Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Achieve precise cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

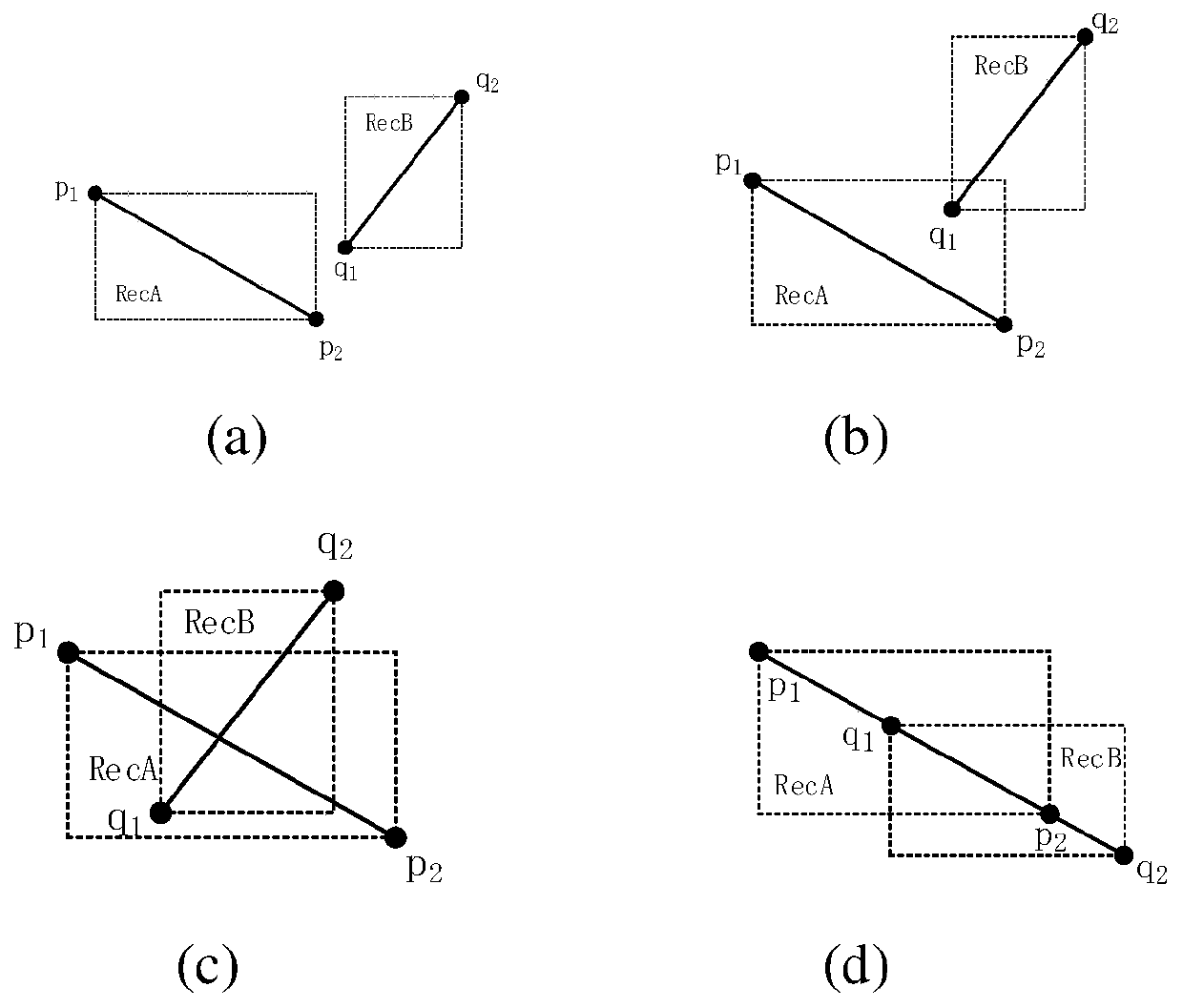

Cutting method along boundary of laser cutting equipment

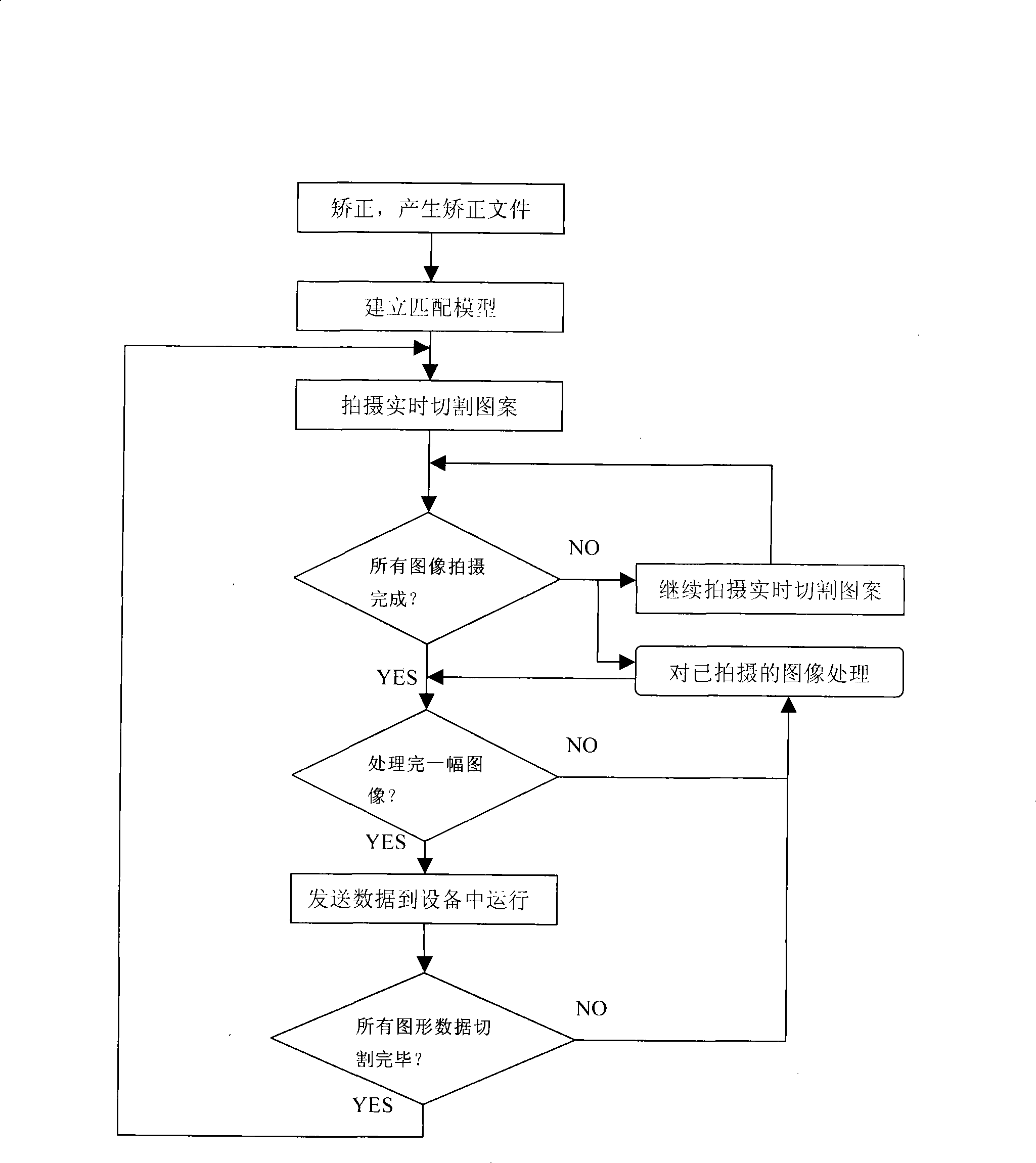

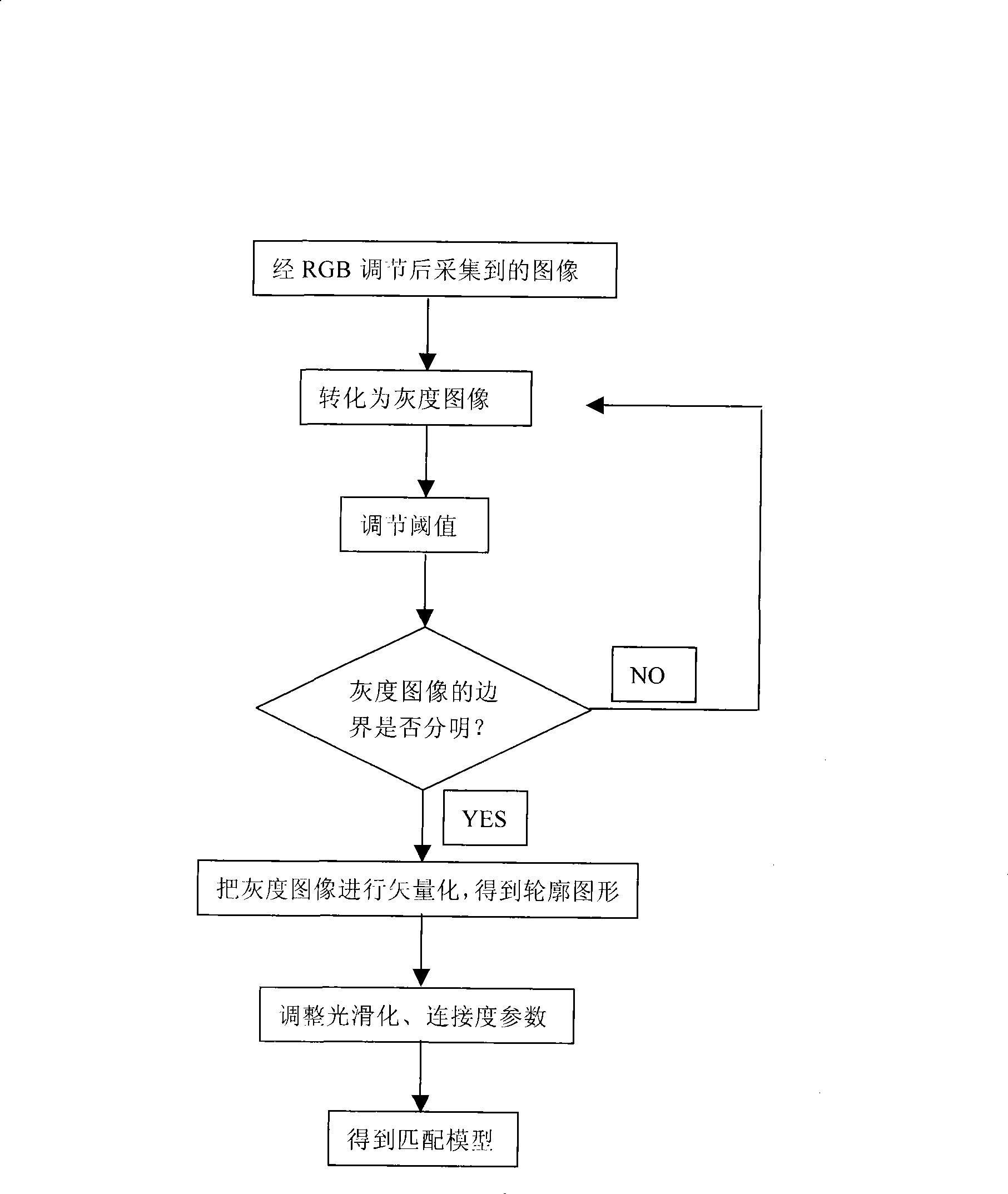

InactiveCN101363188AAchieve precise cuttingReduce waiting timeSevering textilesLaser beam welding apparatusGraphicsPattern recognition

The invention discloses an edge finding cutting method of a laser cutting device which is characterized in that images of an object needing to be cut are collected through a camera. A correcting document is used for the correction to generate a contour graph. Then, based on the contour graph, a matching model is constructed. Then, the patterns cut in real time are collected through the camera according to set parameters. The vectorization treatment is implemented on the collected images to generate graphs. The graphs are compared with the matching model according to the set similarity. An image satisfying the set similarity is the successful matching image. To the successful matching image, cutting data are generated according to the contour graph of the actually paragraphed image. Finally, the cutting data are sent to the laser cutting device to be cut. The cutting method is characterized by automatically adapting to the cut image differences within certain similarity scope and realizing the precise cutting of images.

Owner:瑞安市博业激光应用技术有限公司

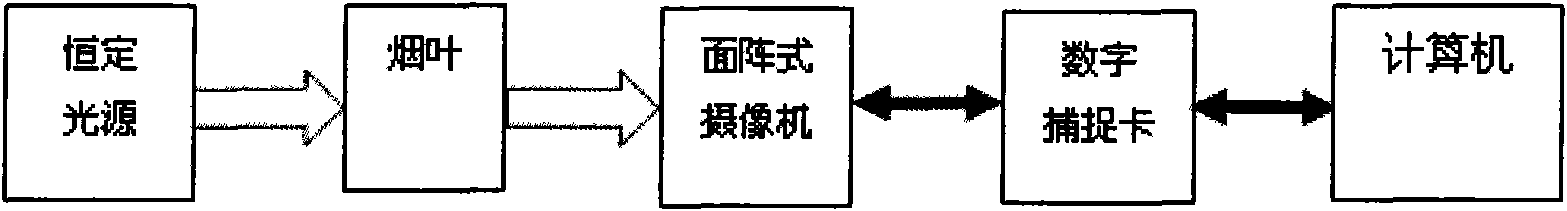

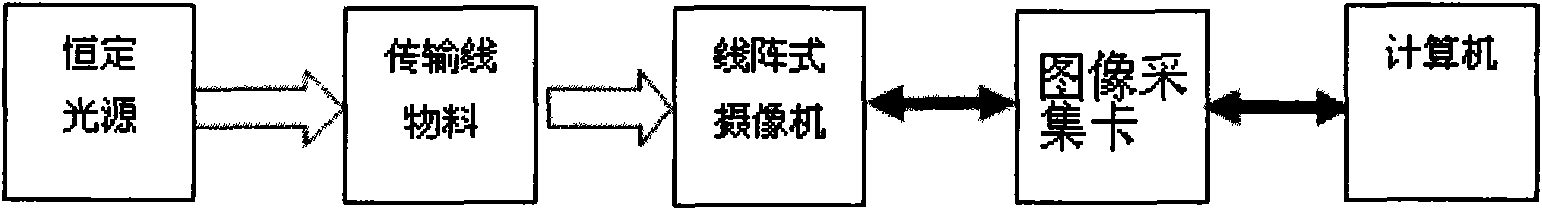

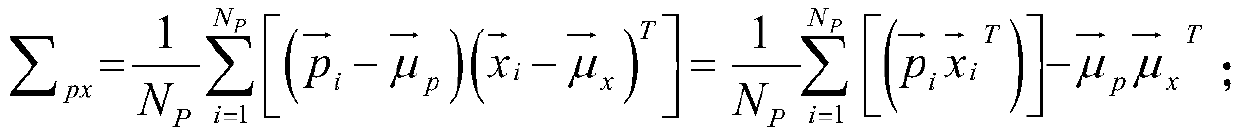

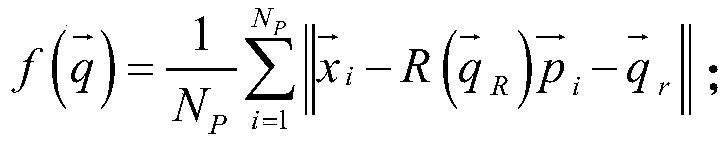

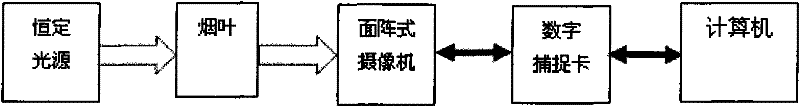

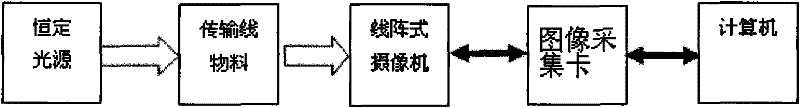

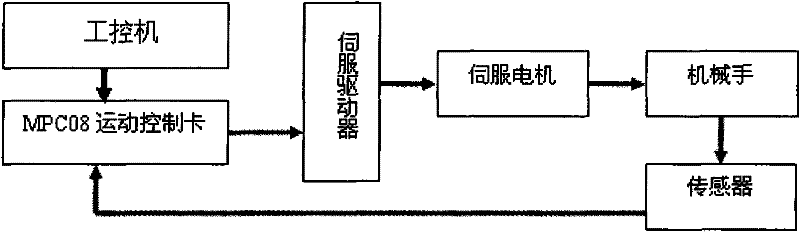

Intelligent positioning method of tobacco bundles

InactiveCN101653289ALighten the load on the swingImprove labor productivityTobacco treatmentCharacter and pattern recognitionEngineeringSmoke

The invention relates to an intelligent positioning method of tobacco bundles, which can rectify the position of the tobacco bundles, lighten the bundle-placing load of workers and improve the labor productivity of the workers after the bundles are placed by the workers. The tobacco stalks can be precisely positioned when the tobacco bundles are cut, and the precise cutting of leaves and stalks isachieved. The cut tobacco leaves and tobacco stalks are respectively conveyed into different devices for processing, the leaves and the stalks are precisely cut, and the problems of material blockage, uneven material flow, more shutdowns, low effective operation efficiency, and the like as the tobacco bundles are wound to each other and devices are wound in threshing are solved.

Owner:HEFEI ANDA ELECTRONICS DETECTION EQUIP FACTORY

Cutting device for vehicle rubber pipe production

InactiveCN107283480ARealize the heat dissipation functionRealize left and right sliding adjustmentMetal working apparatusRotational axisHydraulic cylinder

The invention discloses a cutting device for the production of automobile rubber tubes, which comprises a machine body and a frame. A sliding track is horizontally arranged on the top of the frame, and a sliding block is slidably installed on the sliding track. There is a hydraulic cylinder, the bottom end of the hydraulic cylinder is connected with the rotary motor through the piston rod, the bottom end of the rotary motor is connected with the cutting head through the rotating shaft, and a cooling liquid nozzle is arranged on one side of the cutting head, so A coolant tank is installed on the top of one side of the frame, and a cutting groove is arranged on the top of the body. The invention can realize the precise cutting of the pipe material, and the cutting effect is good. Through the cooling liquid nozzle provided on one side of the cutting head, the heat dissipation function of the cutting head can be realized, so as to avoid the overheating of the cutting head after working for a long time. Cutting effect, can reduce the dust generated in the cutting process, reduce pollution, and simple structure, easy to use, strong practicability.

Owner:枞阳县金源汽车零部件有限公司

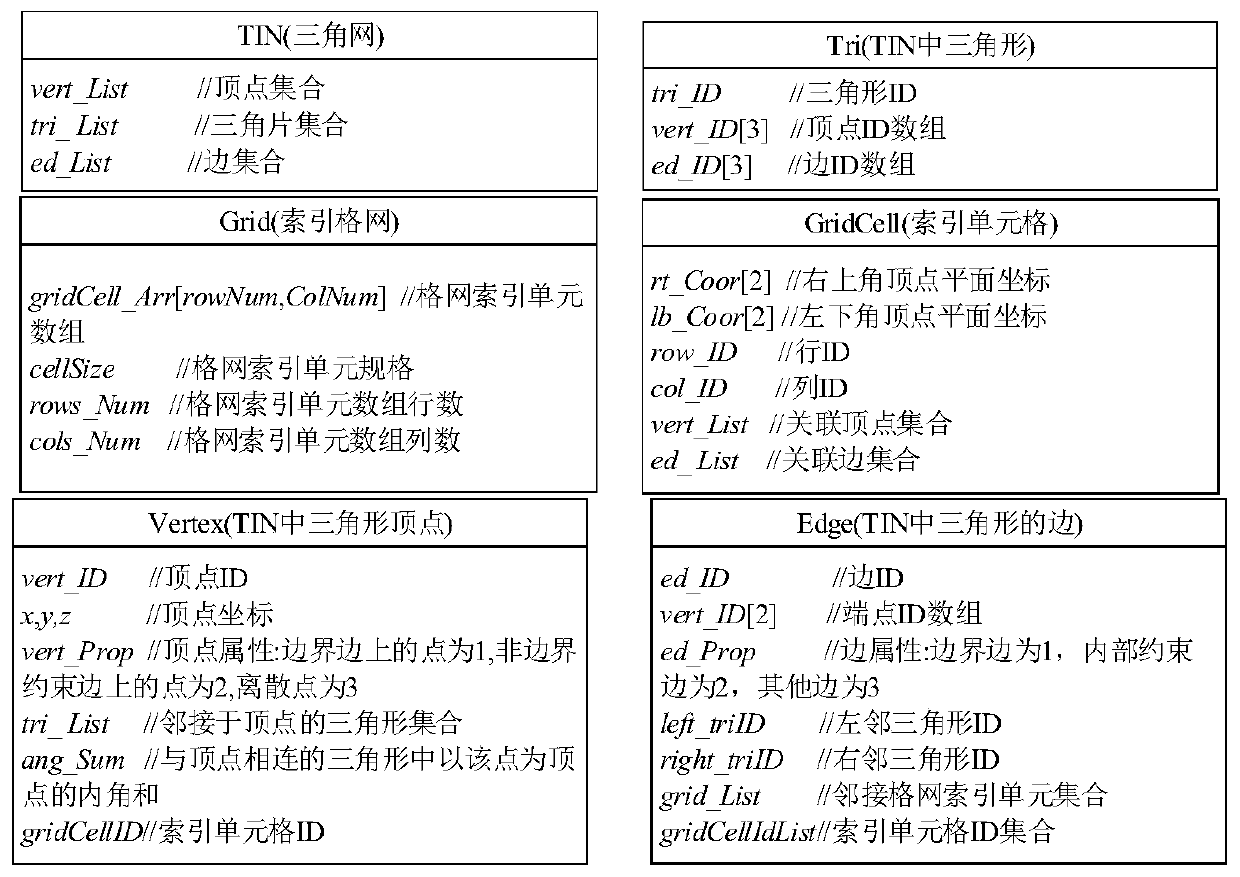

Open pit coal mine DEM accurate cutting method considering local detail characteristics

ActiveCN110032771AAchieve precise cuttingImprove efficiencyDesign optimisation/simulationImage data processingTriangulationEngineering

The invention discloses an open pit coal mine DEM accurate cutting method considering local detail characteristics. The method comprises the steps of establishing the grid indexes of a triangular netto be cut and a cutting polygon; embedding the cut polygons into the triangular net; generating a cut TIN boundary; carrying out the TIN cutting. According to the present invention, on the basis of constructing the DEM to be cut and cutting the polygon grid index, performing the accurate interpolation on the cut polygon based on the to-be-cut TIN, and embedding the cutting polygon into a to-be-cutTIN, and according to the topological relation of the TIN triangular set in the cut polygon, constructing the cut TIN boundary, the triangulation network between the cut polygon and the cut TIN boundary is constructed by adopting an edge-first one-time CDT growth algorithm, the accurate cutting of the DEM described by the TIN is realized, and the experimental verification proves that the implementation method provided by the invention is high in efficiency and stable in operation, and has been successfully applied to the open pit coal mine digital mining design practice.

Owner:LIAONING TECHNICAL UNIVERSITY

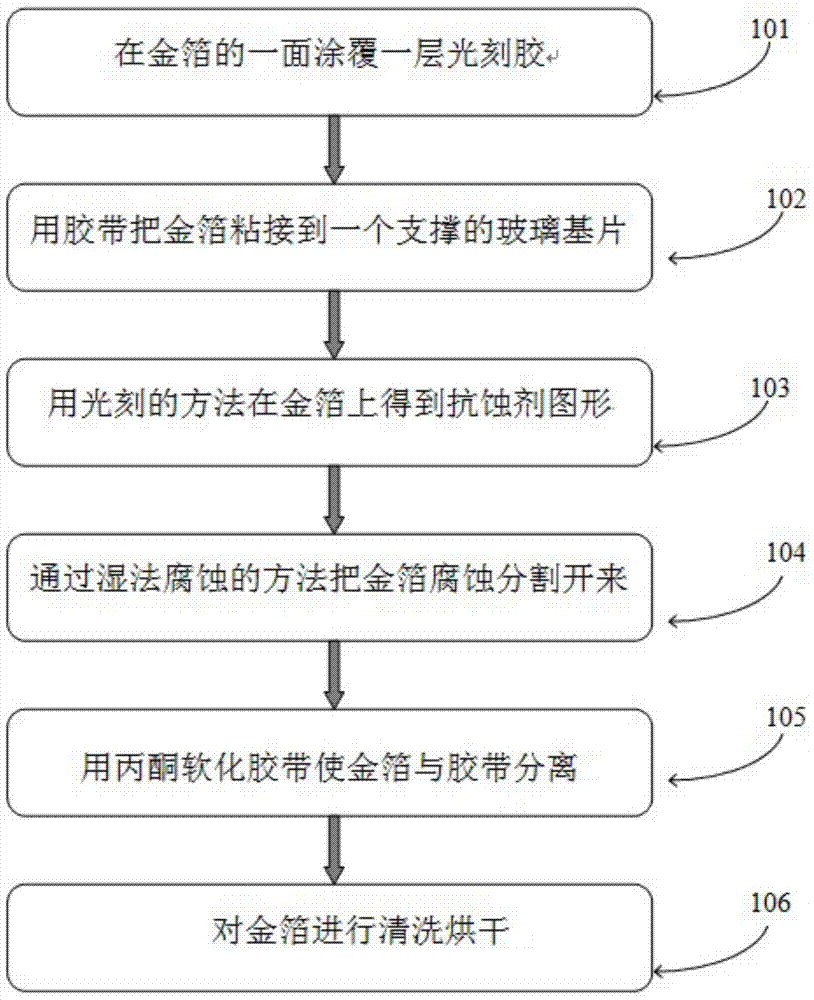

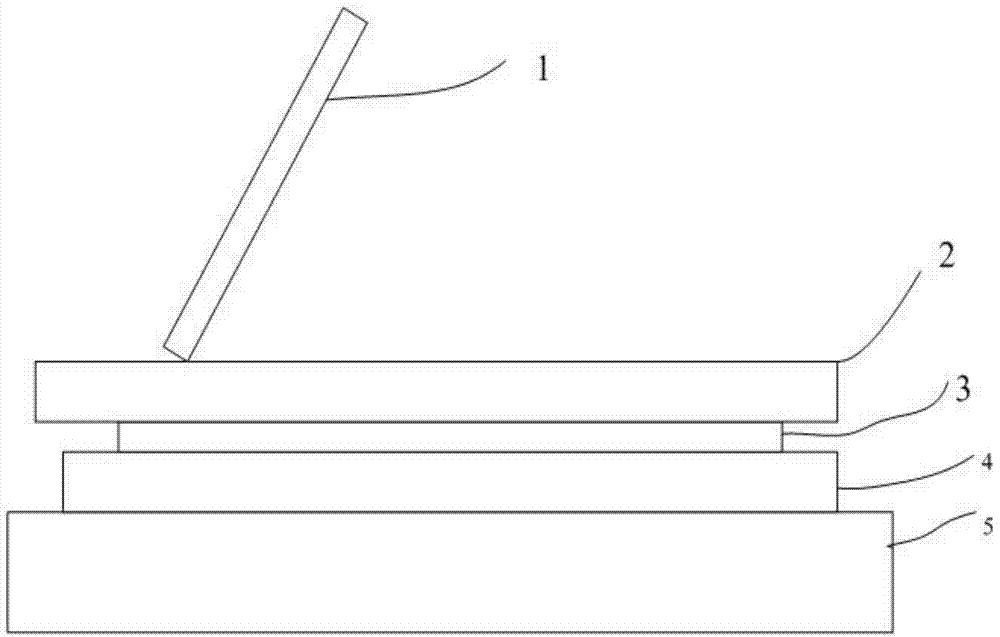

Gold foil cutting method

InactiveCN103716998AImprove consistencyImprove dimensional machining accuracyConductive material chemical/electrolytical removalResistEtching

