Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Adapt to work needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

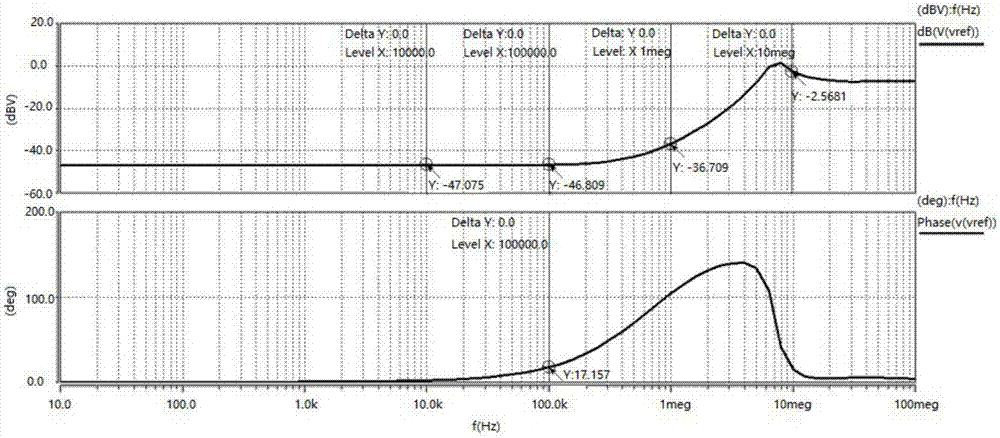

Low-power-consumption reference voltage source

InactiveCN107066003ACompact structureSimple structureElectric variable regulationElectricityMain branch

The invention provides a low-power-consumption reference voltage source which is simple in circuit structure, adjustable in output reference voltage and high in temperature stability. The technical scheme includes that in a main branch comprising a reference voltage generation circuit and a bias current generation circuit, a feedback branch is electrically connected between a grounding source electrode of an NMOS (N-channel metal oxide semiconductor) field effect transistor MN2 and a source electrode of a PMOS (P-channel metal oxide semiconductor) transistor MP4 and comprises an enhanced NMOS field effect transistor MN5, a divider resistor R1 and a resistor R2 which are sequentially connected in series, a grid electrode of the MN5 is electrically connected with a drain electrode of the MP4, a grid end of the MN2 is connected between the divider resistor R1 and the resistor R2, and the threshold voltage of the enhanced NMOS transistor MN2 and the threshold voltage of a depletion type NMOS transistor MN1 are linearly overlapped at a grid electrode of the MN2 by the MP4 to obtain reference voltage VREF outputted from a source electrode of the MN5.

Owner:SOUTH WEST INST OF TECHN PHYSICS

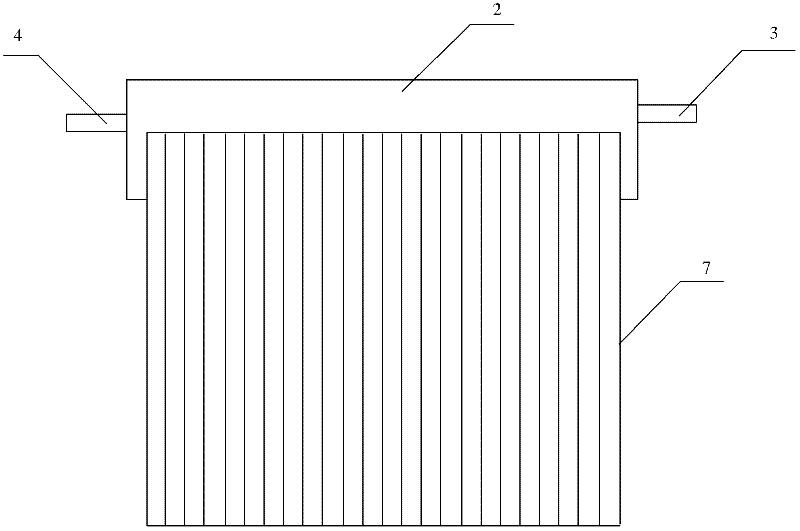

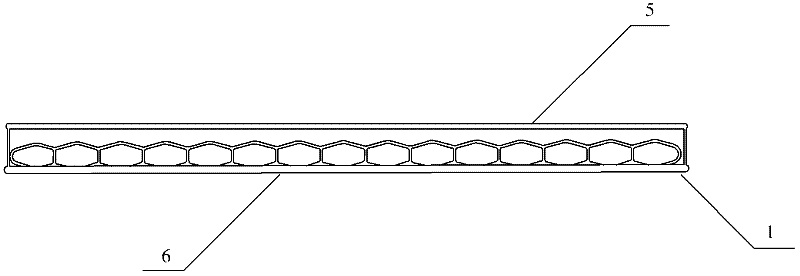

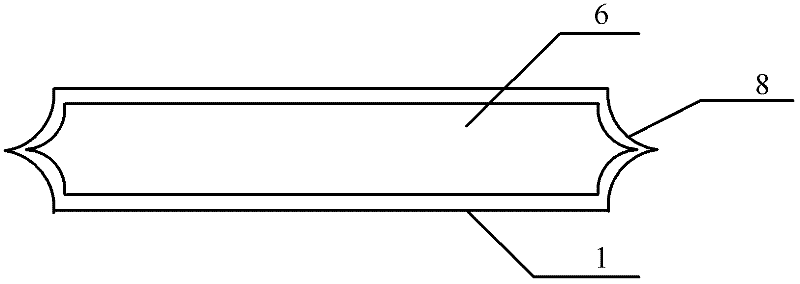

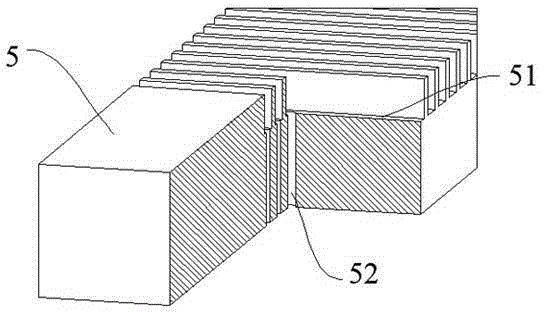

Platy heat pipe and processing technology thereof

InactiveCN102506597AImprove structural strengthWith ultra-thinSolar heating energyIndirect heat exchangersTrunk structureEngineering

The invention provides a platy heat pipe, comprising a platy heat pipe frame, wherein the platy heat pipe frame is internally provided with a microporous pipe trunk structure which is formed by a group of microporous pipes, side walls of the microporous pipes are connected to mutually enhance the strength of each microporous pipe, each microporous pipe is filled with a working medium with a phase inversion heat exchange effect, two ends of the platy heat pipe are sealed, and at least one end is provided with a gradually contractive sealing belt formed by cold welding. The platy heat pipe provided by the invention has the characteristics of high strength, super thinness, high efficiency and high heat transportation volume and can substitute an oscillation heat pipe and a common heat pipe.

Owner:赵耀华

Machining process for internal combustion engine expansion breaking connecting rod

The invention discloses a machining process for an internal combustion engine expansion breaking connecting rod. The machining process includes the steps of forging and pressing forming, wherein a blank is formed to be a workblank of the internal combustion engine expansion breaking connecting rod; normalizing, wherein the workblank of the internal combustion engine expansion breaking connecting rod meets mechanical property requirements for the workblank; shot blasting and flaw detection, wherein oxide skin on the surface of the workblank of the internal combustion engine expansion breaking connecting rod and generated due to heating in the forging and pressing forming is removed, and it is guaranteed that flaw and folding defects do not exist in the surface of a product; chipping machining, wherein the workblank of the internal combustion engine expansion breaking connecting rod is machined to be an internal combustion engine expansion breaking connecting rod finished product. According to the machining process, parameters of mechanical properties such as the tensile strength, the yield limit, elongation and percentage reduction of area of the connecting rod are all increased to some extent, the mechanical properties of the connecting rod are improved on the whole, the tensile property and the impact resistance degree are greatly improved compared with those of existing materials, and the connecting rod can be well adapted to operating needs of high-power internal combustion engines.

Owner:ZHEJIANG YUEJIN MACHINERY

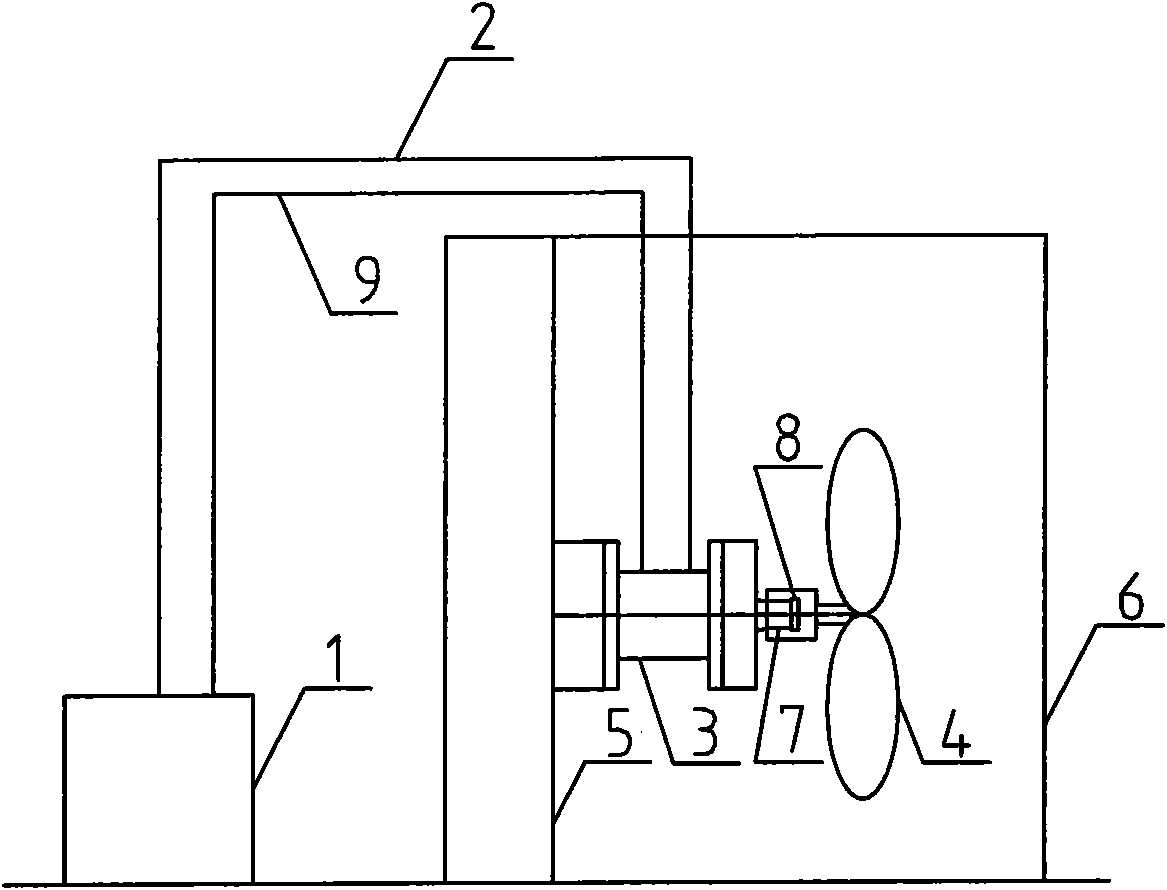

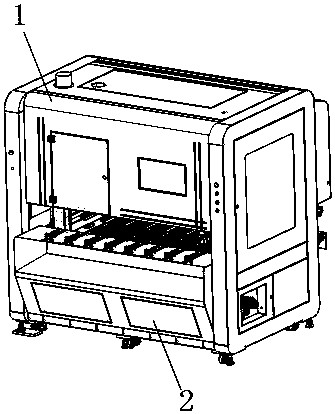

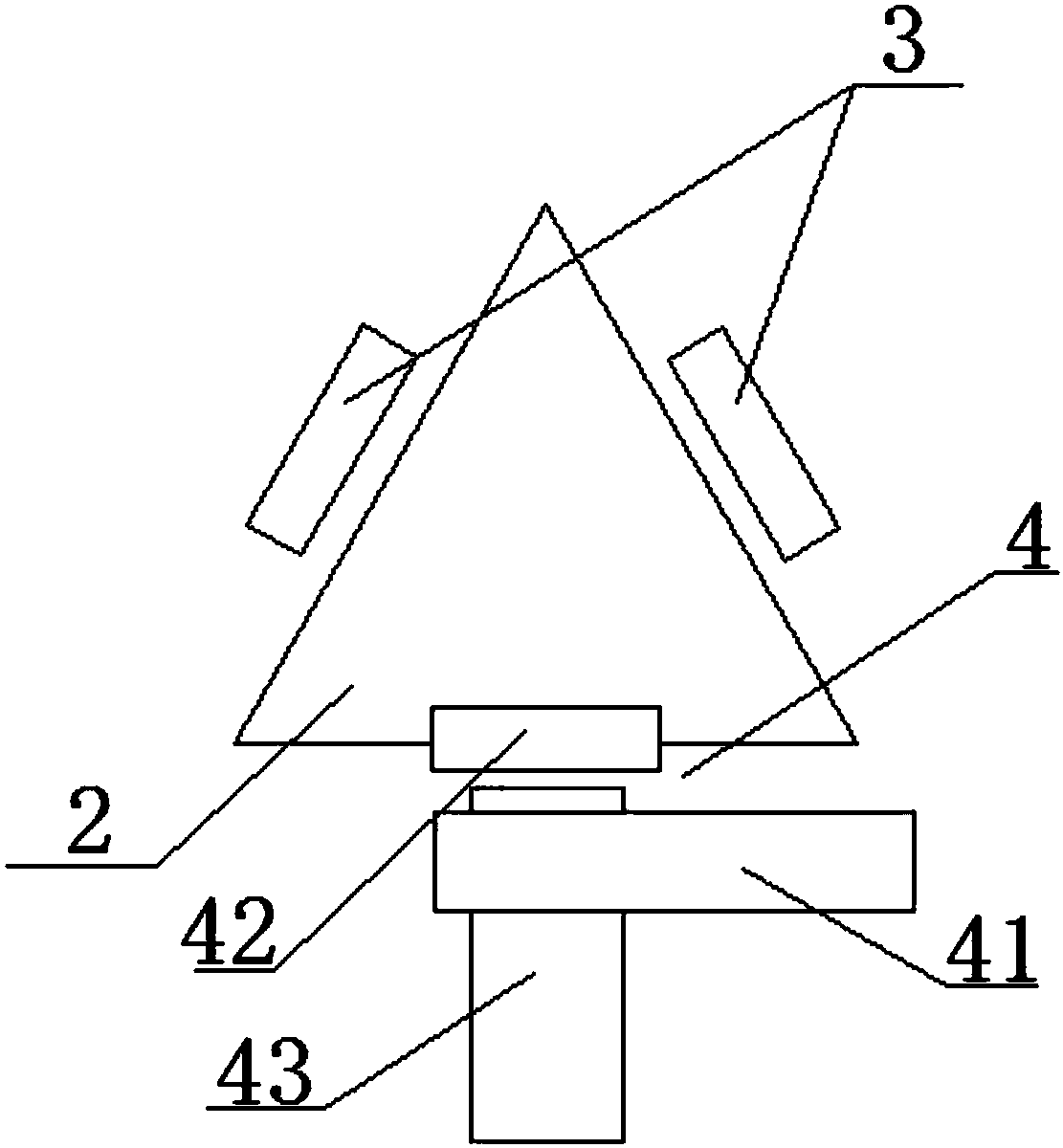

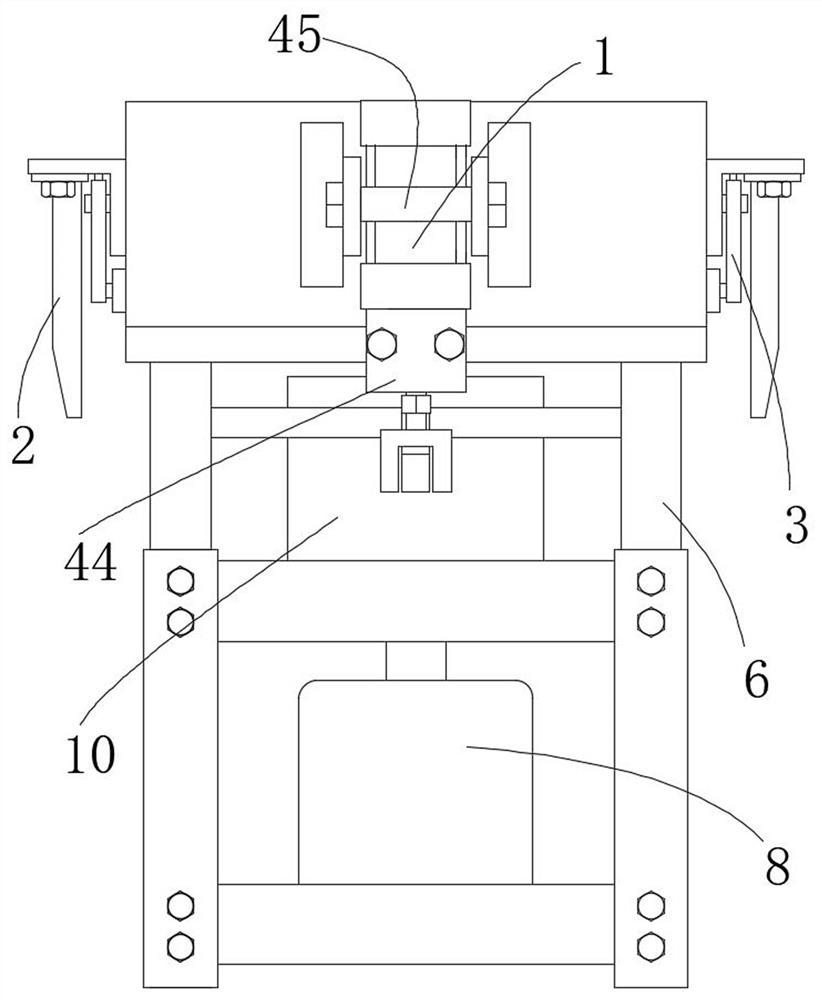

Bending machine

The invention provides a bending machine which comprises a rack, wherein a power mechanism is installed on the upper part of the rack, the power mechanism is connected to an upper die inside the rack, a lower die is disposed at a corresponding position under the upper die, the lower dies is installed on the bottom of the rack, a feeding device is disposed horizontally between the upper die and the lower die, the lower die comprises two triangles with two opposite inclined edges, a driving motor is installed under the lower die, the driving motor drives the triangles of the lower die to move, an included angle between the triangles is adjusted, and the lower part of the driving motor is connected to the rack by an stretchable rod. The bending machine provided by the invention makes the driving motor adjust the included angle of the lower die in order to adjust a bending angle, is used conveniently and saves working hours. By controlling height of the lower die using the stretchable rod, working demands of different work pieces can be adapted.

