Air volume self-adaptive gas water heater control system

A gas water heater and control system technology, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as inability to overcome poor combustion conditions, low feasibility, and complicated control methods, so as to avoid insufficient combustion, The effect of high feasibility and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

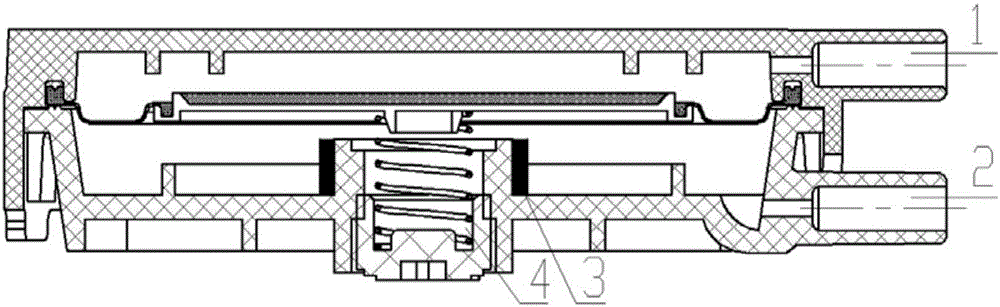

[0025] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

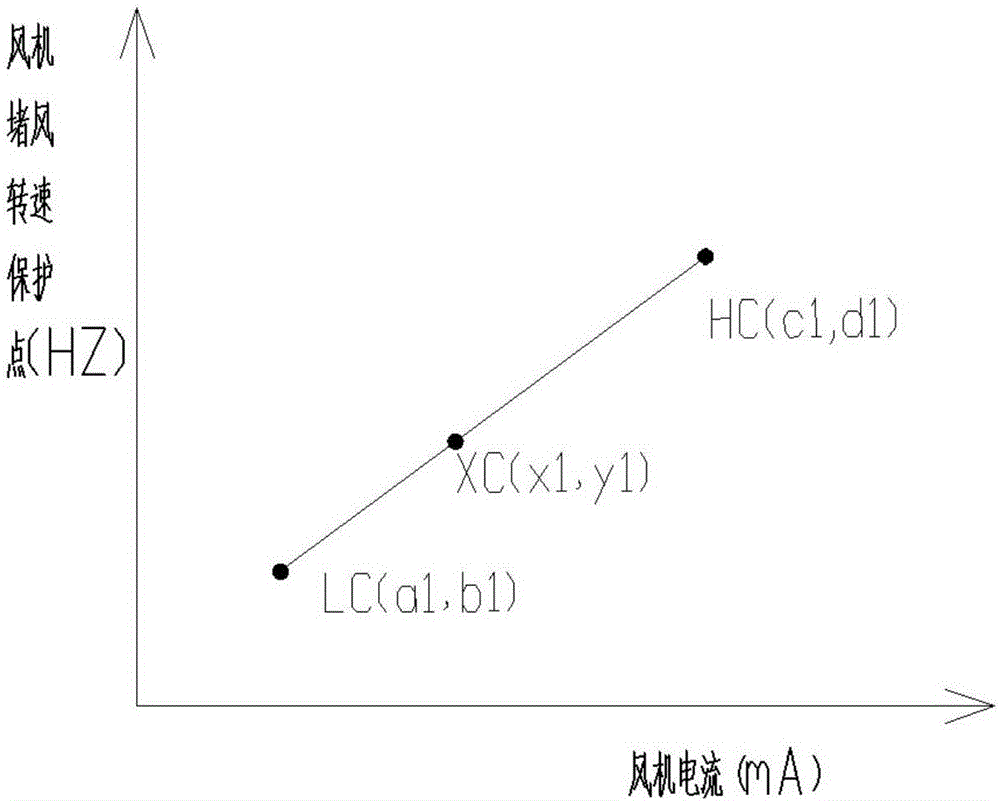

[0026] A gas water heater control system with self-adaptive air volume, including a main controller and a wind pressure sensor connected to the main controller. When the water heater is in a certain heat load state, the main controller changes the fan current so that the output frequency of the wind pressure sensor is always maintained at the corresponding value.

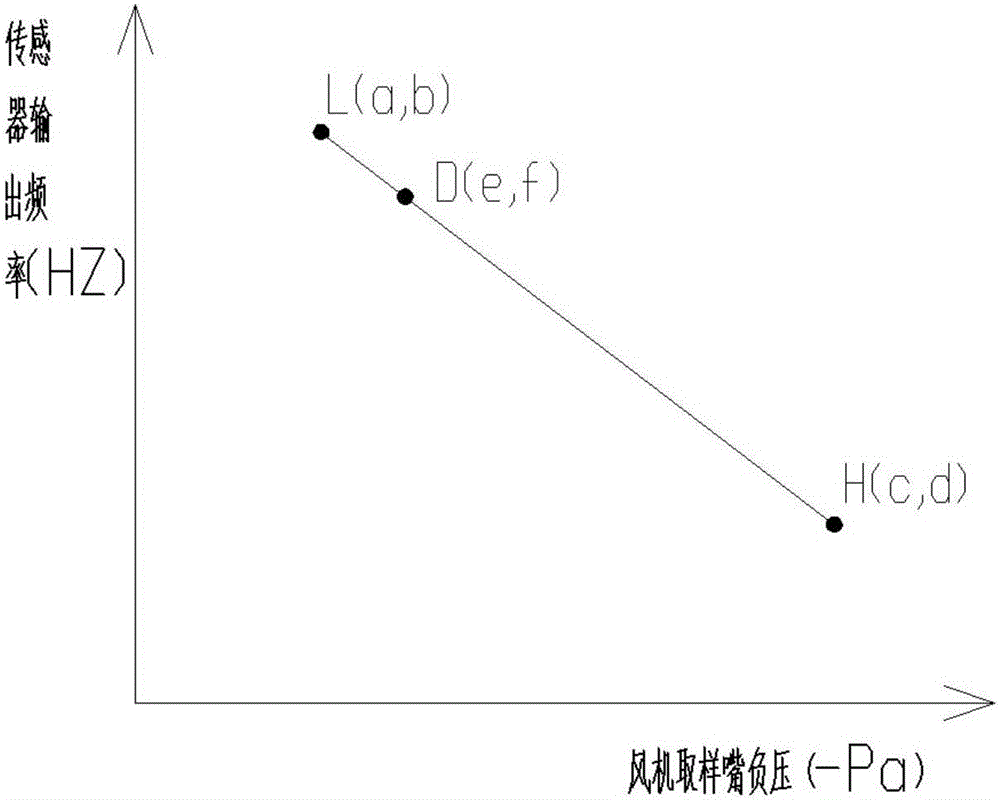

[0027] Such as figure 1 As shown, the corresponding method of each heat load of the gas water heater and the output frequency of the corresponding wind pressure sensor is:

[0028] 1) Determine the output frequency value b of the air pressure sensor and the negative pressure value a of the fan sampling nozzle corresponding to the minimum thermal load of the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com