Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Accurate gear shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

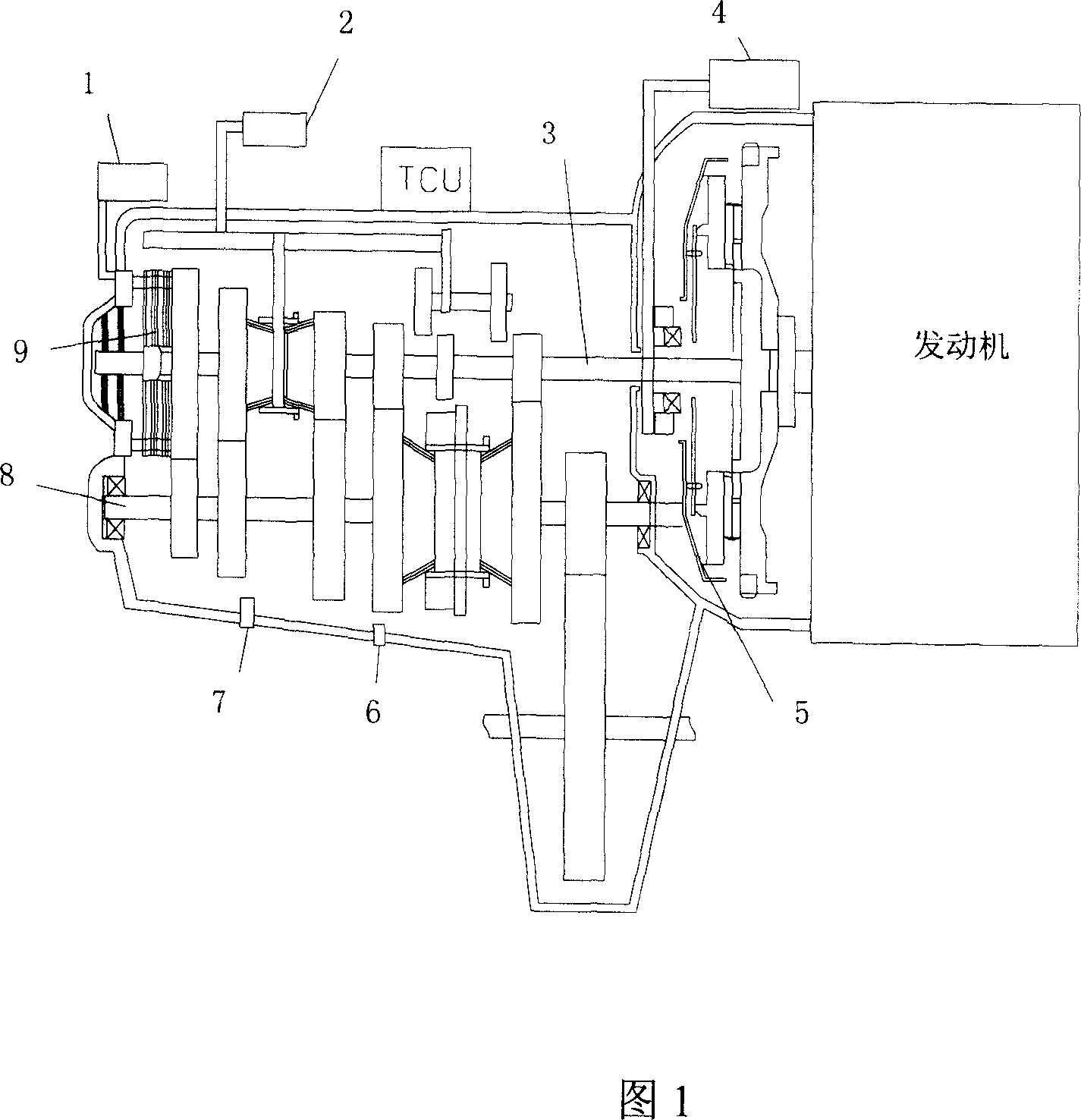

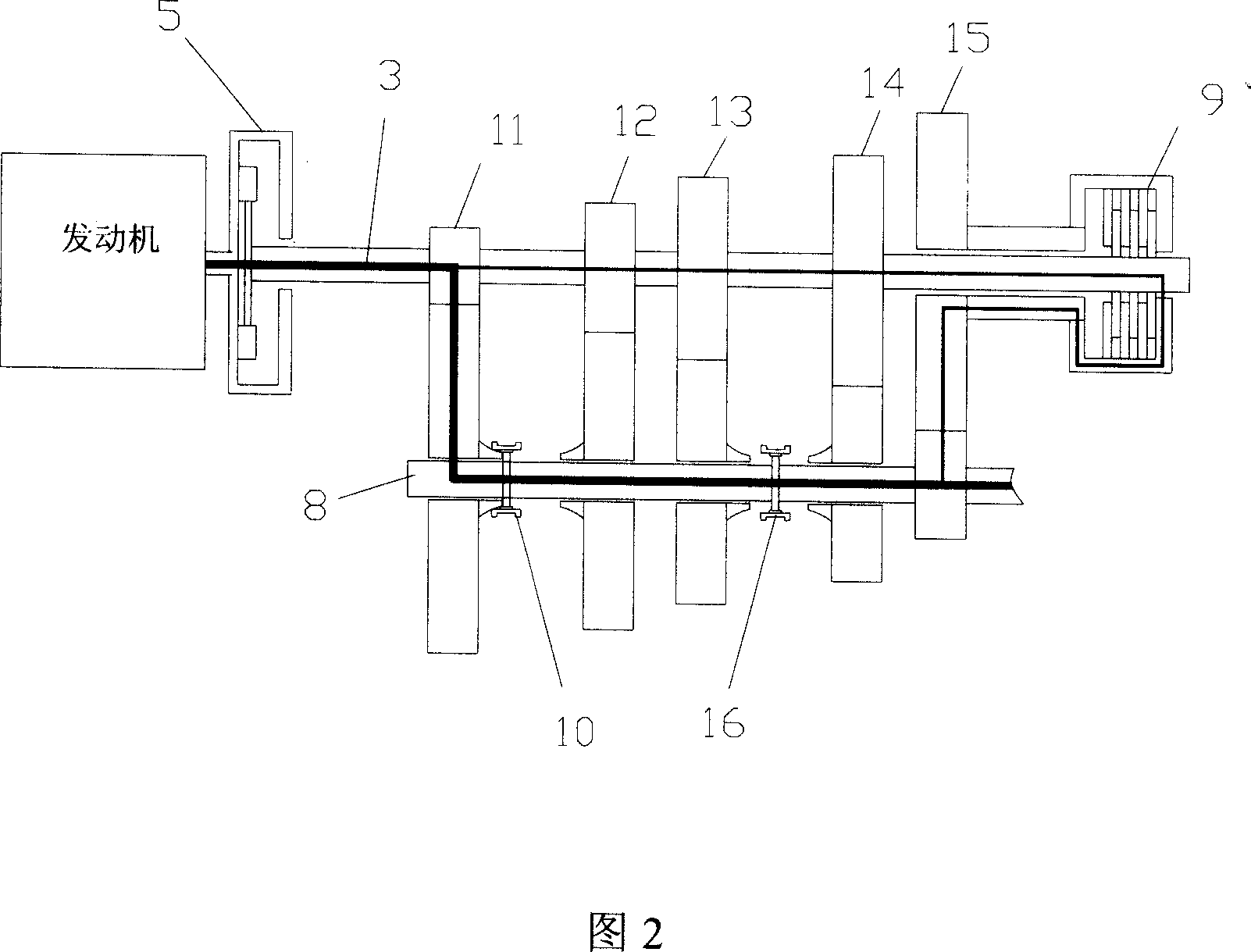

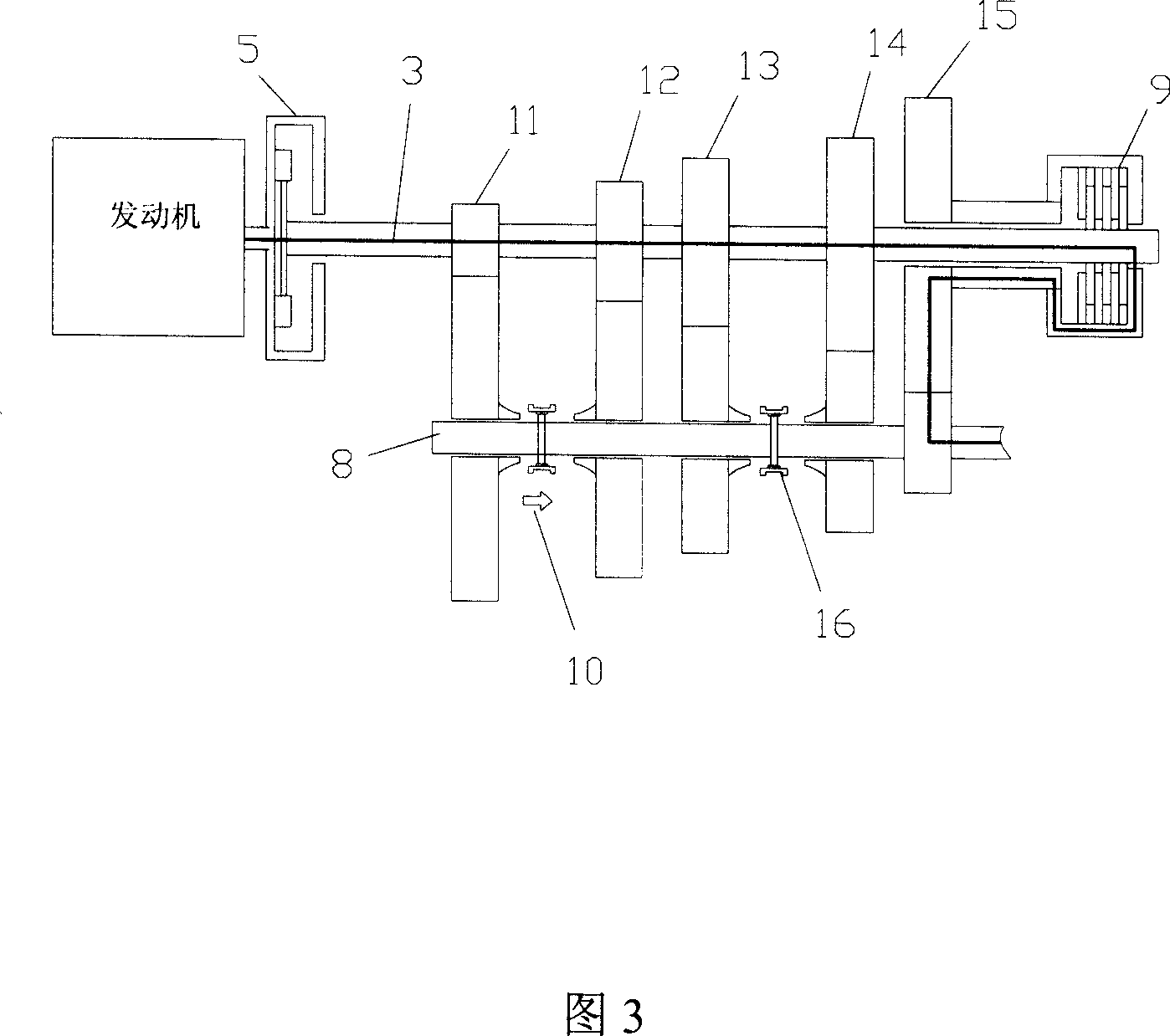

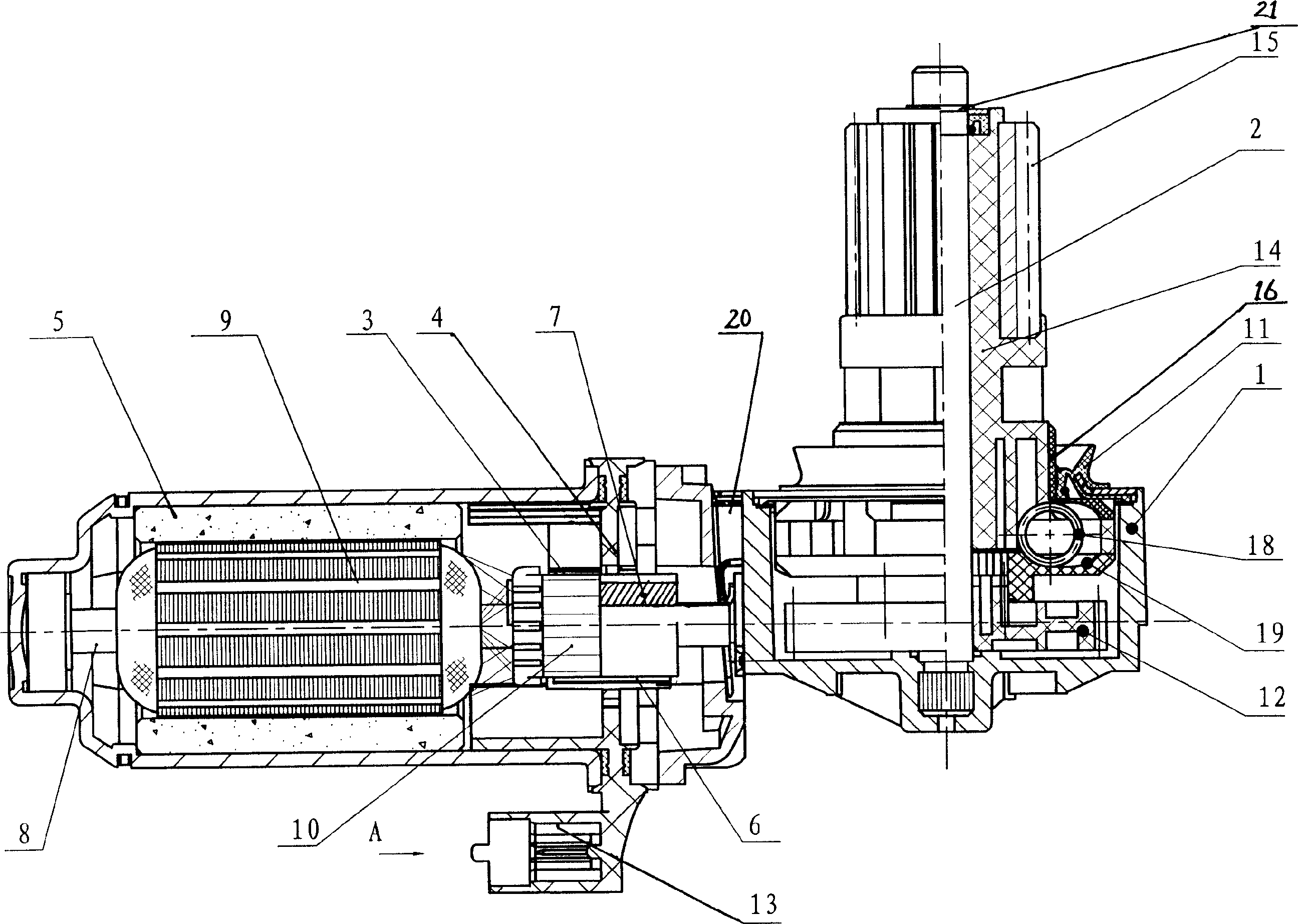

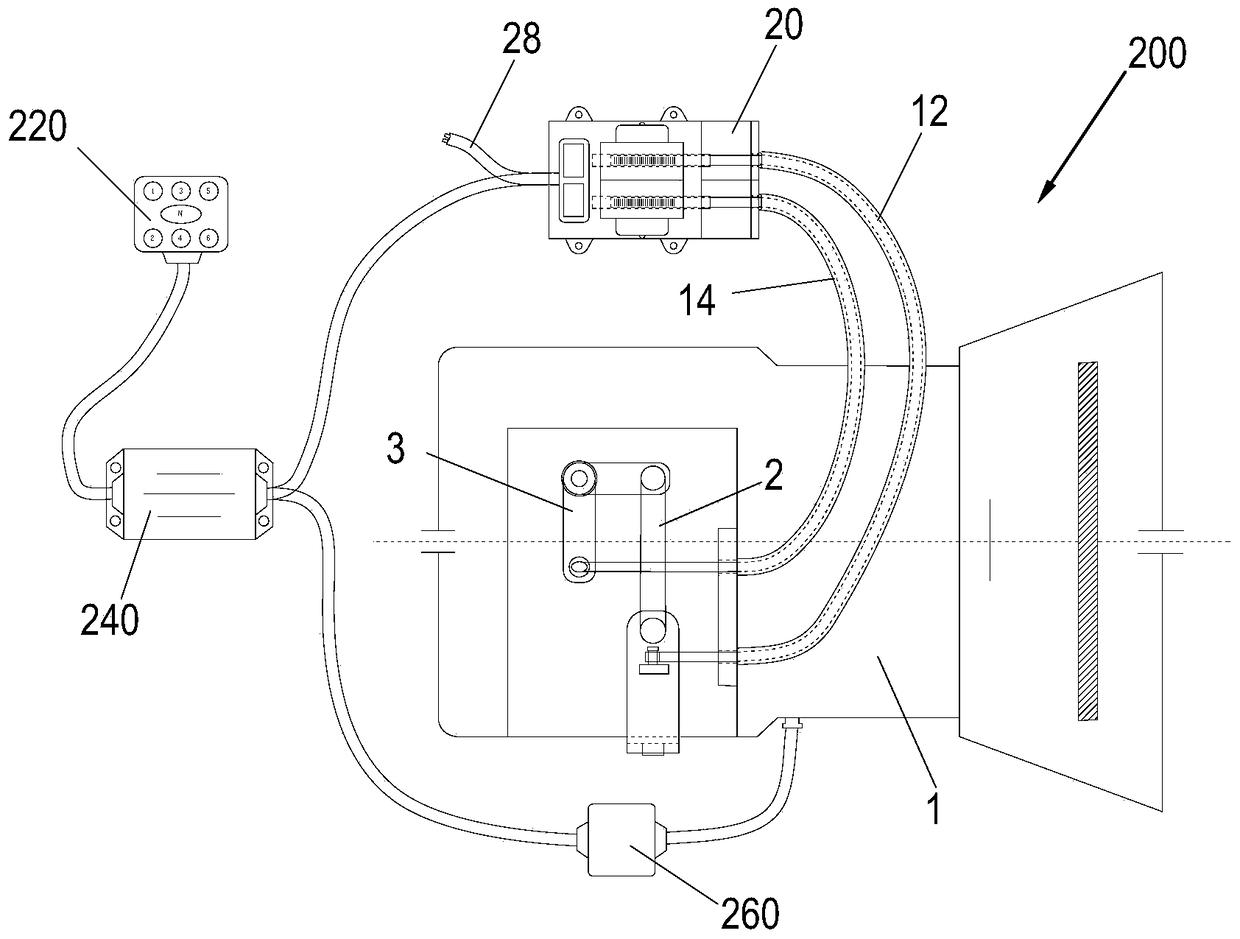

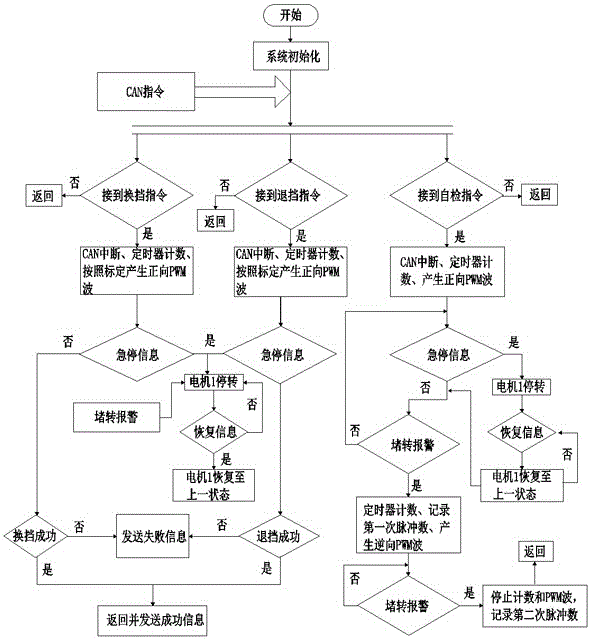

Electric control gear of automobile manual operation and automation integrated automatic speed transmission and control method thereof

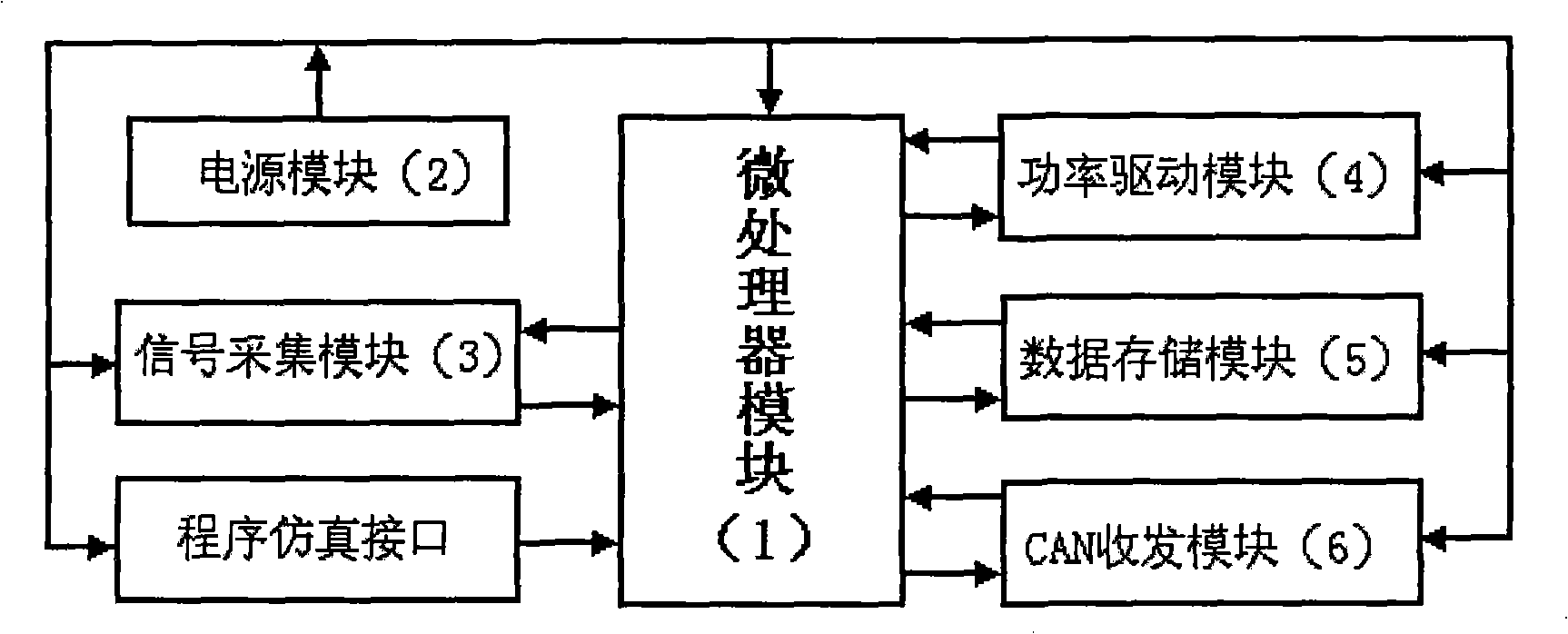

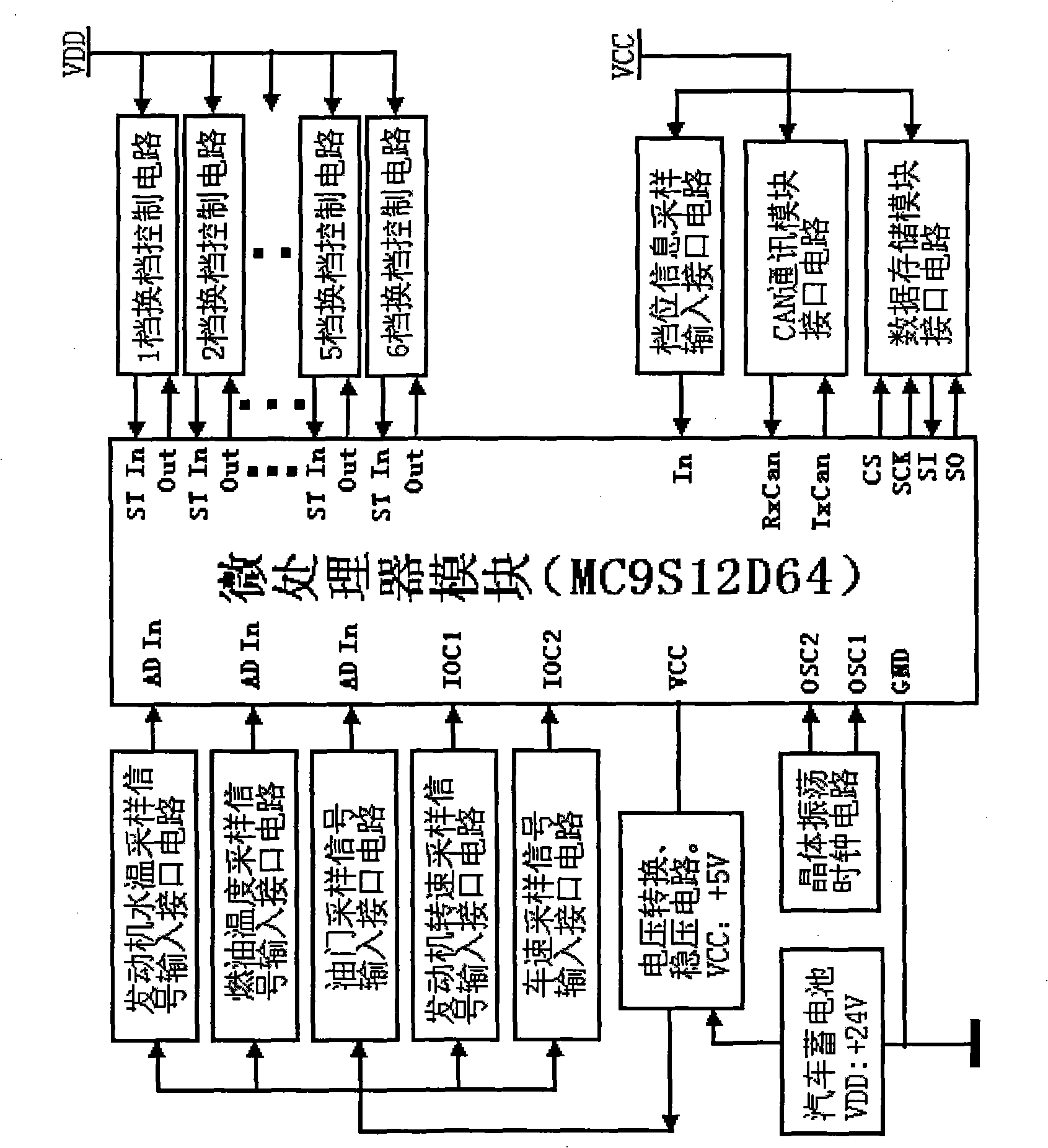

InactiveCN101353017AStable jobWork reliablyGearing controlControl devicesAutomatic transmissionExternal data

The invention aims at solving a technical problem of providing an electronic control device and a realization method of an automatic automobile transmission of manual automatic integration. The electronic control device of the automatic automobile transmission of manual automatic integration comprises a microprocessor module, a power supply module, a signal collection module, a power drive module, a data storage module and a CAN transceiver module. The invention designs various stable and reliable signal collecting and processing circuits, adopts an optimal control method, designs the function of fault self-diagnosis and causes the controller to be characterized by fast and accurate gear shifting, stable and reliable work, etc. At the same time, an external data storage module and the CAN transceiver module are added, which causes the design to have good scalability. Based on the existing hydraulic transmission automatic transmissions (AT), the electronic control device improves the efficiency of gear-shift operation and has the advantages of good production inheritance, low investment cost, high efficiency, easy manufacturing, convenient control, etc.

