A Cave Mining Method of Granite for Facing

A granite and hole mining technology, which is applied in open-pit mining, earth drilling, special mining, etc., can solve the problems of easy damage to the environment, large loss, etc., and achieve the effect of avoiding waste and preventing string holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated in combination with specific embodiments.

[0018] A cave mining method for facing granite, the steps of which are as follows:

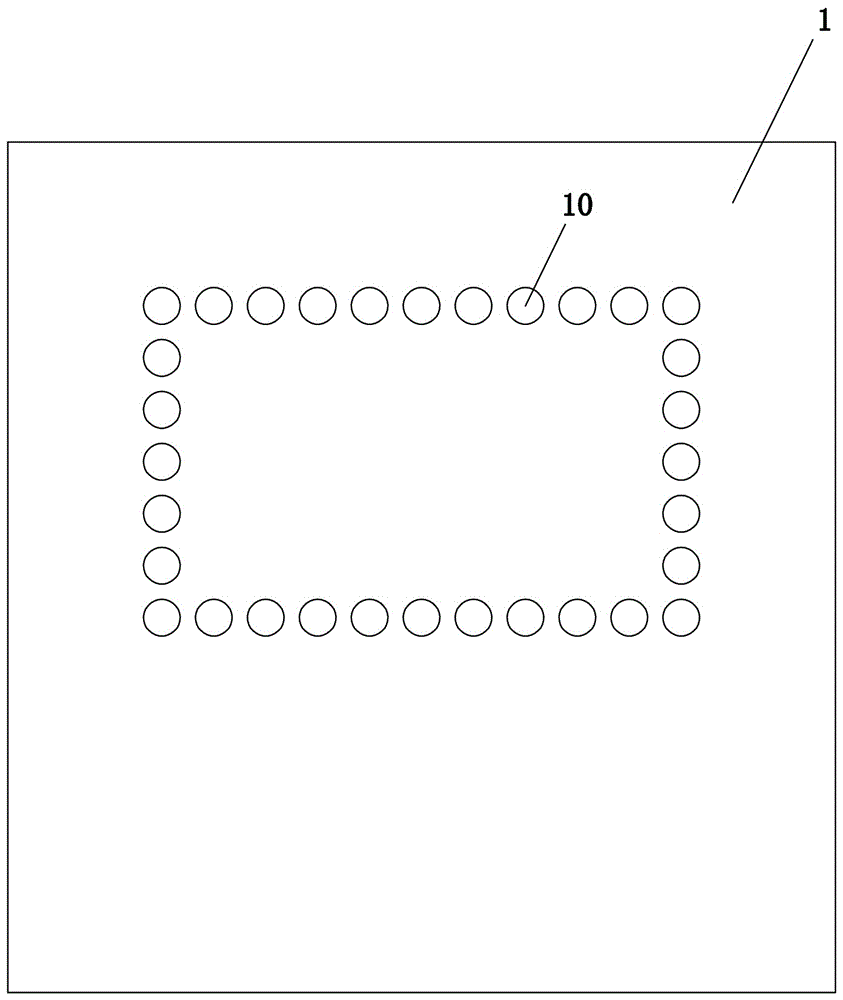

[0019] 1) Reference figure 1 Firstly, a drilling mechanism with a diameter of 3.2 cm is used to open several small holes 10 along a regular quadrilateral path on the side wall of the rock main body 1, because the drilling mechanism will cause errors during the rock drilling process, so that the obtained small holes 10 The actual diameter is between 3.2-3.4cm (such as 3.3cm), the hole distance of adjacent small holes 10 is set to be 4.5-4.7cm (such as 4.6cm), the hole depth is 1.3m, and the upper and lower two of the regular quadrilateral path The distance between horizontal sides is within 75cm.