The invention provides a gold foil cutting method which comprises the following steps: coating one side of a gold foil with a layer of photoresist, using an adhesive tape to adhere the gold foil to a supporting glass substrate, using a photo-etching method to obtain a resist pattern on the gold foil, segmenting gold foil etch through a wet etching method, softening the adhesive tape with the use of acetone to separate the gold foil from the adhesive tape, and cleaning and drying the gold foil to obtain the needed gold foil dimension. The problem that the gold foil is difficult to clamp in the photo-etching process is solved by adding the glass substrate support, and the consistency and dimension processing precision of gold foil cutting are ensured by the use of the photo-etching method. Compared with a manual cutting method, the processing efficiency is greatly improved, and the gold foil cutting method is suitable for mass production and is worthy to be popularized in production.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

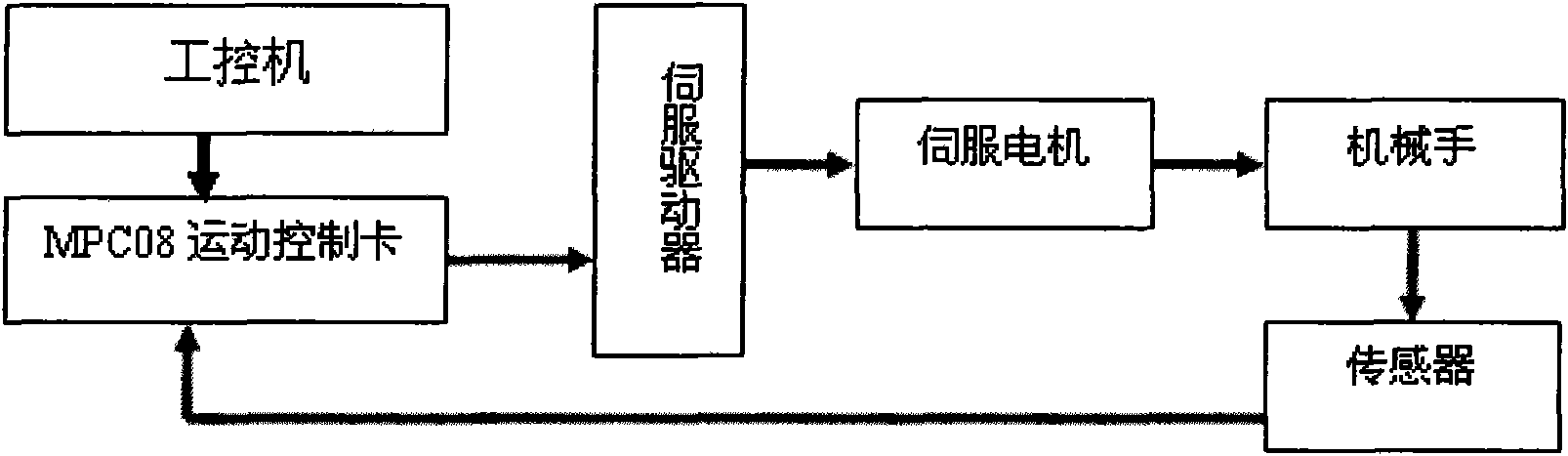

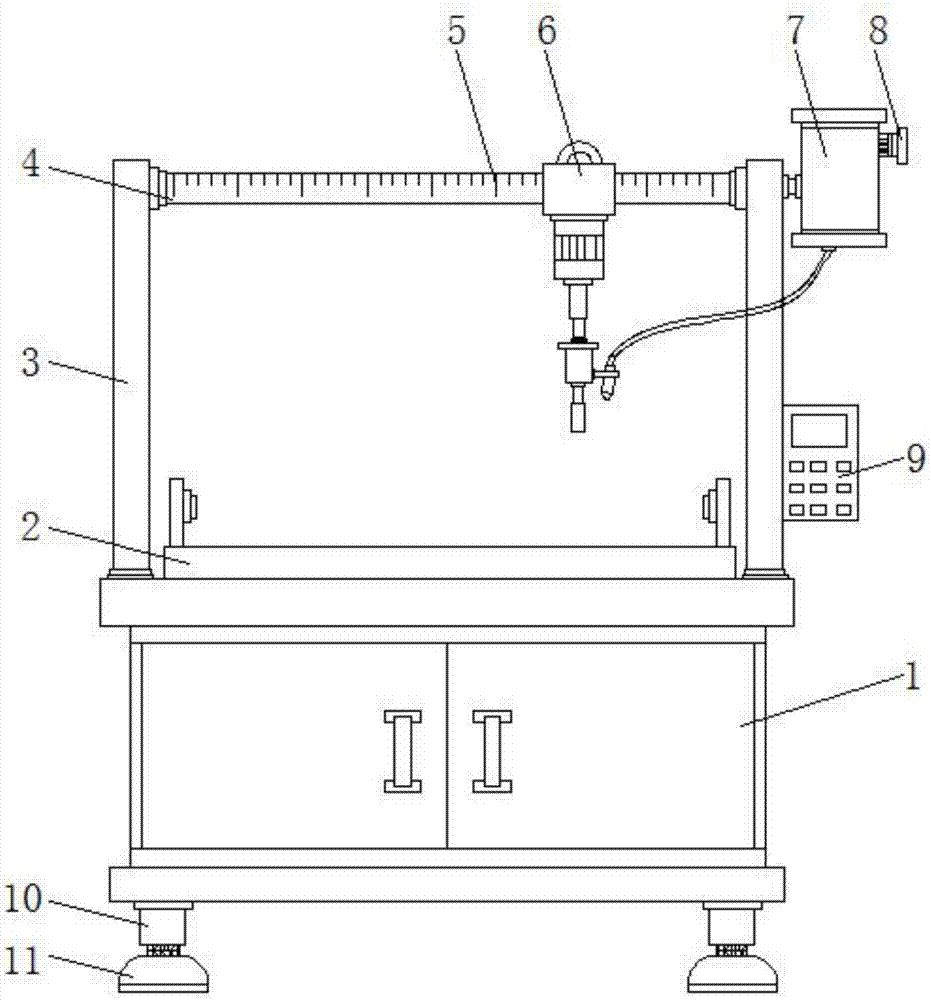

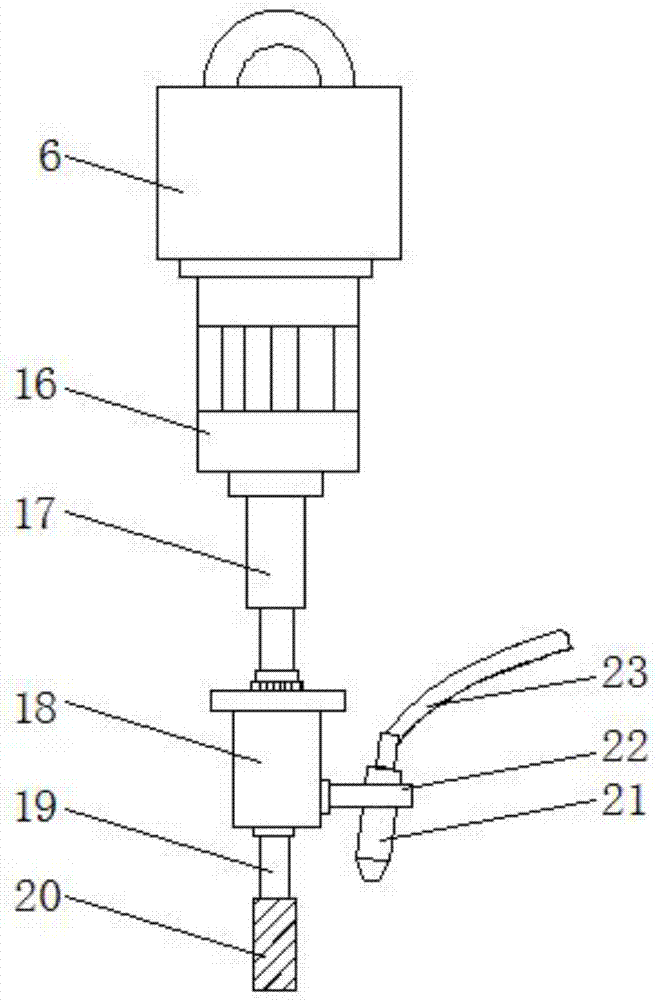

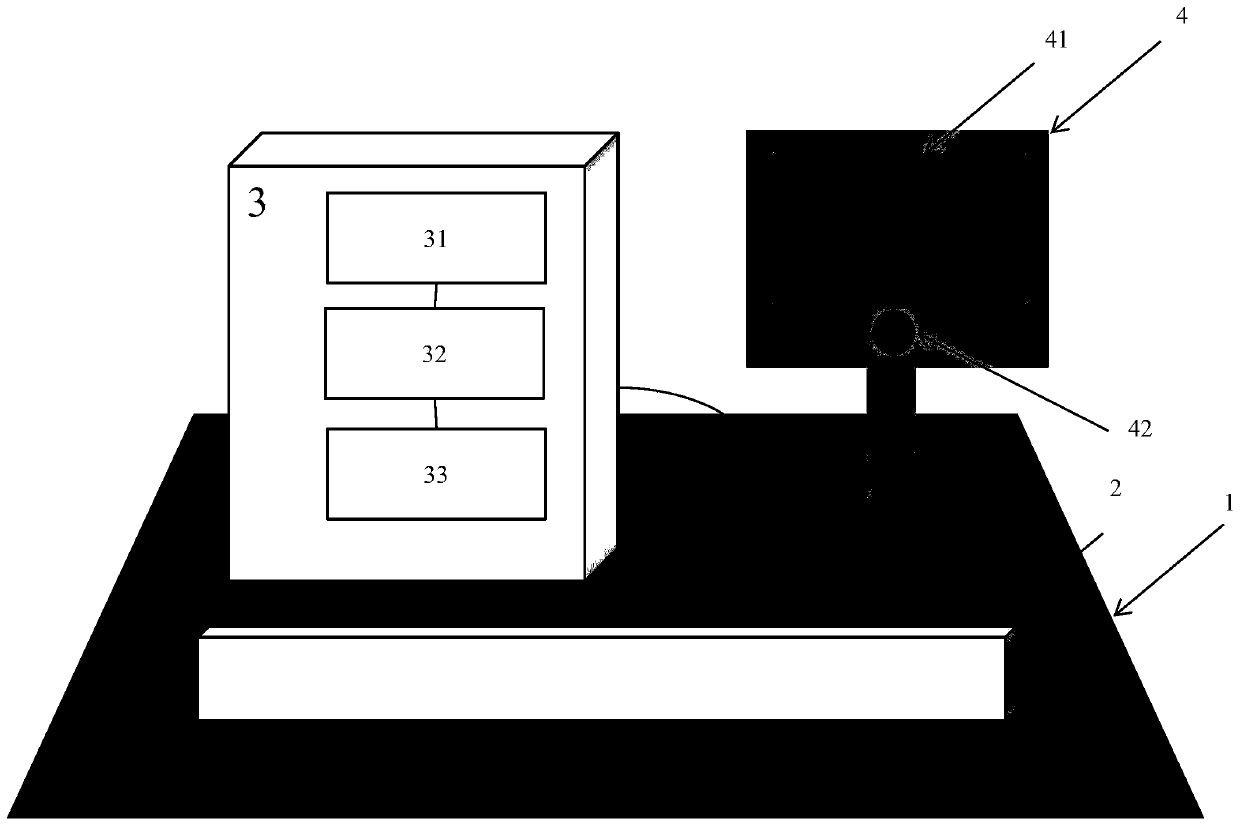

Accurate control system for automatic calibration of workpiece of numerically-controlled (NC) cutting machine

InactiveCN109765845AAchieve precise cuttingSignificant comprehensive benefitsProgramme controlComputer controlLaser rangingControl system

The invention provides an accurate control system for the automatic calibration of a workpiece of a numerically-controlled (NC) cutting machine. A cutting machine automatic feeding system comprises aworkbench, a milling cutter, a detection module and a control console. The detection module is connected with the control console, and can be installed at any fixed position of the workbench. The detection module is composed of a three-dimensional laser scanner and a point laser distance measuring sensor connected in series. The control console is composed of a display screen and a calibration button. Aiming at the problems that during the repeated machining process of soft materials, the deformation is large and the accuracy is low, and the situations that the manual calibration mode is relatively large in error and relatively low in efficiency, the invention designs an automatic workpiece coordinate system calibration system, for performing error compensation and automatic calibration onthe workpiece coordinate system, and thus the accurate machining of the soft materials is achieved, the better benefit is brought to the enterprise, and the market application value is achieved.

Owner:台州稳迅自动化设备有限公司

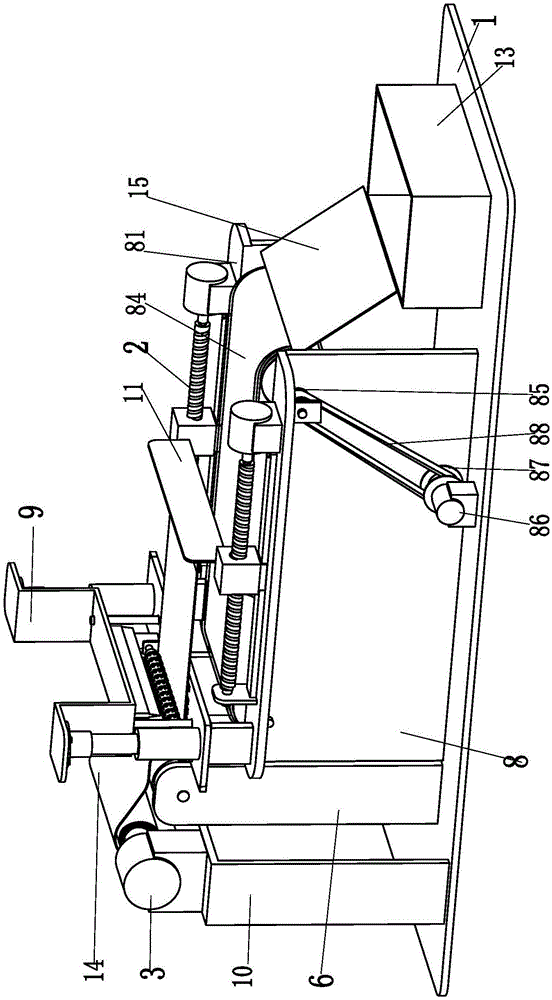

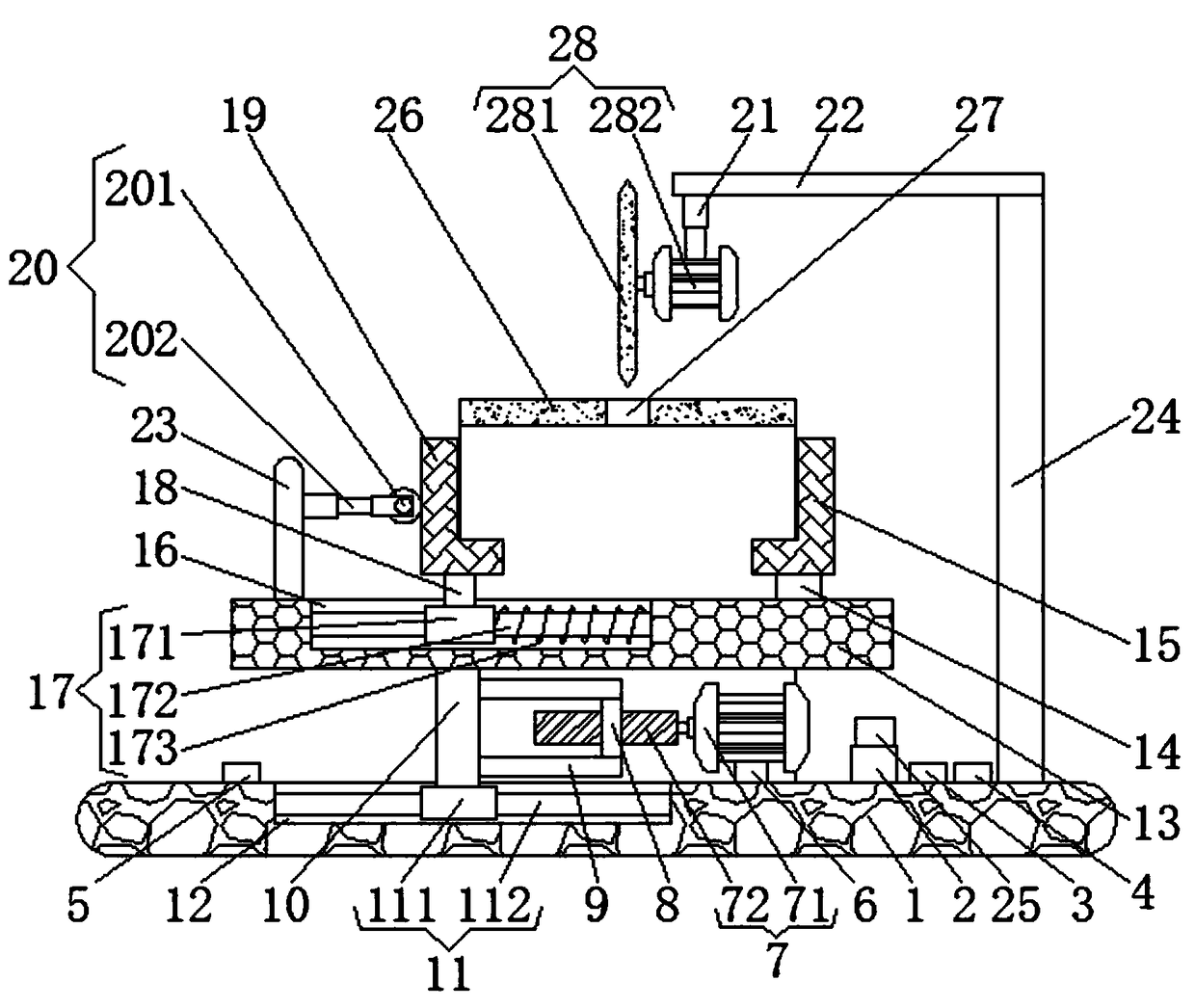

Special processing equipment for pole piece of lithium battery pack of shared battery electric vehicle

The invention relates to special processing equipment for a pole piece of a lithium battery pack of a shared battery electric vehicle. The processing equipment comprises a baseplate, wherein a support frame is arranged at the outer side of the left end of the baseplate; a 1# drive motor is arranged on the support frame through a motor base; an output shaft of the 1# drive motor is connected to a pole piece roll through a shaft coupling; the back end of the pole piece roll is arranged on a baffle through a bearing; the baffle is arranged on the support frame; a conveying mechanism is arranged at the middle of the baseplate; a guide plate which is inclined downward is arranged at the right end of the conveying mechanism; a shearing mechanism is arranged at the left end of the conveying mechanism; two transverse feed mechanisms are symmetrically arranged at the front side and the back side of the conveying mechanism; a connecting plate is arranged between the two transverse feed mechanisms; two pressing mechanisms are arranged on the connecting plate; and a collection box is arranged at the right end of the baseplate. According to the processing equipment, the difficulties of complicated operation and poor stability in the existing shearing process of the pole piece of the lithium battery can be solved and functions of precise cutting and stable conveying of the pole piece of the lithium battery can be realized.

