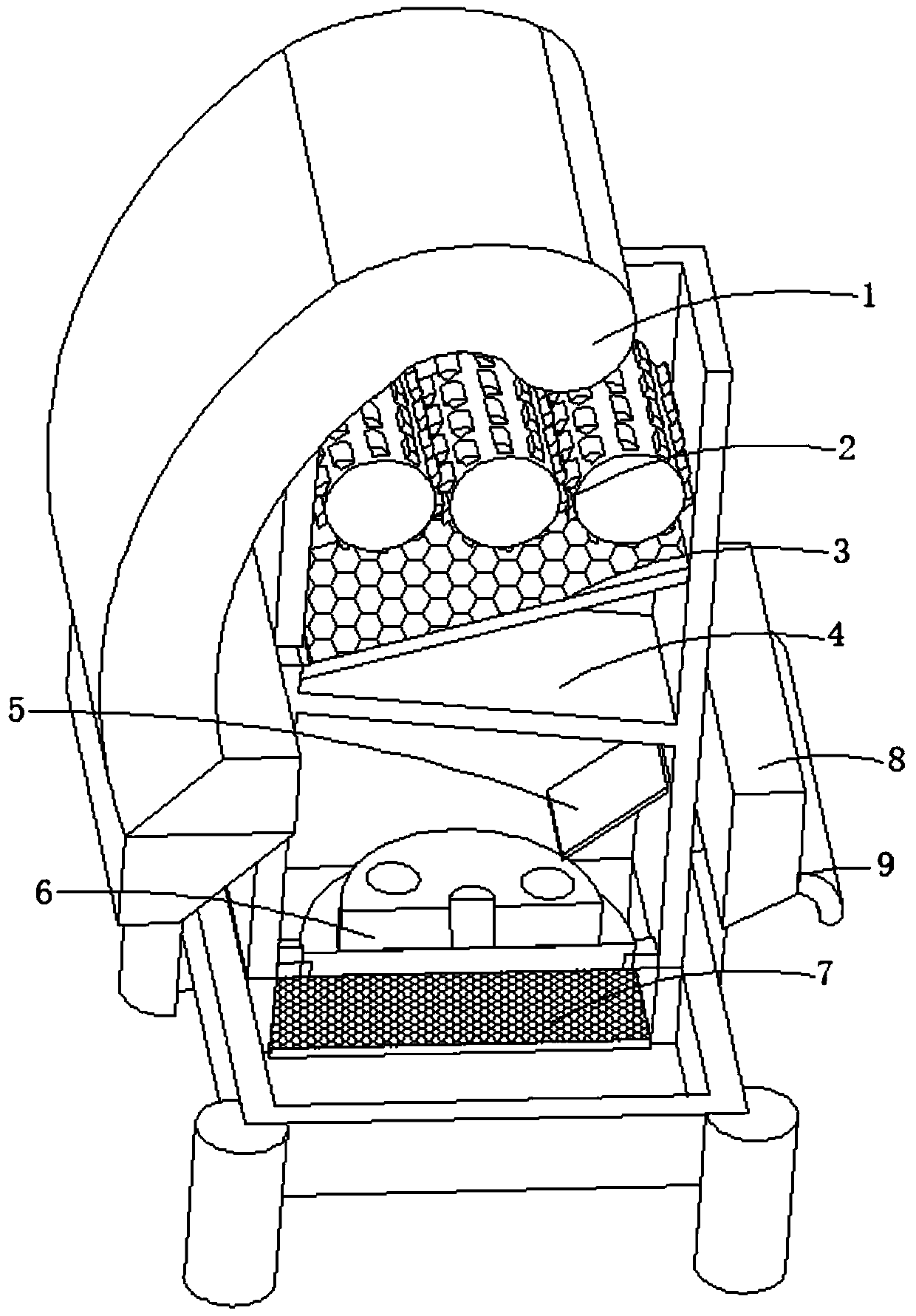

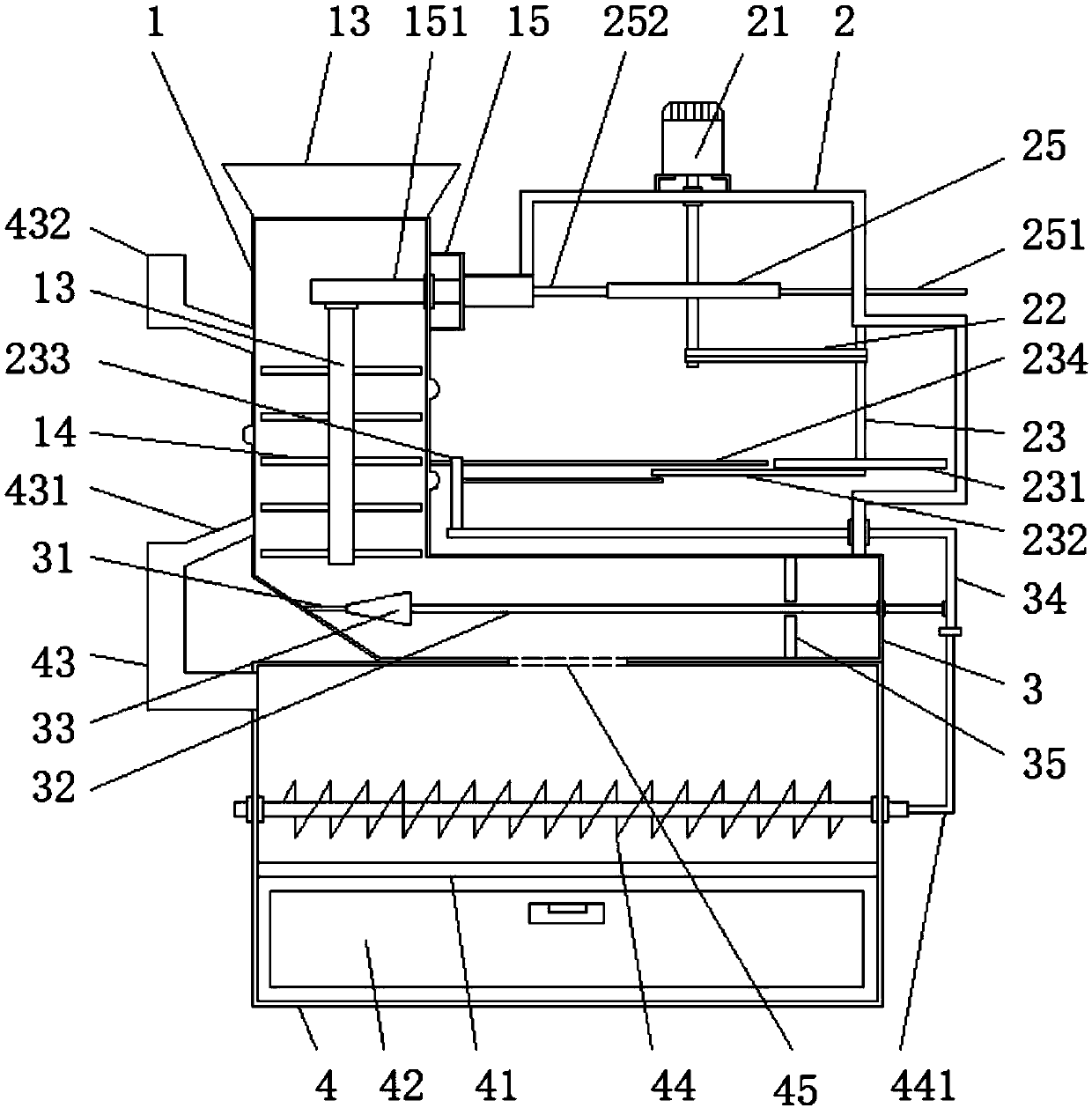

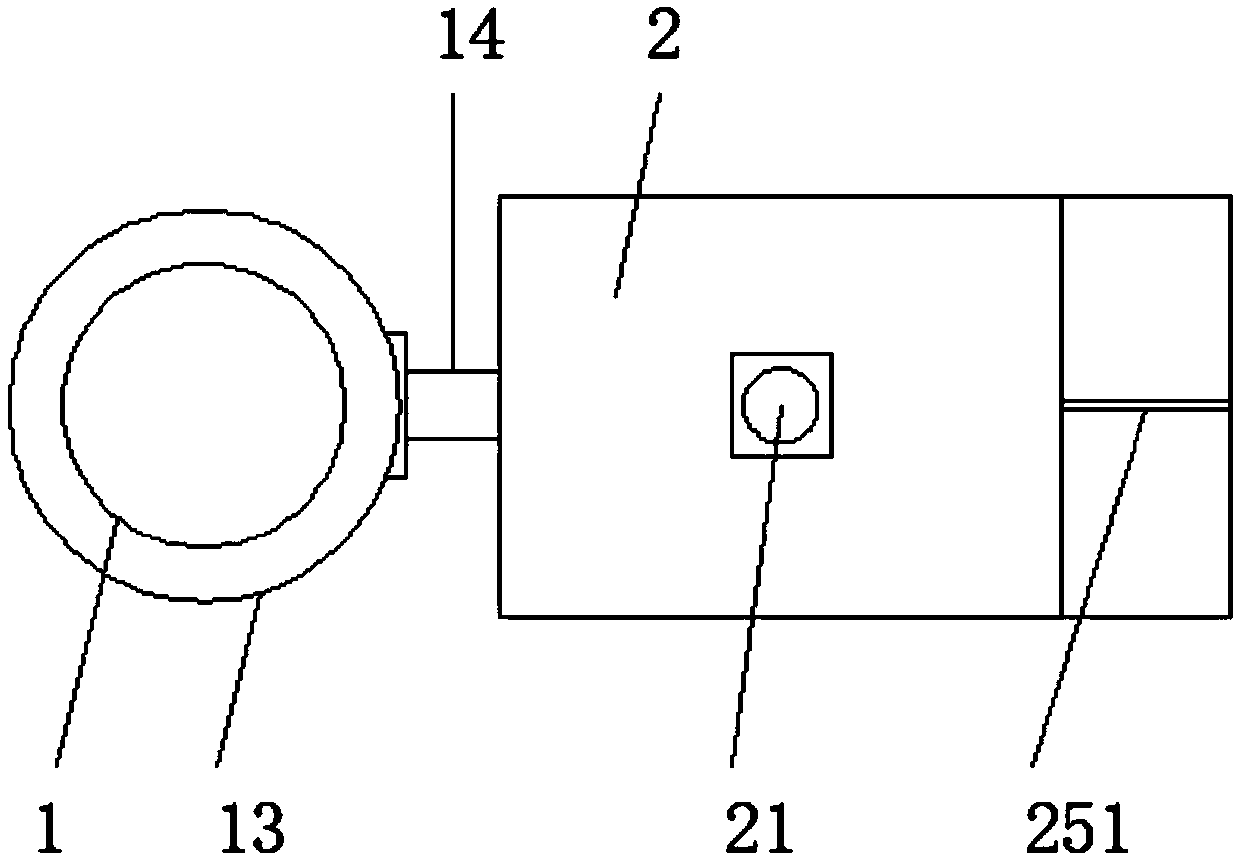

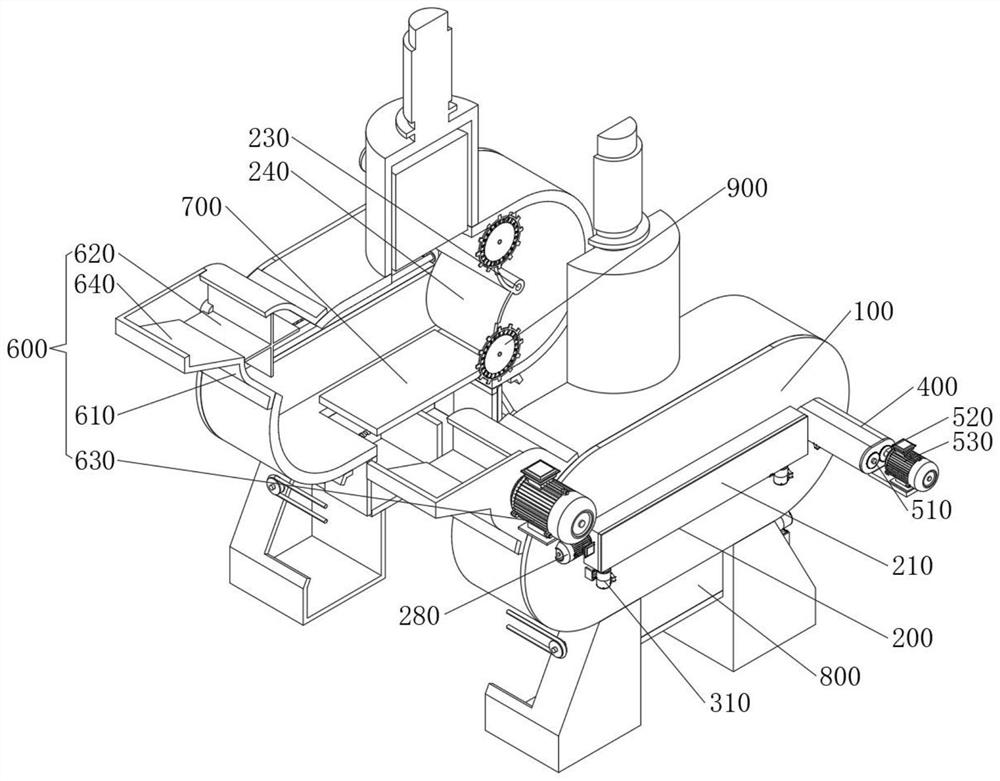

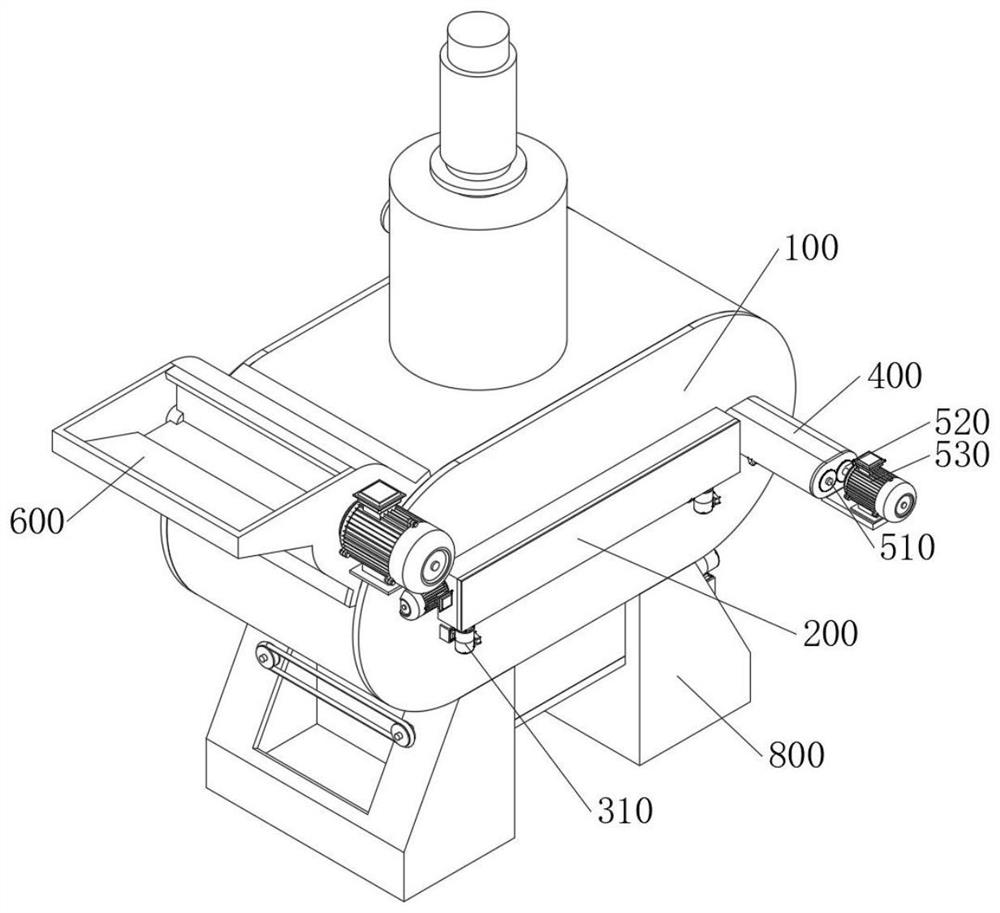

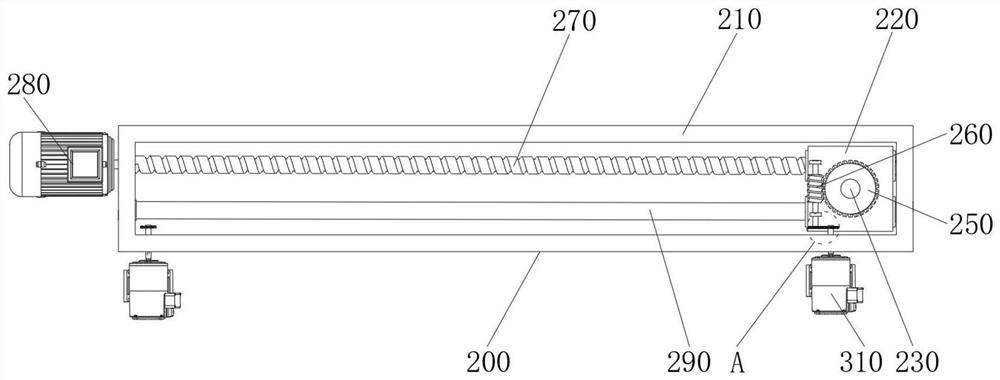

Garbage incinerator with blocking preventing and pre-smashing functions

The invention discloses a garbage incinerator with blocking preventing and pre-smashing functions. The garbage incinerator comprises a smashing chamber, a transmission chamber, a feeding chamber and an incineration chamber. The smashing chamber communicates with the feeding chamber. The smashing chamber communicates with a feeding opening. The transmission chamber is welded to the feeding chamber.The feeding chamber and the incineration chamber are connected in a welded manner. An opening groove is formed in the connecting portion of the feeding chamber and the incineration chamber. The wholegarbage incinerator is composed of the smashing chamber, the transmission chamber, the feeding chamber and the incineration chamber, compared with a traditional garbage incineration device, the device can smash garbage preliminarily in advance before the garbage is incinerated, in this way, when the garbage is smashed, combustion is fuller, the situations that due to insufficient combustion, particle impurities are discharged along with smoke, and environment is polluted can be avoided, meanwhile, the garbage incineration efficiency is improved, and garbage incineration treatment is benefitted.

