Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Avoid electrical contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

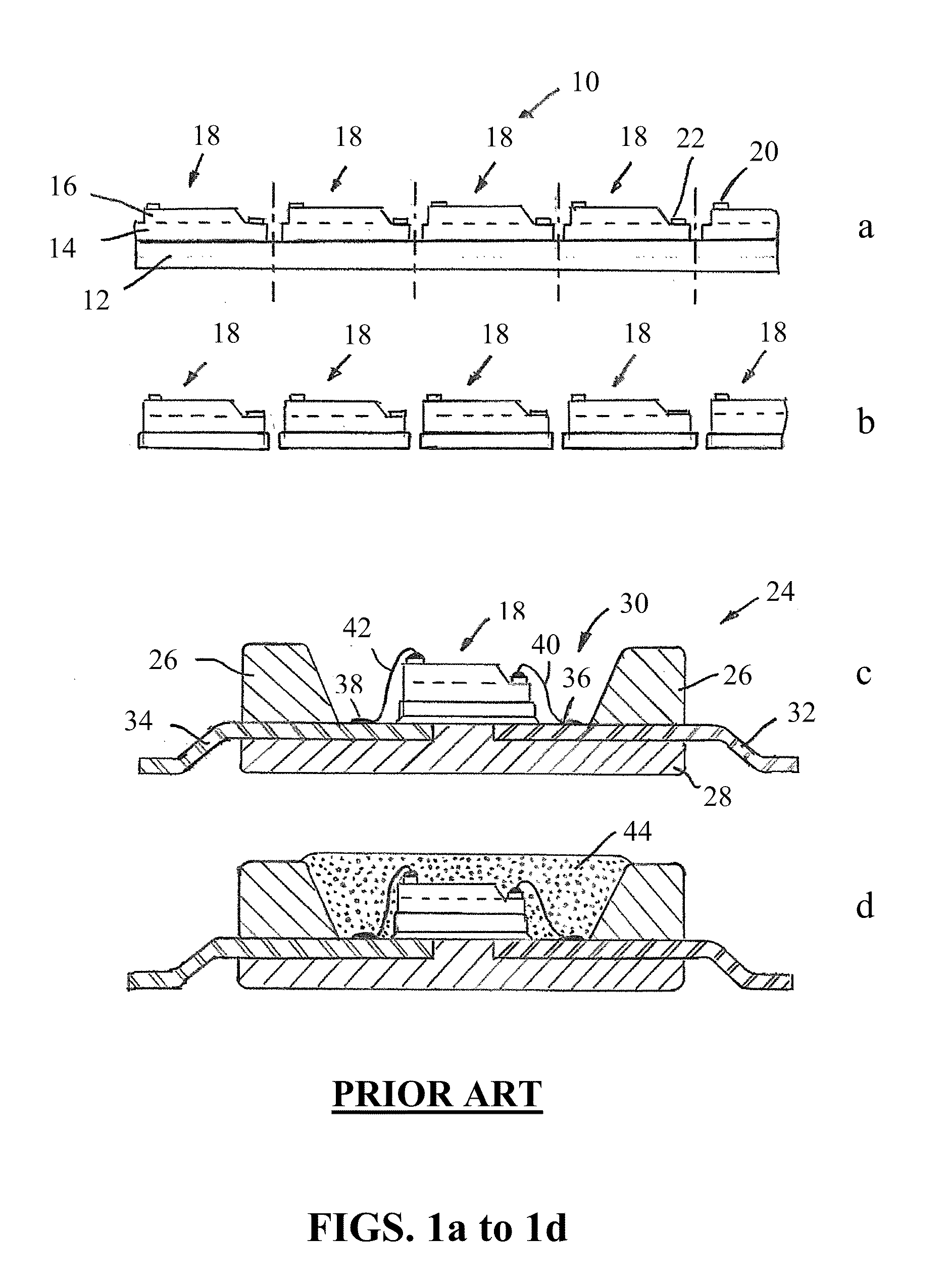

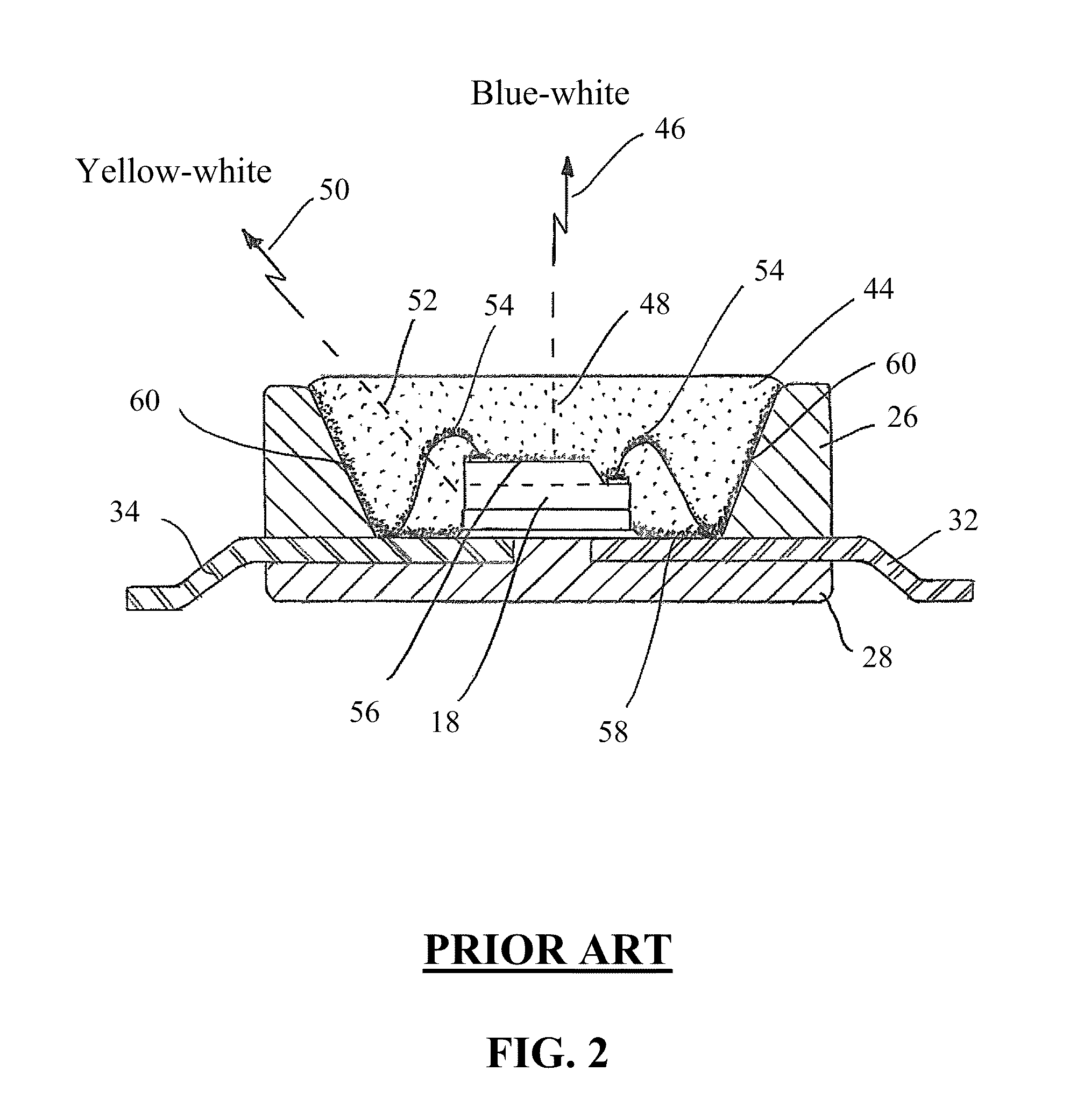

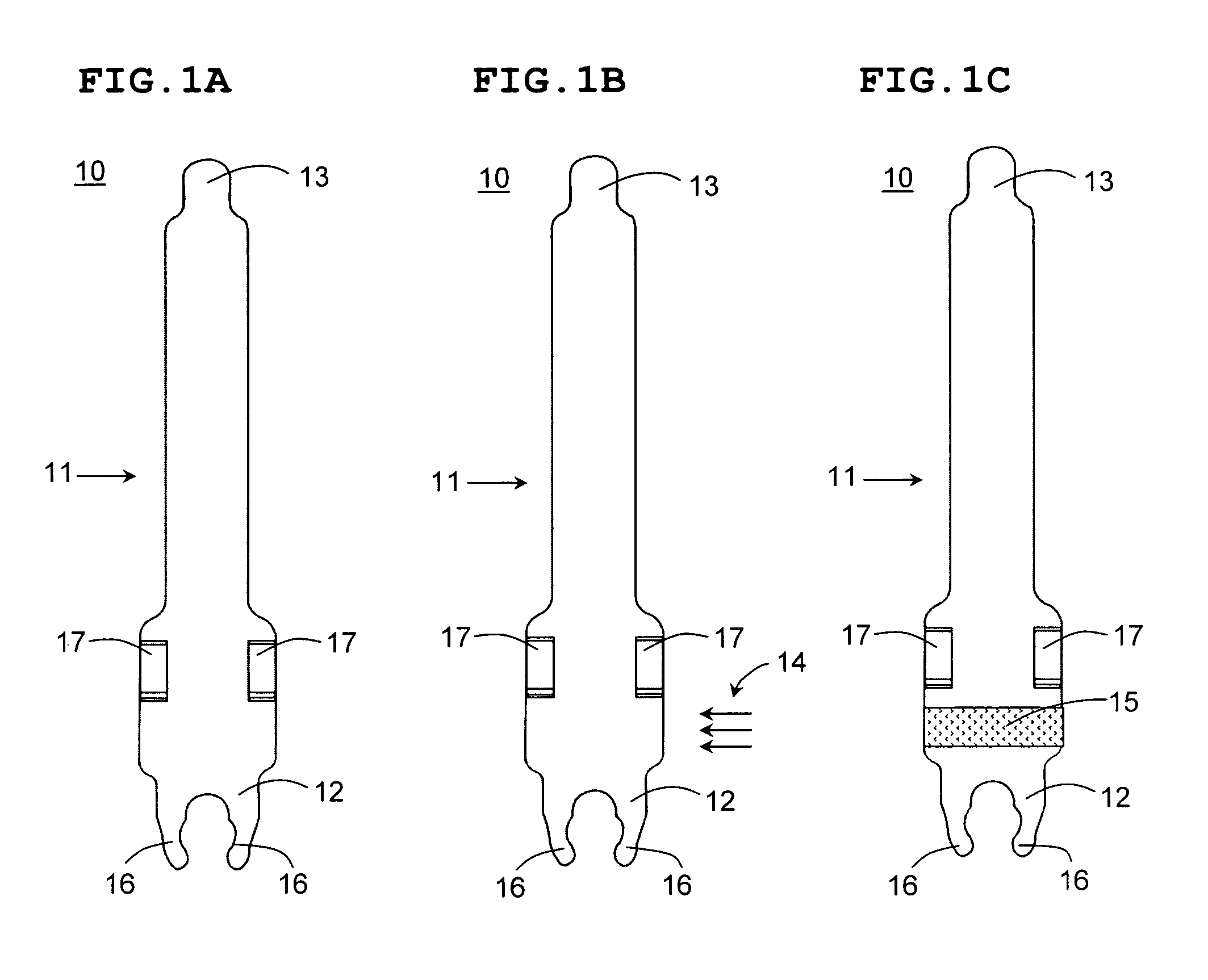

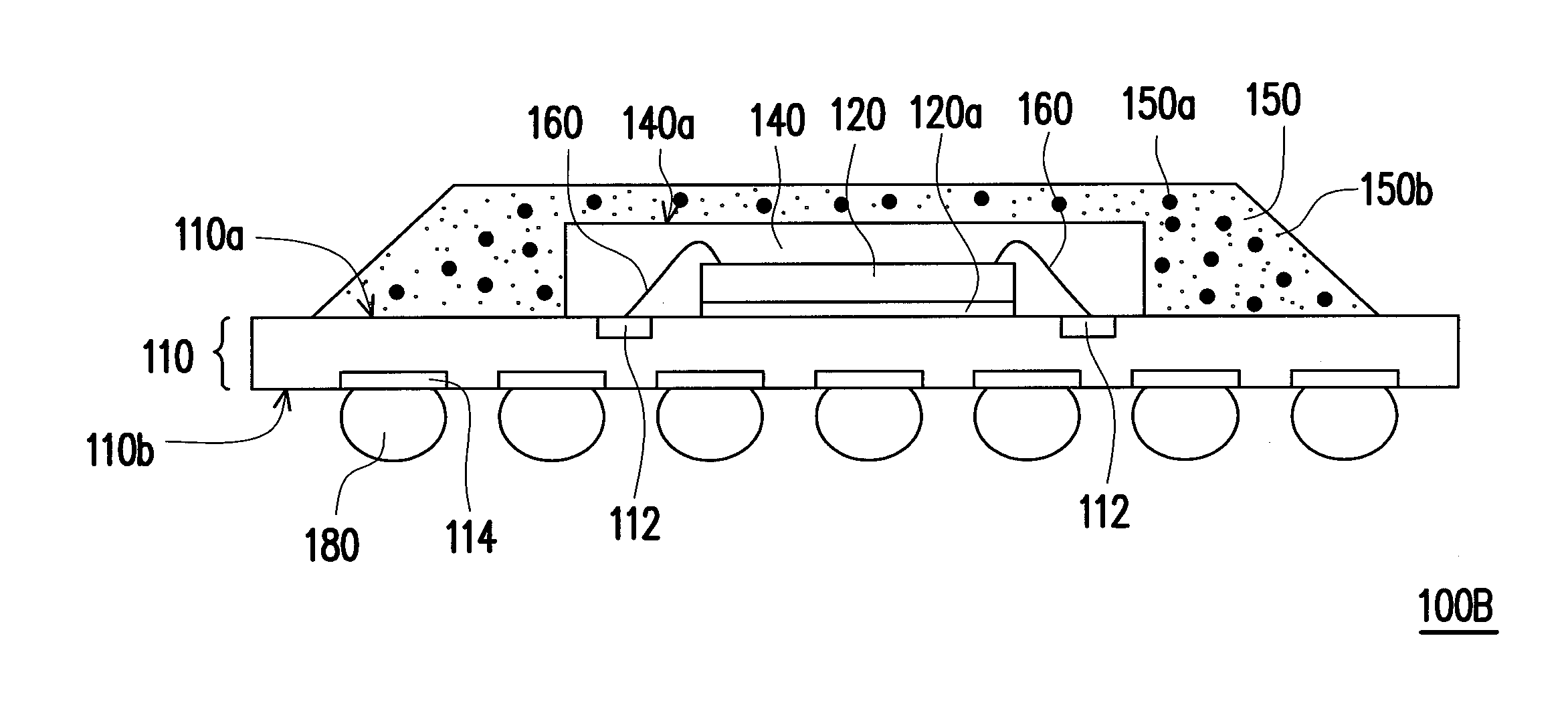

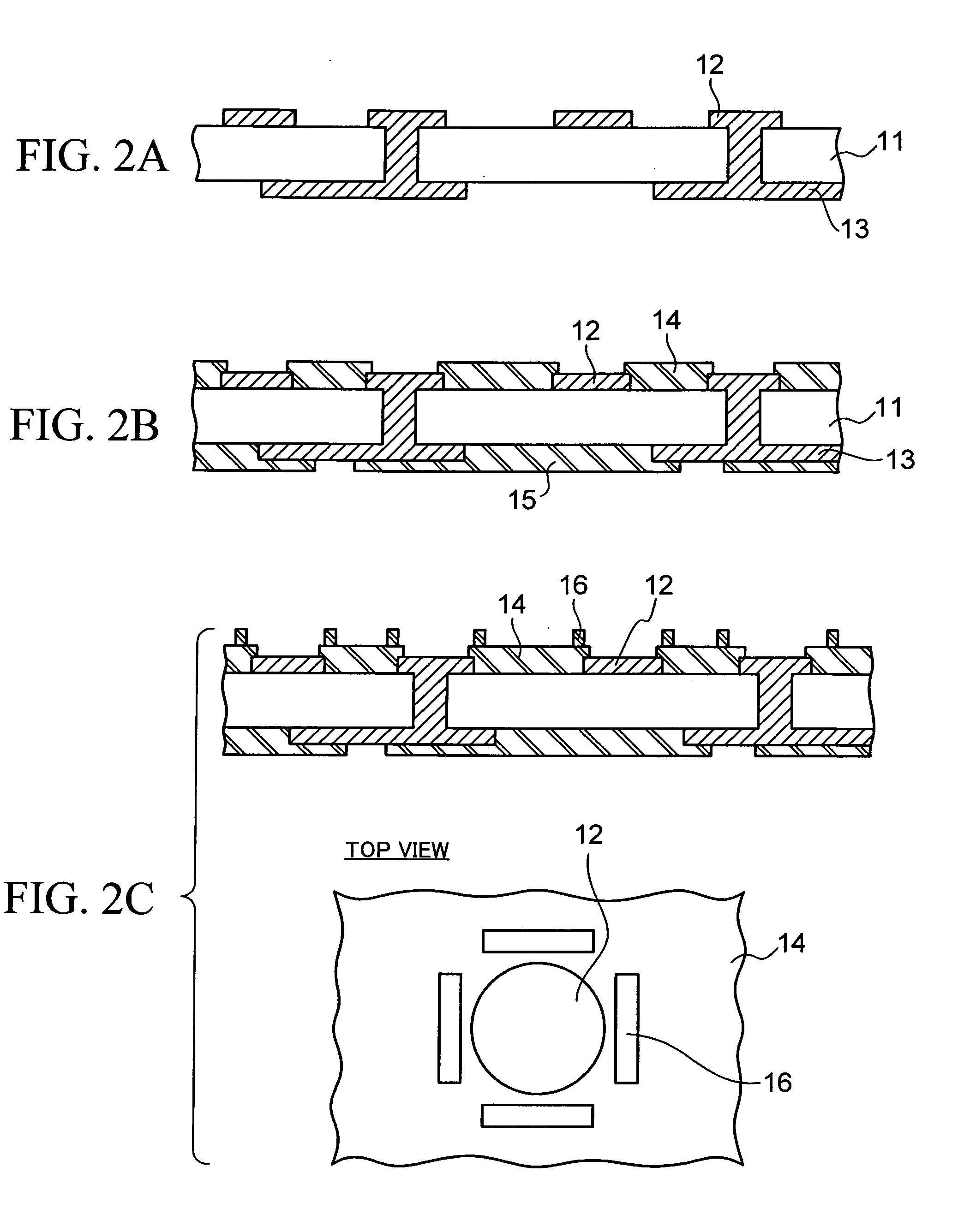

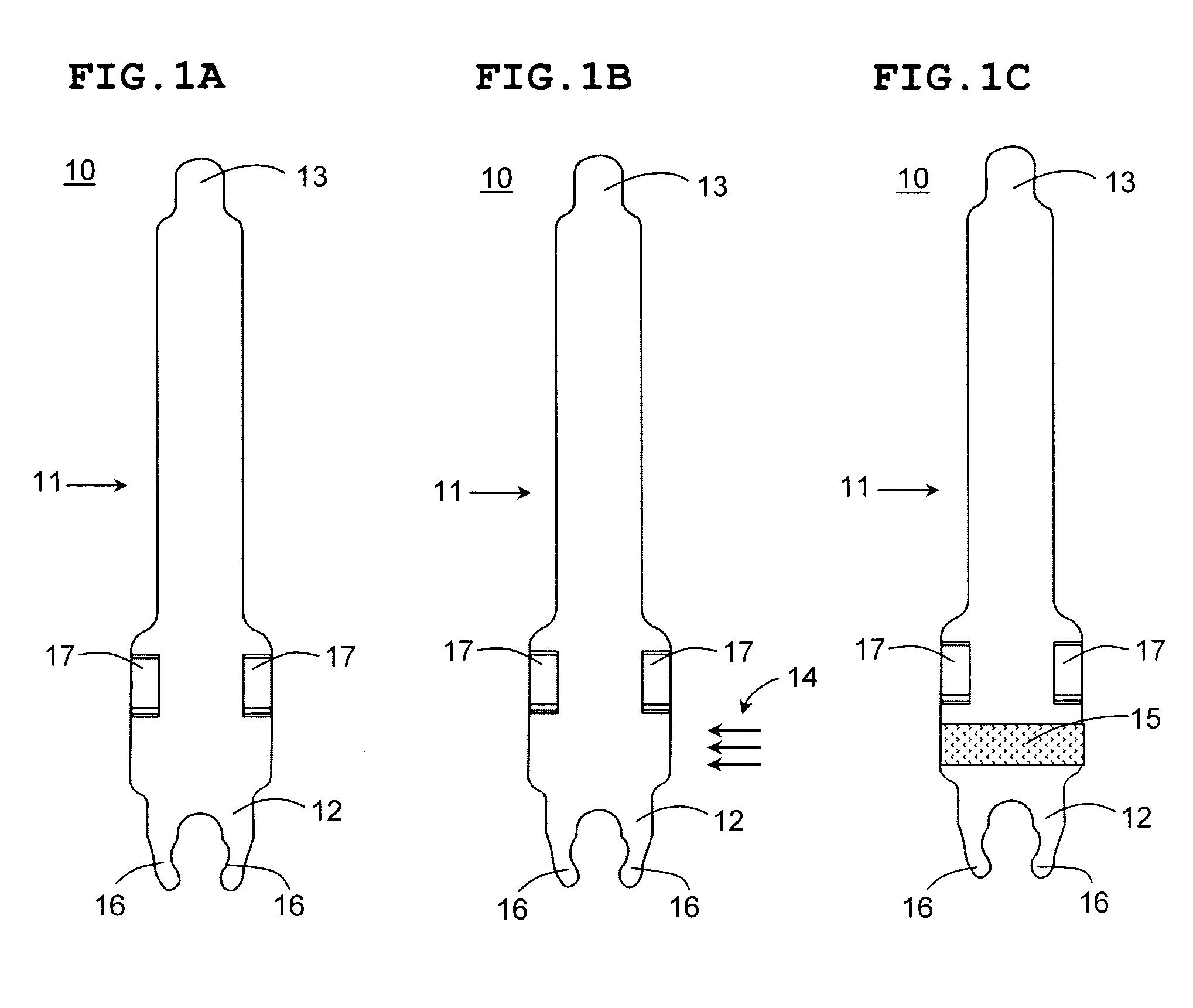

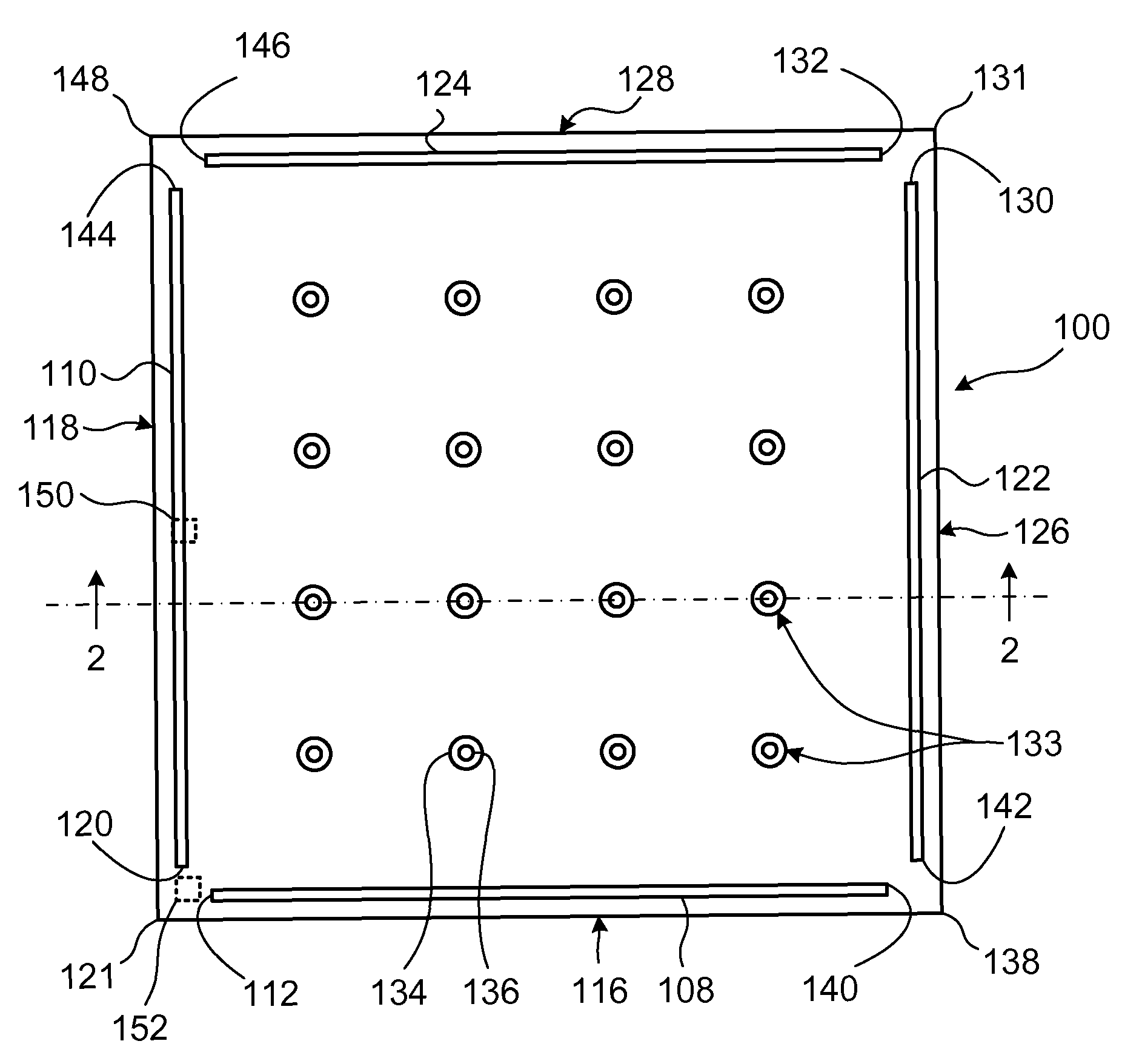

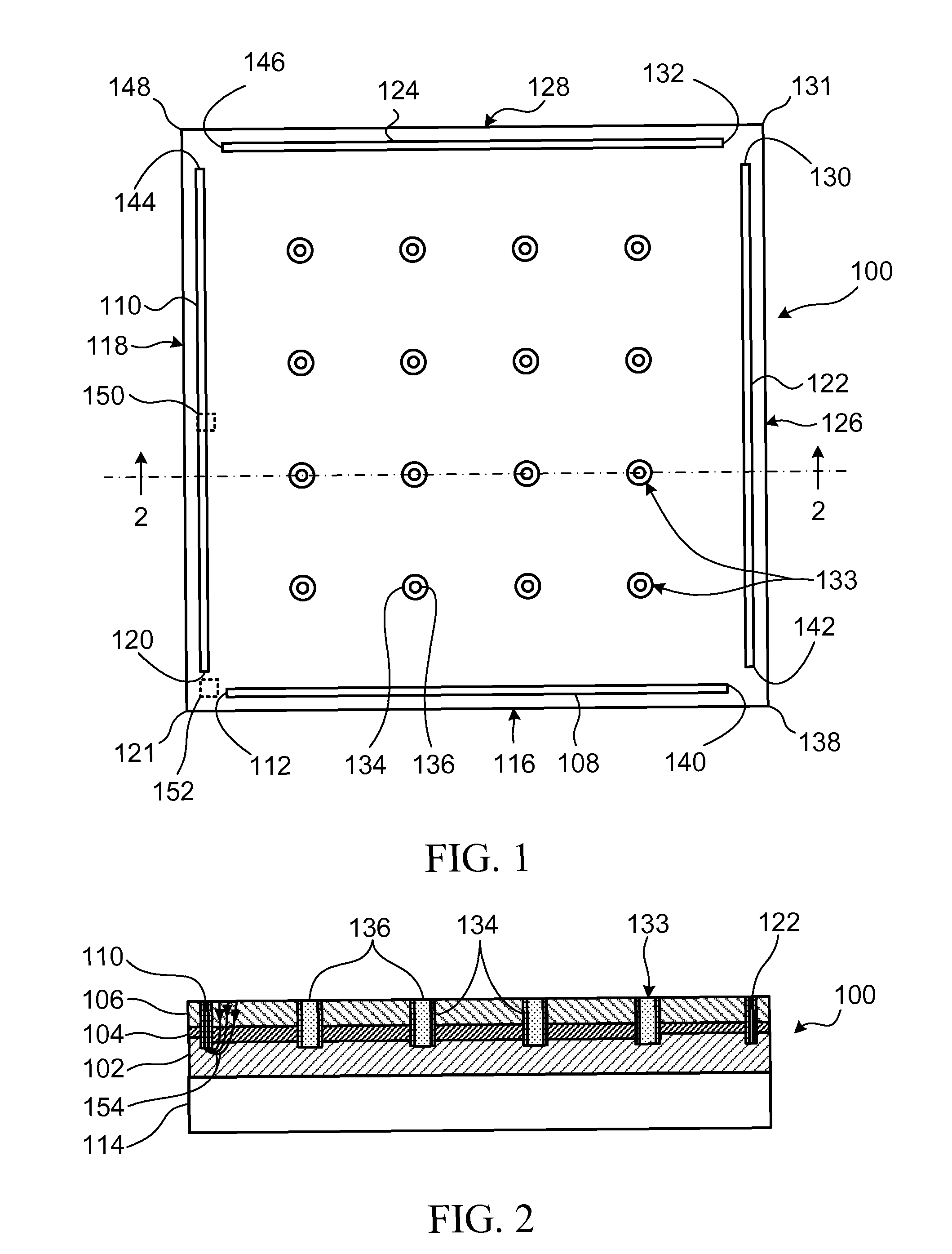

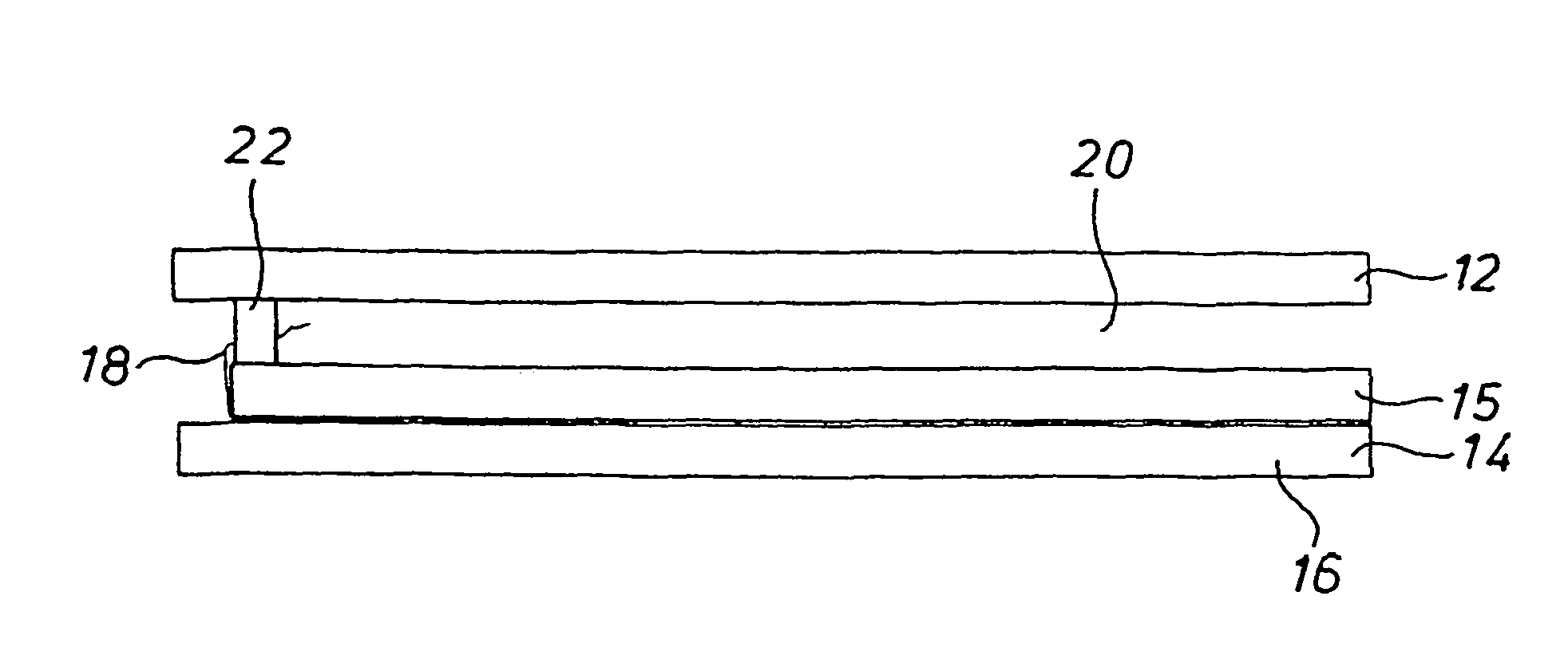

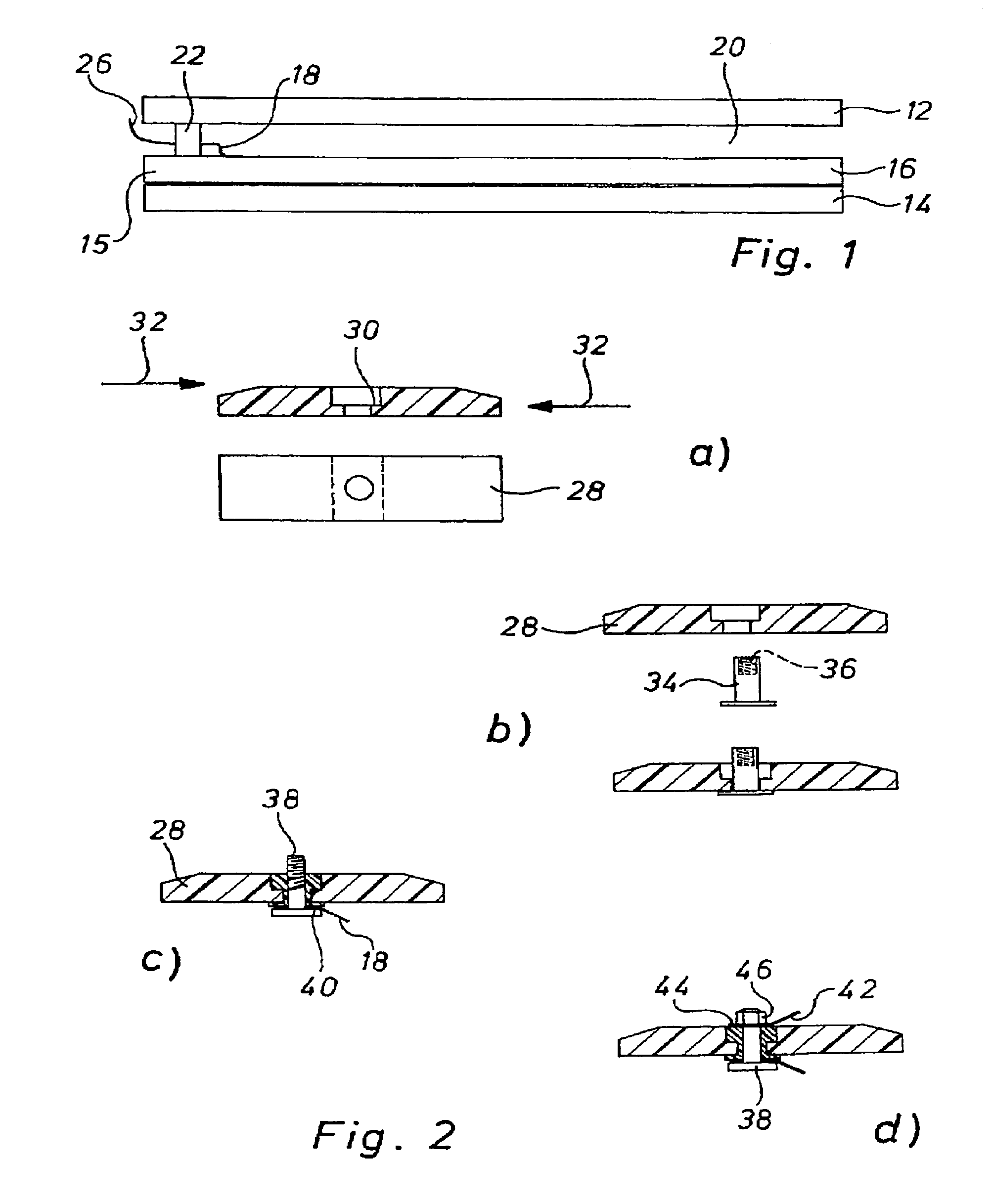

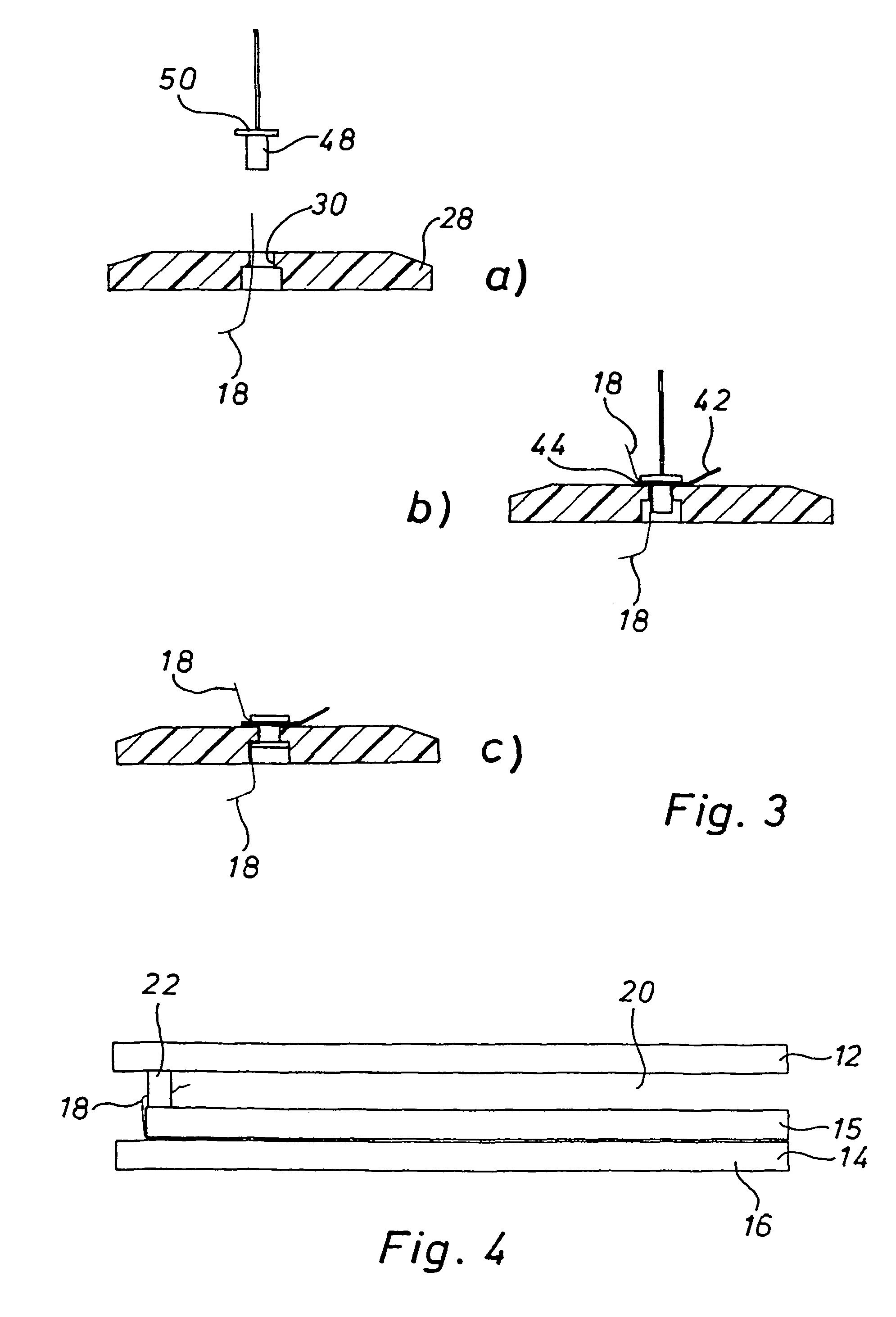

Manufacture of light emitting devices with phosphor wavelength conversion

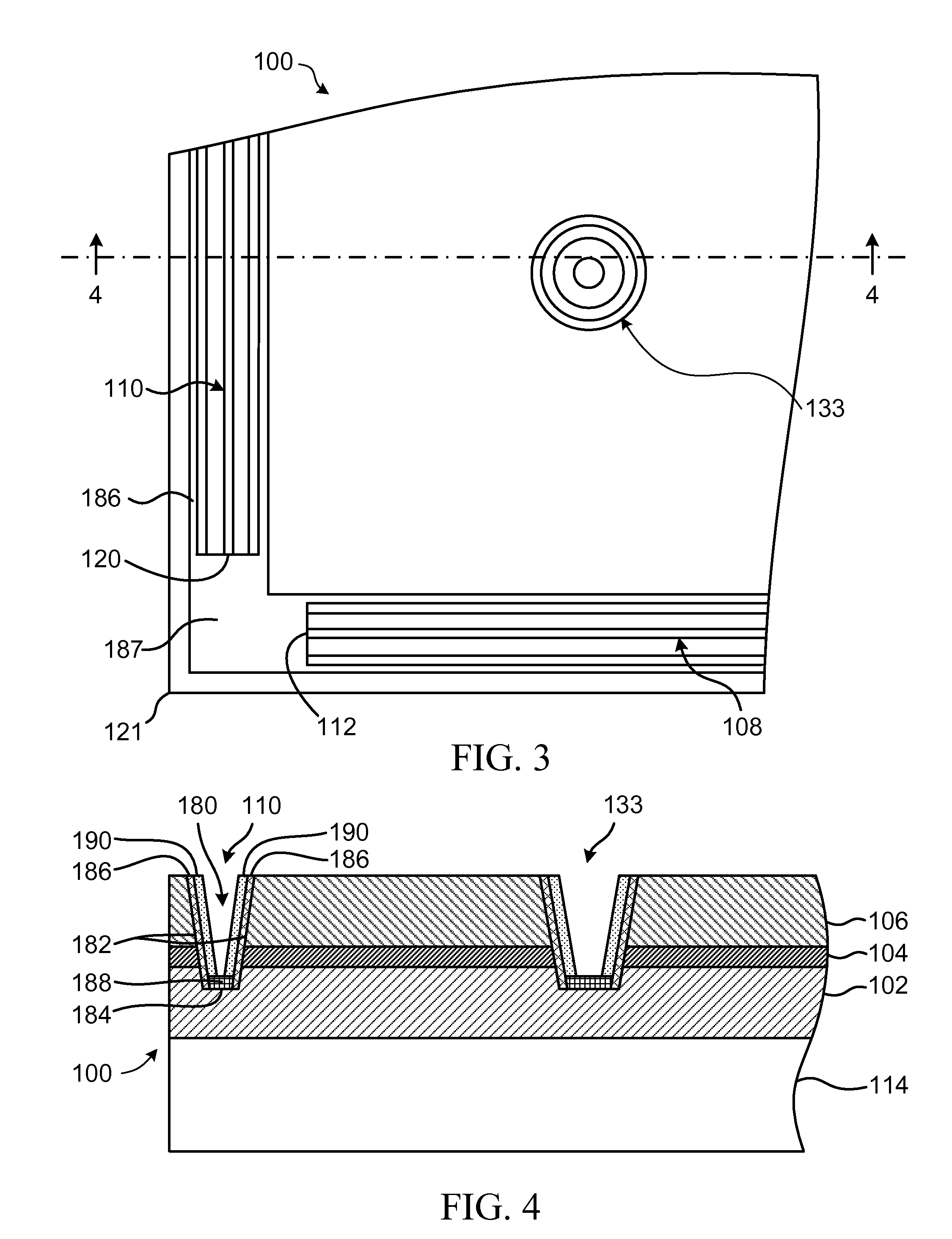

InactiveUS20100295077A1Reduce and even eliminate needYield maximizationSolid-state devicesSemiconductor/solid-state device manufacturingPolymerElectrode Contact

