Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Avoid burnt out situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

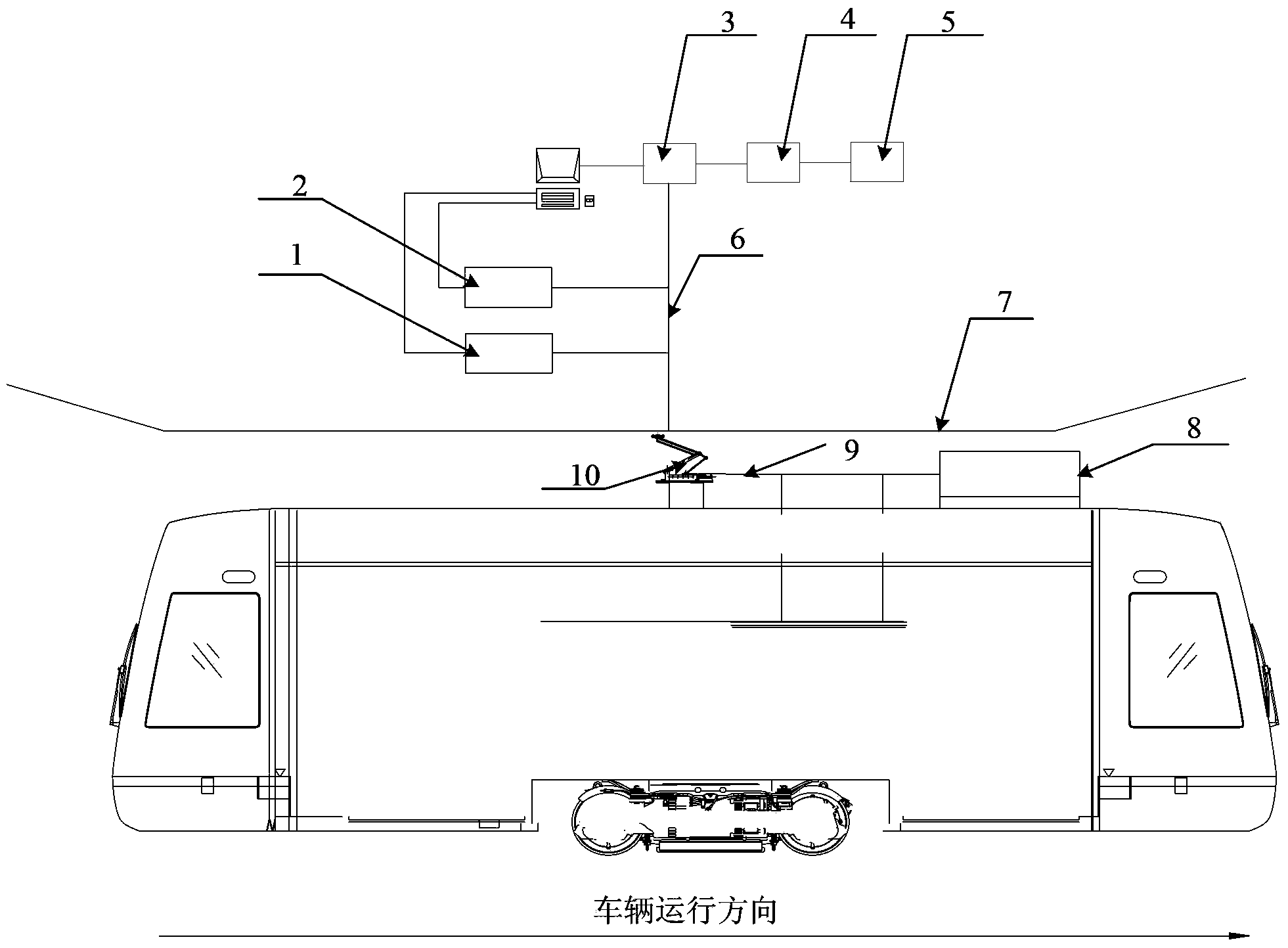

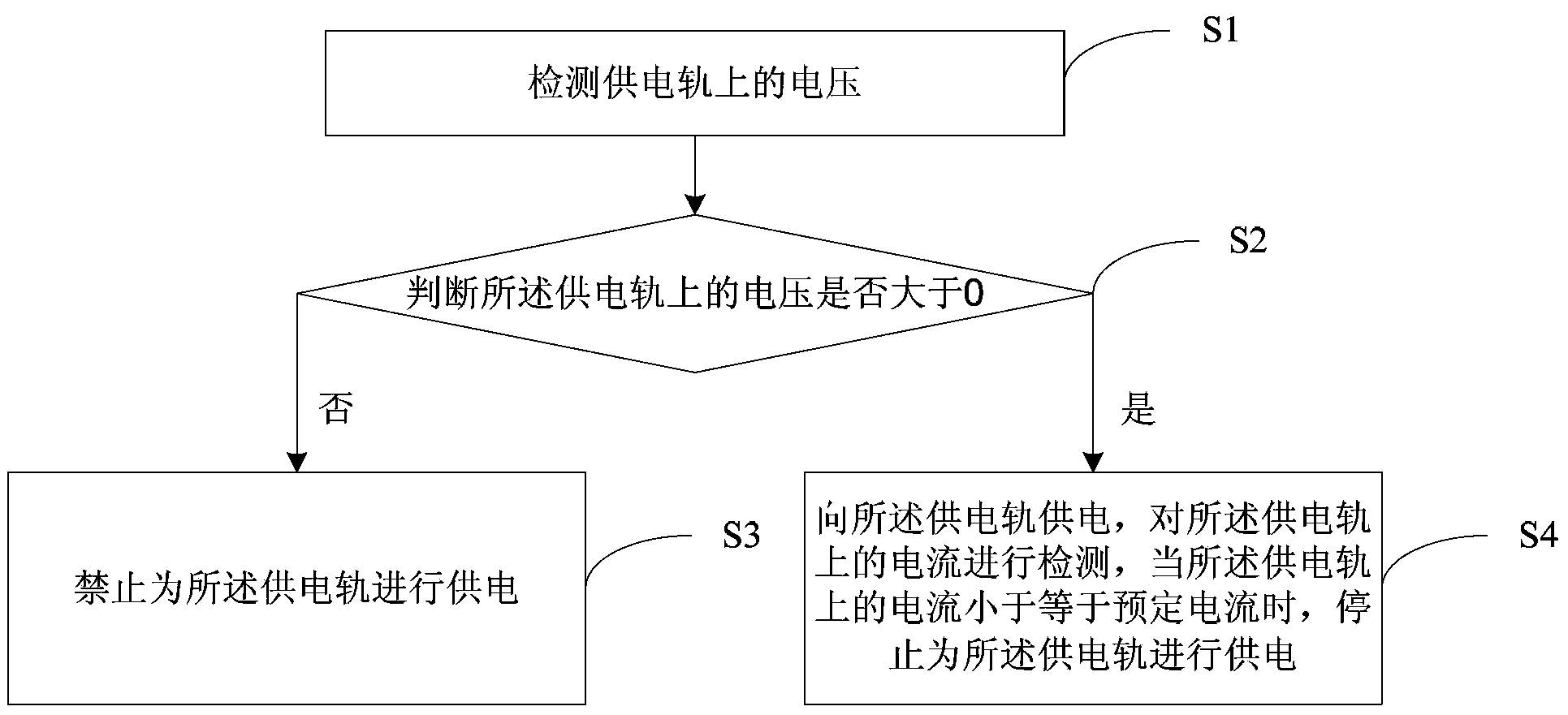

Arc-discharge prevention charging method and system for energy accumulation type electric traction vehicle

ActiveCN103401288AAvoid burnt out situationsExtended service lifeBatteries circuit arrangementsElectric powerElectricityPower flow

The invention discloses an arc-discharge prevention charging method for an energy accumulation type electric traction vehicle. The arc-discharge prevention charging method comprises the following steps of (1) detecting voltage on a power rail; (2) judging whether the voltage on the power rail is more than 0, and if the voltage on the power rail is not more than 0, executing the step (3), otherwise executing the step (4); (3) forbidding power supply to the power rail; (4) supplying power to the power rail, detecting current on the power rail, and if the current on the power rail is less than or equal to preset current, stopping the power supply to the power rail. When the power is supplied to the power rail, a power receiving system is in good contact with the power rail; furthermore, when the power receiving system is separated from the power rail, the power supply to the power rail is stopped; therefore in the processes of contact and separation between the power receiving system and the power rail, electric arc is not produced, so that the phenomenon that the power receiving system and the power rail are burned by the electric arc is effectively avoided; the service lives of the power receiving system and the power rail are effectively prolonged. The invention also discloses a charging system capable of executing the charging method.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

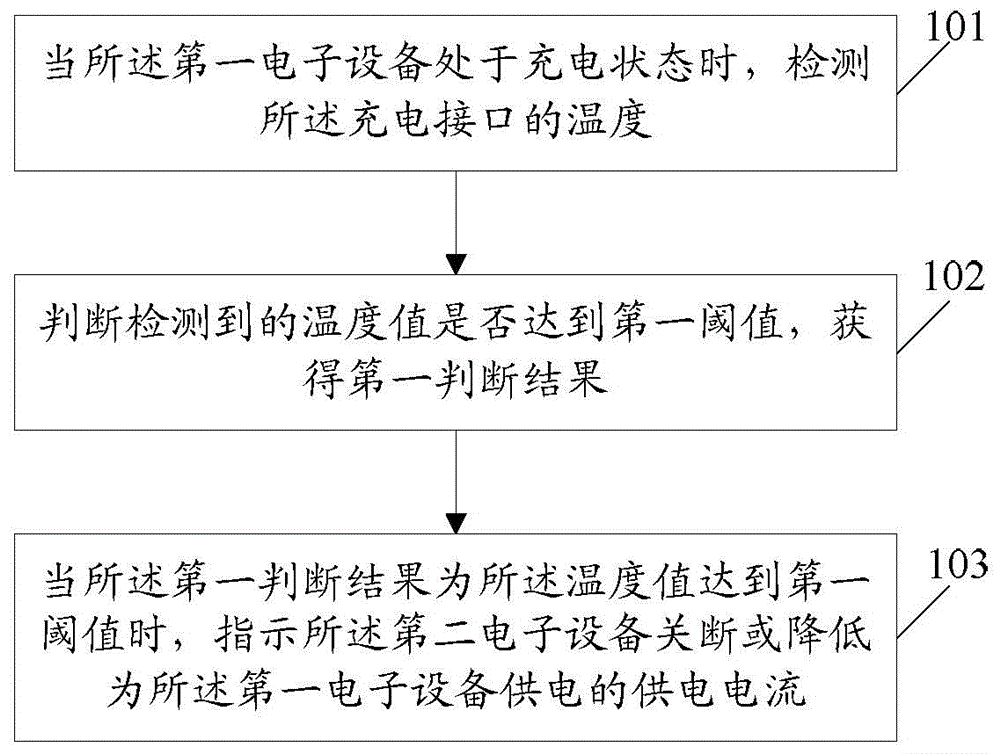

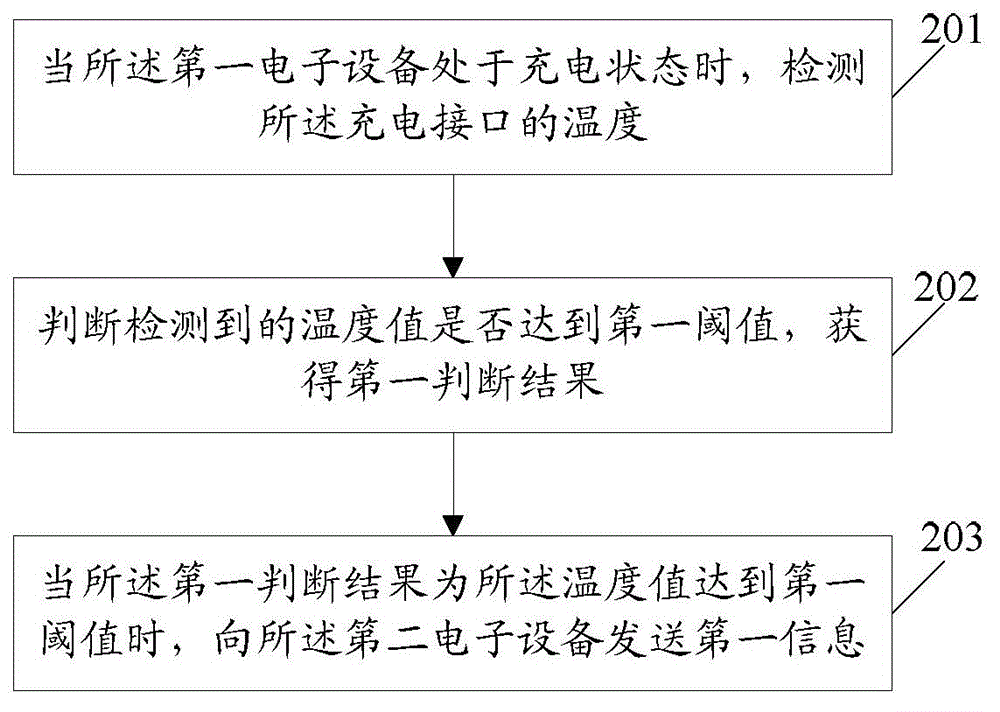

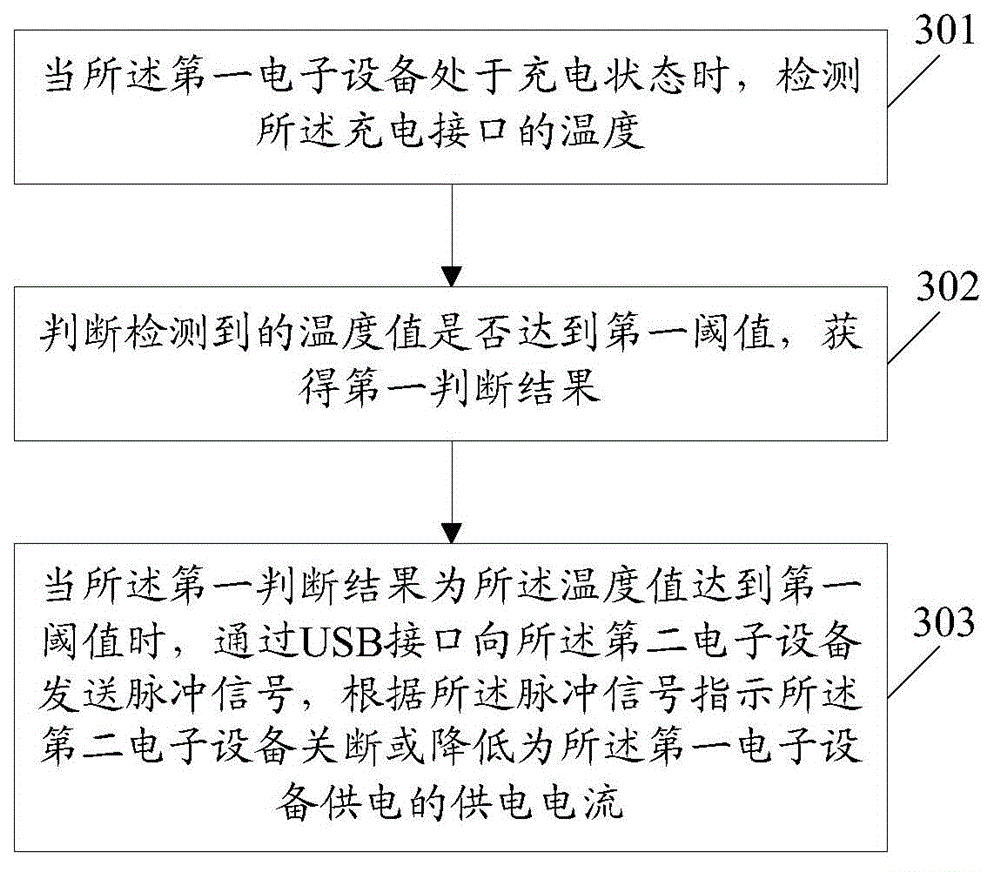

Information processing method, first electronic equipment and second electronic equipment

InactiveCN105471008AAvoid burnt out situationsAvoid situations of property damage or even personal injuryBatteries circuit arrangementsElectric powerInformation processingCharge current

An embodiment of the invention discloses an information processing method, first electronic equipment and second electronic equipment. The first electronic equipment is provided with a charging interface; and the second electronic equipment supplies power to the first electronic equipment through the charging interface. The information processing method comprises the steps of: detecting temperature of the charging interface when the first electronic equipment is in a charging state, and judging whether a detected temperature value reaches a first threshold value to obtain a first judgment result; and indicating the second electronic equipment to switch off or decrease a charging current supplying power to the first electronic equipment when the first judging result is that the temperature value reaches the first threshold value.

Owner:LENOVO (BEIJING) CO LTD

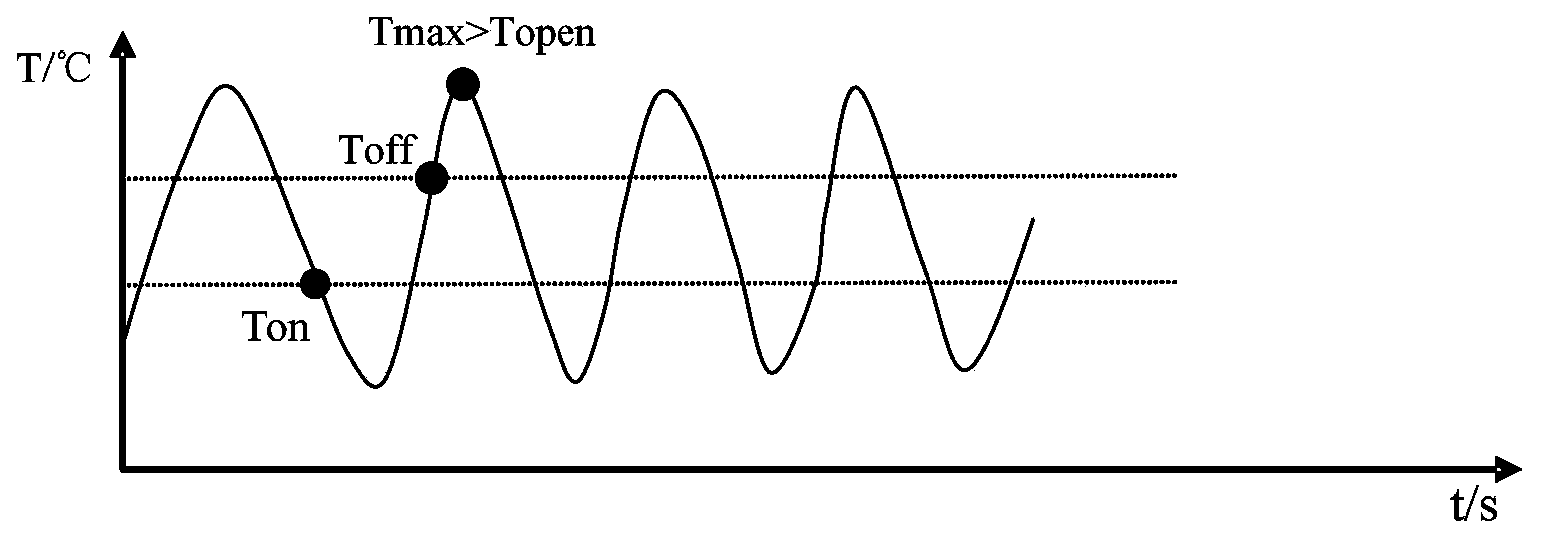

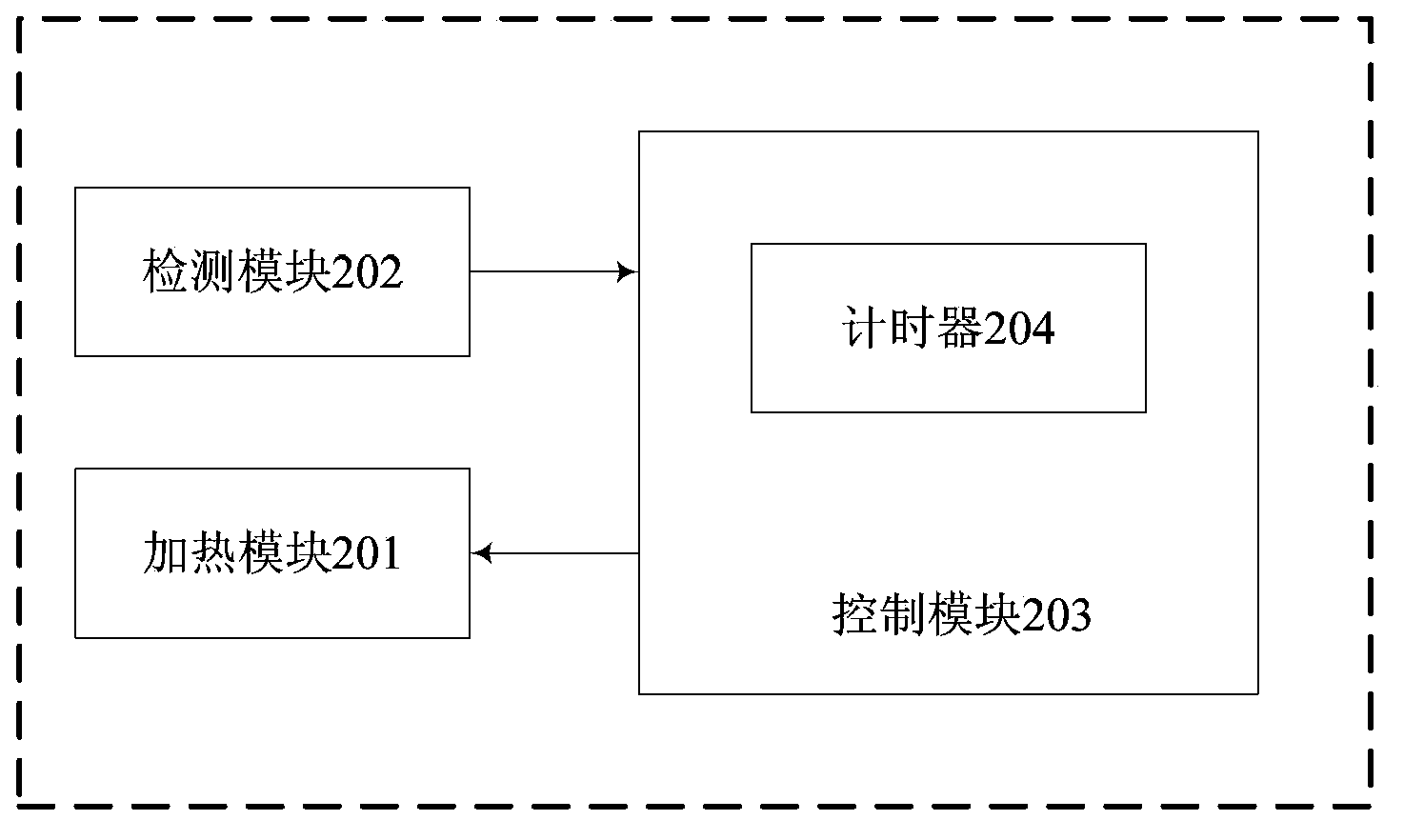

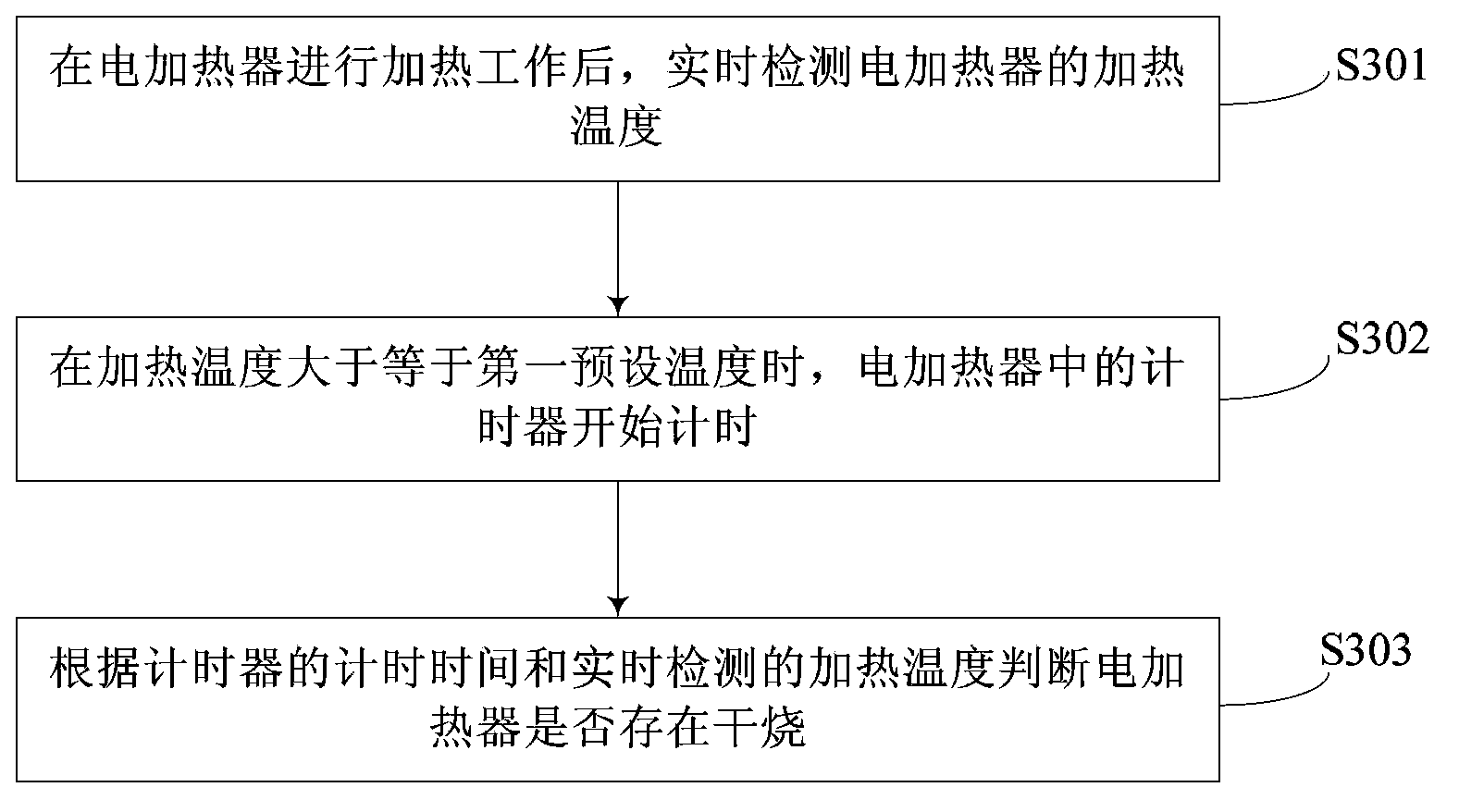

Electric heater with dry-burning identification function and dry-burning identification method thereof

ActiveCN104066211AExtended service lifeAvoid dry burning and thermal fuse burnoutElectric heatingElectricityEngineering

The invention proposes a dry-burning identification method for an electric heater. The method includes the following steps: after the electric heater carries out a heating work, the heating temperature of the electric heater is detected in a real-time manner; when the heating temperature is higher than a first preset temperature, a timer in the electric heater begins timing; and according to a timing time of the timer and the heating temperature which is detected in a real-time manner, whether dry burning of the electric heater exists is judged. The dry-burning identification method of the electric heater is capable of identifying the dry-burning state of an electric heater and preventing a safety problem caused by drying burning of the electric heater and overly high temperature. The invention also proposes the electric heater with a dry-burning identification function at the same time.