Owner:天瑞集团光山水泥有限公司

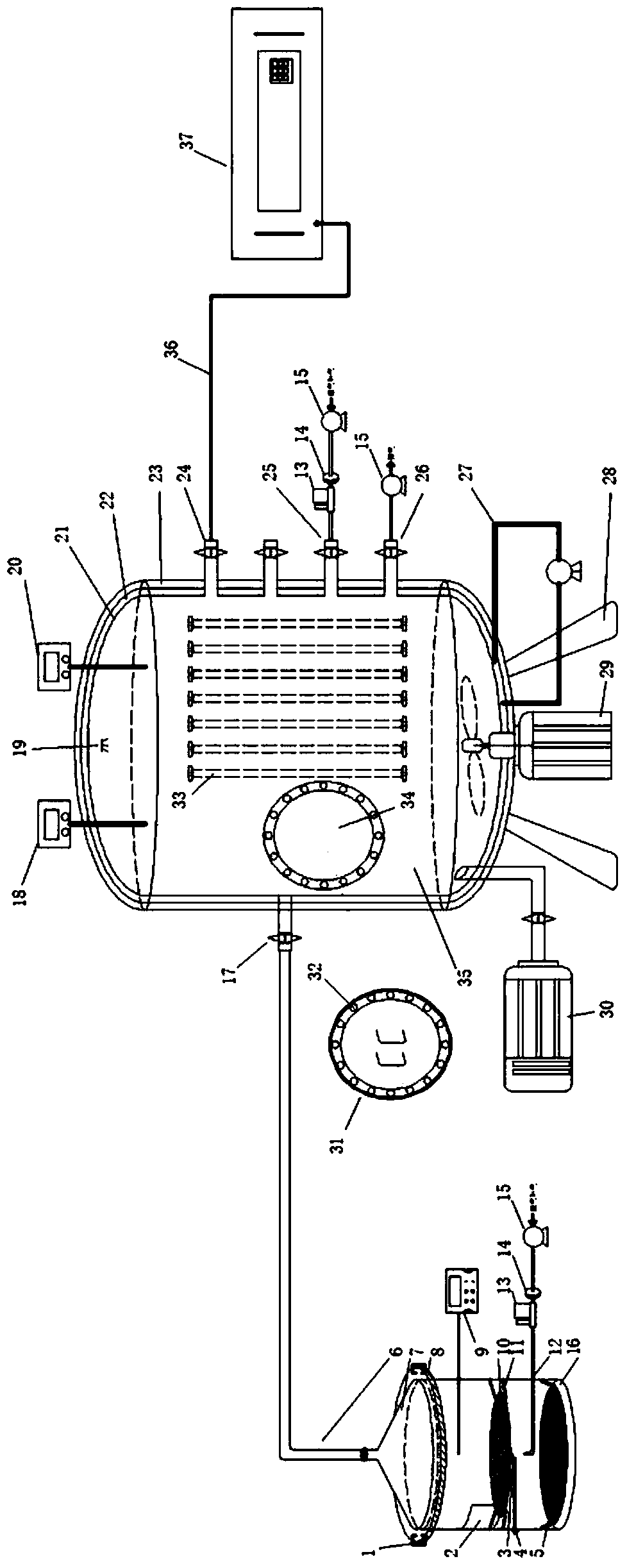

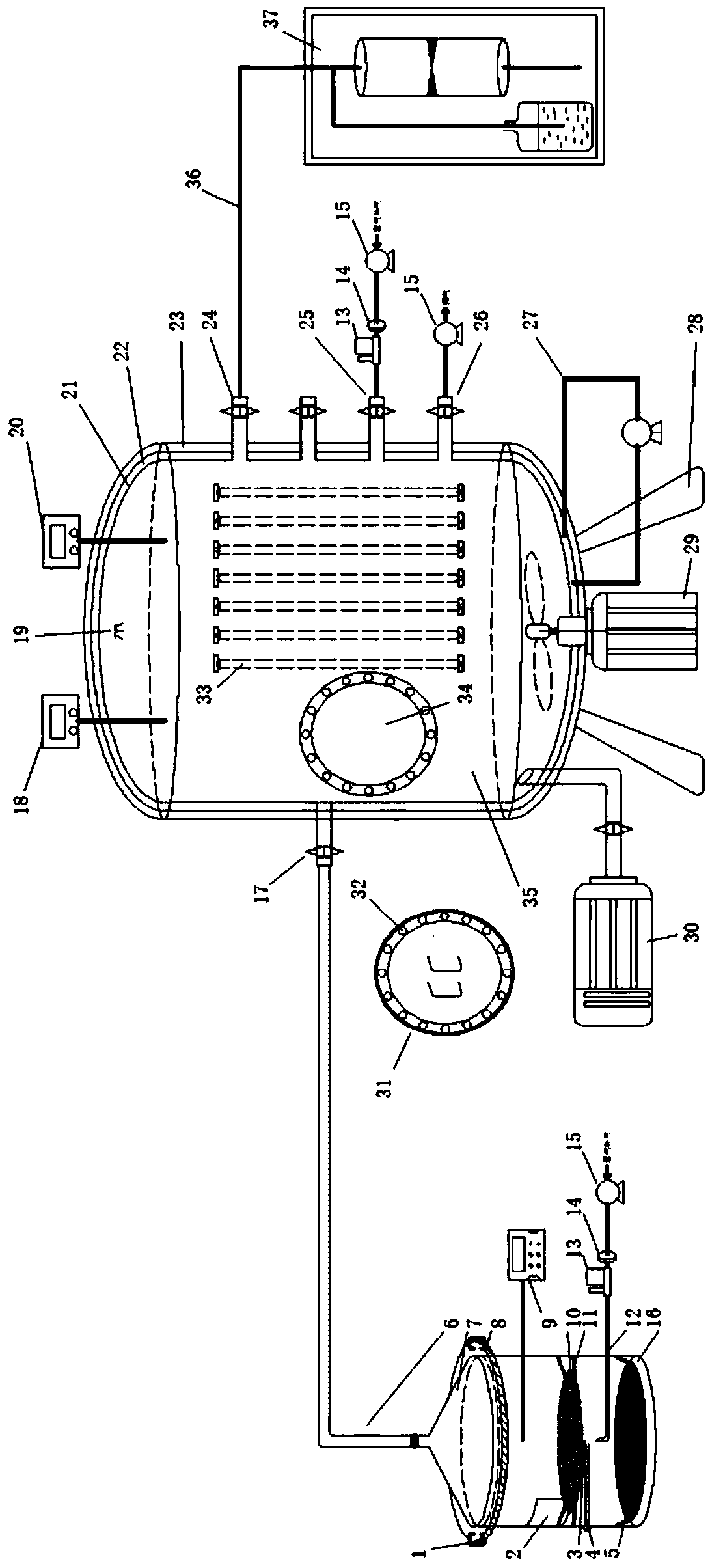

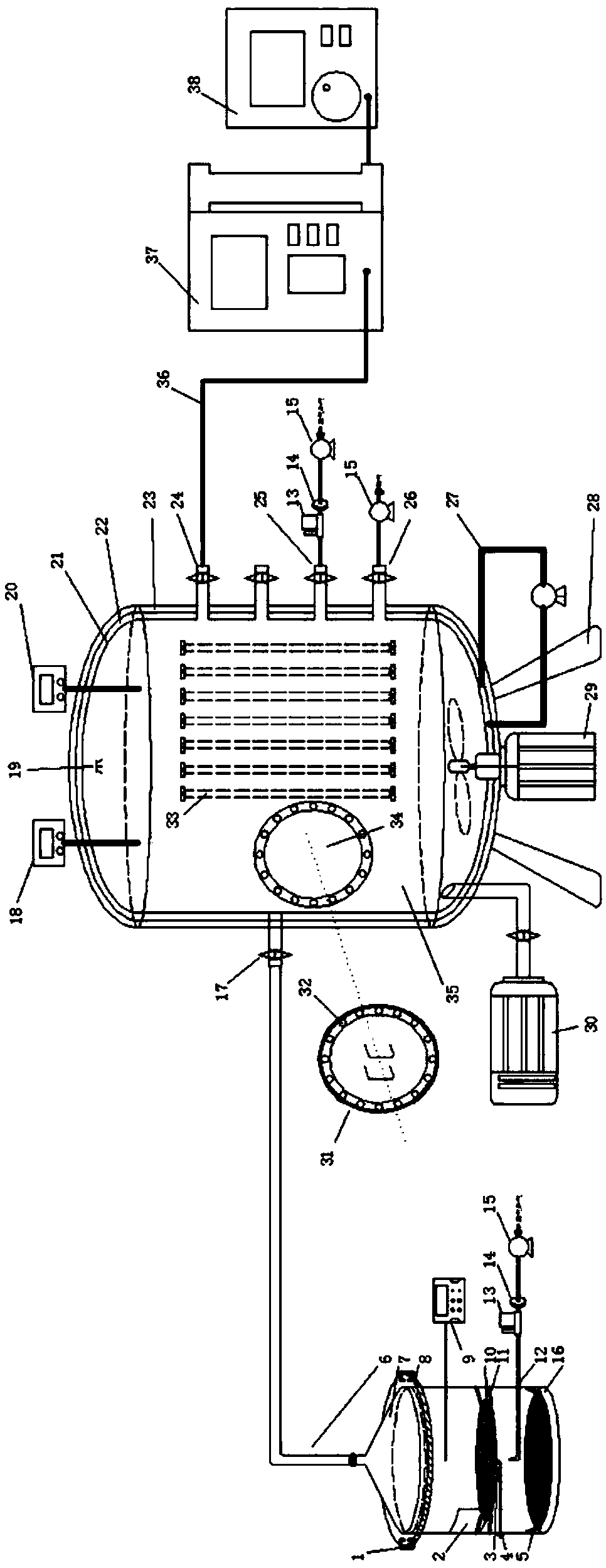

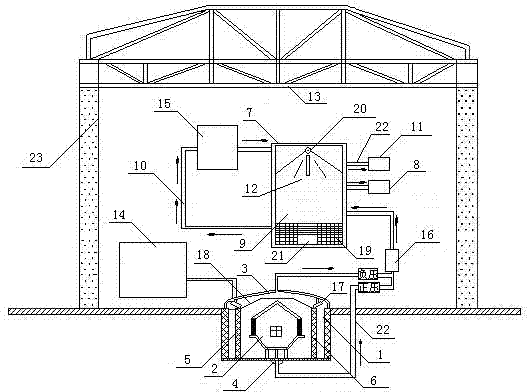

System for measuring carbonaceous concentration in atmospheric particulates

InactiveCN109596472ASimulate the realSimulation is accurateChemical analysis using combustionParticle suspension analysisTerrainParticulates

The invention relates to a system for measuring the carbonaceous concentration in atmospheric particulates. The system comprises a burning device for simulating open burning of biomass, an aerosol smoke box for stimulating a process of discharging atmospheric pollutants into the atmosphere, and a carbon concentration measuring device, wherein a gas transmission pipe on a furnace cover of the burning device communicates with an atmospheric pollutant input pipe of the aerosol smoke box; and a gas testing hole of the aerosol smoke box communicates with the carbon concentration measuring device through a conductive rubber pipe. The system for measuring the carbonaceous concentration in the atmospheric particulates has three functions at the same time, and simulates the process of discharging the atmospheric pollutants in the open burning of the biomass accurately and really; the physical and chemical reactions of the atmospheric pollutants generated in open burning of crop straws at all heights of the troposphere and even the stratosphere can be simulated in an artificially controllable and repeatable manner, and meanwhile, the influence of complex weather, terrains and other factors in the actual environment is eliminated; and the carbonaceous concentration in the particulates generated in the burning of the biomass in a simulated environment is accurately tested.

Owner:FUDAN UNIV

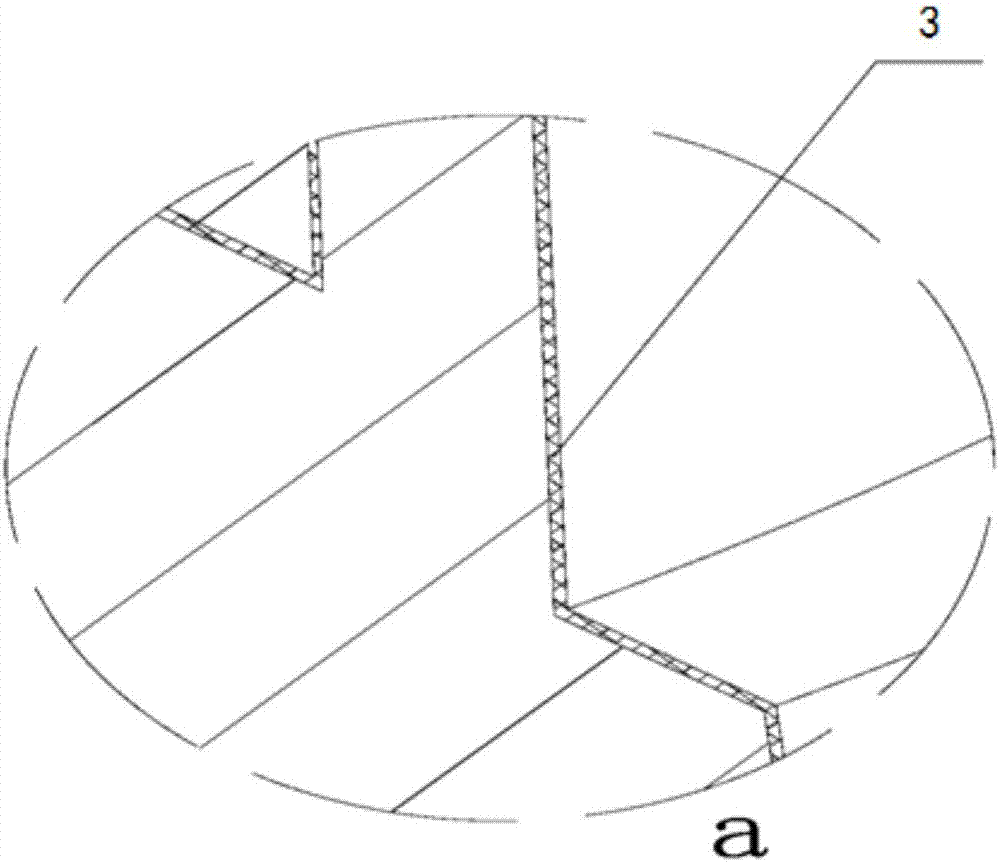

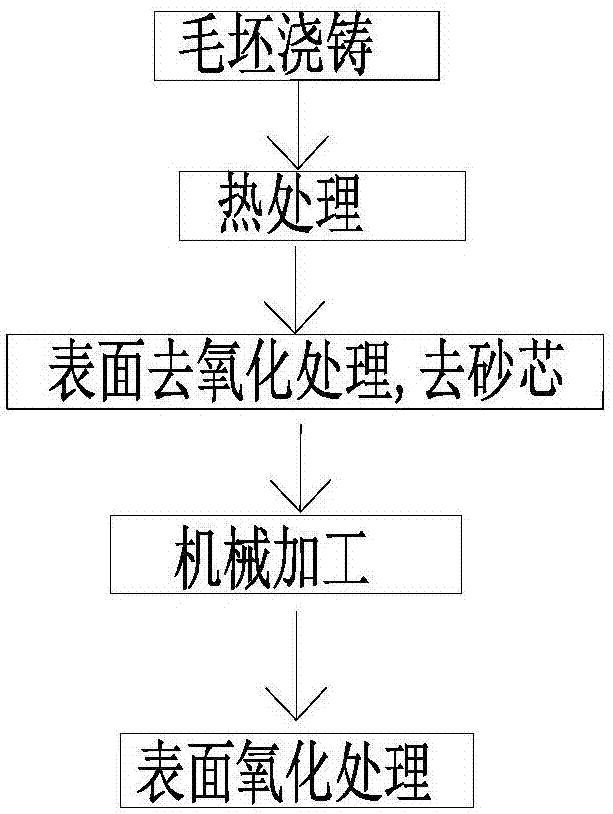

Aluminum alloy furnace end, manufacturing method of furnace end and combustor

ActiveCN107289446AImprove corrosion resistanceAvoid deformationAnodisationGaseous fuel burnerCombustorSilicon

The invention belongs to the field of gas cooking appliances, and particularly provides an aluminum alloy furnace end. The aluminum alloy furnace end comprises a mixing cavity and at least two injection pipes, the mixing cavity and the at least two injection pipes are of an integral structure, the mixing cavity and the injection pipes comprise an aluminum alloy layer, the aluminum alloy layer comprise aluminum and silicon, the proportion of the aluminum is larger than or equal to 75%, the proportion of the silicon ranges from 8% to 20%, the inner surfaces of the mixing cavity and the injection pipes are provided with a compact hard oxide layer, the outer surfaces of the mixing cavity and the injection pipes are provided with a compact hard oxide layer, and therefore when the furnace end is used at the higher temperature, the furnace end is relatively stable, and deformation caused by heating is avoided.

