Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Achieve a win-win effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

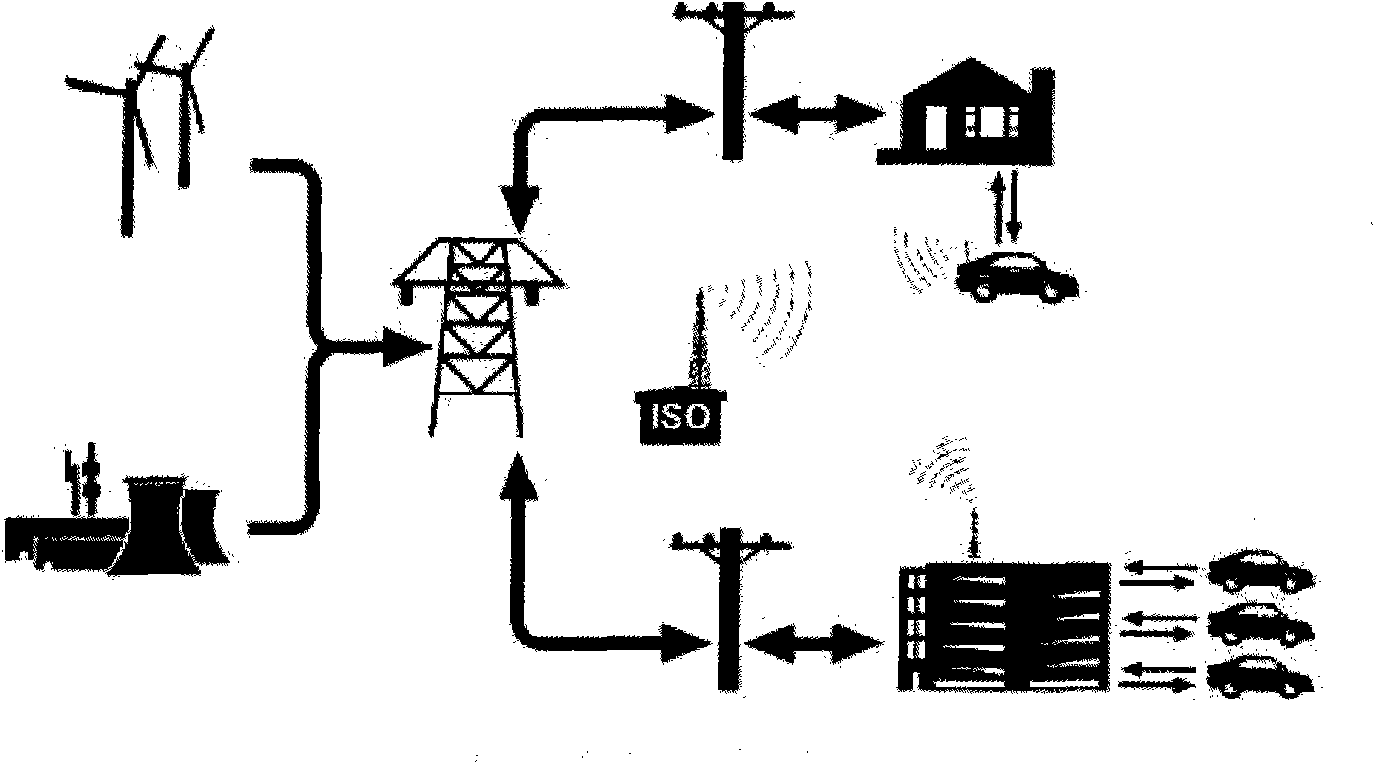

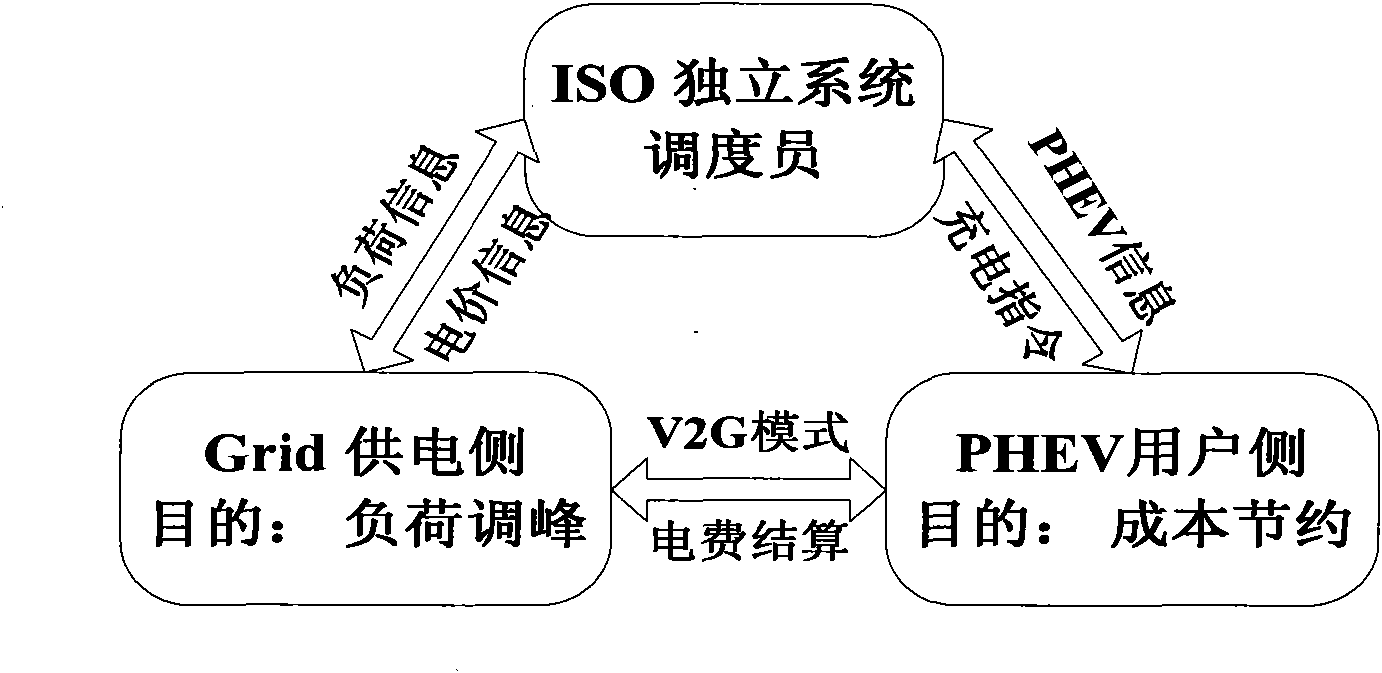

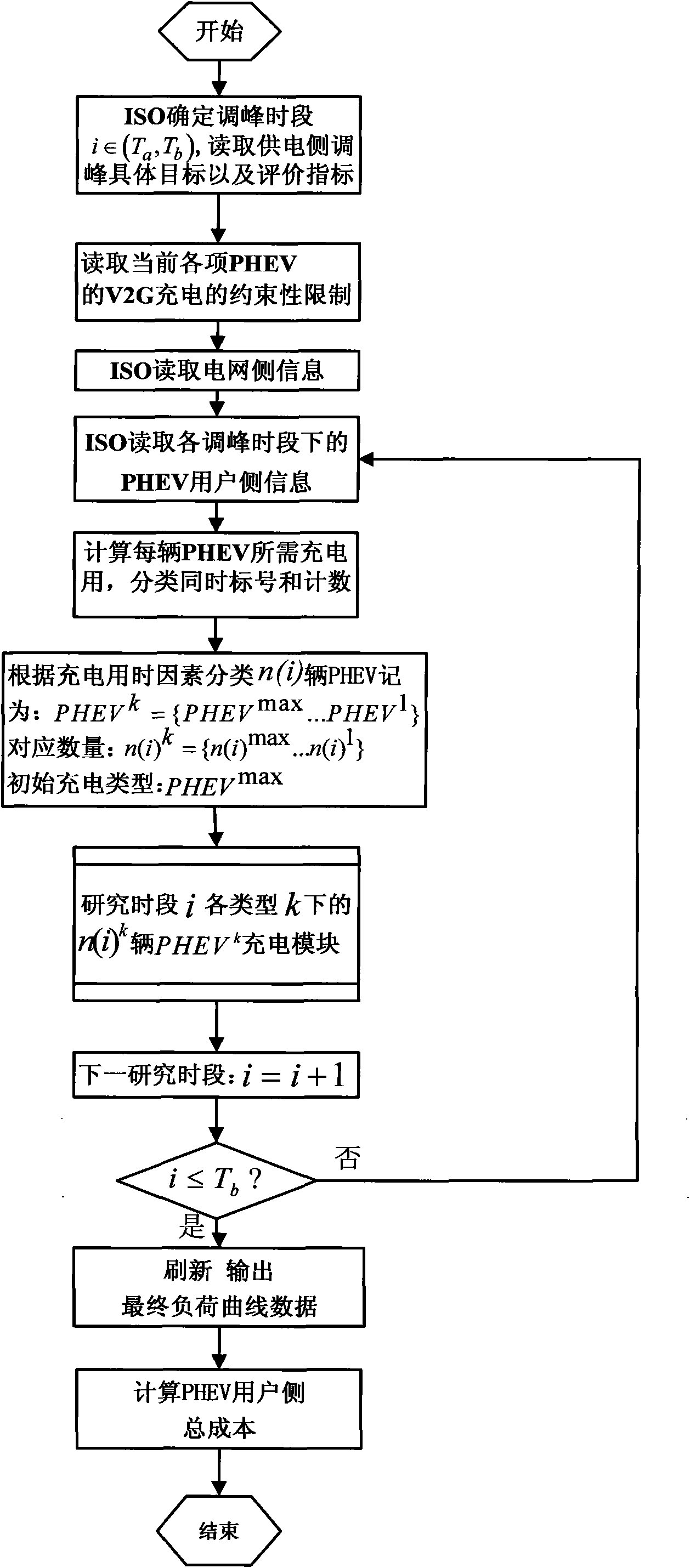

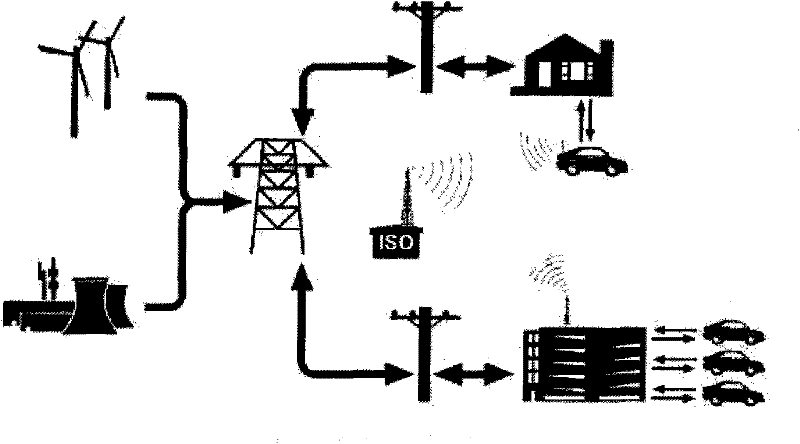

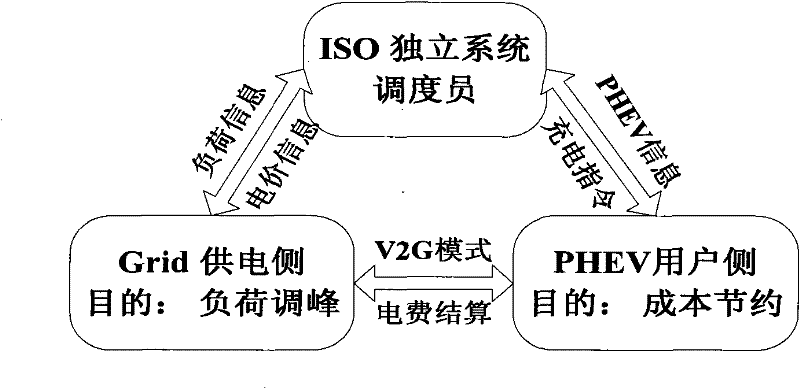

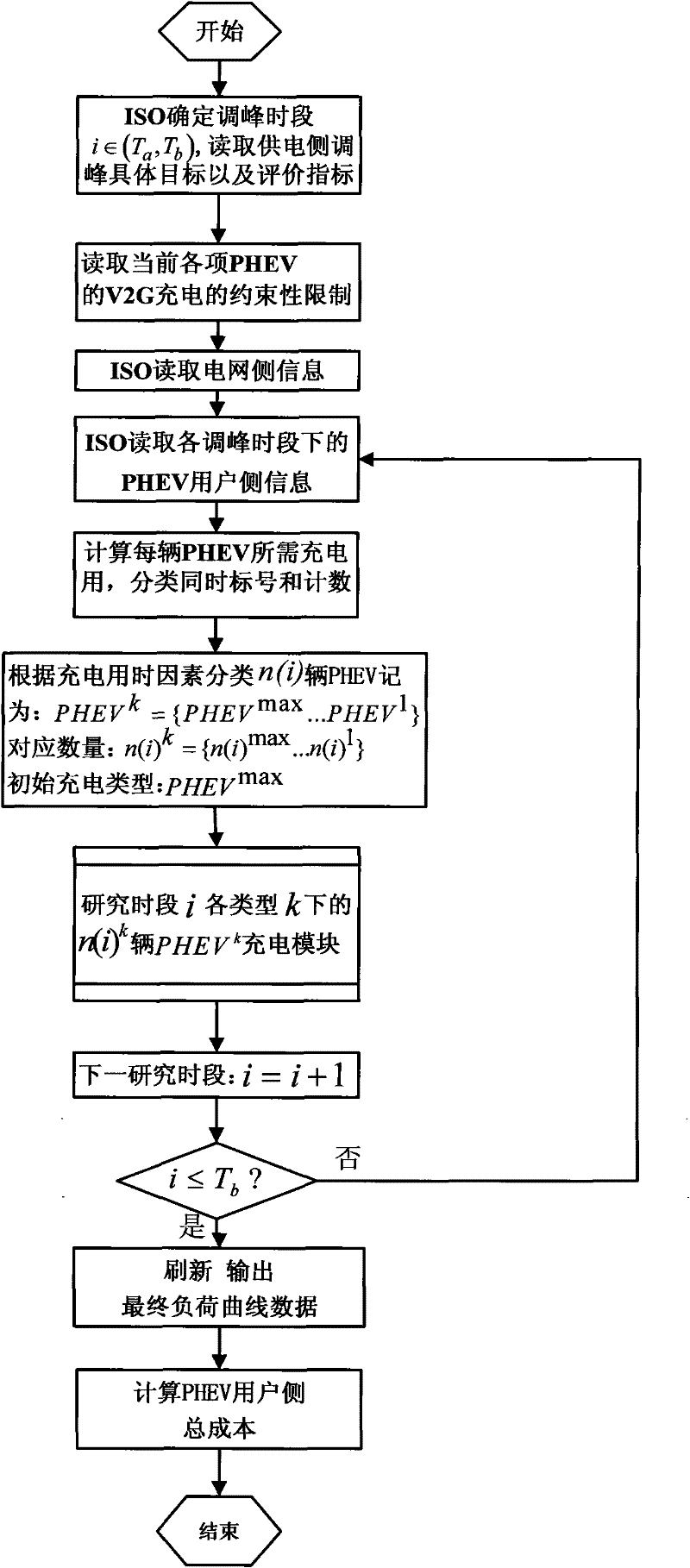

Centralized intelligent dispatching method for charging plug-in hybrid electric vehicle (PHEV)

InactiveCN101901945AReduce the cost of new power generationTo achieve the purpose of side peak regulationSecondary cells charging/dischargingTime informationElectric power system

The invention provides a centralized intelligent dispatching method for charging a plug-in hybrid electric vehicle (PHEV), which belongs to the research field of power system demand side response and is especially suitable for a plug-in hybrid electric vehicle (PHEV) of peak load regulation. The invention is established on the basis of a dynamic estimation interpolation concept, and mainly comprises the following parts: real-time information extraction, PHEV dynamic cataloging, load per-unit transformation, boundary condition detection, singular load analysis, load estimation interpolation, load index evaluation and charging cost calculation. The invention can dynamically dispatch the charging time periods of the PHEV, thereby effectively reducing the risk and hidden danger which are brought by the load singularity of the grid side, indirectly lowering the investment into newly arranged generating equipment at the grid side and saving the charging cost at the user side, and realizing the purpose of benefiting both the grid side and the user side.

Owner:HOHAI UNIV

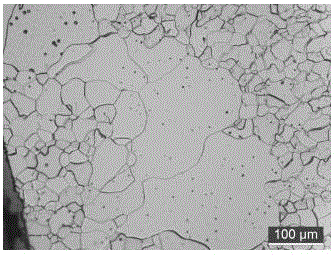

Hot rolled wire rod for ultra-low carbon steel fibers and production method of hot rolled wire rod

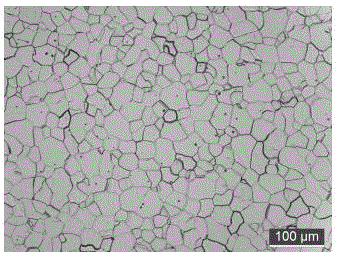

The invention relates to a hot rolled wire rod for ultra-low carbon steel fibers and a production method of the hot rolled wire rod. The wire rod comprises the chemical components of, by mass, less than or equal to 0.010% of C, less than or equal to 0.03% of Si, less than or equal to 0.20% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, greater than or equal to 0.02% of Alt, 0.05-0.12% of Ti and the balance iron and inevitable impurities. The production method comprises the procedures of continuous casting, cogging, heating, rolling, spinning and cooling. By adding the Ti elements to ultra-low carbon steel, through low-temperature rolling, uniform ferrite and pearlite structures are generated, effective combination of strength and plasticity is achieved, thus, the tensile strength of the wire rod with the specification being phi 7.0 mm is 310-360 MPa, the percentage elongation after fracture is greater than or equal to 50.0%, 1300-MPa-class steel fibers are allowed to be produced through the wire rod with the large specification under the condition that existing equipment of downstream customers is not changed, the purchase cost is lowered, and the downstream customer selectivity is increased.