Owner:南通东海机床制造集团有限公司

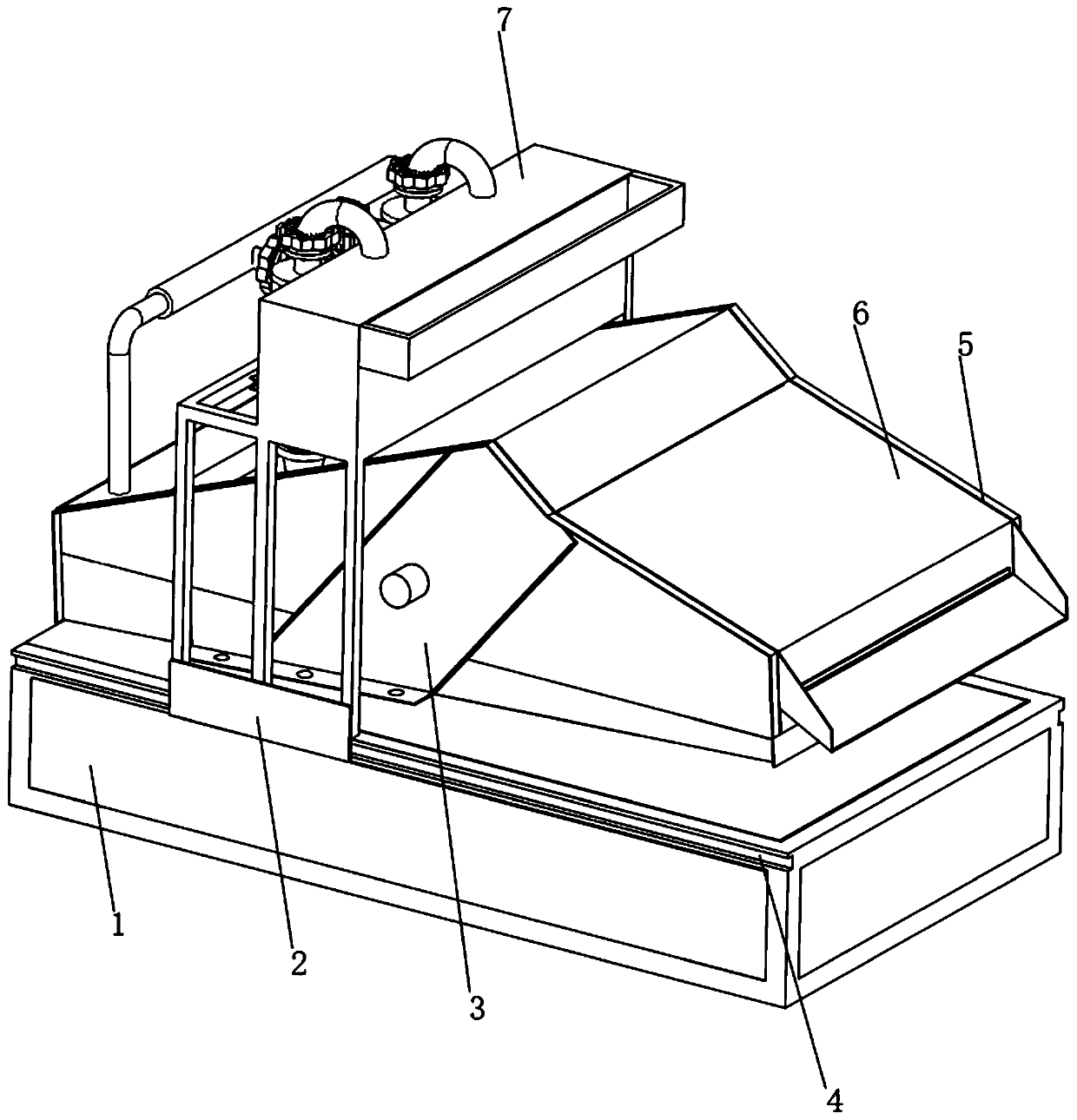

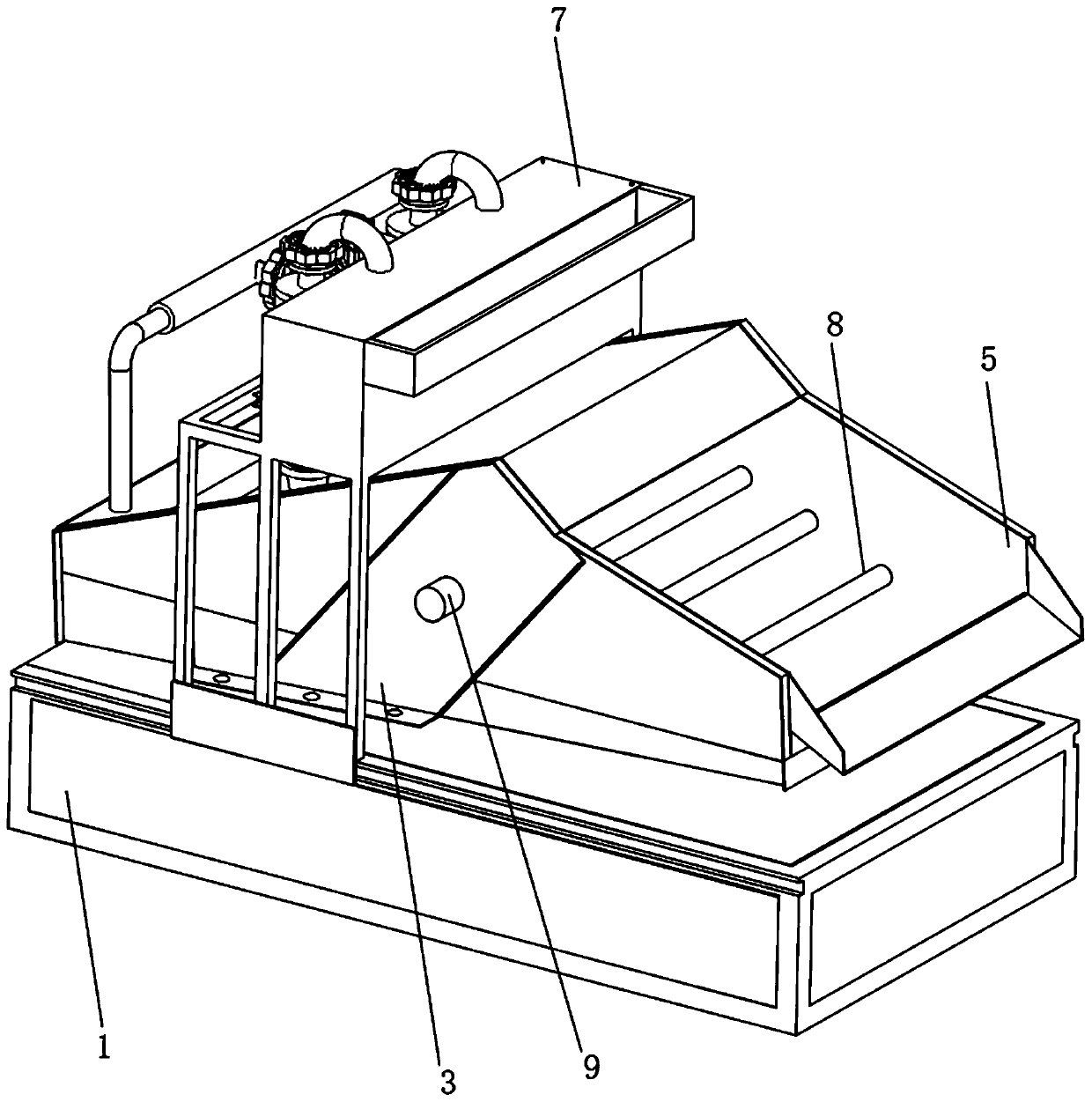

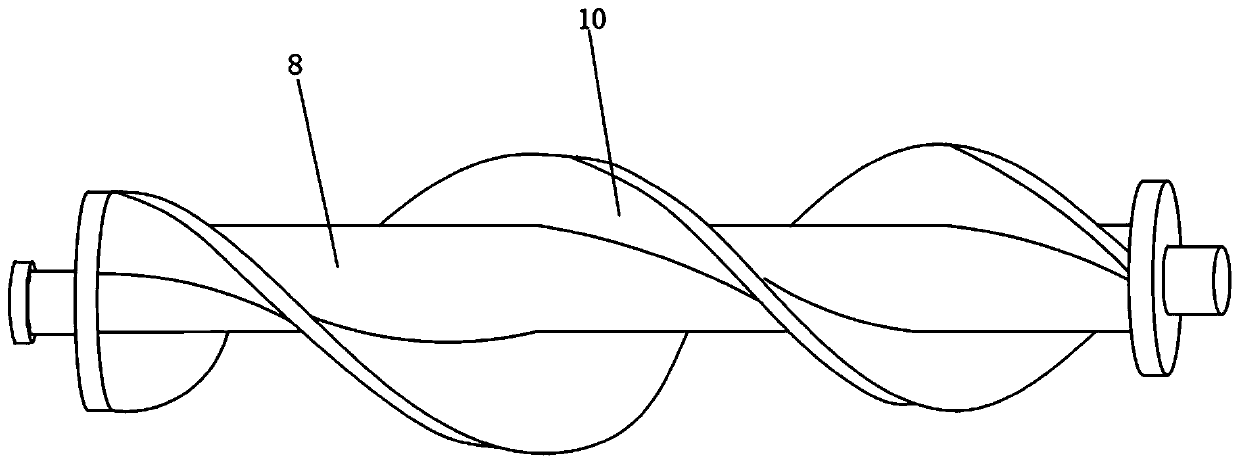

Stirring device for livestock manure full-mixing type fermentation tank

InactiveCN102180708AHigh torqueStir wellClimate change adaptationExcrement fertilisersHydraulic motorLivestock manure

The invention relates to a stirring device of a livestock manure full-mixing type fermentation tank. The stirring device comprises a fermentation tank, a stirrer and a hydraulic motor component, wherein the fermentation tank is used for accommodating a livestock manure mixed medium; the stirrer is positioned in the fermentation tank; and the hydraulic motor component serving as a power source directly drives the stirrer to rotate. The stirring device has a compact structure, is convenient to install and operate, safe, reliable and high in corrosion resistance, and hardly triggers safety accidents such as a fire hazard, explosion, methane leakage and the like.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

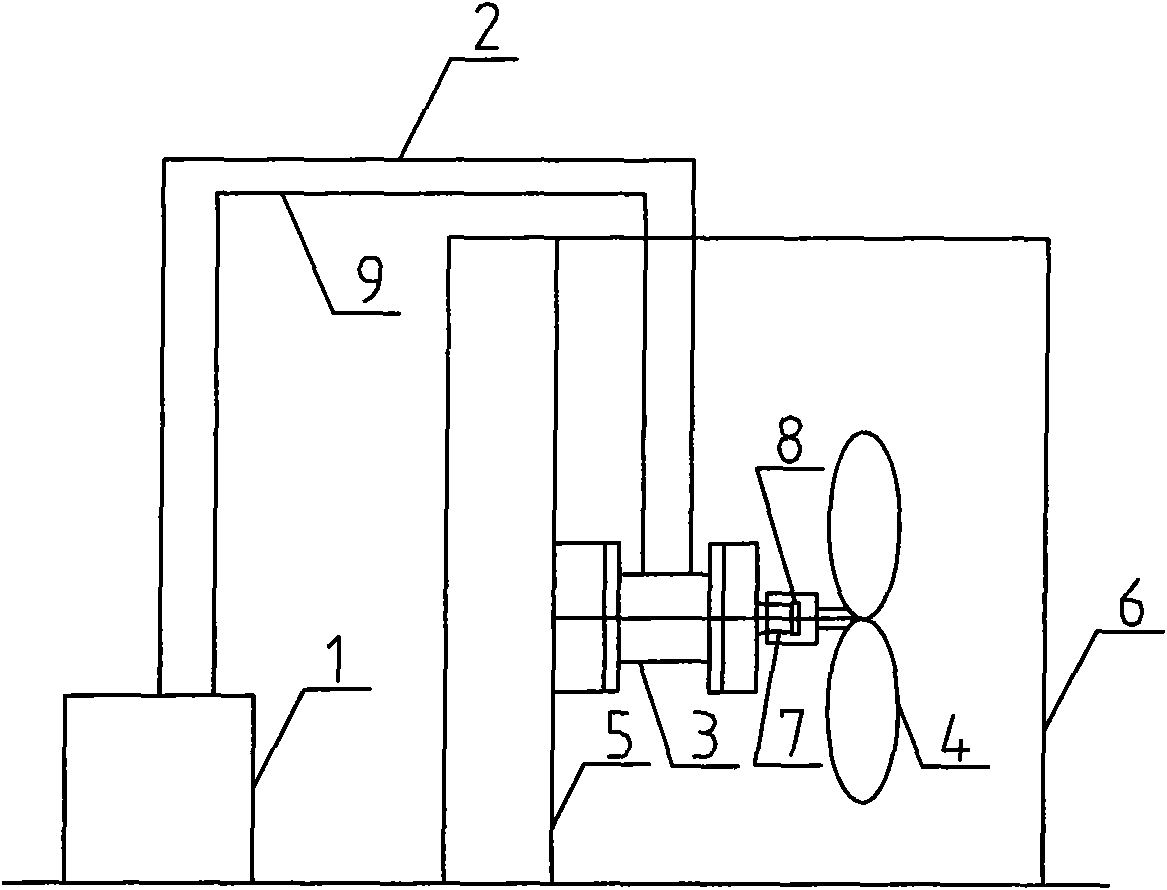

Method and system for controlling indoor quality of automatic assembly lines of medical laboratories

InactiveCN106203786AIncrease flexibilityAdapt to work needsResourcesMedical laboratoryIndoor air quality

The invention discloses a method and system for controlling indoor quality of automatic assembly lines of medical laboratories. The method comprises the following steps of: setting a corresponding quality control rule for each detection project by utilizing a third-party quality management system; carrying out data conversion through a data conversion system so as to transmit the detection projects and the corresponding quality control rules to an assembly line data management system and an assembly line analyzer, wherein the assembly line analyzer is provided with an indoor quality control detection module; receiving an instruction sent by the assembly line data management system by the indoor quality control detection module and acquiring corresponding IQC data by the indoor quality control detection module according to the corresponding quality control rules of the detection projects; transmitting the IQC data to the third-party quality management system through the assembly line data management system and the data conversion system; automatically analyzing the IQC data by the third-party quality management system so as to obtain a result of detecting whether the detection projects are out of control or not, and transmitting the result back to the assembly line data management system. The method and system are basically free of hand participation, high in accuracy and good in flexibility, and can dispatch resources to the greatest extent, thereby improving the efficiency and saving the human cost.

Owner:温冬梅

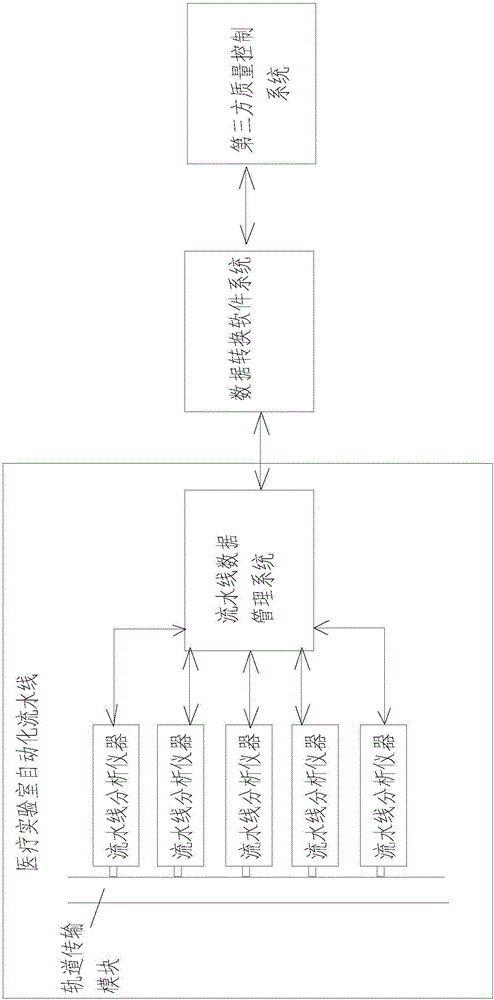

Ultralow-power-consumption temperature-and-humidity intelligent recorder

InactiveCN108548549AReduce power consumptionHigh communication rateRecording measured valuesMeasuring instrumentOperability

The invention provides an ultralow-power-consumption temperature-and-humidity intelligent recorder which belongs to the technical field of a temperature measuring instrument. The temperature-and-humidity intelligent recorder comprises a microprocessor, a storage module, a digital temperature-and-humidity sensor module, a communication module, a display module, a clock module, a button module, a battery, a USB power supply switching module, a power consumption mode switching module, an FLASH parameter storing and reading module, and computer software. The temperature-and-humidity intelligent recorder is connected with the computer software through the communication module. The ultralow-power-consumption temperature-and-humidity intelligent recorder has advantages of small and exquisite appearance, high convenience in carrying and use, ultralow power consumption, long-time use without charging or battery change, high data uploading speed and high data downloading speed through USB communication, and high stability. Through using a digital temperature-and-humidity integrated sensor, high acquisition precision, high sensitivity and high operability are realized.

Owner:河北泽华伟业科技股份有限公司

Dust spraying treatment method

ActiveCN111282898AAdapt to work needsSimple and quick installation and disassemblyDirt cleaningCleaning using gasesThermodynamicsWater storage tank

The invention discloses a dust spraying treatment method. The dust spraying treatment method comprises a framework and a transportation mechanism, wherein the transportation mechanism is mounted inside the framework; the two sides inside the framework are separately provided with an adsorption cavity and a spraying cavity; the top of the framework is connected to a top plate; the bottom of the topplate is equipped with an upper top plate; a bottom plate is mounted below the inner part of the framework; and a plurality of gas spraying tubes are rotatably mounted on the upper part of the bottomplate. In use, inclination angles of the gas spraying tubes and an inclination angle of a dust sucking tube can be freely regulated; after the gas spraying tubes and a rotary shaft on the bottom of the dust sucking tube rotate, the inclination angles of the gas spraying tubes and the inclination angle of the dust absorbing tube also change to adapt to different working needs, so that dust clearing is more complete; and after articles are cleared inside the adsorption cavity, the articles move into the spraying cavity along an upper slide rail, so that a plurality of spraying heads on the bottom of a water storage tank can spray water to to-be-cleared articles, and therefore, dust outside the articles is cleaned, and dust is degraded.

