A kind of preparation method and application of banana fiber chitosan composite hydrogel

A technology of composite hydrogel and banana fiber, which is applied in the directions of gel preparation, chemical instruments and methods, water pollutants, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

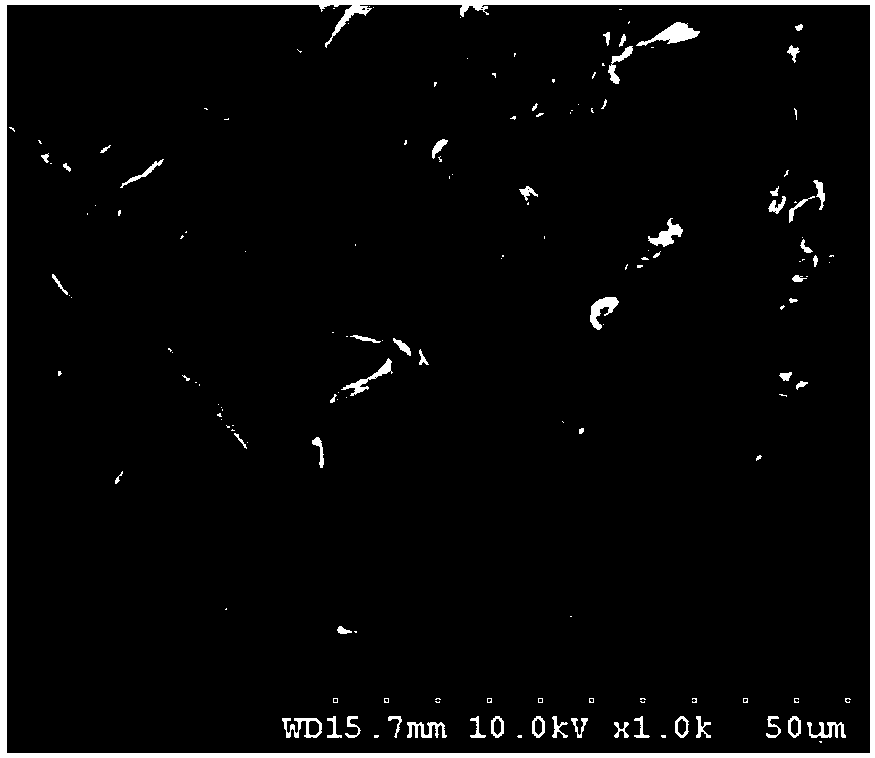

Image

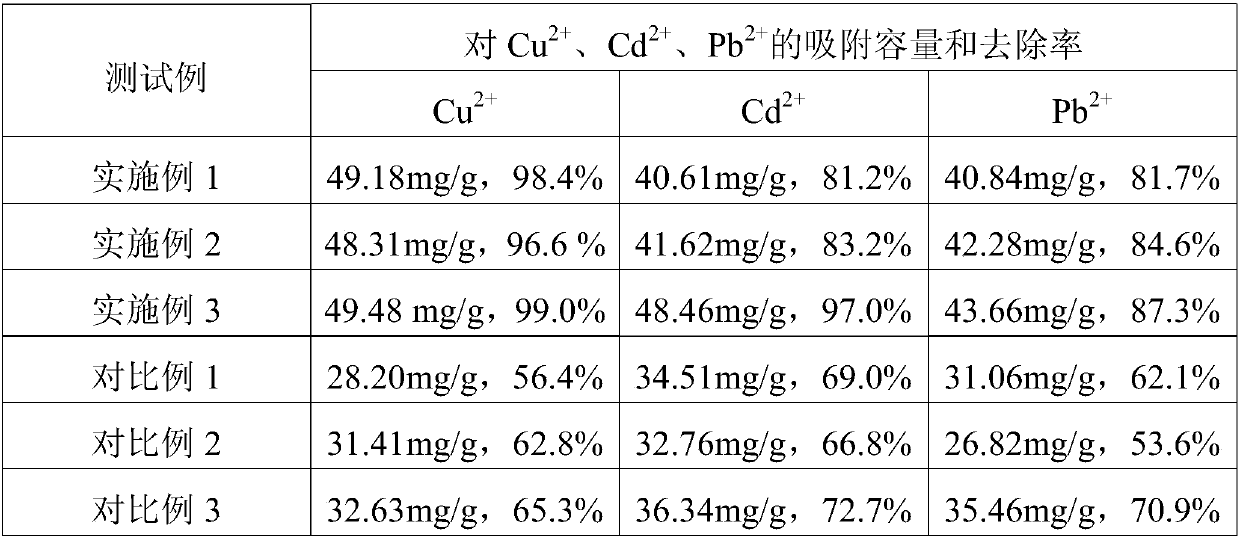

Examples

Embodiment 1

[0025] A preparation method of banana fiber chitosan composite hydrogel, comprising the following steps:

[0026] S1. Purification of banana fiber: after cutting the banana fiber, pickling, secondary alkali boiling, and water washing are carried out to obtain banana cellulose;

[0027] Described pickling is by the sulfuric acid of 1.5g / L, soaks the cut banana fiber at 20 ℃ for 60min, and adds a small amount of penetrating agent JFC (fatty alcohol polyoxyethylene ether), and the banana fiber after pickling is rinsed with deionized water To neutrality; the first time alkali boiling condition of described secondary alkali boiling: in 8%NaOH, 2%Na 2 SiO 3 and 2% Na 2 SO 3 Scouring in the mixed solution for 180min; the second alkali boiling condition: in 2% NaOH, 2% Na 2 CO 3 and 2%H 2 o 2 Scouring in the mixed solution for 120 minutes; the specific operation of the water washing: first wash with distilled water, then wash with 1% dilute sulfuric acid, and finally wash with ...

Embodiment 2

[0034] A preparation method of banana fiber chitosan composite hydrogel, comprising the following steps:

[0035] S1. Purification of banana fiber: after cutting the banana fiber, pickling, secondary alkali boiling, and water washing are carried out to obtain banana cellulose;

