Combustion gas kitchen range

A technology for gas stoves and burners, which can be used in the direction of household stoves/stoves, stoves/stove tops, heating fuel, etc., and can solve problems such as position deviation of brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

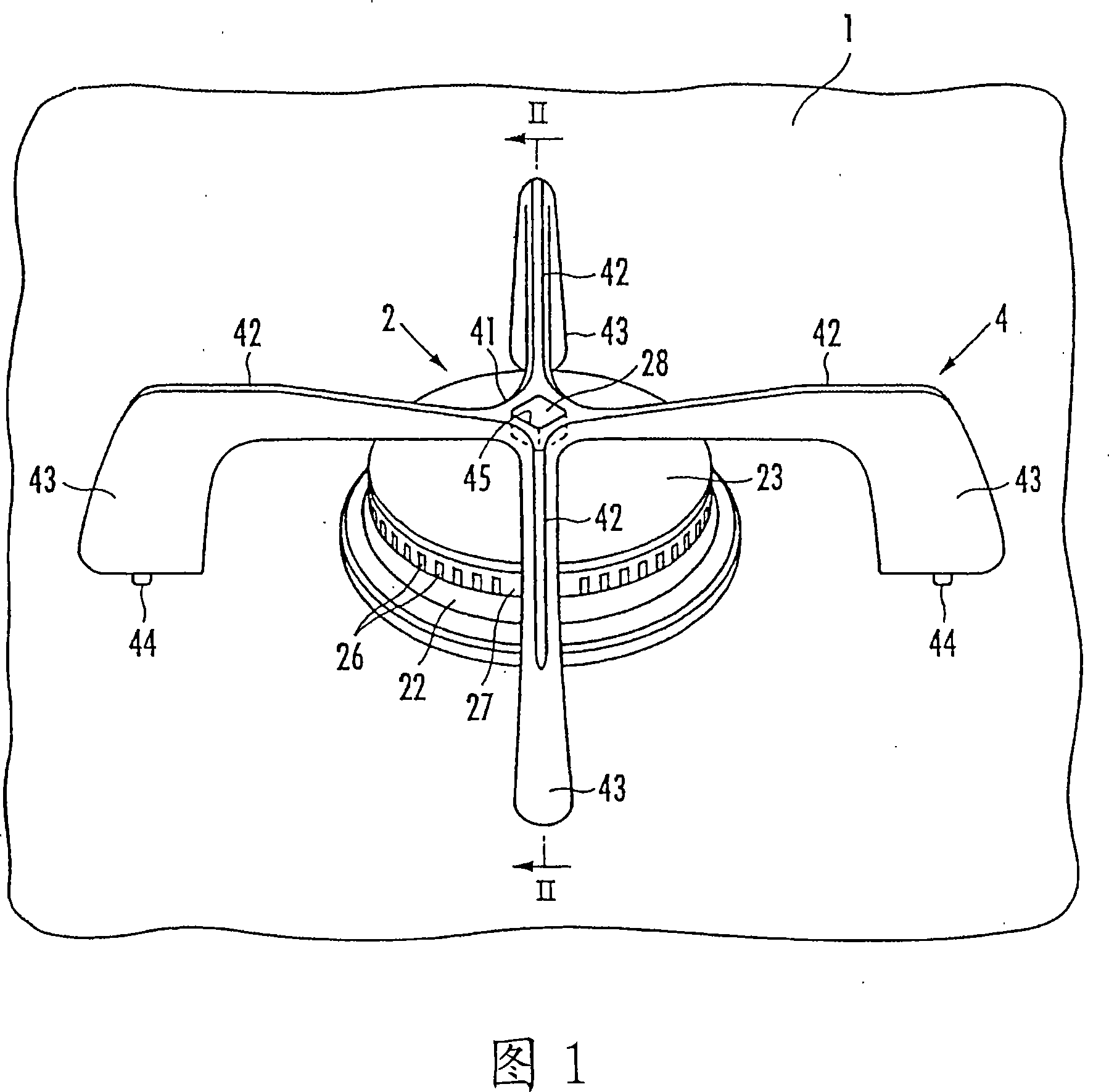

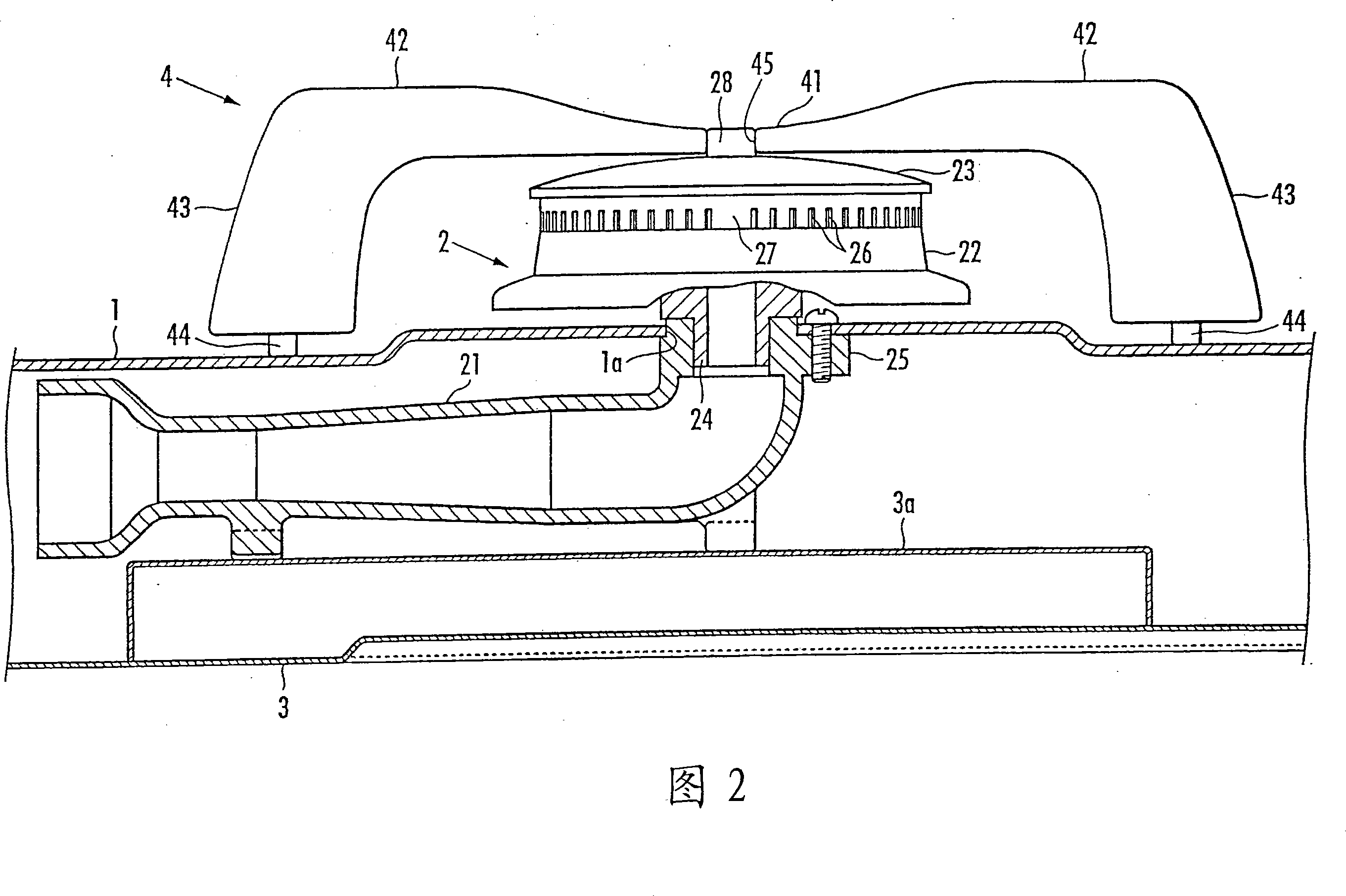

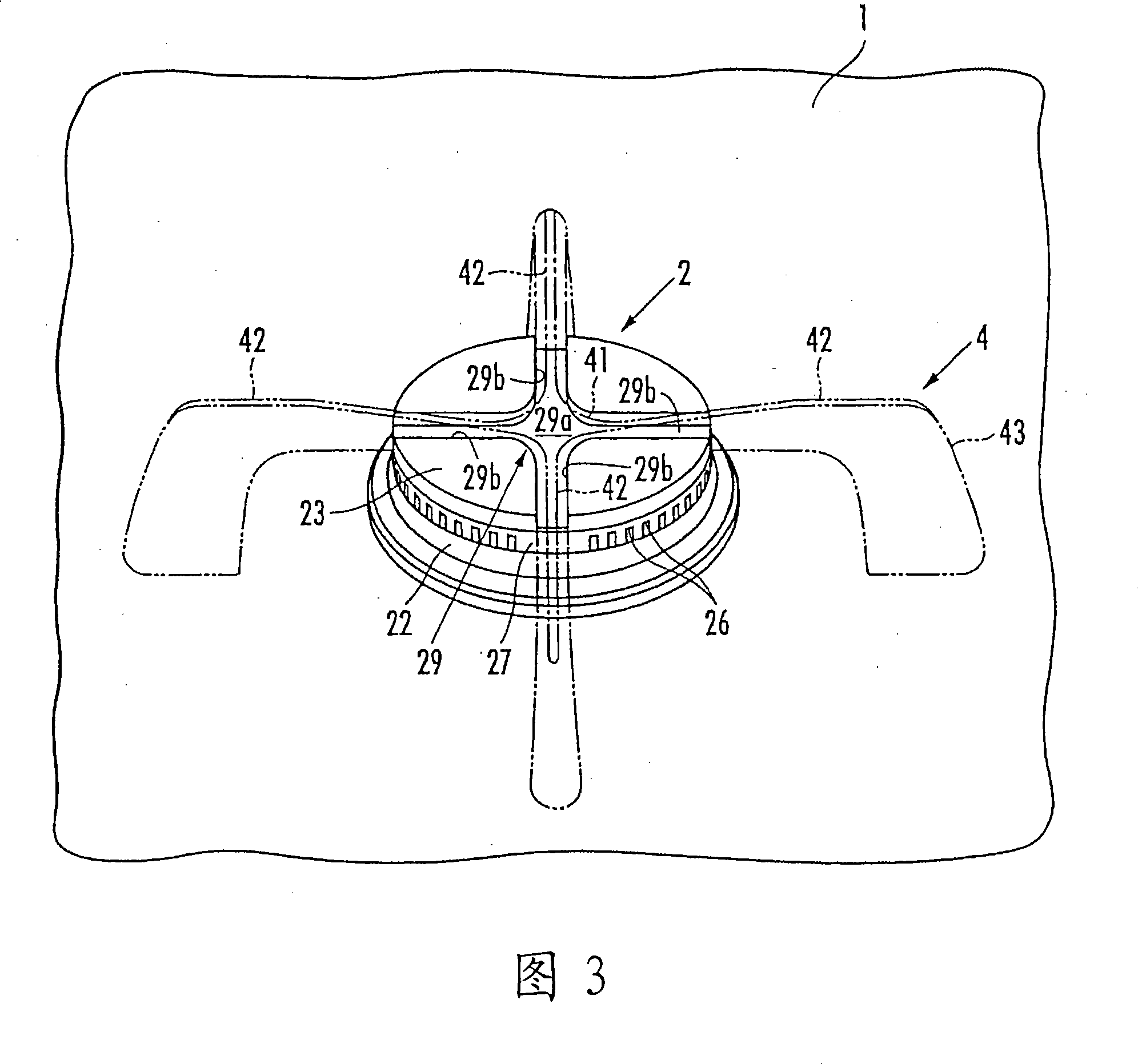

[0020] With reference to Fig. 1, 1 is the panel of gas stove, and 2 is burner. The burner 2, as shown in Figure 2, consists of a mixing tube 21 arranged in the stove body 3 covered by the panel 1, a burner body 22 protruding above the panel 1, and a burner head placed on the burner body 22 23 poses.

[0021] The mixing tube 21 is placed on the bottom frame 3a provided on the bottom of the stove main body 3 and fixed. In the range main body 3 , a gas nozzle, which is omitted from the illustration, is provided facing the upstream end of the mixing tube 21 . The mixed gas (mixed gas) of the gas injected from the gas nozzle and the primary air sucked in from the upstream end of the mixing tube 21 is generated in the mixing tube 21 . The downstream end portion of the mixing tube 21 is bent upward, and fitted into a through hole 1 a formed in the panel 1 . A cylindrical portion 24 vertically provided under the burner main body 22 is fitted to the downstream end portion of the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com