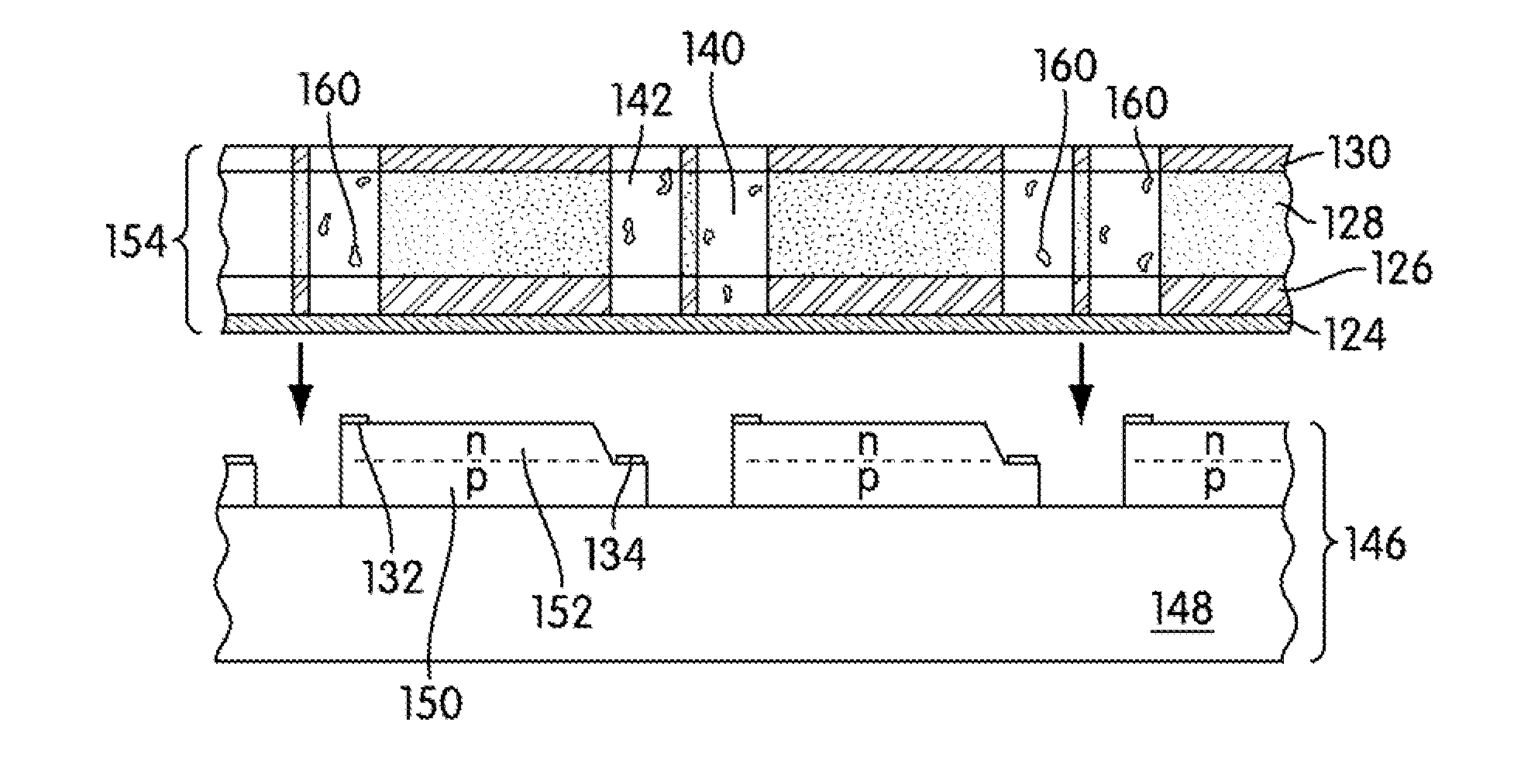

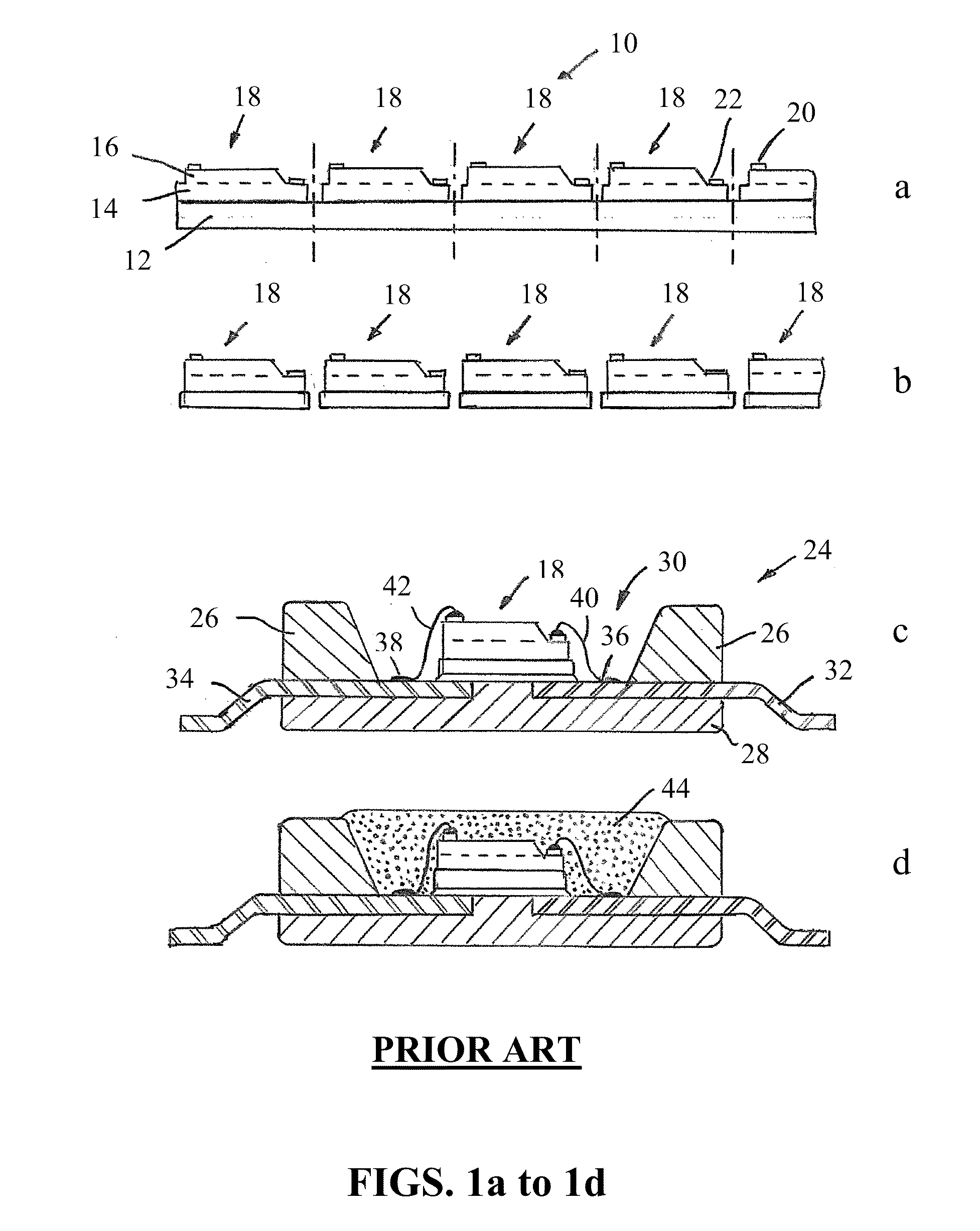

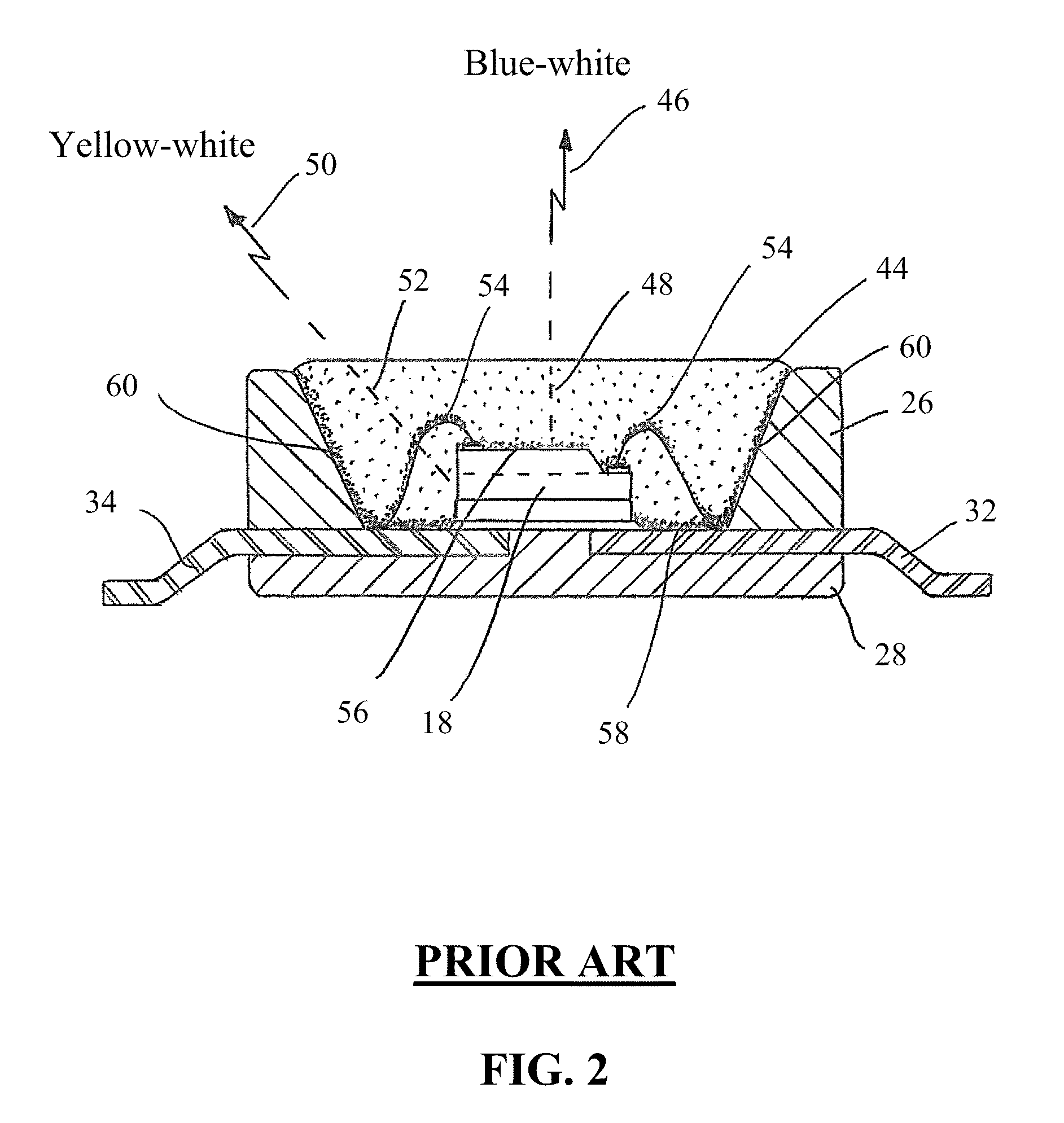

A method of manufacturing a light emitting device: an LED wafer having an array of LEDs formed on a surface thereof, the method comprises: a) fabricating a sheet of phosphor / polymer material comprising a light transmissive polymer material having at least one phosphor material distributed throughout its volume and in which the polymer material is transmissive to light generated by the LEDs and to light generated by the at least one phosphor material; b) selectively making apertures through the phosphor / polymer sheet at positions corresponding to electrode contact pads of the LEDs of the LED wafer; c) attaching the sheet of phosphor / polymer material to the surface of the LED wafer such that each aperture overlies a respective electrode contact pad; and d) dividing the wafer into individual light emitting devices. The method can further comprise, prior to dividing the LED wafer, cutting slots through the phosphor / polymer material that are configured to pass between individual LEDs.

Owner:INTEMATIX

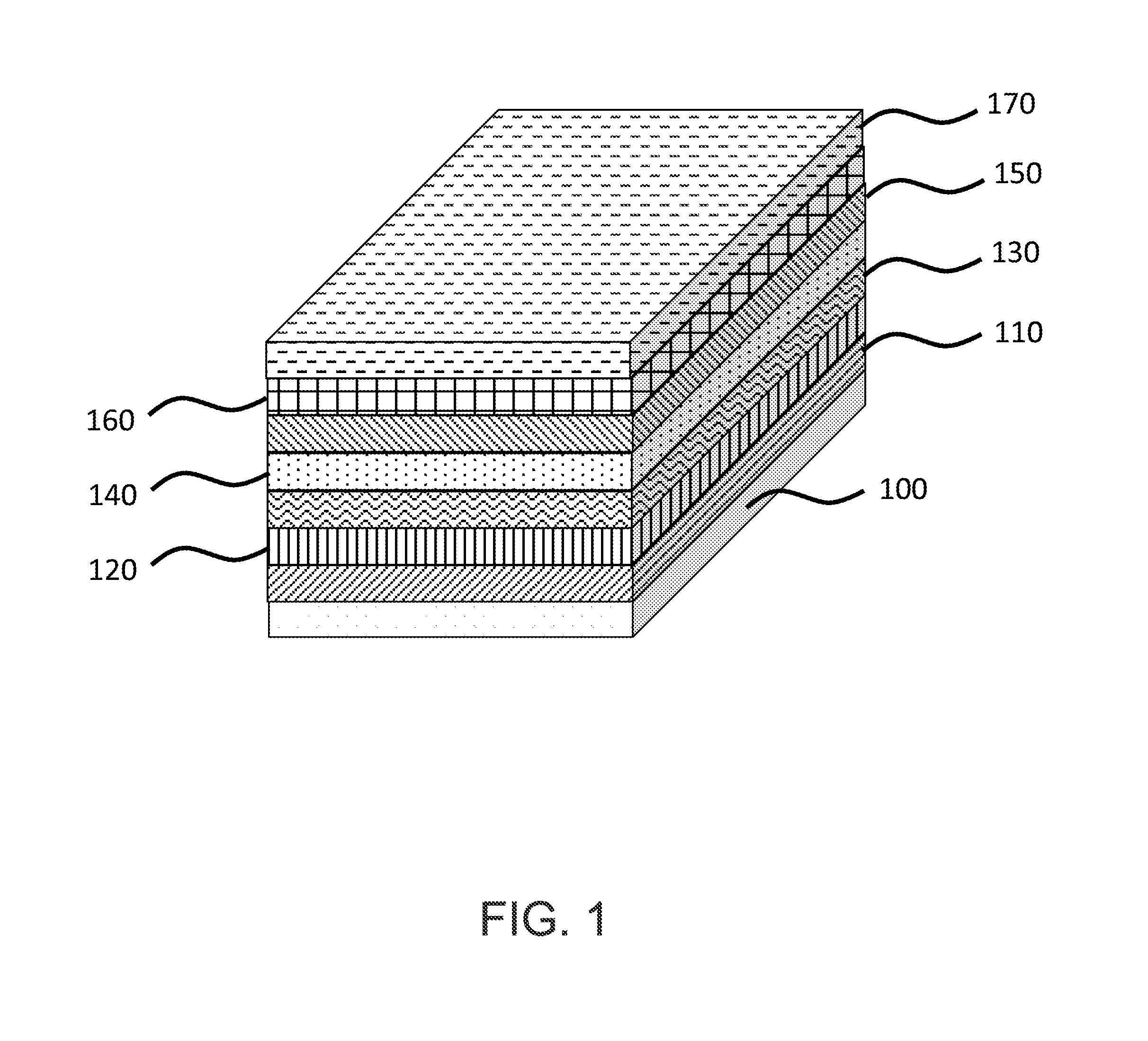

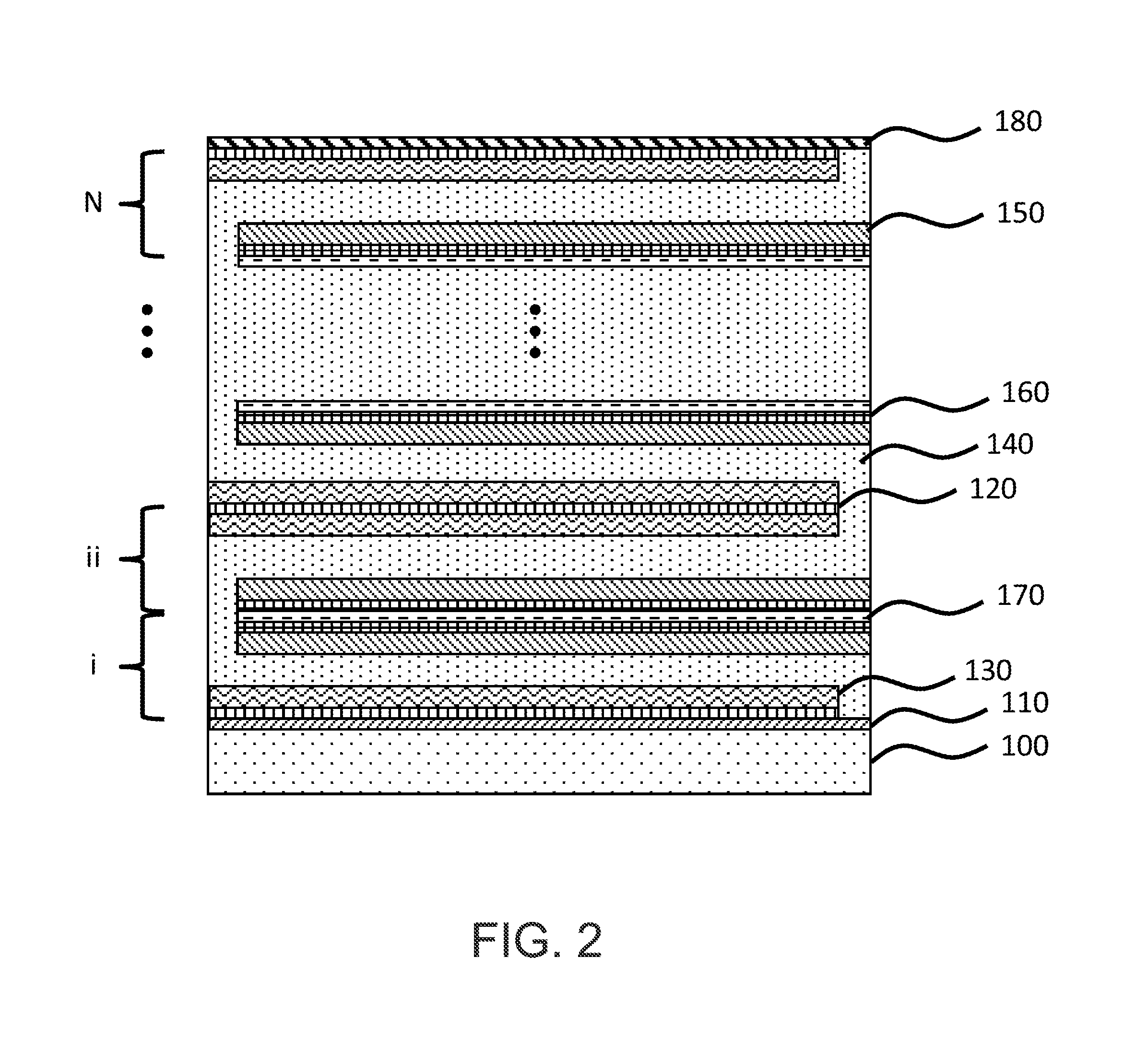

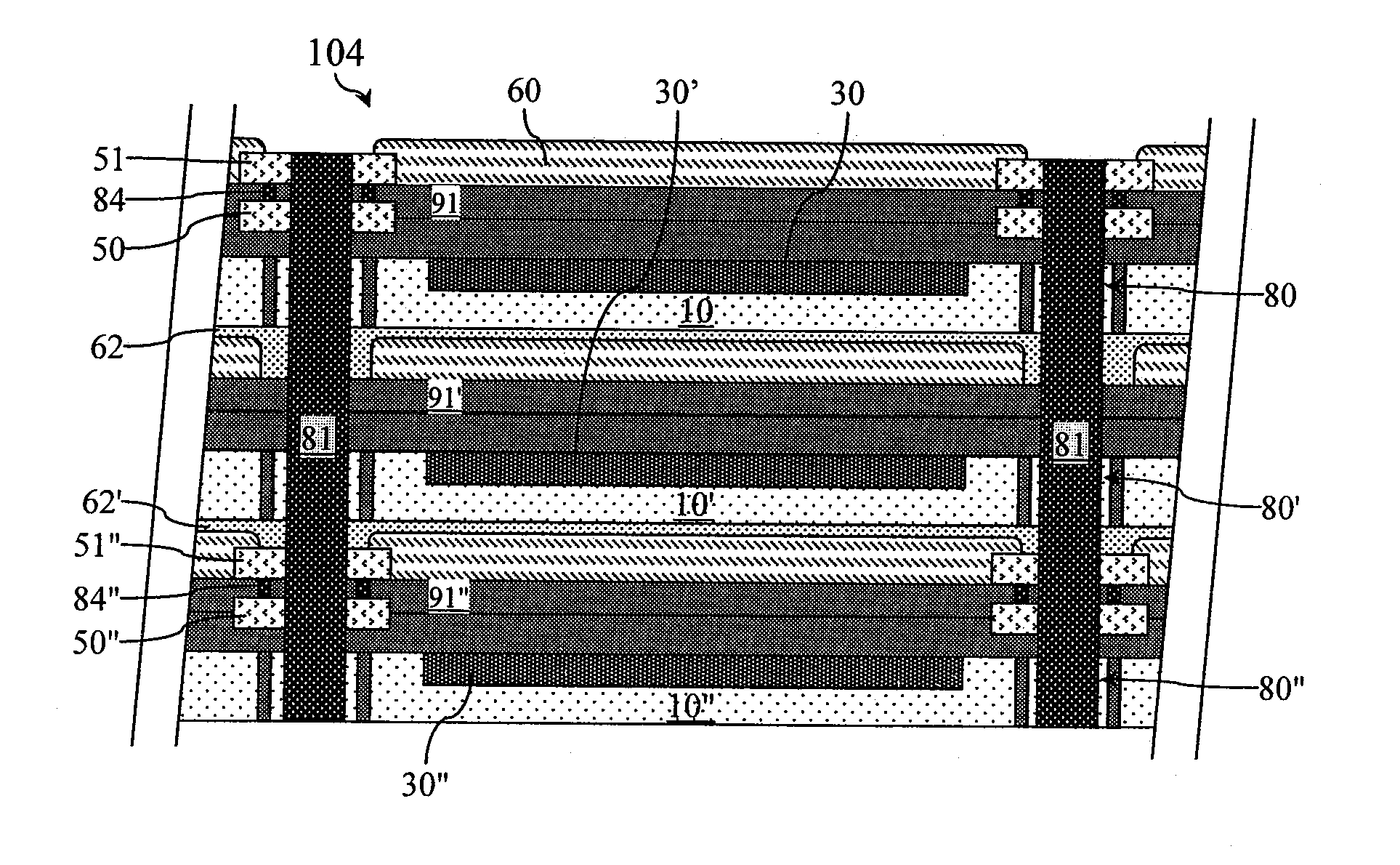

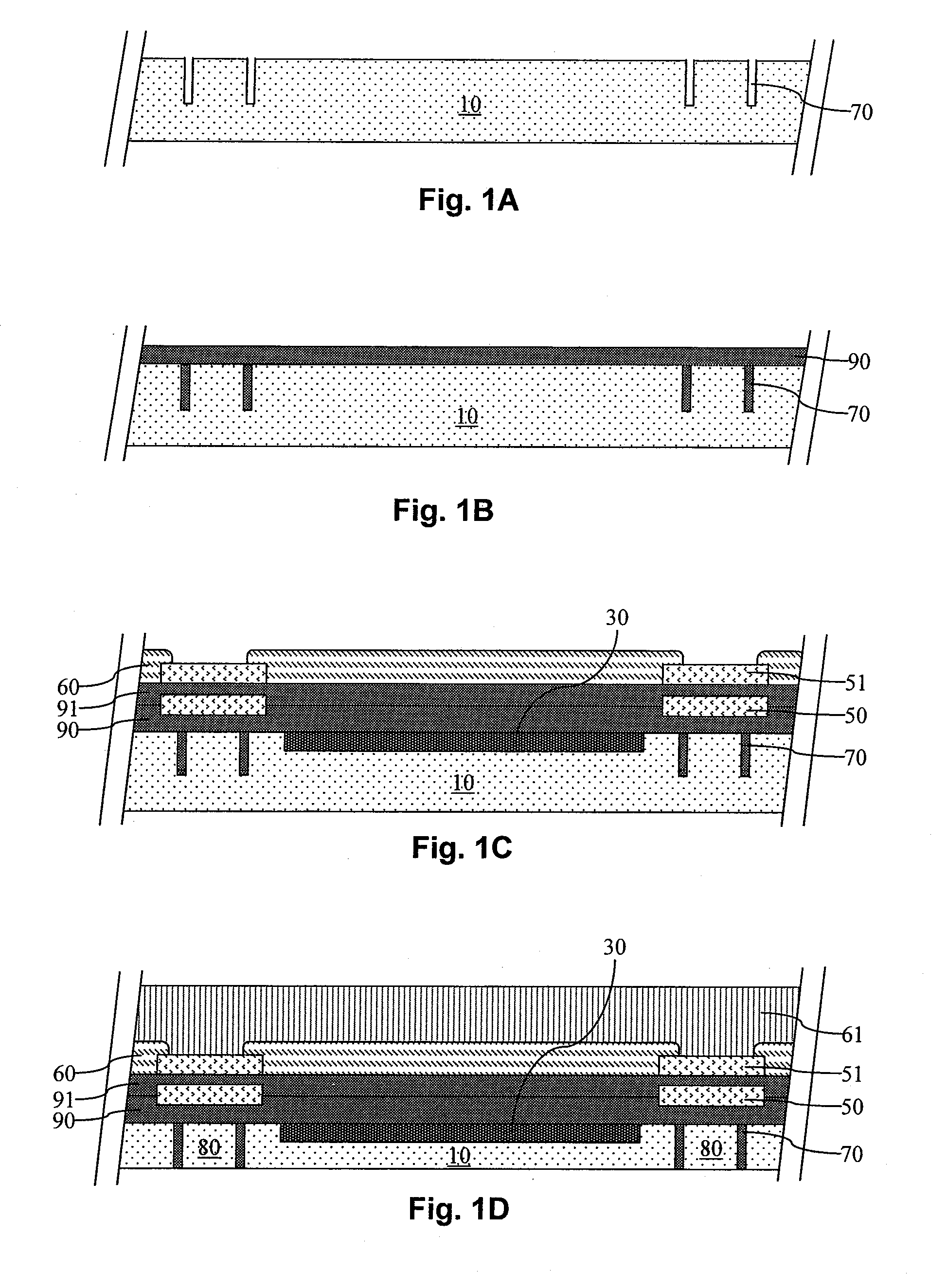

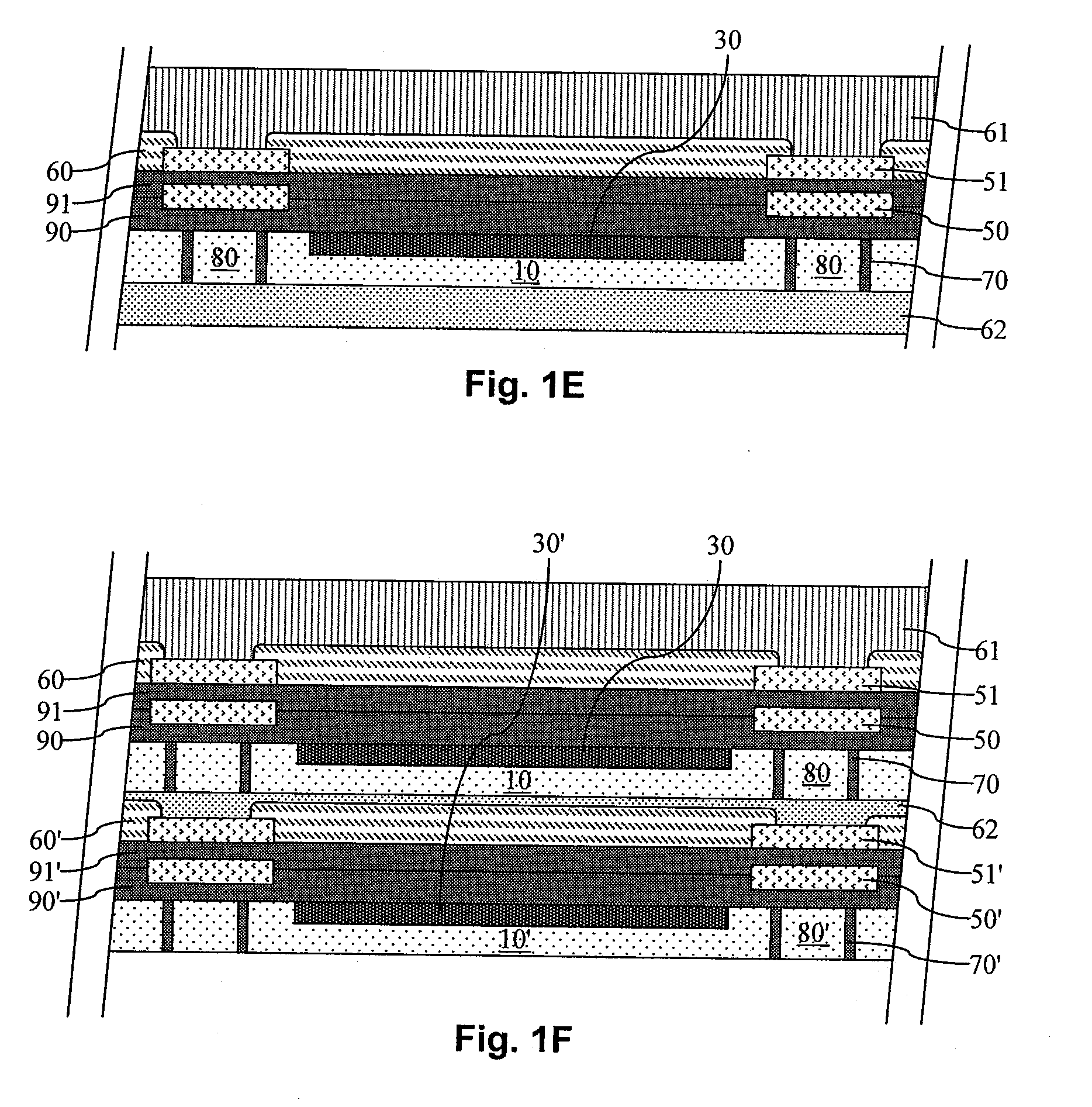

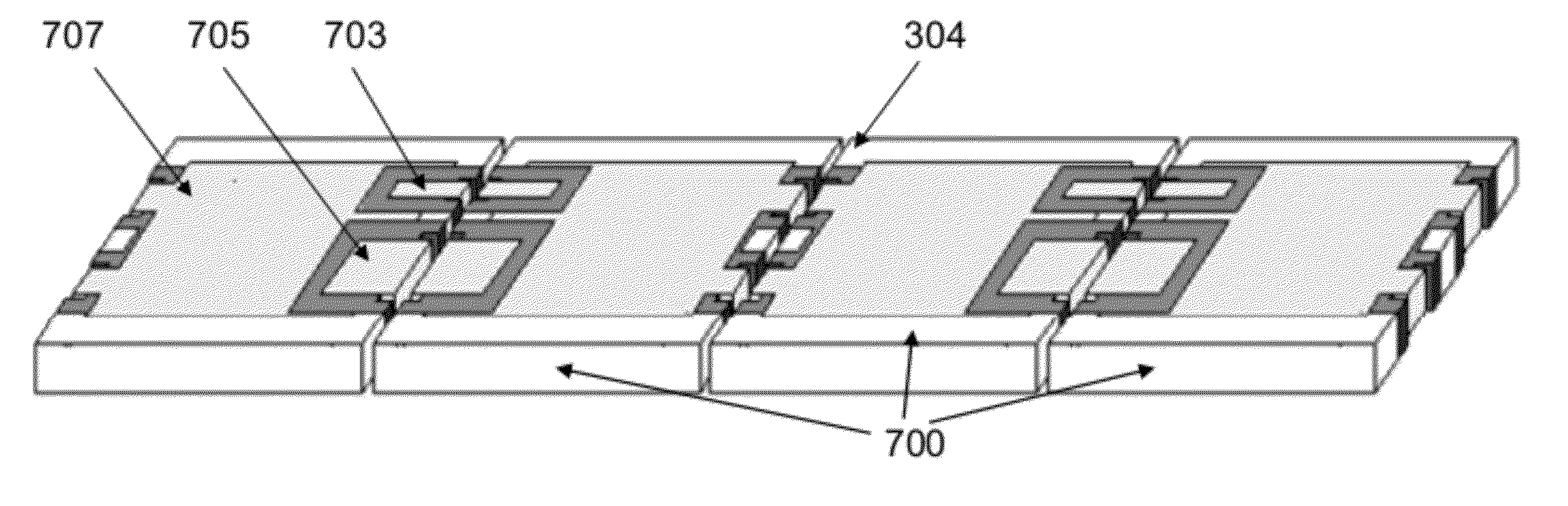

Barrier for thin film lithium batteries made on flexible substrates and related methods

ActiveUS20120040233A1Mitigate stressPrevent electrical contactElectric discharge heatingCell electrodesSolid-state batteryCurrent collector

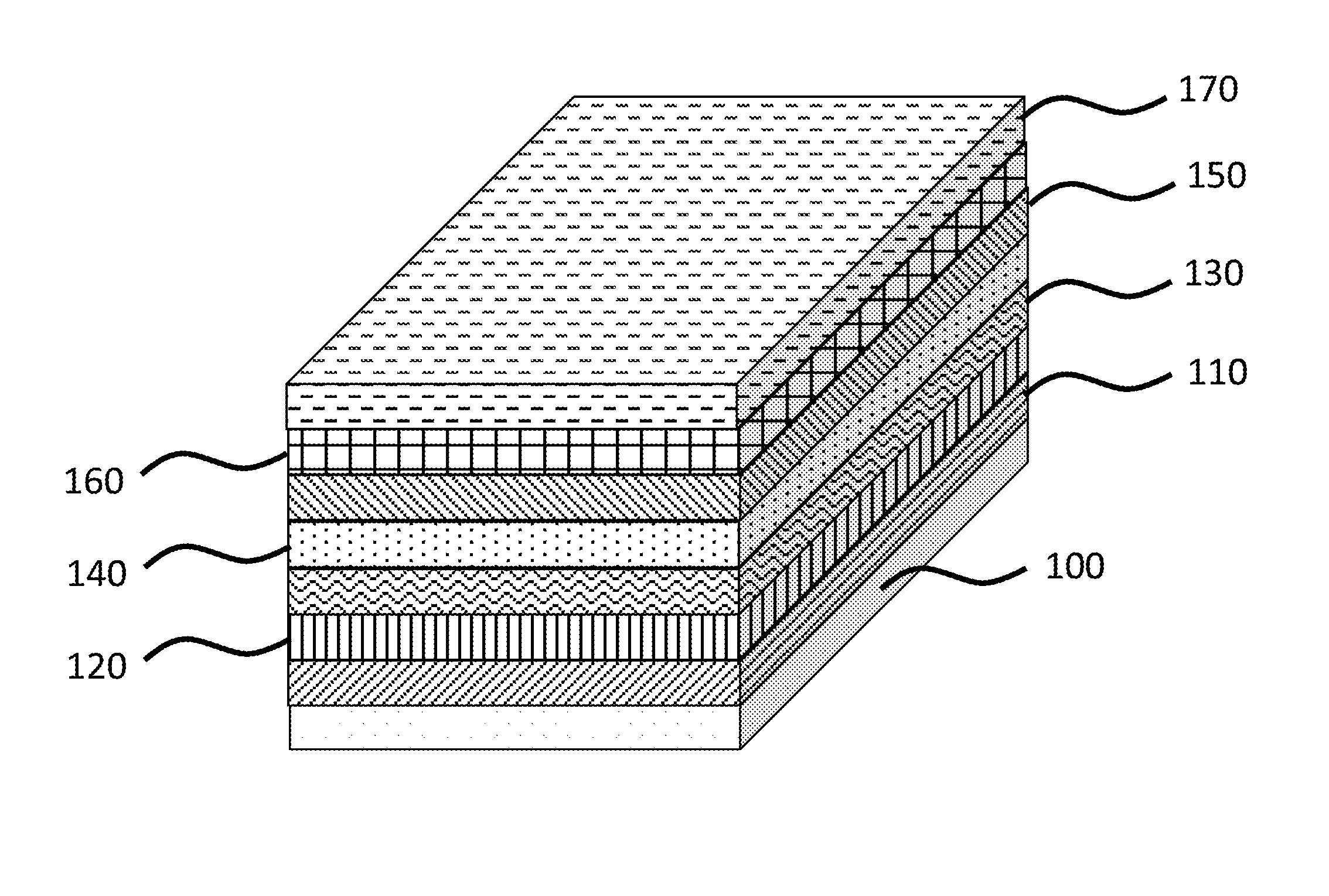

A thin film solid state battery configured with barrier regions formed on a flexible substrate member and method. The method includes forming a bottom thin film barrier material overlying and directly contacting a surface region of a substrate. A first current collector region can be formed overlying the bottom barrier material and forming a first cathode material overlying the first current collector region. A first electrolyte can be formed overlying the first cathode material, and a second current collector region can be formed overlying the first anode material. The method also includes forming an intermediary thin film barrier material overlying the second current collector region and forming a top thin film barrier material overlying the second electrochemical cell. The solid state battery can comprise the elements described in the method of fabrication.