Owner:XINGTAI IRON & STEEL

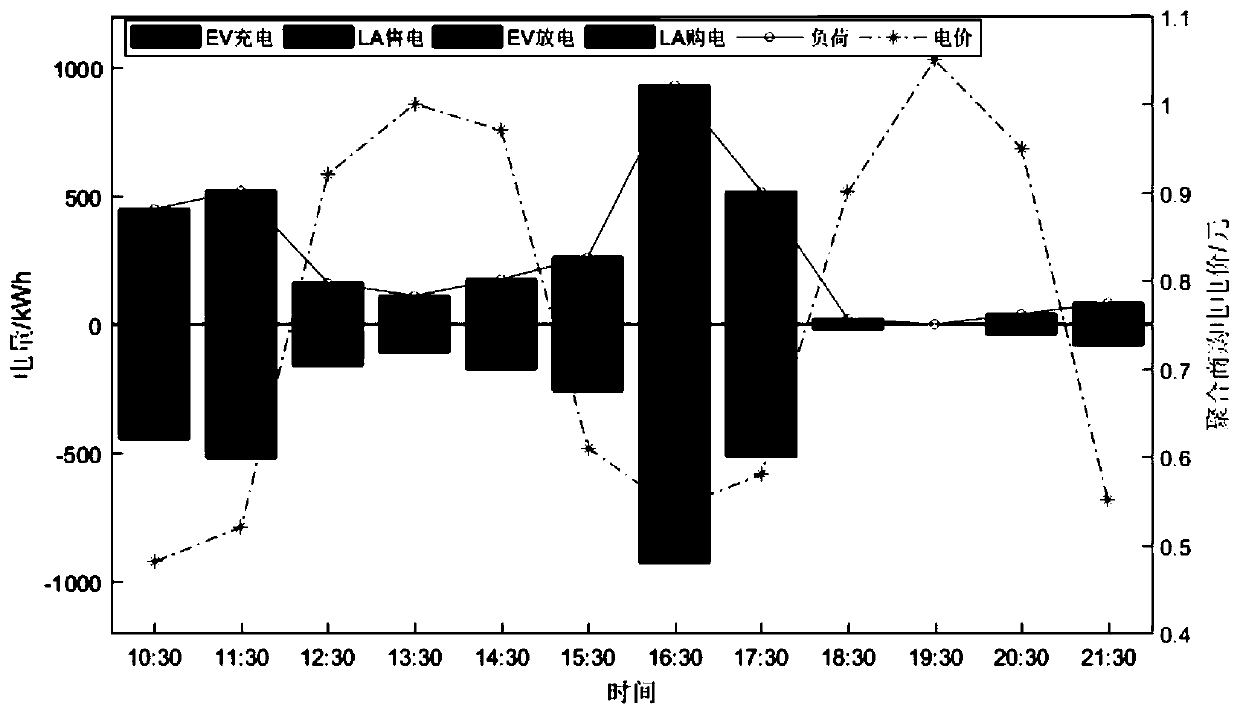

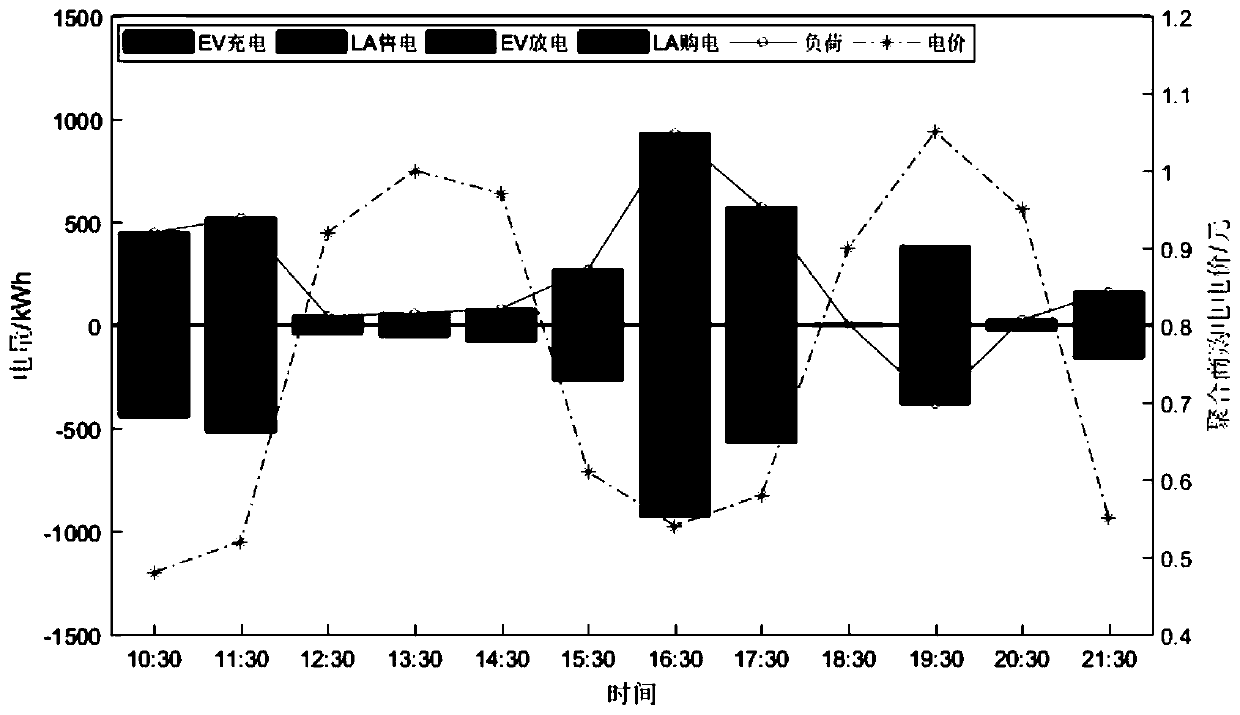

Electric vehicle group scheduling method based on load classification

ActiveCN110472785ATravel needs are not affectedStrong schedulabilityForecastingElectric vehicle charging technologyAutomotive engineeringCharge type

The invention discloses an electric vehicle group scheduling method based on load classification. The method comprises steps of carrying out load prediction and electric vehicle behavior prediction; establishing a charging type electric vehicle load group scheduling objective function and a charging type electric vehicle load group scheduling constraint condition in G2V and V2G modes; optimizing the economic benefit of the power exchange type electric vehicle load aggregator in the G2B mode and the economic benefit of the power exchange type electric vehicle load aggregator in the B2G mode tothe maximum, and establishing a power exchange type electric vehicle load group scheduling objective function and a power exchange type electric vehicle load group scheduling constraint condition in the G2B mode and the B2G mode; determining an electric vehicle load classification scheduling method and charging and discharging schemes for rechargeable electric vehicle batteries; adopting a batterycharging, discharging and battery replacing scheme of the battery replacing type electric automobile; and enabling the aggregator to purchase and sell electricity from the power grid and optimizes the economic benefit of the aggregator. According to the method, the potential of the demand side is fully excavated, and certain guiding significance is achieved for large-scale electric vehicle accessto the power grid in the future.