Owner:MIDEA GRP CO LTD +1

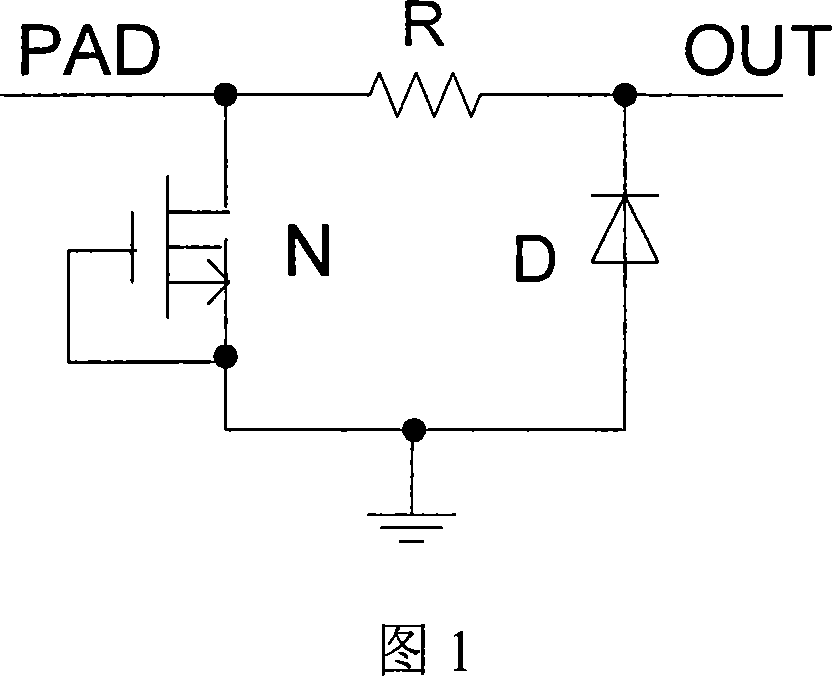

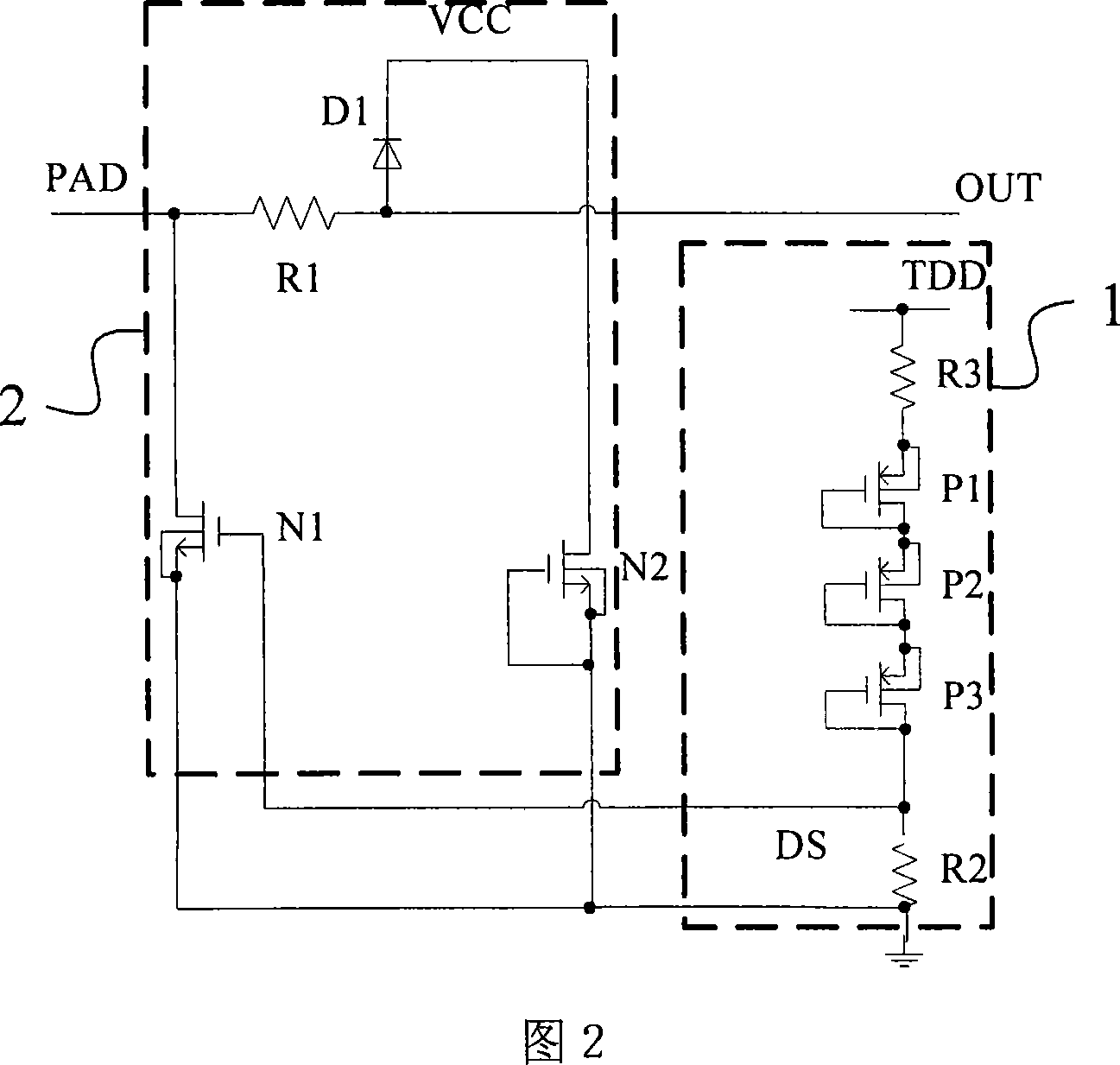

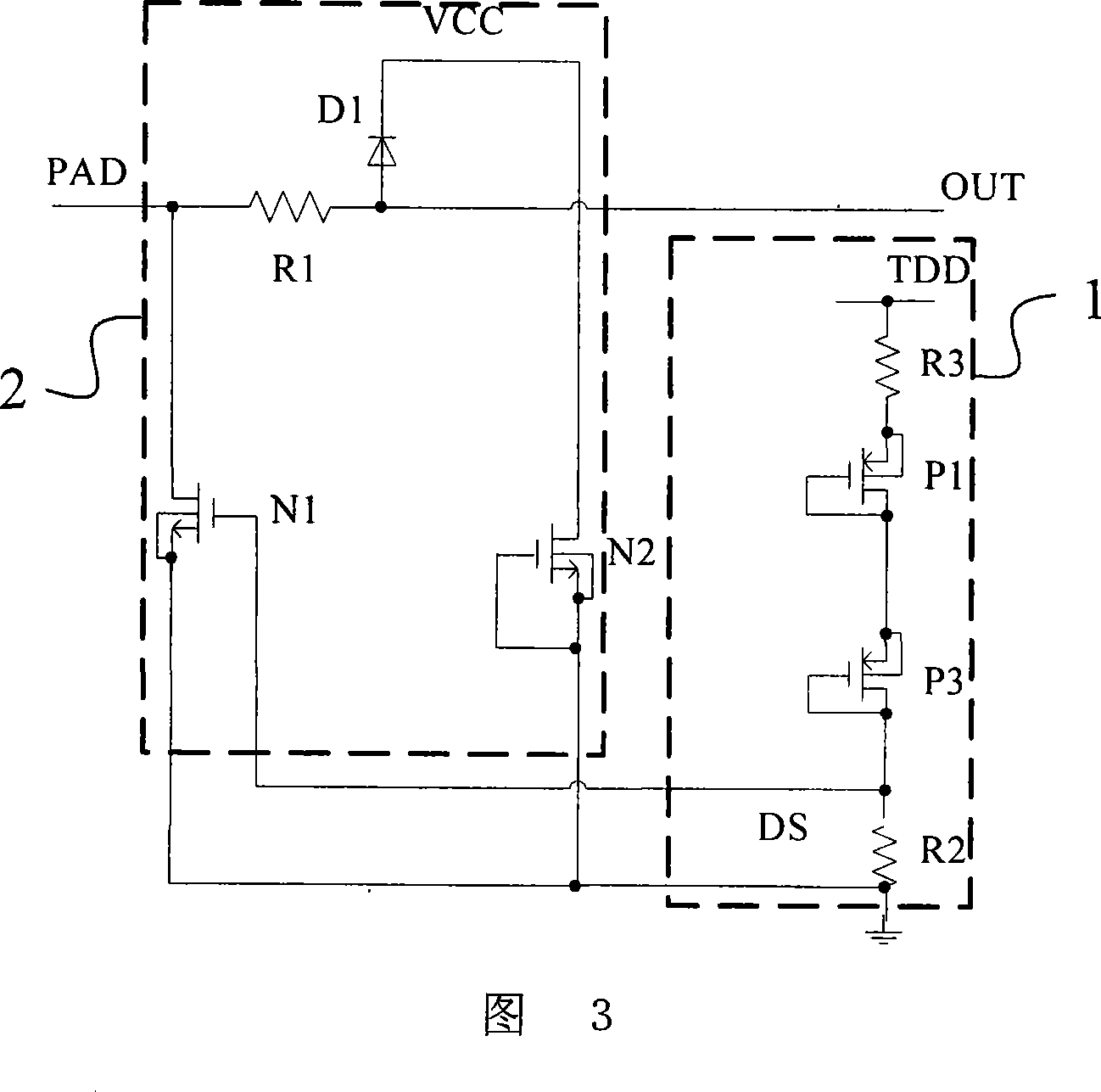

Static protection circuit suitable for radio frequency identification label chip

InactiveCN101046853AImprove stabilityImprove protectionRecord carriers used with machinesElectrostatic chargesCapacitanceComparators circuits

The present invention discloses an electrostatic protection circuit applicable to radio-frequency identification label chip. Said circuit includes voltage comparator circuit and current dumping circuit. Said voltage comparator circuit includes PMOS transistor P1 and P3 and resistor R2 and R3 and is used for detecting and comparing voltage value; and said current dumping circuit includes NMOS transistor N1 and N2, diode D1 and resistor R1 and is used for dumping electrostatic pulse and radio-frequency high-voltage.