Owner:汪成立

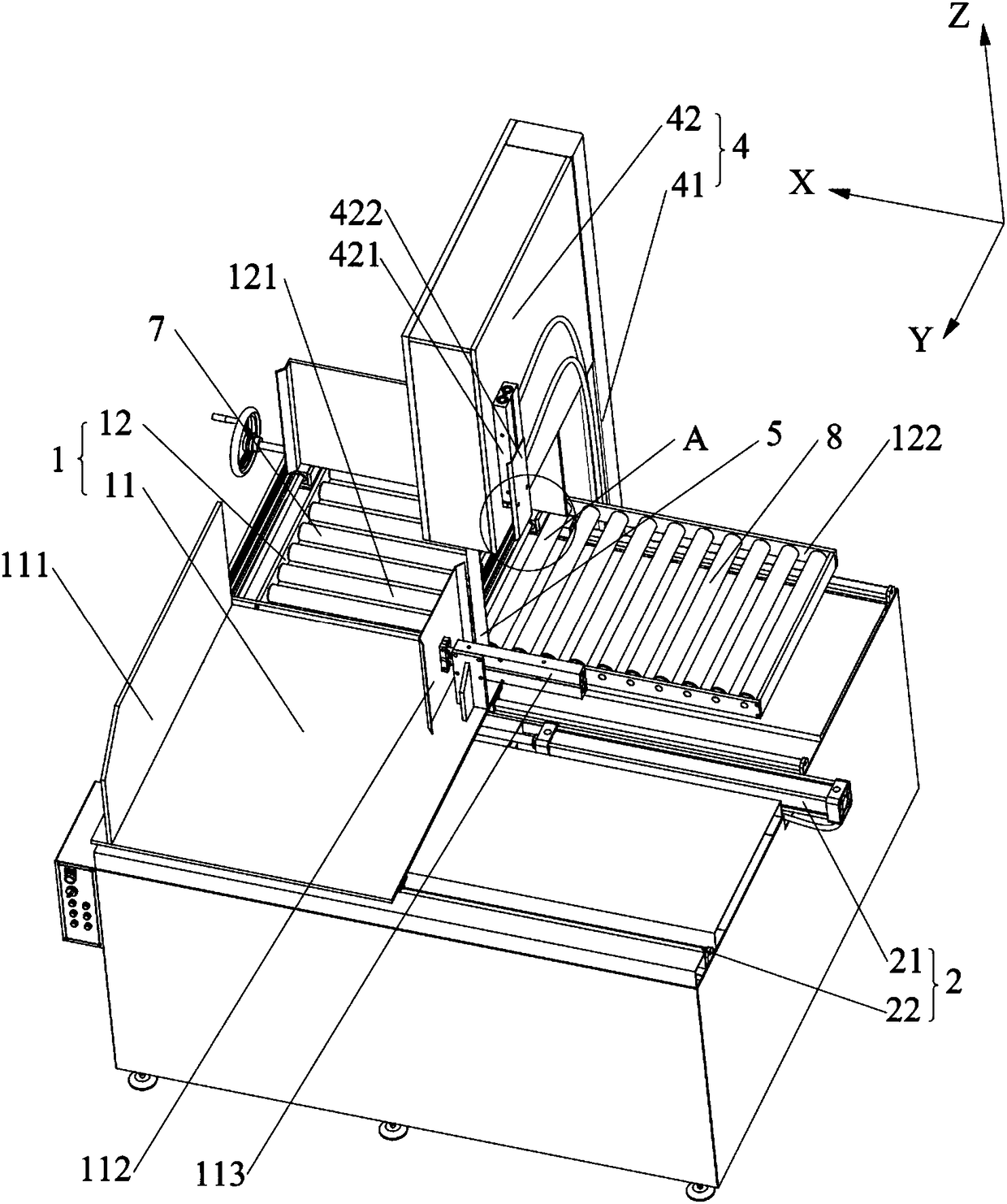

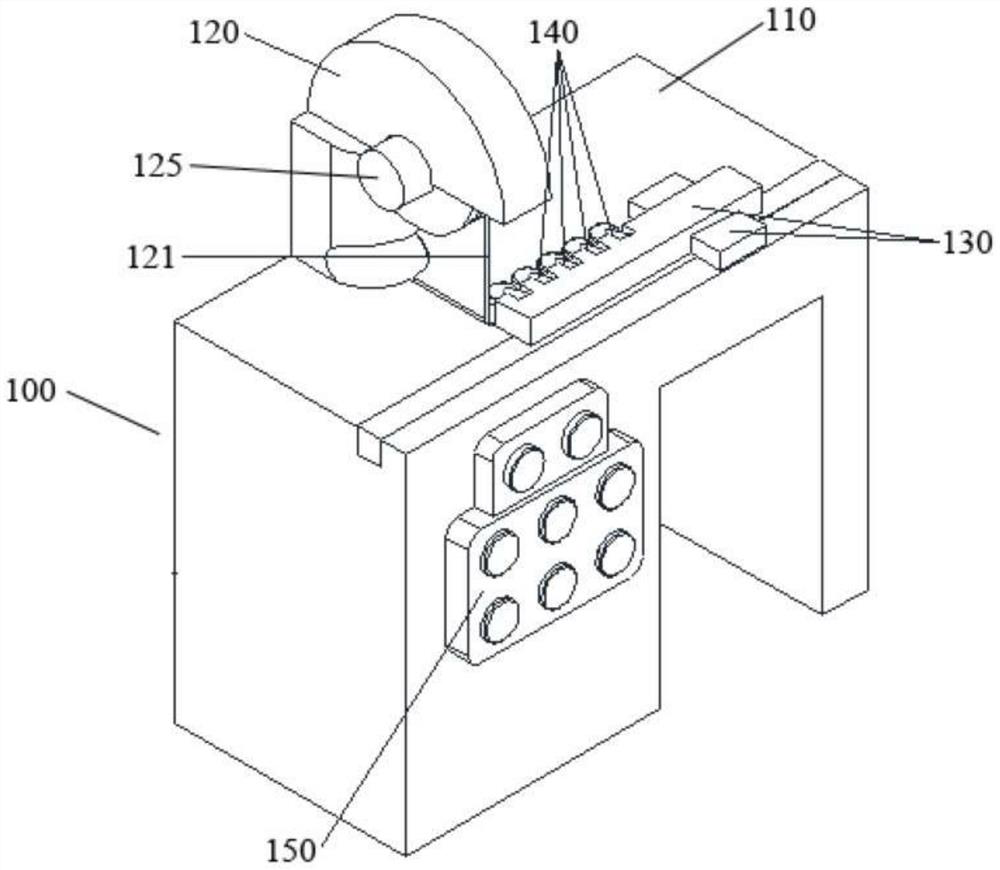

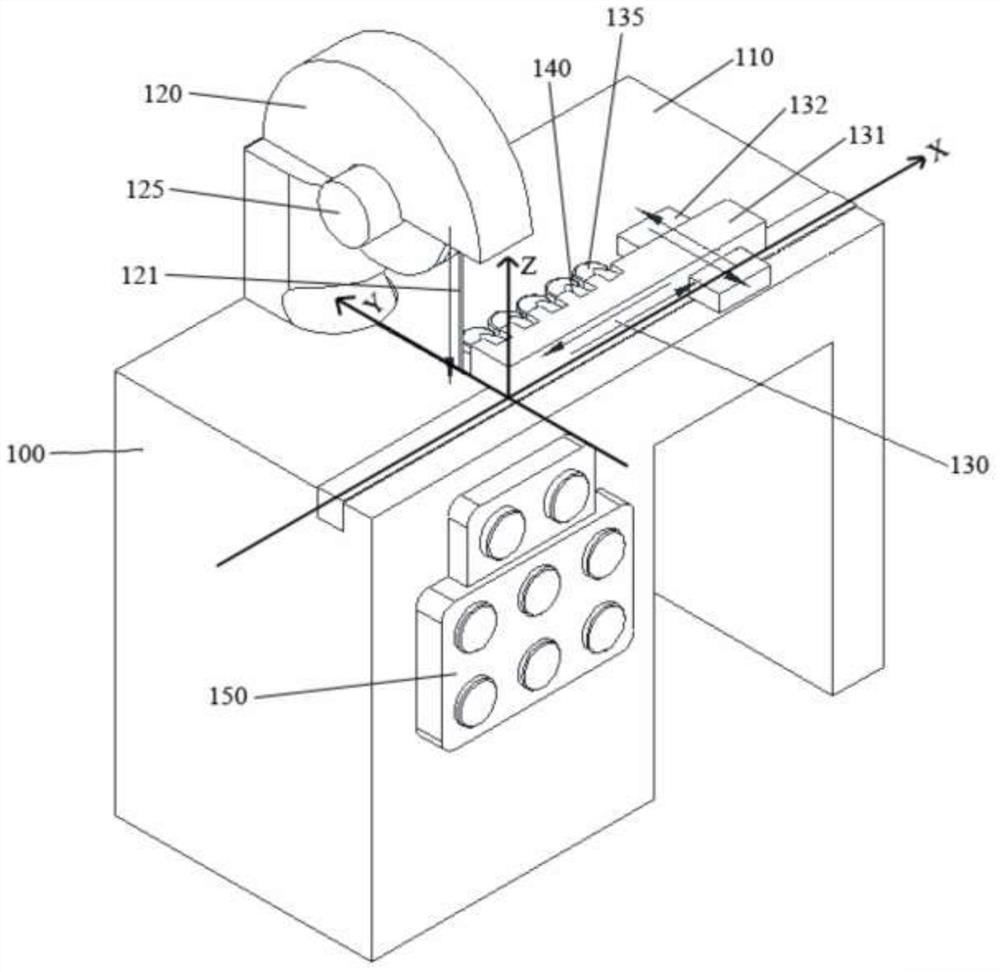

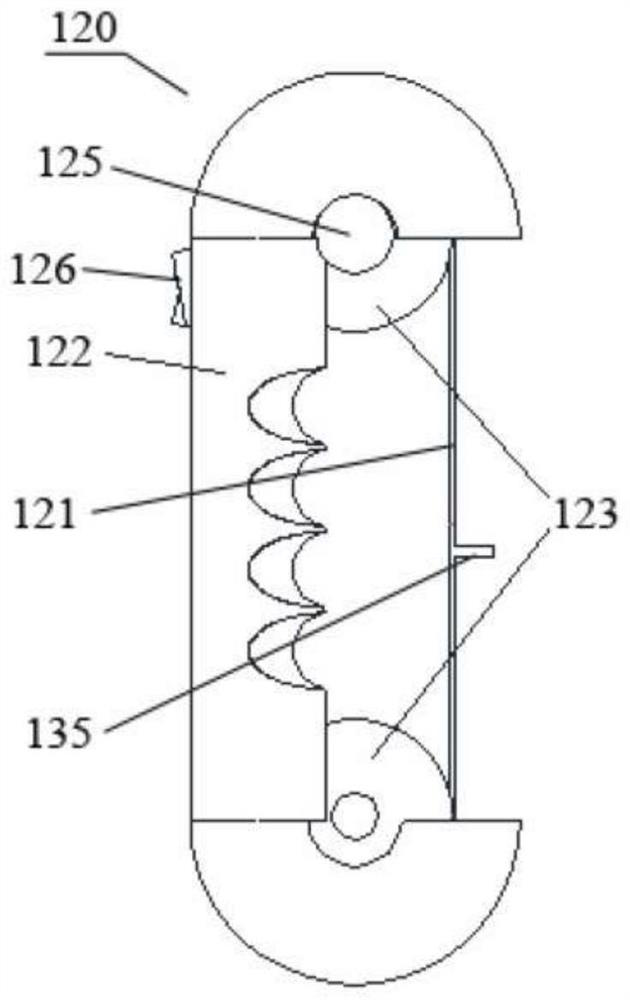

Cardboard cutting machine

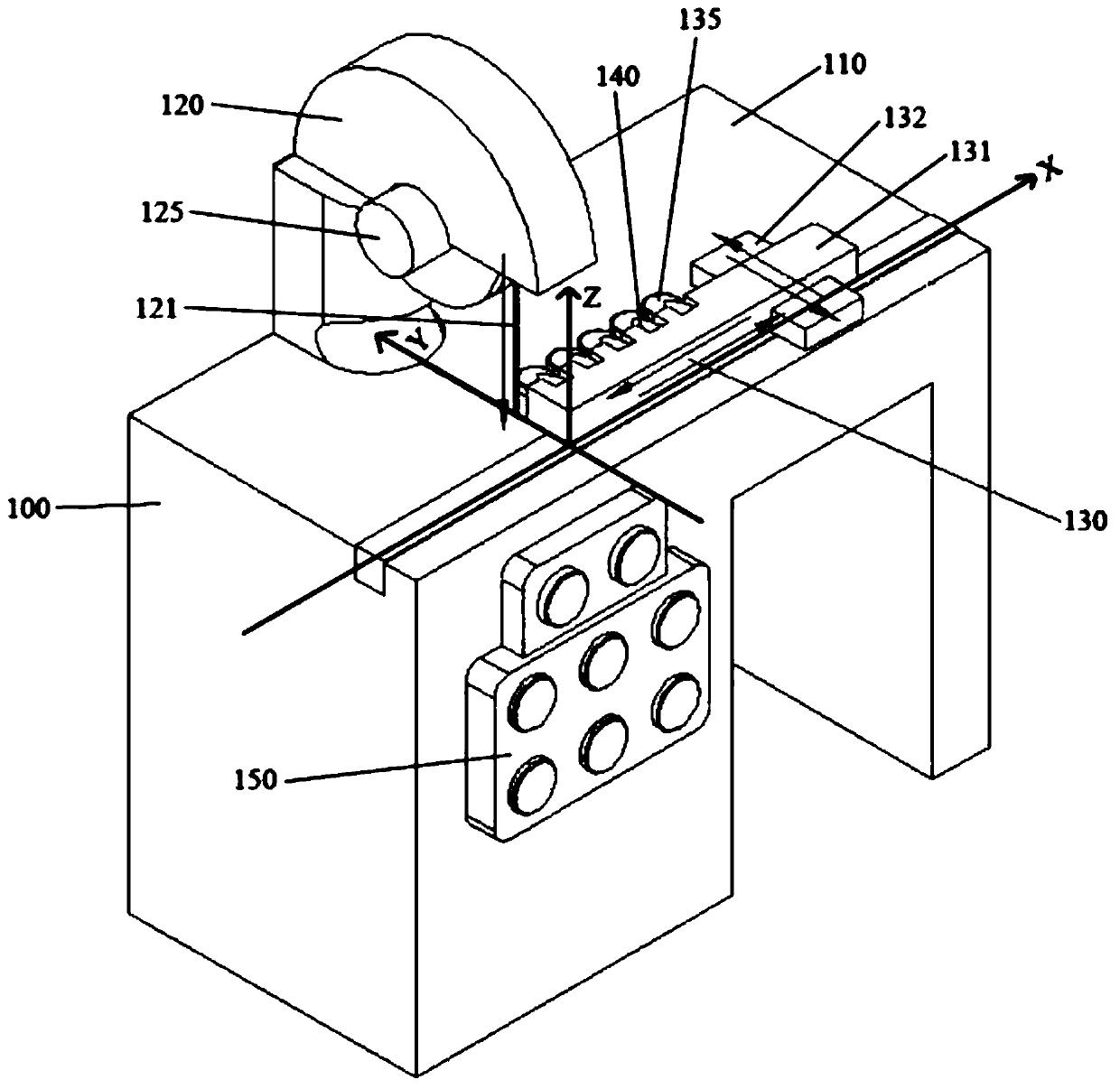

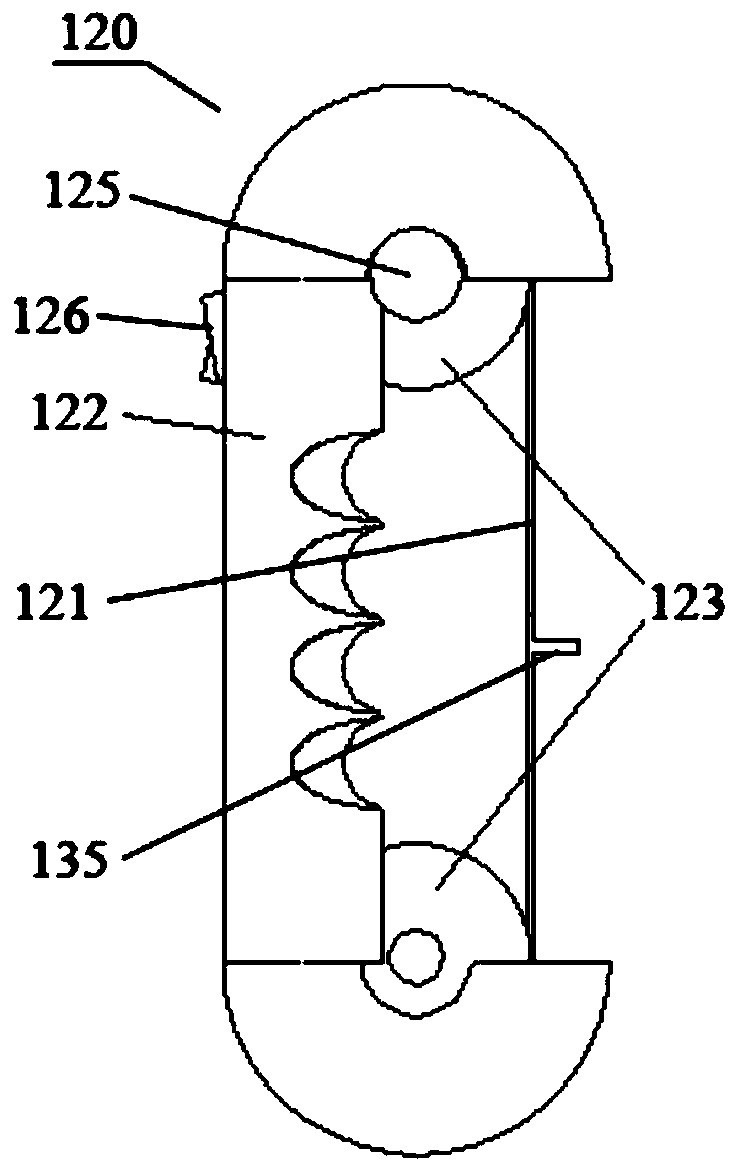

The invention relates to a cardboard cutting machine, and belongs to the technical field of mechanical manufacturing. The machine includes an X-axis drive plate for placing cardboards, an X-axis driveassembly arranged under the X-axis drive plate and driving the X-axis drive plate to move along an X-axis direction, a Y-axis push plate arranged on one side of the X-axis drive plate and is fixedlyprovided with a Y-axis drive assembly driving the Y-axis push plate to move along a Y-axis direction, a Z-axis drive assembly arranged on one side of the X-axis drive plate, and a saw blade fixedly arranged on the Z-axis drive assembly and is driven by the Z-axis drive assembly to move along a Z-axis direction. The cardboard cutting machine can perform overall cutting of the cardboards. The Y-axisdrive assembly pushes the distance of the movement of the Y-axis push plate to adjust the position of the cardboard cutting machine to cut the cardboards, and so the cardboard cutting machine is controllable when cutting the cardboards, thereby accurately cutting the cardboards. Furthermore, the cardboard cutting machine is convenient in operation and easy in realization.

Owner:昆山优源胜机械有限公司

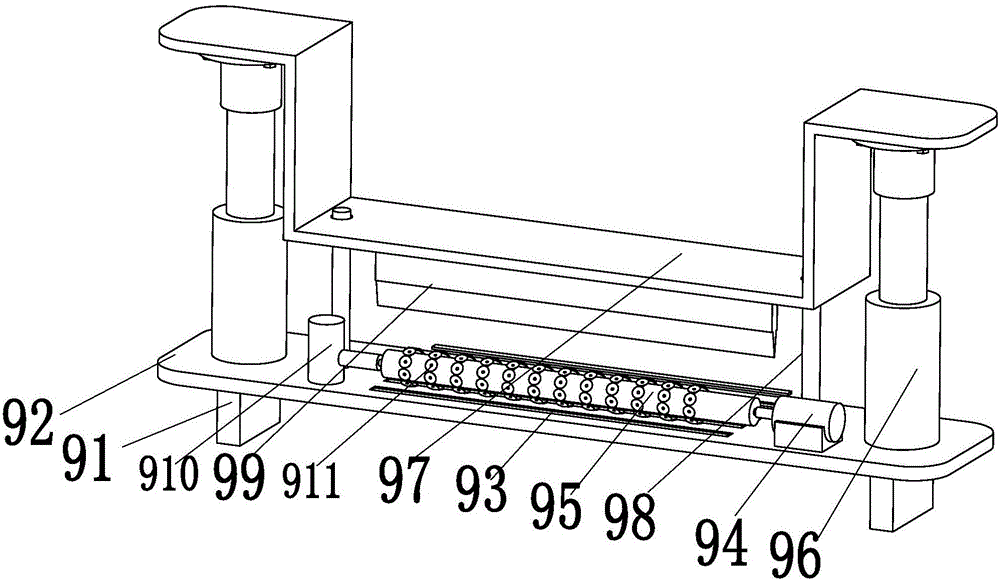

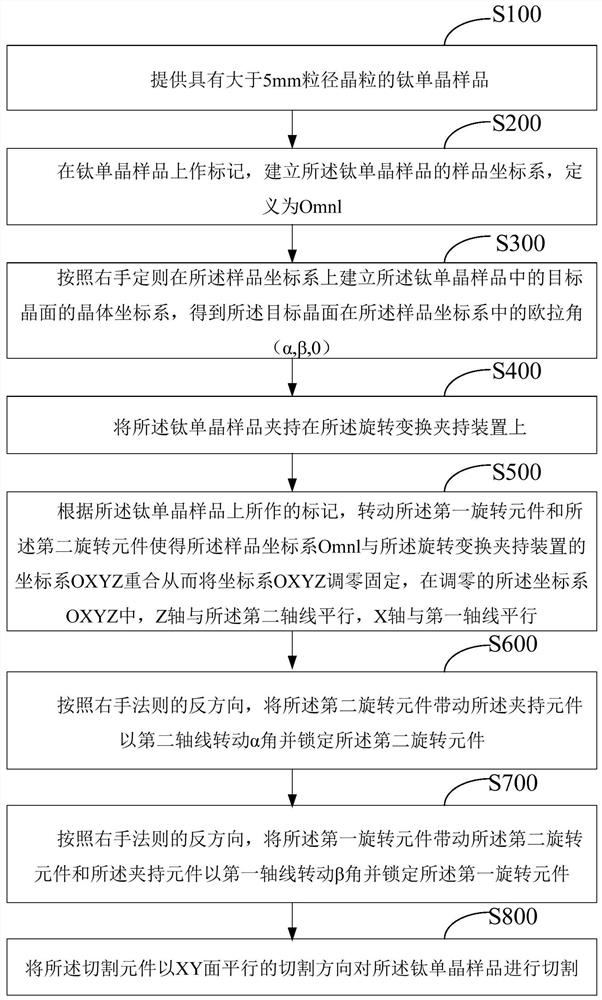

Titanium single crystal with target crystal plane surface and preparation method thereof

