Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about "OLED manufacture/treatment processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

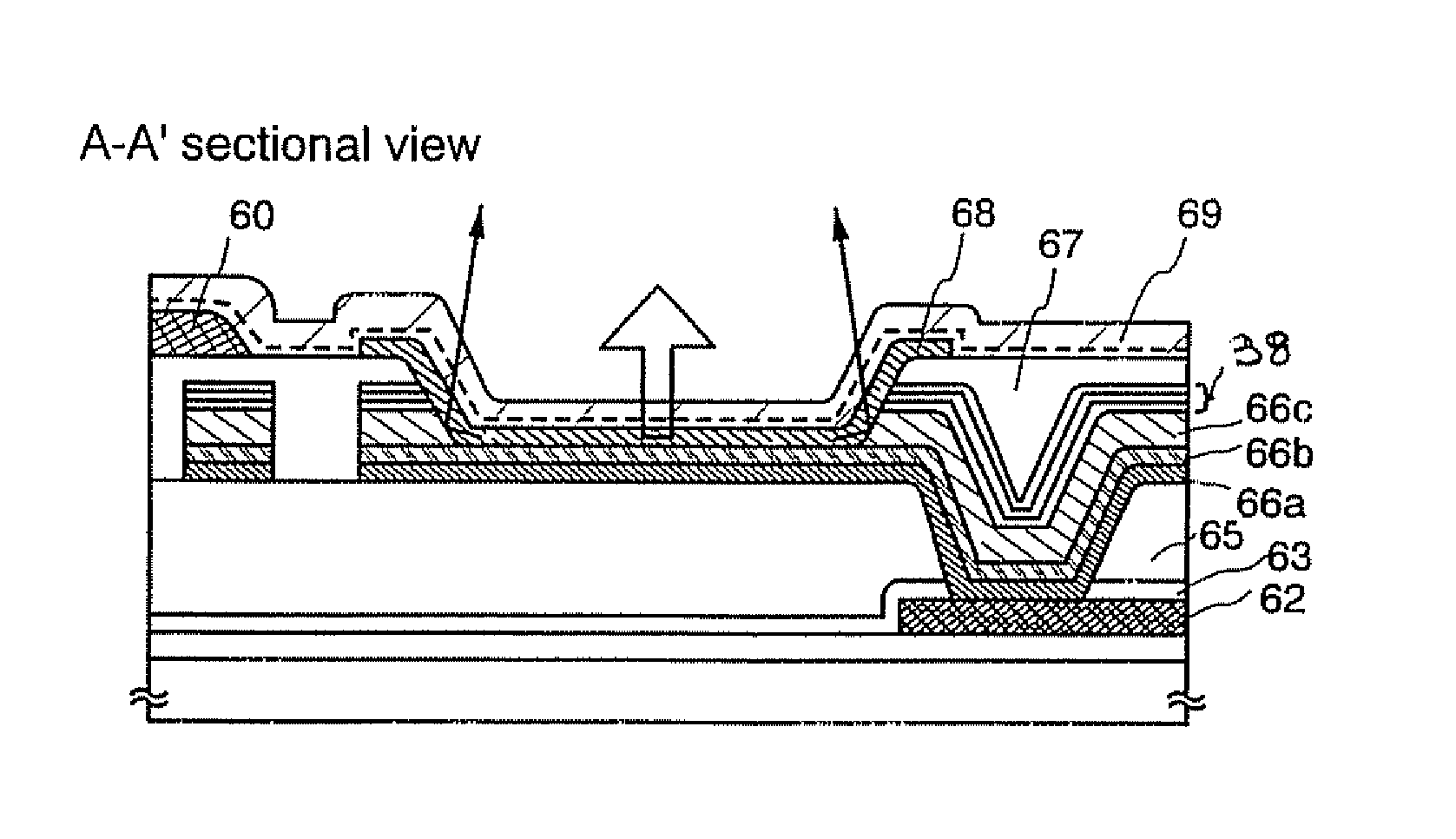

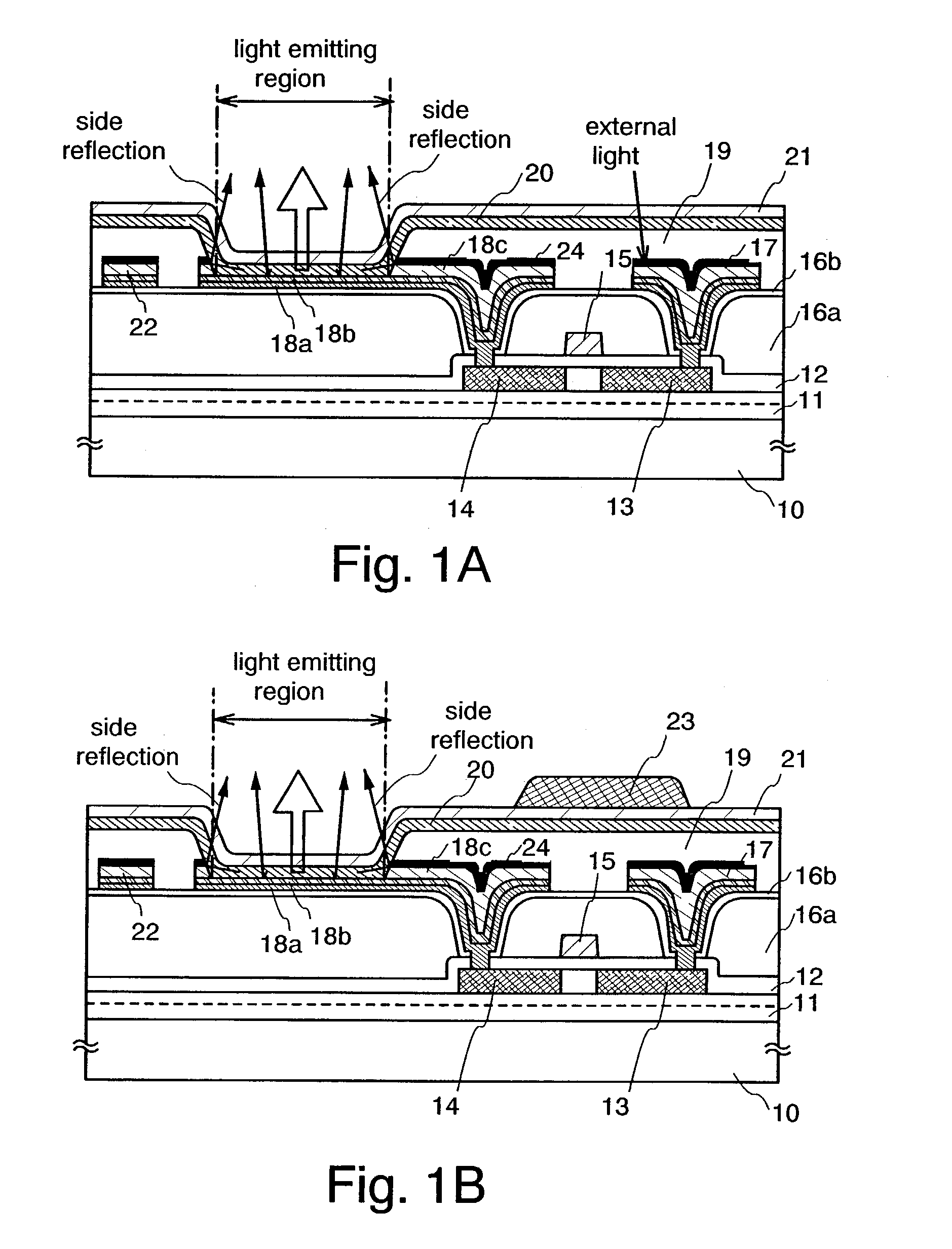

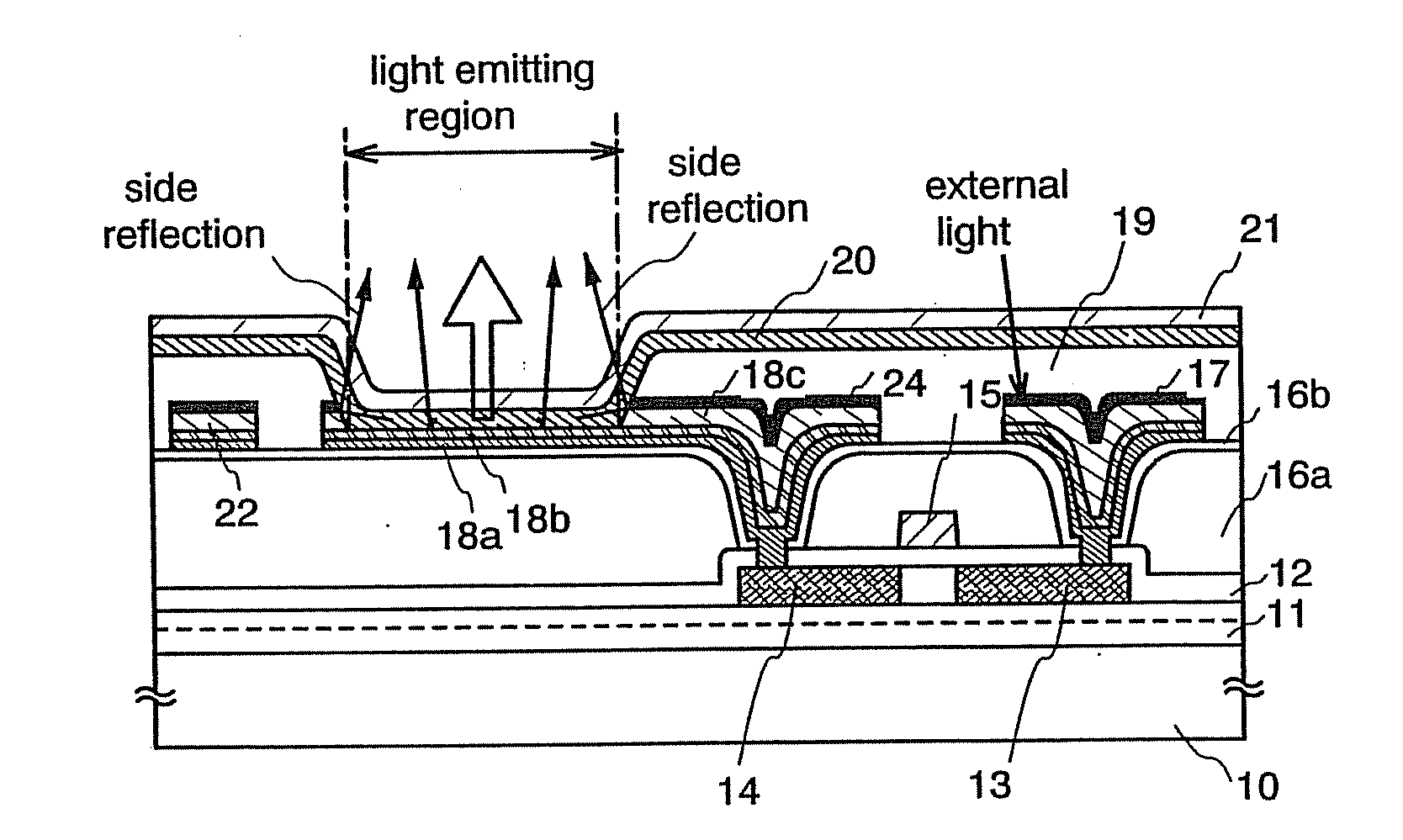

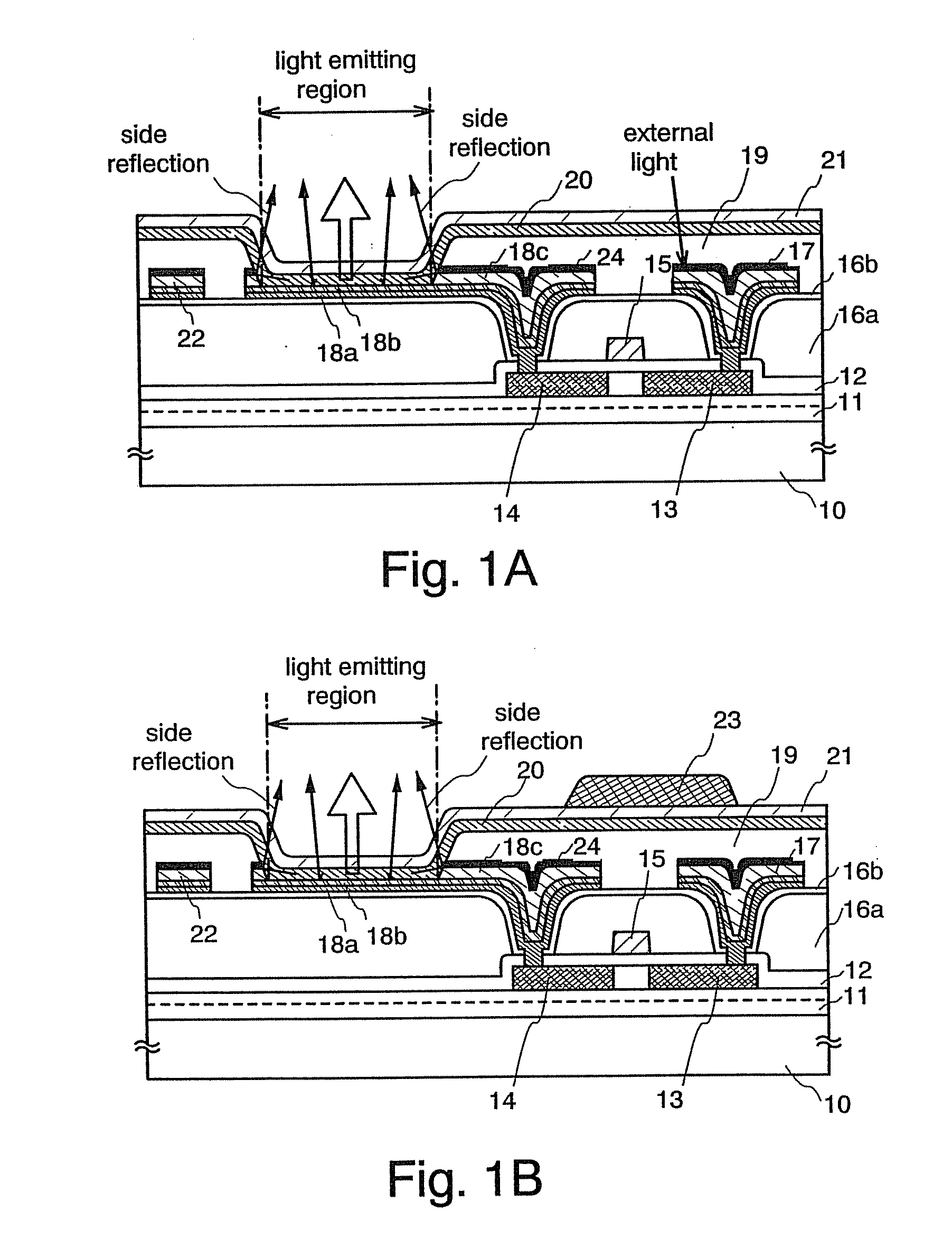

Light emitting device and manufacturing method thereof

InactiveUS20030227021A1High film resistanceLow membrane resistanceOLED manufacture/treatment processesSolid-state devicesSimple Organic CompoundsLight emission

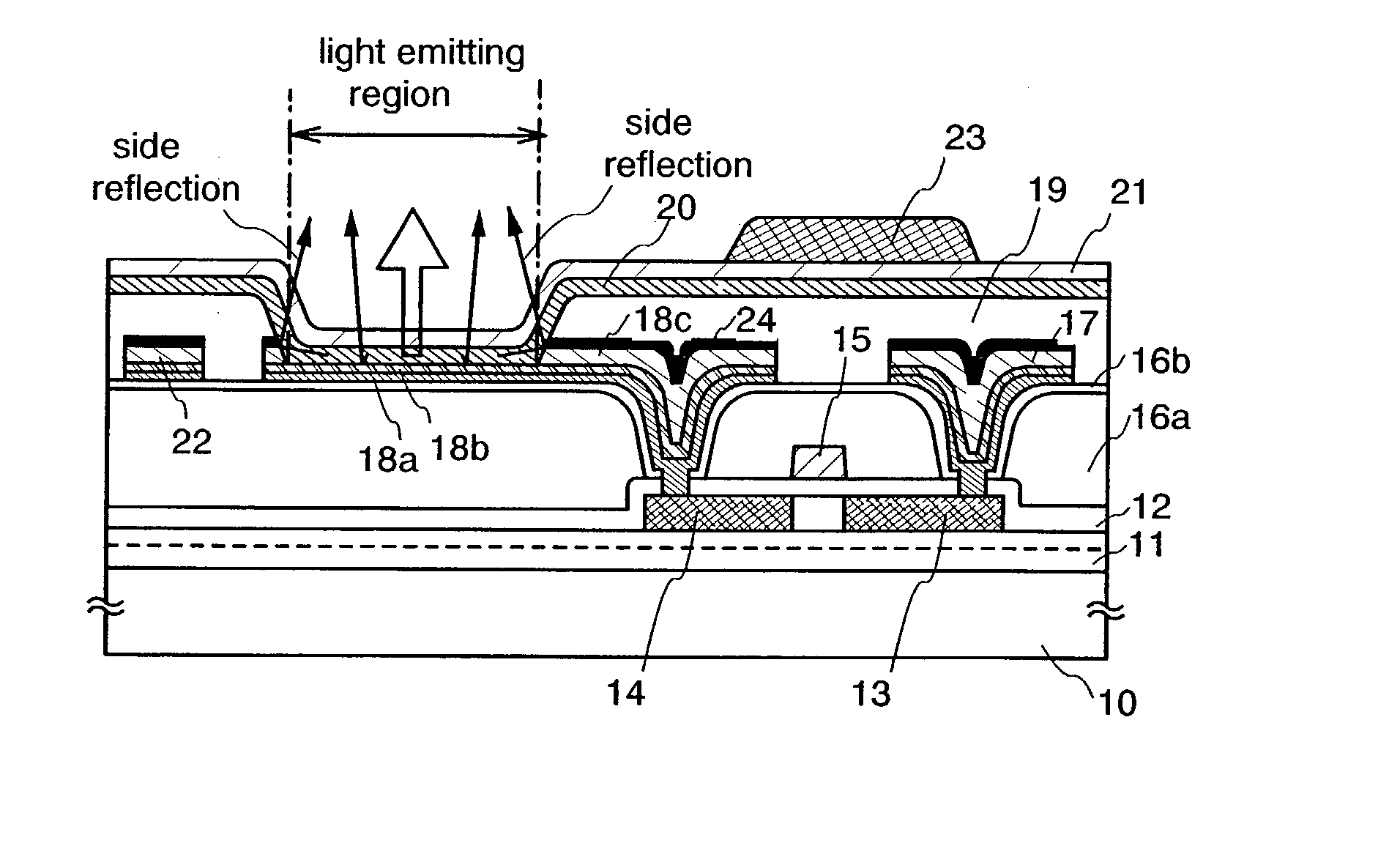

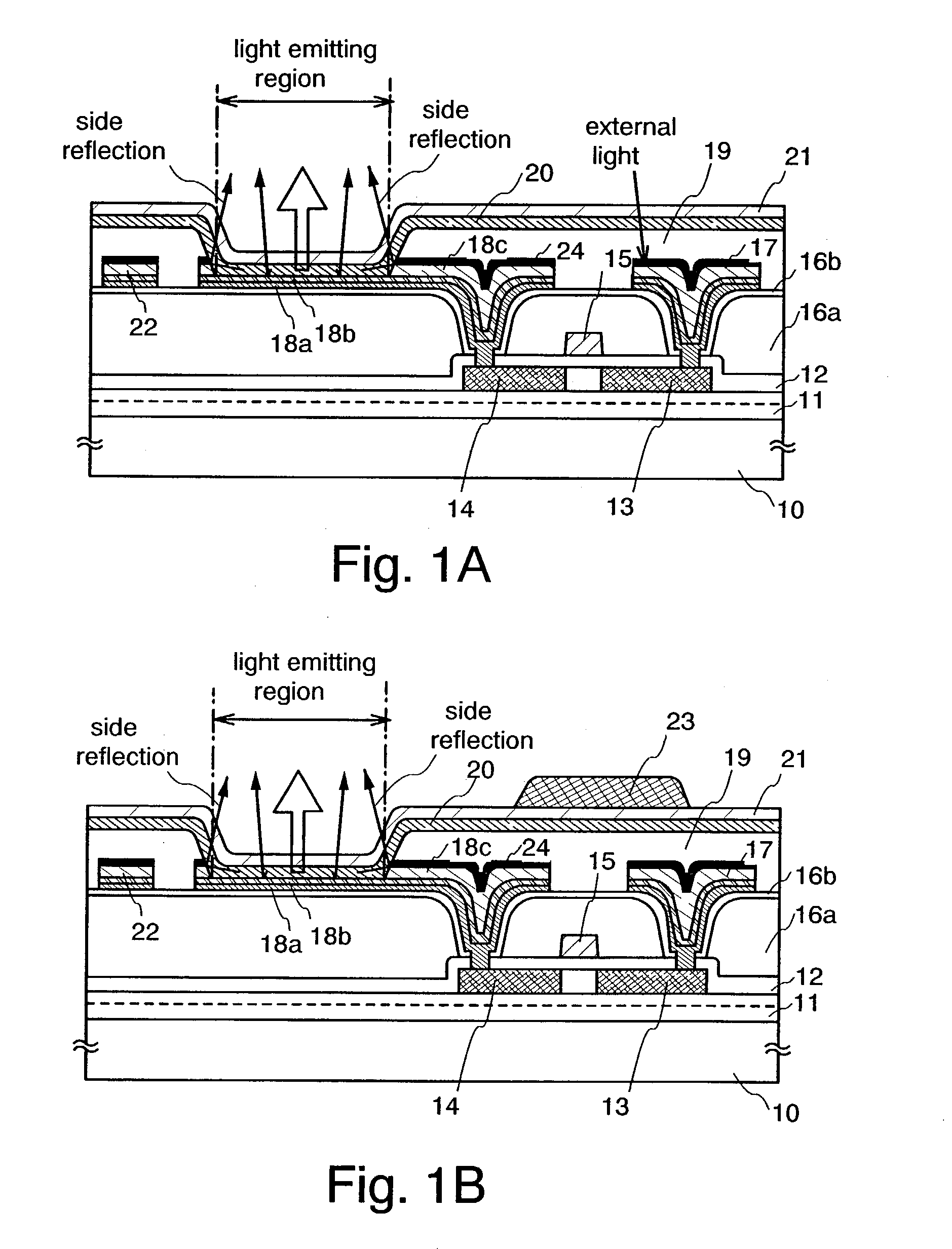

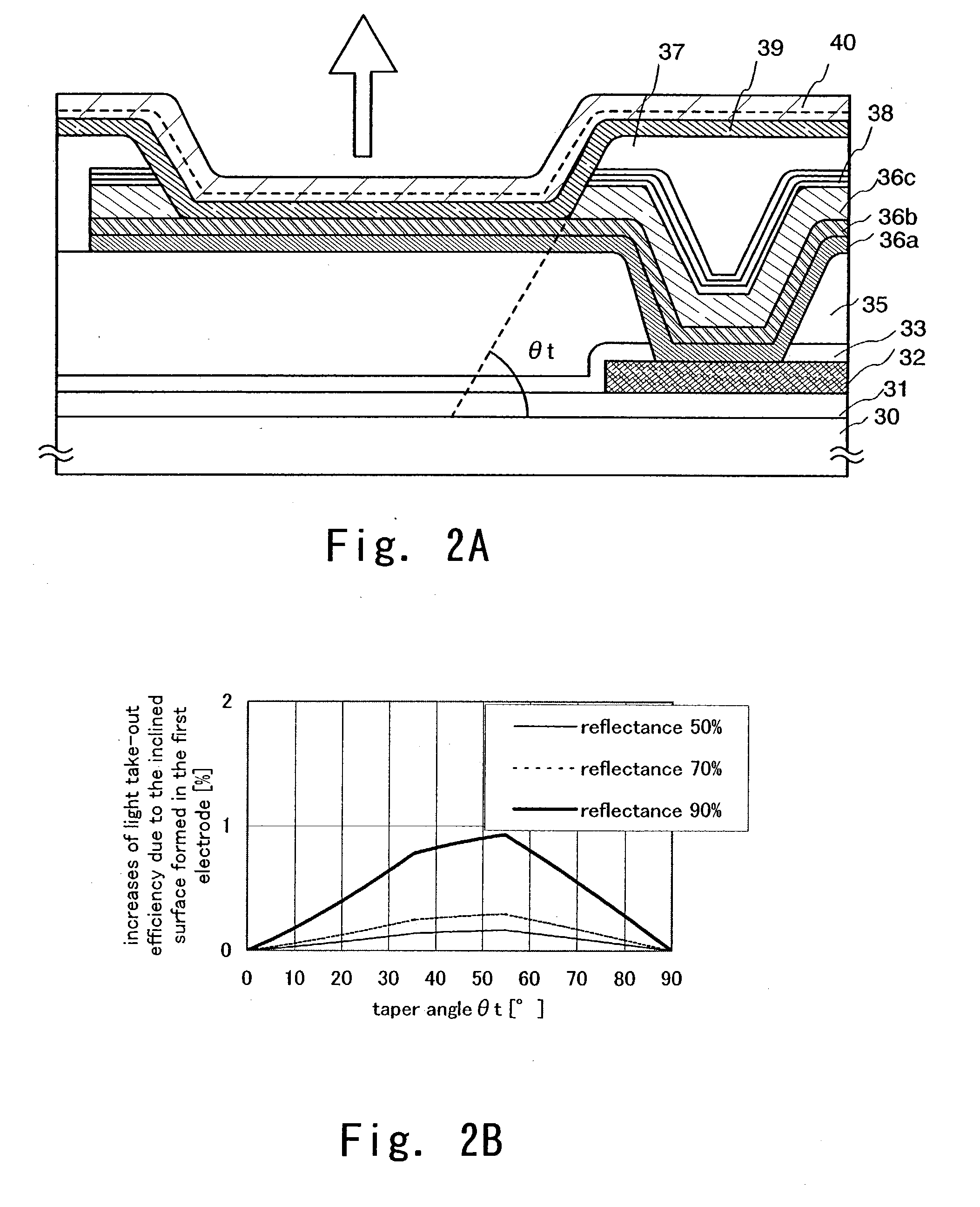

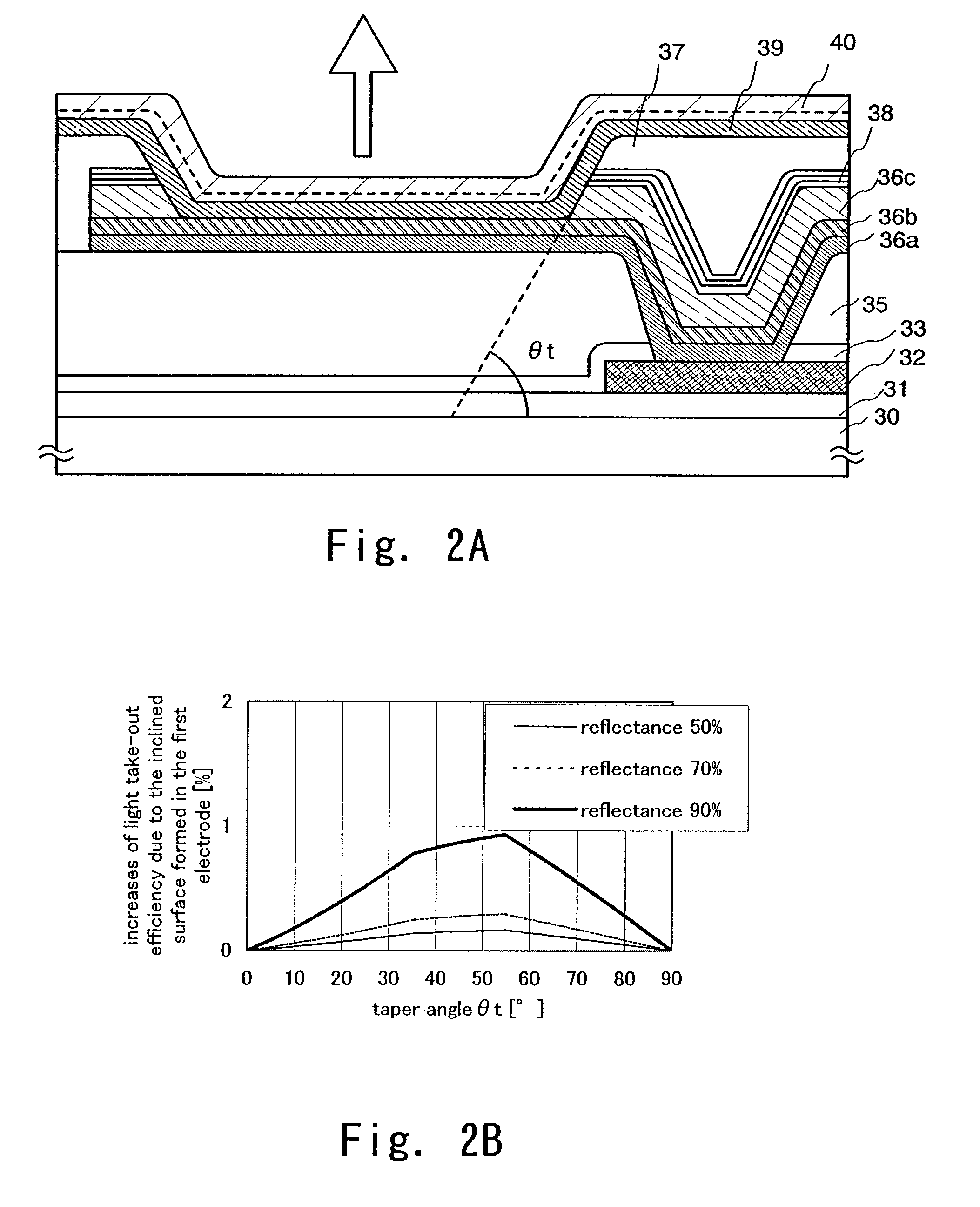

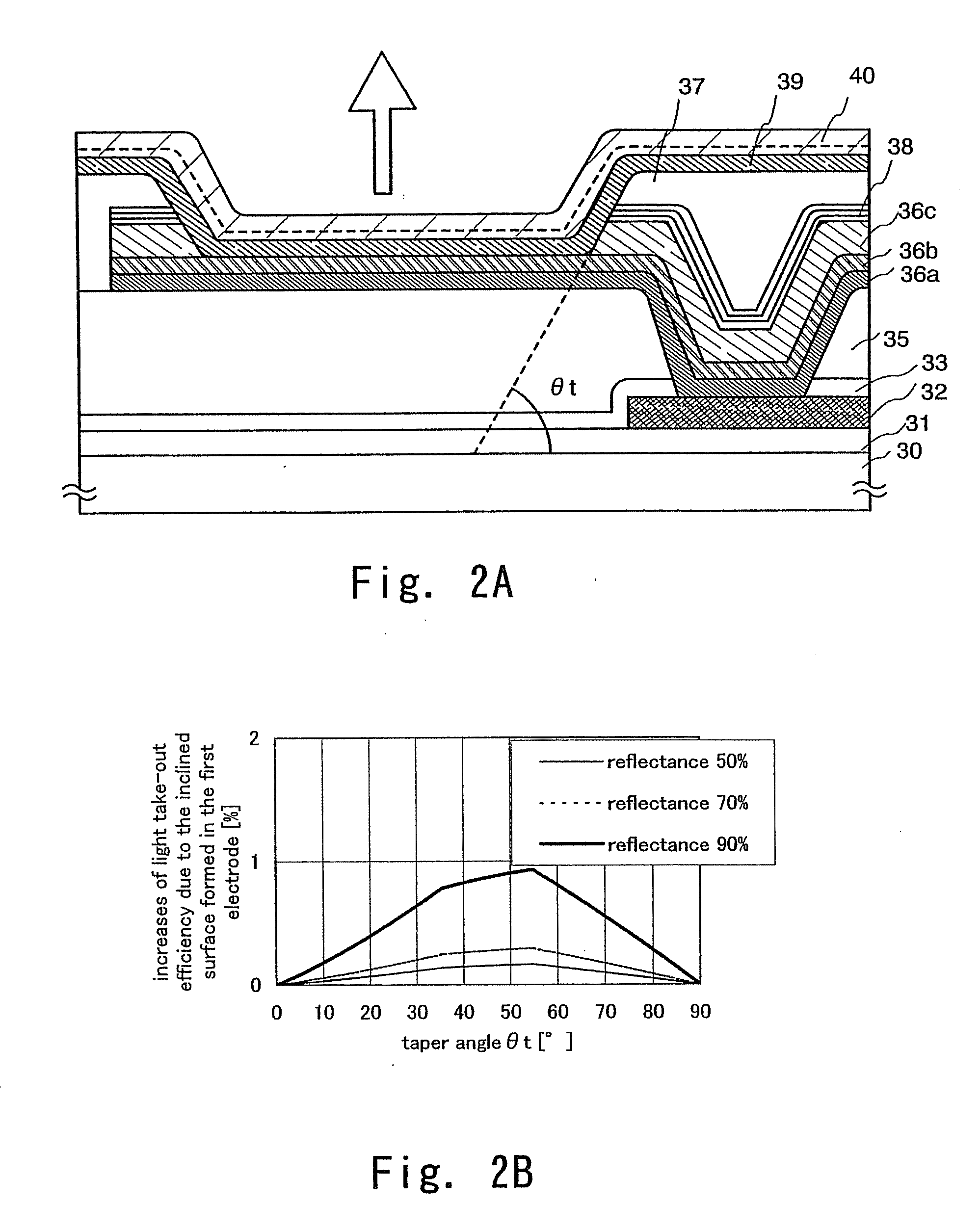

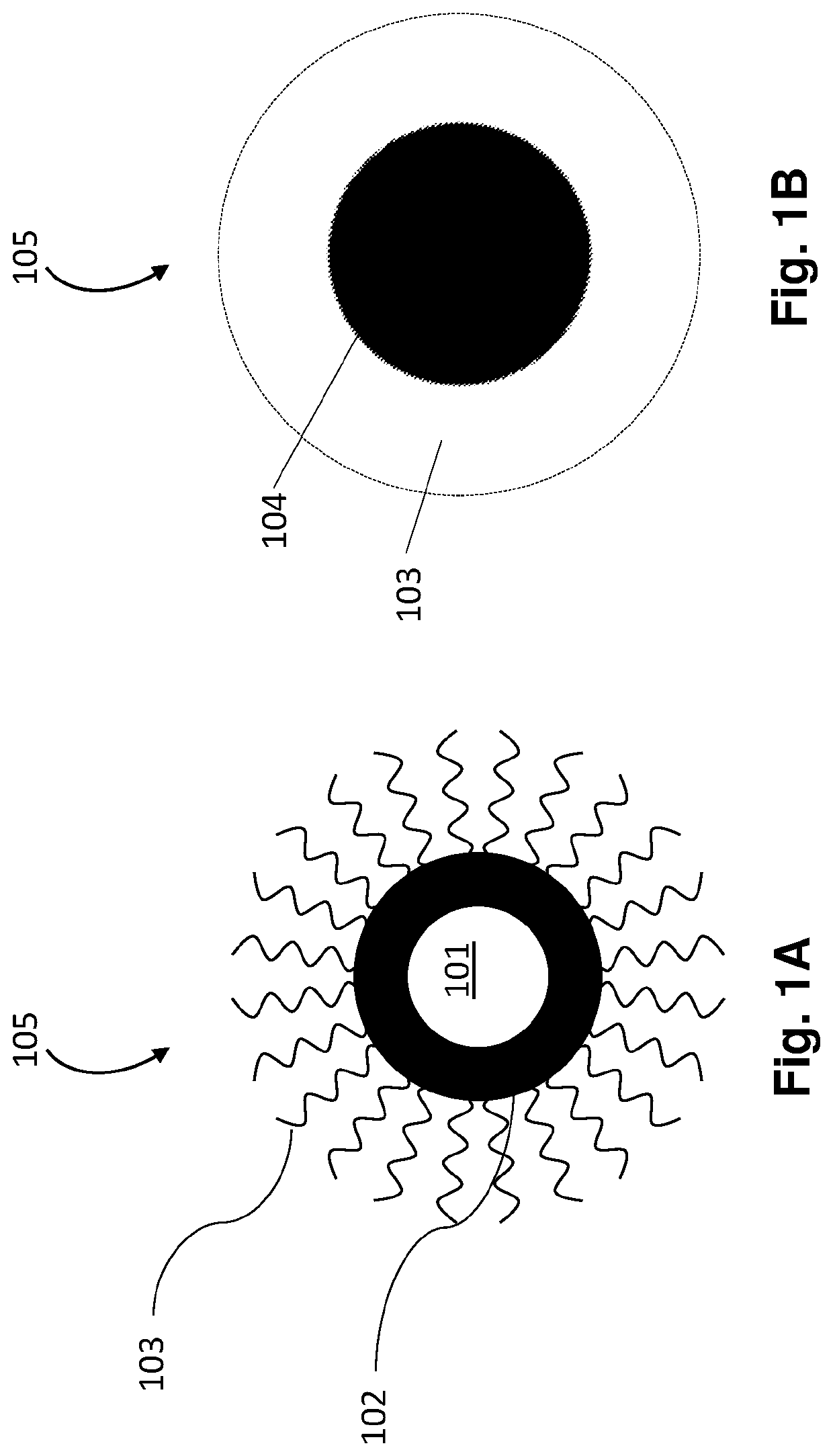

A light emission device manufactured by a method of forming a curved surface having a radius of curvature to the upper end of an insulator 19, exposing a portion of the first electrode 18c to form an inclined surface in accordance with the curved surface, and applying etching so as to expose the first electrode 18b in a region to form a light emission region, in which emitted light from the layer containing the organic compound 20 is reflected on the inclined surface of the first electrode 18c to increase the total take-out amount of light in the direction of an arrow shown in FIG. 1A and, further, forming a light absorbing multi-layered film 24 comprising light absorbing multi-layered film on the first electrode 18c other than the region to form the light emission region, thereby obtaining a light emission device of a structure increasing the amount of light emission taken out in one direction in a light emission element, while not all the light formed in the layer containing the organic compound are taken out from the cathode as a transparent electrode toward TFT but the light was emitted also, for example, in the lateral direction (direction parallel with the plane of the substrate).