Owner:XI AN JIAOTONG UNIV +1

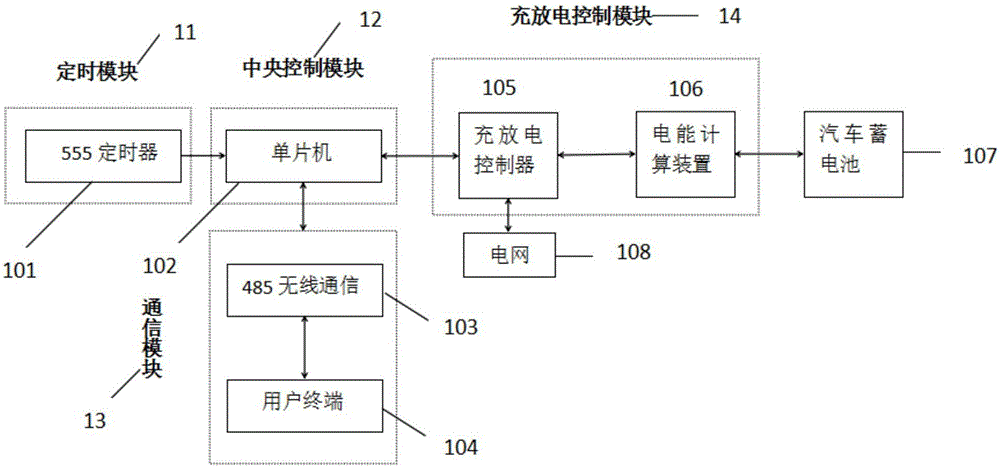

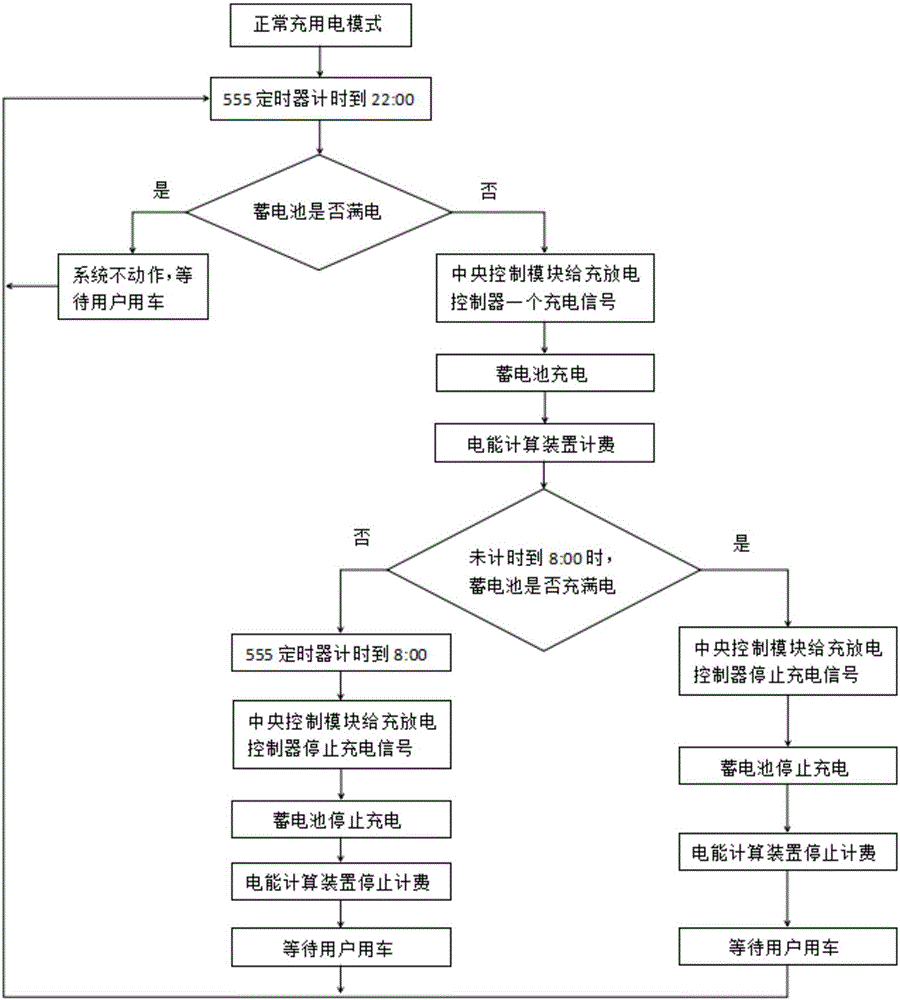

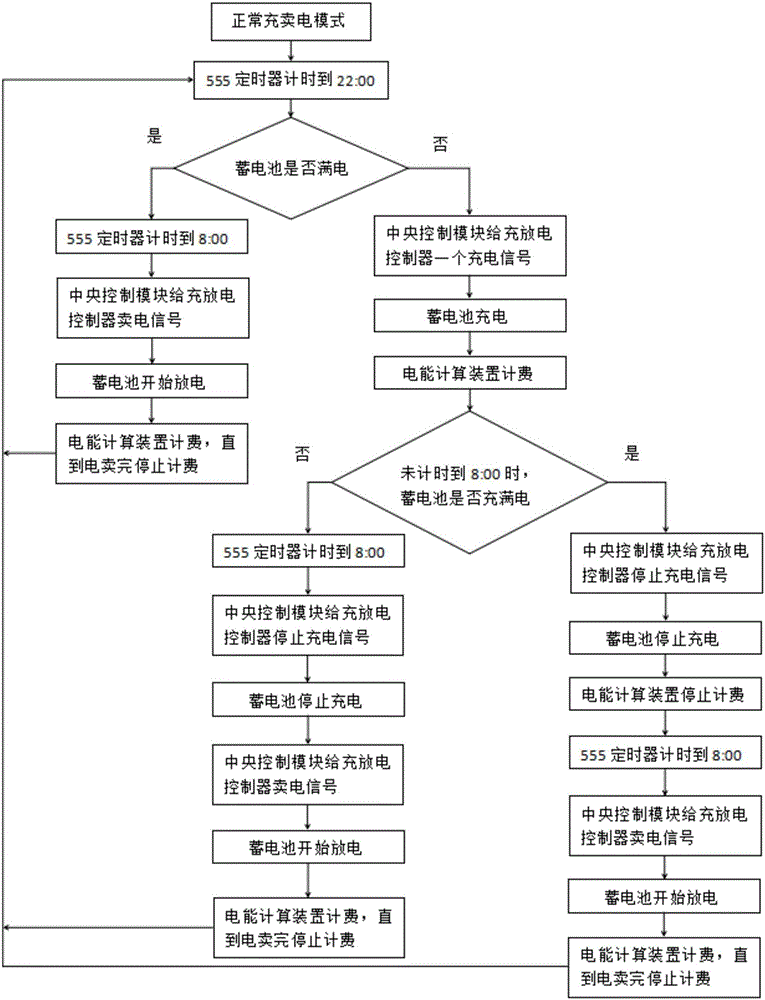

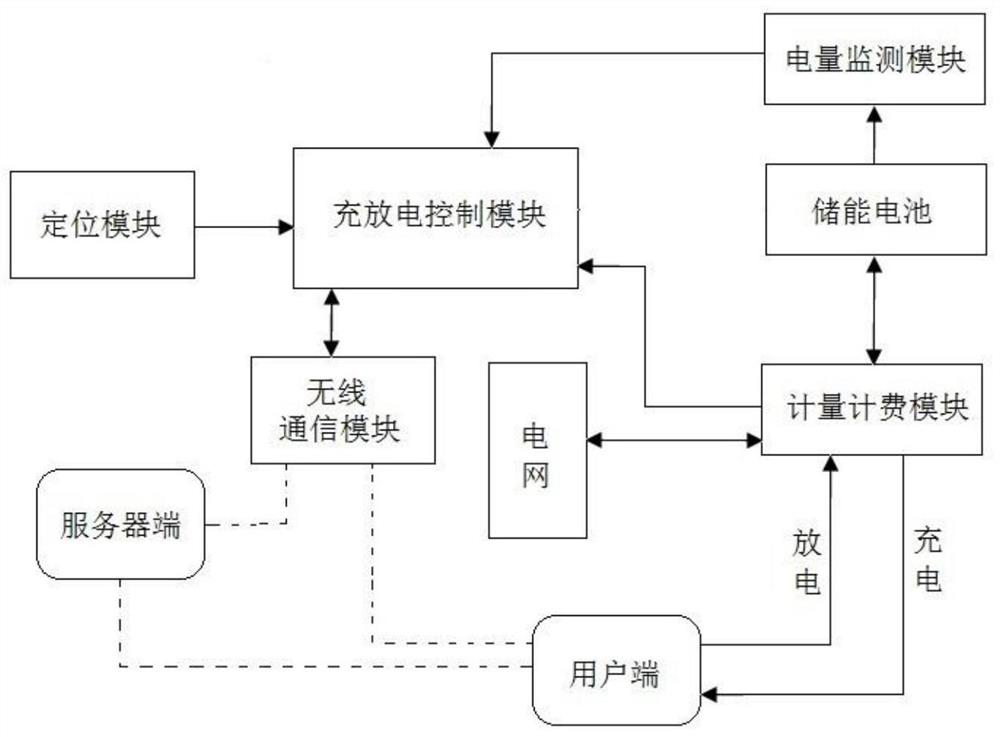

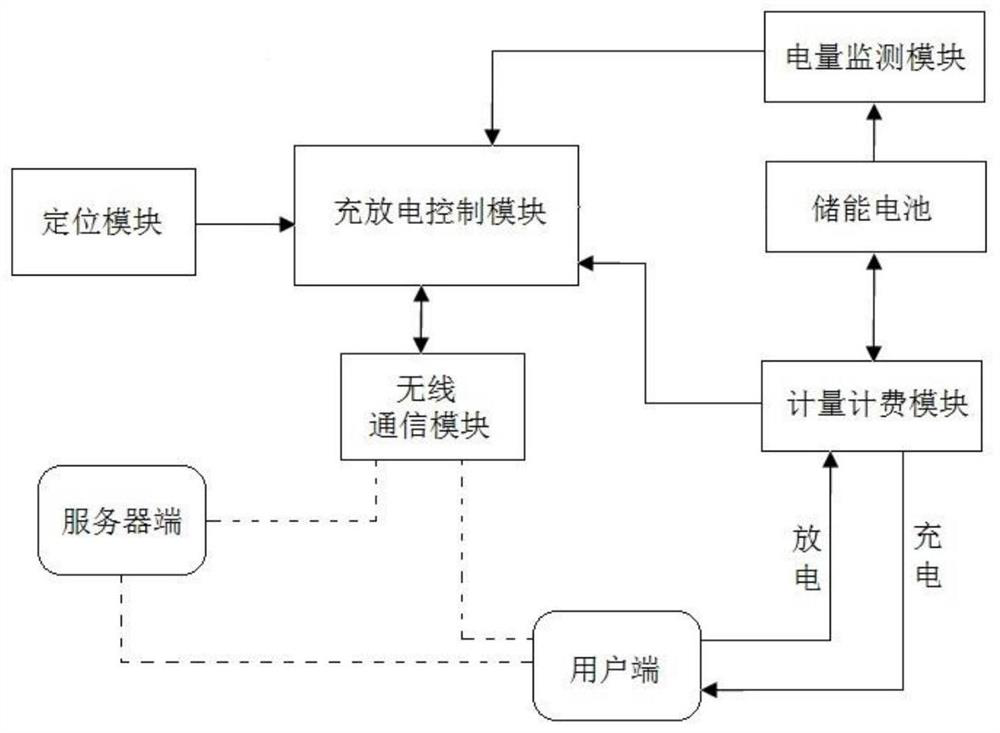

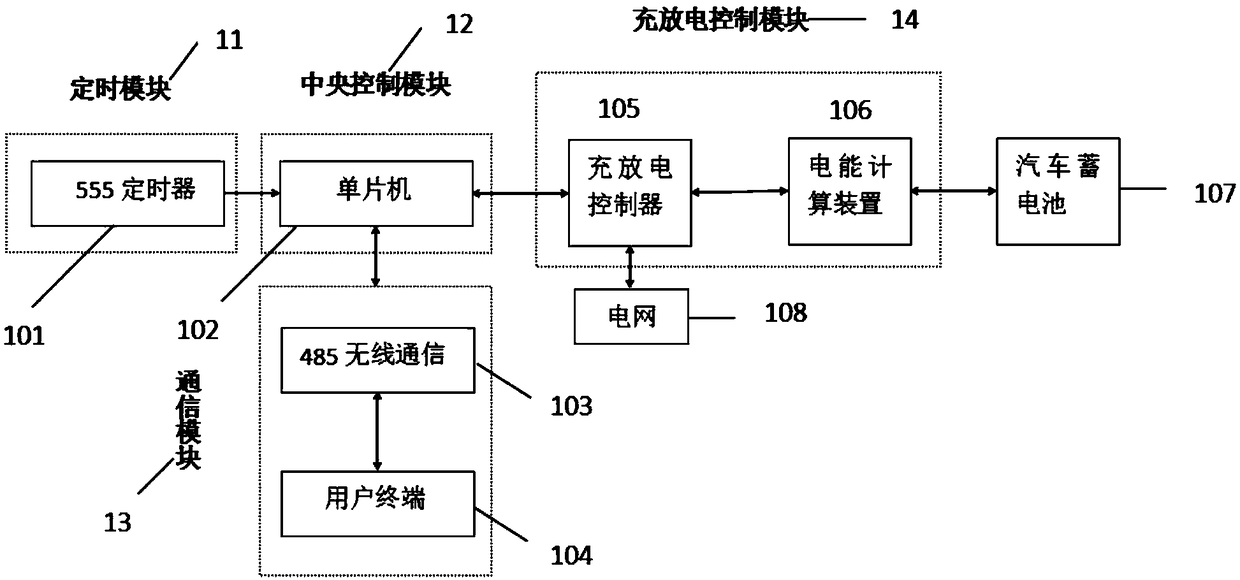

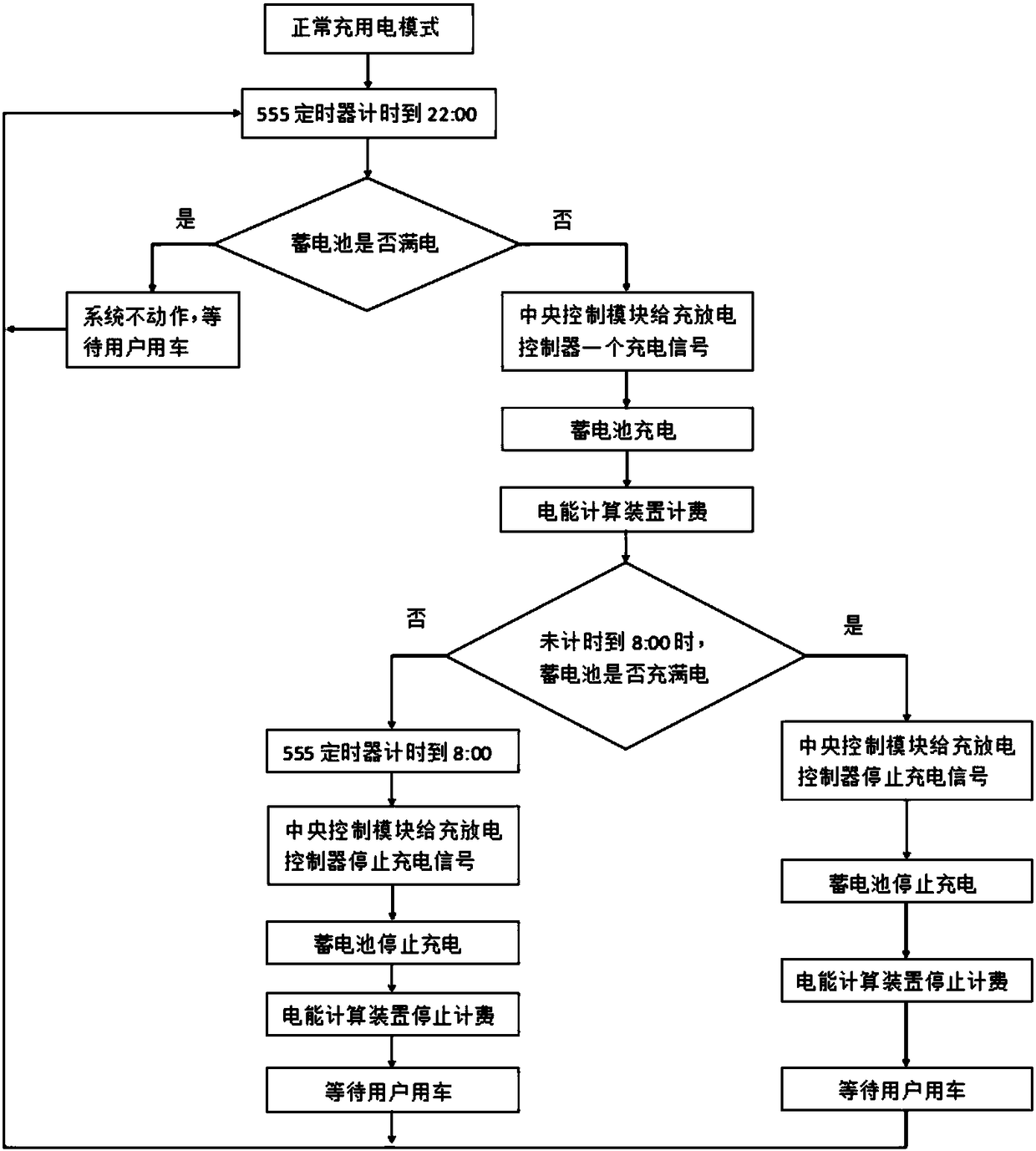

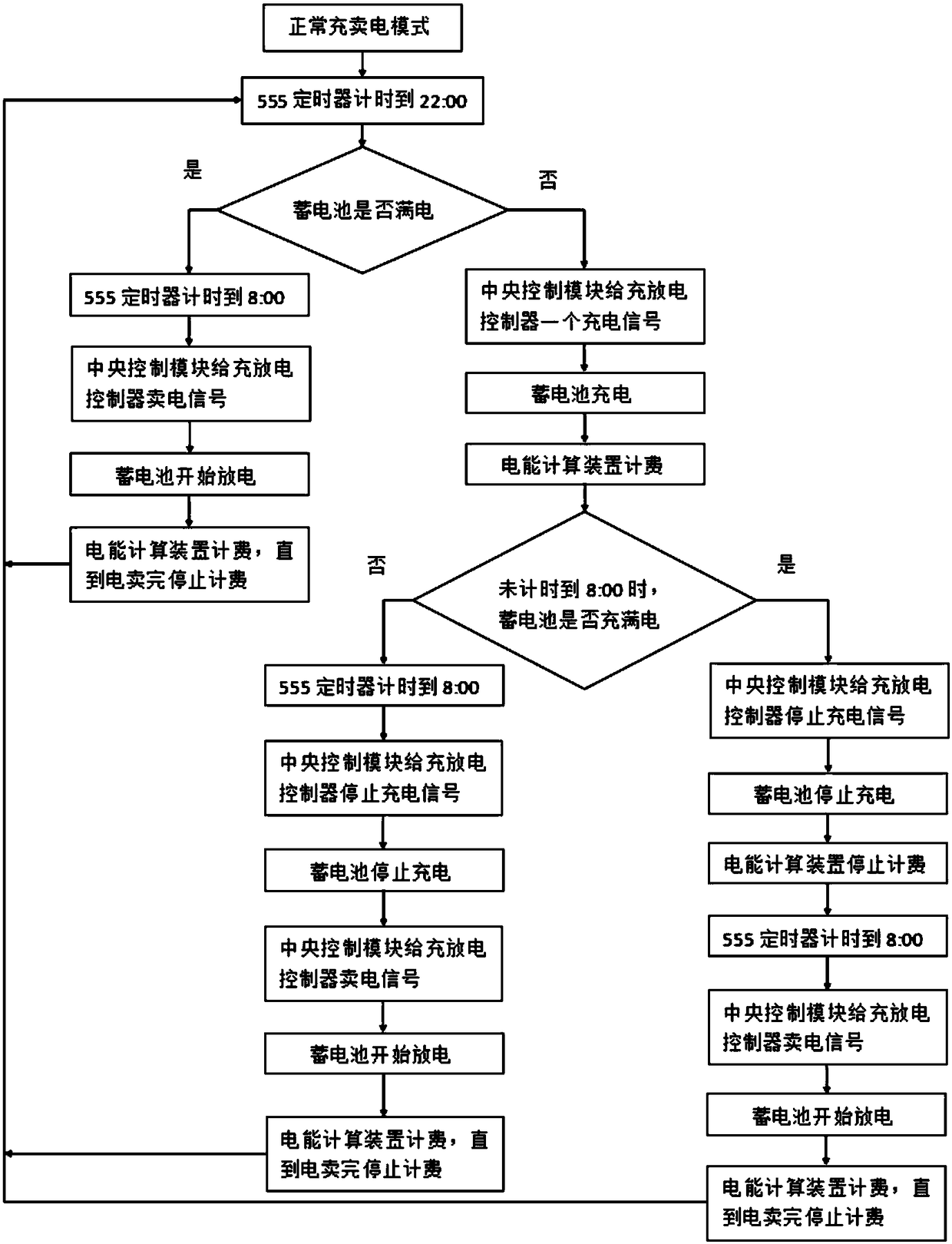

Automatic charging power utilization and selling control system for electric automobile

InactiveCN105818701AReduce stress on the gridFacilitate human-computer interactionCharging stationsAc network load balancingElectrical batteryCharge and discharge

The invention discloses an automatic charging power utilization and selling control system for an electric automobile. The automatic charging power utilization and selling control system for the electric automobile comprises a timing module, a central control module, a charging and discharging control module and a communication module, wherein the timing module is formed by a timer and used for timing and outputting a signal to the central control module; the central control module is formed by a single chip and used for controlling the charging and discharging control module through a control signal; the charging and discharging control module comprises a charging and discharging controller and an electric energy calculating device; the communication module comprises a wireless communication module and a user terminal; the wireless communication module is used for transmitting state information of a battery to the user terminal; and the user terminal is used for monitoring the state of the battery and controlling the system to be switched to a charging power utilization mode or a charging power selling mode. According to the invention, orderly charging and peak load shifting are realized so that power grid pressure is reduced and benefits are created for users; and meanwhile, the development of a communication technology is sufficiently utilized, human-computer interaction is convenient and convenience is provided to people's life.

Owner:SHANGHAI DIANJI UNIV

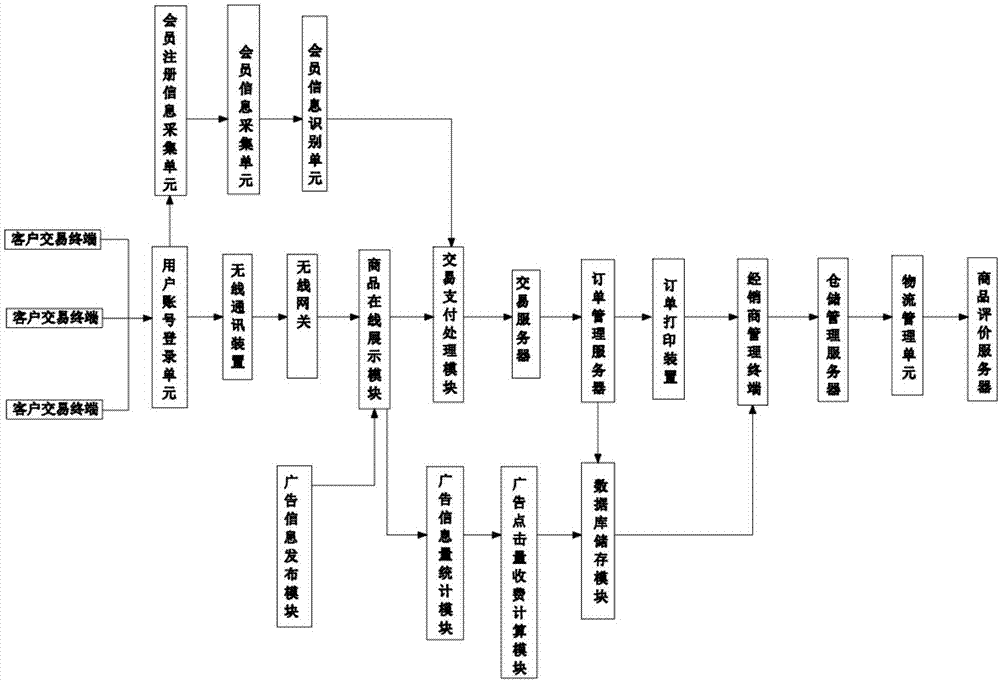

Internet-based real-time commodity online transaction system

InactiveCN107423986AImprove convenienceAchieve a win-win effectDiscounts/incentivesBuying/selling/leasing transactionsWireless gatewayData harvesting

The invention discloses an Internet-based real-time commodity online transaction system which includes a customer transaction terminal, a user account login unit, a wireless communication device, a wireless gateway, a commodity online display module, a transaction payment processing module, a transaction server, an order management server, an order printing device, a dealer management terminal, a warehousing management server, a logistics management unit, a commodity evaluation server, a member registration information acquisition unit, a member information acquisition unit, a member information identification unit, an advertisement information release module, an advertisement click data collection module, an advertisement click fee calculation module, and a database storage module. The system provided by the invention is additionally provided with an identification function in terms of user security payment so that users can get corresponding discounts when making payment and can be attracted to go shopping. The system achieves a win-win effect among users, businesses and platforms, and is beneficial to the rapid promotion and selling of commodities.

Owner:新沂蓝胖子科技有限公司

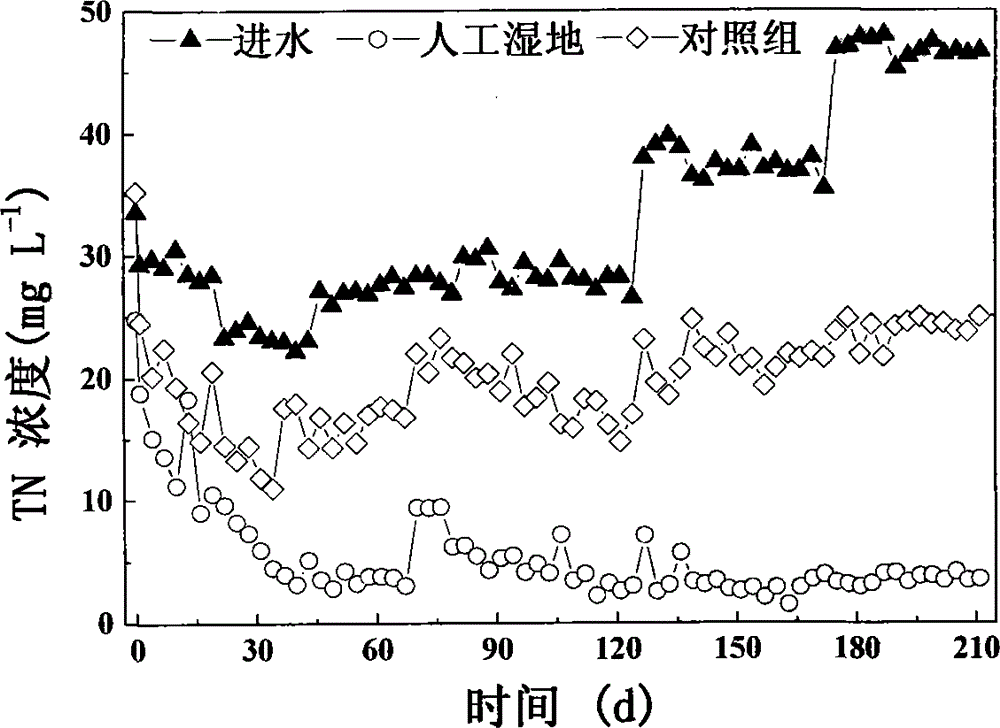

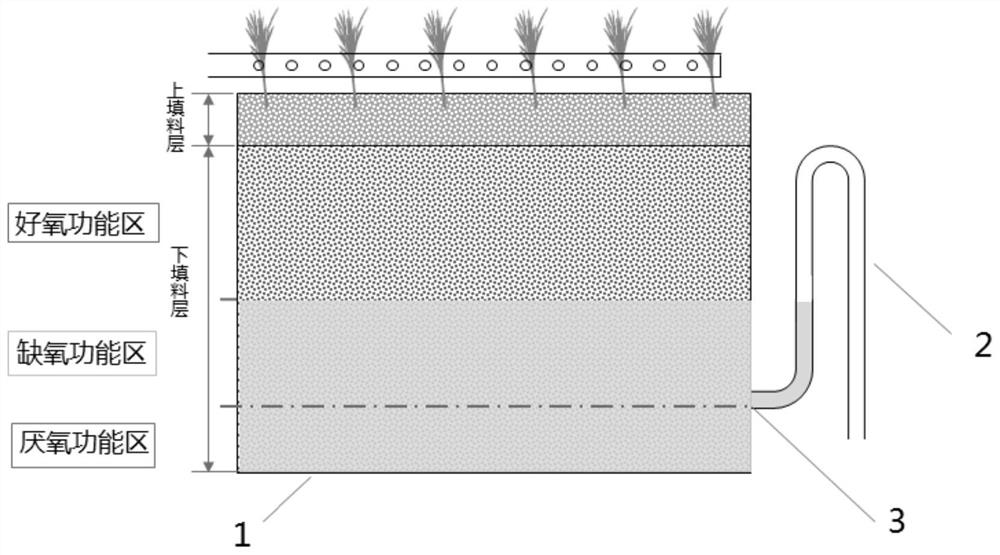

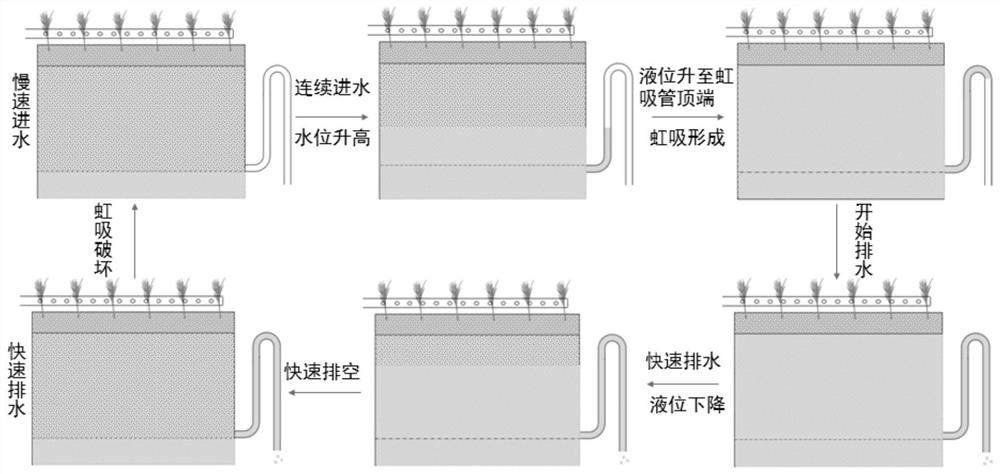

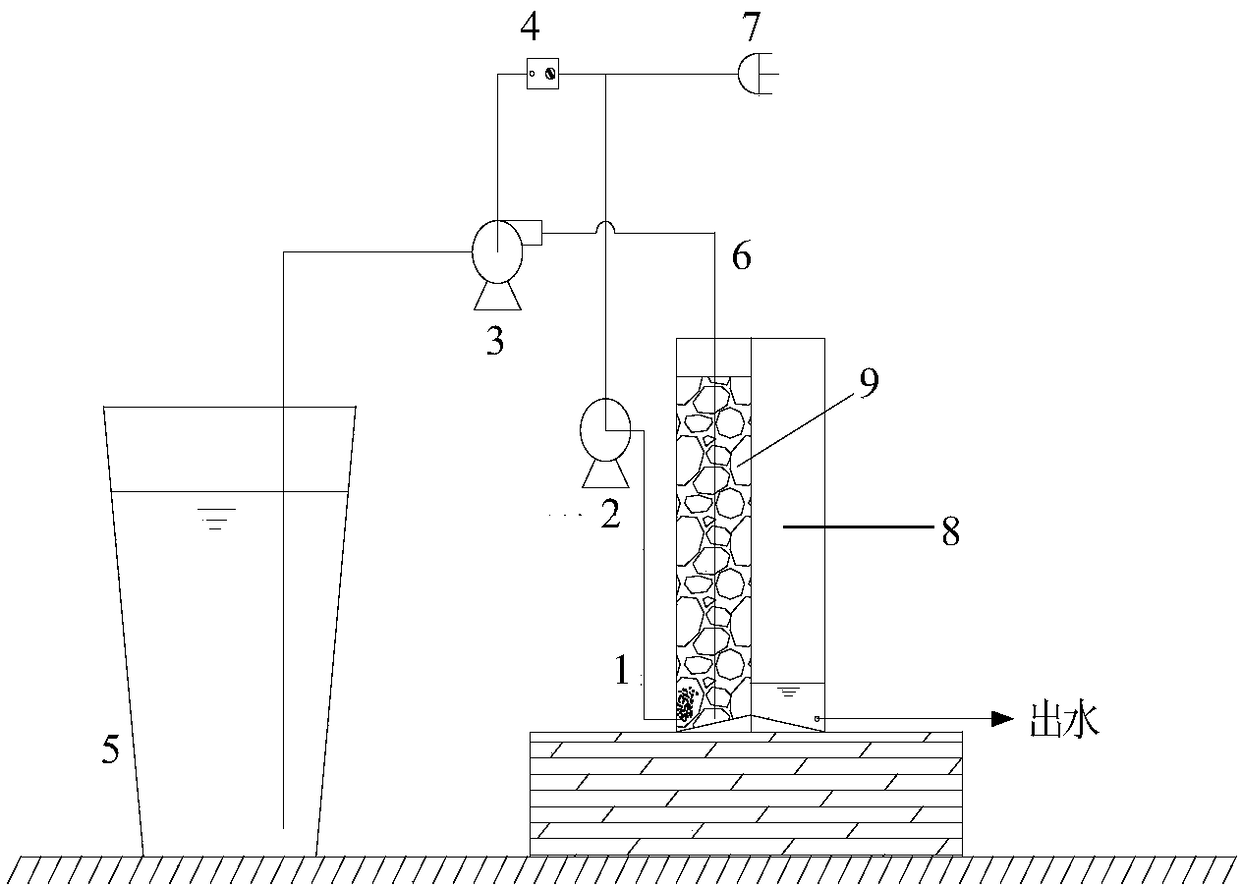

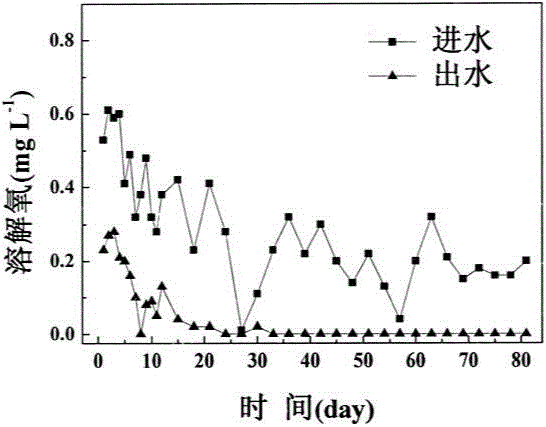

Method and system for nitrogen and phosphorus removal via water treatment plant waste sludge (WTRs) reinforced tidal-flow reactor

