Hydraulic controlled clutch and speed variator

A clutch and hydraulic technology, applied in the direction of clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of strong shifting frustration, complex structure, small load torque, etc., and achieve stable power engagement and separation, and high transmission efficiency , The effect of fast shifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

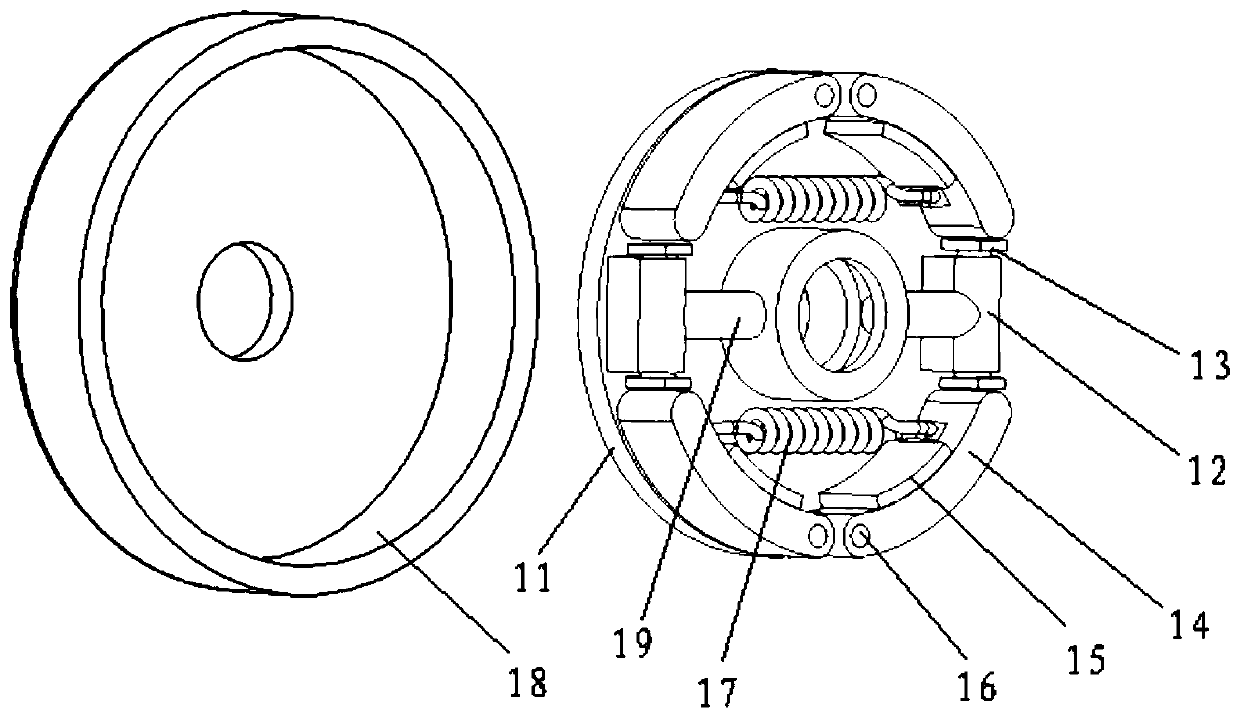

[0030] refer to figure 1 and figure 2 , a specific embodiment of the present invention is: a hydraulically controlled clutch, the clutch 10 includes,

[0031] The brake drum 18 and the brake assembly matching the shape and size of the brake drum 18, the brake assembly is placed inside the brake drum 18, the brake assembly includes a brake base plate 11, a brake cylinder 12 , hydraulic pipeline 19, brake shoe 14, brake shoe baffle 15, support pin 16 and return spring 17;

[0032] There are four brake shoes 14, and the brake shoes 14 are respectively pivotally connected with the support pin 16 along the edge of the brake base plate 11; the brake shoe baffle plate 15 is fixed on the brake base plate 11, and contact with the inner surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com