Owner:SEMICON ENERGY LAB CO LTD

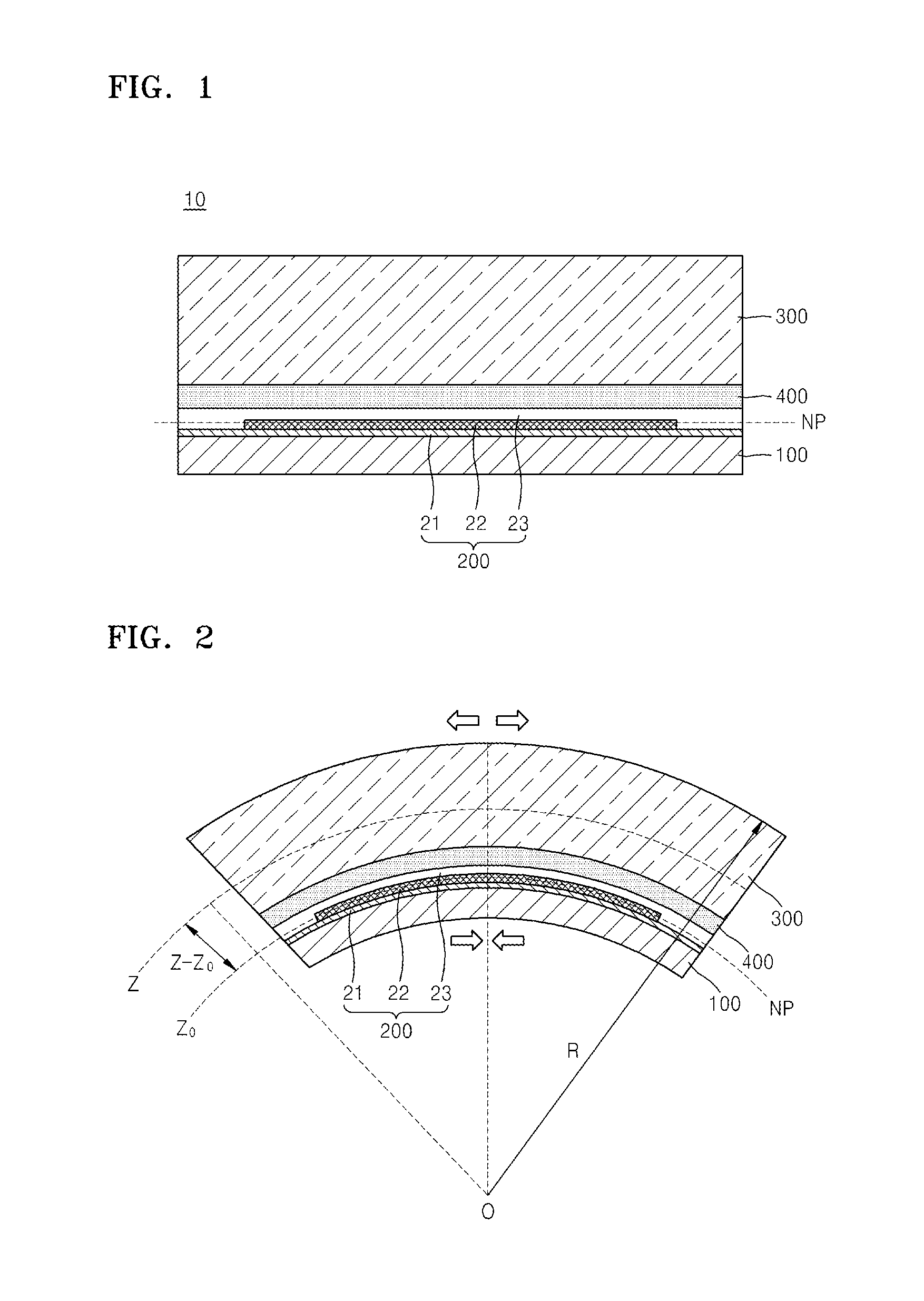

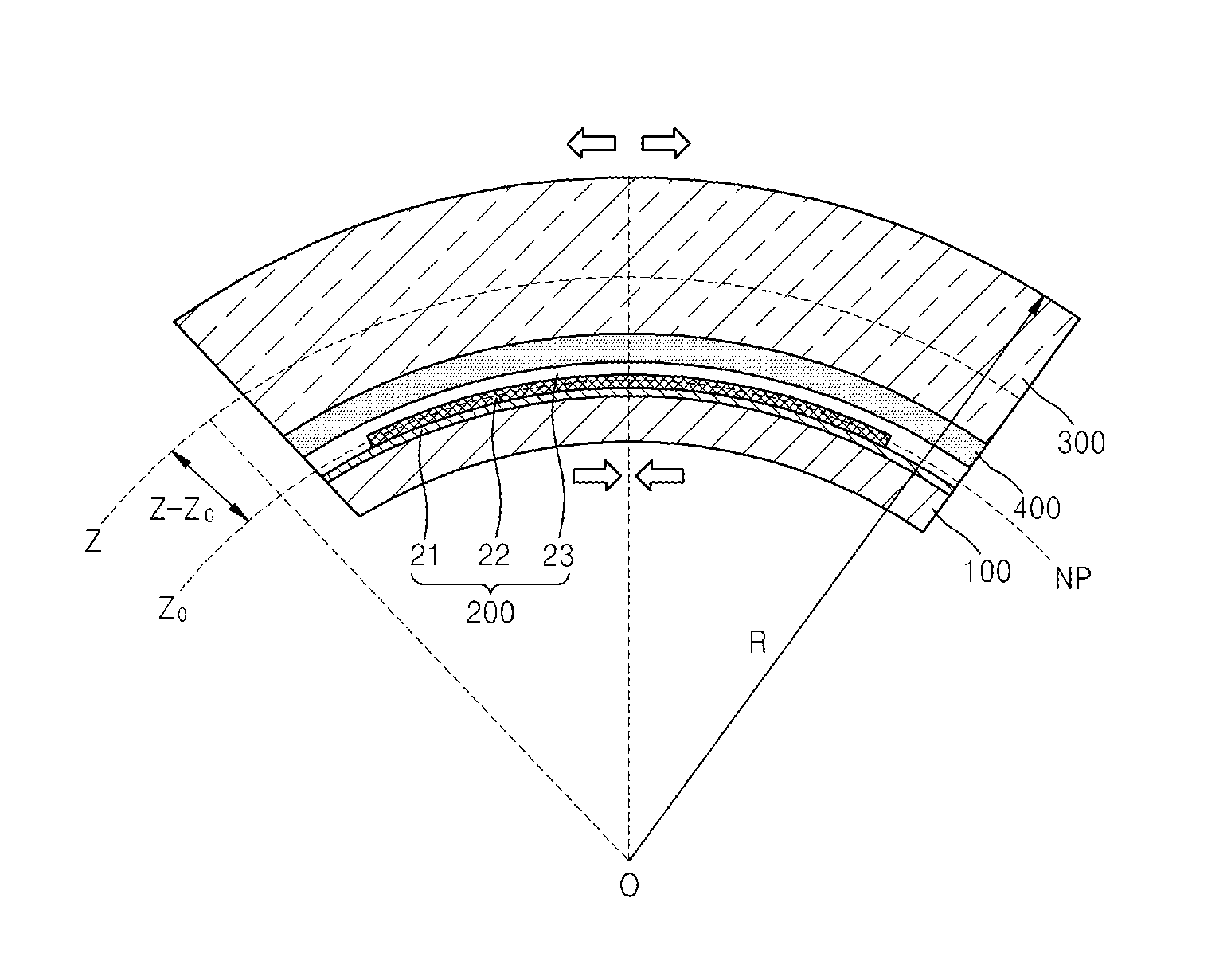

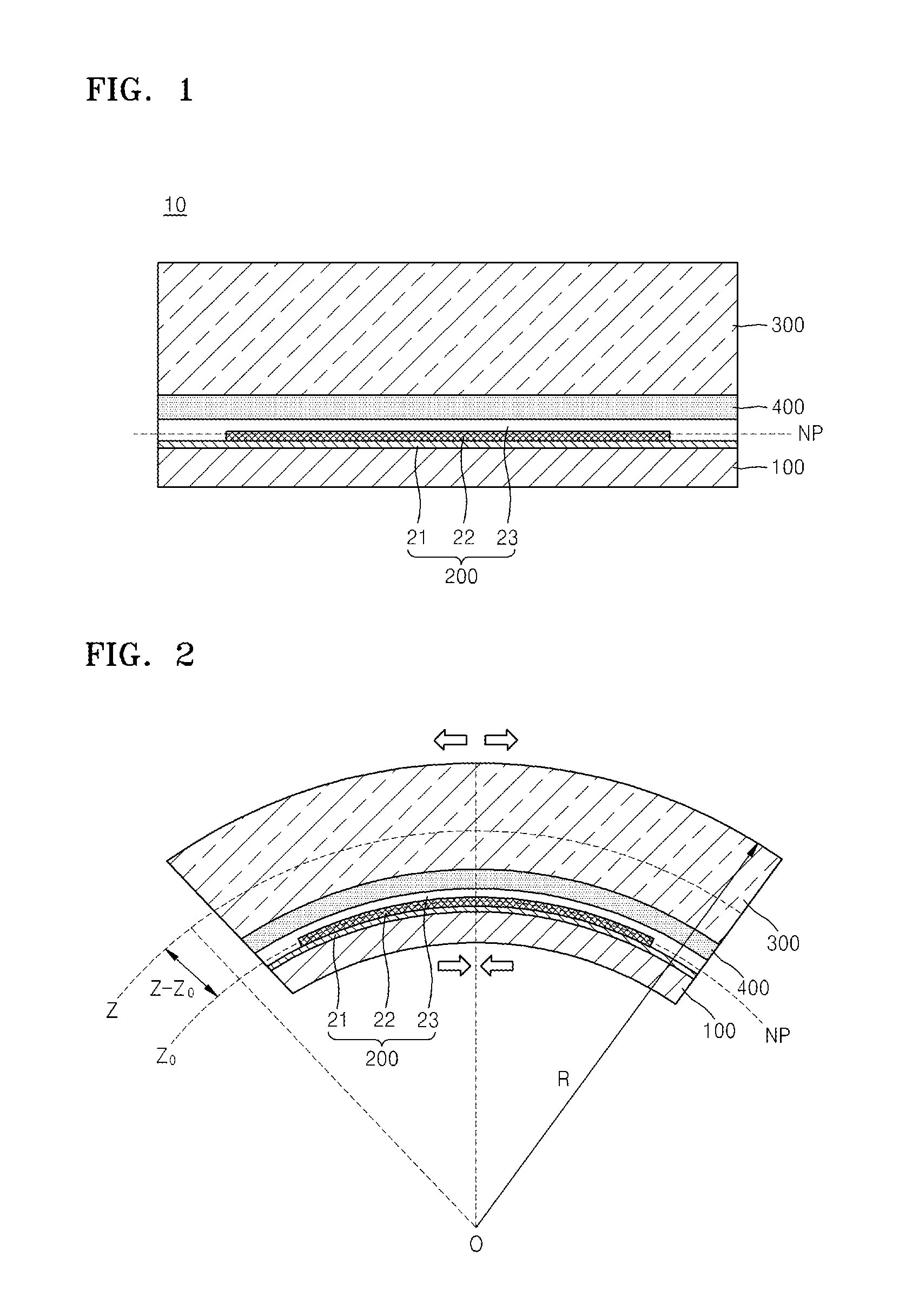

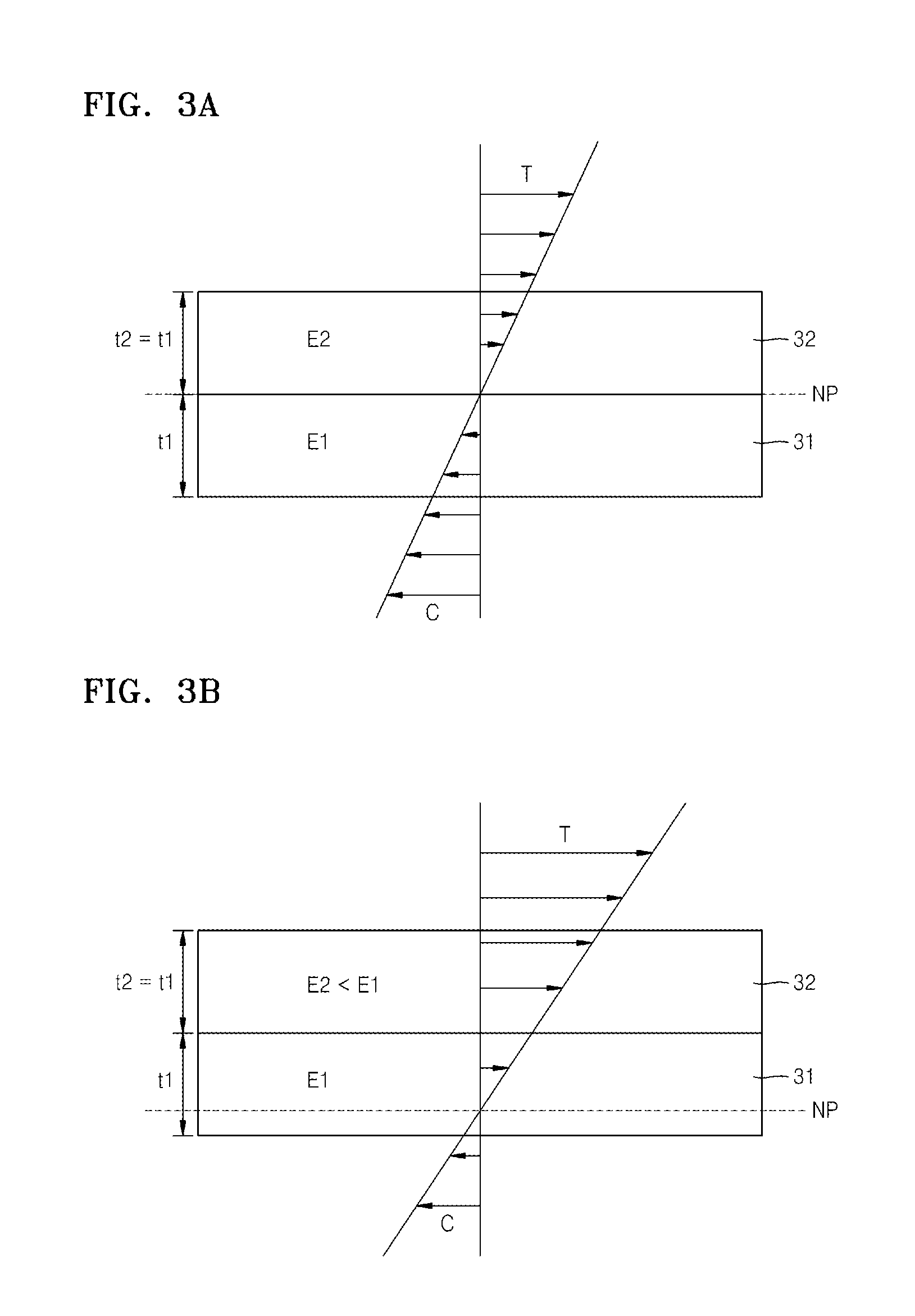

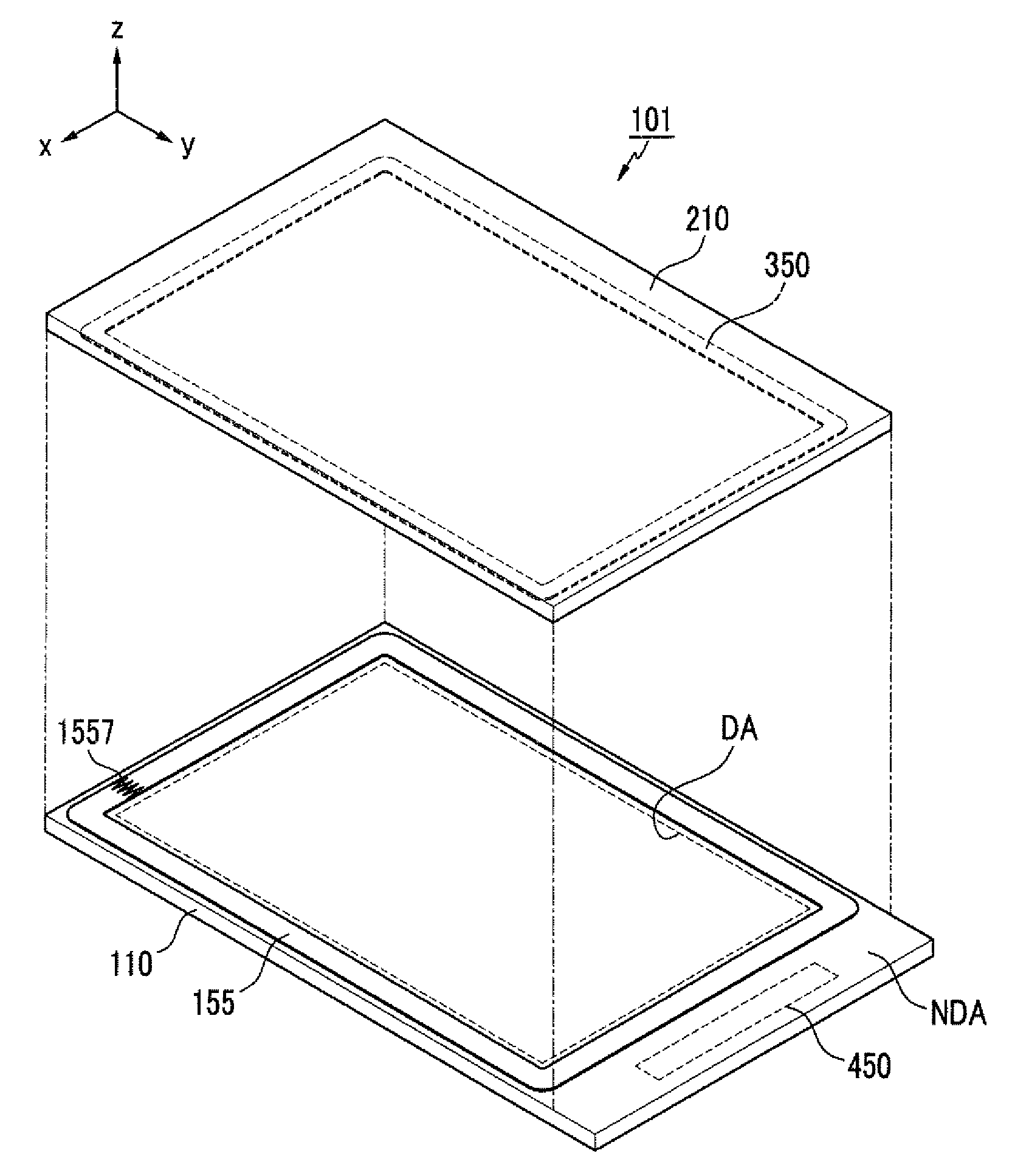

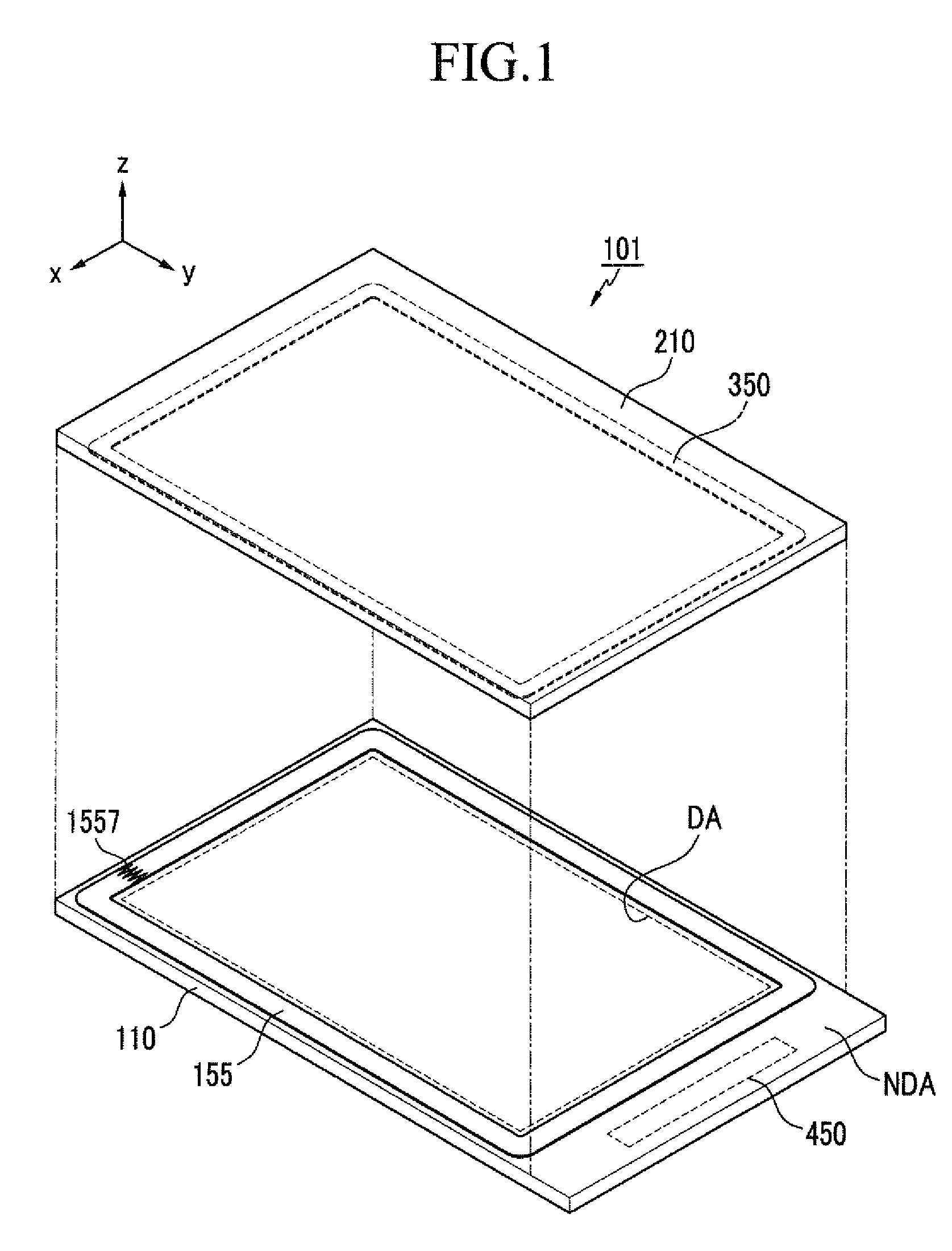

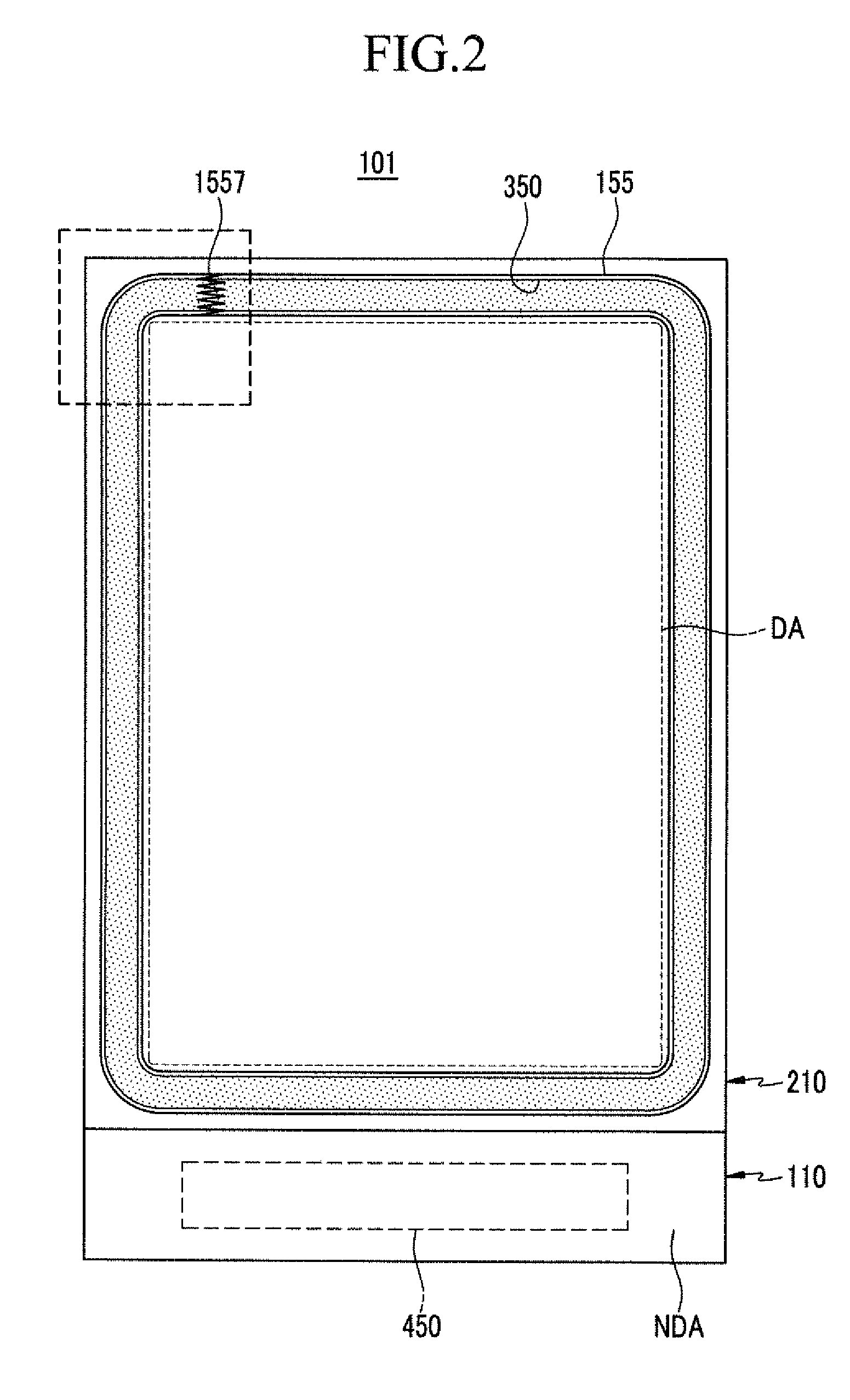

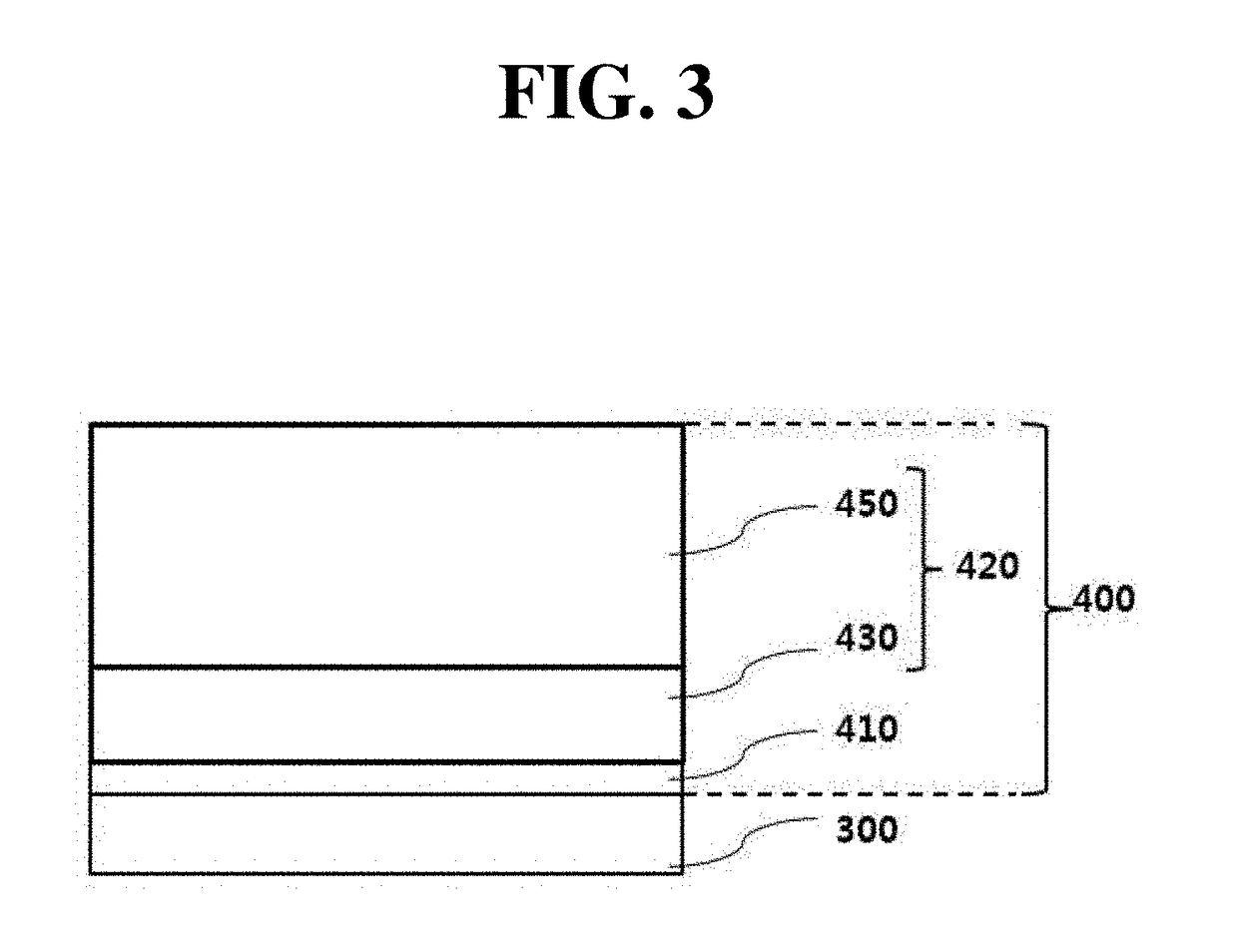

Display apparatus having improved bending properties and method of manufacturing same

ActiveUS20140367644A1Improved durability against bendingMinimizes partOLED manufacture/treatment processesFinal product manufactureNeutral planeEngineering

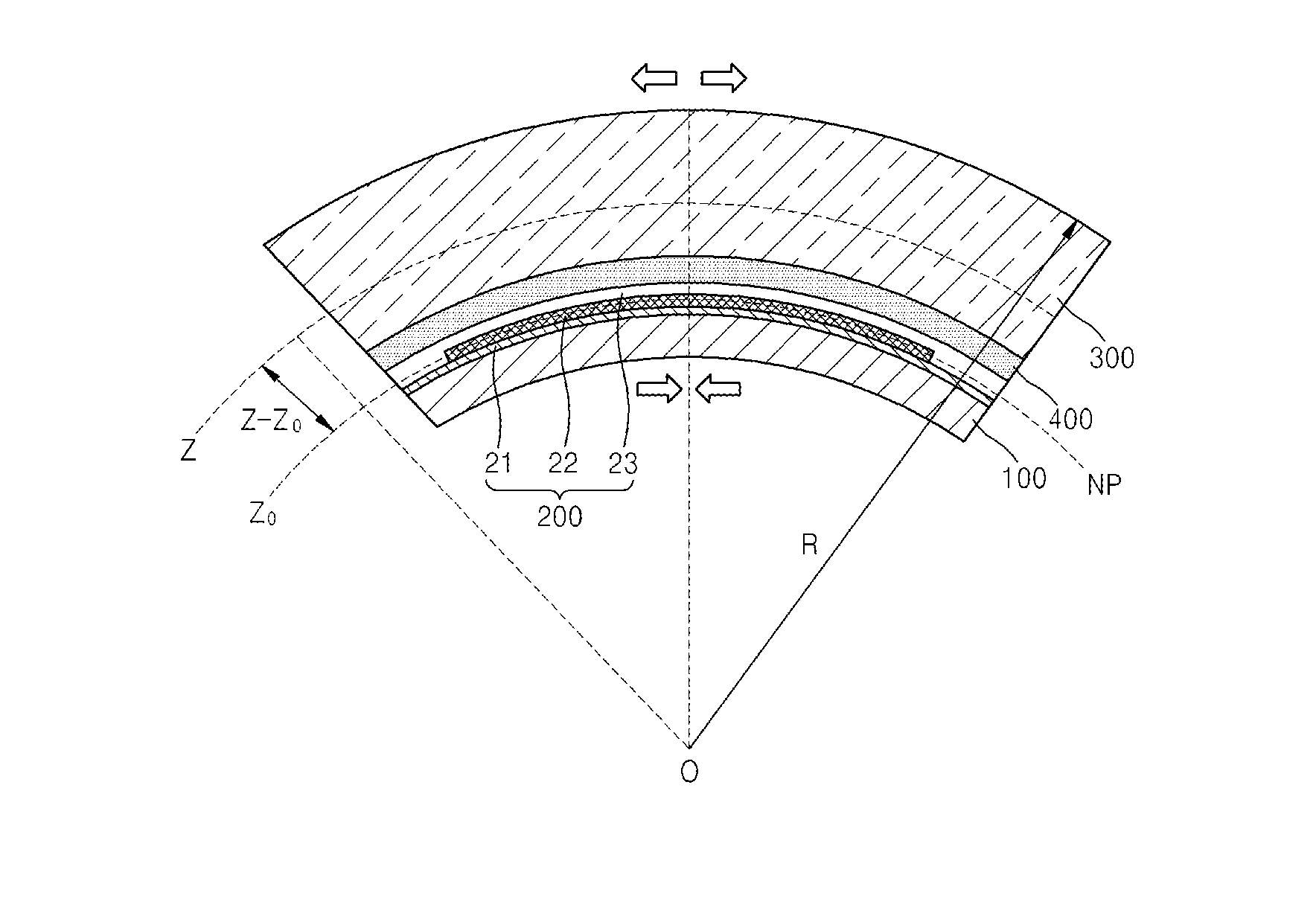

Disclosed is a display apparatus. The display apparatus includes: a display module including a flexible substrate, a display panel, and an encapsulation film; a lower module disposed below the display module; an upper module disposed on the display module; and an elasticity-adjusting layer disposed on or below the display module to adjust a position of a neutral plane in bending of the display apparatus, wherein an elastic modulus of the elasticity-adjusting layer is less than that of at least one of the display module, the lower module, or the upper module, so as to position the neutral plane within or proximate to the display module.

