Milling clamp for finely cutting large-scale double-curvature aircraft skin

An aircraft skin and hyperbolic technology is applied in the field of milling fixtures for fine cutting of large-scale hyperbolic aircraft skins. Precise cutting quality, not easy to shift, to achieve the effect of mechatronics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to understand the purpose, technical solutions and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

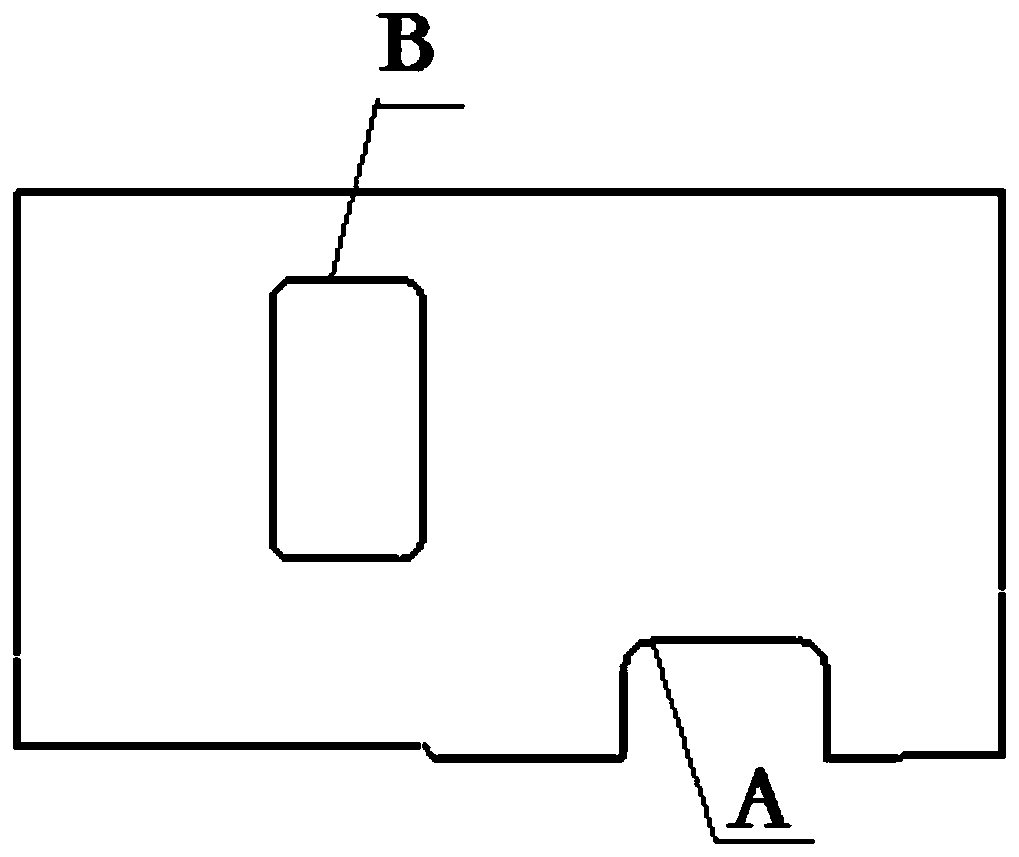

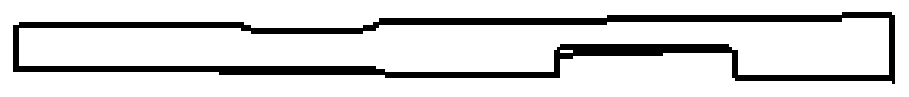

[0016] figure 1 It is the top view of the aircraft skin part in the embodiment; figure 2 for figure 1 Front view of an aircraft skin part in . As shown in the figure, the aircraft skin part is a large hyperbolic aircraft skin, and all openings need to be precisely cut. At present, trimming is carried out manually. However, when manually trimming large hyperbolic aircraft skins, the error of manual trimming is usually large. This method requires a lot of filing and repair work, and it is impossible to realize the assembly and riveting without margin, which seriously affects the production progress of the aircraft.