Owner:SAKTI3

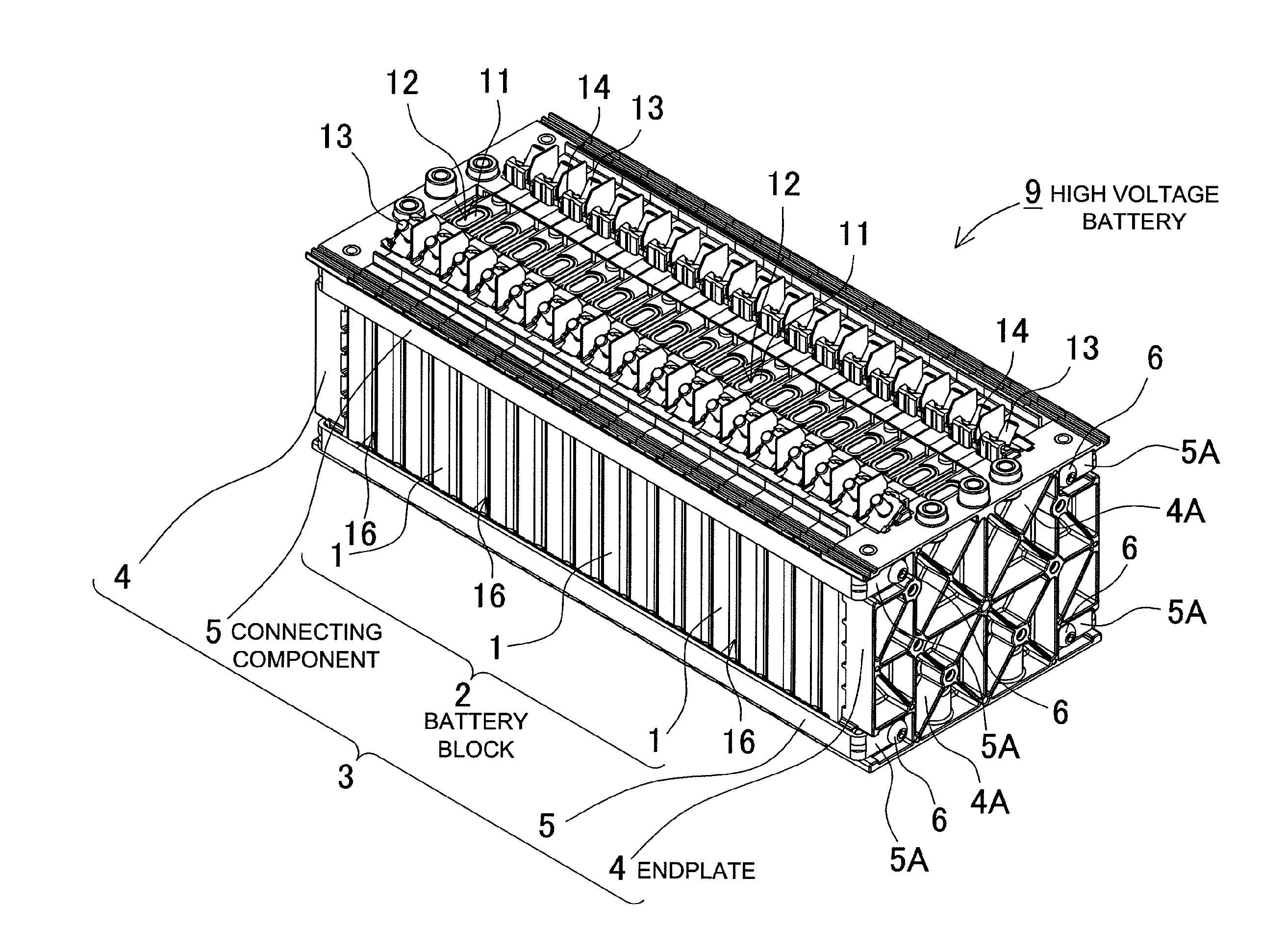

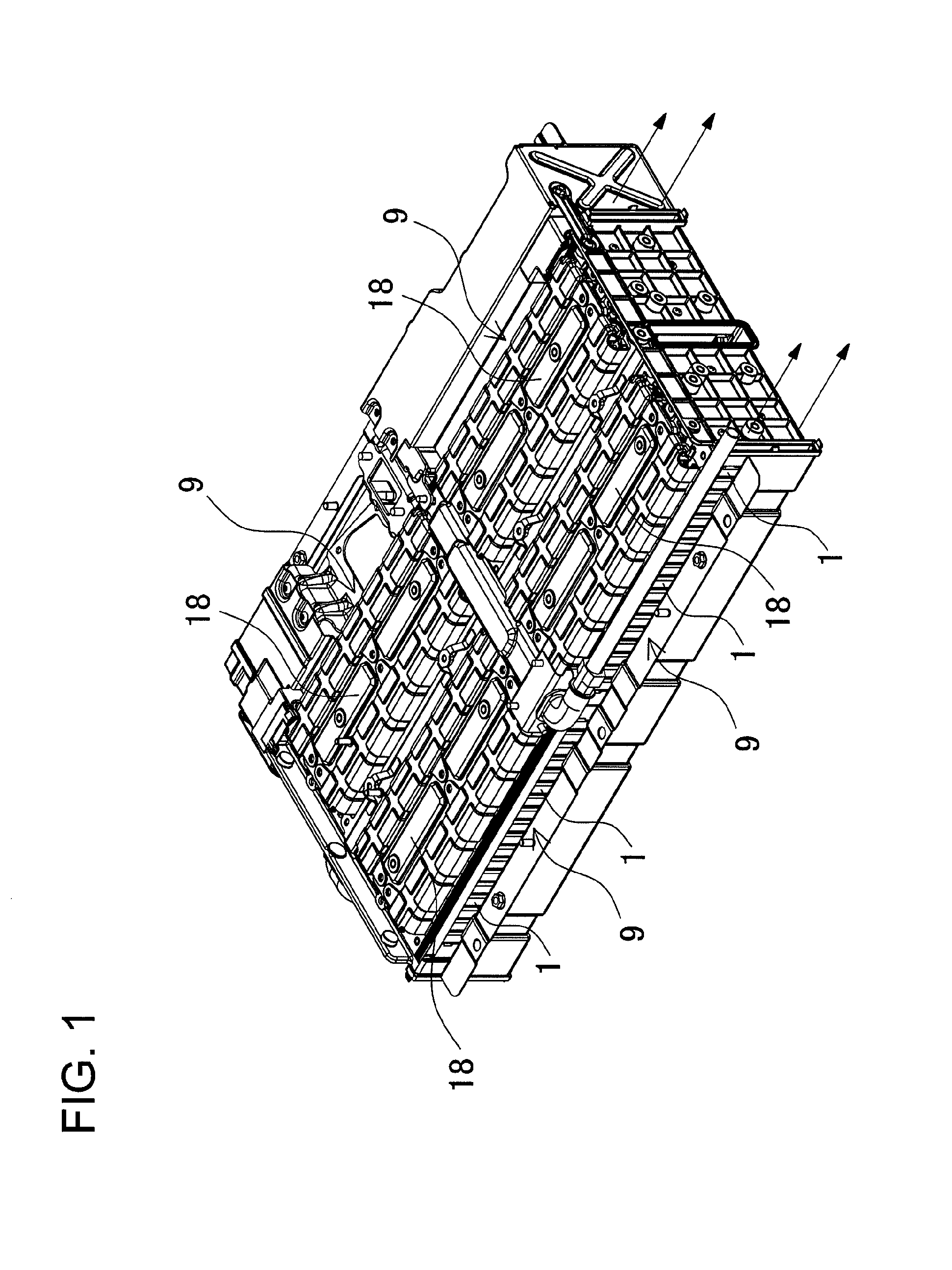

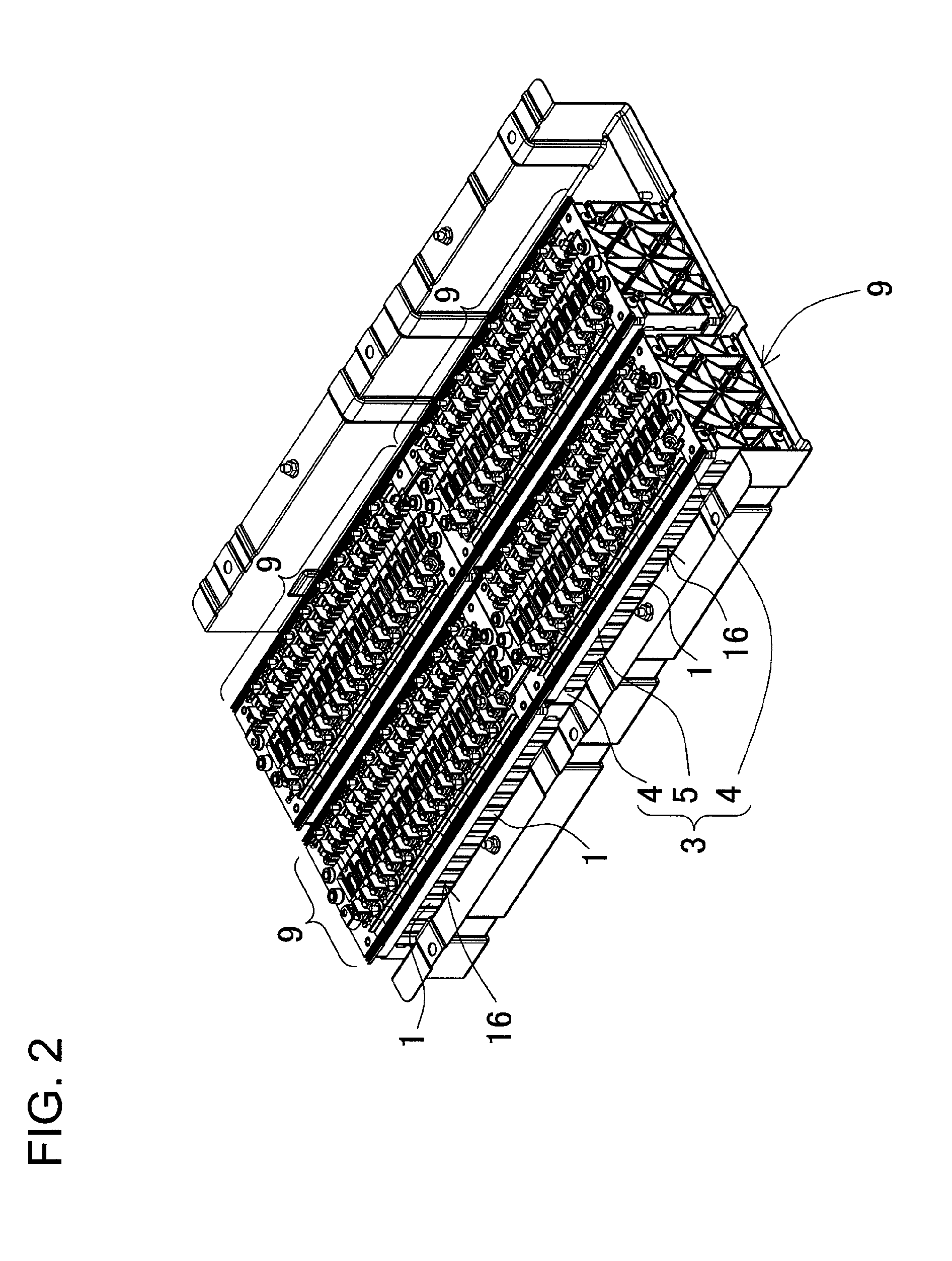

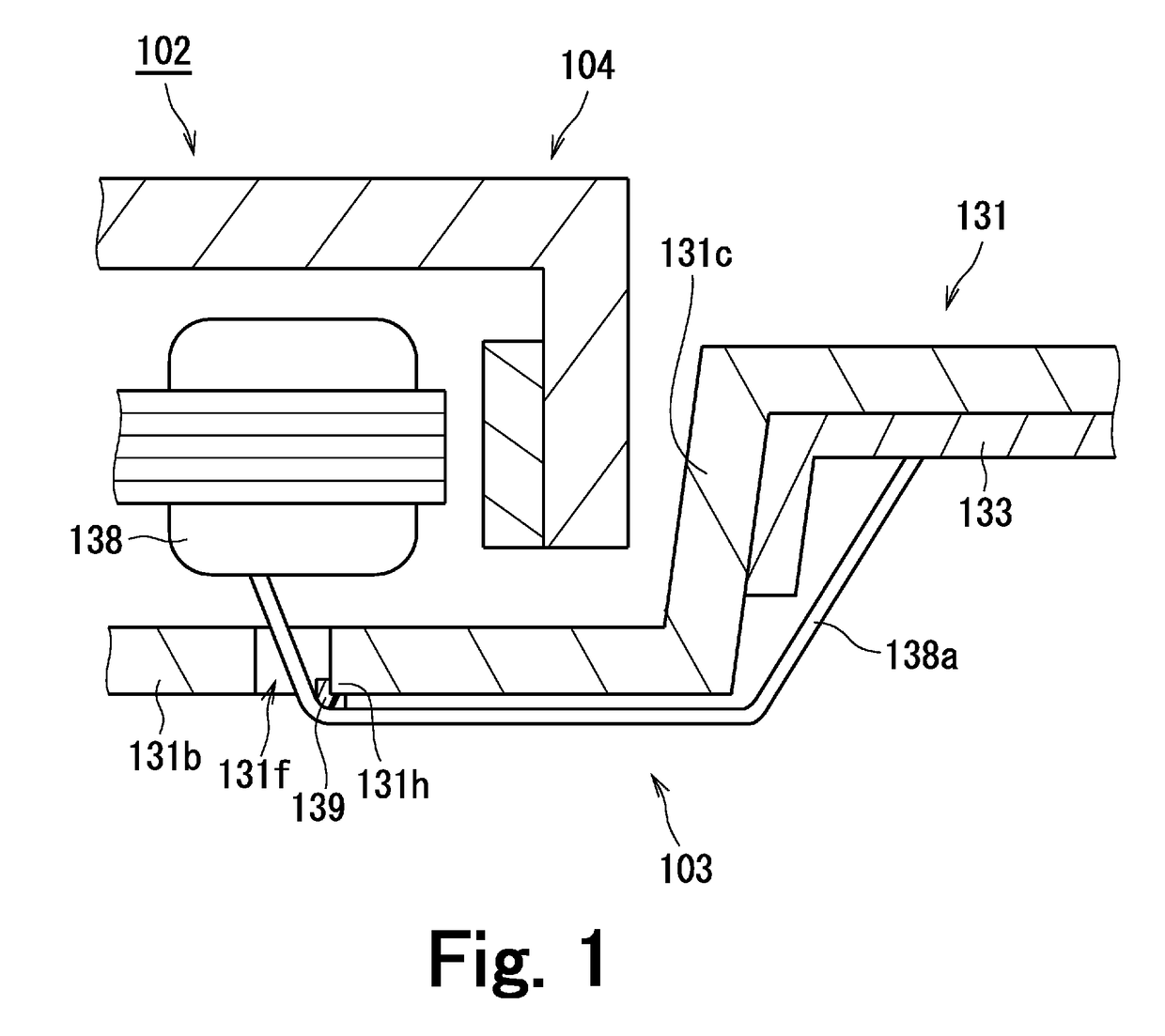

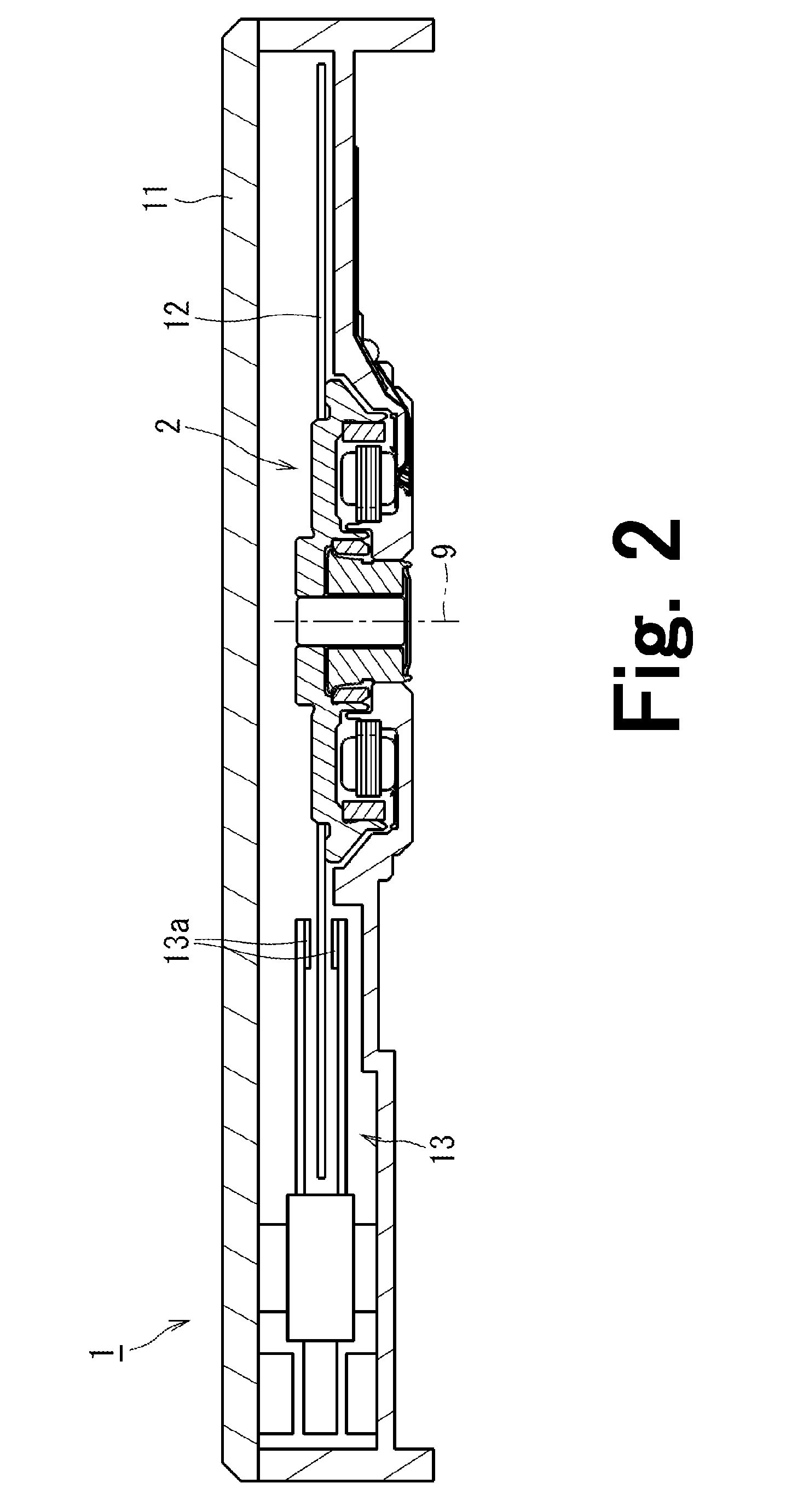

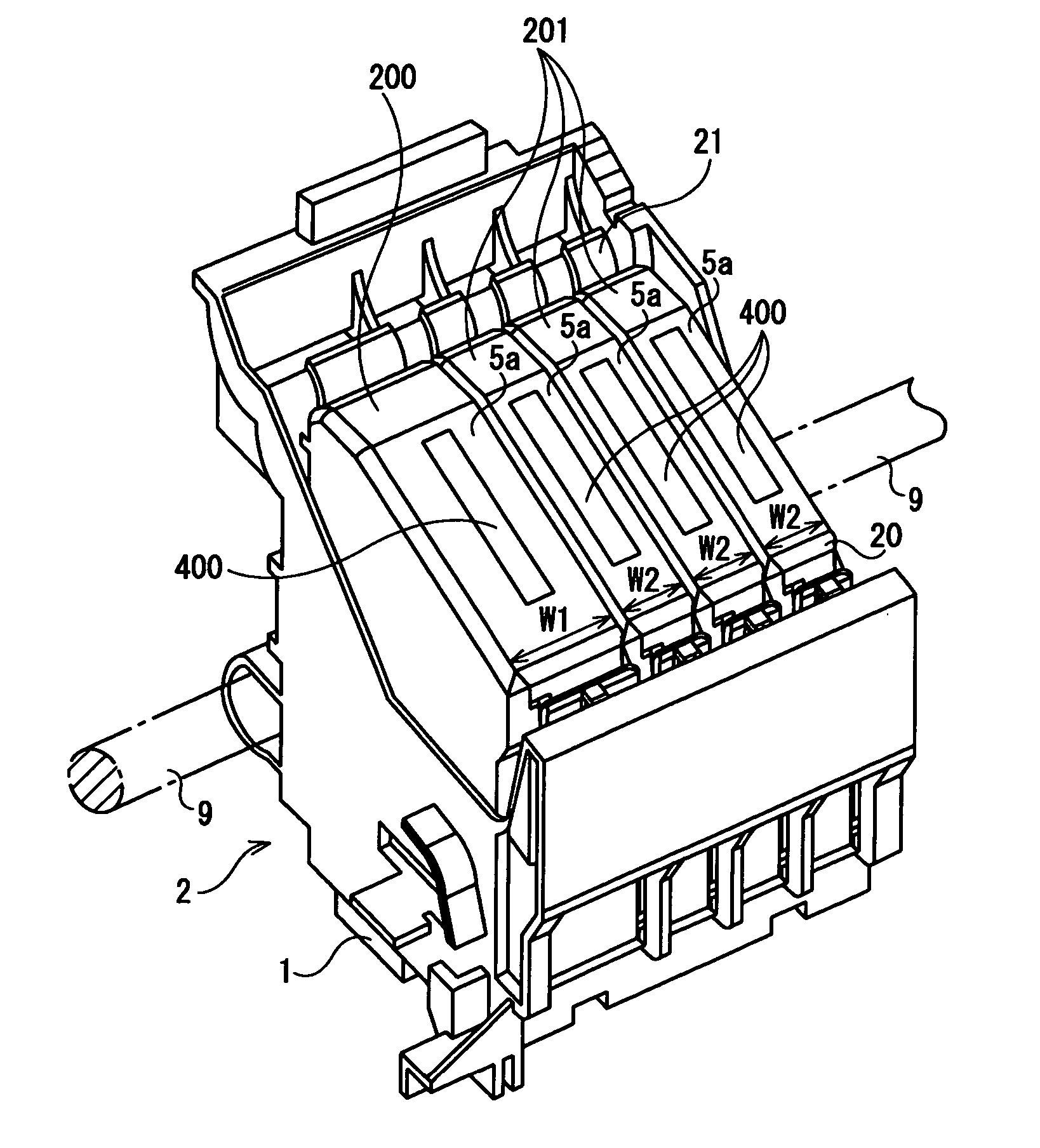

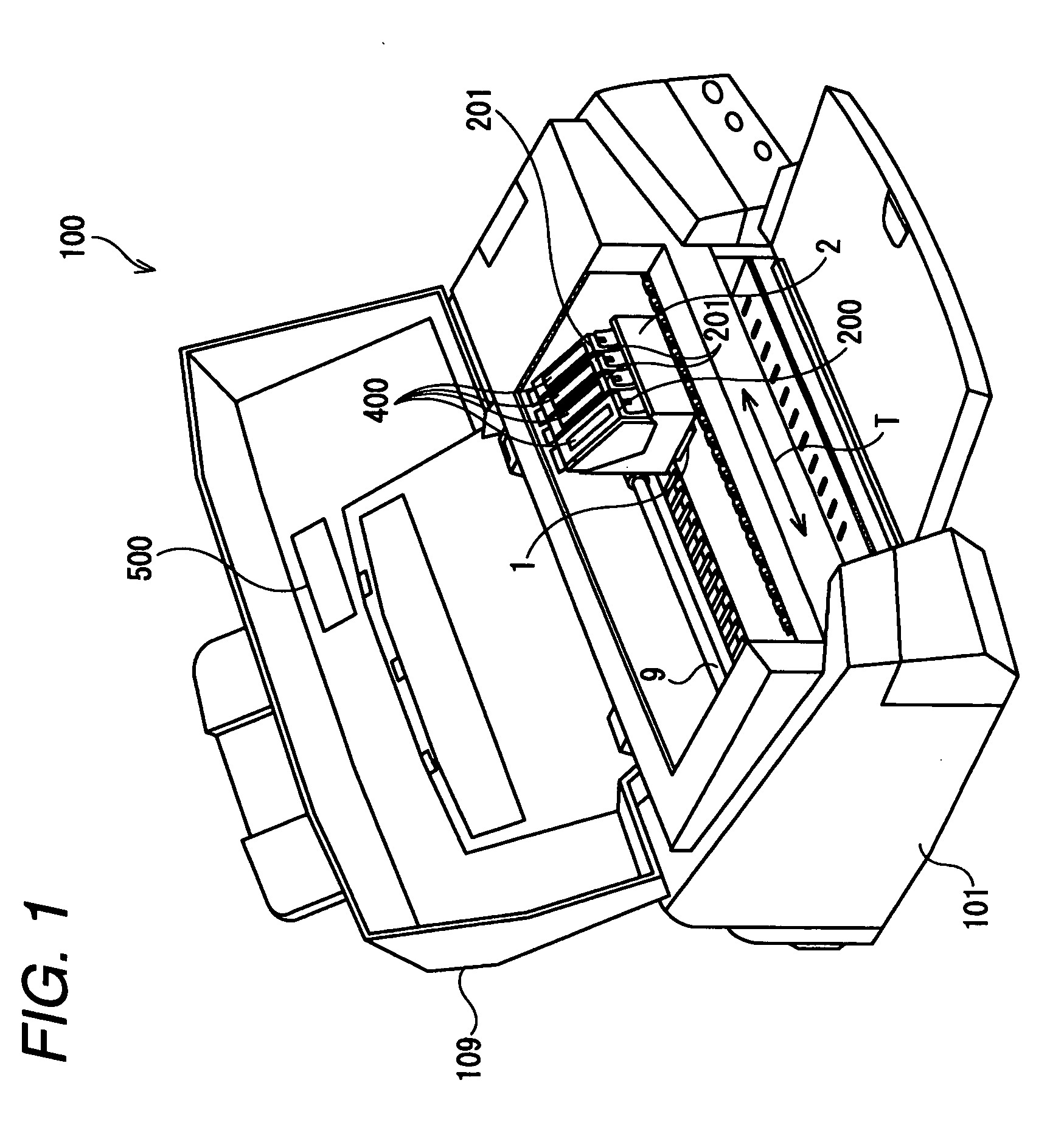

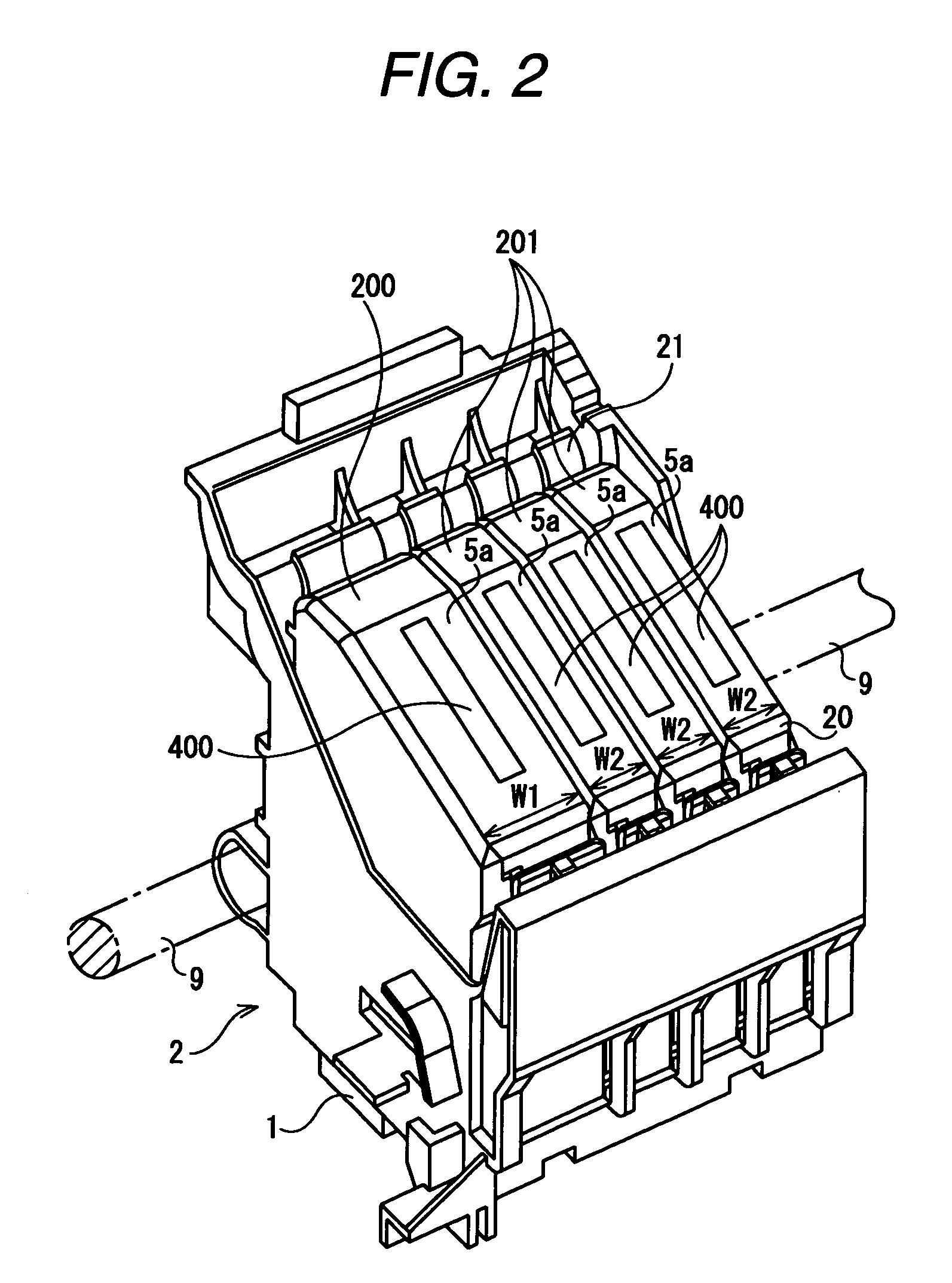

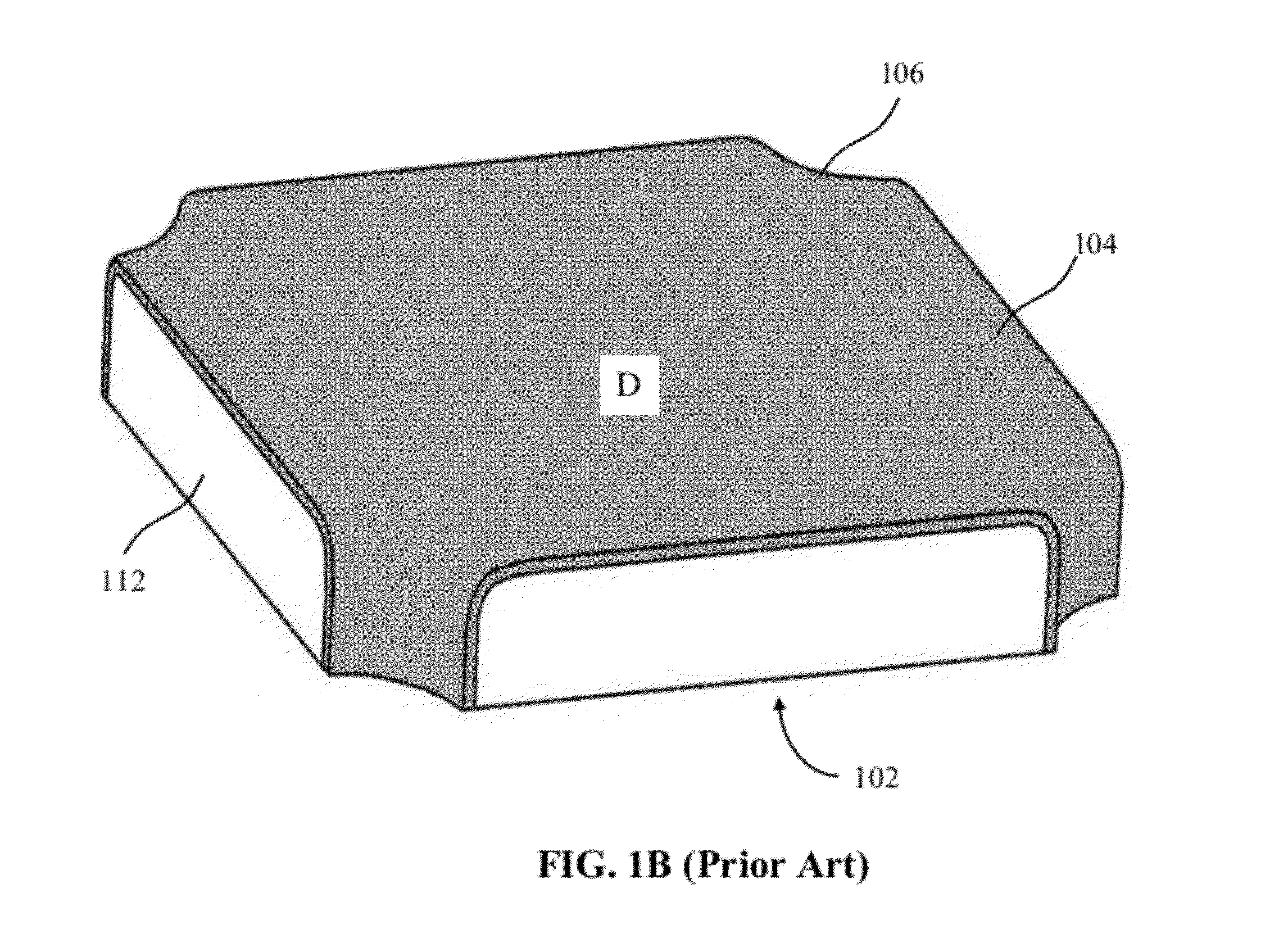

Car power source apparatus

ActiveUS20100167116A1Avoid electrical contactInterrupting total separationPrimary cell to battery groupingBattery isolationInternal pressureEngineering

A case 20 of each battery cell 1 houses a current interrupt device 30 that cuts-off current when internal pressure exceeds a set pressure. The case has a rectangular outline with a pair of opposing planar surfaces 20A. An electrode unit 10, which is a stack of positive and negative electrode plates 10A with intervening separators 10C, and the current interrupt device 30 are disposed between the pair of opposing planar surfaces. A plurality of battery cells is stacked with opposing planar surfaces 20A opposite each other to form a battery block 2. The power source apparatus has a pair of endplates 4 disposed at the ends of the battery block 2, the pair of endplates 4 is connected by connecting components 5, and the pair of endplates 4 holds the battery cells 1 in the stacked configuration applying pressure in a direction perpendicular to the opposing planar surfaces 20A.

Owner:SANYO ELECTRIC CO LTD

Manufacture of light emitting devices with phosphor wavelength conversion

InactiveUS20100295079A1Reduce and even eliminate needAvoid degradationSolid-state devicesSemiconductor/solid-state device manufacturingLed arrayPhosphor

A method of manufacturing a light emitting device comprises: depositing over substantially the entire surface of a LED wafer having a array of LEDs formed on a surface thereof a mixture of at least one phosphor and a polymer material, wherein the polymer material is transmissive to light generated by the LEDs and to light generated by the at least one phosphor material; using laser ablation to selectively make apertures in the phosphor / polymer material corresponding to electrode contact pads of each LED thereby enabling access to each electrode contact pad; and dividing the wafer into individual light emitting devices. The method can further comprise, prior to dividing the wafer, cutting slots in the phosphor / polymer material which are configured to pass between individual LEDs. The slots are configured such that a layer of phosphor / polymer material remains on the edges of each LED after division of the wafer into individual light emitting devices.

Owner:INTEMATIX

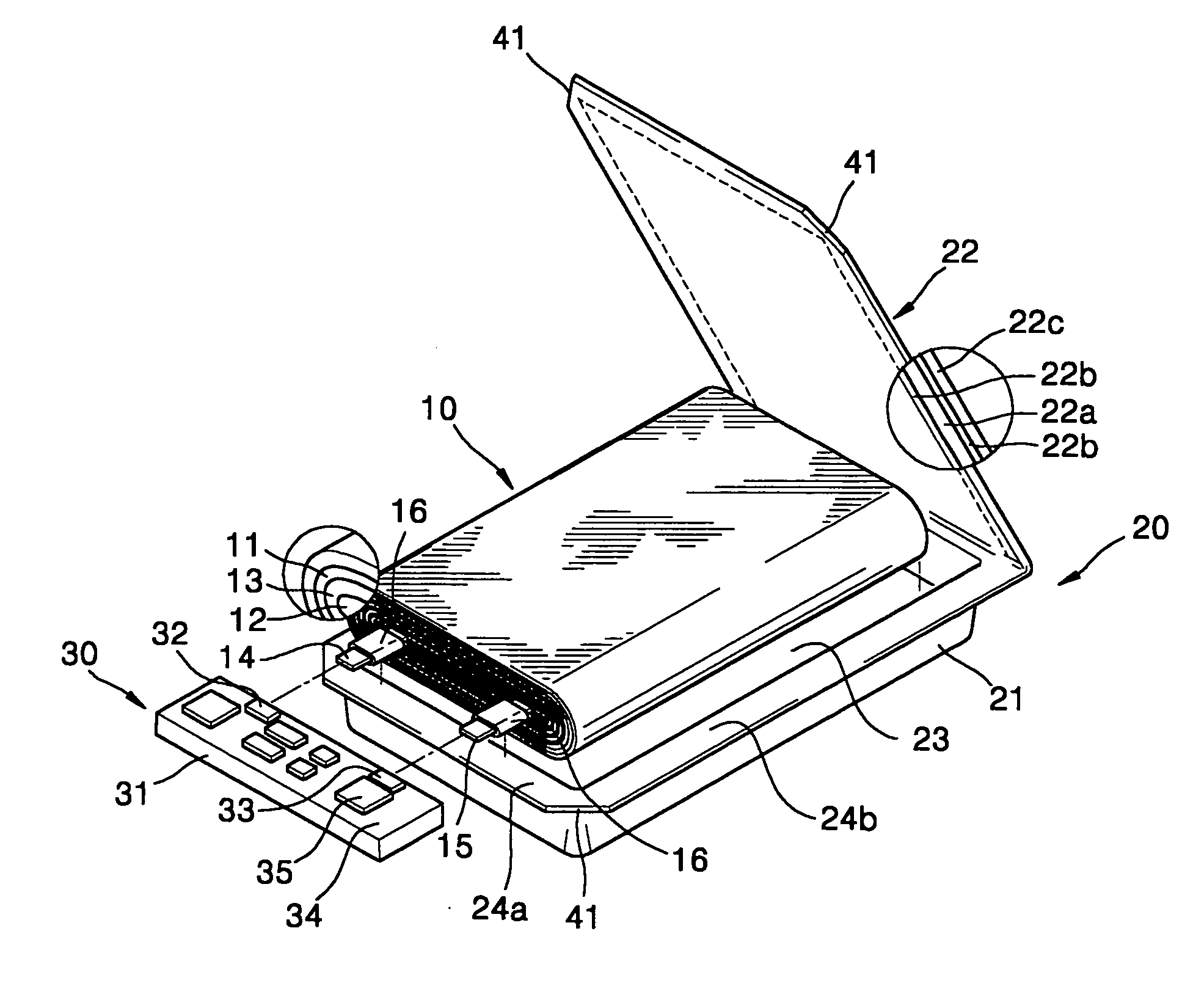

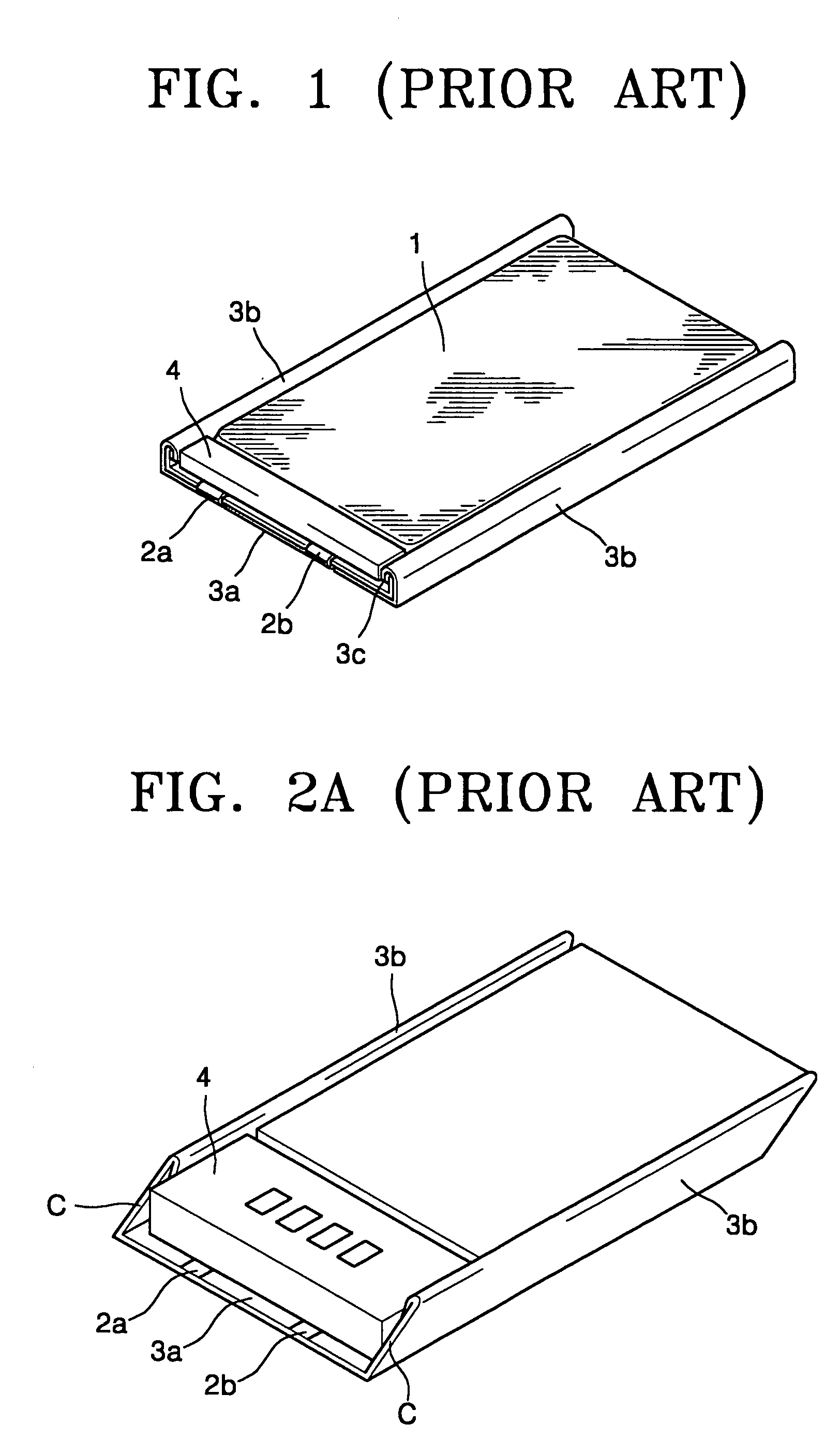

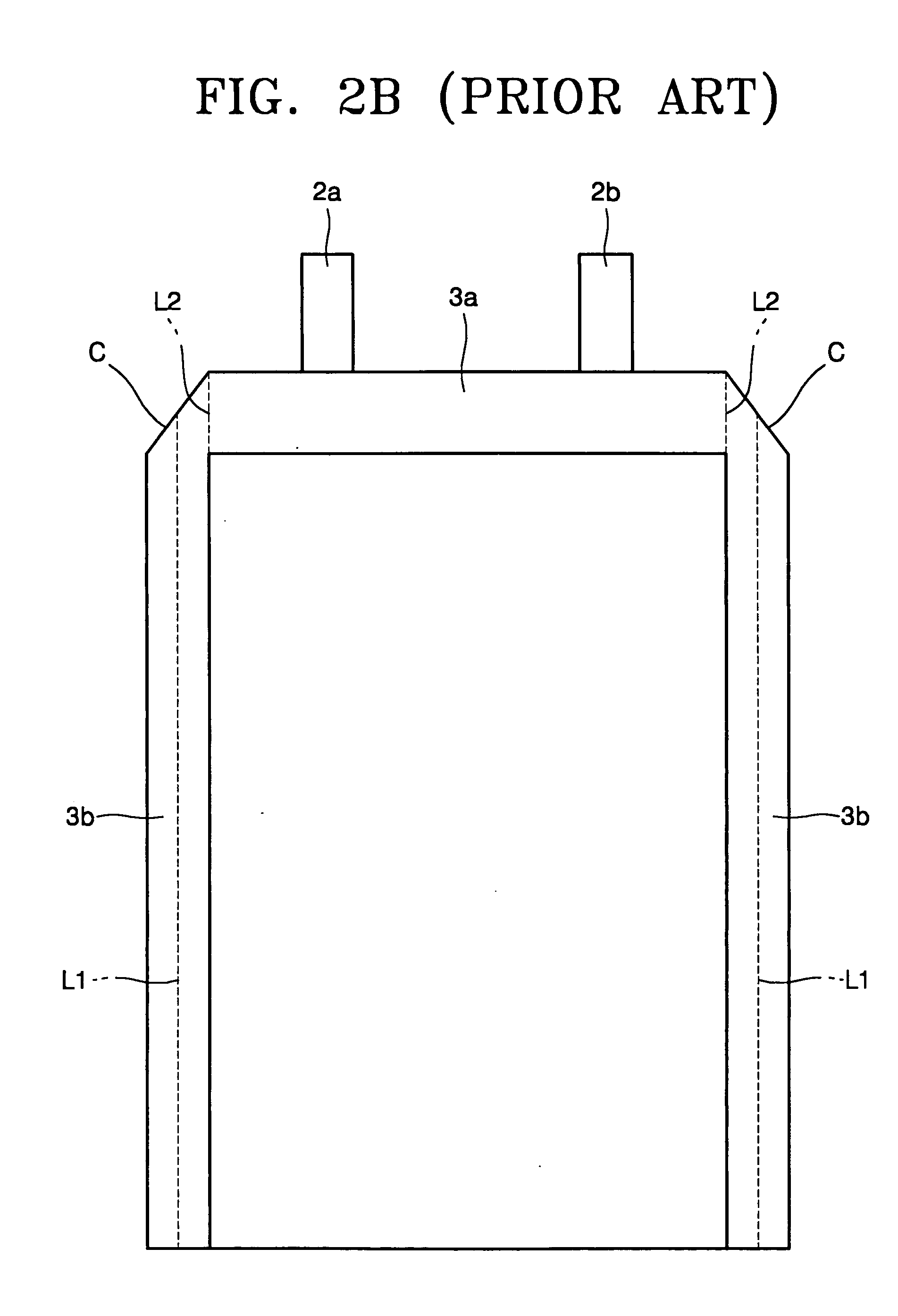

Pouch type secondary battery

ActiveUS20050084749A1Materials is relatively shortImprove securityPrimary cell maintainance/servicingFinal product manufactureBattery cellCorrosion

A pouch type secondary battery which can prevent a cut portion from electrically contacting a protective circuit module, thereby preventing an electrical short circuit and acceleration of corrosion of a core material and enhancing safety includes an electrode assembly having a first electrode plate, a second electrode plate, and a separator; a pouch case made of a flexible material, and having a container, insulated at least on its inner surface and accommodating the electrode assembly, and sealing portions along an edge of the container, the sealing portions including a first sealing portion through which electrode taps of the electrode assembly extend from the pouch case, and a second sealing portion and a third sealing portion respectively positioned at opposite sides of the first sealing portion, the second an third sealing portions being folded at least one time; a protective circuit module connected to the electrode taps and mounted on an outer surface of the first sealing portion; and a short circuit protector formed in at least one among the first through third sealing portions to prevent an electrical short circuit between each sealing portion and the protective circuit module.