Owner:东明智能环保科技(山东)有限责任公司

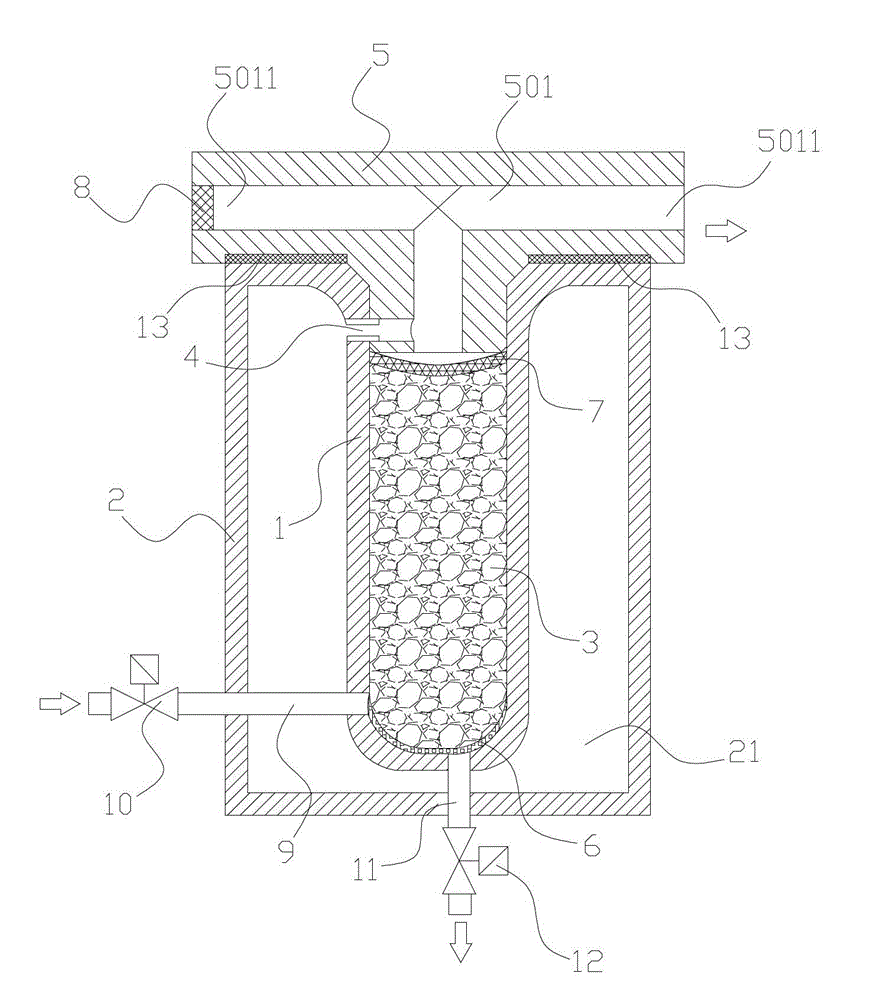

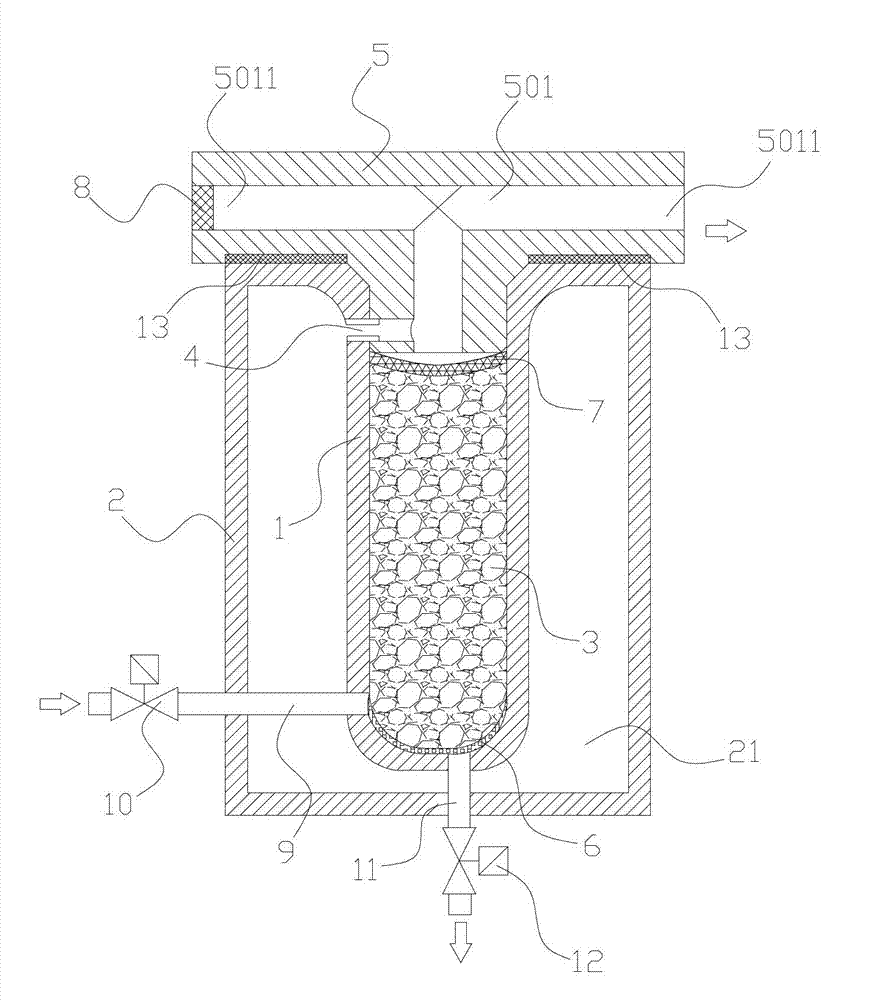

Air drier and method

InactiveCN103143241AMeet the actual needs of dryingAchieve regenerationDispersed particle separationDesiccantAir dryer

The invention discloses an air drier and a method. The air drier comprises a shell and an inner bladder, wherein a closed cavity is formed between the shell and the inner bladder, a drying agent is filled in the inner bladder, the inner bladder is provided with an air inlet, an air outlet and an exhaust port, and the air outlet is respectively communicated with the exterior of the shell and the cavity. According to the method, the air drier can be used for drying compressed air and can realize regeneration of the drying agent. The air drier has a simple structure, is convenient to maintain, occupies a small space, and can meet actual demands on drying of the compressed air.

Owner:GUANGZHOU INST OF RAILWAY TECH

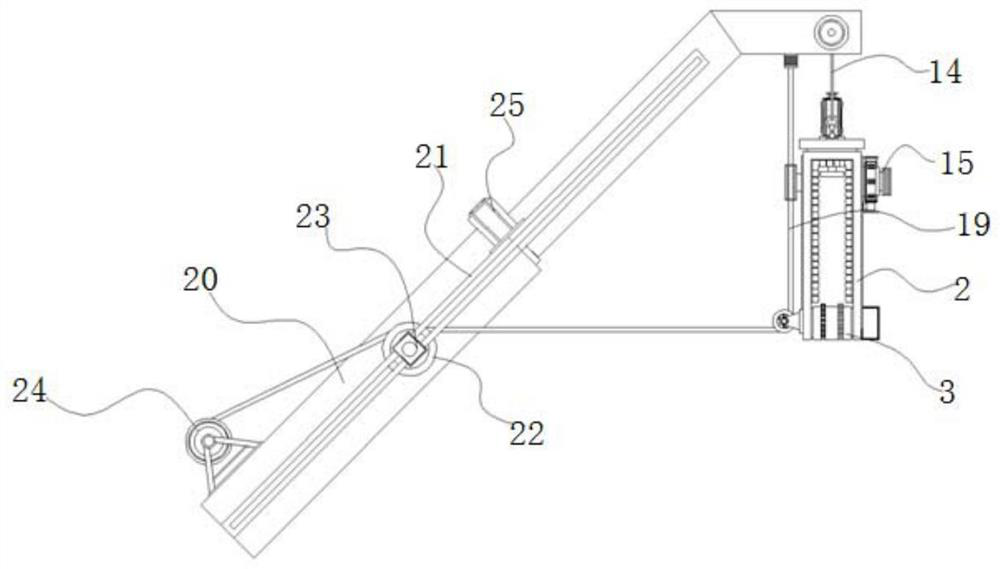

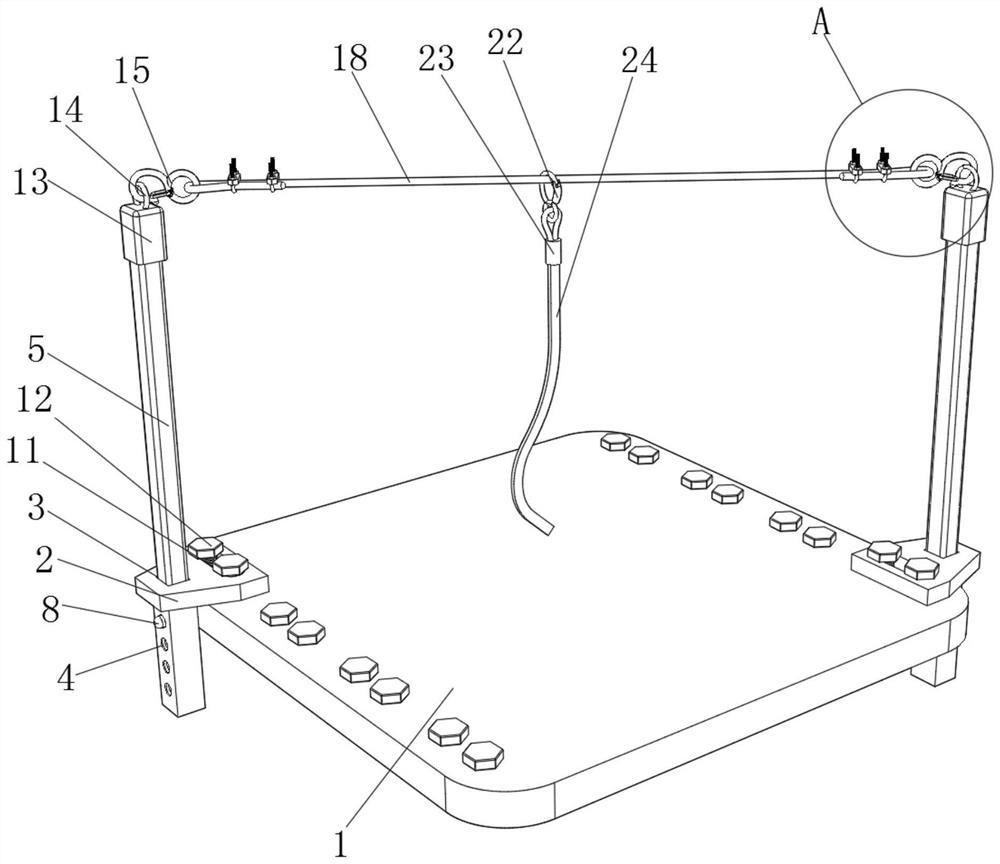

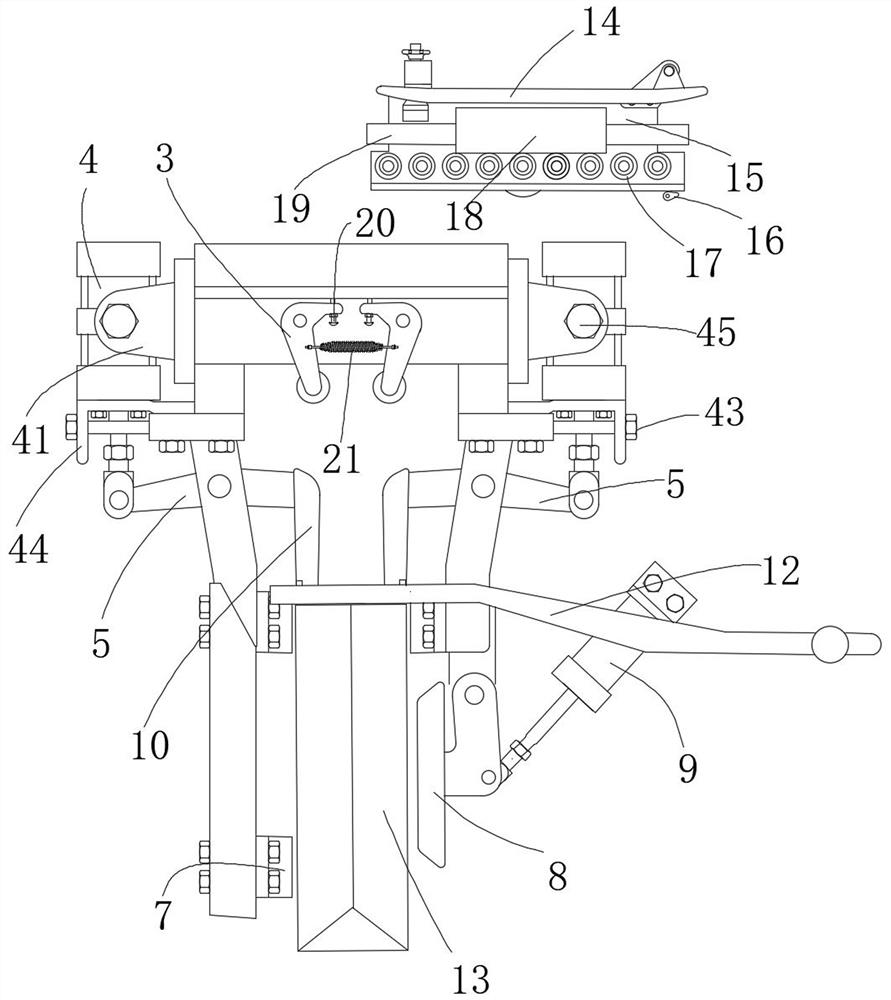

Method for hoisting fabricated light steel keel steel mesh mold lightweight wall

ActiveCN112875545AAvoid shakingImprove stabilityBuilding material handlingVibration suppression adjustmentsStructural engineeringMechanical engineering

The invention discloses a method for hoisting a fabricated light steel keel steel mesh mold lightweight wall, and relates to the technical field of fabricated building hoisting frames. According to the method for hoisting the fabricated light steel keel steel mesh mold lightweight wall, fabricated wall accessories are installed and supported on a hoisting frame, then the wall accessories are hoisted through hoisting arms and lifting steel cables, meanwhile, vertical rolling wheels are controlled to slide along the hoisting arms, so that the vertical rolling wheels, an adjusting rolling wheel in the lifting process and a stable steel rope always form a right angle shape, a steel rope winding barrel is controlled to rotate so that the stable steel rope can be always kept in a tightened state, and finally when the wall accessories reach a designated position, the wall accessories are taken down. By the adoption of the technical scheme, the stability of a wall in the whole hoisting process can be effectively improved, it is guaranteed that the wall accurately reaches the to-be-installed position, the hidden danger of hoisting installation is reduced, and the assembling efficiency is improved.