Owner:HUAZHONG UNIV OF SCI & TECH

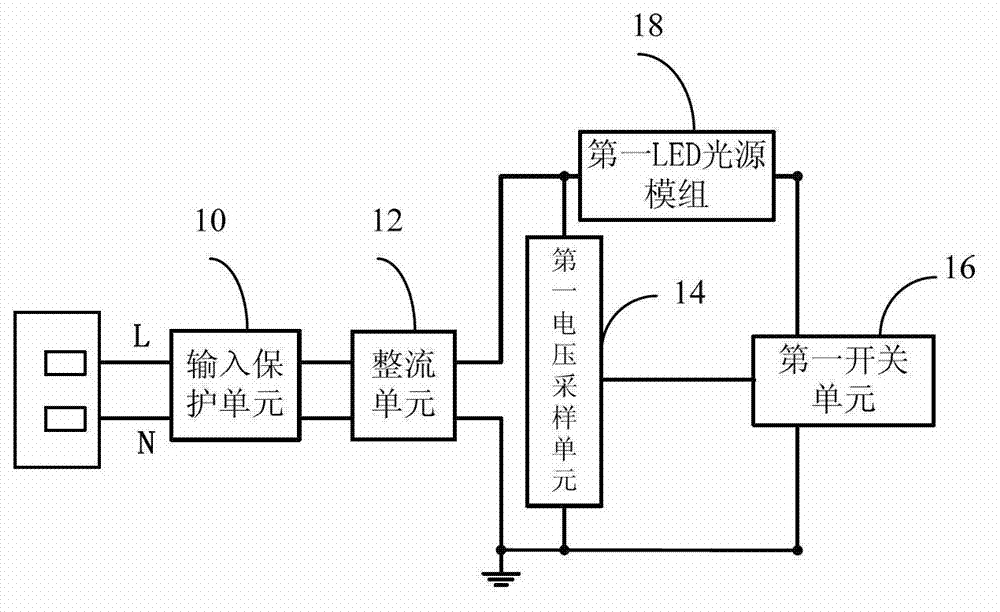

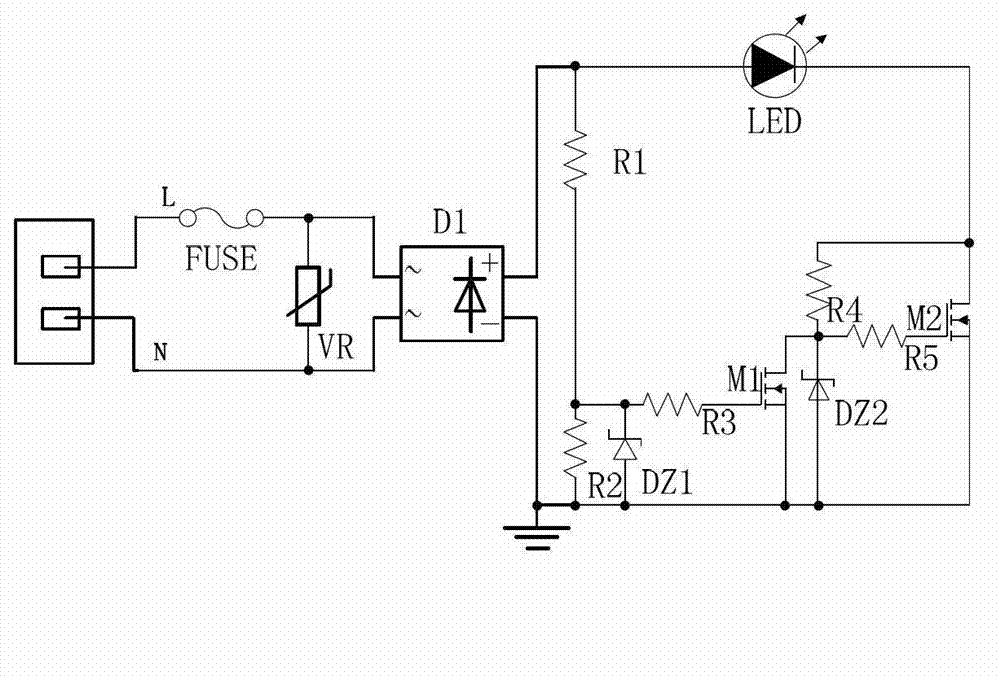

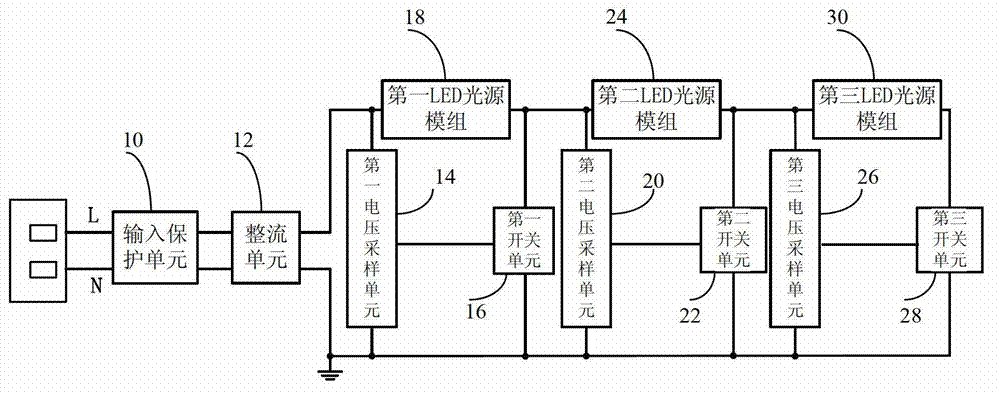

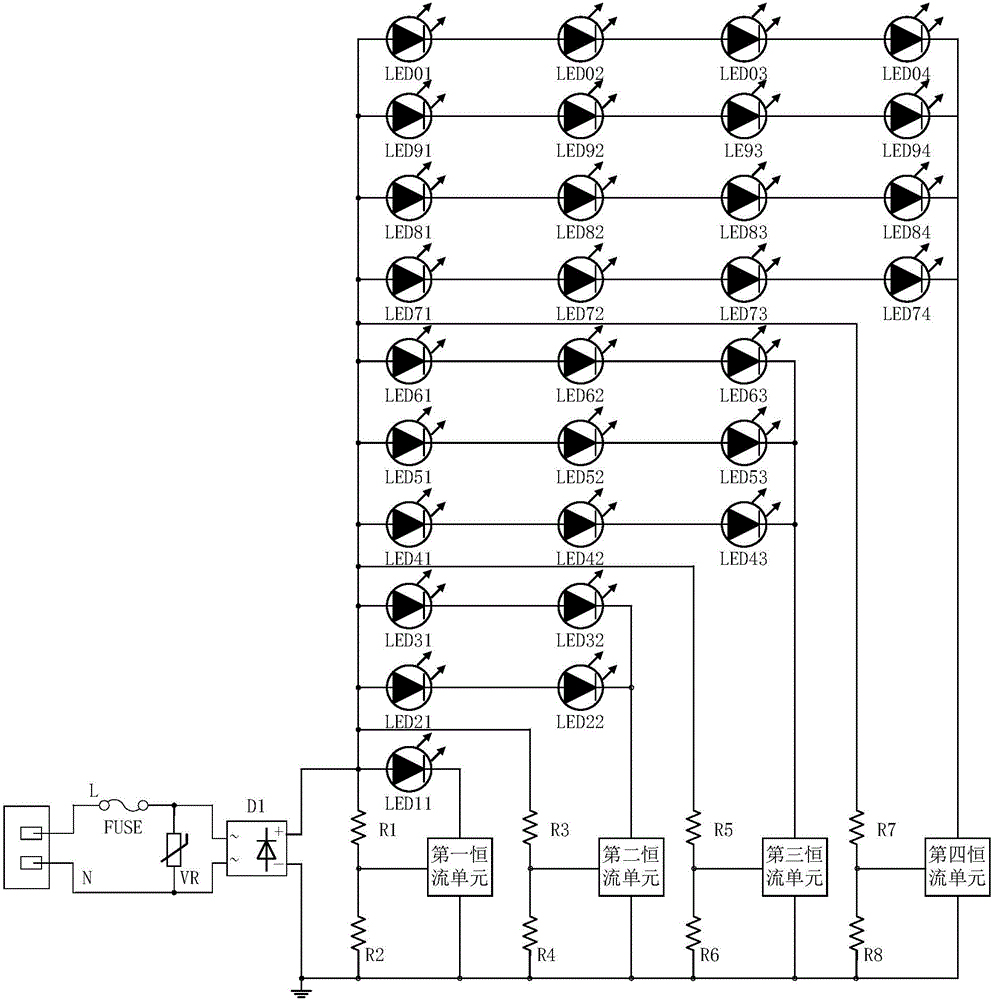

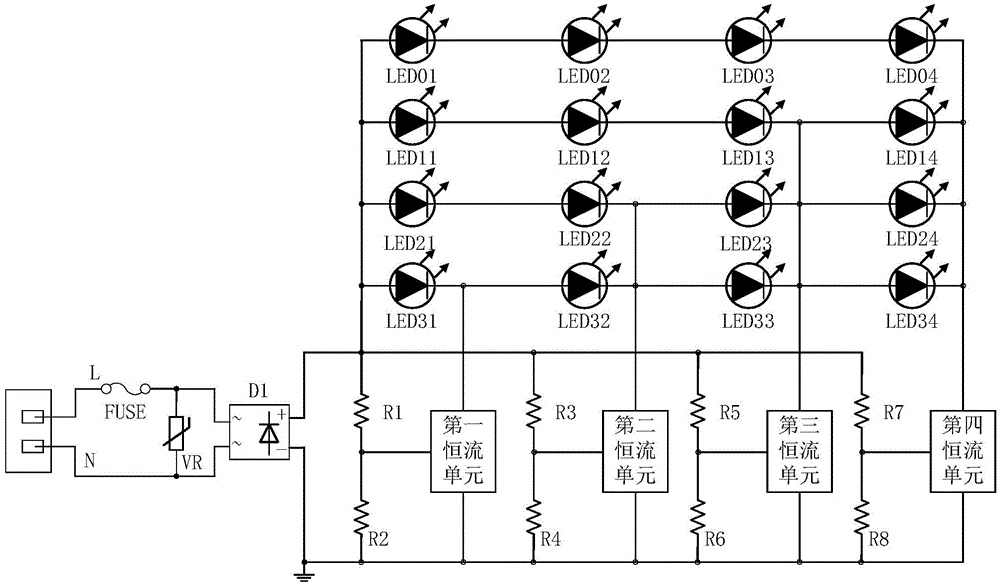

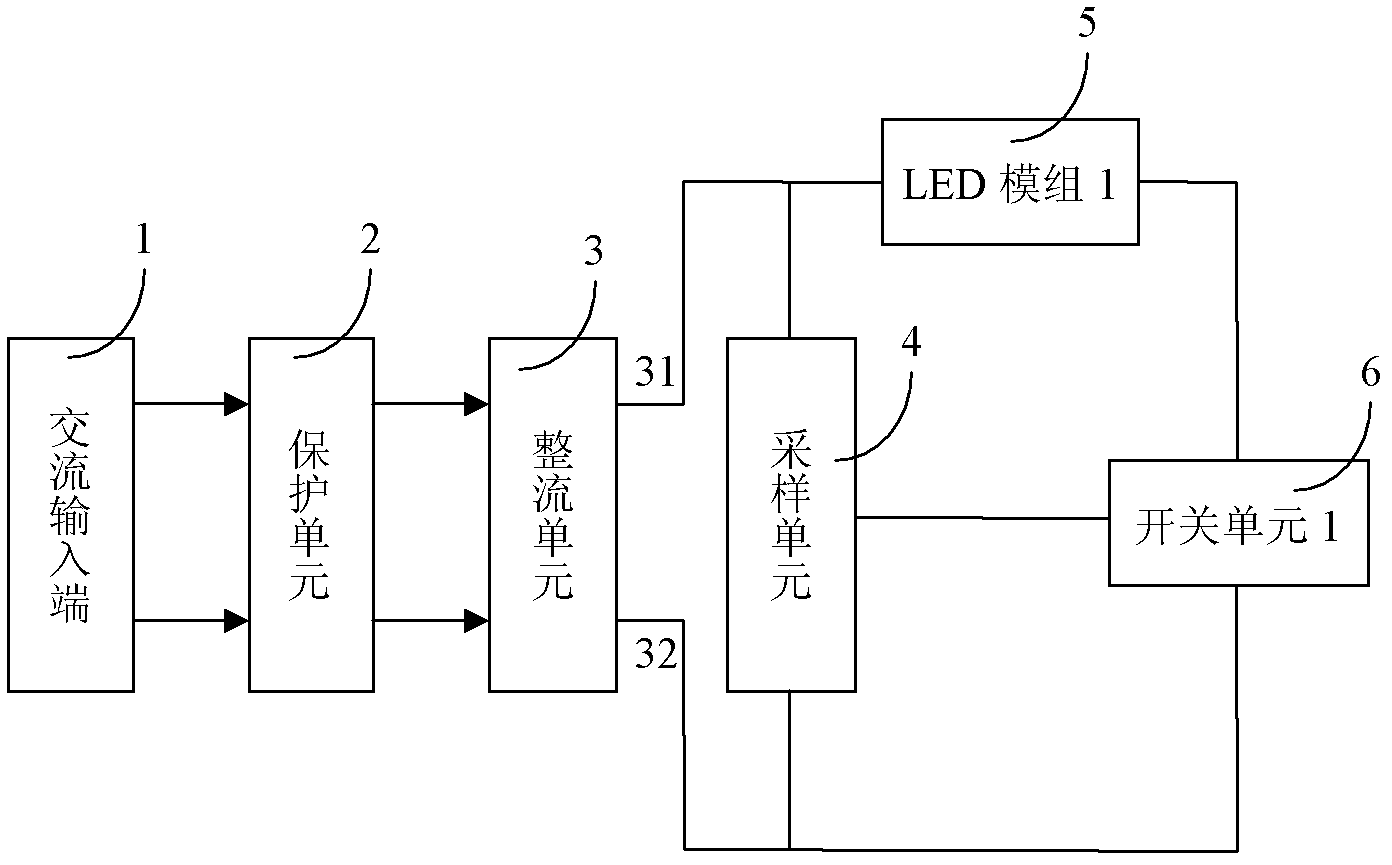

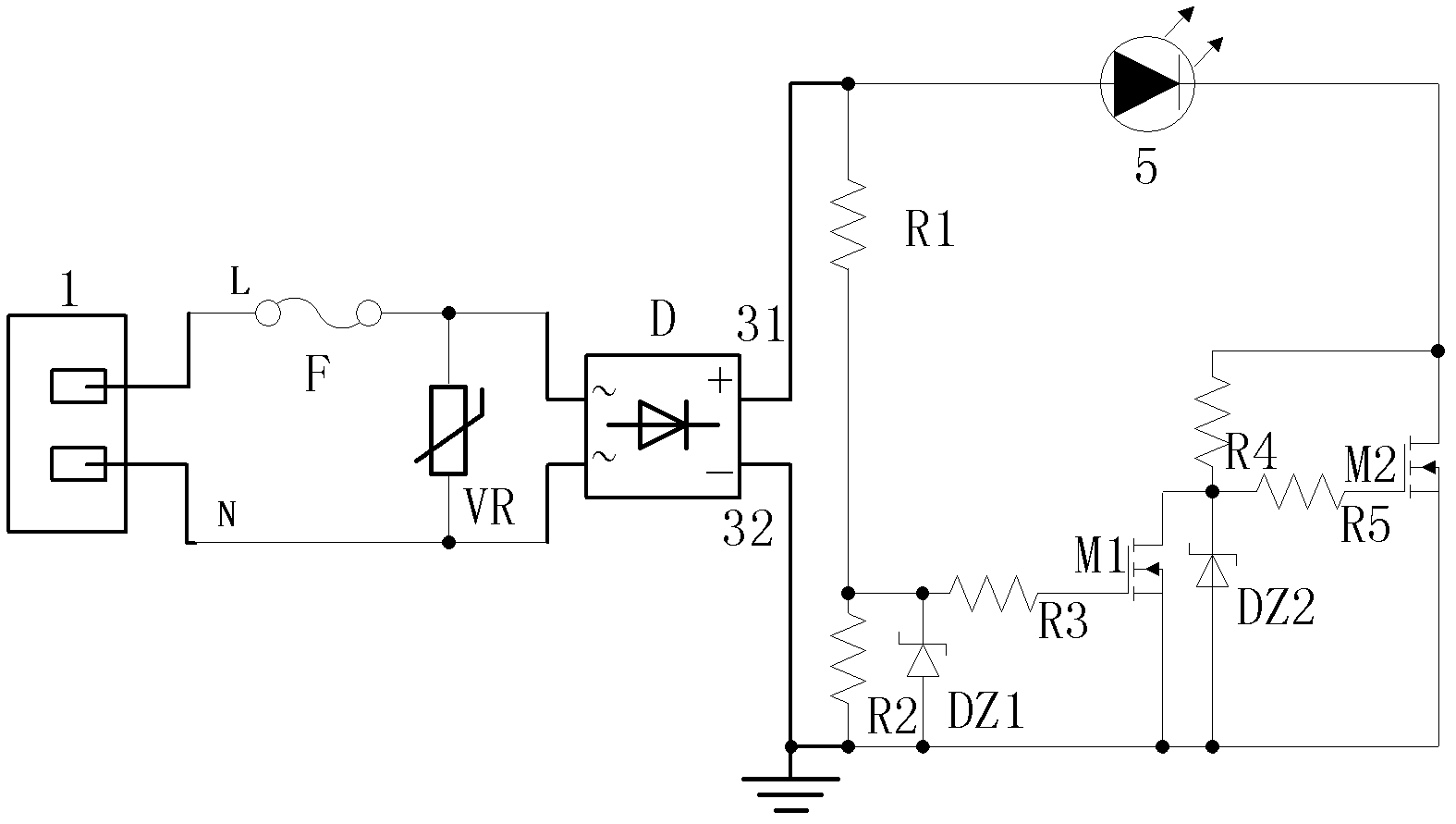

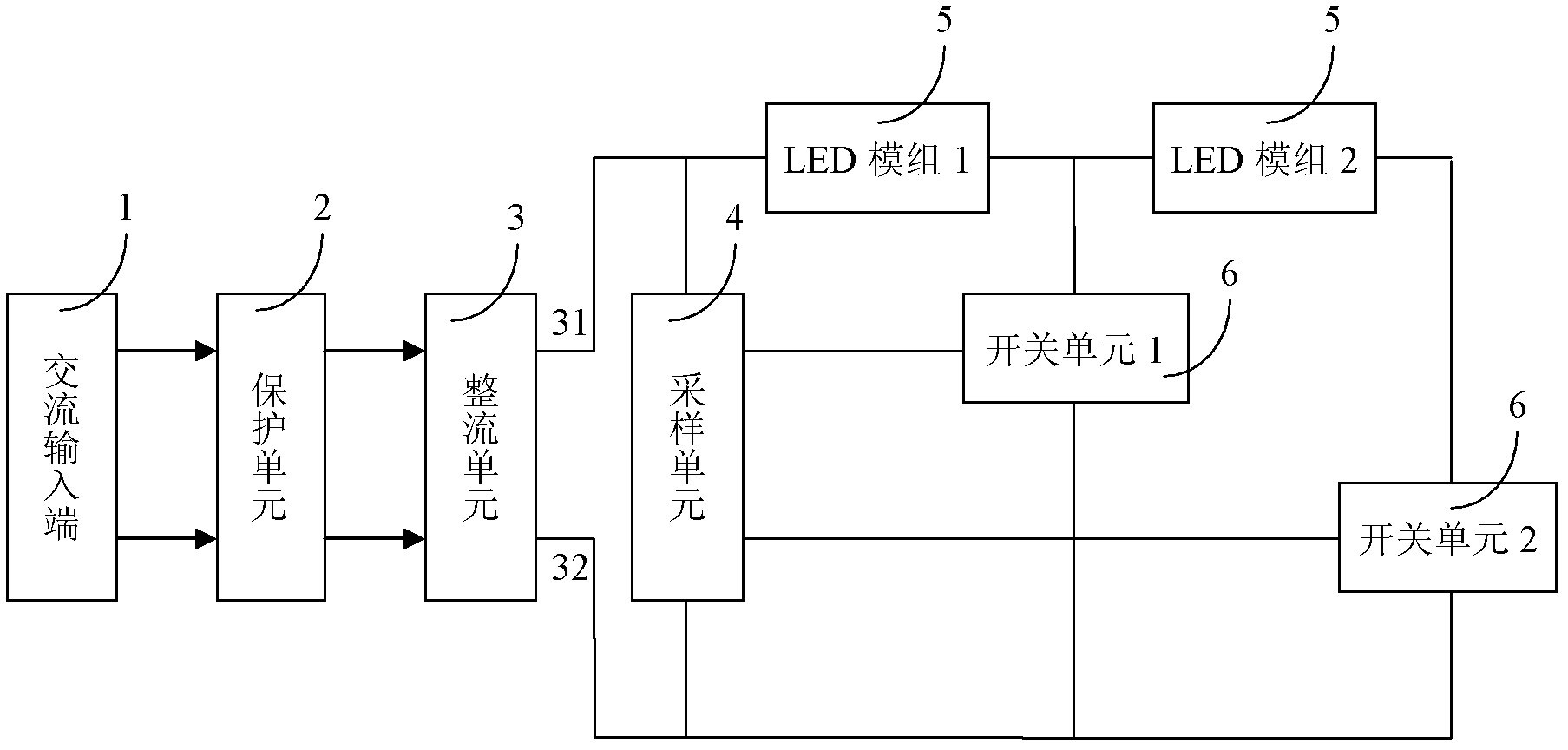

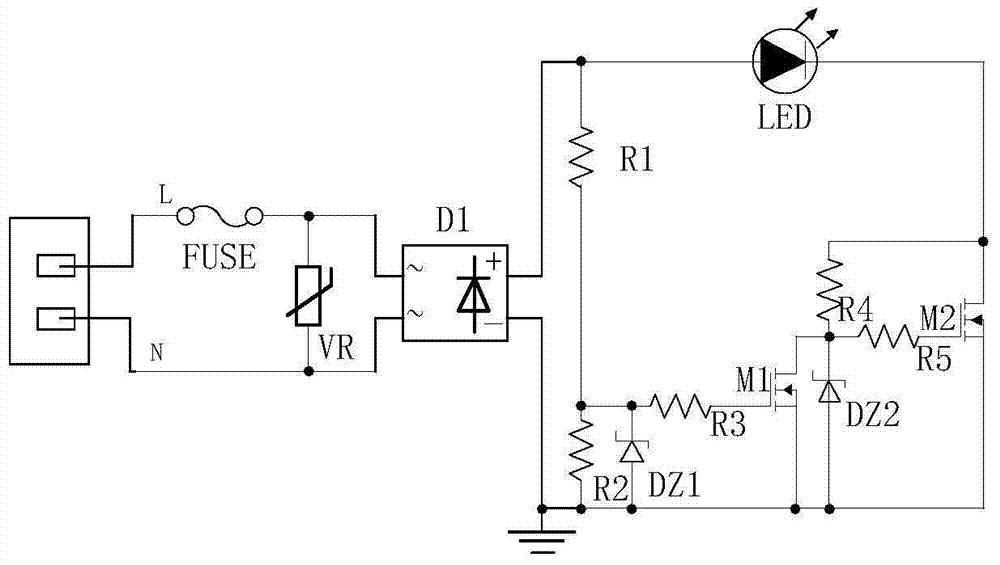

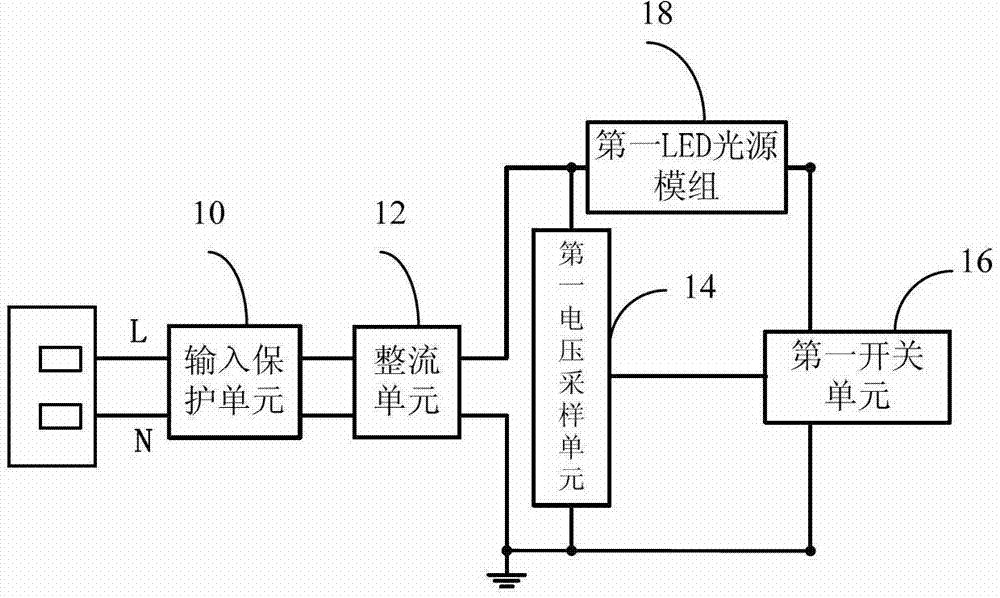

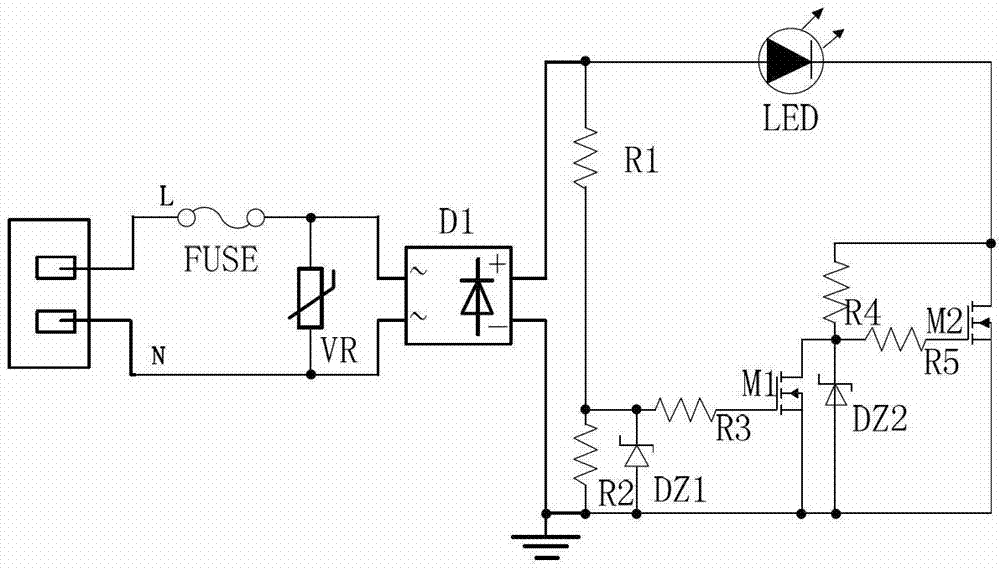

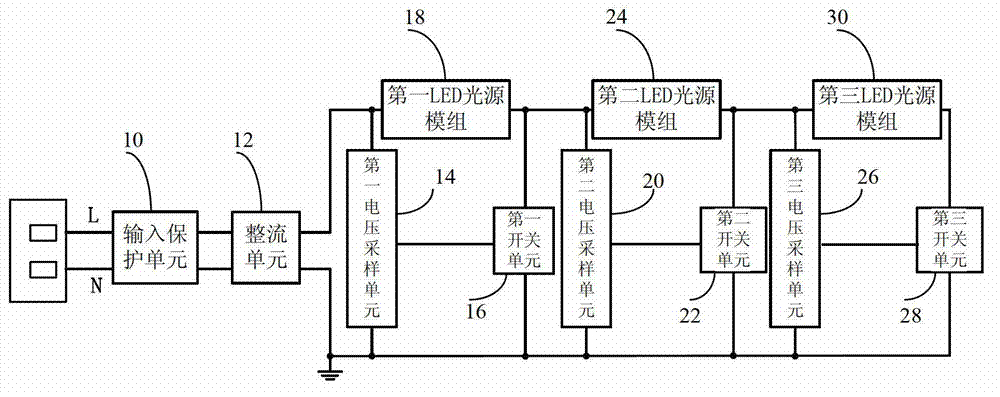

Dimming drive circuit of AC (Alternating Current) direct drive LED module

ActiveCN102892238AColor temperature adjustableColor adjustableElectrical apparatusElectroluminescent light sourcesDriver circuitAlternating current

The invention discloses an AC (Alternating Current) dimming drive circuit for an LED (Light-Emitting Diode). The AC dimming drive circuit comprises a rectification unit and N levels of LED DC (Direct Current) drive circuits, wherein in the ith-level LED DC drive circuit, a first end of an ith voltage sampling unit and the input end of an ith LED light source module directly or indirectly receive the output voltages of the rectification unit; the voltage diving end of the ith voltage sampling unit is connected with a second input end of an ith switching unit; a first input end of the ith switching unit is connected with the output end of the ith LED light source module; the output end of the ith switching unit, a second end of the ith voltage sampling unit and a second output end of the rectification unit are grounded; when the ith switching unit is switched on, the first to ith LED light source modules emit light; and when the ith switching unit is switched off, if i is less than N, the first to (i+1)th LED light source modules emit light, and if i is equal to N, the first to Nth LED light source modules stop emitting light. By utilizing the dimming drive circuit, the AC direct drive LED light source module is realized and cannot twinkle when the AC voltage fluctuates.