Owner:SAMSUNG SDI CO LTD

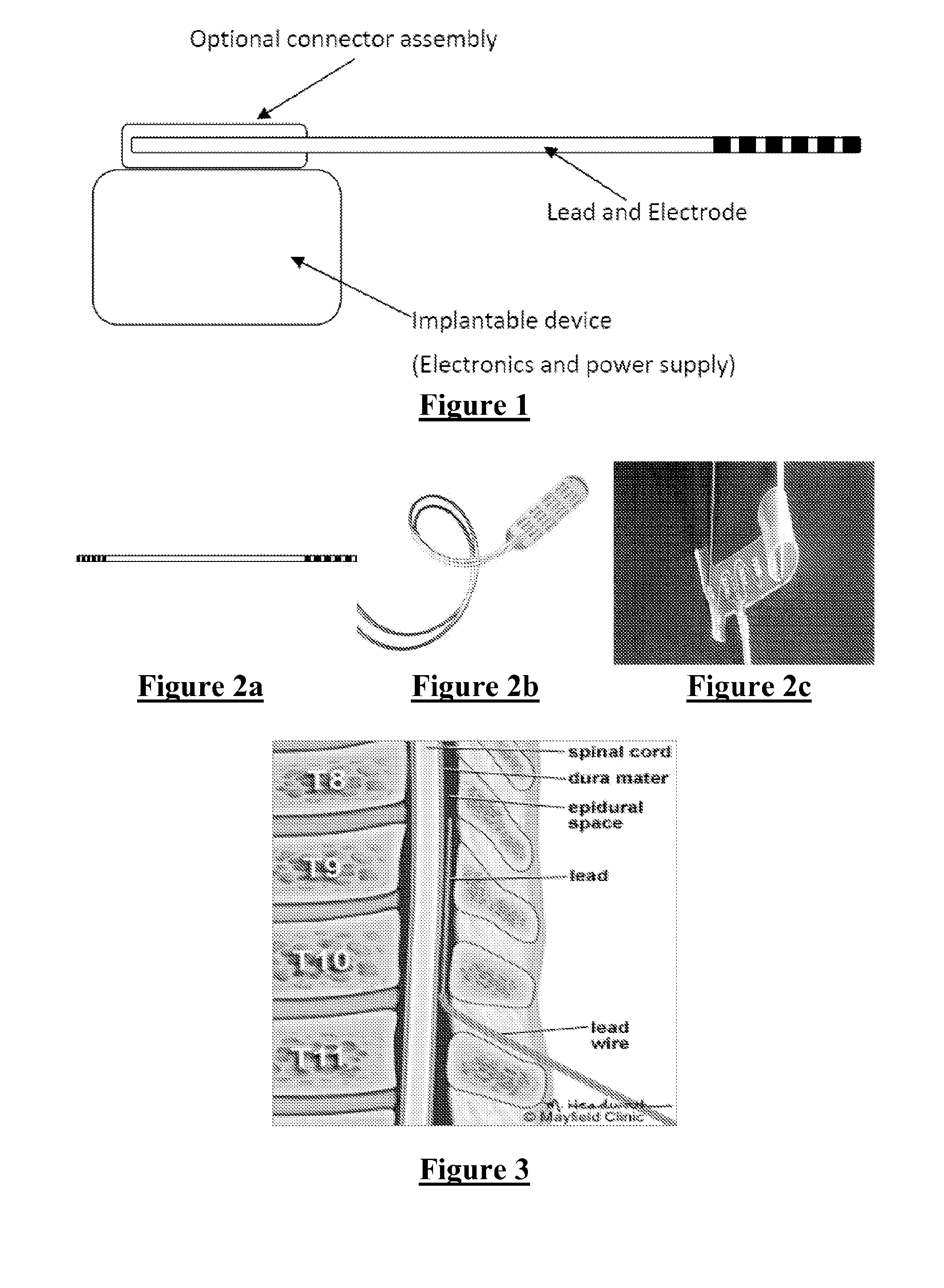

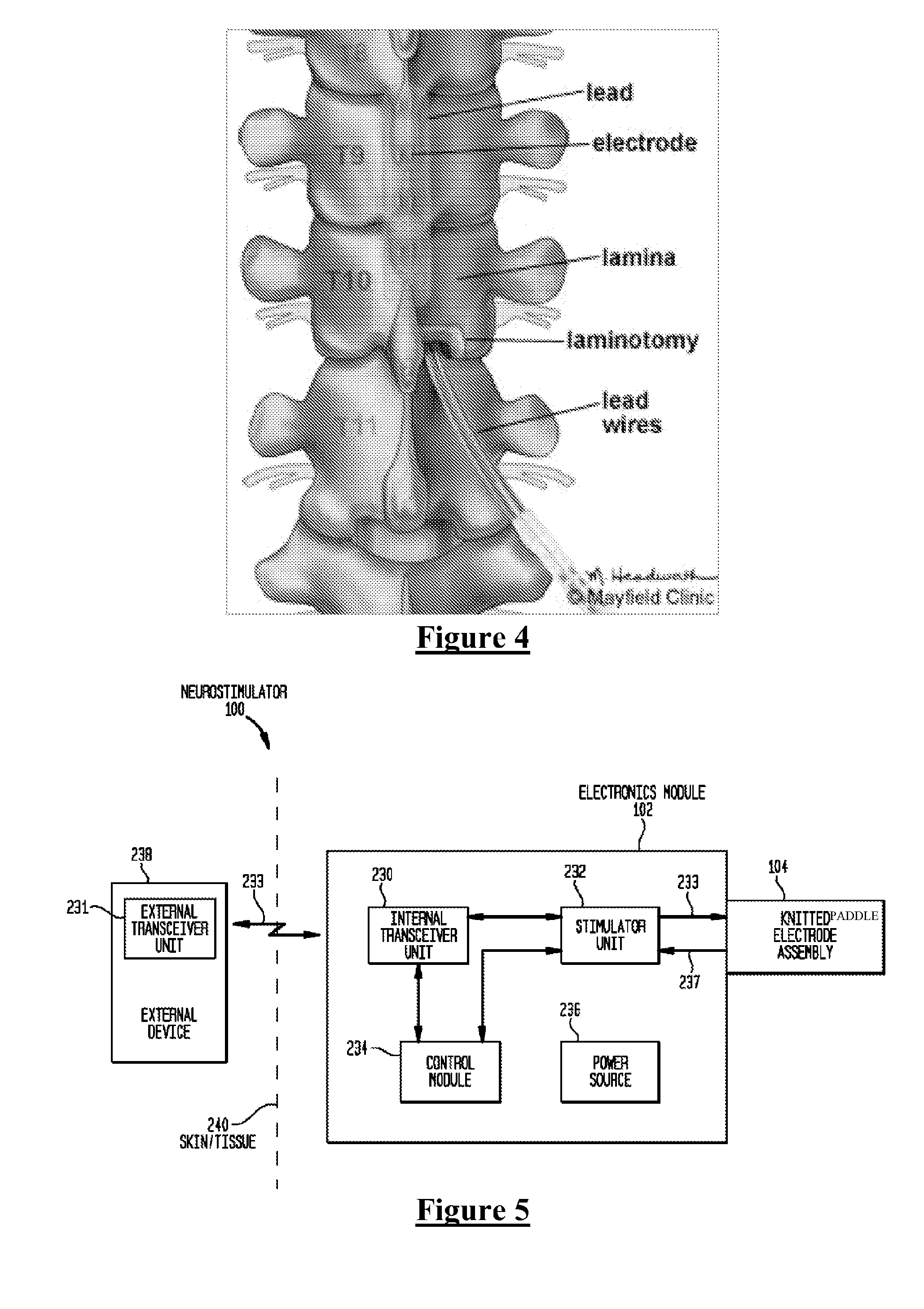

Electrode Assembly for an Active Implantable Medical Device

InactiveUS20140288577A1Reduce exerciseIncrease coverageSpinal electrodesContact member assembly/disassemblyCatheterMedical device

An electrode assembly for an active implantable medical device can be delivered by catheter but expands to become a paddle electrode once implanted. The electrode assembly comprises a support member carrying wires for electrically connecting a control unit to electrodes of the electrode assembly. At least one, and usually two resilient deformable paddle wings are mounted to the support member. The paddle wings can be furled close to the support member under a deformation force to permit implantation via an introducer. The paddle wings resiliently unfurl away from the support member upon release of the deformation force. The paddle wings bear rows and columns of electrodes, and the electrode assembly as a whole has sufficient longitudinal rigidity for implantation via an introducer.

Owner:SALUDA MEDICAL PTY LTD

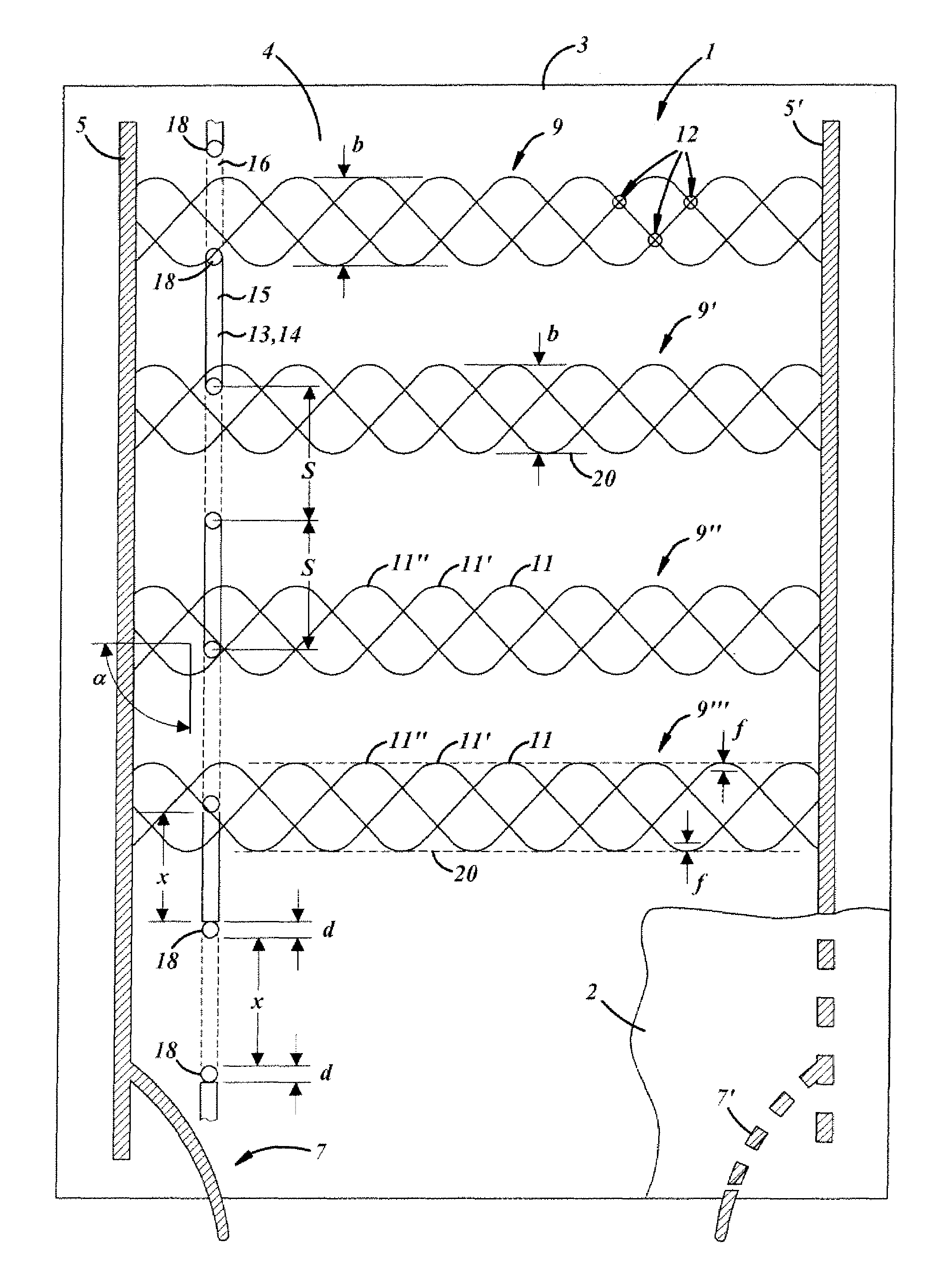

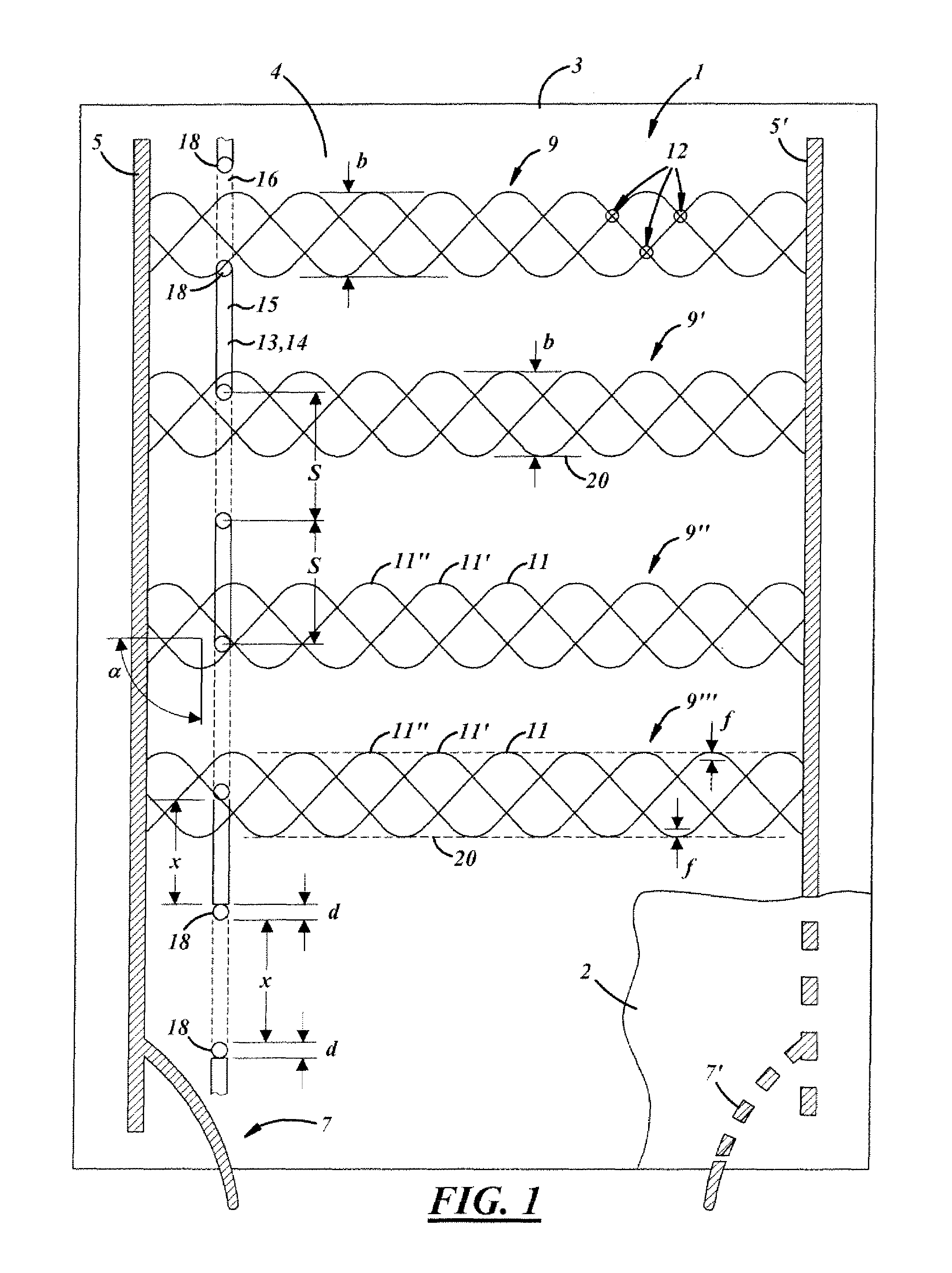

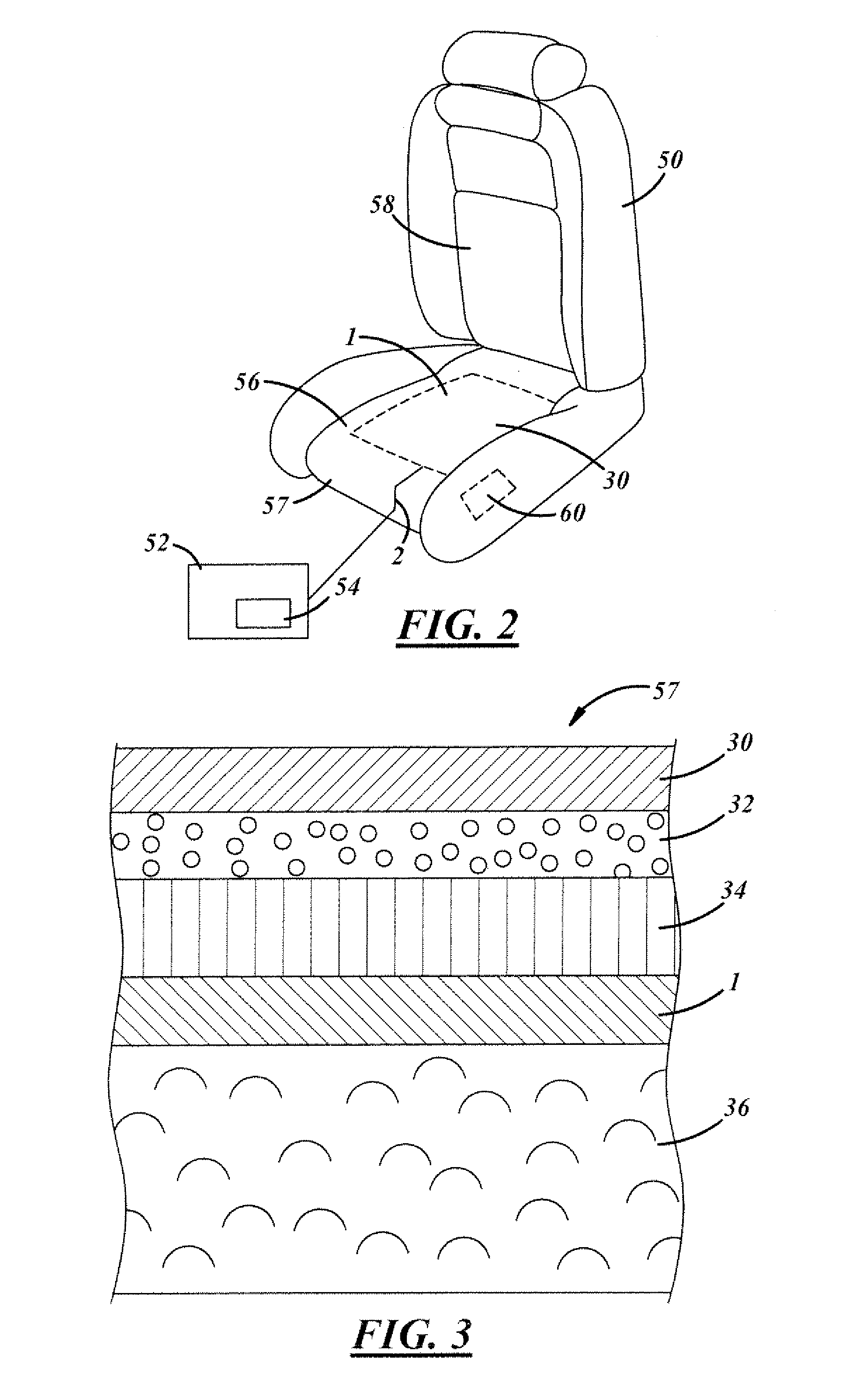

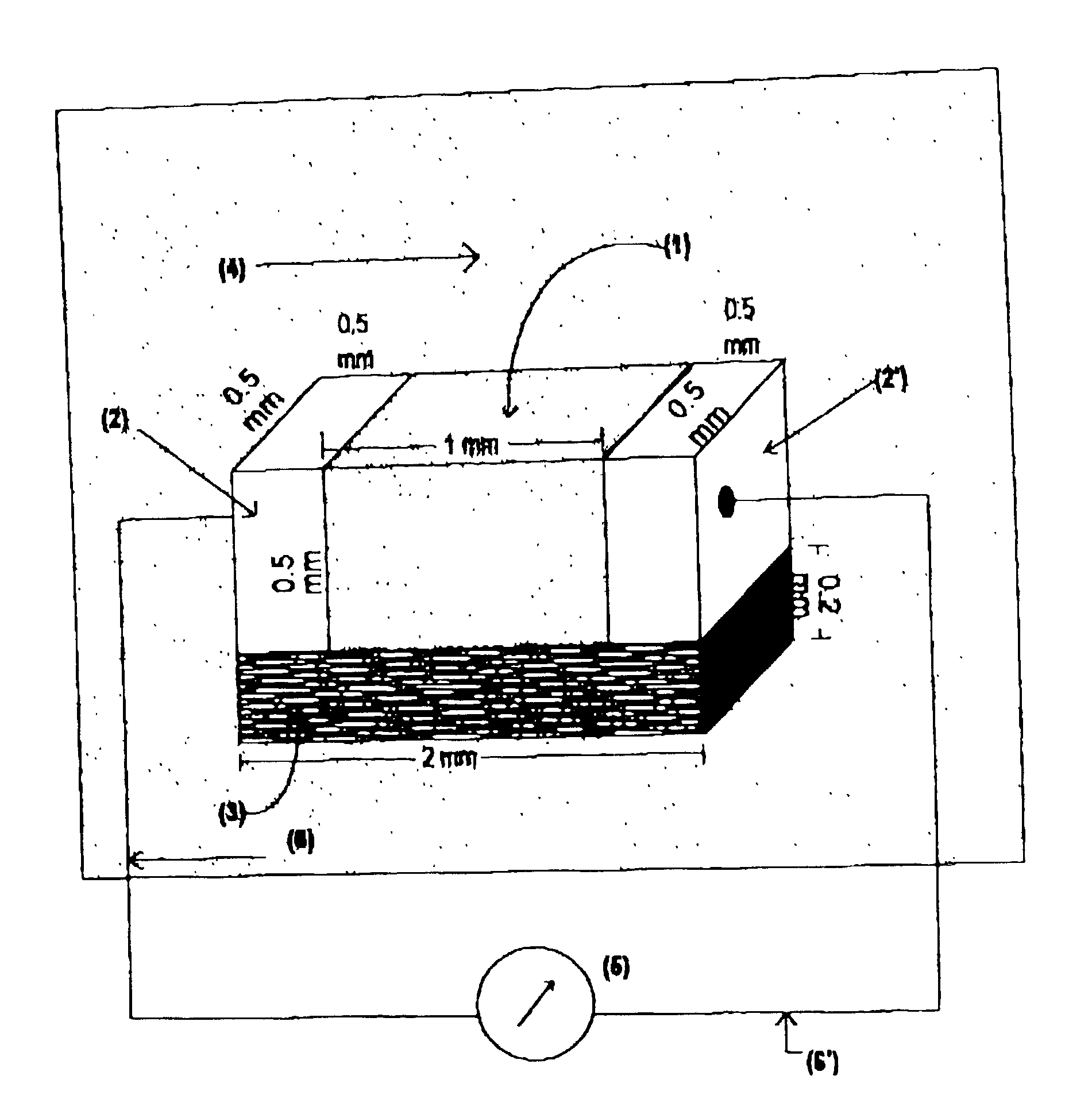

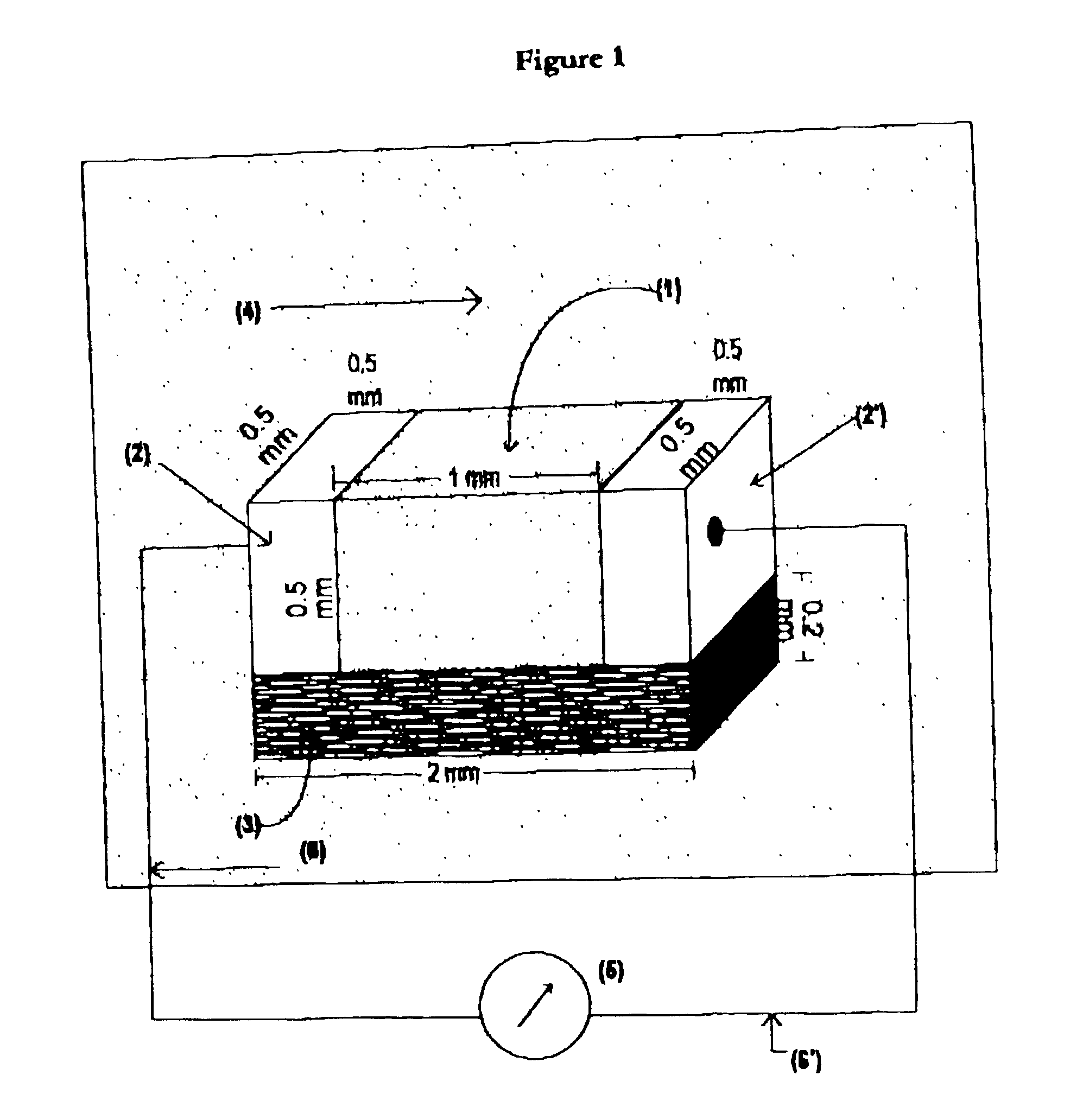

Heating element with a plurality of heating sections

InactiveUS7560670B2Overstitched more easilyIncrease heatHeater elementsHeating element shapesEngineeringElectrical contacts

A heating element (1) featuring at least two electrodes (5, 5′) for supplying the heating element (1) with current, containing a multitude of heating sections (11, 11′, 11″) that, coating at least one part of a base surface to be heated (4), are arranged between the electrodes (5, 5′) and are connected with them by electrical conduction. The heating element (1) has at least two bundles (9, 9′, 9″, 9″) of heating sections (11, 11′, 11″), with the bundles (9, 9′, 9″) being arranged at a distance from one another to avoid electrical contact between the bundles.

