Titanium single crystal with target crystal plane surface and preparation method thereof

A single crystal, crystal face technology, applied in the field of crystals, can solve the problem of inability to obtain titanium single crystals, and achieve the effect of high preparation efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

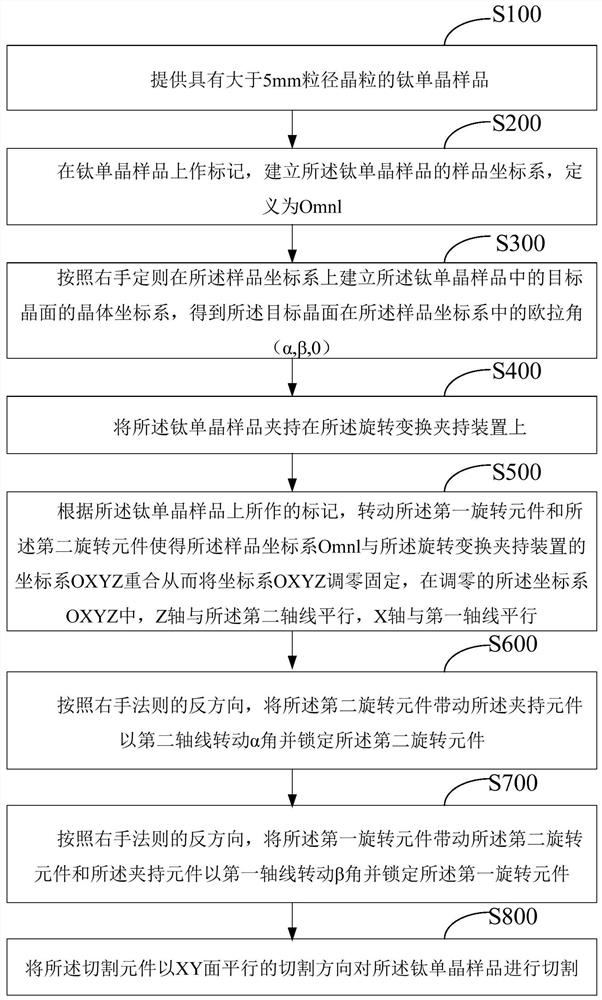

[0040] An embodiment of the present invention provides a method for preparing a titanium single crystal having a target crystal plane surface, using a rotating and transforming clamping device, and including:

[0041] S100, provide a titanium single crystal sample with a grain size greater than 5mm;

[0042] S200, mark on the titanium single crystal sample, and establish a sample coordinate system of the titanium single crystal sample, defined as Omnl;

[0043] S300. Establish the crystal coordinate system of the target crystal plane in the titanium single crystal sample on the sample coordinate system according to the right-hand rule, and obtain the Euler angle (α, β,0);

[0044]S400. Clamp the titanium single crystal sample on the rotation conversion clamping device, the rotation conversion clamping device includes a first rotation element, a second rotation element and a clamping element, and the second rotation element is set On the first rotating element, the clamping e...

Embodiment

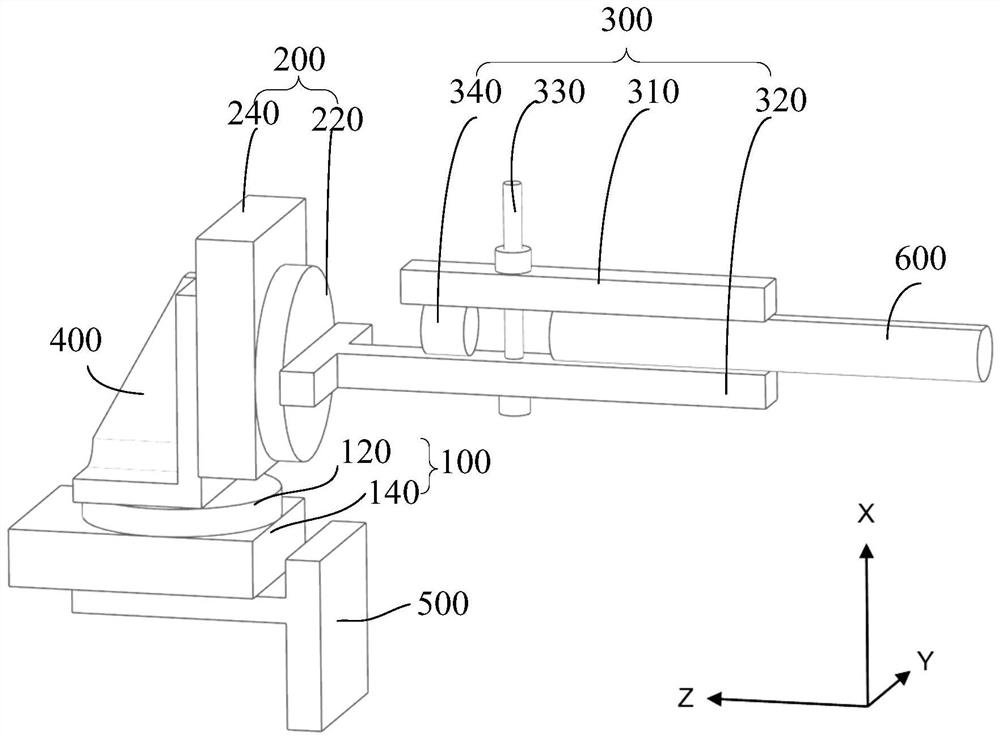

[0086] see figure 2 , the rotation conversion clamping device includes a right-angle fixed block 500 , a first rotation element 100 , a right-angle connection block 400 , a second rotation element 200 and a clamping element 300 connected in sequence. It is stipulated that the coordinate system of the rotation transformation clamping device is OXYZ.

[0087] The right-angle fixed block 500 is the base of the rotation transformation clamping device, and is used to be connected with the workbench of the wire cutting machine with the metal cutting wire, and the bottom surface of the right angle fixed block 500 is the XY plane of the rotation transformation clamping device.

[0088] The first rotating element 100 includes a first base 140, a first rotating platform 120, and a first rotating shaft (not shown) perpendicular to the first base 140 and the first rotating platform 120 and arranged between them. The second rotating element 200 includes a second base 240, a second rotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com