Owner:四川能投智慧光电有限公司

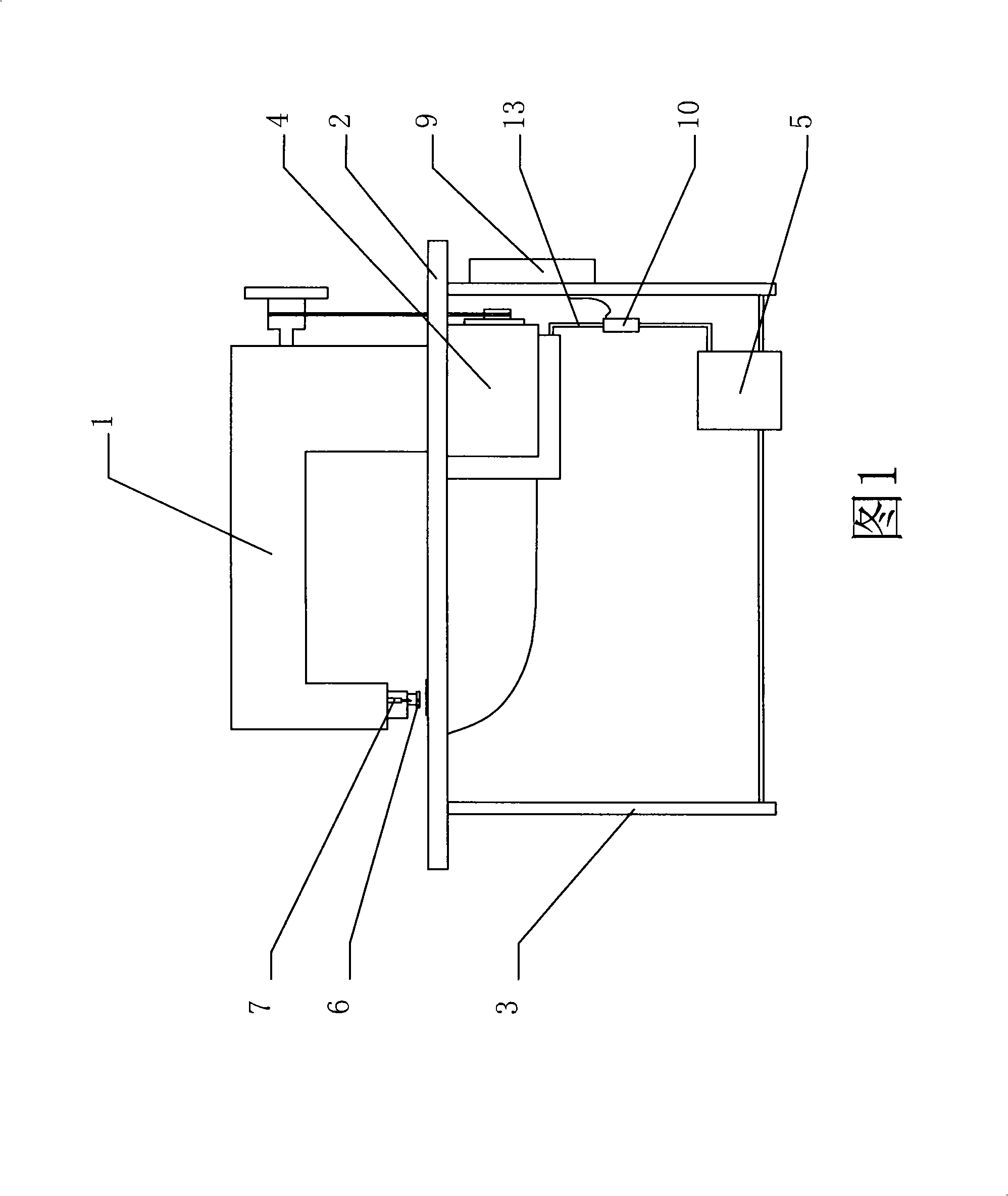

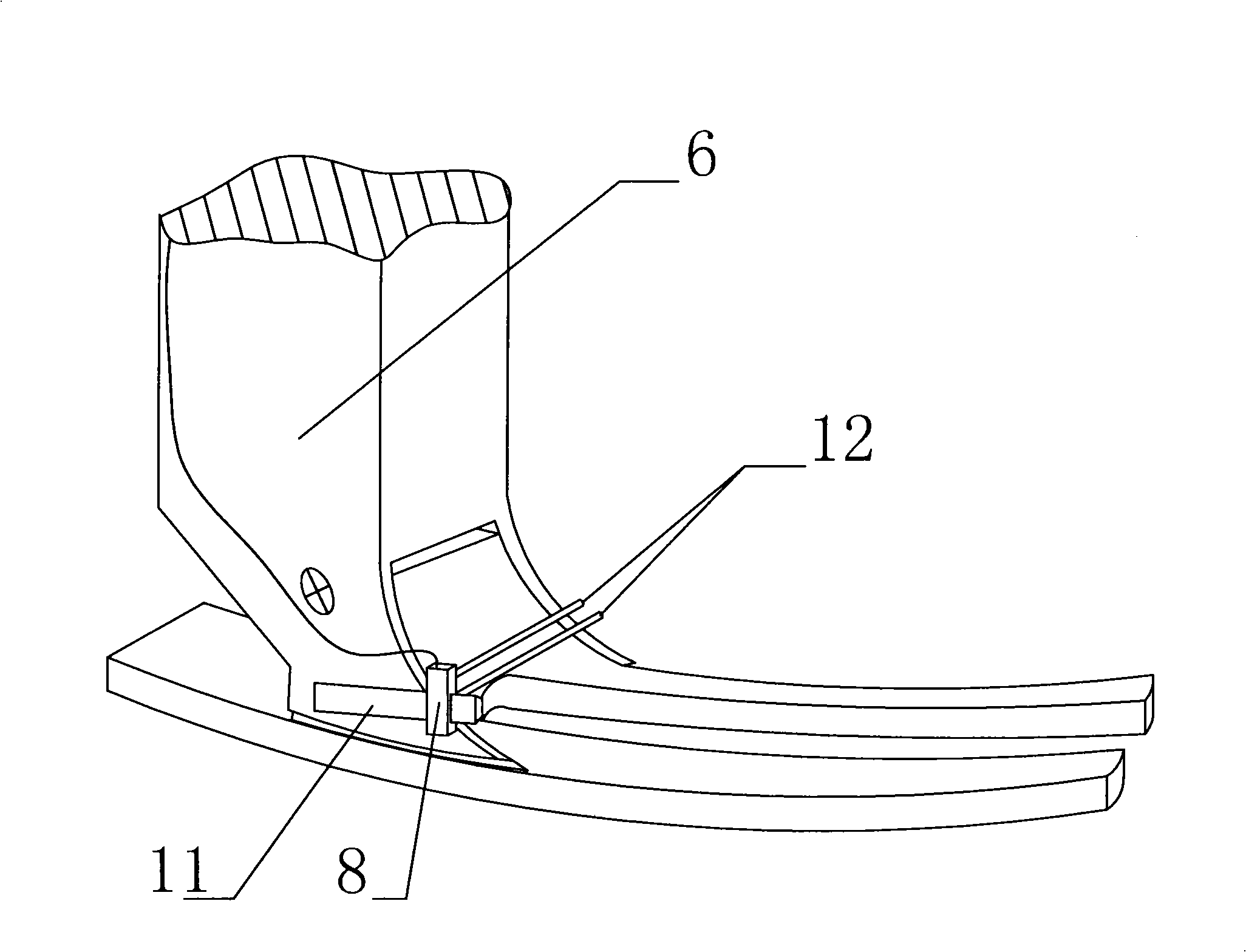

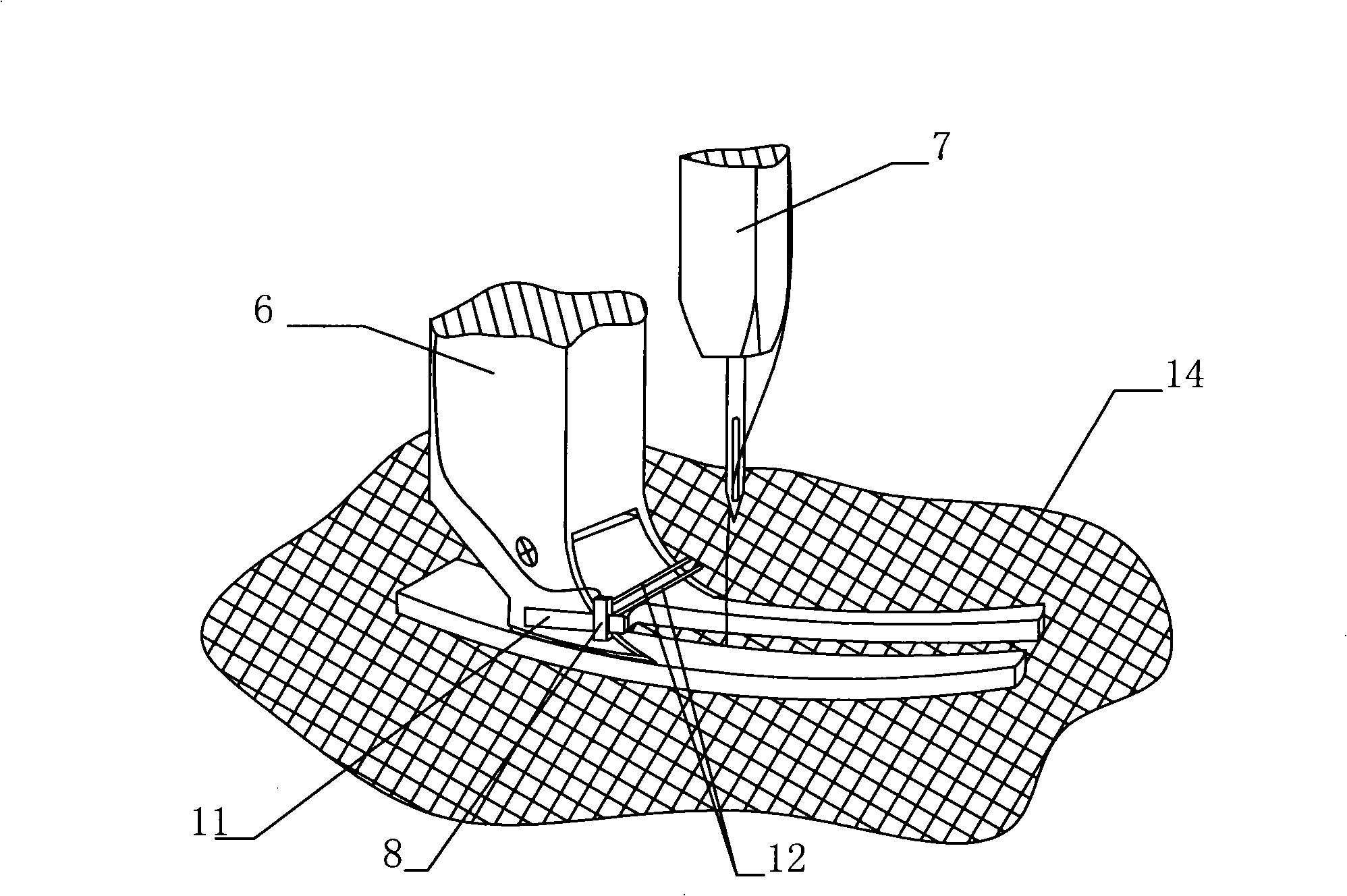

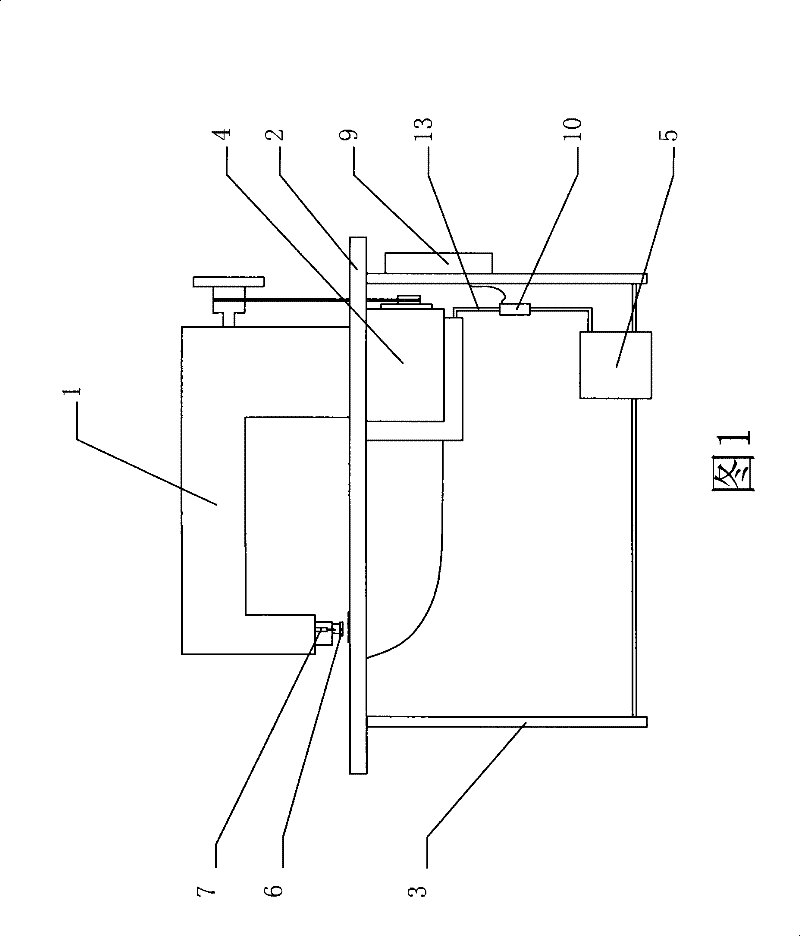

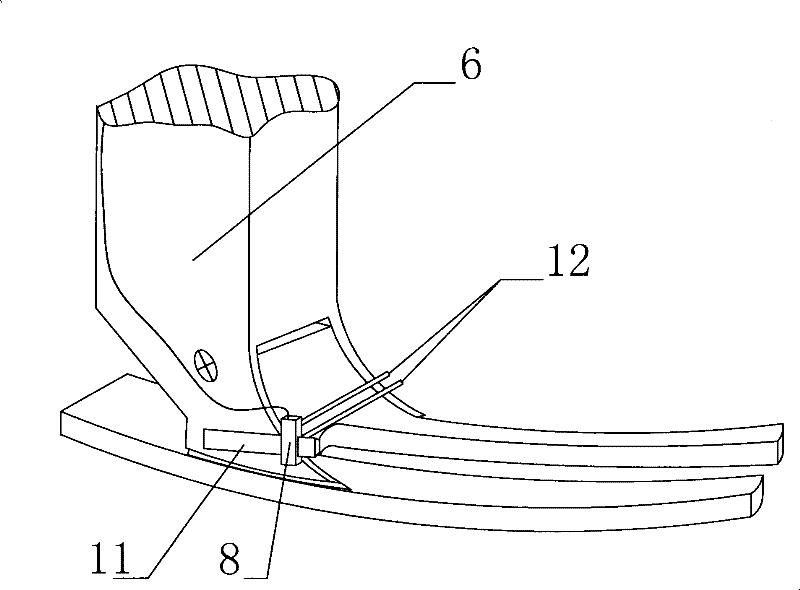

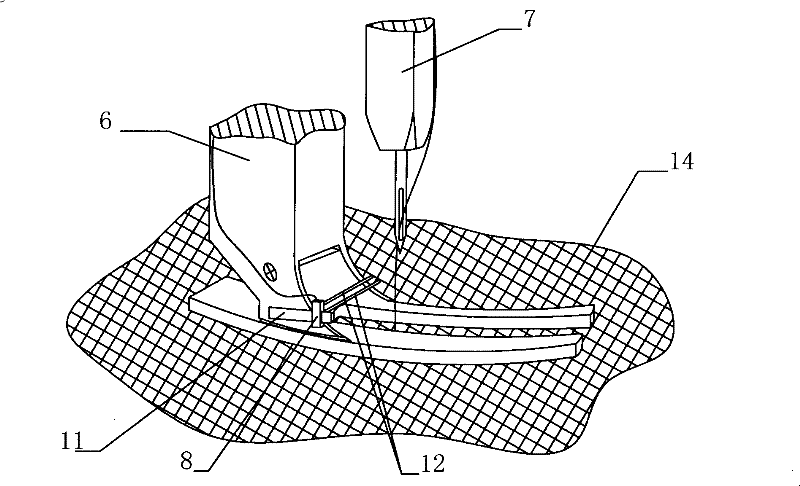

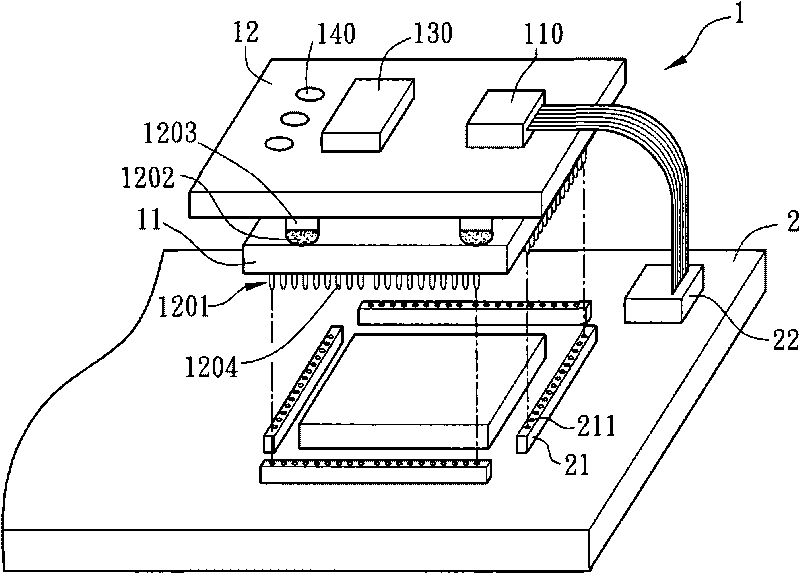

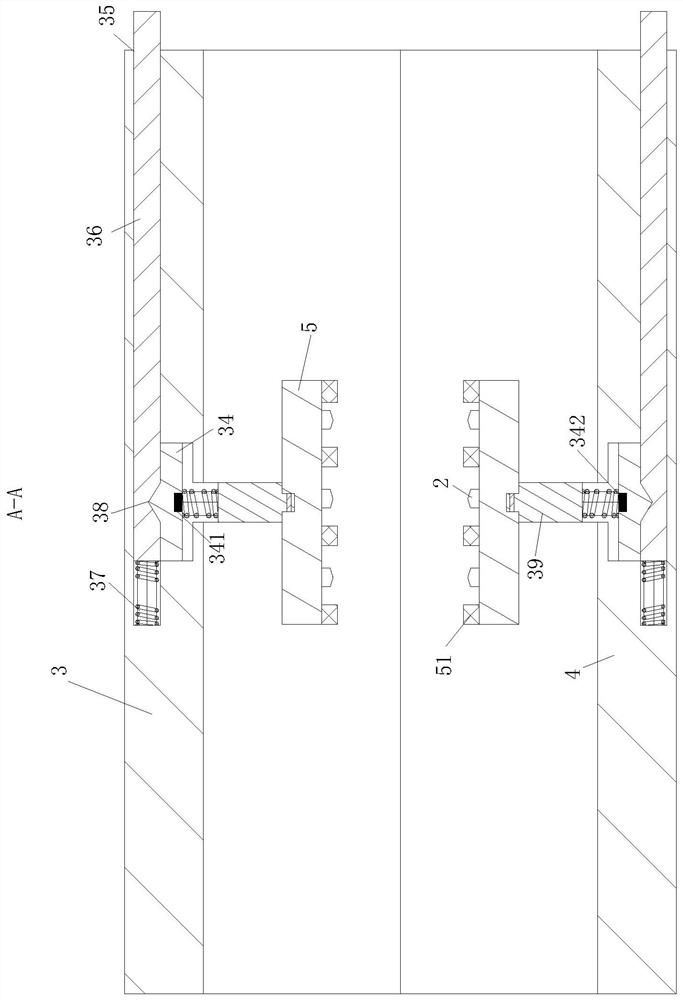

Electric sewing machine

InactiveCN101314899AAvoid burnt out situationsSimple structureSewing-machine control devicesBobbinElectronic control system

The invention discloses an electric sewing machine which comprises a machine head, a bedplate, a stent, an electromotor and a pedal, wherein, the machine head is provided with a presser foot and a machine needle which are arranged in the position opposite to the bedplate; the presser foot is provided with a U-shaped opening; and the electromotor is provided with a clutch which is linked with the pedal through a link lever; and the electric sewing machine also comprises a bobbin thread monitoring apparatus. When the electric sewing machine works at a high speed, and conditions that bobbin threads use up or break, the stitch slips, the bobbin threads loose, etc. happen, a thread position sensor can be triggered by sewing threads on the machine needle, and a signal can be given out to impel the bobbin thread monitoring apparatus to act and enable the electric sewing machine to stop. The bobbin thread monitoring apparatus has the advantages of simple structure and low manufacturing cost, and no need of a complicated electronic control system for realizing the bobbin thread monitoring; and the machine can be stopped when no bobbin thread exits and the bobbin threads breaks, or the stitch slips or the bobbin threads loose, thereby realizing the effect that the sewing material is effectively utilized, saving resources, reducing the product rework rate, and improving the production efficiency.

Owner:李永鹏

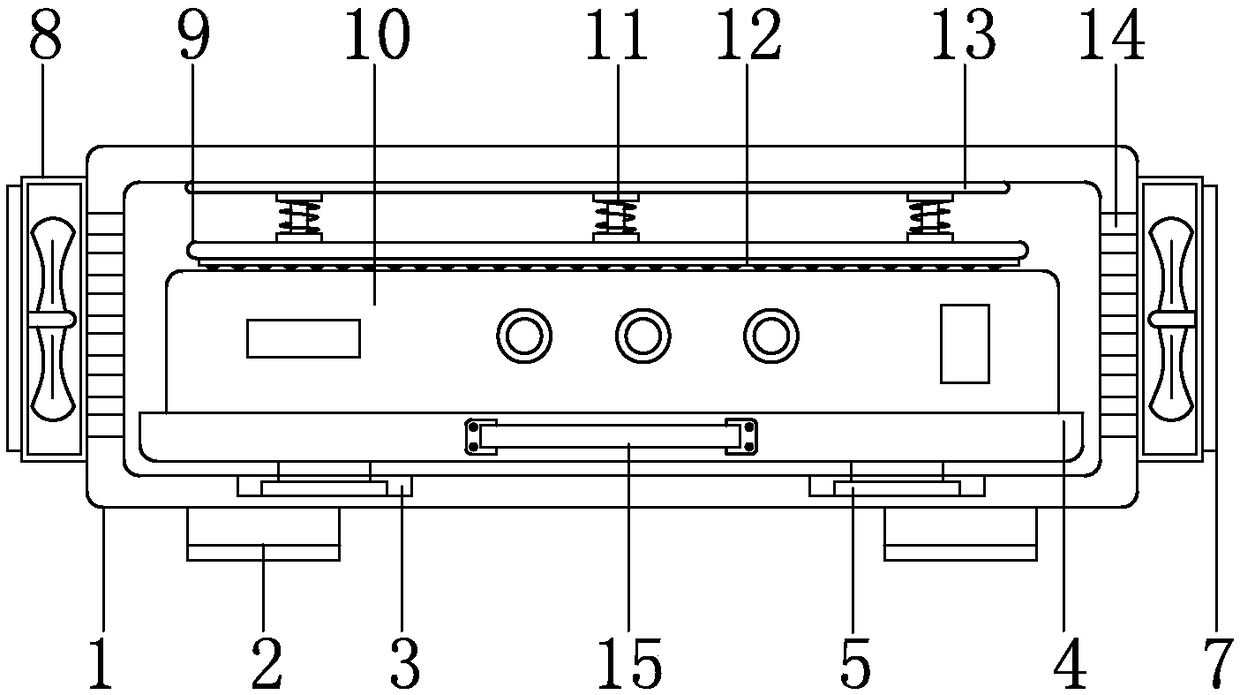

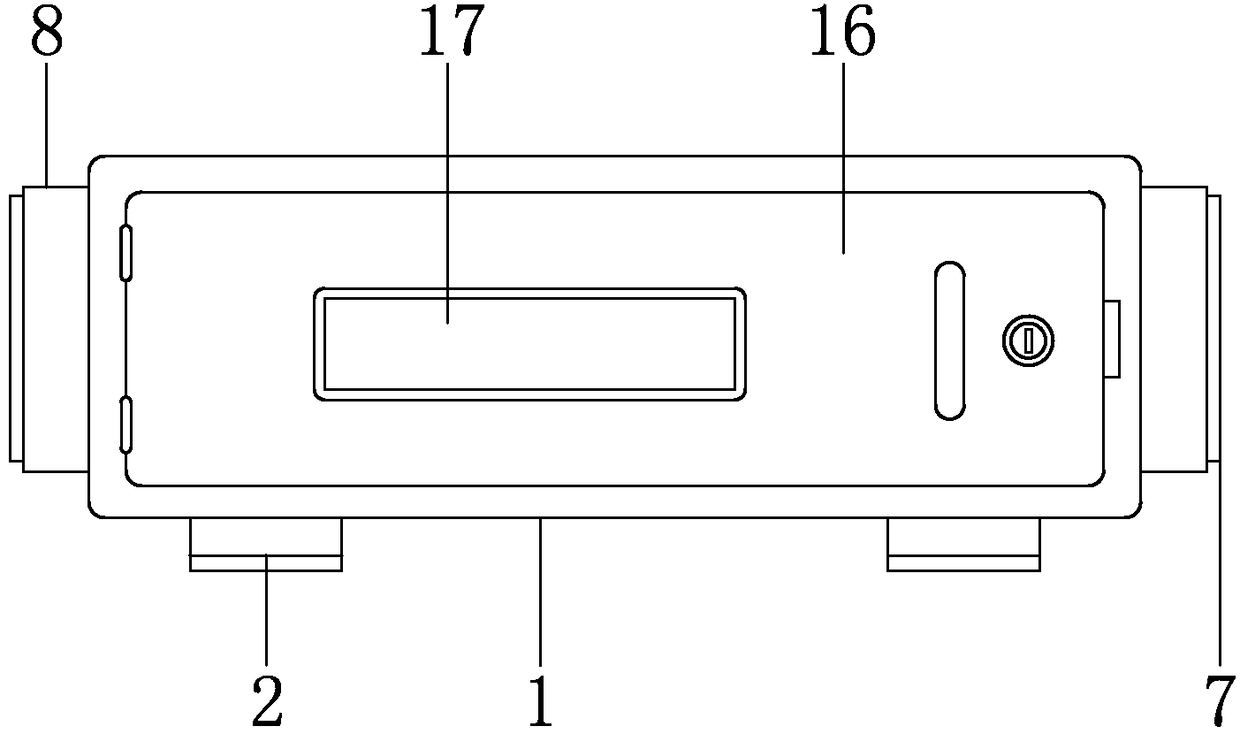

Frequency-modulation advertisement transmitter protective cover

ActiveCN108377152AQuick installationImprove practicalityTransmissionCooling/ventilation/heating modificationsEngineeringFrequency modulation

The invention discloses a frequency-modulation advertisement transmitter protective cover. The protective cover comprises a shell, a fixed plate, radiating fans and an advertisement transmitter; support legs are arranged at the bottom of the shell; two sliding chutes are arranged at the bottom end in the shell, and the fixed plate is arranged on the sliding chutes through sliding blocks; a tensilehandle is arranged on the front of the fixed plate through a mounting part, a placing slot is formed on the upper surface of the fixed plate, and an advertisement transmitter is arranged in the placing slot; and the radiating fans are arranged on the side walls of the shell at the location of the advertisement transmitter. The frequency-modulation advertisement transmitter protective cover disclosed by the invention is composed of the shell, the fixed plate, the radiating fans and the advertisement transmitters and a series structures, and is more convenient for use in comparison with the traditional frequency-modulation advertisement transmitter protective cover; the advertisement transmitter can be quickly mounted and taken out through the cooperation of the sliding chutes and the sliding blocks; a damping spring can effectively lower or reduce the damage on the advertisement transmitter when the protective cover is in collision through the own buffering performance, and the frequency-modulation advertisement transmitter protective cover disclosed by the invention is worthy of popularizing and using.

Owner:浙江联品电子科技有限公司

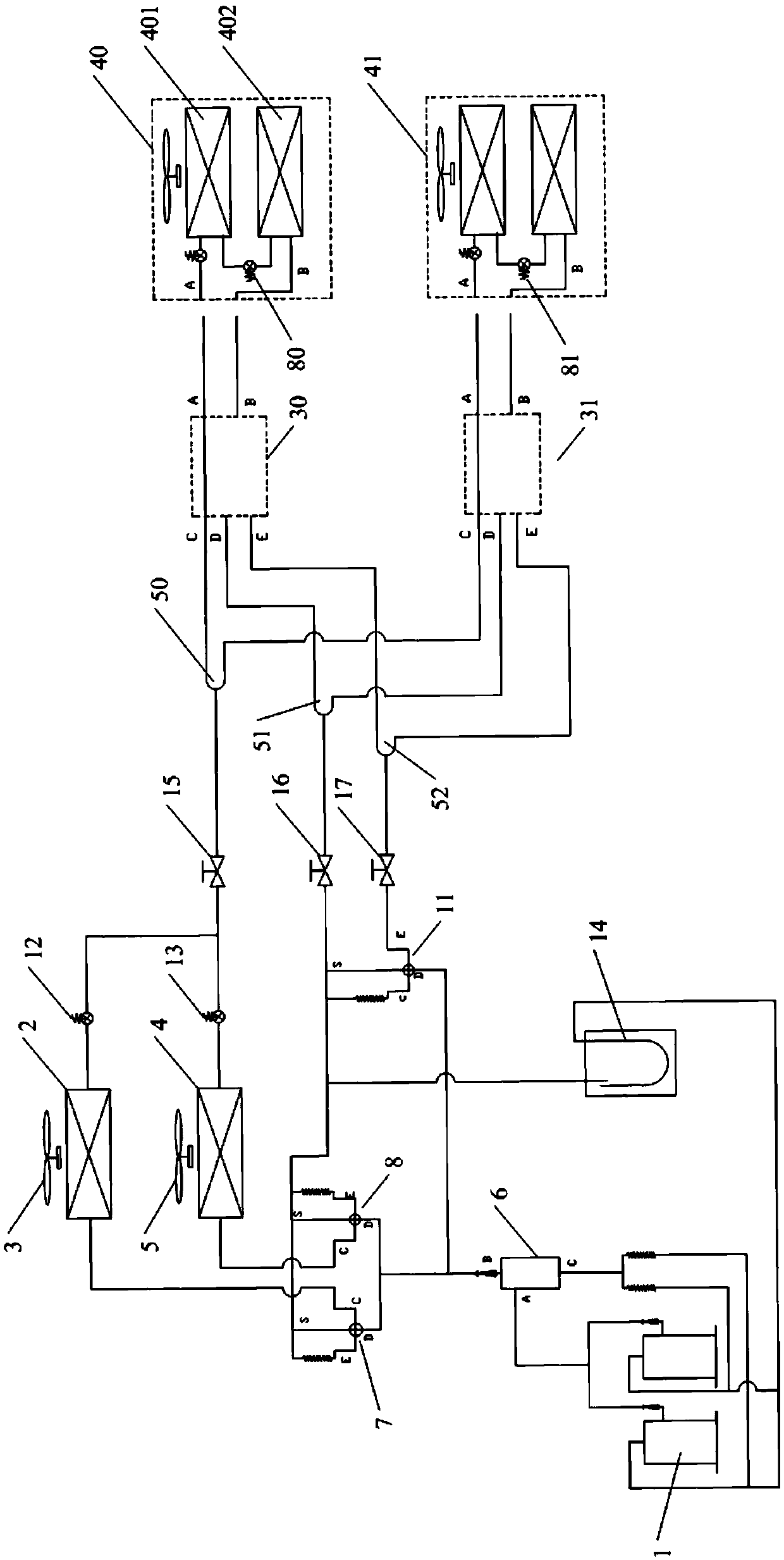

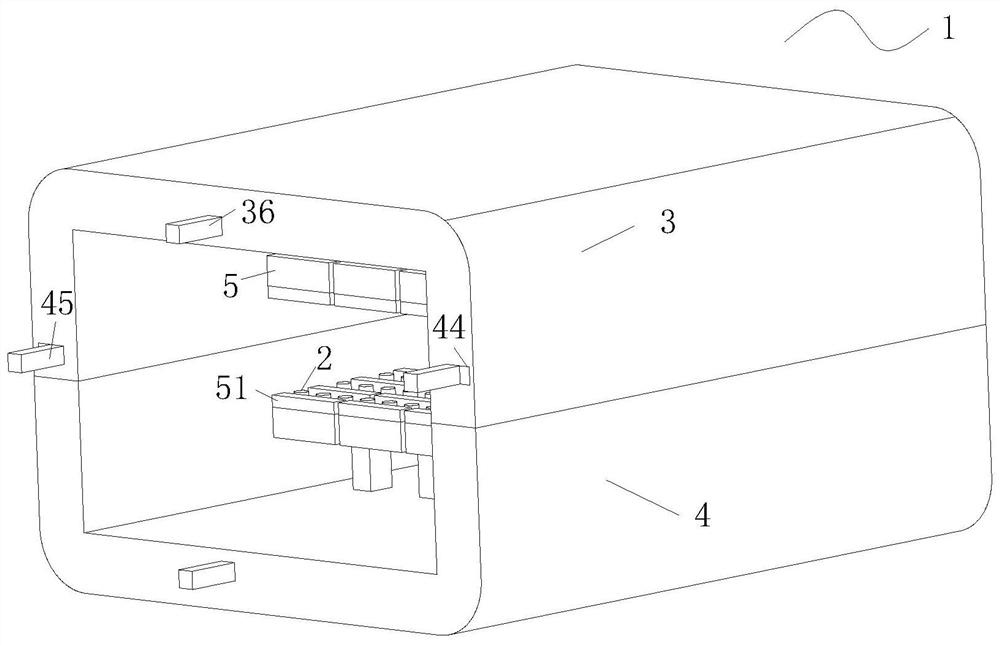

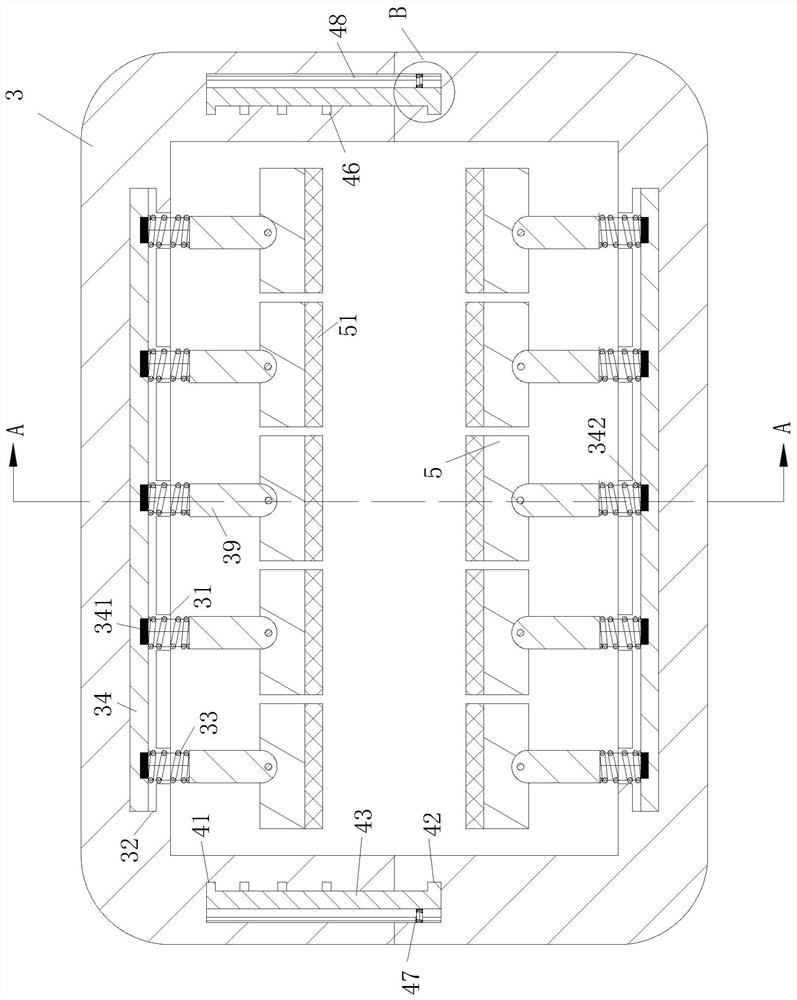

Multi-connected environment treatment system

InactiveCN105509362AAvoid burnt out situationsMechanical apparatusFluid circulation arrangementFour-way valveTurbidity

The embodiment of the invention discloses a multi-connected environment treatment system. The multi-connected environment treatment system aims to solve the problems that in the process of low-temperature or high-turbidity refrigeration and dehumidification process, the environment temperature is lowered, an air-conditioning system easily recycles liquid refrigerants and then a compressor gets burned. The multi-connected environment treatment system comprises a compressor set, a conveying four-way valve set, a recycling four-way valve set, an outdoor heat exchanger set, a refrigerant switching set and an indoor heat exchanger set.