Owner:GENTHERM GMBH

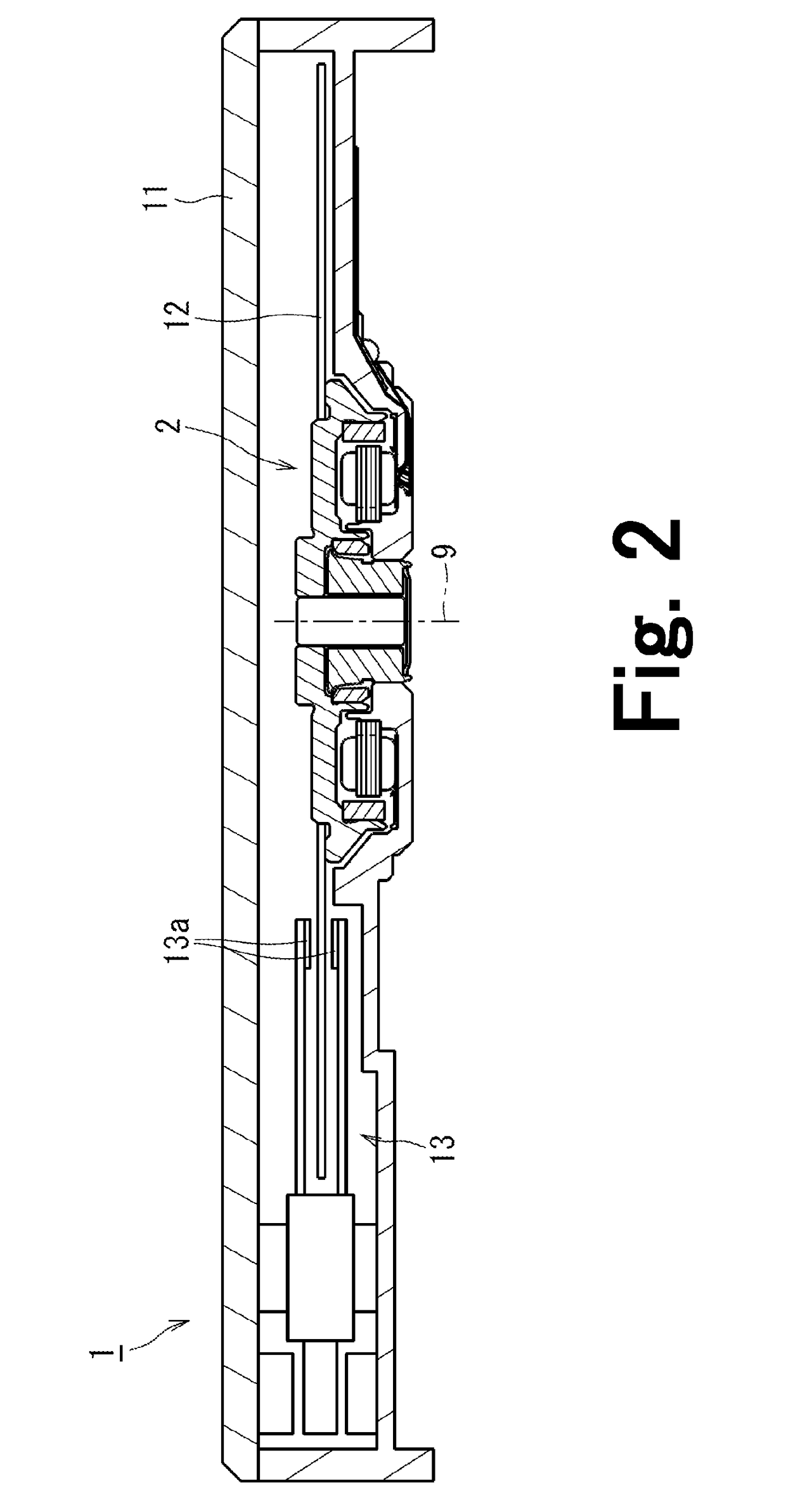

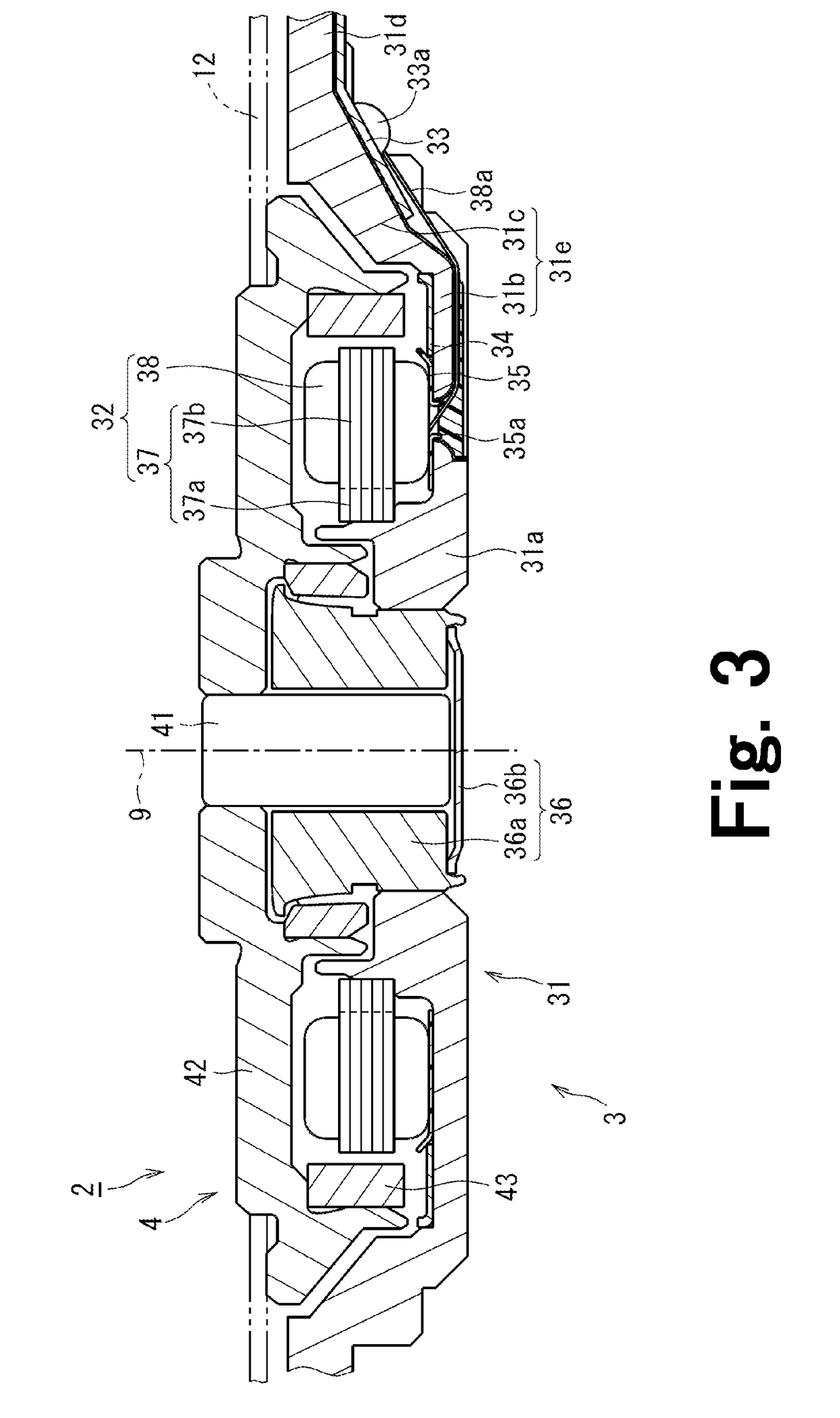

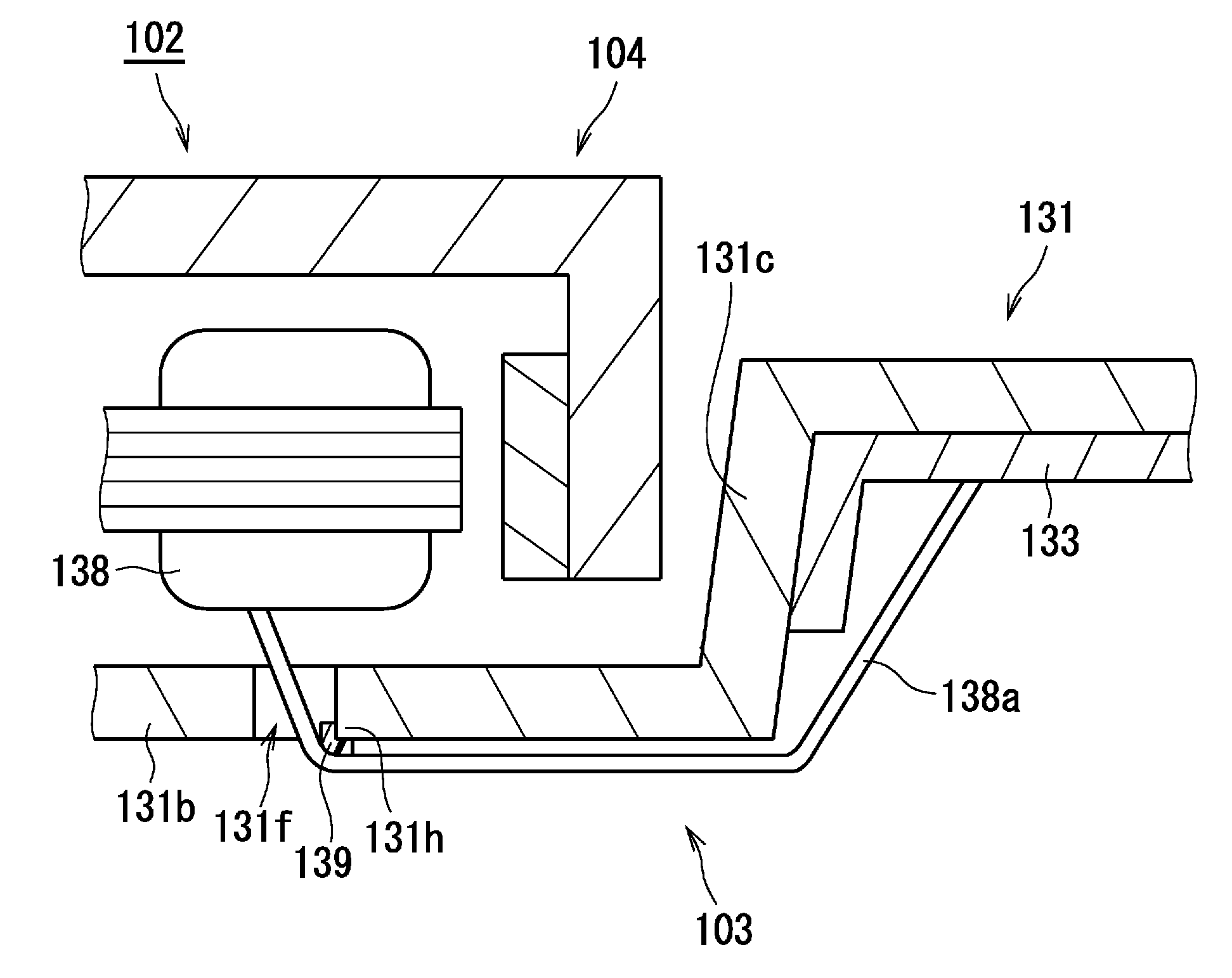

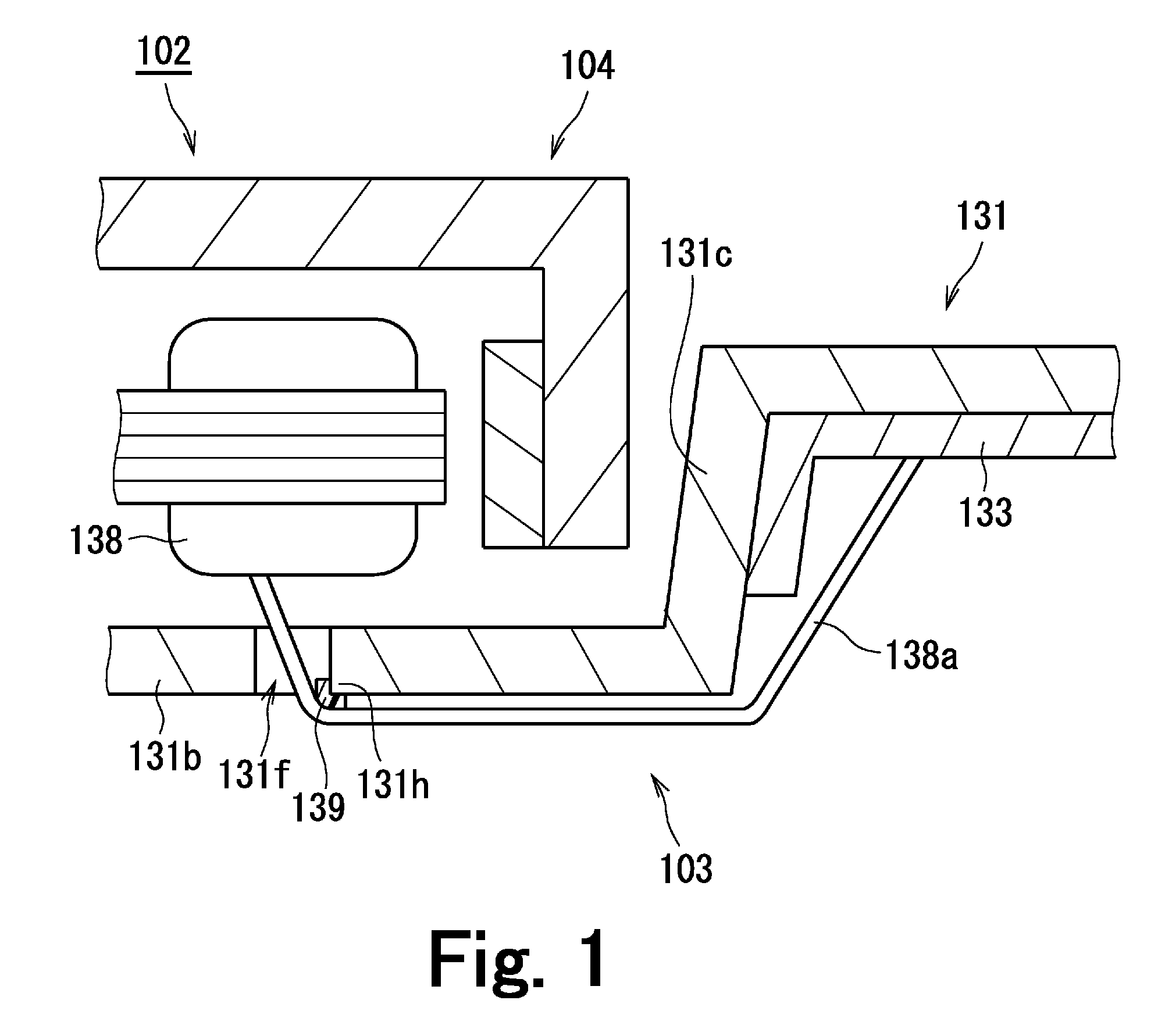

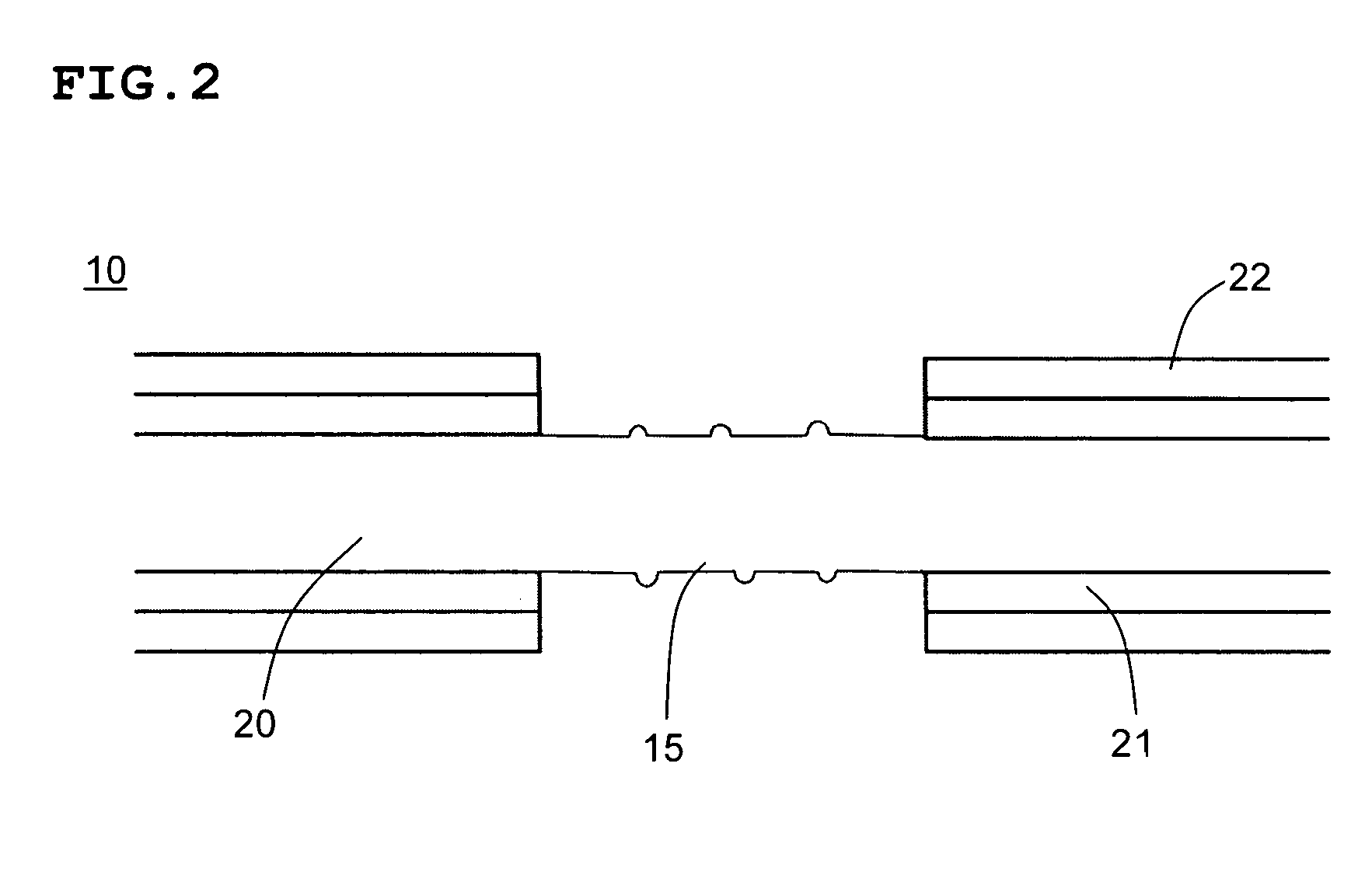

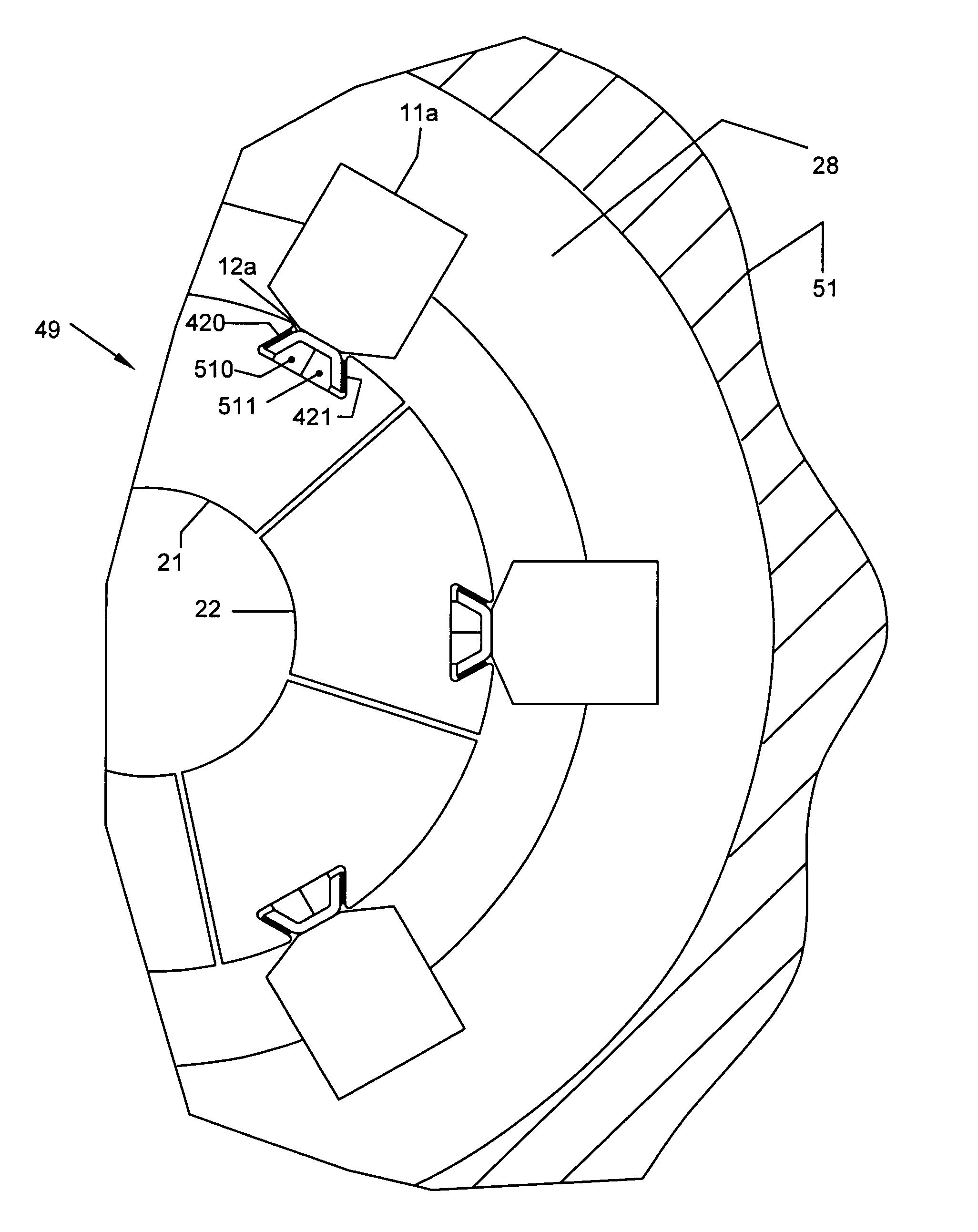

Spindle motor and disk drive apparatus

ActiveUS8120872B2Reduce thicknessAvoid electrical contactAssociation with control/drive circuitsCarrier constructional parts dispositionEngineeringMechanical engineering

A stator portion of a spindle motor includes a substantially cup-shaped base member including a bottom portion expanding in a radial direction, and a wall portion extending upwards from an outer edge portion of the bottom portion. A circuit board is fixed to a lower surface of the base member in a position on the outer side in the radial direction and on the upper side than the bottom portion. Accordingly, the thickness of the spindle motor in the axial direction can be reduced. The base member has a through hole formed axially through the bottom portion. An opening edge portion of the base member is covered with the insulating layer. A conducting wire from a coil is drawn through the through hole, led out along the surface of the insulating layer, and connected to the circuit board positioned on the outer side in the radial direction than the bottom portion. Accordingly, the conducting wire can be led to the circuit board while the electric connection between the conducting wire and the opening edge portion can be prevented.

Owner:NIDEC CORP

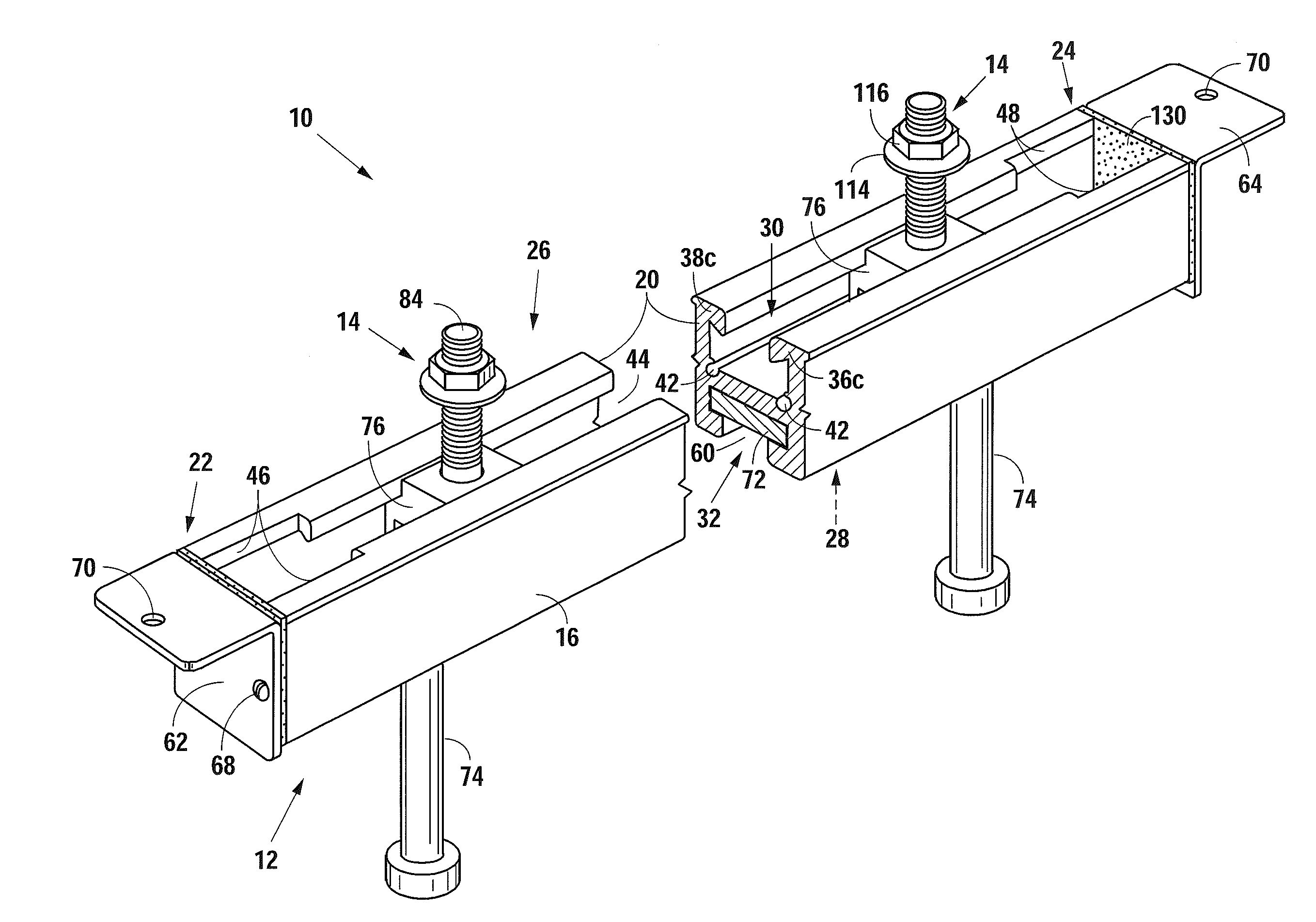

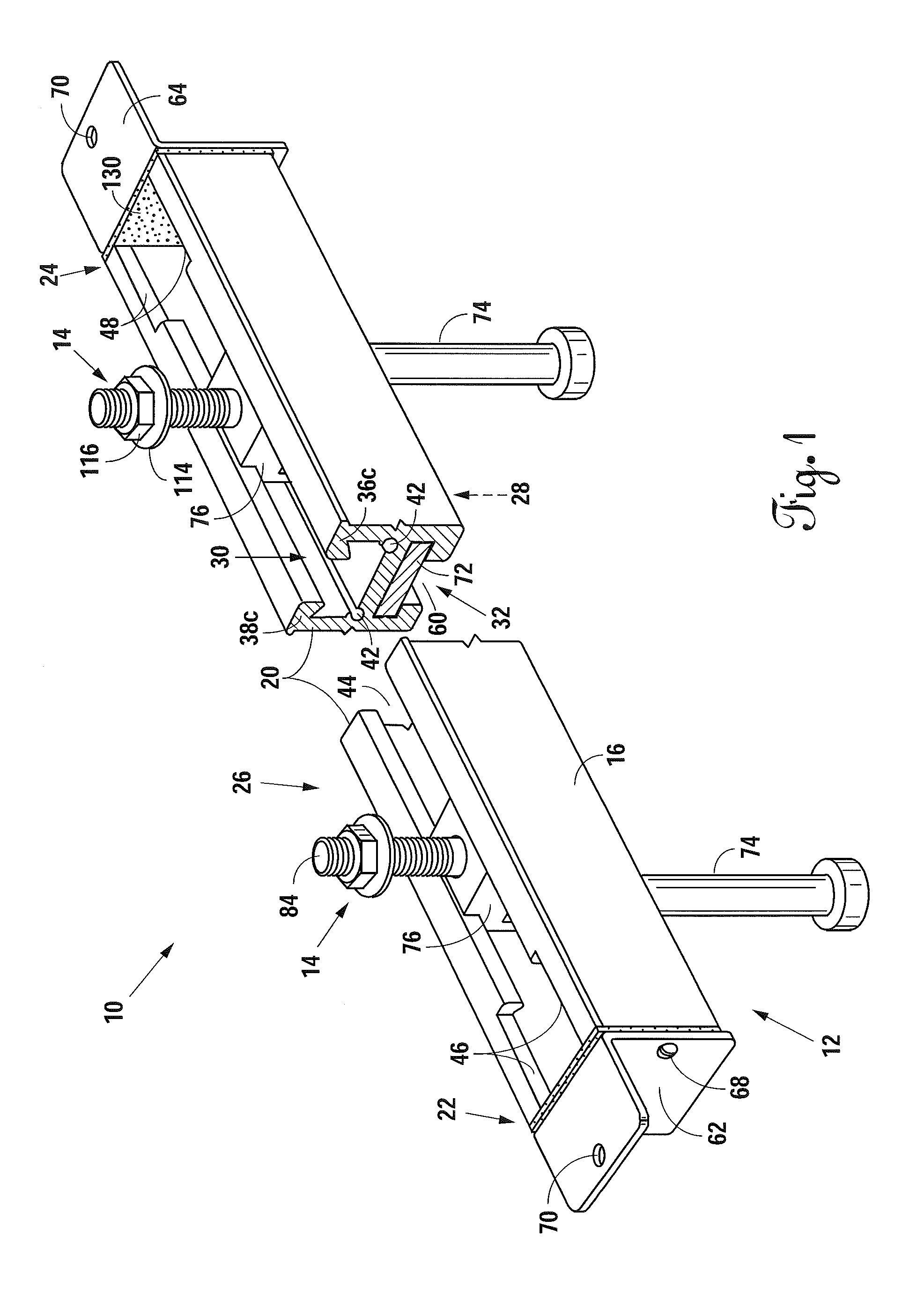

Cast-in anchor system

InactiveUS20140250825A1Connection securityManufacturing techniquePinsNutsMechanical engineeringIndustry standard

A cast-in anchor system for anchoring objects to concrete structures. The preferred system uses an extruded cast-in anchor and an extruded bolt retainer. The cast-in anchor is embedded within concrete with a face left exposed. The bolt retainer has a bolt inserted through it and is placed within an anchor channel on the exposed face of the cast-in anchor. The bolt retainer allows for use of an industry-standard bolt and prevents the bolt from rotating once the bolt-head is seated against it. The cast-in anchor and the bolt are positioned along the length of the anchor channel, with a threaded portion of the bolt extending out of the anchor channel. A workpiece is placed over the threaded portion of the bolt and a nut is tightened. Tightening the nut causes locking surfaces on the bolt retainer to engage with corresponding surfaces on the anchor channel which prevents the bolt retainer from exiting the anchor channel.

Owner:RICHARDSON DOUGLAS S

Spindle motor and disk drive apparatus

ActiveUS20110122530A1Reduce thicknessAvoid electrical contactAssociation with control/drive circuitsWindings insulation shape/form/constructionEngineeringMechanical engineering

A stator portion of a spindle motor includes a substantially cup-shaped base member including a bottom portion expanding in a radial direction, and a wall portion extending upwards from an outer edge portion of the bottom portion. A circuit board is fixed to a lower surface of the base member in a position on the outer side in the radial direction and on the upper side than the bottom portion. Accordingly, the thickness of the spindle motor in the axial direction can be reduced. The base member has a through hole formed axially through the bottom portion. An opening edge portion of the base member is covered with the insulating layer. A conducting wire from a coil is drawn through the through hole, led out along the surface of the insulating layer, and connected to the circuit board positioned on the outer side in the radial direction than the bottom portion. Accordingly, the conducting wire can be led to the circuit board while the electric connection between the conducting wire and the opening edge portion can be prevented.

Owner:NIDEC CORP

Electrical contacts having solder stops

ActiveUS7172438B2Reduced aestheticsReduce the amount requiredLine/current collector detailsElectrically conductive connectionsEngineeringElectrical connector

An electrical contact for use in an electrical connector, includes a contact body made of metal and having a contact head, a contact tail, and an anti-wicking region disposed between the contact head and the contact tail arranged to prevent wicking of a fusible material past the anti-wicking region in a direction toward the contact head. The anti-wicking region is defined by one of a laser-ablated portion, a laser marking material, a UV marking material, and an ink that is permanently disposed on the contact body.

Owner:SAMTEC

Information communicating member, liquid container having information communicating member and liquid ejecting apparatus

InactiveUS20050012766A1Avoid electrical contactErase blockOther printing apparatusPrintingElectricityInformation storage

An information communicating member is adapted to be disposed on a liquid container for supplying a liquid to a liquid ejecting head of a liquid ejection apparatus. The information communicating member includes: an information storing portion storing therein liquid information with regard to the liquid contained in the liquid container; an antenna portion for communicating the liquid information stored in the information storing portion between the information communicating member and the liquid ejection apparatus in a wireless manner; and a base member on which the information storing portion and the antenna portion are disposed. The base member has an electric insulating property and an ultraviolet ray shielding property.

Owner:SEIKO EPSON CORP

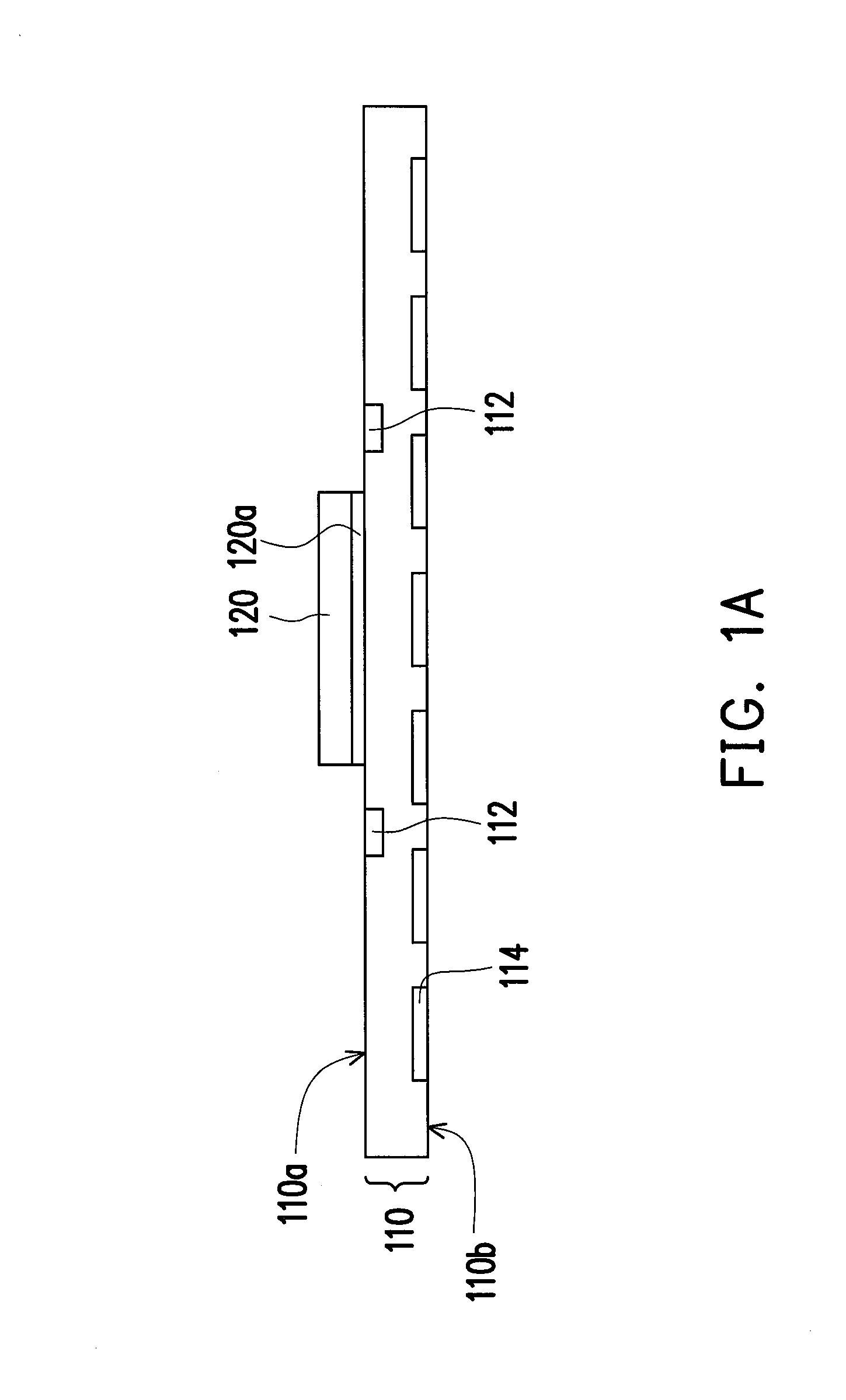

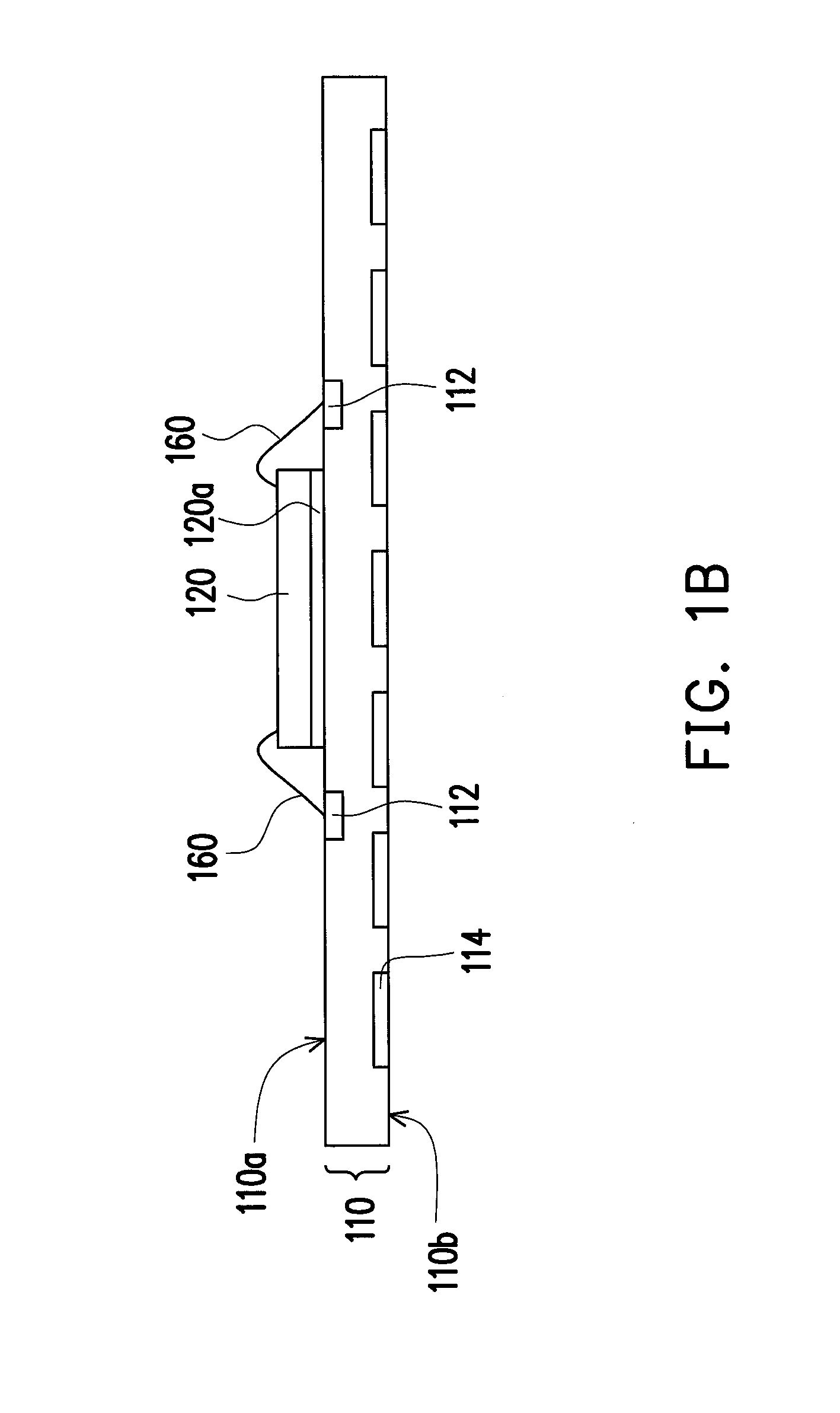

Chip package structure and manufacturing method thereof

InactiveUS20150076670A1Improve assembly yieldReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesElectromagnetic shieldingSealant

A chip package structure and a manufacturing method thereof are provided. The chip package structure includes a substrate, a chip, a plurality of wires, a film layer, a carrier, and an encapsulant. The substrate has an upper surface and a lower surface. The chip is mounted on the upper surface of the substrate. The wires are electrically connected to the chip and the substrate respectively. The film layer is attached to the substrate and entirely encapsulates the chip and the wires. The carrier is adhered on the film layer. The encapsulant is disposed on the upper surface of the substrate, wherein the encapsulant has an electro-magnetic shielding filler. The encapsulant at least partially encapsulates the carrier and the film layer, and the encapsulant covers the chip and the wires.

Owner:CHIPMOS TECH INC

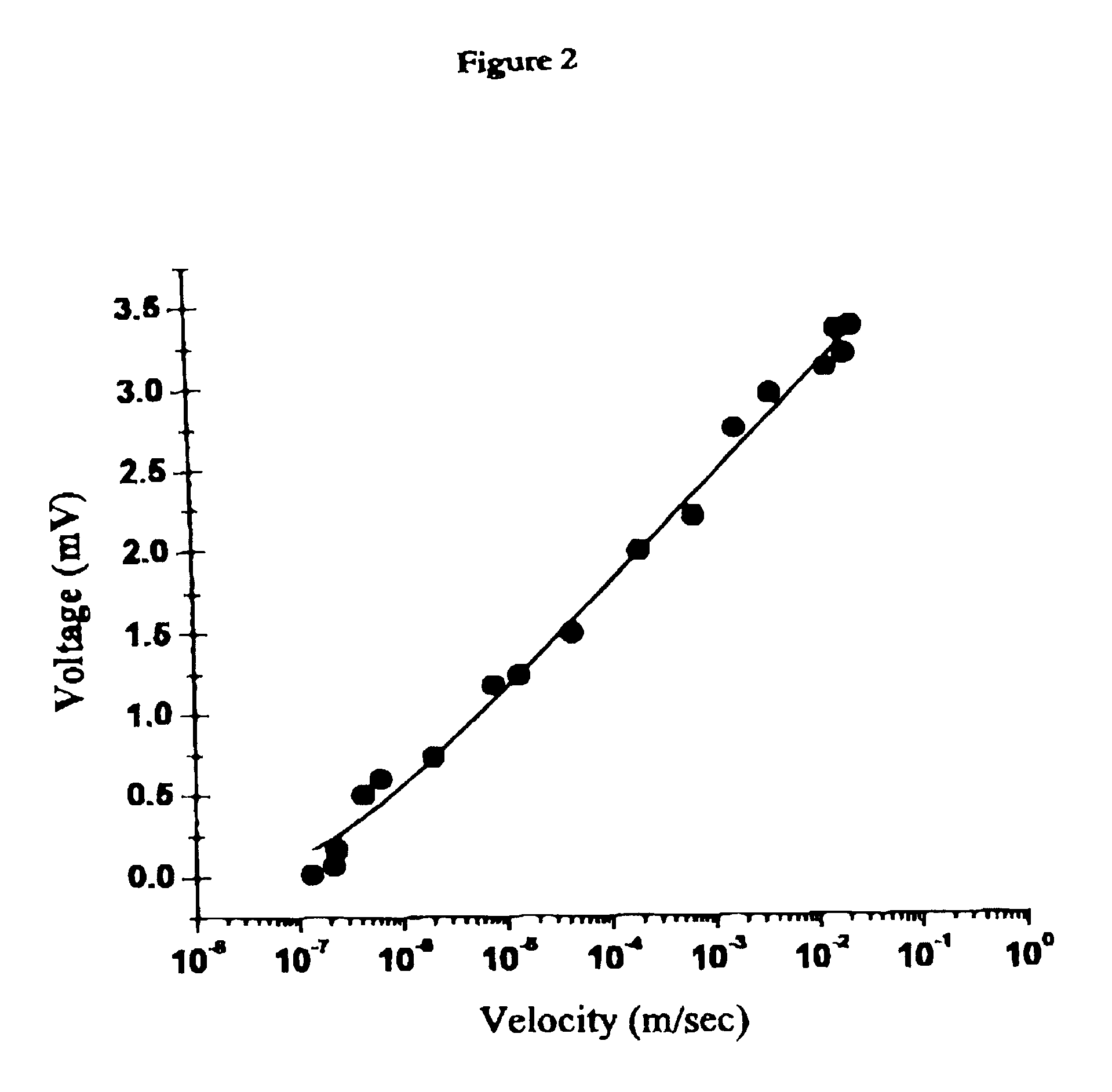

Carbon nanotube flow sensor device and method

InactiveUS6718834B1Measurement accuracyLower average response timeNanotechVolume/mass flow by electric/magnetic effectsCarbon nanotubeBCN nanotube

A method and device for measuring the flow of a liquid utilizes at least one carbon nanotube. More particularly, the velocity of a liquid along the direction of the flow is measured as a function of the current / voltage generated in at least one carbon nanotube due to the flow of the liquid along its surface.

Owner:INDIAN INSTITUTE OF SCIENCE

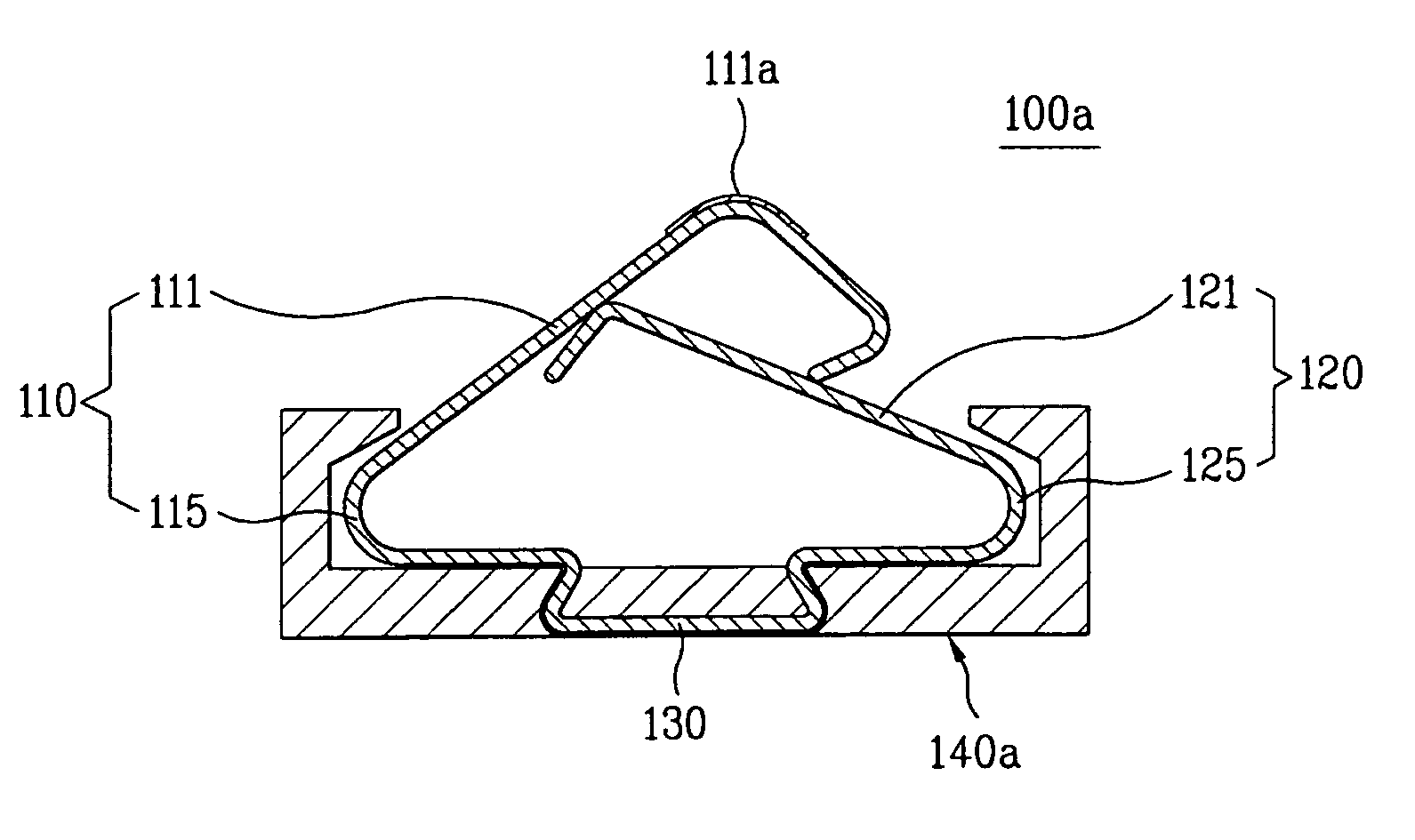

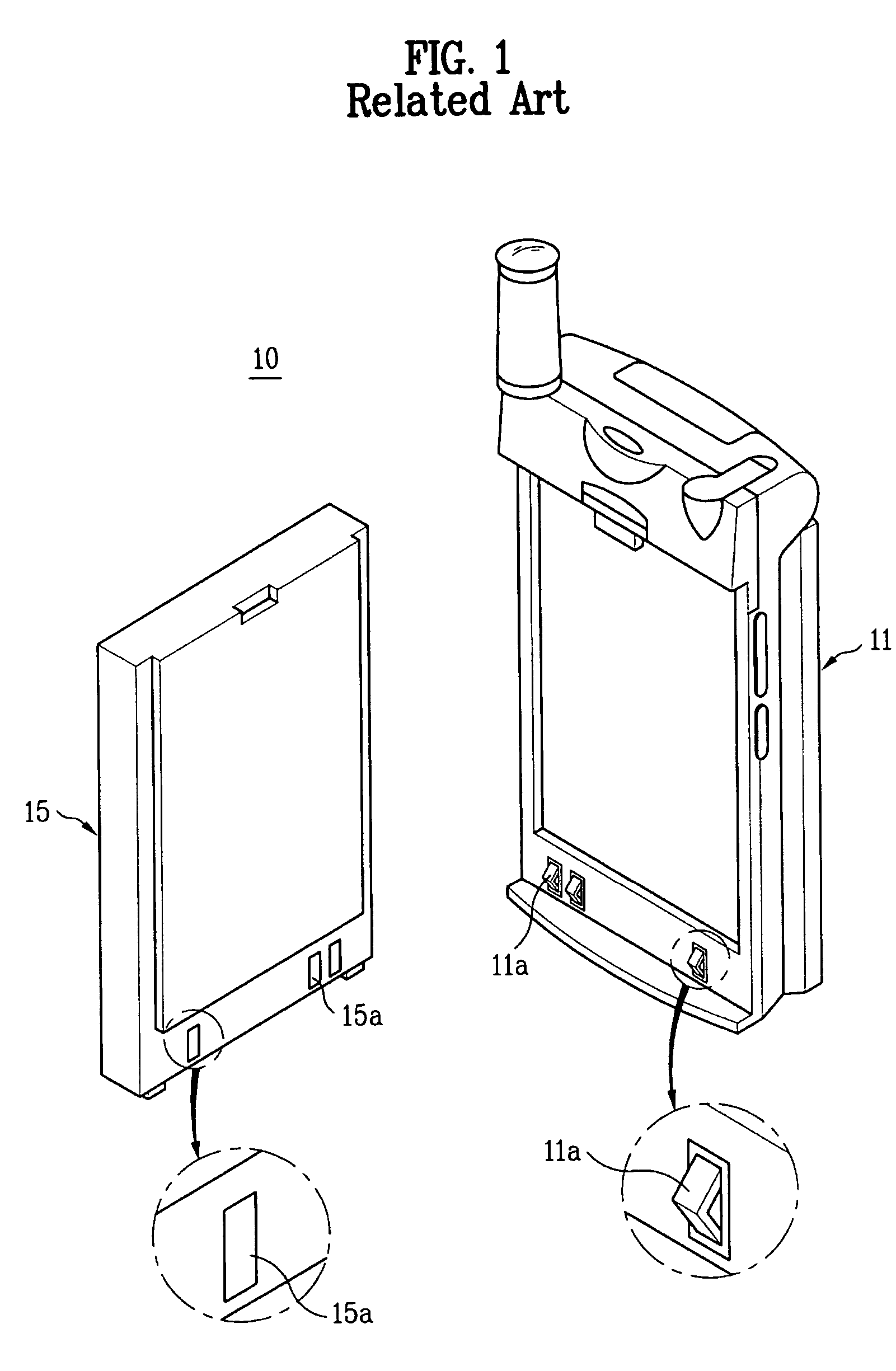

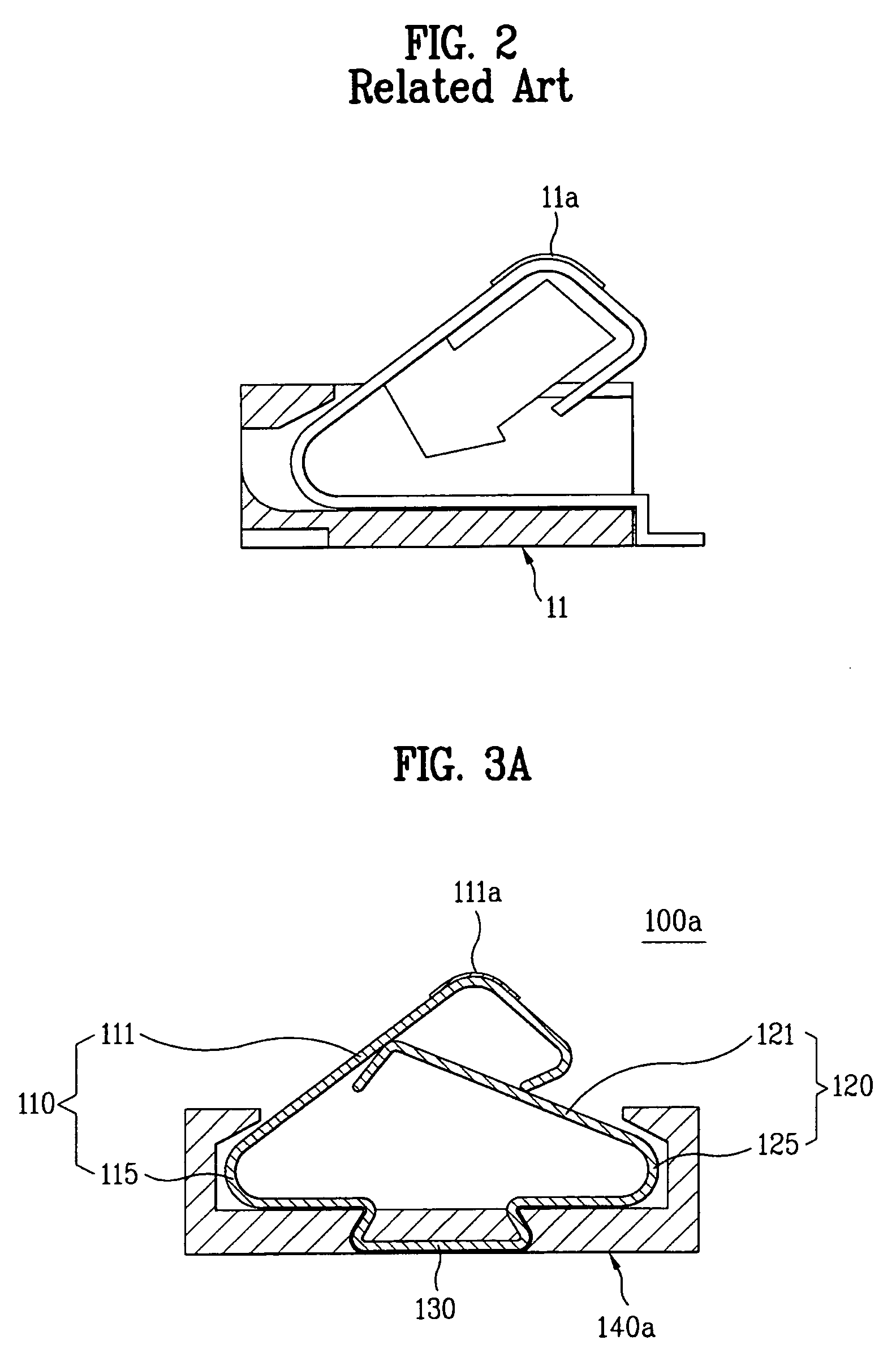

Contact for a portable electronic device

InactiveUS7220152B2Avoid electrical contactCoupling device detailsSubstation equipmentContact methodBiomedical engineering