Owner:浙江文源智能科技有限公司

Coal-fired furnace

InactiveCN105180216AAvoid insufficient combustionImprove flammabilityDomestic stoves or rangesLighting and heating apparatusCombustorCombustion chamber

The invention discloses a coal-fired furnace. Fire grates include the coal containing fire grate and the coke containing fire grate. Both the coal containing fire grate and the coke containing fire grate are arranged in an inclined manner. The coal-fired furnace further comprises a baffle. The baffle stretches into a combustor from the top of a furnace body and is connected with the joint of the coal containing fire grate and the coke containing fire grate in an abutting manner. A plurality of through smoke through holes are formed in the baffle. A chimney communicated with the combustor is arranged at the top, over the coke containing fire grate, of the furnace body. When the coal-fired furnace is in use, fire coal is added on the coal containing fire grate, and coke is added on the coke containing fire grate; due to the fact that the coke has the excellent combustible performance, a high temperature area is formed at the area above the coke containing fire grate; the combustible performance of fire coal is worse than that of coke, the fire coal cannot be sufficiently combusted in the combustion process, the phenomenon of black smoke is generated, and the black smoke needs to enter the high temperature area above the coke containing fire grate through the smoke through holes when needing to be discharged out of the furnace; and at the high temperature area, combustible substances in black smoke are sufficiently combusted, so that the purposes that the phenomenon of black smoke is eliminated and fire coal is sufficiently combusted are achieved.

Owner:天津九州中盛暖通设备制造有限公司

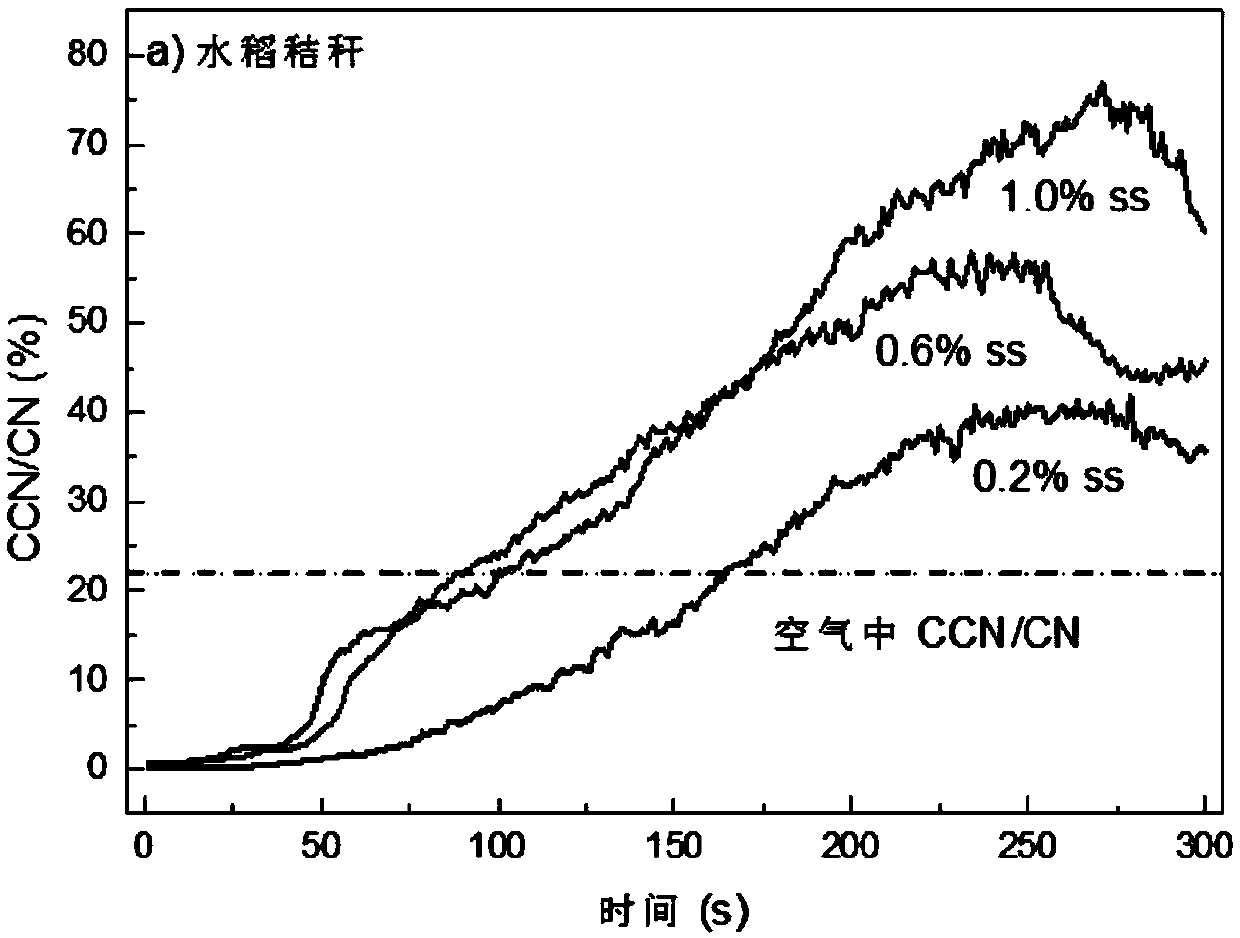

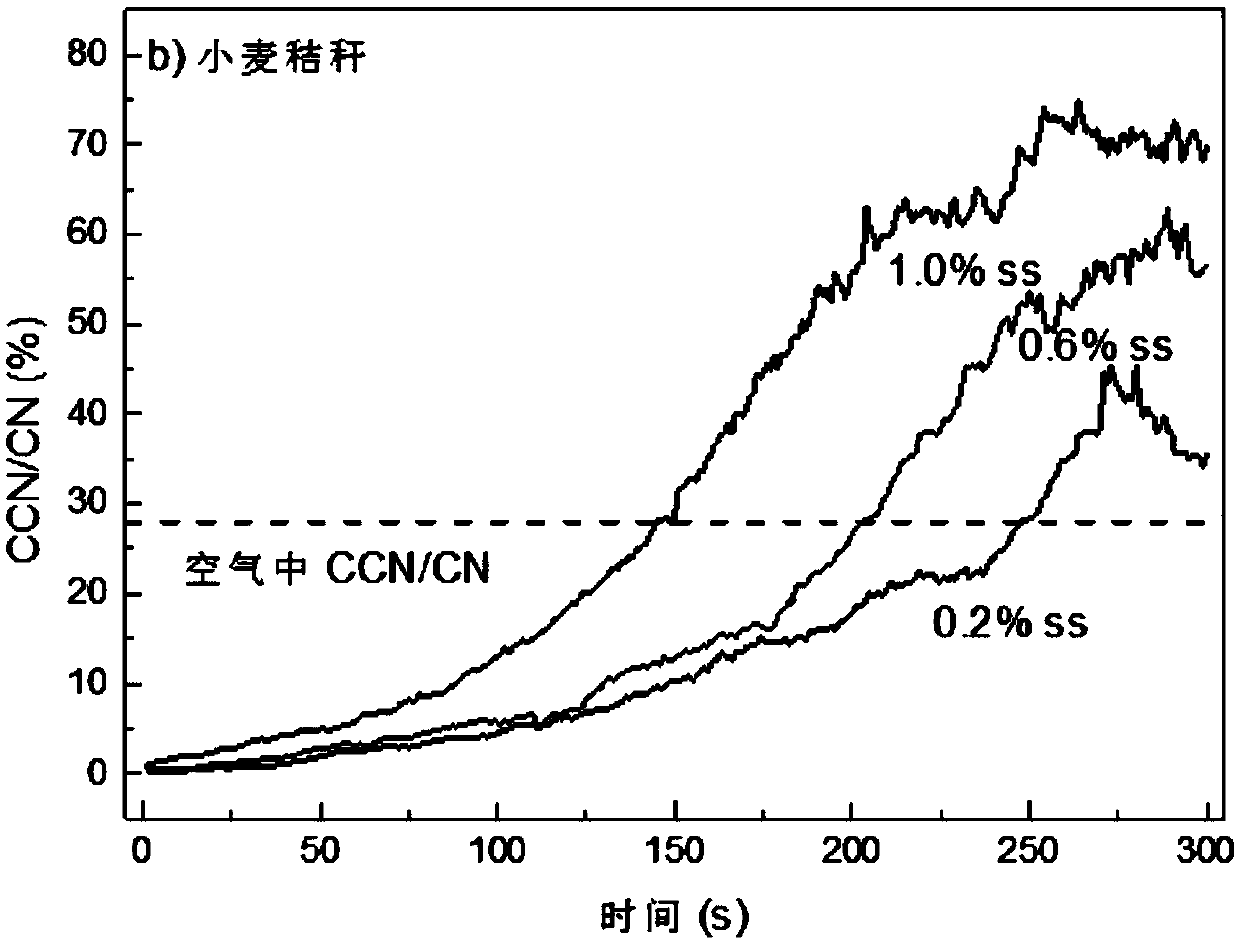

Atmospheric aerosol smoke system for measuring nucleating ability of open burning particulate matters

PendingCN109596474ASimulate the realSimulation is accurateChemical analysis using combustionParticle size analysisParticulatesChemical reaction

The invention relates to an atmospheric aerosol smoke system for measuring the nucleating ability of open burning particulate matters. The atmospheric aerosol smoke system comprises a burning device for simulating biomass open burning, an aerosol smoke box for simulating the discharge of atmospheric pollutants into the atmosphere, and a cloud condensation nucleus instrument, which are connected with each other in sequence; the system provided by the invention simultaneously has three functions to accurately and really simulate the process of discharging the atmospheric pollutants by biomass open burning; the atmospheric aerosol smoke system is artificially controllable and can repeatedly simulate the physical and chemical reactions of the atmospheric pollutants by the open burning of cropstraws at various heights of the troposphere to the stratosphere, and meanwhile the influence of complex meteorological and topographical factors in the actual environment are eliminated; and throughthis system, the cloud condensation nucleus ability of the particulate matters discharged by the biomass burning can be accurately and really reflected, it is discovered through tests that with the change of time, the cloud condensation nucleus ability of aerosol particulate matters generated by burning is gradually improved, and a guidance is provided for the further research on the particulate matters.

Owner:FUDAN UNIV

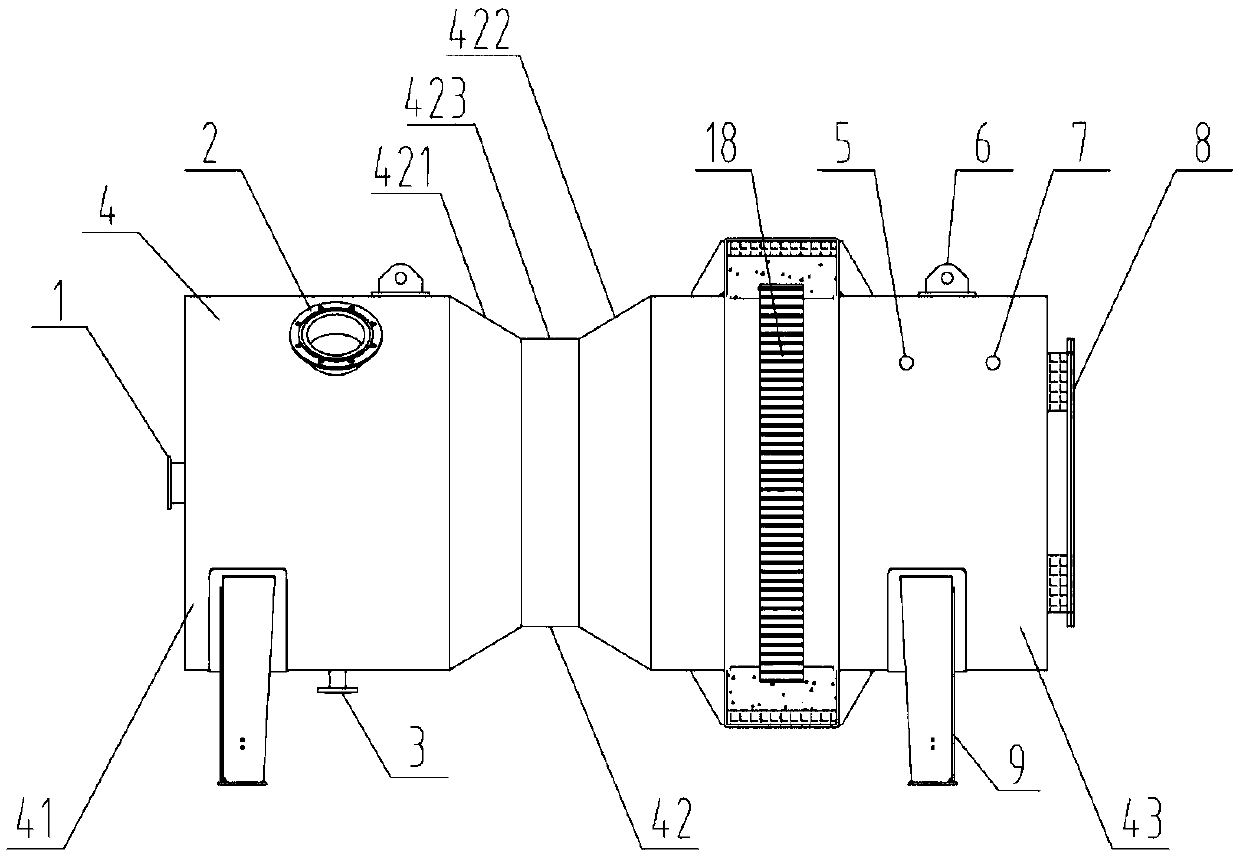

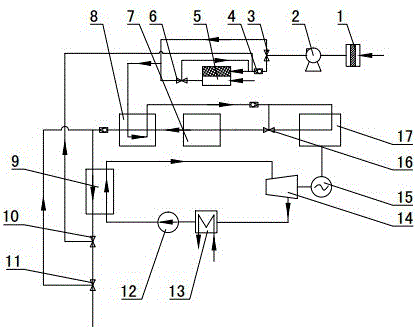

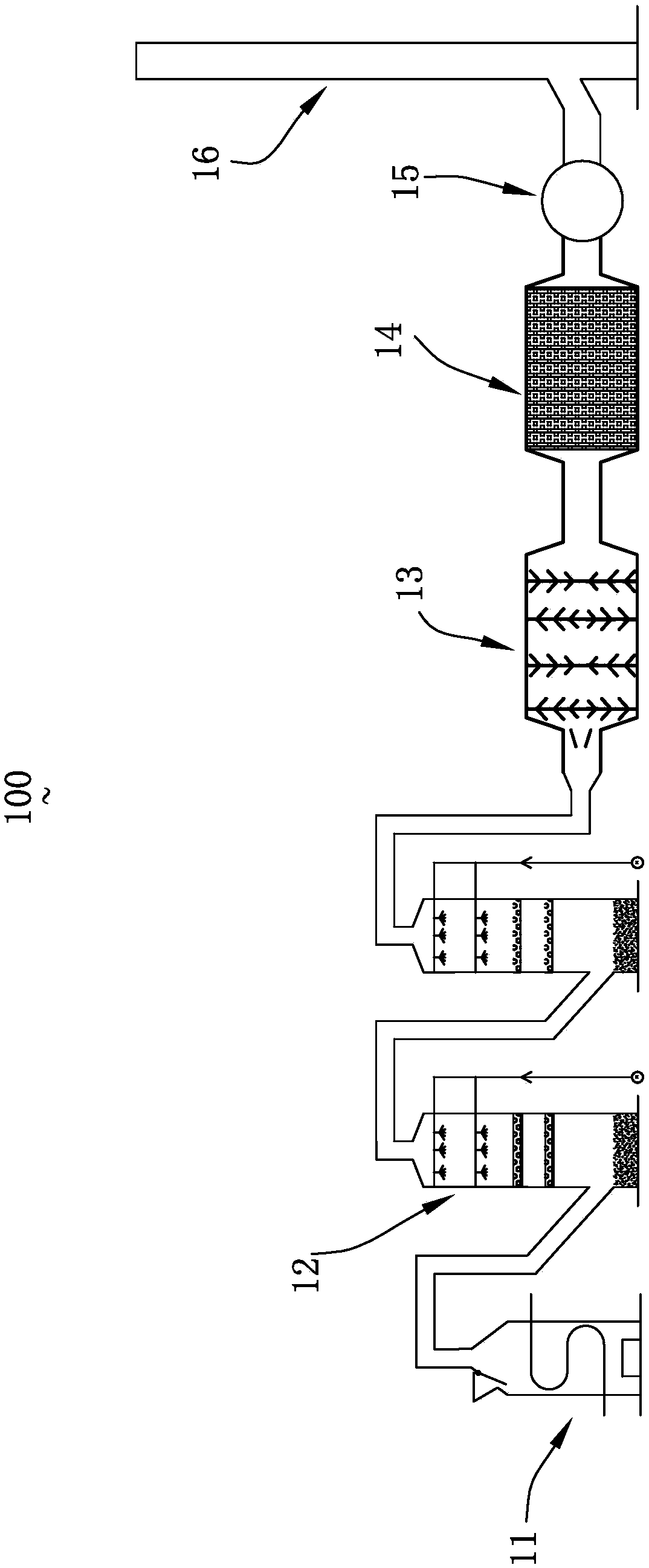

Efficient VOC treatment system and treatment process flow adopting novel heat exchanger