Owner:NANJING TACKING AUTOMOTIVE ELECTRONICS CO LTD

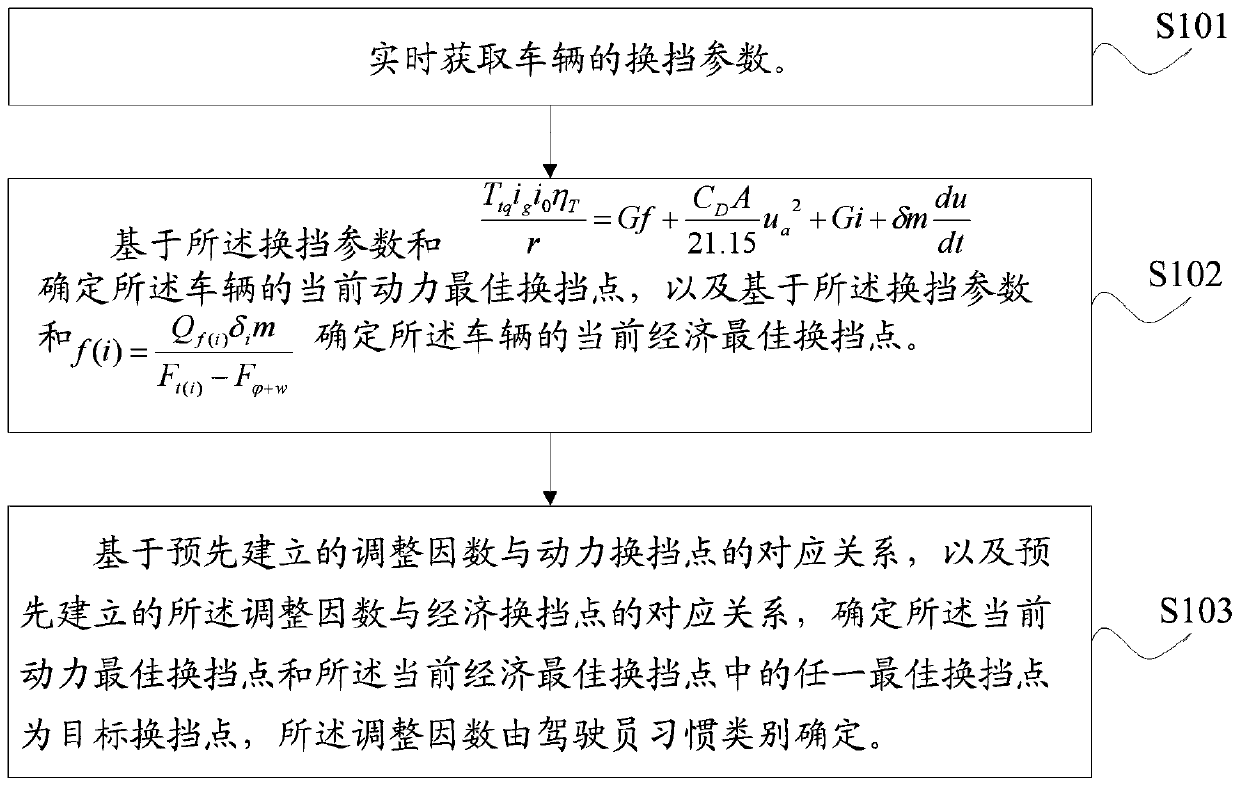

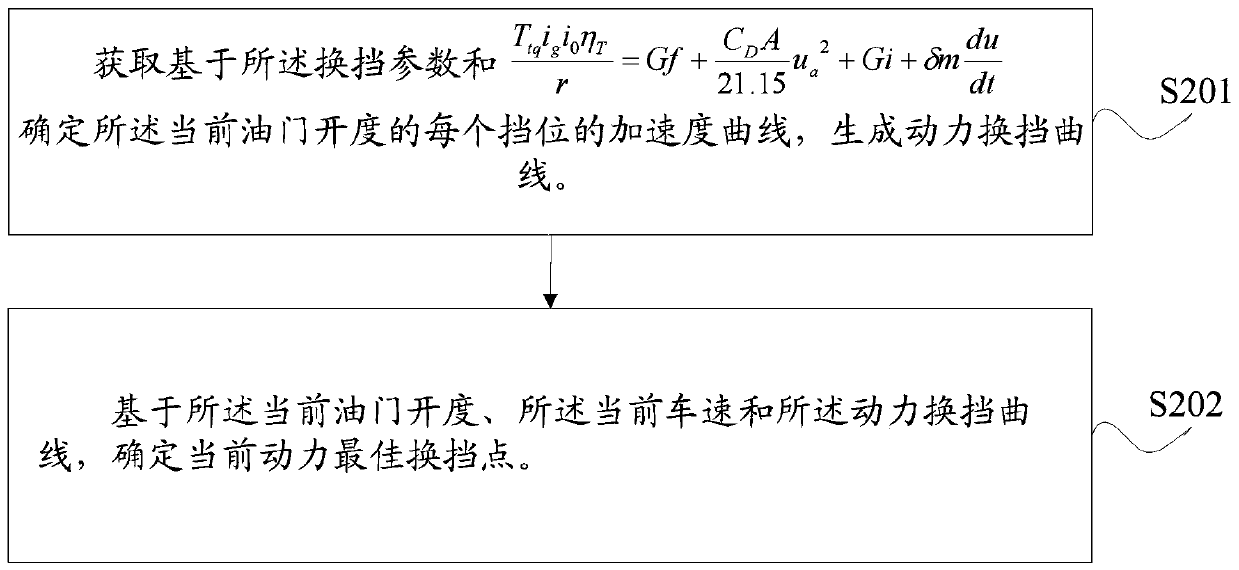

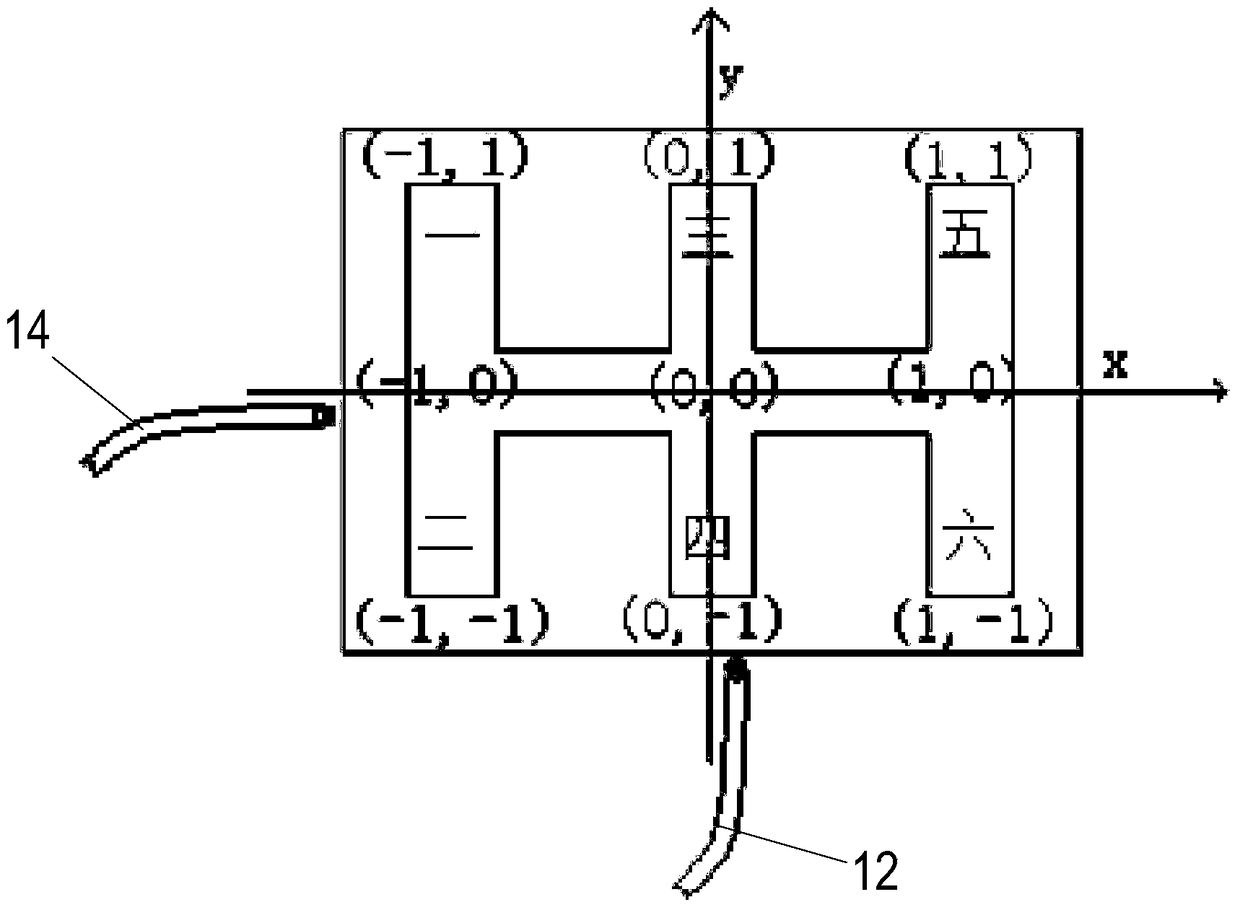

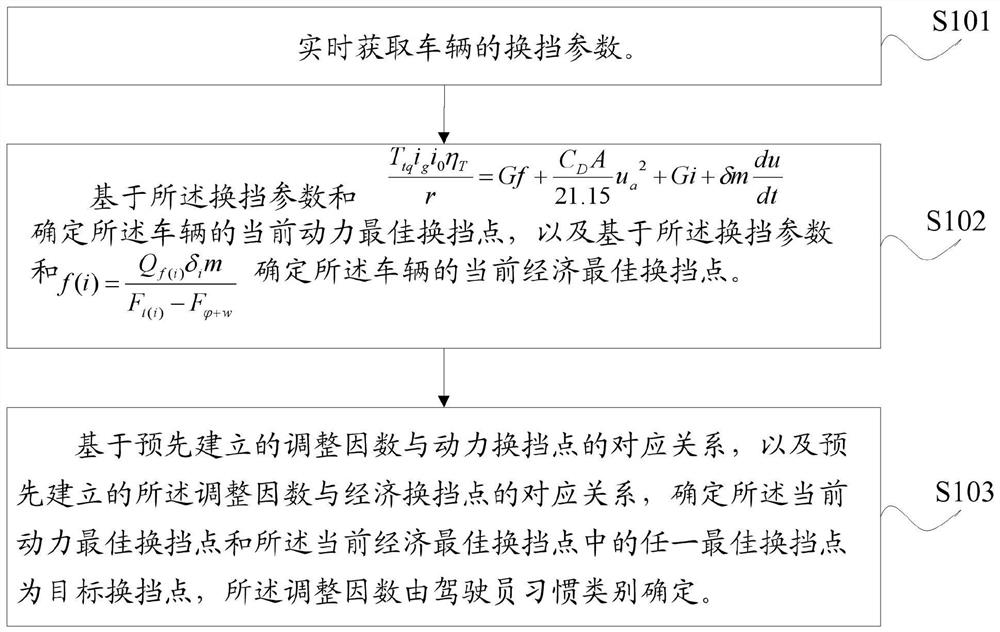

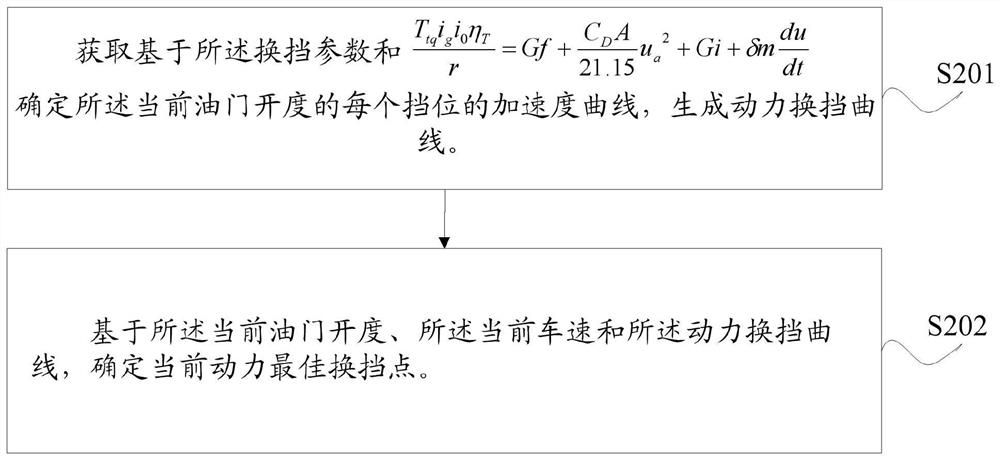

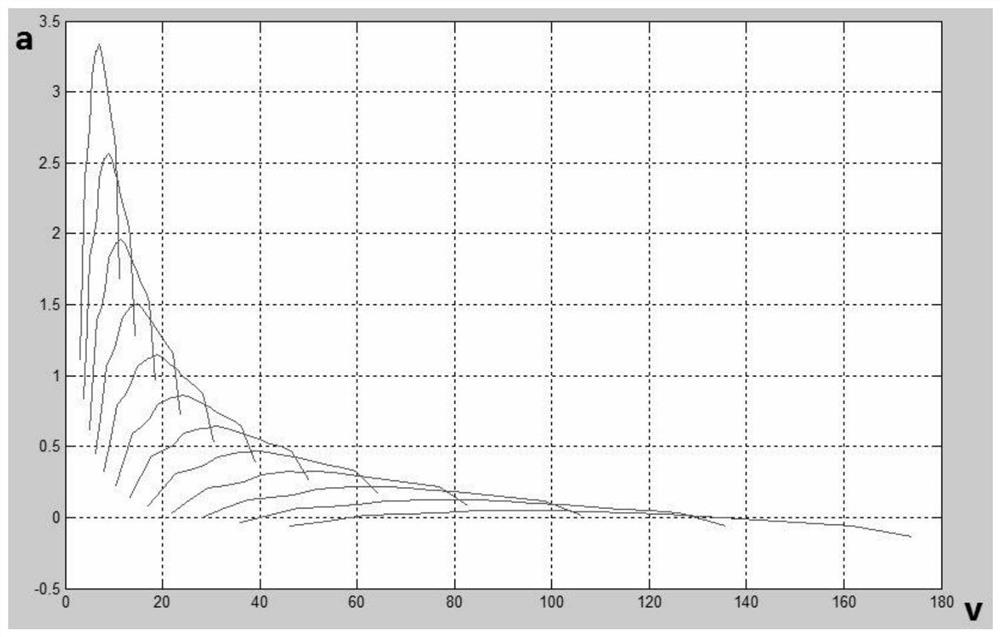

Target gear calculating method and device

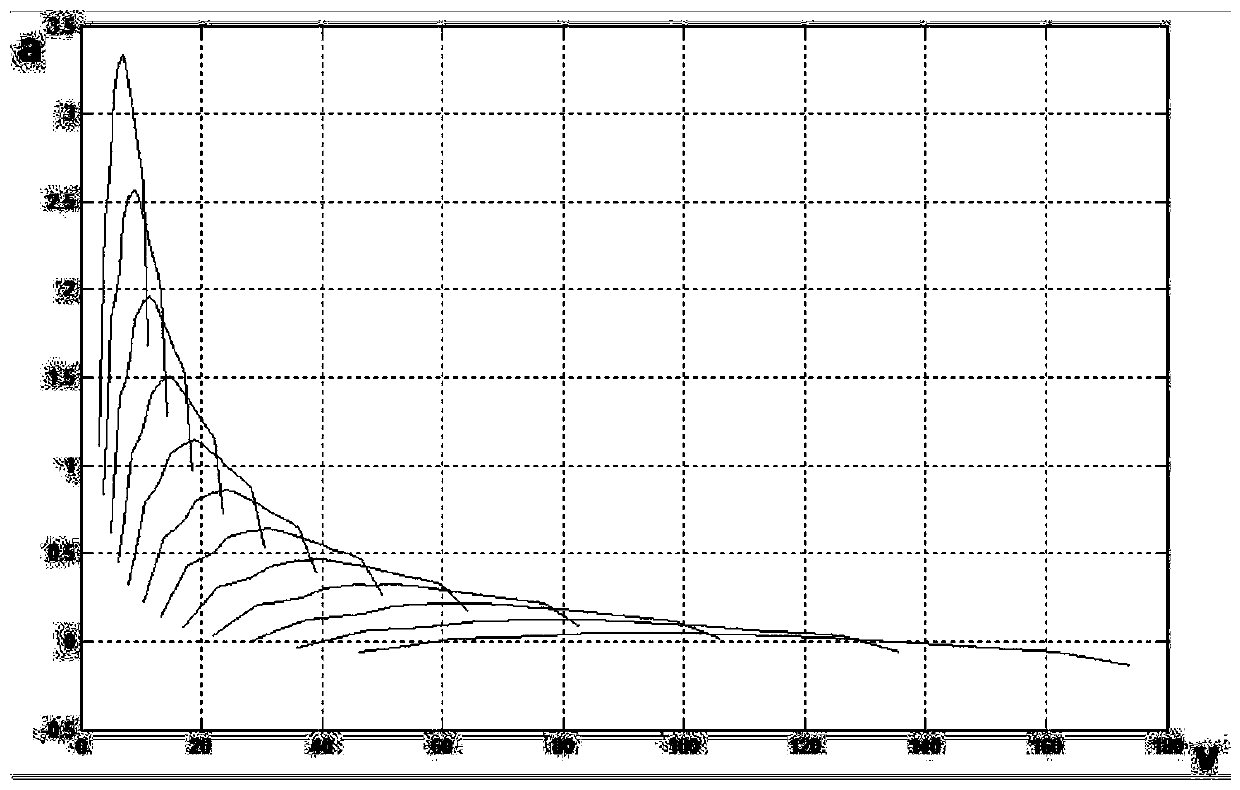

The invention provides a target gear calculating method and system. The target gear calculating method comprises the following steps: obtaining the gearshifting parameter of a vehicle in real time, determining the best gearshifting point of the current power of the vehicle based on the gearshifting parameter and the acceleration curve of each gear, and determining the best gearshifting point of the current economy of the vehicle based on the gearshifting parameter and the fuel consumption curve of each gear; and based on the correspondence between the adjusting factor established in advance and a power gearshifting point and the correspondence between the adjusting factor and the economical gearshifting point of fuel, determining the best gearshifting point of the current power and regarding any best gearshifting point of the best gearshifting points of the current economy as the target gearshifting point. Through the target gear calculating method, the driving habit of a driver is obtained to determine the adjusting factor, and the gearshifting parameters under different working conditions are obtained in real time to realize precise gearshifting under different working conditions.