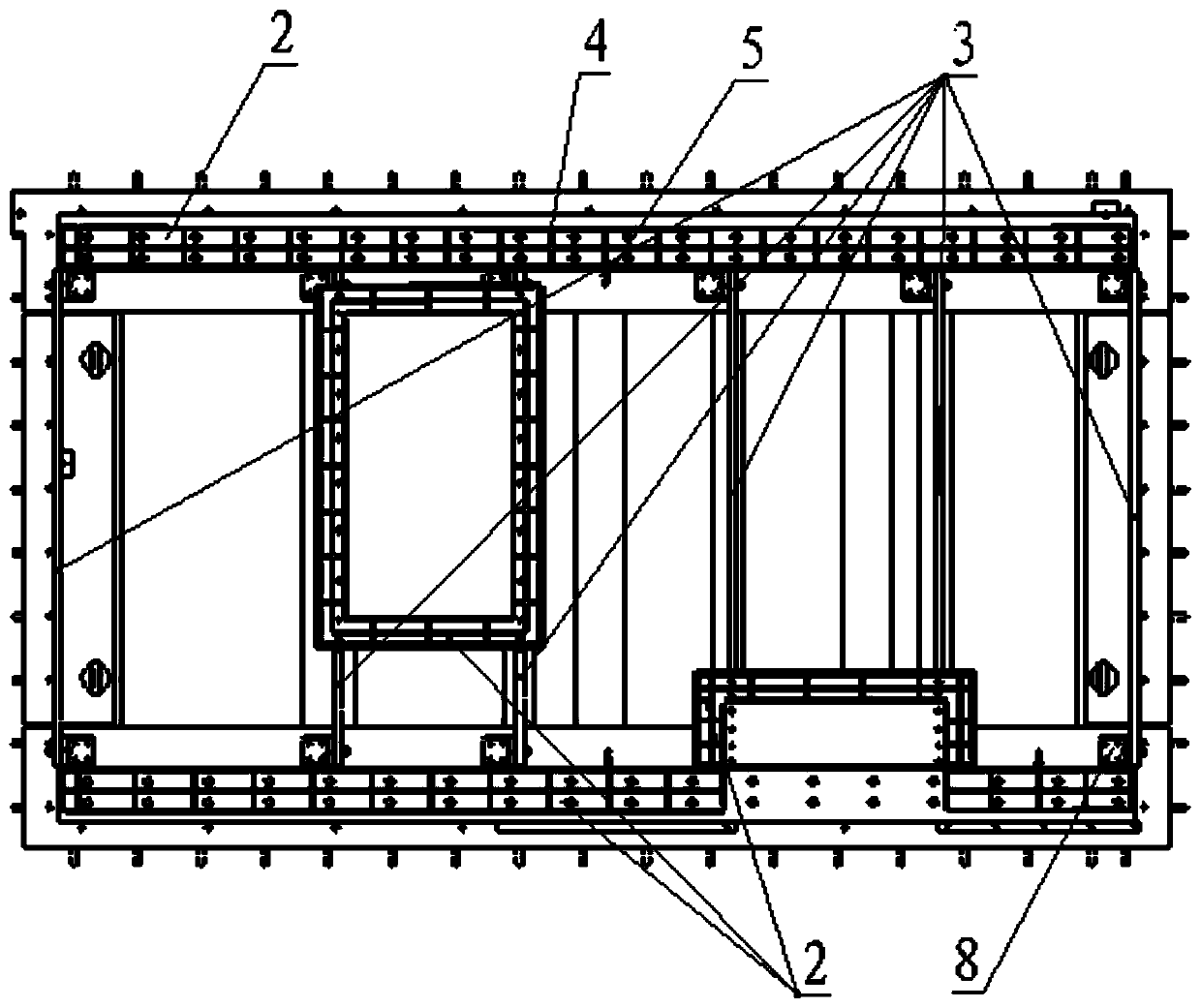

[0017] For this reason, the present invention proposes a kind of milling fixture that is used for the fine cutting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com