Owner:CHINA MCC17 GRP

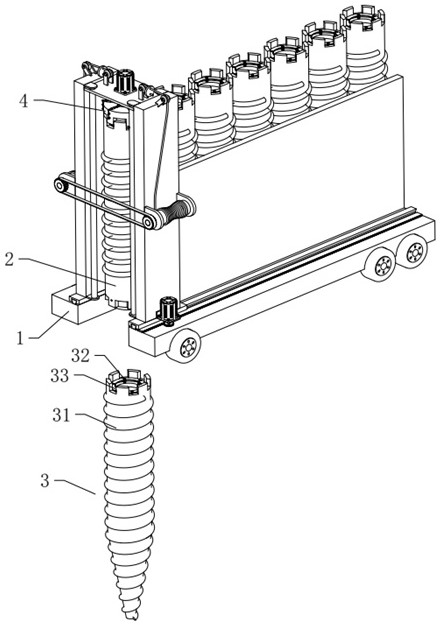

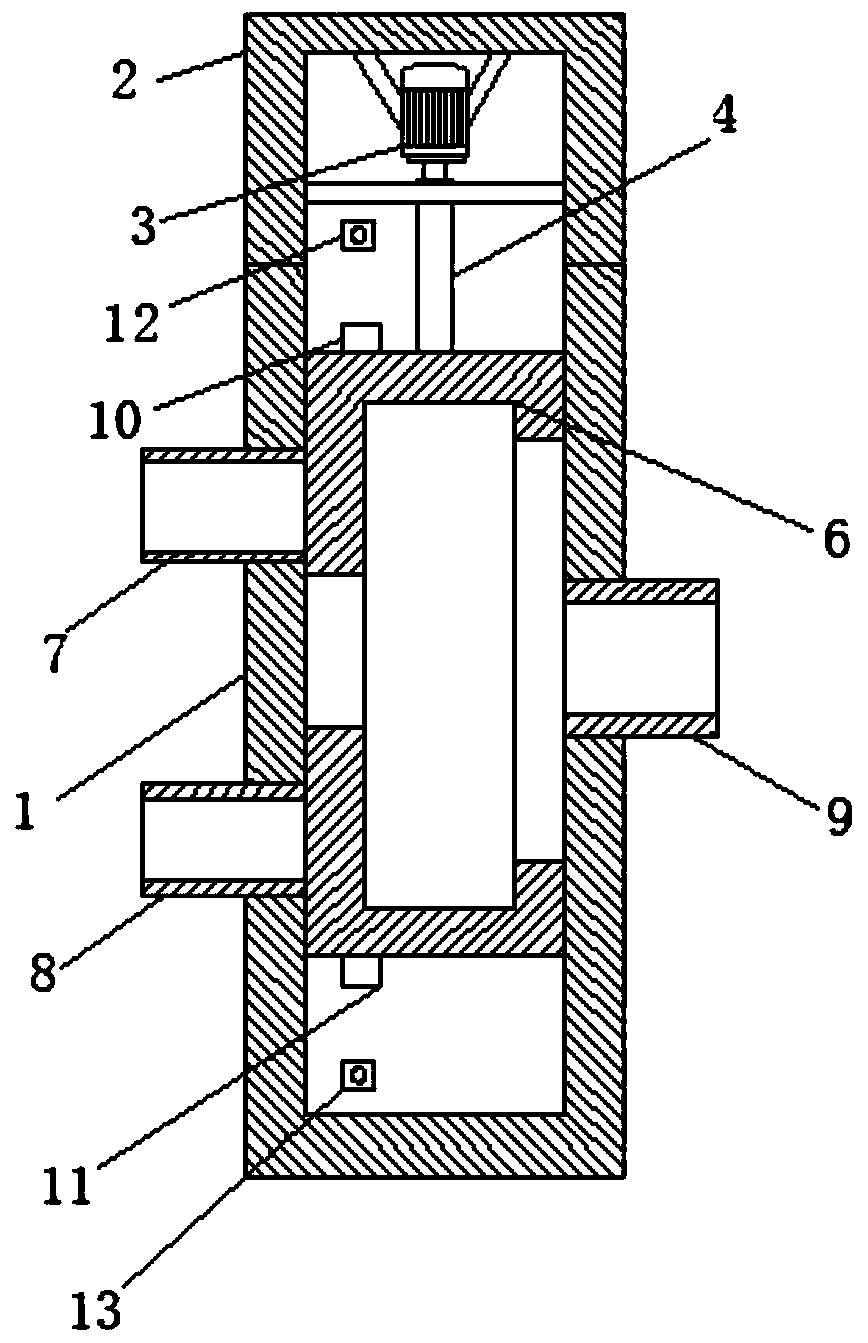

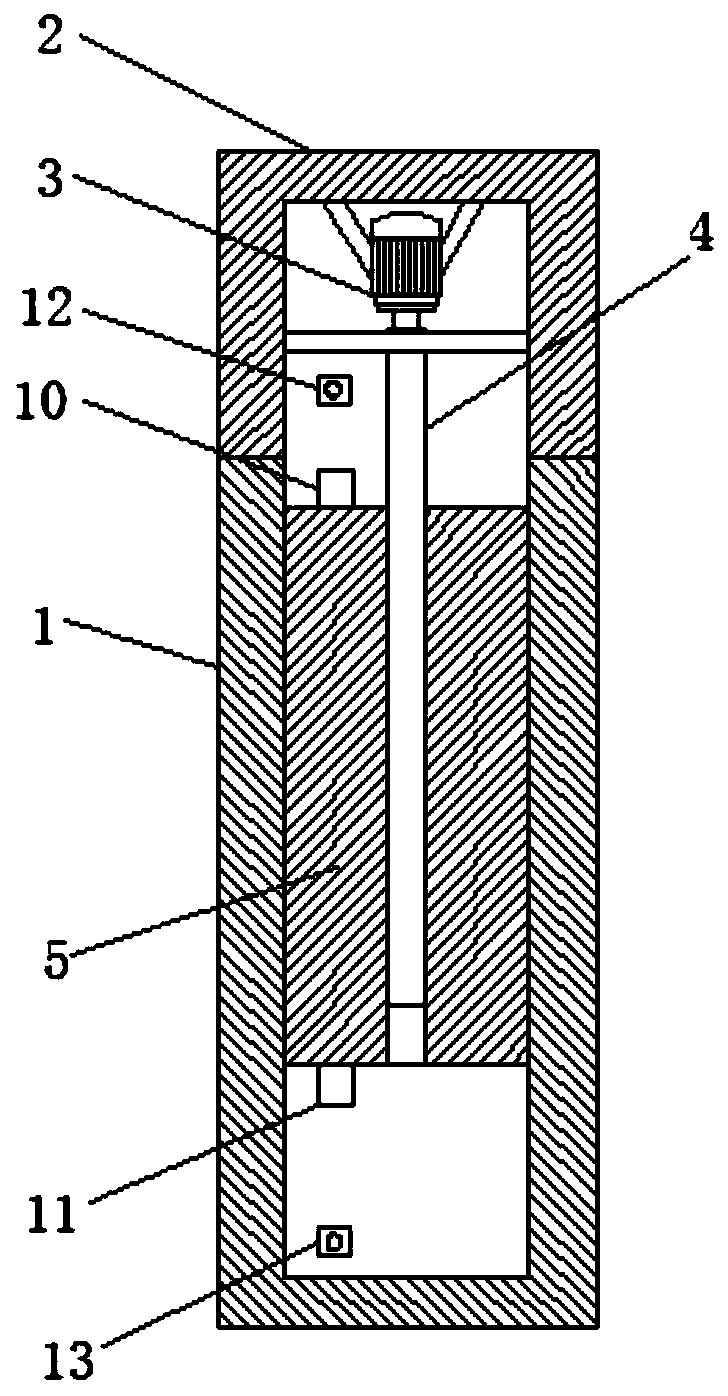

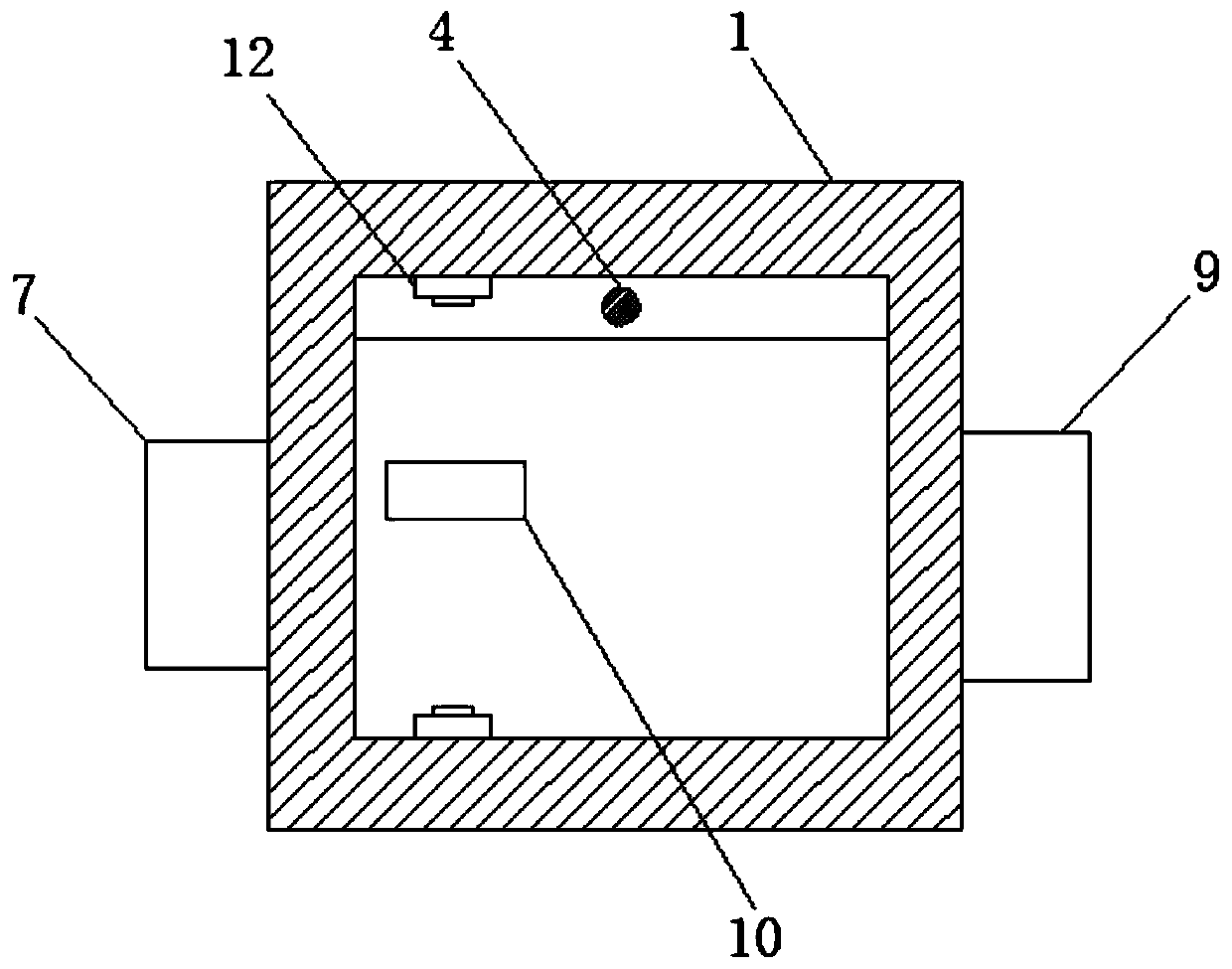

Large-scale exploration drilling and soil taking machine

PendingCN112213144APrecisely Controlled SamplingSafe and reliable structureDrilling rodsWithdrawing sample devicesMachineStructural safety

The invention provides a large-scale exploration drilling and soil taking machine which comprises a machine body, extension drill rods, a main drill rod and a rotary hoisting head, a plurality of extension drill rods can be stored in the machine body, the rotary hoisting head is arranged at the top of the machine body, and the machine body grabs and fixes the tops of the extension drill rods and the main drill rod through the rotary hoisting head. The machine body is driven by the rotary hoisting head to enable the first compression plate to rotate to be tapped into the ground, and the head and the tail of the extension drill rod and the head and the tail of the main drill rod can be fixedly connected in a butt joint mode and detached. The rotary hoisting head mounted on the machine body is used for grabbing the main drill to be in butt joint with the extension drill rod, and the main drill is driven down through rotation of the rotary hoisting head, so that the extension drill rod isdriven down, the main drill rod is lengthened through the extension drill rod loaded on the machine body, so that the main drill rod reaches an exploration site to take a soil sample for research, theexploration depth is accurately controlled for sampling, and the structure is safe and reliable.

Owner:刘骁

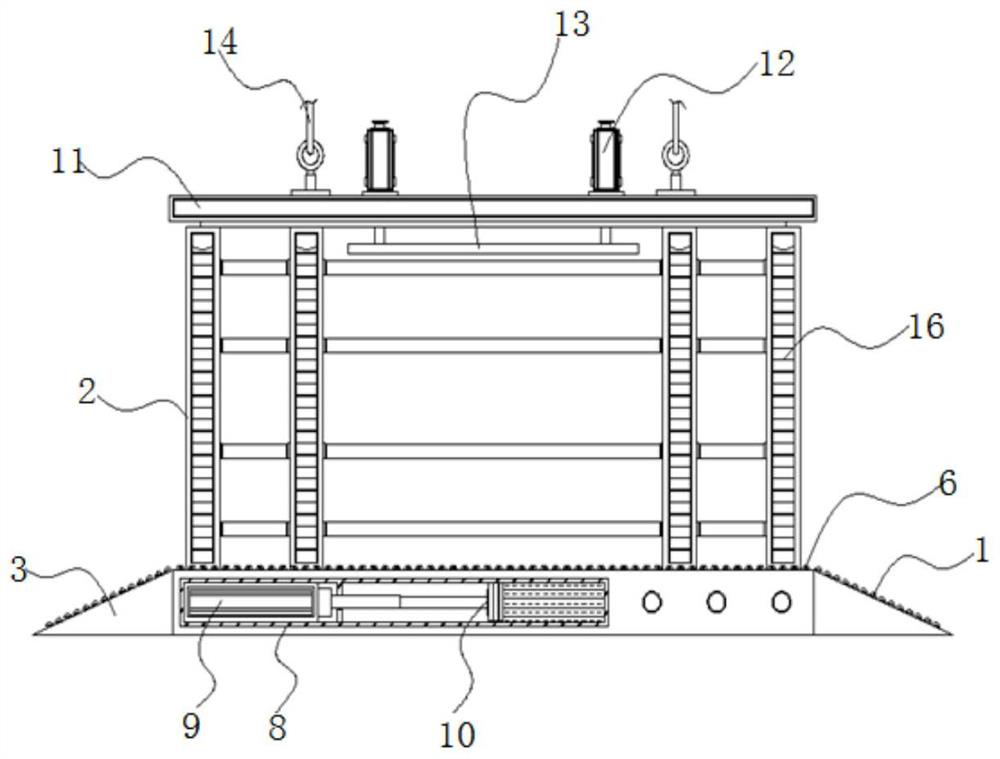

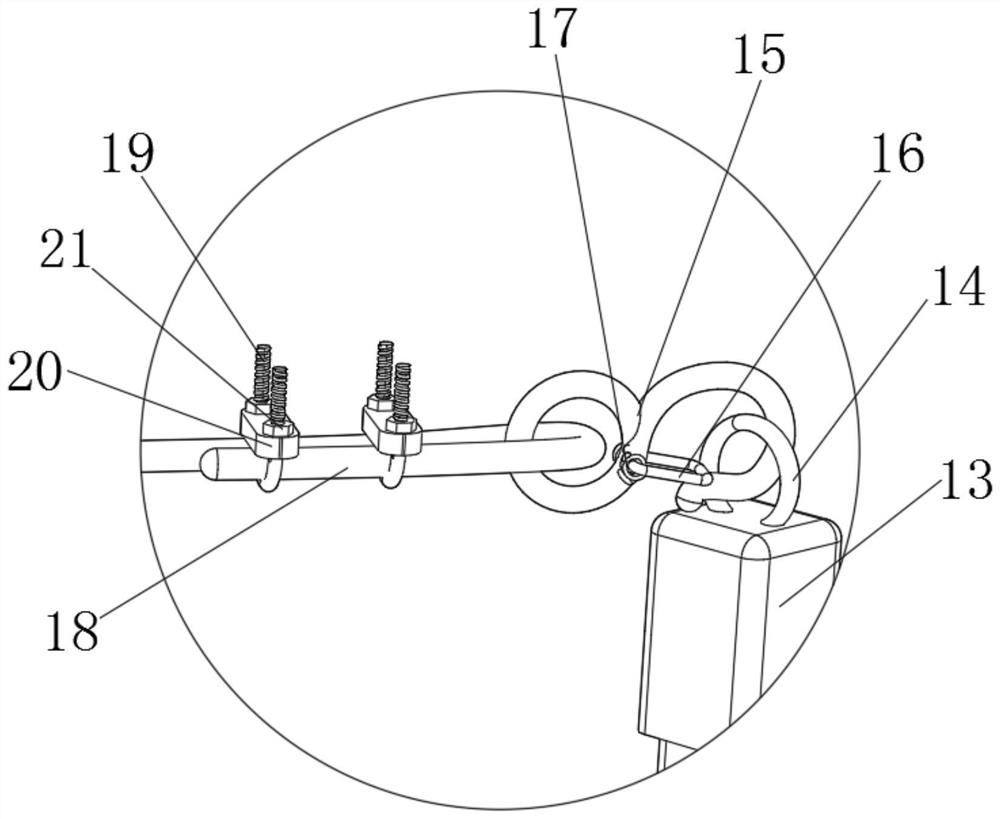

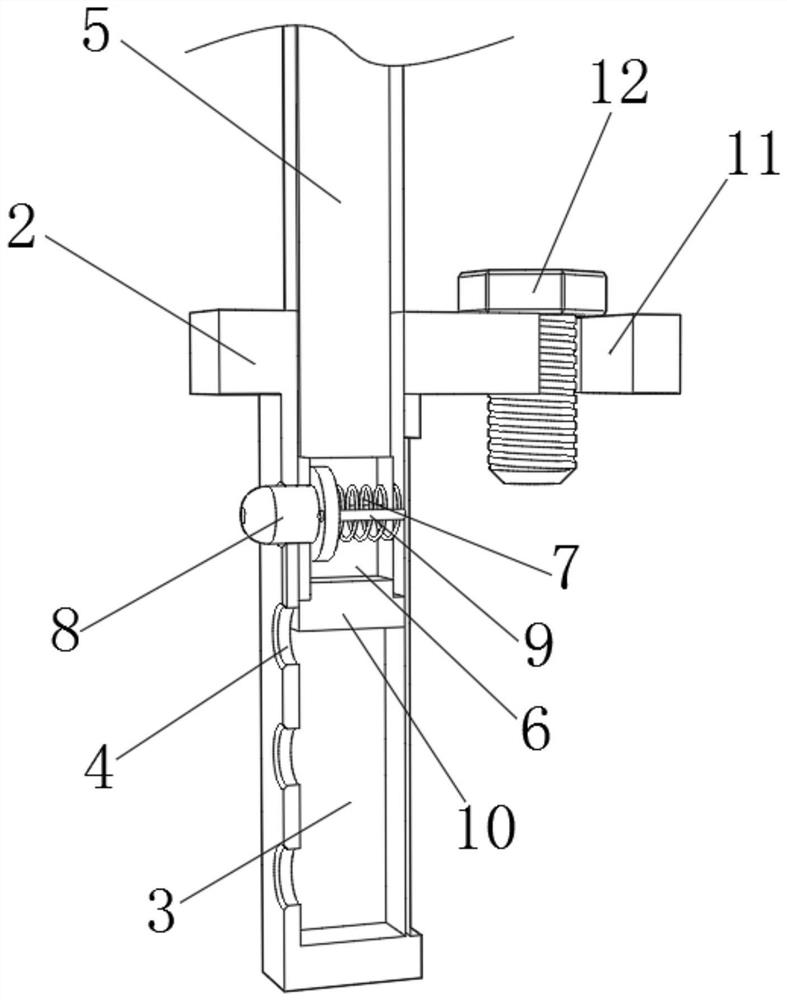

Novel transformer high-falling prevention device

PendingCN112354100AEasy to assemble and disassembleEasy to useSafety beltsSafety harnessElectrical and Electronics engineering

The invention relates to the technical field of transformers, and discloses a novel transformer high-falling prevention device. The novel transformer high-falling prevention device comprises a top plate and two quick-mounting bases, wherein an inserting groove is formed in the upper surface of each quick-mounting base; an insulating rod is arranged in each inserting groove; a plurality of clampingholes are formed in one side of each quick-mounting base; a mounting groove is formed in the bottom end of each insulating rod; a guide rod is movably connected in each mounting groove; one end of each guide rod is fixedly connected with a clamping shaft; each clamping shaft is clamped with the corresponding clamping hole; a first spring is arranged on one side of each guide rod; the top end of each insulating rod is fixedly connected with a mounting head; the top of each mounting head is fixedly connected with a hanging ring; a first hook is arranged on one side of each hanging ring; and a transverse pull rope is arranged on one side of each first hook. According to the novel transformer high-falling prevention device, a safety belt can be changed from traditional fixed-point suspensionto movable suspension, so that the condition that a maintainer loses protection when moving an operation site is avoided, and meanwhile, the moving direction of the maintainer can cover the whole maintransformer.

Owner:国网福建省电力有限公司清流县供电公司 +2

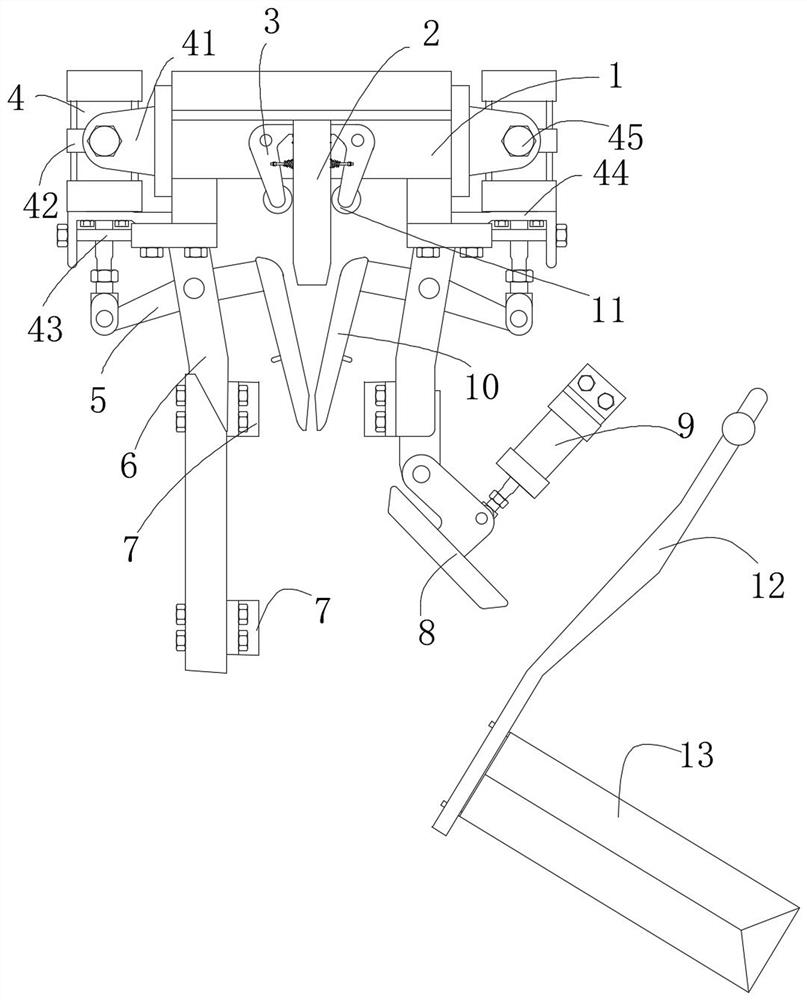

Rivet pulling mechanism and rivet pulling method

The invention discloses a rivet pulling mechanism and a rivet pulling method that the rivet pulling mechanism is adopted to carry out rivet pulling deformation on a blind nut. The rivet pulling mechanism comprises a compressing base, a thrust base and a pulling rod. The compressing base is used for abutting against the blind nut, the compressing base and the thrust base can be rotatably sleeved on the pulling rod around the pulling rod, the thrust base is in threaded connection with the compressing base, a first external thread matched with a first internal thread of the blind nut is arranged at one end, close to the compressing base, of the pulling rod, an axial limiting structure for axially limiting the thrust base is arranged at the other end, close to the thrust base, of the pulling rod, and the thrust base and the axial limiting structure can rotate relatively. The rivet pulling mechanism is simple in structure and low in cost, the rivet pulling method is easy and convenient to practice, needed operation space is very small when the rivet pulling deformation is carried out on the blind nut, and the working demand for small space rivet pulling is well met.

Owner:株洲时代金属制造有限公司

Screening and impurity removing process in rice flour processing

ActiveCN111589714AImprove qualityFully removedSievingShaking/oscillating/vibrating mixersBiotechnologyFiltration mechanism

The invention discloses a screening and impurity removing process in rice flour processing. The screening and impurity removing process comprises the following steps of 1, primary filtration, specifically, putting rice flour to be screened and subjected to impurity removal into a primary filtration mechanism for screening; 2, dispersing, specifically, dispersing the primarily filtered rice flour,dispersing the rice flour in a dispersing mechanism, and enabling the dispersed rice flour to fall into a frame box; and 3, refined filtration, specifically, when the rice flour enters the frame box from the dispersing mechanism, removing impurities through filtration of a second filter screen plate. In the extraction and adsorption processes, particles larger than meshes of a magnetic screen plate are filtered out and fall into a loading box, and the particles cannot enter an extraction pipe. Particles made of other materials are large in weight and are difficult to be sucked into a suction pipe by wind power so that the particles made of the other materials can remain in the loading box and cannot enter a middle frame. Preliminary filtration is conducted, and iron particles doped in therice flour, the particles made of the other materials and the particles larger than the meshes of the magnetic screen plate are screened out.