InactiveCN104787884AEfficient use ofEasy to set upTreatment with aerobic and anaerobic processesWater/sewage treatment by sorptionMicrobial inoculationEutrophication

The invention provides a method and system for nitrogen and phosphorus removal via a WTRs-reinforced tidal-flow reactor, which belongs to the field of water treatment. According to the invention, WTRs is used as matrix, and a tidal-flow reactor is filled with WTRs; deposit is added to realize microbial inoculation of the tidal-flow reactor; and then synthesized waste water with high nitrogen-phosphorus content is added into the tidal-flow reactor, and treatment is carried out. The objective of the invention is to simulate eutrophicated river water and to simultaneously and highly-effectively eliminate nitrogen pollution and phosphorus pollution in the eutrophicated river water. The method and system are characterized in that all the matrix in the tidal-flow reactor is air-dried WTRs with a size of 1 to 3 cm, nitrogen in the tidal-flow reactor is removed mainly through microbial action, and phosphorus pollutants are removed mainly through physical and chemical absorption. According to the invention, the system has a simple structure and is easy to use; materials used in the invention have low cost and are environment-friendly; the method is simple to operate; and while WTRs are recycled, nitrogen and phosphorus pollutants in an eutrophicated water body are removed in virtue of the tidal-flow reactor, so the win-win objectives of waste recycling and ecological restoration are achieved.

Owner:BEIJING NORMAL UNIVERSITY

Chitosan and seaweed fertilizer joint production method

InactiveCN104892795ADifficult to handleFull of nutritionOrganic fertilisersFertilizerPhosphoric acid

The invention provides a chitosan and seaweed fertilizer joint production method and belongs to the technical field of aquatic product processing. In the chitosan production process, potassium hydroxide replaces sodium hydroxide and then potassium hydroxide waste liquor is used as a digestant for seaweed fertilizer production; hydrochloric acid is replaced by nitric acid and nitric acid waste liquor replaces part of phosphoric acid to be used as a neutralizer for a seaweed digestive liquid. The traditional thinking is changed, waste alkali liquor is utilized instead of being treated, the waste is turned into wealth, and treatment of the waste alkali liquor in chitosan production is avoided. Meanwhile, the potassium hydroxide waste liquor contains a large quantity of organic matters such as animal protein and the like, and the nitric acid waste liquor contains abundant calcium and microelements, so that produced seaweed fertilizer is rich in nutrition and better in fertilizer efficiency. Two production technologies are combined, the production cost of chitosan and the seaweed fertilizer is reduced, the quality of the seaweed fertilizer is improved, and the win-win effect is realized.

Owner:青岛海利禾生物科技有限公司

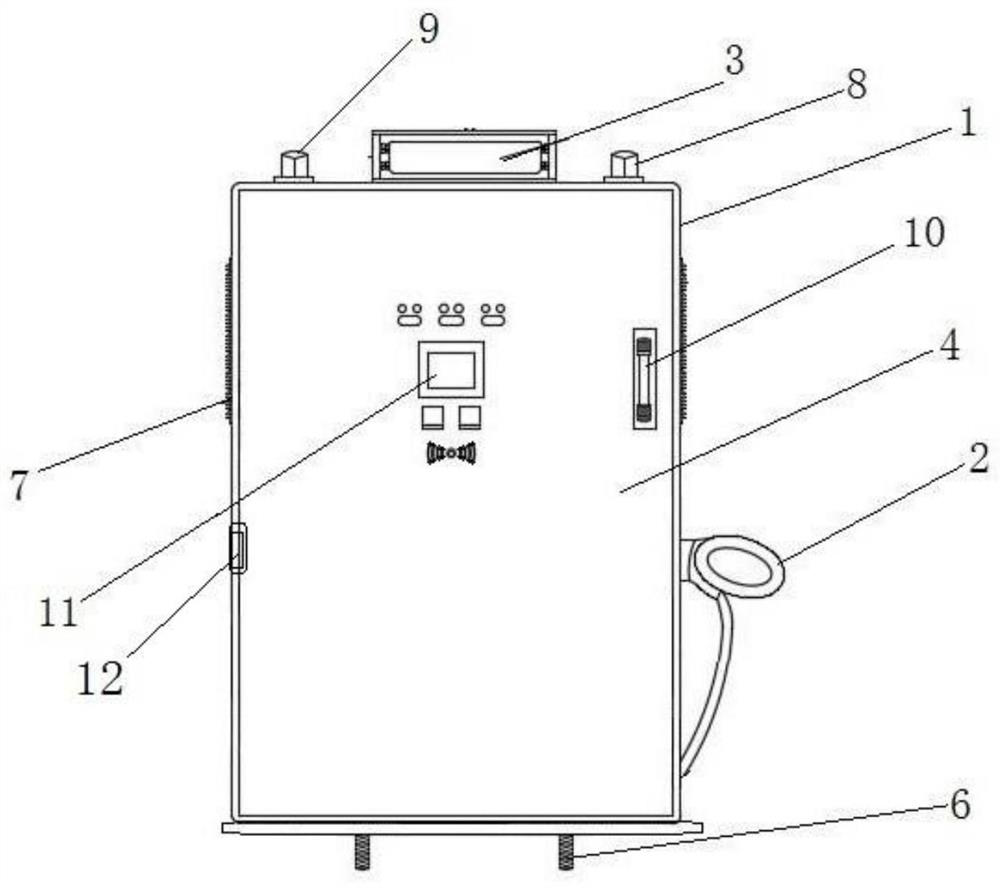

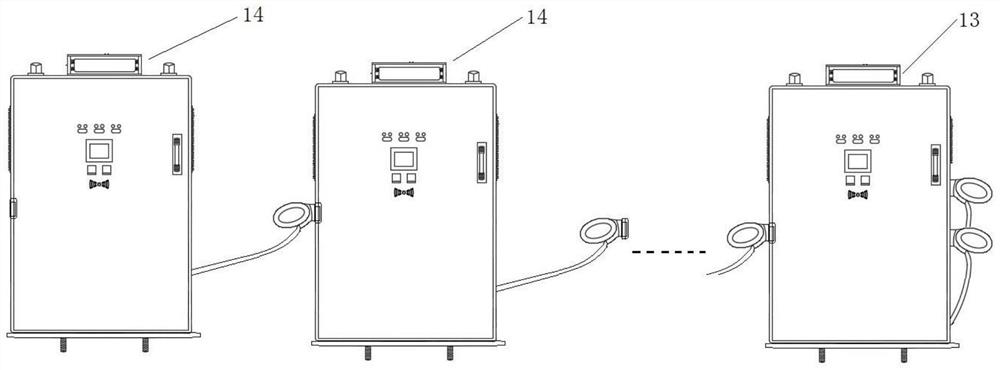

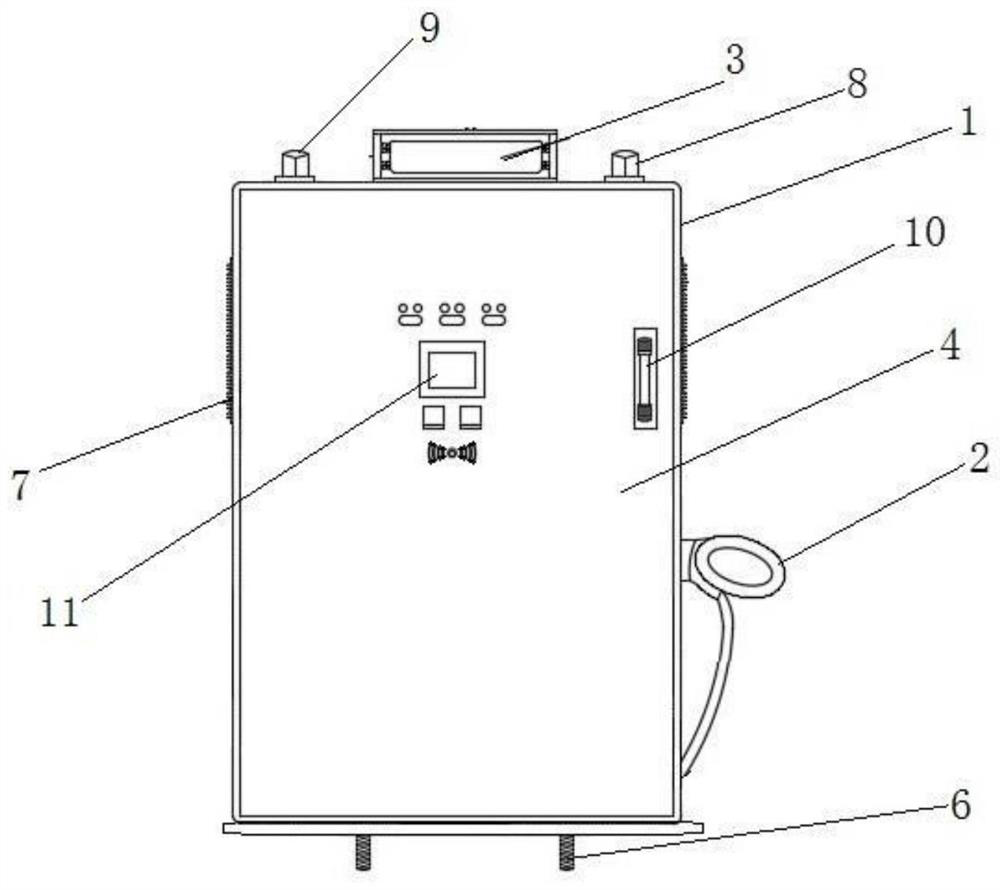

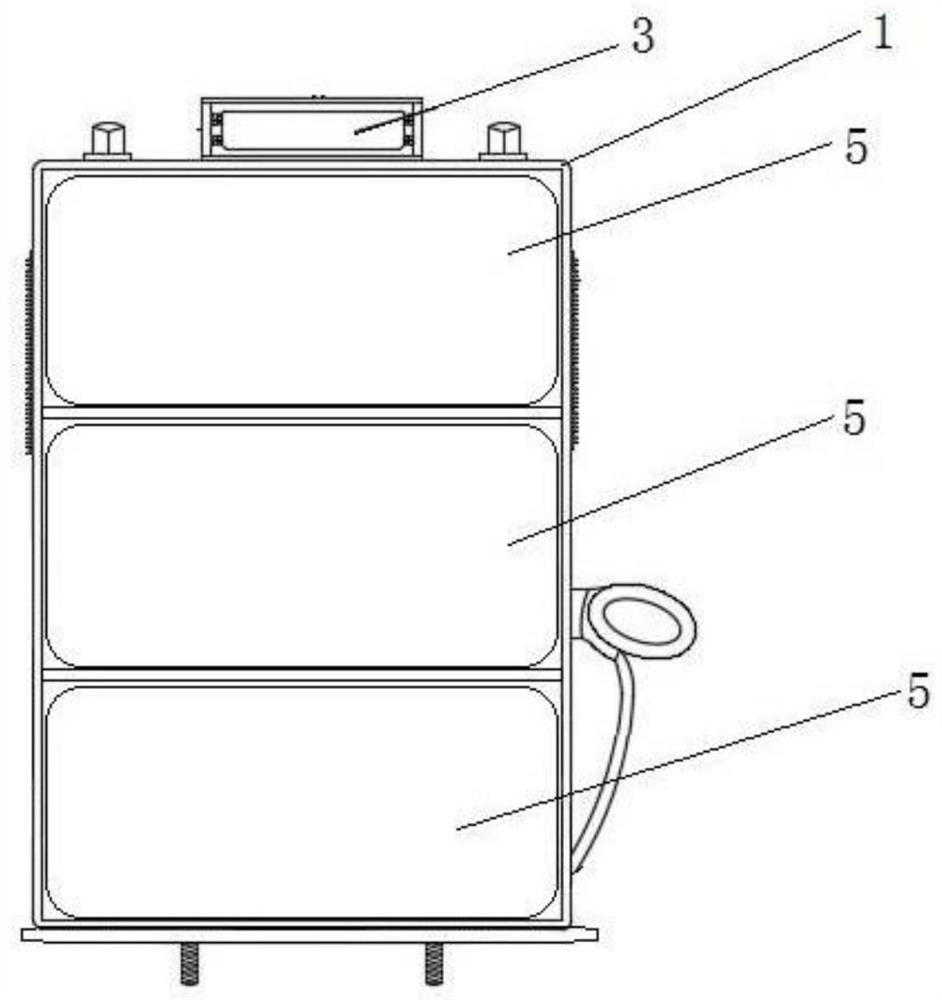

Distributed electric vehicle charging device and charging system based on mobile energy storage battery

PendingCN112248859AFlexible layoutEasy transitionCharging stationsElectric vehicle charging technologyAutomotive engineeringElectrical battery

The invention discloses a distributed electric vehicle charging device and charging system based on a mobile energy storage battery. The charging device comprises a main body charging box, a charginggun and a charging and discharging monitoring module; the main body charging box is provided with a charging gun jack, the interior of the main body charging box is provided with a rechargeable energystorage battery module, and the bottom of the main body charging box is provided with wheels facilitating the movement of the main body charging box; and one end of the charging gun jack is connectedwith the power unit, and the other end is used for inserting a charging gun connected with other charging devices. The charging system comprises a host machine and a slave machine, wherein the host machine and the slave machine both adopt the charging device, the host machine and the slave machine are connected in parallel through series connection of the charging gun and the charging gun jack, and the host machine and the slave machine which are connected in parallel output power to a load together through the charging gun of the host machine. According to the invention, flexible point distribution is realized, the transition is convenient, the limitation of electric power stay wires and geographical positions is avoided, and the charging requirement of a high-power vehicle can be met.

Owner:IPS TECH LTD

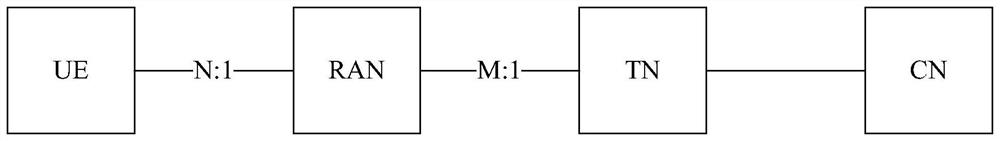

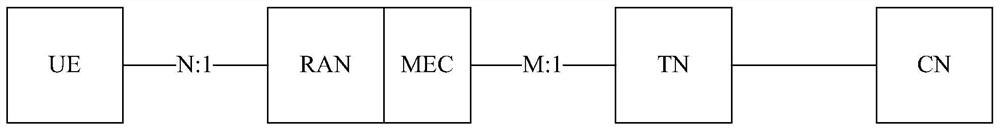

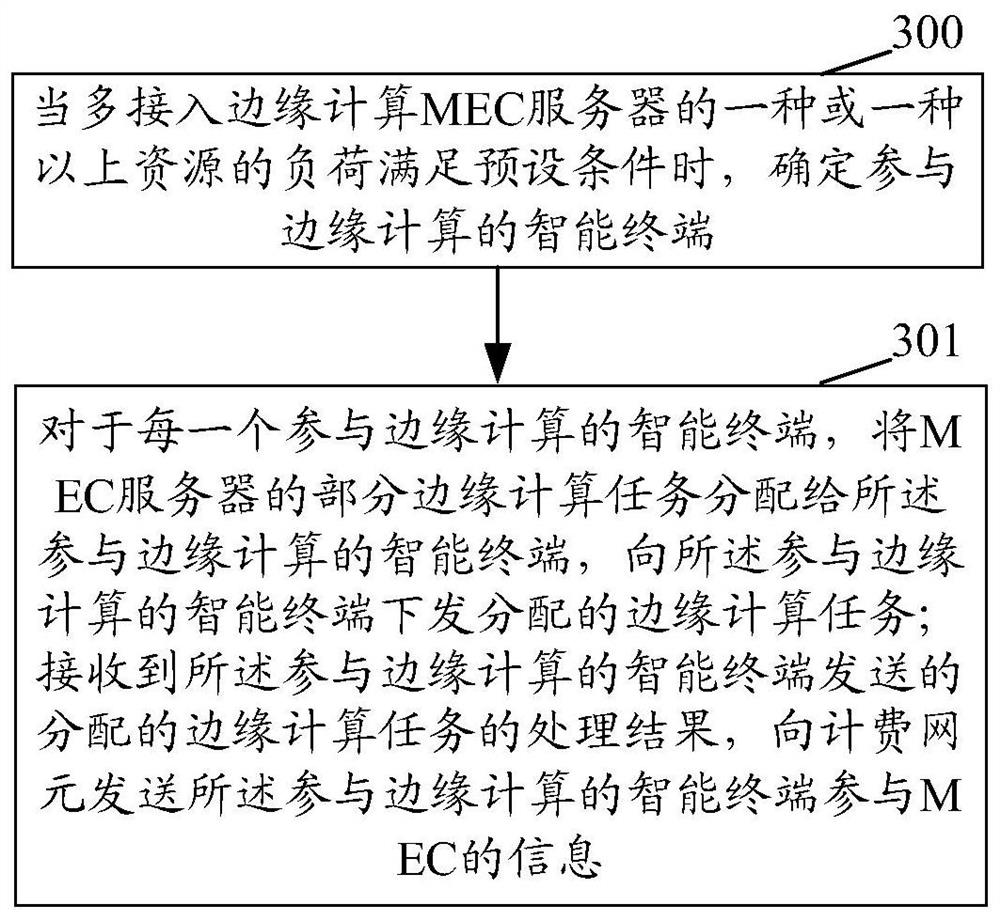

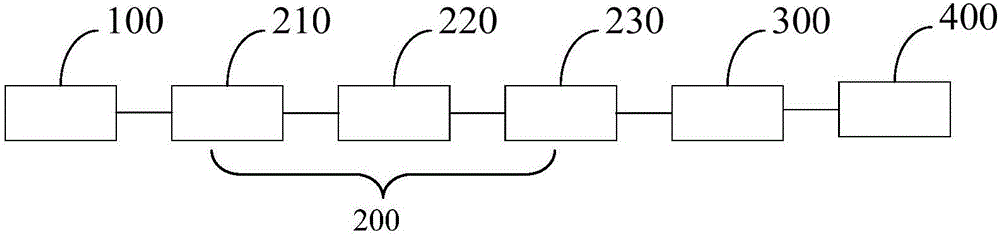

Method, device and system for realizing edge calculation

PendingCN112399388ASave resourcesImprove service qualityService provisioningAccounting/billing servicesQuality of serviceEdge computing

The embodiment of the invention discloses a method, device and system for realizing edge computing. The method comprises steps of determining an intelligent terminal participating in edge computing when the load of one or more resources of a multi-access edge computing MEC server meets a preset condition; for each intelligent terminal participating in edge computing, allocating part of edge computing tasks of the MEC server to the intelligent terminals participating in edge computing, and issuing the allocated edge computing tasks to the intelligent terminals participating in edge computing; and receiving a processing result of the allocated edge computing task sent by the intelligent terminal participating in edge computing, and sending the information that the intelligent terminal participating in edge computing participates in MEC to a charging network element. According to the method, the service quality of the MEC server is improved.