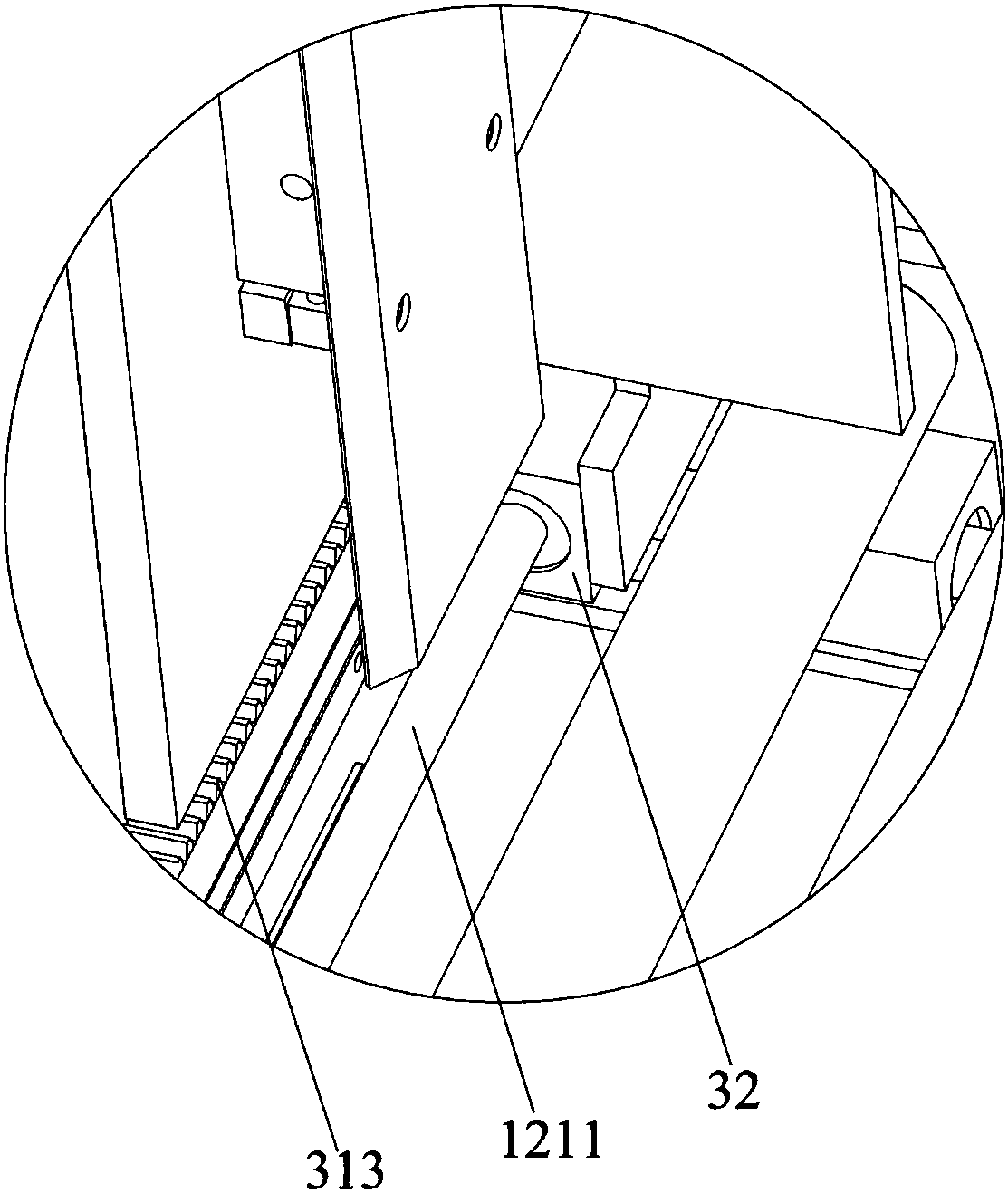

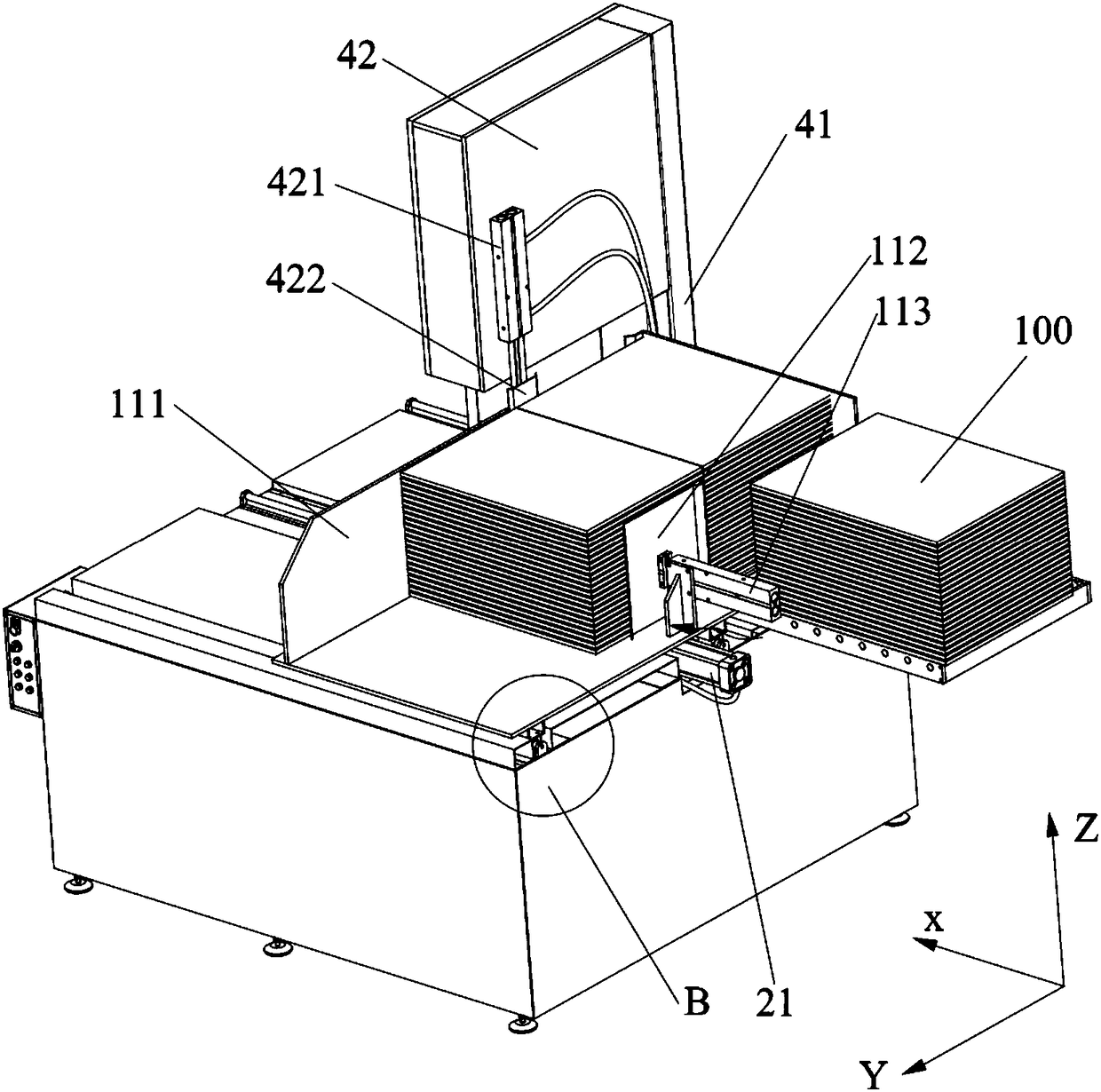

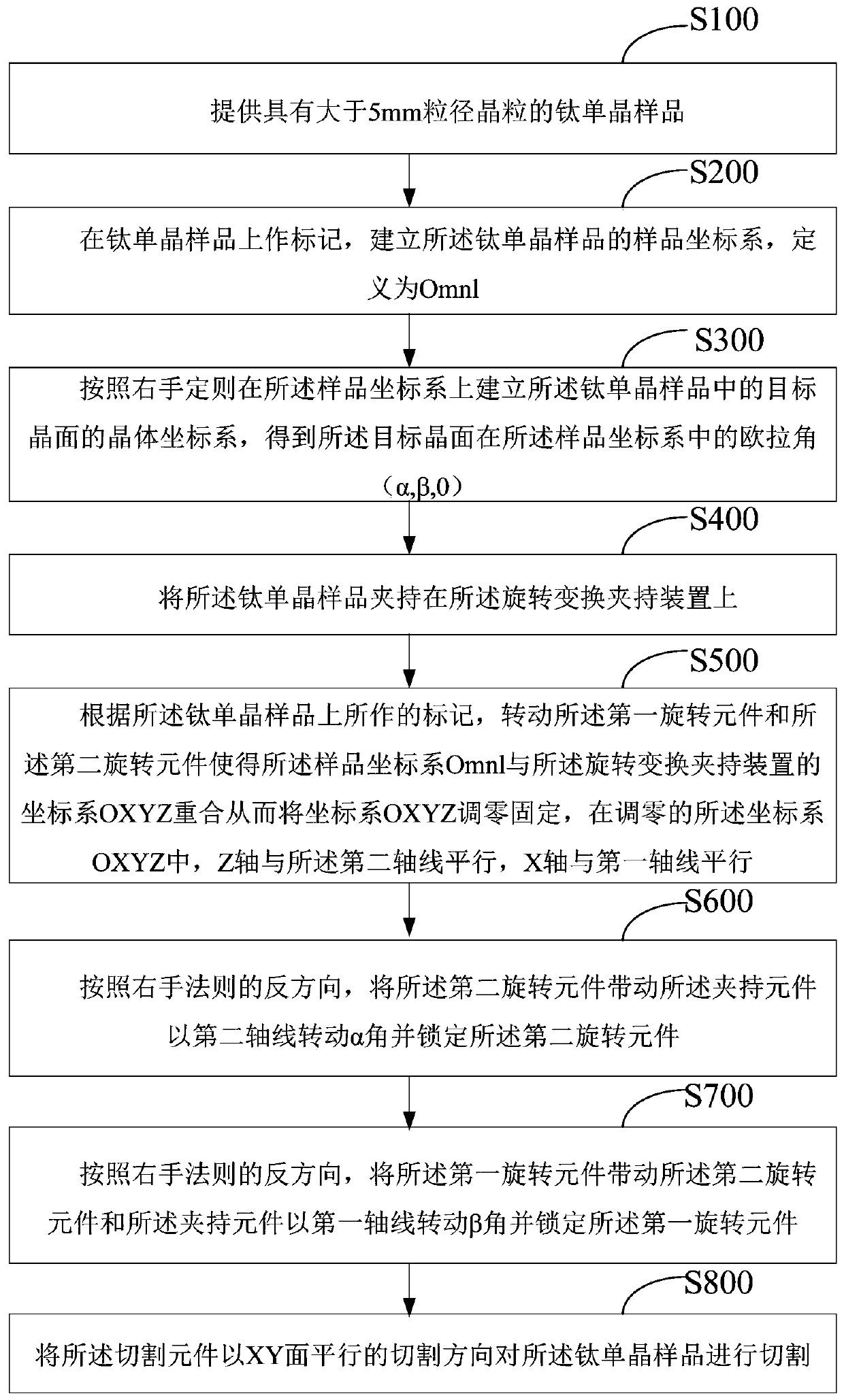

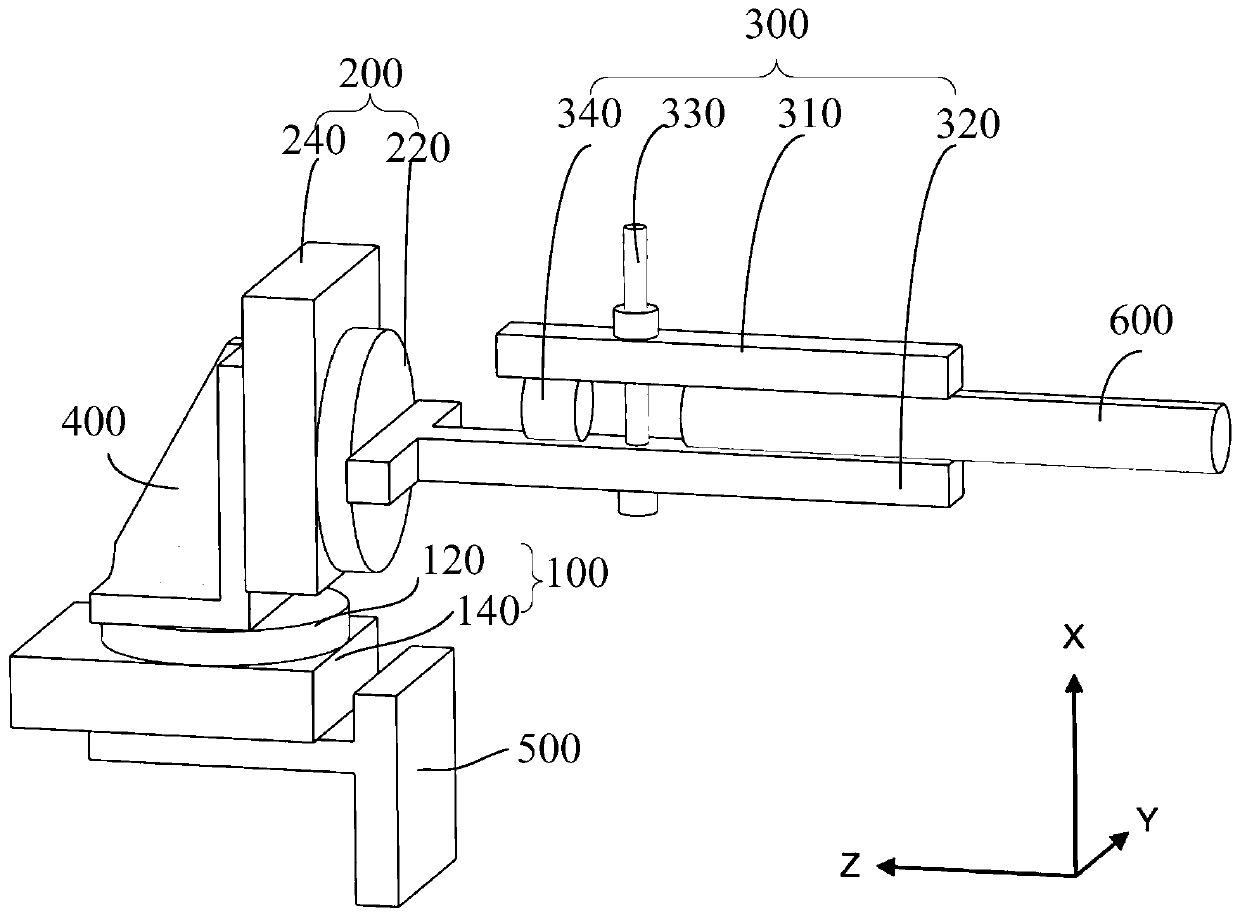

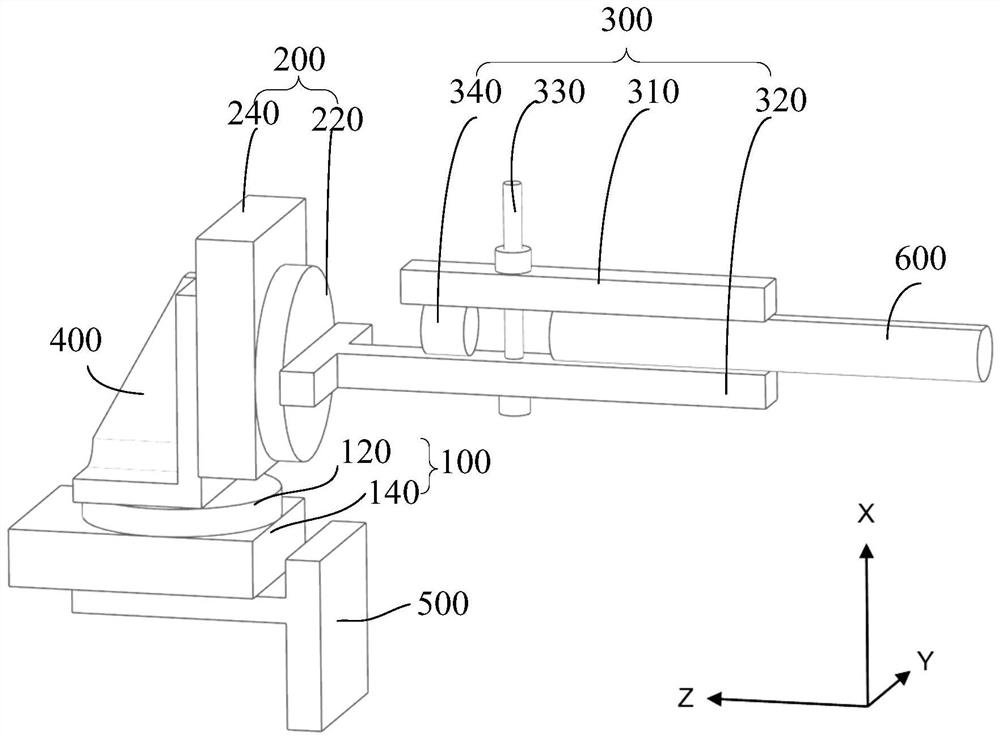

ActiveCN111037765AAchieve any orientationAchieve precise cuttingPolycrystalline material growthWorking accessoriesSingle crystalCrystal plane

The invention discloses a preparation method of a titanium single crystal with a target crystal plane surface. The preparation method adopts a rotating change clamping device and comprises the steps that a titanium single crystal sample with crystal grains with grain size larger than 5mm is provided; the titanium single crystal sample is marked, a sample coordinate system of the titanium single crystal sample is established and defined as Omnl; a crystal coordinate system of a target crystal plane in the titanium single crystal sample is established, and the euler angle (alpha, beta, 0) of thetarget crystal plane in the sample coordinate system is obtained; the titanium single crystal sample is clamped on the rotating change clamping device; according to the mark made on the titanium single crystal sample, a first rotating element and a second rotating element are rotated to make the sample coordinate system Omnl coincide with the coordinate system OXYZ of the rotating change clampingdevice so as to achieve zero setting and fixation of the coordinate system OXYZ; the second rotating element is made to drive a clamping element to rotate by the angle alpha around a second axis; thefirst rotating element drives the second rotating element and the clamping element to rotate by the angle beta around a first axis; and a cutting element cuts the titanium single crystal sample in acutting direction parallel to the XY plane.

Owner:TSINGHUA UNIV

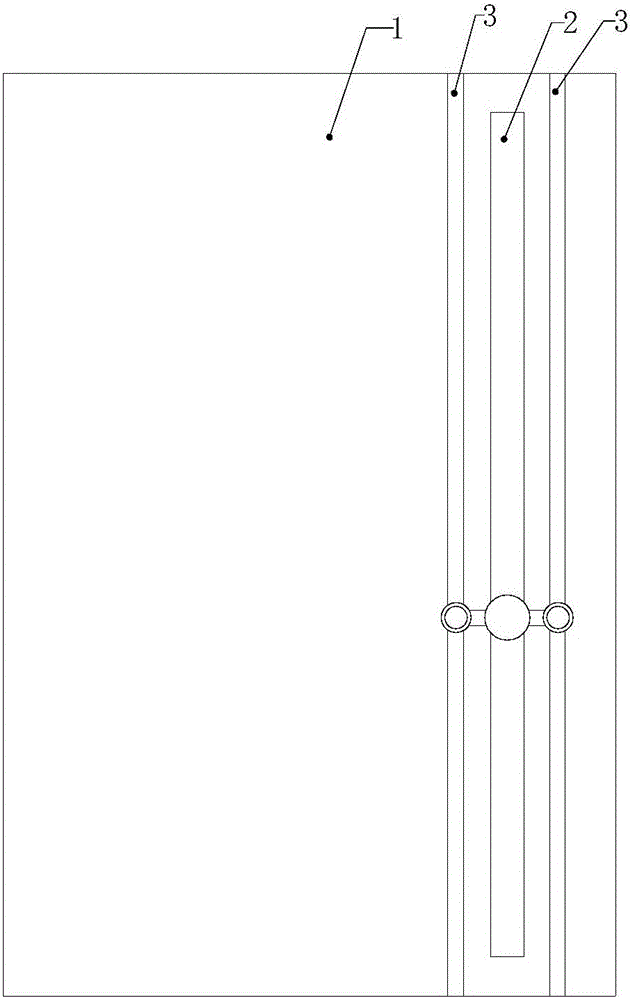

Soft tissue shaping and cutting knife

PendingCN107714158ACutting Width GuaranteedAchieve precise cuttingIncision instrumentsResource utilizationEngineering

The invention relates to the field of medical tools, in particular to a soft tissue shaping and cutting knife. The soft tissue shaping and cutting knife comprises a knife handle, a knife frame and twoblades, the lower end of the knife handle is fixedly arranged on the upper surface of the knife frame, and the two parallel blades are perpendicularly connected to the knife frame. In this way, the two blades are arranged on the knife frame, when the soft tissue or the cartilage is cut, the spacing of the two blades is constant, and therefore during cutting, the cutting width of the soft tissue or the cartilage can be guaranteed; moreover, during cutting, one blade can be utilized to be attached to the edge of one side of the soft tissue or the cartilage, and the other blade is utilized to cut to increase the resource utilization rate.

Owner:PLASTIC SURGERY HOSPITAL CHINESE ACAD OF MEDICAL SCI

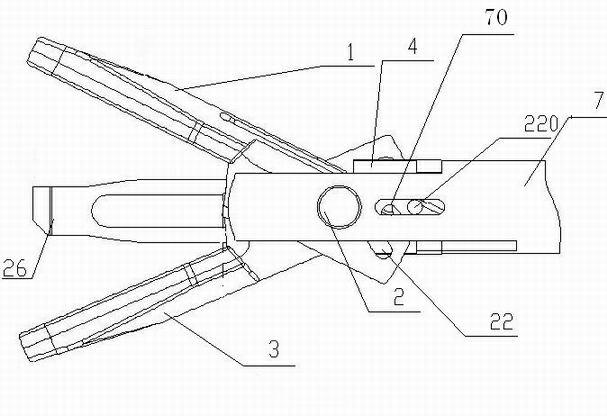

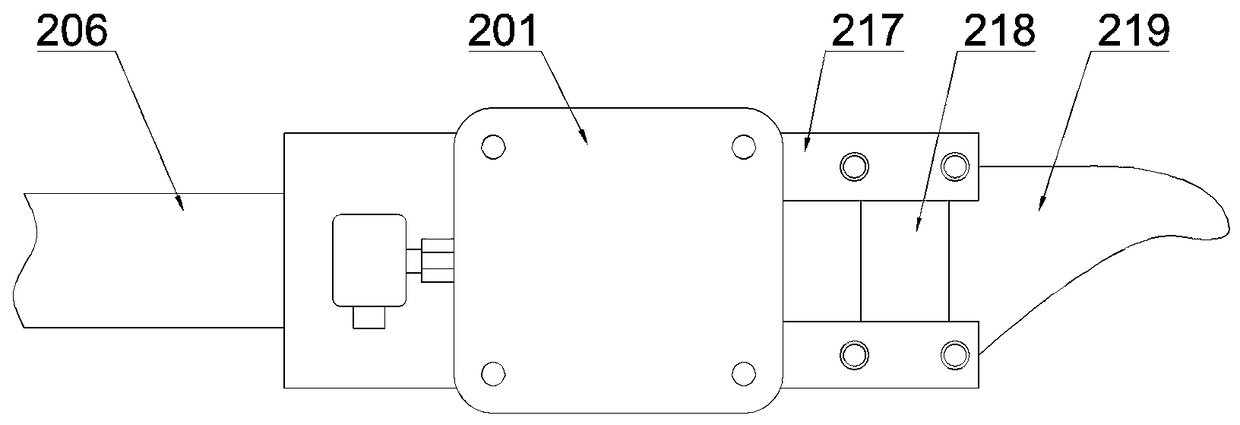

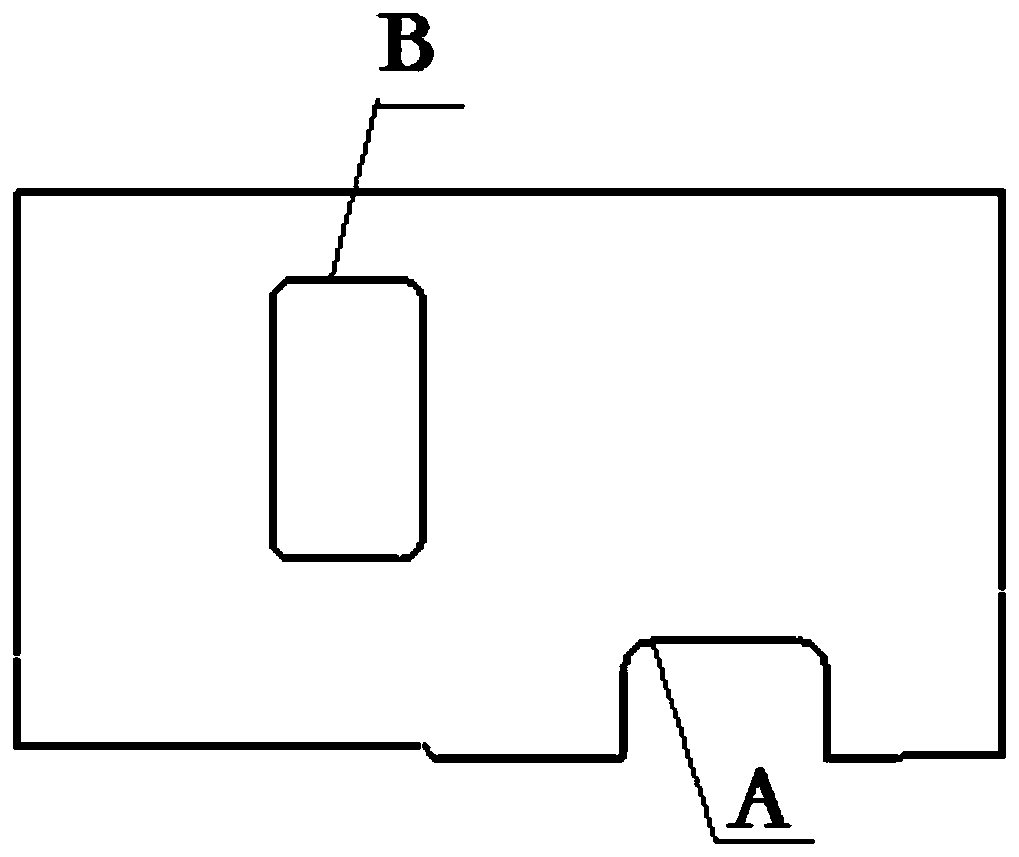

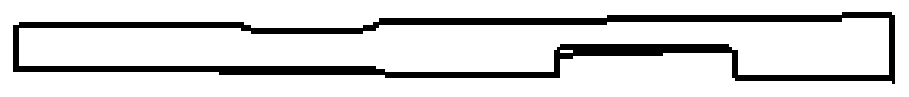

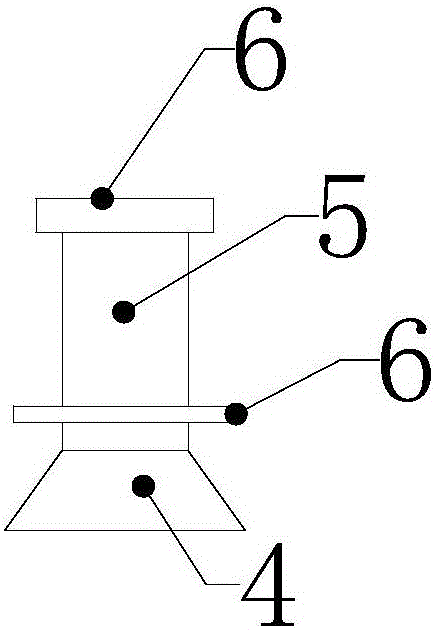

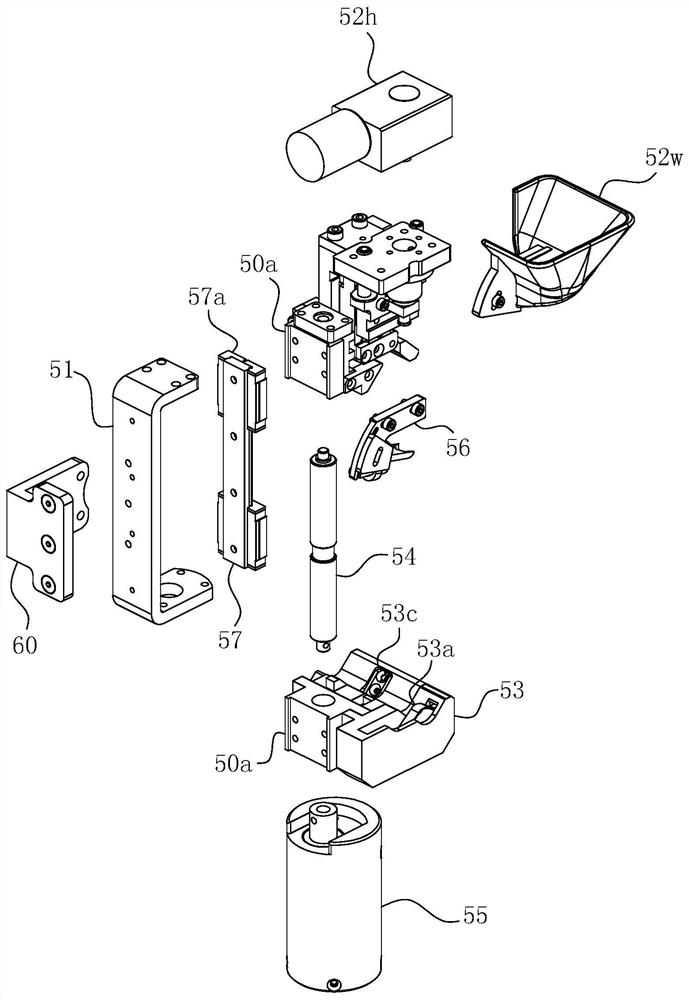

Closed cutting pliers head device of high-frequency bipolar closed cutting pliers

ActiveCN102204844AImprove closing effectEasy to useSurgical instruments for heatingPush and pullBiomedical engineering

The invention relates to a closed cutting pliers head device of high-frequency bipolar closed cutting pliers. The device is characterized by comprising a first closed pliers head (1), a closed pliers head pin (2), a second closed pliers head (3), an insulating pliers head baffle piece (4), a pliers head push-and-pull bar (5), a cutter blade push-and-pull pipe (6), an external aluminum pipe (7) and a cutting blade (26). In the closed cutting pliers head device of the high-frequency bipolar closed cutting pliers, the operation of closing and cutting is separated, a high-frequency bipolar pliers head adopts a single-handle holding mode for open and close, saves labor, is comfortable, is provided with a locking device, is reliable in motion and is convenient to use. By adopting an independent cutting device, accurate cutting at the closing position of the pliers head is realized through hooking a trigger by a forefinger, and the depth of cutting is controllable. By arranging an insulating component at the position of the pliers head of the closed cutting pliers head device of the high-frequency bipolar closed cutting pliers, the closing of the pliers head and the cutting of the blade cannot be affected, effective insulation can be realized, the application of a high-frequency electrode is ensured, and the device is convenient to clean.

Owner:杭州得道医疗设备科技有限公司

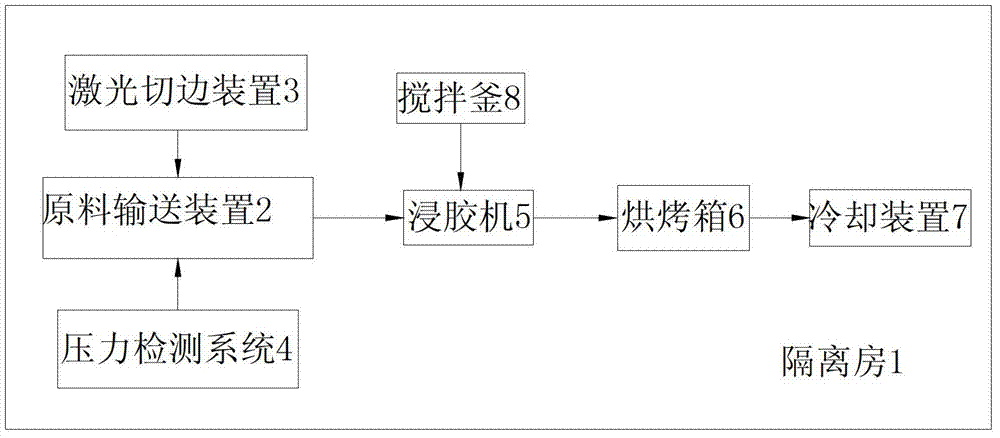

Method and device for producing prepreg

InactiveCN102922864AReduce usageTo achieve the purpose of recyclingLamination ancillary operationsLaminationColloidEngineering

The invention discloses a method for producing a prepreg. The method is specifically that undesirable edges are cut by adopting laser before material coating colloid is reinforced. By using the laser to cut the undesirable edges before the material coating colloid is reinforced, cut edges are not dipped into the colloid and can be recovered by material producing factories to be re-manufactured, the recycling purpose is achieved, and the using amount of the colloid is reduced. According to statistics and compared with traditional cutting method, 200,000 yuan of cost can be saved every year by adopting the method performing cutting while performing gum dipping, no dust cannot be produced in the cutting process of materials, the environment is protected and prevented from being polluted, and simultaneously good health of operating workers is also ensured.