Owner:SAMSUNG DISPLAY CO LTD

Light emitting device and manufacturing method thereof

InactiveUS7897979B2High film resistanceLow membrane resistanceOLED manufacture/treatment processesSolid-state devicesOrganic compoundLight emitting device

A light emission device manufactured by a method of forming a curved surface having a radius of curvature to the upper end of an insulator 19, exposing a portion of the first electrode 18c to form an inclined surface in accordance with the curved surface, and applying etching so as to expose the first electrode 18b in a region to form a light emission region, in which emitted light from the layer containing the organic compound 20 is reflected on the inclined surface of the first electrode 18c to increase the total take-out amount of light in the direction of an arrow shown in FIG. 1A and, further, forming a light absorbing multi-layered film 24 comprising light absorbing multi-layered film on the first electrode 18c other than the region to form the light emission region, thereby obtaining a light emission device of a structure increasing the amount of light emission taken out in one direction in a light emission element, while not all the light formed in the layer containing the organic compound are taken out from the cathode as a transparent electrode toward TFT but the light was emitted also, for example, in the lateral direction (direction parallel with the plane of the substrate).

Owner:SEMICON ENERGY LAB CO LTD

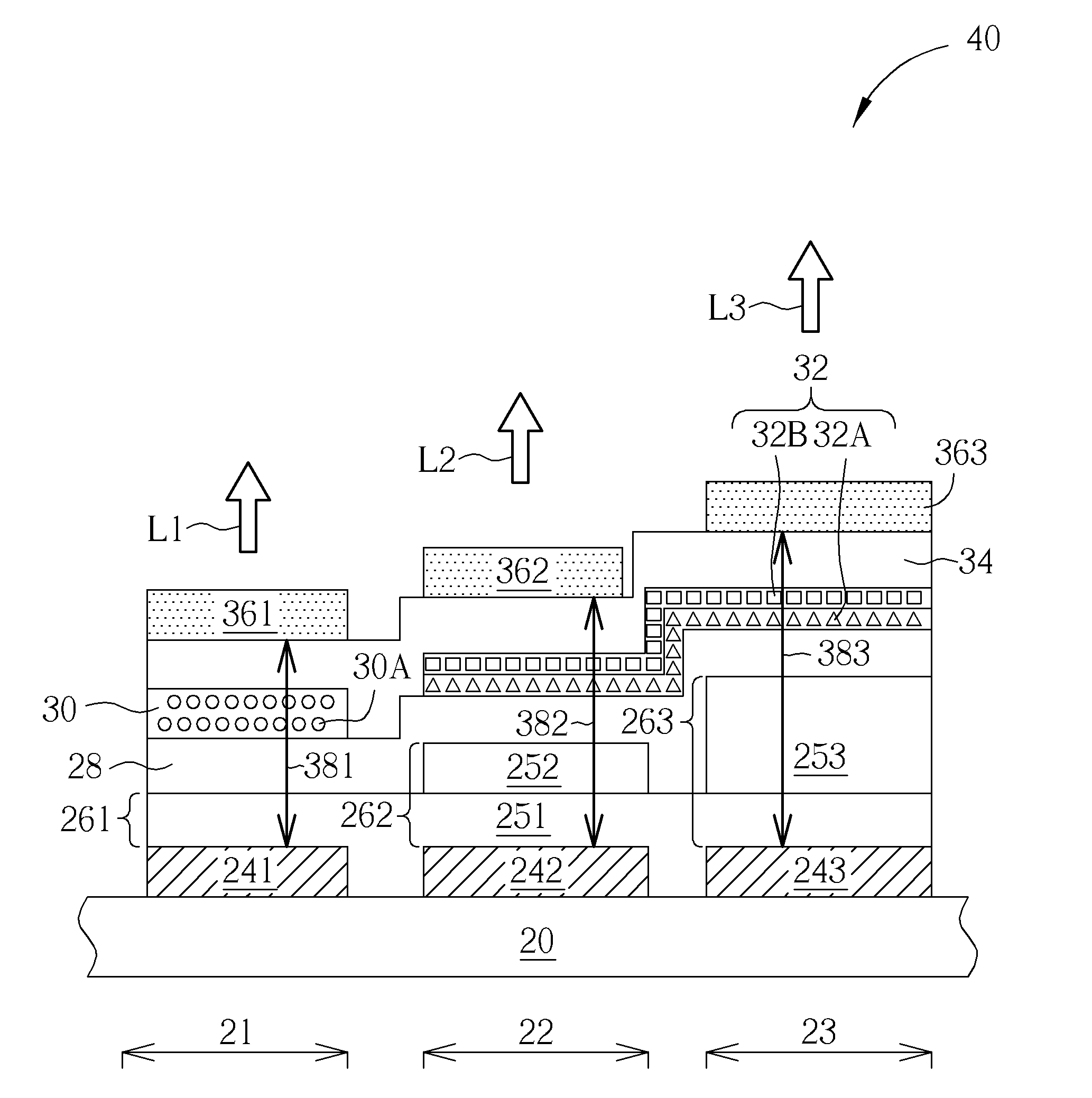

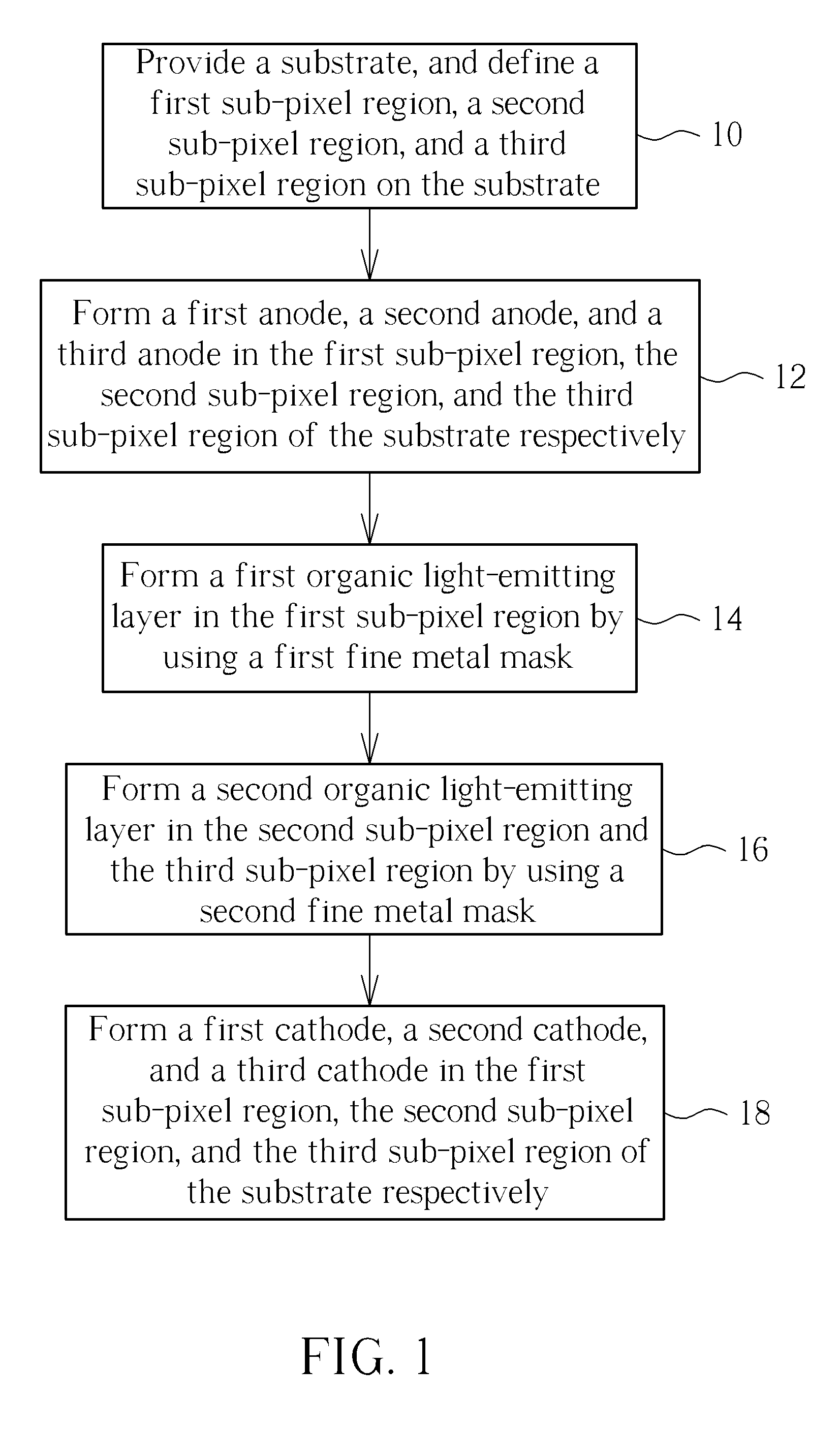

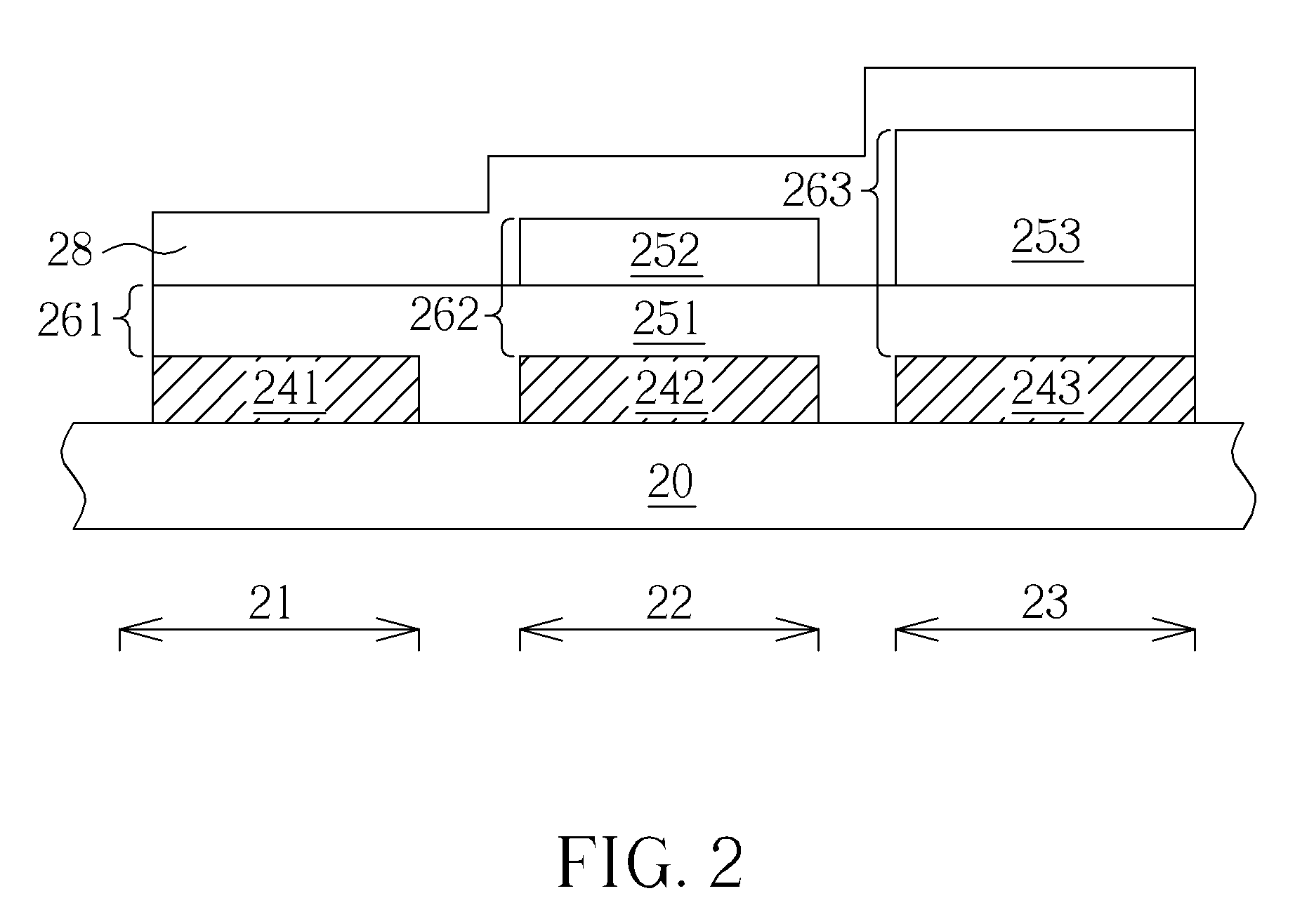

Pixel structure of electroluminescent display panel

ActiveUS20130147689A1Raise the ratioImprove resolutionOLED manufacture/treatment processesWave amplification devicesEngineeringMaterials science

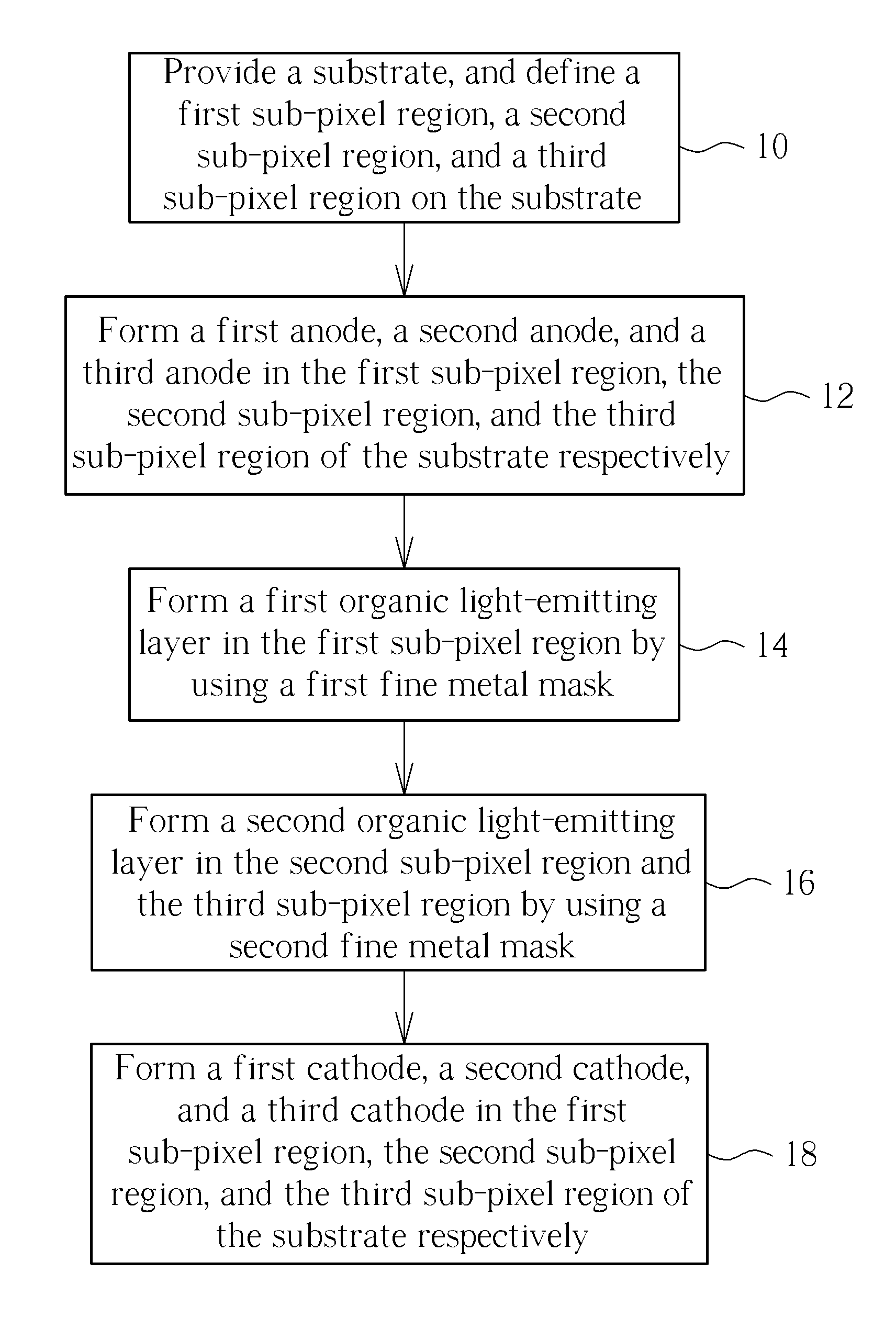

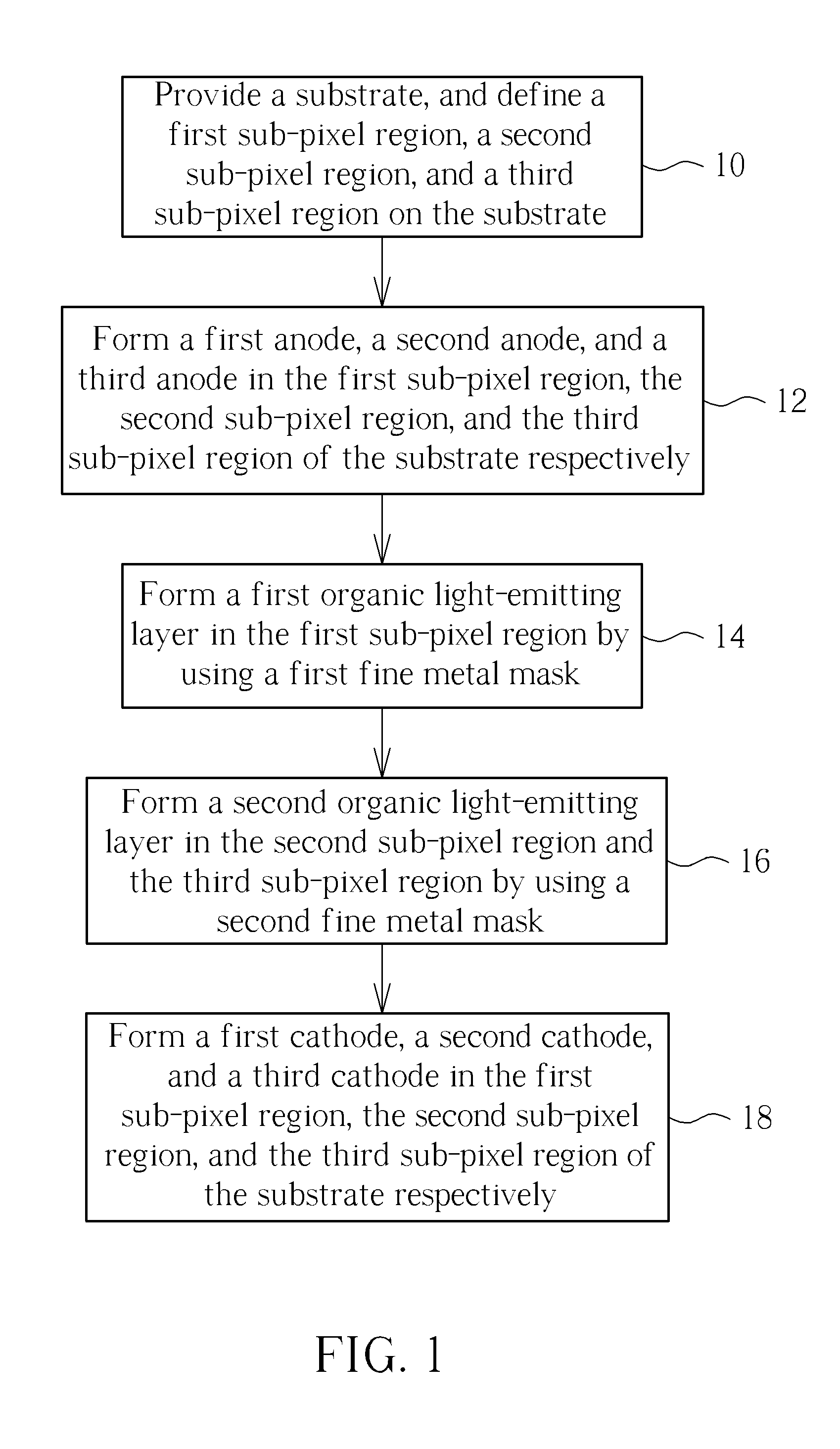

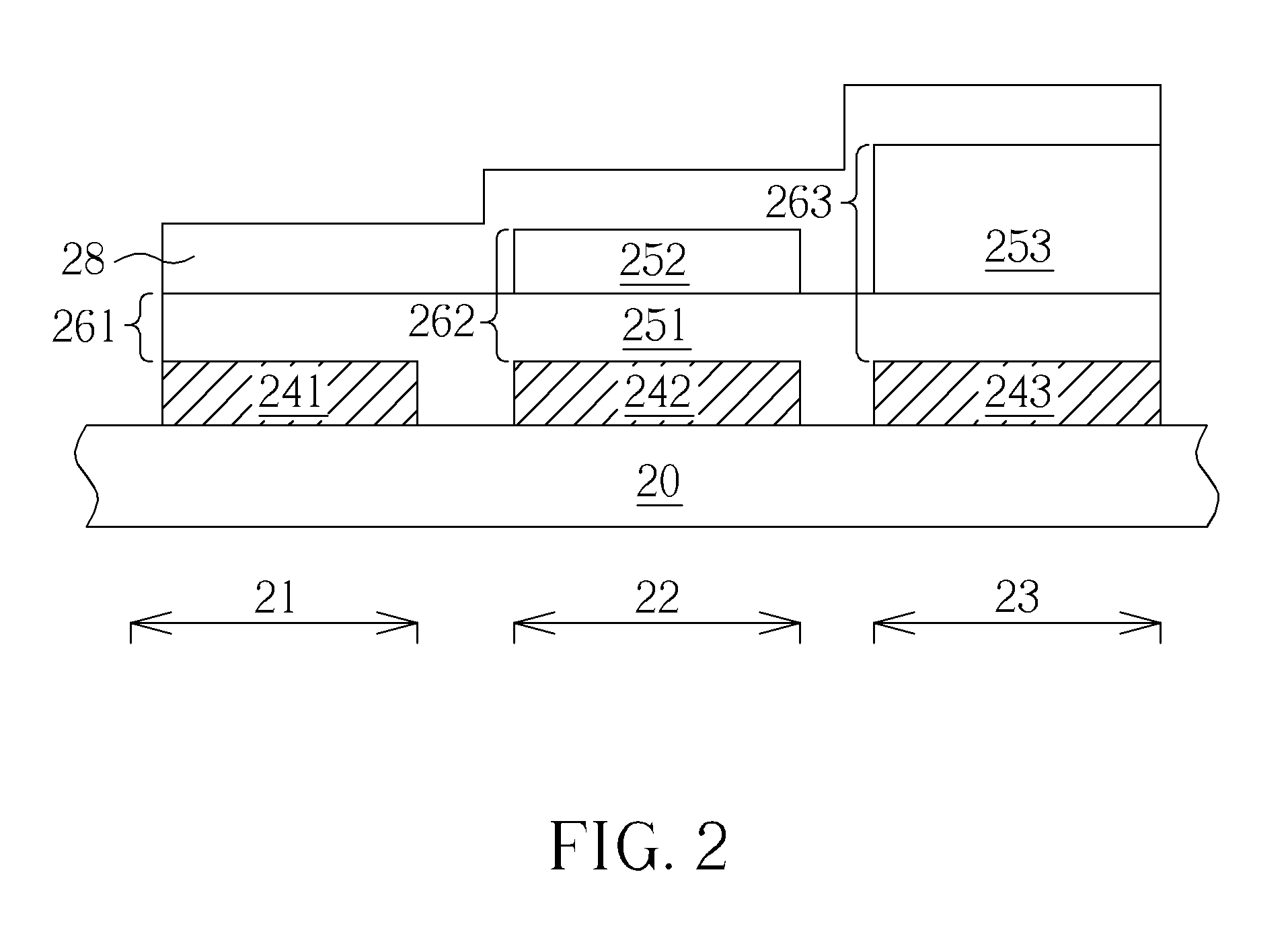

A pixel structure of electroluminescent display panel has a first sub-pixel region, a second sub-pixel region, and a third sub-pixel region. The pixel structure of electroluminescent display panel includes a first organic light-emitting layer, and a second organic light-emitting layer. The first organic light-emitting layer is disposed in the first sub-pixel region for generating a first primary color light in the first sub-pixel region. The second organic light-emitting layer is disposed in the second sub-pixel region, and the third sub-pixel region for generating a second primary color light in the second sub-pixel region, and for generating a third primary color light in the third sub-pixel region. The first sub-pixel region, the second sub-pixel region, and the third sub-pixel region have different cavity lengths.