Owner:郴州湘亦佳食品有限公司

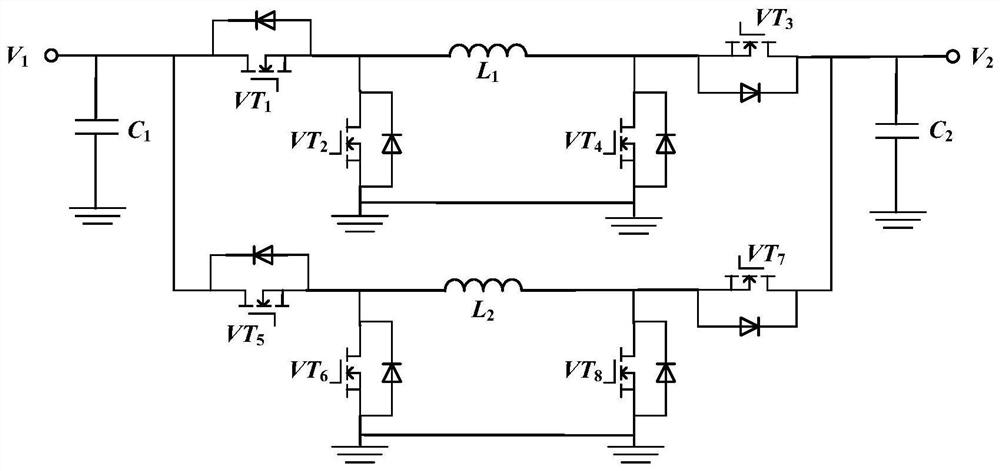

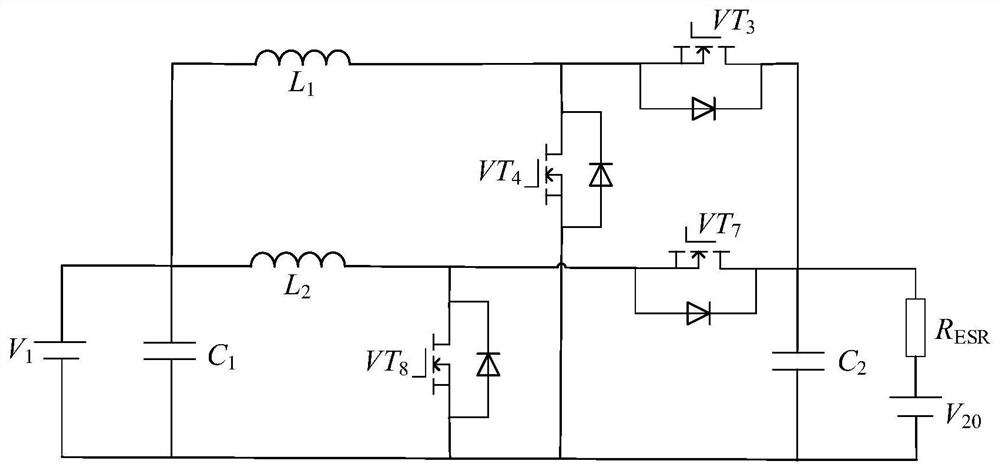

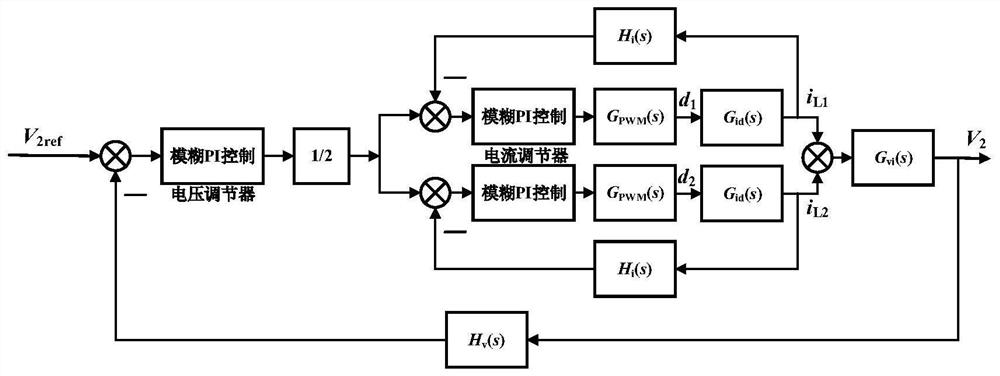

Fuzzy self-tuning PID control algorithm for interleaved parallel bidirectional DC/DC converter

ActiveCN113014098AImprove dynamic performanceFast dynamic responseDc-dc conversionElectric energy managementDc converterPid control algorithm

The invention discloses a fuzzy self-tuning PID control algorithm for an interleaved parallel bidirectional DC / DC converter, and belongs to the technical field of power electronics. The invention provides the fuzzy self-tuning PID control algorithm aiming at the characteristics that the dynamic response speed of a conventional PID control method system is relatively slow and the normal working requirement of an actual power supply system is difficult to meet, and the introduction of fuzzy control enables the dynamic response speed of current and voltage to be faster, the overshoot to be reduced and the current tracking precision to be higher; and aiming at the problem that parameters of each element of an actual working system are difficult to accurately measure, the fuzzy control can ensure the control effect under the condition that the parameters of a controlled system are uncertain. The design of the control process is simple, the response speed of the control system is high, the dynamic characteristic and the static characteristic are good, high stability and robustness are shown, and the control algorithm can be applied to occasions needing electric energy two-way transmission and conversion and the like.

Owner:HARBIN INST OF TECH AT WEIHAI +2

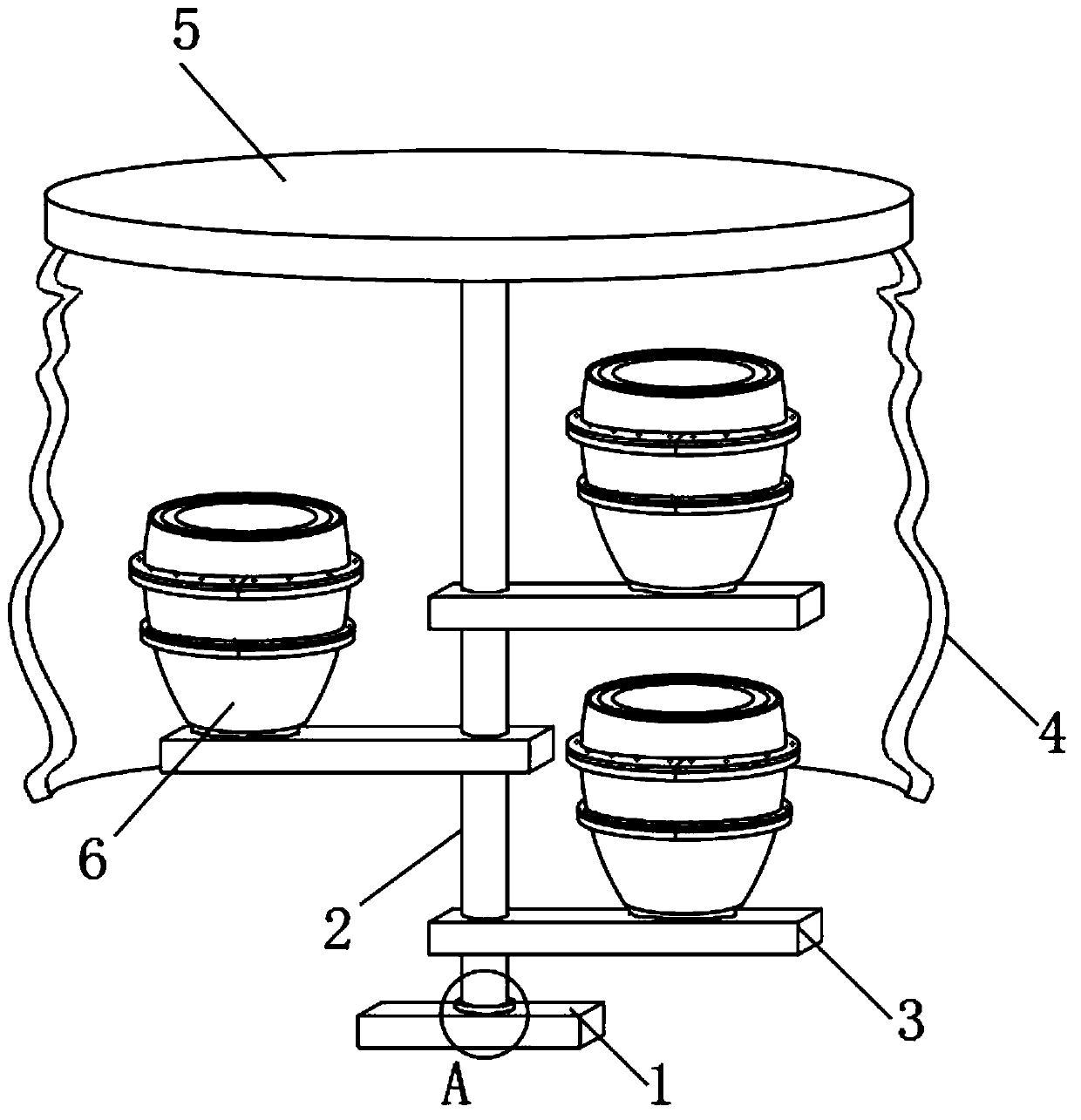

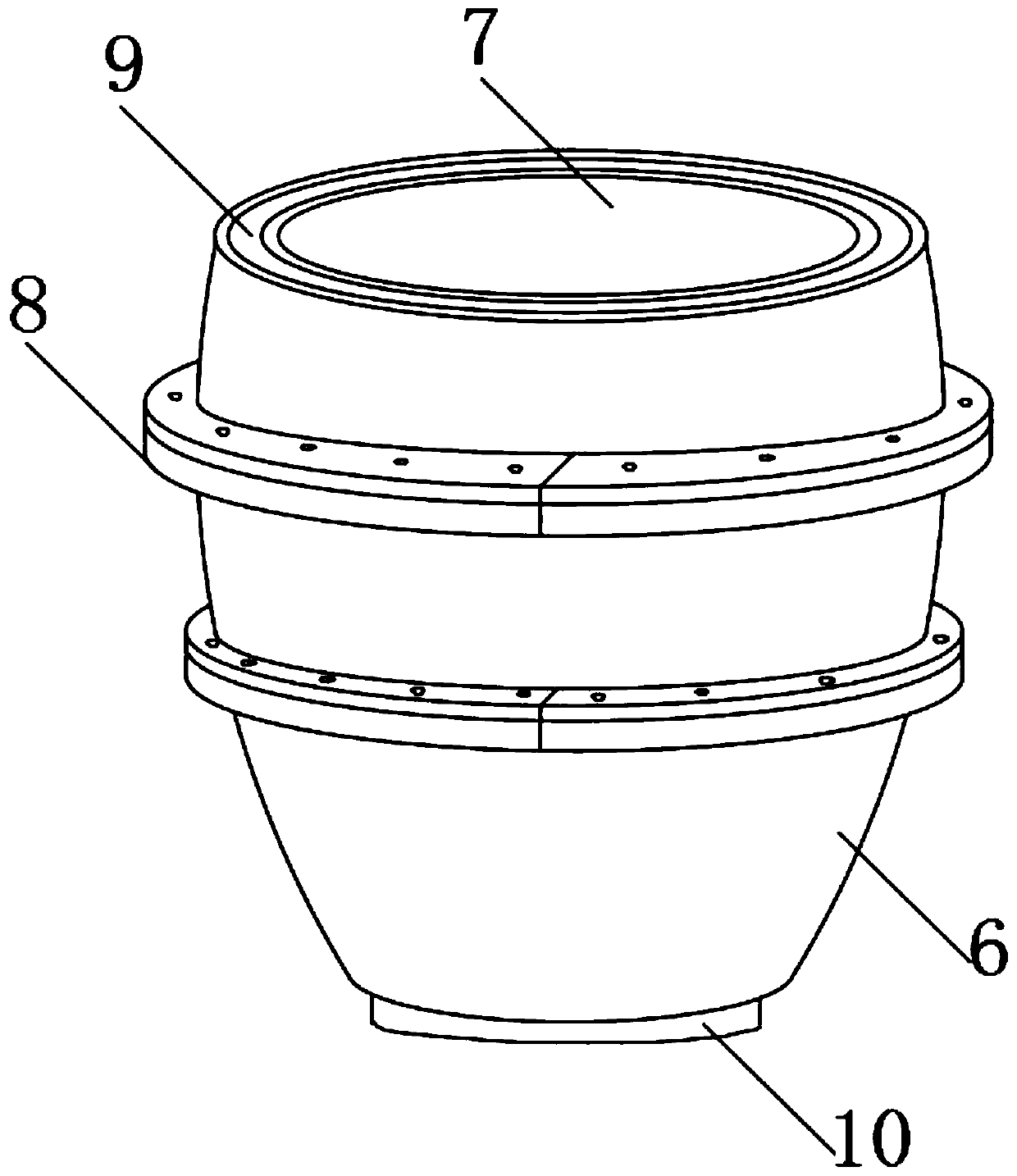

Multi-layer energy saving and environmental protection potted plant maintenance system and method

ActiveCN109744015AEasy to moveAdapt to different work needsDirect liquid fertiliser deliveryReceptacle cultivationEngineeringNutrient solution

The invention discloses a multi-layer energy saving and environmental protection potted plant maintenance system. The multi-layer energy saving and environmental protection potted plant maintenance system comprises a stabilizing seat, supporting rods, bearing plates and loading cylinders, the middle end of the top of the stabilizing seat is connected with the multiple supporting rods which are connected in an end-to-end mode, the bottoms of the supporting rods are connected with the horizontally-arranged bearing plates, and the loading cylinders are fixedly mounted at the tops of the bearing plates; and net plates are connected into the loading cylinders, mounting grooves are formed between the net plates and the inner walls of the loading cylinders and filled with sponge layers, and innerholes are formed in the middle ends inside the loading cylinders. According to the multi-layer maintenance system, the different numbers of the loading cylinders can be mounted according to differentneeds, the planting height is increased, and the planting height can be adjusted according to the size of plants during using. During planting, maintenance is convenient, time and labor saving is achieved during irrigating, a nutrient solution does not drip, the environmental protection effect is achieved, and the plants can be protected from damage in the growing process.

Owner:新昌县大船畈生物科技有限公司

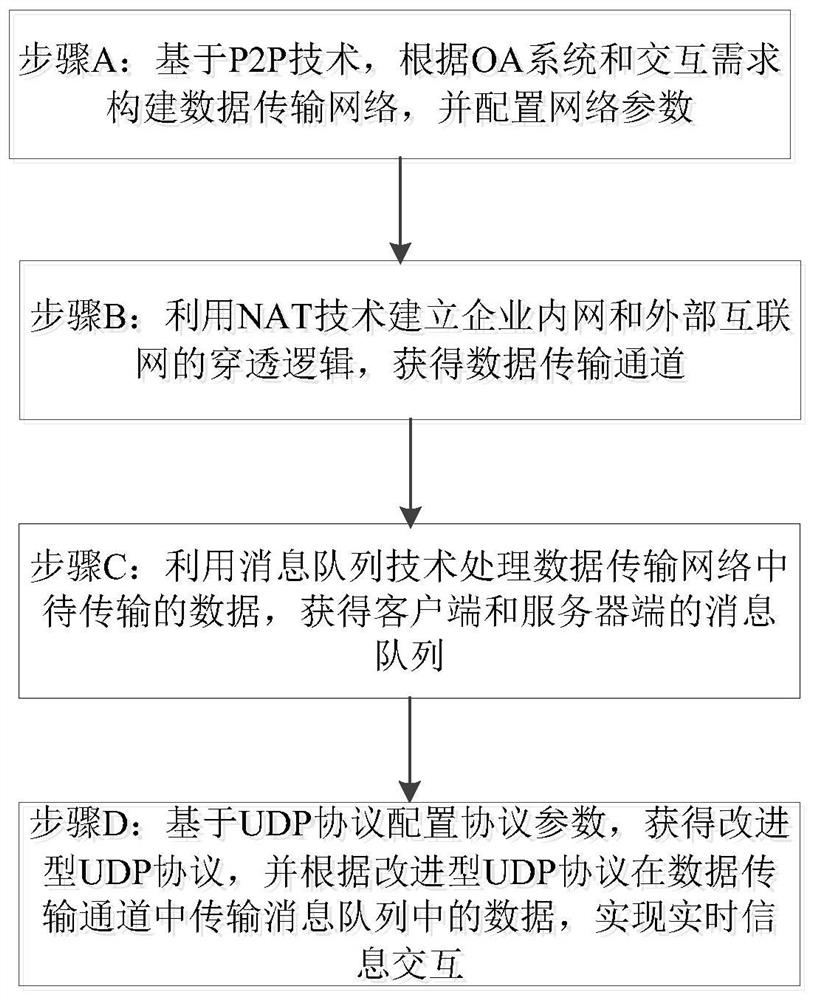

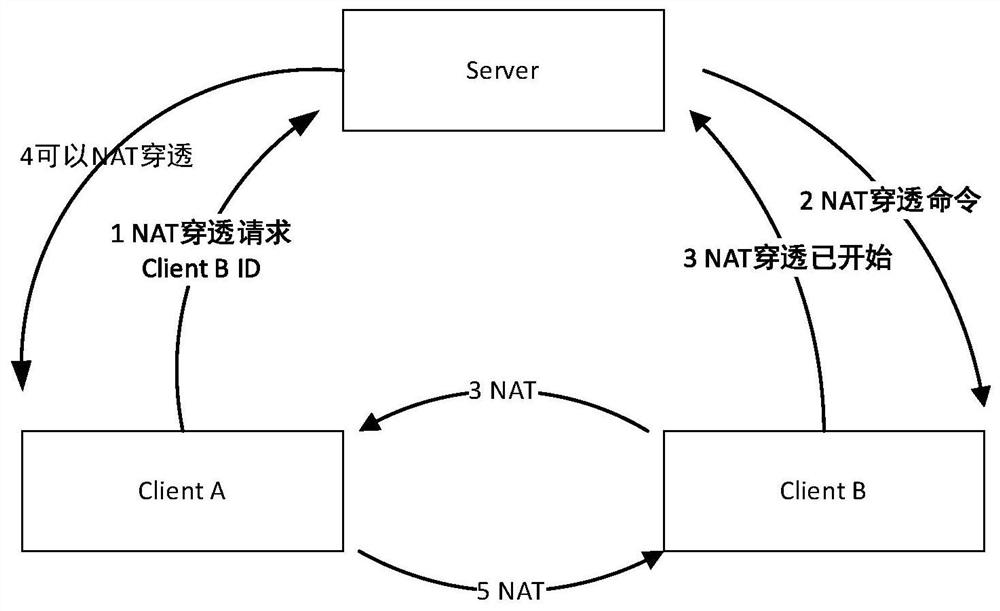

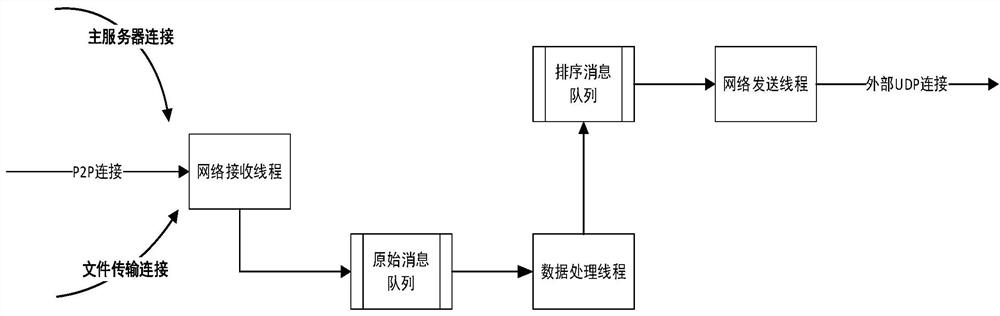

Real-time information interaction method and device for OA system and storage medium

InactiveCN111614546AThe connection relationship is simpleReduce development difficultyOffice automationData switching networksTime informationMessage queue

The invention discloses a real-time information interaction method and device for an OA system and a storage medium, and aims to solve the technical problems of poor real-time information interactionperformance and many messy codes of a traditional OA system based on a UDP protocol. The method comprises the following steps: constructing a data transmission network according to an OA system and aninteraction demand; establishing penetration logic of an enterprise intranet and an external internet by utilizing an NAT technology to obtain a data transmission channel; processing to-be-transmitted data in the data transmission network by using a message queue technology; and transmitting the data in the message queue in the data transmission channel based on the UDP protocol. According to theinvention, real-time information communication and cooperative work functions can be expanded for a traditional OA system based on a UDP protocol, and upstream and downstream full-process and multi-dimensional real-time information communication and cooperative work of the whole enterprise ecological chain across the internal and external networks of the enterprise are realized.