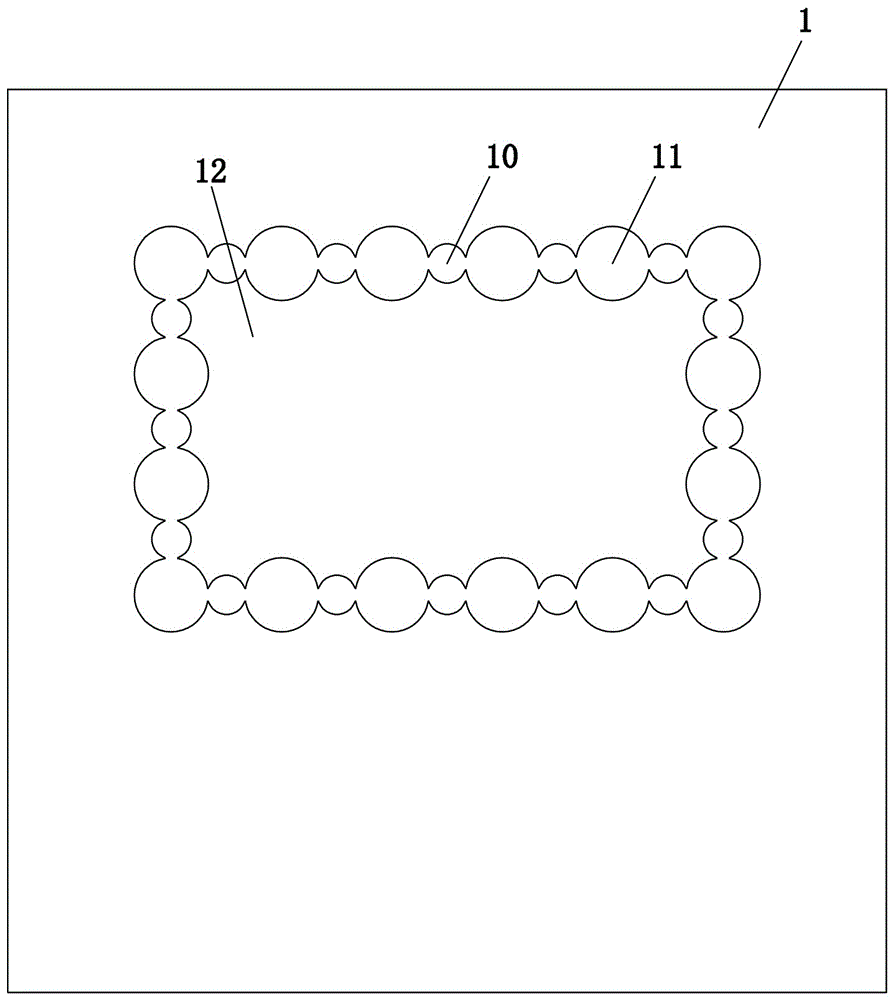

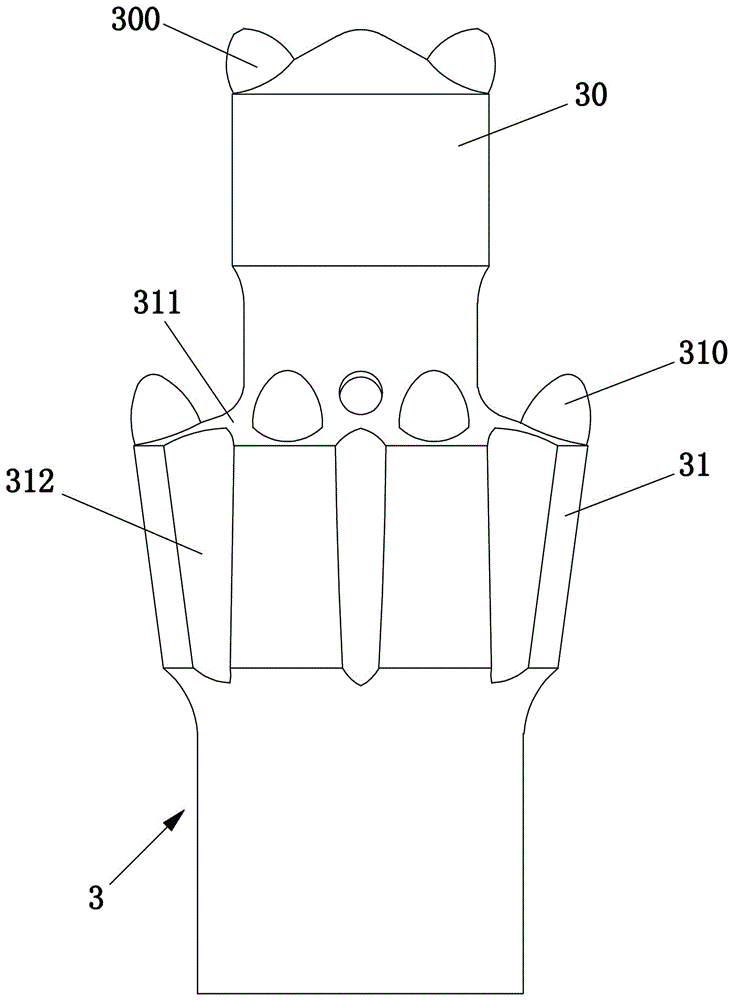

[0020] 2) Refer to figure 2 with image 3 , every other small hole 10 is reamed with a reamer bit 3, the front portion of the reamer bit is a guide cylinder 30 with a diameter of 3.2cm, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com