Rear axle assembly of electric automobile

A technology for electric vehicles and rear axles, which is applied to electric power units, power units, transmission units, etc., can solve the problems of controller burnout, starting electricity consumption, and high vehicle fuel consumption, and achieves fast shifting speed and improved safety. , the effect of low driving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

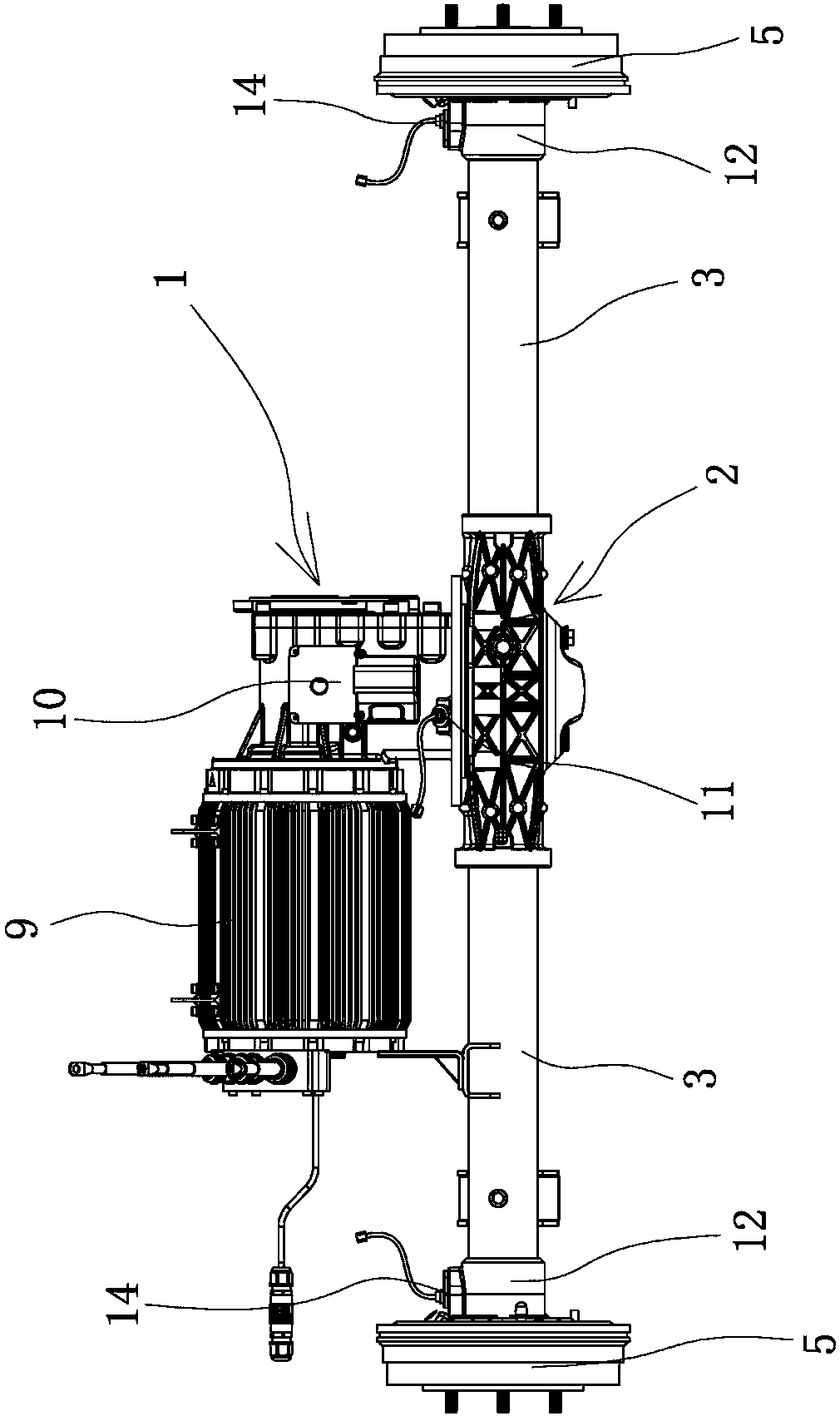

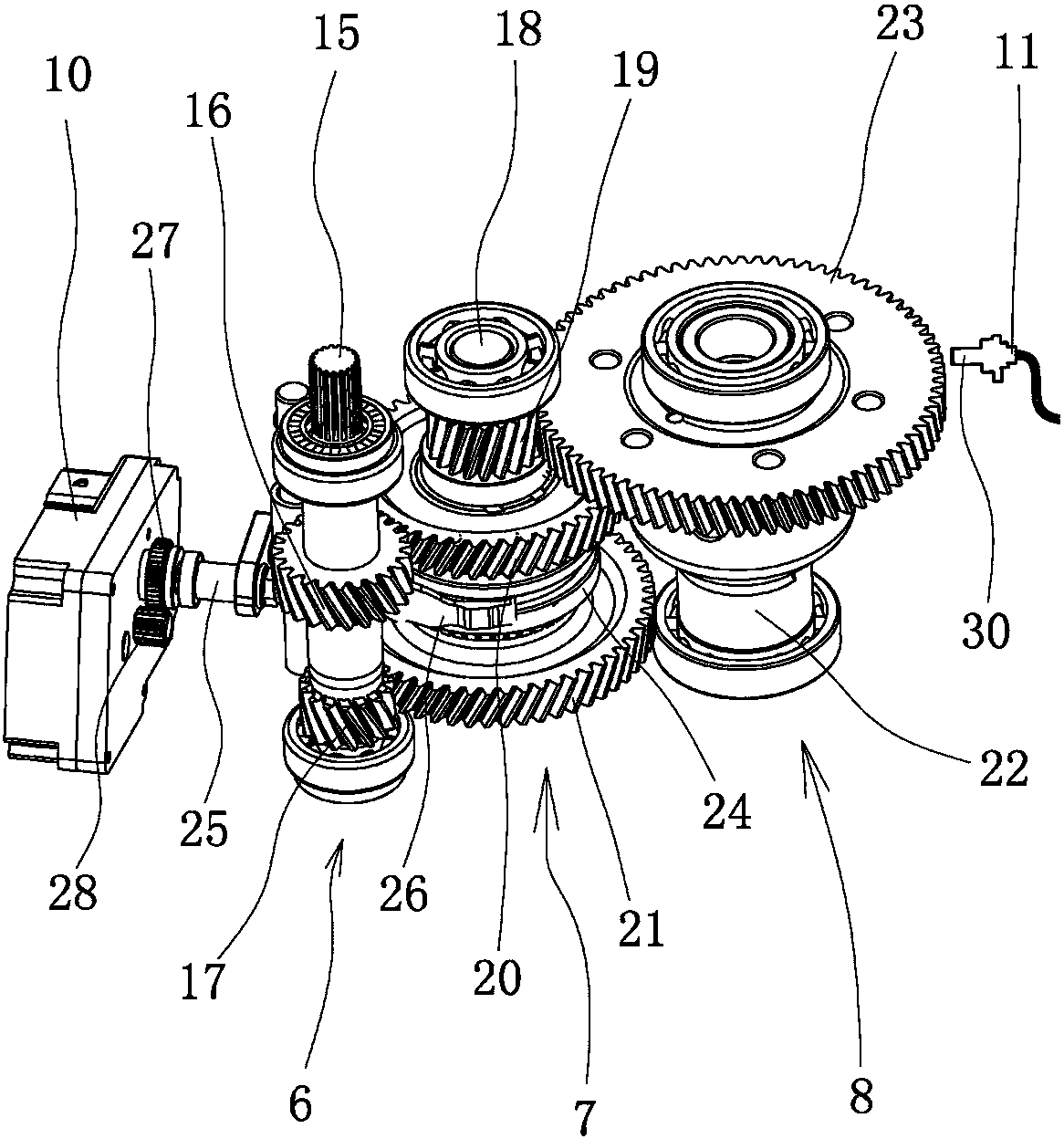

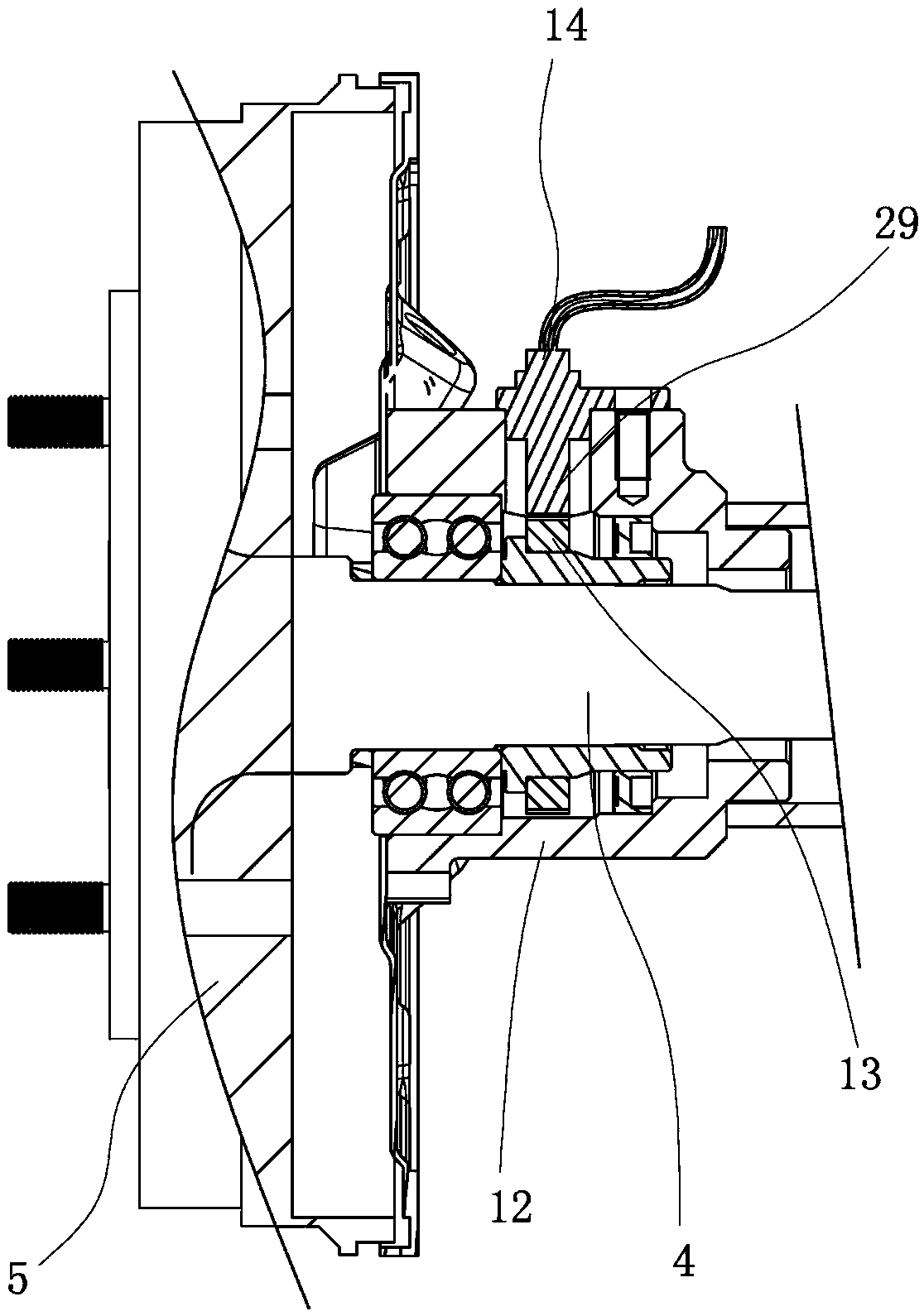

[0021] Such as figure 1 , figure 2 , image 3 As shown, the rear axle assembly of the electric vehicle includes a reducer 1, a differential 2, and two bridge tubes 3 connected to the left and right ends of the housing of the differential 2, and the bridge tube 3 is pierced with The half shaft 4 rotated by the reducer 1, the outer end of the bridge tube 3 is provided with the brake drum 5 driven by the half shaft 4, the reducer 1 is composed of the input gear assembly 6, the shift gear assembly 7 and the output gear 23 components 8, the reducer 1 shell is connected with the main motor 9 that can drive the input gear assembly 6 to work, and is provided with a shift motor 10 that can drive the shift gear assembly 7 to shif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com