Butadiene styrene rubber finished product block packaging bag sealing device

A sealing device and styrene-butadiene rubber technology, applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of poor work continuity, inability to ensure the sealing effect of packaging bags, complex structure, etc., and achieve reasonable setting , compact size, convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

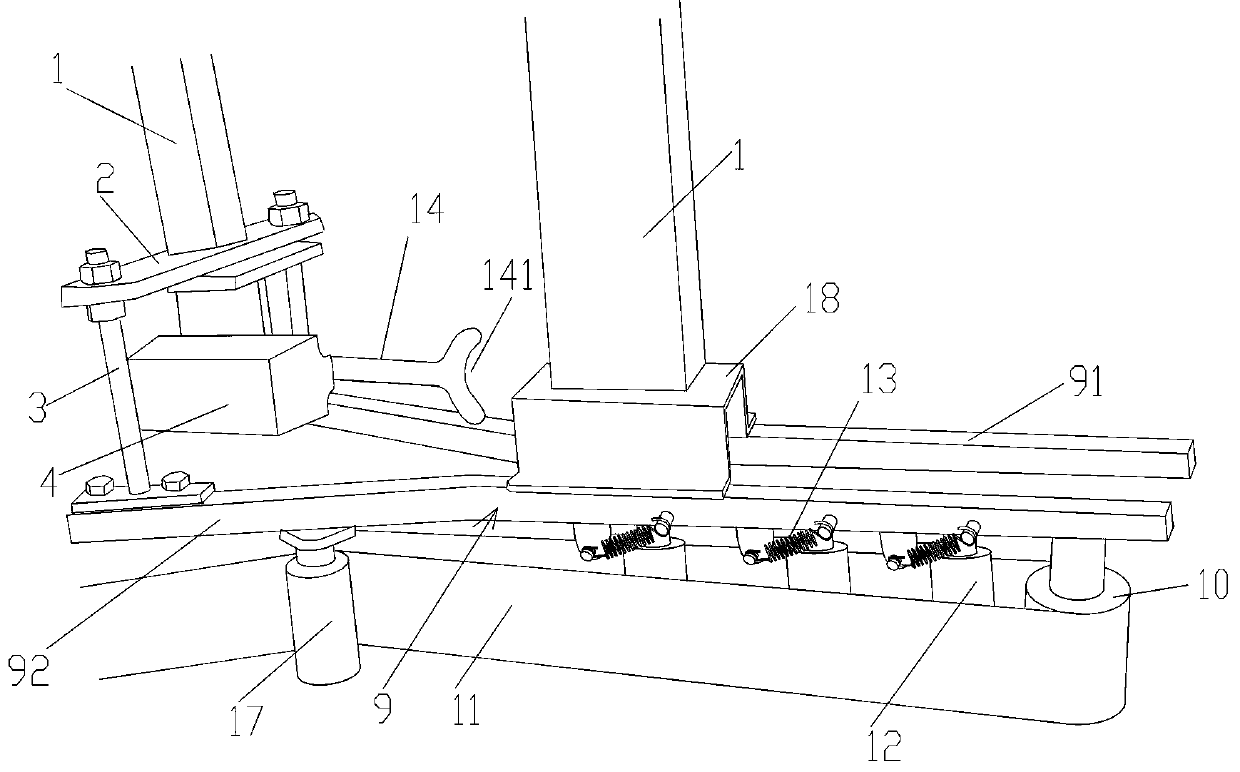

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0025] The packaging bag sealing device is used to sew up the mouth of the packaging bag 16, and the packaging bag 16 is used to pack the styrene-butadiene rubber finished block, and the finished block is a cuboid. In order to adapt to the packaging of finished blocks, a space in the shape of a quadrangular prism may be formed in the applied packaging bag 16 to accommodate the finished blocks. The bottom of packaging bag 16 forms a planar body by the mode of folding and pasting, and after packaging bag 16 suits finished block, the end top of finished block is pressed on this planar body, and the mouth of packing bag 16 is open. When the packaging bag 16 is prepared and molded, it is necessary to form inwardly foldable folds 161 on both sides, see image 3 , 4 The packaging bag 16 is basically folded into a sheet before being assembled into a finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com