Owner:LG ELECTRONICS INC

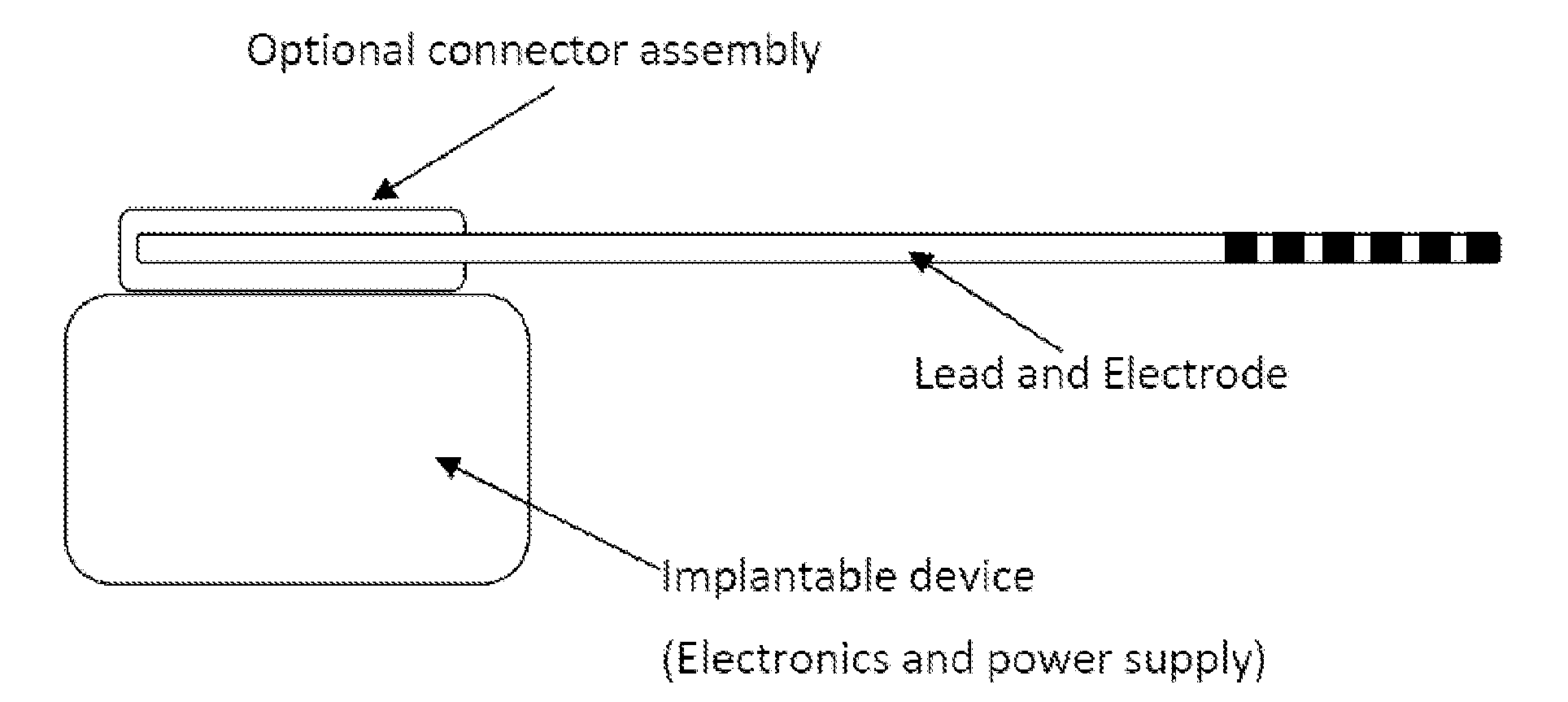

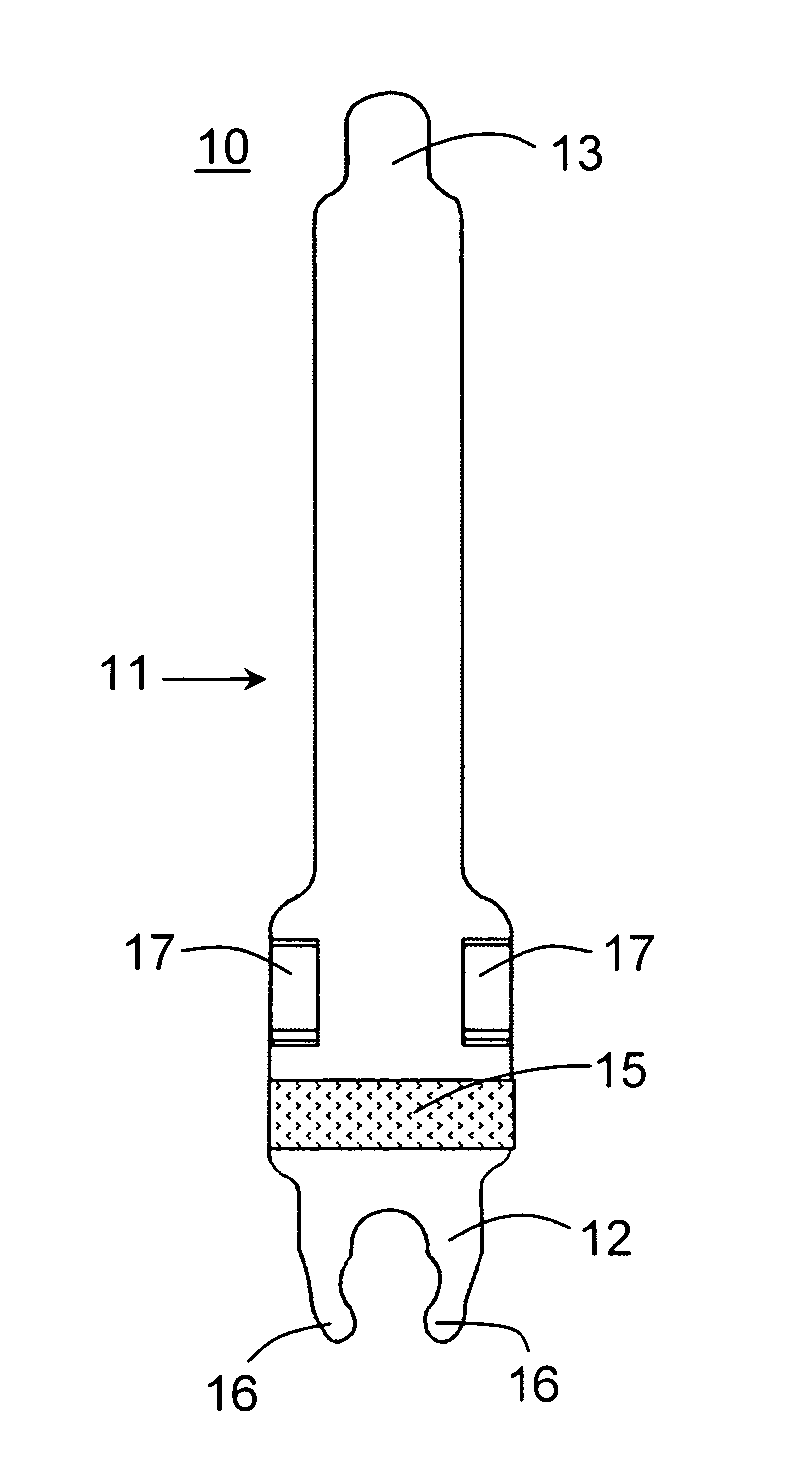

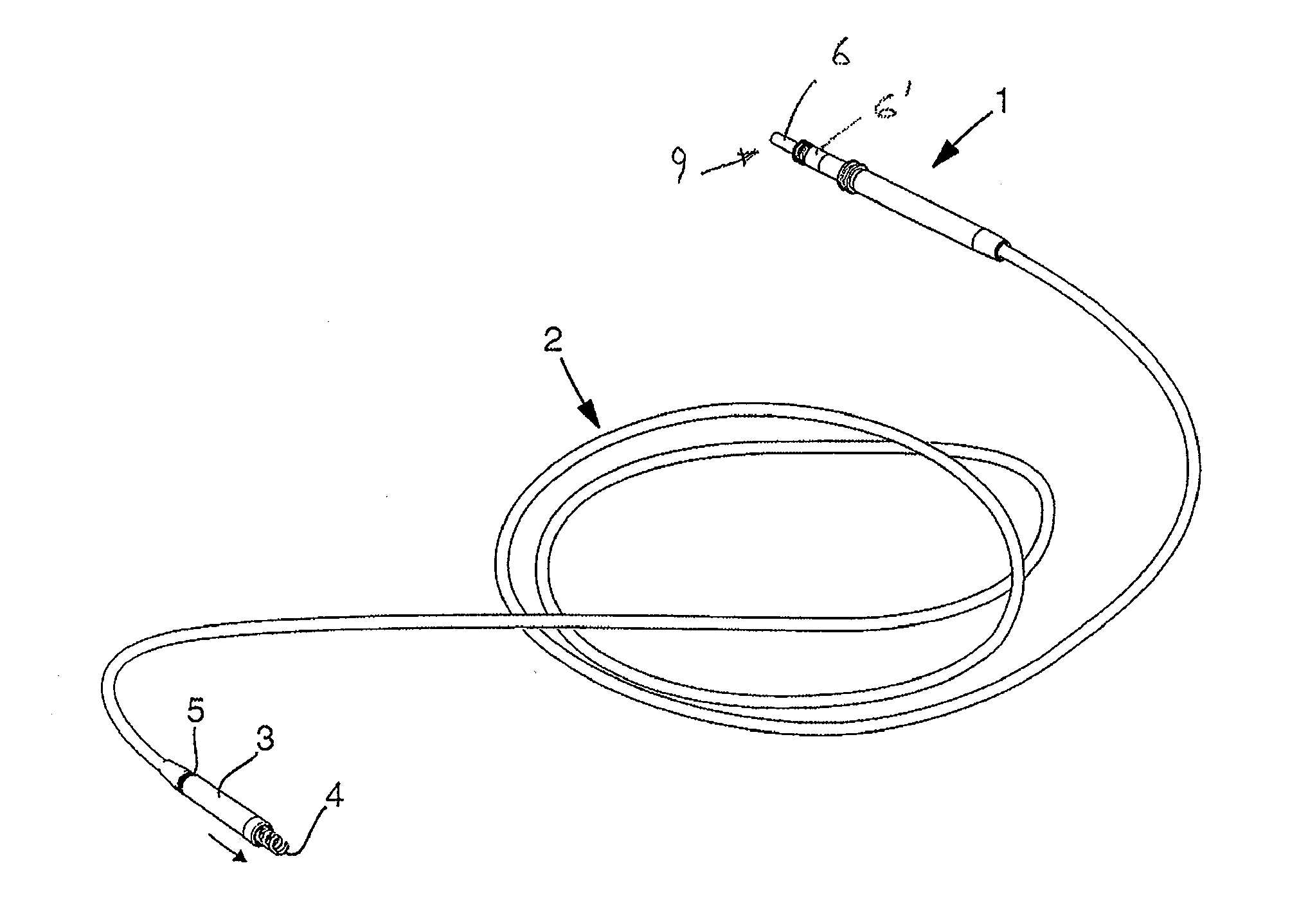

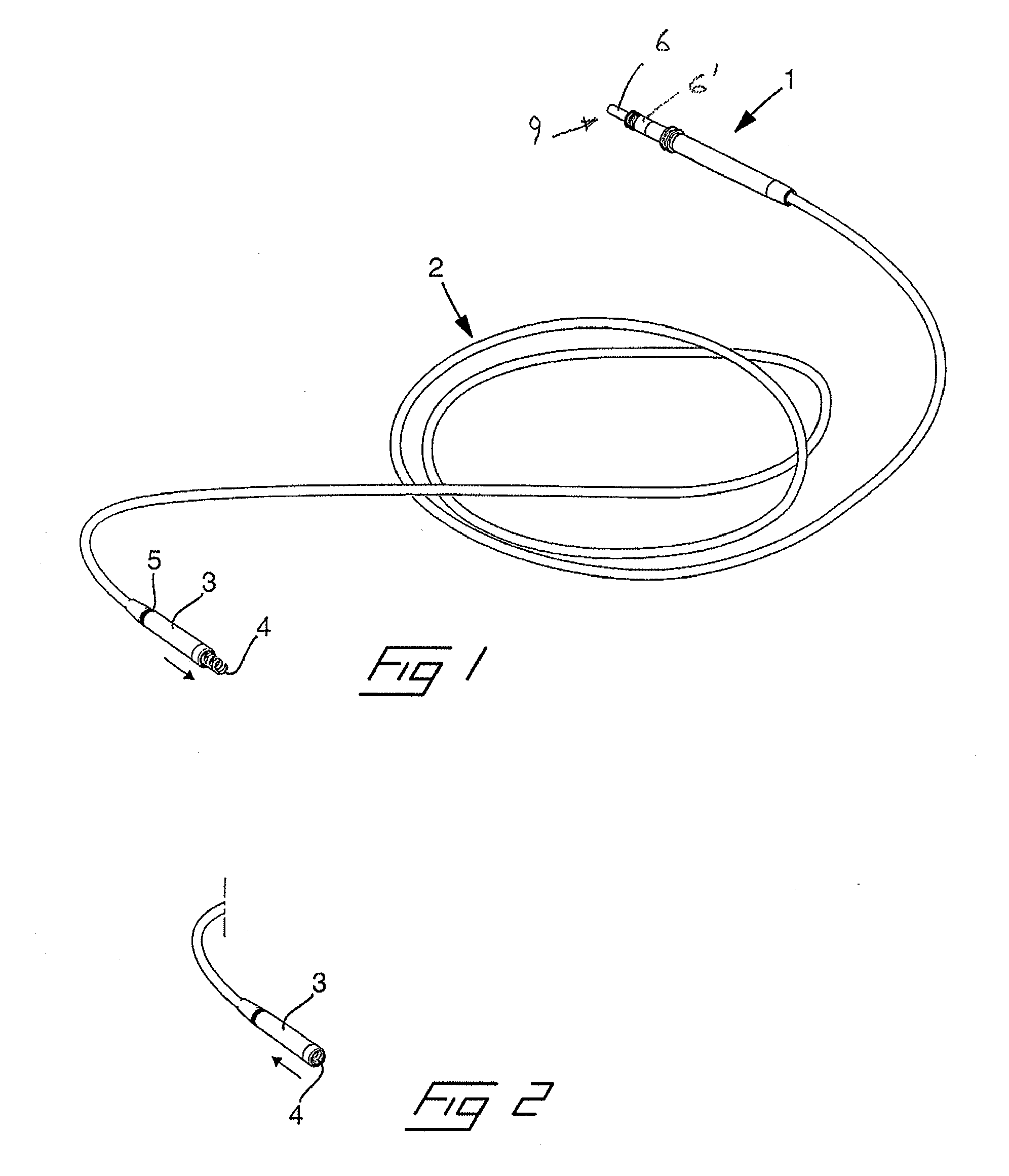

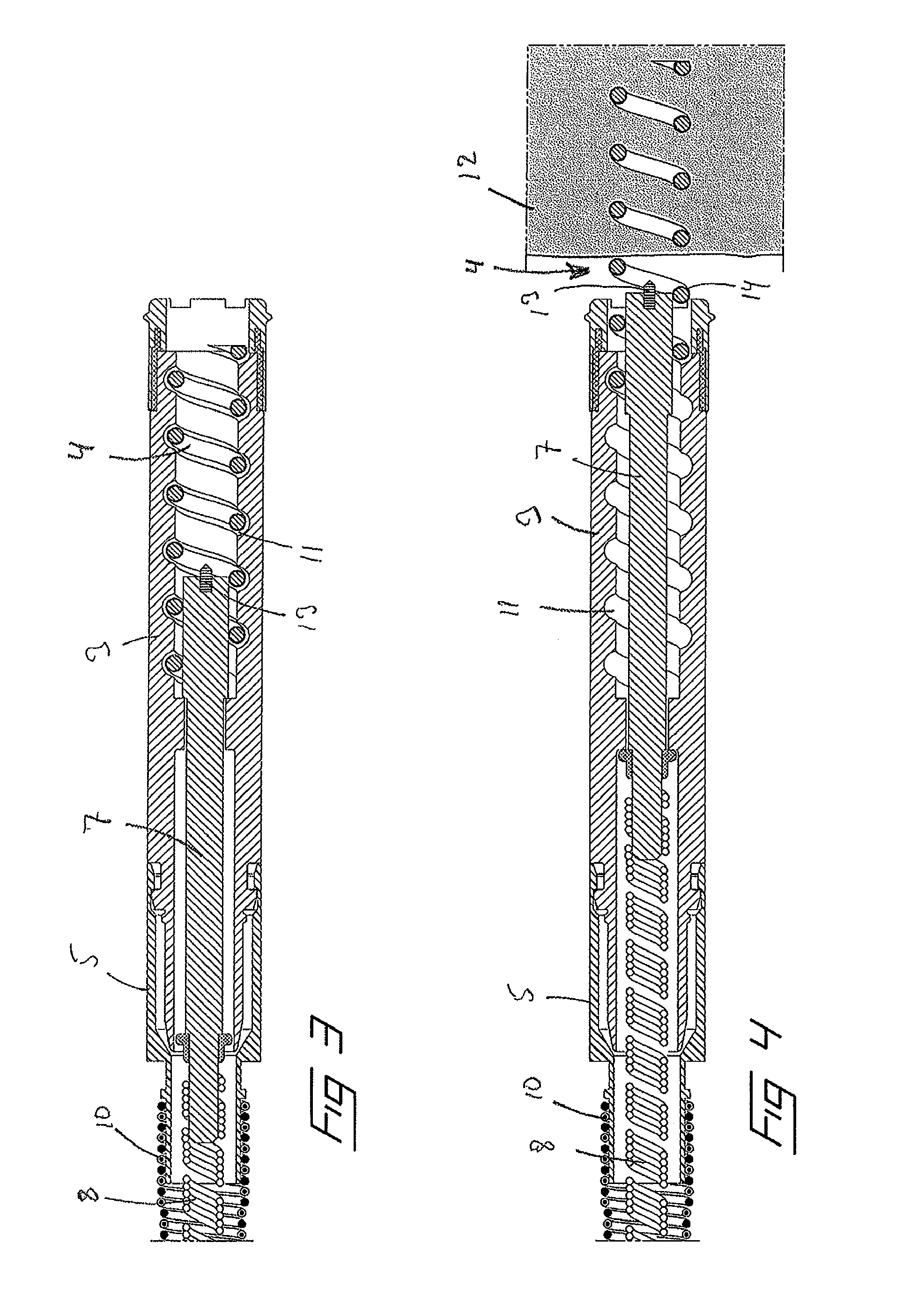

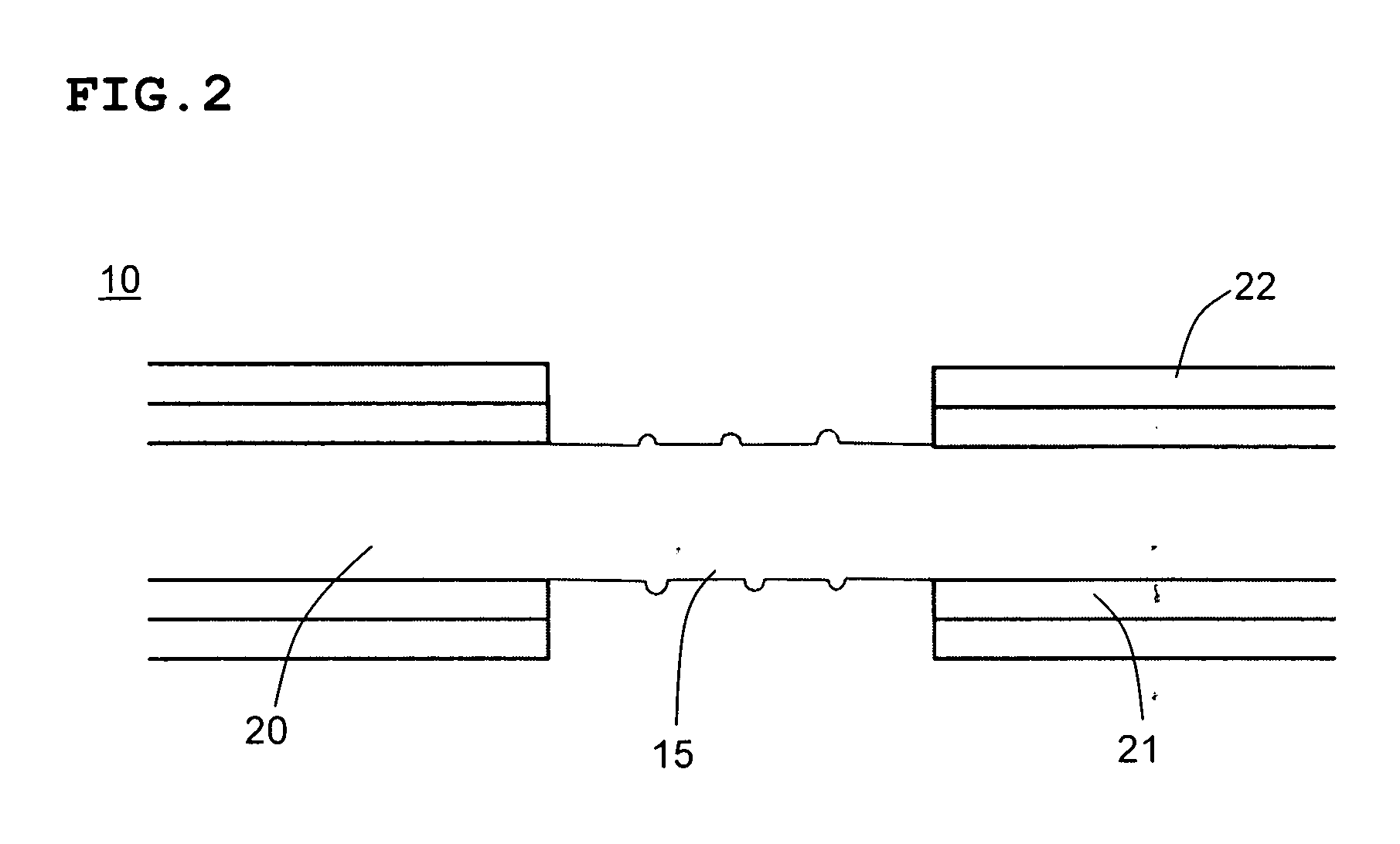

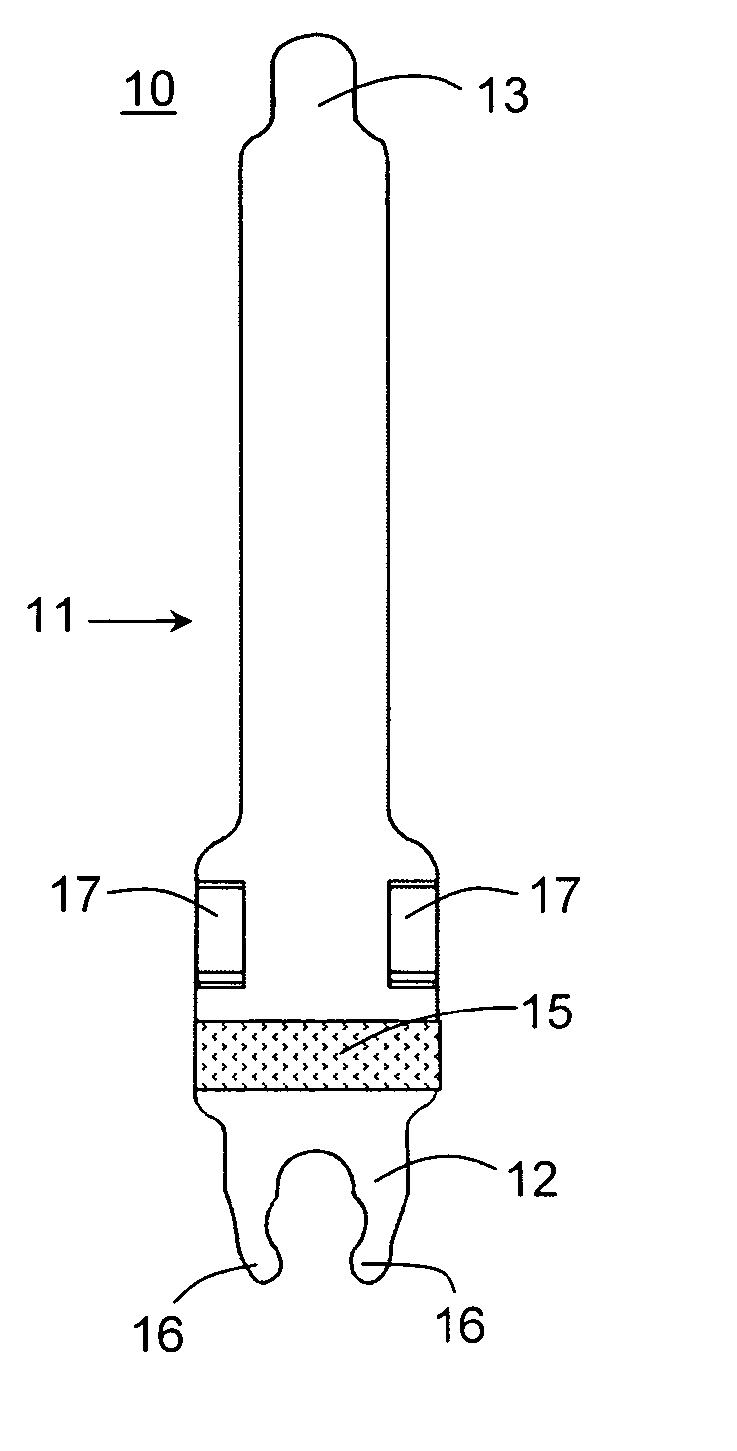

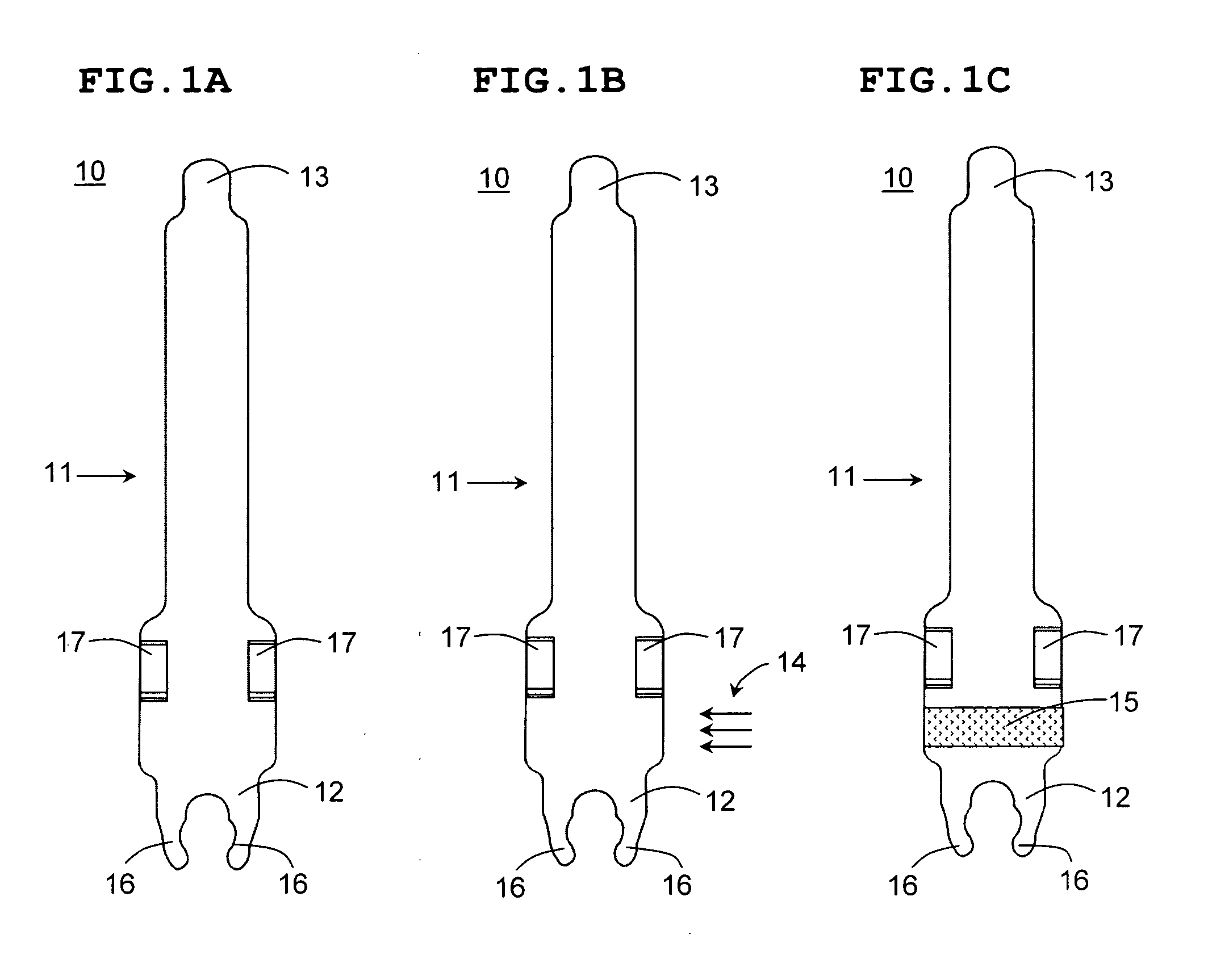

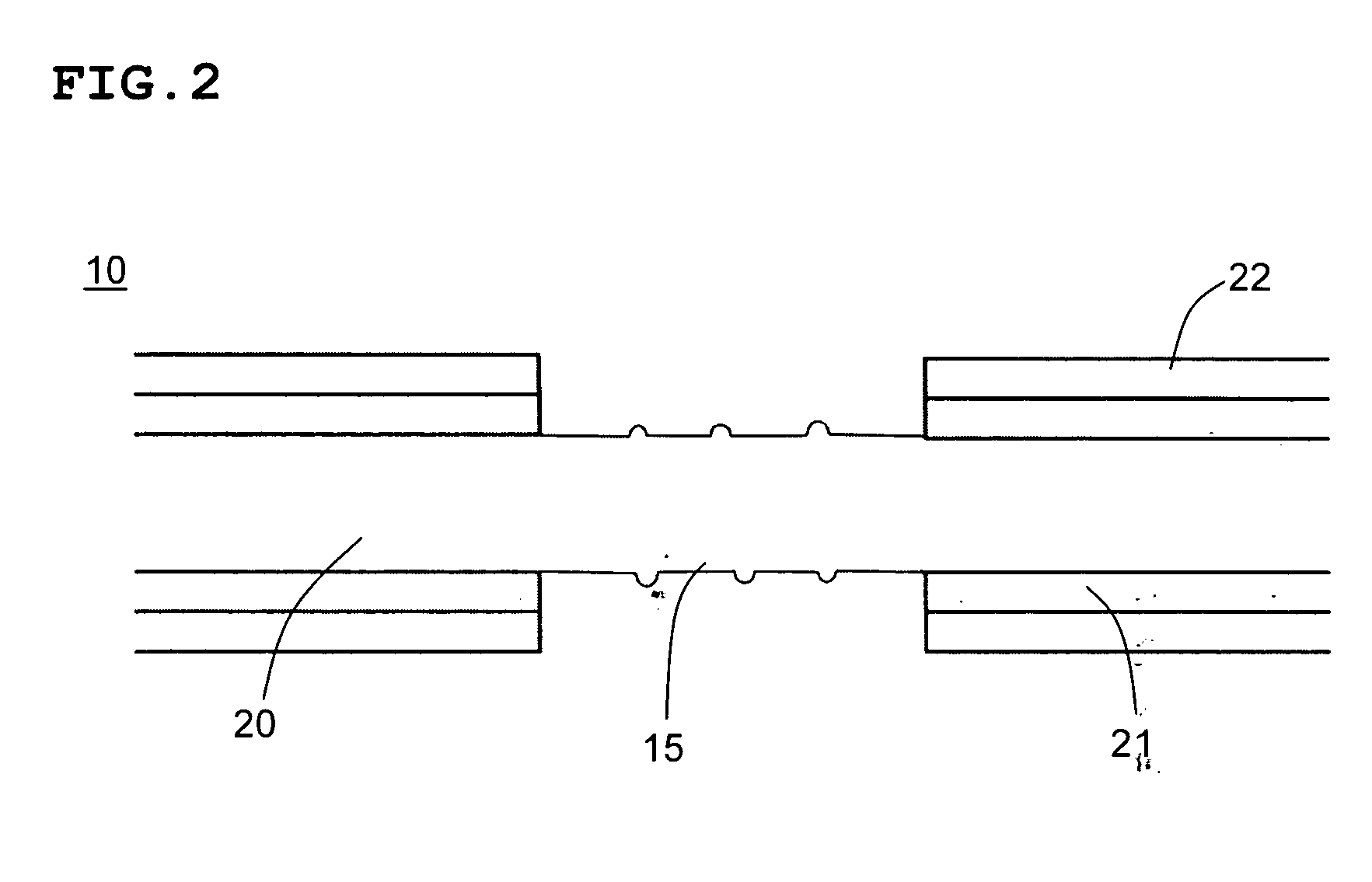

Medical implanatble lead with fixation detection

ActiveUS20120232373A1Avoid electrical contactSufficient amplitudeBioelectric signal measurementInternal electrodesElectricityAnimal body

The invention relates to a medical implantable lead of the kind being adapted to be implanted into a human or animal body for monitoring and / or controlling of an organ inside the body. The lead comprises in a distal end a tubular header (3) inside which a shaft (7) is rotatable as well as extendable and retractable arranged and carries in a distal end a combined fixation means and electrode member in form of a helix (4), which is provided with a first contact surface being electrically connectible to a connector at the proximal end of the lead by means of an electric conductor (8), and which by means of the shaft is rotatable in relation to the lead and extendable out from the distal end to be able to fixate the distal end of the lead to the organ by being screwed into the tissue. The shaft also carries a second contact surface (13) being positioned on or adjacent a proximal portion of the helix and being connectible to a connector at the proximal end of the lead by means of an electric conductor (8). The lead comprises a conduction controlling means (14), which at least during an initial stage after implantation is capable of render the first contact surface electrically inactive and which is capable of render the first contact surface electrically active after the initial stage. By means of the inventive lead it is possible to detect whether the helix is sufficient screwed into the tissue (12) or not.

Owner:ST JUDE MEDICAL

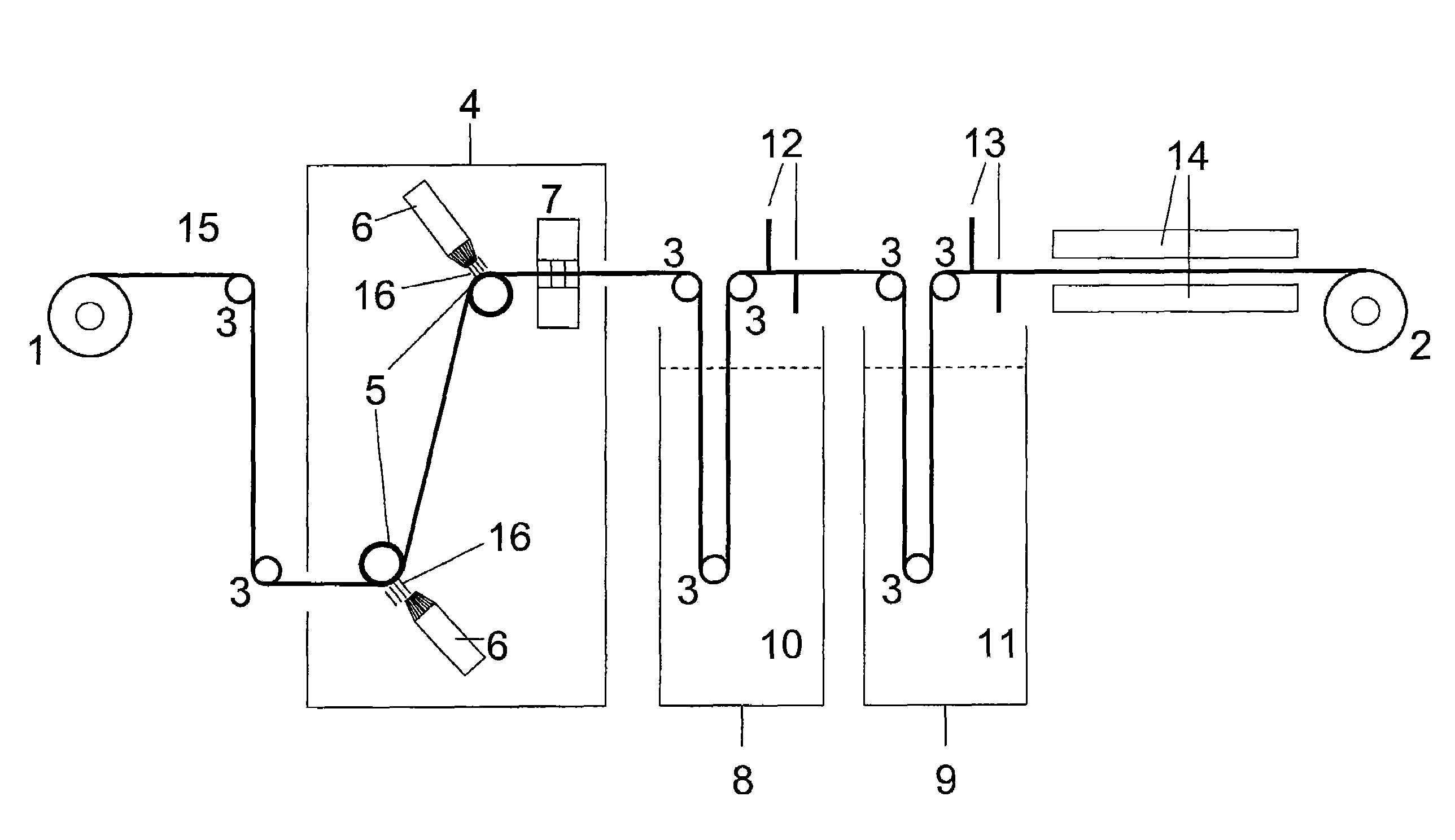

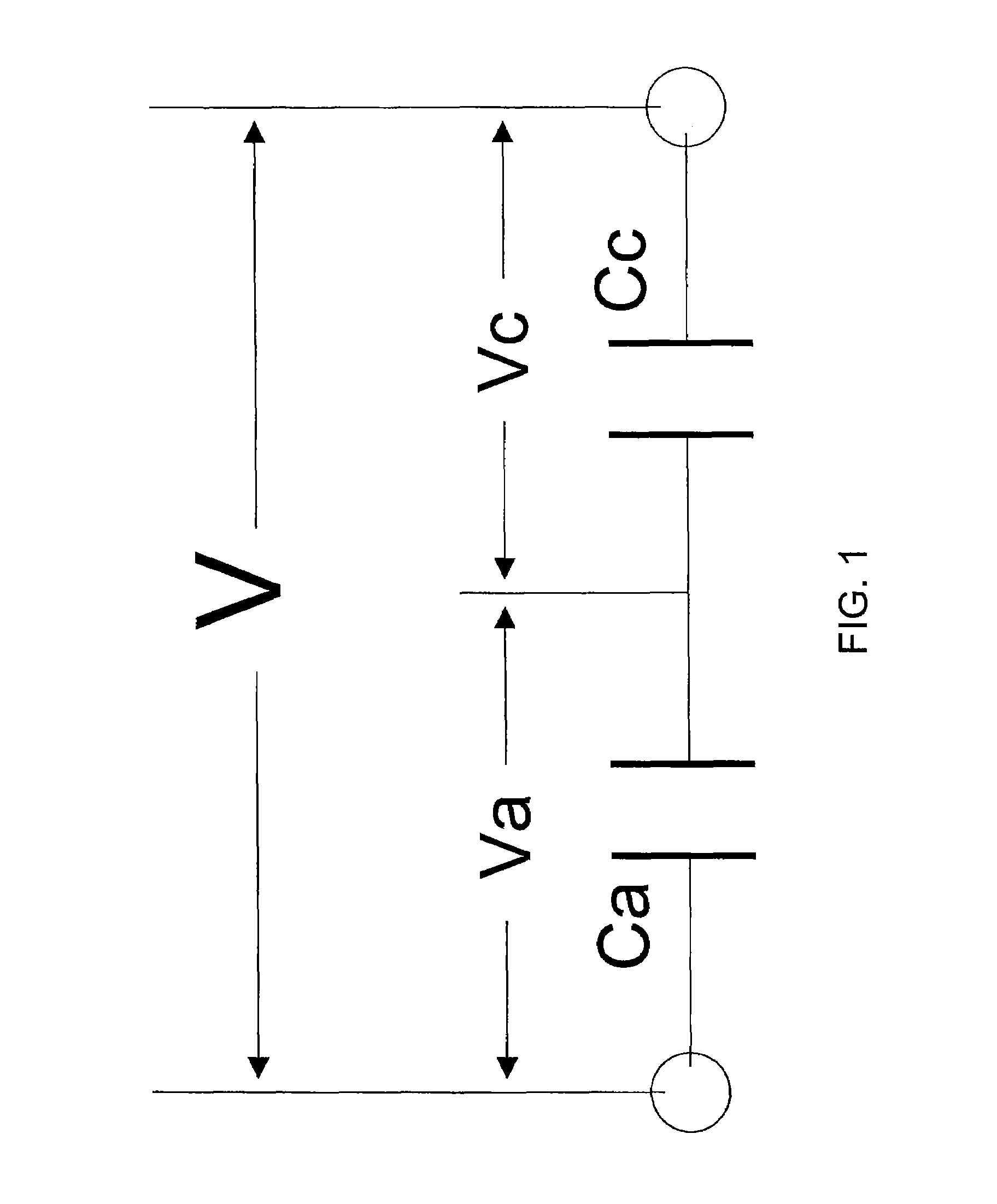

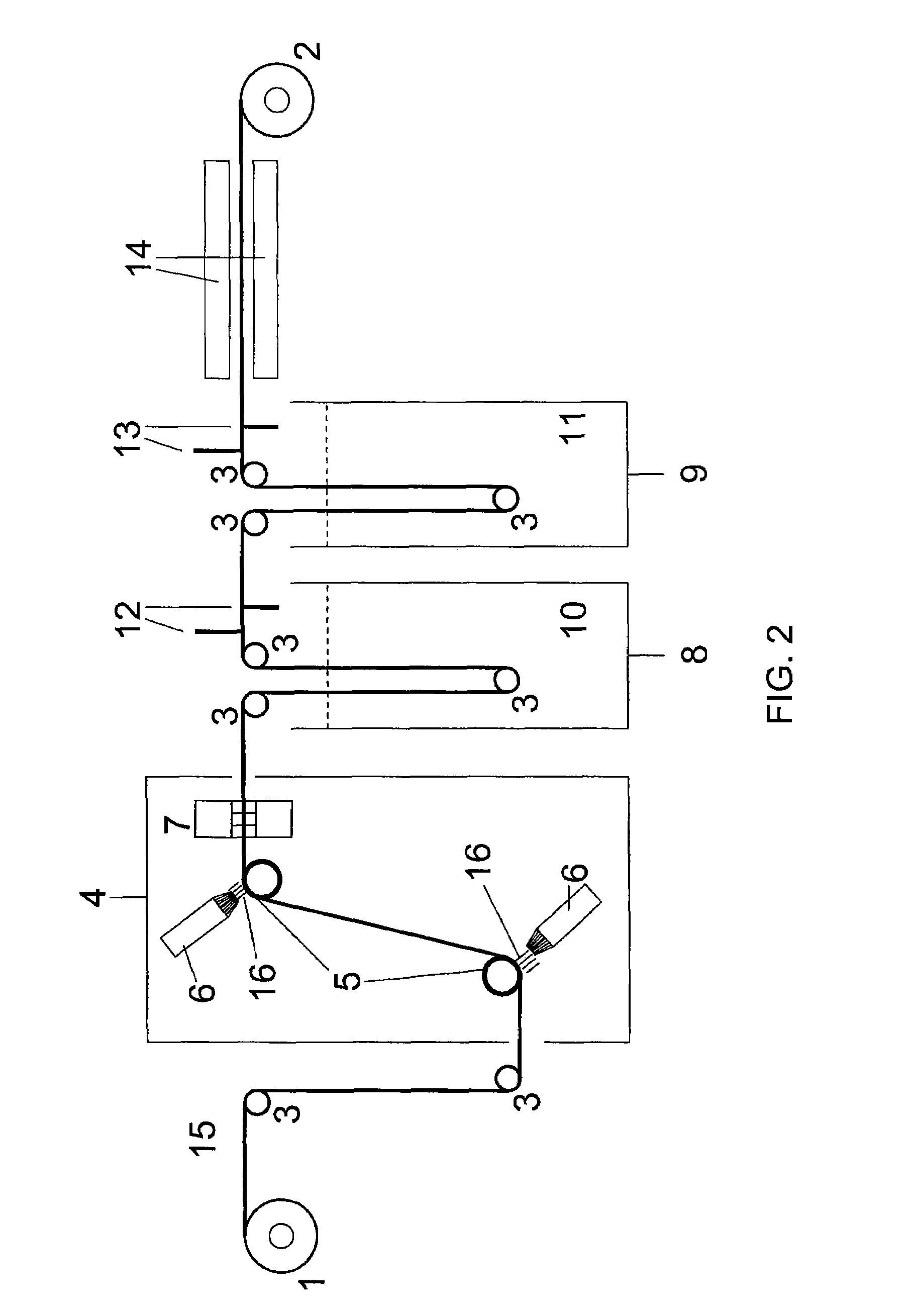

High capacitance cathode foil produced by abrasion process using titanium nitride powder

InactiveUS7402183B1Avoid electrical contactElectrolytic capacitorsSemiconductor/solid-state device manufacturingDouble-layer capacitanceMetal foil

A dry titanium nitride (TiN) powder abrasion method roughens the surface of a valve metal foil for use as a cathode in an electrolytic capacitor. This increases the surface area of the foil, thereby increasing the double-layer capacitance of the cathode, and also mechanically alloys TiN powder to the surface of the foil, thereby increasing the pseudo-capacitance of the cathode. In one embodiment, a piece of thin titanium foil is mounted on a hard metal backing and at least one surface of the foil is abraded with fine titanium nitride powder. In another embodiment, a continuous metal foil tape is fed into a bead blasting box and at least one surface of the metal foil tape is abraded with TiN powder delivered by a bead blasting nozzle located within the bead blasting box. Accordingly, a cathode having increased capacitance capability is provided to more closely match the capacitance of a poly-anode stack.