Owner:WEICHAI POWER CO LTD

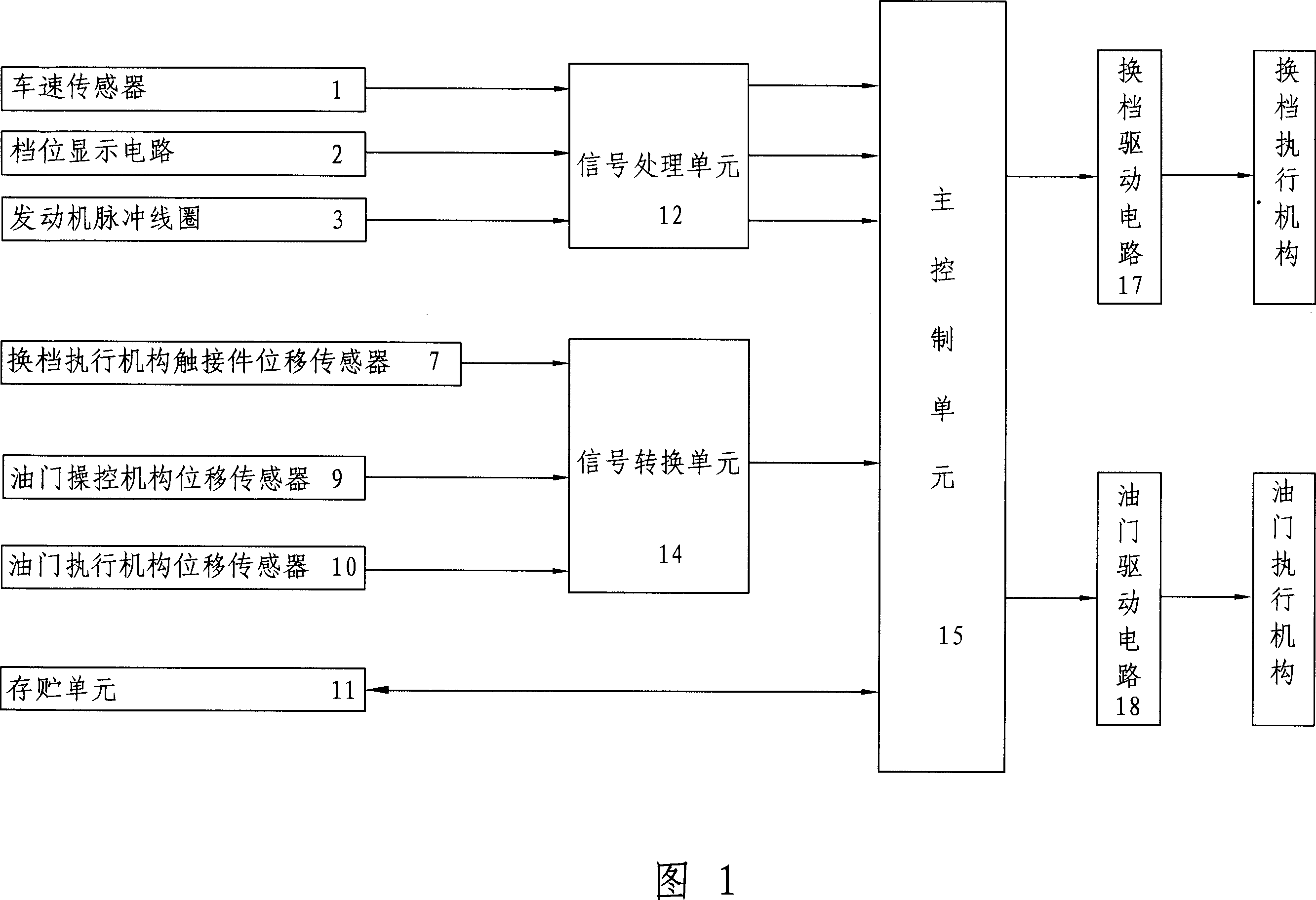

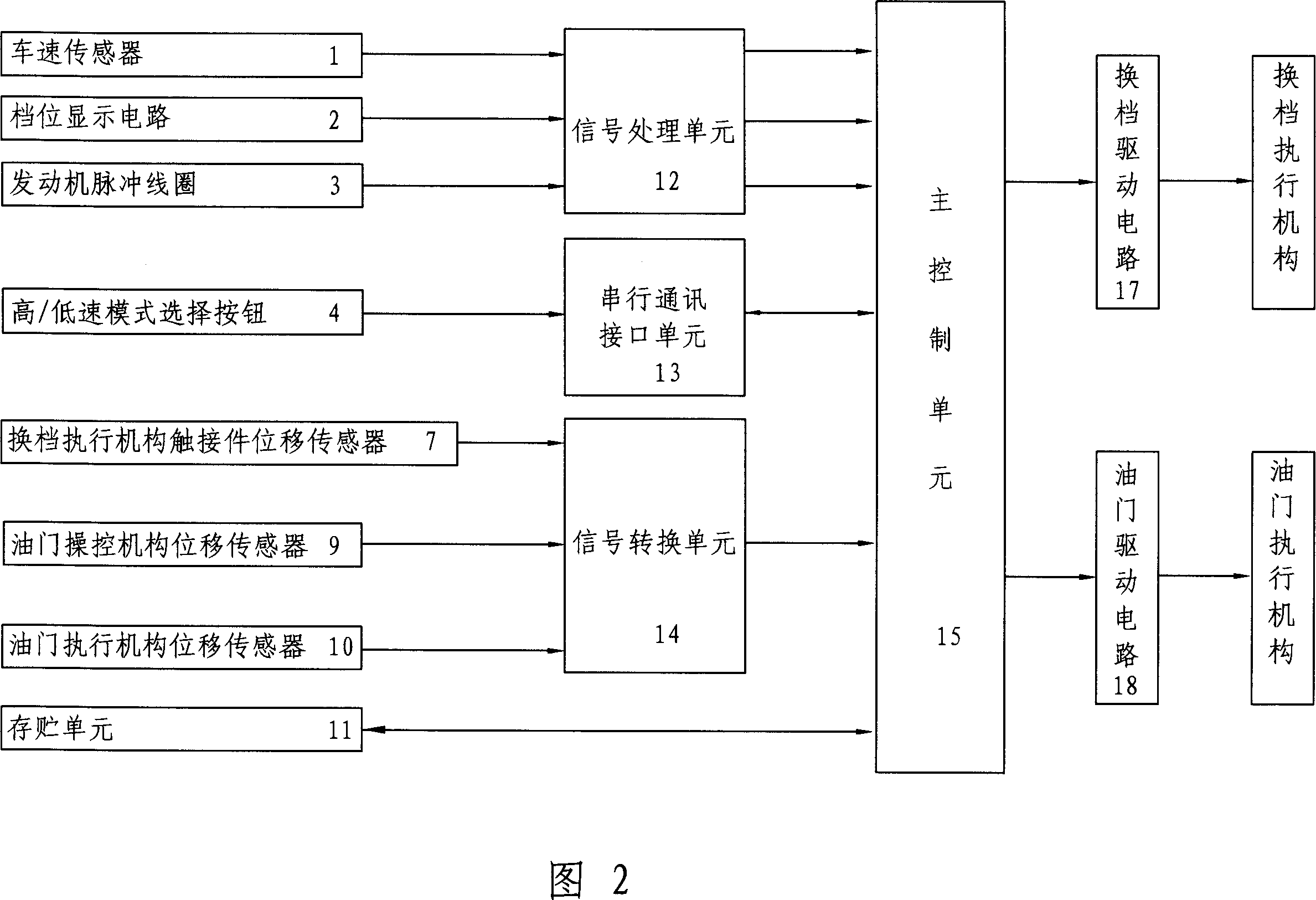

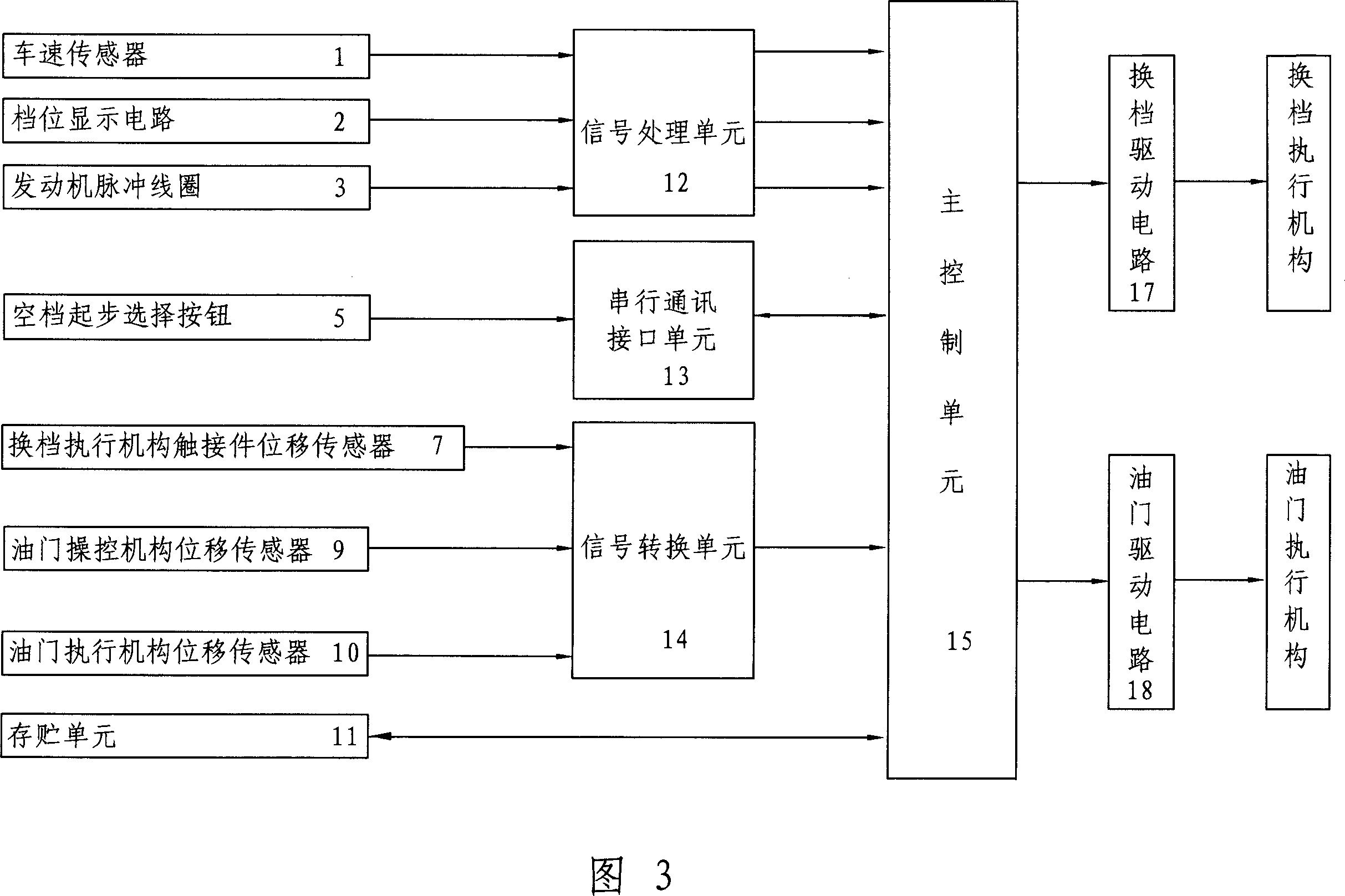

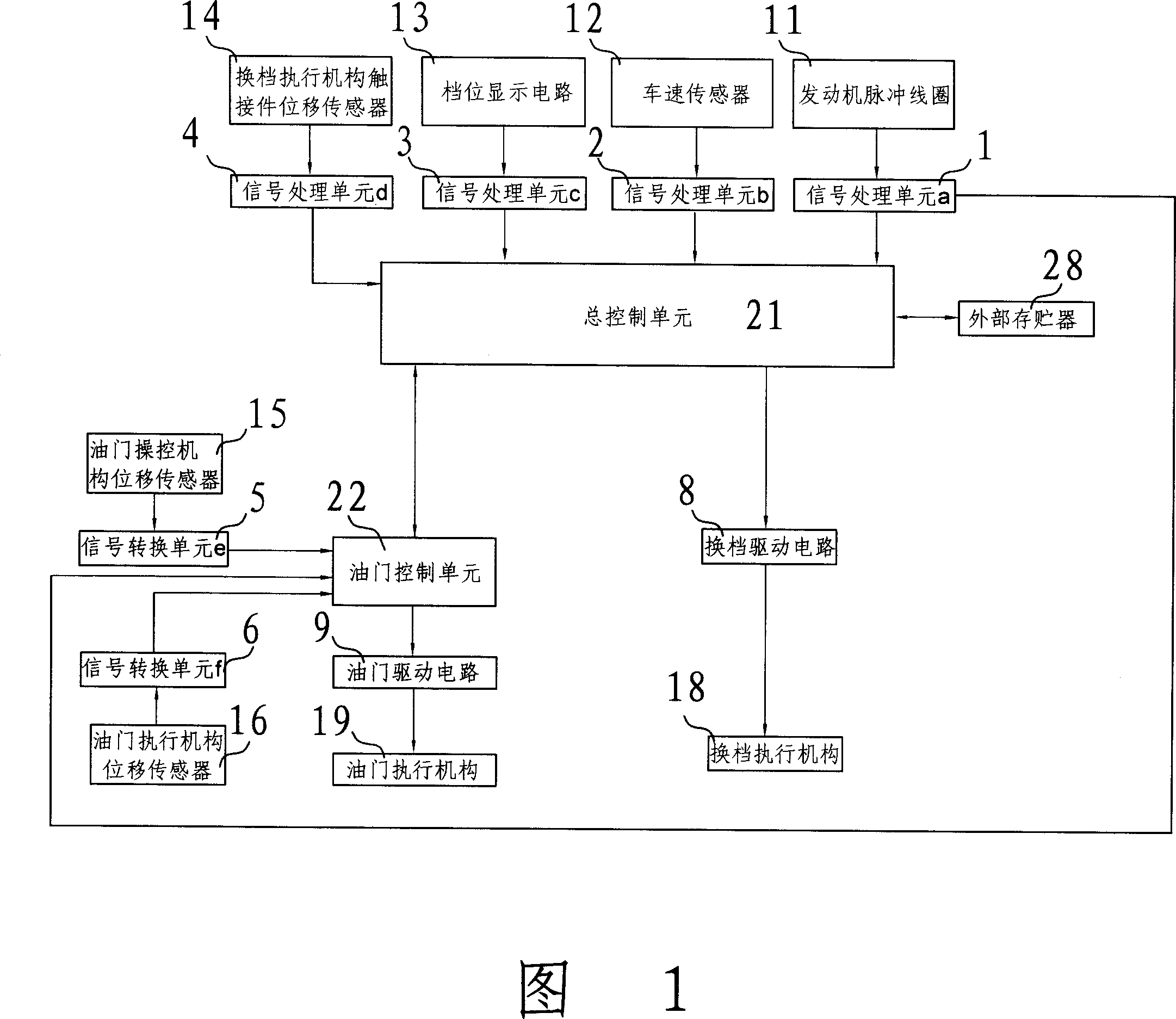

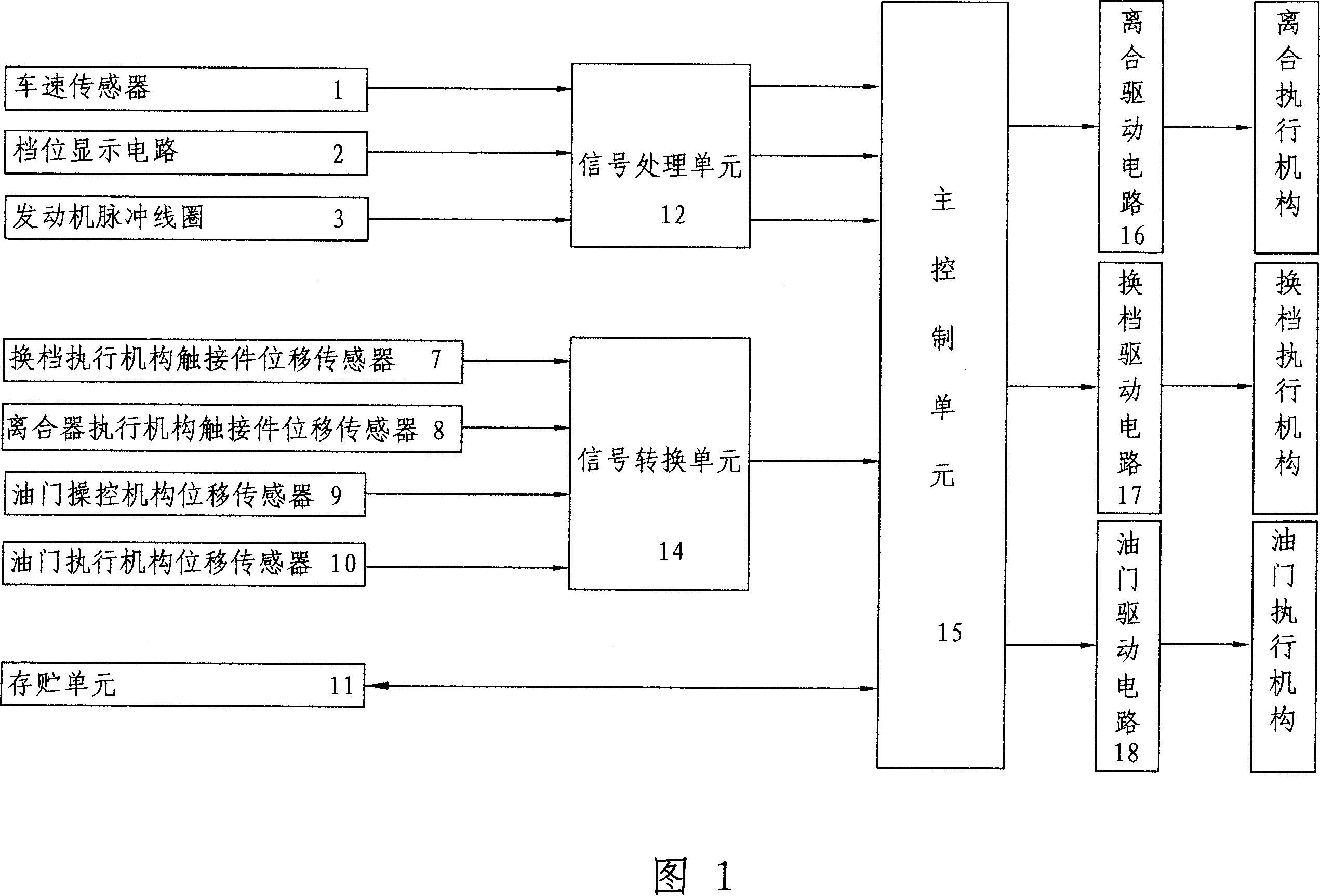

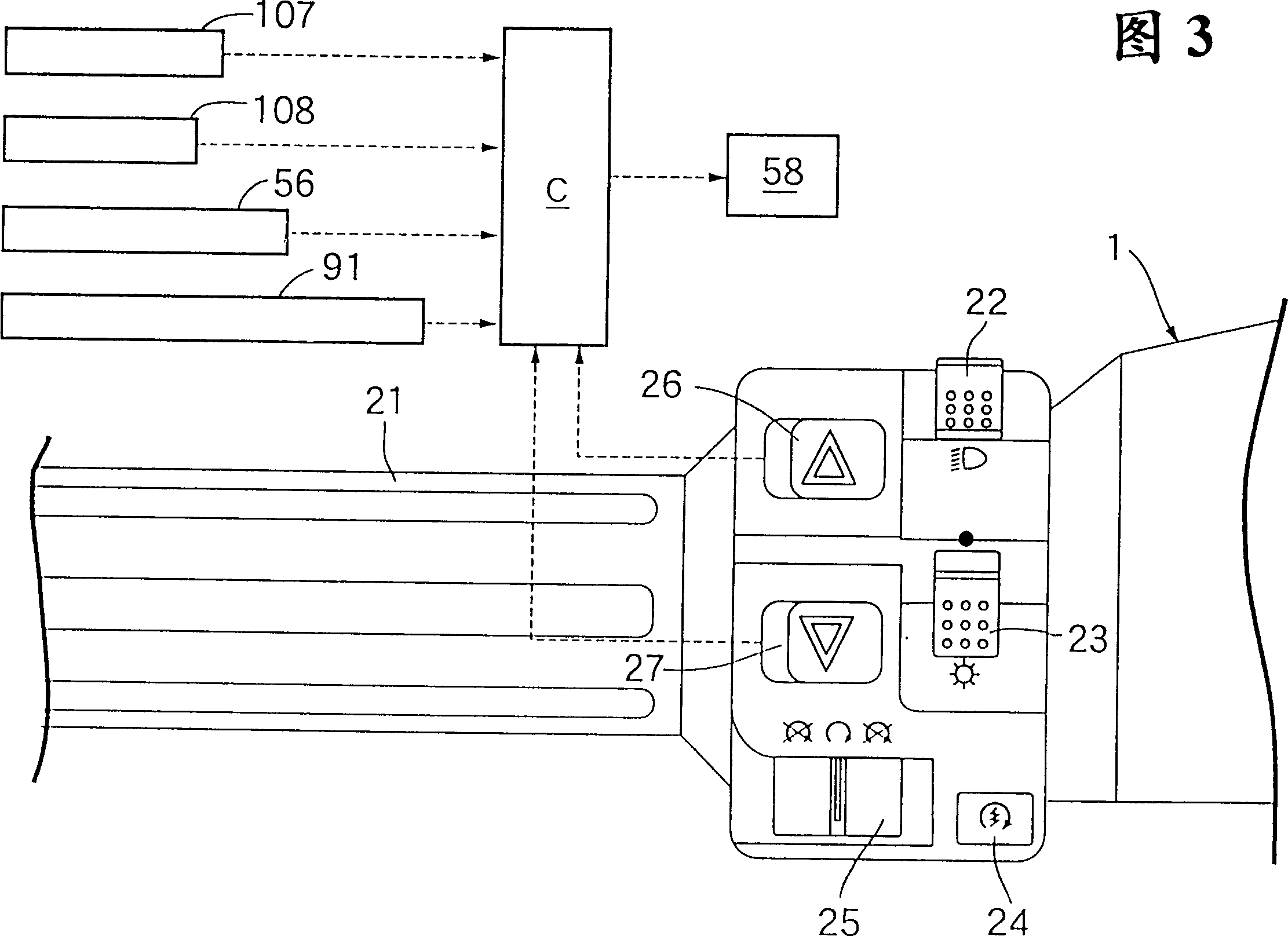

Intelligent control system of motorcycle, and control method

The present invention relates to a motorcycle intelligent control system. Said system is mainly composed of signal processing unit, signal conversion unit and main control unit. Said signal processing unit is connected with speed sensor, transmission display circuit and engine pulse coil; the signal conversion unit is connected with shifting actuator contact-connection component displacement sensor, accelerator control mechanism displacement sensor and accelerator actuating mechanism displacement sensor; the main control unit is connected with gearshift drive circuit and accelerator drive circuit, the gearshift drive circuit is connected with gearshift actuating mechanism and the accelerator drive circuit is connected with accelerator actuating mechanism. Said invention also provides a motorcycle intelligent control method. Said invention mainly is used in motorcycle using automatic clutch engine.

Owner:韩群山

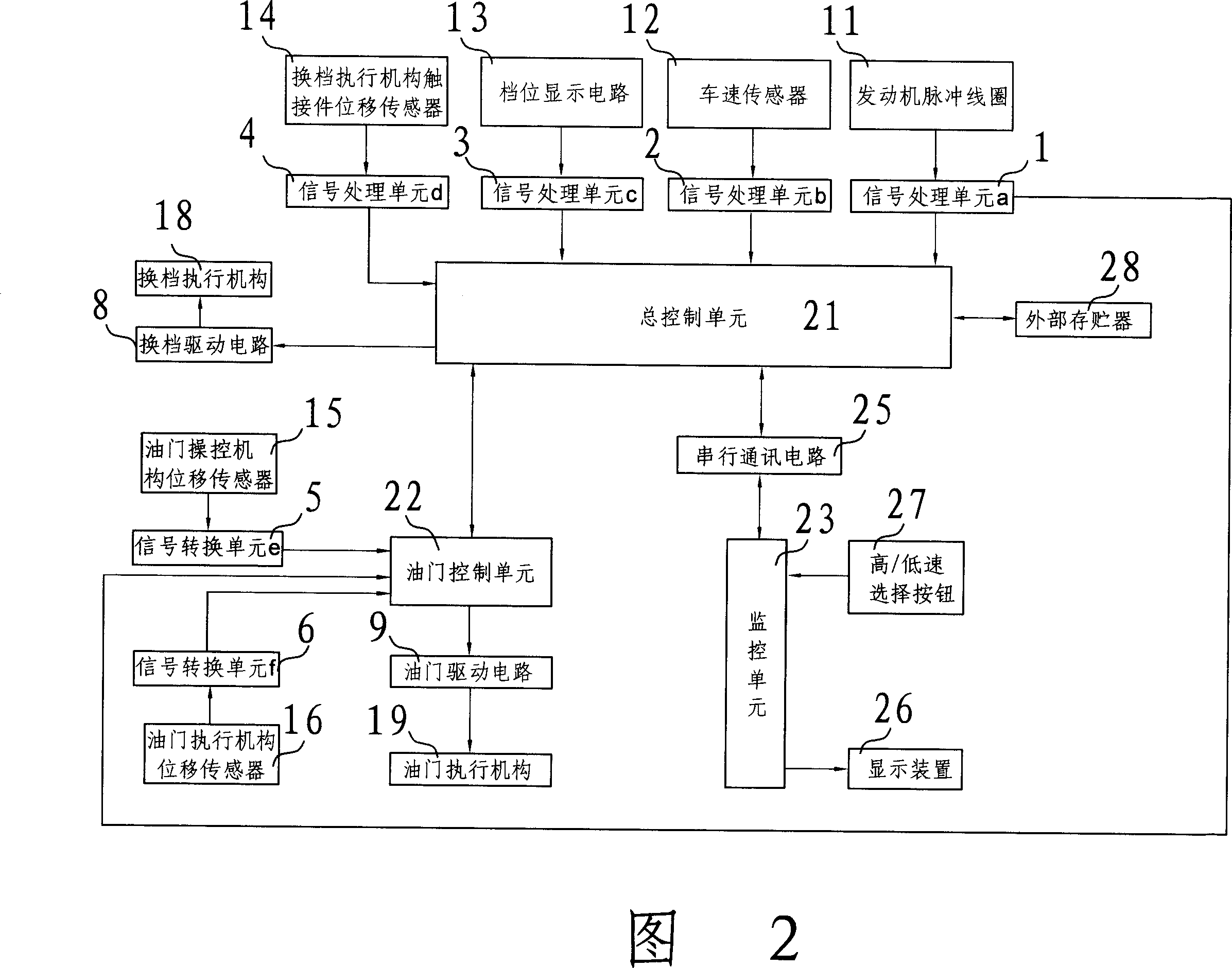

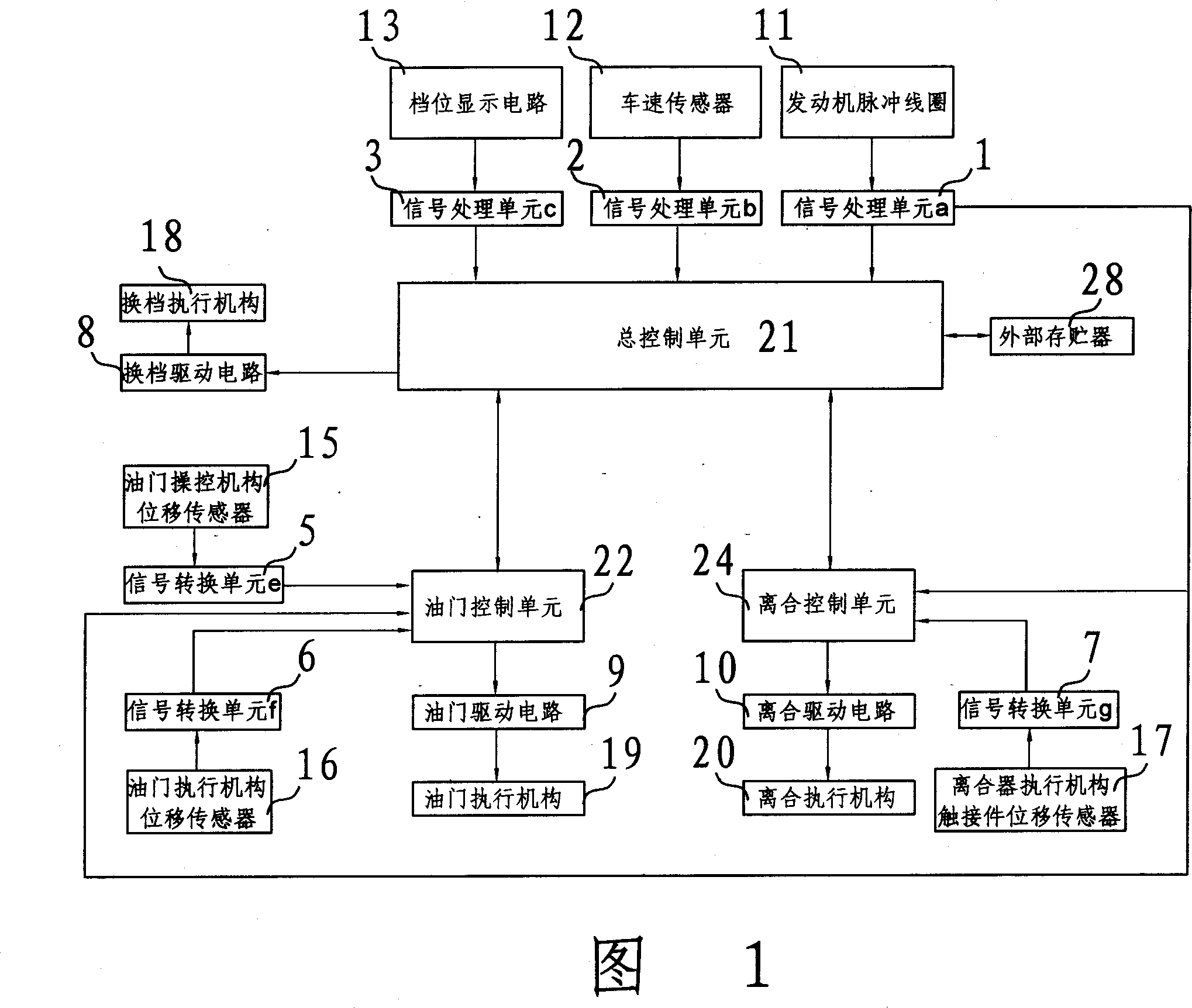

Motorcycle multiple CPU intelligence control system and control method thereof

The invention discloses a motorcycle multi-CPU intelligent control system of automatic on-off engine, comprising throttle intelligent control system constituted by throttle control unit cooperated by total control unit and motorcycle shifting intelligent control system accomplished by the throttle control unit, inspecting unit and the total control unit. The throttle intelligent control system is cooperated with the shifting intelligent control system. Under the cooperation of automatic clutch on motorcycle body multi-CPU control system with the complete process of flaming starting, running, stopping and flameout can be accomplished. The invention also provides a motorcycle multi-CPU intelligent control method. The invention makes motorcycle driving simple and convenient. The invention also solves the problem that after motorcycle starts or shifts up engine flameout is easy, it is not in time to shift up and fuel is wasted in variable speed so on.

Owner:韩群山

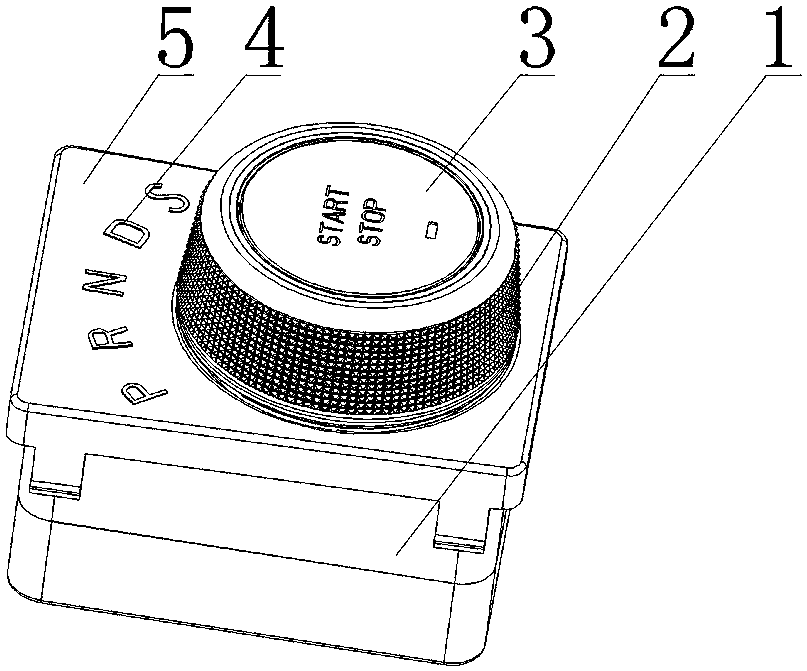

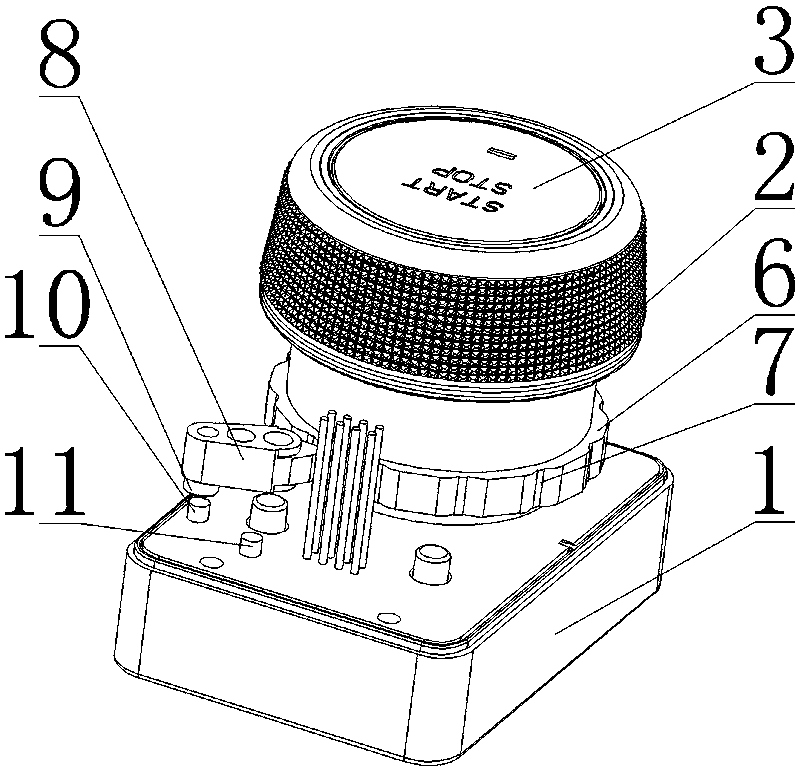

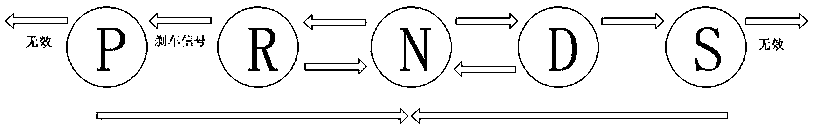

Knob type gear shifting switch of automobile

The invention discloses a knob type gear shifting switch of an automobile. The knob type gear shifting switch of the automobile comprises a housing, a knob and a gear seat, wherein the gear seat is fixed to the housing, and a gear mark is arranged on the gear seat; the knob is rotatably mounted on the gear seat. The knob type gear shifting switch of the automobile is characterized in that a rotating wheel is mounted on the knob; a plurality of arc-shaped grooves are uniformly formed in the periphery of the rotating wheel; an oscillating arm is arranged in the housing, and one end of the oscillating arm is in contact with the rotating wheel while the other end of the oscillating arm is equipped with a magnet; a hall sensor which is corresponding to the magnet is arranged in the housing, andthe hall sensor is connected to a single-chip microcomputer; a hall sensor triggering standing time determining module is arranged in the single-chip microcomputer; if the standing time of the knob is not less than the set time, the gear shifting operation is valid; if a gear is switched to the first gear or the top gear, the knob is rotated reversely, and the gear can be directly switched to a neutral gear. The knob type gear shifting switch of the automobile is outstanding in gear determining capacity, and accurate to shift the gears, and mis-operation can be effectively prevented; the knobtype gear shifting switch of the automobile is convenient to use, and high in safety; and the service life can be effectively prolonged.

Owner:RUIAN HEROWIN AUTOMOBILE PARTS

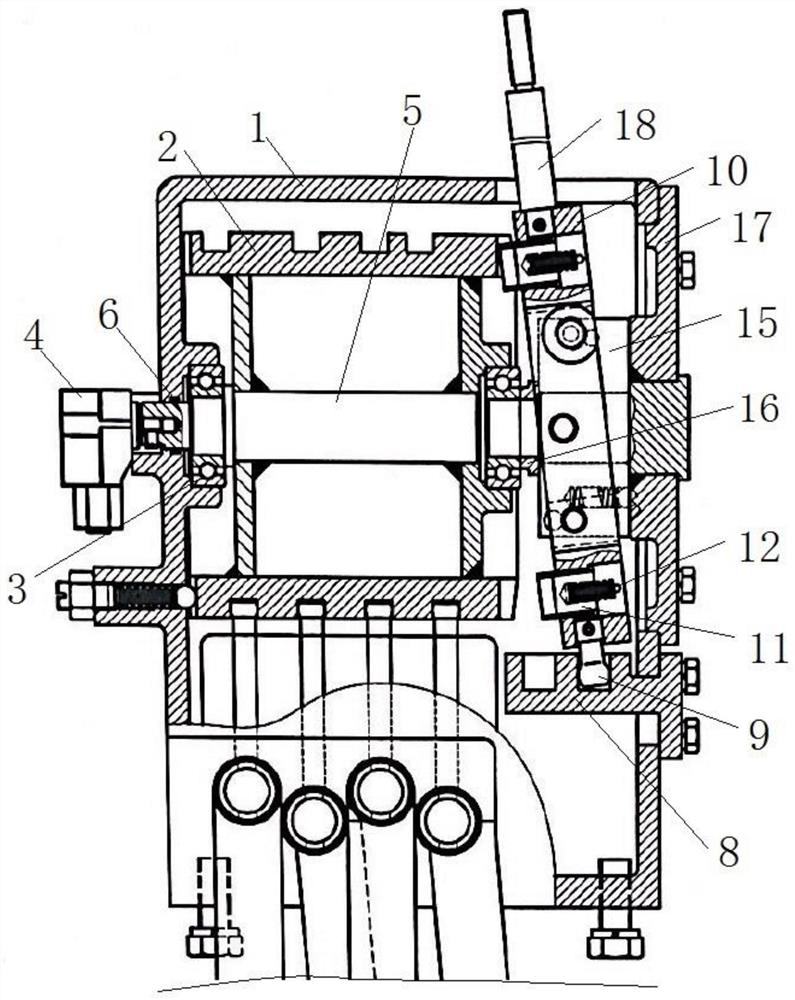

Speed changing box of motor-driven gear shifting mechanism

InactiveCN104315140AStable outputAvoid damageControlled membersGearing controlMotor driveRoller screw

The invention relates to a speed changing box technology, in particular to a speed changing box of a motor-driven gear shifting mechanism. The speed changing box comprises a gear shifting motor, a ball screw, a shifting block, a gear shifting fork and an execution mechanism, wherein the ball screw is connected with an output shaft of the gear shifting motor; an internal thread sleeve is arranged at the upper end of the shifting block and is in threaded connection with the ball screw; the gear shifting fork is fixedly arranged at the lower end of the shifting block and is connected with the execution mechanism. An air cylinder or an oil cylinder is replaced with a motor, so that the gear shifting force is steadily output, and gears are more accurately shifted; moreover, due to the fact that stress on the gear shifting fork is larger, the gear shifting fork is not directly connected with the ball screw to avoid the damage to the ball screw with the adoption of the design of a fork shaft and a guide block.

Owner:唐海滨

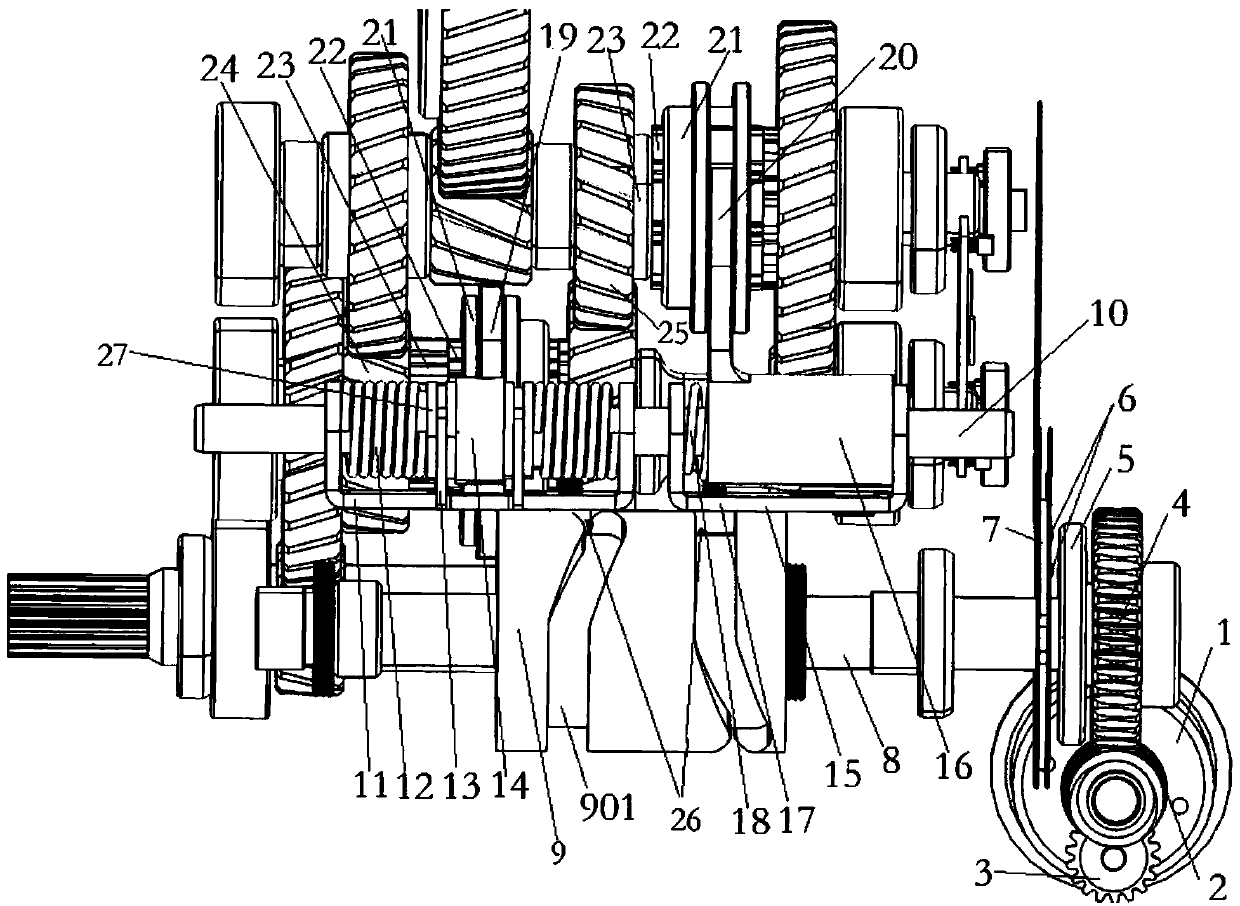

Three-gear double-clutch type automatic gearbox for pure electric bus

InactiveCN104763798AHigh torque transmissionReasonable speed ratio configurationGearboxesToothed gearingsElectric controlShift time

The invention discloses a three-gear double-clutch type automatic gearbox for a pure electric bus. The three-gear double-clutch type automatic gearbox comprises a double clutch and a three-gear transmission mechanism, wherein the odd clutch in the double clutch is connected with transmission chains of the first gear and the second gear of the gear mechanism, and while the even clutch is connected with the transmission chain of the second gear in the gear mechanism. The three-gear double-clutch type gearbox is large in transmission torque, reasonable in speed ratio configuration, accurate to shift under the electric control hydraulic and the control of a TCU, small in shifting time, high in transmission efficiency, and effectively suitable for the pure electric bus.