ActiveCN106369617AGuaranteed concentrationBurn fullyDispersed particle filtrationSteam engine plantsAtmospheric airRecuperator

The invention discloses an efficient VOC treatment system and treatment process flow adopting a novel heat exchanger, and belongs to the technical field of waste gas treatment equipment. The efficient VOC treatment system is characterized in that the gas outlet end of a pre-treatment module communicates with the gas inlet end of a catalytic combustion module; the gas outlet end of the catalytic combustion module communicates with the atmosphere; a heat exchange unit is arranged between a power generation unit and the gas outlet end of the catalytic combustion module; and the power generation module is electrically connected with the catalytic combustion module through a wire and provides electricity for the catalytic combustion module. By adoption of the efficient VOC treatment system adopting the novel heat exchanger, environment pollution is avoided, and heat generated after VOC waste gas is combusted can be fully reutilized, so that self energy supply is guaranteed, and energy waste is effectively avoided; the VOC waste gas is effectively treated by pre-treating the VOC waste gas and exhausting the VOC waste gas into the atmosphere after catalytic combustion; and low-temperature gas after catalytic combustion and primary heat exchange is utilized for heat-exchange power generation by the power generation module through the heat exchange unit, electric energy is provided for heating of the catalytic combustion module, and the utilization rate of the energy sources is increased accordingly.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

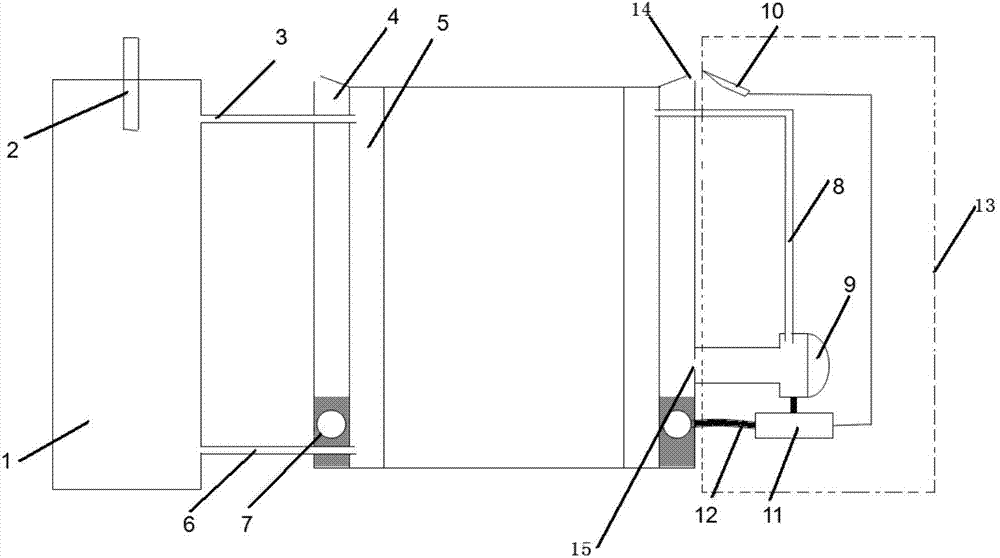

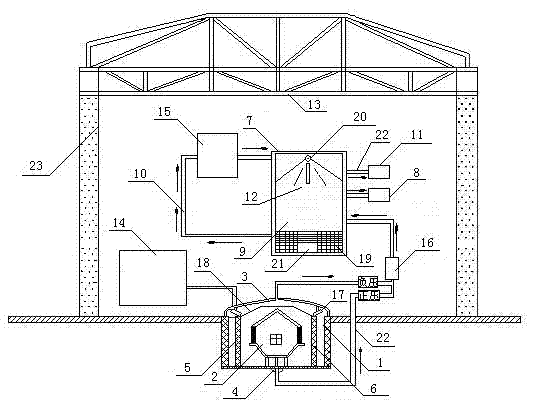

Atmospheric aerosol smoke system for simulating open burning of biomass and measuring number concentration of particulate matters

PendingCN109596468AAvoid smolderingAvoid insufficient combustionChemical analysis using combustionParticle size analysisParticulatesTerrain

The invention relates to an atmospheric aerosol smoke system for simulating open burning of biomass and measuring number concentration of particulate matters. The system comprises a burning device forsimulating the open burning of the biomass, an aerosol smoke box for simulating a process of discharging atmospheric pollutants into the atmosphere, and a particular matter particle size measuring device, which are connected in sequence; the atmospheric aerosol smoke system has three functions at the same time, and stimulates the process of discharging the atmospheric pollutants in the open burning of the biomass accurately and really; the physical and chemical reactions of the atmospheric pollutants generated in open burning of crop straws at all heights of the troposphere and even the stratosphere can be simulated in an artificially controllable and repeatable manner, and meanwhile, the influence of complex weather, terrains and other factors in the actual environment is eliminated; andthe number concentrations of atmospheric particulate matters with different particle sizes discharged in the open burning of the biomass can be accurately reflected.

