Refuse pyrolysis power generation system and application thereof

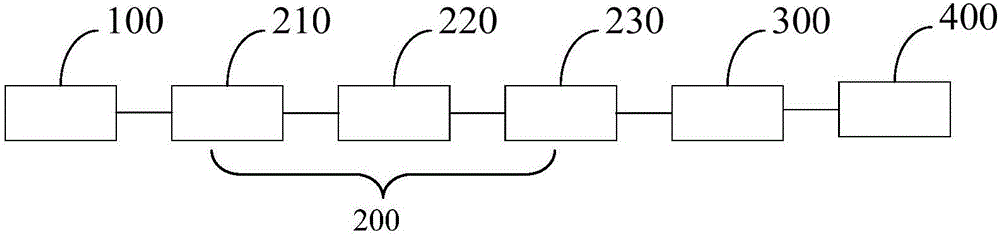

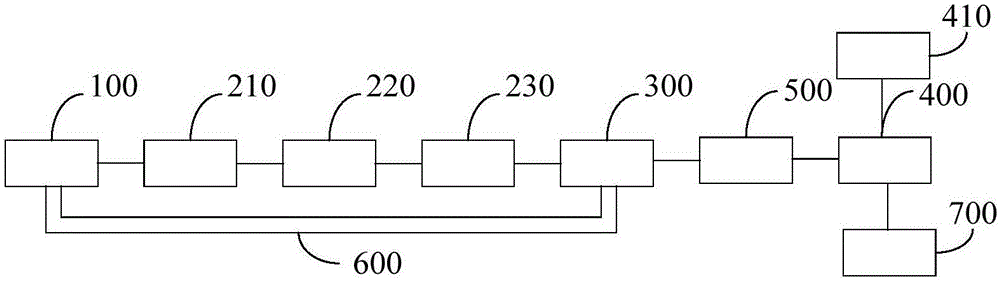

A power generation system and pyrolysis technology, which is applied to circuits, fuel cells, electrical components, etc., can solve the problems of reducing pollutant emissions, pollutant emissions, and the need for improvement of pyrolysis gas power generation systems, so as to reduce pollutant emissions and reduce environmental pollution. The effect of strong adaptability, superior environmental protection and economic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

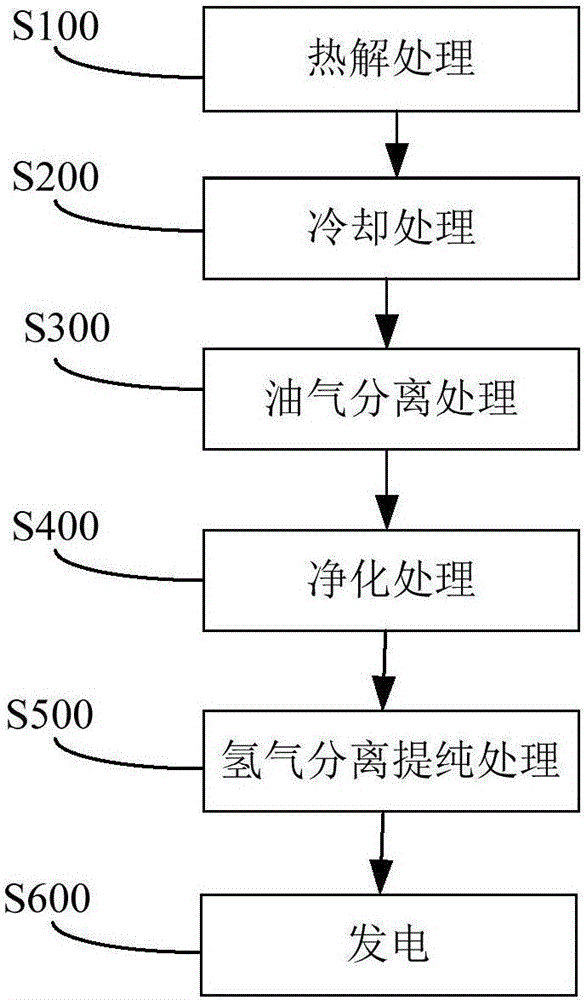

[0091] Utilize the garbage pyrolysis power generation system of the embodiment of the present invention to generate electricity with domestic garbage as raw material, the specific method is as follows Figure 4 As shown, the process is as follows:

[0092] (1) The continuous garbage pyrolysis furnace is used to process domestic garbage, the pyrolysis temperature is 800°C, the pyrolysis time is 2 hours, and the pyrolysis gas output is 4.4×10 3 N m 3 / h.

[0093] (2) The pyrolysis gas generated by the pyrolysis furnace enters the pyrolysis gas cooling tower through a short-distance pipeline for rapid cooling to obtain a high-temperature oil-water mixture and cooled pyrolysis gas. The cooling tower is equipped with a circulating cooling water pump, and the circulating cooling water volume is 800m 3 / h, the pyrolysis gas temperature drops below 80°C. After the circulating cooling water pump transports the low-temperature cooling water at 20°C to the pyrolysis gas cooling tower,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com