Owner:沃新动力系统(上海)有限公司 +1

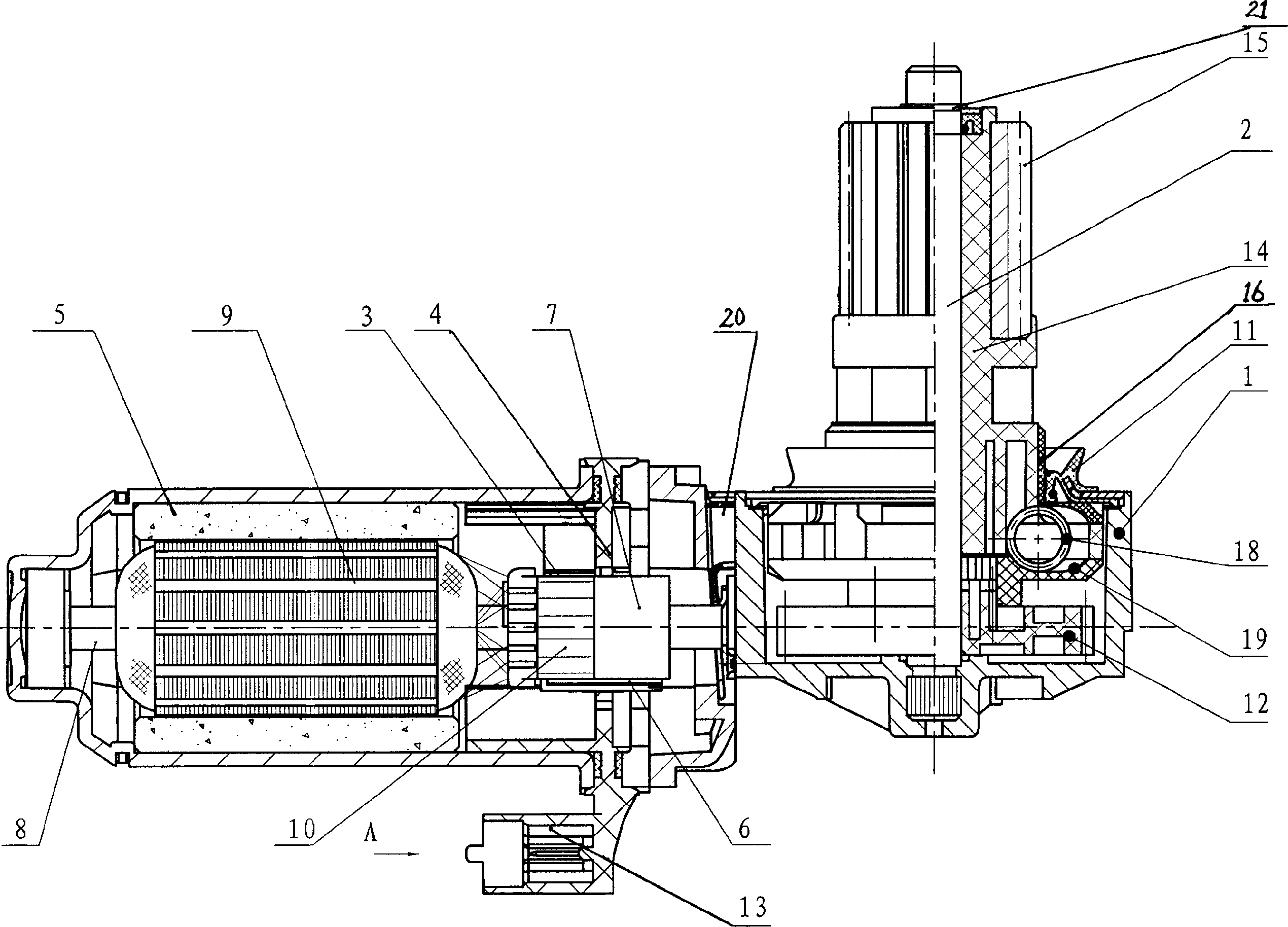

Motorcycle intelligence control system and its control method

InactiveCN101086294AMeet the requirements of relatively large power requirementsReduce wearGearing controlDriver circuitThrottle control

The invention discloses a motorcycle intelligent control system, it mainly consists of signal processing unit, signal conversion unit and main control unit, the signal processing unit is connected with speed sensor, transmission shift display circuit and motor pulse coil; the signal conversion unit is connected with the transmission shift processing device contact component displacement sensor, the lutch processing device contact component displacement sensor, the throttle control device displacement sensor and the throttle processing device displacement sensor; the, main control unit is connected with the clutch drive circuit, transmission shift drive circuit and throttle driver circuit, the clutch drive circuit is connected with the clutch processing device, the transmission shift drive circuit is connected with the transmission shift processing device, the throttle drive circuit is connected with the throttle processing device. The invention also provides a motorcycle intelligent control method, the invention makes the motorcycle driving more simple and easier, solves the problems of motor is easy to flameout, motorcycle pushing, transmission shift is not immediate and fuel waste caused by stepless speed transmission after motorcycle starts and speeds up in the prior motorcycle.

Owner:韩群山

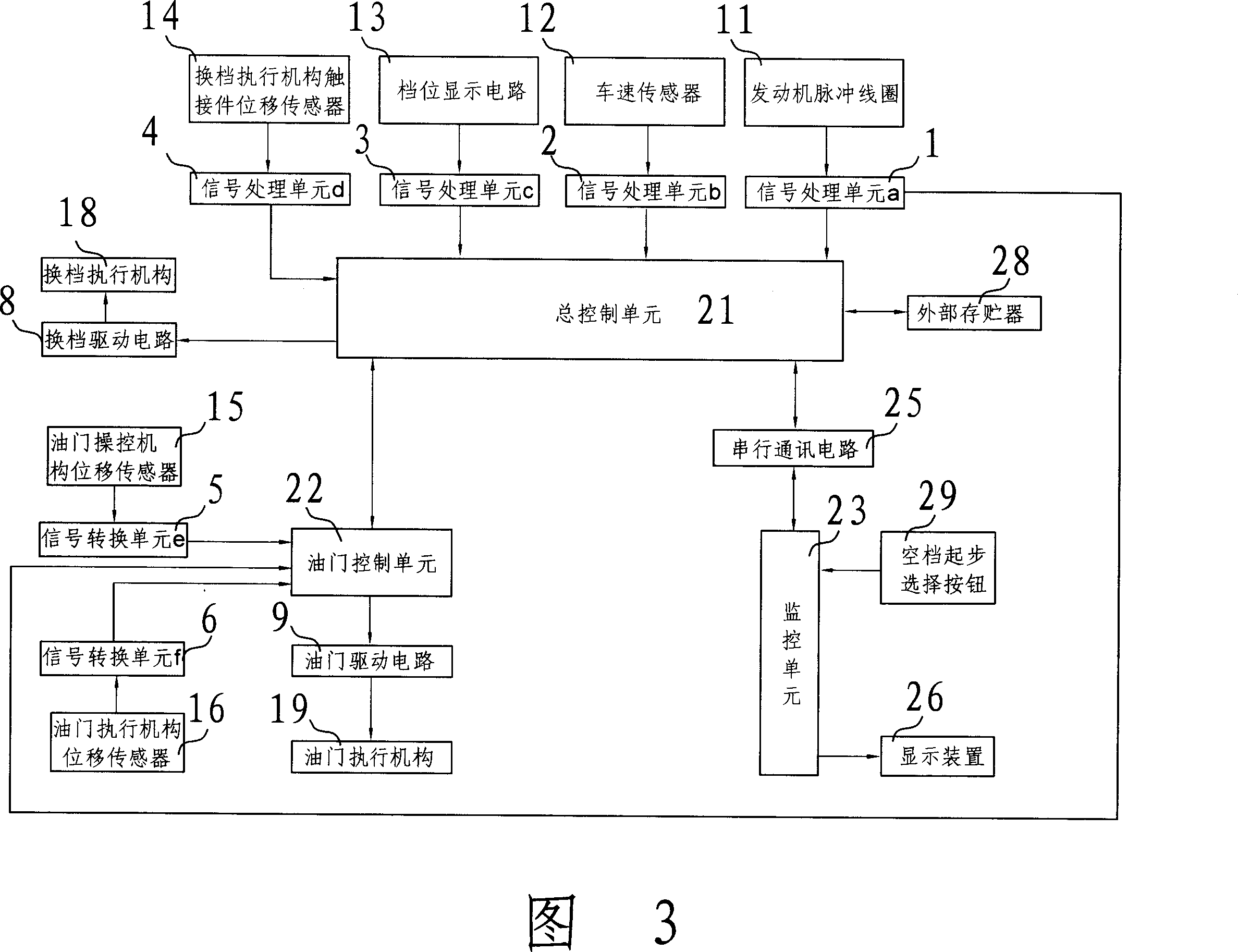

Intellective control system with multiple CPUs for motorcycle and control method

The invention discloses a motorcar multi-CPU intelligent control system that includes gun intelligent control system realized by main control unit matching gun control unit, clutch intelligent control system realized by main control unit matching clutch control unit, motorcar gear shifting intelligent control system realized by gun control unit, clutch control unit and monitoring control unit matching main control unit. The three systems realize the multi-CPU intelligent control system. The invention also discloses a motorcar multi-CPU intelligent control method. It makes the drive of motorcar be easy and convenient and solves problems like engine flameout when changing gear, oil wasting, etc.

Owner:韩群山

Shifting electric motor

InactiveCN1819413AReduce shockProtection securityMechanical energy handlingControl devicesReduction driveMotor shaft

On the brush rocker of the invention a Hall Sensor is mounted and on the motor shaft of rotator set corresponding to the location of Hall Sensor a magnetic ring is sheathed. The case of decelerator is permanently jointed with the gear shaft on which the buffer body is sheathed. On the out side of buffer a buffer gear is sheathed, and on the inner side of buffer a plastic jacket is sheathed. In the inner top portion of the buffer body there is a spring slot in which a buffer spring is mounted, and there is a capping plate gear jointing with the inner top portion of the buffer body and connected with drive gear in mesh. Due to the connection between buffer gear and driven member, and the buffer action of buffer spring, the impact given to the driven member is less. The Hall Sensor can accurately figures out rotation times of electric machine shaft, and is specially suite acceptable for gear shifting in car.

Owner:浙江瑞鹏汽车电器有限公司

Mechanical type automatic transmission

InactiveCN101078436AImprove powerImprove stabilityGearing controlClutch controlAutomatic transmission

The invention relates to an AMT transmission with assisted clutch, comprising manual gearbox, shift control mechanism, starting clutch and the control mechanism, speed sensor of inputting shaft, speed sensor of outputting shaft, shifting position sensor and control cell TCU. It is characterized in that assisted clutch and the control mechanism are set on the inputting shaft and the assisted clutch combines with high-shift gear. By the invention the problem that in shifting process the power of engine can not be transferred to wheels so that power is off is solved. There is no distinct deceleration in shifting and shifting comfort is improved. Good power property and shifting stability of vehicles are guaranteed while oil economy is improved and oil consumption in shifting is decreased.

Owner:BYD CO LTD

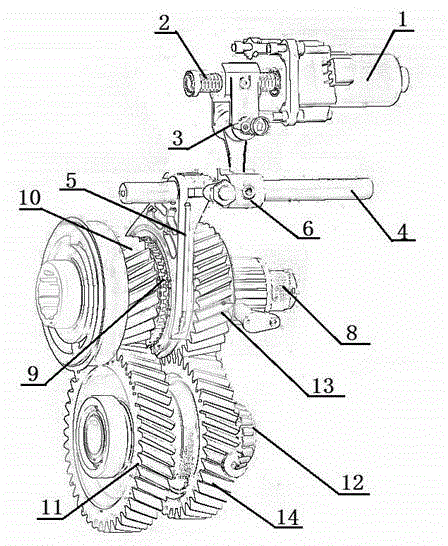

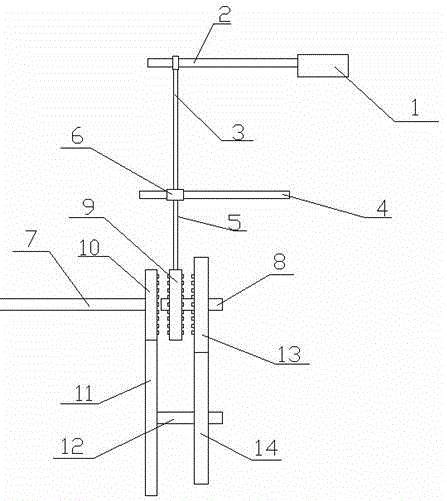

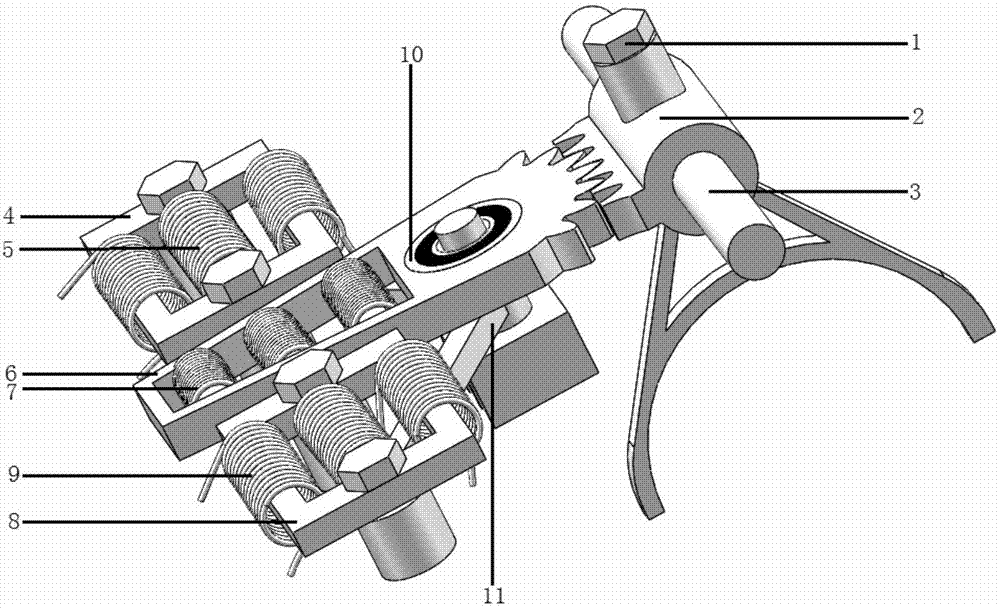

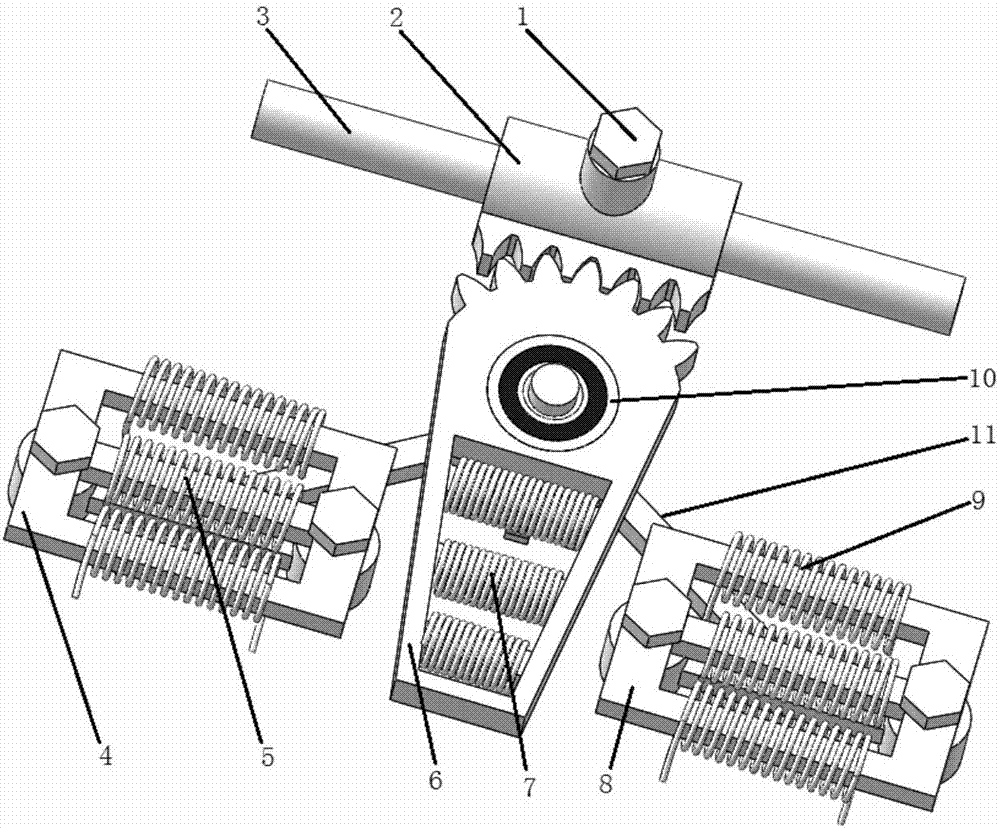

Vehicle automatic gear shifting speed changer assembly

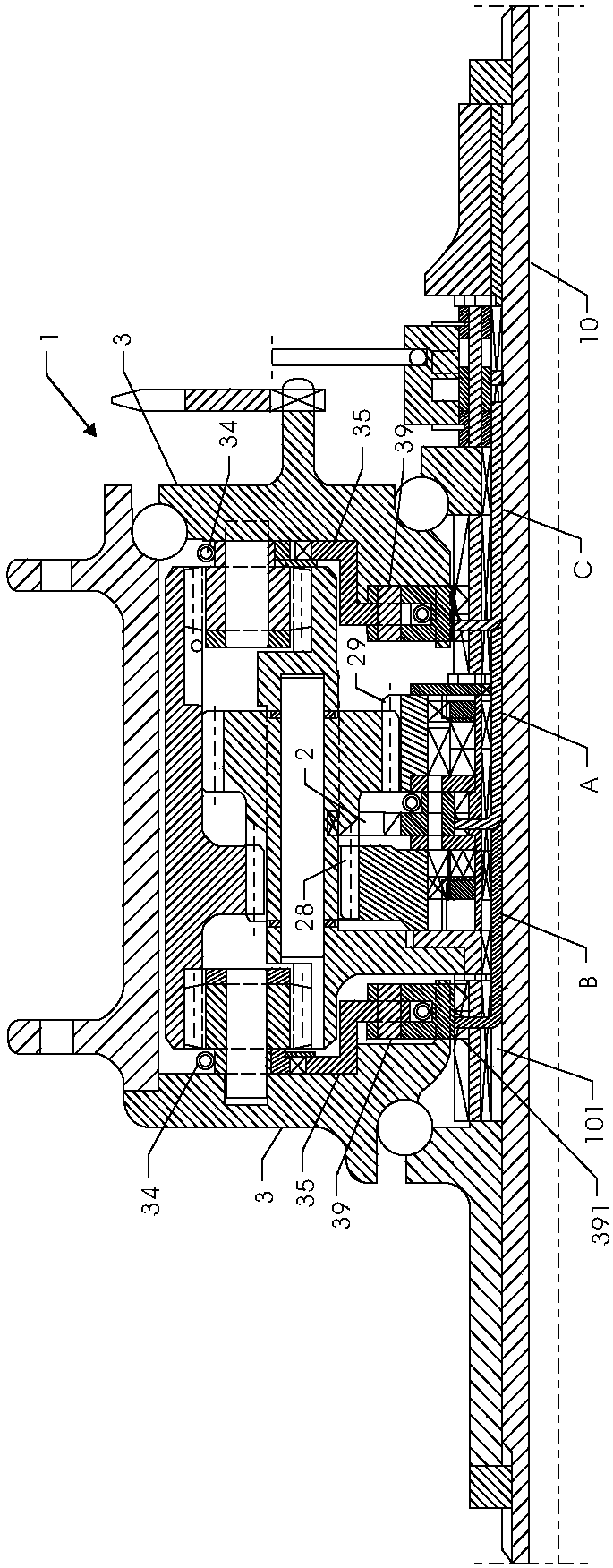

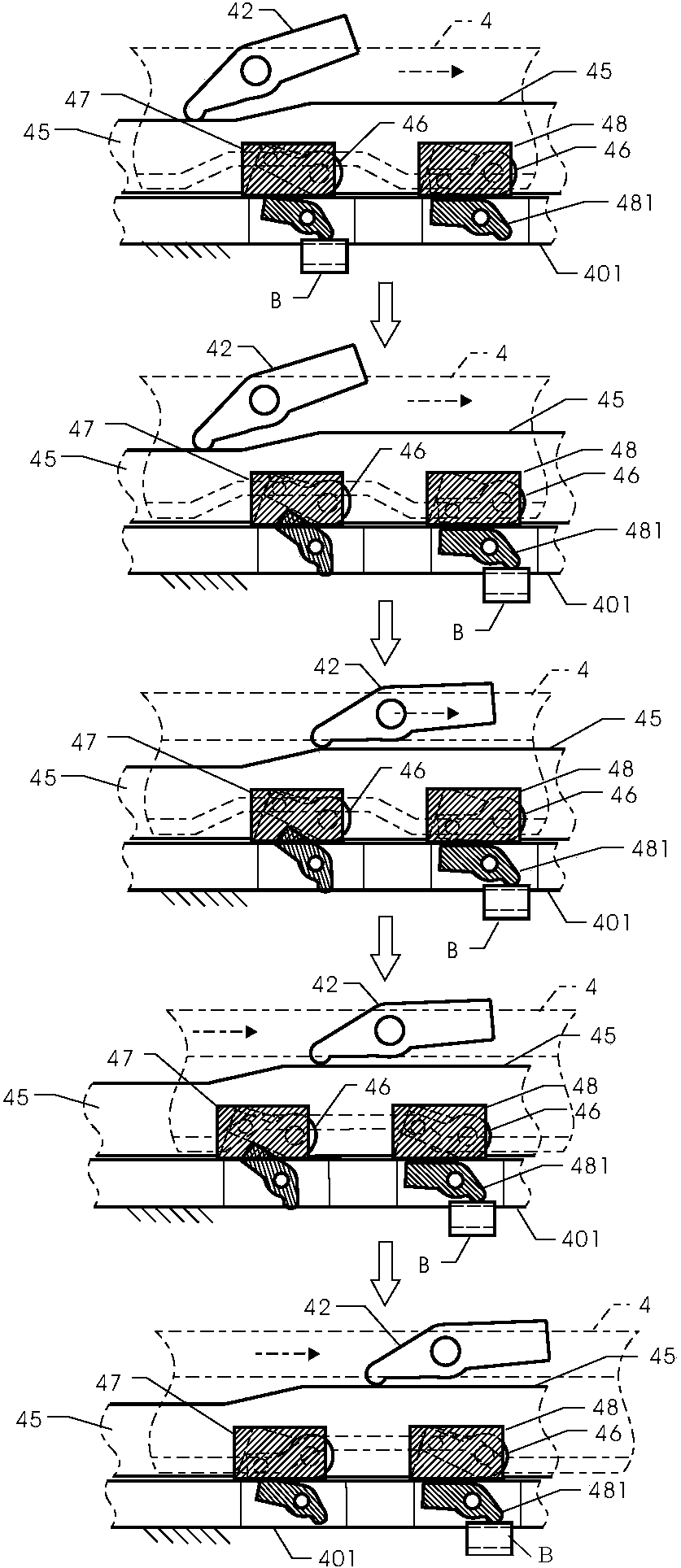

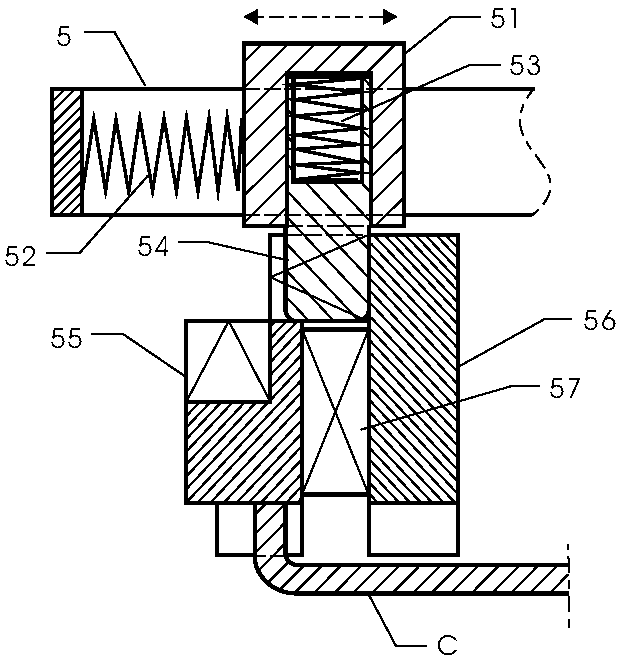

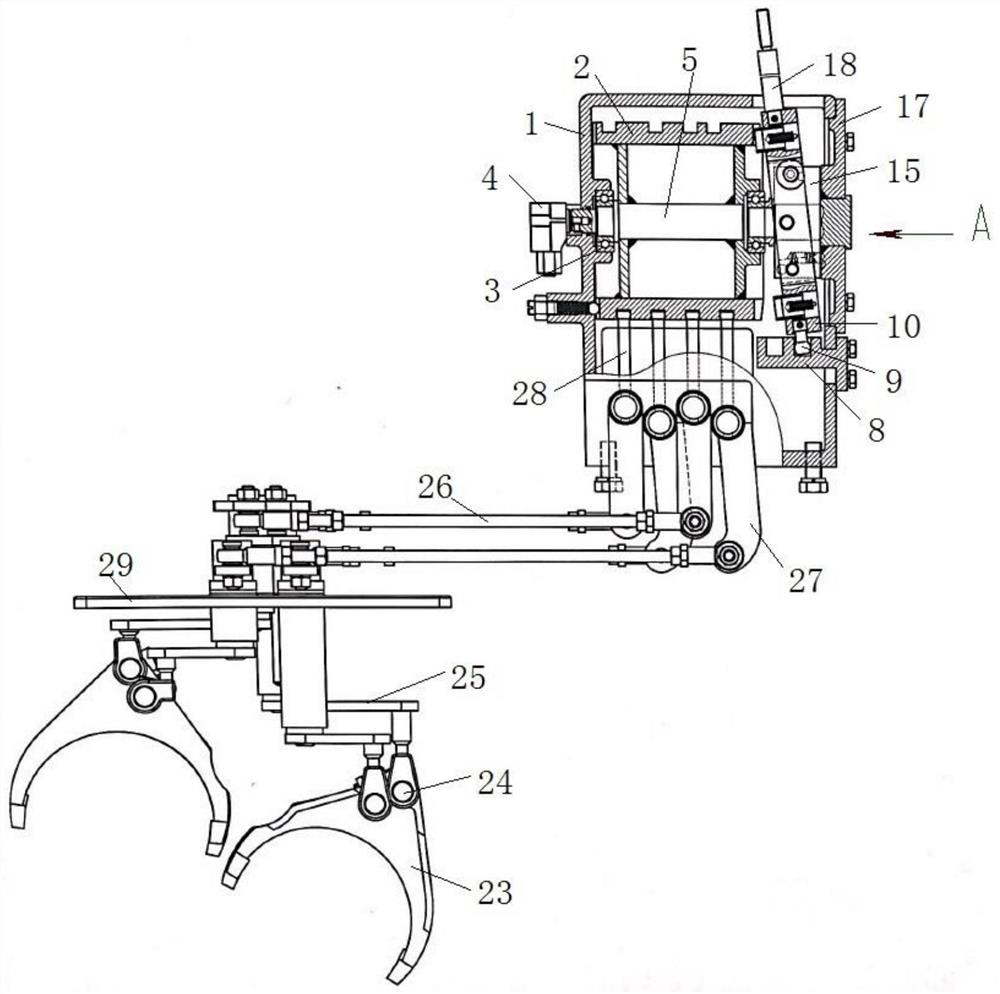

ActiveCN109611545ARealize the transmission connectionAccurate gear shiftControlled membersGearing controlDrive shaftEngineering

The invention discloses a vehicle automatic gear shifting speed changer assembly. A gear shifting rod assembly, a stirring rod assembly and a gear shifting gear assembly are included. The gear shifting rod assembly comprises a motor, a worm and gear mechanism, a gear shifting shaft and a gear shifting column. The stirring rod assembly comprises a fixedly-arranged stirring rod shaft and further comprises a first shifting fork assembly and a second shifting fork assembly which sleeve the stirring rod shaft. The first shifting fork assembly comprises a first base plate, a fork handle used for stirring a first shifting fork which is in connection transmission with a first sliding gear, two cylinder springs and two clamping sleeves. The gear shifting gear assembly comprises a plurality of transmission shaft assemblies, wherein transmission shafts of the two transmission shaft assemblies are provided with a first sliding gear and a first sliding gear correspondingly, one ends of the two sliding gears are coaxially connected with a movable sleeve, the two sliding gears and the movable sleeve rotationally sleeve the transmission shafts where the two sliding gears and the movable sleeve arelocated, and the outer cylinder face of the movable sleeve is provided with an outer spline structure in the axial direction of the movable sleeve. The vehicle automatic gear shifting speed changer assembly is accurate and timely in response and good in reliability.

Owner:CHONGQING XIANYOU TECH DEV

Gear shifting and parking locking mechanism for electric automobile

PendingCN113738867AIncrease rotation speedPrevent rollingGearingGearing controlNew energyControl theory

The invention relates to the technical field of new energy automobiles, in particular to a gear shifting and parking locking mechanism for an electric automobile. The gear shifting and parking locking mechanism for the electric automobile comprises an underframe, a supporting seat, a supporting outer ring, a protective shell, a switching assembly and the like, a supporting base is fixedly installed on the top of the right side of a bottom frame, a supporting outer ring is fixedly installed on the upper left portion of the bottom frame, a protection shell is fixedly installed on the left side of the supporting outer ring, and the switching assembly is arranged on the supporting base. Through cooperation of a first sliding clamping teeth and a second sliding clamping teeth, when an automobile is parked, the first sliding clamping teeth can clamp a first trapezoidal clamping teeth, or the second sliding clamping teeth clamp a second trapezoidal clamping teeth, so that a clamping rod clamps a slotting gear shaft, automobile wheels can be stably clamped, and automobile sliding caused by rotation of the wheels during parking is prevented.