Owner:AU OPTRONICS CORP

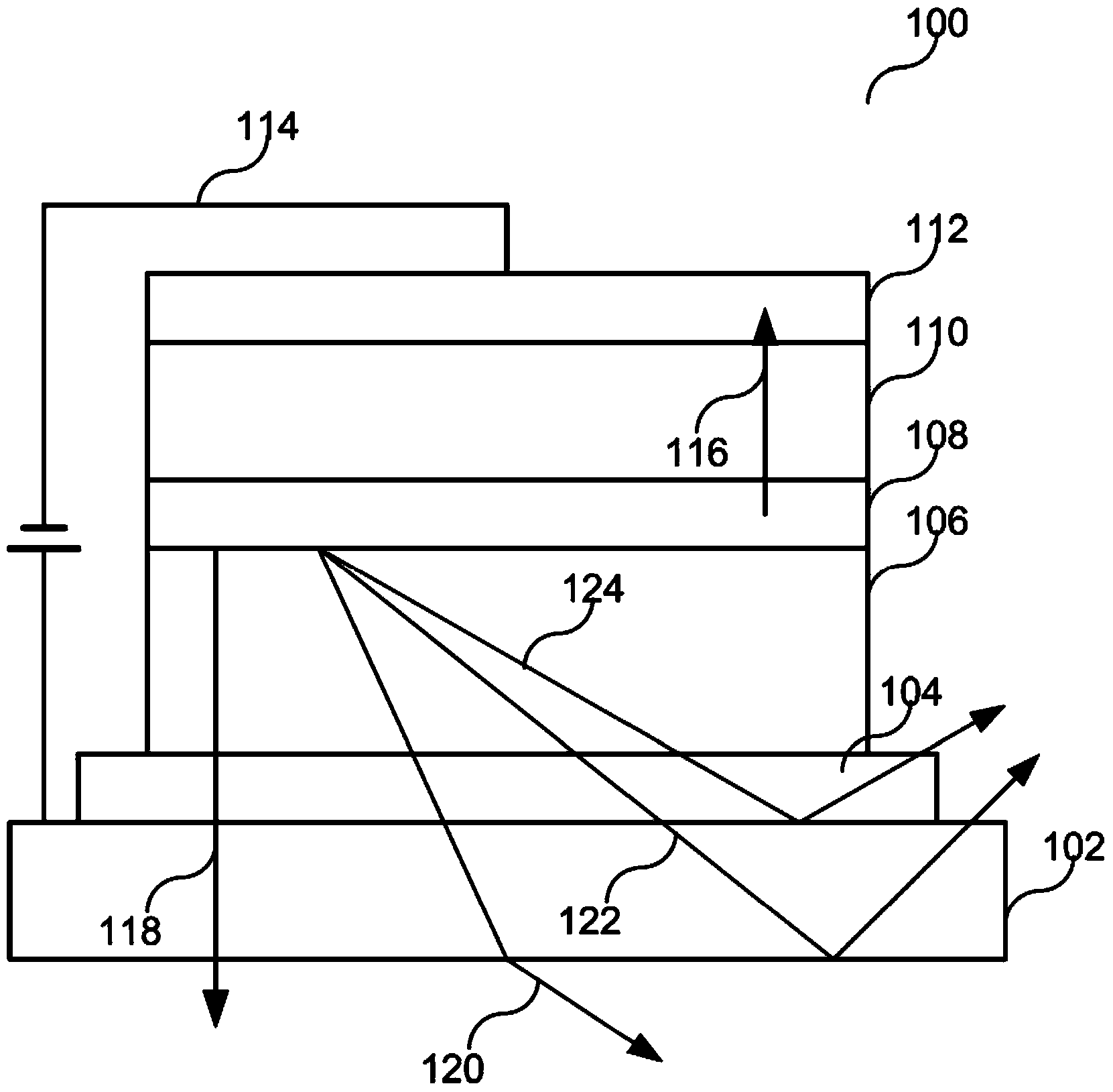

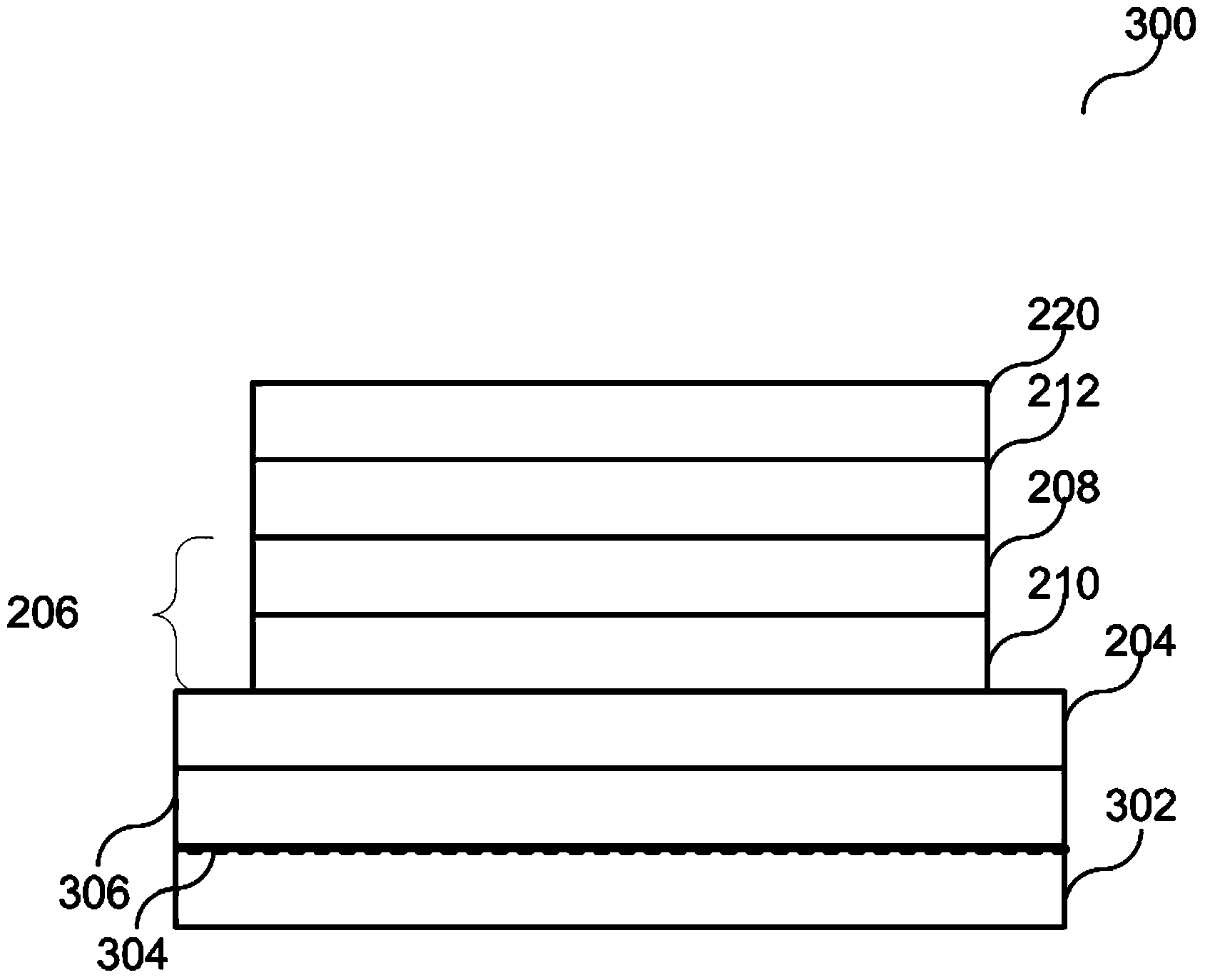

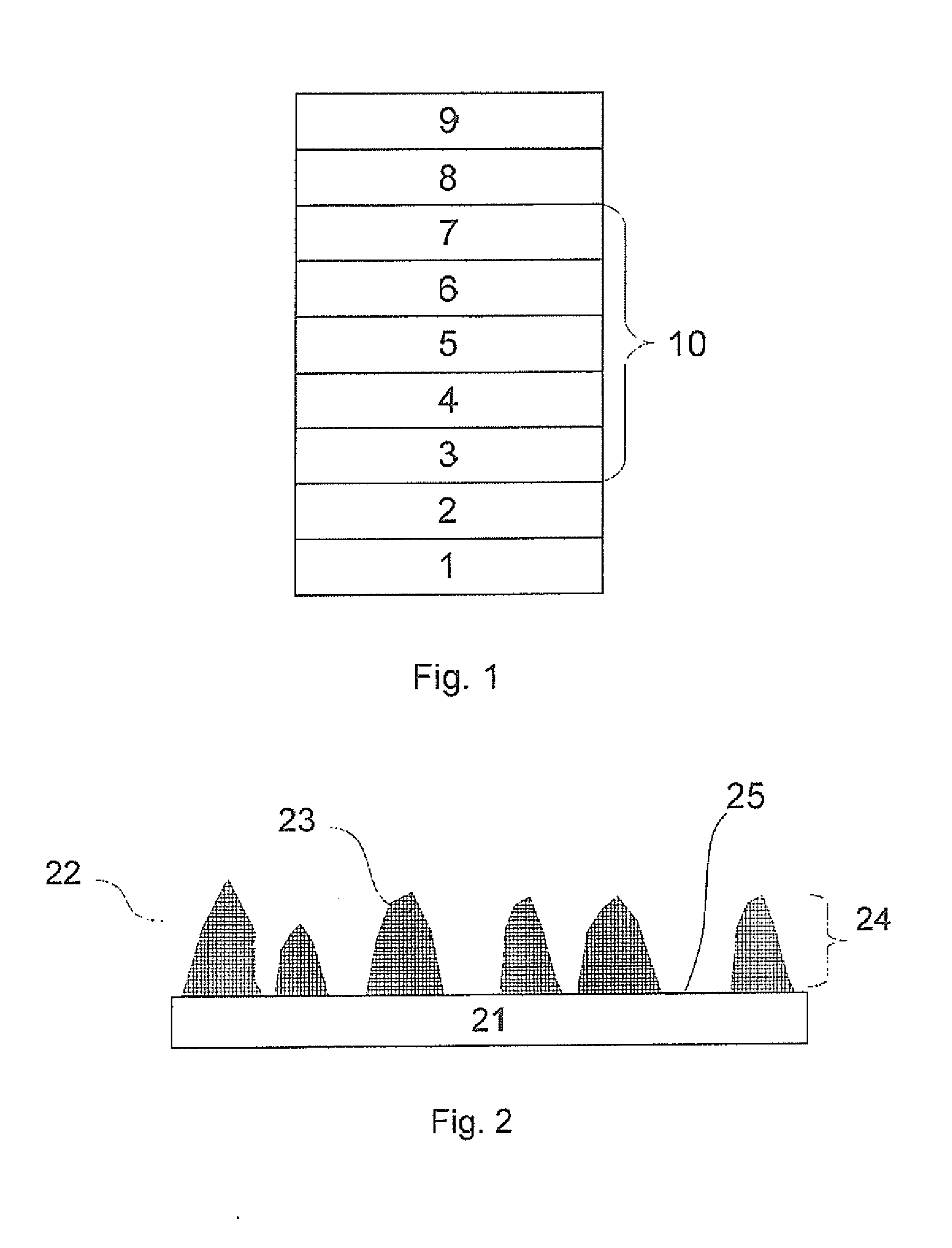

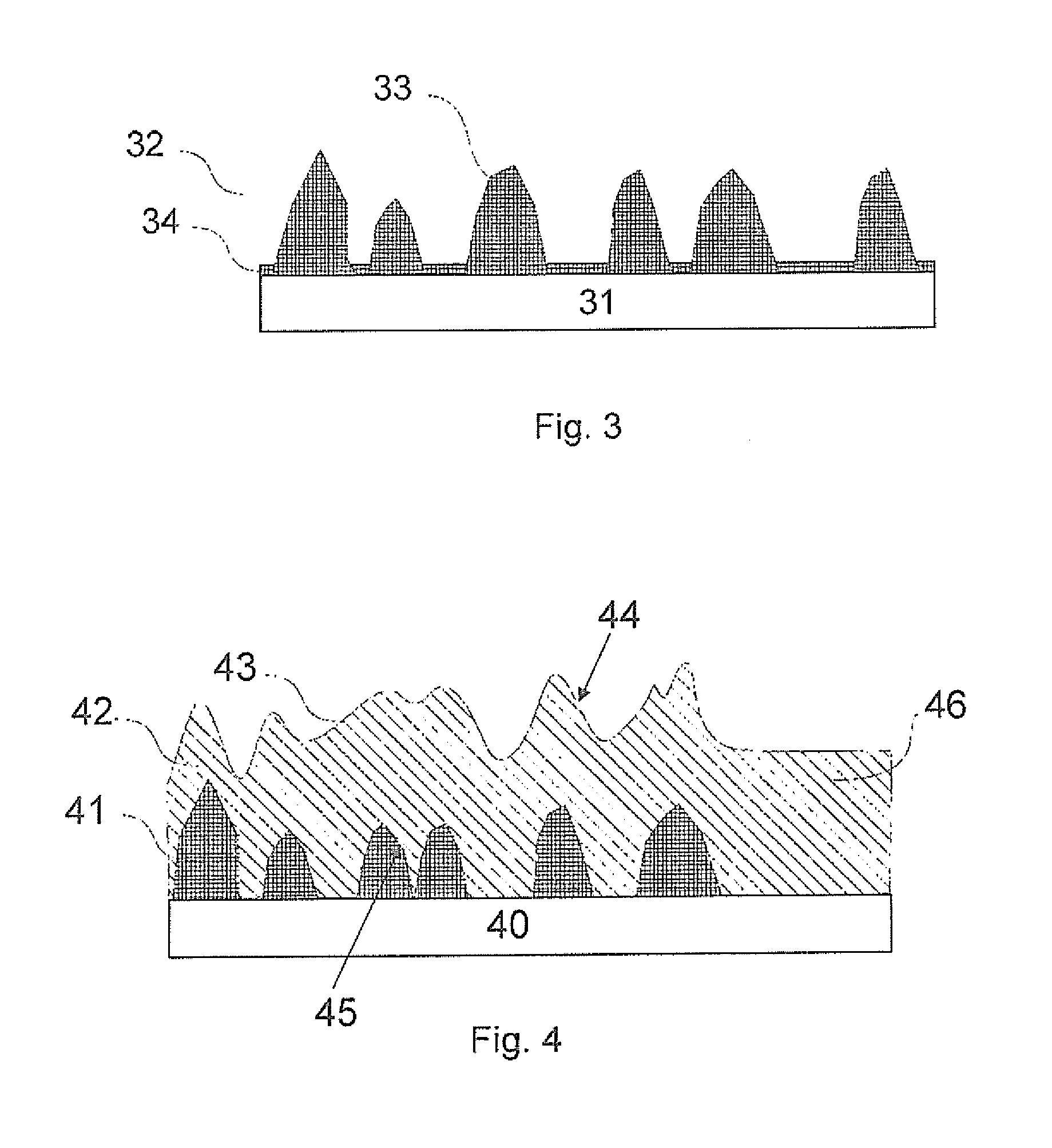

Organic Light Emitting Device and Method of Producing

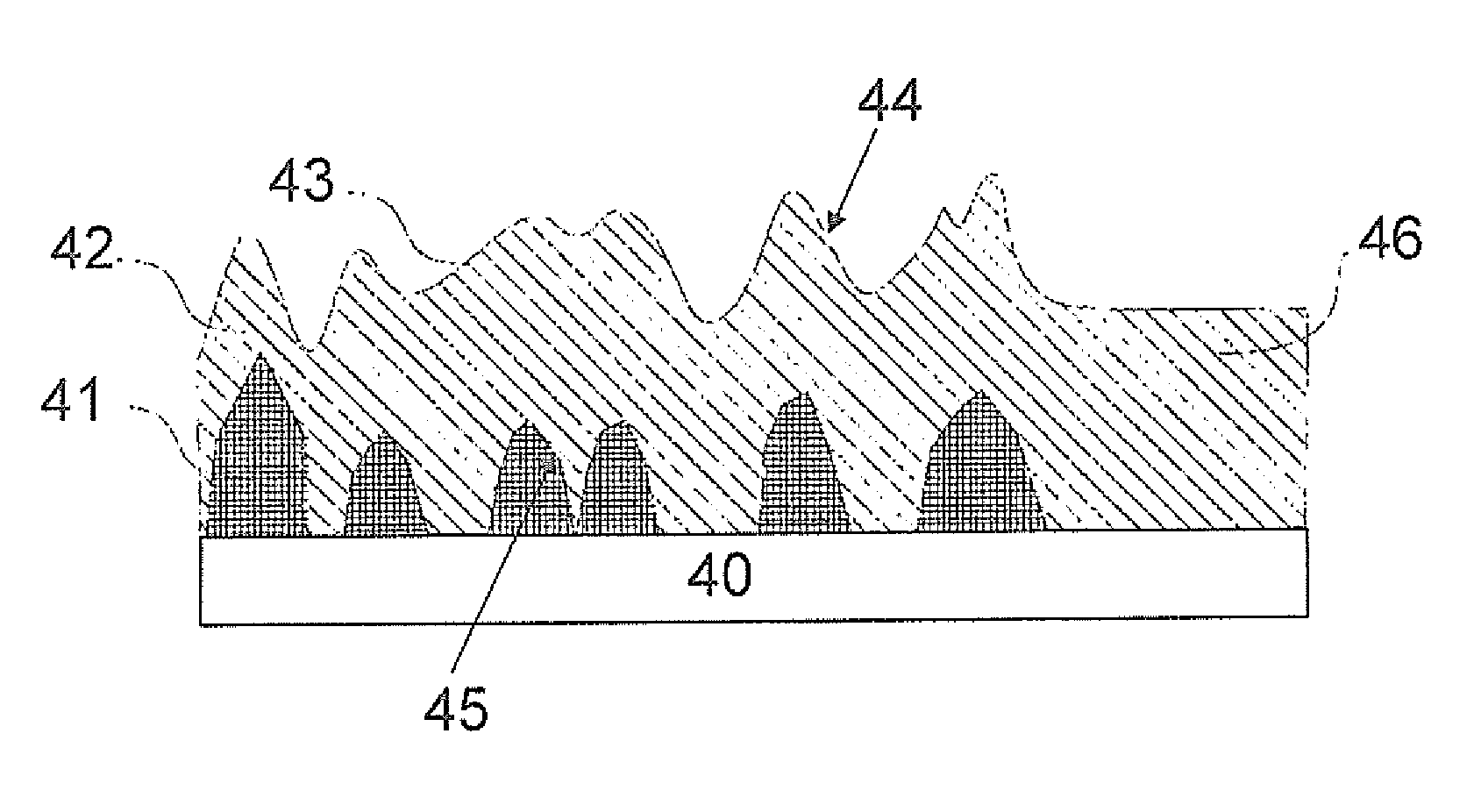

ActiveUS20140332794A1Improved efficiency of coupling out lightOutcoupling efficiency)OLED manufacture/treatment processesSolid-state devicesOrganic light emitting deviceOrganic layer

The invention relates to an organic light emitting device, in a layered structure, comprising a substrate, a bottom electrode, a top electrode, wherein the bottom electrode is closer to the substrate than the top electrode, an electrically active region, the electrically active region comprising one or more organic layers and being provided between and in electrical contact with the bottom electrode and the top electrode, a light emitting region provided in the electrically active region, and a roughening layer, the roughening layer being provided as non-closed layer in the electrically active region and providing an electrode roughness to the top electrode by roughening the top electrode on at least one an inner side facing the electrically active region and an outer side of the top electrode facing away from the electrically active region. Furthermore, a further organic light emitting device, and a method of producing an organic light emitting device are provided.

Owner:NOVALED GMBH

Display apparatus having improved bending properties and method of manufacturing same

ActiveUS9029846B2Improved durability against bendingMinimizes partOLED manufacture/treatment processesFinal product manufactureEngineeringNeutral plane

Owner:SAMSUNG DISPLAY CO LTD

Light Emitting Device and Manufacturing Method Thereof

InactiveUS20110193070A1High film resistanceLow membrane resistanceOLED manufacture/treatment processesSolid-state devicesOrganic compoundLight emission

A light emission device manufactured by a method of forming a curved surface having a radius of curvature to the upper end of an insulator 19, exposing a portion of the first electrode 18c to form an inclined surface in accordance with the curved surface, and applying etching so as to expose the first electrode 18b in a region to form a light emission region, in which emitted light from the layer containing the organic compound 20 is reflected on the inclined surface of the first electrode 18c to increase the total take-out amount of light in the direction of an arrow shown in FIG. 1A and, further, forming a light absorbing multi-layered film 24 comprising light absorbing multi-layered film on the first electrode 18c other than the region to form the light emission region, thereby obtaining a light emission device of a structure increasing the amount of light emission taken out in one direction in a light emission element, while not all the light formed in the layer containing the organic compound are taken out from the cathode as a transparent electrode toward TFT but the light was emitted also, for example, in the lateral direction (direction parallel with the plane of the substrate).

Owner:SANYO ELECTRIC CO LTD +1

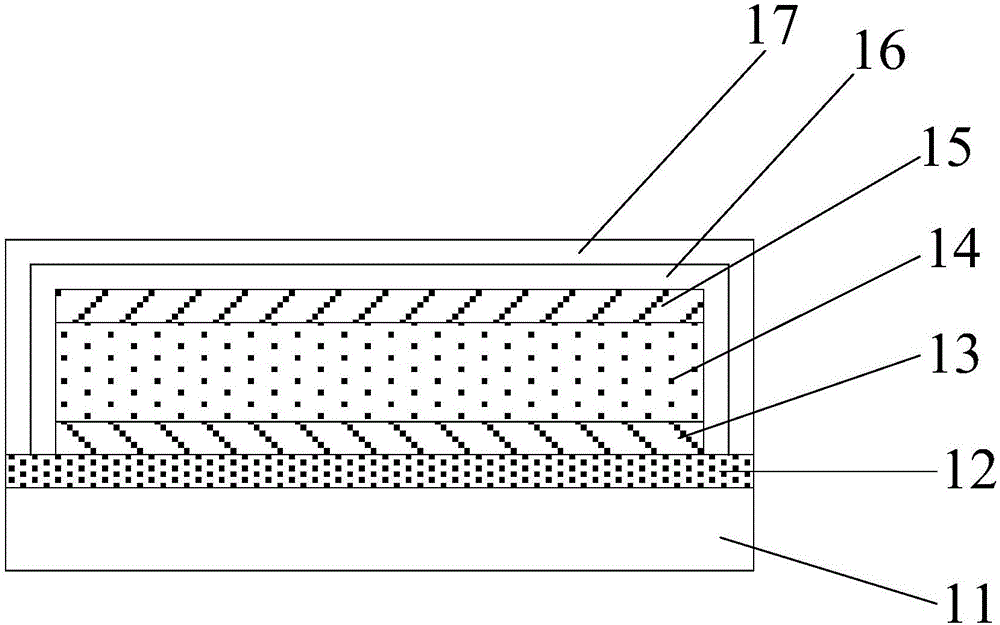

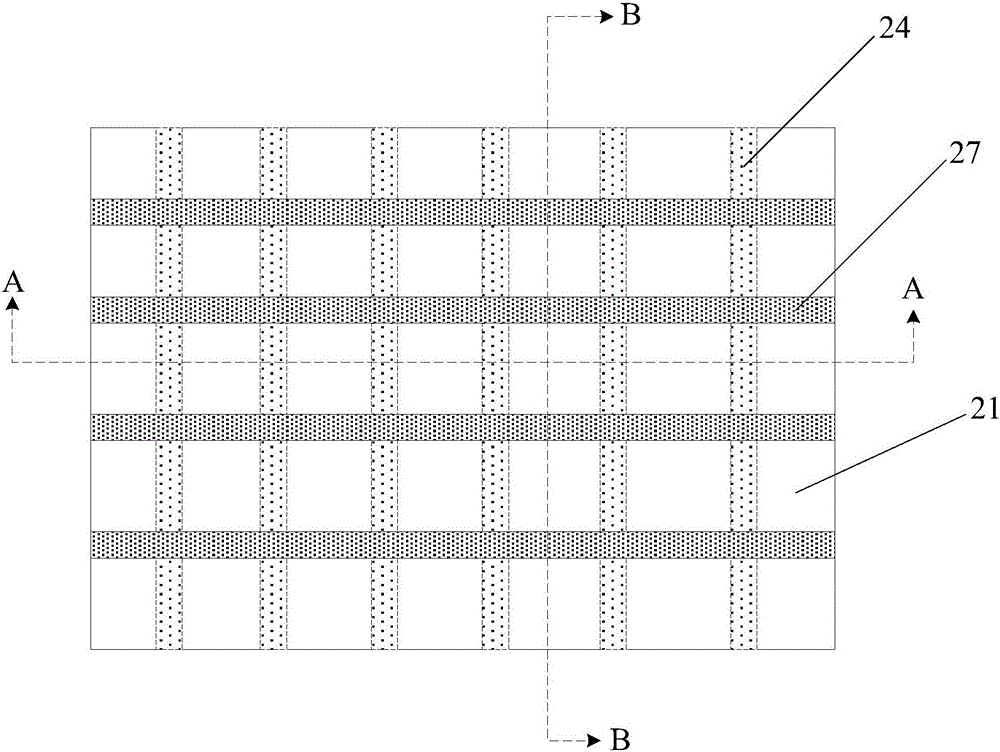

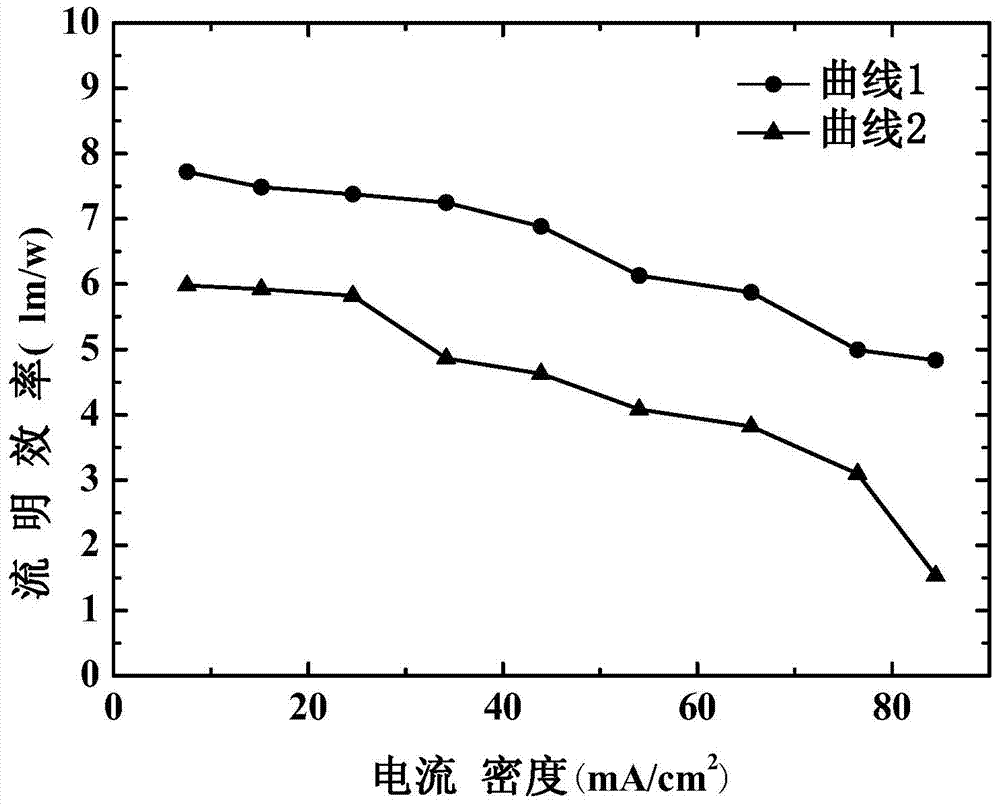

AMOLED device structure and manufacturing method thereof

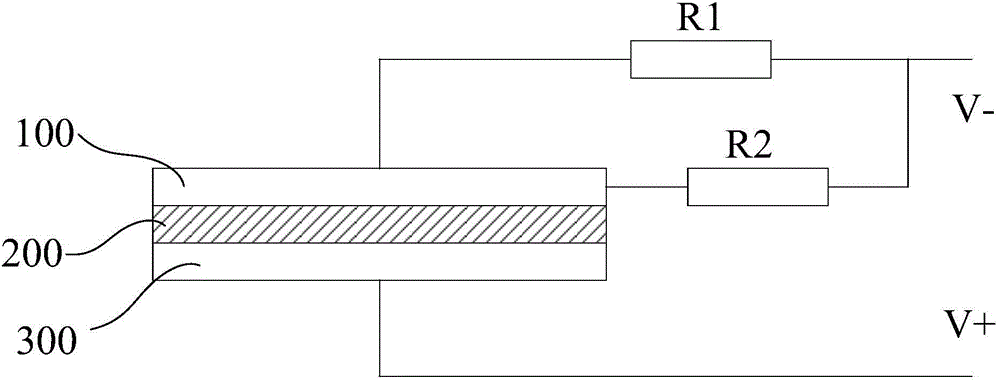

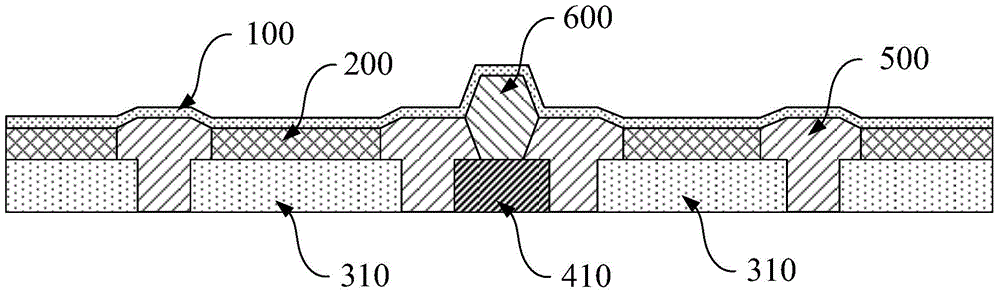

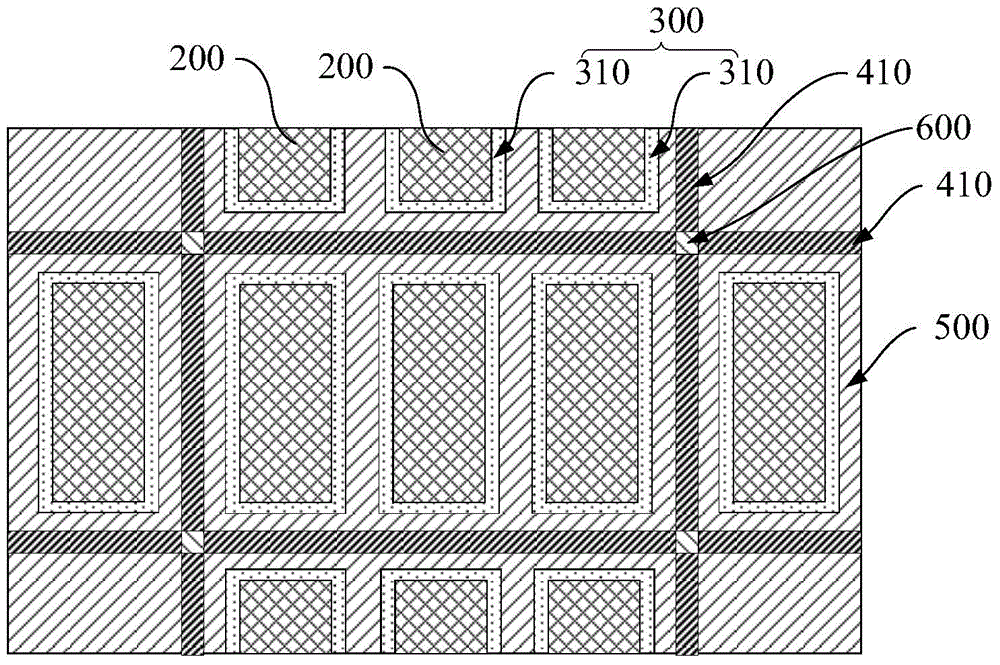

ActiveCN104466021ASolve the problem of excessive cathode resistanceMake full use of spaceOLED manufacture/treatment processesSolid-state devicesOptoelectronicsCathode ray

The invention discloses an AMOLED device structure. The AMOLED device structure comprises a driving voltage device, a cathode layer, an organic light-emitting layer and an anode layer, wherein the cathode layer, the organic light-emitting layer and the anode layer are sequentially arranged in an overlapped mode, the cathode layer is connected with the negative pole of the driving voltage device, and the anode layer is connected with the positive pole of the driving voltage device. The AMOLED device structure is characterized by further comprising a cathode auxiliary layer, and the cathode auxiliary layer is connected with the cathode layer and the negative pole of the driving voltage device. The invention further discloses a manufacturing method of the AMOLED device structure. According to the AMOLED device structure and the manufacturing method of the AMOLED device structure, as the cathode auxiliary layer is arranged in an original structure, the problem that cathode resistance is too large because a cathode is thin or a display screen is large in size can be solved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

