Method and device for producing prepreg

A technology of prepreg and production method, applied in the direction of chemical instruments and methods, layered products, lamination auxiliary operations, etc., can solve the problems of non-recyclable, waste of materials, pollution of the environment, etc., and achieve the effect of saving costs and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

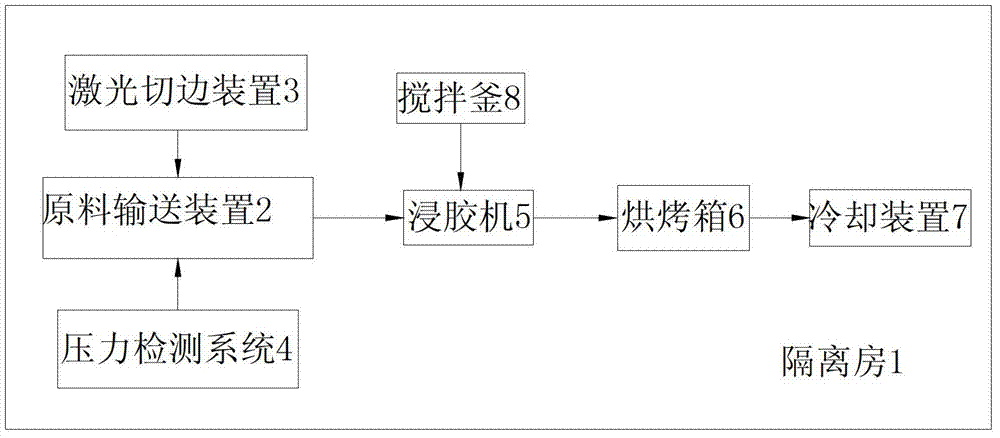

[0055] Such as figure 1 As shown, the production method of the prepreg described in this embodiment includes the following steps (glass fiber cloth is selected as the reinforcing material in this embodiment):

[0056] The first step is to make glue, put the epoxy resin into the industrial stirring tank, and dissolve the curing agent above 40°C, then add the additive, after fully dissolving and fully stirring and mixing, let the glue mature for several hours, let each group The points have enough mutual contact and mutual penetration, and after a period of time, the colloids reach a stable equilibrium state and are ready for use.

[0057] The second step is to send the colloidal solution that has been heat-proportioned in the industrial stirring tank into the impregnation tank of the dipping machine to prepare for dipping.

[0058] The third step is to cut the edge by laser, and cut the edge of glass fiber cloth that does not meet the requirements with laser;

[0059] 1. Equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com