Owner:ZTE CORP

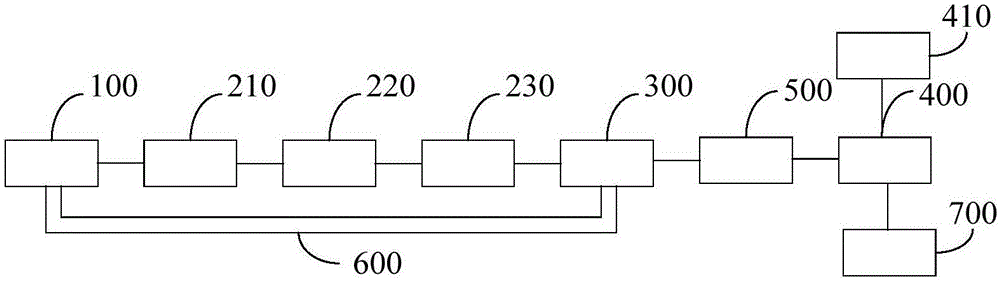

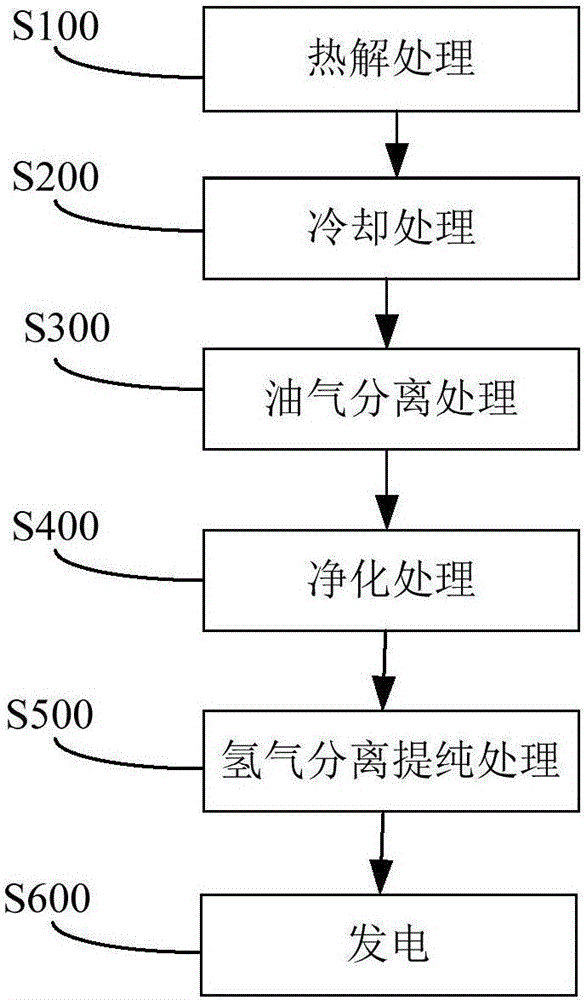

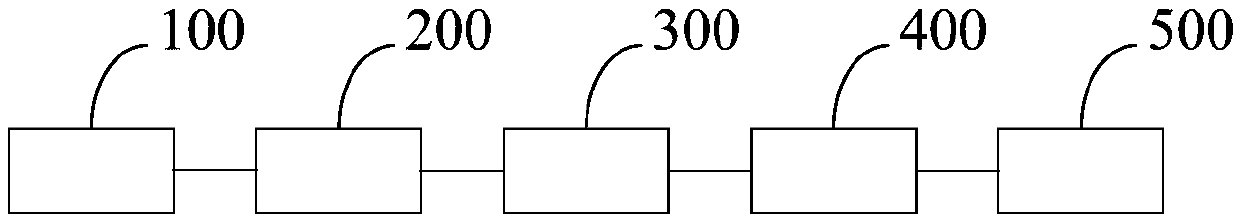

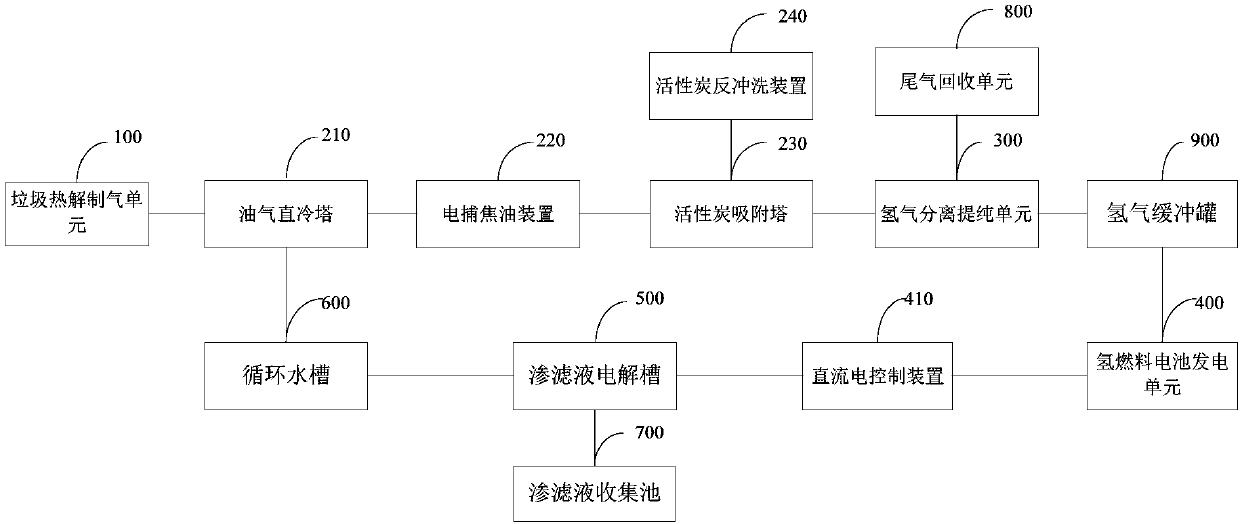

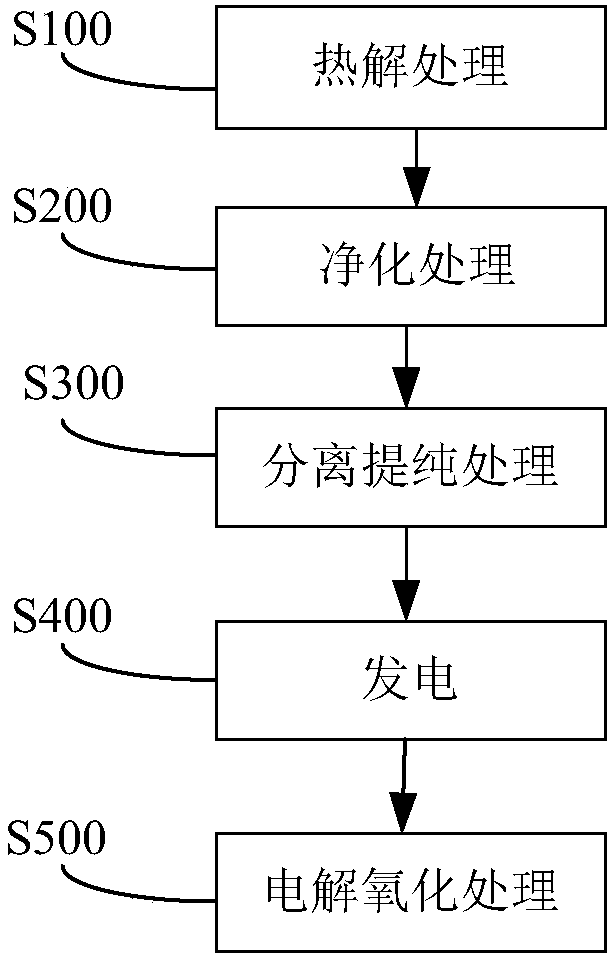

Refuse pyrolysis power generation system and application thereof

PendingCN106602118AEmission reductionEmissions will notSpecial form destructive distillationFuel cellsHydrogen pressureHydrogen fuel cell

The invention discloses a refuse pyrolysis power generation system and application thereof. The refuse pyrolysis power generation system comprises a refuse pyrolysis device, a pyrolysis oil gas purification device, a hydrogen pressure swing adsorption device and a hydrogen fuel cell power generation device, wherein the pyrolysis oil gas purification device comprises a pyrolysis oil gas cooler, a tar catcher and an active carbon adsorption tower. In the refuse pyrolysis power generation system, the hydrogen pressure swing adsorption device is used for performing hydrogen separation and purification processing on pyrolysis gas generated by the refuse pyrolysis device, hydrogen is used as a fuel, a hydrogen fuel cell is used for generating power, the refuse pyrolysis power generation system has the advantages of fast power generation starting speed, stable output electric energy and high adaptive capacity to environment, moreover, the unique by-product of electrochemical reaction is water, the refuse pyrolysis power generation system is energy-saving and environmental-friendly, and the emission of lead, sulfuric acid and other acid pollutants is prevented.

Owner:SHENWU TECH GRP CO LTD

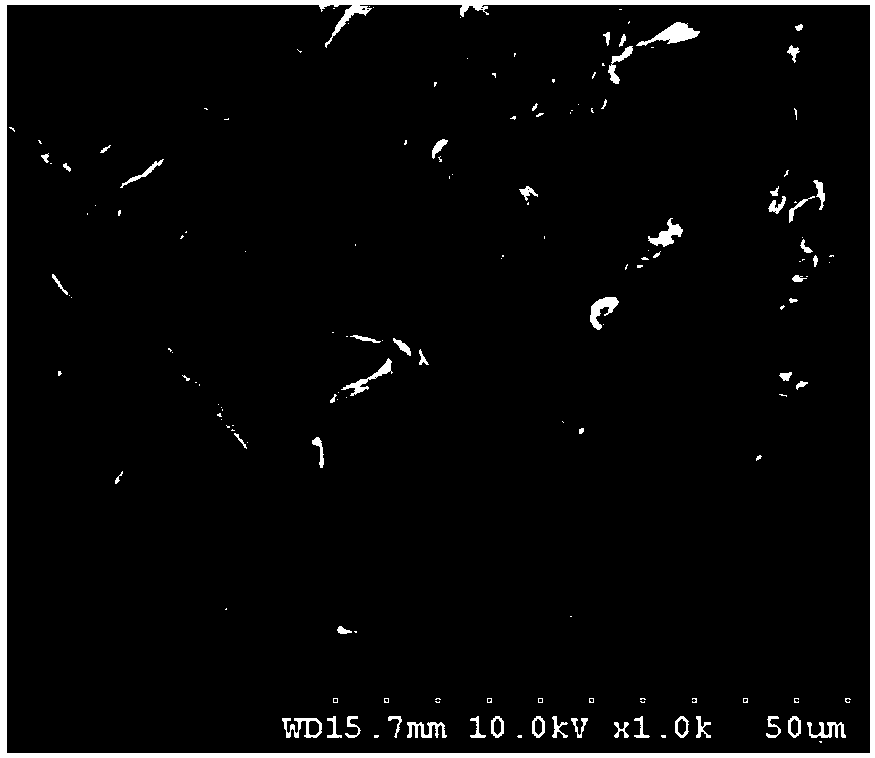

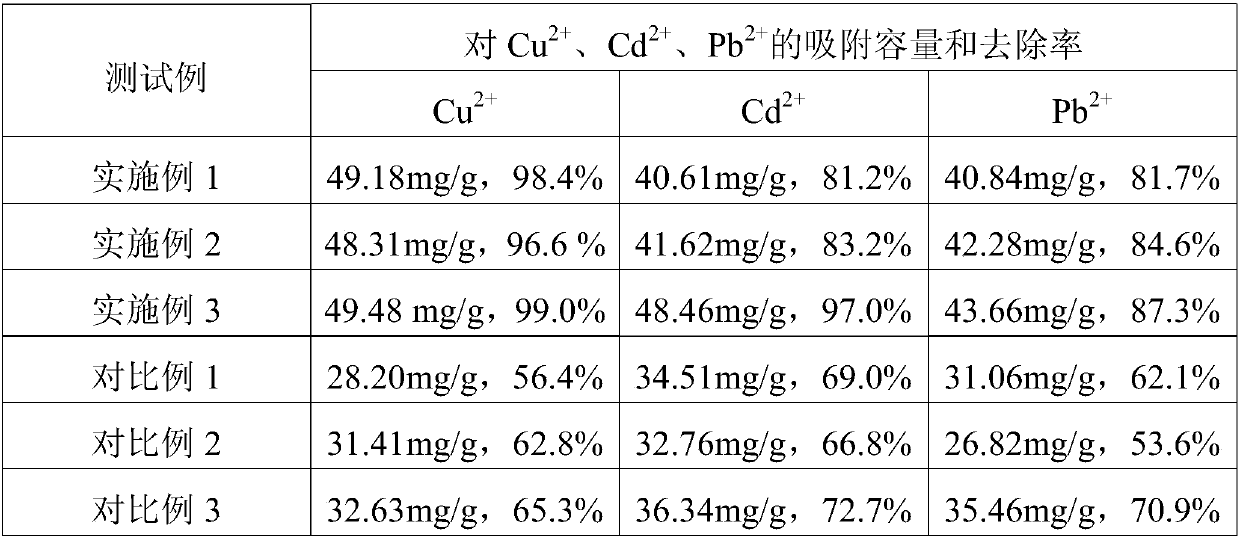

A kind of preparation method and application of banana fiber chitosan composite hydrogel

ActiveCN106964321BImprove solubilityQuality improvementOther chemical processesWater contaminantsCelluloseALLYL SUCROSE

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

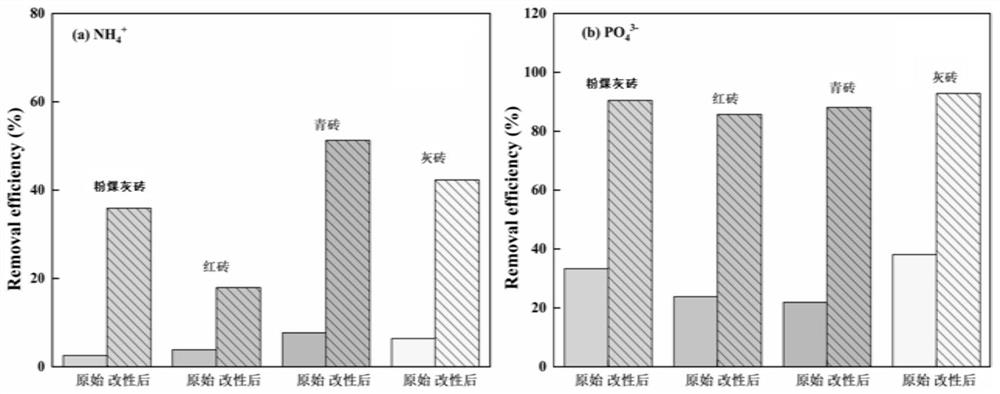

Magnesium hydroxide modified waste brick, preparation method thereof and application of magnesium hydroxide modified waste brick in artificial wetland system

PendingCN114314833AImprove modification efficiencyPromote resource utilizationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersConstructed wetlandBrick

The invention provides a magnesium hydroxide modified waste brick, a preparation method thereof and application of the magnesium hydroxide modified waste brick in an artificial wetland system, and belongs to the field of water environment treatment.The preparation method of the magnesium hydroxide modified waste brick comprises the following steps that 1, building waste bricks are crushed and sieved, and waste brick particles are obtained; (2) carrying out air plasma treatment on the waste brick particles to obtain plasma-etched waste bricks; and (3) dispersing the waste brick subjected to plasma etching into seawater, carrying out first ultrasonic treatment, dropwise adding a sodium hydroxide solution, carrying out second ultrasonic treatment, cleaning, and drying to obtain the artificial wetland filler magnesium hydroxide modified waste brick. The obtained artificial wetland filler magnesium hydroxide modified waste brick is mainly used for preparing an artificial wetland system, and can effectively improve the nitrogen and phosphorus removal efficiency of the artificial wetland and improve the effluent quality.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD

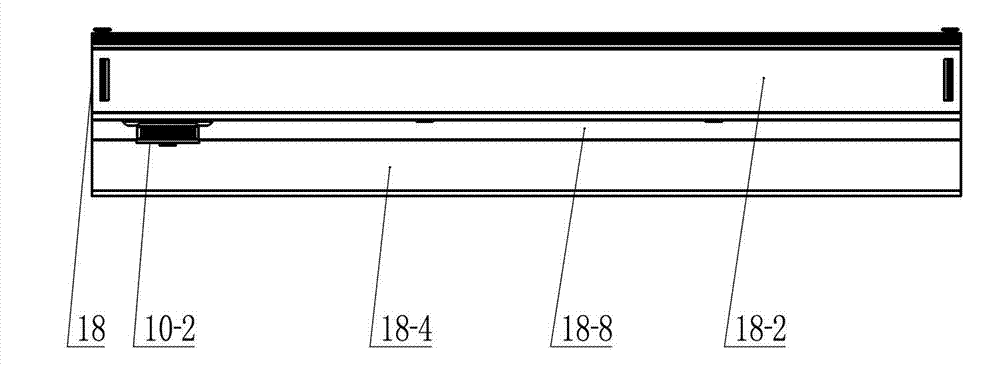

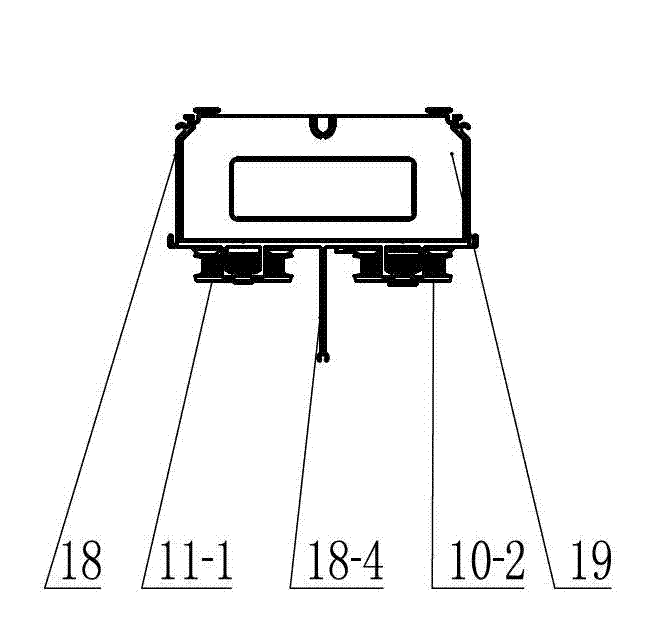

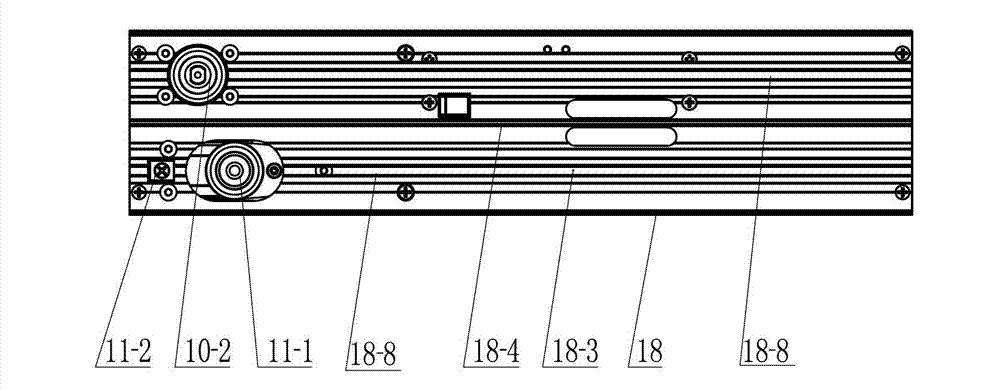

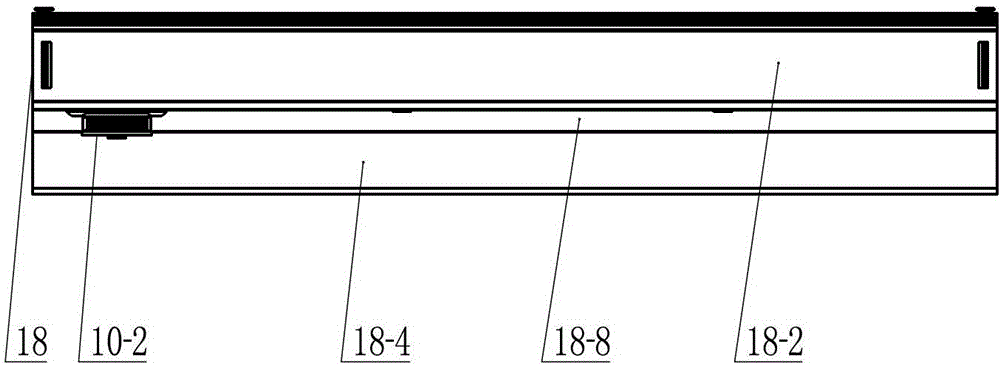

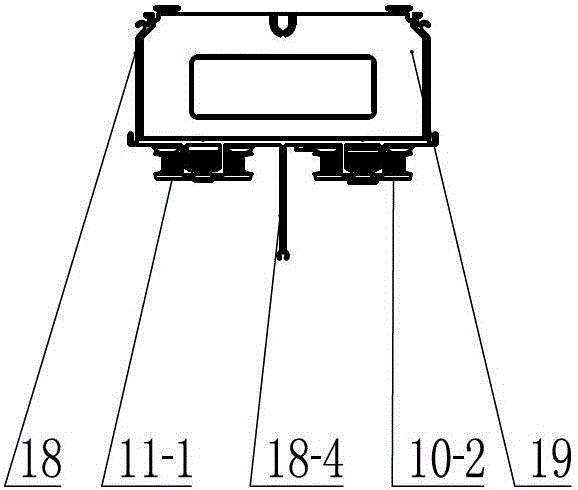

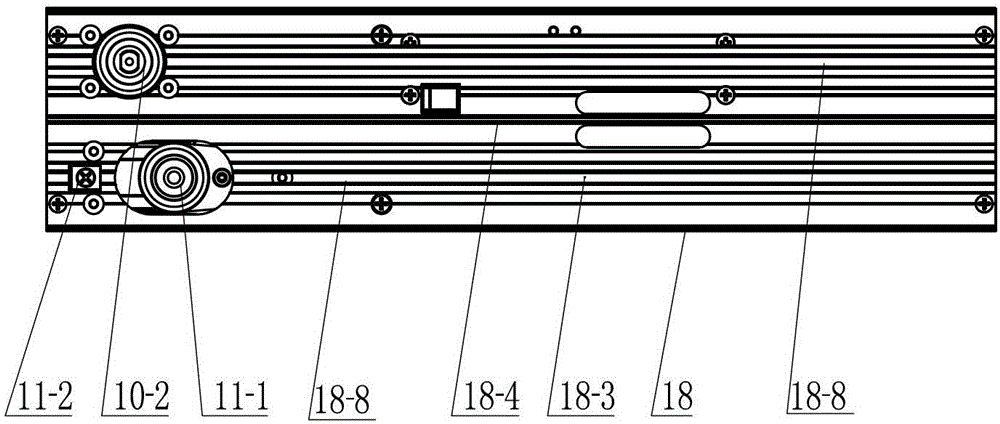

Multistage combination smart partition door transmission system

ActiveCN103089107ACompact assemblyInnovative designPower-operated mechanismDrive wheelElectric machinery

The invention provides a multistage combination smart partition door transmission system and belongs to decoration hardware technology. The multistage combination smart partition door transmission system assembles two reverse smart partition door system box bodies on the left and the right of the partition door page, and assembles a flexible connecting box body in the middle of the two reverse smart partition door system box bodies; a power supply, a smart system, a motor and a belt adjuster are assembled on the transmission system box body; a capstan is assembled below a worm wheel and worm gearbox, a driven wheel is arranged on the belt adjuster, a synchronous belt is arranged on the capstan and the driven wheel, a partition door page is arranged below the synchronous belt in a hanging mode, and the partition door page slides left and right. The multistage combination smart partition door transmission system has the advantages of being novel in design, reasonable in structure, compact in parts assembly and capable of willfully adjusting the length of the partition door. The partition door comprises a partition door page (1) and a flexible connecting piece (15). The multistage combination smart partition door transmission system is characterized in that a smart partition door transmission system box body (18) is assembled on the top portion of the partition door page (1), the flexible connecting box body (21) is connected with the end head of the smart partition door transmission system box body (18); and an end lid (19) and an upper lid (20) are connected on the box body (18).

Owner:许姜德

Independent electric vehicle charging device and charging and discharging system based on mobile energy storage battery

PendingCN112238779AMeet charging needsFlexible layoutCharging stationsTransmission systemsBattery chargeElectrical battery

The invention discloses an independent electric vehicle charging device based on a mobile energy storage battery. The independent electric vehicle charging device comprises an energy storage chargingbox, a charging gun and a charging control module, wheels facilitating movement of the energy storage charging box are arranged at the bottom of the energy storage charging box, and a battery module is detachably installed in the energy storage charging box; the battery module adopts an energy storage battery capable of charging and discharging, and the energy storage battery charges a vehicle tobe charged through charging. According to the invention, the problems of difficult energization and power distribution capacity increase of the fixed charging pile stay wire are solved, flexible pointdistribution is realized, the limitation of the power stay wire and the geographical position is avoided, the charging requirement of the electric vehicle is met anytime and anywhere, the plurality of battery modules are detachable and replaceable, long-time charging use can be realized, and the time-of-use electricity price can also be utilized, and when the electricity price at night is low, the detached battery module is charged or if the charging is convenient on site, the battery module can be directly charged, so that the economic benefit is greatly improved.

Owner:湖南富能宝储能科技有限公司

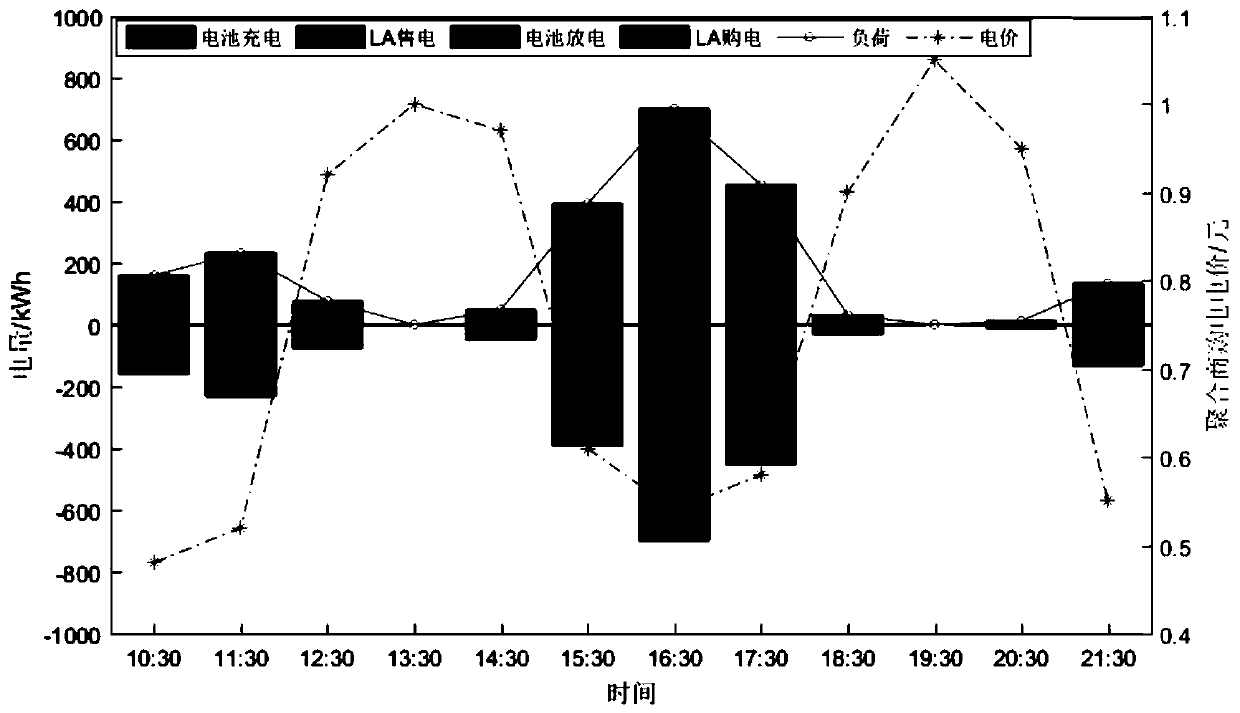

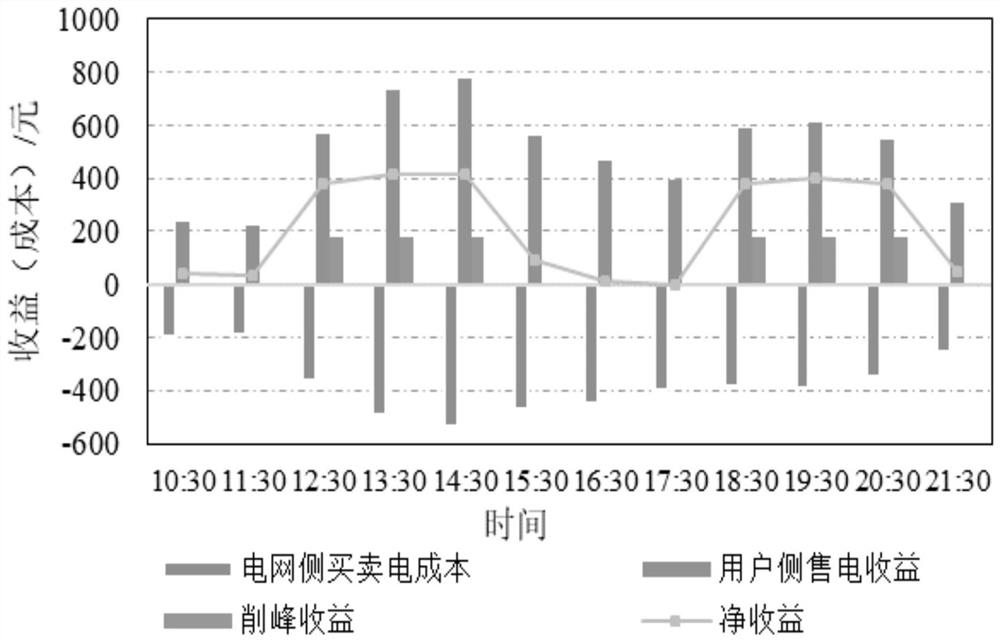

A Distributed Energy Storage Control Right Optimal Scheduling Method Oriented to Load Aggregators

ActiveCN110516855BLow running costDelayed constructionForecastingResourcesSocial benefitsOperation scheduling

The invention discloses a load aggregator-oriented distributed energy storage control optimization scheduling method, which obtains system historical data for load forecasting and new energy output forecasting; establishes user operation self-scheduling objective functions equipped with distributed energy storage and user Self-scheduling constraints; establish the optimal purchase strategy and operation scheduling objective function of distributed energy storage control rights and the optimal purchase strategy and operation scheduling constraints of distributed energy storage control rights; determine the aggregation under the transaction mode of distributed energy storage control rights The energy storage purchase strategy and operation scheduling method of the provider, the purchase plan of optimizing the energy storage control right; the scheduling plan of the aggregator for user load; the cost reduction of users participating in the transaction and the economic benefits of the aggregator. The invention improves the utilization rate of distributed energy storage, reduces the peak-valley difference of the power system, and contributes to social benefits to a certain extent.

Owner:XI AN JIAOTONG UNIV

A kind of hot-rolled wire rod for ultra-low carbon steel fiber and its production method

The invention relates to a hot rolled wire rod for ultra-low carbon steel fibers and a production method of the hot rolled wire rod. The wire rod comprises the chemical components of, by mass, less than or equal to 0.010% of C, less than or equal to 0.03% of Si, less than or equal to 0.20% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, greater than or equal to 0.02% of Alt, 0.05-0.12% of Ti and the balance iron and inevitable impurities. The production method comprises the procedures of continuous casting, cogging, heating, rolling, spinning and cooling. By adding the Ti elements to ultra-low carbon steel, through low-temperature rolling, uniform ferrite and pearlite structures are generated, effective combination of strength and plasticity is achieved, thus, the tensile strength of the wire rod with the specification being phi 7.0 mm is 310-360 MPa, the percentage elongation after fracture is greater than or equal to 50.0%, 1300-MPa-class steel fibers are allowed to be produced through the wire rod with the large specification under the condition that existing equipment of downstream customers is not changed, the purchase cost is lowered, and the downstream customer selectivity is increased.

Owner:XINGTAI IRON & STEEL

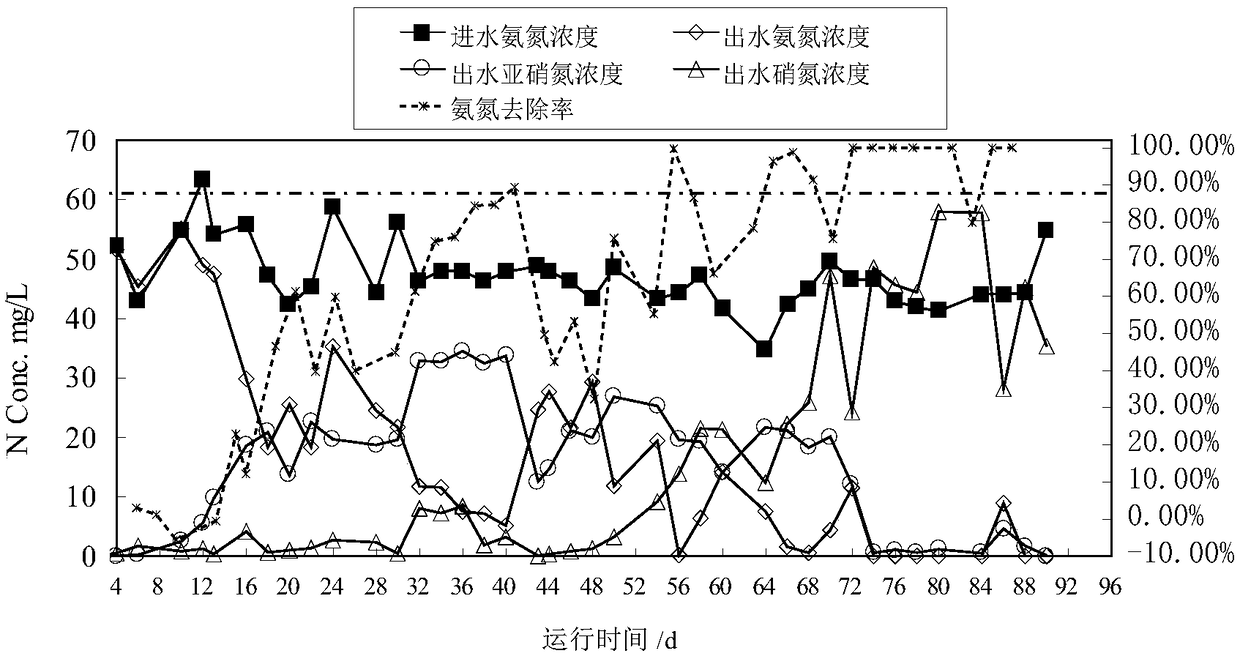

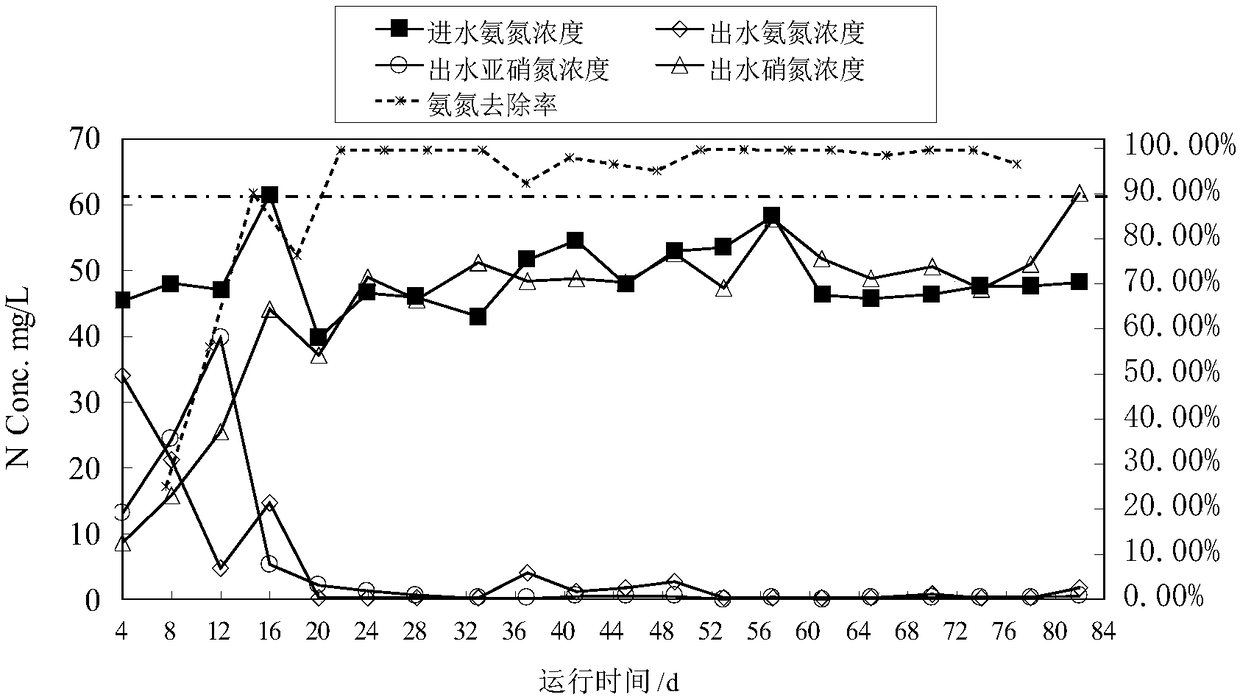

Method for starting bio-filter for processing high salt ammonia containing wastewater

InactiveCN108928909AImprove handling stabilityStrong impact resistanceTreatment using aerobic processesWater contaminantsMangroveSludge

The invention discloses a method for starting a bio-filter for processing high salt ammonia containing wastewater, and relates to the field of aeration bio-filters. According to the method, mangrove forest deposited wet sludge is added into an oyster shell filling material aeration bio-filter to obtain a mixed solution; then a cleaned and dried oyster shell filling material is added into the oyster shell filling material aeration bio-filter; raw water is added into the oyster shell filling material aeration bio-filter until raw water reaches an overflowing opening; the bio-filter is connectedto an aeration machine, which is operated in an intermittent enclosed aeration mode, thus the mangrove forest deposited sludge can fully adhere on the surface and inner holes of the oyster shells; after enclosed aeration, the bio-filter is connected to a raw water inlet pipe, water is continuously introduced into the bio-filter, continuous aeration is carried out; water samples and mud samples arecollected periodically; all indexes of the effluent of the bio-filter are measured, if the removal rate of NH4<+> and N is stably more than 80%, the bio-film culturing is success, and if the removalrate of NH4<+> and N is stably more than 90%, the bio-filter, which takes mangrove forest deposited sludge as the seed mud, is successfully trained and started.