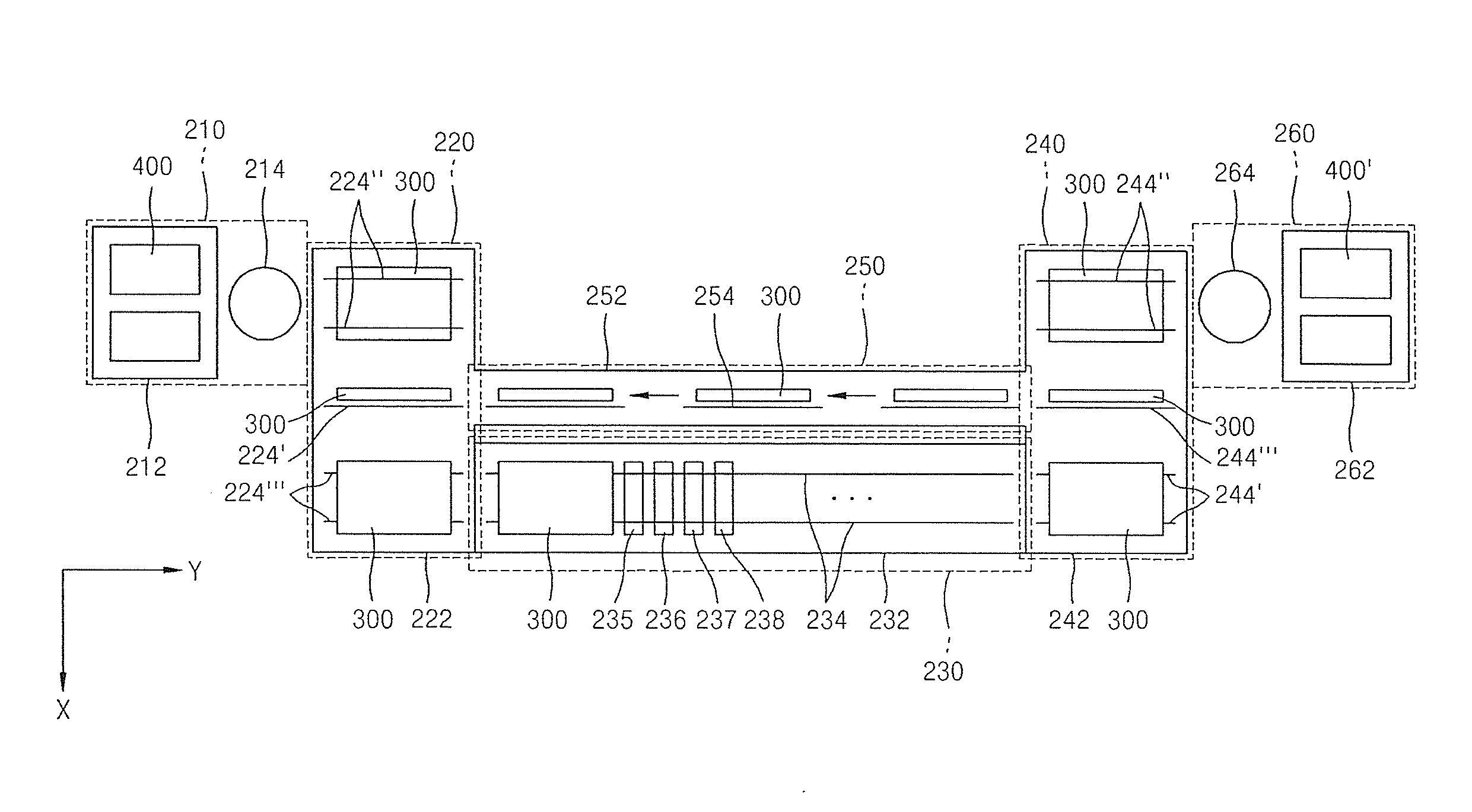

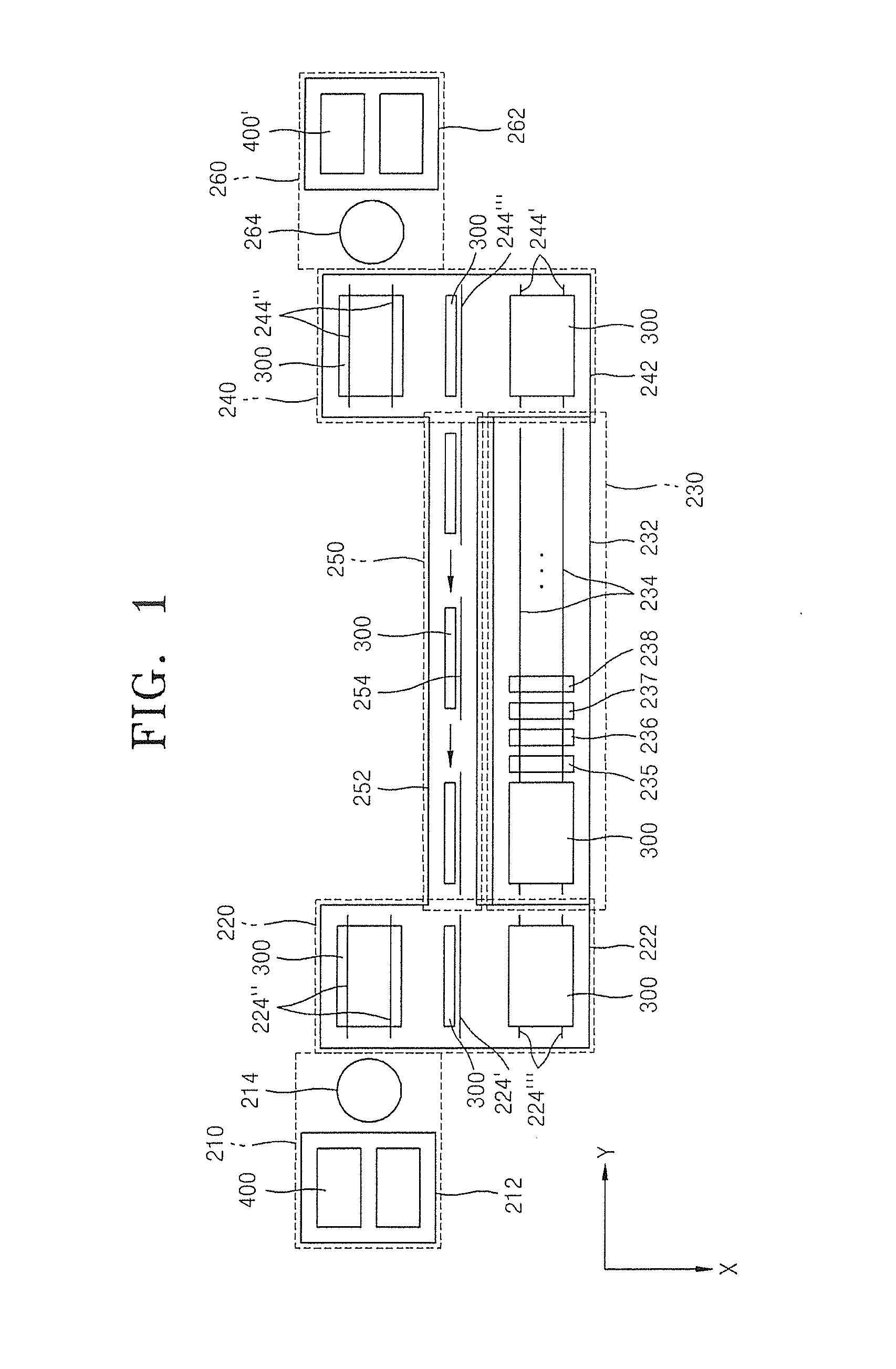

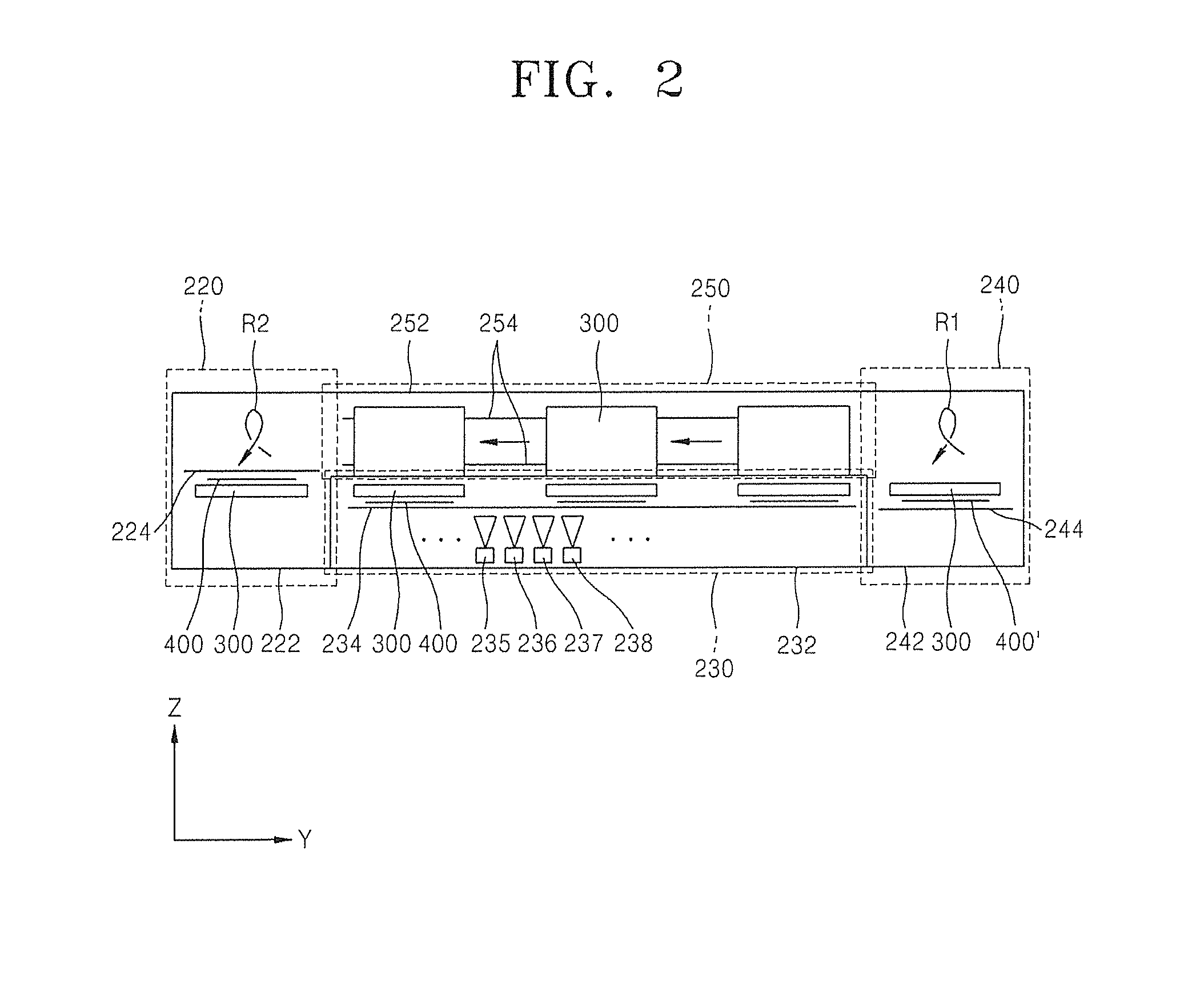

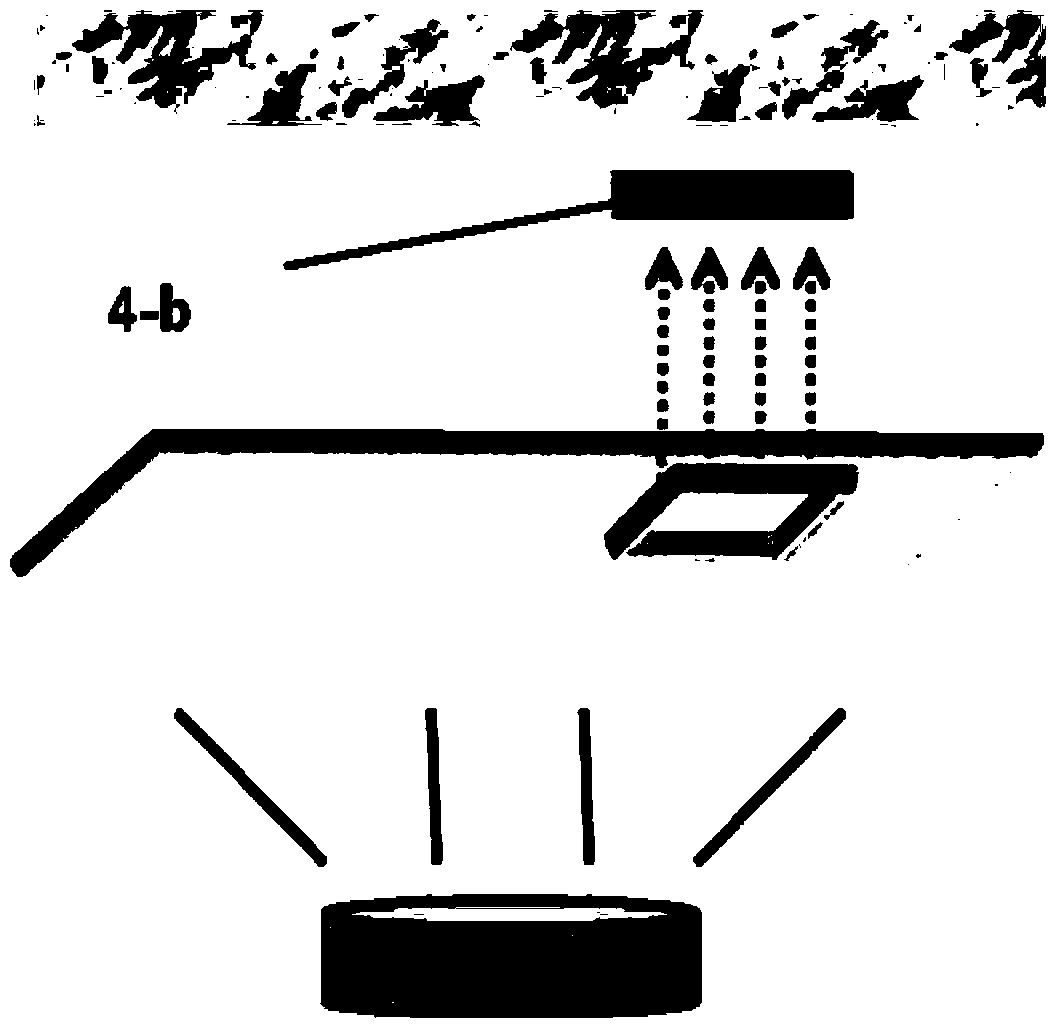

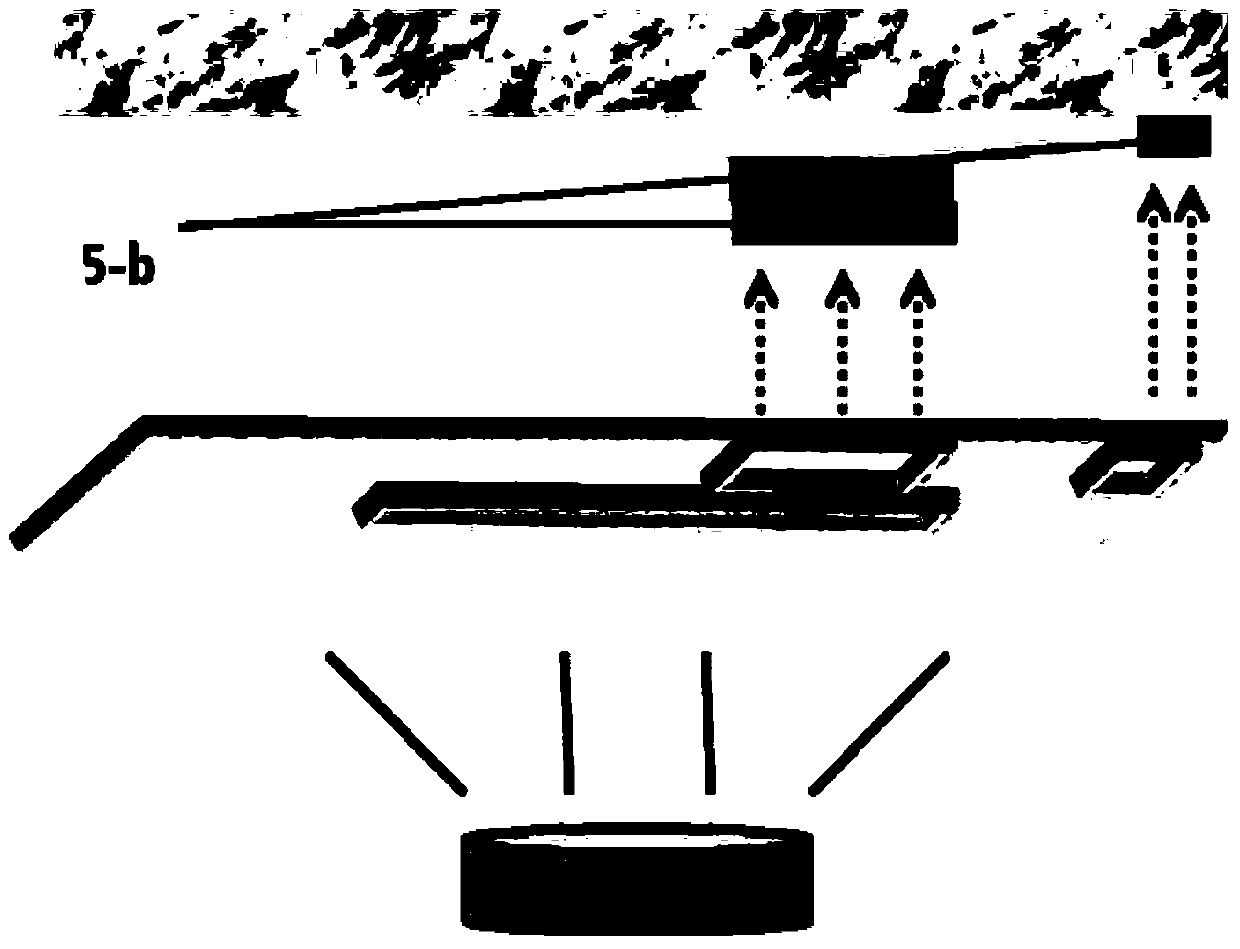

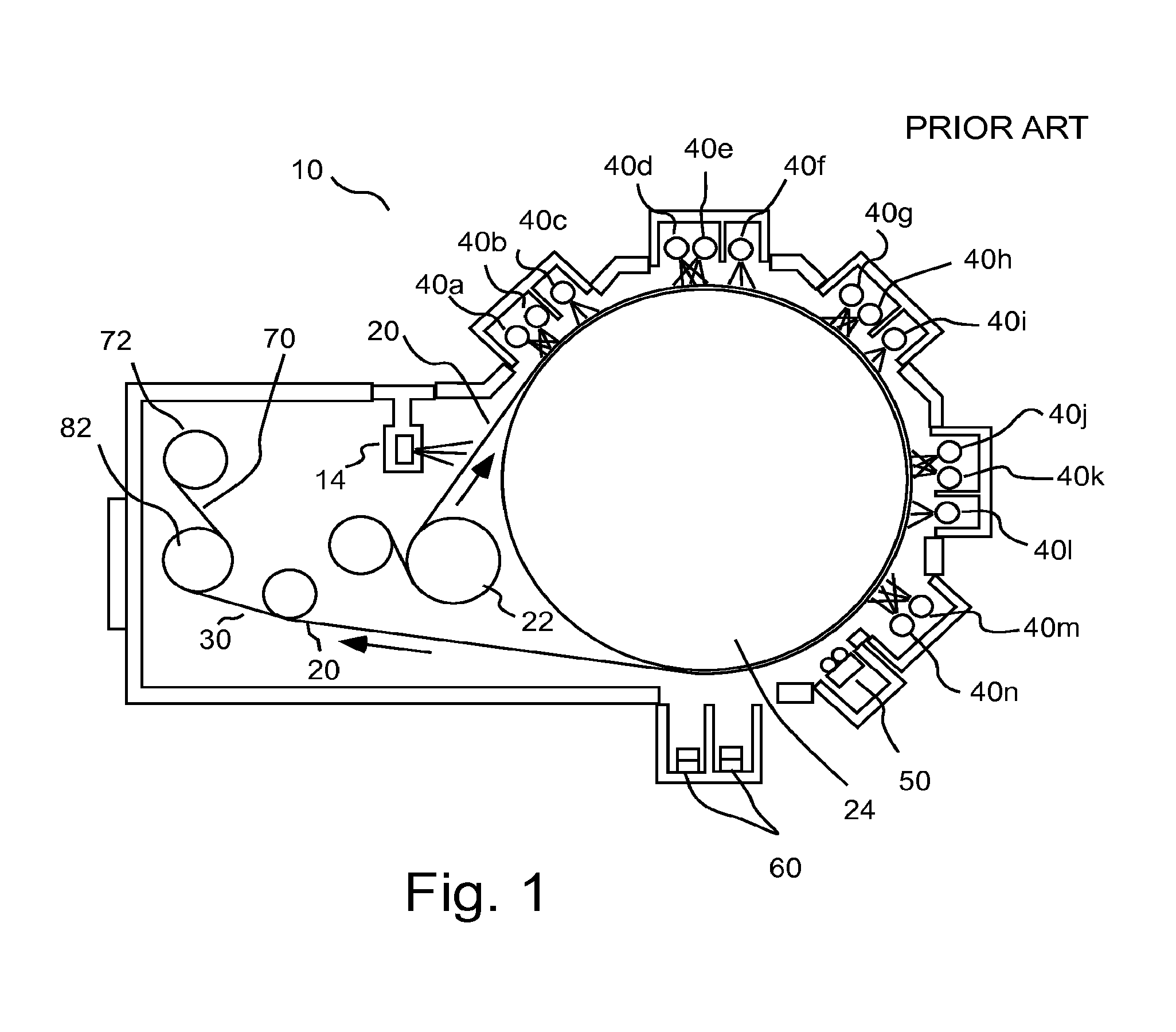

Method of manufacturing organic light-emitting display apparatus, deposition apparatus using the method, and organic light-emitting display apparatus manufactured by using the method

InactiveUS20140284559A1Easy maintenanceOLED manufacture/treatment processesElectroluminescent light sourcesEngineeringSet distance

A method of manufacturing an organic light-emitting display apparatus, a deposition apparatus using the method, and an organic light-emitting display apparatus manufactured by the method, in which substrate effluence is blocked during transportation of a transport unit. The method includes: rotating a transfer unit, to which a substrate is placed or is to be placed, by first and second flip transport units, in a first rotational direction or in an opposite rotational direction to the first rotational direction, by a set angle; forming a layer by depositing a material emitted from a deposition assembly, on the substrate while placing the deposition assembly and the substrate to be separated from each other by a set distance and moving the substrate relatively with respect to the deposition assembly in a first direction via a first transfer unit; and transporting the transport unit in the opposite direction to the first direction after deposition.

Owner:SAMSUNG DISPLAY CO LTD

Organic Light Emitting Diode Display and Method for Manufacturing the Same

ActiveUS20120293064A1Improve uniformityEfficient preparationDischarge tube luminescnet screensOLED manufacture/treatment processesClosed loopDisplay device

An OLED display according to an exemplary embodiment includes: a first substrate; a second substrate arranged opposite to the first substrate; a sealant arranged in the shape of a closed loop along an edge of the second substrate between the first substrate and the edge of the second substrate; and a metal wire formed along the sealant between the first substrate and the sealant. One area of the metal wire has an opening pattern.

Owner:SAMSUNG DISPLAY CO LTD

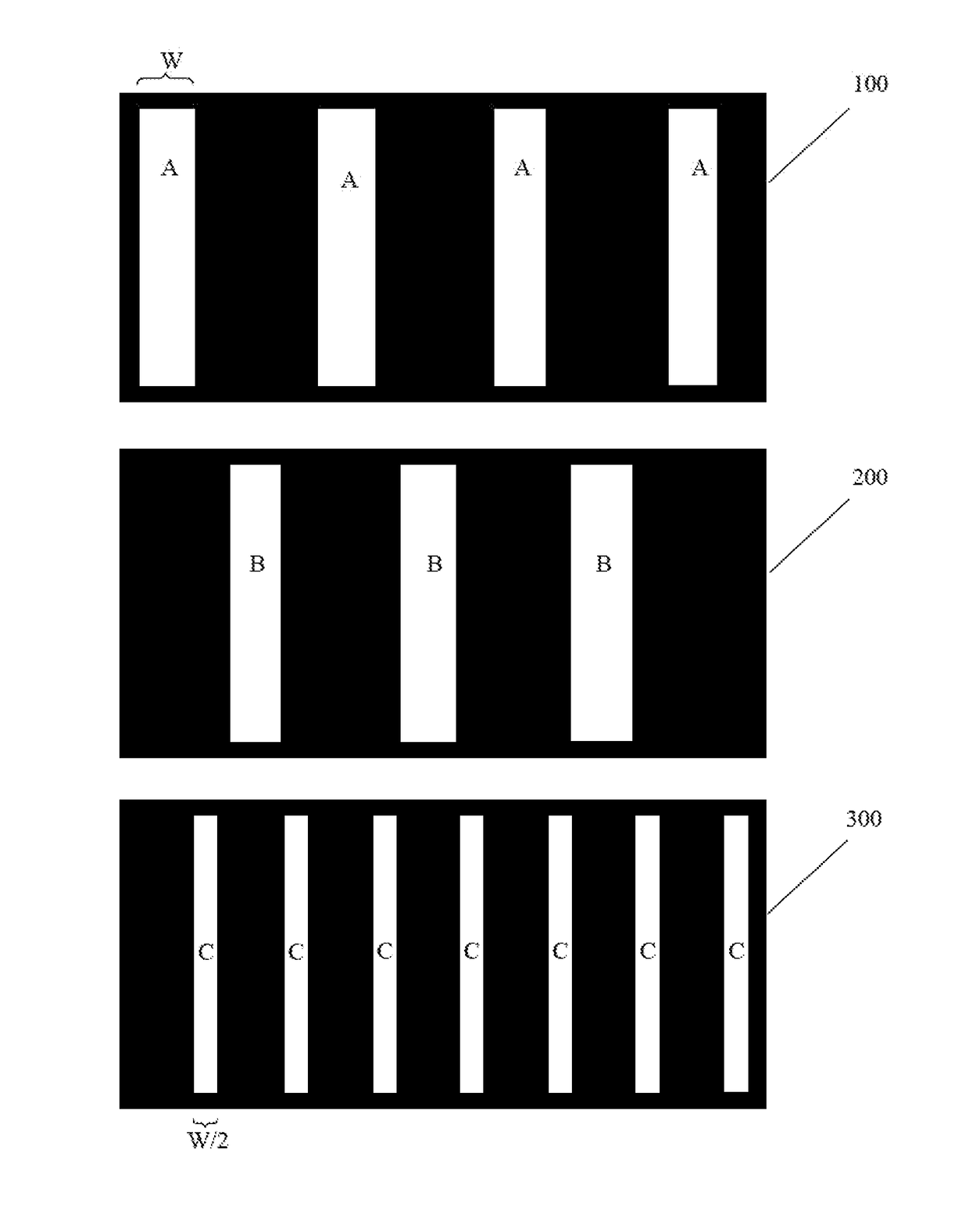

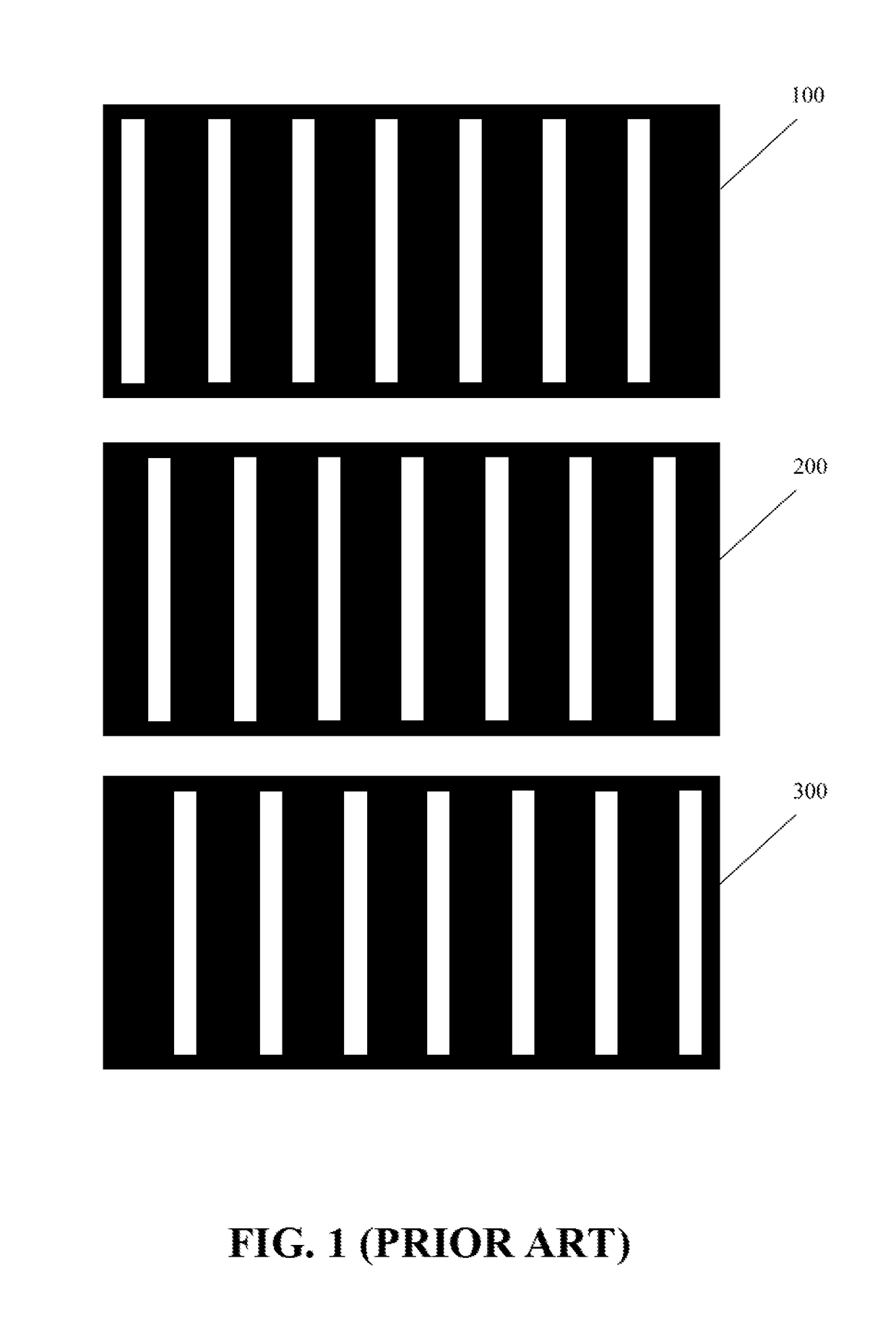

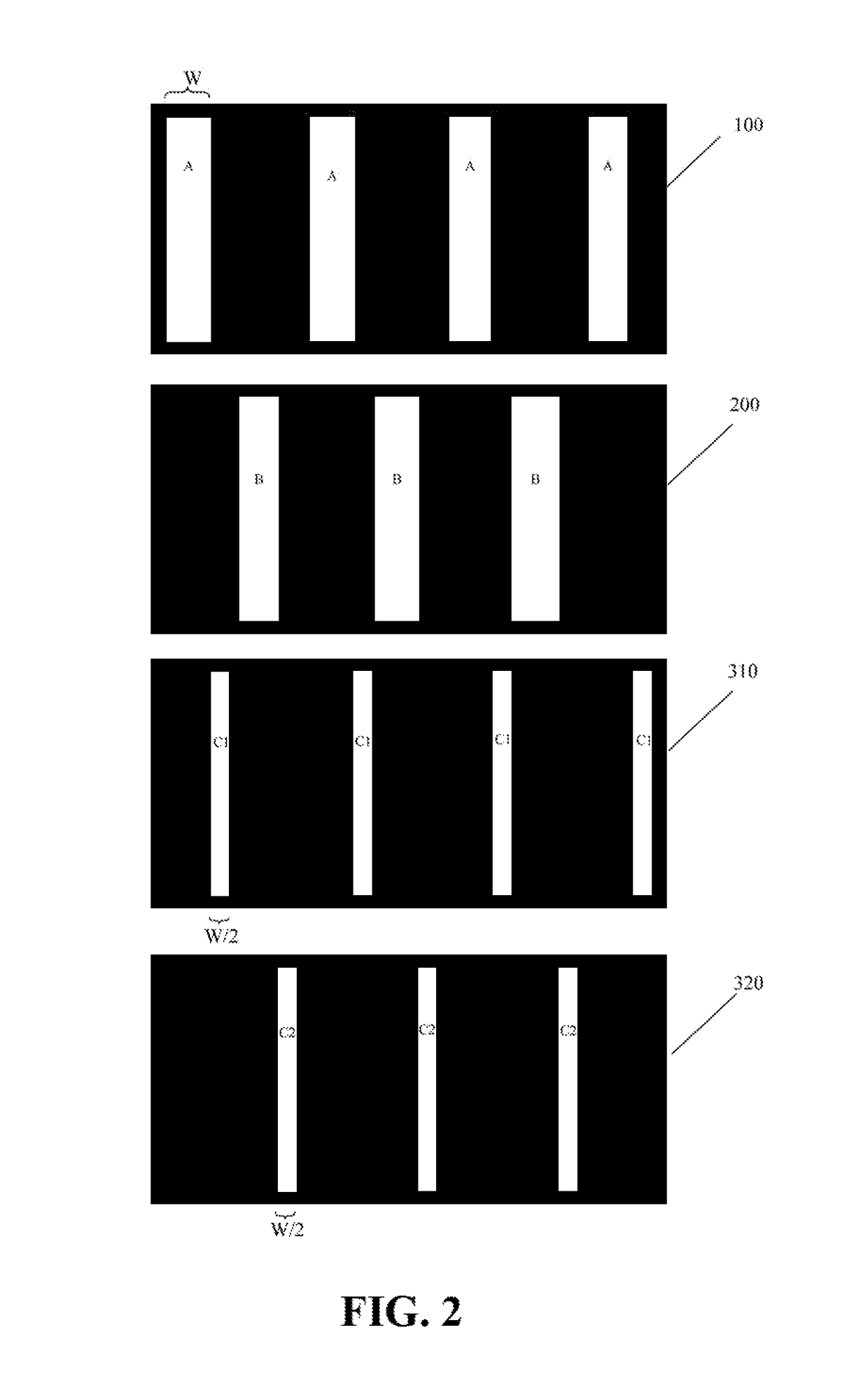

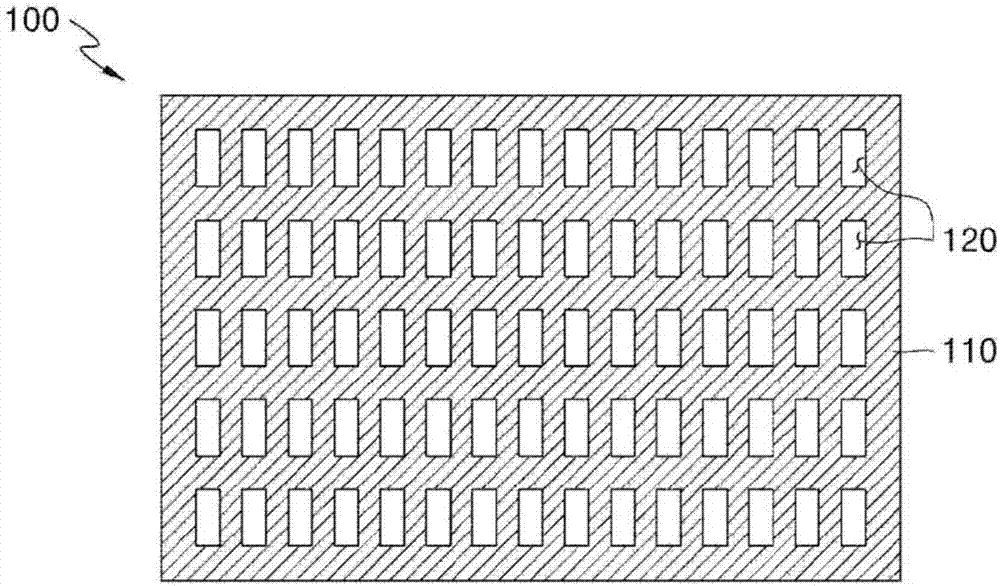

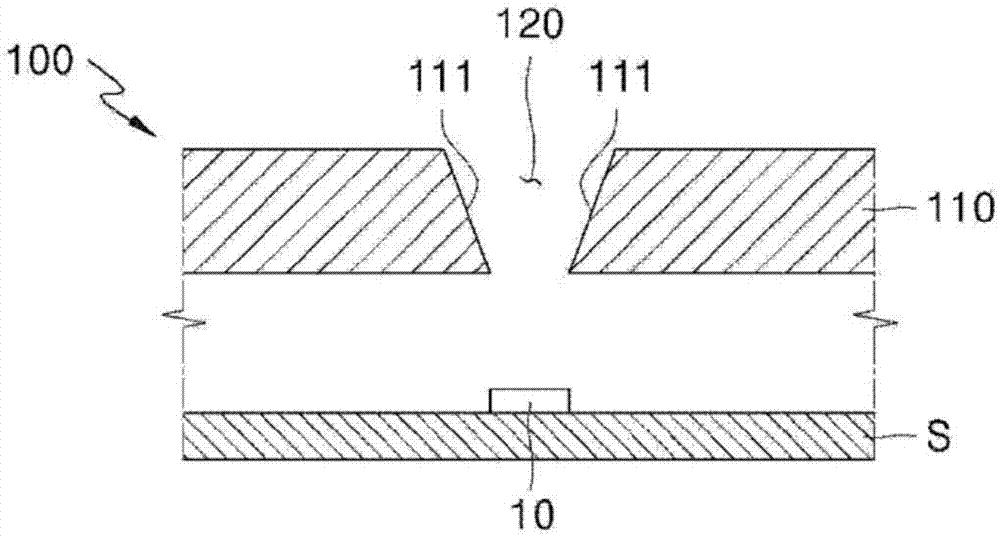

Mask group and method for fabricating an organic luminescence layer, display panel and driving method

ActiveUS20170179442A1Effectively prevent deforms at openings and gridsOLED manufacture/treatment processesVacuum evaporation coatingEngineeringLuminescence

The disclosure provides a mask plate assembly, a method for fabricating an electroluminescent layer, a display panel and a method for driving the same. The mask plate assembly includes a first color mask plate, a second color mask plate, and a third color mask plate each having a plurality of rectangular openings. First openings of the first color mask plate and second openings of the second color mask plate are of a length in a row direction, which is substantially twice as that of third openings of the third color mask plate in the row direction. When the respective mask plates are aligned with one another, the first openings, the second openings, and the third openings are arranged alternately in an order of a first opening, a third opening, a second opening, and another third opening.