Owner:SCANFIL HANGZHOU CO LTD

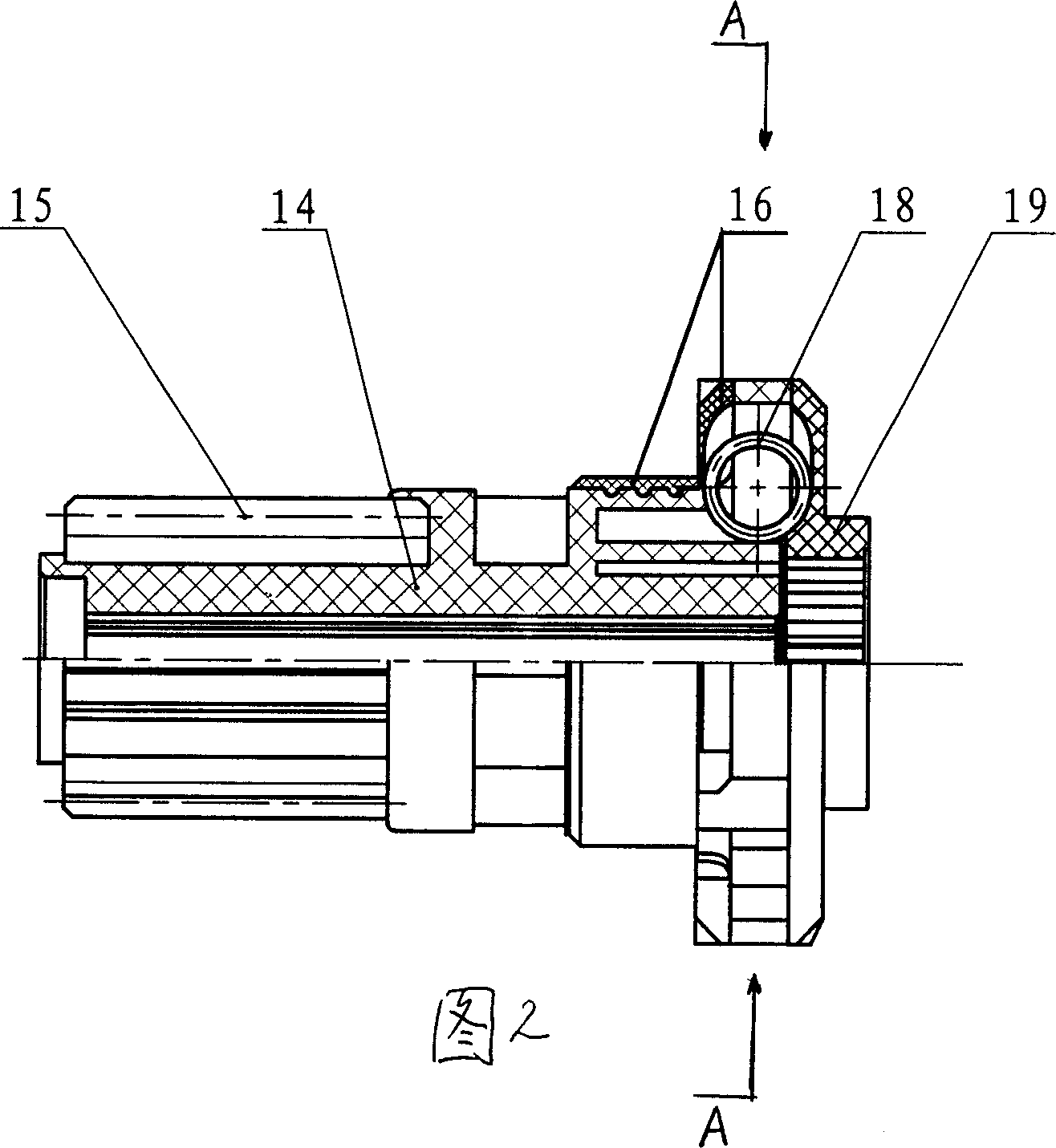

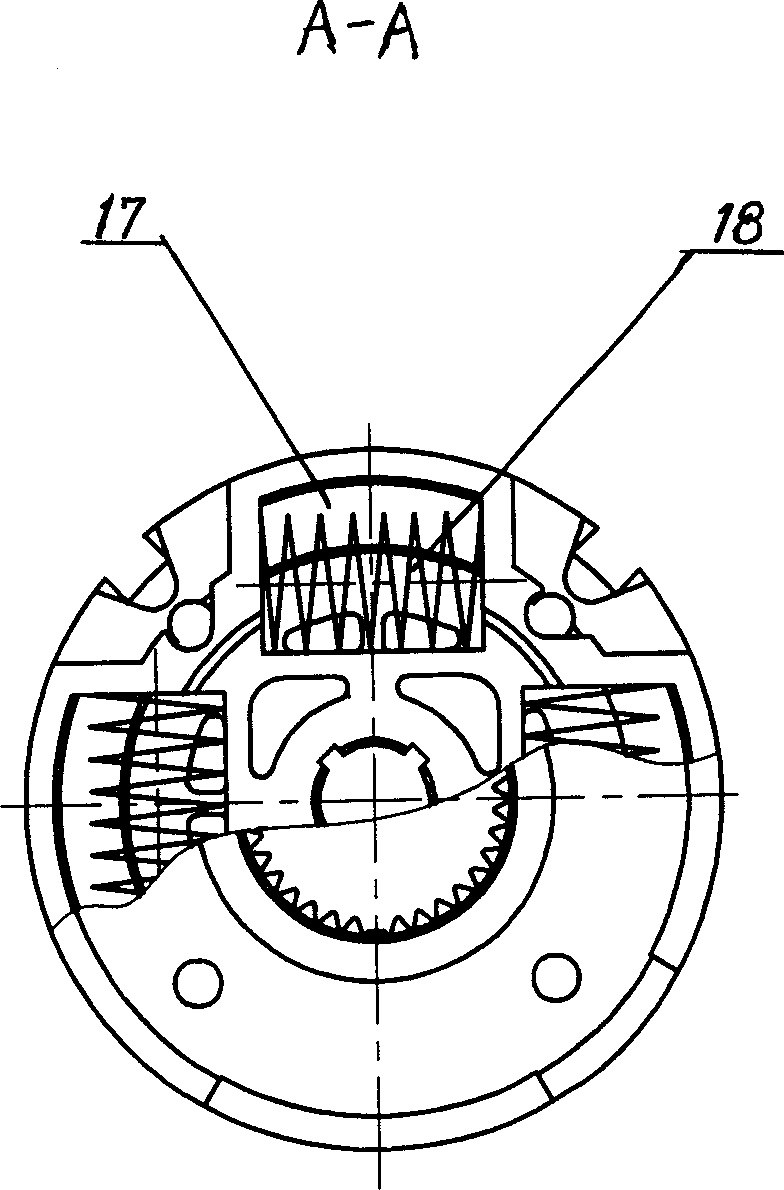

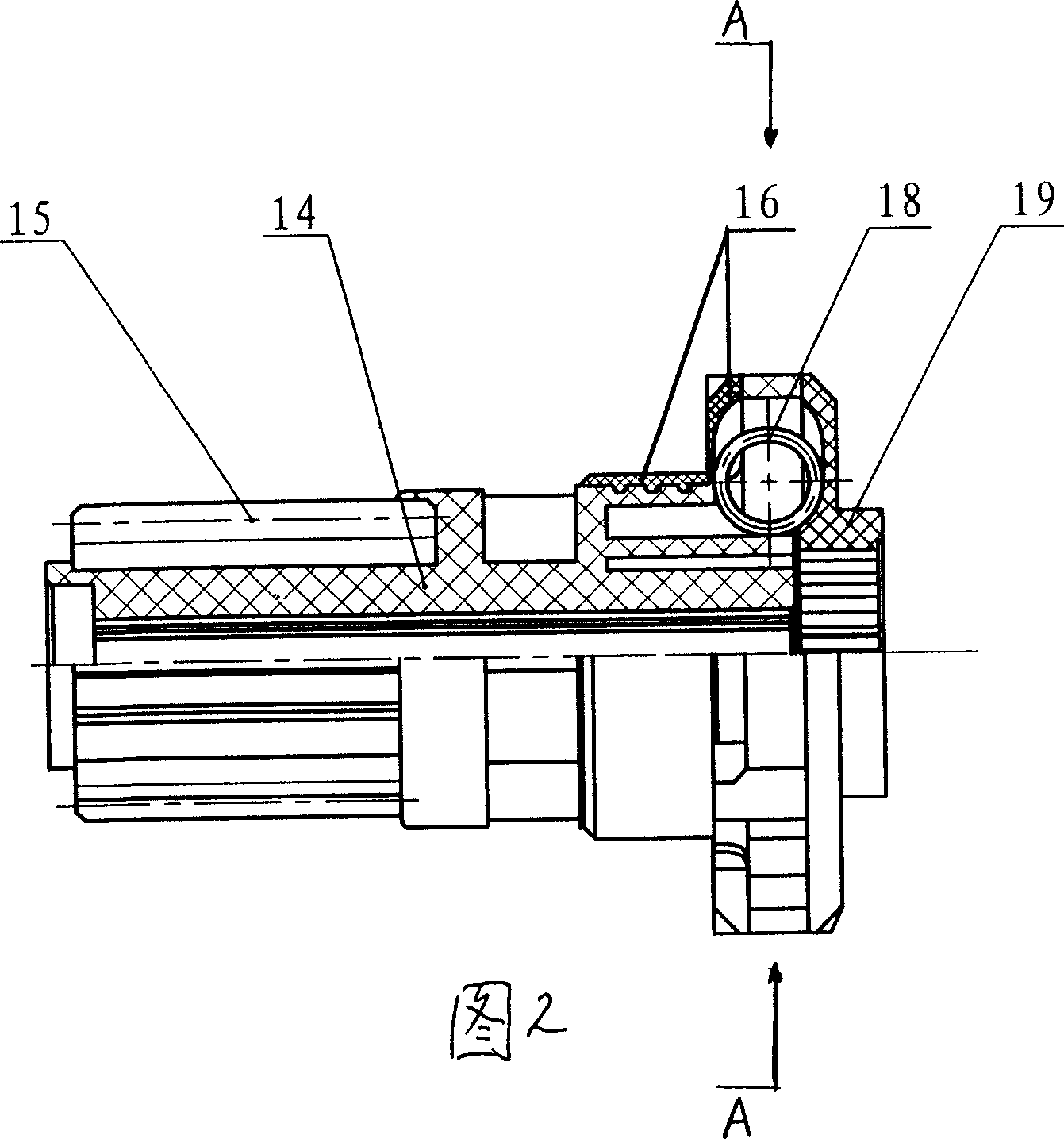

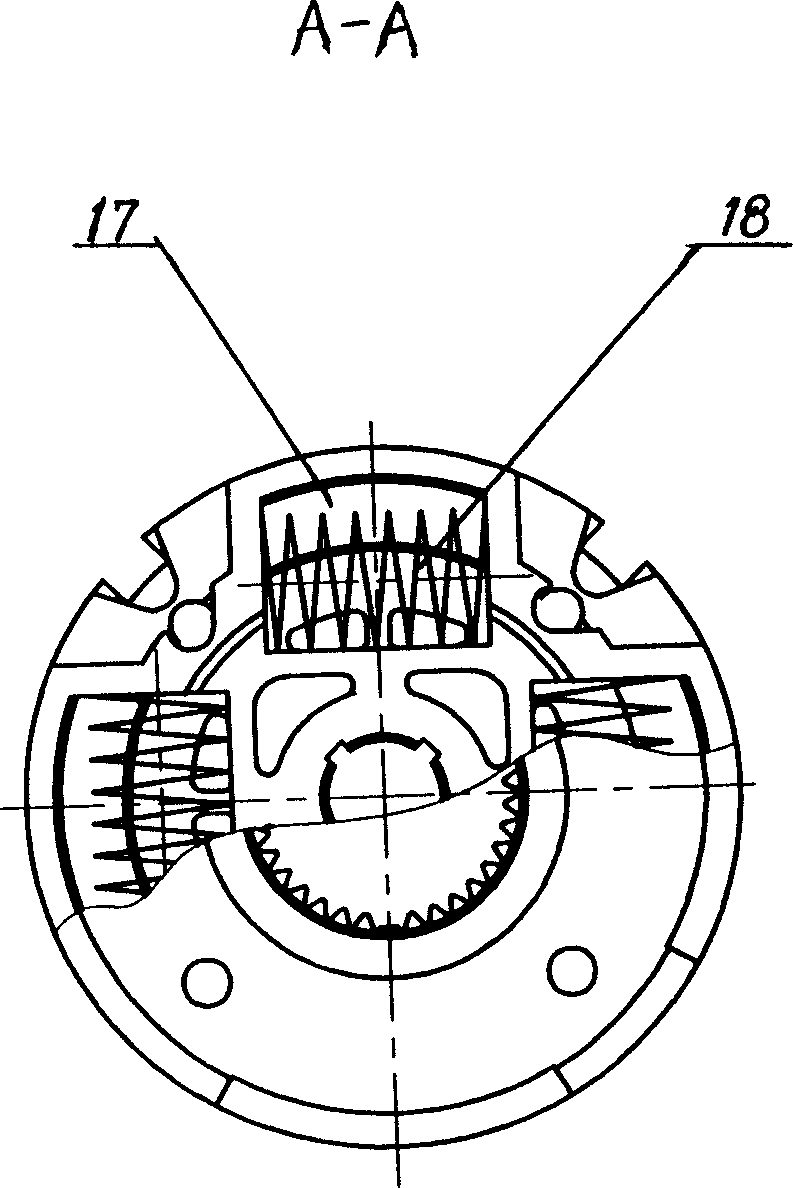

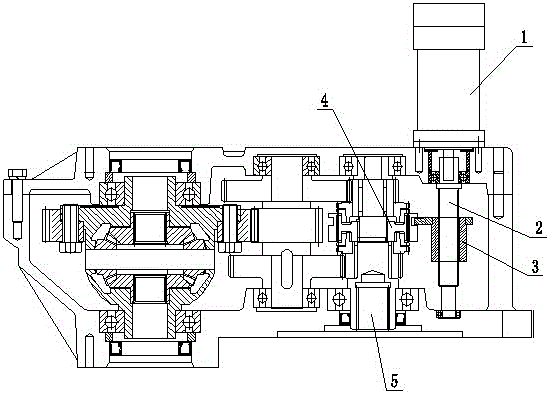

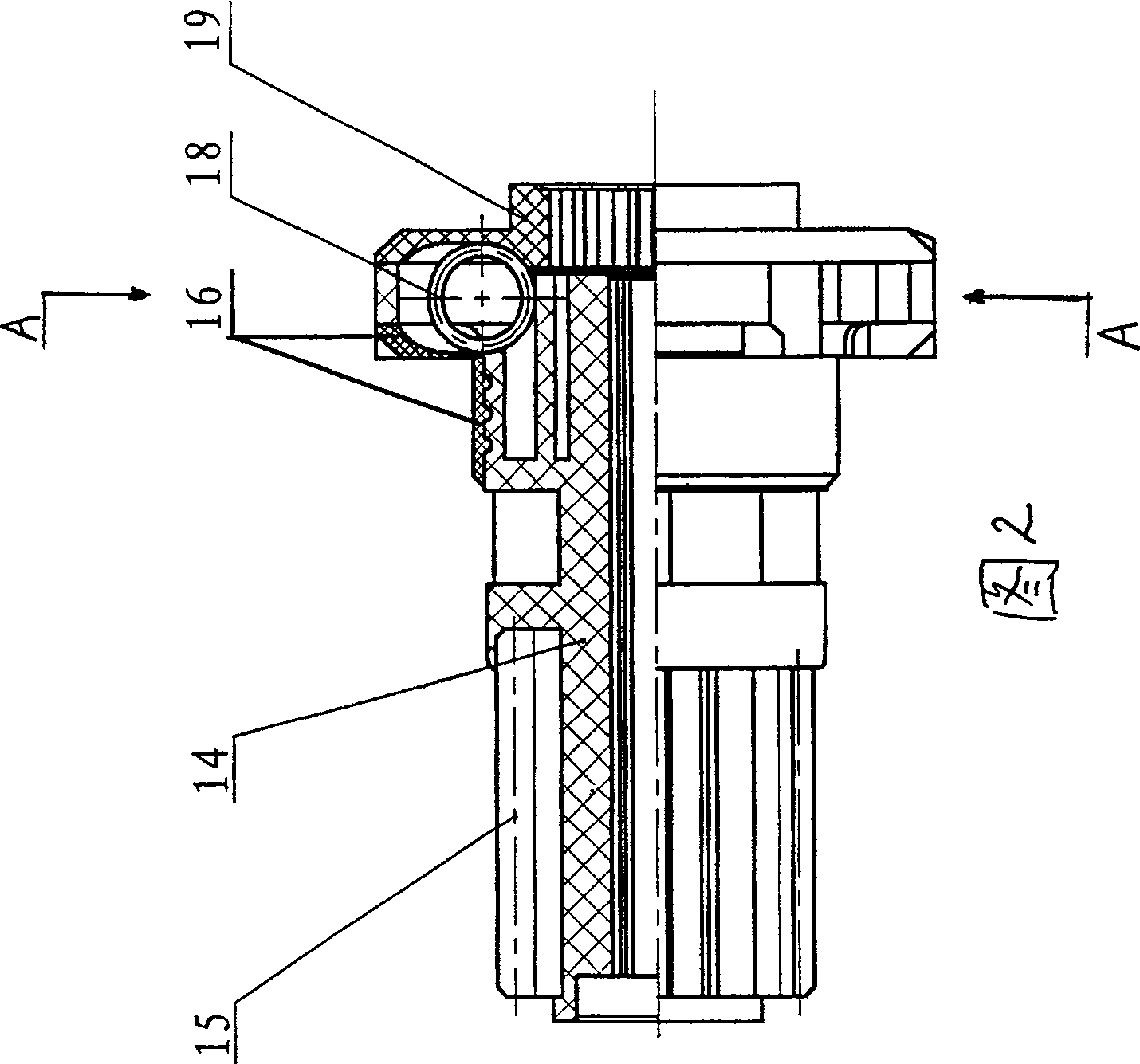

Gear shifting motor

InactiveCN1877968AReduce shockProtection securityStructural associationMechanical energy handlingReduction driveGear wheel

The invention discloses a shift motor, which is characterized by the following: loading Hall inducer 6 with magnetic property on the brush rocker 4 of brush rocker component; casing induction counting gear 7 corresponding to Hall inducer on the motor shaft 8 of rotor component; connecting reducer case 1 of reducer case component and gear shaft 2; casing buffer bulk 14 on the gear shaft 2; casing buffer gear 15, plastic sleeve 16 on the outer and inner sides of buffer bulk 14 separately; opening spring groove 17 with buffer spring 18 on the top of buffer bulk 14; connecting lid gear 19 in the inner part of buffer bulk 14; gearing lid gear 19 and positive gear 12. The invention protects driven part effectively, which is fit for automobile fork and shift sequently and precisely.

Owner:浙江瑞鹏汽车电器有限公司

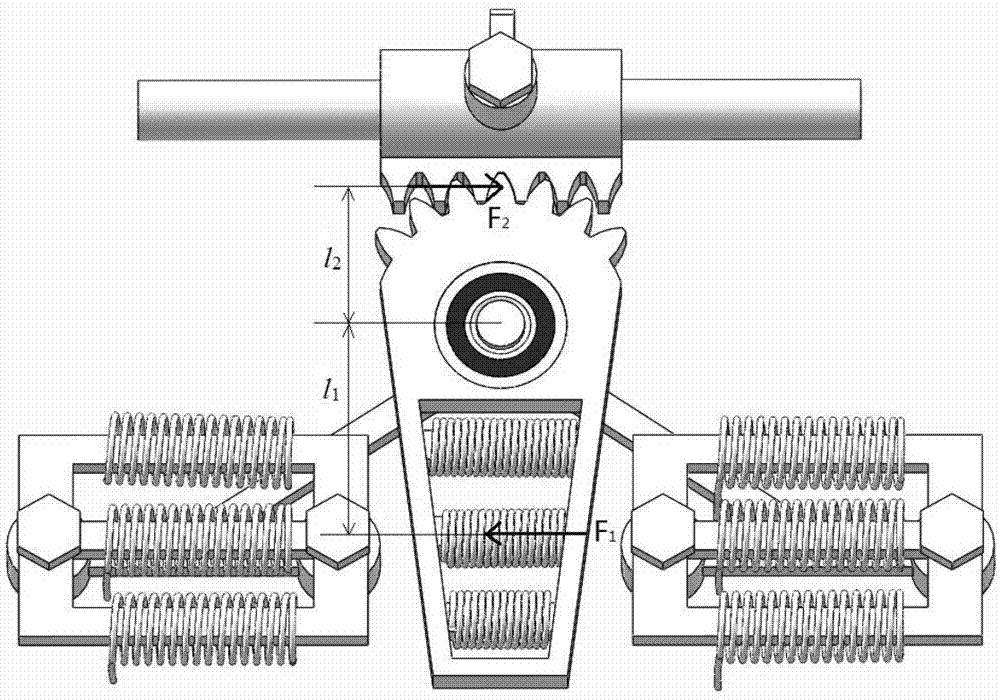

Electromagnetic boosting type gear shifting mechanism

The invention discloses an electromagnetic boosting type gear shifting mechanism. The electromagnetic boosting type gear shifting mechanism comprises a self-locking device, a sliding shifting fork, a guide rail shaft, a first coil mounting rack, first coils, a sector gear, middle coils, a second coil mounting rack, second coils, a locating bearing, an assembly support, an infrared photoelectric reflective sensor and an ECU. When the electromagnetic boosting type gear shifting mechanism is in a neutral gear, the sliding shifting fork is located in the middle position of the guide rail shaft. The ECU controls connection and disconnection of electricity and current conditions of the first coils, the middle coils and the second coils to enable the first coils, the second coils and the middle coils to generate electromagnetic force simultaneously and act on the mounting ends of the middle coils. By means of the lever principle, the rotating arm force of the mounting ends of the middle coils is greater than that of the gear end. Under the energizing action of the sector gear, the sliding shifting fork is made to slide on the guide rail shaft to achieve the gear shifting action. Moreover, when the sliding shifting fork stops sliding, the self-locking device conducts self-locking.

Owner:JIANGSU UNIV

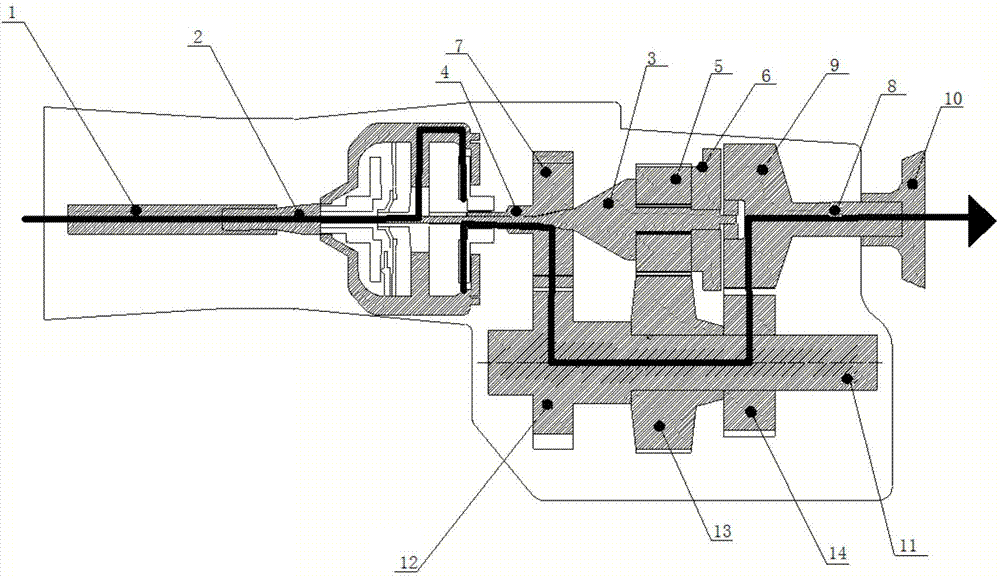

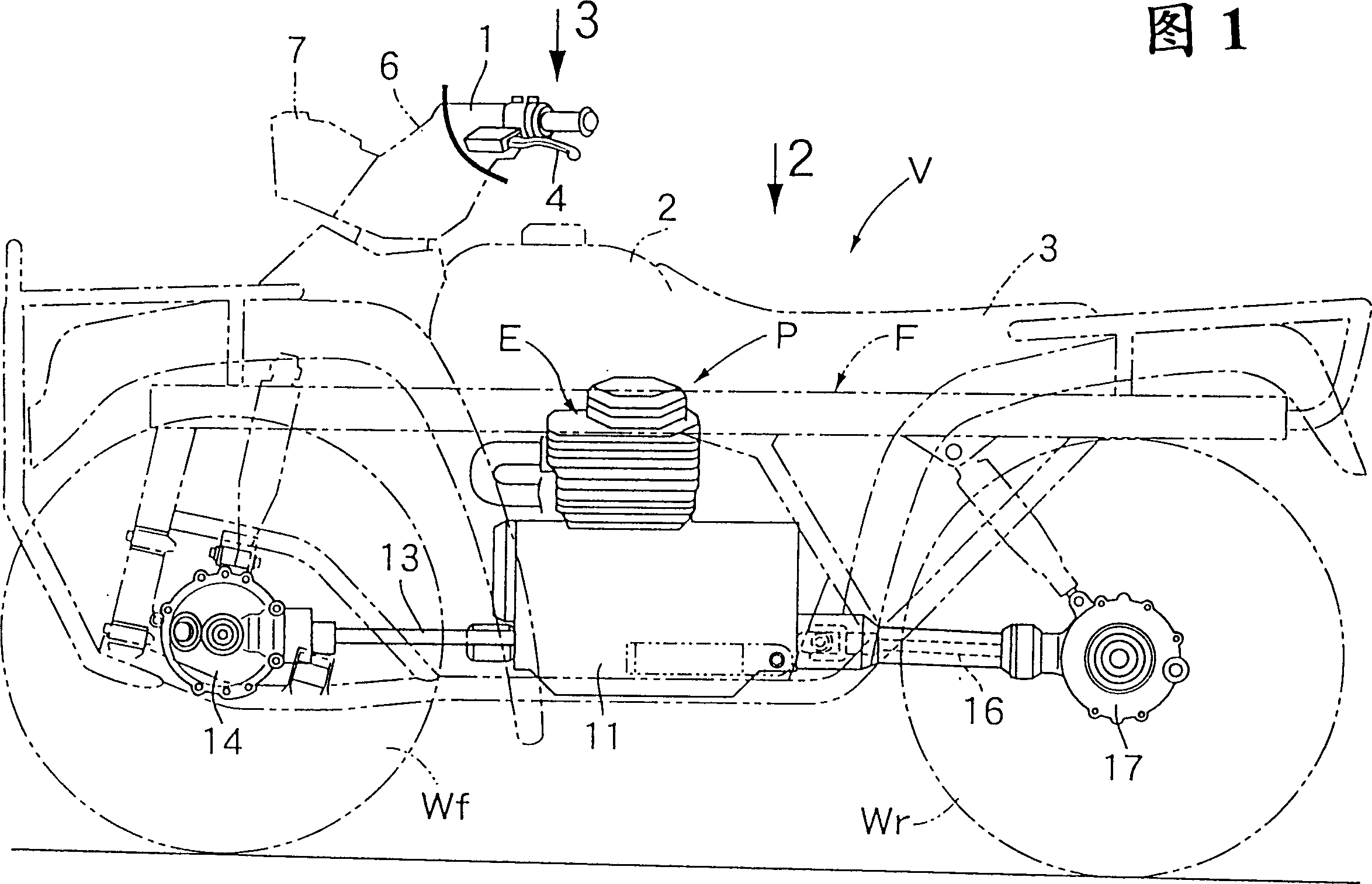

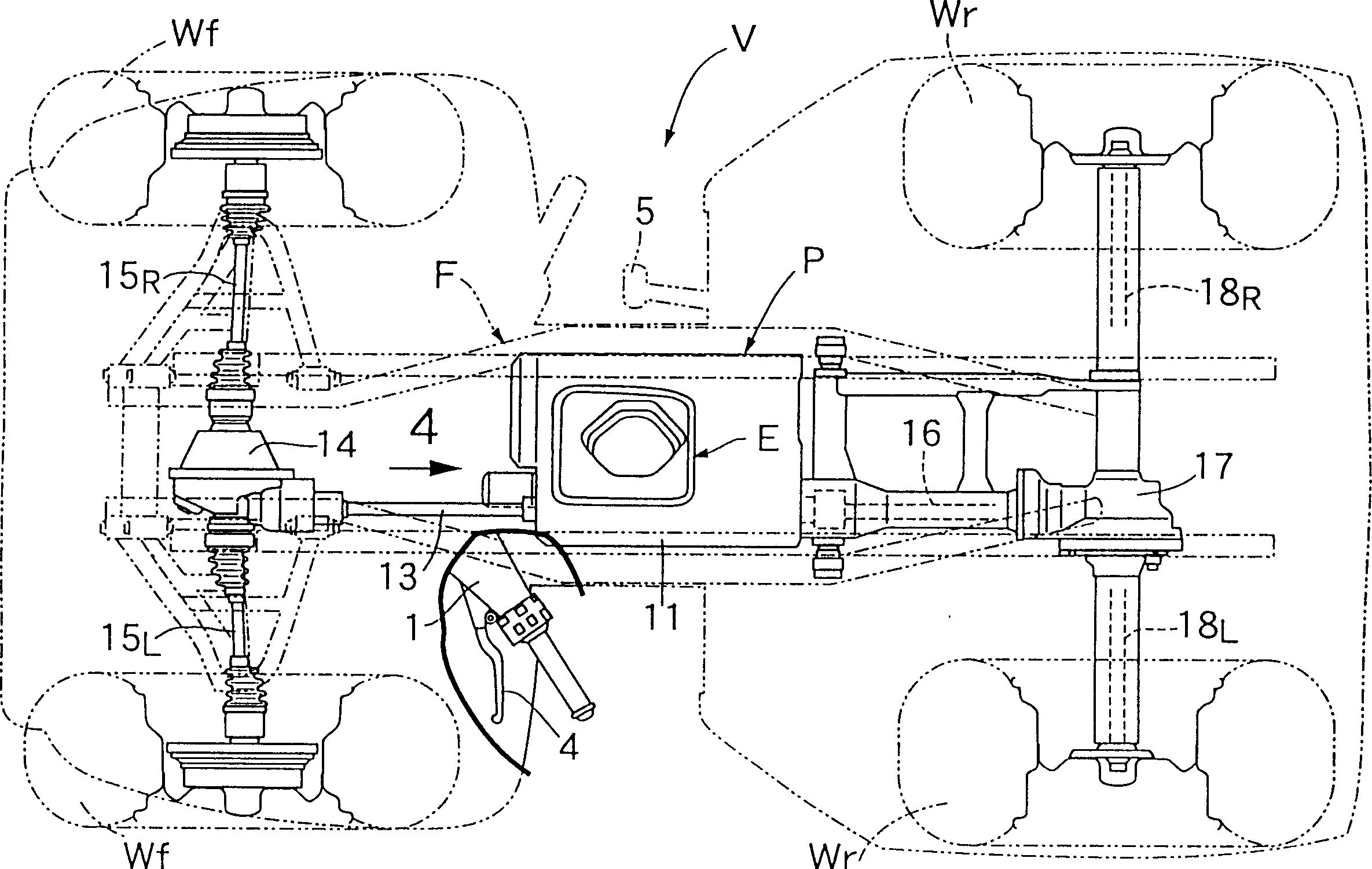

Power transmission device for vehicle

InactiveCN1204351CAccurate gear shiftAccurate operationClutchesGearing controlDriver/operatorEngineering

Easy and precise shifting is possible without using a shift pedal and a shift lever. The vehicle power transmission device is equipped with a speed changer installed between the engine and the driving wheels, a speed change clutch, and a motor that can control the forward and reverse rotation of the speed change clutch according to the command signal issued by the operating member operated by the driver. , which is characterized in that the motor is driven with a power ratio of 100% when the clutch is disconnected, the rotation angle of the motor is feedback controlled when the clutch is connected, and the speed of disconnecting the clutch is controlled so that the motor is driven outside the clutch connection area, at least when the clutch is connected The speed in the area is lower than that, so that the connection speed of the transmission clutch is slower than the speed of disconnection; the transmission is equipped with a gear set that can establish multiple gear stages, a shift fork that changes the meshing of the gear set, and a shift roller that drives the shift fork 1. Drive the transmission shaft of the transmission drum, the transmission clutch is connected and disconnected according to the rotation of the transmission shaft, and the motor is feedback-controlled according to the signal sent by the rotation phase detection mechanism.