Owner:PACESETTER INC

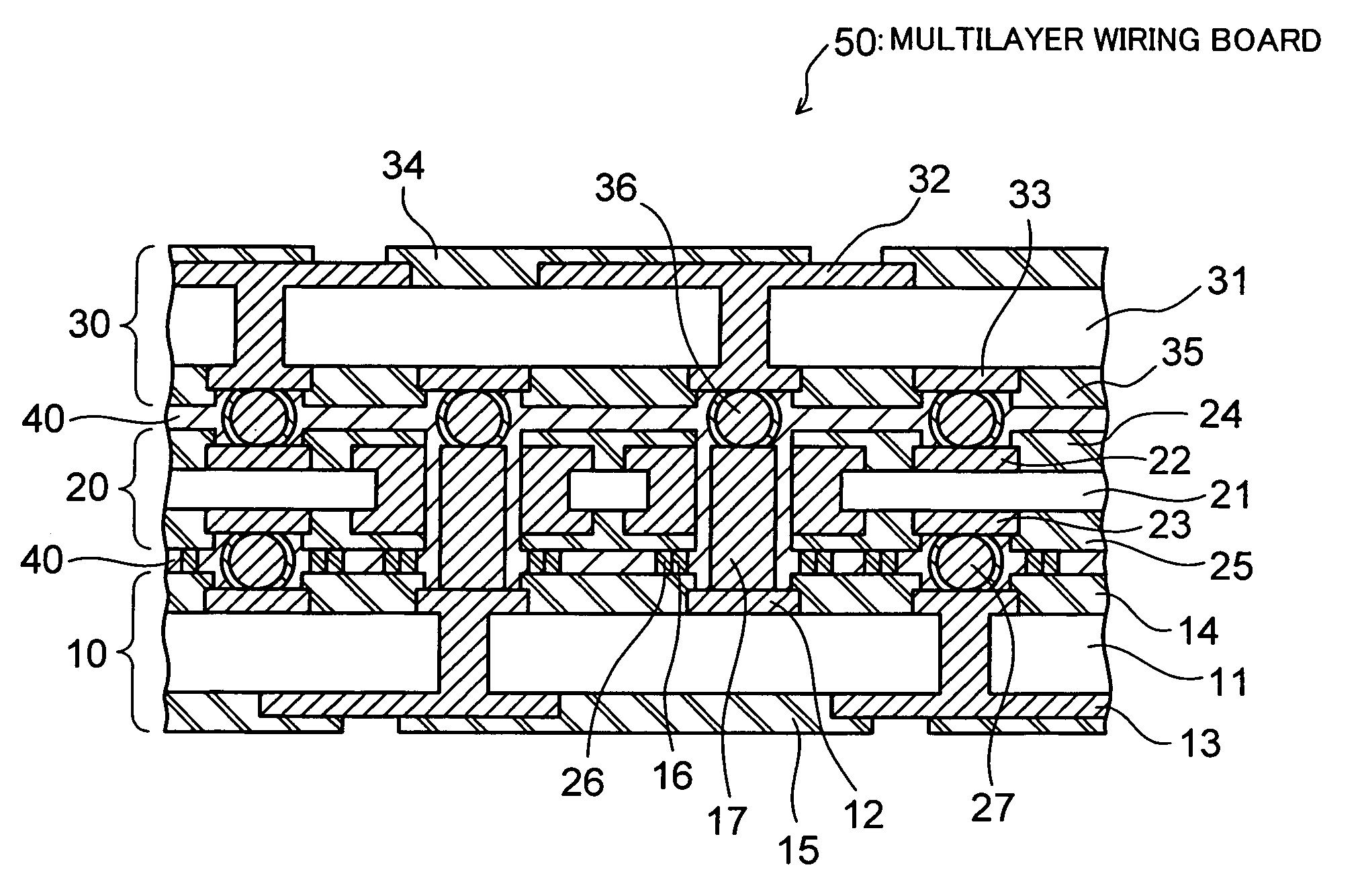

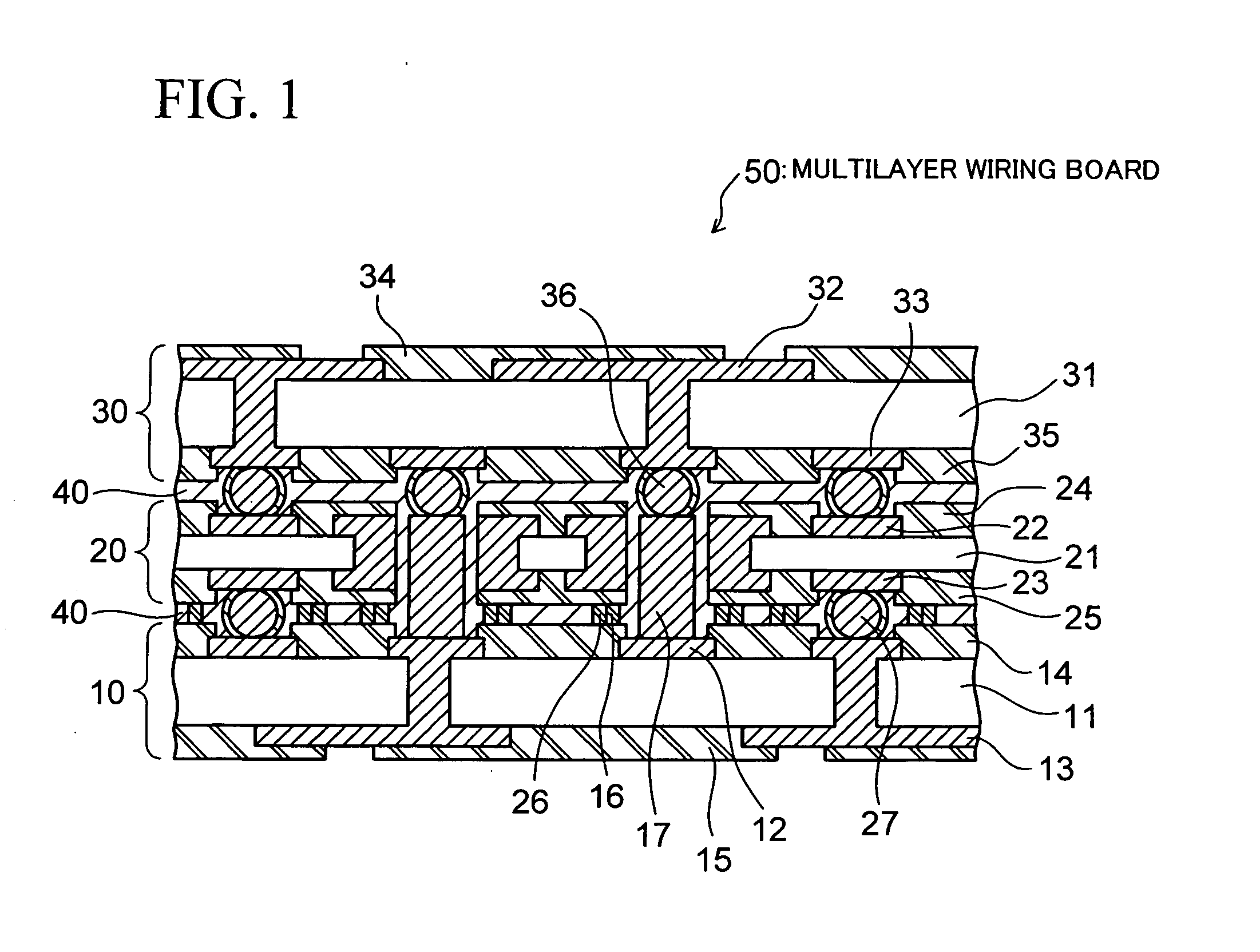

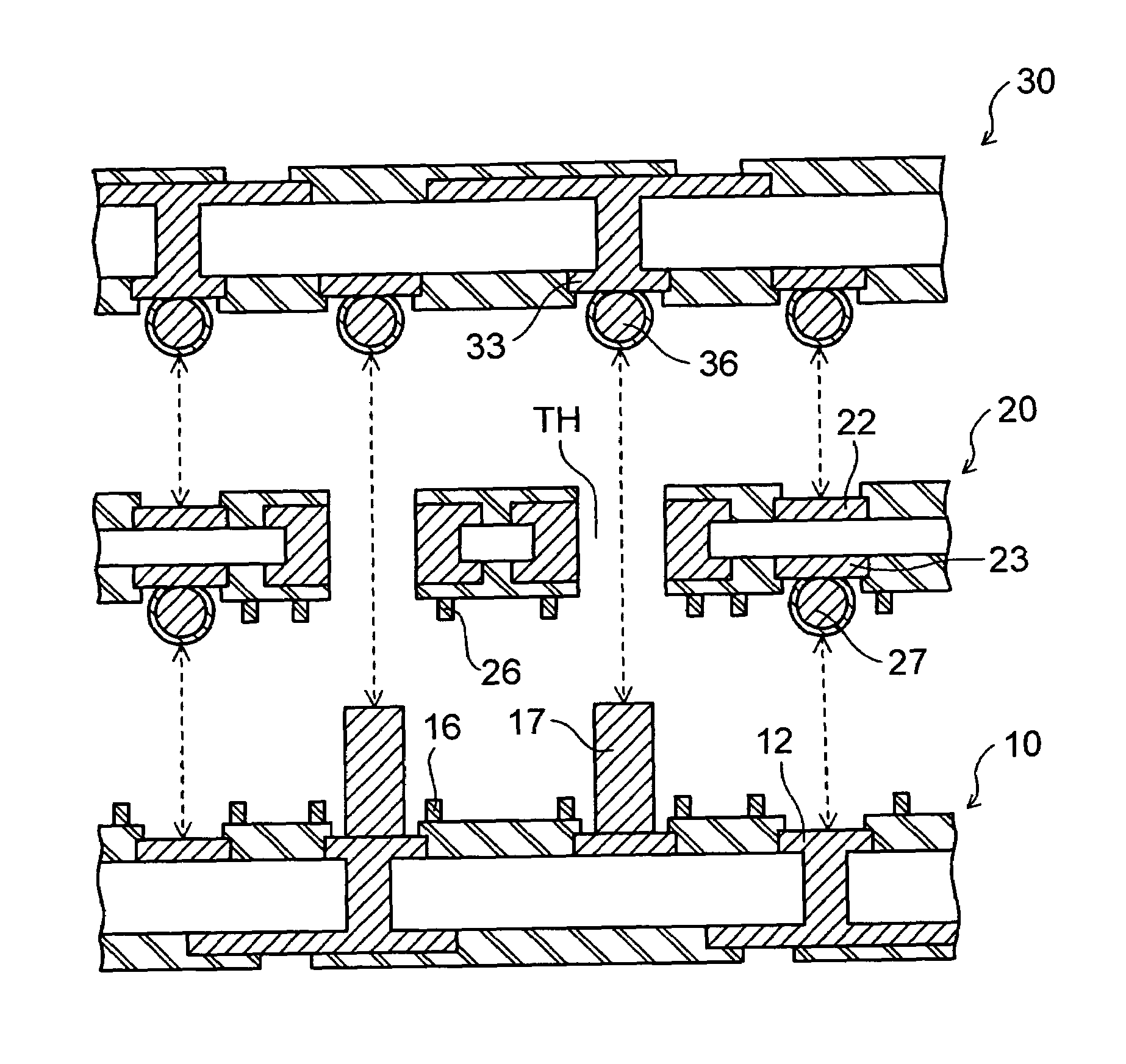

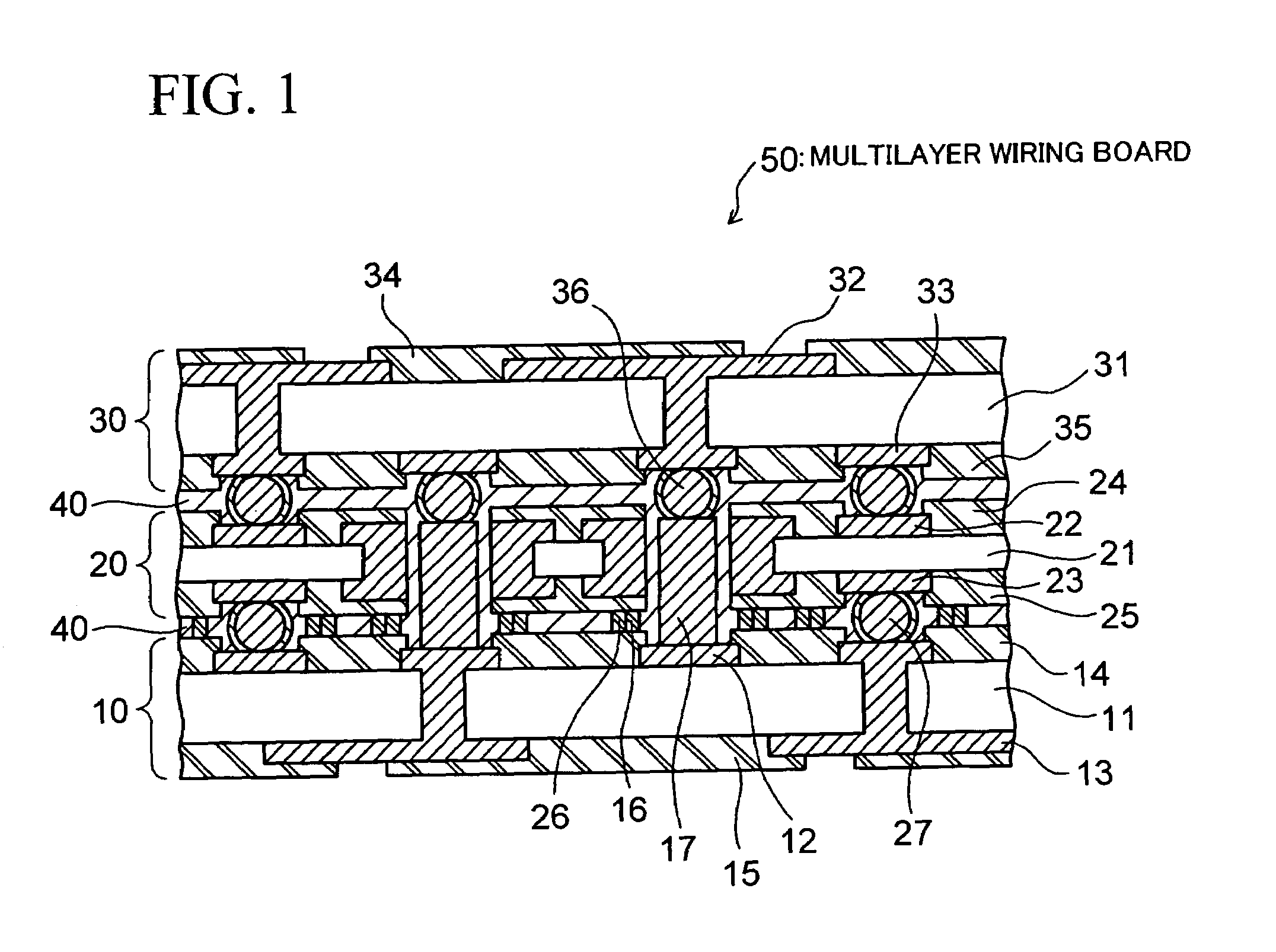

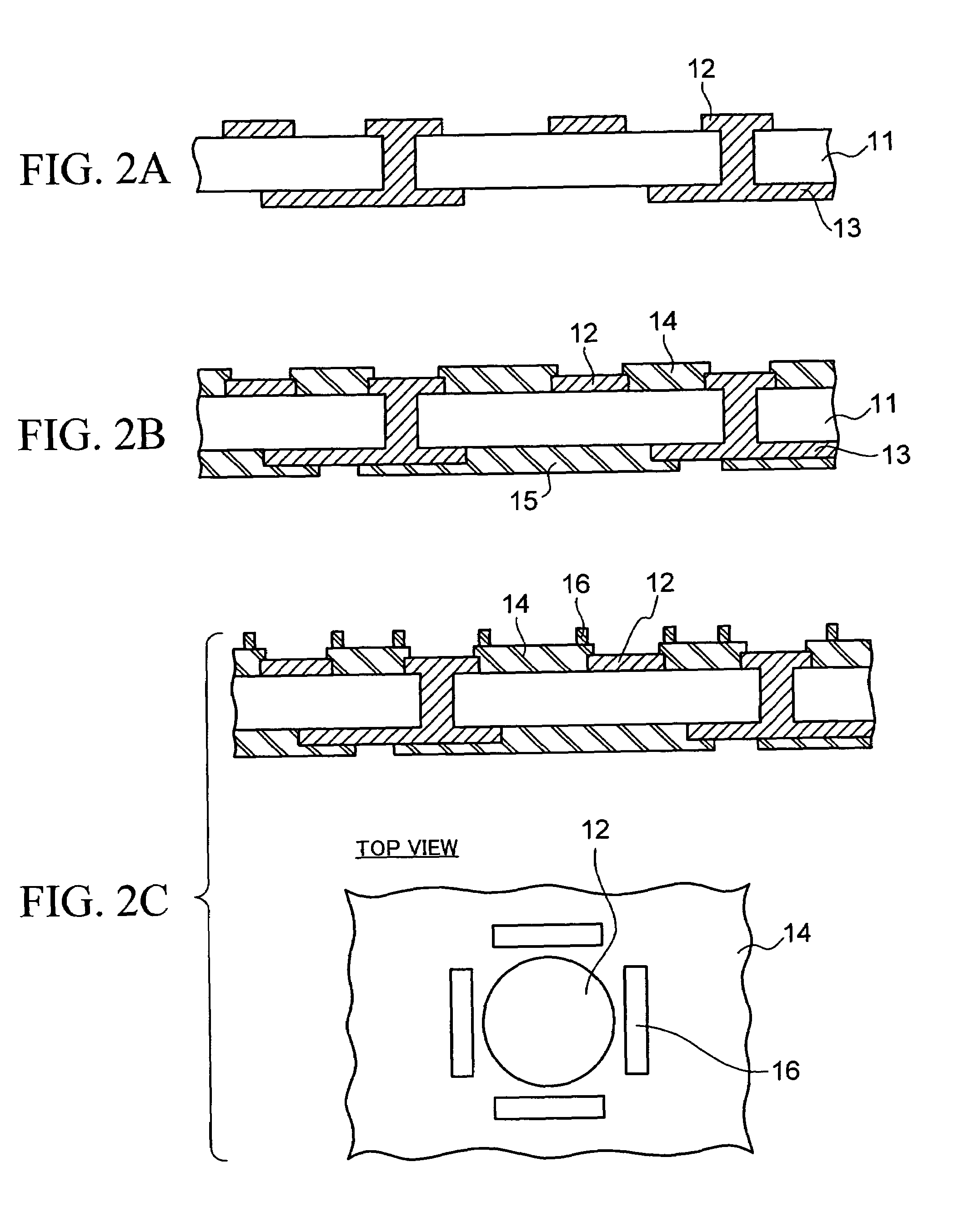

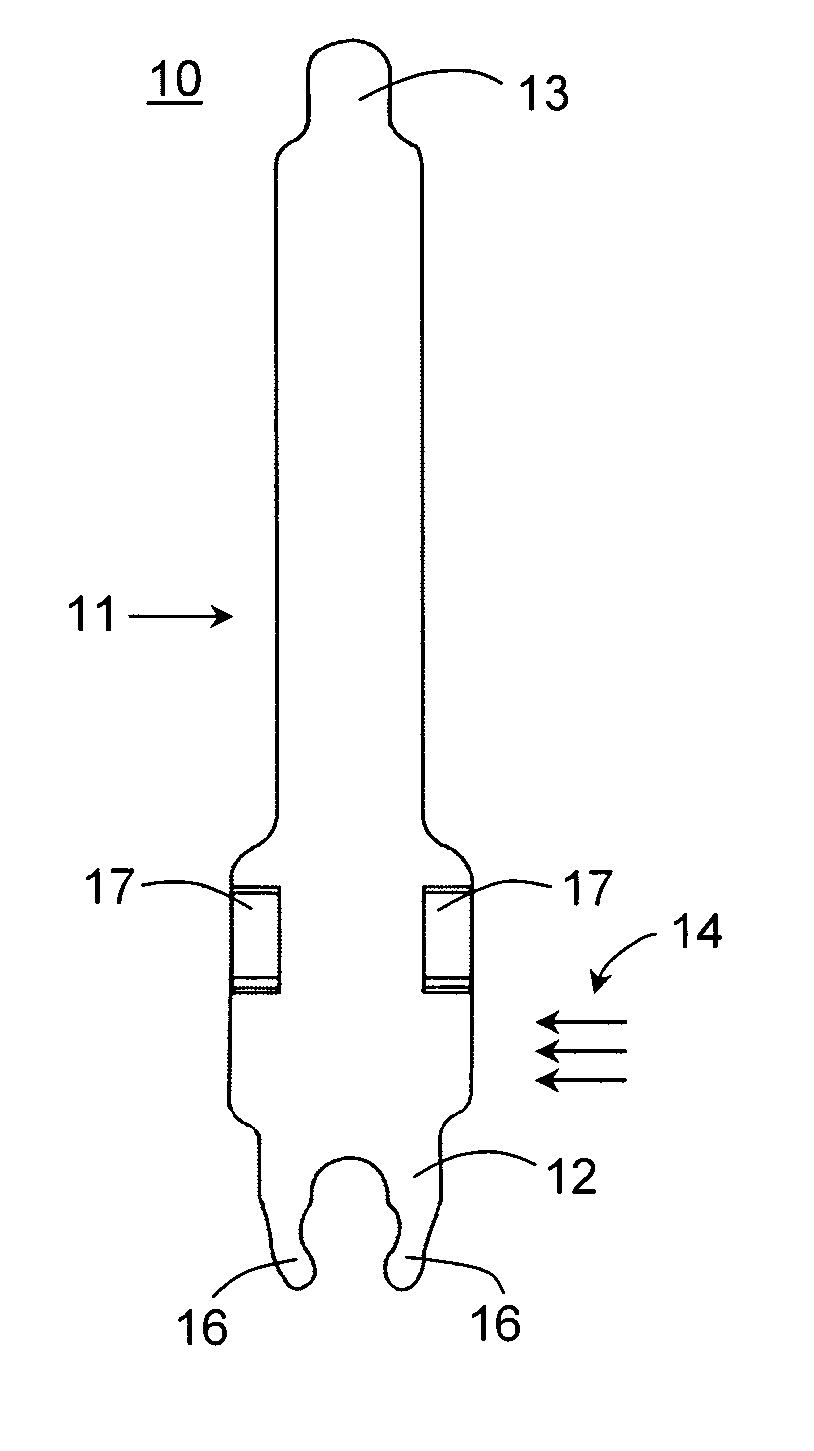

Method of manufacturing multilayer wiring board

InactiveUS20080184555A1Shorten the time periodIncrease productionPrinted circuit assemblingPrinted circuit aspectsIn planeEngineering

First, a plurality of wiring boards are fabricated at separate steps. The first wiring board includes a Cu post formed on a wiring layer on one surface of a substrate, and a first stopper layer formed at a desired position around the Cu post. The second wiring board includes a through hole for insertion of the Cu post therethrough, a connection terminal formed on a wiring layer on one surface of a substrate, and a second stopper layer that engages the first stopper layer and functions to suppress in-plane misalignment. The third wiring board includes a connection terminal formed on a wiring layer on one surface of a substrate. Then, the wiring boards are stacked up, as aligned with one another so that the wiring layers are interconnected via the Cu post and the connection terminals, to thereby electrically connect the wiring boards. Thereafter, resin is filled into gaps between the wiring boards.

Owner:SHINKO ELECTRIC IND CO LTD

Method for stacking and interconnecting integrated circuits

ActiveUS20100133645A1Avoid electrical contactSemiconductor/solid-state device detailsSolid-state devicesElectrically conductiveIntegrated circuit

A method for stacking and interconnecting integrated circuits includes providing at least two substrates; forming a trench in each substrate; filling the trench with an insulating material; forming, in each substrate, at least one conductive area; thinning each substrate until reaching at least the bottom of the trench, to obtain in each substrate at least one electrically insulated region within the closed perimeter delineated by the trench; bonding the substrates together; making at least one hole through the bonded substrates so that the hole passes at least partially through the conductive areas and passes through the insulated region of each substrate; and filling the hole with an electrically conductive material so as to obtain a conductive column that traverses the isolated region of each substrate and is in lateral electrical contact with the conductive areas.

Owner:STMICROELECTRONICS SRL

Method of manufacturing multilayer wiring board

InactiveUS7624501B2Shorten the time periodIncrease productionPrinted circuit assemblingPrinted circuit aspectsIn planeEngineering

First, a plurality of wiring boards are fabricated at separate steps. The first wiring board includes a Cu post formed on a wiring layer on one surface of a substrate, and a first stopper layer formed at a desired position around the Cu post. The second wiring board includes a through hole for insertion of the Cu post therethrough, a connection terminal formed on a wiring layer on one surface of a substrate, and a second stopper layer that engages the first stopper layer and functions to suppress in-plane misalignment. The third wiring board includes a connection terminal formed on a wiring layer on one surface of a substrate. Then, the wiring boards are stacked up, as aligned with one another so that the wiring layers are interconnected via the Cu post and the connection terminals, to thereby electrically connect the wiring boards. Thereafter, resin is filled into gaps between the wiring boards.

Owner:SHINKO ELECTRIC IND CO LTD

Methods of manufacturing electrical contacts having solder stops

InactiveUS20060196857A1Prevents wickingIncrease production costContact member manufacturingElectrically conductive connectionsEngineeringElectrical connector

A method of forming an electrical contact for use in an electrical connector that includes a contact body made of metal and having a contact head, a contact tail, and an anti-wicking region disposed between the contact head and the contact tail arranged to prevent wicking of a fusible material past the anti-wicking region in a direction toward the contact head. The anti-wicking region is defined by one of a laser-ablated portion, a laser marking material, a UV marking material, and an ink that is permanently disposed on the contact body.

Owner:SAMTEC

Prevention of core failures in large electric machines

InactiveUS8179028B1Reduce riskAvoid laminationMagnetic circuit stationary partsSupports/enclosures/casingsElectric machineEngineering

The keybar that is attached to the frame of a dynamoelectric machine is broken into a bald keybar with mini-dovetails attached to it. The bald keybar is identical to the bolt portion of a conventional keybar. The mini-dovetail is a trapezoidal or U-shaped strip with insulated slanted arms. The core packet is inserted loosely over an array of mini-dovetails. Devices such as wedges, threaded rods flex the slanted arm and press them against the slot faces of the core packet, thereby locking the core packet to the frame. Insulation on the slanted arms prevents large eddy currents due to shorted laminations, increasing the machine efficiency. Preventing large eddy currents also eliminates hot spots which could otherwise cause a core failure. Locking the core packets also prevents rattling of laminations. The locking method also distributes the torque forces evenly around the periphery.

Owner:RAO DANTAM K

Electrical contacts having solder stops

ActiveUS20060199447A1Prevents wickingIncrease production costLine/current collector detailsElectrically conductive connectionsElectrical connectorElectrical contacts

An electrical contact for use in an electrical connector, includes a contact body made of metal and having a contact head, a contact tail, and an anti-wicking region disposed between the contact head and the contact tail arranged to prevent wicking of a fusible material past the anti-wicking region in a direction toward the contact head. The anti-wicking region is defined by one of a laser-ablated portion, a laser marking material, a UV marking material, and an ink that is permanently disposed on the contact body.

Owner:SAMTEC

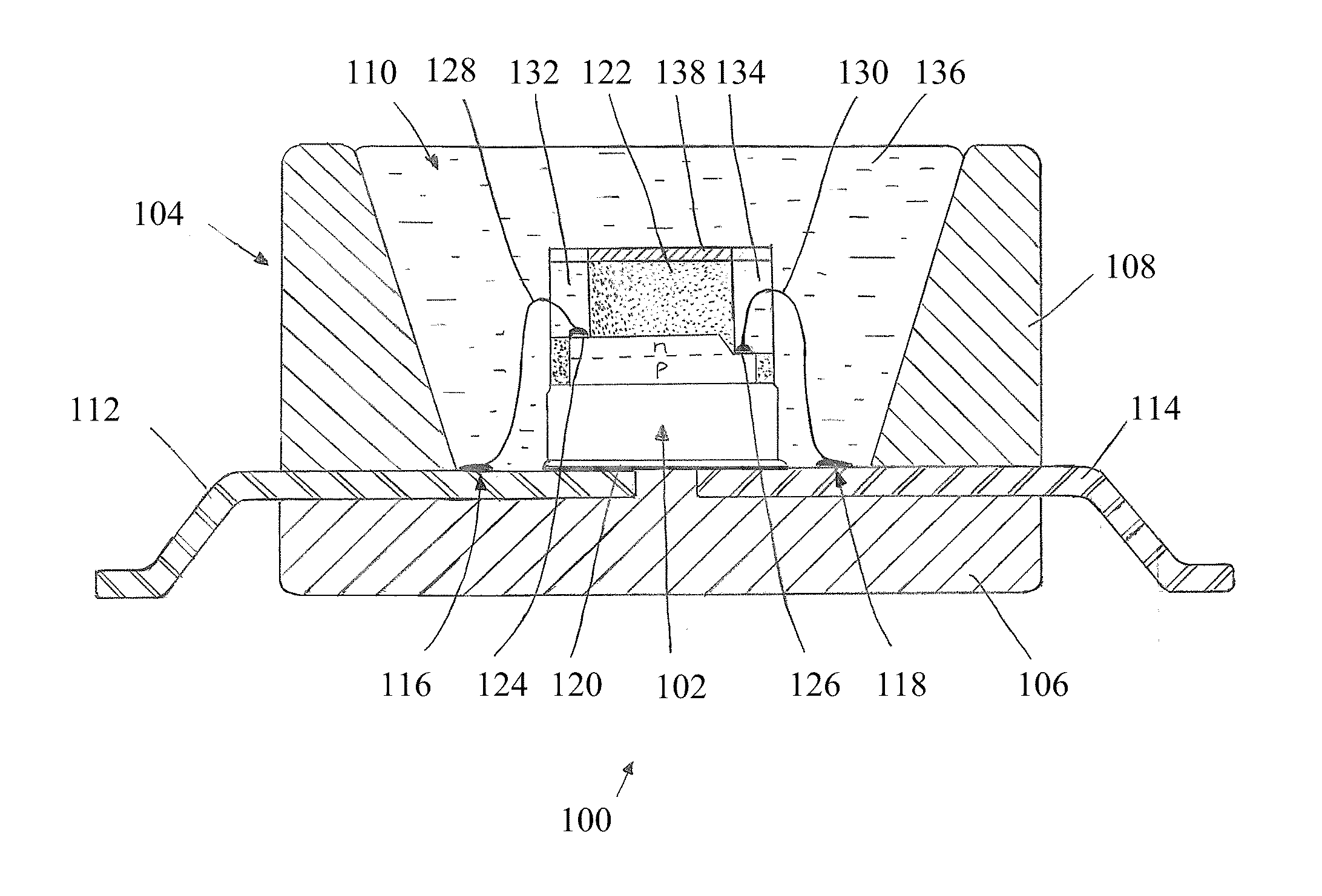

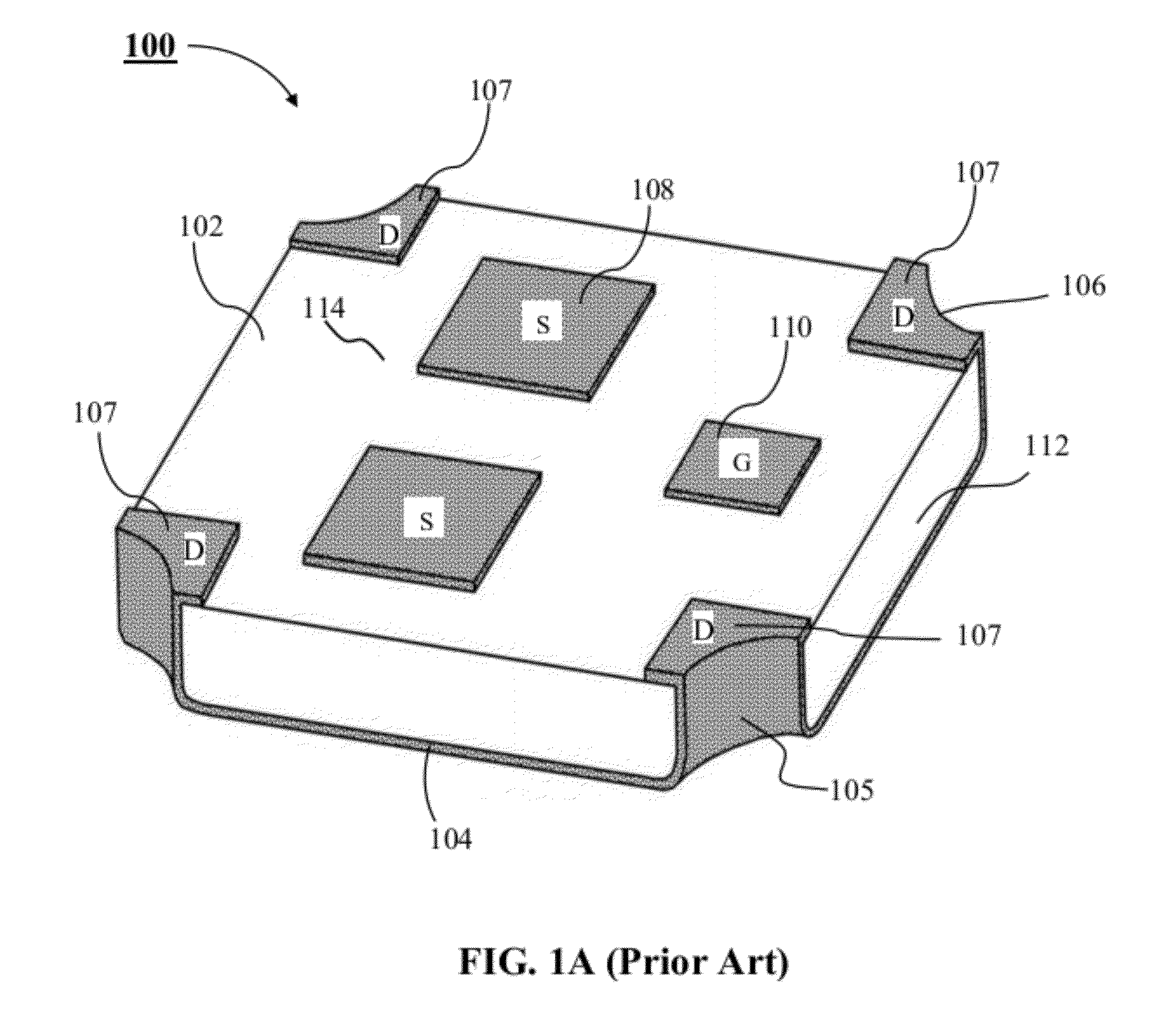

Electrical contacts for a semiconductor light emitting apparatus

ActiveUS7842963B2Facilitate supplying currentAvoid electrical contactSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical connectionEngineering

A process for forming electrical contacts for a semiconductor light emitting apparatus is disclosed. The light emitting apparatus has a first layer of first conductivity type, an active layer for generating light overlying the first layer, and a second layer of second conductivity type overlying the active layer. The process involves forming at least a first and a second elongate electrical contact through the second layer and the active layer to provide electrical connection to the first layer, the first and second contacts oriented at an angle to each other, the first contact having a first end in proximity with the second contact, the first end being sufficiently spaced apart from the second contact such that when current is supplied to the first layer through the contacts, current contributions from the first end of the first contact and the second contact in an area generally between the first end and the second contact cause a current density in the area that is approximately equal to a current density elsewhere along the first and second contacts.