Owner:BOE TECH GRP CO LTD +1

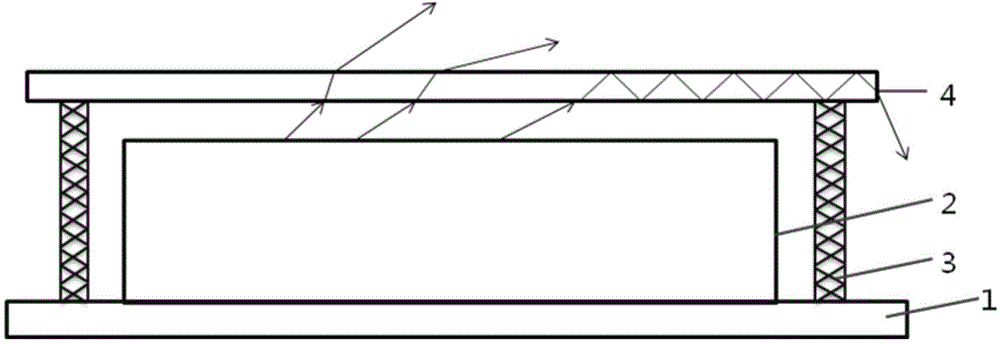

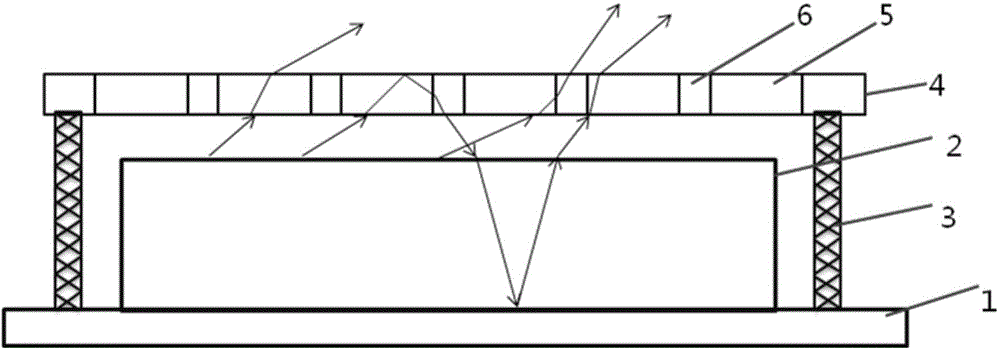

Encapsulating cover plate and application thereof in organic electroluminescence device

ActiveCN104409657AImprove exit efficiencyImprove viewing angleOLED manufacture/treatment processesSolid-state devicesRefractive indexEngineering

The invention belongs to the technical field of panel display, and discloses an encapsulating cover plate and application thereof in an organic electroluminescence device. The encapsulating cover plate uses a piece of photosensitive glass with photoinduced refractive index change or a transparent substrate provided with a transparent photosensitive material, interference pattern irradiation enables the photosensitive glass with photoinduced refractive index change or the transparent substrate provided with the transparent photosensitive material to present blended distribution of high and low refractive indexes, an original total reflection structure of the photosensitive glass or the transparent substrate is destroyed, and the light originally lost because of total reflection is reused after the light is reflected on the encapsulating cover plate, so that the dispersion effect of emergent light is improved, the emergent efficiency of the light and the angle of view are improved, and meanwhile, an effect of antireflection is achieved on the light in the external environment to a certain degree.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

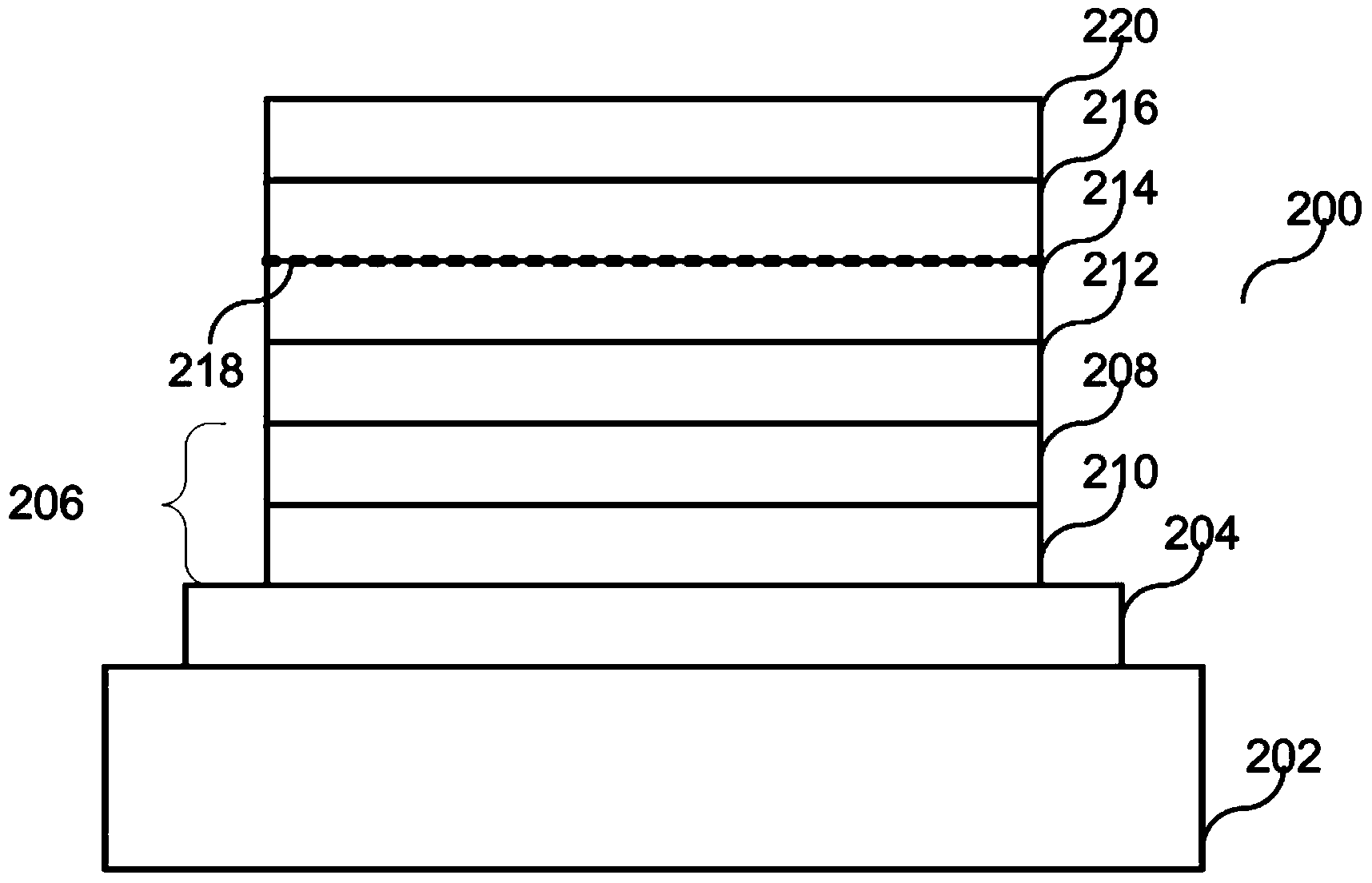

Organic light-emitting component and method for producing an organic light-emitting component

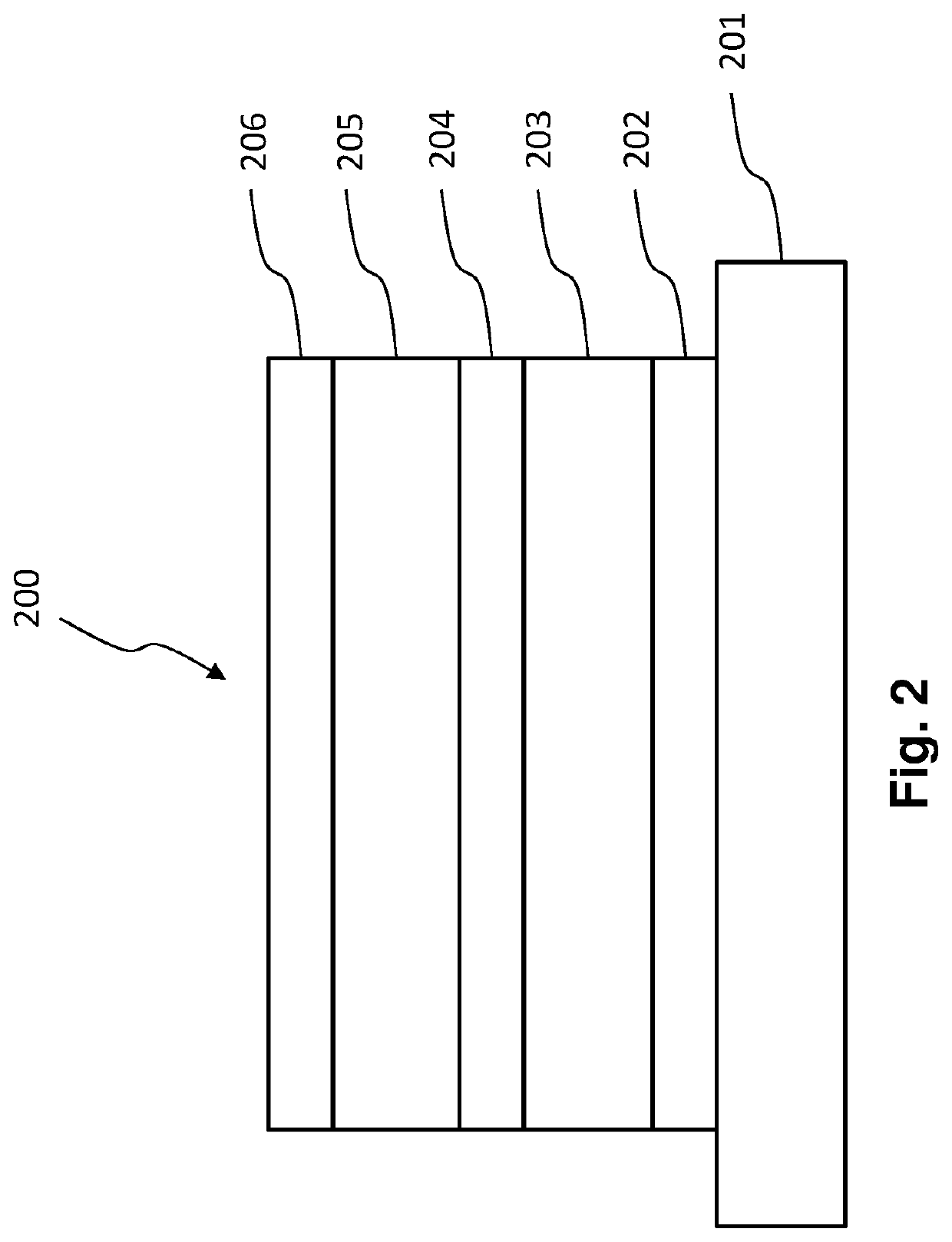

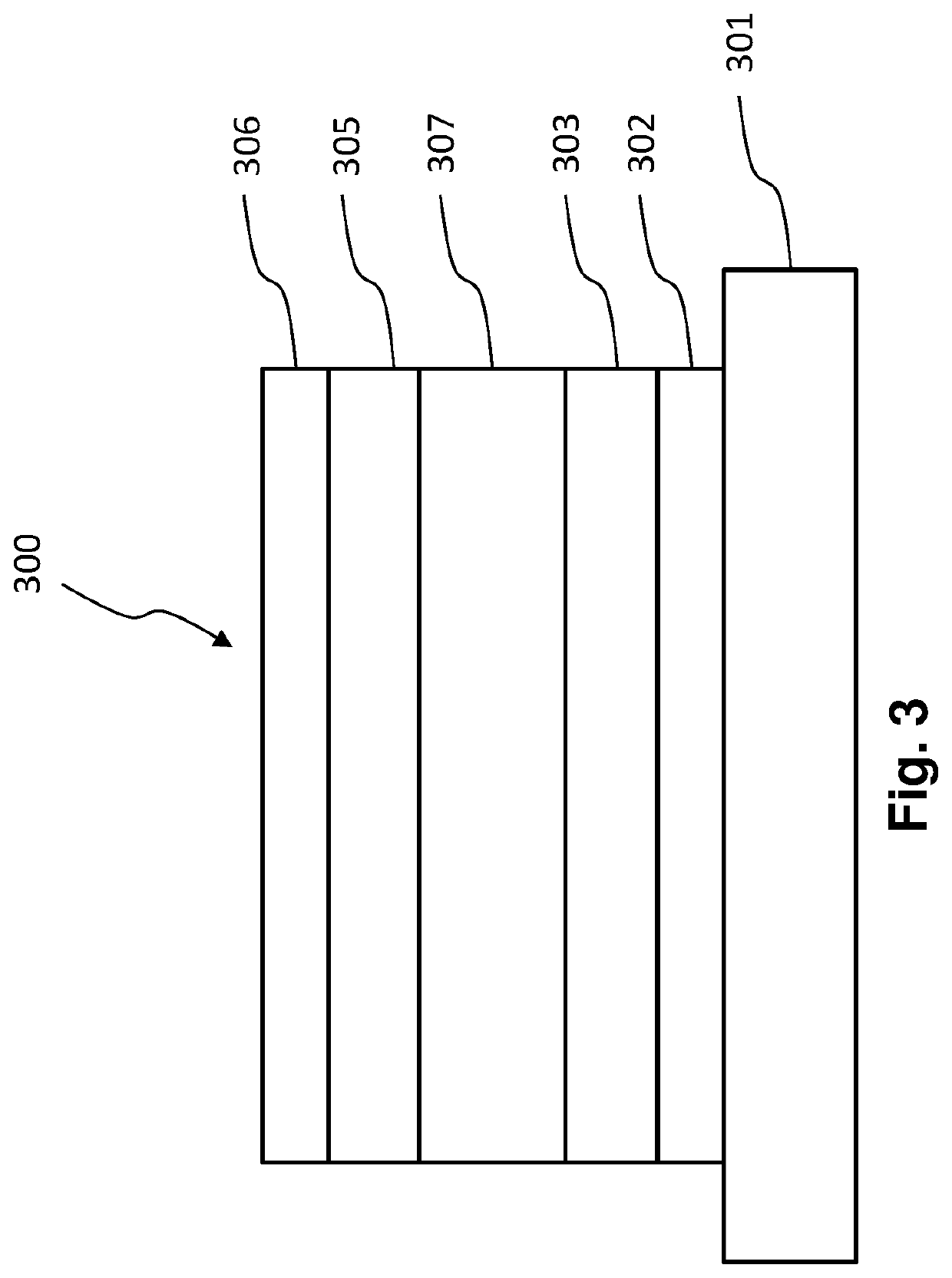

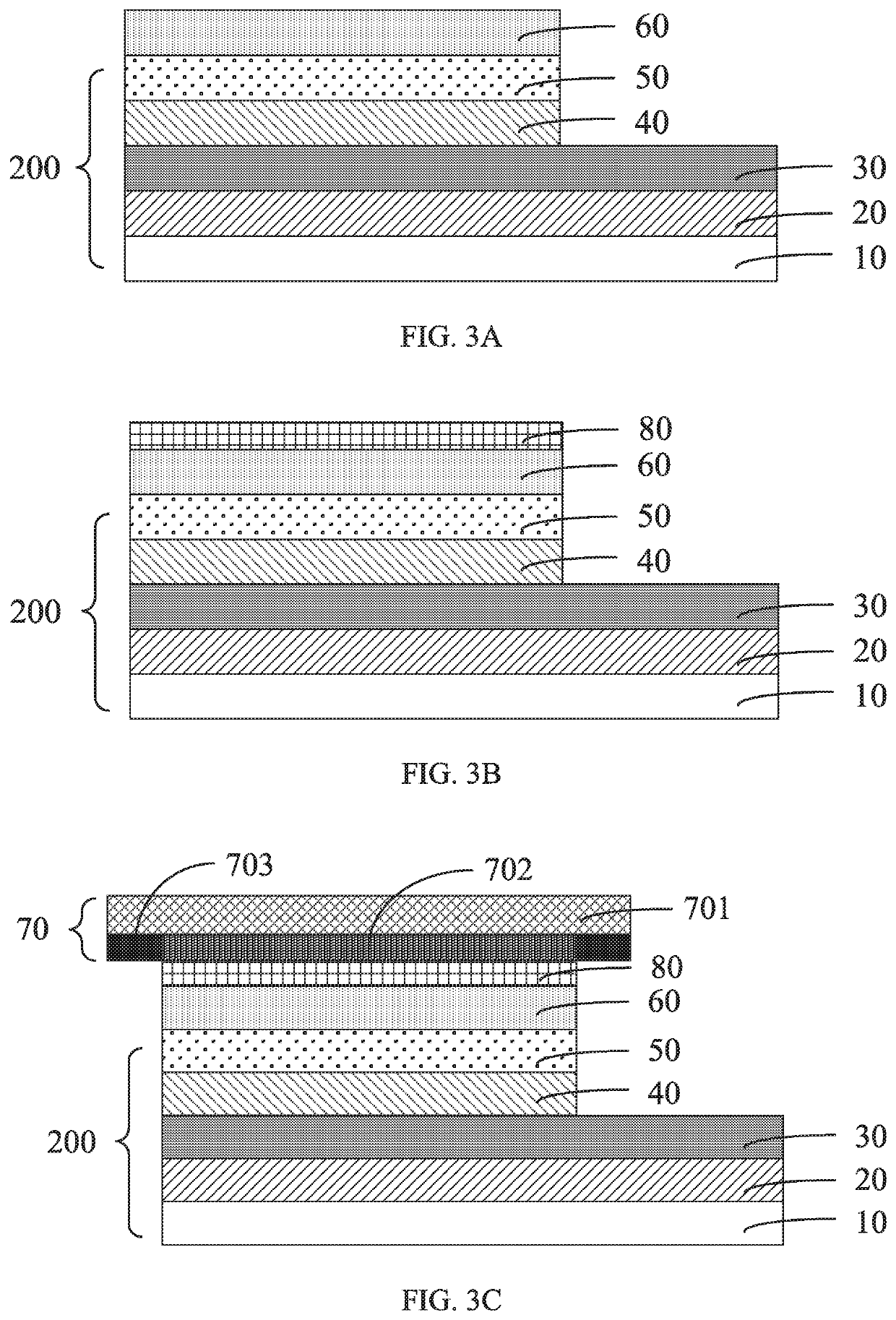

InactiveCN103650196AOLED manufacture/treatment processesSolid-state devicesOrganic light emitting deviceSemi transparent

The invention relates to an organic light-emitting component (200), which is provided in various embodiment examples. The organic light-emitting component (200) can have a first translucent electrode (204); an organic light-producing layer structure (206) on or over the first electrode (204); a second translucent electrode (212) on or over the organic light-producing layer structure (206); an optically translucent layer structure (214) on or over the second electrode (212); and a mirror layer structure (216) on or over the optically translucent layer (214), wherein the mirror layer structure (216) has a light-scattering structure (218) on the side of the mirror layer structure (216) facing the optically translucent layer structure (214).

Owner:OSRAM OPTO SEMICONDUCTORS GMBH

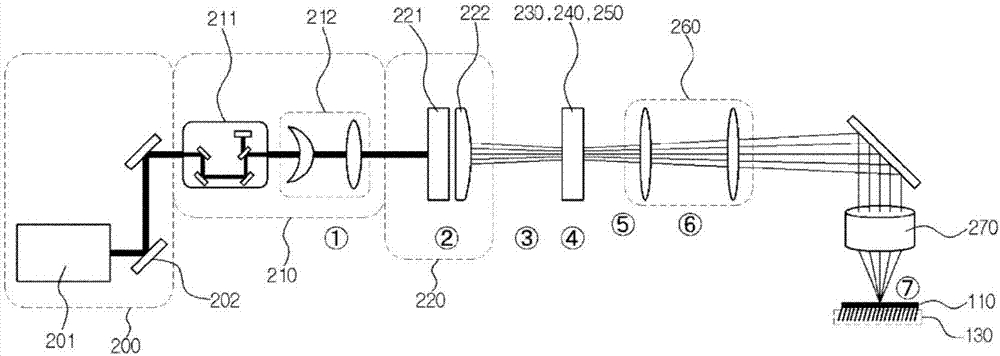

Apparatus for manufacturing shadow mask using laser patterning and method for manufacturing shadow mask using laser patterning

ActiveCN107427964AShorten the timeSimplify the manufacturing processOLED manufacture/treatment processesSolid-state devicesLaser patterningMechanical engineering

An apparatus and a method for manufacturing a shadow mask according to the present invention comprise: a step of positioning, on the top of a base, a masking part provided with a masking pattern which corresponds to a mask pattern to be manufactured; and a step of preparing, on the base, a mask pattern which corresponds to the masking pattern by irradiating a laser beam from the top of the masking part and treating the base with the laser beam, which has passed through the masking part, wherein a plurality of masking patterns are provided to have different widths, and the masking pattern of which the width is narrower towards the direction on which the base is positioned is provided so that the laser beam irradiated from the top of the masking part is irradiated on the base after passing through the plurality of masking patterns step by step. Moreover, the strength around a pattern is gradually adjusted using a phase shift mask and a slit mask, thereby enabling a taper-shaped process required for a deposition mask.

Owner:AP SYST INC

Pixel structure of electroluminescent display panel

ActiveUS8847857B2Raise the ratioImprove resolutionOLED manufacture/treatment processesStatic indicating devicesPhotonPrimary color

A pixel structure of electroluminescent display panel has a first sub-pixel region, a second sub-pixel region, and a third sub-pixel region. The pixel structure of electroluminescent display panel includes a first organic light-emitting layer, and a second organic light-emitting layer. The first organic light-emitting layer is disposed in the first sub-pixel region for generating a first primary color light in the first sub-pixel region. The second organic light-emitting layer is disposed in the second sub-pixel region, and the third sub-pixel region for generating a second primary color light in the second sub-pixel region, and for generating a third primary color light in the third sub-pixel region. The first sub-pixel region, the second sub-pixel region, and the third sub-pixel region have different cavity lengths.

Owner:AU OPTRONICS CORP

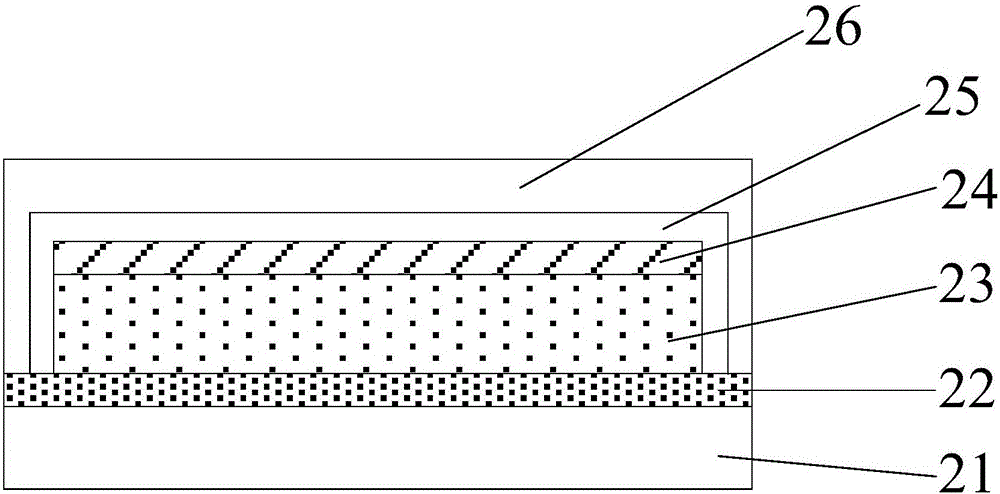

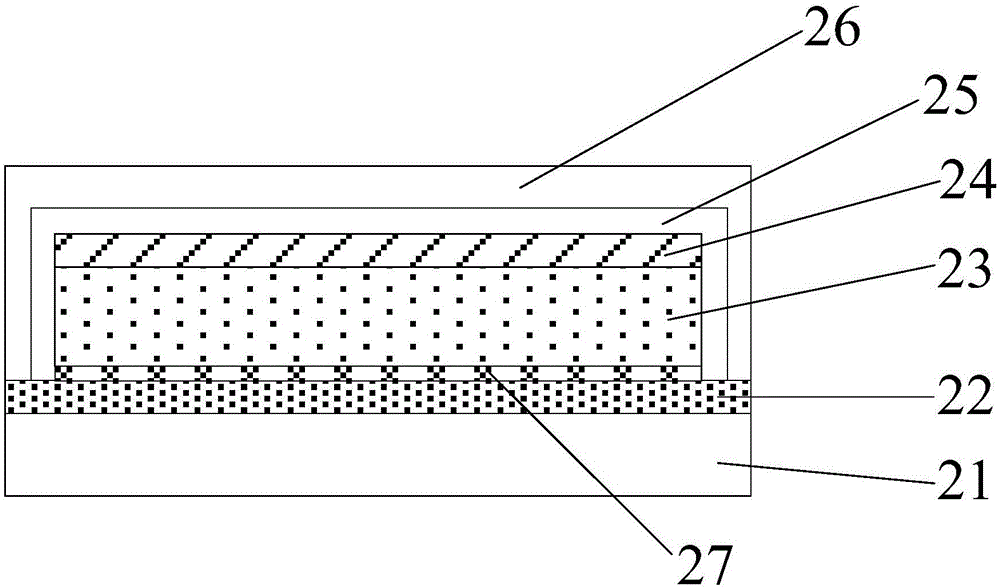

Luminous device and manufacturing method thereof

InactiveCN106784378AReduce manufacturing process stepsReduce manufacturing costOLED manufacture/treatment processesSolid-state devicesWater vaporOxygen

The invention discloses a luminous device and a manufacturing method thereof, wherein the luminous device comprises a base plate, a conducting hydrophobic layer, an organic luminous layer, an electrode layer and a passivation layer, wherein the conducting hydrophobic layer is arranged on the base plate; the organic luminous layer is arranged on the conducting hydrophobic layer; the electrode layer is arranged on the organic luminous layer; the passivation layer is arranged on the electrode layer so as to at least cover the organic luminous layer and the electrode layer. Therefore the conducting hydrophobic layer is arranged between the base plate and the organic luminous layer; meanwhile, an effect of preventing water vapor and oxygen from entering the luminous device and the electrode is achieved; the process steps of additionally installing the blocking layer can be omitted, so that the manufacturing technical steps of the luminous device can be reduced; the manufacturing cost of the luminous device is reduced.

Owner:GUAN YEOLIGHT TECH CO LTD

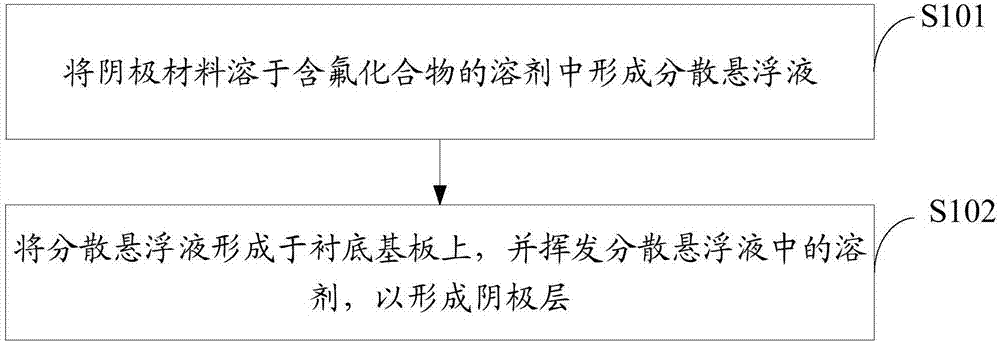

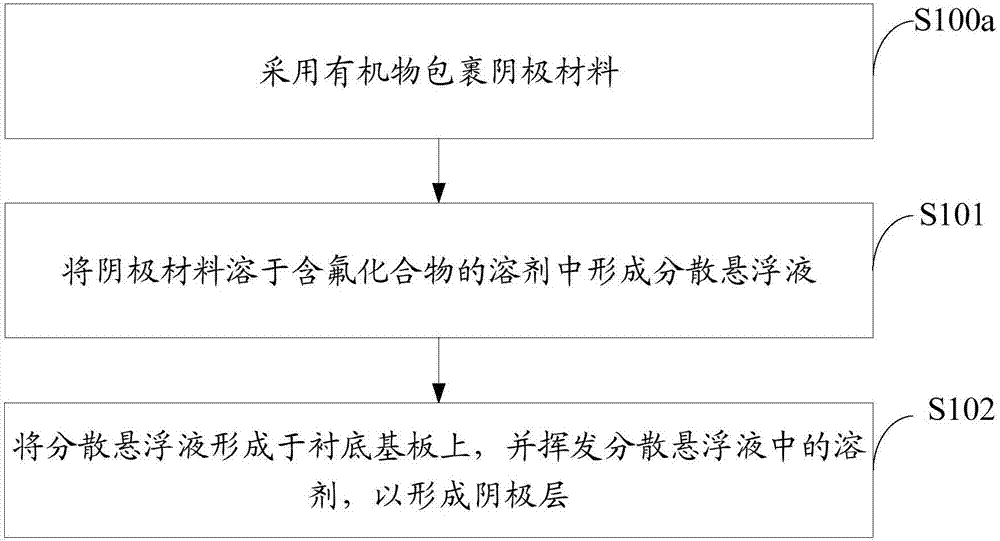

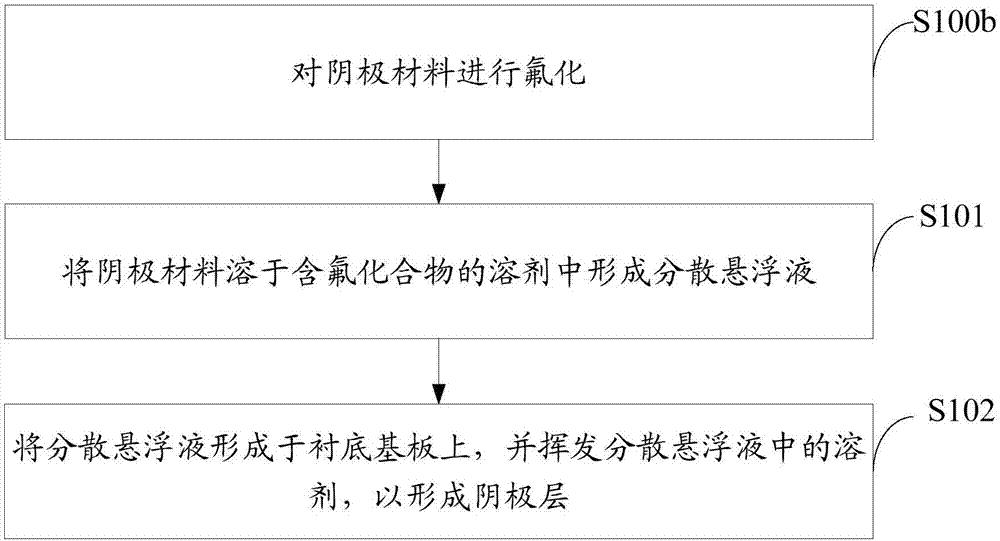

OLED device cathode and display panel making method, display panel and display device

ActiveCN107275513AAchieve mass productionEasy to mass produceOLED manufacture/treatment processesSolid-state devicesOrganic filmOrganic layer

The invention discloses an OLED device cathode and display panel making method, a display panel and a display device. The organic electroluminescent device cathode making method comprises steps that a cathode material is dissolved in a solvent containing fluorine compound to form dispersed suspension; the dispersed suspension is formed on a substrate, and the solvent of the dispersed suspension is volatilized to form a cathode layer. The cathode making method is advantaged in that utilizing a solution method to make a cathode is realized, adverse influence caused by utilizing a cavity coating method to make the cathode is avoided, making cost is relatively low, the method is applicable to the substrate in various specifications or prepared by various materials, for example, glass, plastic, metal or silicon materials can be utilized to make the substrate, the solvent containing the fluorine compound has no adverse influence on an organic layer of an organic electroluminescent device, process butt joint with an organic film layer of the solution method can be easily realized, and batch production of the organic electroluminescent device can be easily realized.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

LTPS technology

InactiveCN103972169AShorten the timeLow costOLED manufacture/treatment processesSolid-state devicesOptoelectronicsThermal treatment

The invention relates to an LTPS technology. Compared with a traditional technology, the LTPS technology comprises the following steps that according to the type of a transistor, P- or B+ is doped to a source electrode or a drain electrode of the transistor; thermal treatment is conducted through a furnace to activate doped impurities; an oxide pattern with the thickness shown in the specification is formed through an electron beam evaporator and a mask plate in a vapor deposition mode, so that a gate electrode metal layer and the like are formed. The LTPS technology has the advantages that compared with an LTPS technology in the background art, cost is reduced and productivity is improved. The steps that a passivation insulation film with the thickness shown in the specification is formed through PECVD in a vapor deposition mode and a contact hole pattern for anode contact is formed through photoetching and etching are omitted, wherein the passivation insulation film can prevent an anode and a metal wire from generating a short circuit. The processes of vapor deposition, photoetching, etching and PR are simplified into a mask plate manufacturing process so that the time for manufacturing a TFT array set can be shortened and production cost can be reduced. The LTPS technology is not only suitable for the MIC but also suitable for the conditions of different crystallization methods such as MILC or MICC.

