High precision numerical control machine tool

A CNC machine tool and high-precision technology, which is applied to metal processing machinery parts, metal processing, drive devices, etc., can solve the problems of high work intensity of workers, inconvenient shifting of machine tools, complex spindle structure, etc., so as to reduce labor costs and reduce labor costs. The effect of compact structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

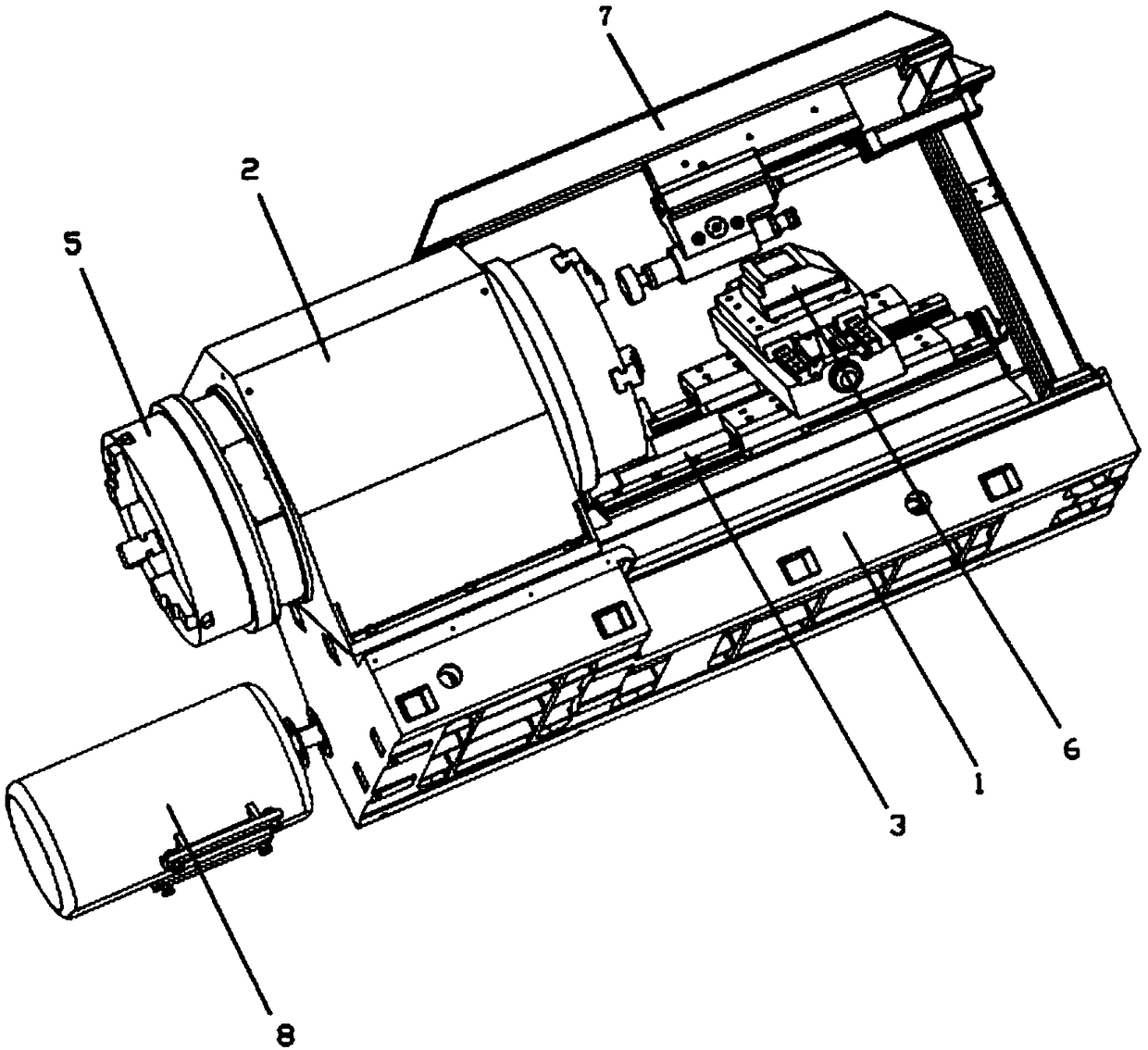

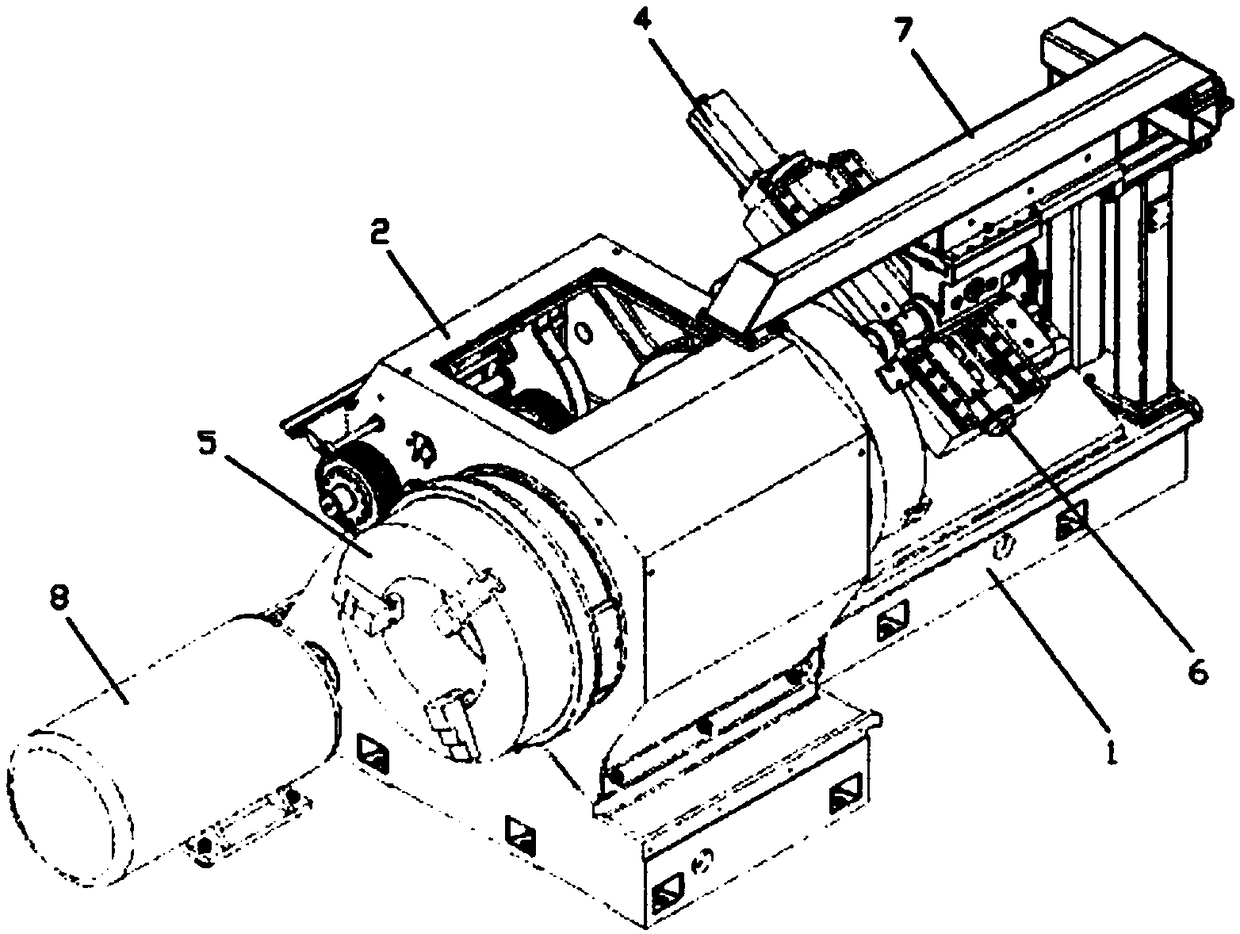

[0010] Attached below Figure 1-2 An embodiment of the present invention is described.

[0011] The high-precision numerical control machine tool of the present invention is used for processing steel pipes, including a bed 1, a spindle box part 2 arranged on the bed 1, a longitudinal servo feed system 3, a lateral servo feed system 4, and an active power device system 5 , Tool holder system 6, positioning device 7 and electrical system 8.

[0012] The main power device system 5 is provided with a roller bearing and an oil cylinder, the main power device system 5 is a main shaft system, and the roller bearings are sleeved on both ends of the main shaft of the main shaft system. The tool holder system 6 includes a large pallet 61 positioned on the bed 1 , a middle pallet 62 arranged above the large pallet 61 , and a tool holder spacer arranged above the middle pallet 62 63. The electrical system 8 is a motor.

[0013] Since the roller bearings are sleeved at both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com