Owner:HONDA MOTOR CO LTD

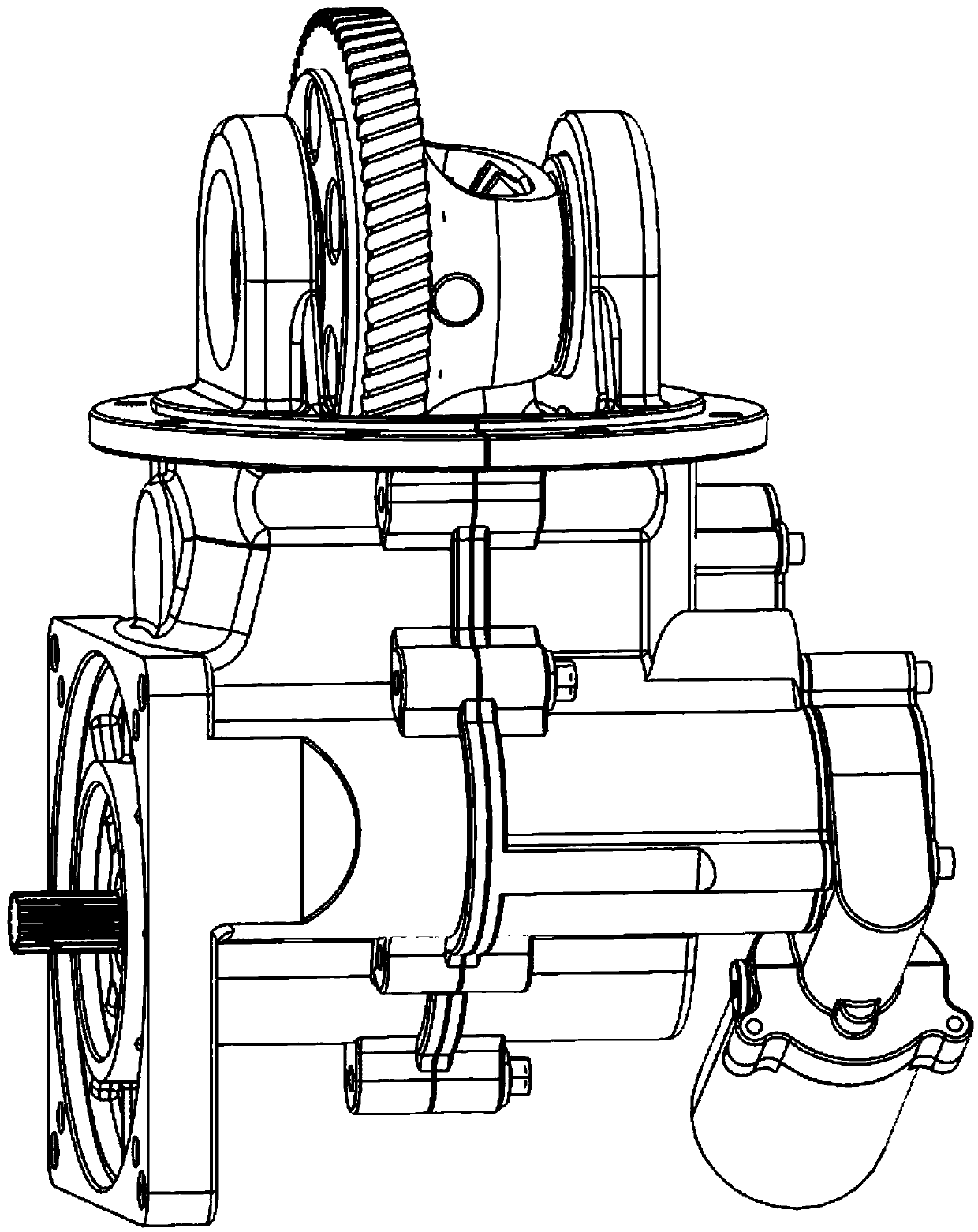

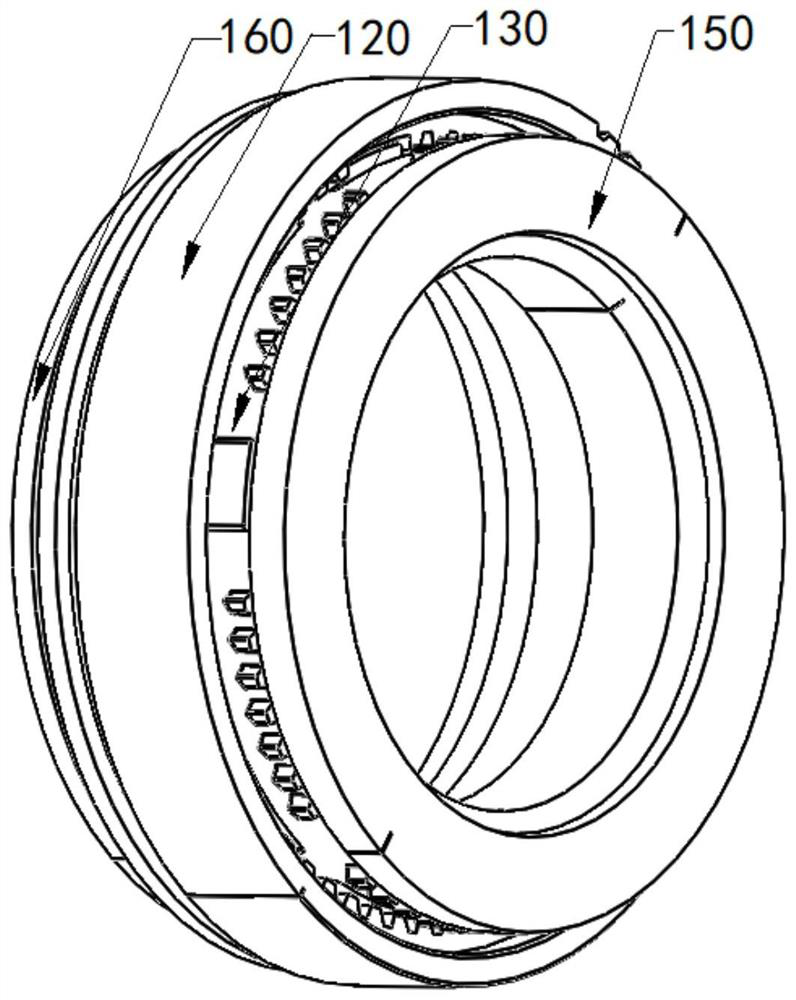

A selector shift mechanism for a transmission

ActiveCN106812929BReduce manufacturing costOptimizing the Design SpaceControlled membersGearing controlDrive motorEngineering

The invention provides a gear selecting and shifting mechanism for a speed changer and relates to a vehicle part. The gear selecting and shifting mechanism comprises a drive motor, a first slot opening, a first shifting fork, a second slot opening and a second shifting fork. The drive motor is provided with an output shaft for outputting power, and the output shaft is provided with an increase portion with the diameter being increased; the first slot opening is formed in the increase portion, the first slot opening corresponds to at least one gear position, and the gear positions are configured to surround the outer circumferential face of the increase portion; the first shifting fork is configured to rotate along the first slot opening when the output shaft is rotated so that the movement state of a vehicle can be changed according to the gear positions in the first slot opening; the second slot opening is configured in the increase portion, the second slot opening is provided with at least one gear position, and the gear positions are configured to surround the outer circumferential face of the increase portion, and the second slot opening and the first slot opening are formed in a spaced manner; and the second shifting fork is configured to move along the second slot opening when the output shaft is rotated so that the movement state of the vehicle can be changed according to the gear positions in the second slot opening. By means of the gear selecting and shifting mechanism, problems of gear selecting and gear shifting are solved through one motor.

Owner:NINGBO SHANGZHONGXIA AUTOMATIC TRANSMISSION

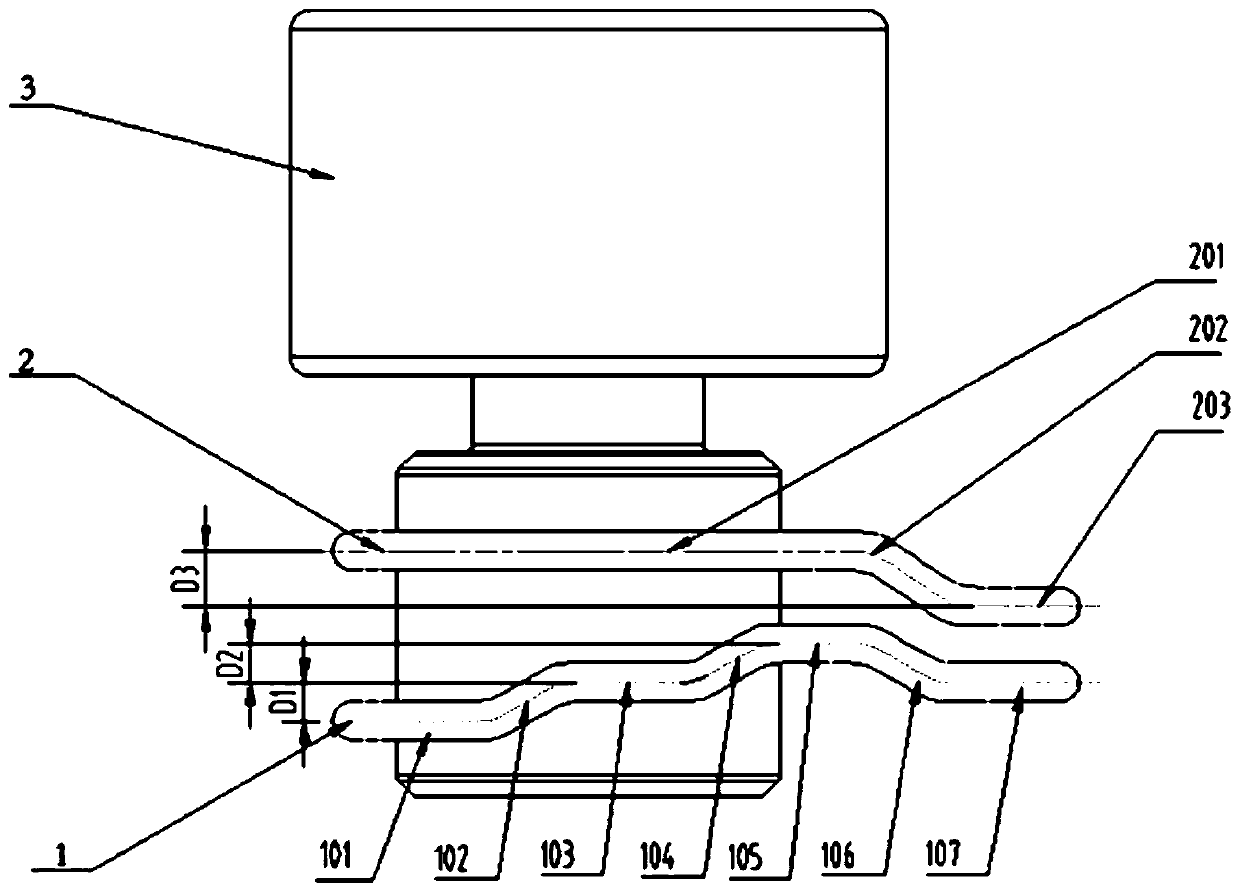

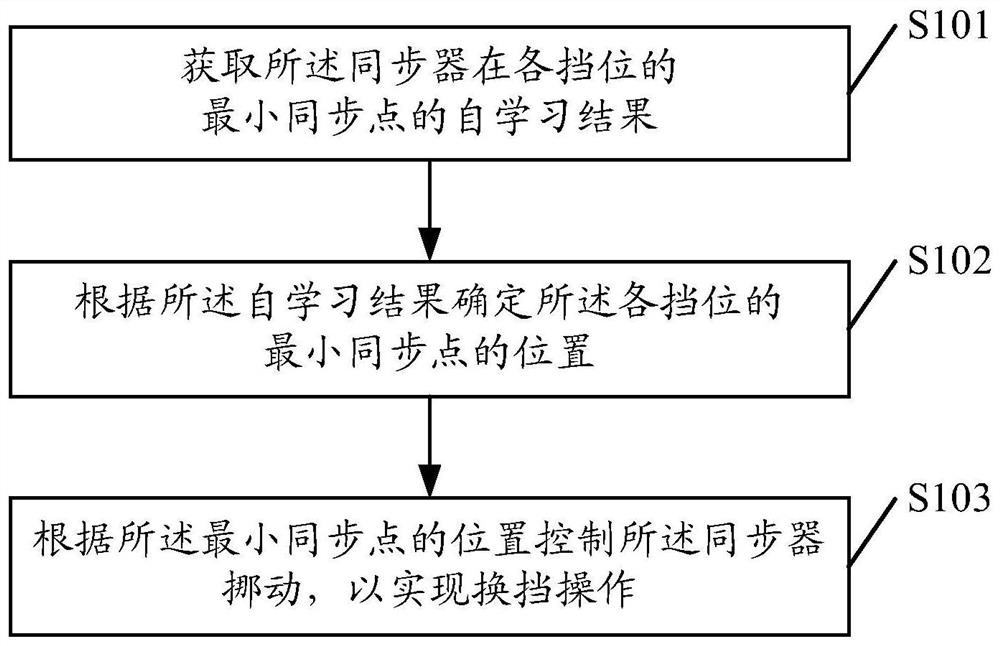

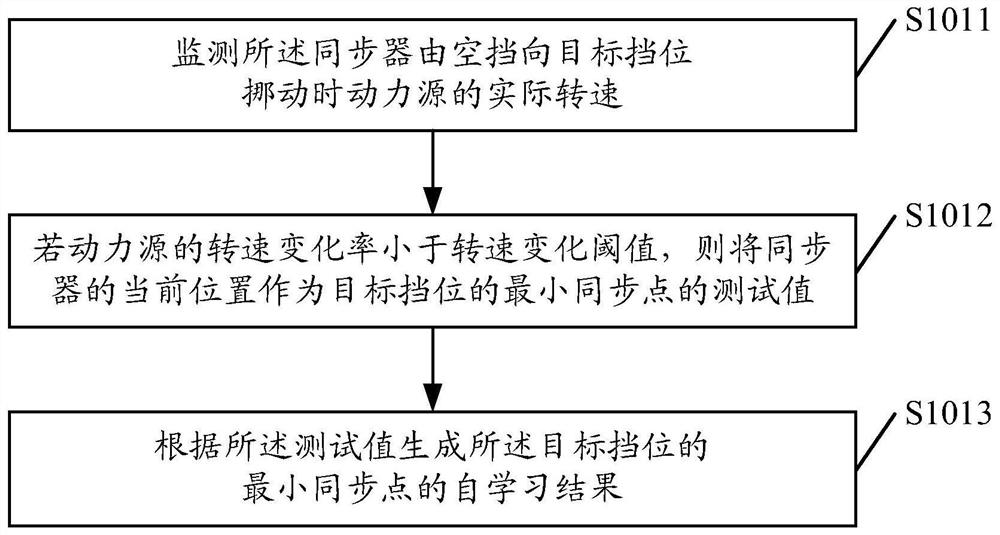

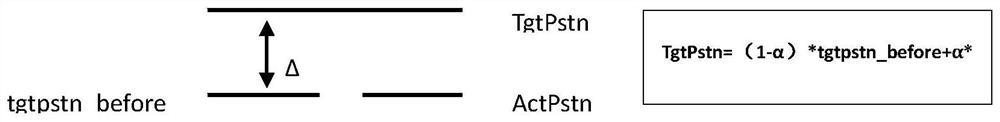

Method and device for controlling a synchronizer

The present application discloses a control method of a synchronizer, which includes obtaining the self-learning result of the minimum synchronization point of the synchronizer in each gear; the self-learning result represents the test value of the minimum synchronization point of the synchronizer; and then, according to The self-learning result determines the position of the minimum synchronization point of each gear; finally, the synchronizer is controlled to move according to the position of the minimum synchronization point, so as to realize the gear shifting operation. Compared with the traditional shifting method, the method provided in this embodiment can perform self-learning for each gearbox, fully considering the differences caused by the gearbox hardware itself and assembly, therefore, the minimum synchronization point determined based on the self-learning method is more accurate. Accurate, so as to realize the precise control of the synchronizer, reduce the probability of hitting the tooth or hitting the end point, and the shifting is more precise. The application also discloses a control device for a synchronizer.