[0036]The pickling is 5.0g / L acetic acid, soaking the cut banana fiber at 60°C for 20min, and adding a small amount of penetrant JFC, and washing the pickled banana fiber with deionized water to neutrality; The first alkali boiling condition of soda cooking: in 18% NaOH, 5% Na 2 SiO 3 and 3% Na 2 SO 3 Scouring in the mixed solution for 90 minutes; in the second alkali boiling conditions: 8% NaOH, 5% Na 2 CO 3 and 8%H 2 o 2 Scouring in the mixed solution for 60 minutes; the specific operation of the water washing: first wash with distilled water, then wash with 1% dilute sulfuric acid, and finally wash with distilled water until neutral;

[0037] S2. Banana cellulose dissolution: dissolve the ba...

Embodiment 3

[0043] A preparation method of banana fiber chitosan composite hydrogel, comprising the following steps:

[0044] S1. Purification of banana fiber: after cutting the banana fiber, pickling, secondary alkali boiling, and water washing are carried out to obtain banana cellulose;

[0045] The pickling is 3.0g / L acetic acid, soaking the cut banana fiber for 40min at 40°C, and adding a small amount of penetrant JFC, and washing the pickled banana fiber with deionized water to neutrality; Soda cooking conditions for the first time: in 13% NaOH, 4% Na 2 SiO 3 and 2% Na 2 SO 3 Scouring in the mixed solution for 135min; the second alkali boiling condition: in 5% NaOH, 4% Na 2 CO 3 and 6%H 2 o 2 Scouring in the mixed solution for 90 minutes; the specific operation of the water washing: first wash with distilled water, then wash with 1% dilute sulfuric acid, and finally wash with distilled water until neutral;

[0046] S2. Banana cellulose dissolution: dissolve the banana cellulo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com