Owner:XIAMEN UNIV

Multi-section combined intelligent partition door drive system

ActiveCN103089107BCompact assemblyAchieve a win-win effectPower-operated mechanismDrive wheelElectric machinery

The invention provides a multistage combination smart partition door transmission system and belongs to decoration hardware technology. The multistage combination smart partition door transmission system assembles two reverse smart partition door system box bodies on the left and the right of the partition door page, and assembles a flexible connecting box body in the middle of the two reverse smart partition door system box bodies; a power supply, a smart system, a motor and a belt adjuster are assembled on the transmission system box body; a capstan is assembled below a worm wheel and worm gearbox, a driven wheel is arranged on the belt adjuster, a synchronous belt is arranged on the capstan and the driven wheel, a partition door page is arranged below the synchronous belt in a hanging mode, and the partition door page slides left and right. The multistage combination smart partition door transmission system has the advantages of being novel in design, reasonable in structure, compact in parts assembly and capable of willfully adjusting the length of the partition door. The partition door comprises a partition door page (1) and a flexible connecting piece (15). The multistage combination smart partition door transmission system is characterized in that a smart partition door transmission system box body (18) is assembled on the top portion of the partition door page (1), the flexible connecting box body (21) is connected with the end head of the smart partition door transmission system box body (18); and an end lid (19) and an upper lid (20) are connected on the box body (18).

Owner:许姜德

Refuse leachate electrolysis treatment system and application thereof

PendingCN106698596AShorten the electrolytic treatment processAchieve a win-win effectWater/sewage treatment apparatusContaminated groundwater/leachate treatmentElectrolysisHydrogen fuel cell

The invention discloses a refuse leachate electrolysis treatment system and application thereof. The refuse leachate electrolysis treatment system comprises a refuse pyrolysis and gas making unit, a pyrolysis oil gas purification unit, a hydrogen gas separation and purification unit, a hydrogen fuel battery power generation unit and a leachate electrolysis bath. In the system, refuse pyrolysis gas is subjected to hydrogen gas separation and purification through the hydrogen gas separation and purification unit, and hydrogen gas is used by the hydrogen fuel battery power generation unit to generate powder, thereby realizing high power generation efficiency and stable power generation and output; and the power generation process almost produces no new pollutant and is low in noise, clean and environment-friendly. Meanwhile, direct current generated by the fuel battery does not need to be converted into alternating current and can be directly used in the leachate electrolysis bath for sewage electrolysis treatment, thereby shortening the leachate electrolysis treatment process flow and reducing electric energy loss of the electrolysis unit. Thus, the system combines domestic refuse power generation treatment and leachate electrolysis treatment and production, and achieves a win-win effect of solid waste treatment and sewage treatment.

Owner:SHENWU TECH GRP CO LTD

Centralized intelligent dispatching method for charging plug-in hybrid electric vehicle (PHEV)

InactiveCN101901945BReduce the cost of new power generationTo achieve the purpose of side peak regulationSecondary cells charging/dischargingTime informationElectric power system

The invention provides a centralized intelligent dispatching method for charging a plug-in hybrid electric vehicle (PHEV), which belongs to the research field of power system demand side response and is especially suitable for a plug-in hybrid electric vehicle (PHEV) of peak load regulation. The invention is established on the basis of a dynamic estimation interpolation concept, and mainly comprises the following parts: real-time information extraction, PHEV dynamic cataloging, load per-unit transformation, boundary condition detection, singular load analysis, load estimation interpolation, load index evaluation and charging cost calculation. The invention can dynamically dispatch the charging time periods of the PHEV, thereby effectively reducing the risk and hidden danger which are brought by the load singularity of the grid side, indirectly lowering the investment into newly arranged generating equipment at the grid side and saving the charging cost at the user side, and realizing the purpose of benefiting both the grid side and the user side.

Owner:HOHAI UNIV

A new type of shotcrete material and its application method for suppressing spontaneous combustion of waste rock

ActiveCN111233426BReduce porosityBarrier entryFire rescueFire extinguisherSpontaneous combustionShotcrete

The invention discloses a novel shotcrete material for suppressing spontaneous combustion of gangue hills and an application method thereof, and belongs to the field of coal gangue spontaneous combustion fire extinguishing; the raw material of the shotcrete material of the present invention is mainly coal-based solid waste, including power plants using coal as fuel The by-product fly ash and desulfurization gypsum, also the by-product calcium carbide mud of PVC plant, the by-product silica fume powder of ferrosilicon smelter, and compound admixture; Use spraying machine to spray the spraying material of the present invention on gangue A solidified layer can be formed on the surface to prevent wind and block leaks, isolate air, prevent air from entering the internal fire source of the gangue dump, and inhibit spontaneous combustion of the gangue dump.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

A clean production process of chitin

ActiveCN104877044BEliminate processingRaise the pHOrganic fertilisersPhosphoric acidPotassium hydroxide

A chitin clean production process belongs to the technical field of aquatic product processing. In the process of producing chitin, potassium hydroxide is used instead of sodium hydroxide, and then potassium hydroxide waste liquid is used as a digestant for seaweed fertilizer production; nitric acid is used Instead of hydrochloric acid, nitric acid waste liquid was used instead of part of phosphoric acid as a neutralizer for seaweed digestion liquid. The present invention changes the traditional thinking, changes the treatment of waste lye to use waste lye, uses potassium hydroxide instead of sodium hydroxide, and then uses potassium hydroxide waste liquid as a seaweed digester in the production process of seaweed fertilizer, turning waste into treasure, The treatment of waste lye from chitin production is exempted. At the same time, in the chitin production process, potassium hydroxide waste liquid contains a large amount of animal protein and other organic matter, and nitric acid waste liquid is rich in calcium and trace elements, making the produced seaweed The fertilizer is more nutritious and the fertilizer effect is better.

Owner:青岛海时代生物工程有限公司

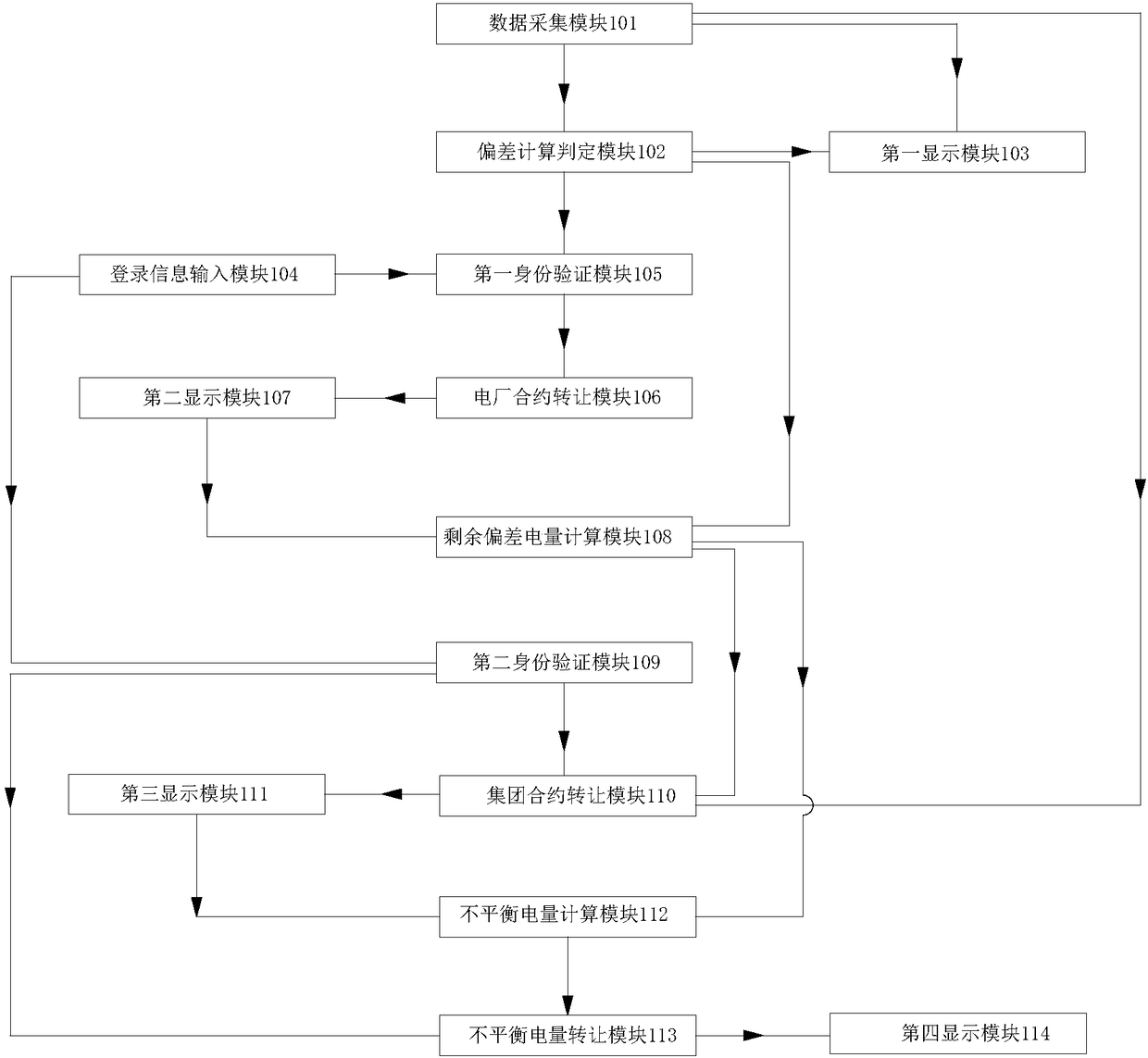

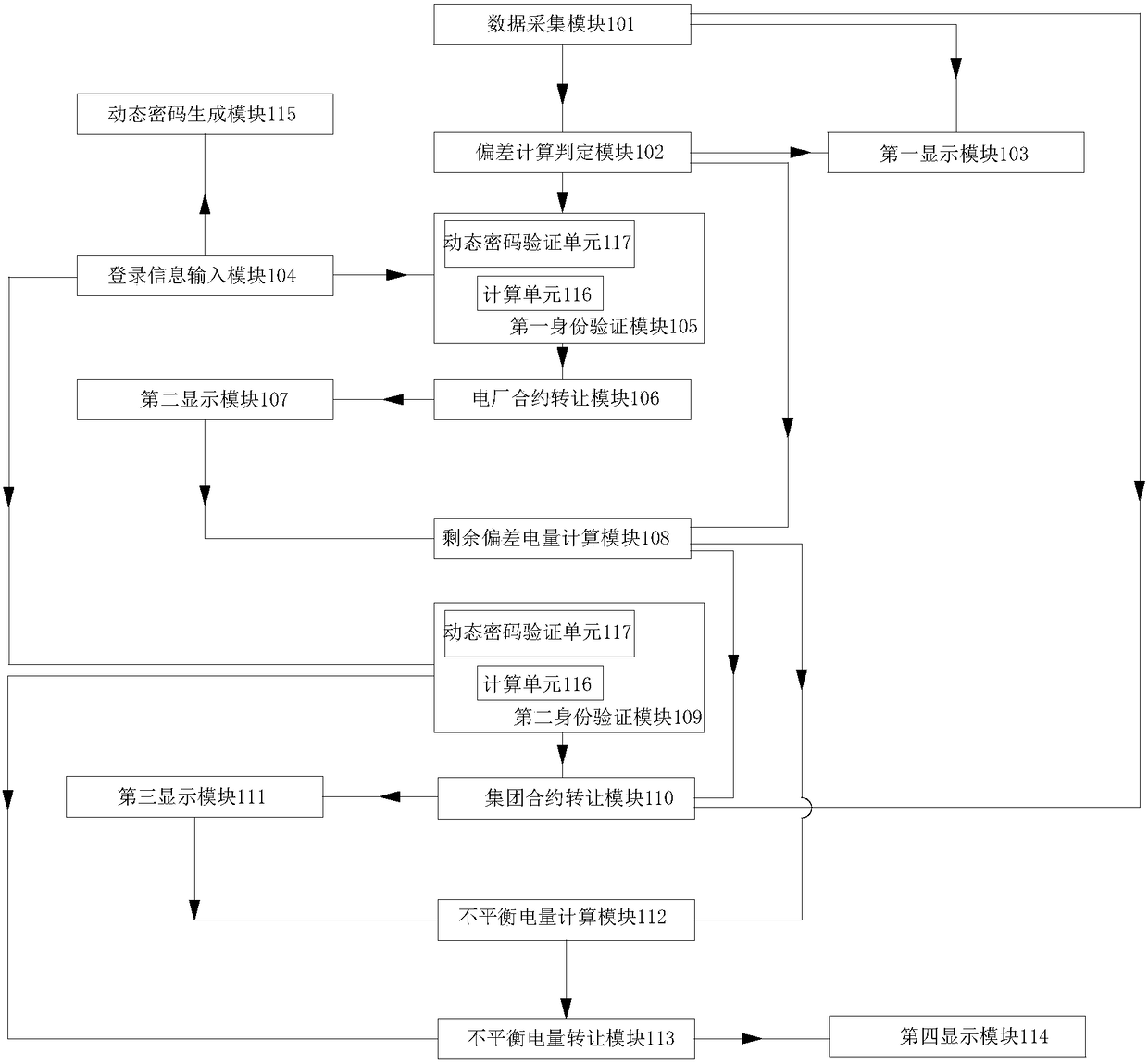

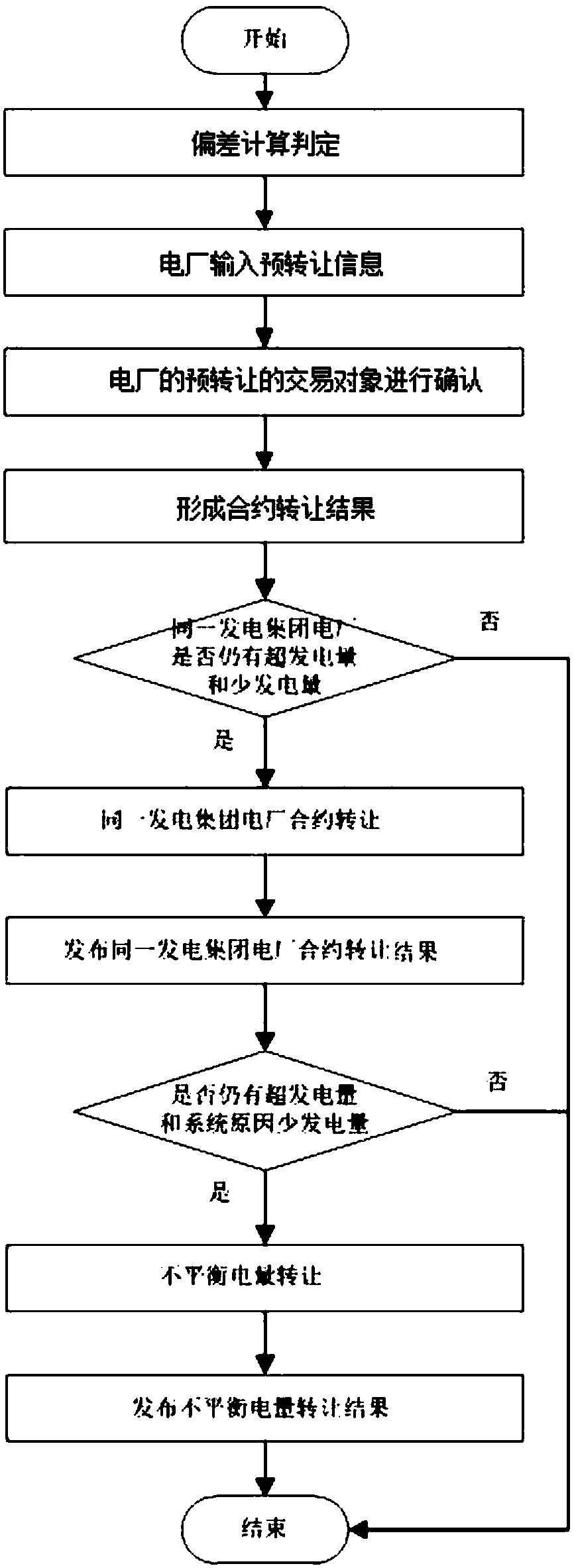

A monthly power generation contract transfer trading system and trading method

ActiveCN107507066BIncrease electricity revenueReduce power generationBuying/selling/leasing transactionsInformation technology support systemPower stationElectricity market

The invention relates to a monthly power generating contract transfer transaction system and a transaction method, and belongs to the power market transaction system technical field; the method comprises the following four steps: deviation calculating determination, power plant contract transferring, group contract transferring and imbalance electric quantity transferring. The system and method can improve the electricity charge incomes of a super power plant, can reduce insufficient generating capacity examinations caused by power plant self reasons, and can reduce the insufficient generating capacity compensations caused by power plant system reasons, thus providing multi-party win-win effects.