Owner:GUANGDONG SHENGYI SCI TECH

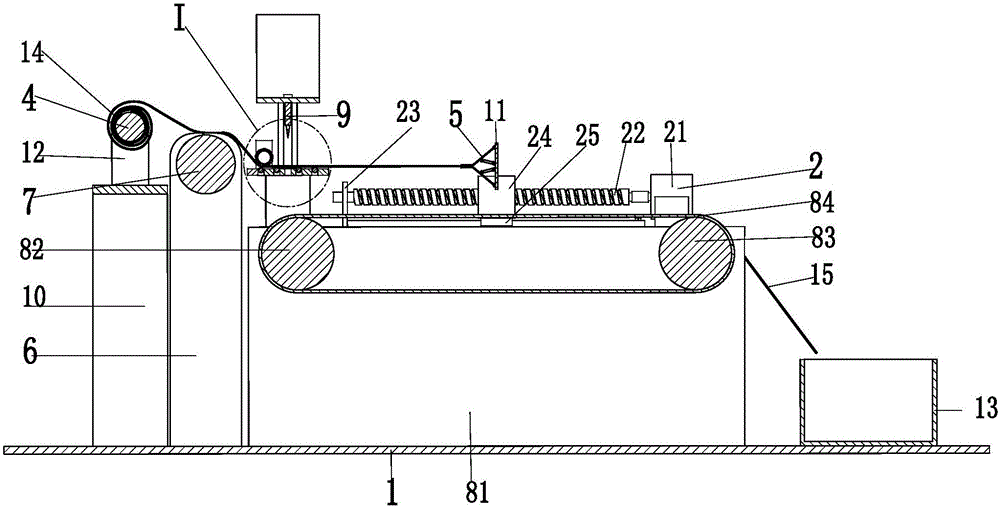

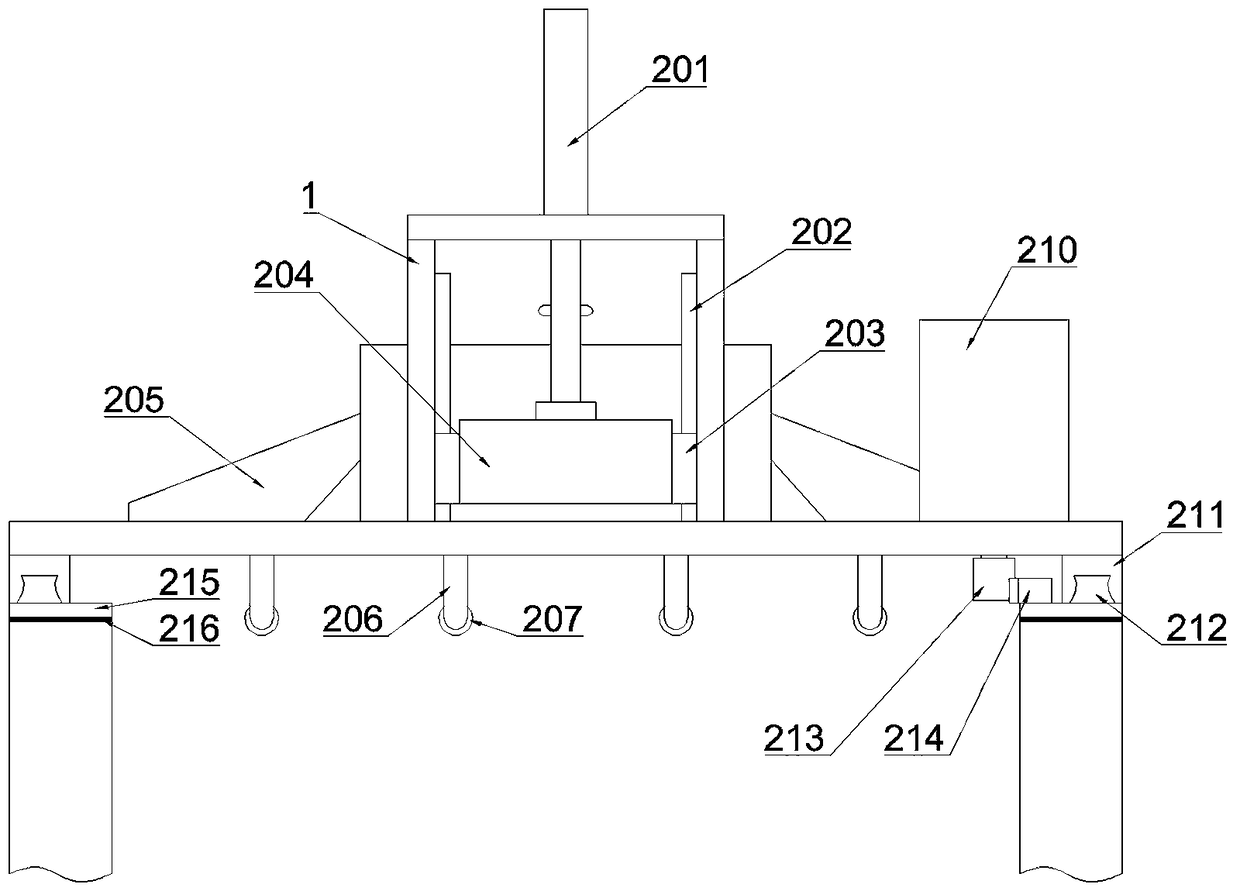

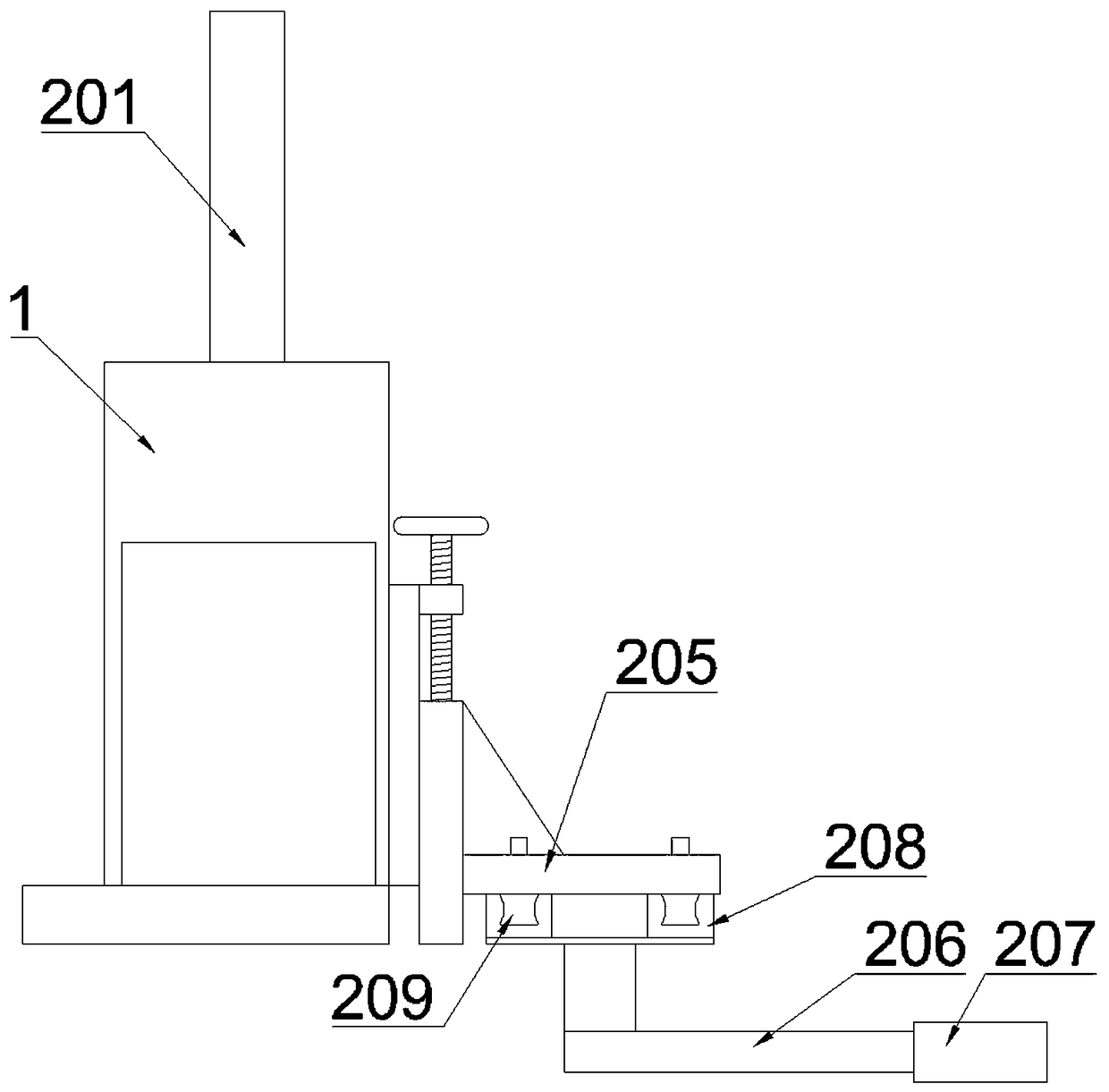

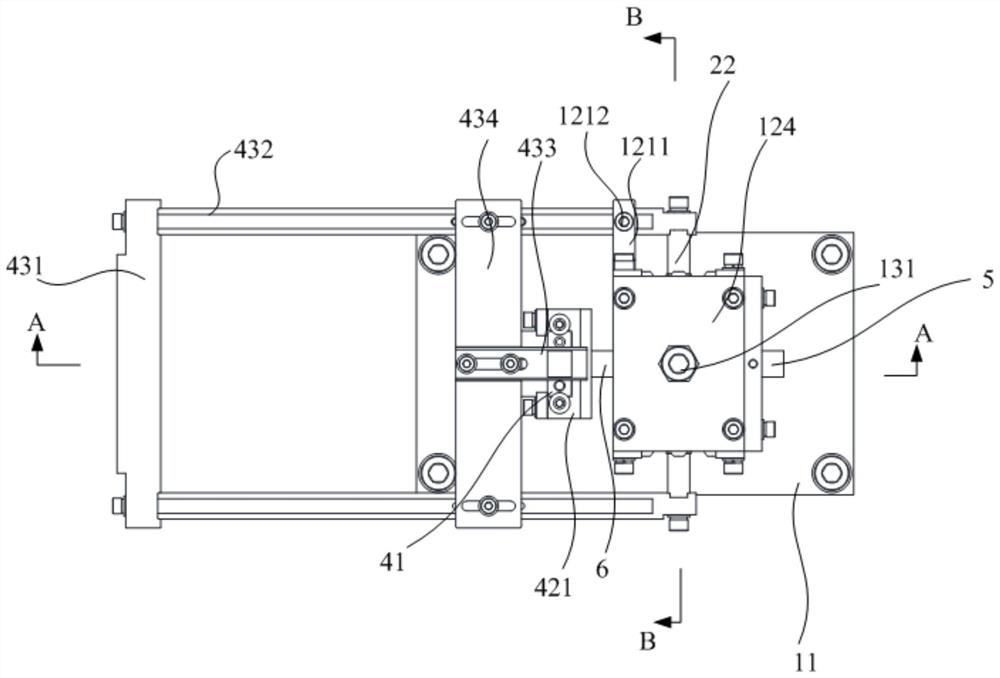

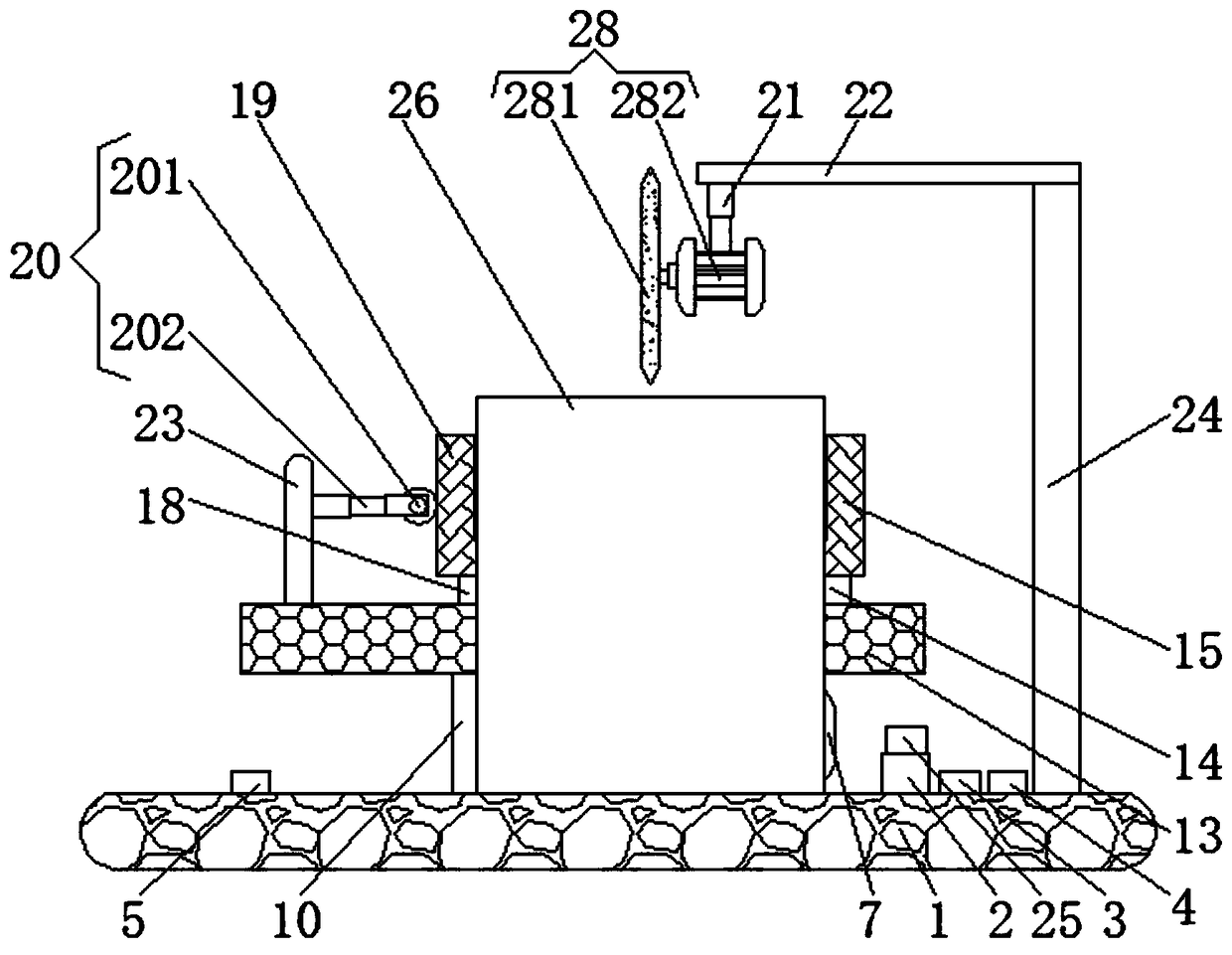

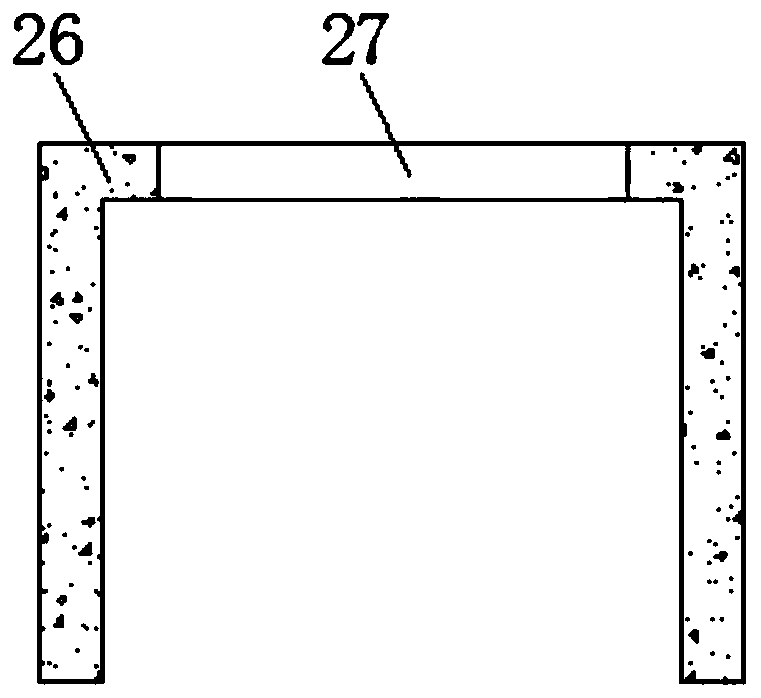

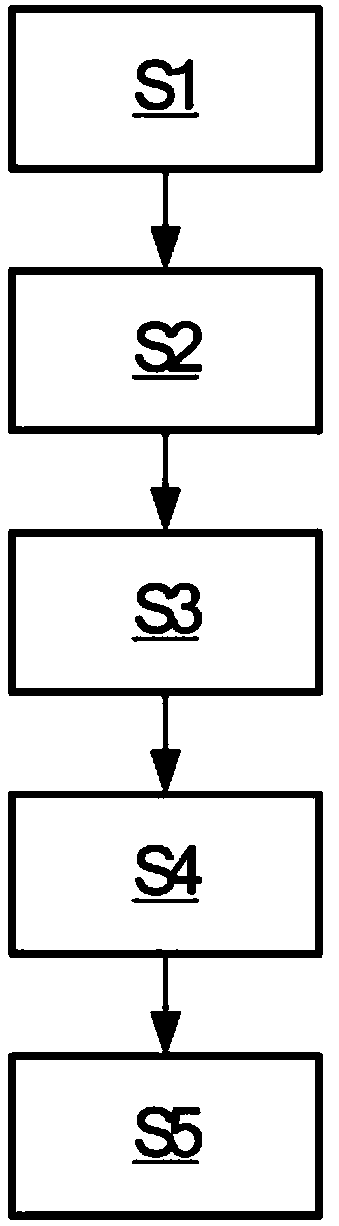

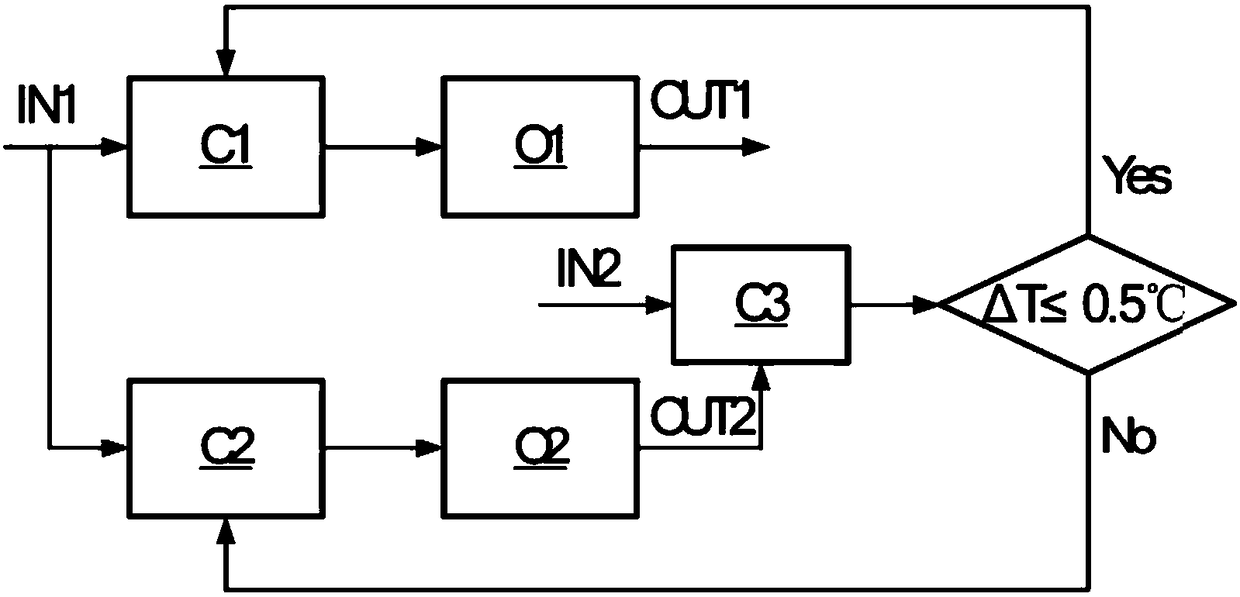

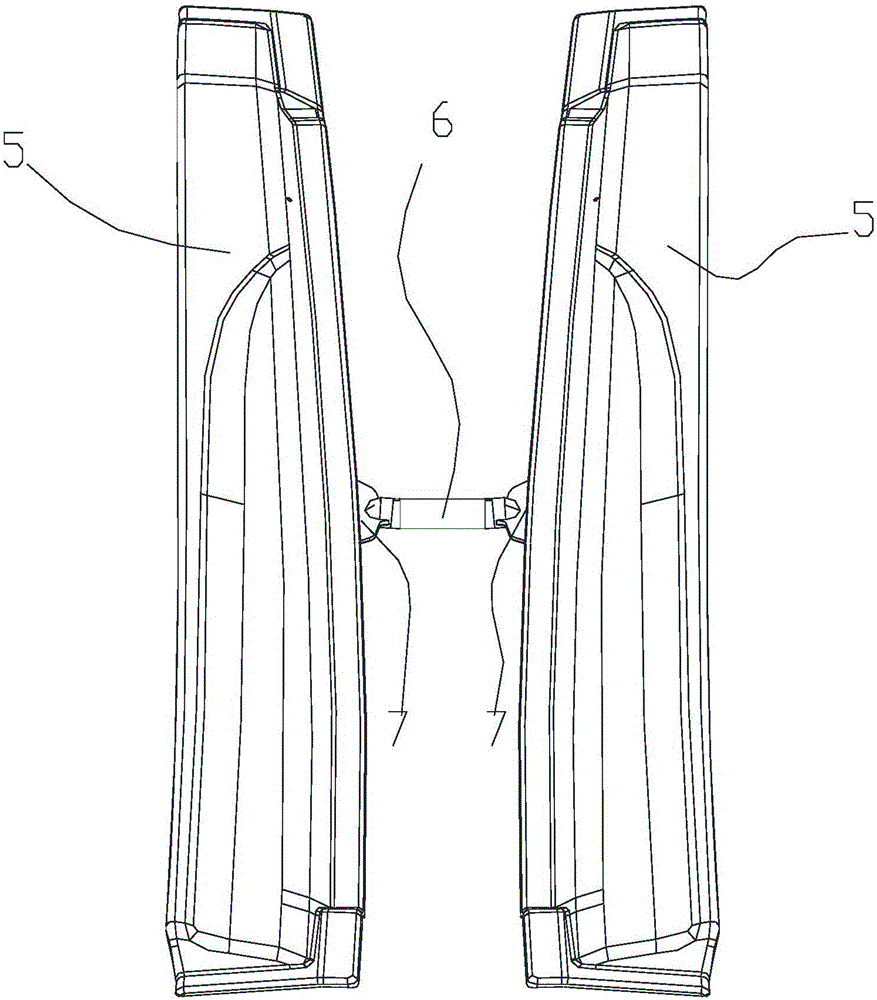

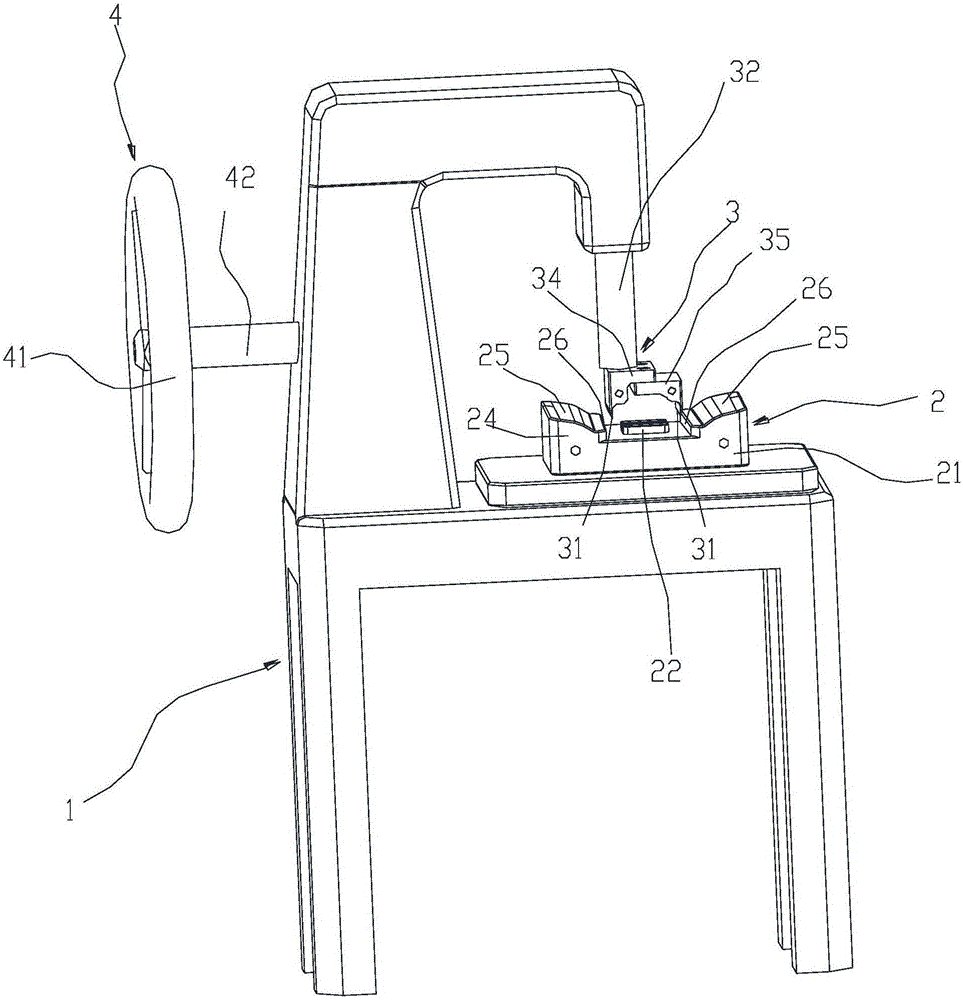

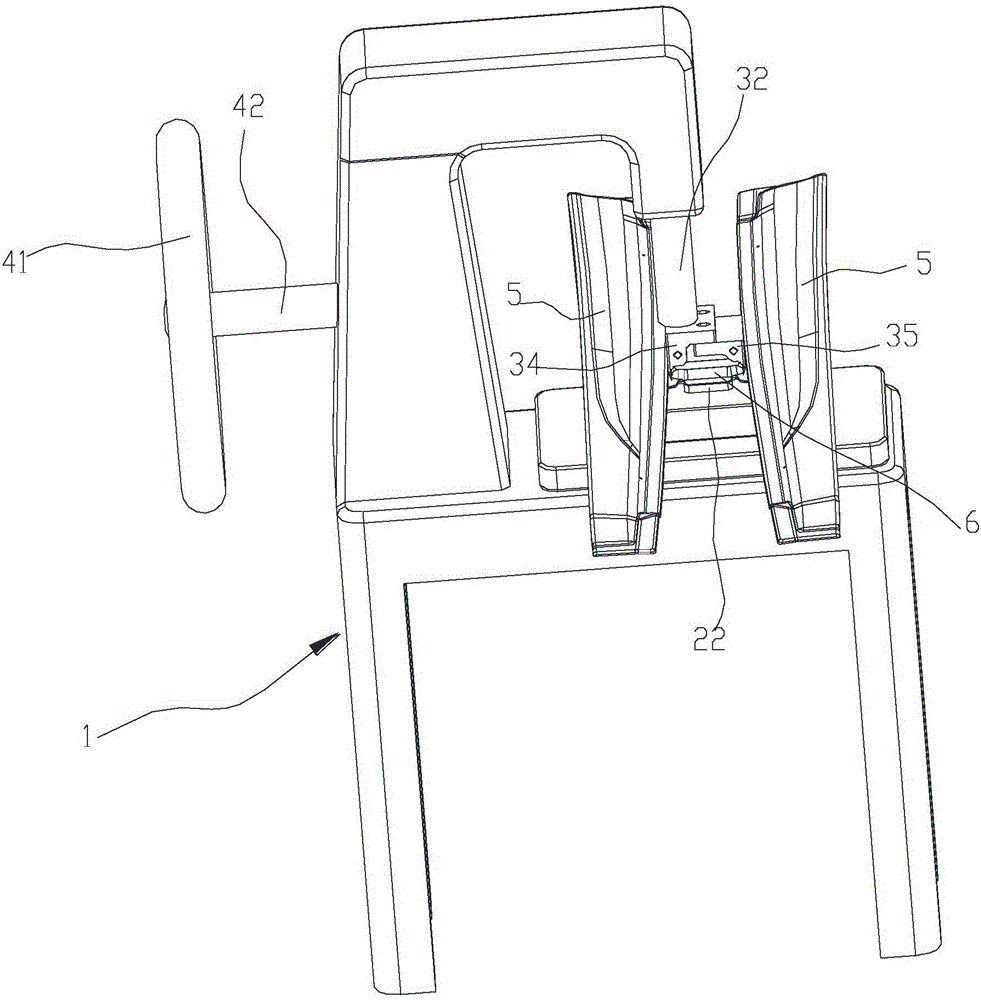

Sectional material cutting device

PendingCN108581020AAchieve precise cuttingNovel structureShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention provides a sectional material cutting device, and provides a device for automatically cutting and processing a sectional material of a sectional material door and window. The device comprises a sectional material clamping mechanism, a sectional material conveying mechanism, a sectional material aligning mechanism and a sectional material positioning and cutting mechanism, wherein theconveying mechanism comprises a conveying track; the clamping mechanism is arranged at one end of the conveying track and can move on the conveying track; the aligning mechanism is arranged in the middle part of the conveying track; and the positioning and cutting mechanism is arranged at the other end of the conveying track. The device is novel in structure, and ingenious in ideal; the sectionalmaterial can be automatically accurately cut, so that labor is saved; the processing speed is increased; the efficiency is high; the quality is high; and the effect is obvious.

Owner:河南宏基重工科技有限公司

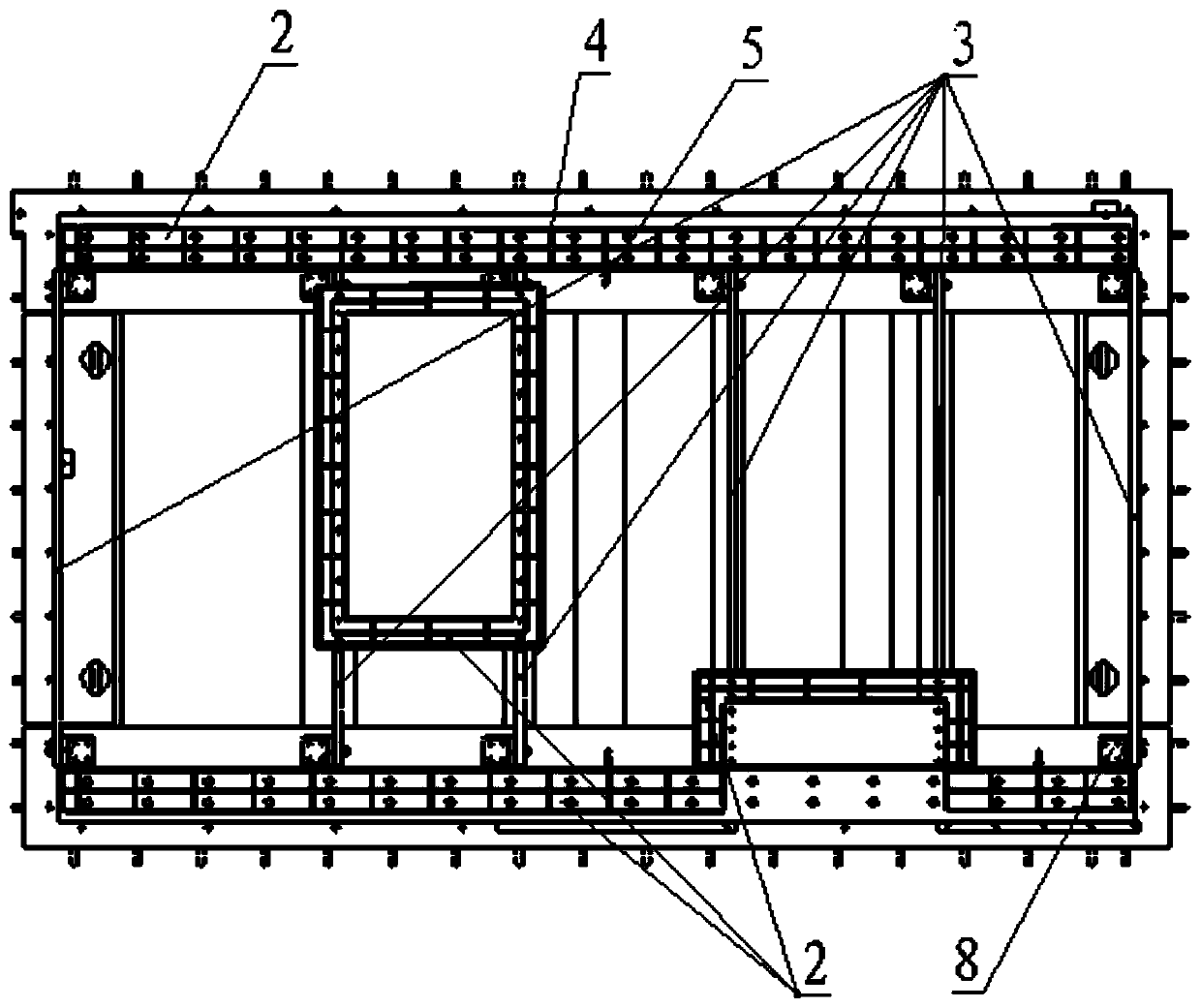

Milling clamp for finely cutting large-scale double-curvature aircraft skin

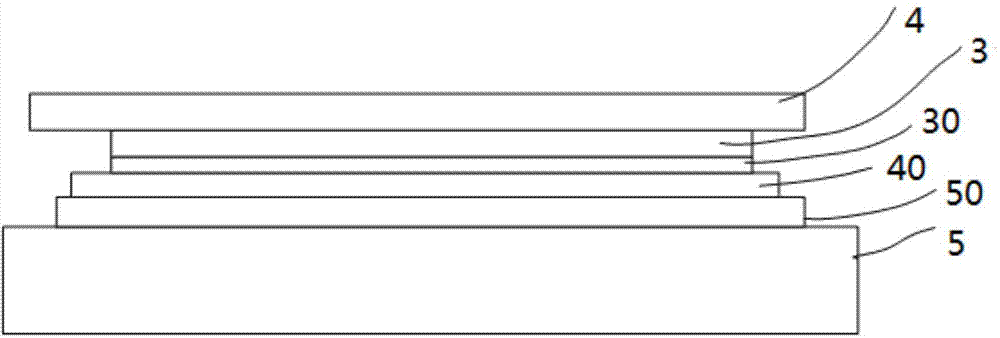

InactiveCN110682124ANot easy to shiftGuaranteed fine cutting qualityAircraft assemblyMilling equipment detailsPhysicsAirplane

The invention discloses a milling clamp for finely cutting large-scale double-curvature aircraft skin. The milling clamp comprises a positioning suction assembly (2), an auxiliary clamping plate positioning assembly and a base platform (7). The positioning suction assembly (2) is fixed on the base platform (7), the profile of the positioning suction assembly (2) is consistent with the profile of the aircraft skin, and an air extraction groove is arranged in the positioning suction assembly (2). The auxiliary clamping plate positioning assembly comprises an auxiliary clamping plate (3) and a positioning seat (8), wherein the positioning seat (8) is fixed on the inner side of the positioning suction assembly (2) and fixed on the base platform (7), and the auxiliary clamping plate (3) is fixed on the positioning seat (8). The positioning suction assembly (2) and the auxiliary clamping plate (3) are attached to the aircraft skin together. The base platform (7) is provided with a joint (5)which is connected with a vacuum pump and is used for vacuumizing a formed cavity. According to the milling clamp, full vacuum suction is adopted, compression of the aircraft skin and the milling clamp is achieved, displacement is not prone to being generated, the precision cutting quality is guaranteed, and precise shape cutting with no margin can be realized.

