Heat-sensitive sensor and temperature measuring method

A thermal sensor and sensor technology, applied in the sensor field, can solve problems such as thermal sensor damage, user error message prompts, safety hazards, etc., and achieve the effect of increasing the scope of use, prolonging the service life, and improving the use experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

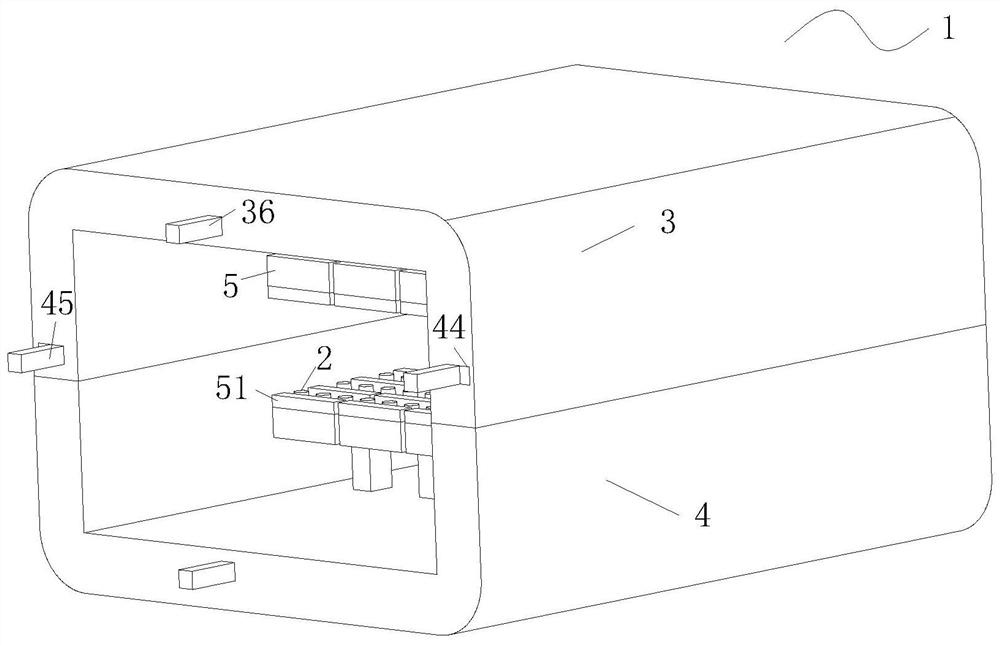

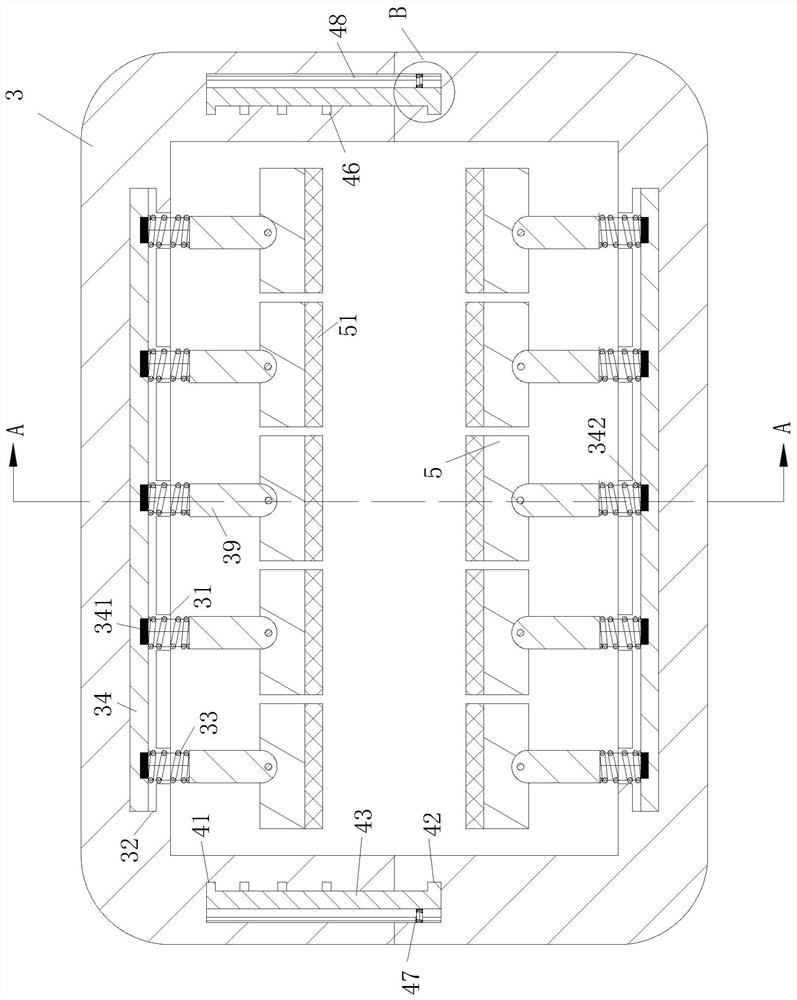

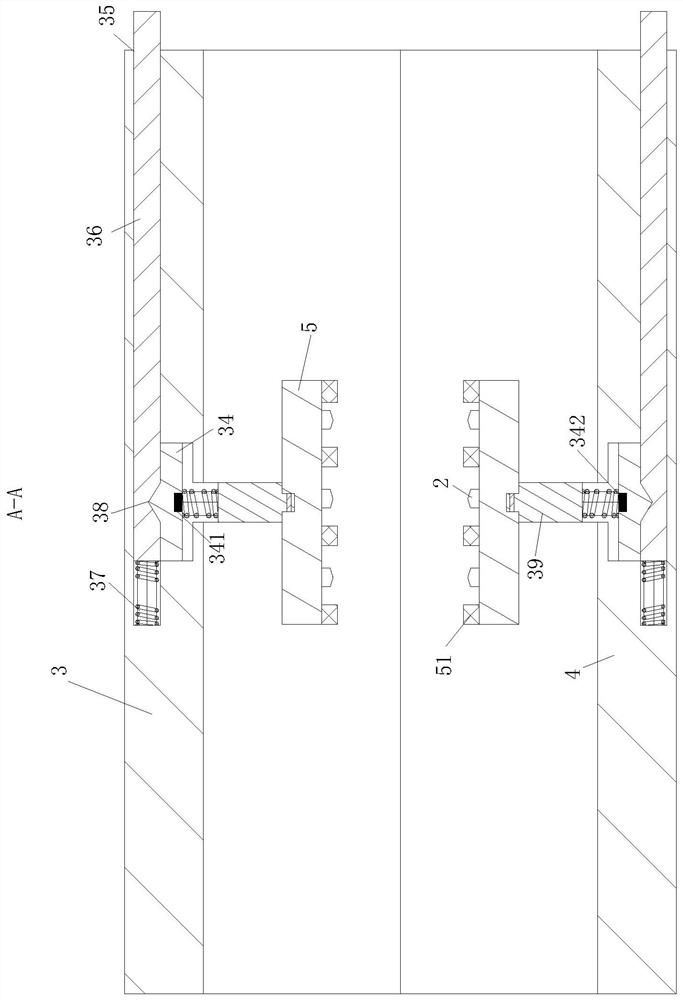

[0038] As an embodiment of the present invention, the surface of the clamping plate 5 is fixed with a flexible layer 51; the flexible layer 51 is spaced from the sensor 2, and the thickness of the flexible layer 51 is greater than the thickness of the sensor 2;

[0039] When working, the clamping plate 5 clamps the lithium battery, and the lithium battery first contacts with the flexible layer 51, and the flexible layer 51 is deformed under extrusion, and is closer to the shell of the lithium battery, increasing the friction so that the lithium battery cannot be dropped. At the same time, after the deformation of the flexible layer 51, the sensor 2 can be in contact with the lithium battery, so that the sensor 2 will not be squeezed by the lithium battery when it is clamped;

[0040] In the present invention, a flexible layer 51 is firmly connected to the surface of the clamping plate 5, and the flexible layer 51 and the sensor 2 are placed at intervals, and then the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com