Owner:昆明电力交易中心有限责任公司

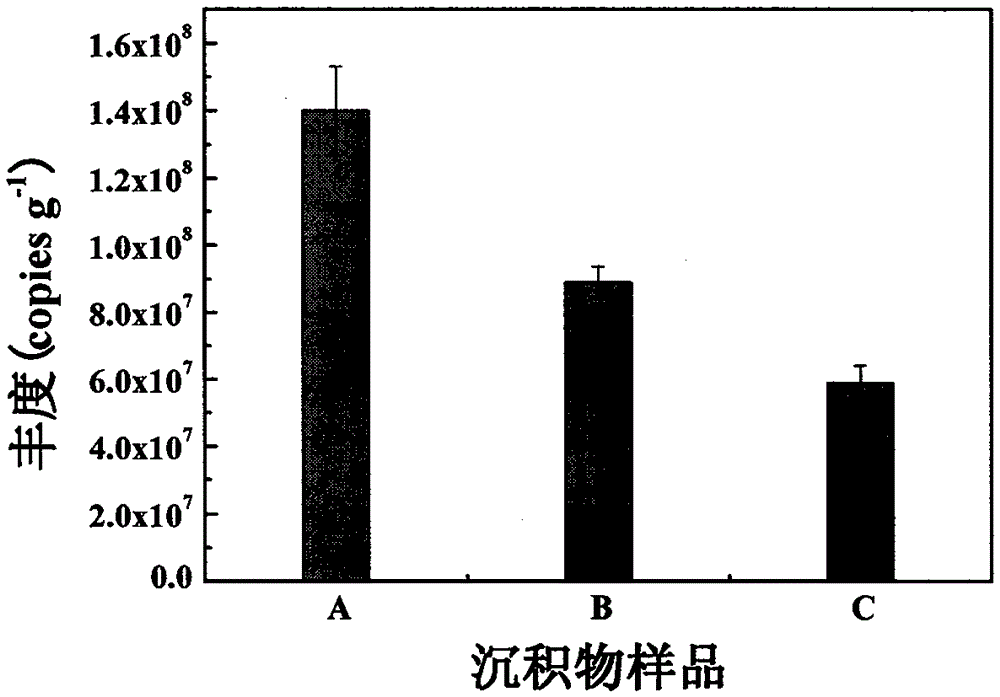

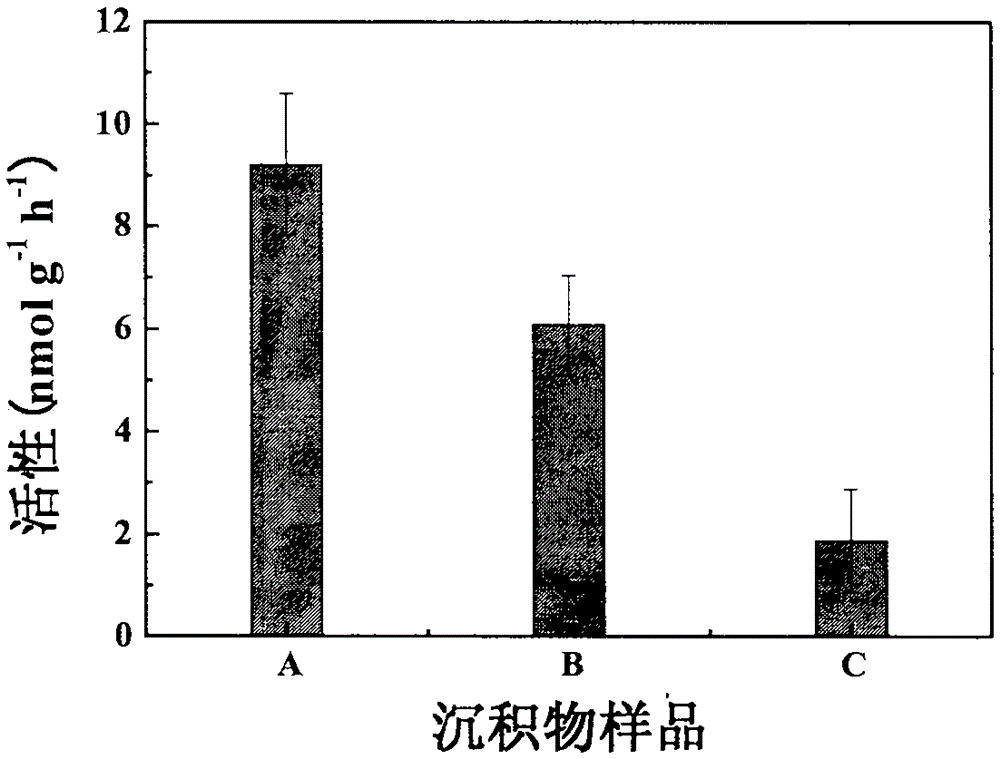

A method for enhancing anaerobic ammonium oxidation in sediments using waste sludge from water purification plants

ActiveCN104512962BEasy to operateImprove habitatTreatment with anaerobic digestion processesDry weightHigh activity

The invention provides a method for enhancing the anaerobic ammoxidation effect of a deposit by using water treatment plant waste mud (WTRs) as a carrier, and belongs to the technical field of water treatment. The method is characterized in that the deposit and the WTRs are enriched through a closed anaerobic cylindrical device, and a deposit-WTRs mixture with the wet-to-dry weight ratio of 10:1 is added to synthetic water rich in ammonia nitrogen and is enriched for a period of time to obtain a deposit containing high activity and high abundance anaerobic ammoxidation bacteria. The purposes comprise the stimulation of the in situ environment of the deposit in eutrophic water and the provision of much interception indication for the anaerobic ammoxidation bacteria by using the large specific surface area of the WTRs as a carrier. The WTRs contain a large amount of iron, can weaken the inhibition effect of P, heavy metals and other substances in the deposit on the anaerobic ammoxidation effect, and provide suitable living environment for the anaerobic ammoxidation bacteria. The method ahs the advantages of low cost of the used materials, environmental protection, simple technological operation, solving of the treatment problem of the WTRs, realization of the effective control of endogenous release of the eutrophic water, and 'using waste to treat waste' purpose realization facilitation.

Owner:BEIJING NORMAL UNIVERSITY

Chitin cleaning production technique

ActiveCN104877044AEliminate processingRaise the pHOrganic fertilisersLiquid wastePotassium hydroxide

The invention discloses a chitin cleaning production technique and belongs to the technical field of aquatic product processing. In the chitin production process, potassium hydroxide replaces sodium hydroxide, and potassium hydroxide liquid waste is used as seaweed fertilizer production digestive; nitric acid replaces hydrochloric acid, and nitric acid liquid waste replaces some phosphoric acid to serve as seaweed digestive juice neutralizing agent. The chitin cleaning production technique changes traditional thinking, changes waste lye treatment into waste lye use, uses the potassium hydroxide to replace the sodium hydroxide, uses the potassium hydroxide liquid waste as the seaweed digestive in the seaweed fertilizer production process, turns waste into wealth and omits the chitin production waste lye treatment, and meanwhile, in the chitin production technique, the potassium hydroxide liquid waste includes a lot of animal protein and the like organic substance, the nitric acid liquid waste includes abundant calcium and micro-element, the produced seaweed fertilizer nutrition is richer, and the fertilizer efficiency is better.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

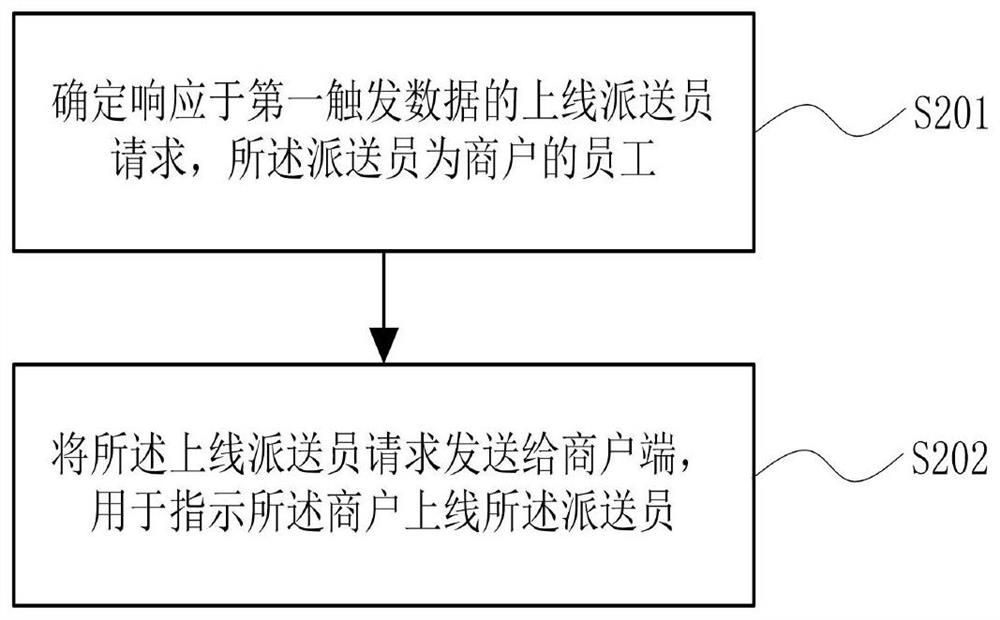

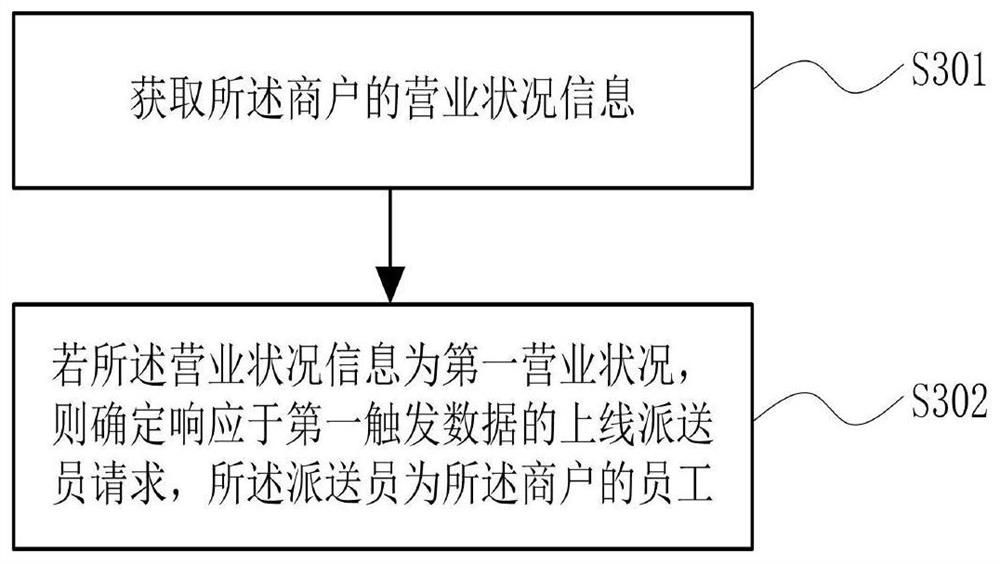

Delivery man online method, device and equipment and storage medium

PendingCN112348413ALow costTake advantage ofBuying/selling/leasing transactionsResourcesComputer networkOperations management

The invention relates to the field of logistics distribution, and provides a deliveryman online method, device and equipment and a storage medium. The method specifically comprises the following steps: determining an online deliveryman request in response to first trigger data, wherein a deliveryman is an employee of a merchant; and sending the online deliveryman request to the merchant for indicating the merchant to online the deliveryman. The deliveryman online method has the characteristics that the deliveryman cost is reduced, and the social human resource waste is reduced.

Owner:梅州神寻科技有限公司

A control system for automatic charging, consumption and charging and selling of electric vehicles

InactiveCN105818701BAvoid settingReduce the burden onCharging stationsAc network load balancingMicrocontrollerElectricity

The invention discloses an automatic charging power utilization and selling control system for an electric automobile. The automatic charging power utilization and selling control system for the electric automobile comprises a timing module, a central control module, a charging and discharging control module and a communication module, wherein the timing module is formed by a timer and used for timing and outputting a signal to the central control module; the central control module is formed by a single chip and used for controlling the charging and discharging control module through a control signal; the charging and discharging control module comprises a charging and discharging controller and an electric energy calculating device; the communication module comprises a wireless communication module and a user terminal; the wireless communication module is used for transmitting state information of a battery to the user terminal; and the user terminal is used for monitoring the state of the battery and controlling the system to be switched to a charging power utilization mode or a charging power selling mode. According to the invention, orderly charging and peak load shifting are realized so that power grid pressure is reduced and benefits are created for users; and meanwhile, the development of a communication technology is sufficiently utilized, human-computer interaction is convenient and convenience is provided to people's life.

Owner:SHANGHAI DIANJI UNIV

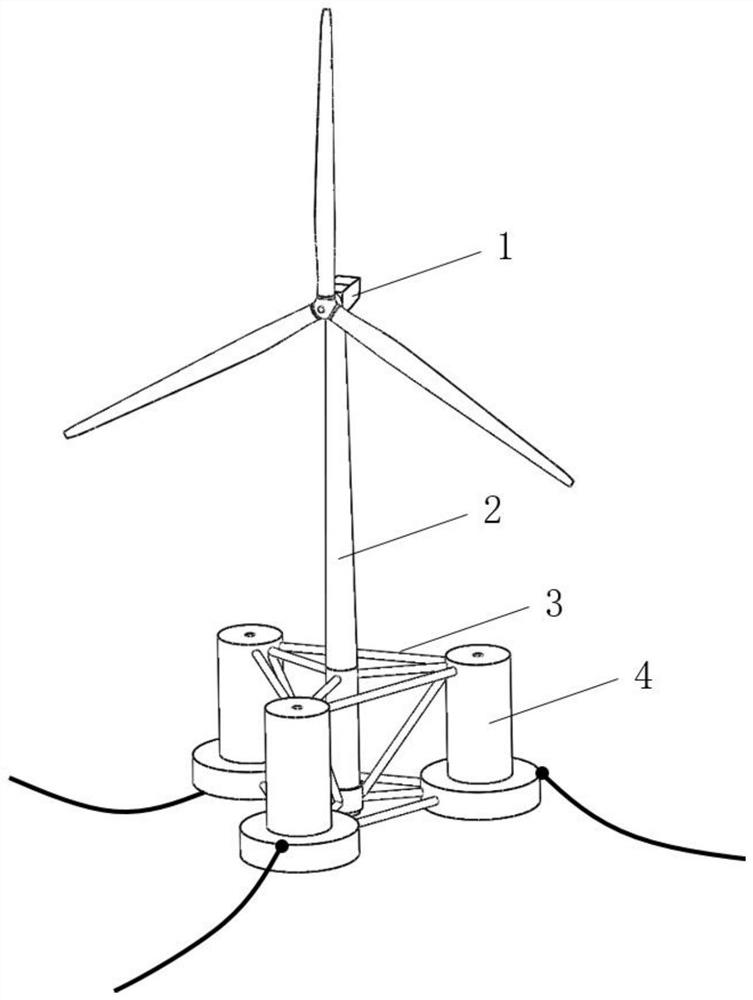

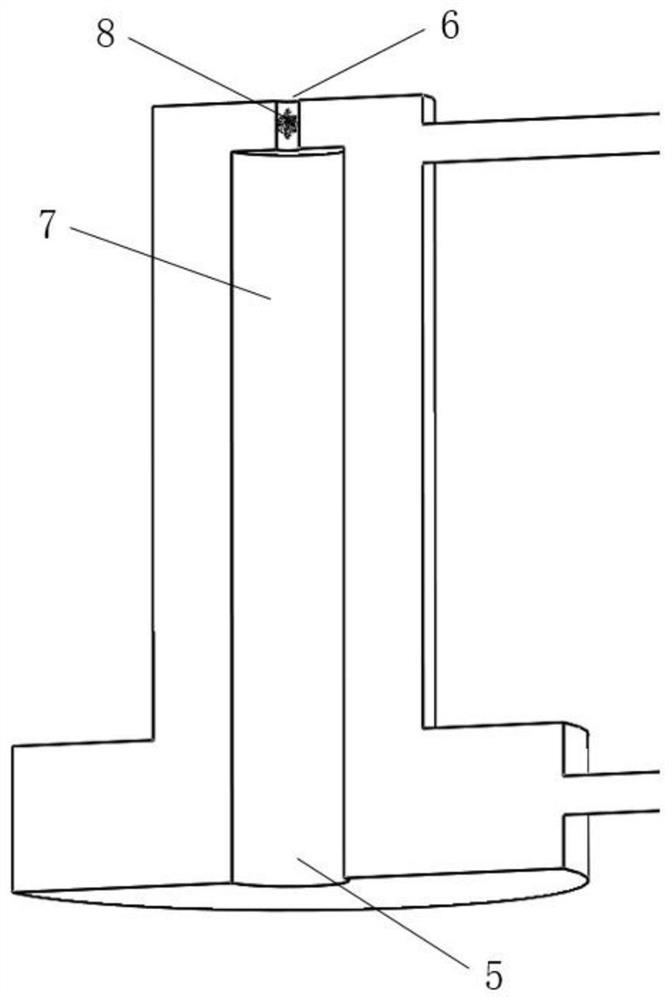

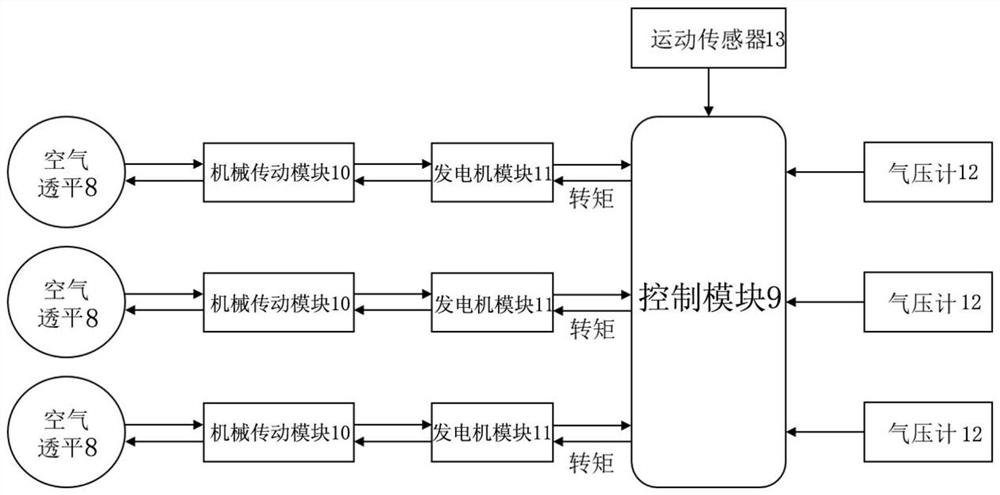

Floating wind turbine and control method of oscillating water column wave energy device

ActiveCN113236501BImprove stabilityReduced motor responseWind motor supports/mountsHydro energy generationBuoyWave power

Owner:海南浙江大学研究院 +1

A kind of combined production method of chitosan and seaweed fertilizer

The invention provides a chitosan and seaweed fertilizer joint production method and belongs to the technical field of aquatic product processing. In the chitosan production process, potassium hydroxide replaces sodium hydroxide and then potassium hydroxide waste liquor is used as a digestant for seaweed fertilizer production; hydrochloric acid is replaced by nitric acid and nitric acid waste liquor replaces part of phosphoric acid to be used as a neutralizer for a seaweed digestive liquid. The traditional thinking is changed, waste alkali liquor is utilized instead of being treated, the waste is turned into wealth, and treatment of the waste alkali liquor in chitosan production is avoided. Meanwhile, the potassium hydroxide waste liquor contains a large quantity of organic matters such as animal protein and the like, and the nitric acid waste liquor contains abundant calcium and microelements, so that produced seaweed fertilizer is rich in nutrition and better in fertilizer efficiency. Two production technologies are combined, the production cost of chitosan and the seaweed fertilizer is reduced, the quality of the seaweed fertilizer is improved, and the win-win effect is realized.

Owner:青岛海利禾生物科技有限公司

Calcination-free desulfurized gypsum walling plastering dry-mixed mortar

ActiveCN102643071BReasonable ratioRaw materials are easy to getThermal insulationUltimate tensile strength

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com