Owner:GUANGDONG CHIGO HEATING & VENTILATION EQUIP CO LTD

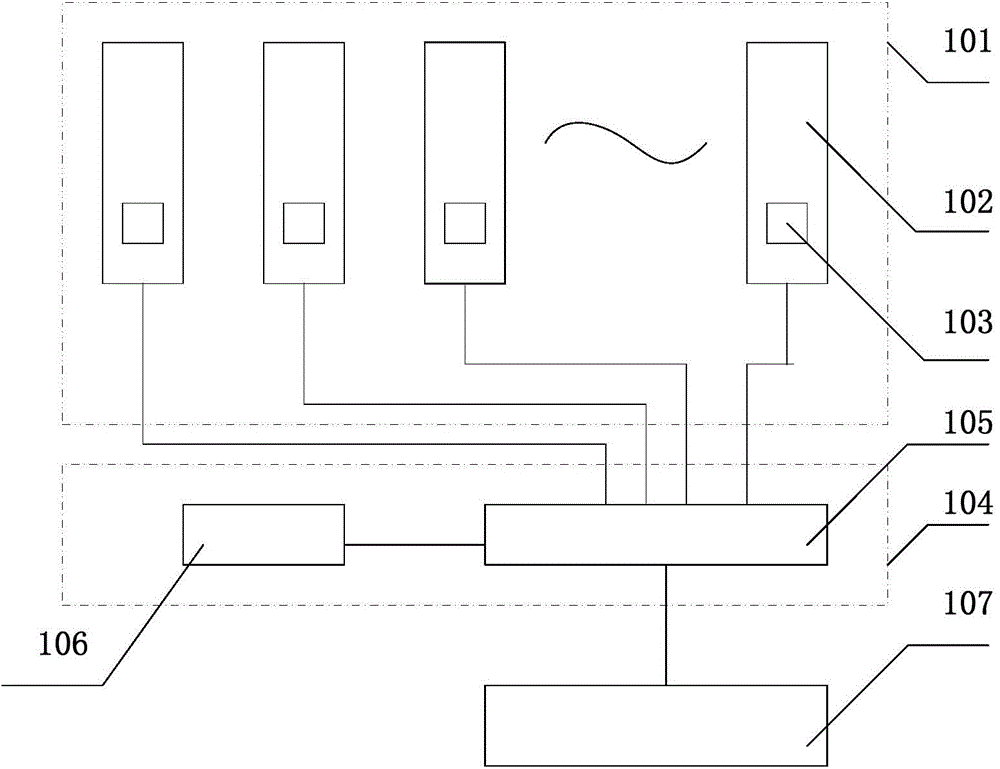

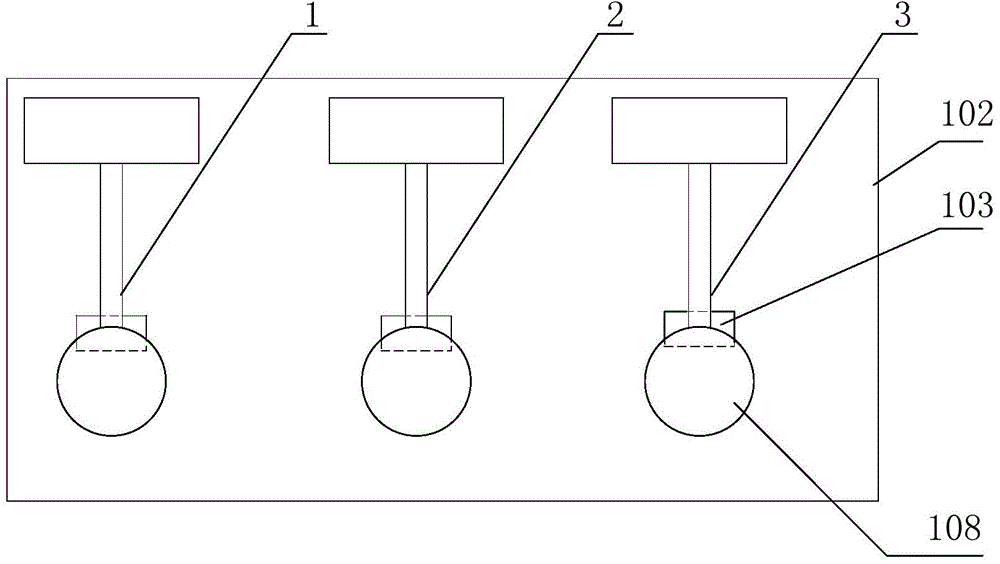

System for monitoring temperature of switching distribution cabinet online

InactiveCN104406713AAvoid burnt out situationsAccurate temperature dataThermometer detailsThermometers using physical/chemical changesMonitoring temperatureDigital signal

The invention provides a system for monitoring temperature of a switching distribution cabinet online. The system comprises a sensor, a monitoring device and an application device; the sensor is used for collecting temperature information of the switching distribution cabinet and converting the temperature information into optical information; the monitoring device is used for converting the optical information into a digital signal and warning on high temperature; the application device is used for generating the temperature information of the switching distribution cabinet and warning drive information according to the digital signal; the warning drive information is used for controlling the monitoring device to perform warning on the high temperature. The system has the advantages that external temperature information is converted into the optical information for online testing of the temperature of the switching distribution cabinet, accurate temperature data are acquired, temperature monitoring interval is shortened, temperature measuring is more timely, and burnout of the switching distribution cabinet is avoided.

Owner:STATE GRID CORP OF CHINA +1

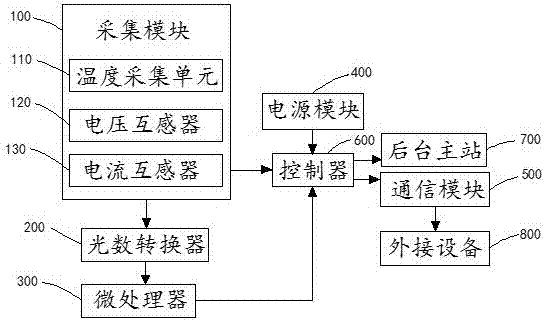

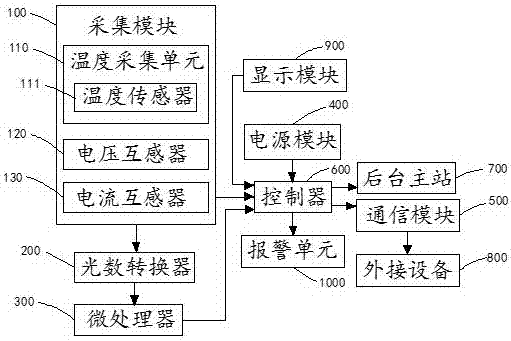

Real-time monitoring system for low-voltage power distribution cabinet

InactiveCN107171444AMonitor temperature in real timeSave manpower and material resourcesCircuit arrangementsSustainable buildingsElectricityTransceiver

The invention discloses a real-time monitoring system for a low-voltage power distribution cabinet. The real-time monitoring system comprises an acquisition module, an optical-digital converter, a microprocessor, a power supply module, a communication module and a controller, wherein the acquisition module is used for acquiring temperature information, voltage, power, electric energy and current information in the low-voltage power distribution cabinet; the optical-digital converter is used for converting optical information into a digital signal; the microprocessor generates temperature information and alarm information of the low-voltage power distribution cabinet according to the digital signal; the power supply module is used for converting an electricity-taking method; the communication module is used for establishing communication with external equipment by means of a wireless transceiving device; and the controller is used for transmitting the obtained current operating situations of the low-voltage power distribution cabinet to a background main station. The monitoring system can monitor the temperature inside the low-voltage power distribution cabinet in real time, sends out prompts and alarms timely when the temperature is too high or abnormal failure of power operation occurs, and saves the cost of manual detection and maintenance.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

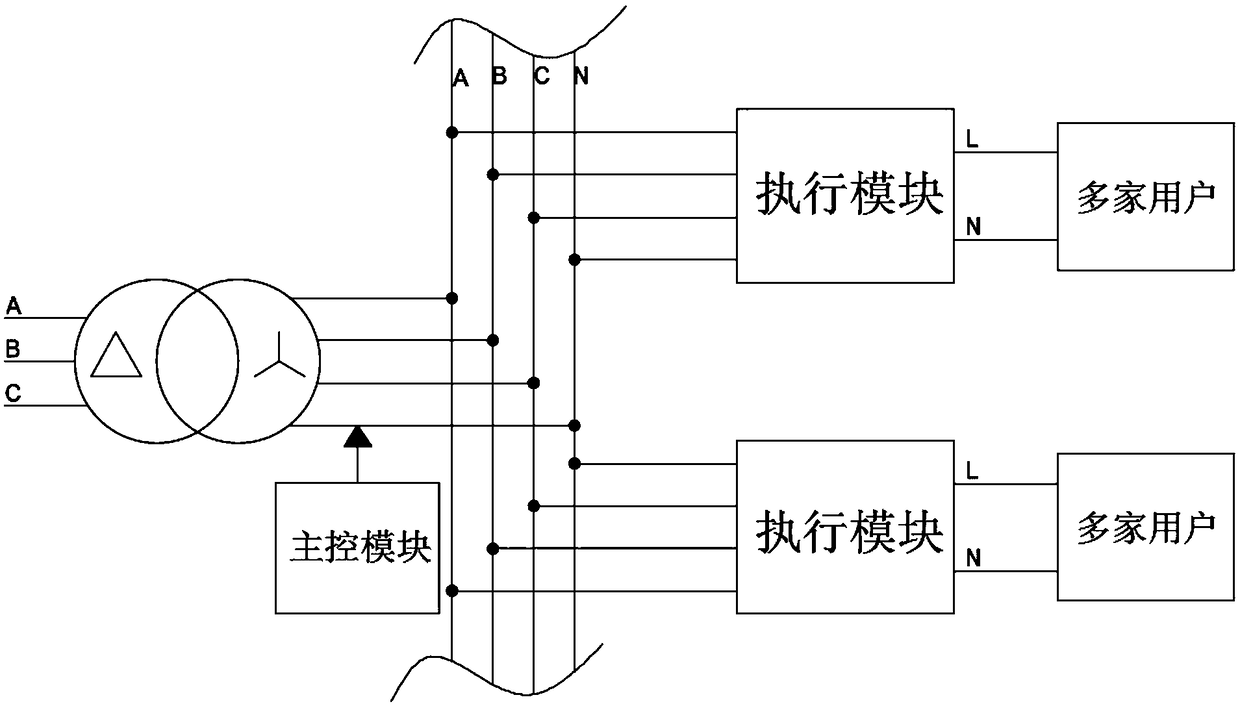

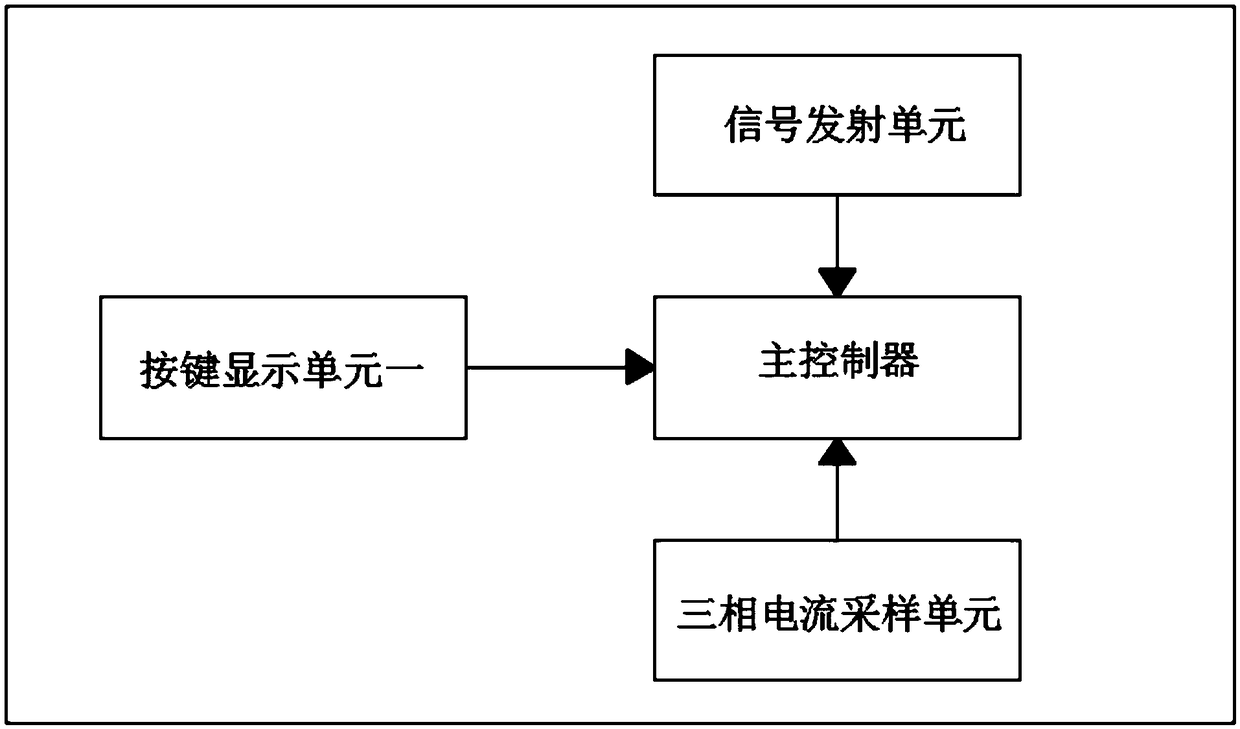

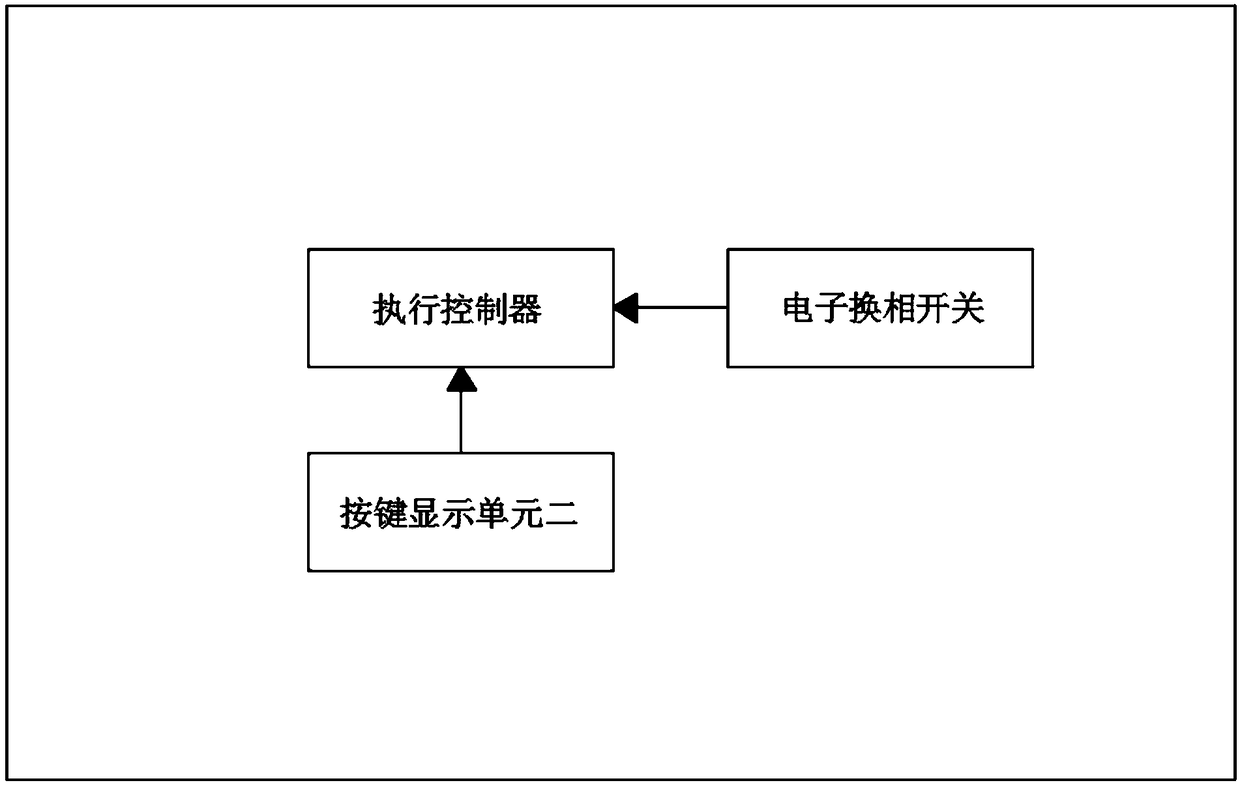

Multifunctional automatic phase changing system for medium/low voltage line and phase changing method thereof

ActiveCN108649592AReduce line lossGuarantee power qualityPolyphase network asymmetry elimination/reductionFault location by conductor typesPower qualityDistribution transformer

The invention discloses a multifunctional automatic phase changing system for a medium / low voltage line and a phase changing method thereof. The phase changing system comprises a master control moduleand multiple execution modules; each execution module corresponds to multiple users that are connected in parallel; the master control module comprises a master controller and a three-phase current sampling unit; each execution unit includes an electronic phase changing switch; and the electronic phase changing switch selects, according to a switching command, one phase corresponding to the switching command from three power supply phases of a transformer to supply a power to the multiple users corresponding to the execution modules. According to the multifunctional automatic phase changing system for the medium / low voltage line and the phase changing method thereof, the master control module and the execution modules are provided, lines in a power distribution area are divided, and the multiple execution modules are controlled via the master control module arranged at a power distribution transformer end to switch three phases of each line, so that three-phase power loads of all switched lines tend to balance; and thus, the unbalancedness of the three phases is improved, the line loss of the power distribution area is reduced, the power quality of the users is guaranteed, and thepurposes of saving the energy and reducing an electricity price are implemented.

Owner:ANHUI ZENITH ELECTRICITY & ELECTRONICS

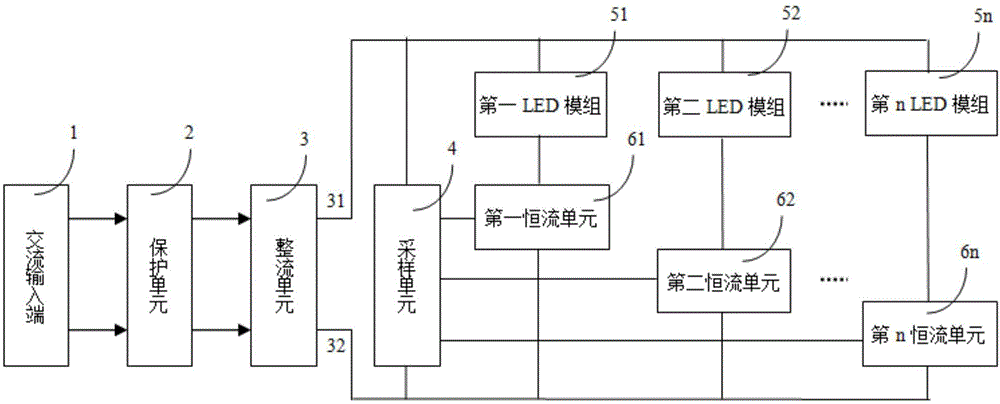

LED light source module

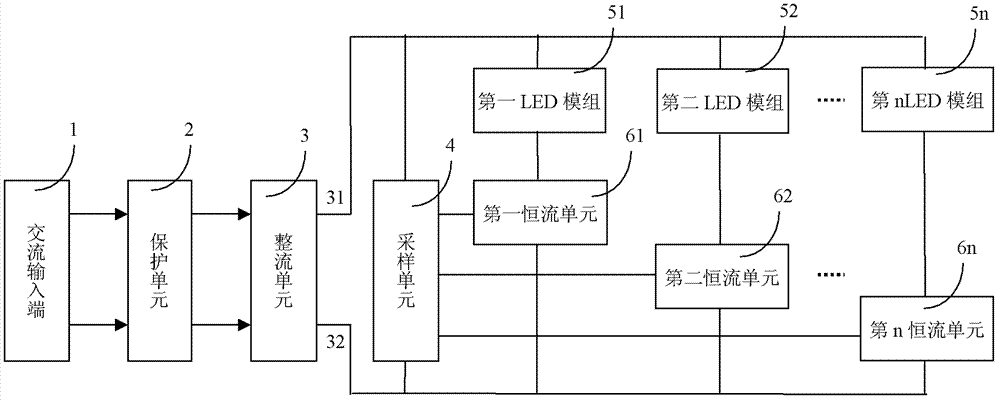

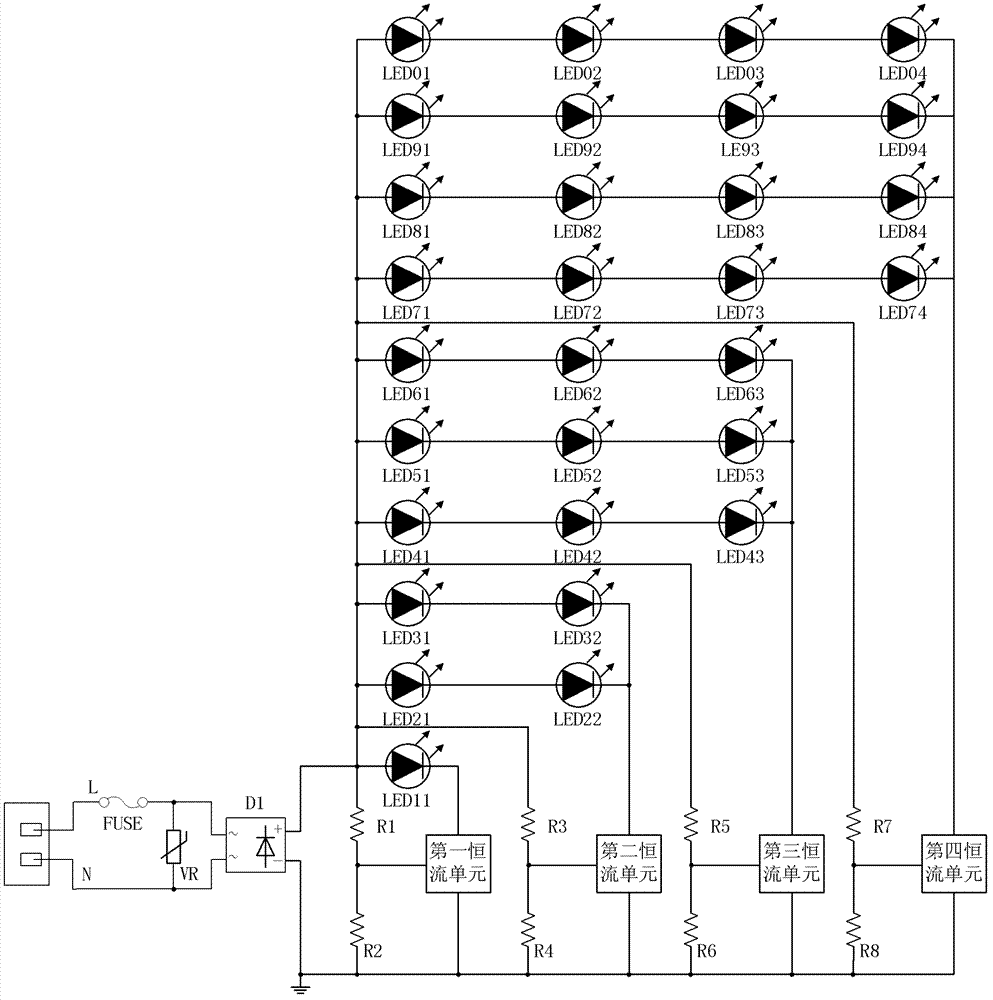

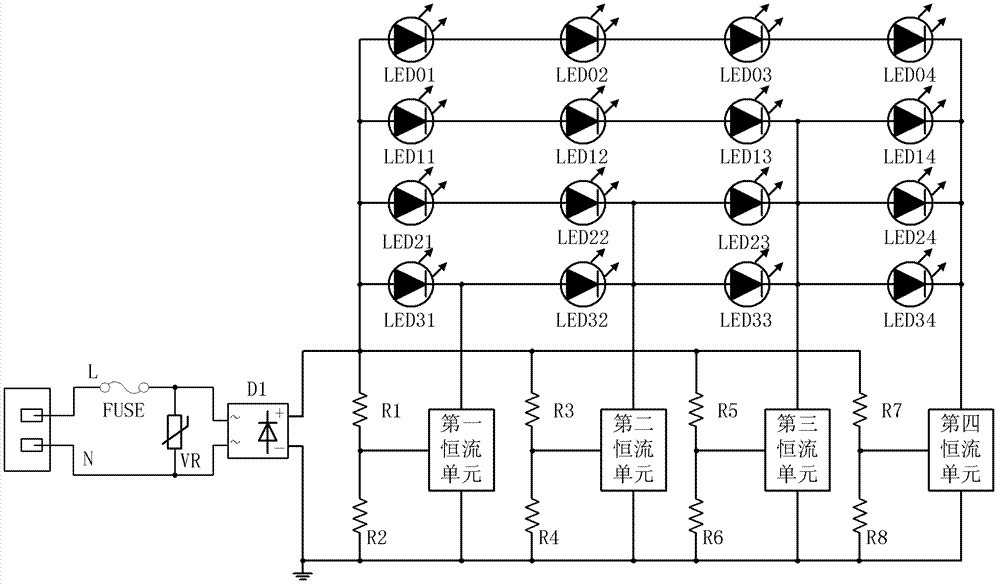

InactiveCN104582160AReduce volumeReduce weightElectric light circuit arrangementDriving currentPower flow

The invention discloses an LED light source module which comprises a sampling unit, a first branch formed through series connection of a first LED module and a first constant current unit, a second branch formed through series connection of a second LED module and a second constant current unit,... and an nth branch formed through series connection of an nth LED module and an nth constant current unit, wherein the sampling unit is connected with the constant current units; by means of different arrangement manners of LEDs in the LED modules as well as current values and turn-off and turn-on voltage set for the constant current units of the branches, the periodical blinking phenomenon caused by alternating voltage change can be avoided; current of each branch is constant, LED current change caused by junction temperature change can be prevented, and the reliability is improved; with increase of the number of branches, the drive current waveform can approximate to the form of sine wave, and power factor and efficiency of the light emitting device are improved; particularly, the LED modules are formed by the LEDs with controllable light emitting life, so that the LED blinking phenomenon caused by alternating current can be further prevented by means of LED light emitting afterglow.

Owner:SICHUAN SUNFOR LIGHT

Electric sewing machine

InactiveCN101314899BAvoid burnt out situationsSimple structureSewing-machine control devicesBobbinElectronic control system

The invention discloses an electric sewing machine which comprises a machine head, a bedplate, a stent, an electromotor and a pedal, wherein, the machine head is provided with a presser foot and a machine needle which are arranged in the position opposite to the bedplate; the presser foot is provided with a U-shaped opening; and the electromotor is provided with a clutch which is linked with the pedal through a link lever; and the electric sewing machine also comprises a bobbin thread monitoring apparatus. When the electric sewing machine works at a high speed, and conditions that bobbin threads use up or break, the stitch slips, the bobbin threads loose, etc. happen, a thread position sensor can be triggered by sewing threads on the machine needle, and a signal can be given out to impel the bobbin thread monitoring apparatus to act and enable the electric sewing machine to stop. The bobbin thread monitoring apparatus has the advantages of simple structure and low manufacturing cost, and no need of a complicated electronic control system for realizing the bobbin thread monitoring; and the machine can be stopped when no bobbin thread exits and the bobbin threads breaks, or the stitch slips or the bobbin threads loose, thereby realizing the effect that the sewing material is effectively utilized, saving resources, reducing the product rework rate, and improving the production efficiency.

Owner:李永鹏

White-light light emitting diode (LED) light-emitting device directly driven by alternating current

ActiveCN103188850AMature technologyRapid responseElectrical apparatusSemiconductor lamp usageEngineeringAlternating current

The invention relates to a white-light light emitting diode (LED) light-emitting device. Specific to the defects of light emitting flicker caused by directly driving an LED light-emitting device by alternating current in the prior art, the invention discloses a white-light LED light-emitting device directly driven by alternating current. The white-light LED light-emitting device directly driven by the alternating current is matched with LED modules formed by light-emitting service life controllable LEDs, LED light-emitting afterglow can be used for further overcoming the phenomenon of the LED flicker caused by the alternating current, efficiency of the LED light-emitting device is improved, and service life of the LED is prolonged. An LED light-emitting device circuit is composed of n levels of LED modules in cascade connection, a sampling unit is used for properly presetting turn-off and switch-on voltages of each level of LED modules corresponding to a switch unit, and therefore flicker phenomenon caused in the process of alternating voltage fluctuation can be avoided. By particularly by applying the light-emitting service life controllable LEDs, the flicker phenomenon is further overcome, the effect is obvious with increase of the number of the LED modules.