Owner:SAIC MOTOR

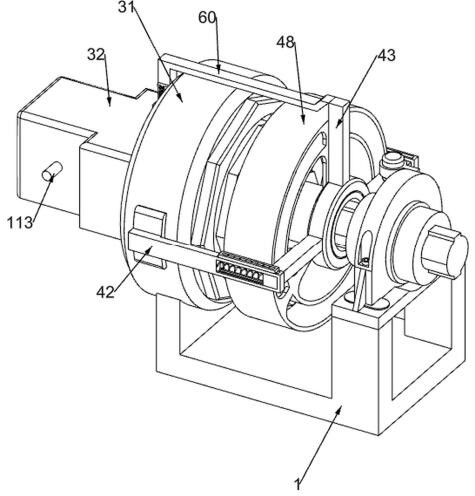

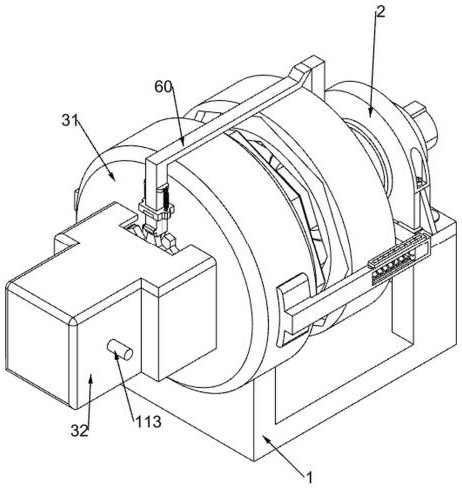

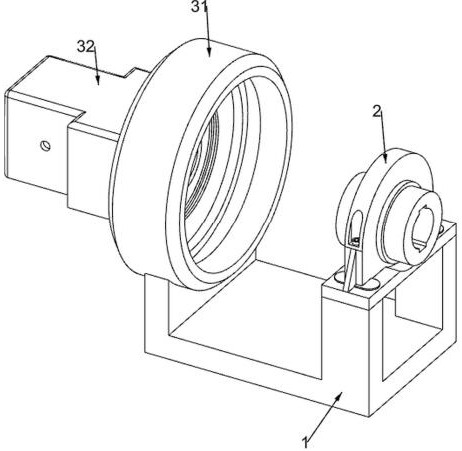

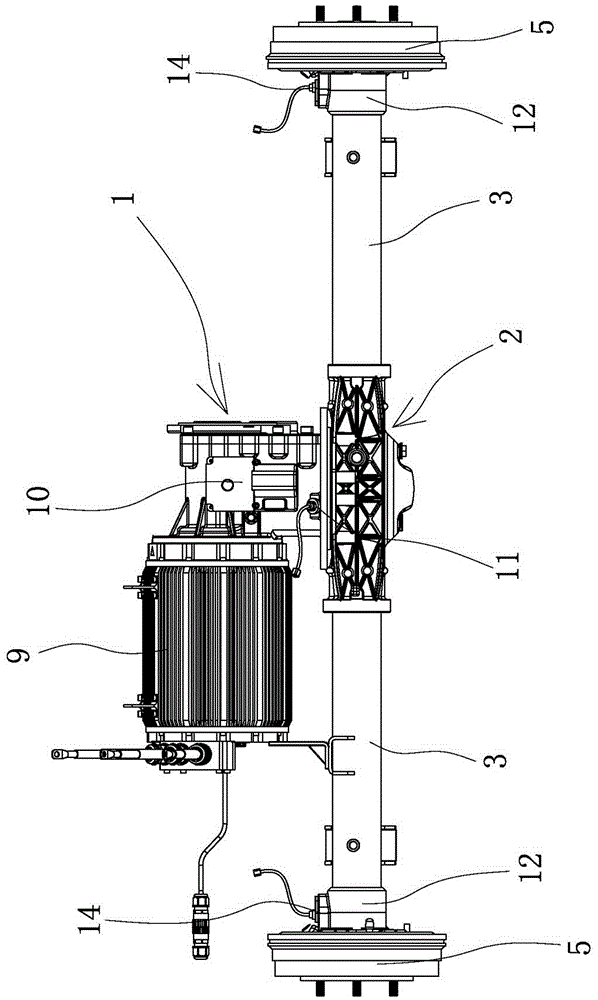

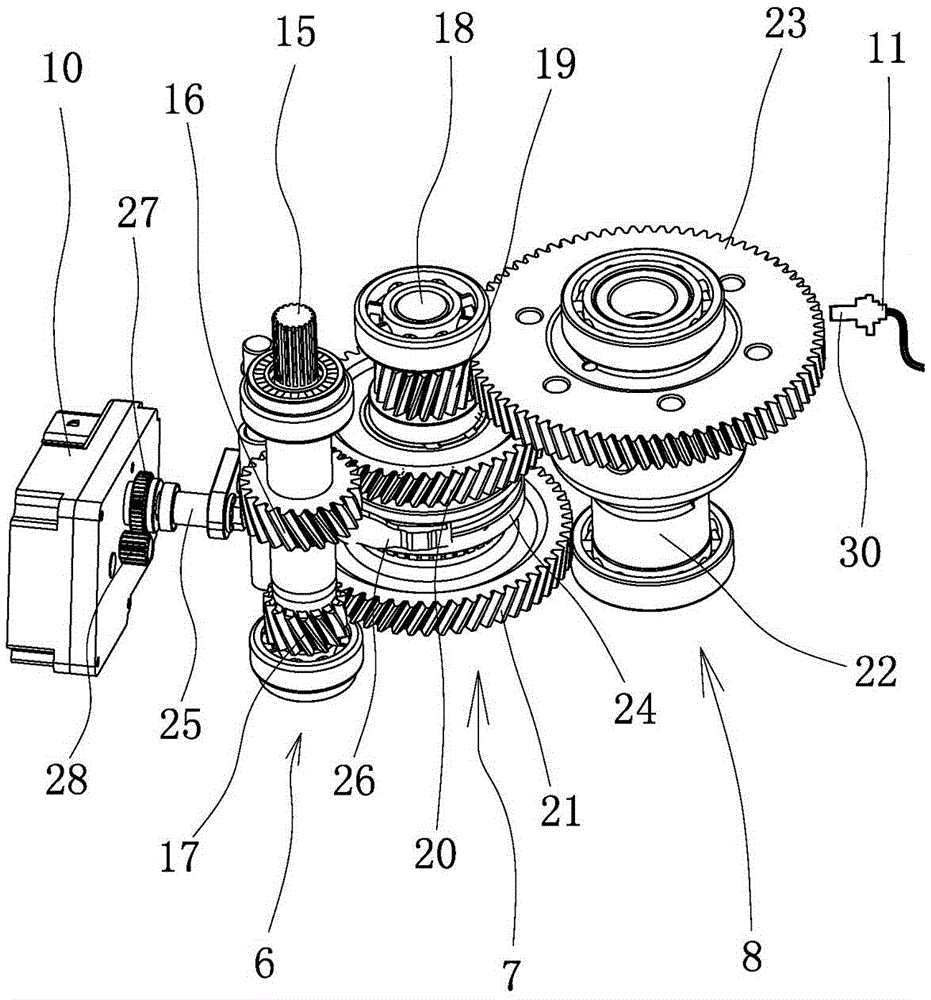

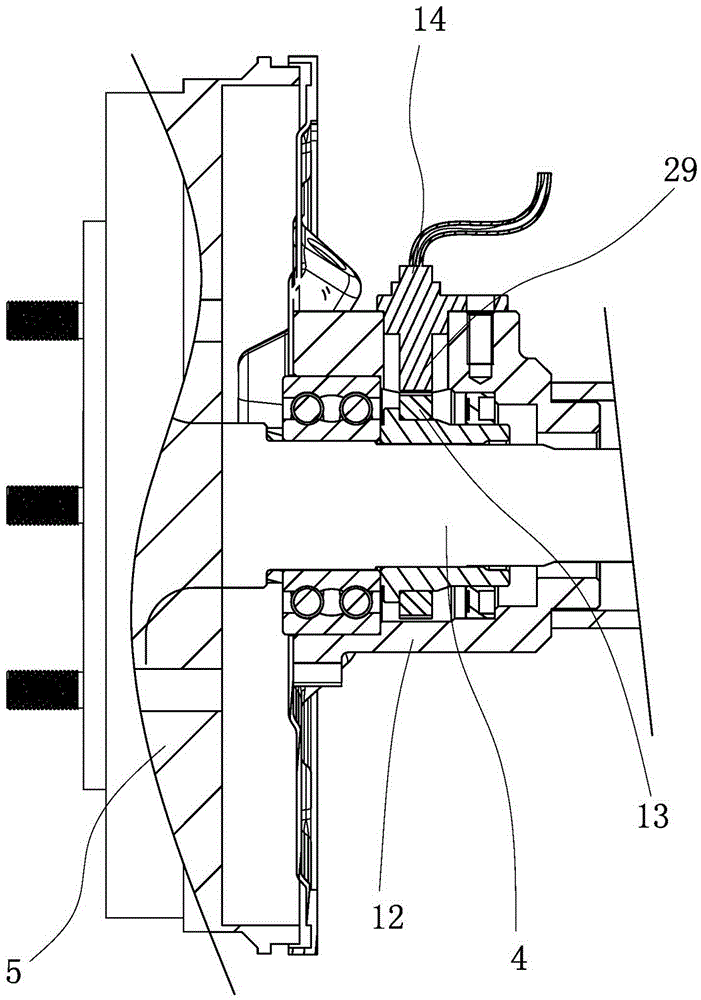

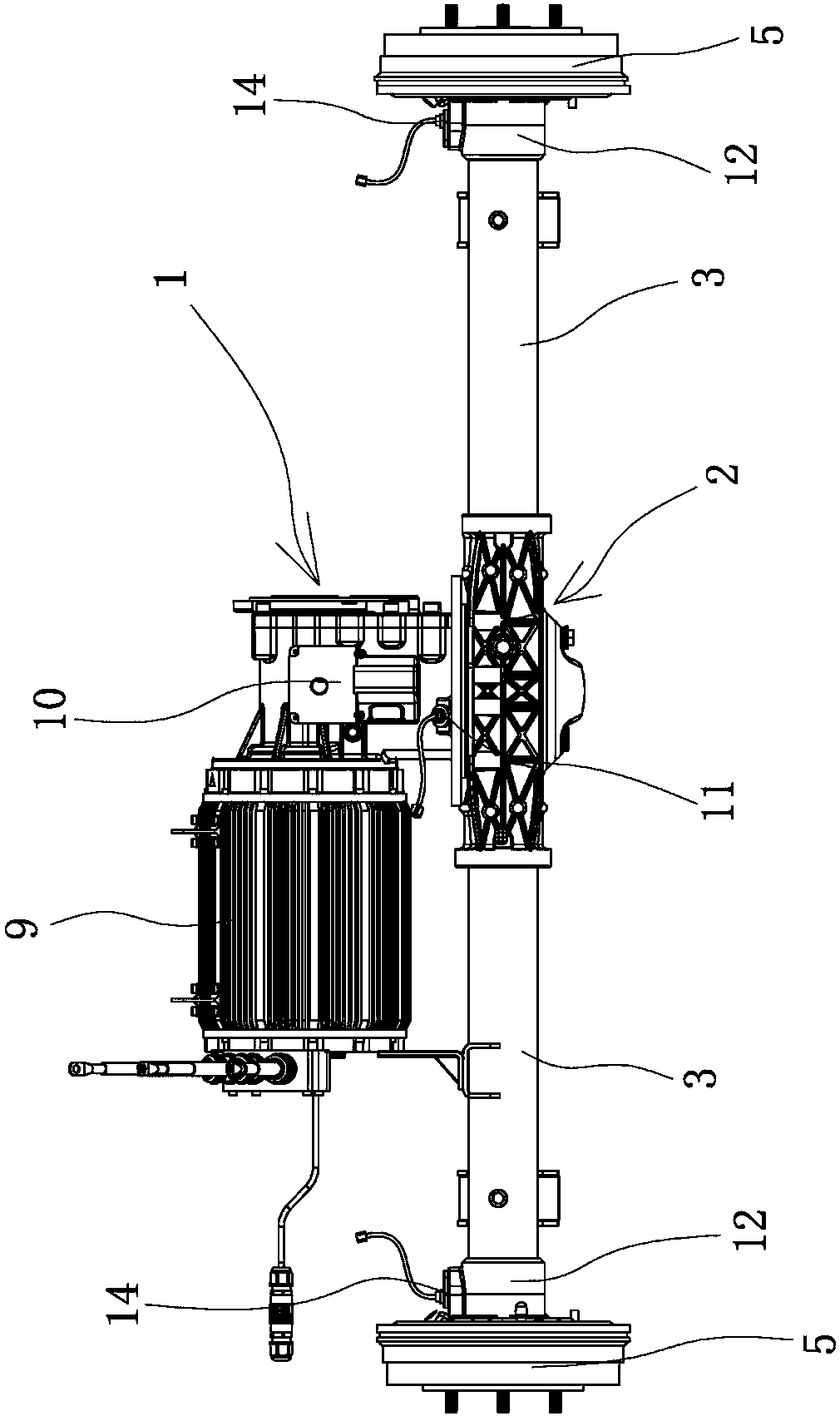

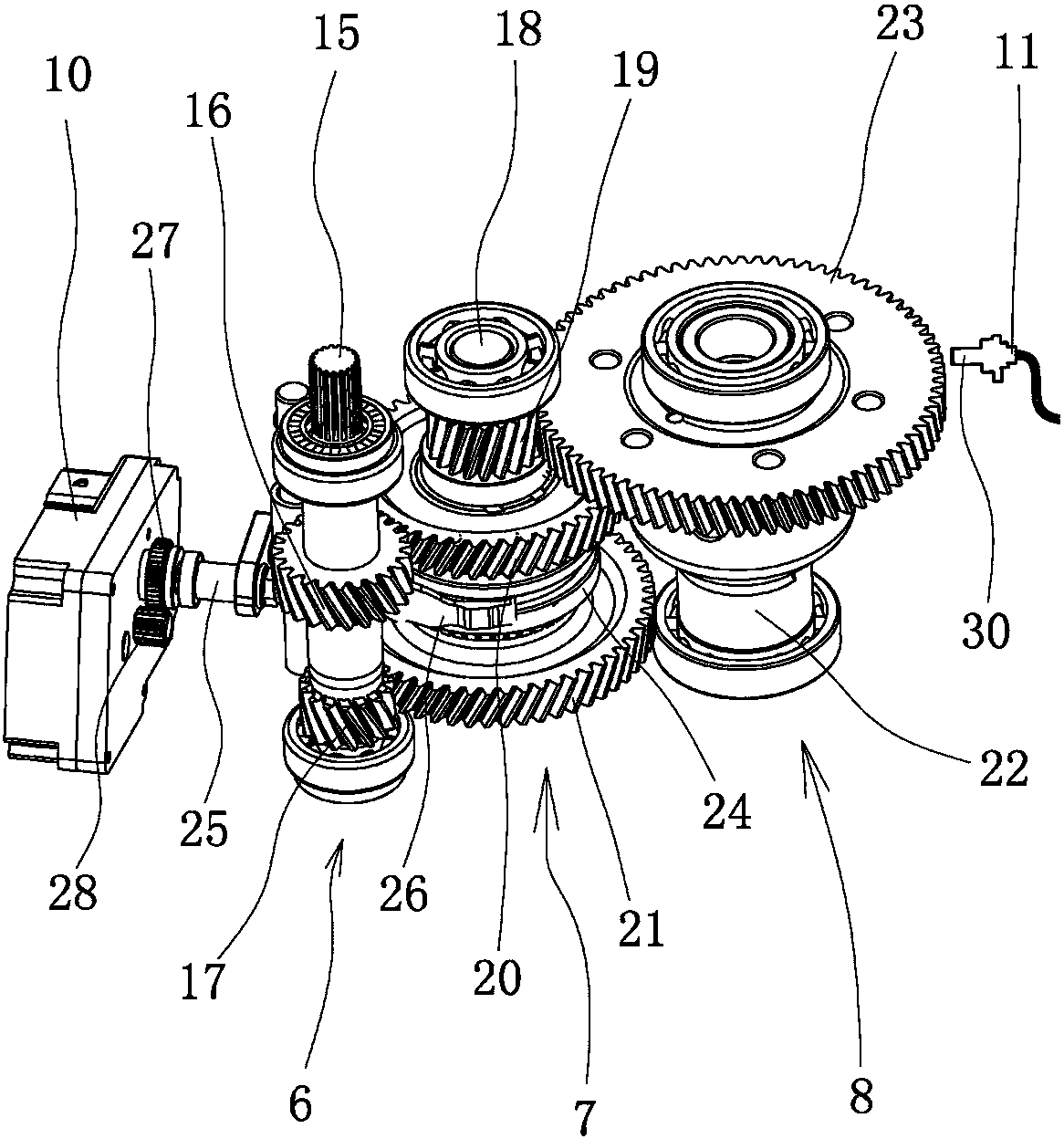

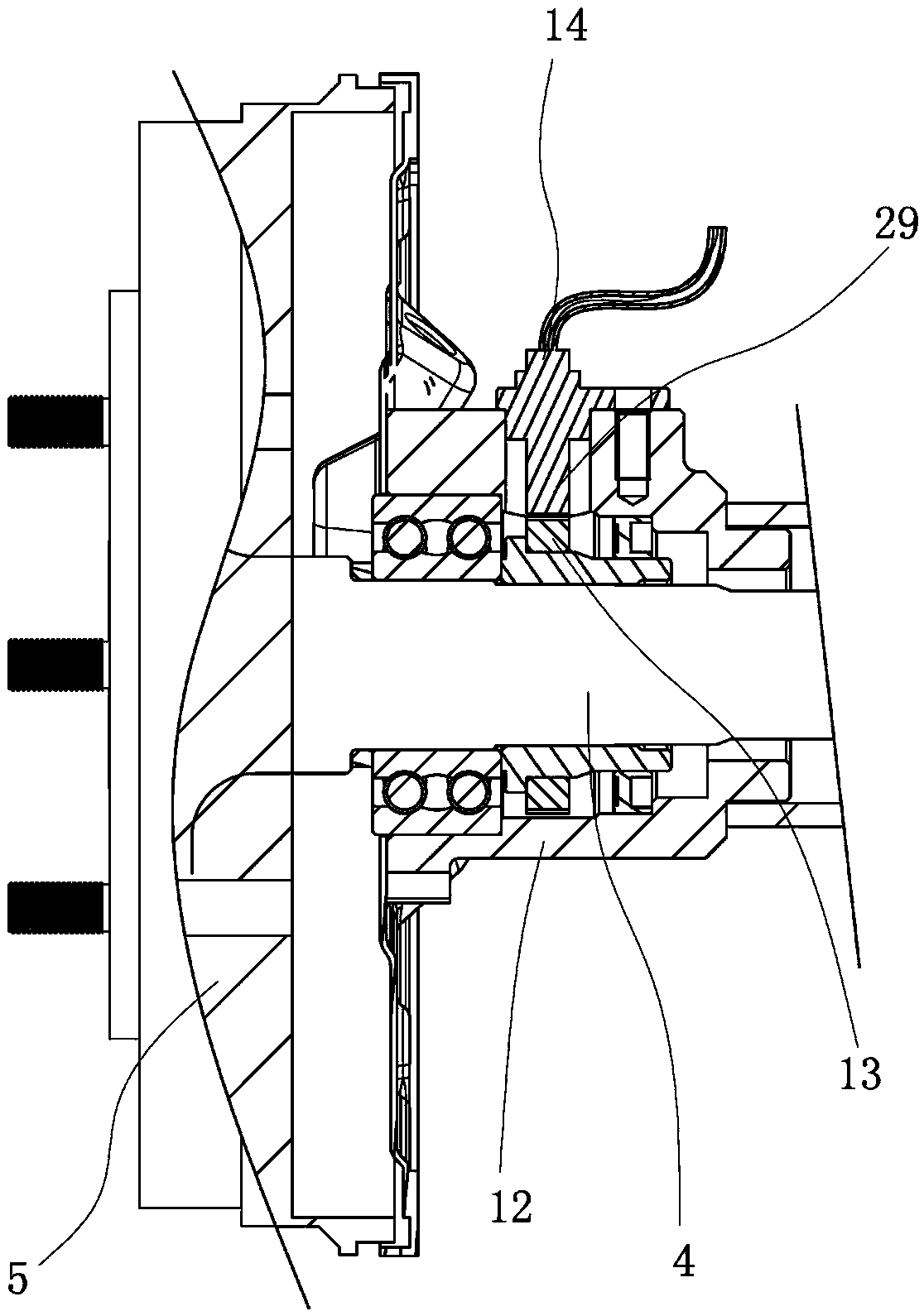

Electric automobile rear axle assembly with an ABS automatic shifting function

PendingCN106585348AFast gear shiftAccurate gear shiftElectric propulsion mountingGearing controlMotor driveElectric machine

The invention provides an electric automobile rear axle assembly with an ABS automatic shifting function, and belongs to the technical field of electric automobiles. According to the electric automobile rear axle assembly, the problems that energy consumption of an existing electric automobile rear axle is high and shifting cannot be conducted automatically are solved. The electric automobile rear axle comprises a decelerator, a differential mechanism and two bridge tubes connected on the differential mechanism. Half shafts penetrate through the bridge tubes, and braking drum plates driven to rotate by the half shafts are arranged at the outer ends of the bridge tubes. The decelerator is composed of an input gear assembly, a shifting gear assembly and an output gear assembly; a shell of the decelerator is connected to a main motor driving the input gear assembly to work, and a shifting motor capable of driving the shifting gear assembly to shift; and the shell of the decelerator is further provided with a speed sensor capable of monitoring the speed of the output gear assembly, signals monitored by the speed sensor are transmitted to a trip computer, and the trip computer sends shifting commands to the shifting motor after analyzing the signals. The electric automobile rear axle assembly with the ABS automatic shifting function has the advantages of high degree of automation, low energy consumption and accurate shifting.

Owner:TAIZHOU HENGYUE IND & TRADE CO LTD

Rear axle assembly of electric automobile

InactiveCN109795299AFast gear shiftAccurate gear shiftElectric propulsion mountingToothed gearingsReduction driveElectric machine

The invention provides a rear axle assembly of an electric automobile, and belongs to the technical field of electric automobiles. The assembly solves the problems that the rear axle of the existing electric automobile has high energy consumption and cannot automatically shift gears. The rear axle of the electric automobile comprises a speed reducer, a differential and two bridge tubes connected to the differential, wherein half shafts are arranged in the bridge tubes in a penetrating manner; brake drum discs driven to rotate by the half shafts are arranged at the outer end parts of the bridgetubes; the speed reducer consists of an input gear assembly, a shift gear assembly and an output gear assembly; a main motor capable of driving the input gear assembly to work is connected to an outer shell of the speed reducer; a shift motor capable of driving the shift gear assembly to shift gears is arranged on the outer shell of the speed reducer; a speed sensor capable of monitoring the output gear assembly is arranged on the outer shell of the speed reducer; a signal monitored by the speed sensor is transmitted to a traveling computer; and the traveling computer analyzes the signal andsends a shift instruction to the shift motor. The assembly has the advantages of high automation degree, low energy consumption and accurate gear shifting.

Owner:TAIZHOU HENGYUE IND & TRADE CO LTD

internal transmission control mechanism

The invention discloses an inner transmission control mechanism used in a chainless drive vehicle and a chain drive vehicle. According to the inner transmission control mechanism, a clutch mechanism to be controlled is driven to perform disengage or engage action by a power rotating part (such as an input ring, an inner gear, a planet carrier and an output ring) in an inner transmission via a cam or cam-like structure, or a linkage device is driven by the cam or cam-like structure to rotate or translate so as to enable the clutch mechanism to be controlled to perform disengage or engage action, then a rapid switching effect of the control mechanism is completed by rotating the cam or cam-like structure or the linkage device for a certain angle, main transmission power is supplied by the power rotating part instead of a shifting rod for controlling the switching action, the shifting rod can act relatively slightly, the transmission operation can be relatively accurate, the overall control mechanism is relatively simple and easy, the weight can be relatively reduced, the size can be relatively reduced, and furthermore the overall industrial practicability and the practicable performance of the inner transmission can be improved.

Owner:NEW KAILUNG GEAR

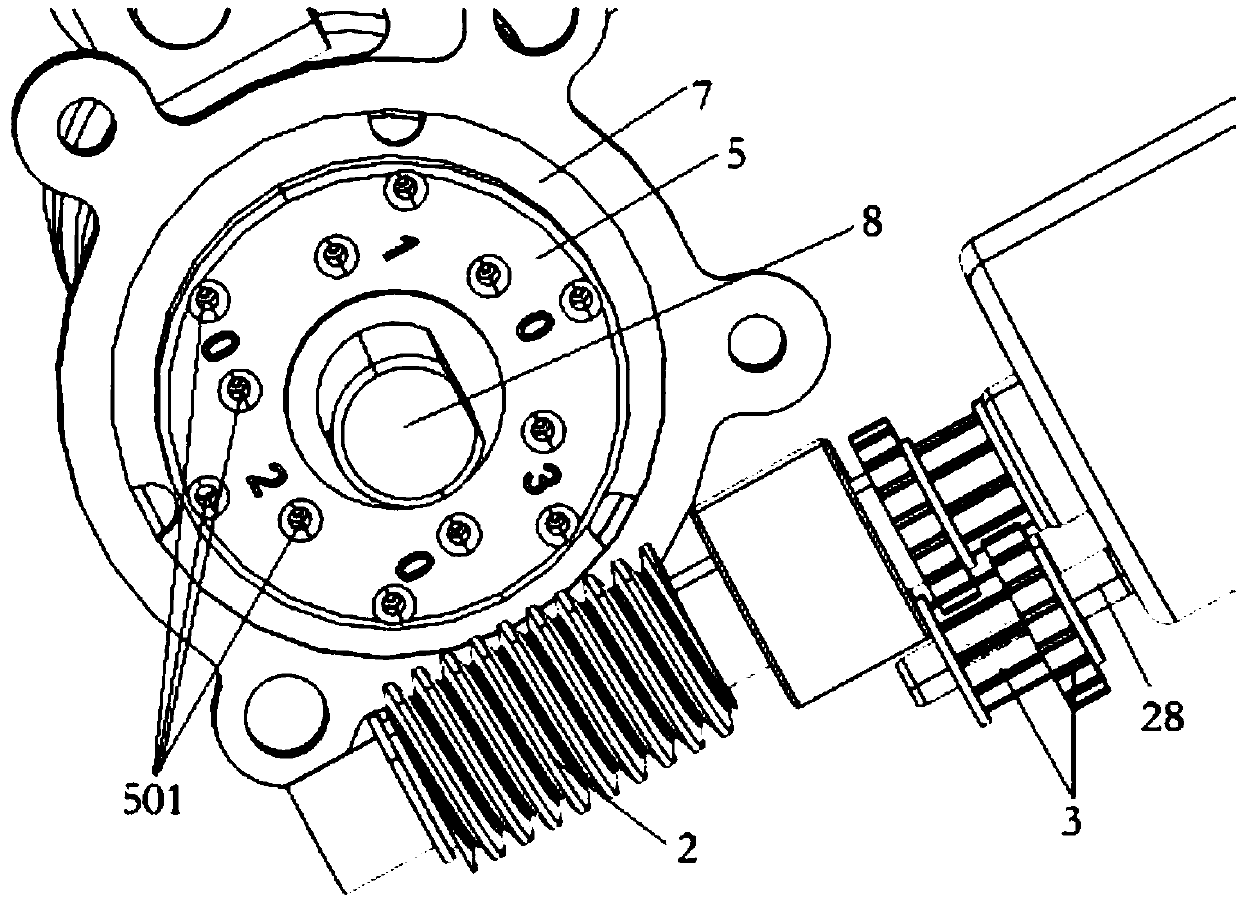

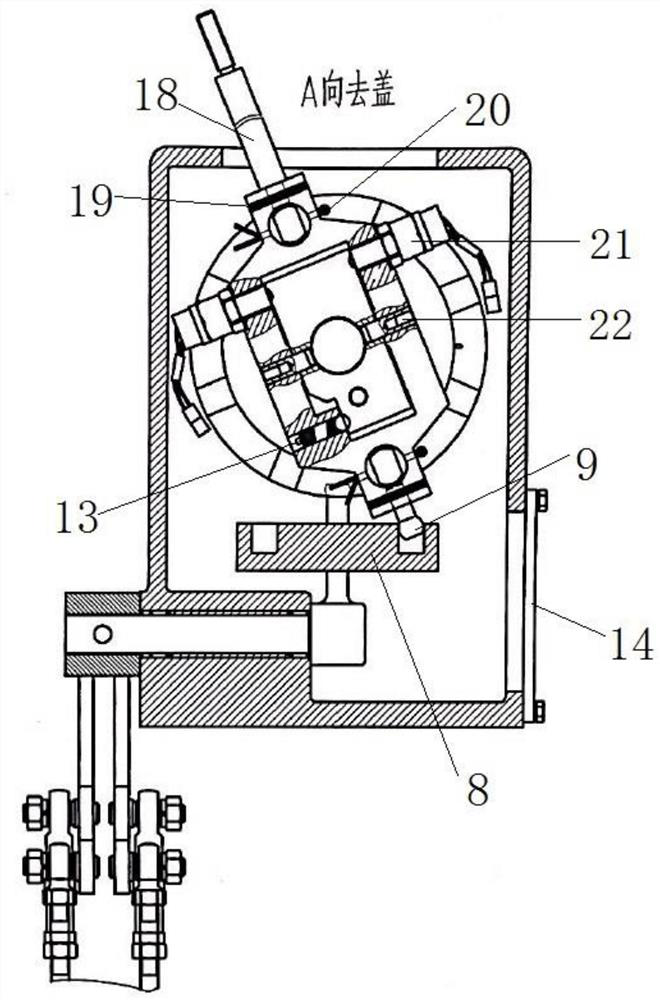

Double-clutch preset gear control mechanism

The invention relates to the technical field of gear shifting control mechanisms, in particular to a double-clutch preset gear control mechanism. The double-clutch preset gear control mechanism comprises a cam assembly, an angle sensor, starting switches, a limiting block, a swing block, shifting fork assemblies and a control cover, the cam assembly comprises a cam, and a plurality of lead groovesand a plurality of gear grooves are formed in the cam; the limiting block is mounted below the cam assembly, and a limiting groove used for mounting a lead rod is formed in the limiting block; the swing block is connected with a control rod and the lead rod, and the swing block cooperates with the gear grooves through positioning pins at the two ends for gear shifting; the swing block can rotateleft and right to switch upshift and downshift; the shifting fork assemblies are mounted in the lead grooves of the cam through rocker arm assemblies; and the control cover is mounted on a gearbox body, and a pipe sleeve used for supporting the rocker arm assemblies is mounted on the control cover. Gear shifting and upshift and downshift switching are easy and convenient to operate, and the shifting fork assemblies are more convenient to overhaul.

Owner:JIANGSU WORLD AGRI MACHINERY

Electric commercial vehicle rear auxiliary box gear shifting executing mechanism

PendingCN114877067AReduce driving pressureLow powerControlled membersGearing controlBrushless motorsControl theory

According to the electric commercial vehicle rear auxiliary box gear shifting executing mechanism, a direct-current brushless motor drives a lead screw to rotate, a lead screw nut drives a gear shifting fork shaft to transversely move, a lever structure drives a gear shifting fork, and therefore a high-gear and low-gear sliding sleeve is driven to move towards a high-gear conical hub or a low-gear conical hub; the high-gear synchronizing ring and the low-gear synchronizing ring are circumferentially bounced off by a certain angle under the action of elastic force of a spring, and gear teeth are always staggered by half of teeth, so that when the synchronizing ring on one side is meshed with the gear teeth of the high-low-gear sliding sleeve, the conical surface of the gear teeth of the synchronizing ring on the other side is opposite to the conical surface of the gear teeth of the high-low-gear sliding sleeve. The gear shifting device has the advantages of increasing gear shifting force, being simple and efficient and being accurate and rapid in gear shifting.

Owner:青岛科麟智传汽车科技有限公司

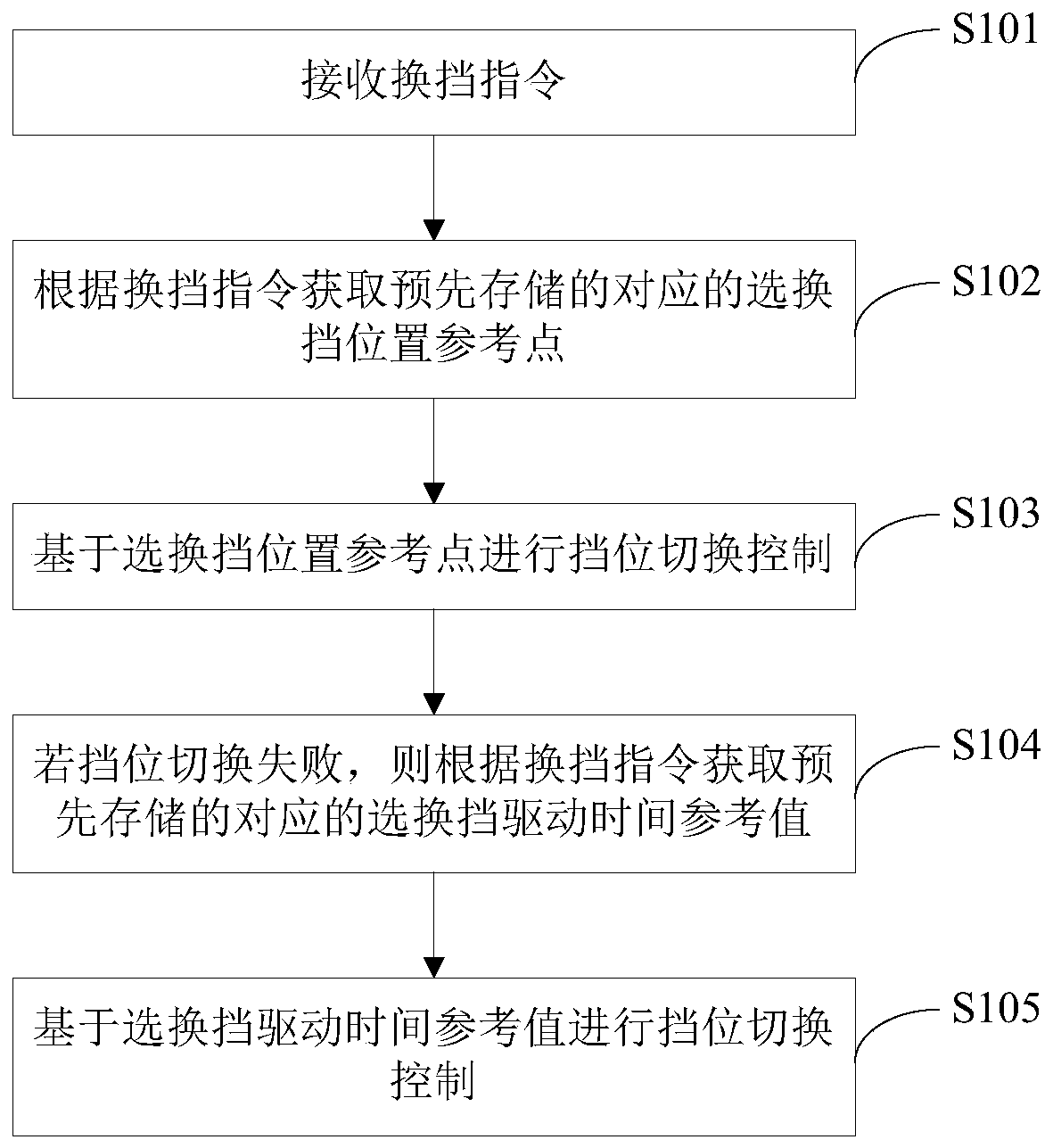

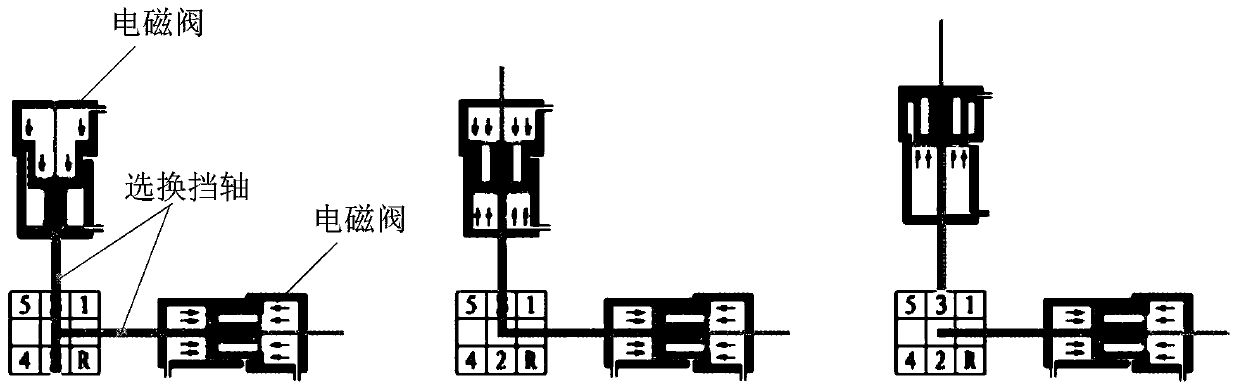

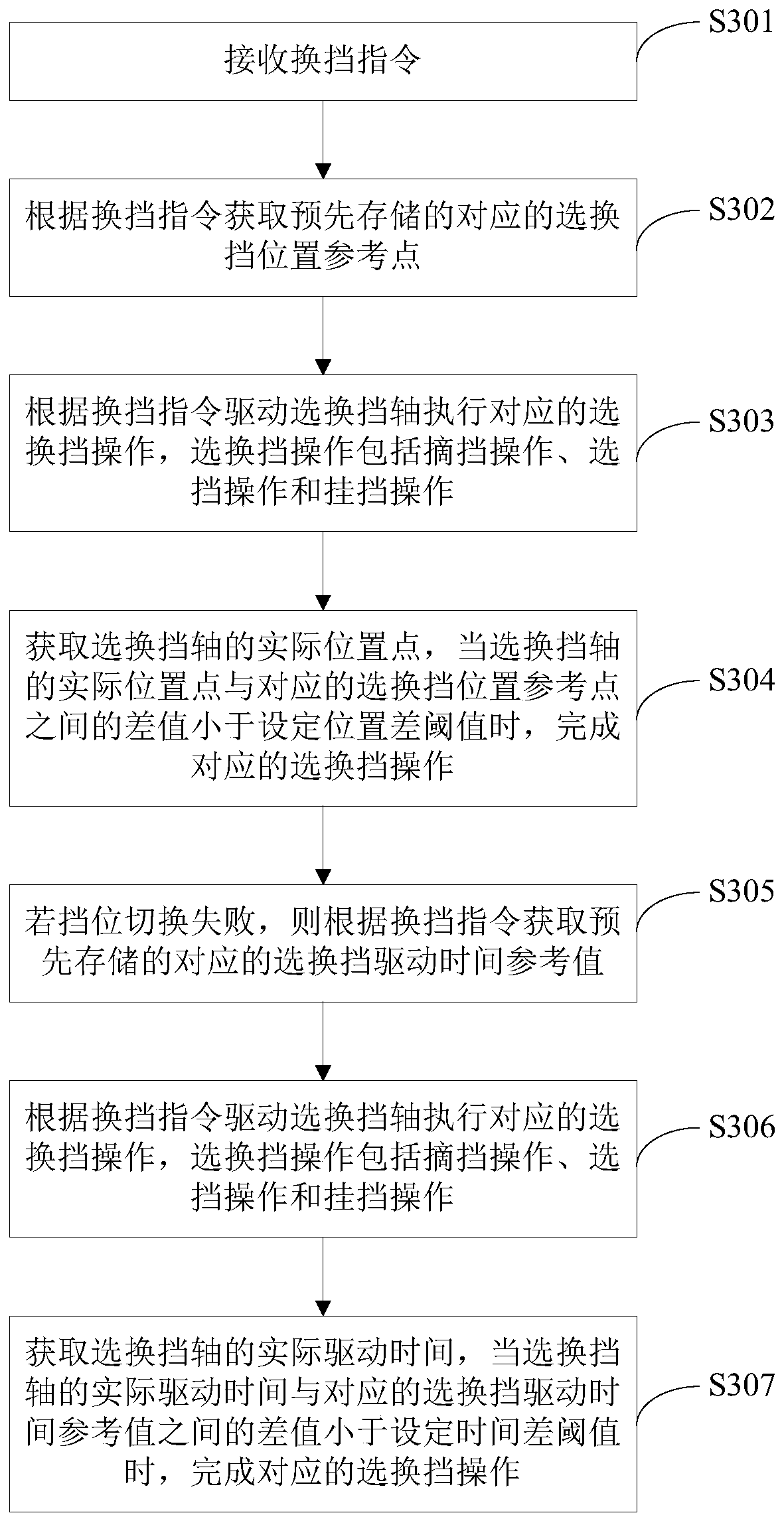

Gear switching control method, device and automatic transmission control unit

ActiveCN107178610BAvoid shifting sticking and other phenomenaAccurate gear shiftGearing controlAutomatic transmissionEngineering

The invention provides a gear-shifting control method and device and an automatic gearbox control unit. The gear-shifting control method comprises the steps that a gear-shifting command is received; a corresponding pre-stored gear-selecting and gear-shifting position reference point is obtained according to the gear-shifting command; gear-shifting control is conducted based on the gear-selecting and gear-shifting position reference point; if gear shifting fails, a corresponding pre-stored gear-selecting and gear-shifting driving time reference value is obtained according to the gear-shifting command; and gear-shifting control is conducted based on the gear-selecting and gear-shifting driving time reference value. According to the gear-shifting control method and device and the automatic gearbox control unit, under the condition that gear-shifting control based on the gear-selecting and gear-shifting position reference point fails, gear-shifting control is conducted based on the gear-selecting and gear-shifting driving time reference value, so that the phenomenon of unsmooth gear shifting caused by abrasion of the gearbox or interference to a position sensor or failures is avoided, and rapid and accurate gear shifting is achieved accordingly.

Owner:BEIJING ELECTRIC VEHICLE

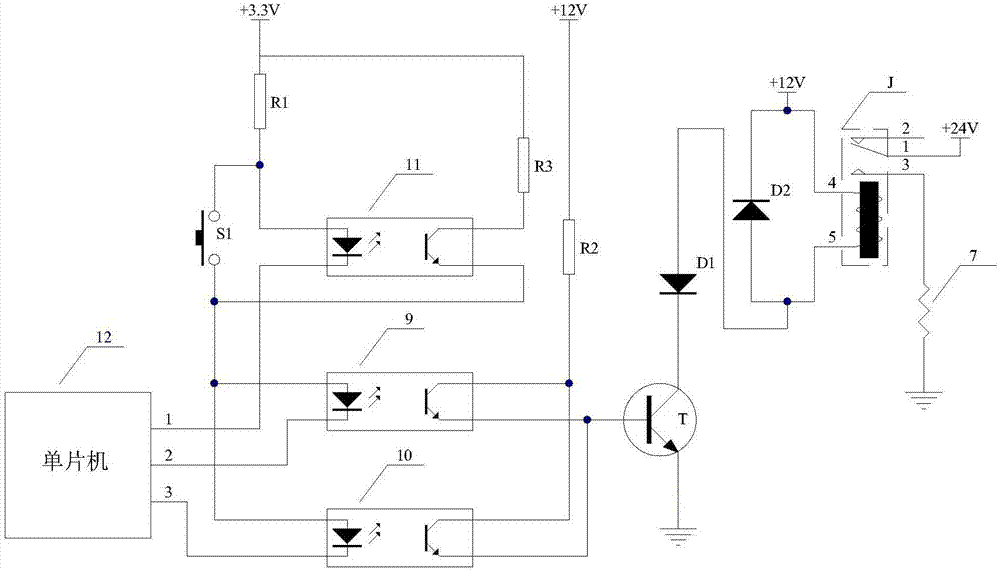

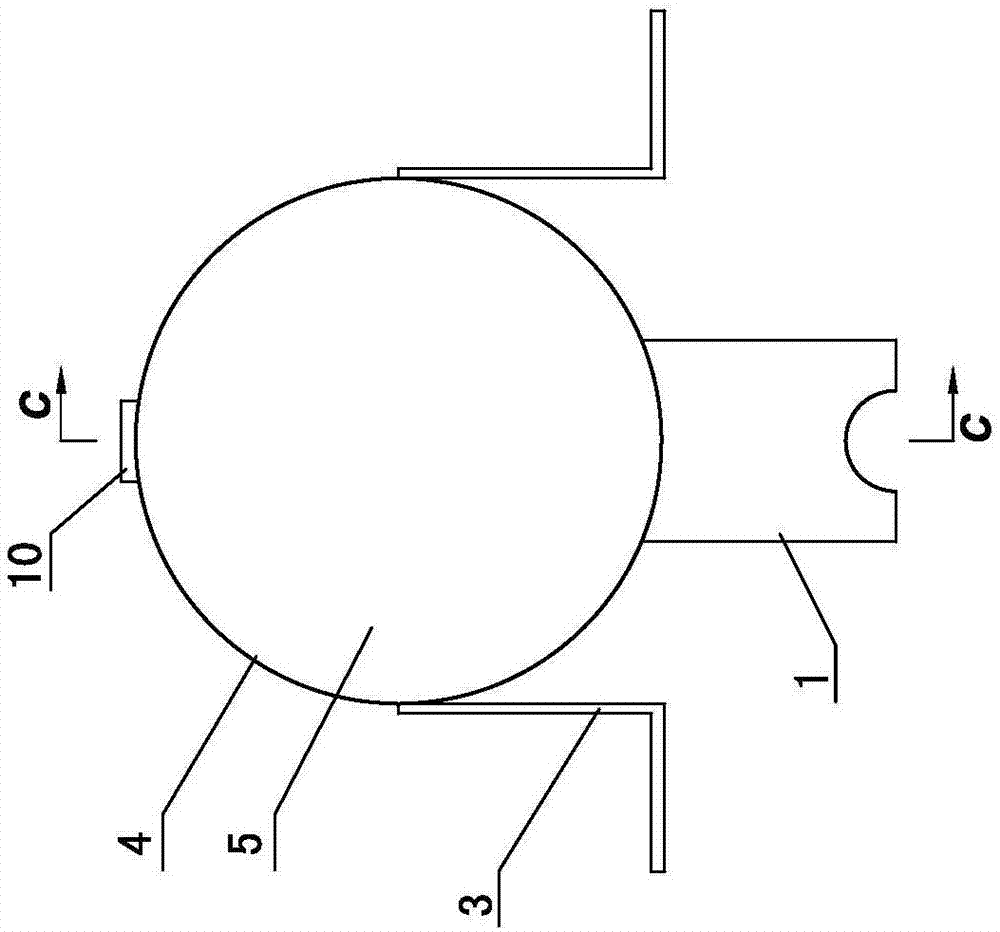

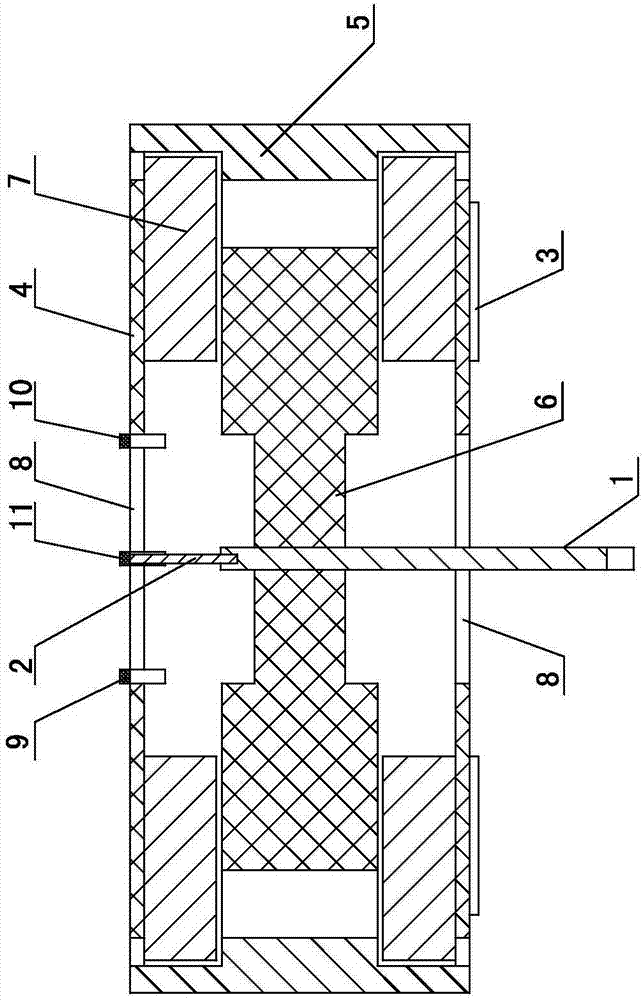

Electromagnetic actuator used for gear shifting of electric automobile

The invention provides an electromagnetic actuator used for gear shifting of an electric automobile. The electromagnetic actuator comprises a shifting fork, an iron piece, a base, a tubular shell mounted on the base, side end covers for fixedly plugging the two ends of the shell, an iron core, and coils for sleeving the two ends of the iron core in a spaced mode; the coils are fixedly connected with the shell, two windows are formed in the side wall of the shell, and three notched optocouplers are fixedly arranged in one window in the axial direction and correspond to the first gear, the neutral gear and the second gear of the automobile; the shifting fork perpendicularly and fixedly penetrates through the iron core, one end of the shifting fork is fixedly connected with the iron piece, the other end of the shifting fork penetrates out of a gap of the other window, and the other end of the iron piece penetrates into a notch in one notched optocoupler in a spaced mode; and an electric control module comprises a single chip microcomputer, a relay, an audion, a diode and a switch, wherein the three PWM output ends of the single chip microcomputer are connected with the input ends of the first gear optocoupler, the second gear optocoupler and the neutral gear optocoupler correspondingly. The coils are controlled to be on or off by controlling the corresponding optocouplers to be on or off, electromagnetic force generated when the coils are electrified drives the shifting fork to move, and gear shifting is smoothly completed.