Owner:PHILIPS LUMILEDS LIGHTING CO LLC

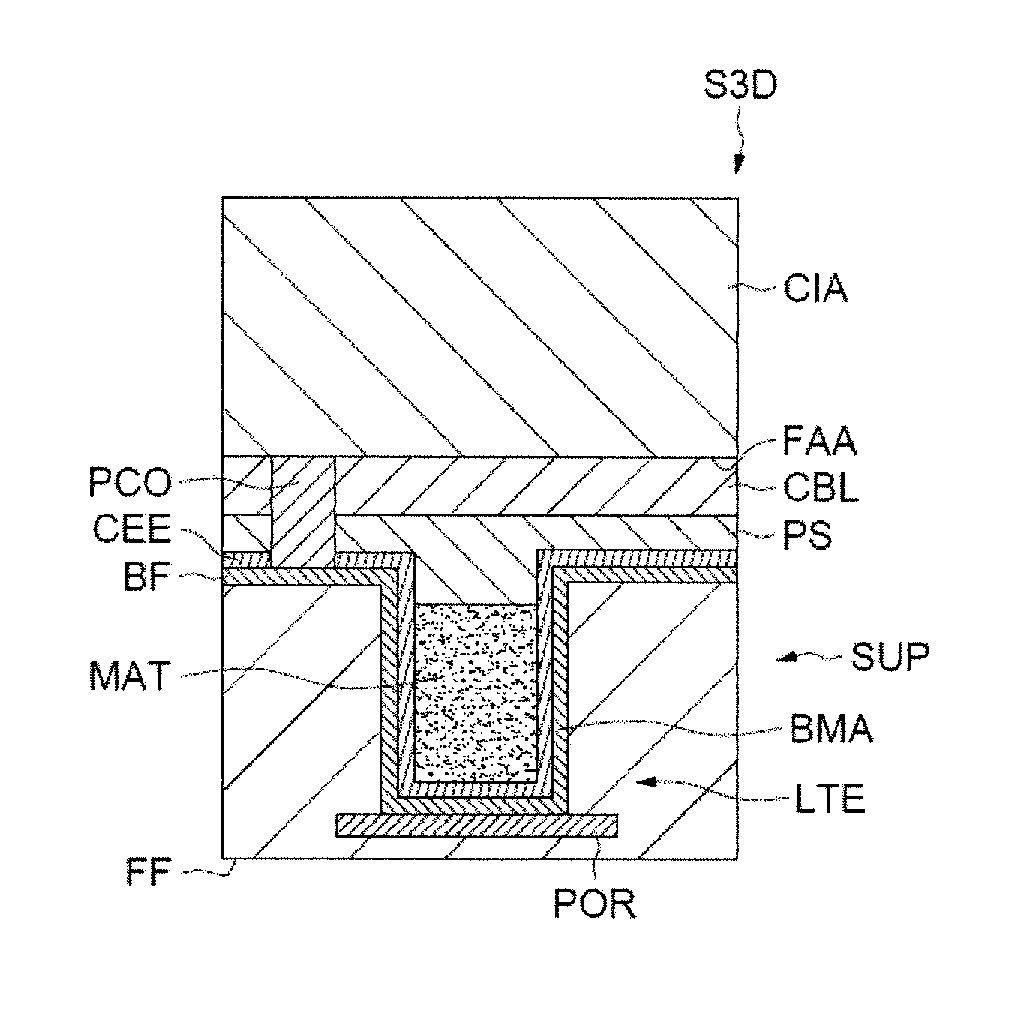

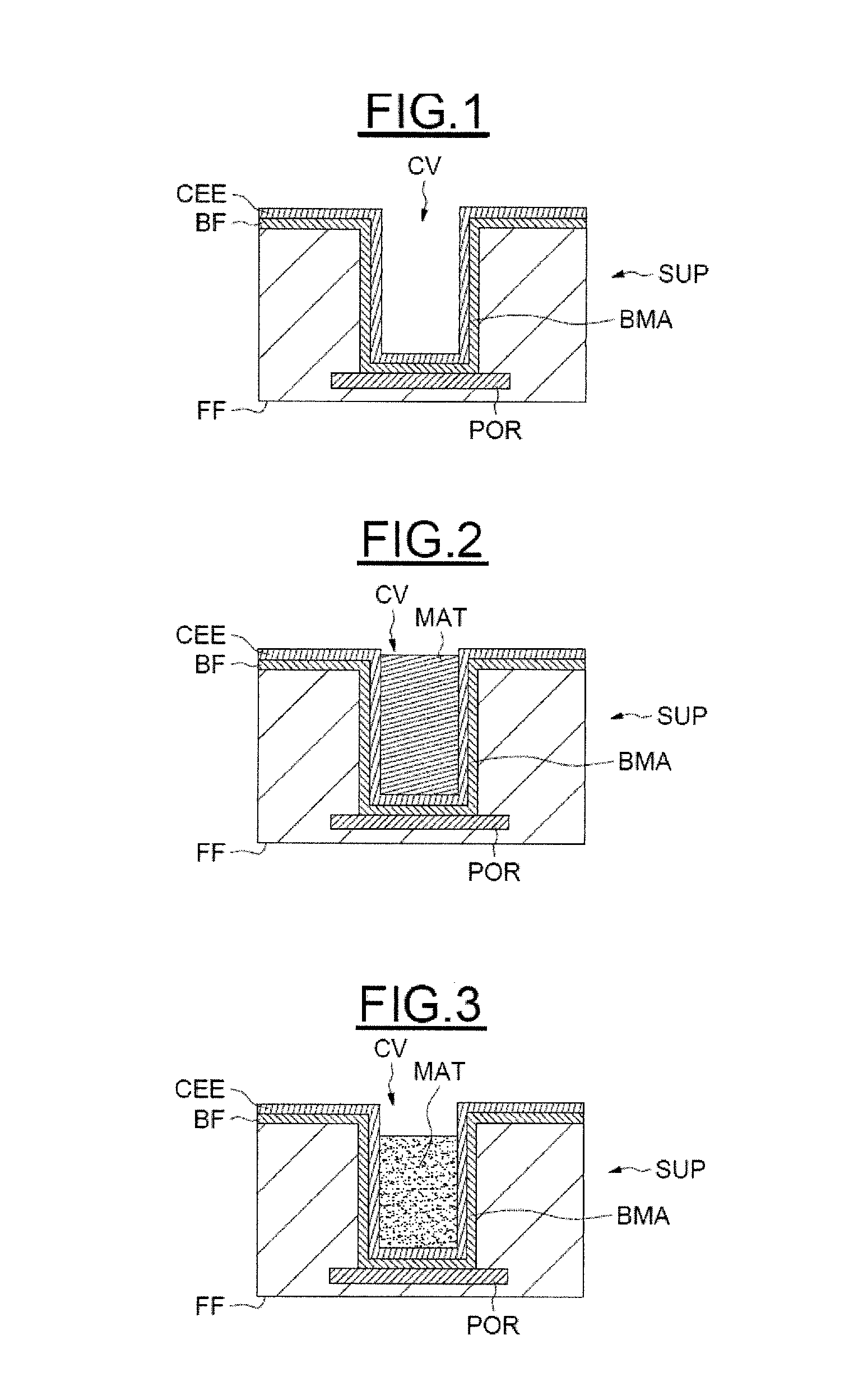

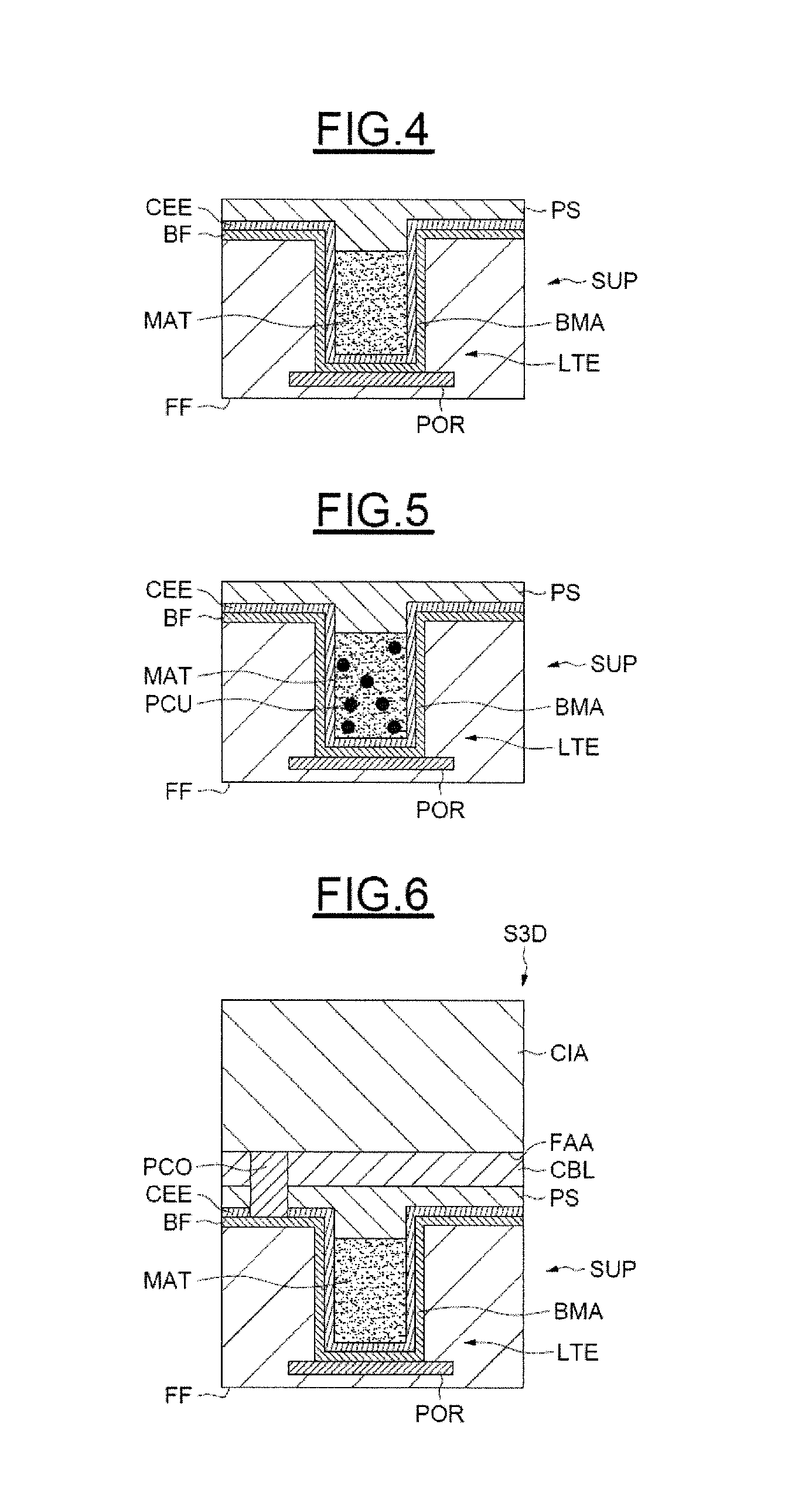

Process for producing at least one through-silicon via with improved heat dissipation, and corresponding three-dimensional integrated structure

ActiveUS20140361440A1Improve cooling effectAvoid electrical contactSemiconductor/solid-state device detailsSolid-state devicesEngineeringPhase-change material

A method for producing at least one through-silicon via inside a substrate may include forming a cavity in the substrate from a first side of the substrate until an electrically conductive portion is emerged onto. The method may also include forming an electrically conductive layer at a bottom and on walls of the cavity, and at least partly on a first side outside the cavity. The process may further include at least partially filling the cavity with at least one phase-change material. Another aspect is directed to a three-dimensional integrated structure.

Owner:STMICROELECTRONICS INT NV

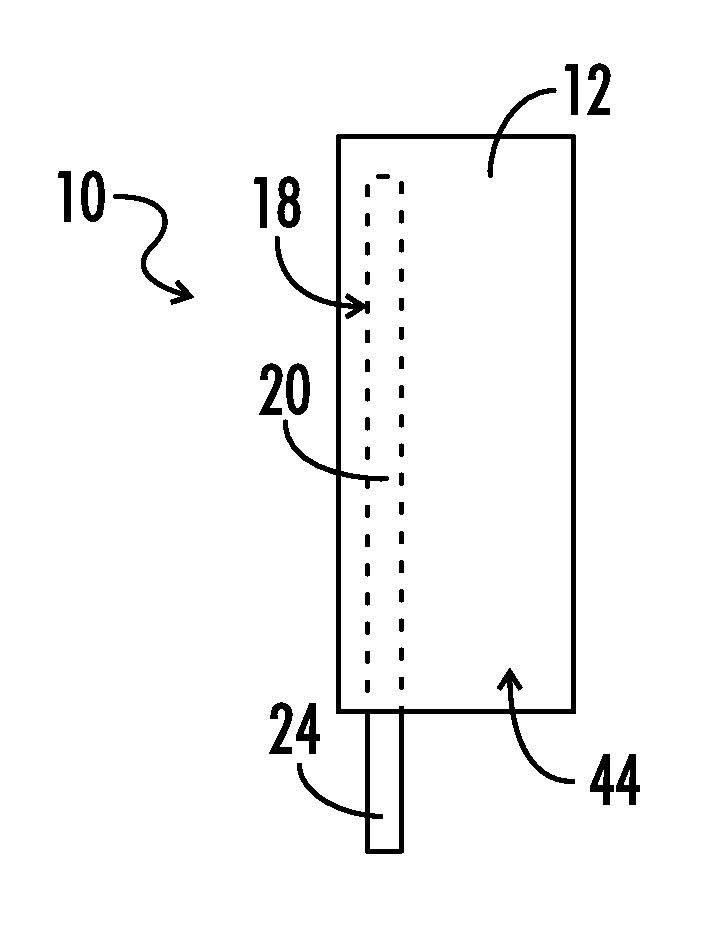

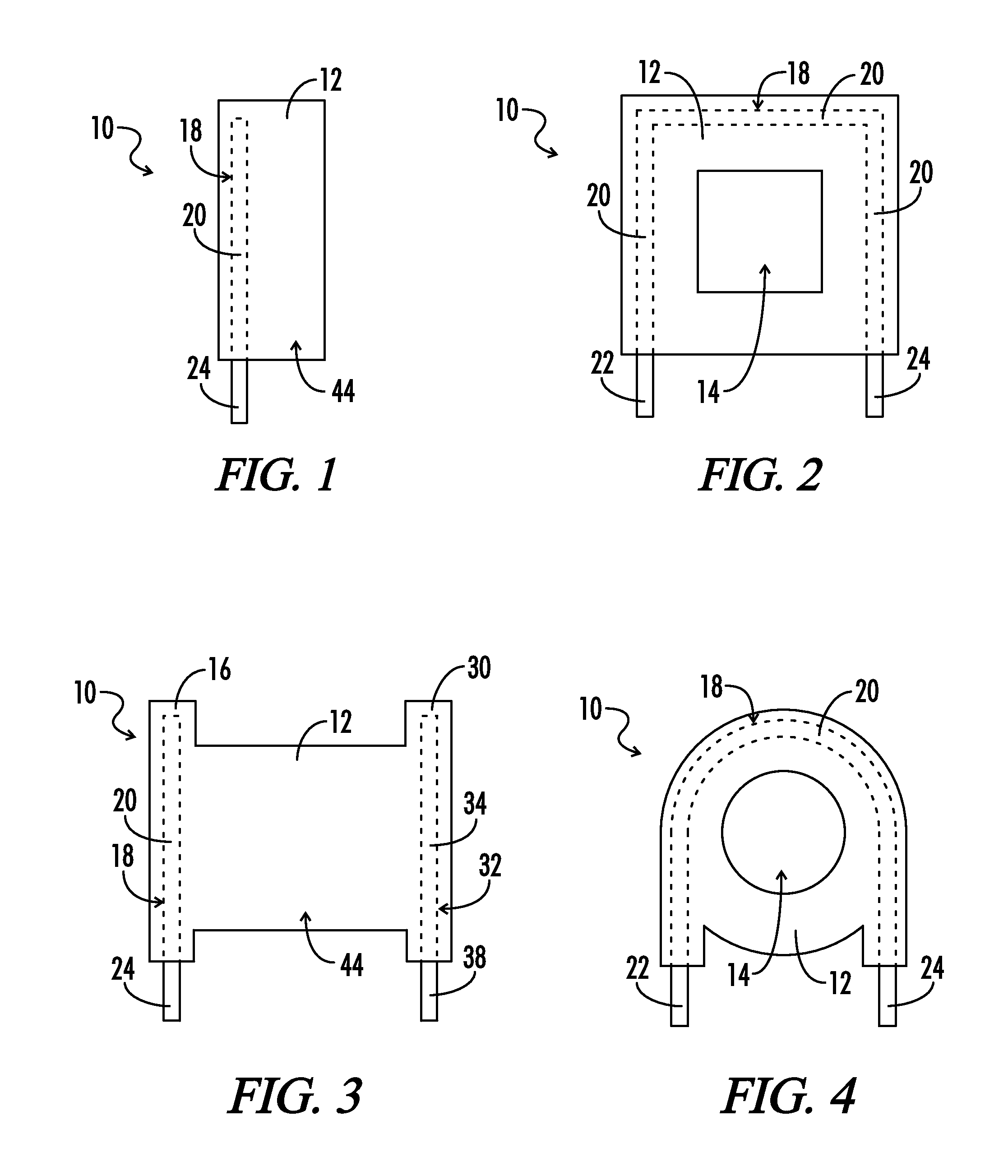

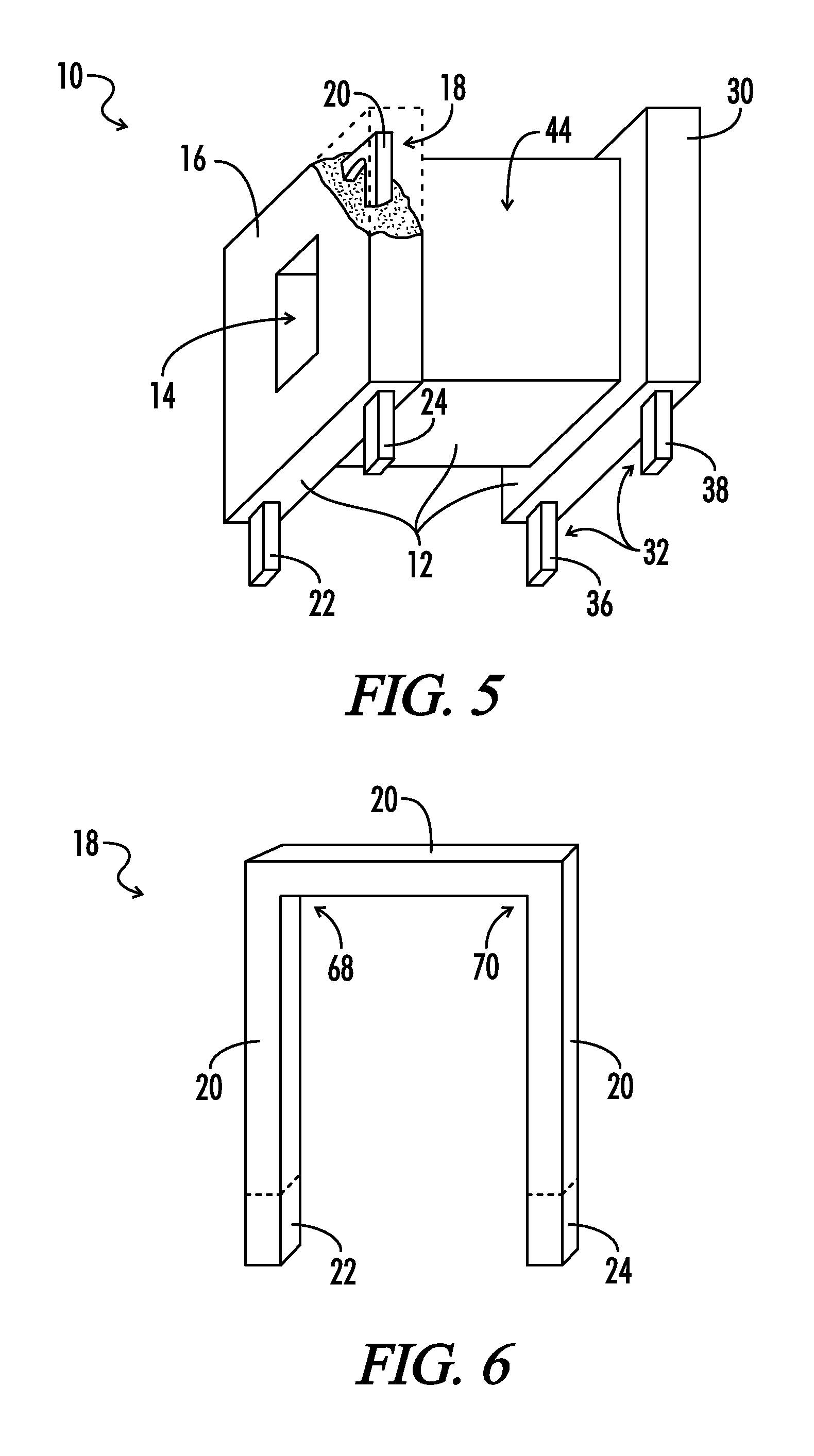

Magnetic component having a bobbin structure with integrated winding

InactiveUS8031040B1Shorten the timeAvoid electrical contactTransformers/inductances coils/windings/connectionsCoilsBobbinConductive materials

A magnetic component has a bobbin structure for winding a conductive material. The bobbin structure includes a bobbin body having a first winding embedded in the bobbin body. The first winding is made of a conductive material. The first winding includes a winding body and two terminal ends. The terminal ends protrude from the bobbin body for connection to a circuit. The winding body of the first winding is embedded inside the bobbin body. Alternatively, the first conductive winding is embedded in a bobbin flange included on the bobbin body. The bobbin structure generally includes a hollow interior cavity shaped for inserting a ferrite core.

Owner:UNIVERSAL LIGHTING TECHNOLOGIES

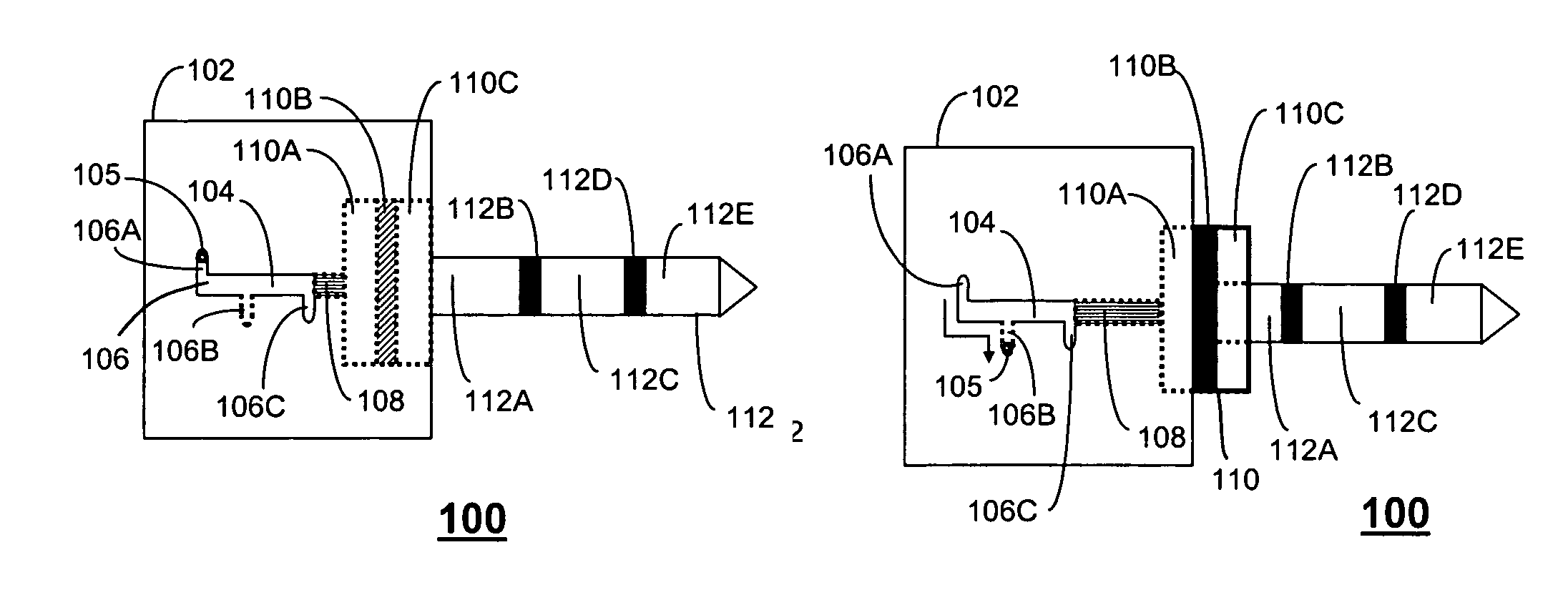

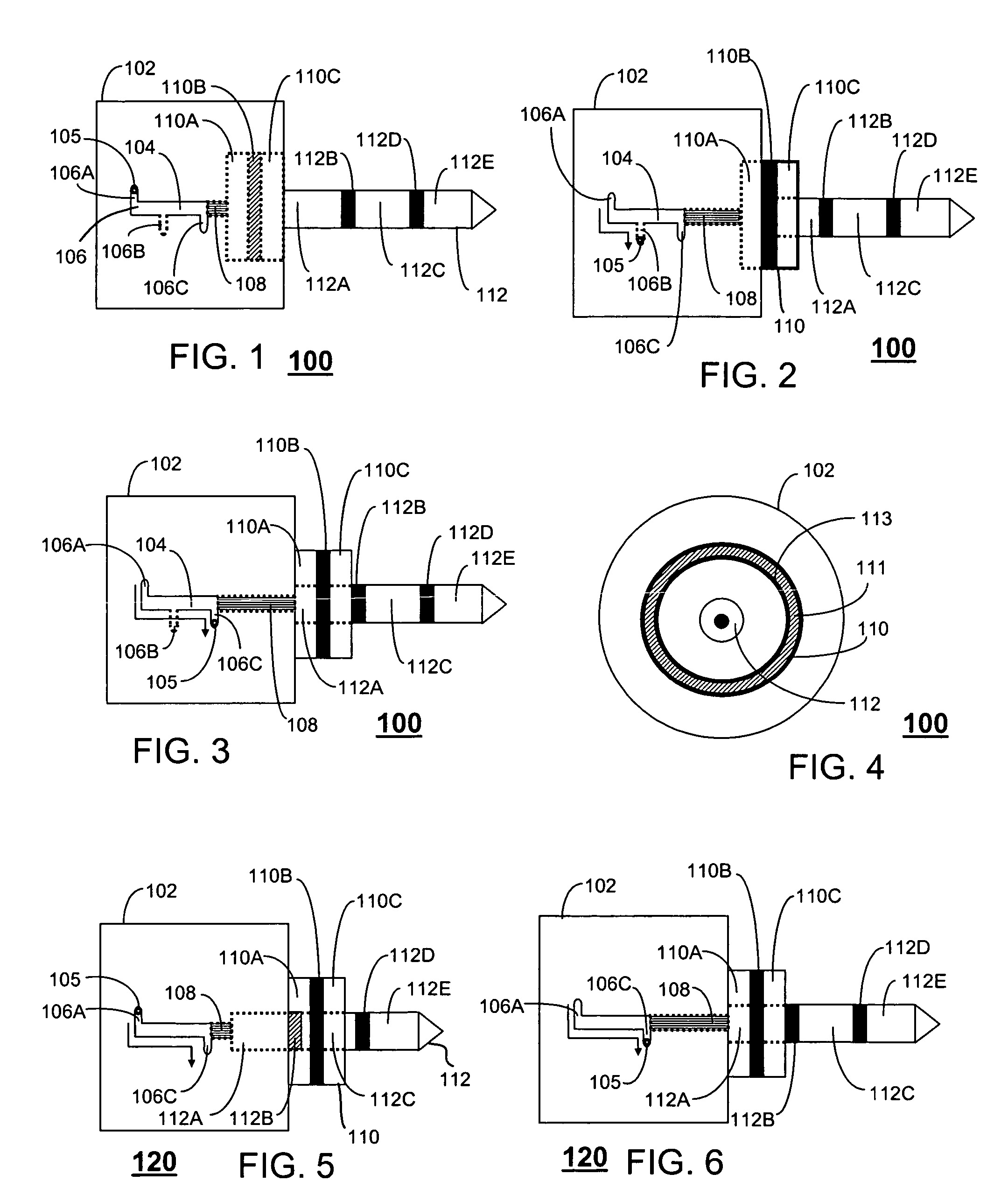

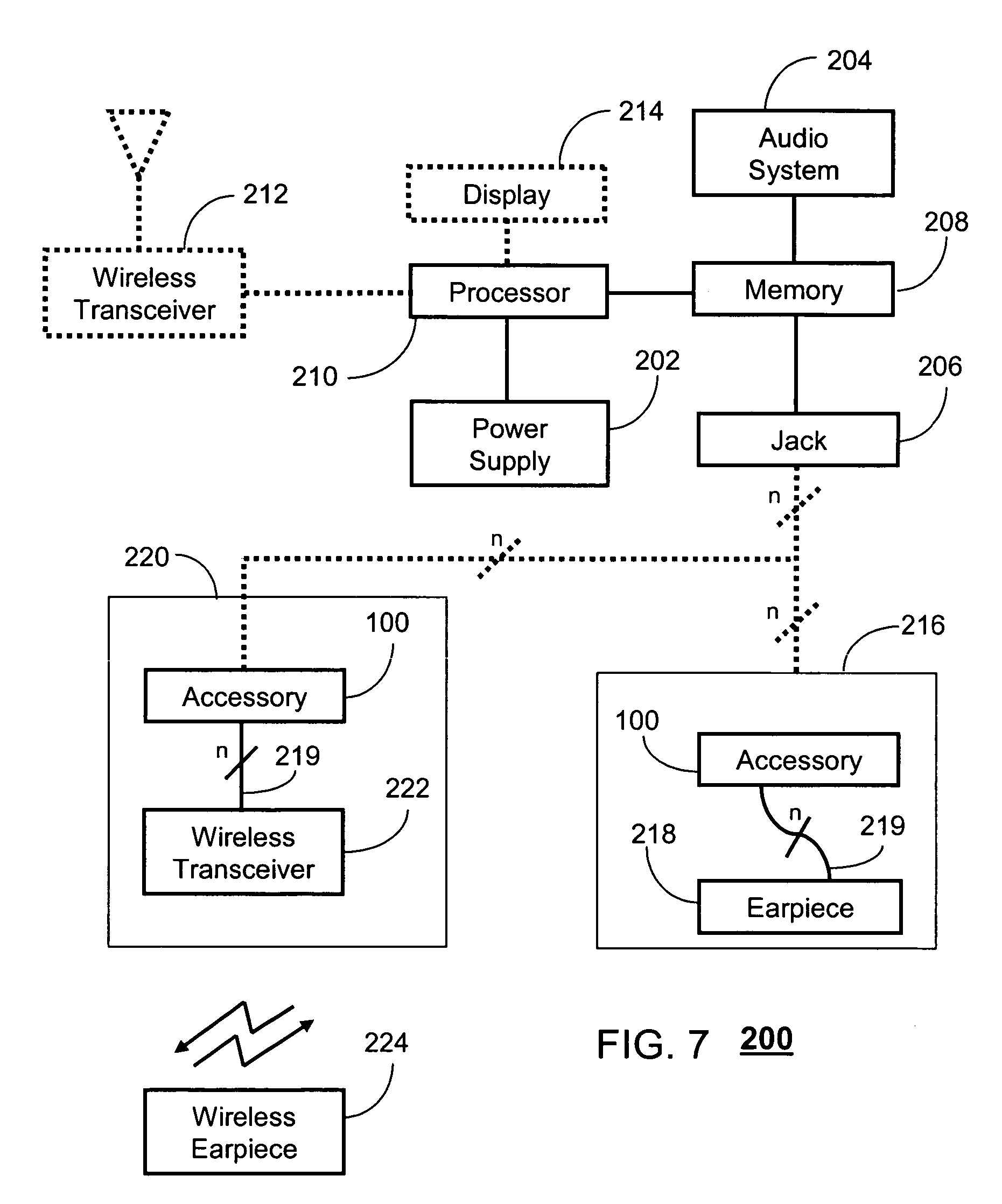

Apparatus for altering poles on an accessory

InactiveUS7601032B2Avoid electrical contactExposure was also limitedTwo pole connectionsStereophonic circuit arrangementsEngineeringMechanical engineering

An accessory (100) has a housing (102) for varying a number of accessible poles (110A, 110C, 112A, 112C, 112E). The accessory includes a plurality of projections (110, 112) each having at least one pole coupled to an insulator (110B, 112B, 112D) to prevent electrical contact with another pole, a plurality of conduction wires (219) each insulated and connected at a first end to a corresponding pole of the plurality of projections, and at least one lever (105) coupled to a corresponding one or more of the plurality of projections for sliding one or more projections in and out of the housing in a plurality of positions (106A-C) after a force is applied on such lever, thereby controlling the exposure of a portion of at least one pole of each of one or more of the projections.

Owner:GOOGLE TECH HLDG LLC

Wafer level chip scale package

ActiveUS20120025298A1Increase the use of spaceIncrease the on-resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrically conductiveEngineering

A semiconductor device, a method of manufacturing semiconductor devices and a circuit package assembly are described. A semiconductor device can have a semiconductor substrate with first and second surfaces and a sidewall between them. First and second conductive pads on the first and second surfaces are in electrical contact with corresponding first and second semiconductor device structures in the substrate. An insulator layer on the first surface and sidewall covers a portion of the first conductive pad on the first surface. An electrically conductive layer on part of the insulator layer on the first conductive pad and sidewall is in electrical contact with the second conductive pad. The insulator layer prevents the conductive layer from making electrical contact between the first and second conductive pads.

Owner:ALPHA & OMEGA SEMICON INC

Photovoltaic insulating glazing

InactiveUS7834265B2Avoid squeezingIncreased sealing material coverageLiquid crystal compositionsPV power plantsEngineeringIntermediate space

The invention relates to a photovoltaic insulating glazing comprising a multi-layer glazing with a photovoltaic module. The glazing is further characterized in that two contact strips for contacting the photovoltaic module are led out from an intermediate space between the glass layers and a spacer spaces the glass layers apart, thereby forming the intermediate space.

Owner:GLASWERKE ARNOLD

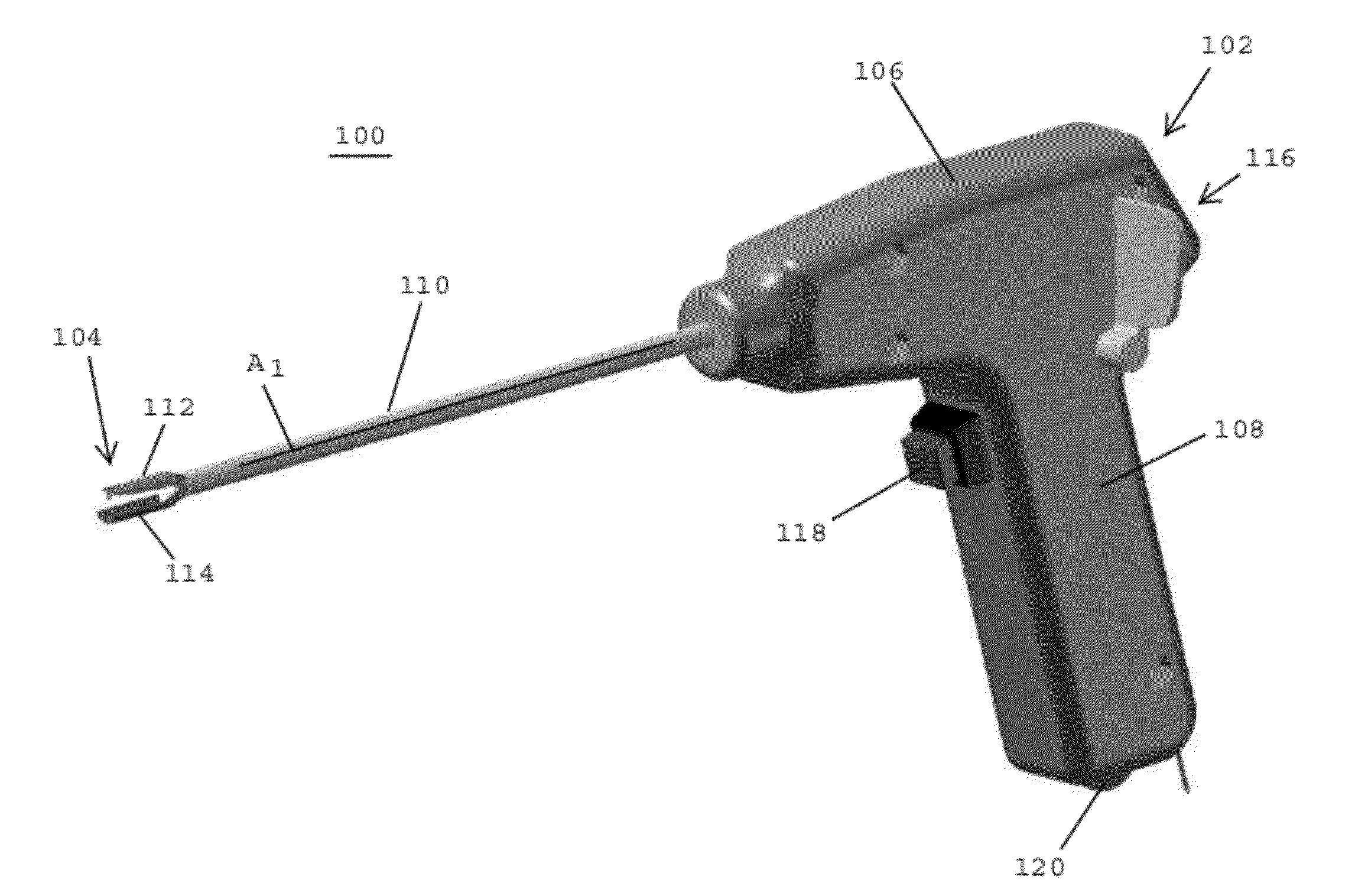

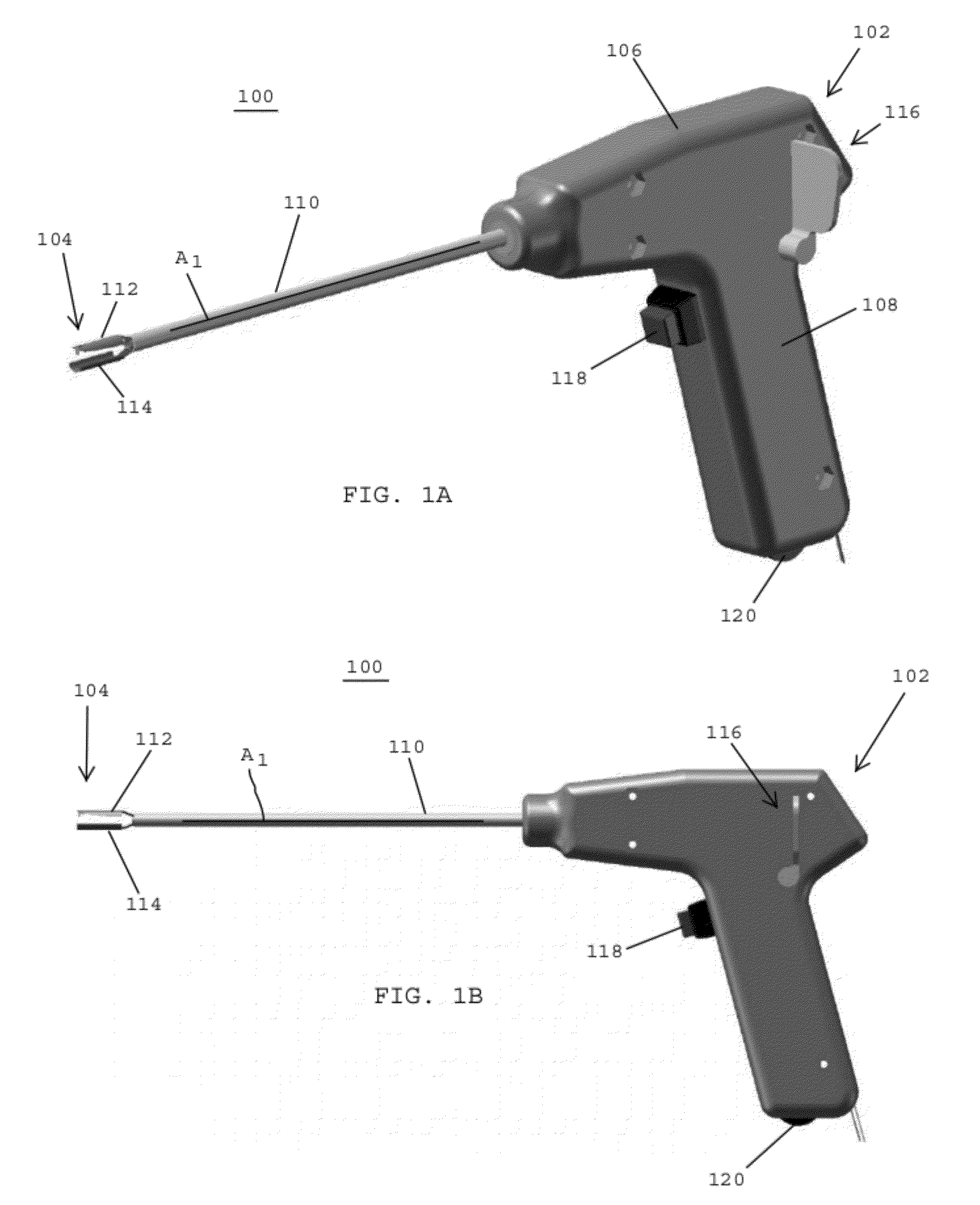

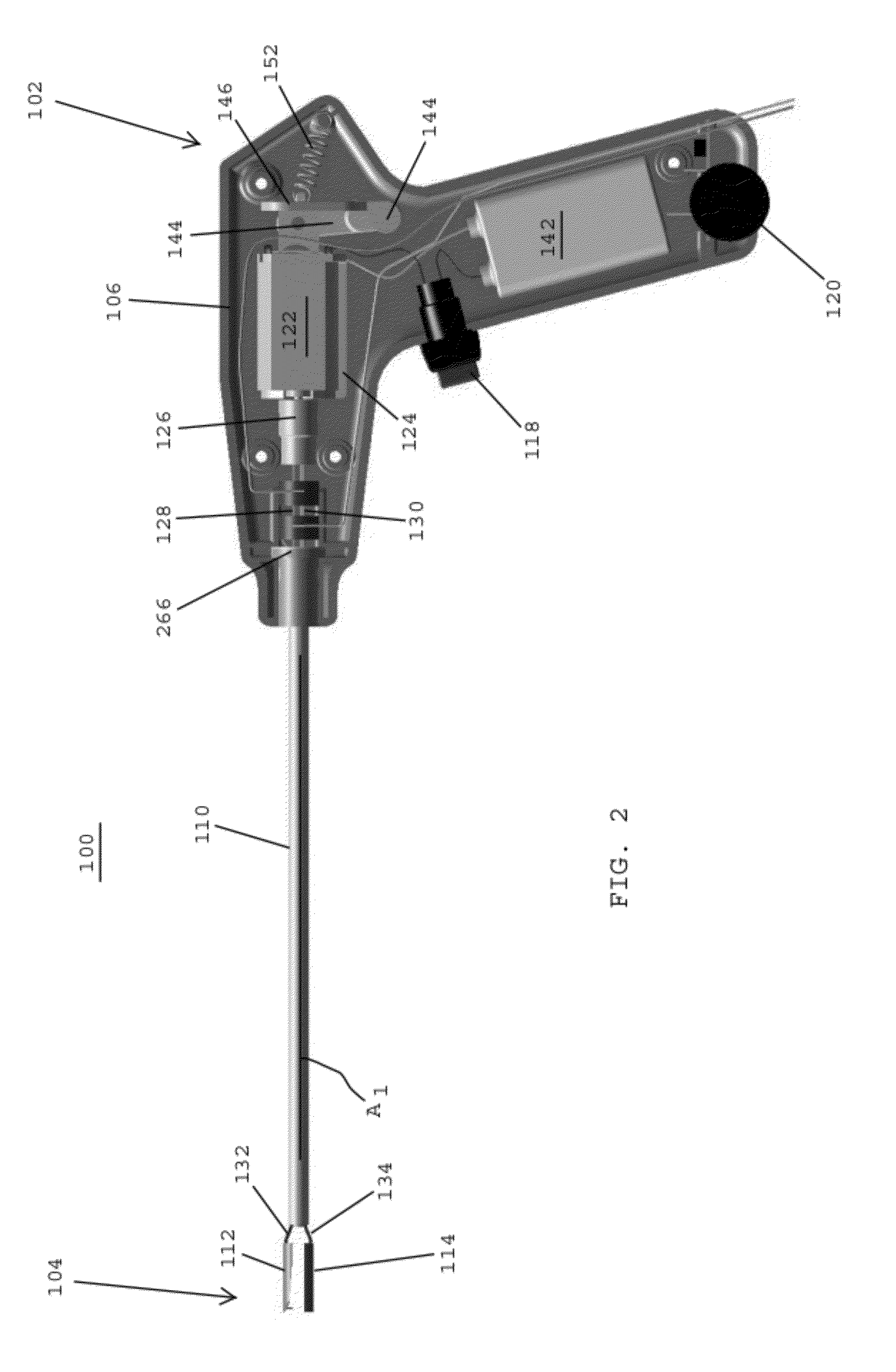

Bipolar medical devices for extracting tissue and methods therefor

ActiveUS20120150179A1Eliminate needLess traumaSurgical instruments for heatingSurgical forcepsEngineeringMedical device

A bipolar medical device for extracting tissue including a handle, and an outer tube projecting from the handle, the outer tube extending along a longitudinal axis and including a proximal end connected with the housing and a distal end spaced from the proximal end. The medical device includes a split tube disposed within the outer tube, the split tube having a distal end including a first cutting element and an opposing second cutting element, a motor coupled with the split tube for selectively rotating the split tube and the first and second cutting elements about the longitudinal axis, and an electrosurgical generator coupled with the split tube, whereby the first cutting element is connectable with a first pole of the electrosurgical generator and the second element is connectable with a second pole of the electrosurgical generator for passing electrical current between the first and second cutting elements.

Owner:ETHICON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com