Owner:SHAANXI AIRCRAFT CORPORATION

Plate cutting device

ActiveCN109465918AAchieve precise cuttingNot prone to offsetProfiling/shaping machinesMechanical engineeringEngineering

The invention relates to the field of part processing and particularly discloses a plate cutting device. The plate cutting device comprises a machine table and cutters, and further comprises a rotating conveying wheel and a limiting mechanism for limiting plates. The conveying wheel is rotationally installed on the machine table and is in contact with the plates. The machine table is provided witha plurality of cutter holes allowing the cutters to penetrate through, and the distances between the cutter holes and the limiting mechanism are different. The cutting device in the scheme can perform accurate cutting on the plates.

Owner:CHONGQING JIANZHU COLLEGE

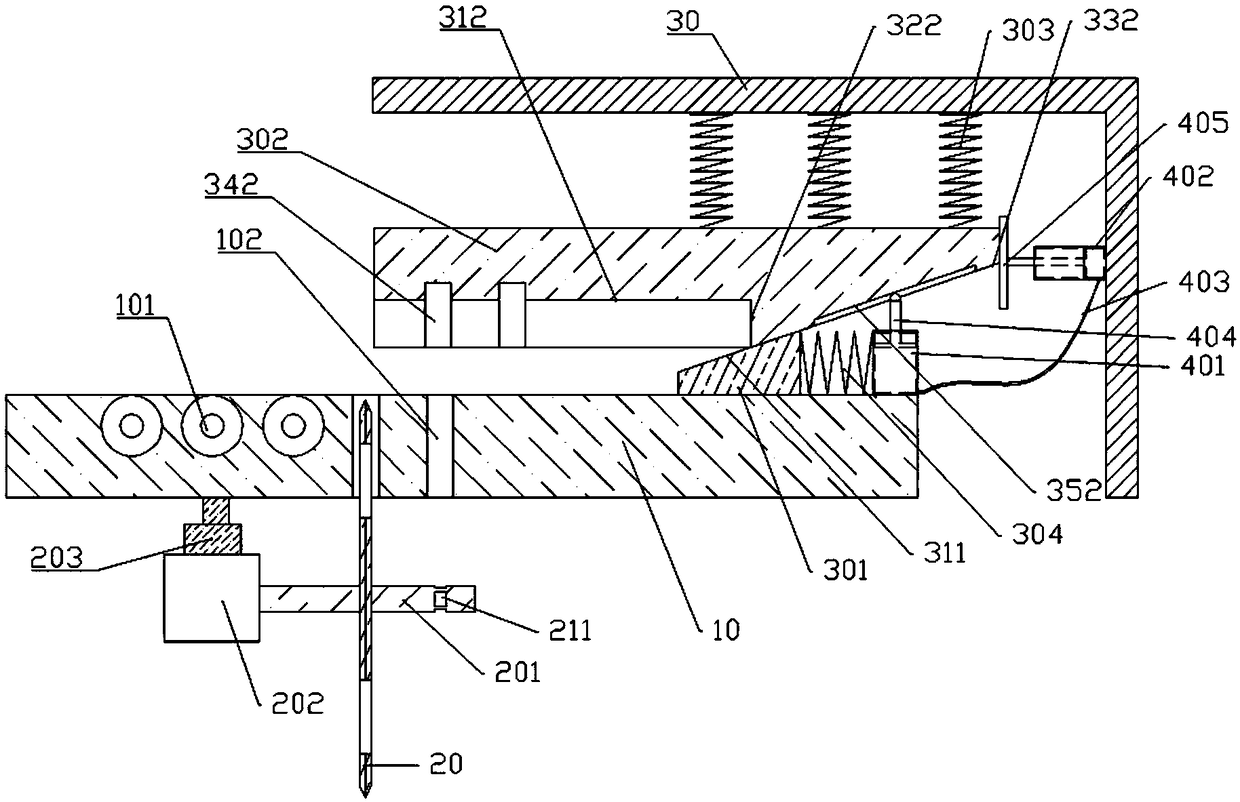

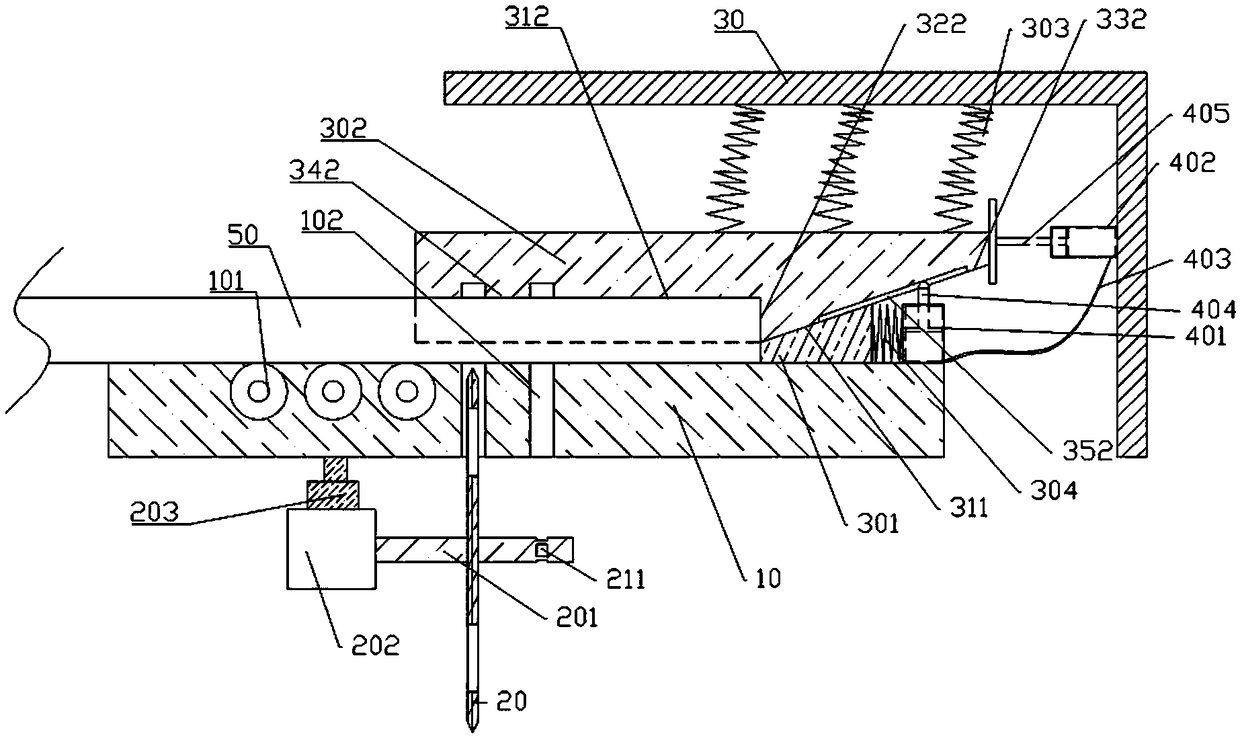

Cutting mechanism

ActiveCN113370281AEnsure one-way transferHigh precisionControl devices for conveyorsMetal working apparatusEngineeringStructural engineering

The invention discloses a cutting mechanism which comprises a mounting frame, a driving roller, a driven roller and a cutting device. The driving roller comprises a first roller body, a first rotating shaft and a one-way bearing; the first rotating shaft is rotationally connected with the mounting frame; the first roller body rotationally sleeves the first rotating shaft; the one-way bearing is arranged between the first roller body and the first rotating shaft; the driven roller is rotationally arranged on the mounting frame; the driven roller and the first roller body are arranged in a spaced mode to form a conveying channel used for conveying materials; the conveying channel has the feeding direction; the one-way bearing enables the materials to be conveyed in the feeding direction in a one-way mode; the cutting device comprises a cutting frame and a cutter; the cutting frame is connected with the first rotating shaft; the cutter is arranged on the cutting frame; the cutter and the first rotating shaft are arranged in a spaced mode; and the cutting frame drives the first rotating shaft to rotate and drives the cutter to be close to or away from the materials. According to the cutting mechanism provided by the invention, the cutting frame drives the first rotating shaft to rotate, so that material conveying and precise material cutting can be achieved; and power does not need to be additionally provided for the driving roller, the structure is simple, and the cost is low.

Owner:GOERTEK INC

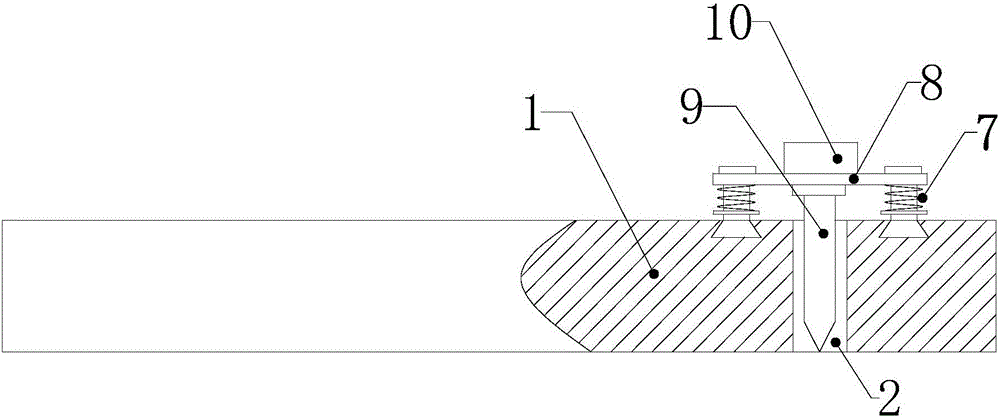

Ruler

InactiveCN106585213AAchieve precise cuttingAchieve protectionStraightedgesMetal working apparatusFlangeStraightedge

The invention relates to a ruler. With the ruler, paper can be cut conveniently, and hands are not hurt easily. The ruler comprises a ruler body; a slit is formed in the upper surface of the ruler body; guide rails are arranged on two sides of the slit respectively; sliding bodies are arranged in the two guide rails respectively; each sliding body comprises a sliding block and a stand column arranged on the sliding block, flanges are arranged at the top of the outer side surface of the stand column and at the bottom of the outer side surface of the stand column respectively, and an elastic device is arranged between the two flanges of the stand column; the ruler further comprises a connecting plate, a blade and a handle; the stand columns located on two sides of the slit are sleeved with two ends of the connecting pate respectively; each end of the connecting plate is located between the two flanges of the corresponding stand column; the top ends of the elastic devices make contact with the bottom surface of the connecting plate; the top end of the blade is fixedly arranged on the bottom surface of the connecting plate; the bottom end of the blade is arranged in the slit; the handle is fixedly arranged on the top surface of the connecting plate; and when the connecting plate is pressed to move downwards to the limit position, the bottom end of the blade extends out of the lower surface of the ruler.

Owner:李洁

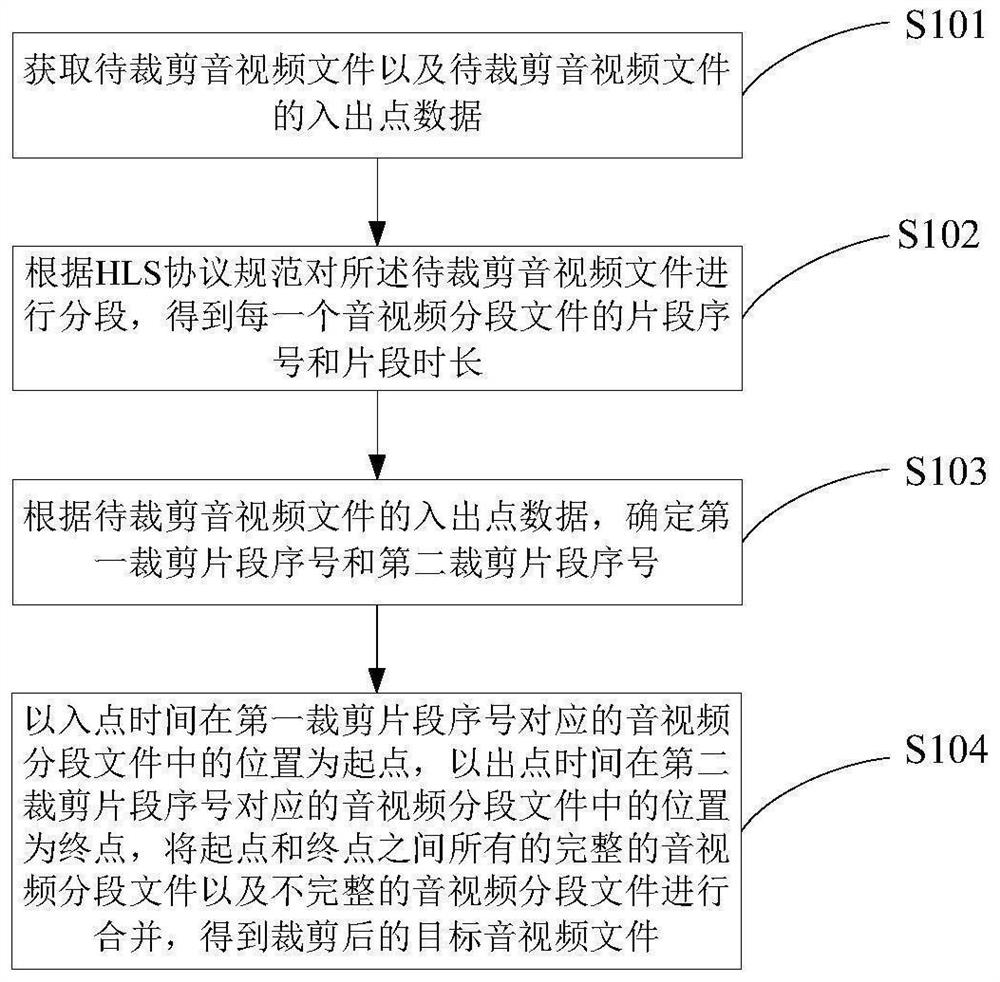

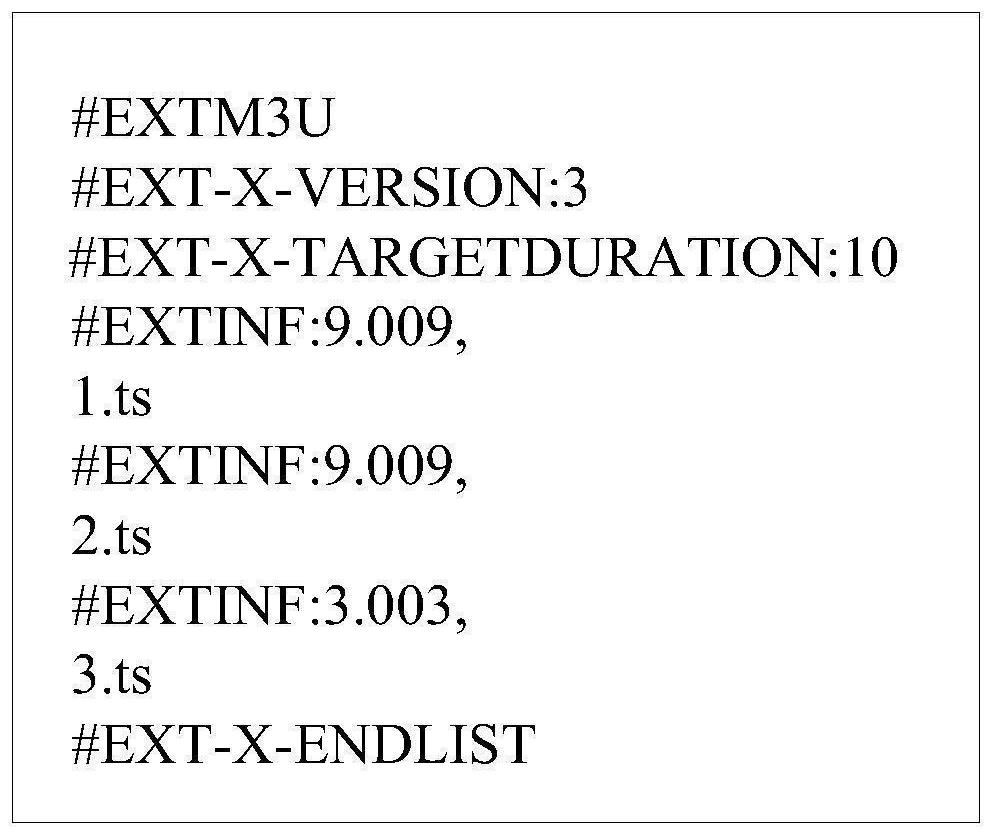

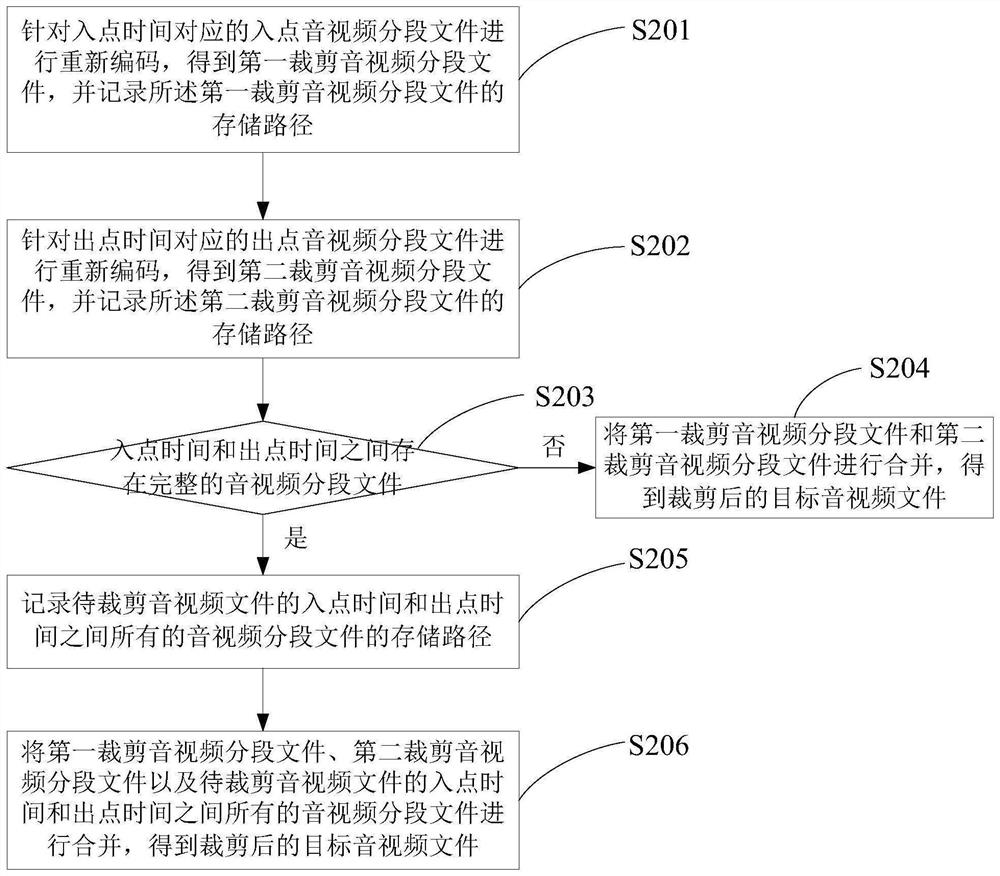

Audio and video clipping method and device

PendingCN112218118ACutting time is shortenedAchieve precise cuttingSelective content distributionClipping (audio)Computer graphics (images)

The invention discloses an audio and video clipping method and device, wherein the method comprises the steps: obtaining a to-be-clipped audio and video file and in-out point data, carrying out segmentation of the to-be-clipped audio and video file according to an HLS protocol specification, and determining a first clipping segment serial number where the in-point time is located and a second clipping segment serial number where the out-point time is located according to the in-out point data of the to-be-clipped audio and video file; and taking the position of the in-point time in the audio and video segment file corresponding to the first clipping segment serial number as a starting point, taking the position of the out-point time in the audio and video segment file corresponding to thesecond clipping segment serial number as an ending point, and combining all the audio and video segment files between the starting point and the ending point to obtain a clipped target audio and videofile. The audio and video segment file appointed in an HLS protocol is generally about 10 seconds, so that the longest recoding time is the longest segment time of a single chip of the current HLS index file, the accurate clipping of the audio and video file is realized, the audio and video clipping time consumption is reduced, and the clipping efficiency is improved.

Owner:HUNAN HAPPLY SUNSHINE INTERACTIVE ENTERTAINMENT MEDIA CO LTD

New material cutting device with protection function

InactiveCN109290618AWith protective functionAchieve precise cuttingShearing machinesPositioning apparatusSputteringEngineering

The invention discloses a new material cutting device with a protection function, and relates to the technical field of new materials. The device comprises a base, the upper surface of the base is fixedly connected with the bottom end of a third fixing rod, the top end of the third fixing rod is fixedly connected with the lower surface of a first driving device, a thread nut is in threaded connection with the outer wall of the first driving device, the upper surface and the lower surface of the thread nut are fixedly connected with the opposite faces of two connection rods, and the left ends of the two connection rods are both fixedly connected with the right side face of a supporting rod. According to the new material cutting device with the protection function, by means of the combined action of a first motor, a thread column, the thread nut, the connection rods, the supporting rod, a first sliding rod, a first sliding sleeve, a second electric push rod, a U-shaped plate, a second motor and a cutting blade, new materials are accurately cut, waste scraps are prevented from sputtering and injure people in the cutting process, and workers are protected.

Owner:郭银芝

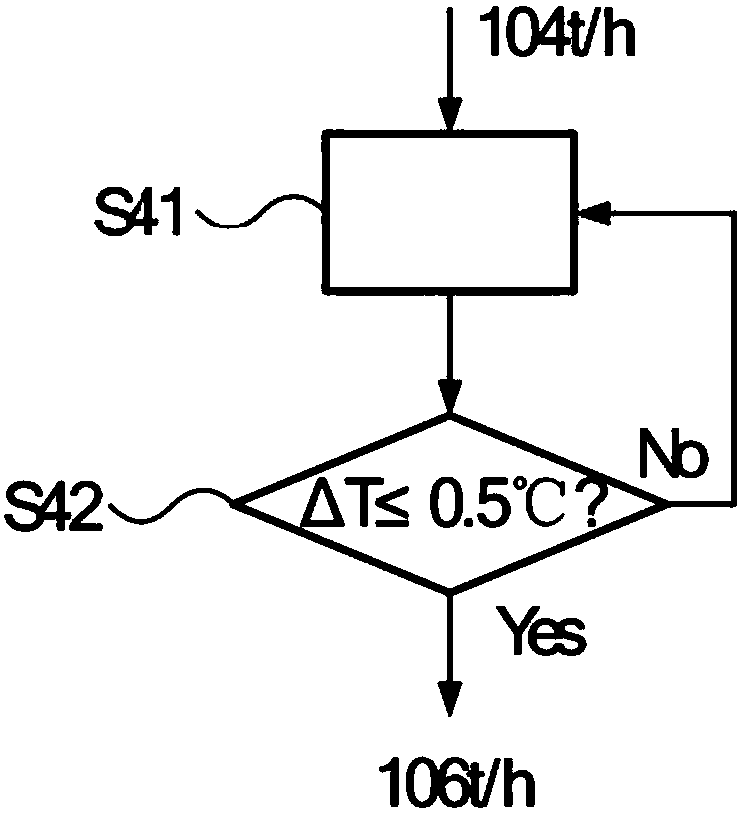

Method and system for optimizing top cycle oil flow rate of catalytic cracking fractionating tower during gasoline and diesel cutting process

ActiveCN108732940AAchieve precise cuttingAdjust the yield reasonablyHydrocarbon distillation control/regulationSimulator controlDynamic modelsDistributed control system

The invention relates to a method for optimizing a top cycle oil flow rate of a catalytic cracking fractionating tower during a gasoline and diesel cutting process. According to the method, in order to improve the gasoline yield, a catalytic cracking fractionating tower dynamic model is established by utilizing an SIMIT simulation framework, and a distributed control system simulator is established. If an actually measured crude gasoline endpoint is less than a process card crude required value and exceeds a first predetermined value, operating parameters of the current fractionating tower areinput into the catalytic cracking fractionating tower dynamic model by means of the distributed control system simulator, so as to obtain a simulated crude gasoline endpoint and compare the simulatedcrude gasoline endpoint with the process card required endpoint, if the simulated crude gasoline endpoint is lower than the process card required endpoint and exceeds the first predetermined value, the top cycle oil flow rate in the operating parameters is increased by step-length, so as to update the simulated crude gasoline endpoint, the steps are circulated till the updated simulated crude gasoline endpoint is lower than the required endpoint and does not exceed the first predetermined value, thus the optimized cycle oil flow rate is obtained, and the optimized cycle oil flow rate is output.