Owner:四川能投智慧光电有限公司

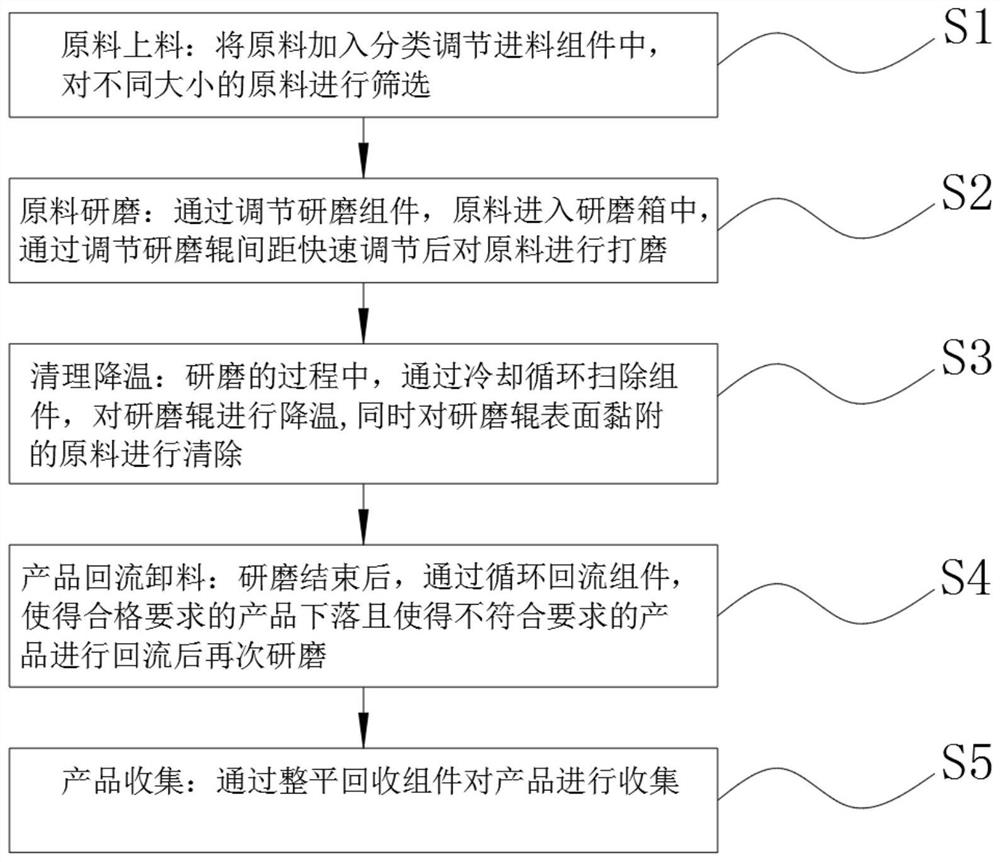

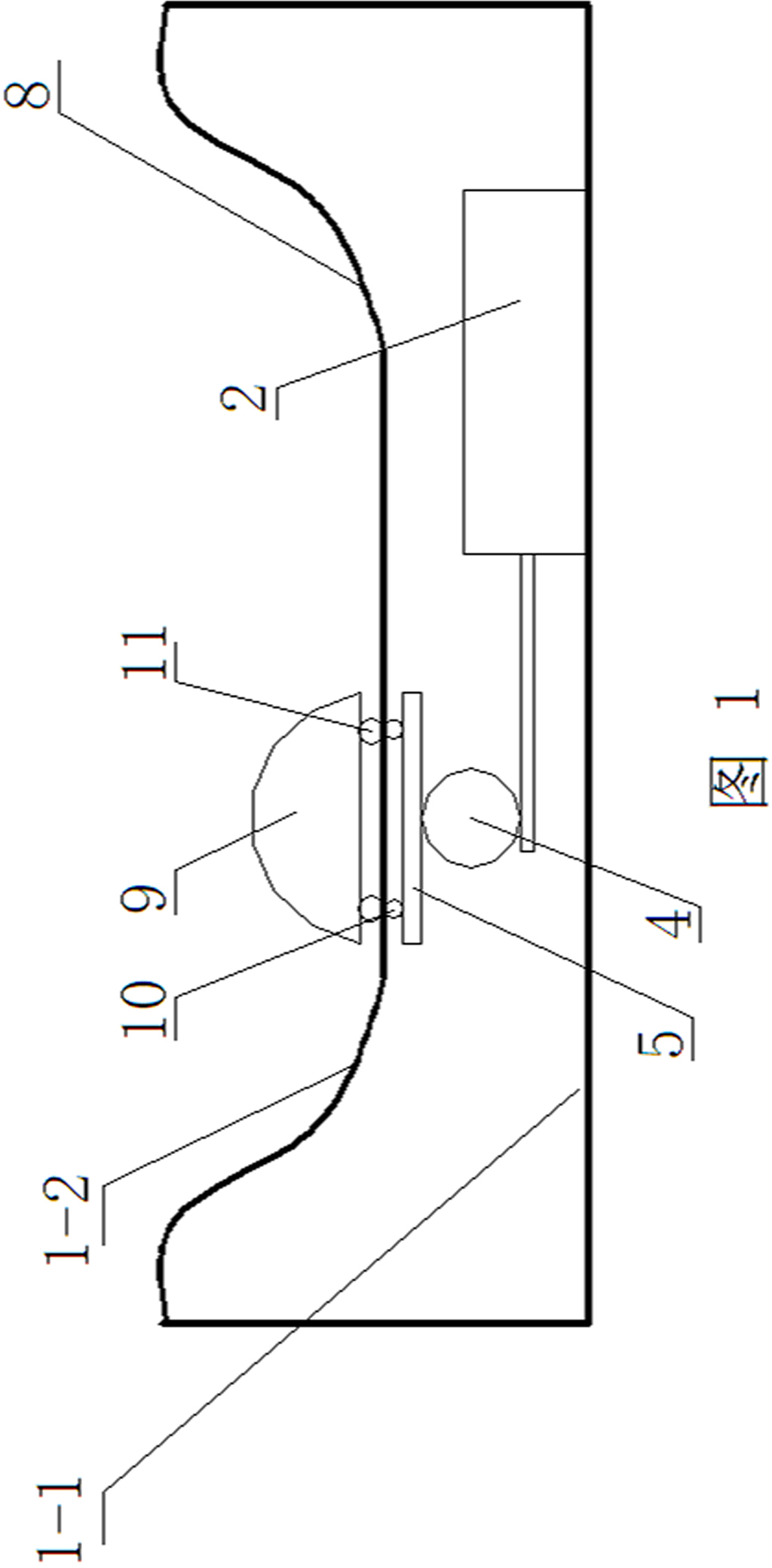

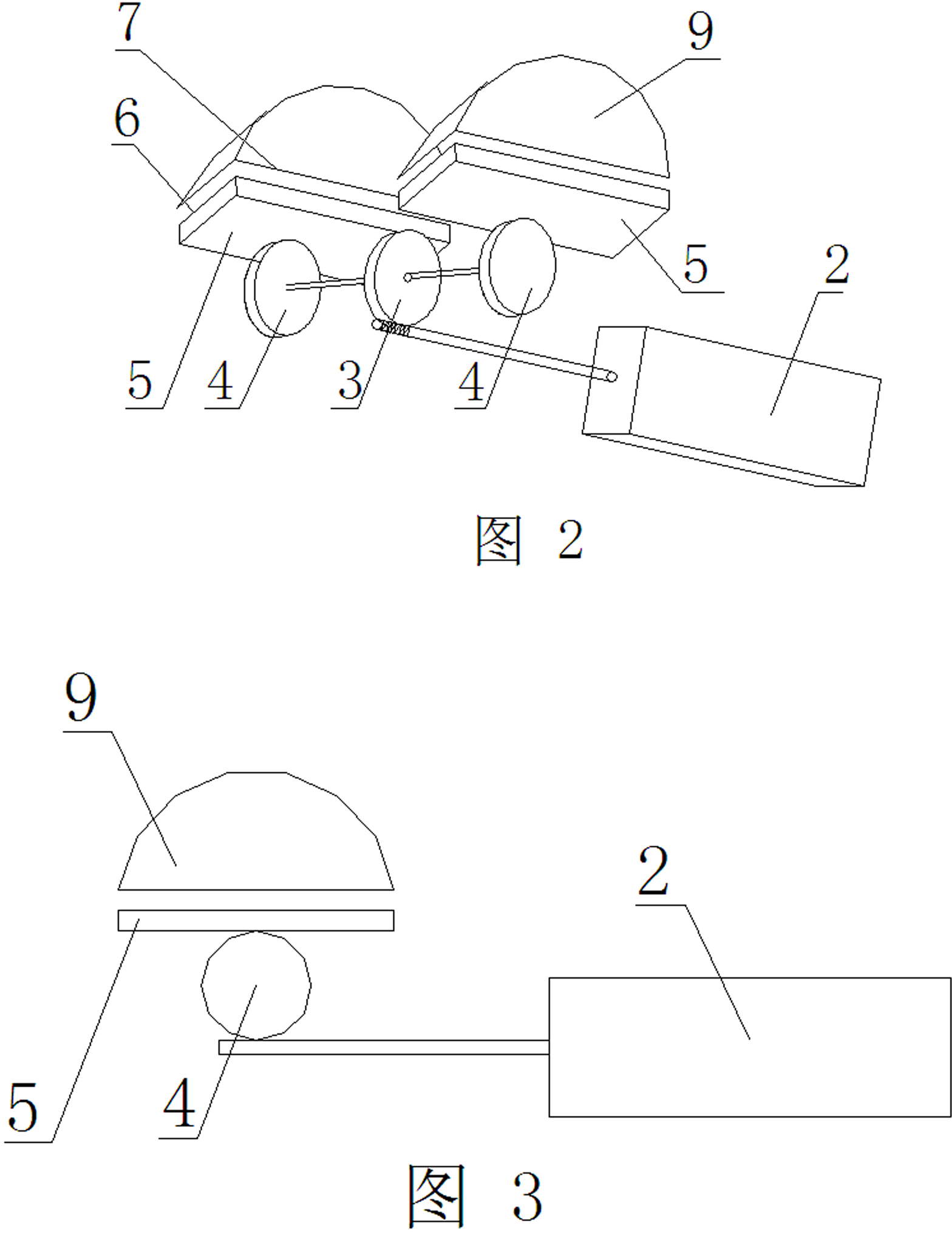

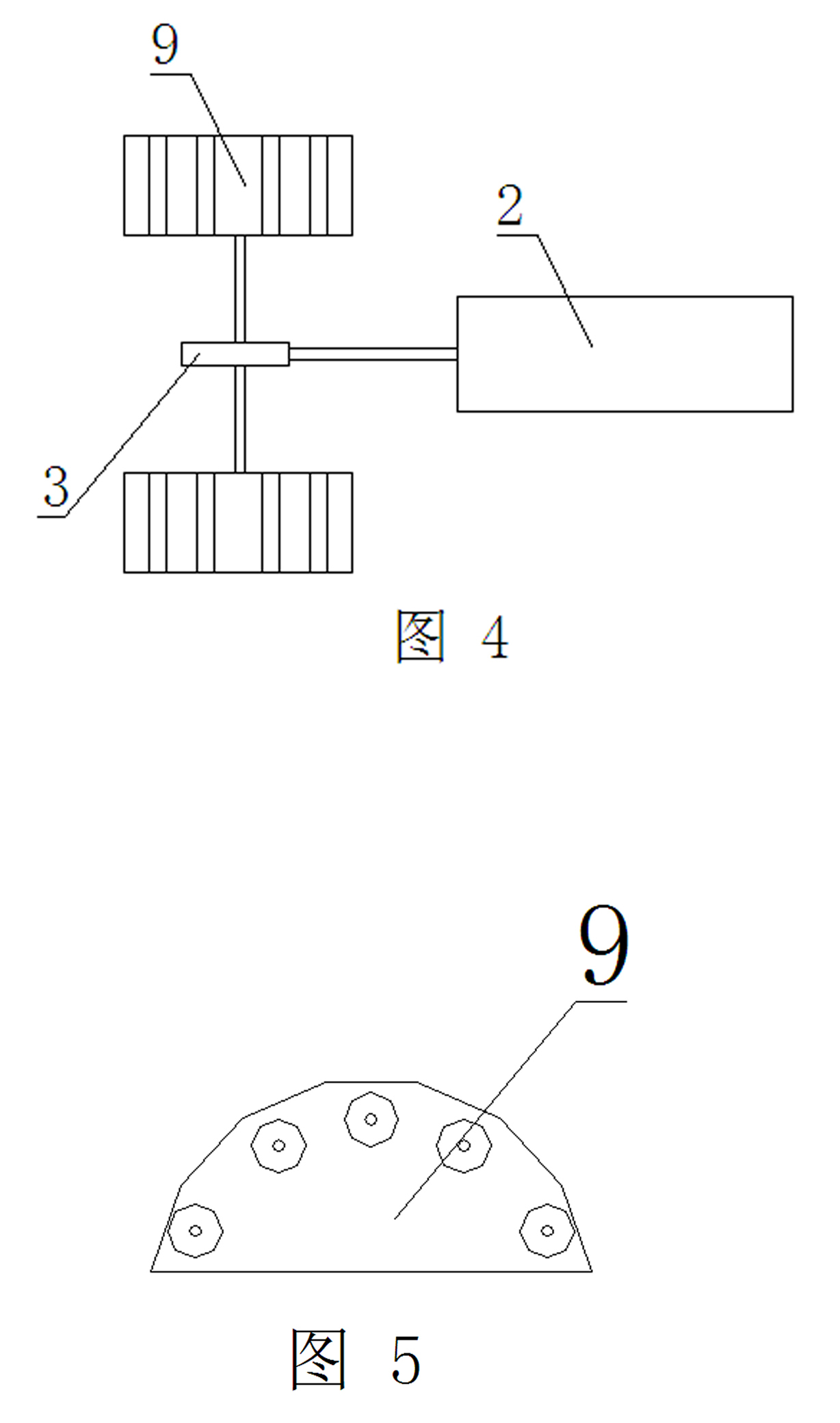

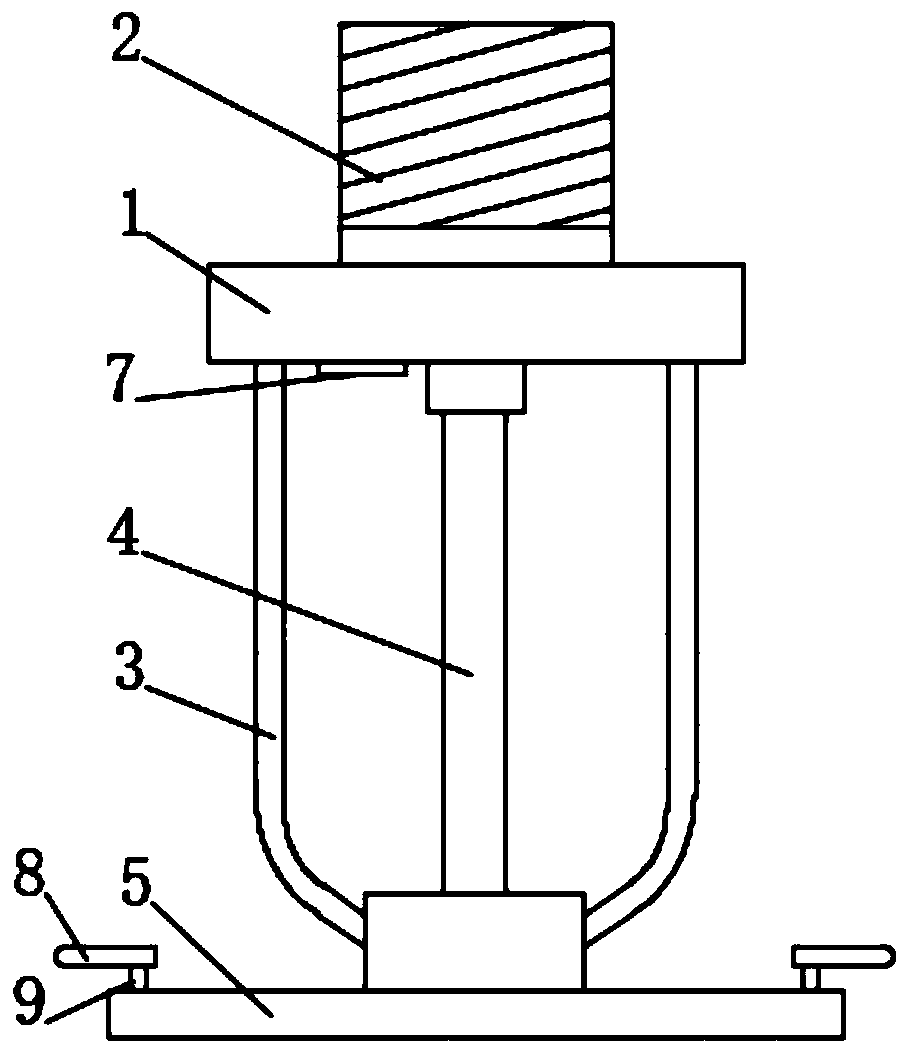

Preparation method for heat-conduction insulation silicone grease

ActiveCN111841719AScientific and reasonable structureSafe to useGrain treatmentsThermal insulationGrinding

The invention discloses a preparation method for heat-conduction insulation silicone grease. The preparation method comprises a grinding box, wherein an installation rod is installed between the innerwalls of the grinding box through bolts; two ends of the installation rod are independently provided with a T-shaped groove; a T-shaped block is independently in sliding connection in each T-shaped groove; a shaking plate is in sliding connection in a shaking groove; the middle of the outer side of a rotary shaft is fixedly sheathed with a convex rod; two ends of the top surface of a filtering net are independently welded with a convex block; one end of the grinding box is provided with a fan; and positions, which are positioned on the bottom end positions of two bearing plates, of one end ofthe fan are independently connected with an air blowing pipe. Compared with the prior art, the preparation method is characterized in that a grinded product carries out inclined circular-arc movement, so that the product is even in dispersion to achieve a purpose of even blanking. A bottom end blocking problem of the grinding box enables raw materials which are not completely grinded to form circular arc shaped reflux, through the circular arc shaped reflux, the raw materials which are not completely grinded can enter between two grinding rollers along a raw material falling tangent direction, grinding quality and efficiency can be improved, and the problem of incomplete grinding is avoided.

Owner:苏州晶之电科技有限公司

Magnetic driven walking massager

InactiveCN101879121AEliminate the hidden danger of leakageReduce structural linksElectrotherapyBathsElectric machineryMassager device

The invention provides a magnetic driven walking massager with simple structure, safety and reliability. The magnetic driven walking massager comprises a massaging device and a driving device for driving the massing device to move, the driving device comprises a motor, a transmission device driven by the motor, and a magnetic driving device arranged between the transmission device and the massaging device; the magnetic driving device is formed by two magnetic boards which are not mutually connected and respectively provided with a magnetic material, one end of the one magnetic board is connected with the transmission device which drives the magnetic board, and one end of the other magnetic board is connected with the massaging device which is driven by the magnetic board to do walking and translational motion. The invention has the advantages that due to the adoption of a novel driving mode combining motor driving and magnetic material driving, the motions inside and outside a foot bath basin can be realized without mutually connected driving shafts, thus the water bath inside the foot bath basin is completely isolated with the motor outside the foot bath basin, thereby putting and end to the hidden danger of electric leakage.

Owner:FUAN AOBAILI ELECTRONICS

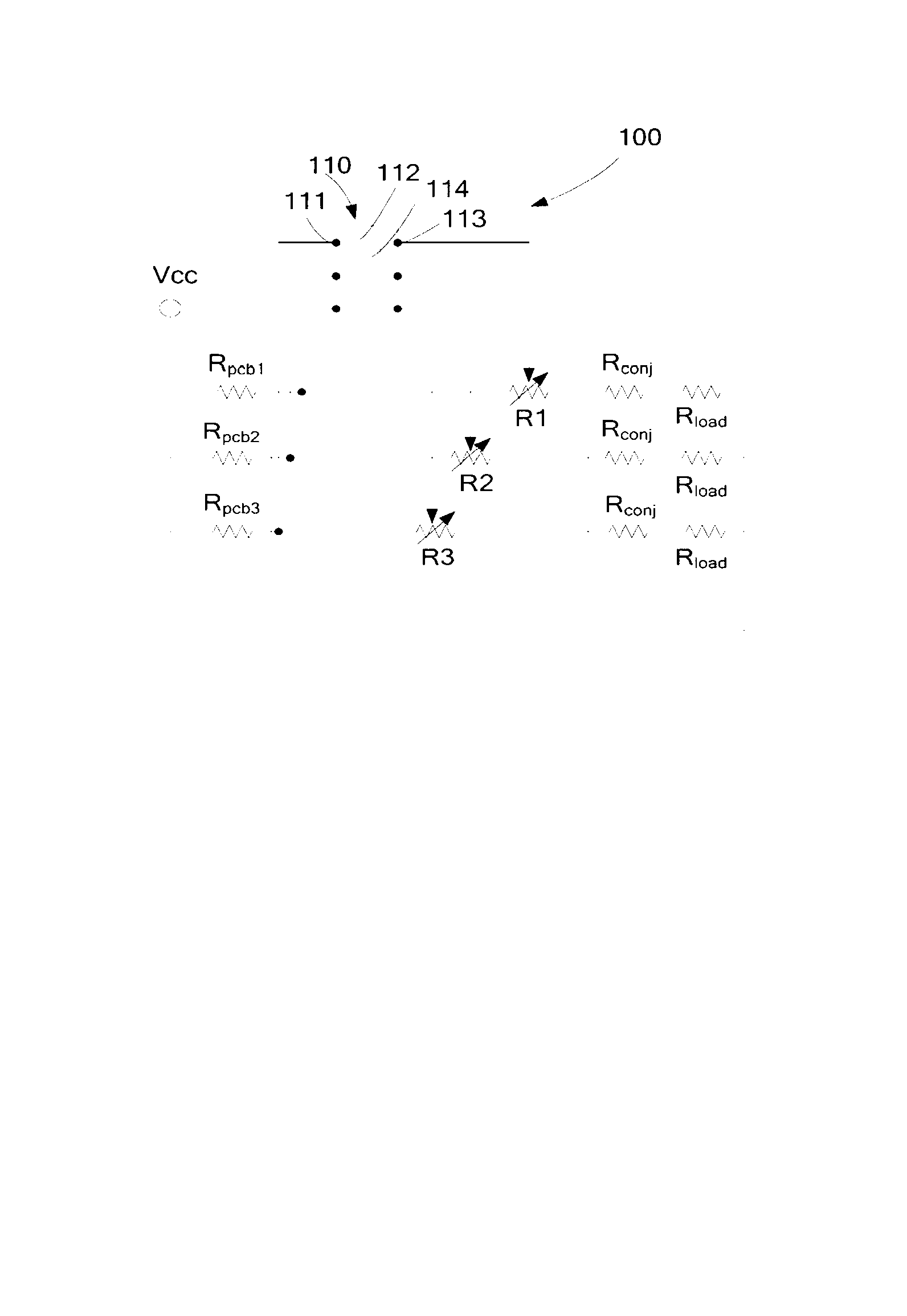

Light emitting diode (LED) luminous device directly driven in constant current by alternating current

ActiveCN103200729AIncrease powerImprove efficiencyElectrical apparatusElectric light circuit arrangementPower factorJunction temperature

The invention relates to an alternating current direct constant current driving technology of a light emitting diode (LED) luminous device, discloses the LED luminous device directly driven in a constant current by an alternating current, and aims at the problem that the LED luminous device is directly driven by the alternating current in the prior art. The technical scheme includes that a parallel branch composed of n LED modules and a constant current unit connected in series is connected on the output end of a rectifying circuit, and cyclical flickering phenomenon caused by alternating voltage change can be avoided by setting current values, turn-off voltages and connecting voltages of branch constant current units. Because current of each branch is constant, LEDs in the LED modules can not cause current change because of change of junction temperature, and reliability is improved. Increasing of branch numbers enables a wave form of a driving current to approach a sine wave, and power factor and efficiency of the luminous device are improved through theory analysis.

