Wall template bottom plugging device, template supporting system and formwork construction method

A plugging device and formwork technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of inability to achieve flexible adjustment, plugging and sticking. Insufficient fit, poor pulp stop effect, etc., to achieve the effect of promoting overall quality improvement, convenient replacement and replacement, and high turnover rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below in conjunction with the accompanying drawings.

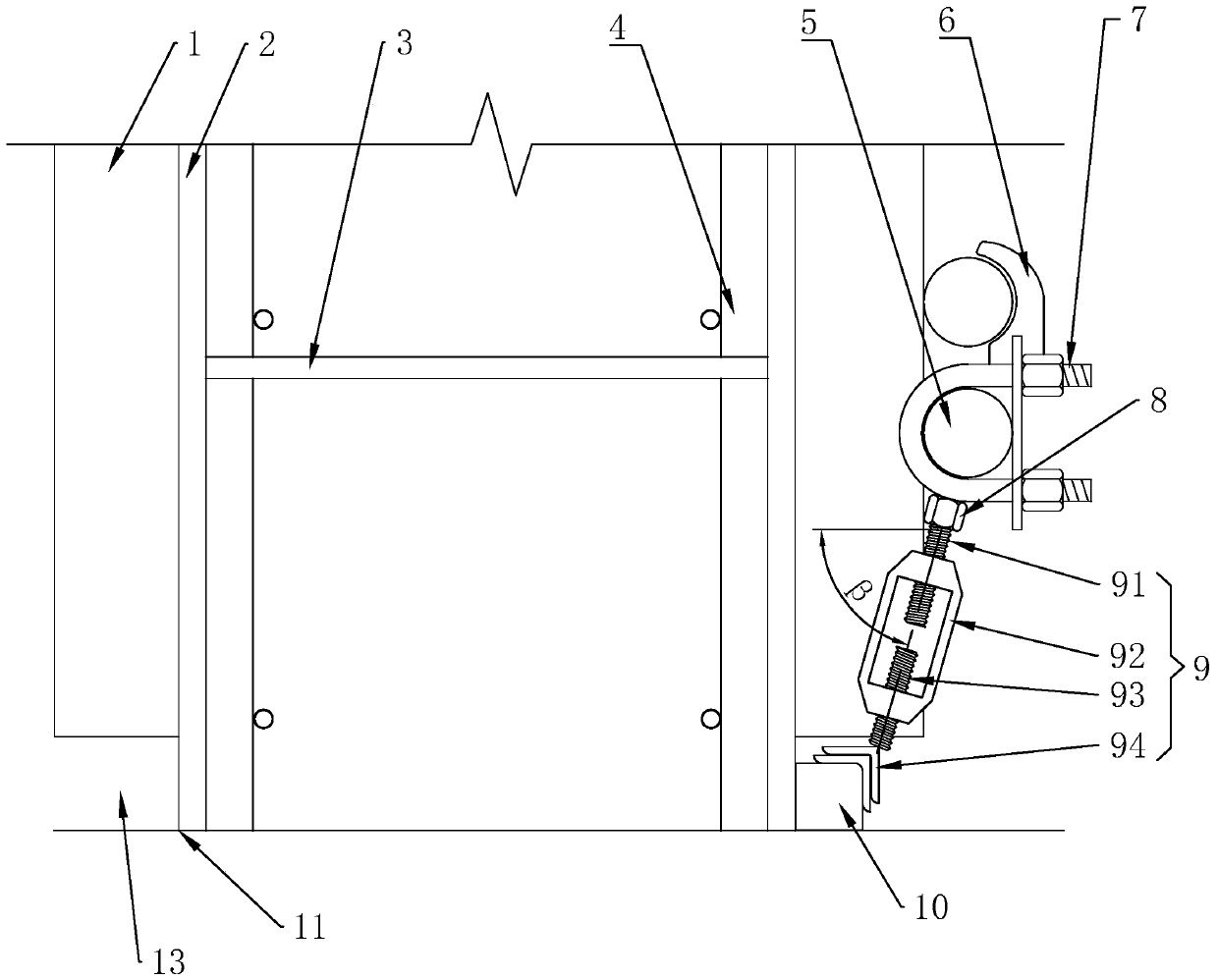

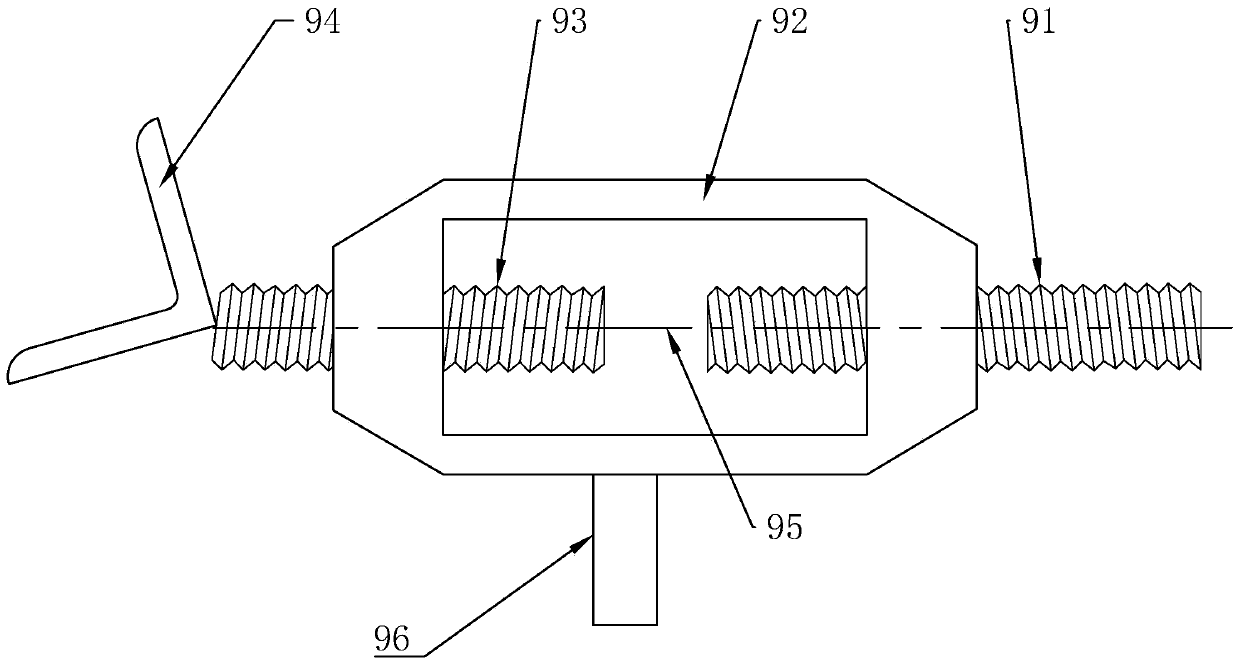

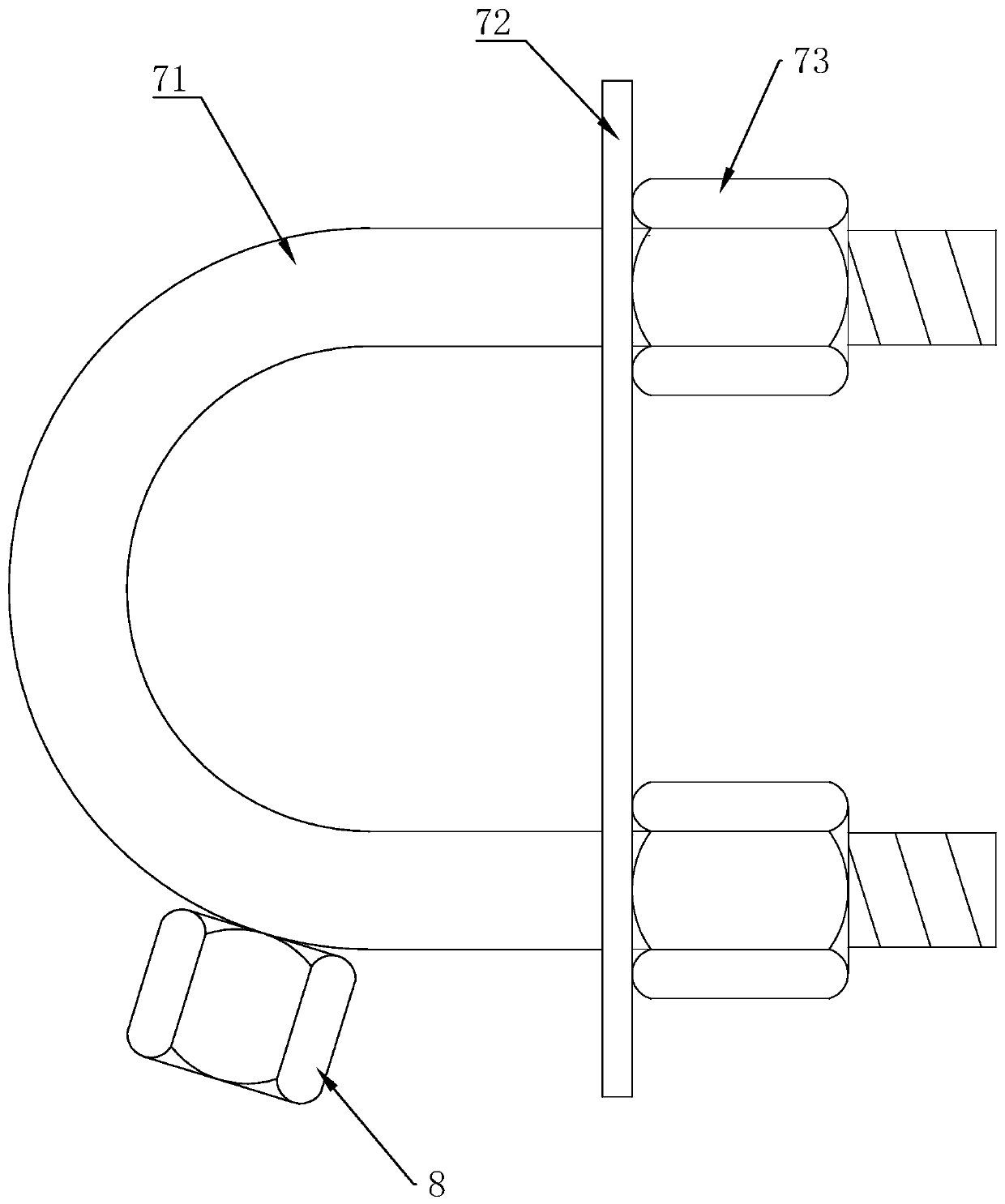

[0058] Please also refer to figure 1 and figure 2 as well as Figure 4 As shown, it is a wall formwork bottom sealing device disclosed by the present invention, which is installed in a formwork structure provided with a steel pipe main keel 5, and includes a locker 7, a grout-stopping structure 10 and an adjustment structure 9; the locker 7 and the most The lower steel pipe main keel 5 is detachably connected; the slurry stop structure 10 includes a flexible sealing body 101 for abutting against the part 11 to be blocked at the bottom of the formwork; the adjustment structure 9 includes an adjustment frame 92, and one end is threadedly connected to the adjustment frame 92 The first adjusting screw 91 and the second adjusting screw 93 and the first connecting body 94 used to compress the slurry structure 10, the first adjusting screw 91 and the second adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com