Owner:NARI INFORMATION & COMM TECH

Air drier and method

InactiveCN103143241BMeet the actual needs of dryingAchieve regenerationDispersed particle separationDesiccantAir dryer

The invention discloses an air drier and a method. The air drier comprises a shell and an inner bladder, wherein a closed cavity is formed between the shell and the inner bladder, a drying agent is filled in the inner bladder, the inner bladder is provided with an air inlet, an air outlet and an exhaust port, and the air outlet is respectively communicated with the exterior of the shell and the cavity. According to the method, the air drier can be used for drying compressed air and can realize regeneration of the drying agent. The air drier has a simple structure, is convenient to maintain, occupies a small space, and can meet actual demands on drying of the compressed air.

Owner:GUANGZHOU INST OF RAILWAY TECH

Automatic labeling device for packaging box

The invention discloses an automatic labeling device for packaging boxes, which comprises a base. The upper surface of the base is provided with a triangular work table, the center of the work table is provided with a driving gear, the drive gear is connected to the output shaft of a motor, and the work table is provided with a working track. There is a rotating table on the track, and the outer periphery of the rotating table is provided with gear teeth meshing with the driving gear. The working track includes an outer track and an inner track. The outer track has three straight tracks and an arc track. The straight track and the arc track form a closed The triangular track, the inner track is a circular track, the circular track intersects with the straight track, the outer side of the straight track is hinged with a guide rod, one end of the guide rod is provided with a front protrusion, and the other end of the guide rod is provided with a rear protrusion, two of which are connected to each other. The outer side of the adjacent straight track is equipped with the same one-side labeling device, and the other straight track is equipped with a box-taking device; the present invention realizes a fully automatic labeling operation with a simple structure and convenient operation.

Owner:CHENGDU LINGGAN YUANSU TECH CO LTD

Device for draining water from vacuum environment to normal pressure environment

InactiveCN103803475AAchieve dischargeLow running costLiquid flow controllersLiquid transferring devicesAtmospheric airWater flow

The invention belongs to the technical field of free jet ground simulation tests, and particularly relates to a device capable of draining water from an environment with pressure lower than atmospheric pressure to an atmospheric pressure environment. According to the technical scheme, the device for draining the water from a vacuum environment to a normal pressure environment comprises upper drain pipes (2), a liquid level switch (4), an upper drain valve (5), a vent valve (7) and lower drain pipes (9), the upper drain pipes (2) enable a vacuum tank (1), an upper drain flange (3) and a drain tank (6) to be connected, the liquid level switch (4) and the upper drain valve (5) are arranged on the upper drain pipes (2), the vent valve (7) is arranged on the drain tank (6), and the lower drain pipes (9) enable the drain tank (6), a lower drain flange (8) and a lower drain valve (10) to be connected. According to the device for draining the water from the vacuum environment to the normal pressure environment, the principle that water flows downwards is utilized, the fact that water in the vacuum environment is drained into the normal pressure environment is achieved, and the device for draining the water from the vacuum environment to the normal pressure environment has the advantages of being simple in structure, low in operation cost and capable of adapting work demands well.

Owner:BEIJING POWER MACHINERY INST

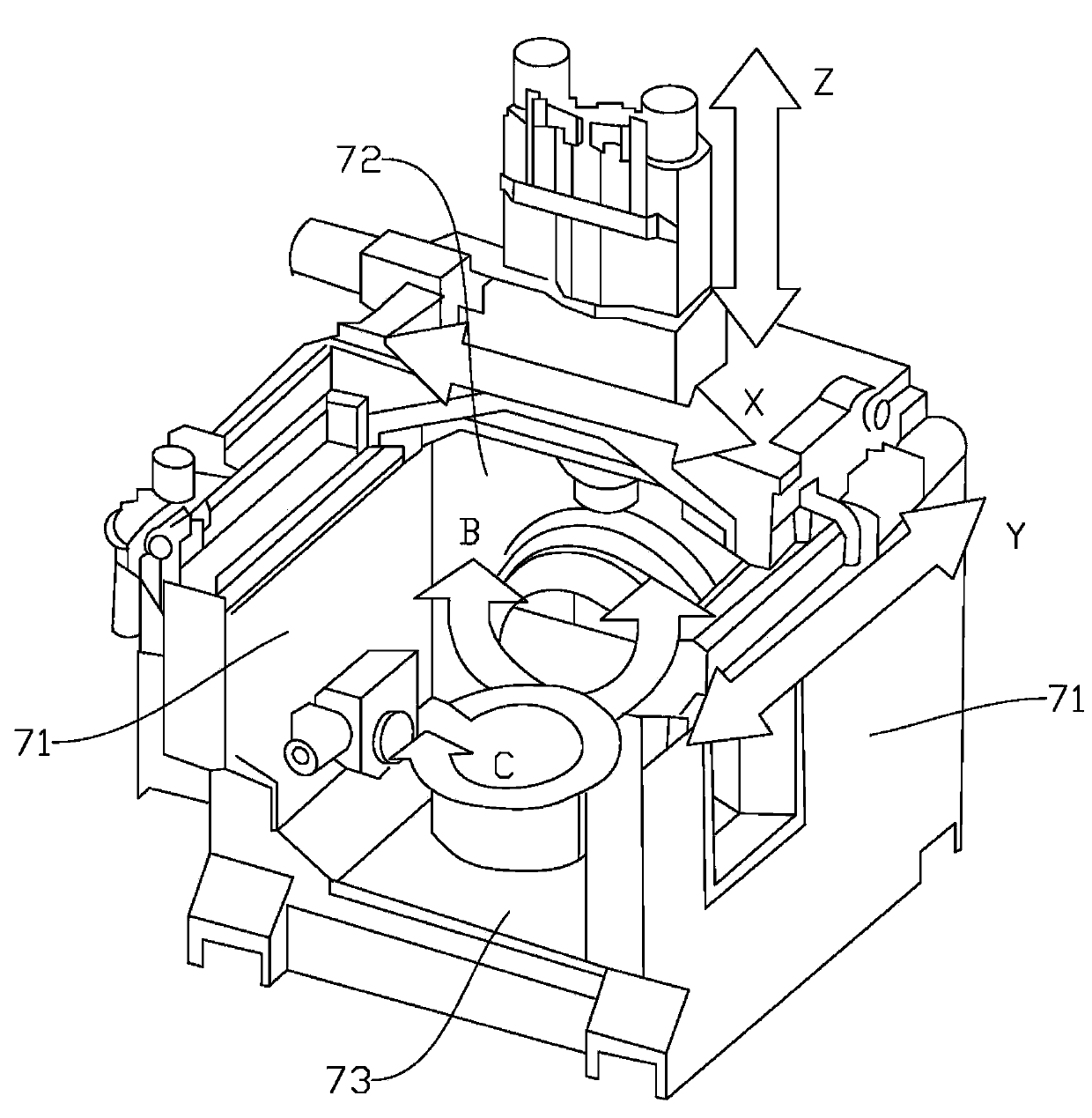

High-wall compact high-speed precision vertical machining center

InactiveCN103722453AImprove rigid stateCompact structureFeeding apparatusLarge fixed membersGratingEngineering

Provided is a high-wall compact high-speed precision vertical machining center. The high-wall compact high-speed precision vertical machining center is characterized in that a lathe base is of a box type structure which is composed of three vertical walls and a base plate in a sealing connection mode, an X-direction feeding mechanism is arranged on the top of the rear vertical wall, a Y-direction feeding mechanism is arranged on the top of one side vertical wall, and a Z-direction feeding mechanism is also arranged on the top of the rear vertical wall; the high-wall compact high-speed precision vertical machining center further comprises a B-axis and C-axis double-pendulum workbench which is arranged in the space defined by the lathe base, and is provided with a circular grating; center blind holes are formed in a lead screw of the X-direction feeding mechanism, a lead screw of the Y-direction feeding mechanism and a lead screw of the Z-direction feeding mechanism respectively, steel tubes are arranged in the center blind holes respectively, inner cavities of the steel tubes serve as liquid inlet flow channels, and are communicated with cooling liquid inlets respectively, a liquid turning flow channel is formed by one end of each steel tube and the blind end of the corresponding blind hole, and a liquid outlet flow channel is formed between the outer wall of each steel tube and the inner wall of the corresponding blind hole, and is communicated with a cooling liquid outlet. According to the high-wall compact high-speed precision vertical machining center, the purposes that the lengths of overhanging portions of shafts of a lathe are small, the overall rigidity is good, accuracy is improved, and the speed of rapid movement is increased can be achieved.

Owner:JINAN FIRST MACHINE TOOL GROUP

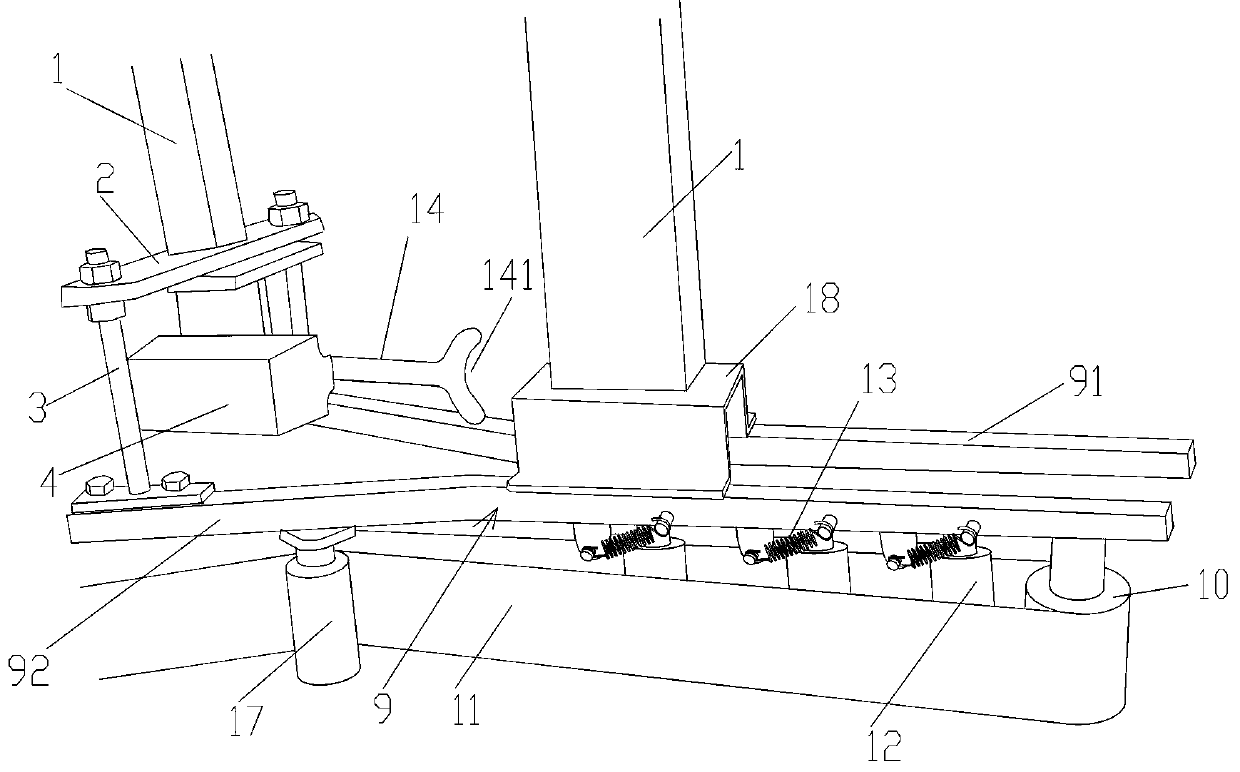

Butadiene styrene rubber finished product block packaging bag sealing device

PendingCN111017335AStrong pressing forceEasy crimpingWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses a butadiene styrene rubber finished product block packaging bag sealing device. The butadiene styrene rubber finished product block packaging bag sealing device solves the problems that an existing packaging bag sealing device is complex in structure relatively, and packaging bag continuous seal work cannot be conveniently achieved. The butadiene styrene rubber finished product block packaging bag sealing device comprises a machine sewing device and a conveying belt arranged below the machine sewing device and is characterized in that two pressing belts are arranged onthe upstream side of the machine sewing device, the conveying belt is located on the lower sides of the pressing belts, the upstream ends of the two pressing belts are opened towards the two sides inthe horizontal direction, and the downstream end sides are arranged next to each other side by side. The conveying belt is used for vertically conveying packaging bags contained with finished blocks,and an opening part of a packaging bag is pressed and attached by the two pressing belts, and is sewn by the machine sewing device.