Owner:SHANDONG UNIV OF TECH

Electronically controlled shift control method, transmission electronically controlled shift control device and system

Owner:ZOOMLION HEAVY MASCH CO LTD

A kind of target gear calculation method and device

The invention provides a target gear calculating method and system. The target gear calculating method comprises the following steps: obtaining the gearshifting parameter of a vehicle in real time, determining the best gearshifting point of the current power of the vehicle based on the gearshifting parameter and the acceleration curve of each gear, and determining the best gearshifting point of the current economy of the vehicle based on the gearshifting parameter and the fuel consumption curve of each gear; and based on the correspondence between the adjusting factor established in advance and a power gearshifting point and the correspondence between the adjusting factor and the economical gearshifting point of fuel, determining the best gearshifting point of the current power and regarding any best gearshifting point of the best gearshifting points of the current economy as the target gearshifting point. Through the target gear calculating method, the driving habit of a driver is obtained to determine the adjusting factor, and the gearshifting parameters under different working conditions are obtained in real time to realize precise gearshifting under different working conditions.

Owner:WEICHAI POWER CO LTD

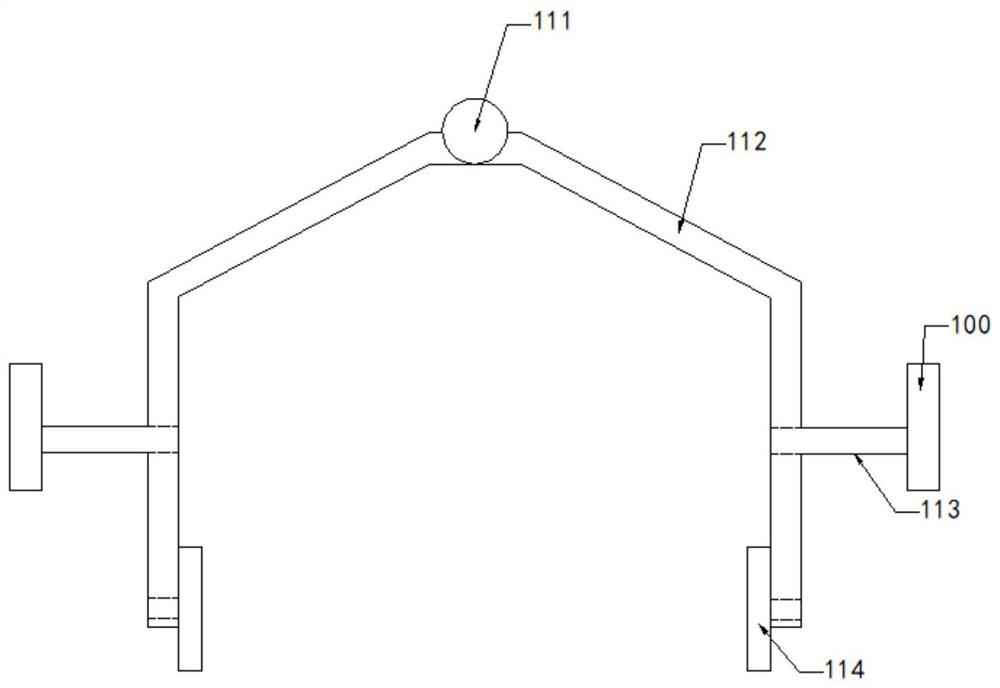

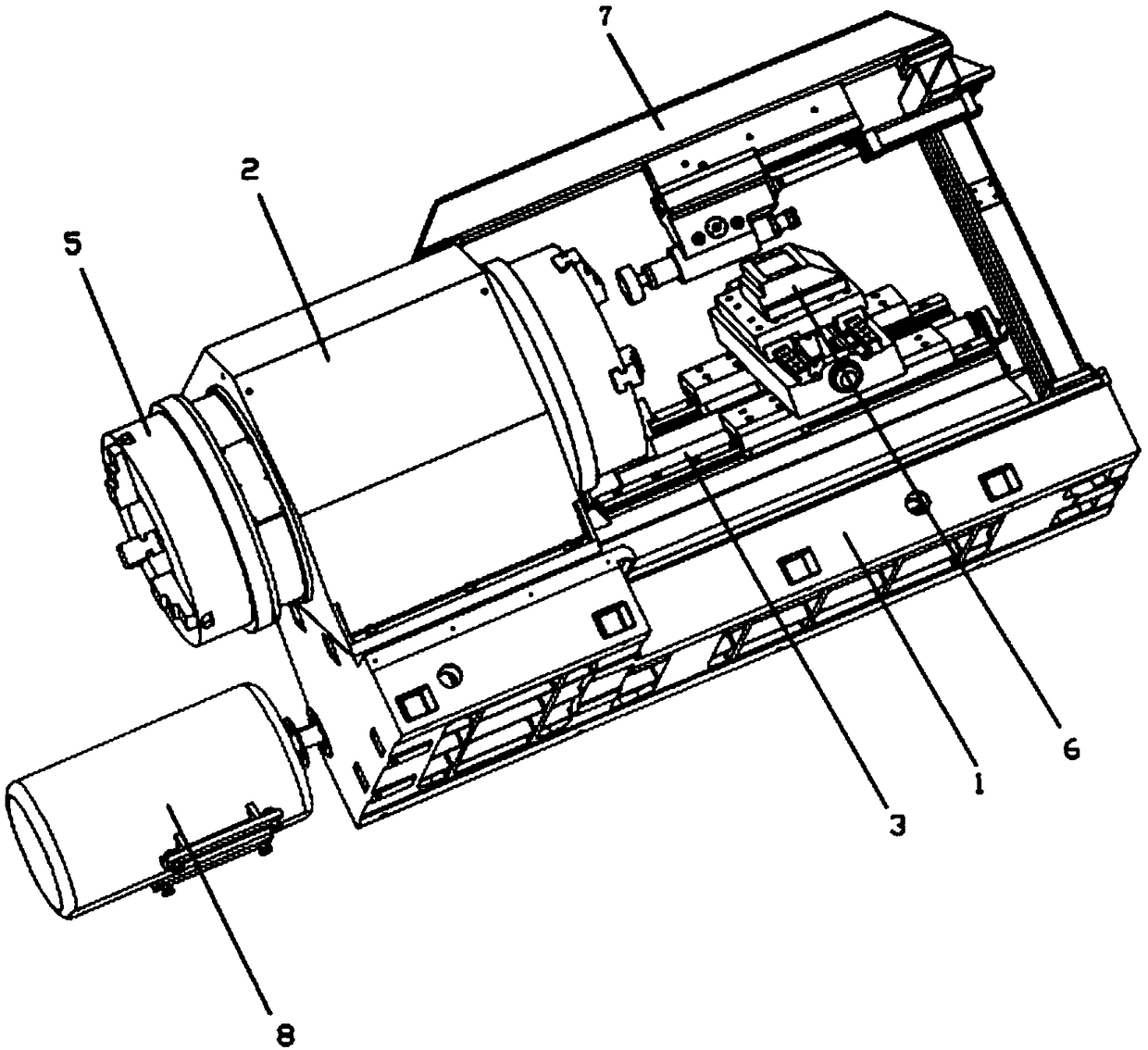

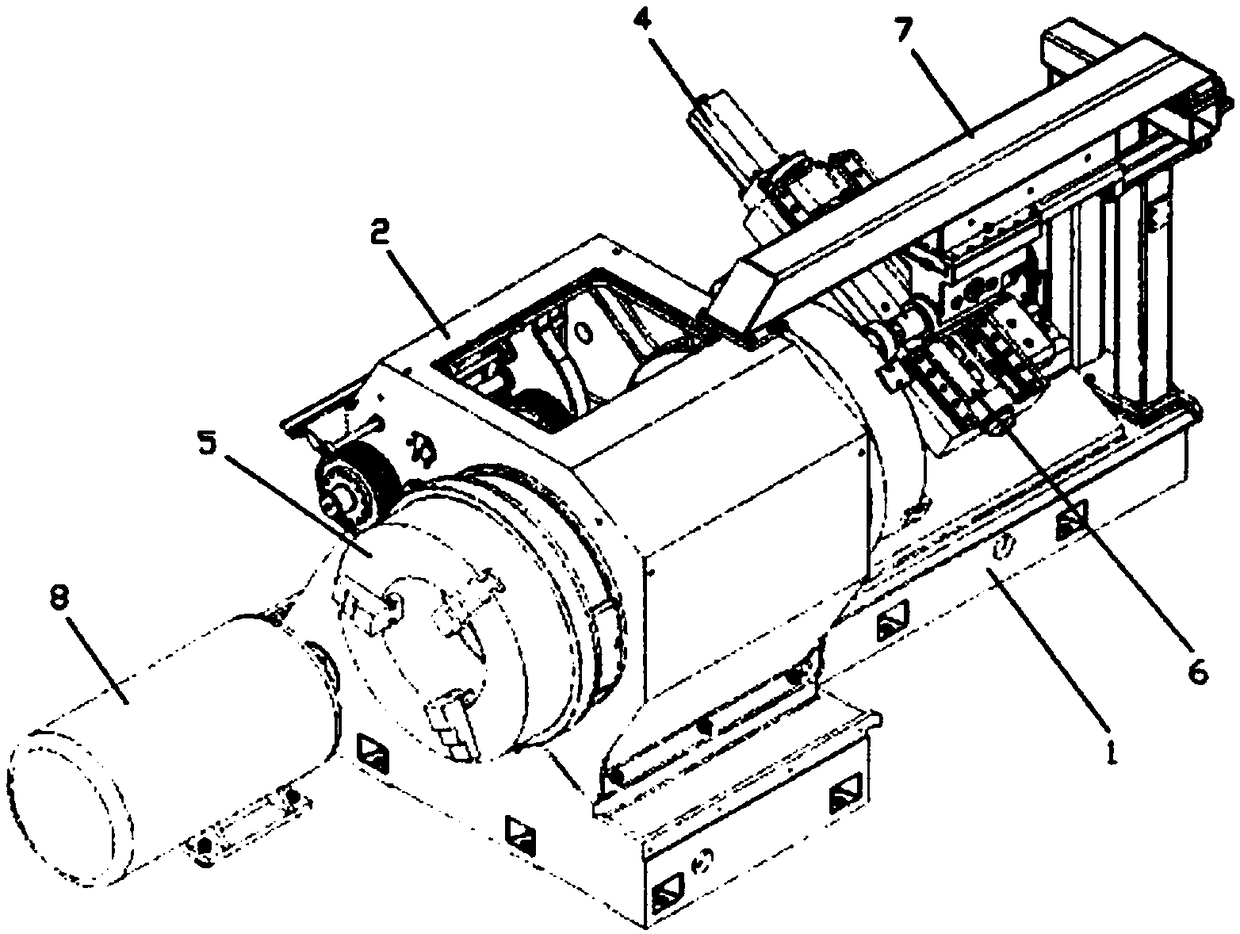

High precision numerical control machine tool

InactiveCN108857528AImprove machining accuracyImprove completenessDriving apparatusMetal working apparatusNumerical controlEngineering

The invention provides a high precision numerical control machine tool. The tool comprises a bed body, a spindle box component disposed on the bed body, a longitudinal servo feed system, a transverseservo feed system, a main power device system, a tool holder system, a positioning device and an electrical appliance system, and the main power device system is provided with a roller bearing and anoil cylinder. The main power device system is provided with a roller bearing and a cylinder, a steel pipe is processed by spindle rotation, thereby improving the machining precision of the machine tool, the whole machine structure is more compact, a spindle bearing has longer service life, and an oil cylinder shift mode is used for gear shifting, which increases the degree of mechanized production, reduces labor costs, reduces the work intensity of workers, and makes machine tool shifting more convenient, faster and more accurate.

Owner:南通永锠数控机械科技有限公司

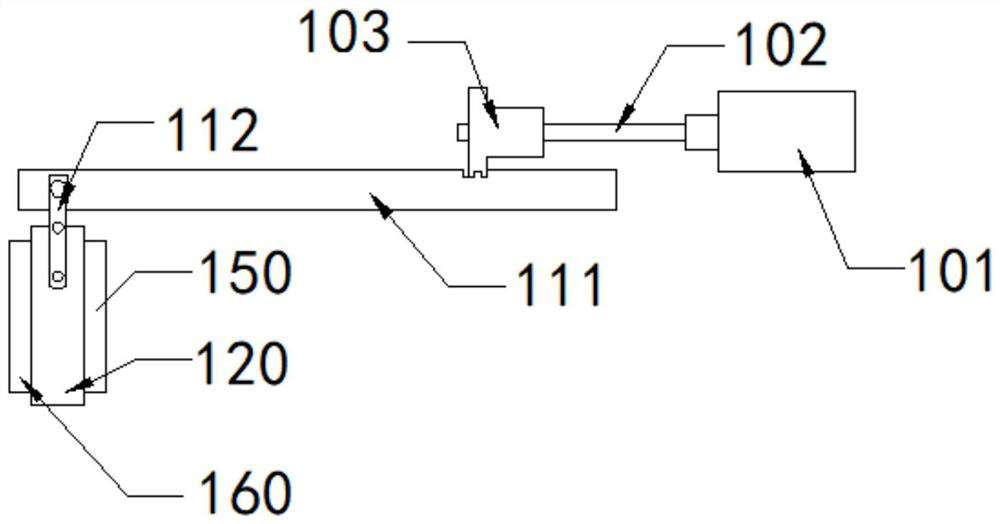

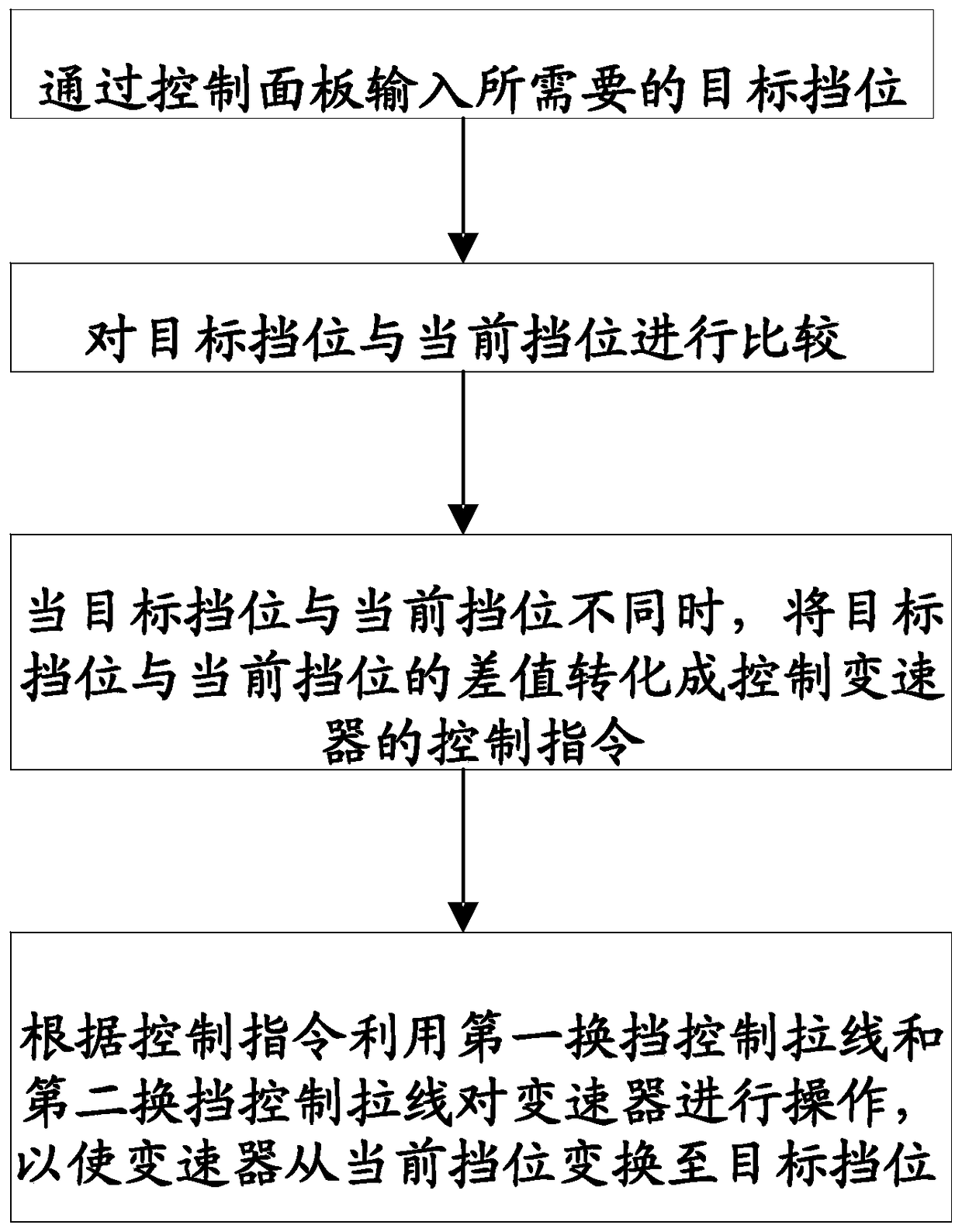

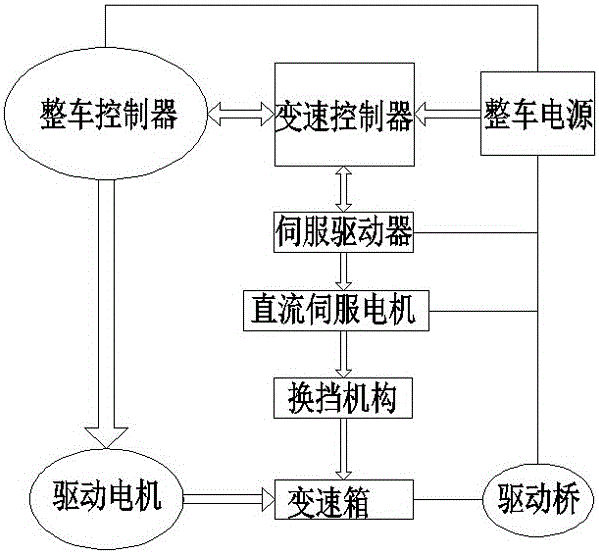

Pure electric vehicle two-speed mechanical automatic transmission shift control system and control method thereof

The invention discloses a two-speed mechanical automatic transmission control system for a pure electric vehicle and a control method thereof. The system includes a vehicle controller, a drive motor, a speed change controller, a servo driver and a DC servo motor. The gear shifting is controlled by the number of PWM pulses. spacing, shifting quickly, accurately, and in one step, effectively avoiding the traditional method of using a displacement sensor that is easily restricted by the spatial position of the gearbox; the shifting mechanism adopts a transmission screw and a shift fork structure with a nut, which has a simple structure and accurate shifting. , and has a self-locking function; the shifting action is completed within 1 second, the shifting time is short, the pulse is constant, the shifting is accurate, in place, and the impact is small, effectively achieving fast and smooth shifting; by updating the pulse number of the global variable , realizes intelligent detection of shift intervals, ensures the accuracy and speed of each shift, and solves the problem of insufficient shift accuracy caused by manufacturing errors in mechanical structures such as shift mechanisms and gearboxes.

Owner:郑州得力齿轮有限公司

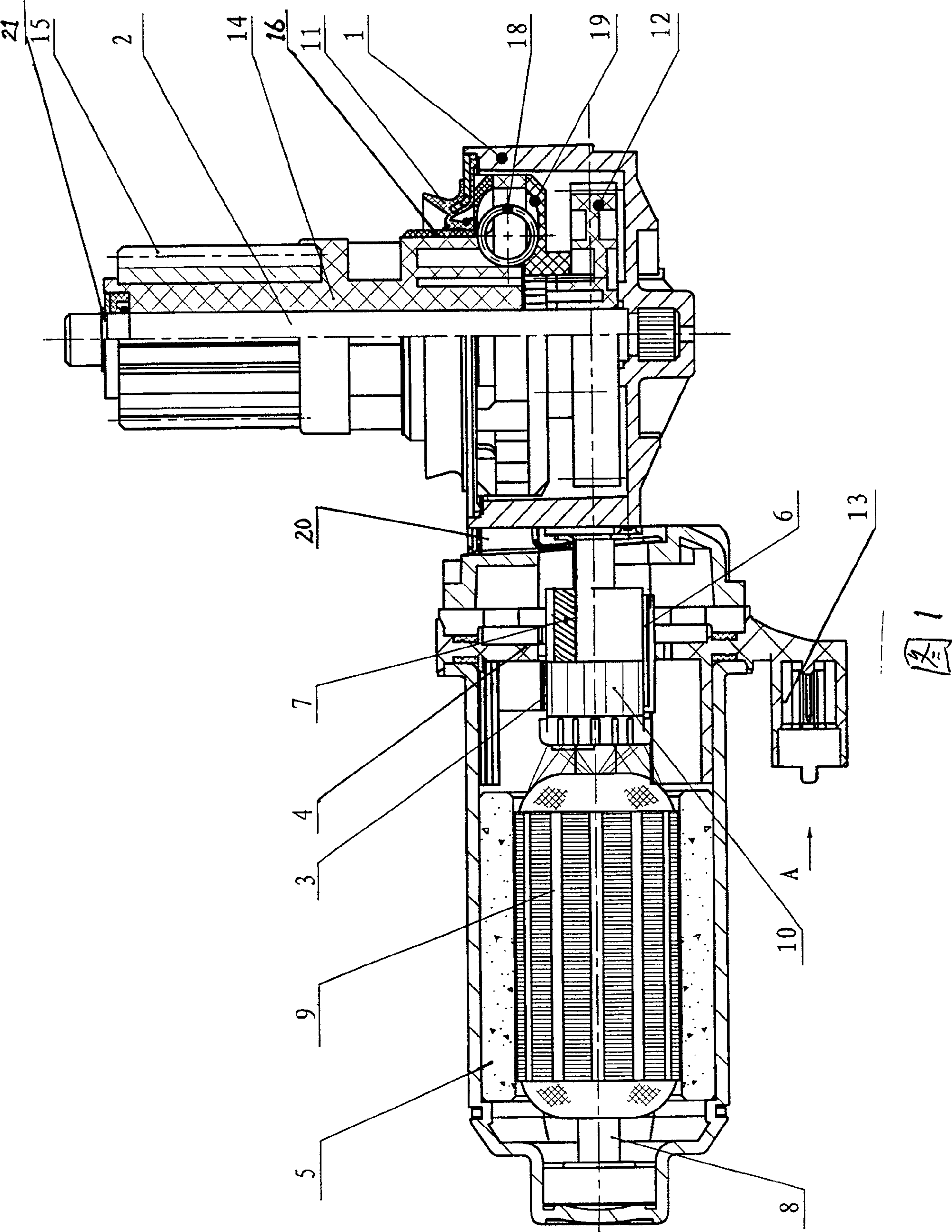

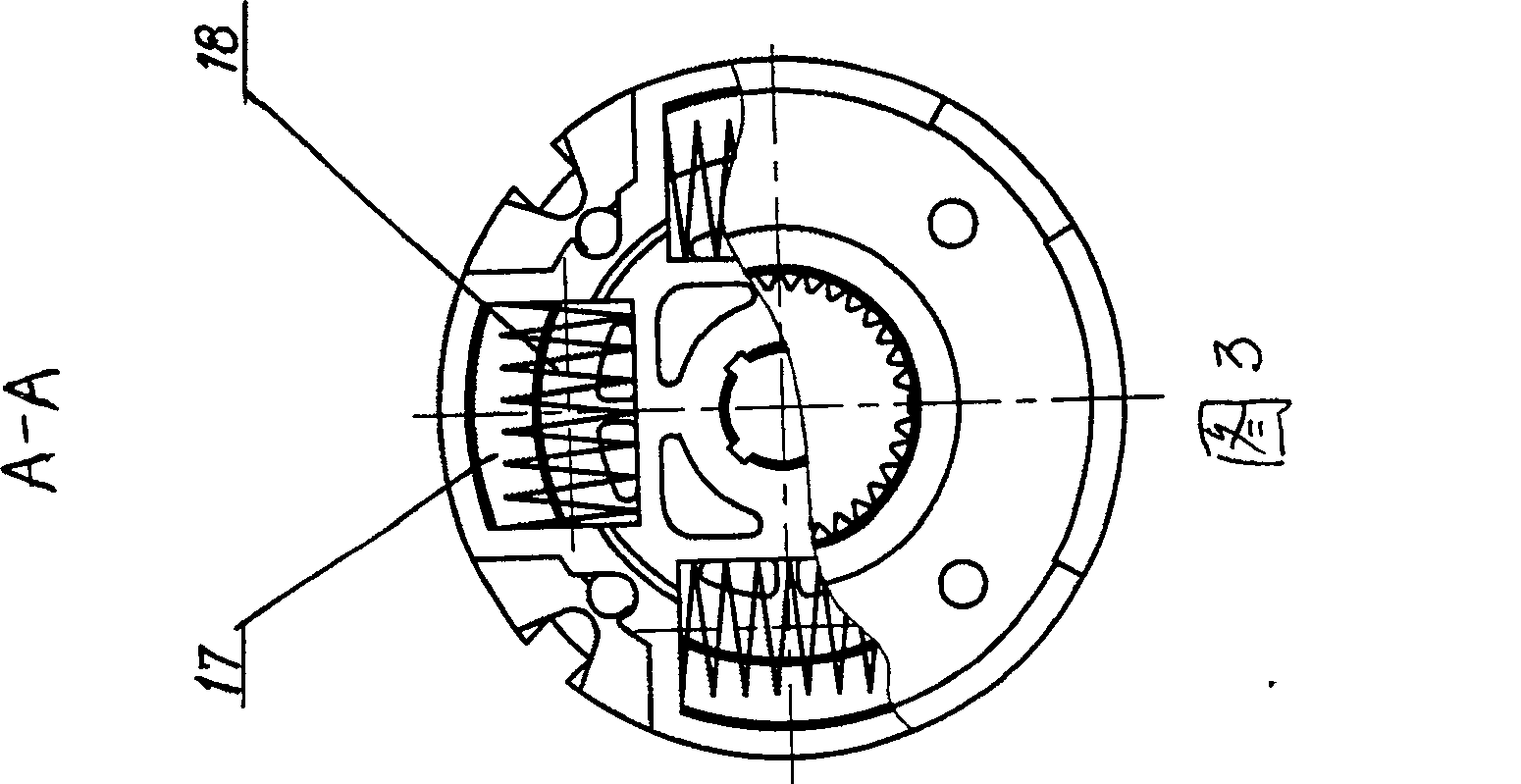

Gear shifting motor

InactiveCN100488005CReduce shockProtection securityMechanical energy handlingStructural associationReduction driveGear wheel

The invention discloses a shift motor, which is characterized by the following: loading Hall inducer 6 with magnetic property on the brush rocker 4 of brush rocker component; casing induction counting gear 7 corresponding to Hall inducer on the motor shaft 8 of rotor component; connecting reducer case 1 of reducer case component and gear shaft 2; casing buffer bulk 14 on the gear shaft 2; casing buffer gear 15, plastic sleeve 16 on the outer and inner sides of buffer bulk 14 separately; opening spring groove 17 with buffer spring 18 on the top of buffer bulk 14; connecting lid gear 19 in the inner part of buffer bulk 14; gearing lid gear 19 and positive gear 12. The invention protects driven part effectively, which is fit for automobile fork and shift sequently and precisely.

Owner:浙江瑞鹏汽车电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com