Owner:SIEMENS CHINA

Intelligent positioning method of tobacco bundles

InactiveCN101653289BLighten the load on the swingImprove labor productivityTobacco treatmentCharacter and pattern recognitionEngineeringSmoke

The invention relates to an intelligent positioning method of tobacco bundles, which can rectify the position of the tobacco bundles, lighten the bundle-placing load of workers and improve the labor productivity of the workers after the bundles are placed by the workers. The tobacco stalks can be precisely positioned when the tobacco bundles are cut, and the precise cutting of leaves and stalks is achieved. The cut tobacco leaves and tobacco stalks are respectively conveyed into different devices for processing, the leaves and the stalks are precisely cut, and the problems of material blockage, uneven material flow, more shutdowns, low effective operation efficiency, and the like as the tobacco bundles are wound to each other and devices are wound in threshing are solved.

Owner:HEFEI ANDA ELECTRONICS DETECTION EQUIP FACTORY

Vehicle sun/rain shield glue inlet shearing device

ActiveCN106003604AAchieve precise cuttingAchieve positioningMetal working apparatusElectrical and Electronics engineering

Owner:GUANGZHOU XINHUI AUTOMOBILE PARTS

Tablet cutting equipment

InactiveCN110169919AAchieve precise cuttingRealize automatic cuttingOral administration deviceMetal working apparatusLinear motionEngineering

The invention discloses tablet cutting equipment, comprising a working table, a cutting device mounted on the working table, a feeding device and a clamping device, wherein the cutting device comprises a driving mechanism and a wire, and is adapted to drive the wire through the driving mechanism for high-speed linear motion to cut a tablet; the feeding device is mounted on the working table and adapted to move relative to the working table; the clamping device is mounted on the feeding device, and the clamping device is adapted to clamp the tablet to be cut and adapted to feed relative to thecutting device under the driving of the feeding device to realize cutting of the tablet. The tablet cutting equipment disclosed by the invention has the advantages of simple structure, stable system and high cutting efficiency, and can cut the tablet in various ways.

Owner:朱峰

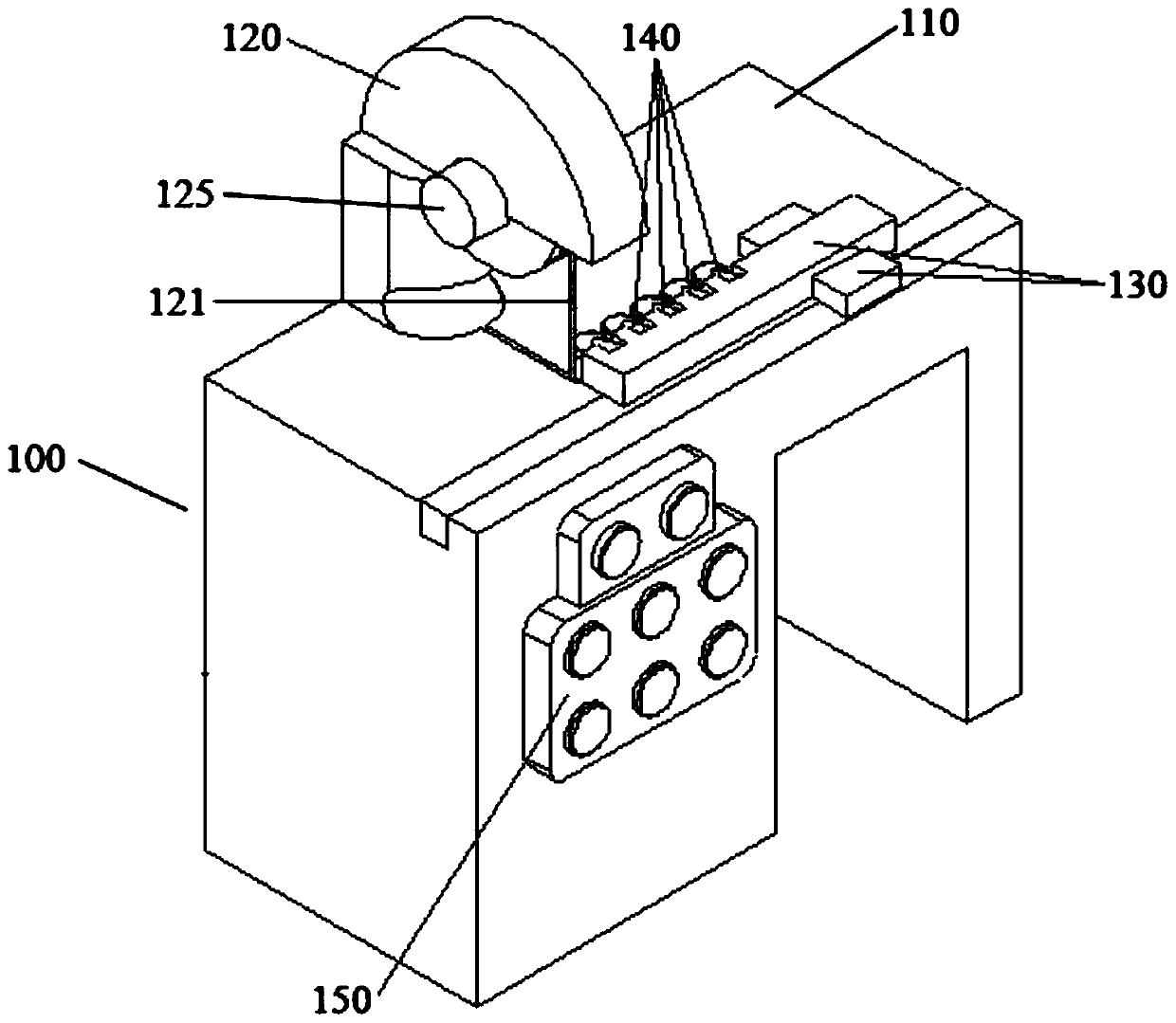

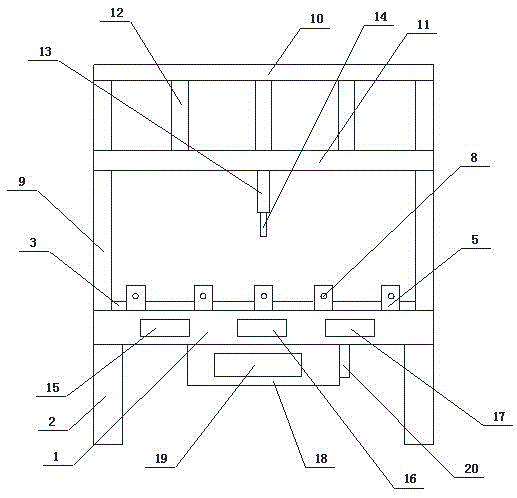

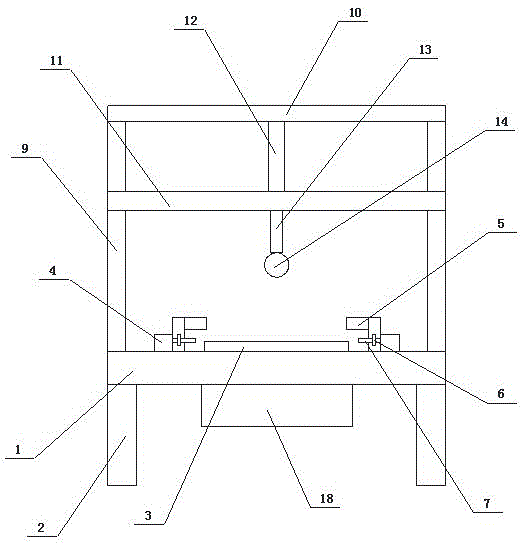

Precision cutting machine for processing aluminum alloy doors and windows

InactiveCN106808023AAchieve precise cuttingPositioning apparatusMetal-working holdersEngineeringSlide plate

The invention discloses a precision cutting machine for processing aluminum alloy doors and windows, which comprises a rectangular parallelepiped workbench. Several pneumatic clamps driven by cylinders are arranged symmetrically on the basis of the conveyor belt. The side of the pneumatic clamp is provided with an air duct connected to the fan through a fixed buckle. The upper surface of the workbench is equipped with a The corresponding travel switch, the four corners of the upper surface of the workbench are equipped with sliding rods, the top of the sliding rod is provided with a cover plate, the sliding rod is provided with a sliding plate slidingly connected with it, and the top of the sliding plate is provided with one end and Connect the other end to the hydraulic lifting rod that drives the slide plate to move up and down on the slide rod that is connected to the bottom of the cover plate. The invention can accurately cut the aluminum alloy and guarantee the cutting effect.

Owner:CHONGQING YUANHUA DOORS & WINDOWS

co 2 Laser Live Wire Insulation Cutting System and Cutting Method

ActiveCN105914664BAchieve precise cuttingAvoid damageApparatus for removing/armouring cablesControl systemGalvanometer

Owner:ANSHAN LANLING JIDIAN PROTECTION +2

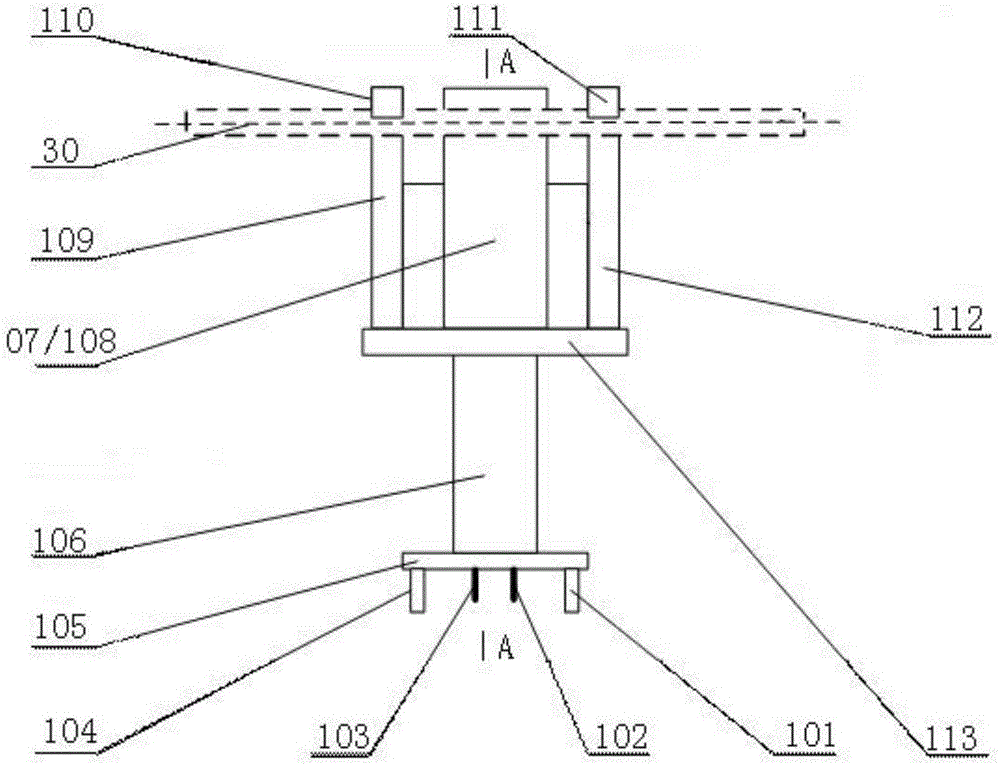

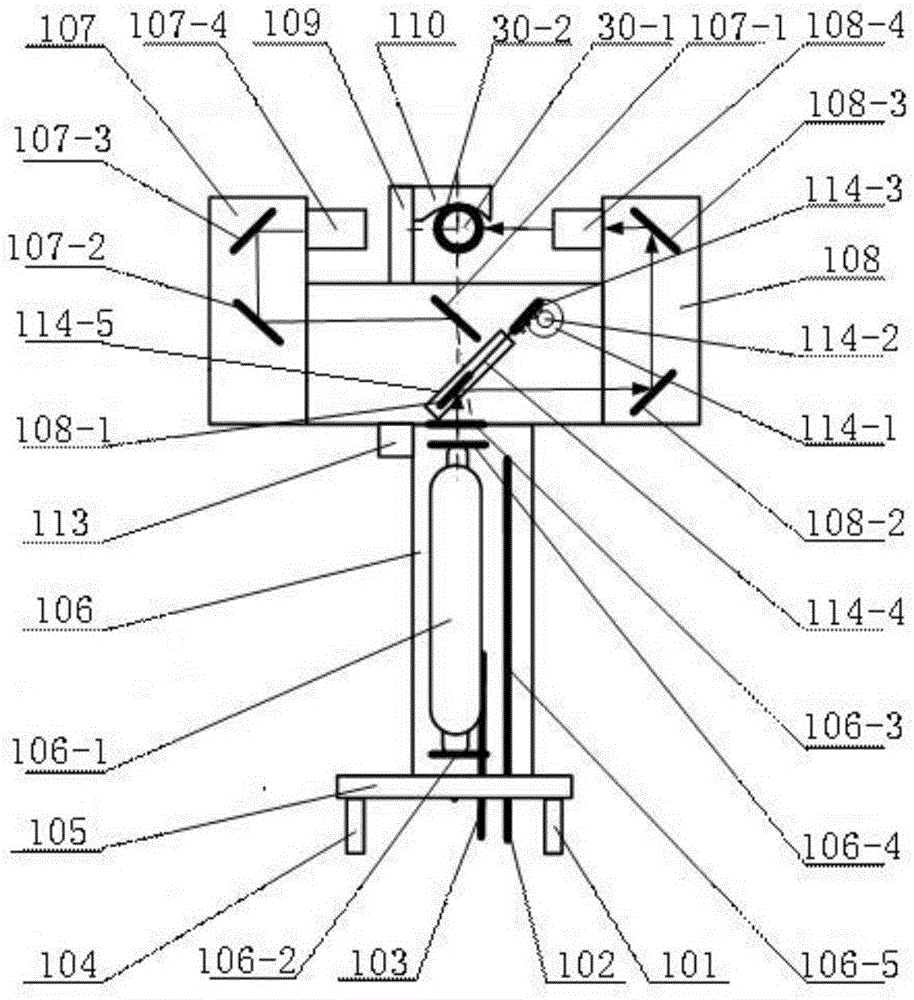

CO2 laser live conductor insulating sheath cutting system and method

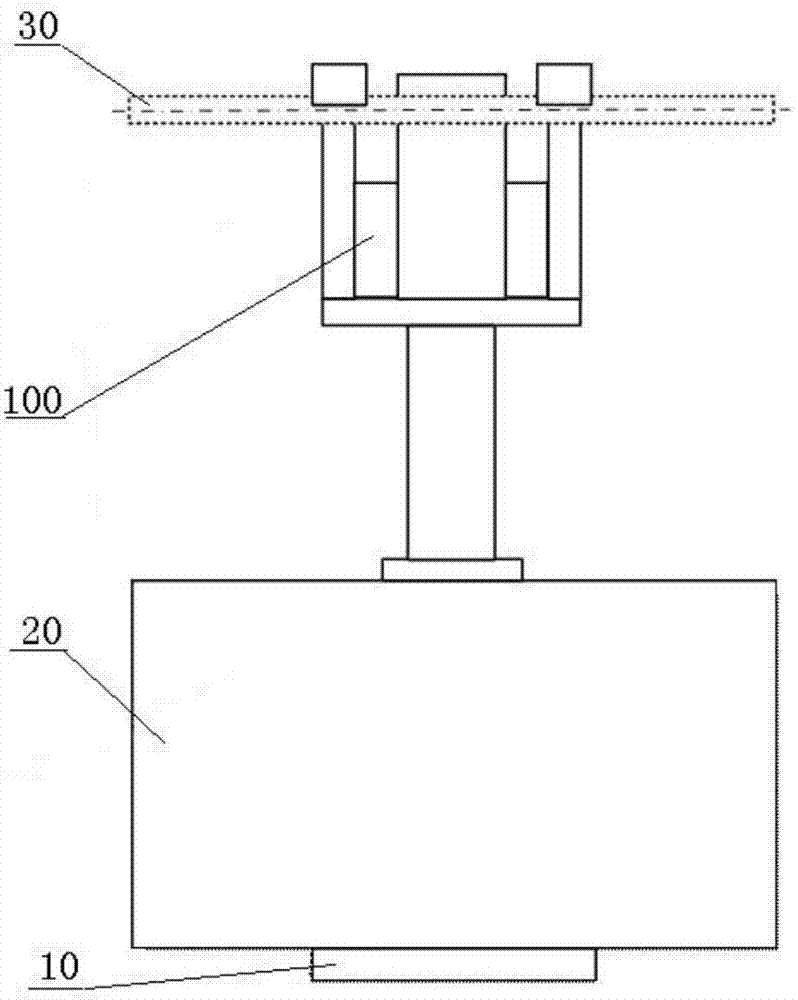

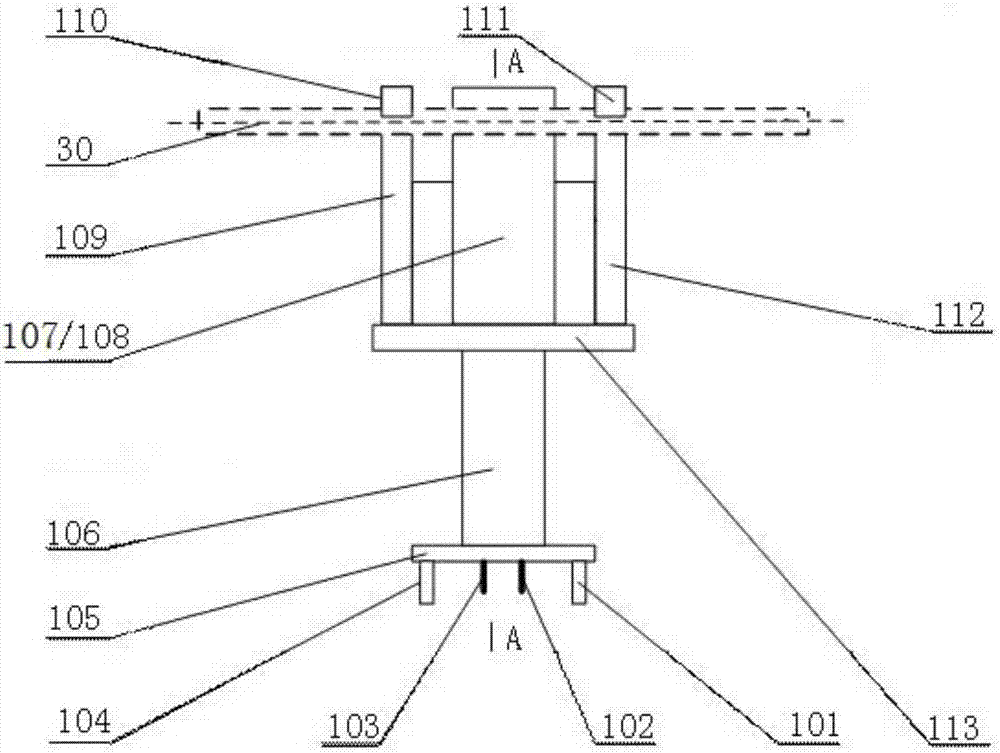

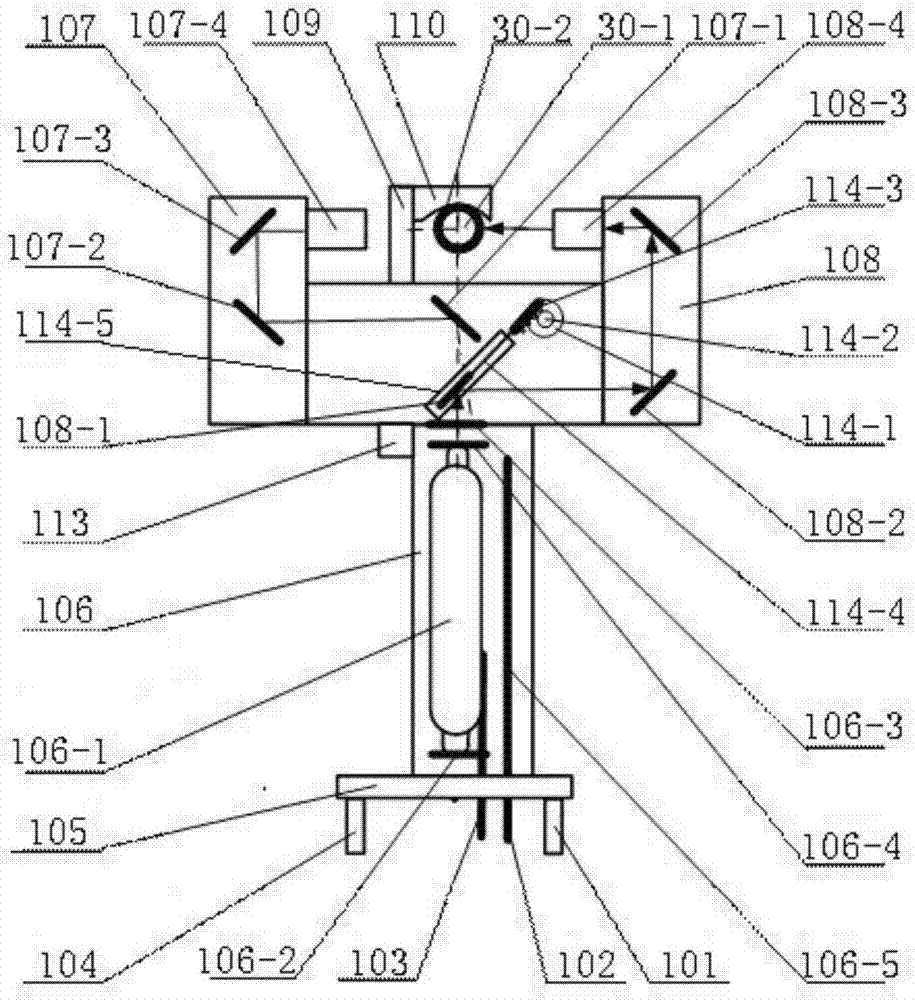

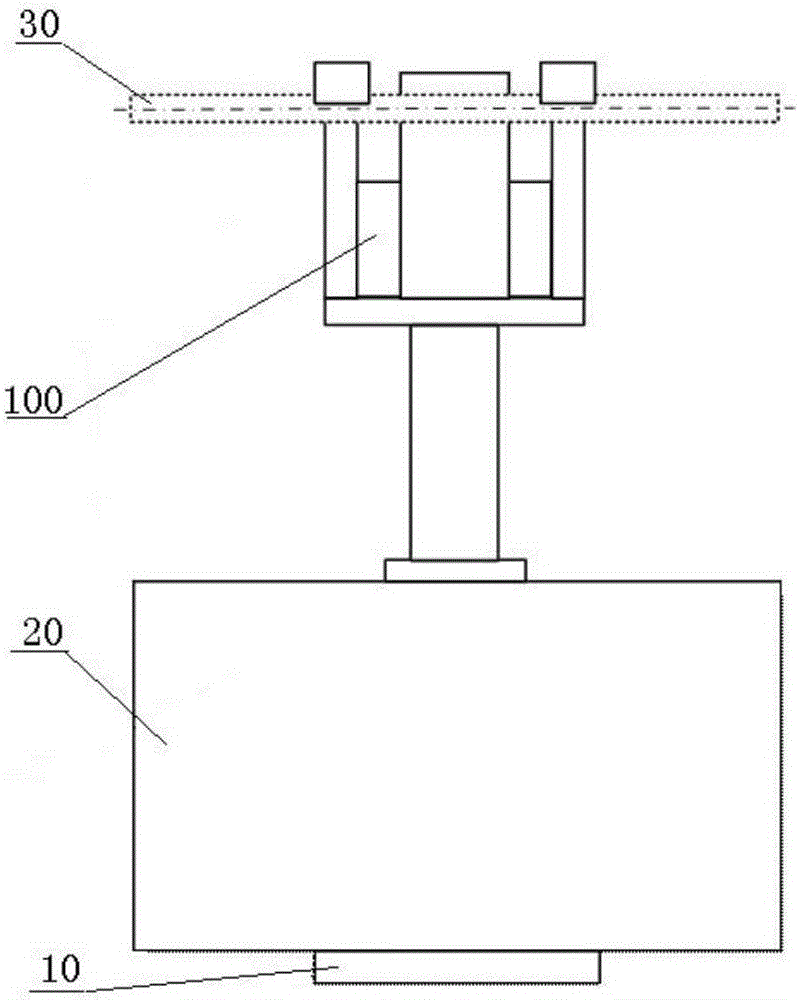

ActiveCN105914664AEasy for remote monitoringPrecise positioningApparatus for removing/armouring cablesControl systemGalvanometer

The invention relates to a CO2 laser live conductor insulating sheath cutting system and method. A left optical path system and a right optical path system are symmetrically suspended at two sides of a live conductor through a suspending mechanism, and a CO2 laser is disposed below. The left optical path system consists of a left reflector group and a left galvanometer box, and the right optical path consists of a reflector group and a right galvanometer box. The first left reflector and the first right reflector are arranged vertically, wherein the lower one of the first left and right reflectors is provided with a reflector moving device. The CO2 laser, the left galvanometer box, the right galvanometer box and the reflector moving device are respectively connected with a control system. Through different physical burning characteristics of CO2 laser for rubber and metal and the guide effect of the galvanometer boxes on a laser beam, the double-optical-path system cuts H-shaped notches at two sides of the insulating sheath of a live conductor, and achieves the complete cutting of the insulating sheath through precise alignment. One CO2 laser is used for achieving the time-sharing operation of double optical paths, and can achieve the omnibearing remote monitoring.