Owner:SICHUAN CCO DISPLAY TECH

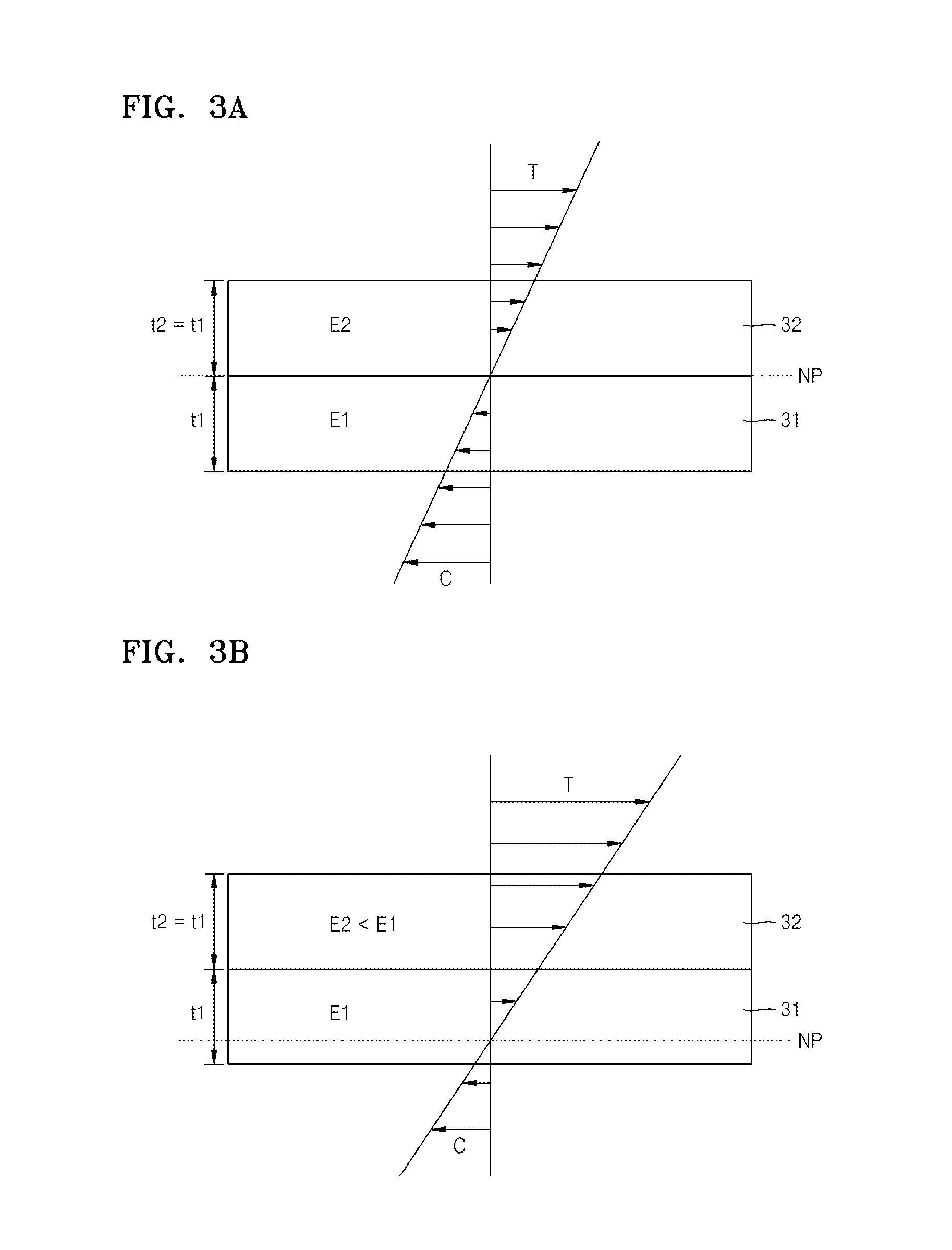

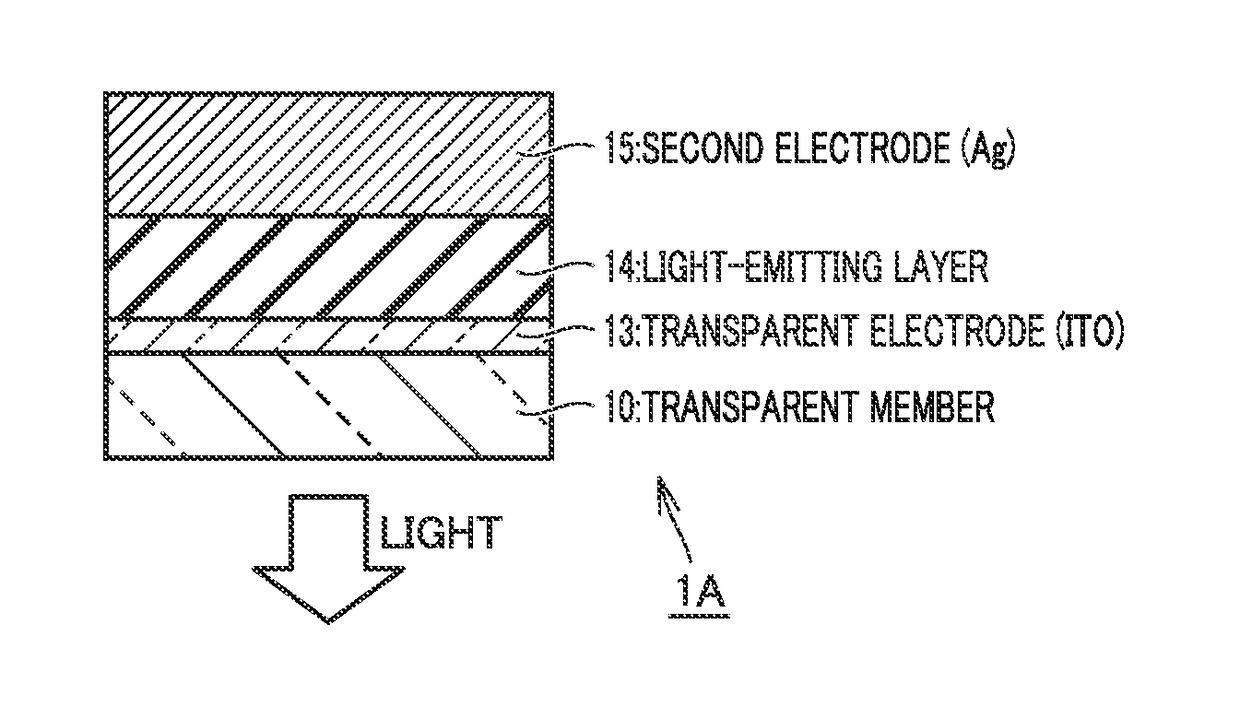

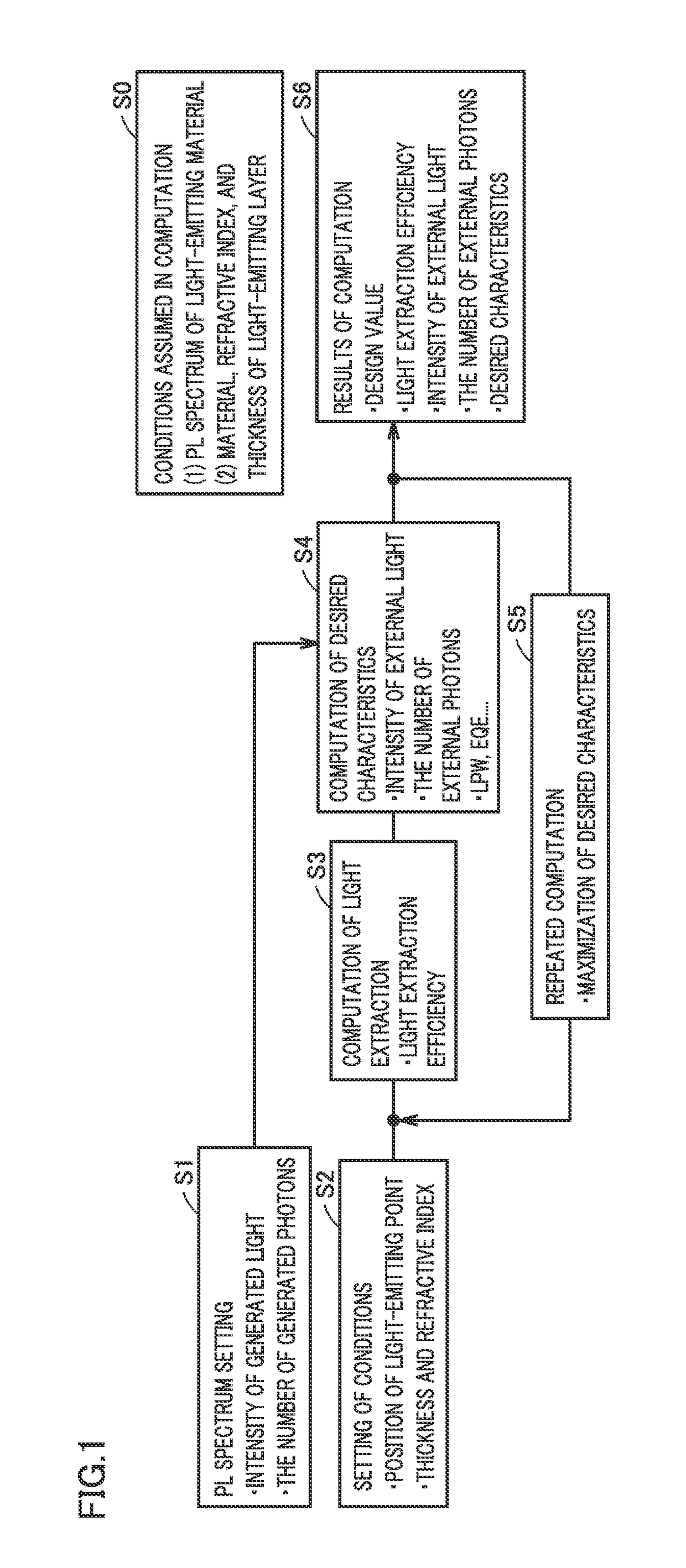

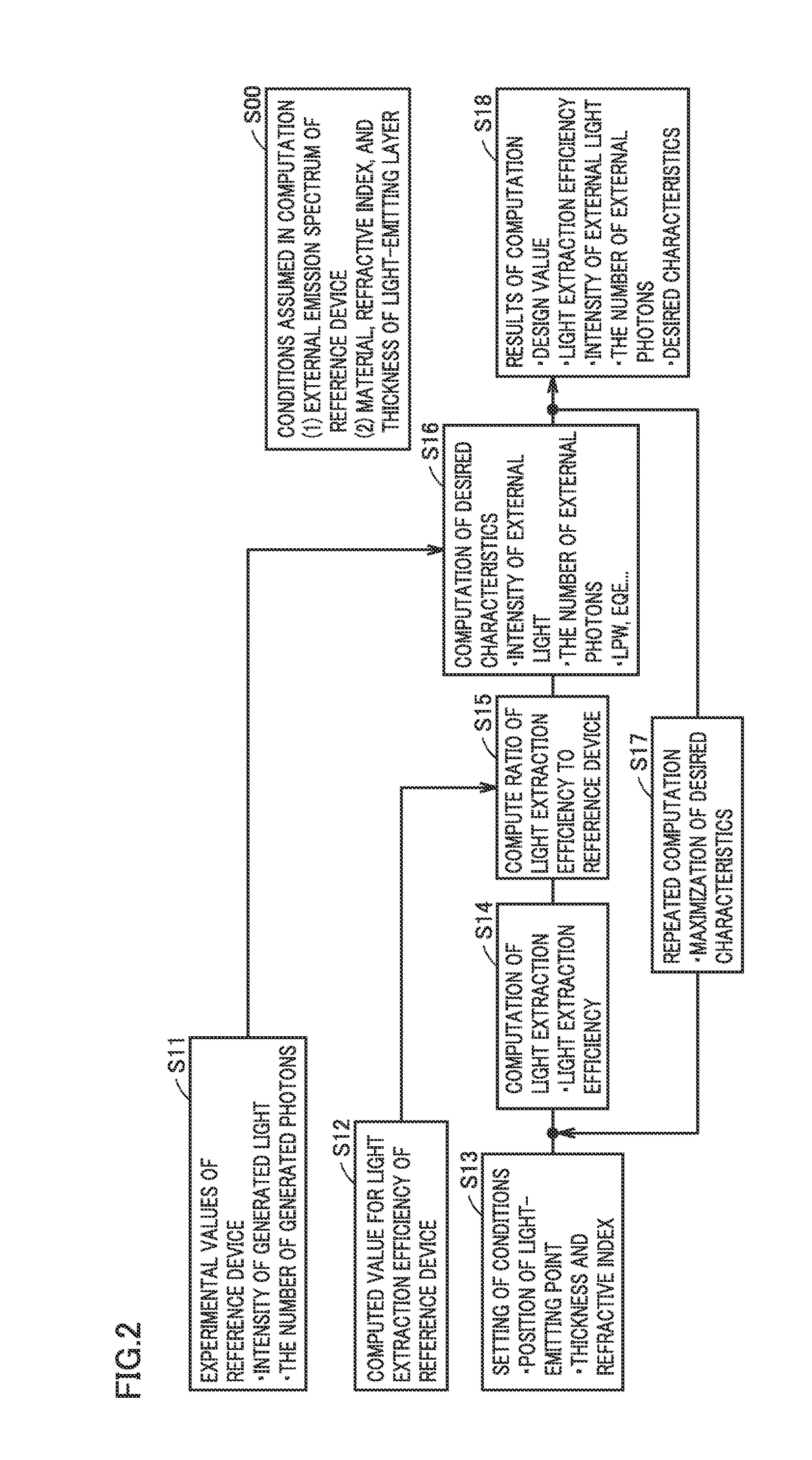

Method of Designing Electroluminescent Device, Electroluminescent Device Manufactured with the Design Method, and Method of Manufacturing Electroluminescent Device with the Design Method

ActiveUS20170179443A1Accurate calculationAccurate estimateOLED manufacture/treatment processesElectroluminescent light sourcesElectricityPower flow

A method of designing an electroluminescent device allows more accurate computation of an external emission spectrum output to the outside in a current injection state and accurate estimate of a quantity and / or a color of light extracted to the outside, an electroluminescent device manufactured with the design method, and a method of manufacturing an electroluminescent device with the design method.

Owner:MERCK PATENT GMBH

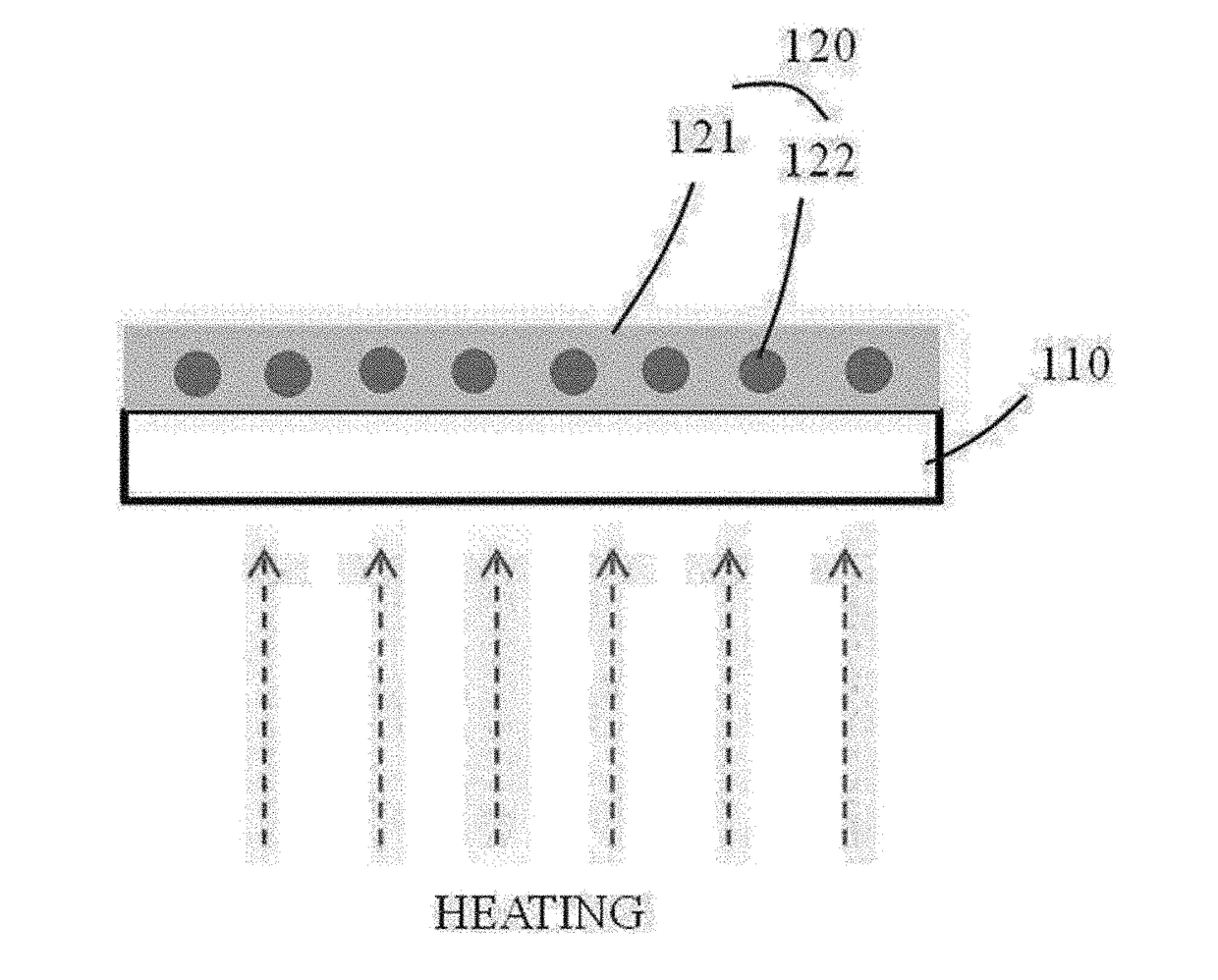

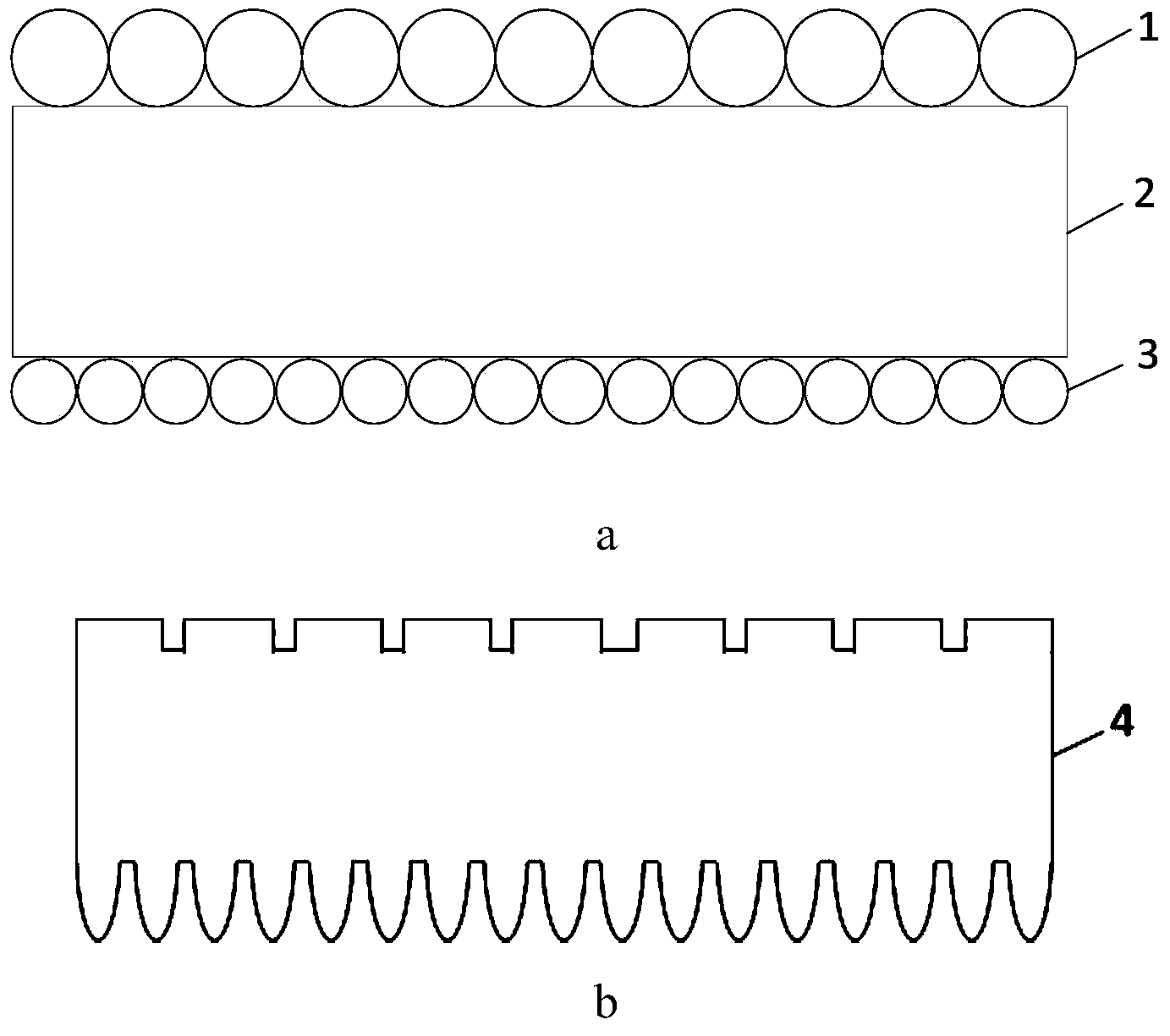

Ligands for quantum dots in cross-linked emissive layer of quantum dot light emitting diodes

ActiveUS20210408416A1Enhanced structure of layerIncrease heightOLED manufacture/treatment processesSolid-state devicesQuantum dotLight-emitting diode

A light-emitting device includes an anode, a cathode, and a crosslinked emissive layer disposed between the anode and the cathode in which quantum dots are dispersed. The crosslinked layer includes a crosslinked material and quantum dots dispersed in the crosslinked mater, the quantum dots having ligands respectively bonded to the quantum dots. The quantum dots are distributed unevenly within the crosslinked material. The ligands have a concentration relative to the weight of the quantum dots of 10 to 45 wt %. A method of forming a crosslinked emissive layer of a light-emitting device in which quantum dots are dispersed includes the steps of depositing a mixture on a deposition surface and subjecting at least a portion of the mixture to an activation stimulus to crosslink the cross-linkable material.

Owner:SHARP KK

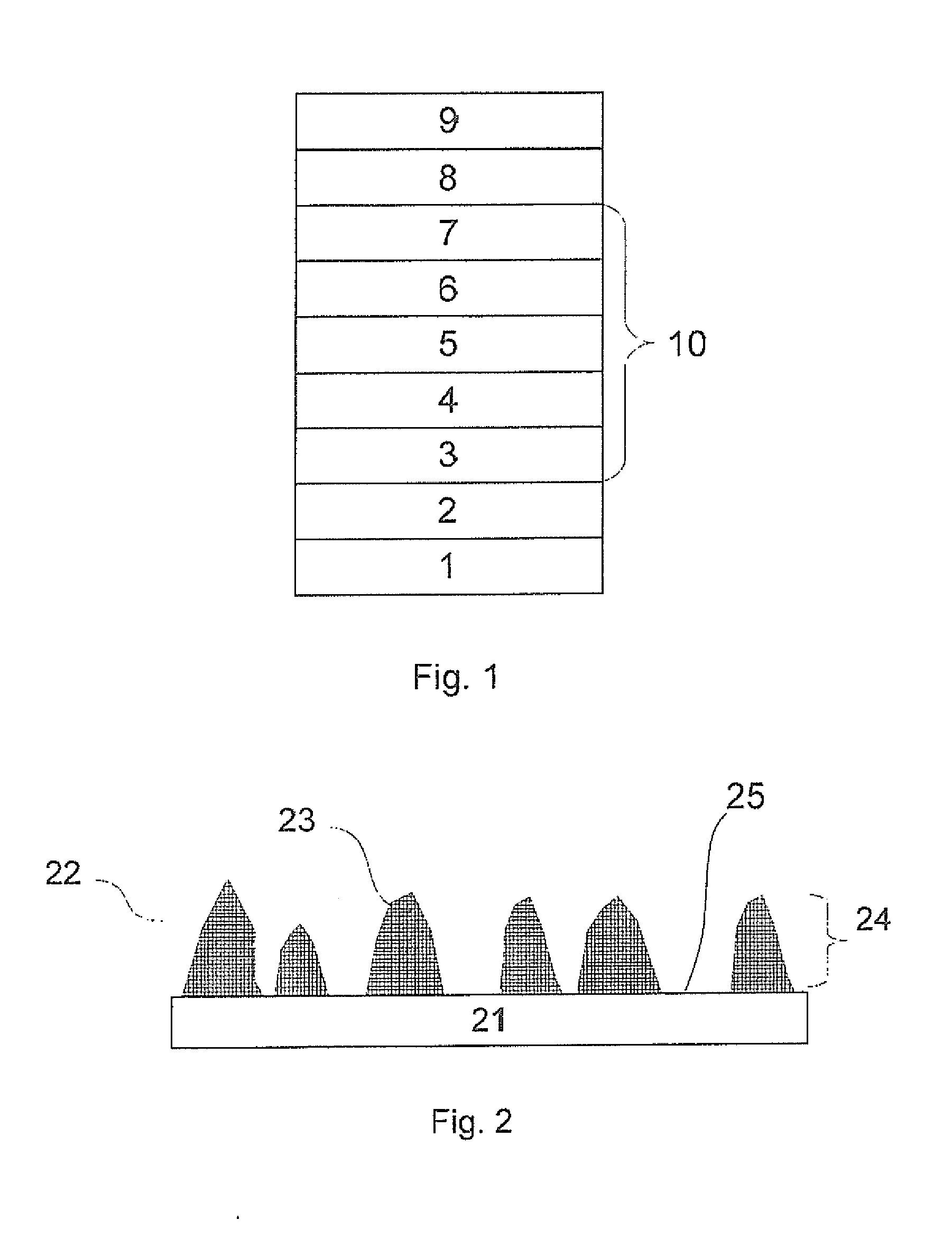

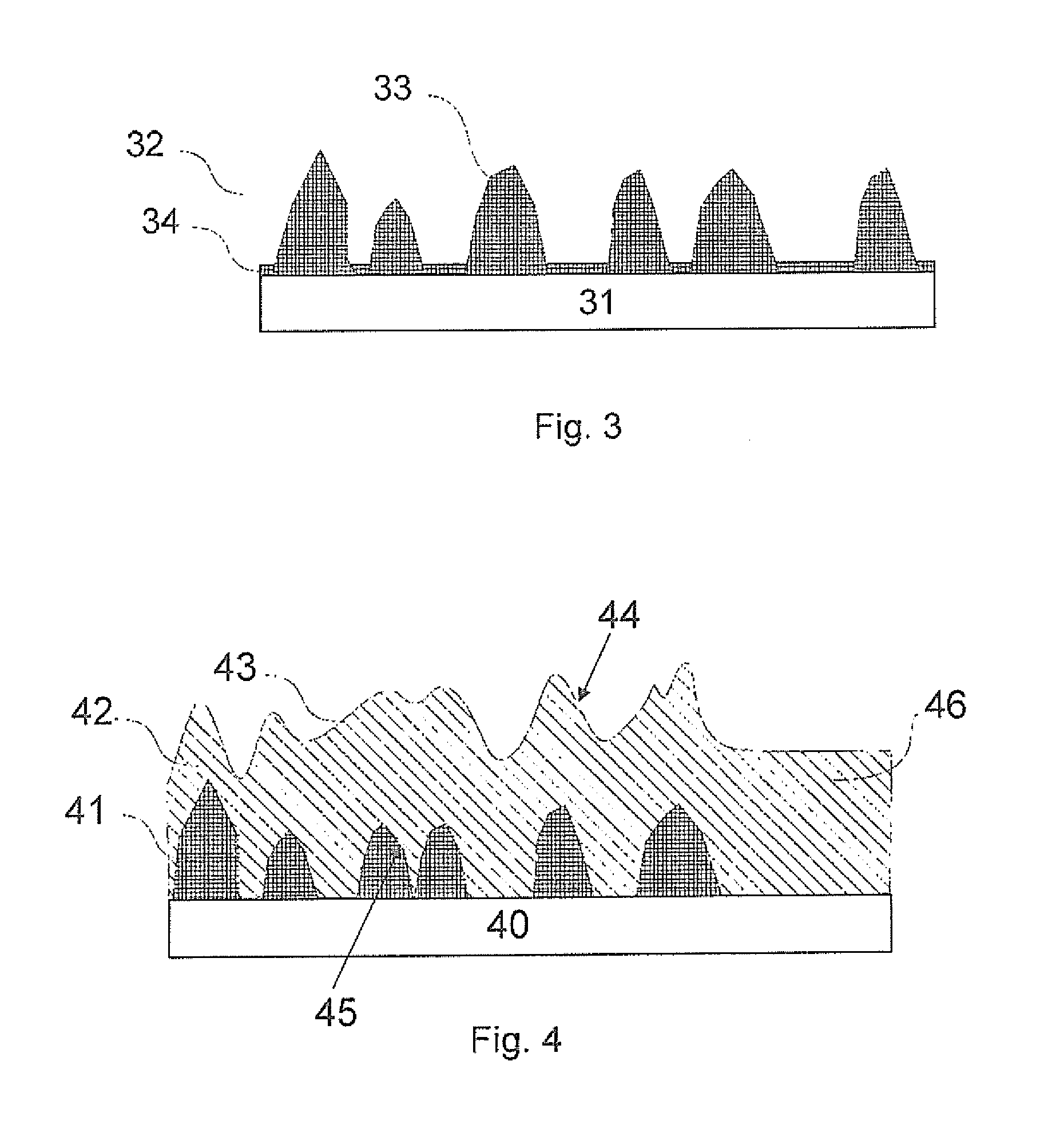

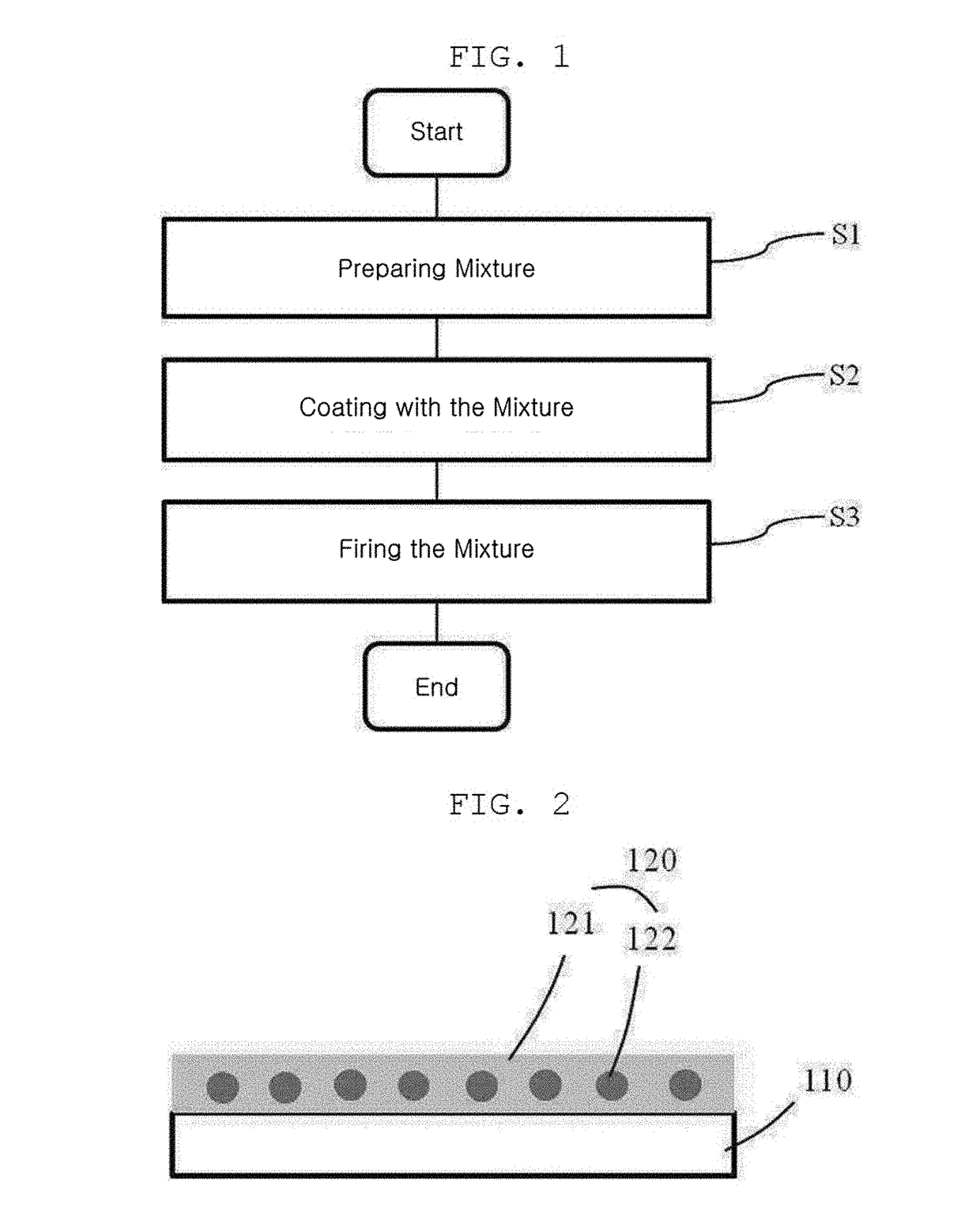

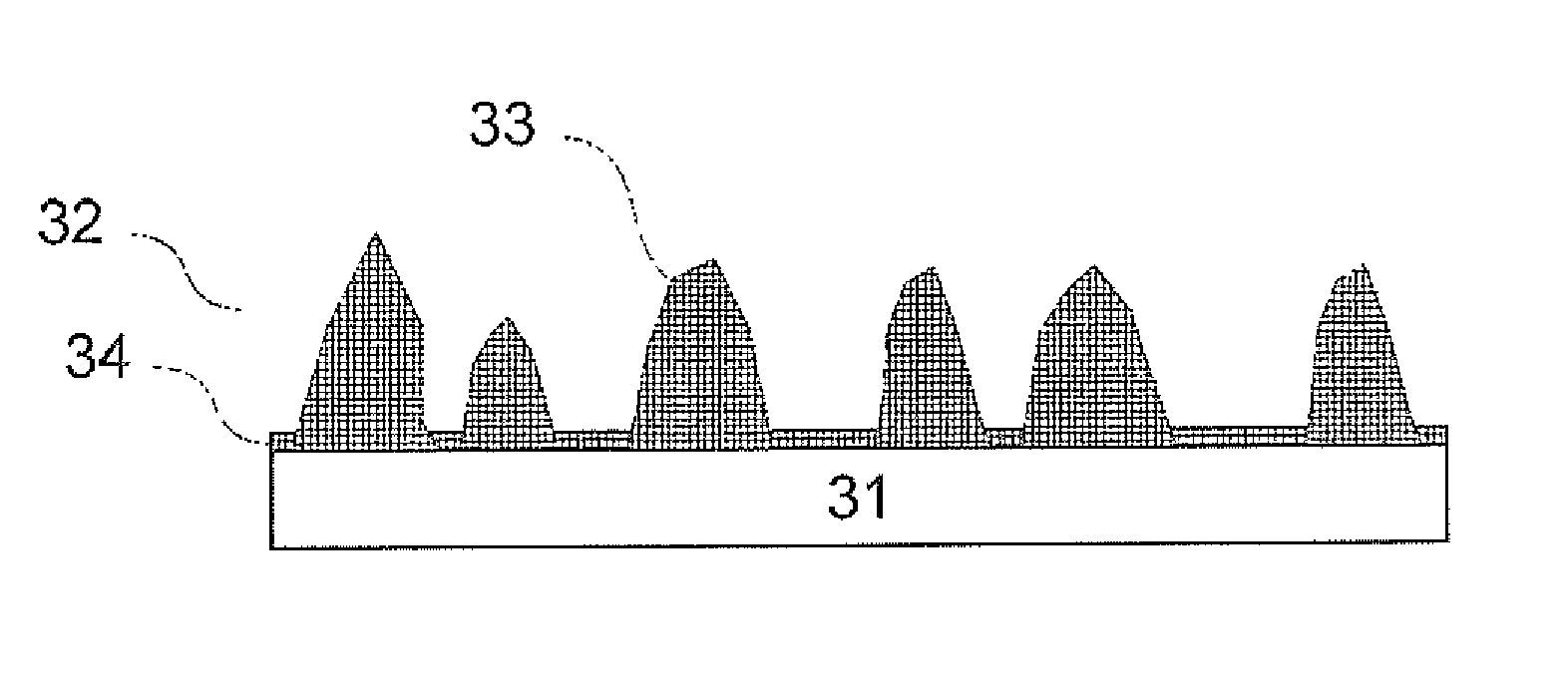

Method for manufacturing light extraction substrate for organic light emitting element, light extraction substrate for organic light emitting element, and organic light emitting element including same

ActiveUS20170358776A1Light extraction efficiency can be improvedReduce thicknessOLED manufacture/treatment processesFinal product manufactureOptoelectronicsNanometre