Owner:FUDAN UNIV

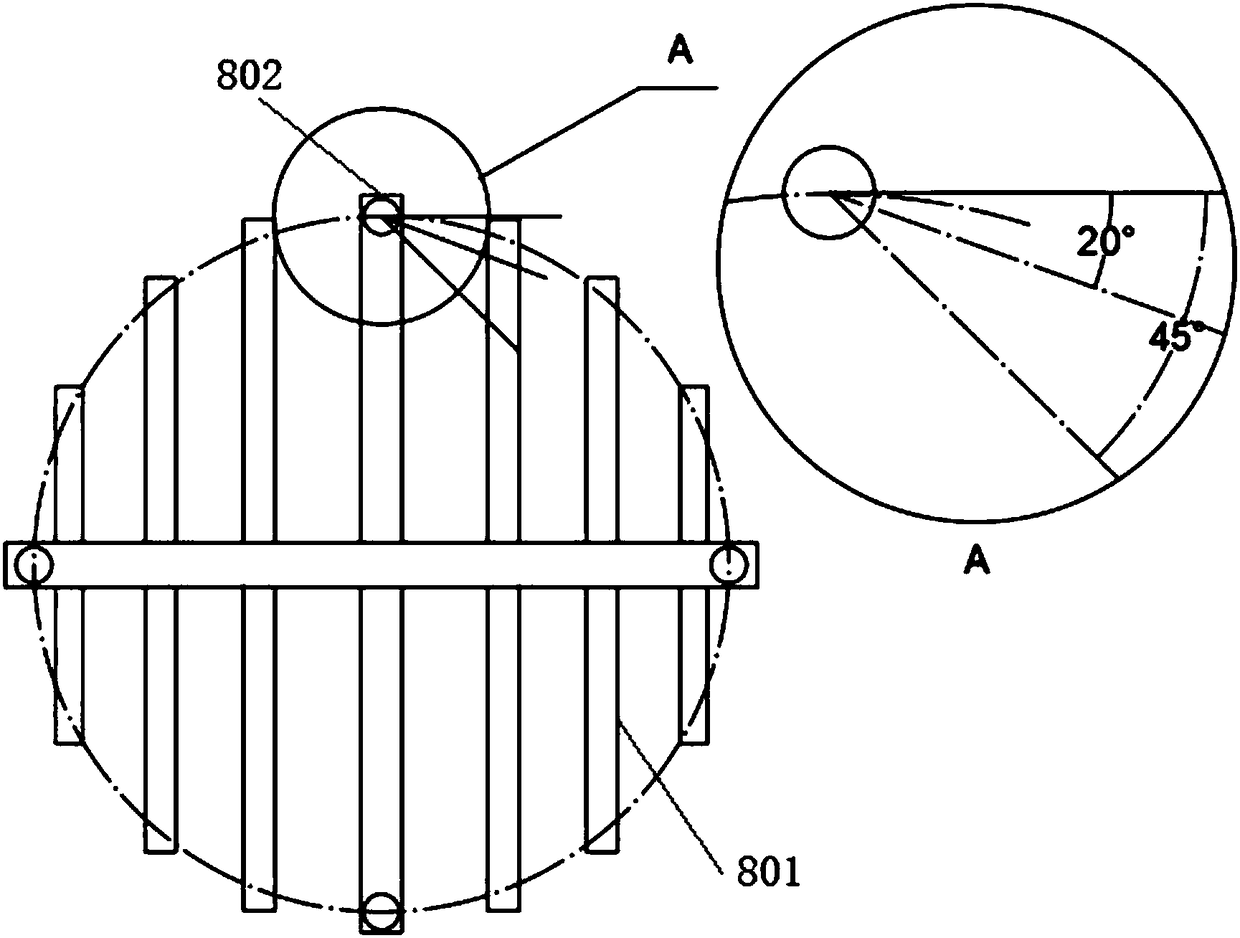

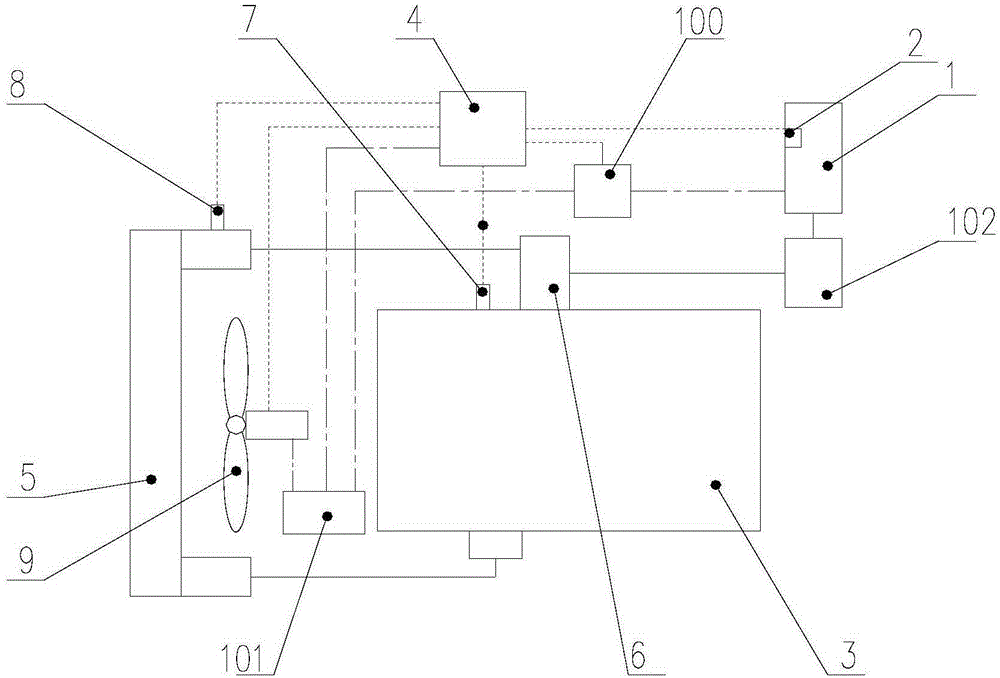

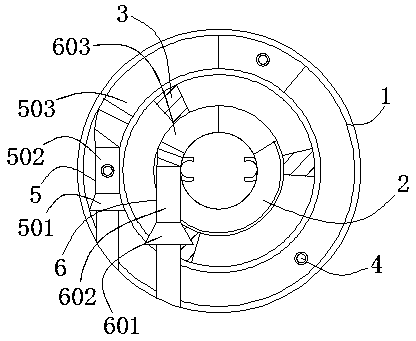

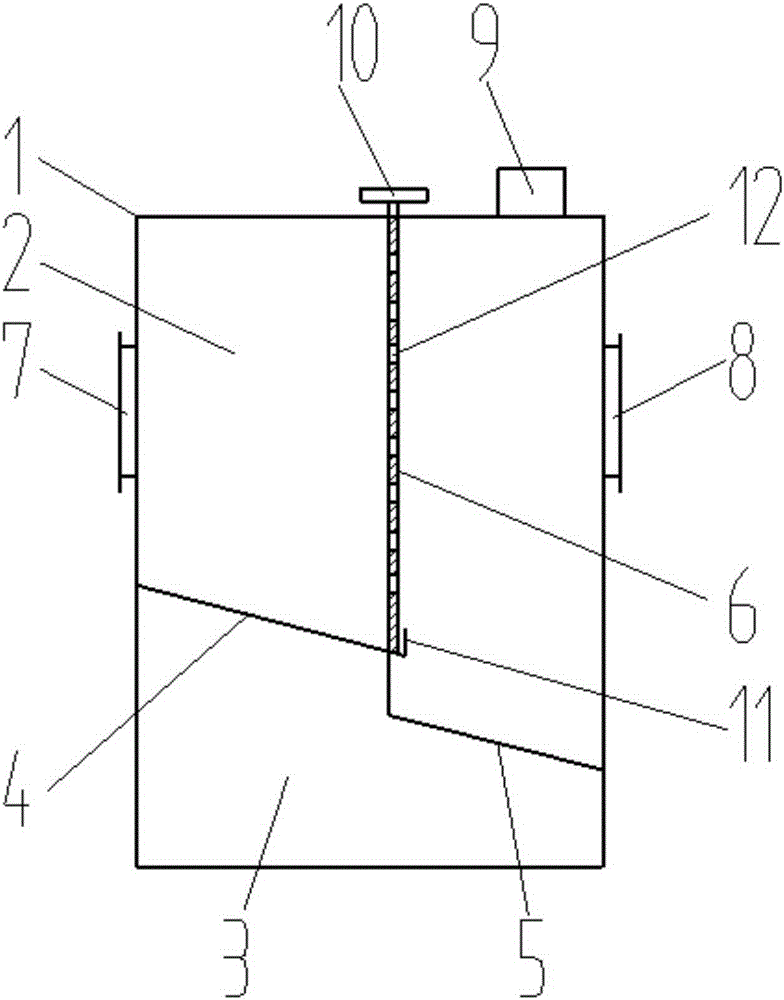

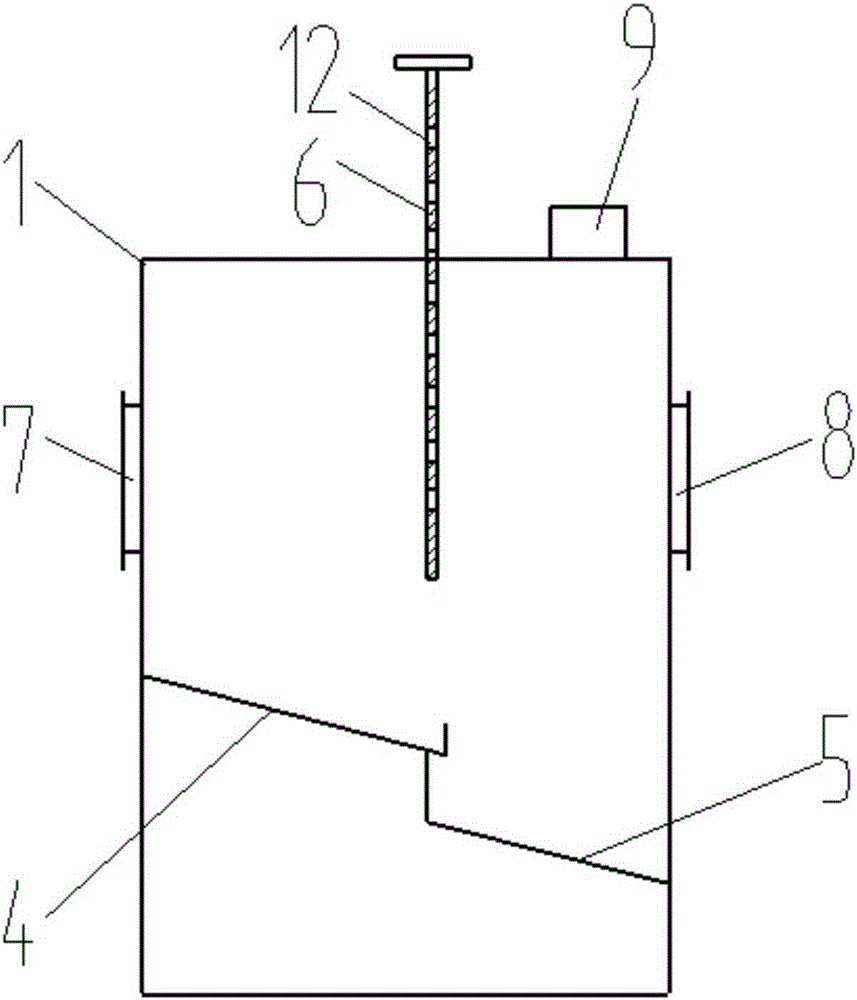

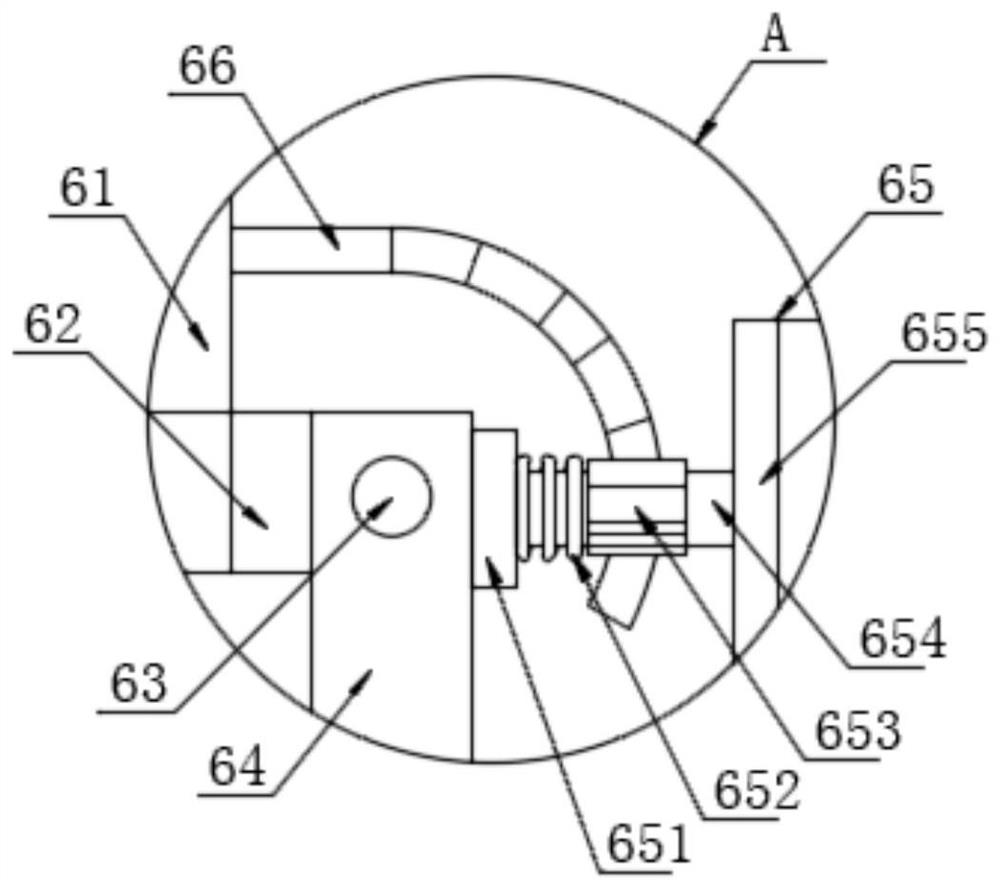

Air volume linear adjusting method and adjusting device for air blower

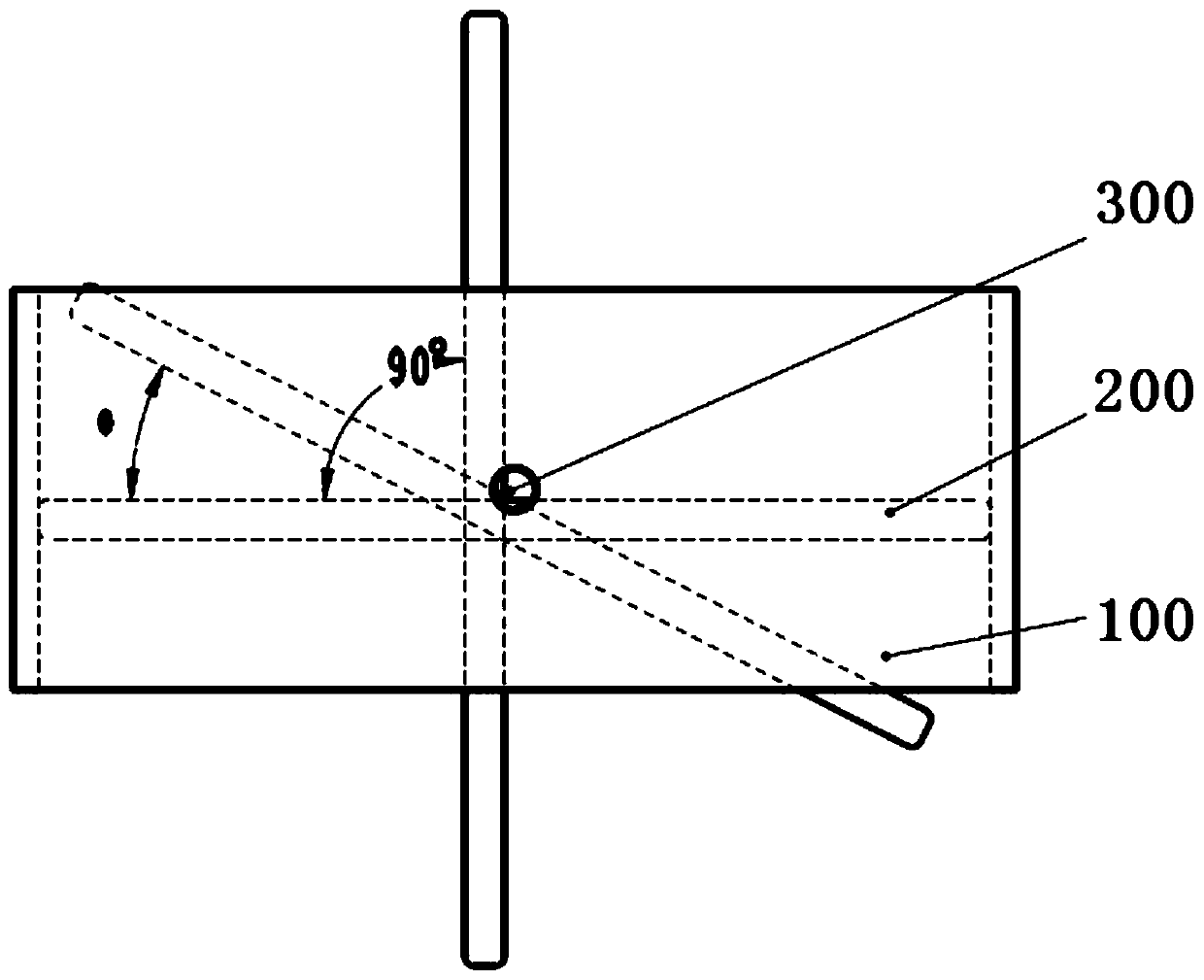

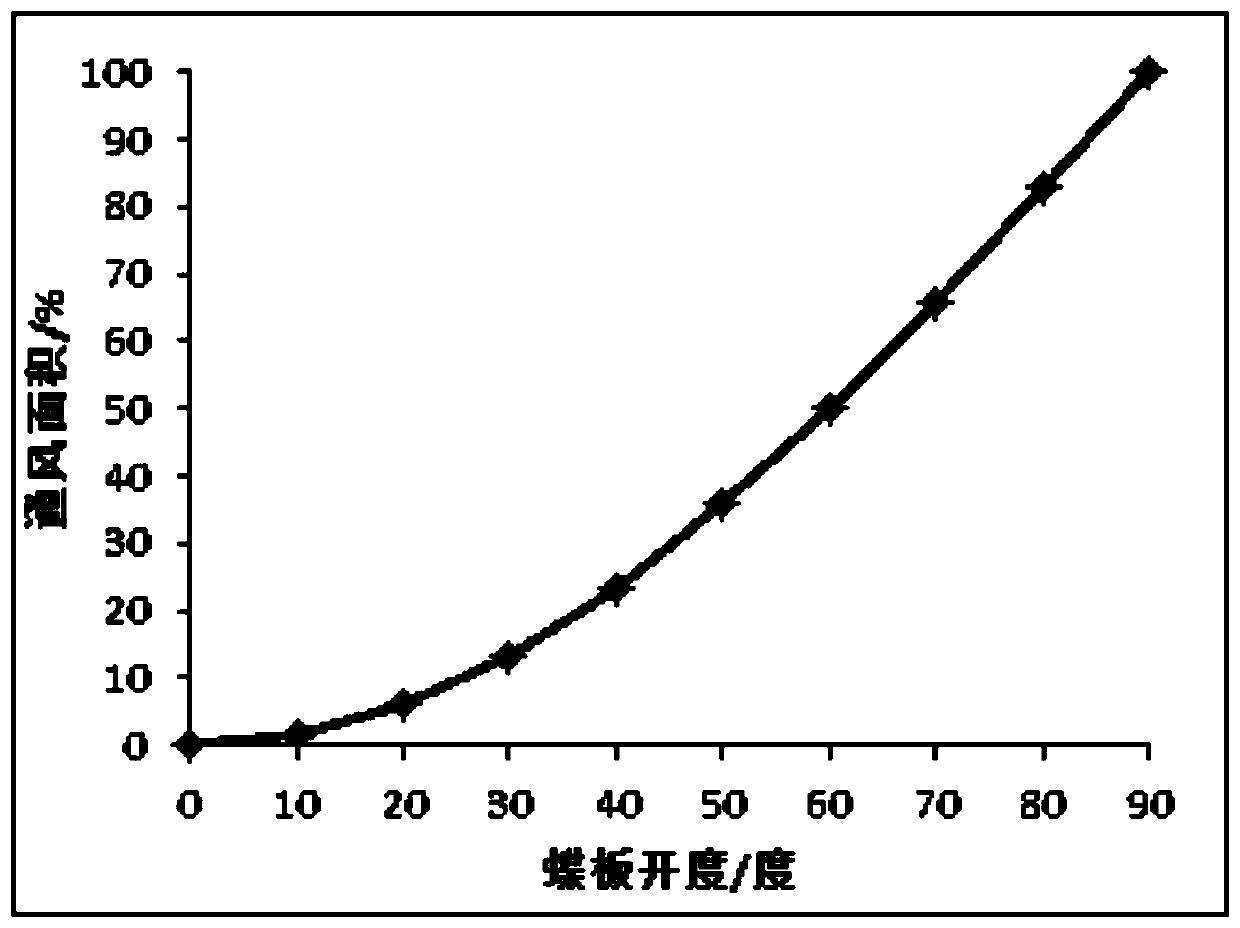

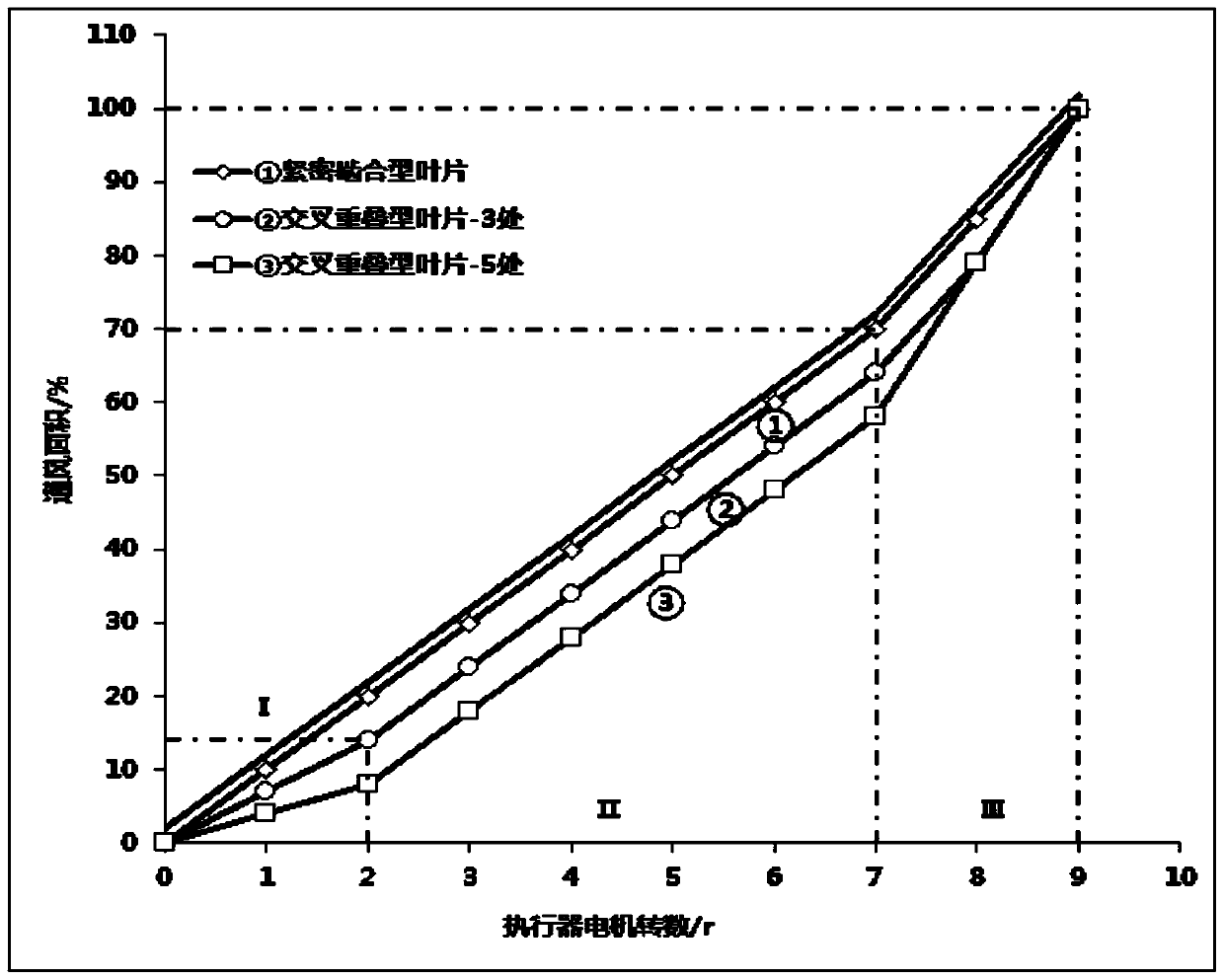

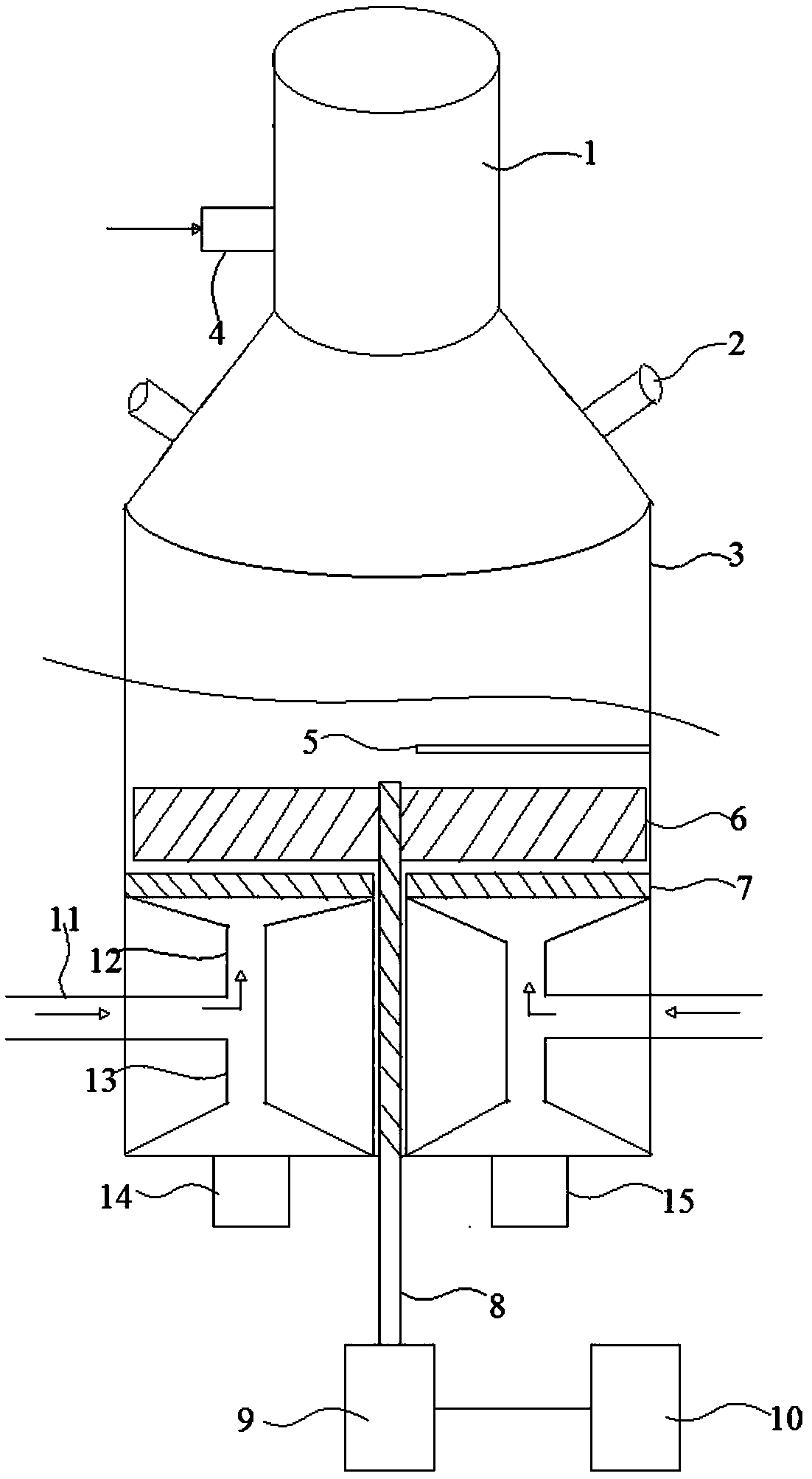

PendingCN110906357AUniform air intakeAvoid insufficient combustionAir supply regulationDamper arrangementThermodynamicsAir volume