Owner:四川能投智慧光电有限公司

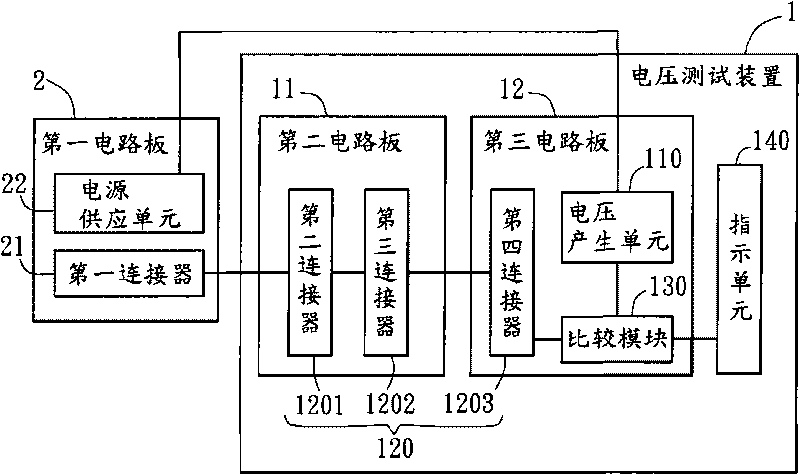

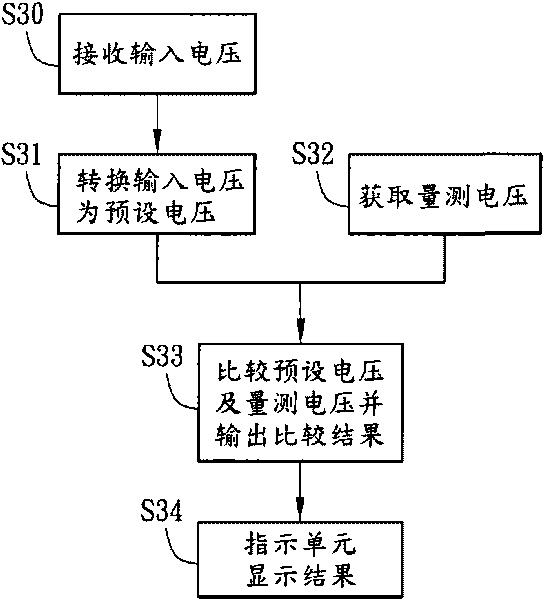

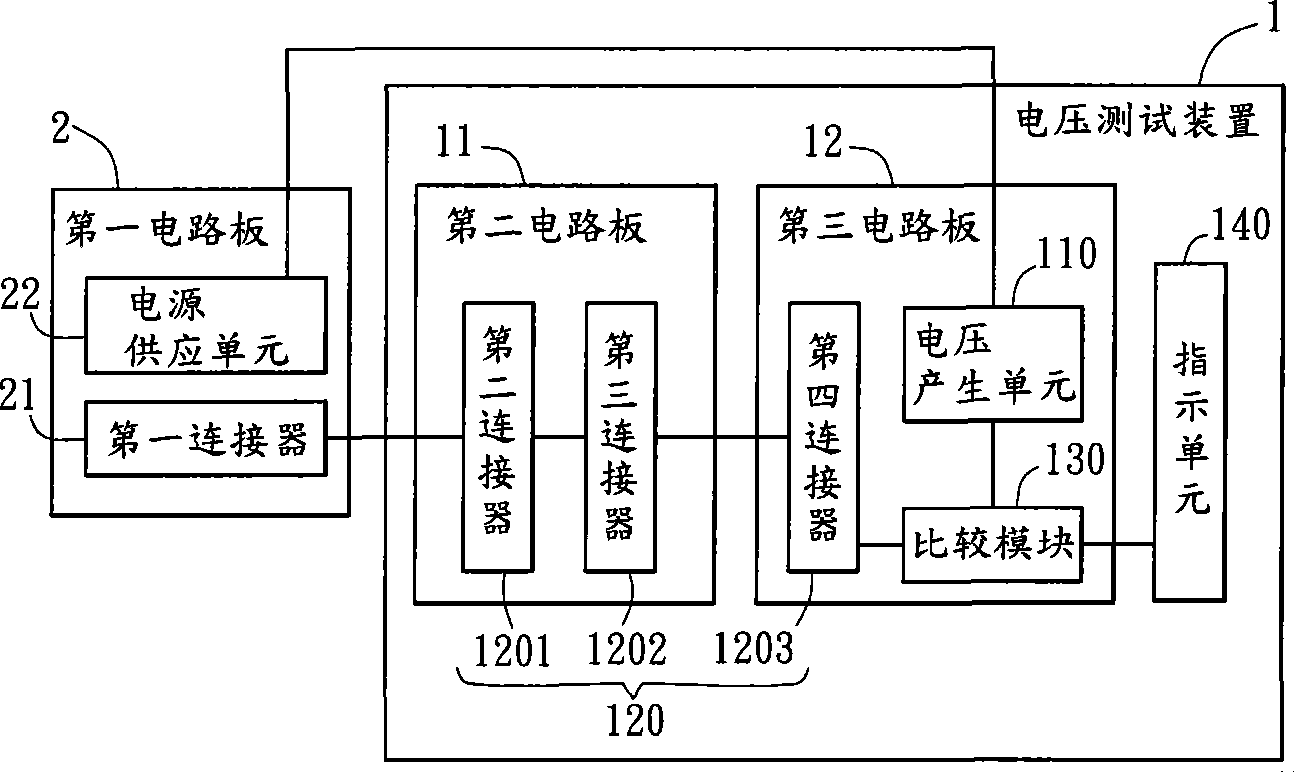

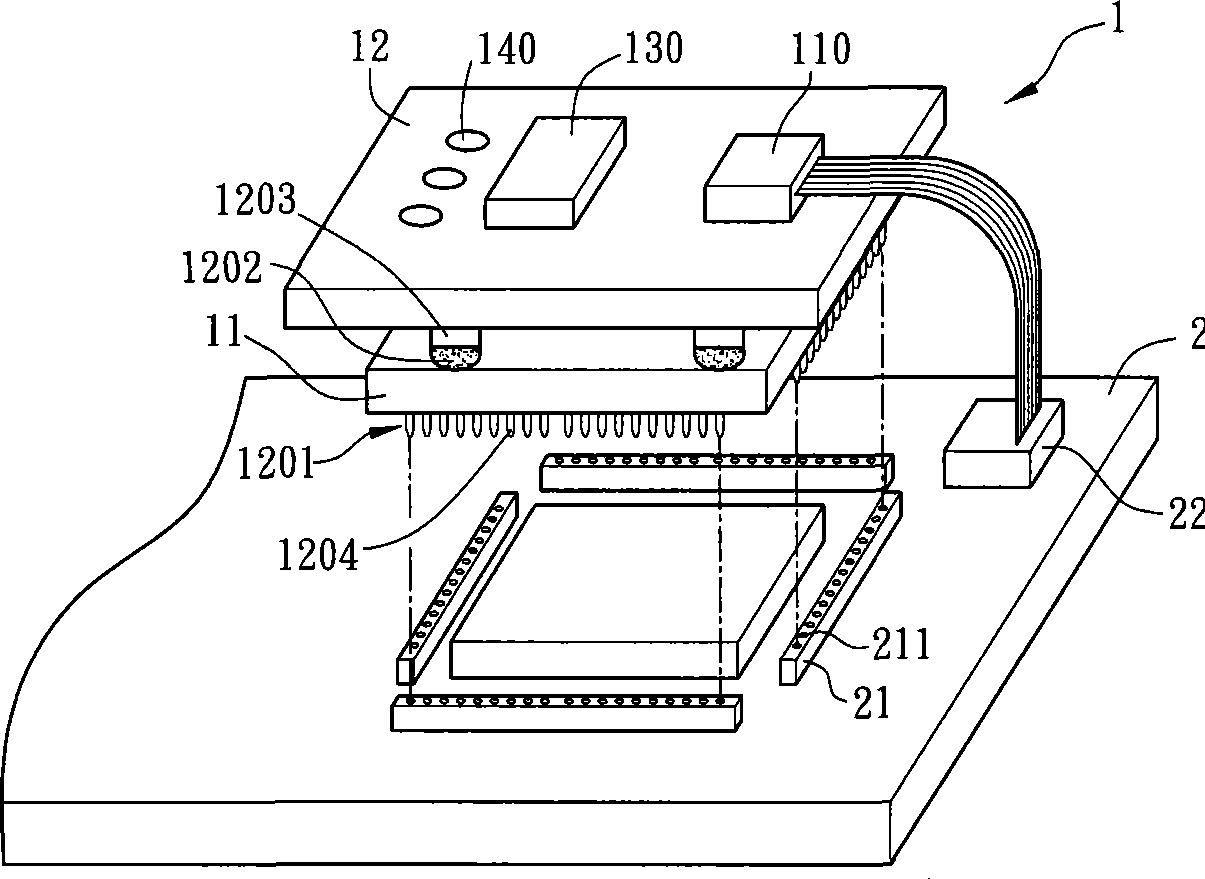

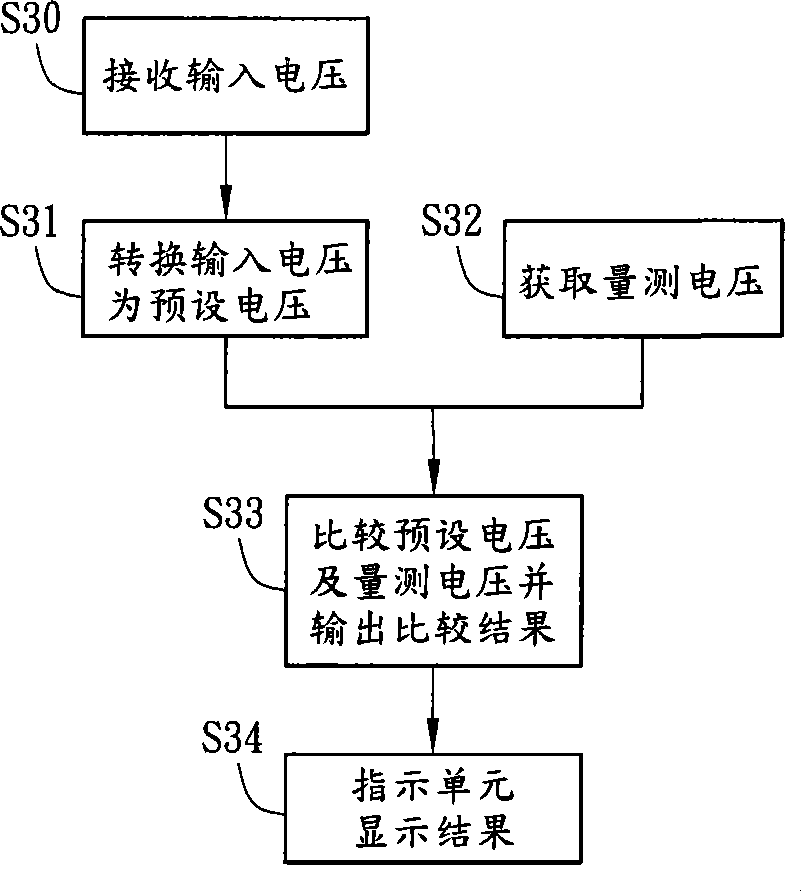

Voltage test device and voltage test method

ActiveCN101738534ADetect power supply capabilityAvoid burnt out situationsElectronic circuit testingCurrent/voltage measurementFistEngineering

The invention discloses a voltage test device and a voltage test method. The voltage test device is used to test a first circuit board, wherein the circuit board comprises a fist connector. The voltage test device is couple with a power supply unit so as to obtain input voltage from the power supply unit, and the power supply unit provides a power supply for the first circuit board. The voltage test device comprises a voltage generating unit, a connection part and a comparison module, wherein the voltage generating unit is used to receive the input voltage and converts the input voltage to a preset voltage; the connection part is used to be coupled with the fist connector of the first circuit board and obtain a first measurement voltage from the fist connector; and the comparison module is coupled with the connection part and the voltage generating unit separately, receives the first measurement voltage and the preset voltage and compares the first measurement voltage with the preset voltage to provide the test result.

Owner:MINGSHUO COMP (SUZHOU) CO LTD +1

Heat-sensitive sensor and temperature measuring method

PendingCN113790812AExtended service lifeImprove user experienceThermometer detailsThermometer applicationsEngineeringMechanical engineering

The invention relates to the technical field of sensors, in particular to a heat-sensitive sensor and a temperature measuring method. The heat-sensitive sensor comprises shells, a sensor and a controller, wherein first grooves are uniformly formed in the corresponding inner end surfaces of a first shell and a second shell; a second groove communicates with a cavity; one end of a sliding rod is fixedly connected with the bottom of the second groove through a second spring; the end, away from the first shell, of a first spring is fixedly connected with a movable column; a clamping plate is hinged to the end, away from a fixing plate, of the movable column; and the surface of the clamping plate is fixedly connected with the sensor. According to the invention, limiting of the fixing plate is released by pressing the sliding rod, and then the fixing plate drives the first spring and the movable column to drive the clamping plate to clamp a lithium battery, so the purpose that the sensor is not damaged when the lithium battery is installed is achieved, temperature detection can be carried out on lithium batteries of different shapes, the application range of the heat-sensitive sensor is improved, and the service life of the heat-sensitive sensor is prolonged.

Owner:王林成

led dimming drive circuit

ActiveCN104540287BColor temperature adjustableColor adjustableElectric light circuit arrangementDriver circuitTerminal voltage

The invention relates to an LED dimming driving circuit, which includes a rectifying unit and an N-level LED direct current driving circuit. Wherein, the i-th LED DC drive circuit is composed of an i-th voltage sampling unit, an i-th switching unit and an i-th LED light source module. N is a natural number, i=1,2,3,...,N; the first end of the i-th voltage sampling unit and the input end of the i-th LED light source module are jointly connected to the first output end of the rectification unit when i is 1 , when i is not 1, they are commonly connected to the output end of the i‑1th LED light source module. The second end of the i-th voltage sampling unit is grounded, and the voltage dividing end of the i-th voltage sampling unit is connected to the second input end of the i-th switch unit. The first input end of the i-th switch unit is connected to the output end of the i-th LED light source module, and the output end of the i-th switch unit and the second output end of the rectification unit are grounded. The invention is compatible with traditional thyristor dimmers, and realizes adjustment of brightness, color temperature or color without separate wiring.

Owner:SICHUAN SUNFOR LIGHT

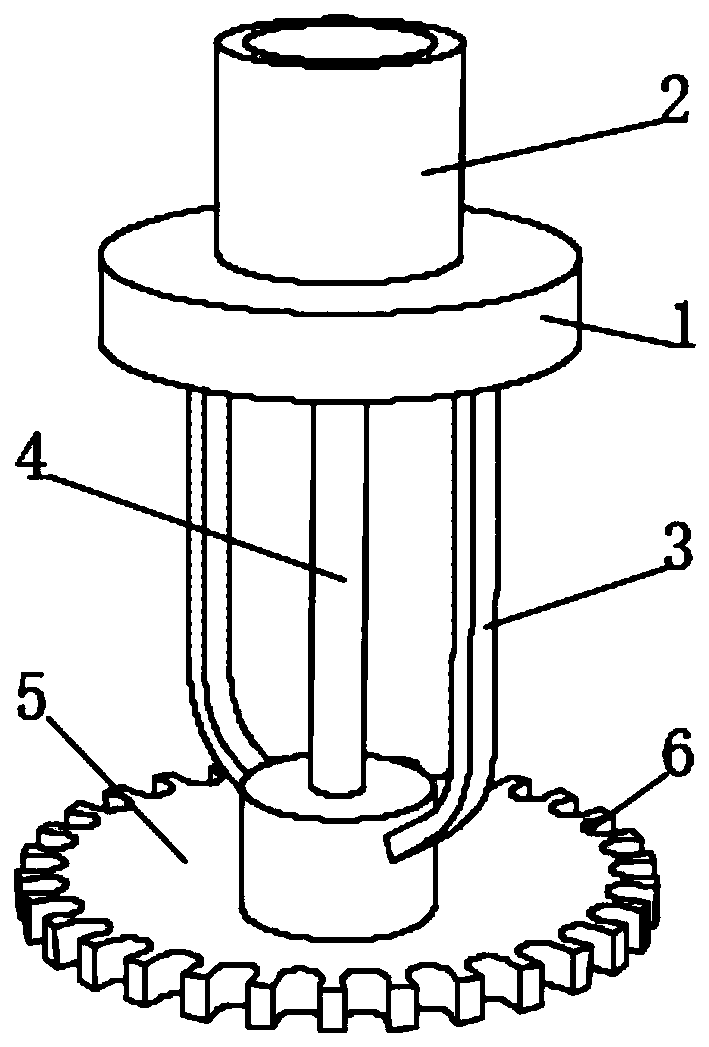

Fire-fighting long-distance spraying power-assisted nozzle and application method thereof

ActiveCN111214793AIncrease the areaExpand the spraying rangeFire rescueStructural engineeringCentrifugal force

The invention discloses a fire-fighting long-distance spraying power-assisted nozzle and an application method thereof, and belongs to the field of fire-fighting nozzles. The fire-fighting long-distance spraying power-assisted nozzle comprises a nozzle body, wherein a threaded connecting end is fixedly connected to the upper end of the nozzle body, and a splash disk is arranged at the lower end ofthe nozzle body. According to the fire-fighting long-distance spraying power-assisted nozzle and the application method thereof, through the arrangement of a power-assisted diffusion ring, the power-assisted diffusion ring can be controlled to diffuse when the fire spreading temperature is too high, and a plurality of superposed diffusion plates on the power-assisted diffusion ring further diffuse and unfold under the action of centrifugal force, so that on one hand, the area of water spraying and the water spraying amount per unit time are increased, on the other hand, the water spraying range is also increased under the action of centrifugal force, and the effect of power-assisted water spraying is achieved; and meanwhile, the water spraying effect of a nozzle in the prior art is matched, and the double water spraying can effectively improve the suppression effect of the fire-fighting nozzle on fire spread, so that more reaction time is gained for firefighters, and the safety is obviously improved.

Owner:东莞市美泰喷雾技术有限公司

Starting circuit for automobile

ActiveCN103807077AAvoid burnt out situationsPrevention of burnt caseElectric motor startersMachines/enginesElectricityEngineering

Provided is a starting circuit for an automobile. The starting circuit for the automobile comprises a storage battery, a battery main switch and a starter, wherein the positive pole of the storage battery is connected with one end of the battery main switch through a power line, the other end of the battery main switch is connected with the positive pole of the starter through a starter positive wire, the negative pole of the starter is connected with the negative pole of the storage battery through a negative bond strap, a bonding piece is arranged on the negative bond strap, the bonding piece is connected with a common bonding point on a frame, the positive pole of the storage battery is connected with the input end of a finished automobile electrical appliance constant-electricity load and the input end of a finished automobile electrical appliance non-constant-electricity load, and the output end of the finished automobile electrical appliance constant-electricity load and the output end of the finished automobile electrical appliance non-constant-electricity load are connected with the common bonding point and other bonding points on the frame through a frame harness respectively. According to the starting circuit for the automobile, the phenomenon that electricity of the starting circuit goes to other circuits by mistake can be effectively prevented, the phenomena that the electricity goes to a frame harness by mistake and a fire breaks out are effectively avoided, safety and reliability are high, and the application range is wide.

Owner:DONGFENG COMML VEHICLE CO LTD

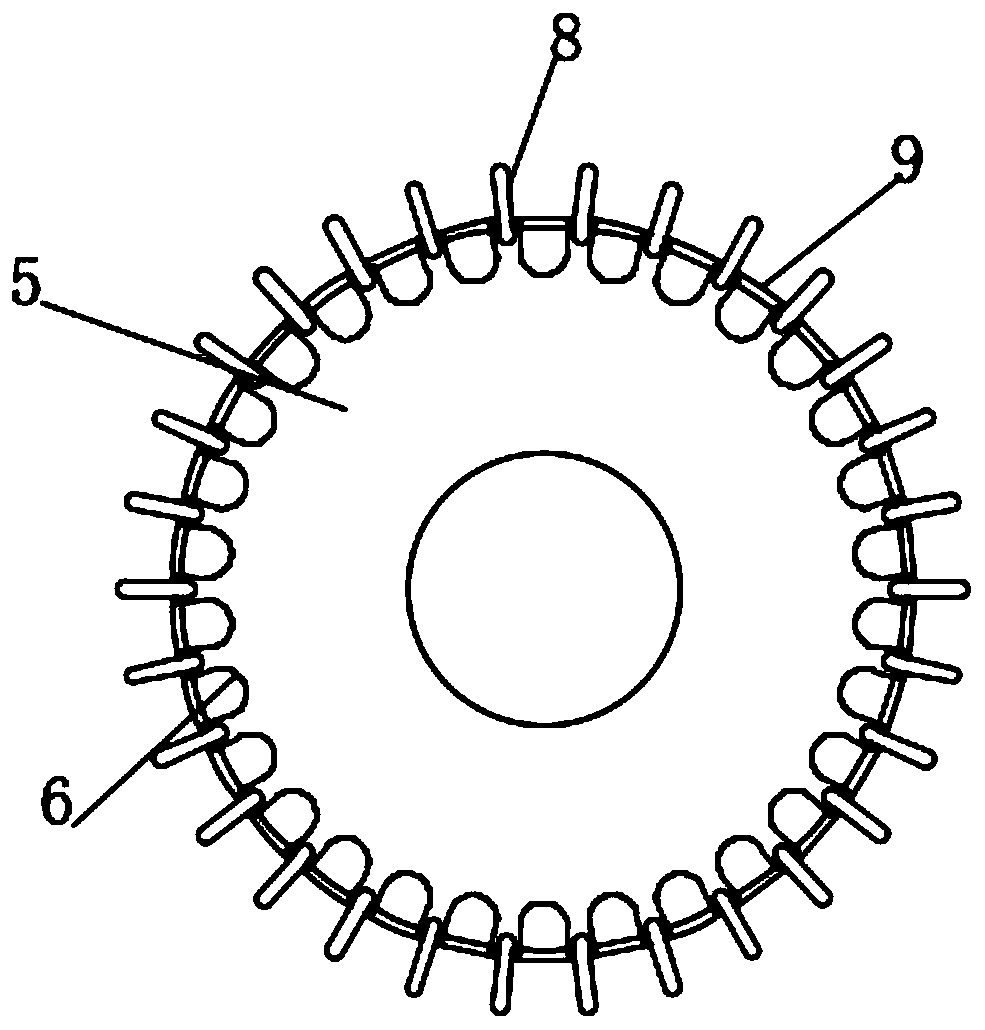

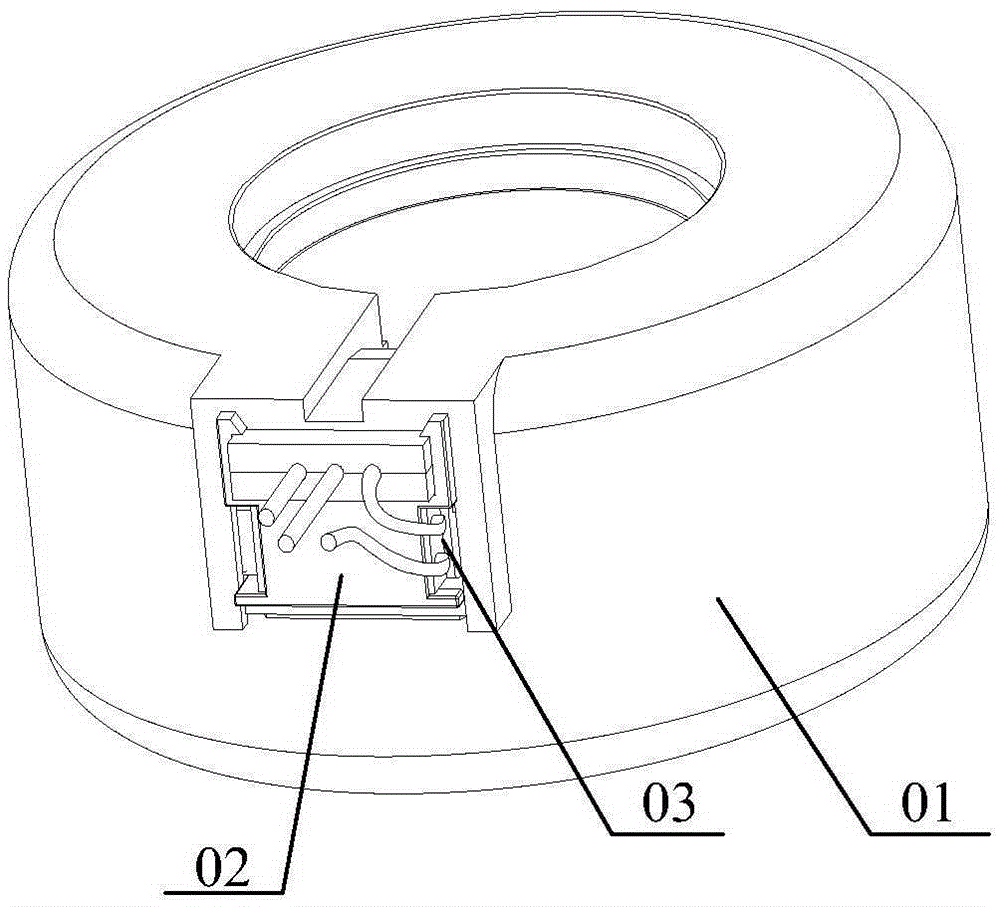

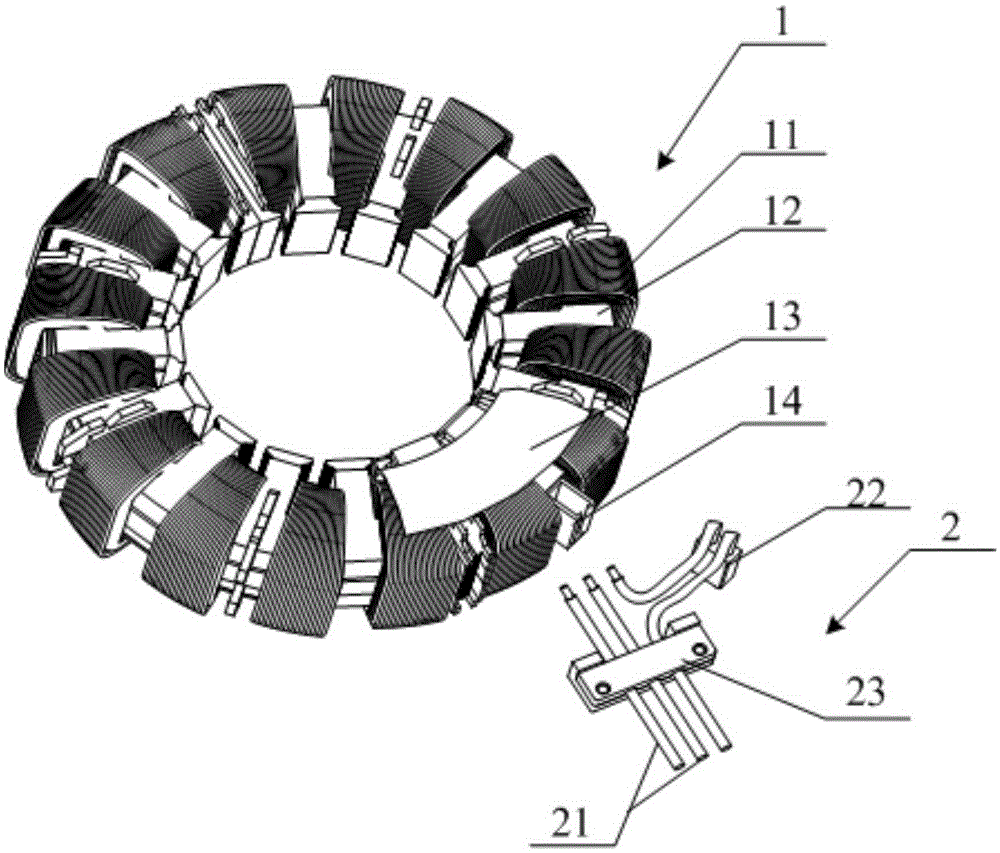

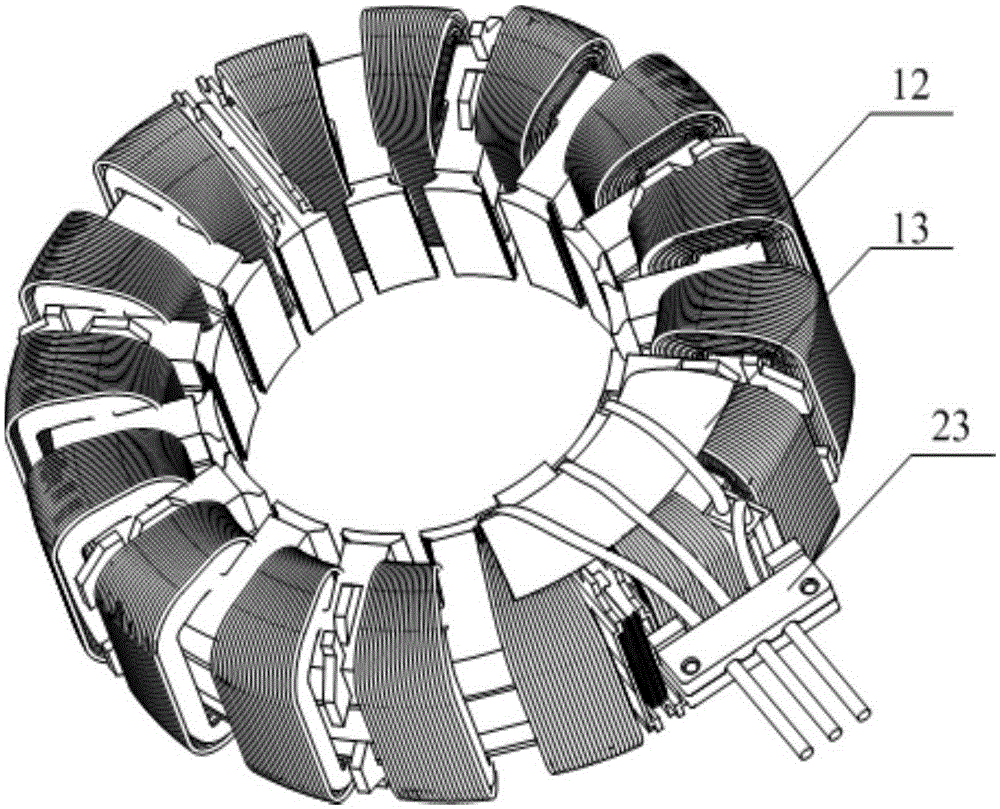

Plastic package motor, plastic package stator and air-conditioner indoor unit

ActiveCN105305729ASmall sizeFacilitate the development of light and thinWindings insulation shape/form/constructionStructural associationEngineeringConductor Coil

The invention discloses a plastic package motor, which comprises a thermal protector, a plastic shell and a stator assembly packaged in the plastic shell, wherein the thermal protector is contacted with the stator assembly and packaged inside the plastic shell. The thermal protector is injection molded inside the plastic shell and directly contacted with the stator assembly, so that the thermal protector can detect the actual temperature of a stator winding directly, thereby effectively avoiding occurrence of a circumstance that a motor winding is burnt out because of delay of the thermal protector; and because the thermal protector is plastic packaged inside the plastic shell directly, a traditional thermal protector bracket is saved, thereby enabling the size of the whole plastic package stator to be reduced, and being conducive to lightening and thinning development of a motor. The invention further discloses a plastic package motor adopting the plastic package stator, and an air conditioner indoor unit adopting the plastic package motor.