Owner:ANSHAN LANLING JIDIAN PROTECTION +2

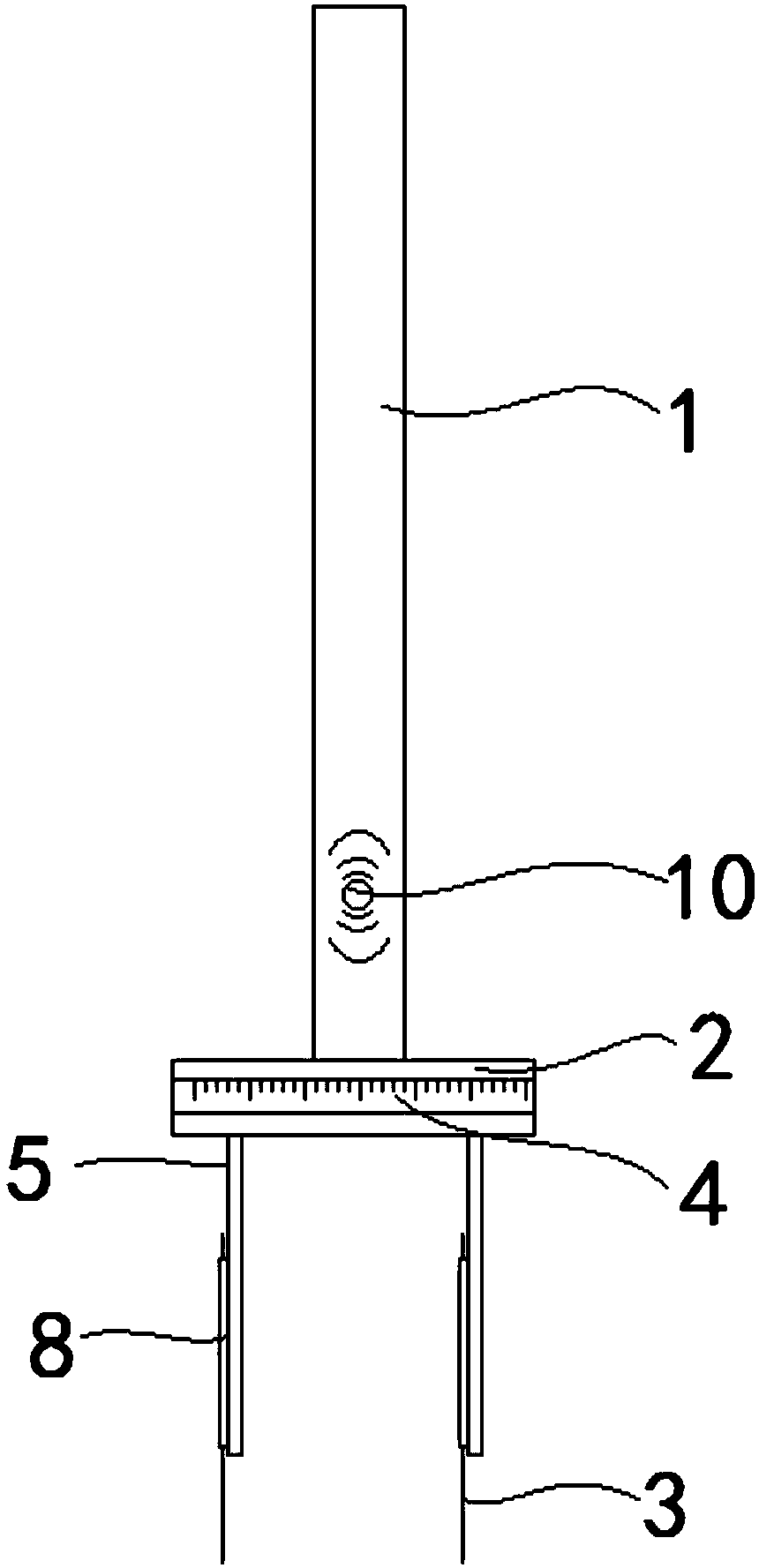

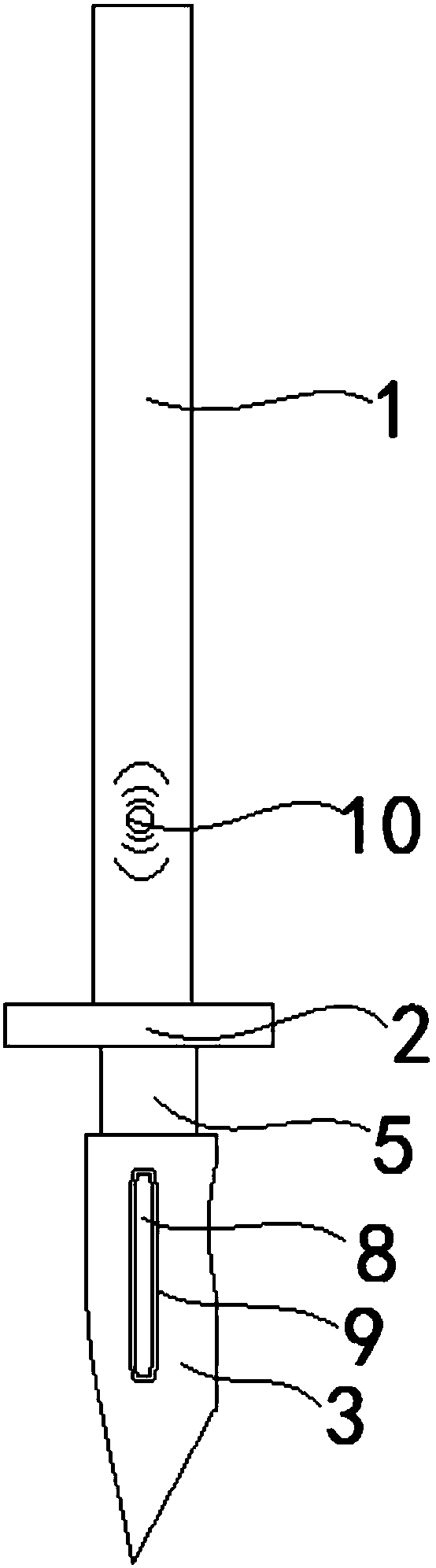

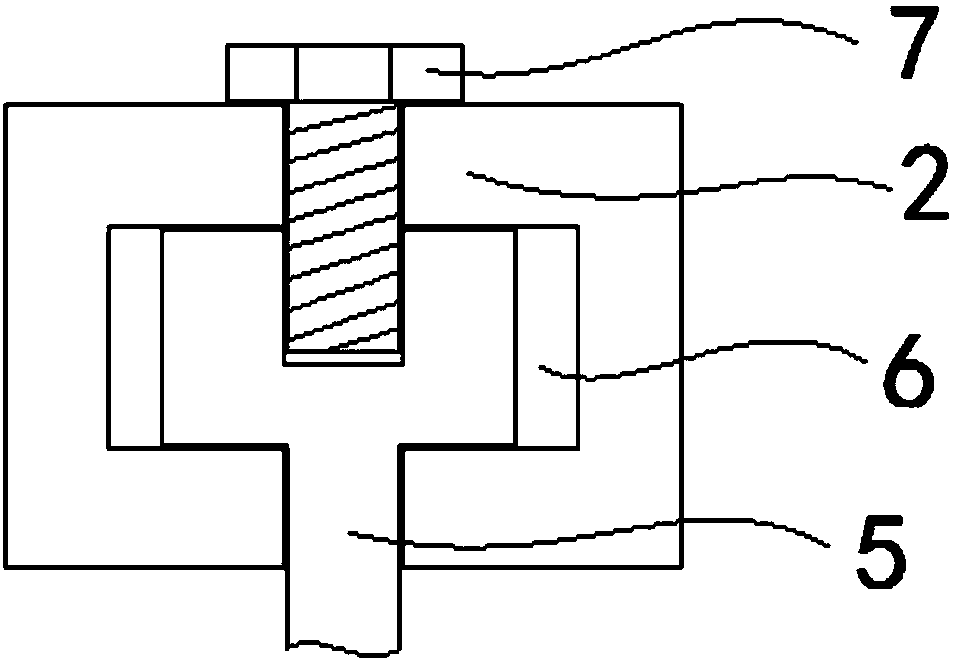

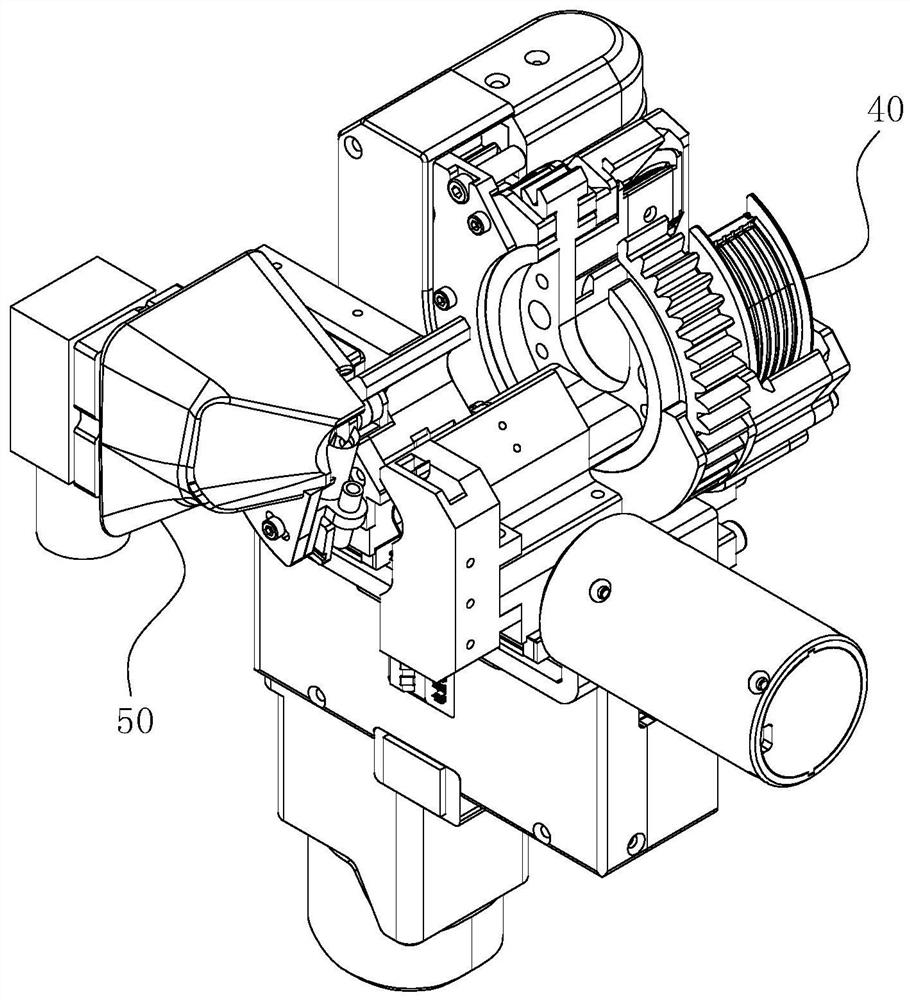

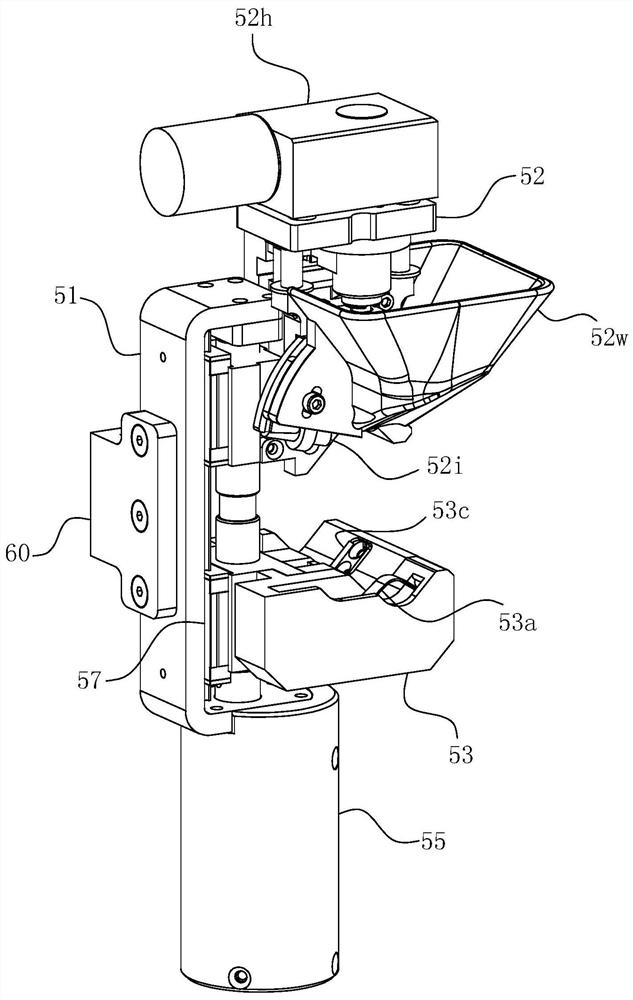

A zero reference adjustment method for a peeler based on a zero reference adjustment device

ActiveCN110768168BTo achieve depth adjustment effectRealize adaptive adjustment functionLine/current collector detailsApparatus for removing/armouring cablesSlide plateControl theory

The invention belongs to the technical field of cable stripping, and in particular relates to a zero reference adjustment method for a stripper based on a zero reference adjustment device. The zero reference adjustment device of the present invention comprises the following components: a zero reference slide plate, a knife depth adjustment slider, a pressure plate, a knife depth adjustment thread seat, an elastic compression damping member, a knife depth adjustment bolt, and a rotating sleeve; and the zero position The reference adjustment method includes the following steps: 1), a zero reference correction step; 2), a zero search step; 3), an absolute feed amount adjustment step. The present invention can flexibly realize the self-adaptive adjustment function of the feed amount of the cutter according to the diameter of the current cable to be clamped. The present invention can achieve the purpose of adjusting the consistency between the amount of cutting and the actual cutting depth of the cable in one step, thereby achieving the effect of adjusting the absolute cutting depth and greatly improving the actual peeling efficiency of the cable.

Owner:CAS HEFEI INST OF TECH INNOVATION +1

Tablet Cutting Equipment

InactiveCN110169919BAchieve precise cuttingRealize automatic cuttingOral administration deviceMetal working apparatusEngineeringWorkbench

Owner:朱峰

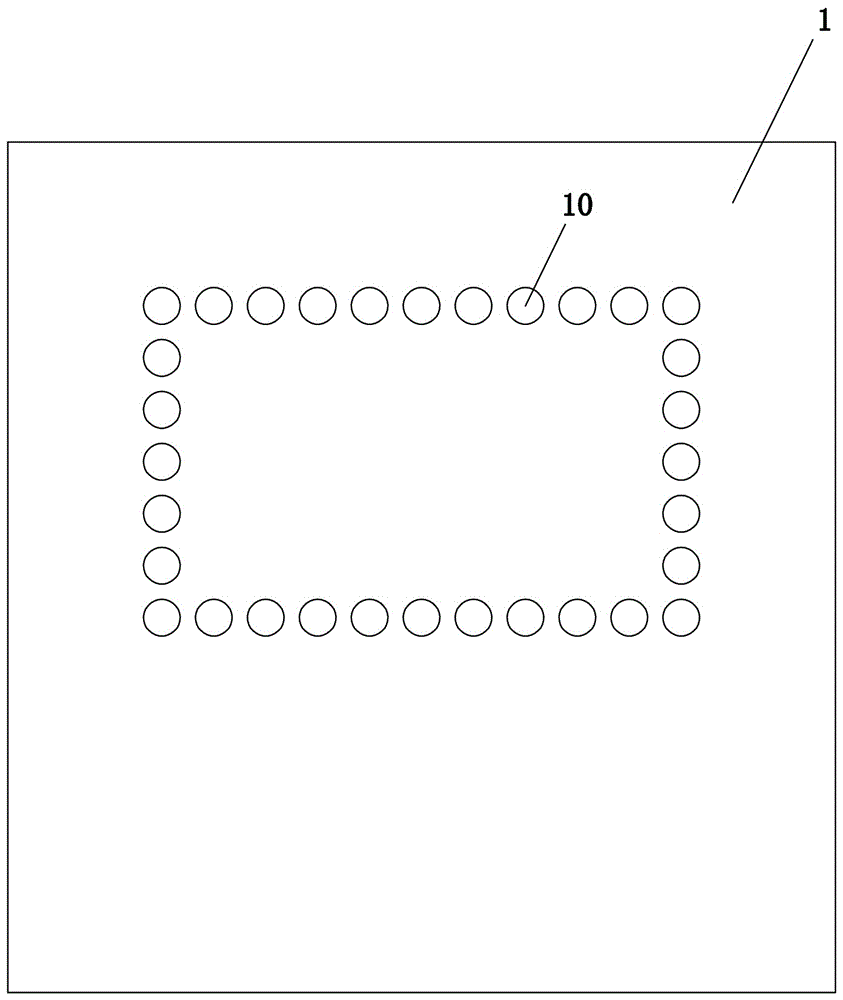

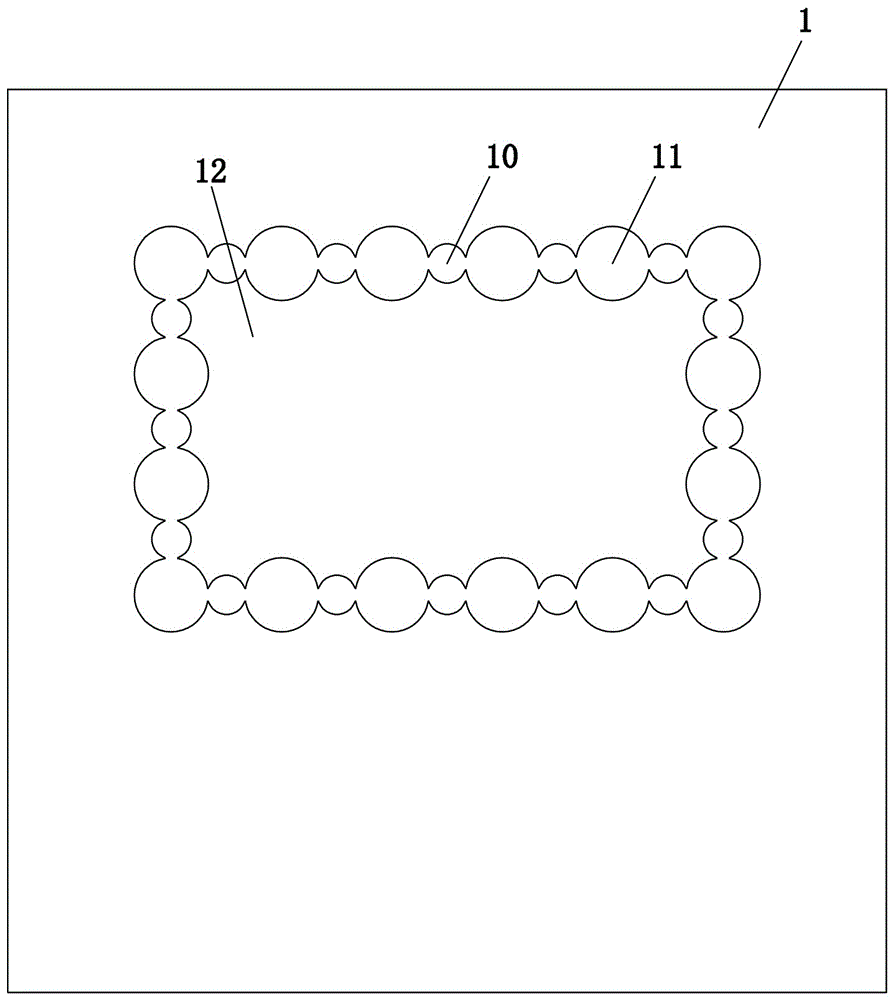

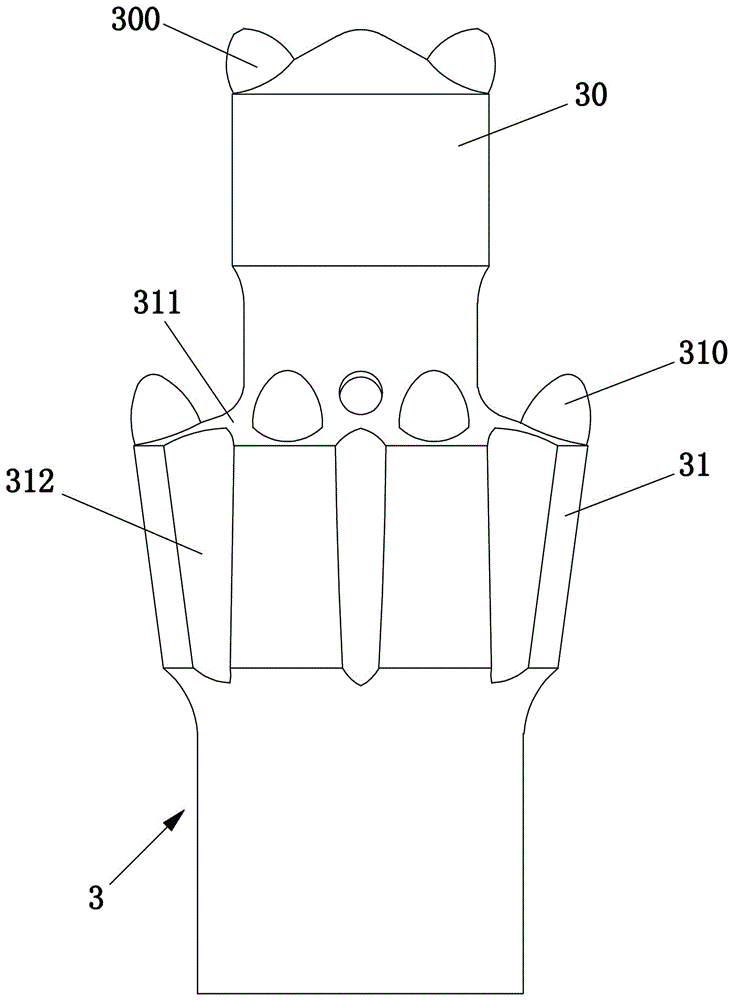

A Cave Mining Method of Granite for Facing

The invention discloses a cave mining method for granite used for a veneer. The method comprises the following steps that 1 multiple holes are formed in the side wall of a rock main body at intervals along a closed path through a punching mechanism; 2 a reamer bit is used to conduct chambering to every other hole, each large hole obtained by chambering are communicated with two adjacent small holes, and a continuous and closed fractured frame is formed at the periphery of a rough stone block to be mined; 3 the inner side of the rough stone block is made to be disconnected with the rock main body by the method of mechanical splitting, then the fractured tough stone block is pulled out, and the required stone materials are obtained. The cave mining method has the advantages that plants are not damaged, the yield is high and the like.

Owner:林永强

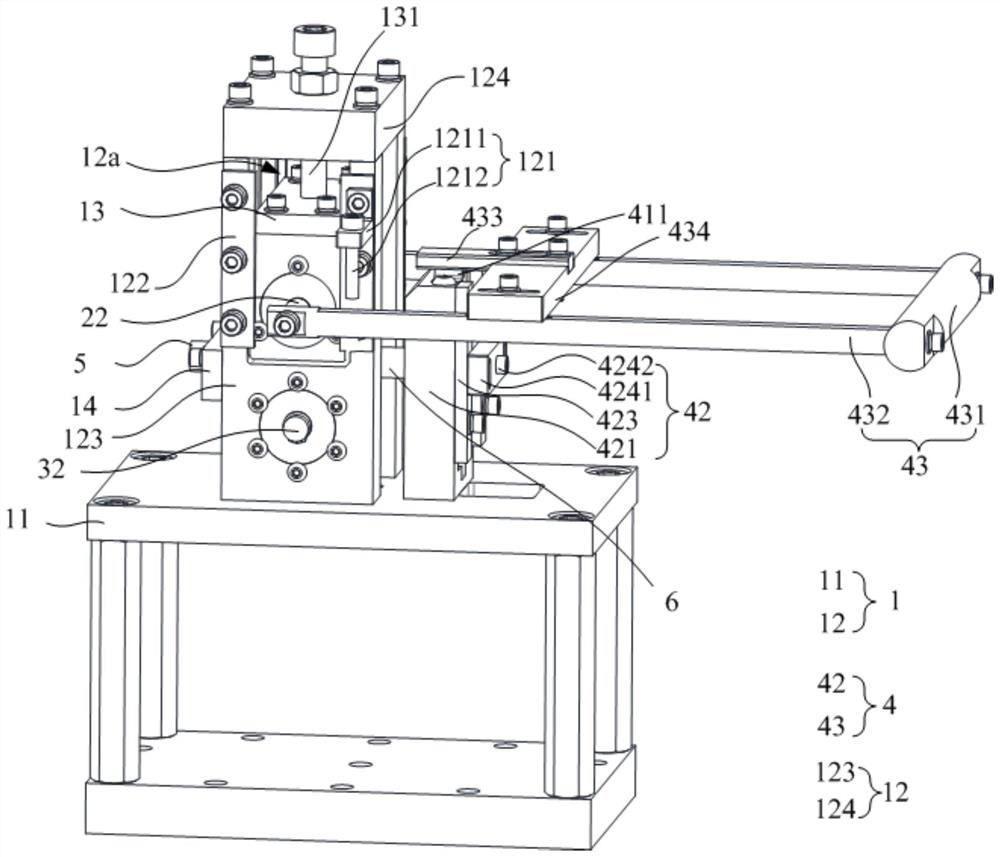

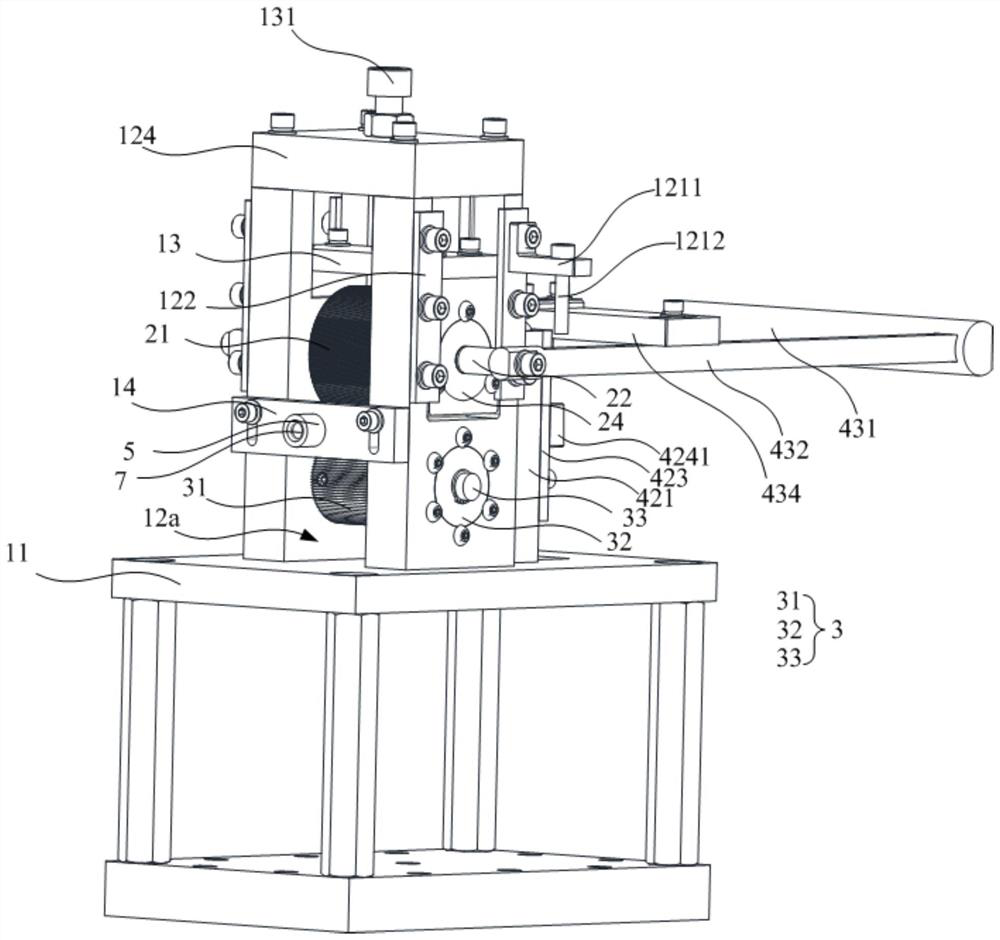

Titanium single crystal with target crystal plane surface and preparation method thereof

ActiveCN111037765BAchieve any orientationAchieve precise cuttingPolycrystalline material growthWorking accessoriesSingle crystalMaterials science

The invention discloses a method for preparing a titanium single crystal with a target crystal plane surface, which adopts a rotating and transforming clamping device, and includes: providing a titanium single crystal sample with a grain size larger than 5 mm; making a titanium single crystal sample on the titanium single crystal sample mark, establish the sample coordinate system of the titanium single crystal sample, defined as Omnl; establish the crystal coordinate system of the target crystal plane in the titanium single crystal sample, and obtain the Euler angles (α, β, 0 ); the titanium single crystal sample is clamped on the rotation conversion clamping device; according to the marks made on the titanium single crystal sample, the first rotating element and the second rotating element are rotated so that the sample coordinate system Omn1 and the coordinates of the rotation conversion clamping device The coordinate system OXYZ is coincident so that the coordinate system OXYZ is zero-adjusted and fixed; the second rotating element drives the clamping element to rotate an angle α on the second axis; the first rotating element drives the second rotating element and the clamping element to rotate an angle β on the first axis ; and cutting the titanium single crystal sample with the cutting element in a cutting direction parallel to the XY plane.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com