The invention discloses an air volume linear adjusting device and adjusting method for an air blower. The air volume linear adjusting device comprises two adjusting blades which are arranged in the radial direction of a ventilation pipeline, and the two adjusting blades can be driven by a power system to move along a rail in the same direction or in the opposite directions, so that the ventilationarea of the ventilation pipeline between the two adjusting blade clamping spaces is increased or decreased. By the adoption of the air volume linear adjusting device and adjusting method, full-rangeair volume adjustment can be achieved, the air inlet amount is more uniform, and the combustion sufficiency is guaranteed; the two-stage air volume adjustment, the ventilation area and the number of turns of an actuator are in a multi-section linear function relationship, and the air volume is accurately adjusted; and the air volume adjusting device is of a movable structure, the manufacturing precision requirement is low, and the maintenance is convenient.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Novel biomass fixed bed combustion boiler capable of operating continuously

ActiveCN108916860ACompact structureEasy to operateSolid fuel combustionAir/fuel supply for combustionCombustionFixed bed

The invention discloses a novel biomass fixed bed combustion boiler capable of operating continuously, and belongs to the technical field of combustion boilers. The Novel biomass fixed bed combustionboiler capable of operating continuously comprises a boiler body which is composed of a bed layer and a free space combustion section; the bed layer is mainly composed of a fire grate and a grid; thefire grate is divided into an air feeding zone and an ash discharging zone, the air feeding zone is provided with air flowing holes, an air chamber is arranged below the air flowing holes in a corresponding mode, and an ash discharging chamber is arranged below the ash discharging zone in a corresponding mode; and the grid is arranged above the fire grate and connected with a rotation driving mechanism located at the bottom of the boiler, and the rotation speed of the grid is controlled by the program. According to the novel biomass fixed bed combustion boiler capable of operating continuously, the staying time of biomass fuel in the boiler is controlled through motion of the grid, and continuous boiler operation is ensured. The boiler is compact in overall structure, the combustion efficiency of the biomass fuel can be effectively improved, compared with traditional grate-fired furnaces, the boiler has the outstanding characteristics of being small in occupied area, easy to operate, low in building cost and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

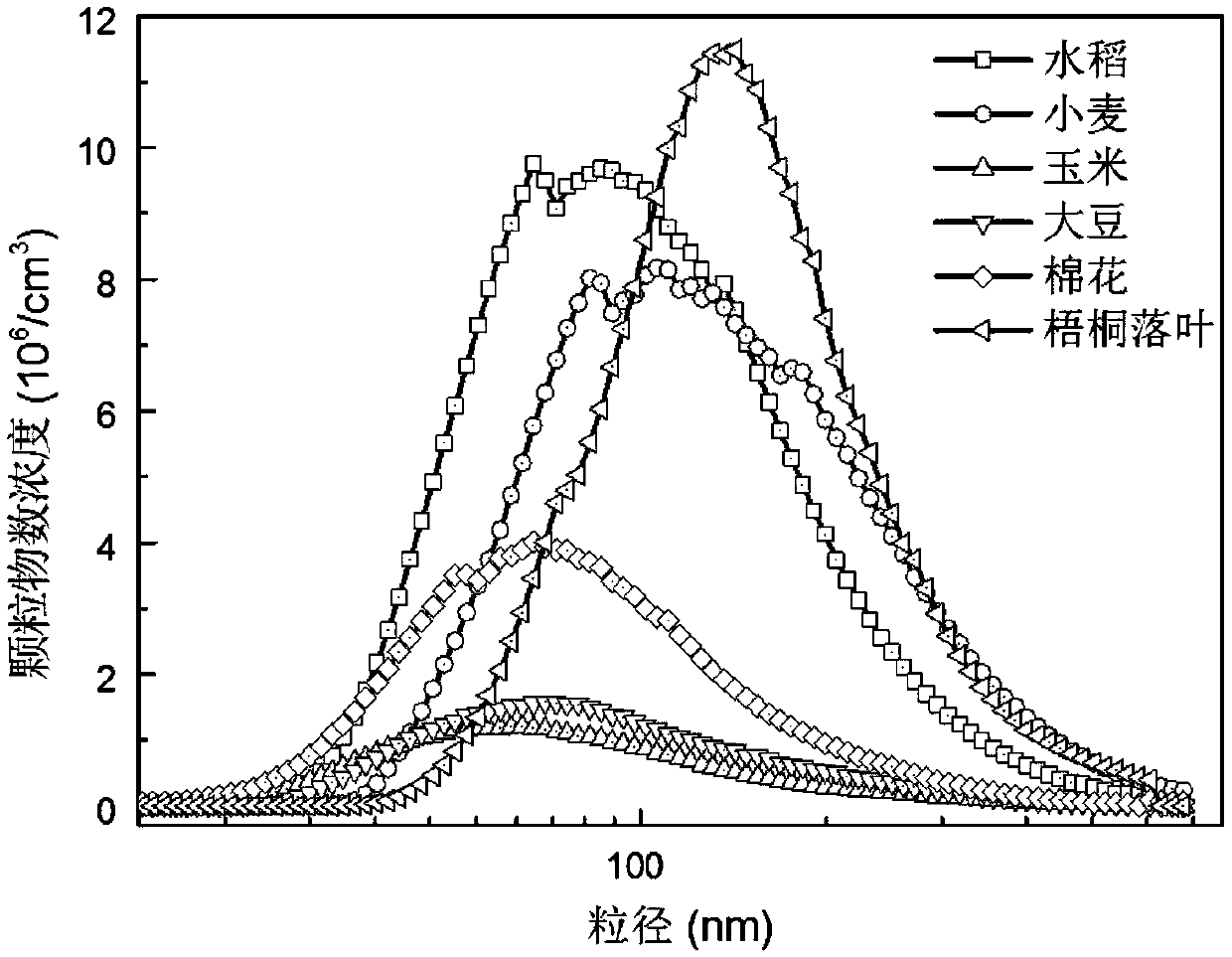

Atmospheric aerosol smog system for measuring particle size distribution of particulates in simulation environment

PendingCN109596481ASimulate the realSimulation is accurateChemical analysis using combustionParticle size analysisParticulatesTerrain

The invention relates to an atmospheric aerosol smog system for measuring particle size distribution of particulates in a simulation environment. The atmospheric aerosol smog system comprises a combustion device for simulating open burning of a biomass, an aerosol smog chamber for simulating an atmospheric pollutant to discharge to an atmosphere, and a particulate particle size and concentration measuring instrument, wherein the combustion device, the aerosol smog chamber and the particulate particle size and concentration measuring instrument are connected sequentially. The atmospheric aerosol smog system for measuring the particle size distribution of the particulates in the simulation environment provided by the invention simultaneously has three functions, and simulates the process ofthe open burning of the biomass to discharge the atmospheric pollutant accurately and authentically; the physicochemical reaction of the atmospheric pollutant, generated by open burning of crop straw,at each height of a convection layer or even an advection layer is simulated artificially, controllably and repeatedly; meanwhile, the influences of factors such as complex weather and terrain in anactual environment are eliminated; and the particle size distribution of the particulates in the simulation environment is obtained accurately via a WPS-1000XP wide-range particle spectrometer, and the degree of accuracy is high, so the defect that the particle size distribution of the particulates cannot be measured or is measured inaccurately is prevented.

Owner:FUDAN UNIV

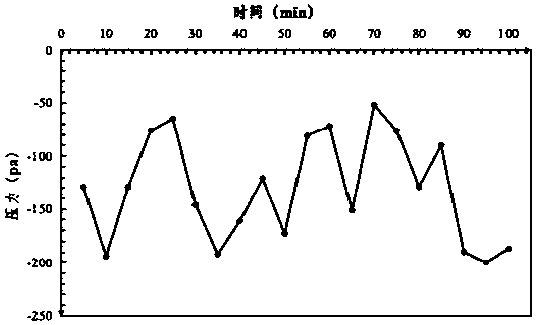

Silicon carbide environmentally-friendly smelting process and device thereof

The invention relates to a silicon carbide environmentally-friendly smelting process which is characterized by adopting underground smelting, overground smoke purification utilization and control by virtue of an overground computer monitoring system. The invention also relates to a silicon carbide environmentally-friendly smelting device which is characterized by comprising a silicon carbide underground smelting workshop, an underground closed type silicon carbide kiln, an underground closed type silicon carbide kiln top negative hot pressure smoke acquiring louver device, an explosion-proof screen and a camera, a hot smoke acquirer at the bottom of the underground silicon carbide kiln, a movable explosion-proof wall, a movable explosion-proof wall overground smoke purifying and distributing chamber, a carbon dioxide acquirer and a dry ice device, a hydrogen sulphide and sulphur dioxide reaction lime pond, a precipitated water circulating recycling system, a carbon monoxide acquirer and a boiler, a methyl mercaptan and combustible gas acquirer, an overground travelling car and an overground computer monitoring system, an overground water supply system and a hot smoke induced draught system. By adopting the method provided by the invention, components in the hot smoke of silicon carbide are purified and decomposed, and neutralization and utilization are carried out, thus the hot smoke is completely environmentally-friendly.

Owner:青海星言商贸有限公司 +2

Environment-friendly incineration device for garbage disposal and with circulating remelting structure

InactiveCN113007714AAvoid insufficient combustionGuarantee stability and comprehensivenessIncinerator apparatusProcess engineeringRefuse Disposals

The invention relates to the technical field of garbage disposal equipment, in particular to an environment-friendly incineration device for garbage disposal and with a circulating remelting structure. The device comprises an incineration tank main body, wherein the incineration tank main body is in a rectangular box shape, the left side and the right side of the incineration tank main body are semicircular, a reciprocating stirring mechanism is mounted in the incineration tank main body, and the reciprocating stirring mechanism comprises a driving bin box. According to the incineration device, garbage on the left side of the interior of the incineration tank main body is stirred to the right side of the interior of the incineration tank main body through overturning movement of a stirring plate, a crushing mechanism arranged on the right side of the interior of the incineration tank main body is used in cooperation, garbage which is not fully combusted is crushed and broken by means of a crushing roller, through the cooperation of movement and rotation of the stirring plate, the crushed garbage is pushed to the left end of the interior of the incineration tank main body again for incineration operation, so that the situation that internal combustion is insufficient during garbage incineration is effectively avoided, and the stability and comprehensiveness of the device on garbage incineration treatment are conveniently guaranteed.