Owner:浙江维泰橡胶有限公司

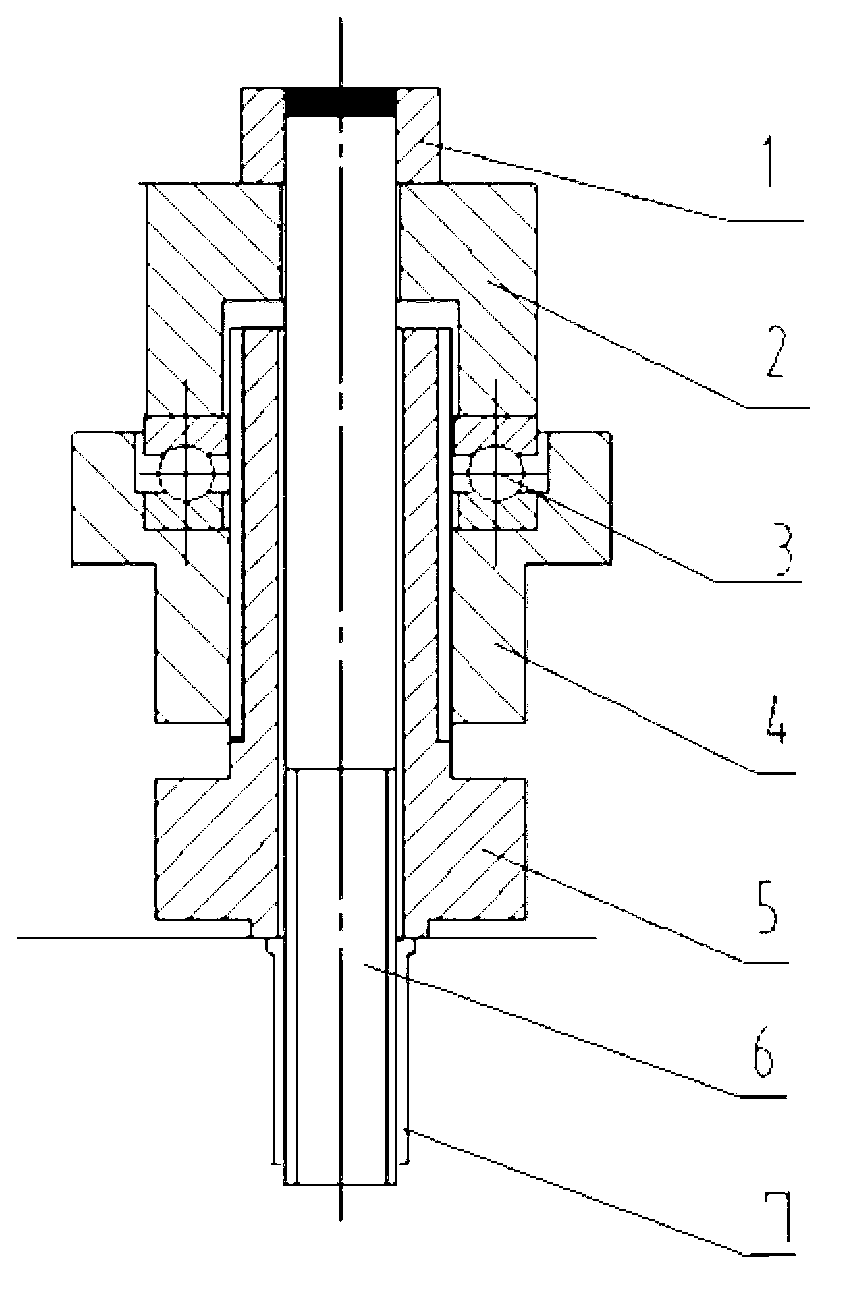

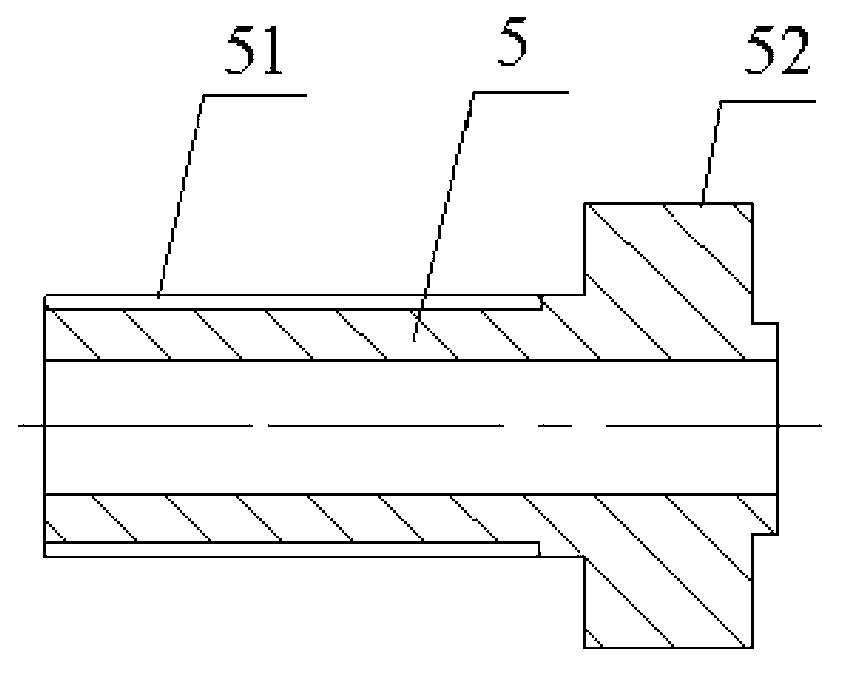

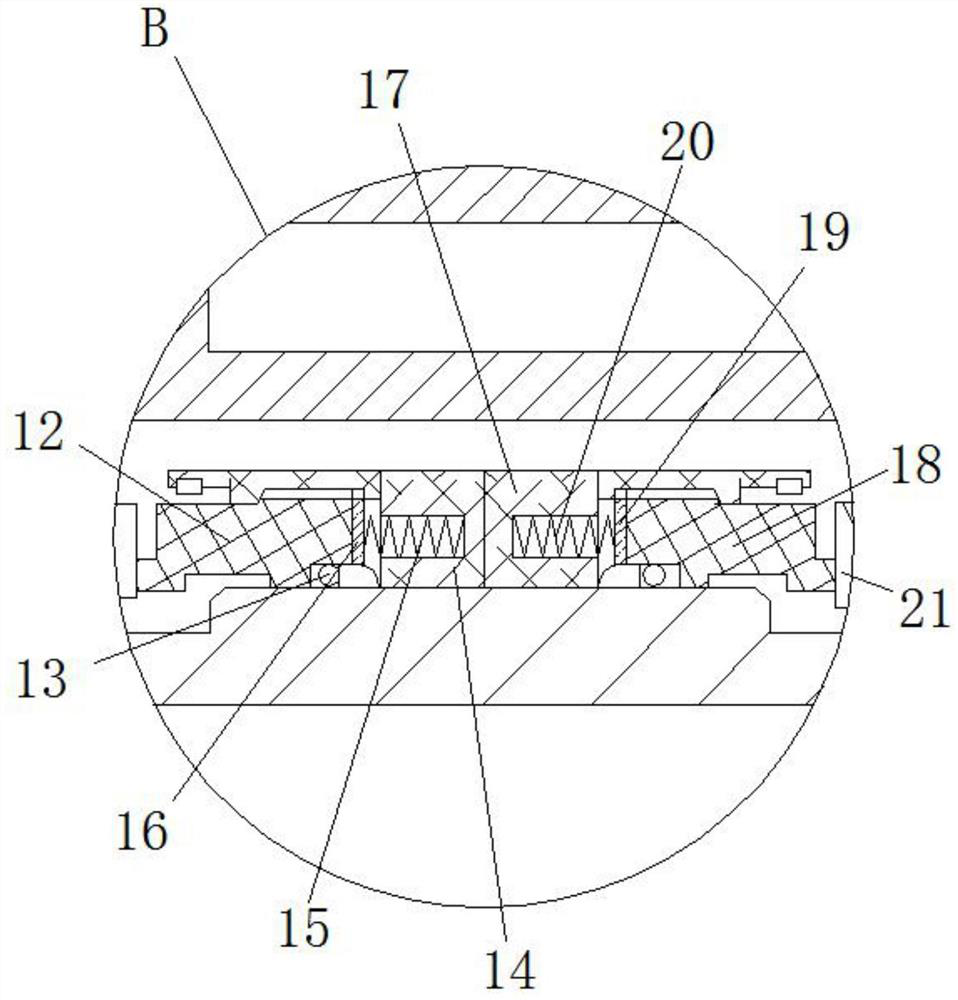

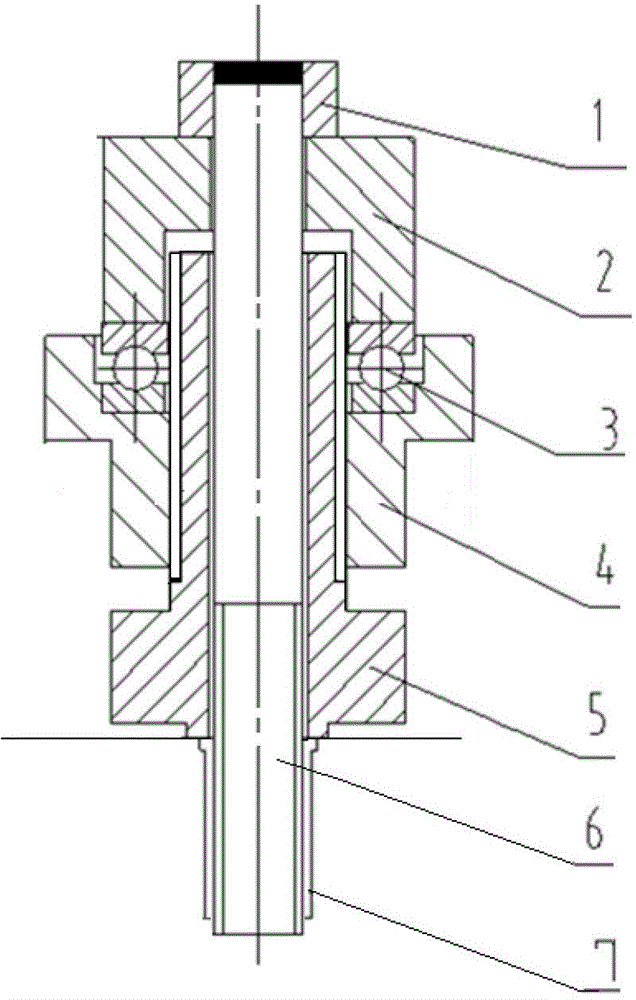

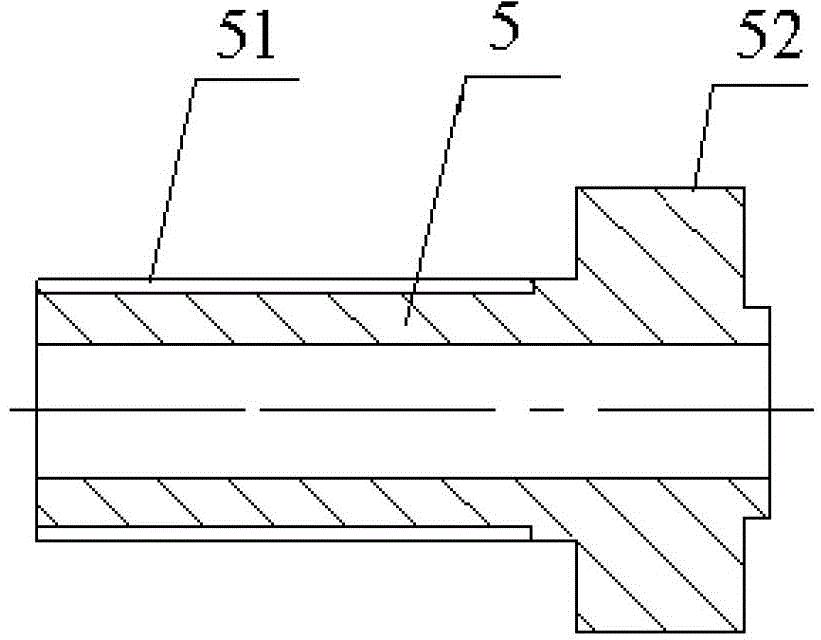

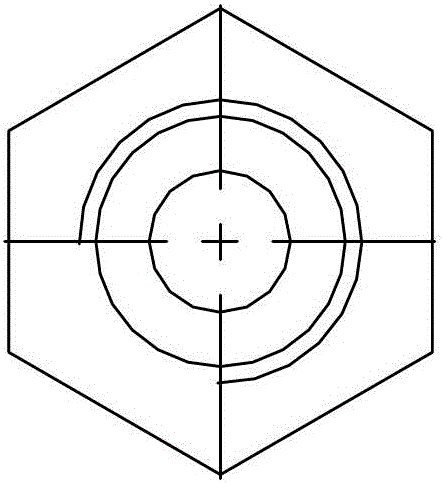

Large-axial-movement double-end-face mechanical sealing device for rake type dryer

PendingCN114087364AIncrease the amount of axial movementMeet the movement requirementsEngine sealsBearing unit rigid supportEnd face mechanical sealEngineering

The invention relates to a large-axial-movement double-end-face mechanical sealing device for a rake type dryer. The device comprises a shaft sleeve, a medium end static ring seat and an atmosphere side static ring seat are arranged on the shaft sleeve, a sealing seat is installed between the medium end static ring seat and the atmosphere side static ring seat, a corrugated pipe is installed at the left end of the shaft sleeve, a medium end flange is installed at the left end of the corrugated pipe, the medium end flange is connected with the medium end static ring seat through a screw, a single-end-face sealing assembly is arranged on the inner side of the medium end flange, a medium end sealing assembly and an atmosphere end sealing assembly are arranged on the shaft sleeve on the right side of the medium end static ring seat, and the medium end sealing assembly and the atmosphere end sealing assembly are both located on the inner side of the sealing seat. According to the large-axial-movement double-end-face mechanical sealing device for the rake type dryer, the axial movement amount can be increased through the corrugated pipe, then the movement requirement of the rake type type can be met, and dust in a medium can be prevented from entering the sealing face of a double-end-face mechanical sealing device through the single-end-face sealing assembly arranged at the medium end.

Owner:无锡全世全流体科技有限公司

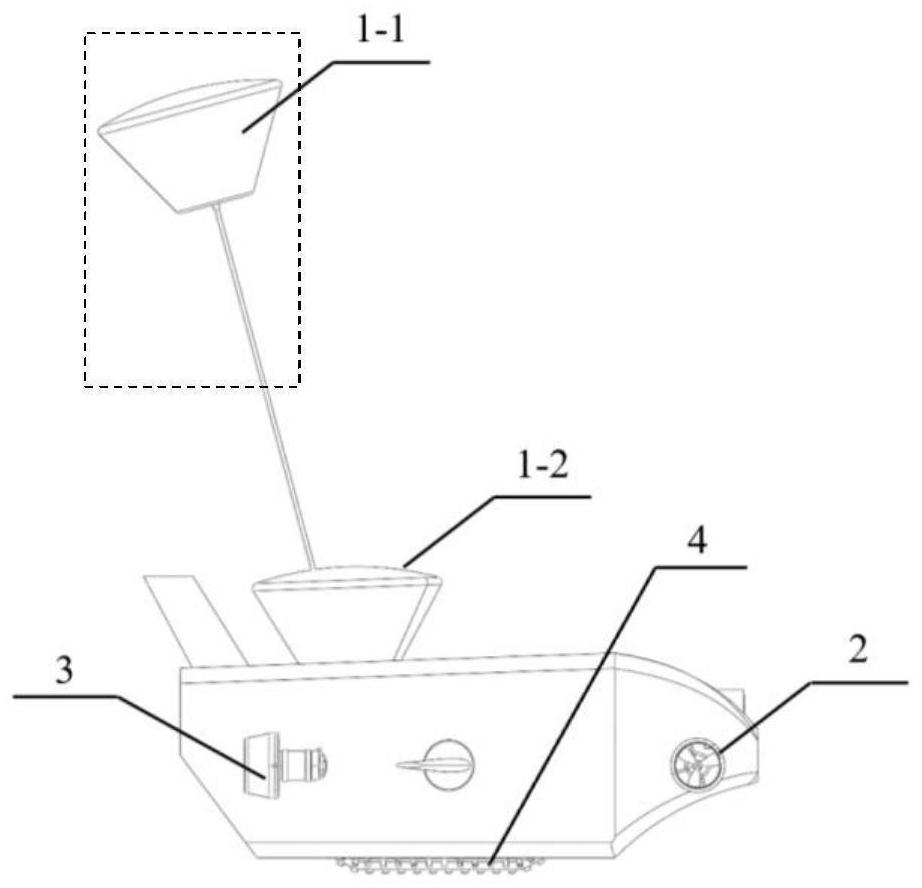

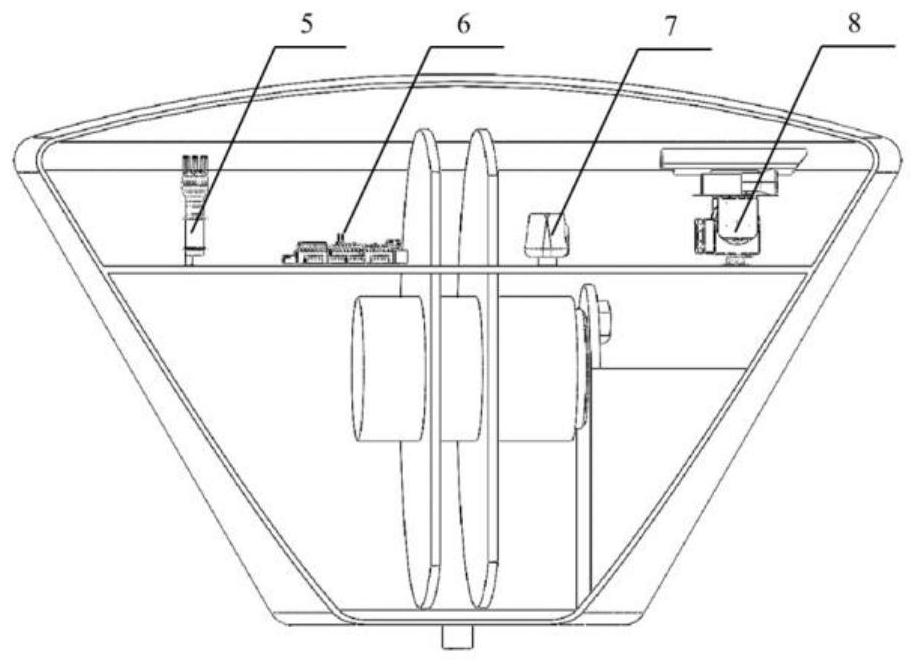

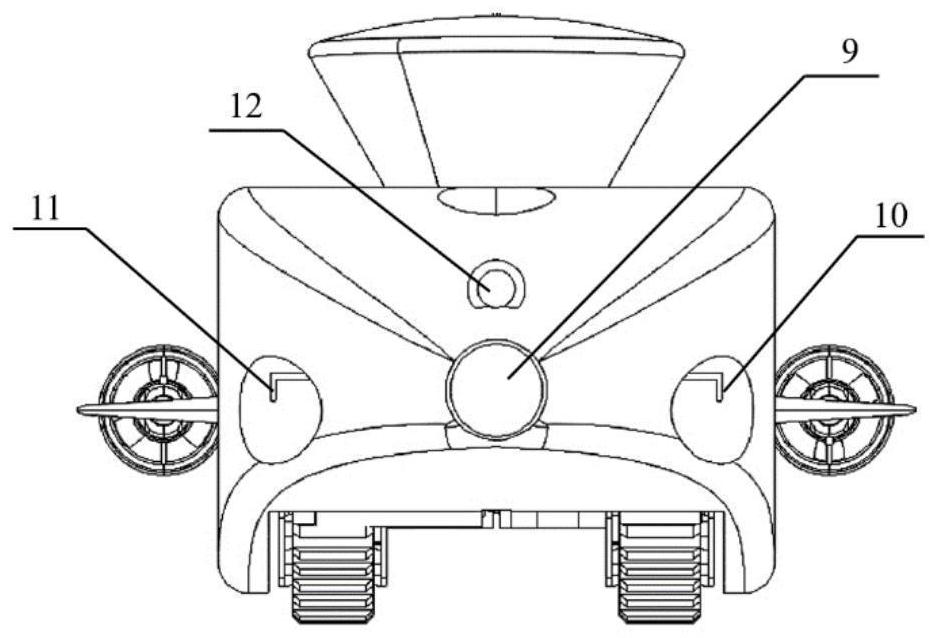

Mode self-adaptive switching method of amphibious unmanned vehicle

PendingCN114274719AOvercomes the disadvantage of requiring remote control by the operatorReduce workloadAmphibious vehiclesControl engineeringWorking environment

The invention relates to a mode self-adaptive switching method of an amphibious unmanned vehicle, and belongs to the technical field of vehicle engineering and ship industry. The invention provides a novel mode adaptive switching method in order to solve the problems that an existing amphibious unmanned vehicle is limited in autonomous function, and people need to control and switch modes of the amphibious unmanned vehicle in real time at an amphibious interface. According to the method, on the basis of structural feature models of the amphibious unmanned vehicle in three different working environments of land, water surface and underwater, an omnibearing mode self-adaptive switching method is built, so that the autonomous ability of the amphibious mode is improved, and the burden of operators is greatly relieved. The invention can be applied to the technical field of ship industry and the technical field of amphibious unmanned vehicles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

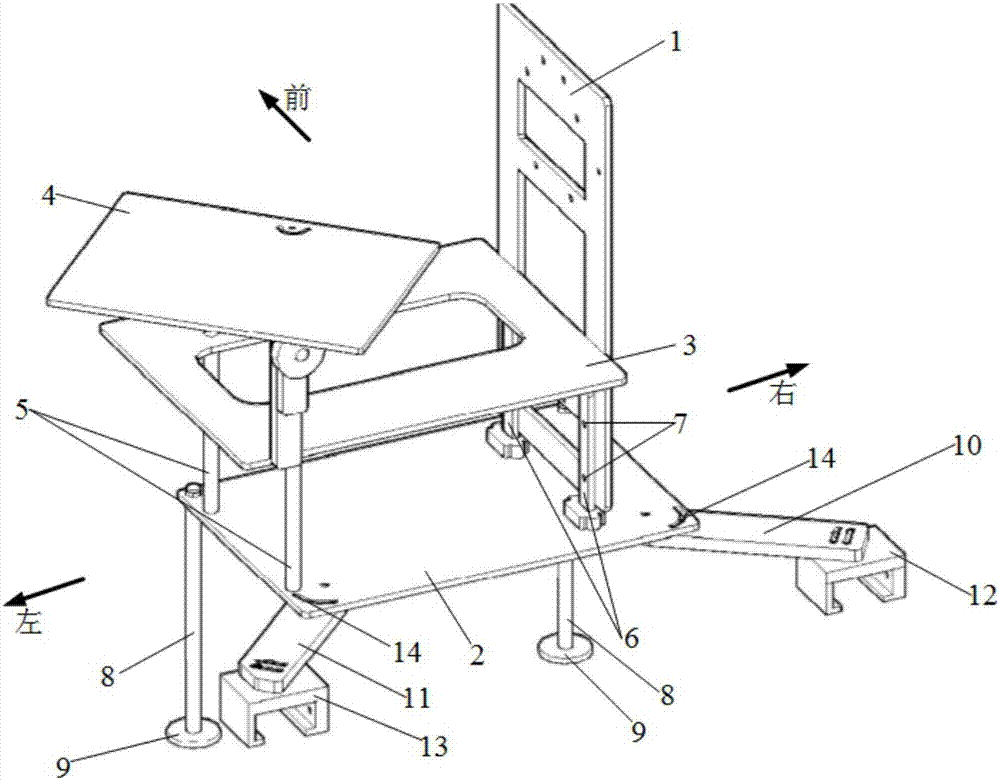

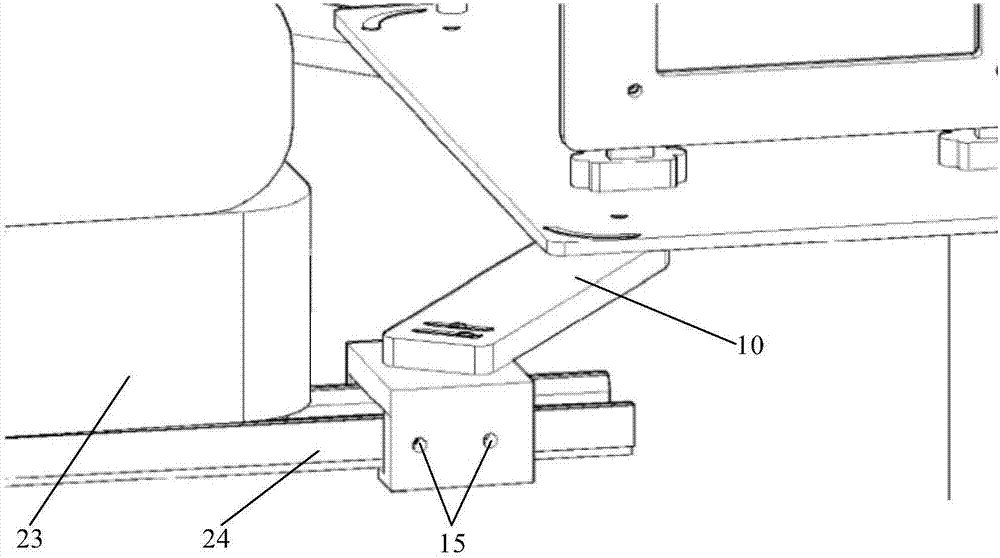

Vehicle-mounted equipment installation frame and map collection vehicle

The invention relates to the field of map collection vehicles and particularly relates to a vehicle-mounted equipment installation frame. The installation frame comprises at least one layer of flat installation plate and at least one vertical installation plate which are used for forming equipment installation positions; the equipment installation positions are fixed on a slide rail of an automobile seat by a slide rail fixing device. The invention further discloses a map collection vehicle. The installation frame is integrally connected with the vehicle body through fixation on the slide rail of the automobile seat, and the installation frame is stable and anti-knock, convenient to dismount and mount and good in compatibility; different equipment installation positions are arranged so that different equipment can be placed in classification; the flat installation plates are used for horizontally mounting the vehicle-mounted equipment, and the vertical installation plates are used for vertically mounting the vehicle-mounted equipment, so that the installation and use requirements of different equipment can be well met. According to the vehicle-mounted equipment installation frame and the map collection vehicle, connection cables of all vehicle-mounted equipment are effectively reduced, commissioning and management of operation staff are facilitated, the system stability and the heat dissipation performance are improved greatly, and at the same time, the space in the vehicle is saved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