Owner:ZHUHAI KAIBANG MOTOR MFR +4

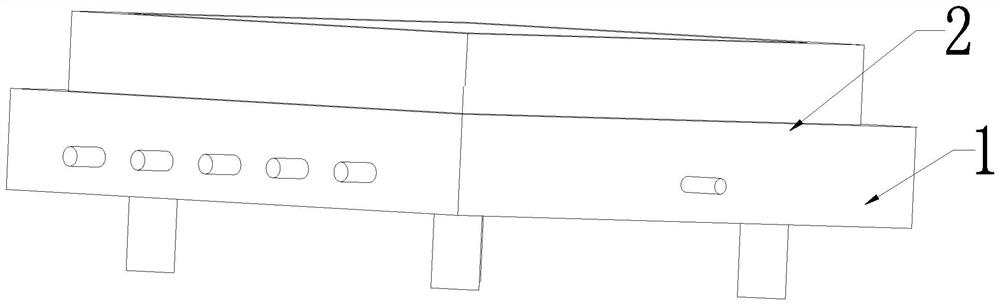

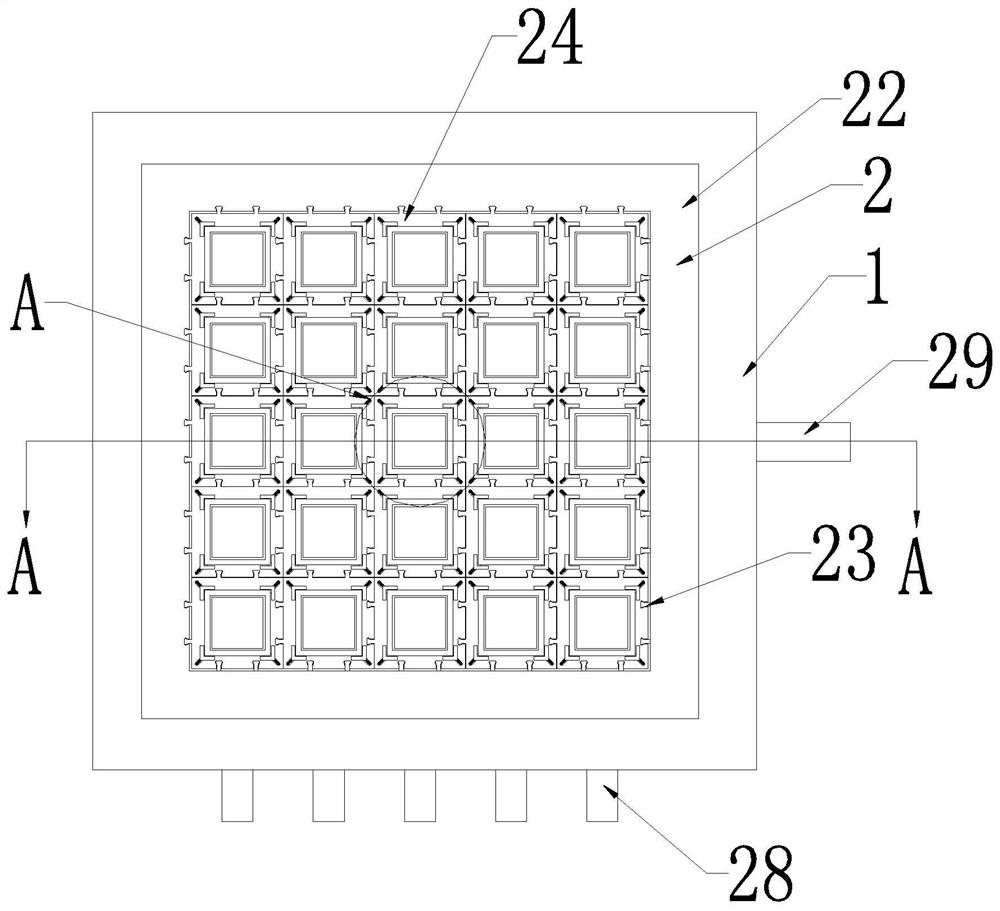

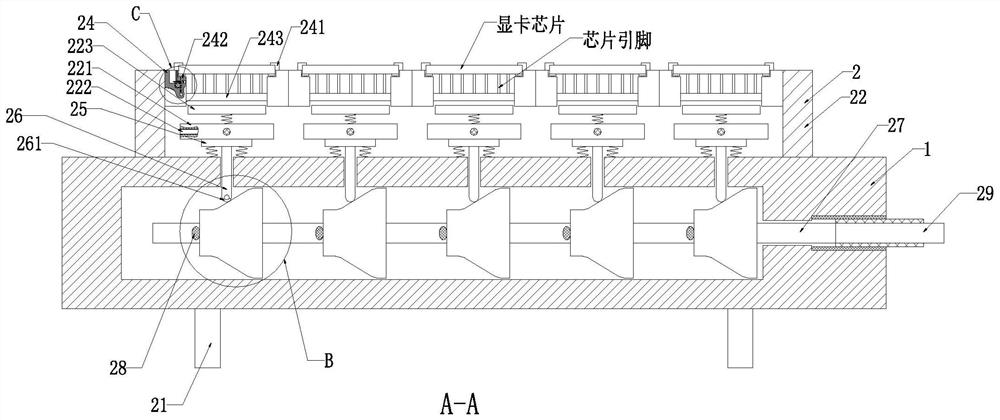

Computer graphics card chip fixing and processing equipment

ActiveCN111952236AProne to burnoutAchieve a fixed purposeSemiconductor/solid-state device manufacturingGraphicsGraphic card

The invention relates to computer graphics card chip fixing and processing equipment which comprises a mounting substrate and a fixing sleeve, the fixing sleeve is mounted on the mounting substrate, and the computer graphics card chip fixing and processing equipment can solve the problems that when an existing graphics card chip is mounted, a, when the existing graphics card chip is mounted, pinsof a display card chip are often damaged during fixing, so that the display card chip is damaged, the cost is greatly wasted, and the production efficiency is influenced; and b, when an existing display card chip is stored, a certain amount of moisture often exists on the display card chip due to environmental reasons, and when the display card chip containing the moisture is installed on the display card and powered on, the display card chip is extremely easy to burn out, and the cost is wasted.

Owner:LUOYANG NORMAL UNIV

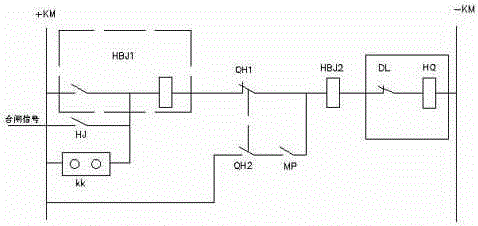

Multi-stroke realizing circuit and multi-stroke control method for circuit breakers

ActiveCN105261530AImprove closing success rateImprove security assuranceProtective switch operating/release mechanismsBurning outPositive control

The invention discloses a multi-stroke realizing circuit and a multi-stroke control method for circuit breakers. The multi-stroke realizing circuit comprises a microprocessor, a positive control bus +KM, a negative control bus -KM, a first current self-holding relay HBJ1, a circuit breaker auxiliary normally closed contact DL, a closing coil HQ, a closing relay HJ and a manual closing operation switch KK, and further comprises a switching relay QH, a second current self-holding relay HBJ2 and a transient wave relay MP. First, the microprocessor controls the switching device and further controls on-off of the closing coil so as to make the circuit breaker auxiliary normally closed contact do stroke movement repeatedly when the circuit breaker auxiliary normally closed contact fails to be closed in the first stroke of the closing coil, thus avoiding the situation in which a circuit breaker is burned out when the circuit breaker receives a closing instruction but fails to be closed; and then, the microprocessor makes the closing coil of the circuit breaker do stroke movement repeatedly, which can improve the success rate of circuit breaker closing under the condition that the circuit breaker is in the state of sub-health and cannot be closed by a single action.

Owner:STATE GRID HENAN LINGBAO POWER SUPPLY CO

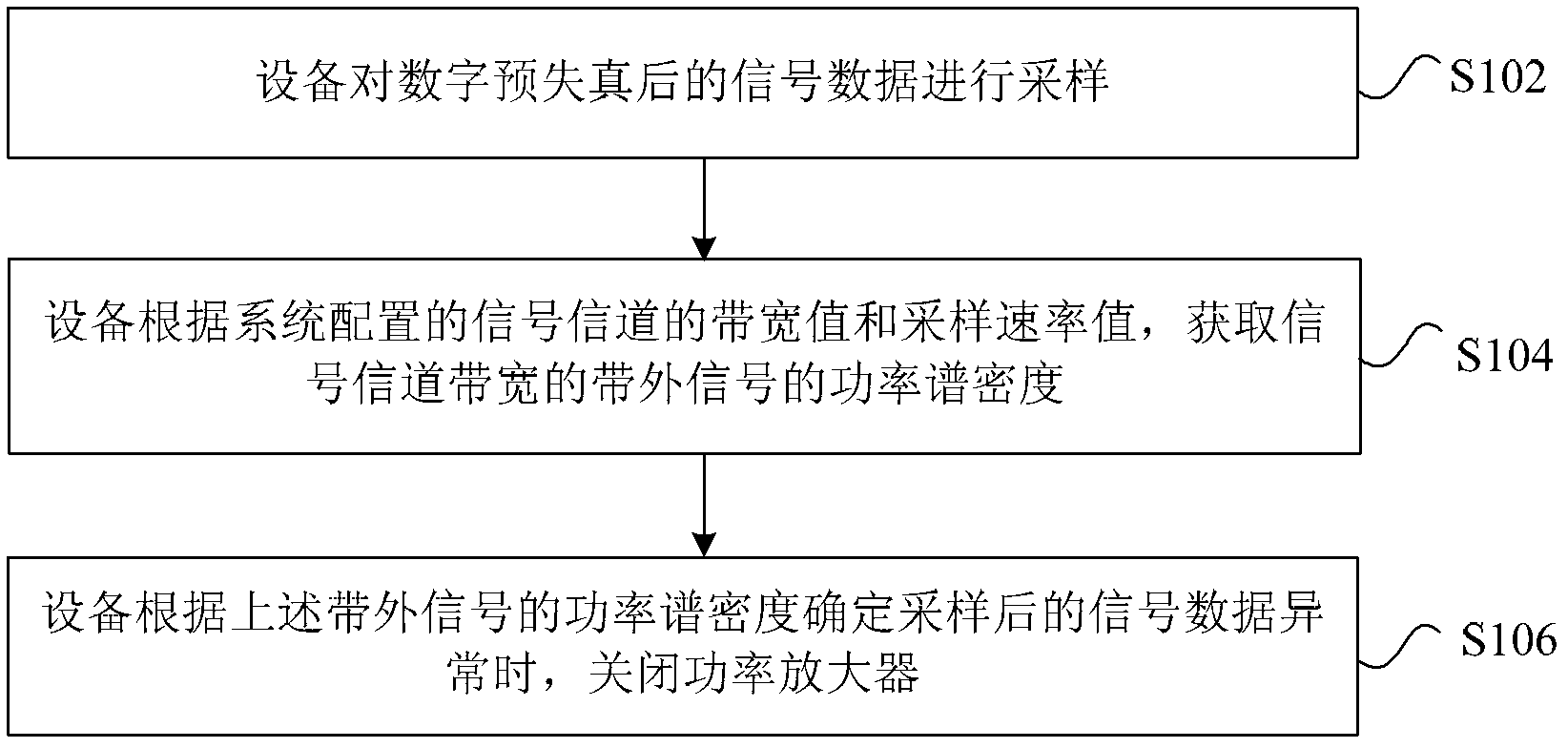

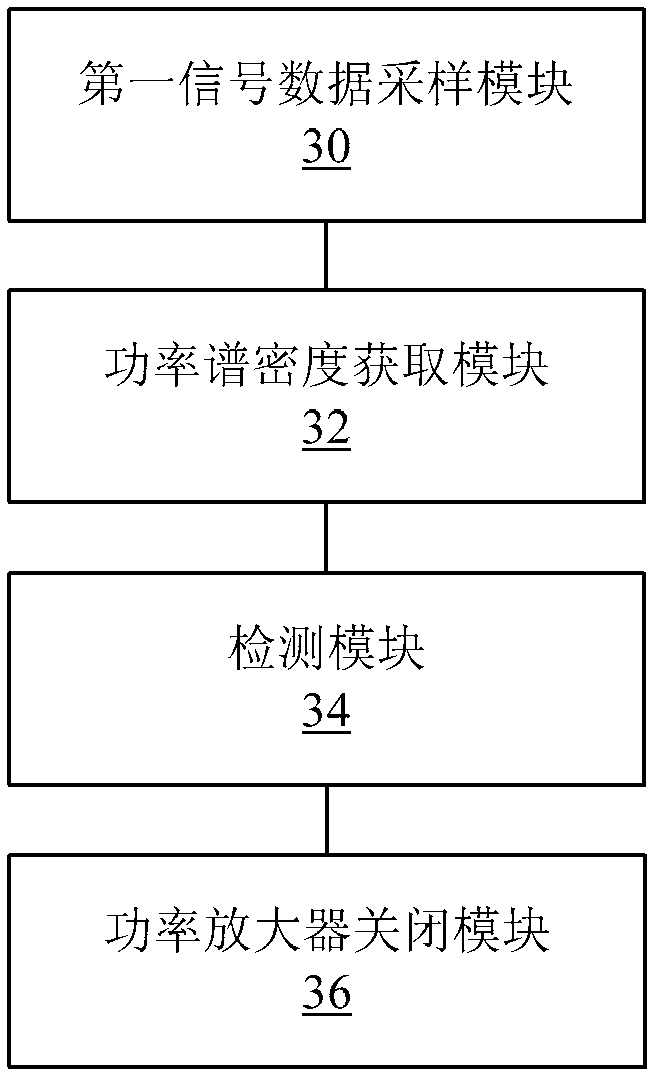

Method and device for protecting power amplifier

ActiveCN103326674AImprove protectionAvoid burnt out situationsAmplifier protection circuit arrangementsAudio power amplifierVIT signals

The invention discloses a method and a device for protecting a power amplifier. The method comprises steps as follows: signal data subjected to digital pre-distortion are sampled; a power spectrum density of an out-of-band signal with a signal channel bandwidth is acquired according to a bandwidth value of a signal channel configured by a system as well as a sampling rate; and when the sampled signal data are determined to be abnormal according to the power spectrum density of the out-of-band signal, the power amplifier is closed. By means of the method and the device, the problem that the power amplifier cannot be effectively protected when encountering signals with abnormal wide spectrums due to the fact that the power amplifier is protected according to a power average value of an input signal in correlation techniques is solved, and conditions that the signals with abnormal wide spectrums caused by digital pre-distortion are corrected due to insufficient protection of the power amplifier according to the power average value and the power amplifier is burnt due to the signals with abnormal wide spectrums are avoided, so that the protection of the power amplifier is enhanced.

Owner:ZTE CORP

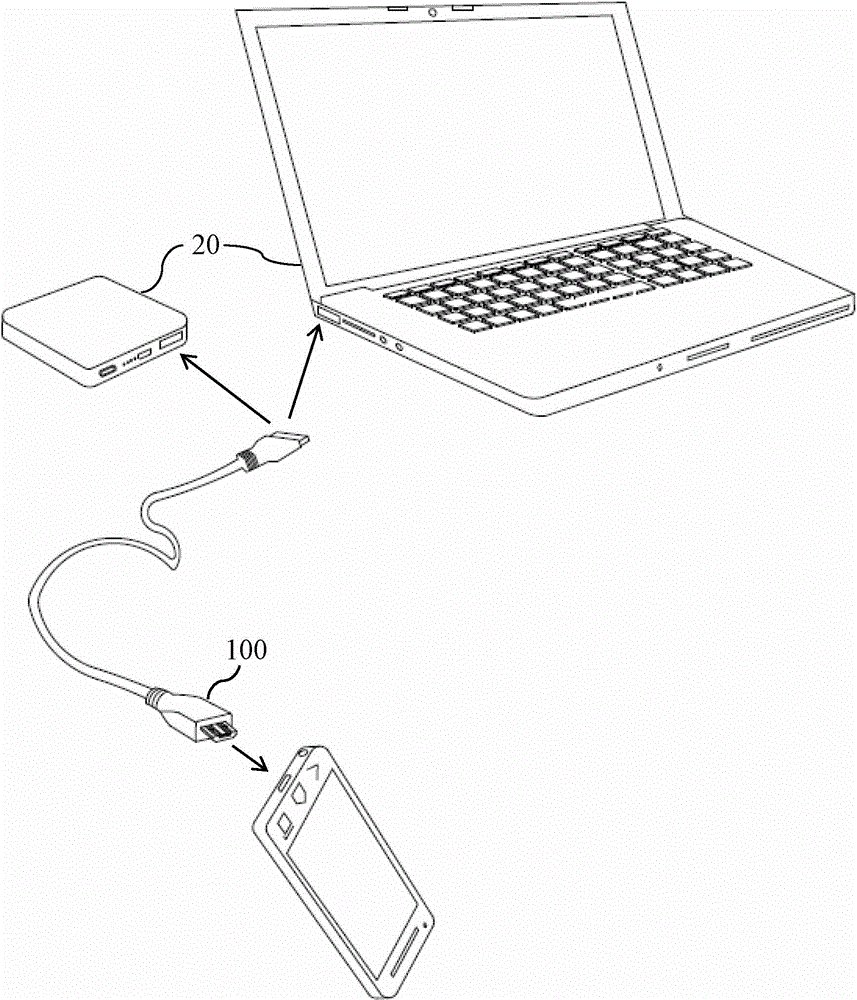

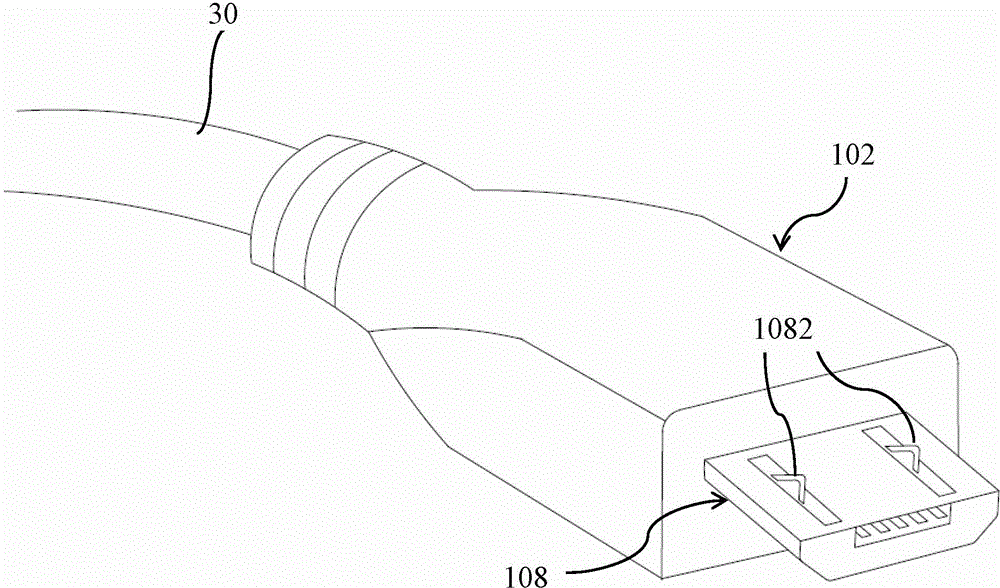

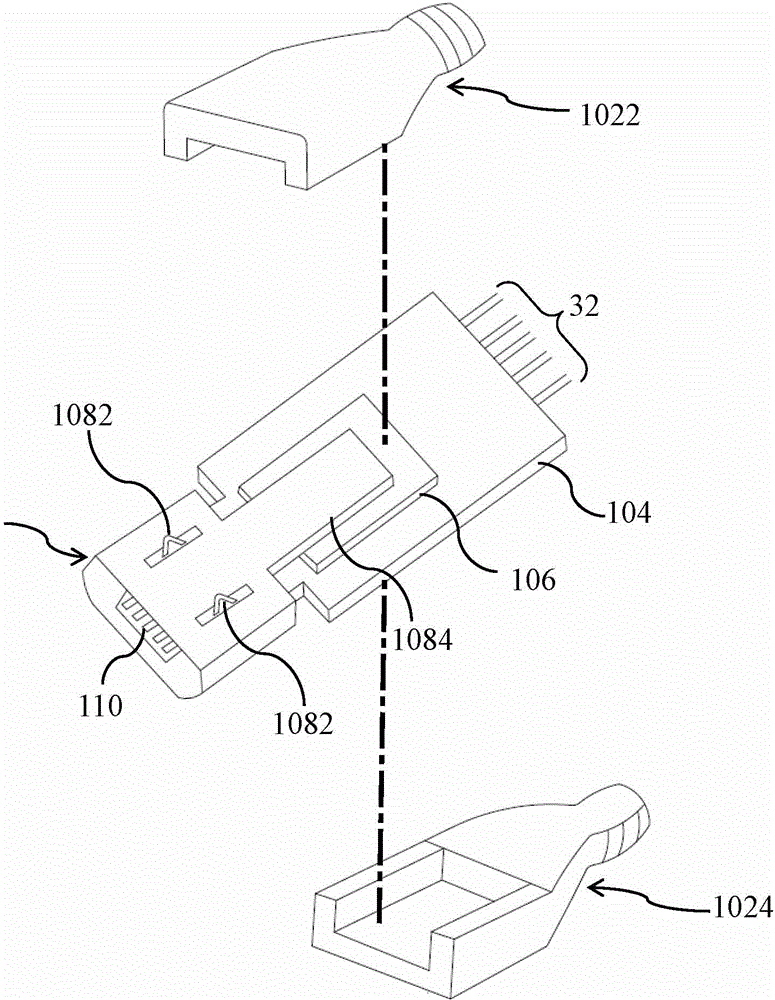

Universal serial bus with temperature sensing

ActiveCN105990770AAvoid burnt out situationsCoupling device detailsTemperature senseTemperature sensing

The invention provides a Universal Serial Bus (USB) device with improved structure. The USB device includes a housing, a circuit board, a temperature sensing assembly, a interface portion and a plurality of pins. The circuit board is positioned in the housing. The temperature sensing assembly is coupled to the circuit board. The interface portion, located on the end of the housing, includes an extended portion which extends to contact with the temperature sensing assembly. One end of a plurality of pins is coupled to the circuit board, and another end of pins is positioned on the inside of the interface portion, wherein the extended portion is used for transferring the temperature generated by the plurality of pins or the circuit board to the temperature sensing assembly. When the temperature reaches a default value, the temperature sensing assembly starts a breaking mechanism.

Owner:PHIHONG TECH CO LTD

Circuit board

InactiveCN102762024AAvoid thermal crashesAvoid burnt out situationsPrinted circuit detailsEngineeringBranch current

The invention relates to a circuit board, which comprises a plurality of branch circuits and a branch circuit regulating and controlling module, wherein the branch circuit regulating and controlling module is used for monitoring the current of each branch circuit to determine the minimum branch current and regulating and controlling the current of each branch circuit having the current greater than the minimum branch current, so as to enable the current to be approximate to or equal to the minimum branch current.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Dimming drive circuit of AC (Alternating Current) direct drive LED module

ActiveCN102892238BColor temperature adjustableColor adjustableElectrical apparatusElectroluminescent light sourcesDriver circuitEngineering

Disclosed is an alternating current dimming drive circuit for an LED, comprising a rectification unit and N stages of LED direct current drive circuits. In the ith stage of LED direct current drive circuit, a first end of the ith voltage sampling unit and an input end of the ith LED light source module directly or indirectly receive the output voltage of the rectification unit; a voltage division end of the ith voltage sampling unit is connected to a second input end of the ith switch unit; and a first input end of the ith switch unit is connected to an output end of the ith LED light source module, and an output end of the ith switch unit, a second end of the ith voltage sampling unit and a second output end of the rectification unit are grounded. When the ith switch unit is switched on, the first to the ith LED light source modules emit light. When the ith switch unit is switched off, if i is less than N, the first to the (i + 1)th LED light source modules emit light, and if i is equal to N, the first to the Nth LED light source modules stop emitting light. The present invention realizes an alternating current directly-driven LED light source module and will not flicker in the case of alternating current voltage fluctuation.

Owner:四川能投智慧光电有限公司

Voltage test device and voltage test method

InactiveCN101738534BDetect power supply capabilityAvoid burnt out situationsCurrent/voltage measurementElectronic circuit testingFistEngineering

Owner:MINGSHUO COMP (SUZHOU) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com