Owner:合肥数喆信息科技有限公司

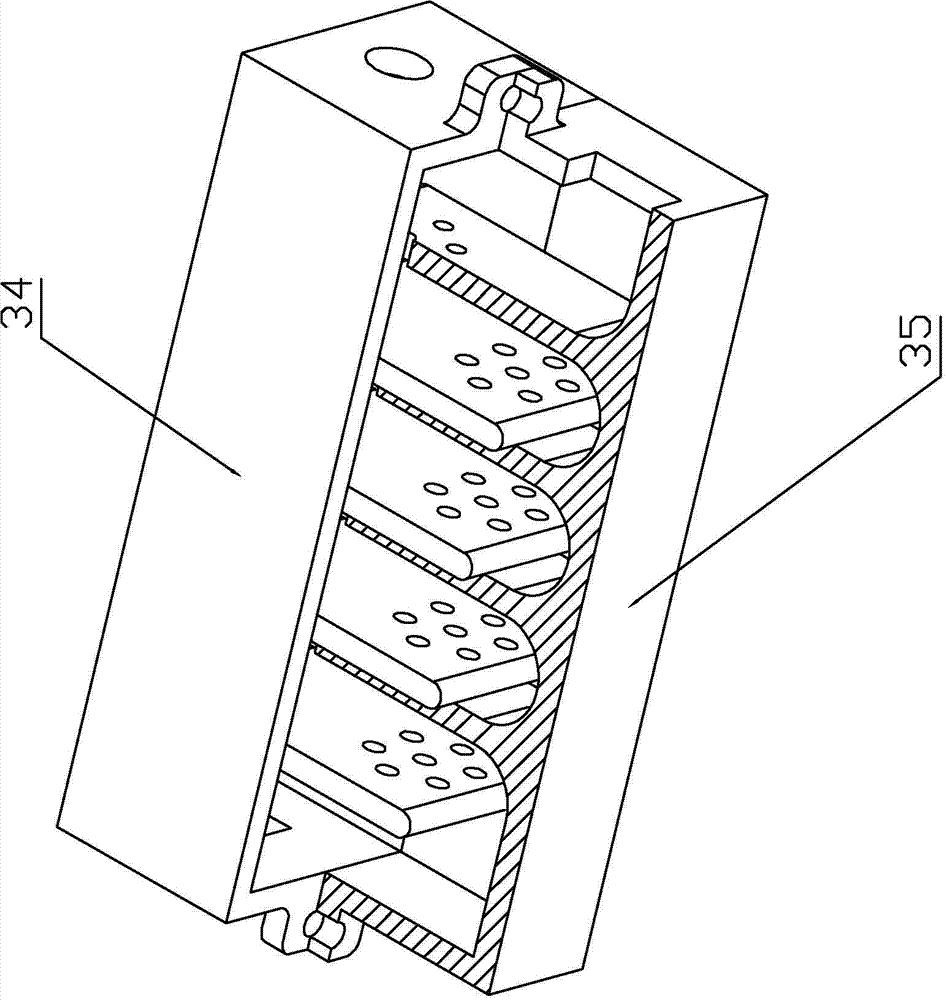

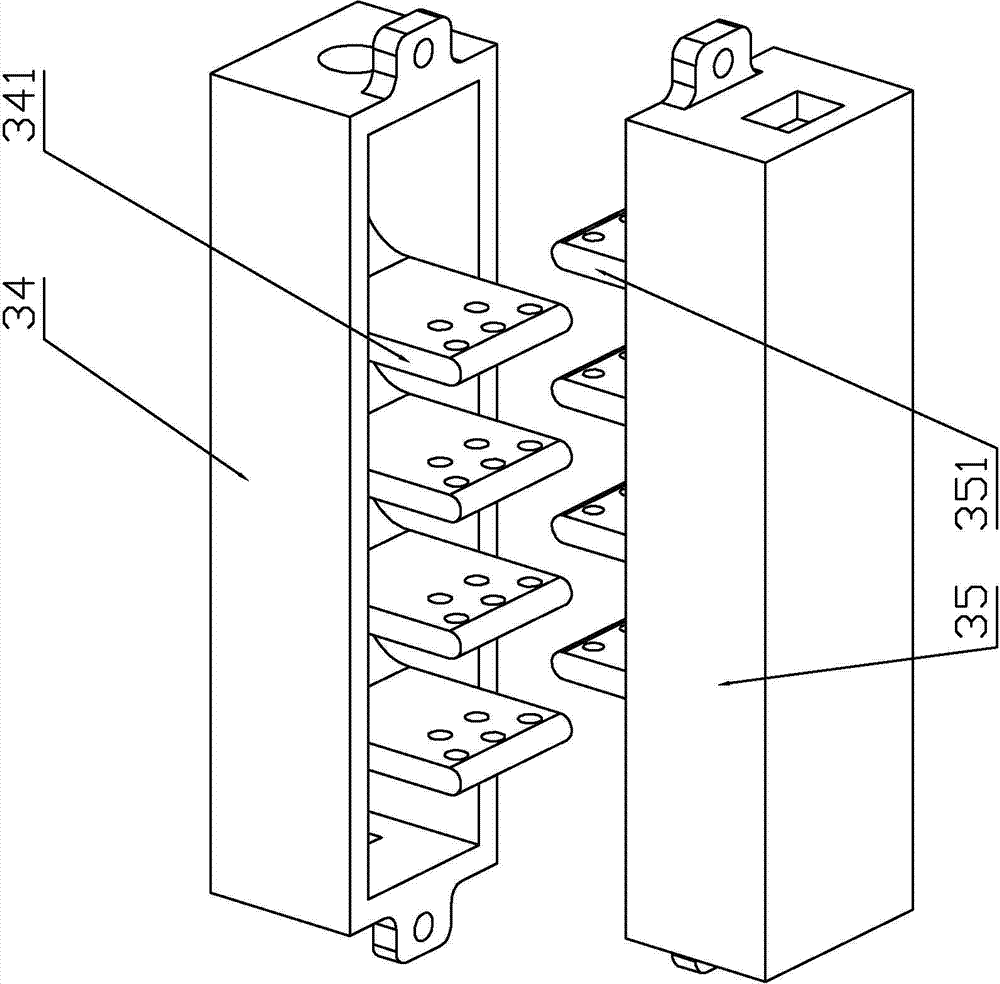

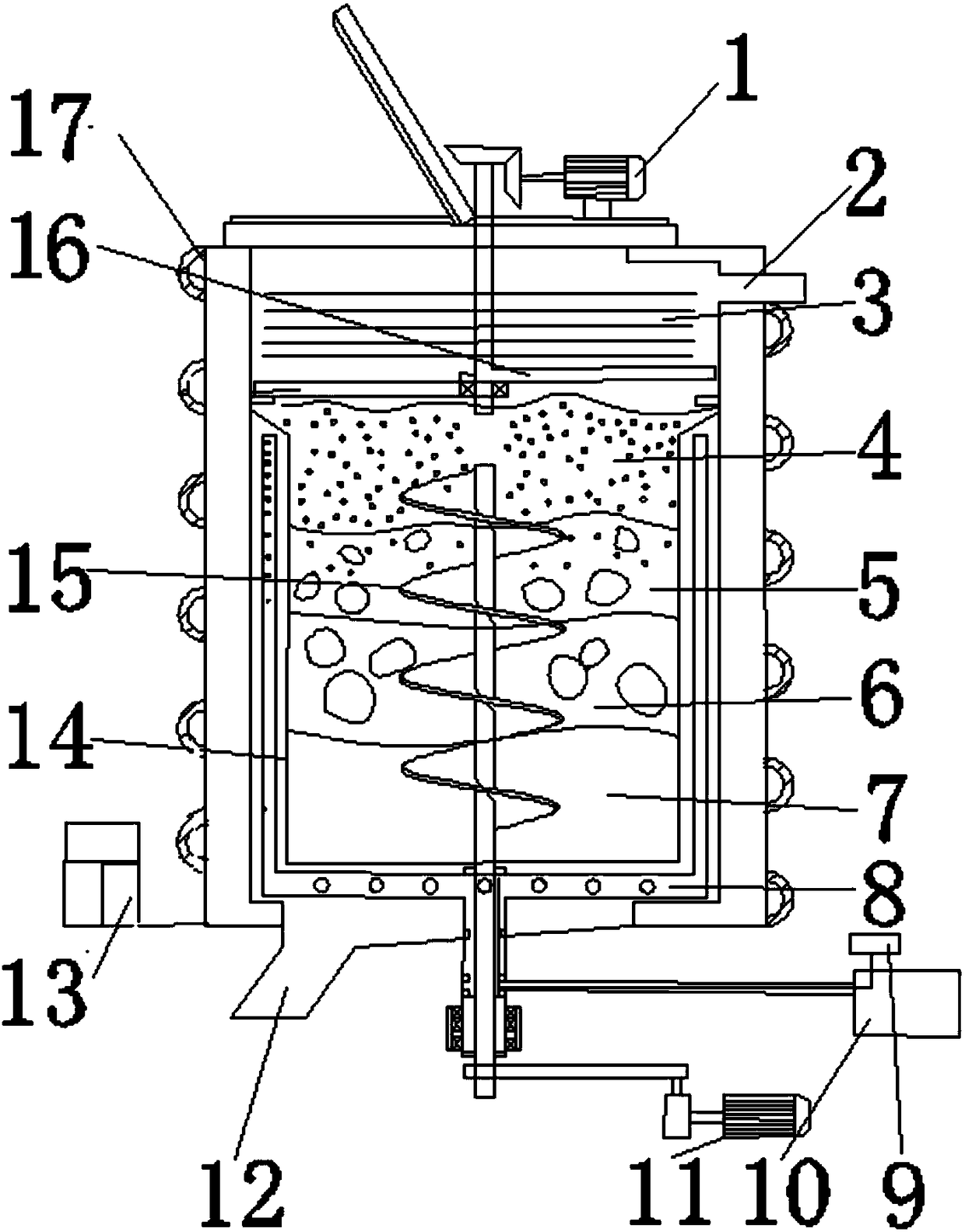

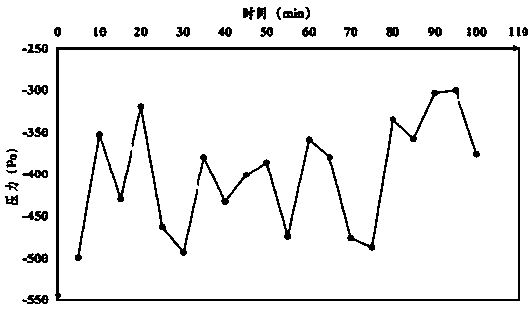

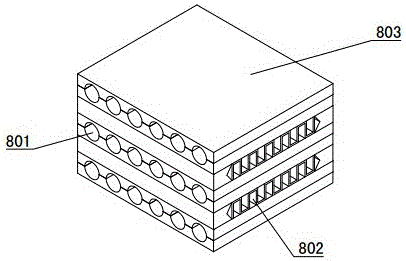

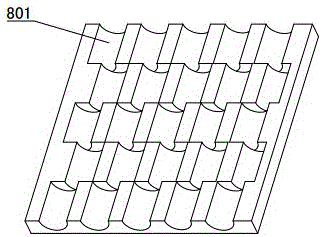

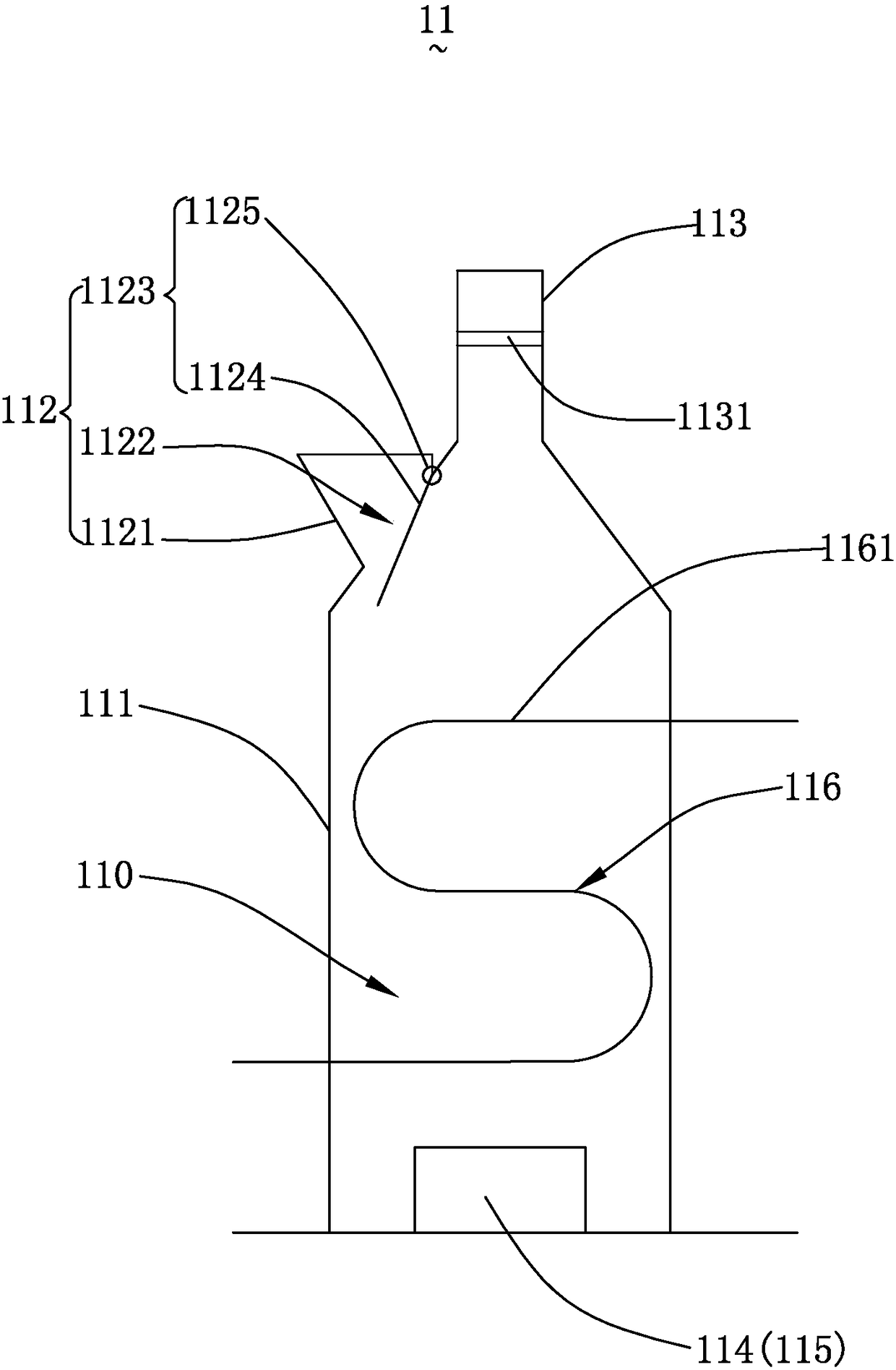

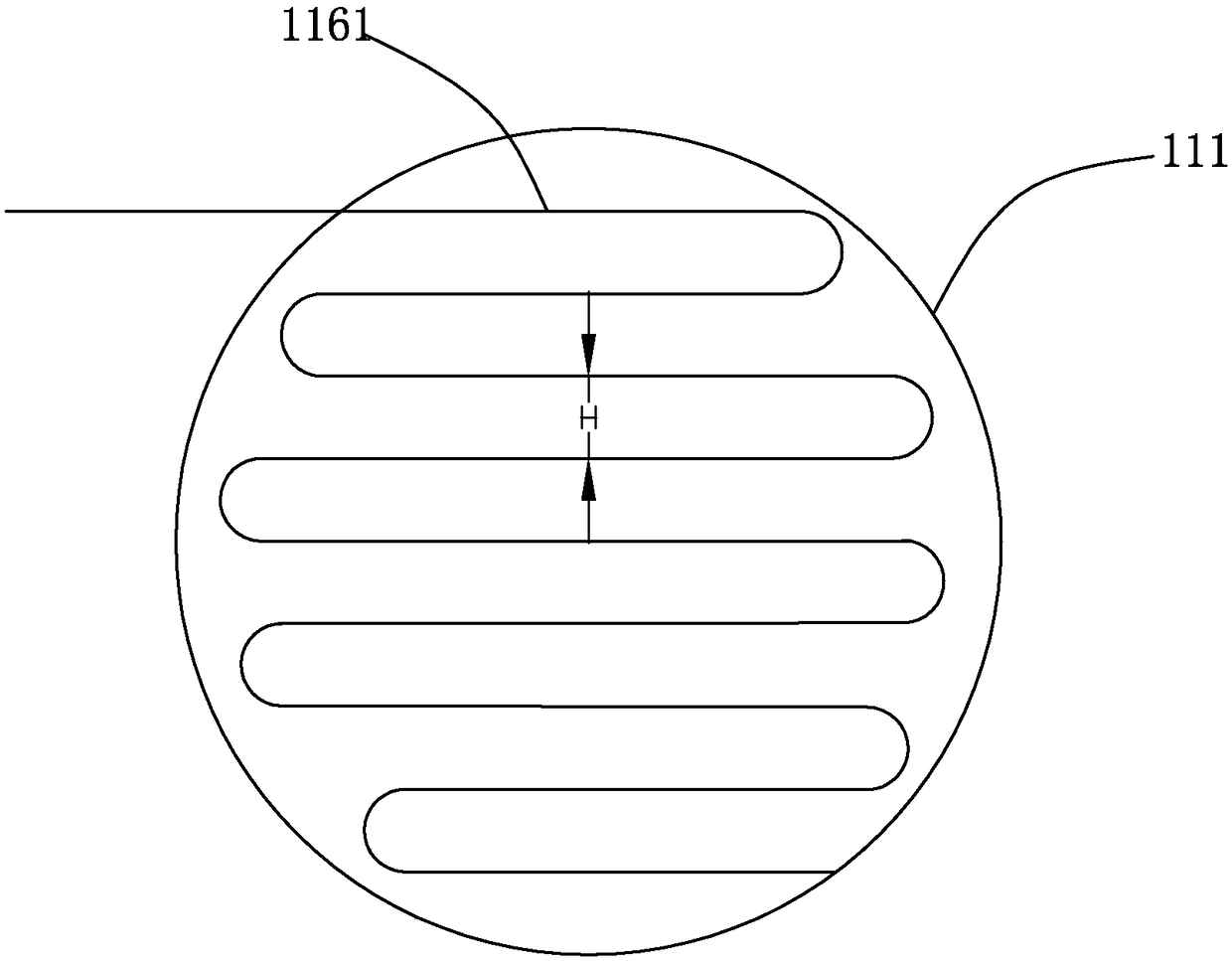

Small domestic garbage incineration purification treatment system

InactiveCN108072043APrevent pilesAvoid insufficient combustionEmission preventionIncinerator apparatusActivated carbonHeat transmission

The invention discloses a small domestic garbage incineration purification treatment system. The small domestic garbage incineration purification treatment system comprises a garbage incinerator, a spraying absorption tower, a smog removal device, an activated carbon adsorption device and an exhaust chimney, wherein the garbage incinerator, the spraying absorption tower, the smog removal device, the activated carbon adsorption device and the exhaust chimney are connected in sequence. The garbage incinerator comprises a furnace body with a hearth, and a heat transmitter arranged in the hearth.The heat transmitter comprises multiple layers of heat transmission pipes which are arranged perpendicular to the flow direction of air flows and communicate with one another. Each layer of heat transmission pipes are distributed in the shape of a snake. The interval between every two adjacent layers of heat transmission pipes increases step by step in the direction from air inlet to air outlet. According to the small domestic garbage incineration purification treatment system, garbage can sufficiently and effectively burn quickly, the amount of generated toxic and harmful smoke can be reduced, and purification treatment can be effectively carried out on the generated smoke.