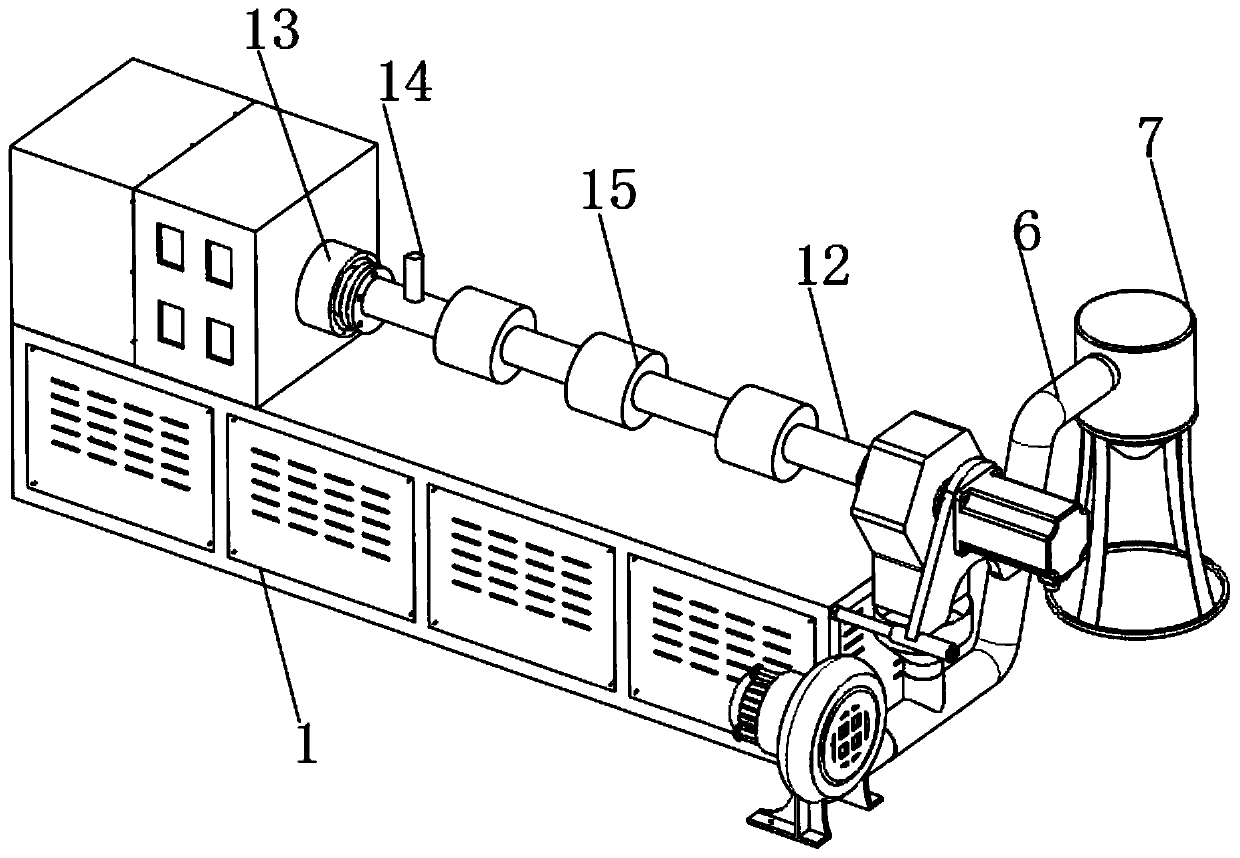

Injection device for production for insulation protection cover of fuse, and use method thereof

The invention discloses an injection device for production for an insulation protection cover of a fuse. The injection device for production for the insulation protection cover of the fuse comprises aloading pipe, a heating tank and a discharge head, wherein the loading pipe is installed on the upper part of a base; an end part seat and a bearing table are connected to the two ends of the top ofthe base separately; the two ends of the loading pipe are connected with the end part seat and the bearing table, and a rotary shaft rod is rotationally installed in the loading pipe in a penetratingmanner in a length direction; and the rotary shaft rod is rotationally installed between the end part seat and the bearing table. A raw material can be driven to move in the loading pipe through the rotation of a plurality of impeller sheets, and then moves towards one end of the heating tank, and the raw material enters into a middle-part pipe in the movement process; and a plurality of crushingrods outside an annular plate crush the raw material in the middle-part pipe, so that the volume of the raw material is reduced, and then the raw material is more convenient during movement, smaller in resistance, and smoother in flowing.

Owner:戴文忠

Rivet pulling mechanism and rivet pulling method

The invention discloses a rivet pulling mechanism and a rivet pulling method that the rivet pulling mechanism is adopted to carry out rivet pulling deformation on a blind nut. The rivet pulling mechanism comprises a compressing base, a thrust base and a pulling rod. The compressing base is used for abutting against the blind nut, the compressing base and the thrust base can be rotatably sleeved on the pulling rod around the pulling rod, the thrust base is in threaded connection with the compressing base, a first external thread matched with a first internal thread of the blind nut is arranged at one end, close to the compressing base, of the pulling rod, an axial limiting structure for axially limiting the thrust base is arranged at the other end, close to the thrust base, of the pulling rod, and the thrust base and the axial limiting structure can rotate relatively. The rivet pulling mechanism is simple in structure and low in cost, the rivet pulling method is easy and convenient to practice, needed operation space is very small when the rivet pulling deformation is carried out on the blind nut, and the working demand for small space rivet pulling is well met.

Owner:株洲时代金属制造有限公司

Air pressure conversion device used for air-powered vehicle

InactiveCN109779692ASimple device structureReasonable designMachines/enginesSafety/regulatory devicesPistonPiston cylinder

The invention discloses an air pressure conversion device used for an air-powered vehicle. The air pressure conversion device comprises a piston cylinder, the piston cylinder is of a rectangular cavity structure, the top of the piston cylinder is in opening design, a rectangular box is fixed to the top of the piston cylinder, the bottom of the rectangular box is in opening design, the top of the rectangular box is fixedly provided with a conversion motor through a motor rack, the output shaft end of the conversion motor is fixedly provided with a screw, the surface of the screw is movably connected with a sliding block, a conversion sliding block is fixed to the front face of the sliding block, an air inlet is formed in the left side wall of the conversion sliding block, and an air outletgroove is formed in the right side wall of the conversion sliding block. The device is simple in structure, reasonable in design, small in size, and convenient to mount, cost is saved to a certain degree, maintaining difficulty is reduced, through fit of the conversion motor and the conversion sliding block, the air pressure in the conversion sliding block changes in a reciprocating and circulating manner, and the device adapts to work needs.

Owner:冯梁苌

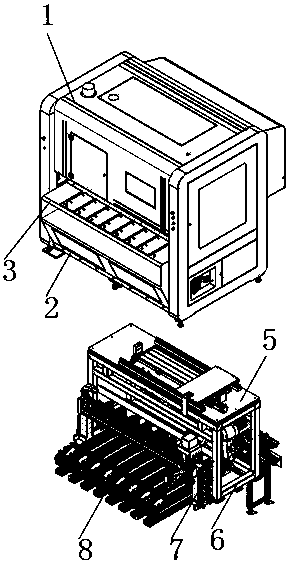

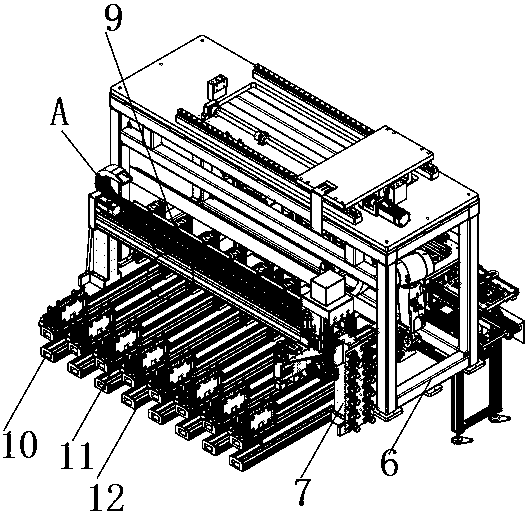

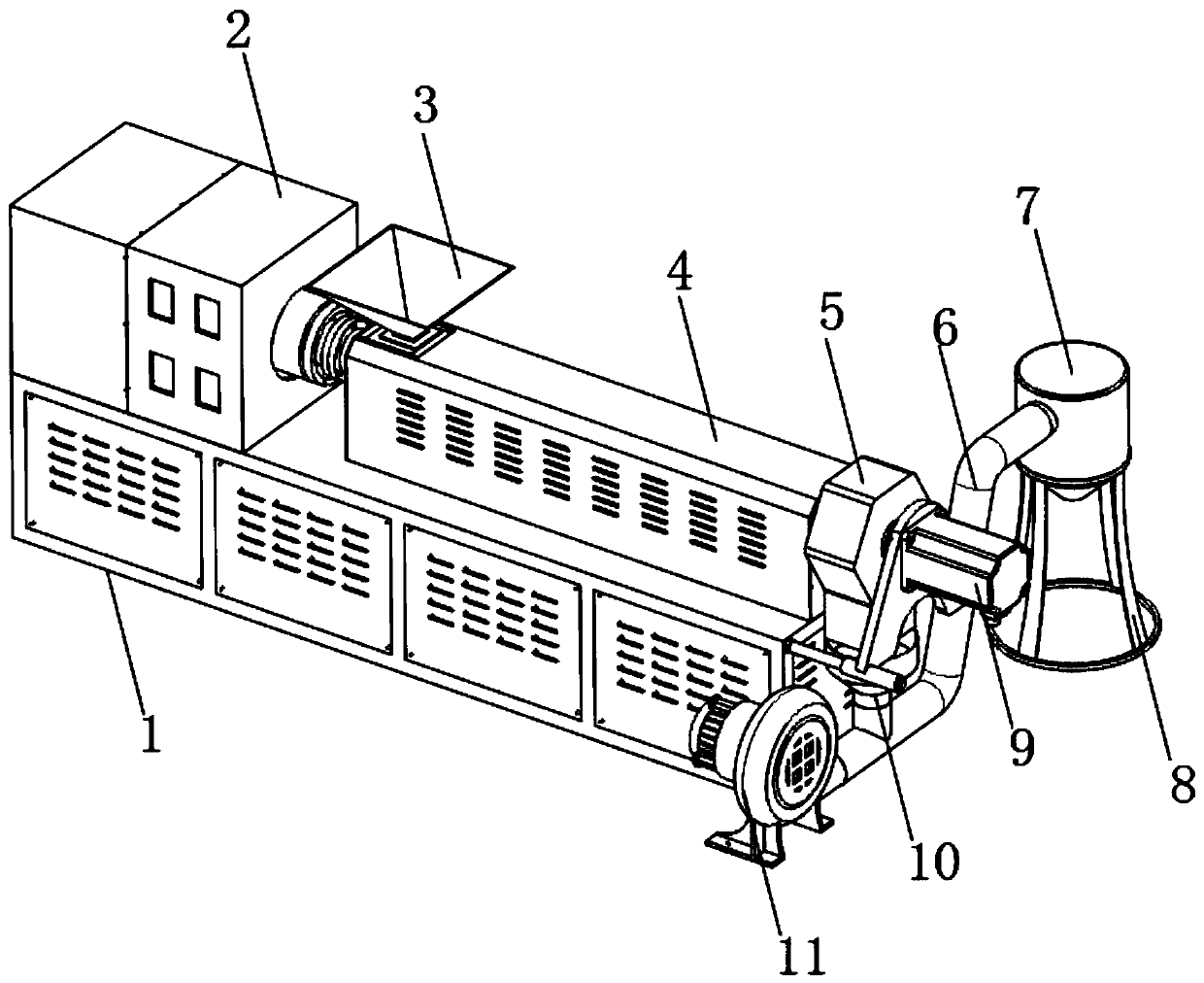

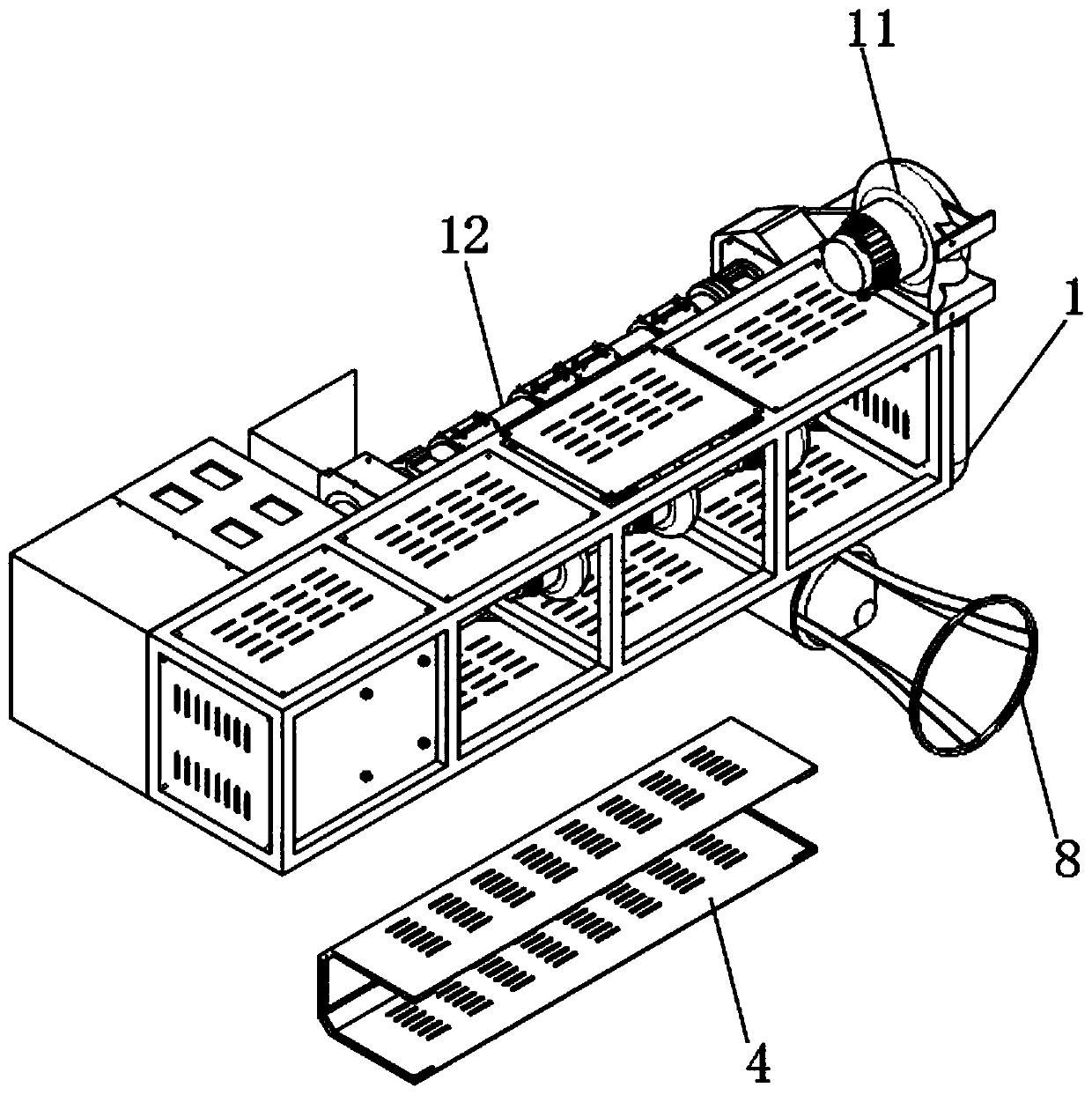

Styrene Butadiene Rubber Finished Block Packaging Mechanism

ActiveCN111017331BHigh degree of automationAdapt to work needsPackagingStructural engineeringConveyor belt

The invention discloses a packaging mechanism for finished styrene-butadiene rubber blocks, which solves the problems that the existing styrene-butadiene rubber finished blocks are inconveniently packaged and cannot well adapt to the work requirements of a styrene-butadiene rubber production line. The technical measures adopted are: 1. A styrene-butadiene rubber finished product block packaging mechanism is arranged on the outlet end side of the production line, and includes a connecting seat in which a conveying channel for the finished product block to pass is formed, and is characterized in that a conveying frame is arranged on the upstream side of the conveying channel, The conveying frame is rotatably arranged on the upper side of the connecting seat, and the conveying frame is connected with the power mechanism to transport the finished product block output from the outlet end of the preparation line into the conveying channel; the lower side of the connecting seat is provided with a packaging bag The mouth is socketed in the mouth structure, the lower side of the mouth structure is provided with a conveyor belt, and the conveying channel extends downward to the mouth structure, so that the finished product block directly enters the packaging bag from the conveying channel, and under the action of gravity , so that the packaging bag falls onto the conveyor belt together with the finished pieces.

Owner:浙江维泰橡胶有限公司

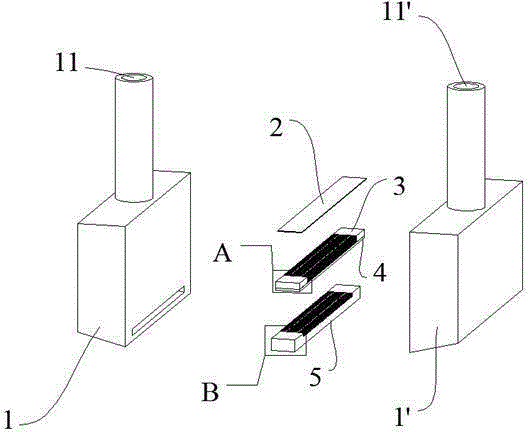

Inkjet print head and inkjet printer

ActiveCN103496257BBraking structure is simpleLarge amount of deformationInking apparatusComputer printingInk printer

The invention discloses an inkjet printing head, which comprises at least one ejection unit, a cover film matched with the ejection unit, a piezoelectric ceramic actuator and a cover plate, a fluid inflow pipeline, a fluid outflow pipeline and a driving circuit device ; The piezoelectric ceramic brake and the cover plate are connected to form a number of independent piezoelectric ceramic units that are not connected to each other; the cover plate is connected to the injection unit, and the connection contact surface is provided with a number of fluid grooves on one side of the injection unit. The position of the unit corresponds to the position of the groove of the fluid tank; the fluid channel and the cover plate form a fluid channel, and each fluid channel is correspondingly equipped with at least one nozzle leading to the outside, so that the inkjet print head forms side or end surface spraying. Correspondingly, the invention also discloses an inkjet printer. With the present invention, on the premise of increasing the deformation of the piezoelectric ceramic brake and realizing the effective ejection action of the large-diameter ink, adjacent nozzles can operate simultaneously so that all nozzles can work simultaneously, thereby improving work efficiency.

Owner:JIN GANG NEW MATERIALS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com