Owner:湖南云平环保科技有限公司

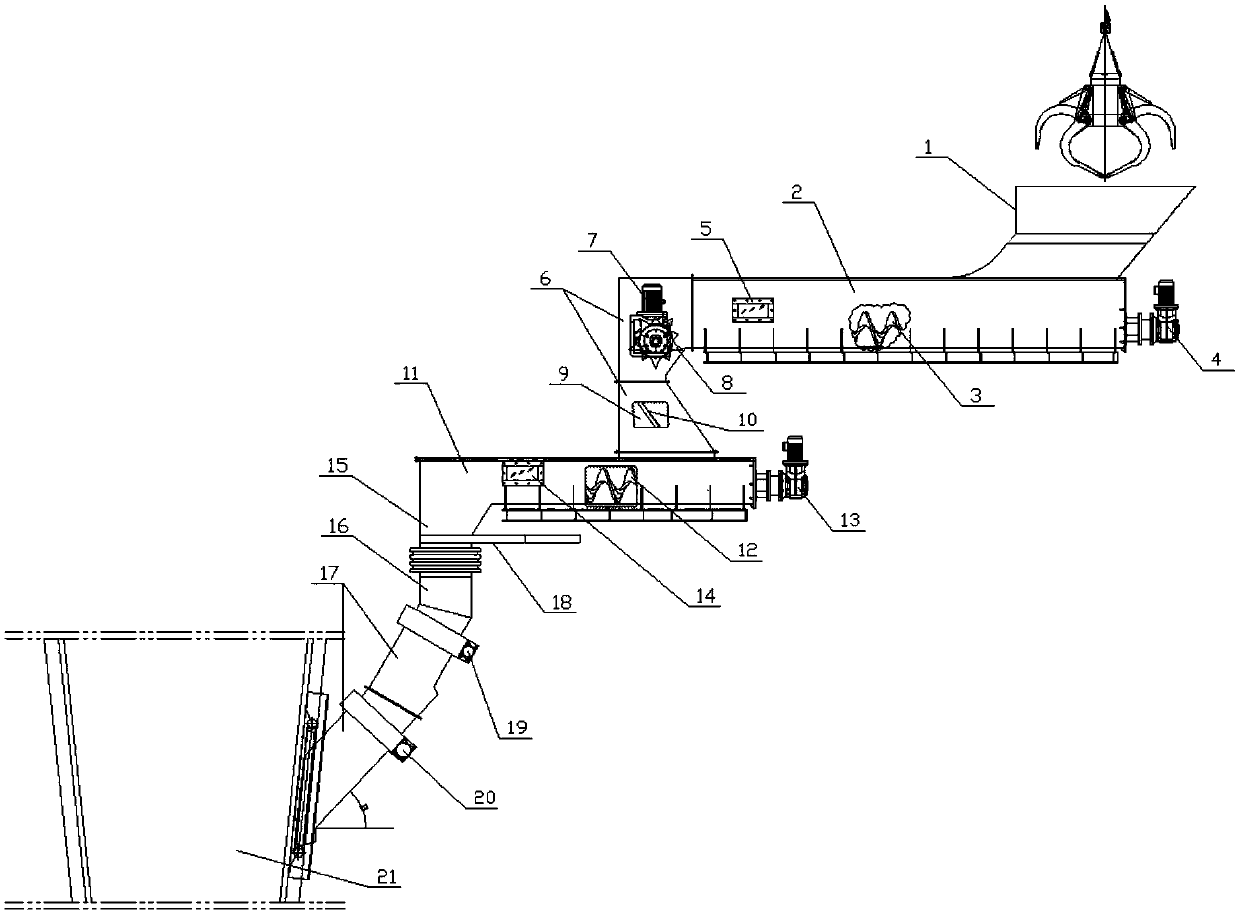

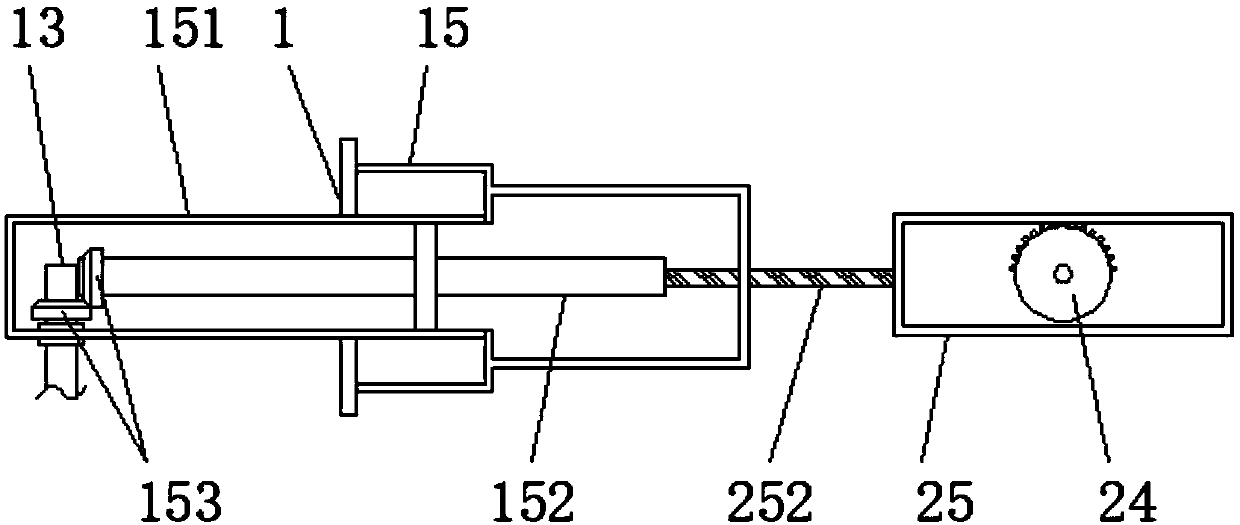

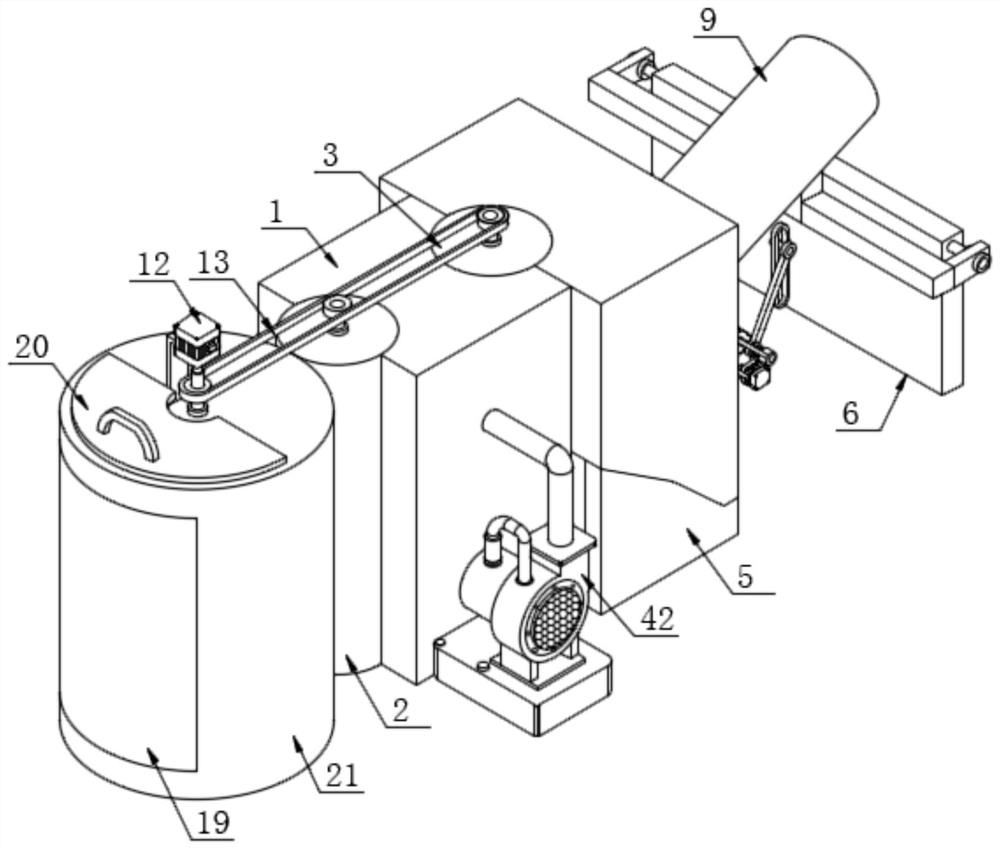

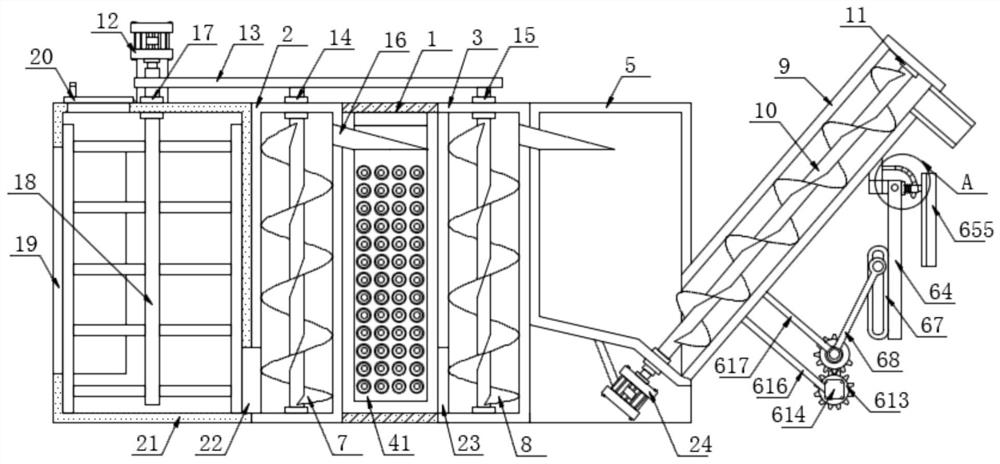

Biomass boiler feeding device and using method thereof

PendingCN114165804AKeep dryBurn fullyFuel feeding arrangementsSolid fuel pretreatmentGear wheelPollutant emissions

The invention discloses a biomass boiler feeding device and a using method thereof, and particularly relates to the technical field of biomass boilers. Fuel is dried before feeding, so that the dryness of the fuel can be improved, the fuel can be combusted more easily, the combustion efficiency is improved, the boiler starting time can be effectively shortened, and the energy consumption is reduced. The production and processing process is guaranteed, meanwhile, pollutant emission can be reduced, the device can drive an extension plate to swing left and right by adopting a movable rod control mode, then left-right feeding of fuel can be achieved, and in the left-right swing process, the fuel can be continuously fed without driving equipment, so that the production efficiency is improved. The front-back movement of the feeding plate is completed through cooperation of the first gear and the toothed bar, then fuel can be guided to be fed front and back, the fuel can be fed in multiple directions through left-right swing and front-back swing, the requirement for uniform feeding can be better met, and therefore the purpose of sufficient combustion of the fuel can be guaranteed.

Owner:光谷蓝焰(团风)新能源有限公司

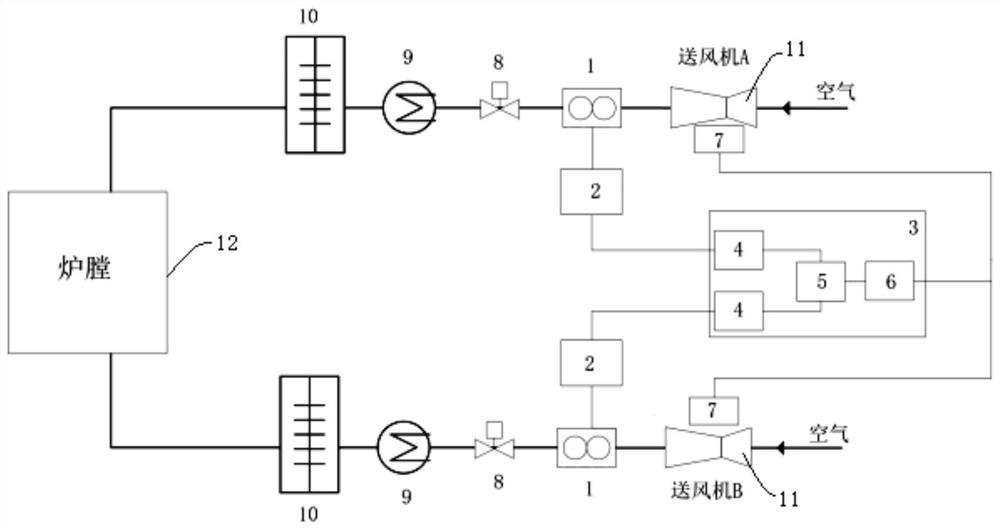

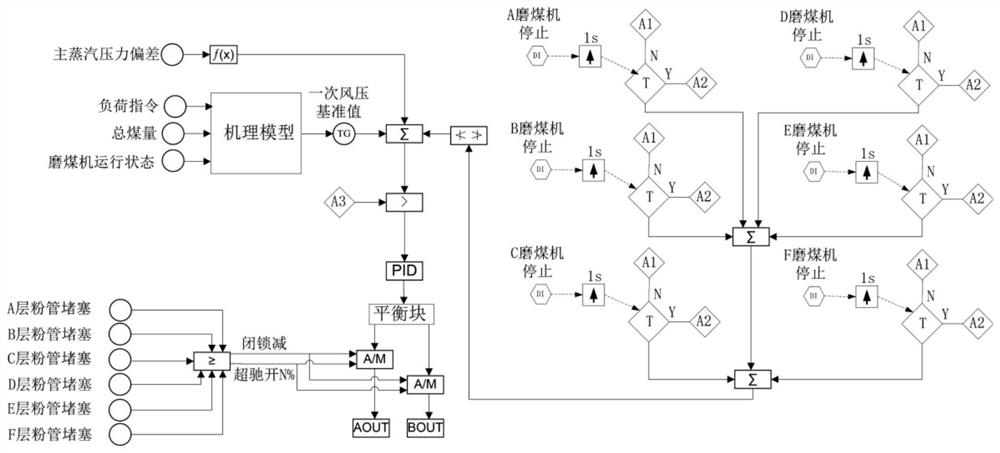

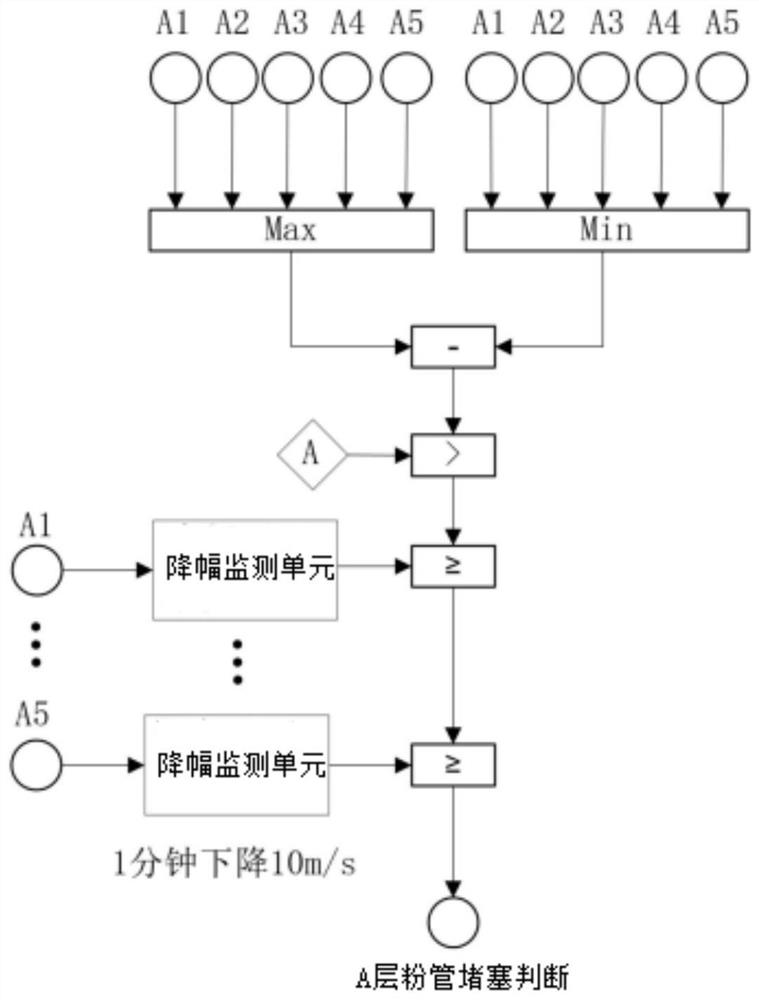

Thermal power generating unit air volume and air pressure decoupled control method

ActiveCN112363554AImprove controlRealize decoupling controlSimultaneous control of multiple variablesThermodynamicsAir volume

The invention discloses a thermal power generating unit air volume and air pressure decoupled control method. The method comprises the steps that: a primary fan outlet air volume serves as a total primary air volume, and an air feeder outlet air volume serves as a total secondary air volume; and the total secondary air volume serves as a total air volume in boiler combustion control, and the totalair volume of a boiler is controlled by controlling the total secondary air volume. According to the method of the invention, the total primary air volume is separated from the total air volume control; hot primary main pipe air pressure serves as a target value of the primary air control; the primary air pressure control logic is optimized, so that the primary air volume is indirectly controlledthrough controlling the primary air pressure, and meanwhile, the total secondary air volume serves as the total air volume in the boiler combustion control so as to be controlled; and therefore, thedecoupled control over the total primary air volume and the total secondary air volume in the total air volume is achieved. When the total primary air volume and the total secondary air volume are coupled, combustion is insufficient or pollutants exceed the standard, and a combustion effect is poor due to the unreasonable ratio of the total primary air volume and the total secondary air volume, with the the method adopted, the problems can be solved; and the combustion control effect of the boiler is improved.

Owner:SICHUAN GUANGAN POWER GENERATION CO LTD

Energy-saving furnace

InactiveCN105222161AAvoid insufficient combustionImprove flammabilityDomestic stoves or rangesLighting and heating apparatusEngineeringHot Temperature

The invention provides an energy-saving furnace. In the use process, a coal containing fire grate is arranged at the bottoms of sliding boards by operating a lifting unit. Coal is added to the coal containing fire grate. Coke is added to a coke containing fire grate. The coal is located in the space defined by the sliding boards and cannot fall to the coke containing fire grate. Due to the fact that the coke is excellent in combustion performance, a high-temperature region is formed in the region above the coke containing fire grate. The combustion performance of the coal is inferior to that of the coke, the coal cannot be fully burnt in the combustion process, the black smoke phenomenon is generated, and black smoke is exhausted out of the furnace through a chimney over the coke containing fire grate. In the exhausting process, the black smoke passes the high-temperature region above the coke containing fire grate, combustible substances in the black smoke are fully burnt in the high-temperature region, and therefore the purposes that the black smoke phenomenon is eliminated, the problem of incomplete coal combustion is solved, and energy is saved are achieved.

Owner:天津九州中盛暖通设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com