The present invention relates to a method for manufacturing a light extraction substrate for an organic light emitting element, a light extraction substrate for an organic light emitting element, and an organic light emitting element that includes the same and, more specifically, to a method for manufacturing a light extraction substrate for an organic light emitting element, a light extraction substrate for an organic light emitting element, and an organic light emitting element that includes the same, which can enhance the light extraction efficiency of an organic light emitting element and, in particular, can reduce the process cost. To this end, the present invention provides the method for manufacturing a light extraction substrate for an organic light emitting element, the light extraction substrate for an organic light emitting element, and the organic light emitting element that includes the same, the method comprising: a mixture preparation step for preparing a mixture by mixing a plurality of thermoplastic polymers in a metal oxide nano-dispersion solution; a mixture coating step for coating the mixture on a base substrate; and a mixture firing step for firing the coated mixture, wherein during the mixture firing step, the plurality of thermoplastic polymers are gasified, and when the mixture firing step is completed, the metal oxide nano-dispersion solution is made as a matrix layer, and closed pores are formed in the positions within the matrix layer that were occupied by the thermoplastic polymers before the gasification.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

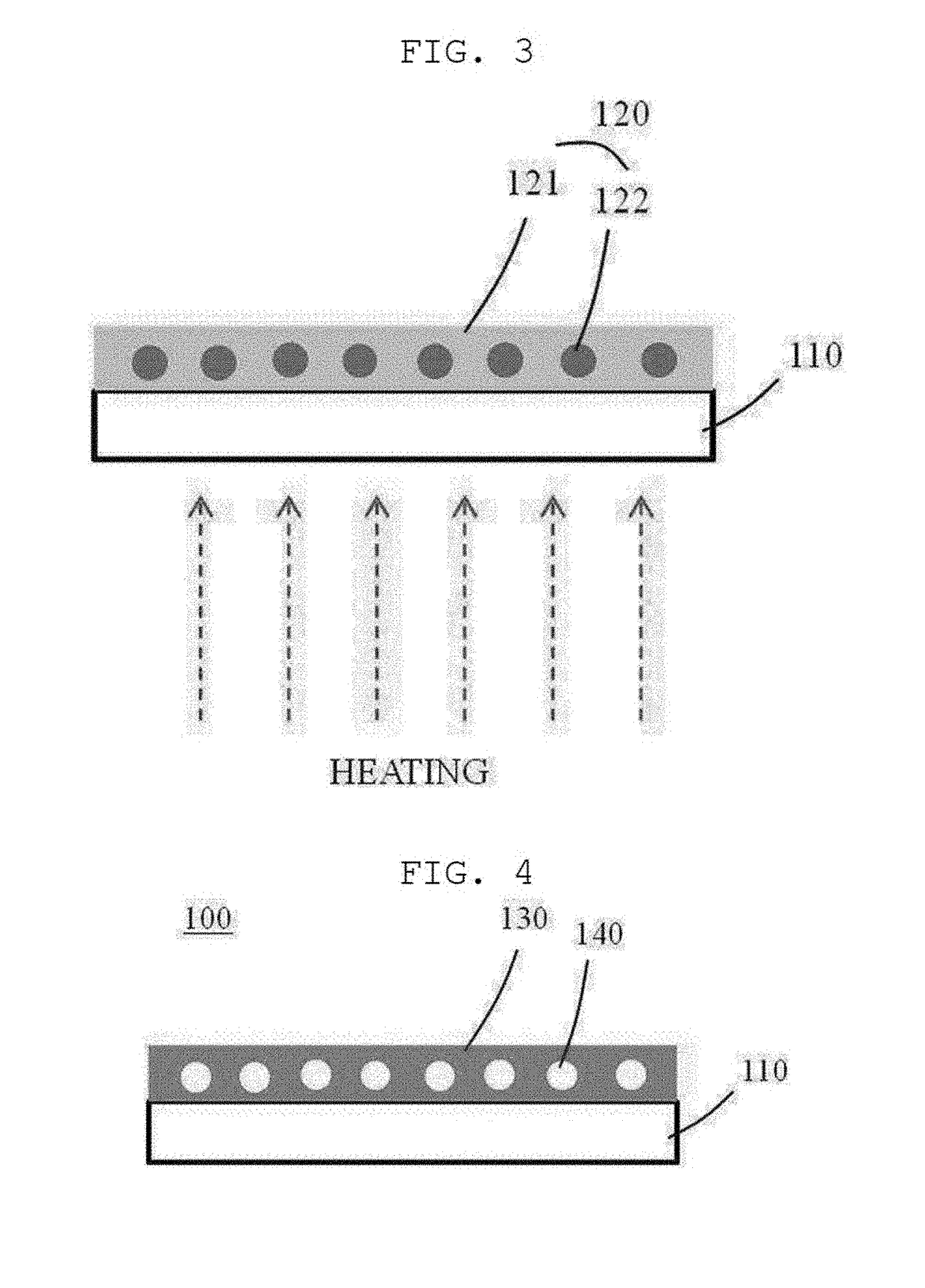

Manufacturing method of OLED of double-face submicron order structure

InactiveCN103515545AImprove transmittanceImprove light extraction efficiencyOLED manufacture/treatment processesSolid-state devicesAngle dependenceEvaporation

The invention discloses a manufacturing method of an OLED of a double-face submicron order structure, and belongs to the technical field of OLED manufacturing. The method includes the following steps: (1) the two faces of a quartz substrate are simultaneously coated by single-layer silicon dioxide nanoballs in a spinning mode; (2) the well-distributed single-layer silicon dioxide nanoballs serve as masks, submicron order graph structures are etched on the two faces of the quartz substrate; (3) the quartz substrate with the submicron order graph structures is evenly coated by an ITO conductive film in a spinning mode to obtain an OLED anode; (4) an electron hole conveying layer, an evaporation light-emitting layer and an electronic conveying layer are sequentially evaporated on the OLED anode, finally a cathode is evaporated and the OLED of the double-face submicron order structure is obtained. The quartz substrate manufactured in the method has an OLED component of a double-face structure, a light-emitting model of the quartz substrate is close to a Lambert reflector, spectral line deviation and obvious angle dependence do not exist, the optical extraction efficiency of the component is improved, and meanwhile, performance regression does not occur.

Owner:XI AN JIAOTONG UNIV

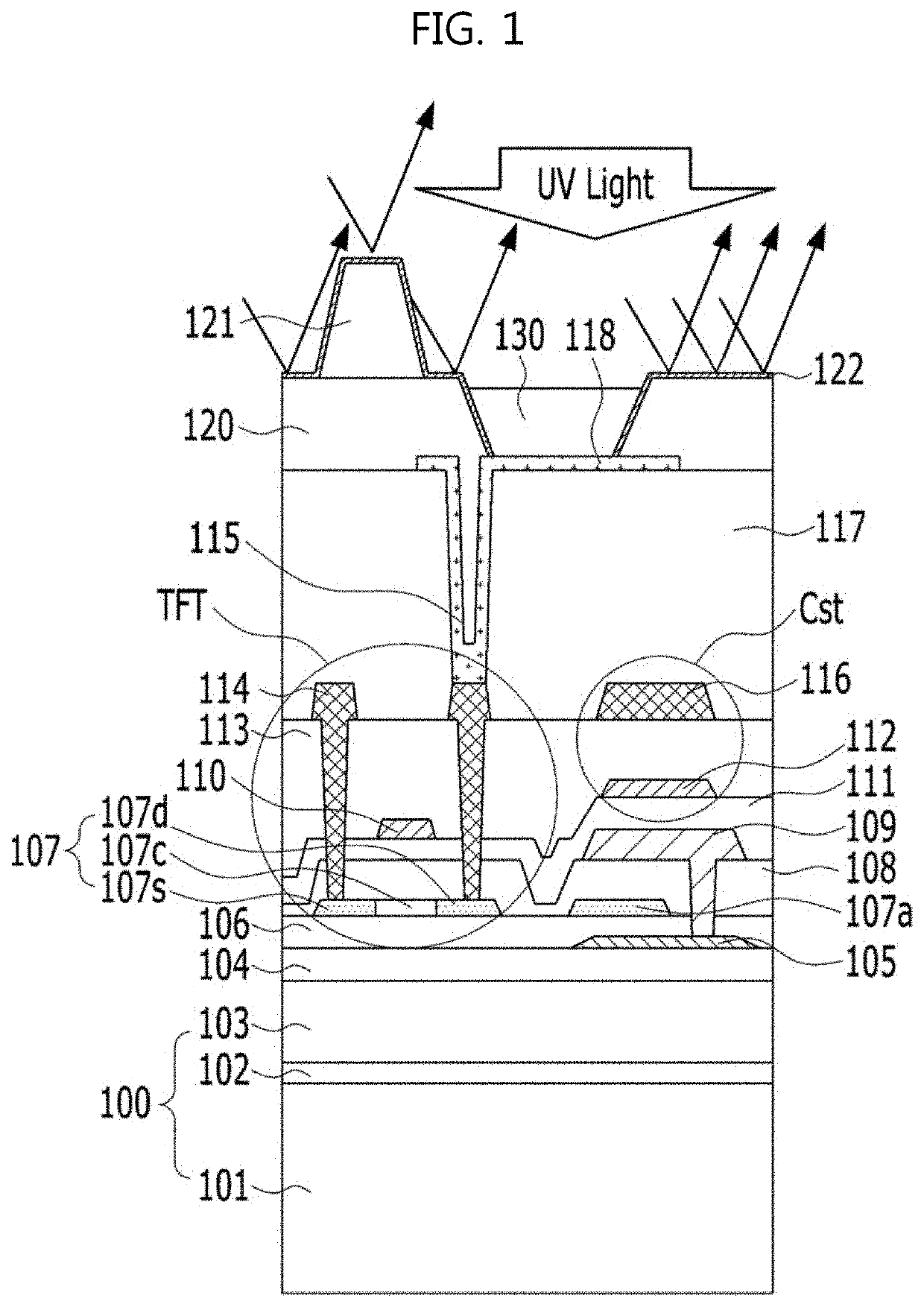

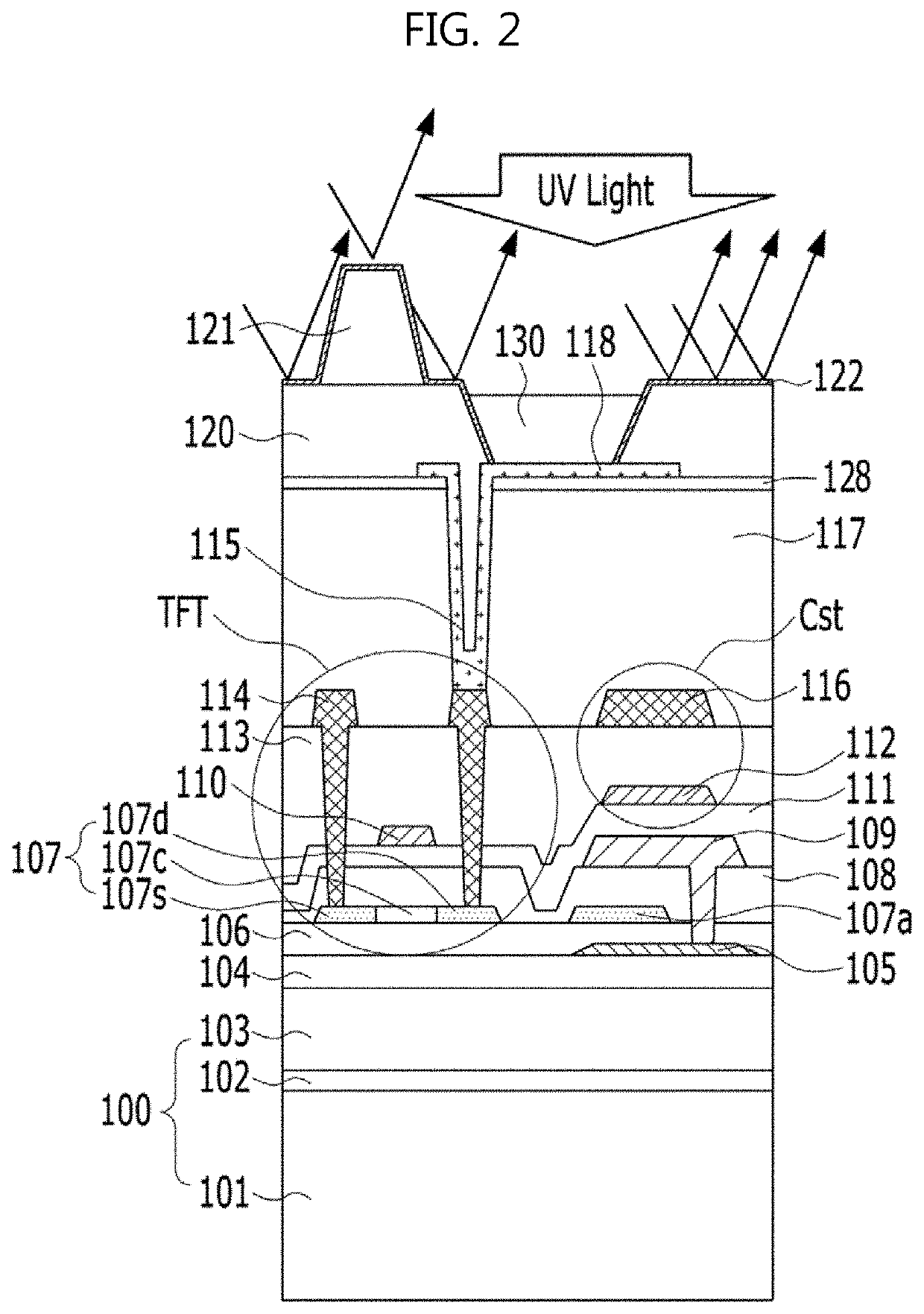

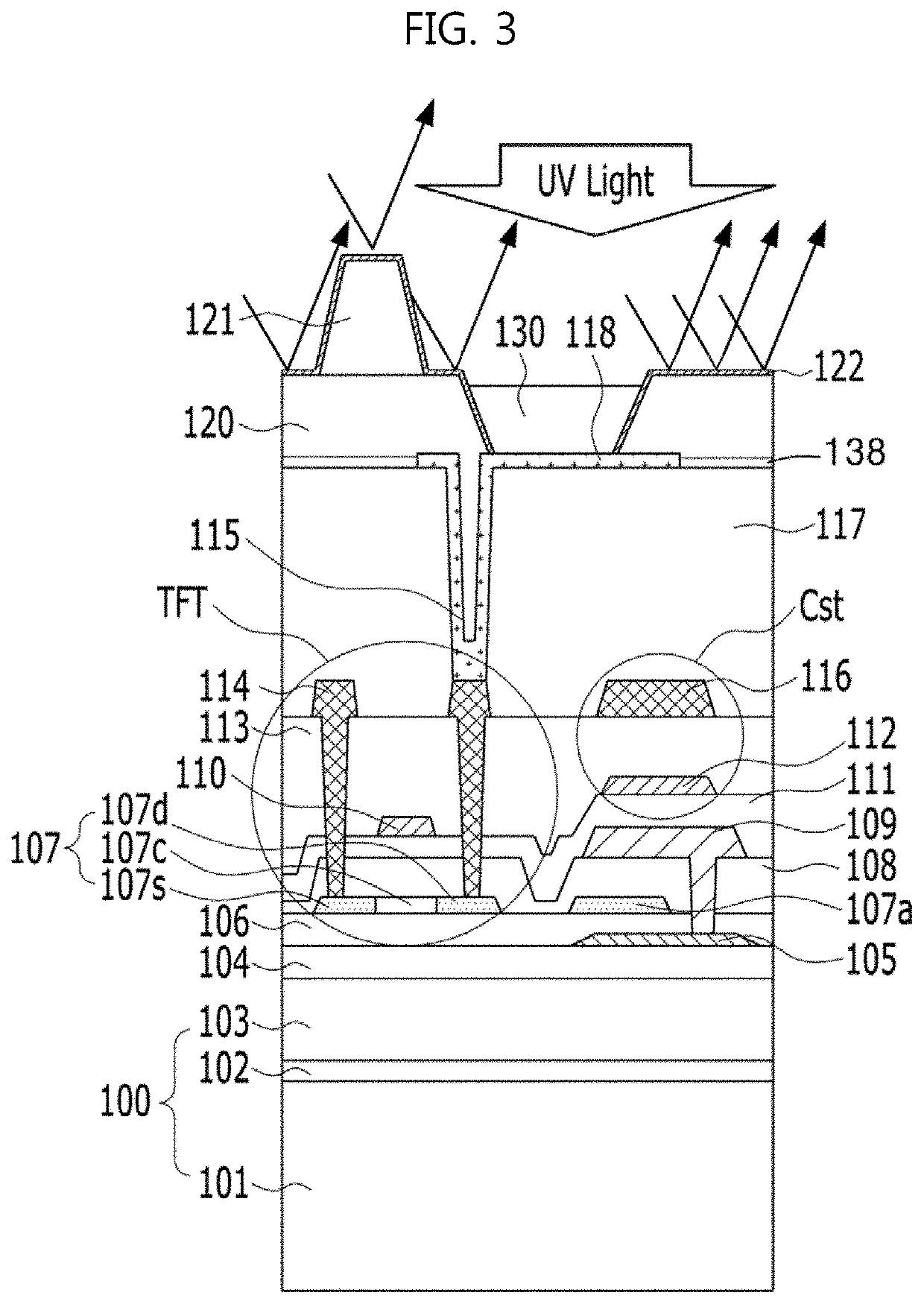

Organic light emitting display device

ActiveUS20200212331A1OLED manufacture/treatment processesSolid-state devicesOrganic filmDisplay device

Disclosed is an organic light emitting display device using an ultraviolet (UV) blocking film which addresses outgassing from an organic film provided in the display device in environments, such as a UV reliability test or outdoor use for a long time, and addresses degradation of an organic stack in an organic light emitting diode caused by the outgassing.

Owner:LG DISPLAY CO LTD

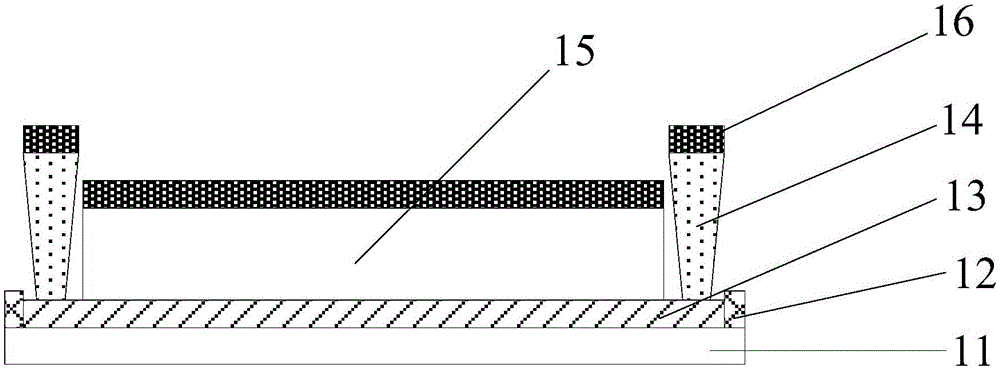

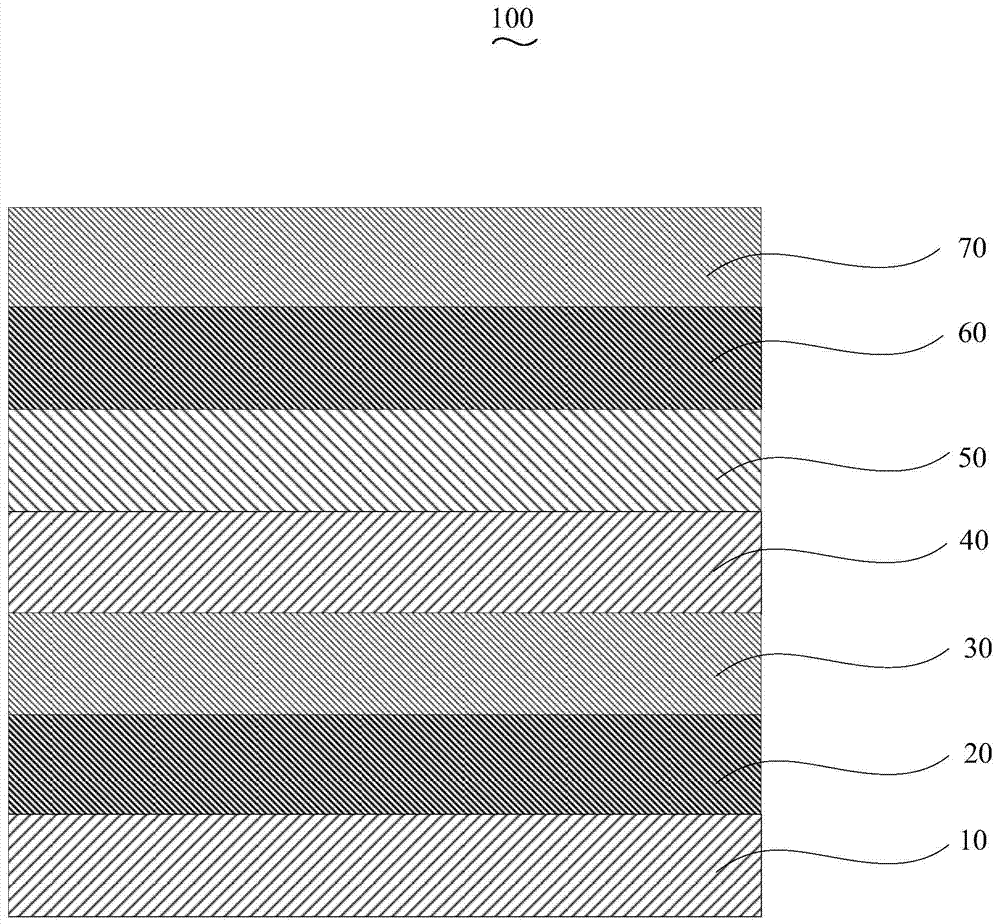

Organic light-emitting device and manufacturing method thereof

ActiveCN106784352AImplement determinant scanOLED manufacture/treatment processesSolid-state devicesOrganic light emitting deviceEngineering

The invention discloses an organic light-emitting device and a manufacturing method thereof. The organic light-emitting device comprises a substrate, first isolation columns, transparent electrode layers and organic light-emitting layers, wherein the first isolation columns are formed on the substrate and arranged in the first direction of the substrate; the transparent electrode layers are formed on the substrate between two adjacent first isolation columns and on the first isolation columns; the transparent electrode layers formed on the substrate are mutually separated from the transparent electrode layers formed on the first isolation columns; and the organic light-emitting layers are formed on the corresponding transparent electrode layers on the substrate. Therefore, through utilization of a height difference between each first isolation column and the substrate, the transparent electrode layers in a second direction are naturally separated from each other, and an additional transparent electrode layer etching procedure is not needed.

Owner:GUAN YEOLIGHT TECH CO LTD

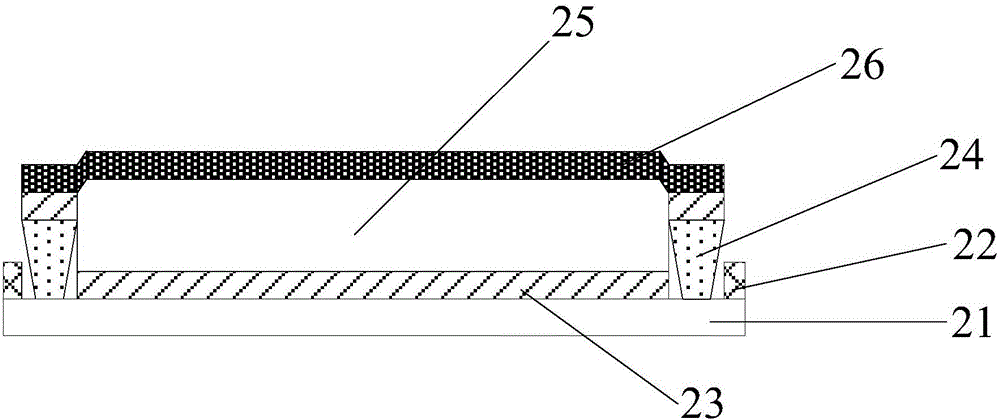

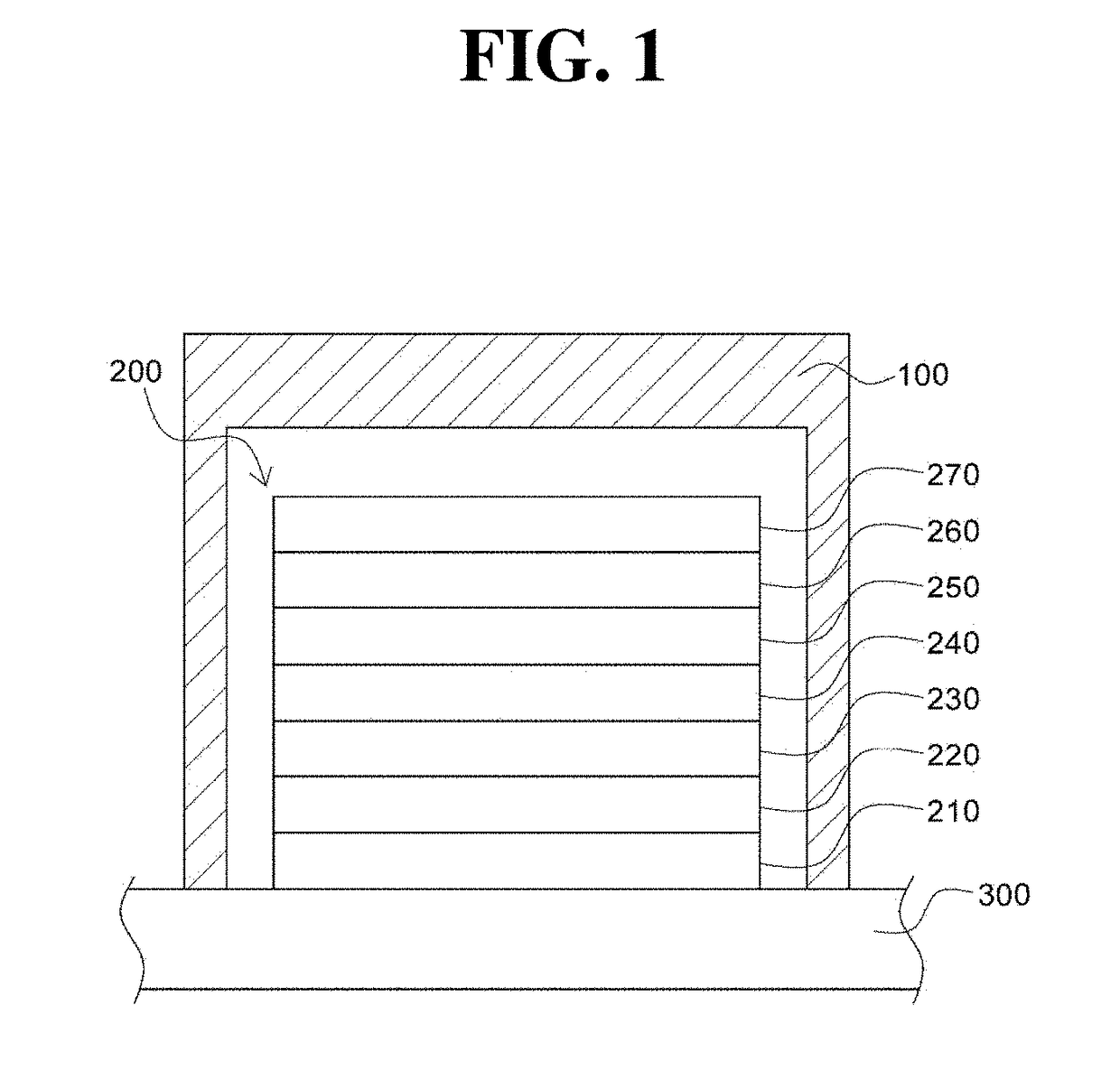

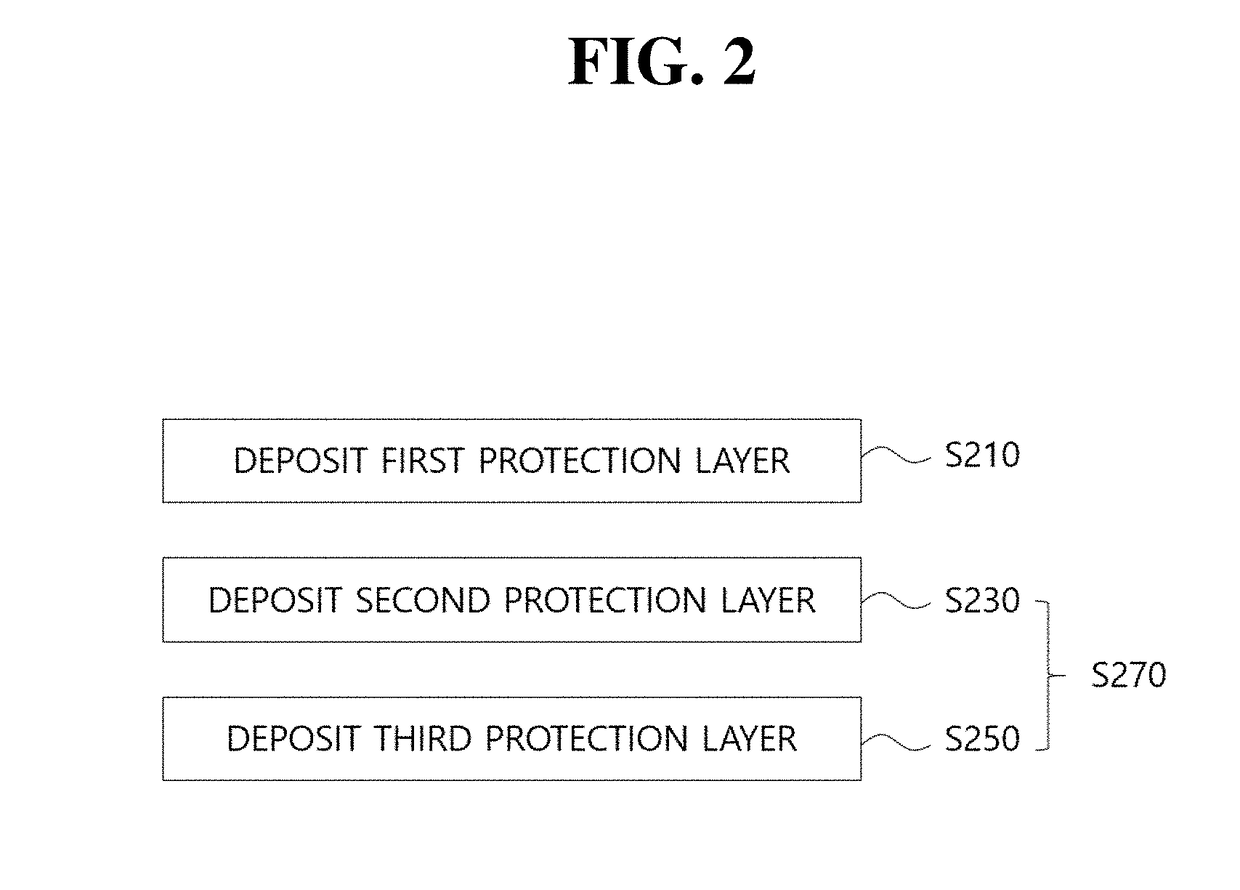

Method For Depositing Protection Film Of Light-Emitting Element

ActiveUS20190078208A1Prevent moisture penetrationPreventing penetration of oxygenOLED manufacture/treatment processesSolid-state devicesTectorial membraneGas phase

The present invention relates to a method for depositing a protection film of a light-emitting element, the method comprising the steps of: depositing a first protection layer on a light-emitting element of a substrate by means of the atomic layer deposition method; and depositing at least one additional protection layer on the first protection layer by means of the plasma-enhanced chemical vapor deposition method.

Owner:TES CO LTD

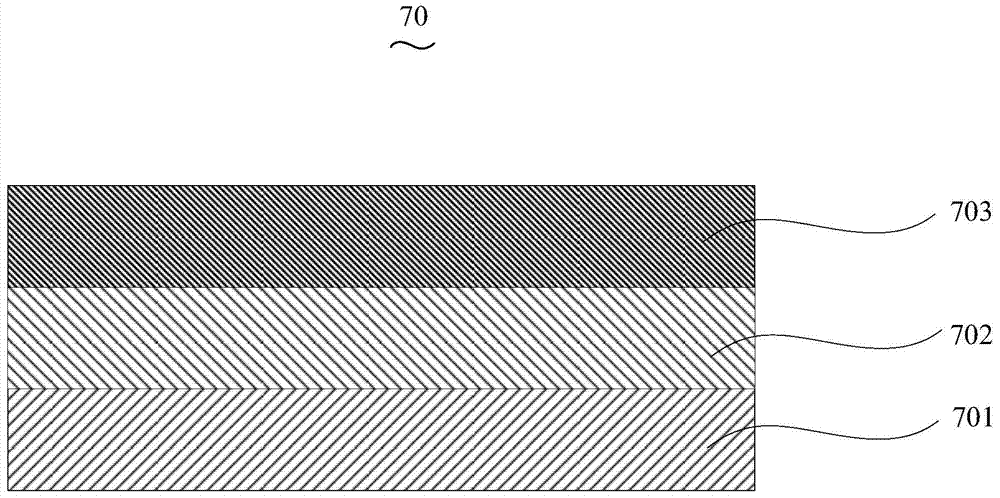

Organic light emitting device with roughening layer and method of producing

ActiveUS9318705B2Improved efficiency of coupling out lightOutcoupling efficiencyOLED manufacture/treatment processesSolid-state devicesOrganic light emitting deviceMaterials science

The invention relates to an organic light emitting device, in a layered structure, comprising a substrate, a bottom electrode, a top electrode, wherein the bottom electrode is closer to the substrate than the top electrode, an electrically active region, the electrically active region comprising one or more organic layers and being provided between and in electrical contact with the bottom electrode and the top electrode, a light emitting region provided in the electrically active region, and a roughening layer, the roughening layer being provided as non-closed layer in the electrically active region and providing an electrode roughness to the top electrode by roughening the top electrode on at least one an inner side facing the electrically active region and an outer side of the top electrode facing away from the electrically active region. Furthermore, a further organic light emitting device, and a method of producing an organic light emitting device are provided.

Owner:NOVALED GMBH

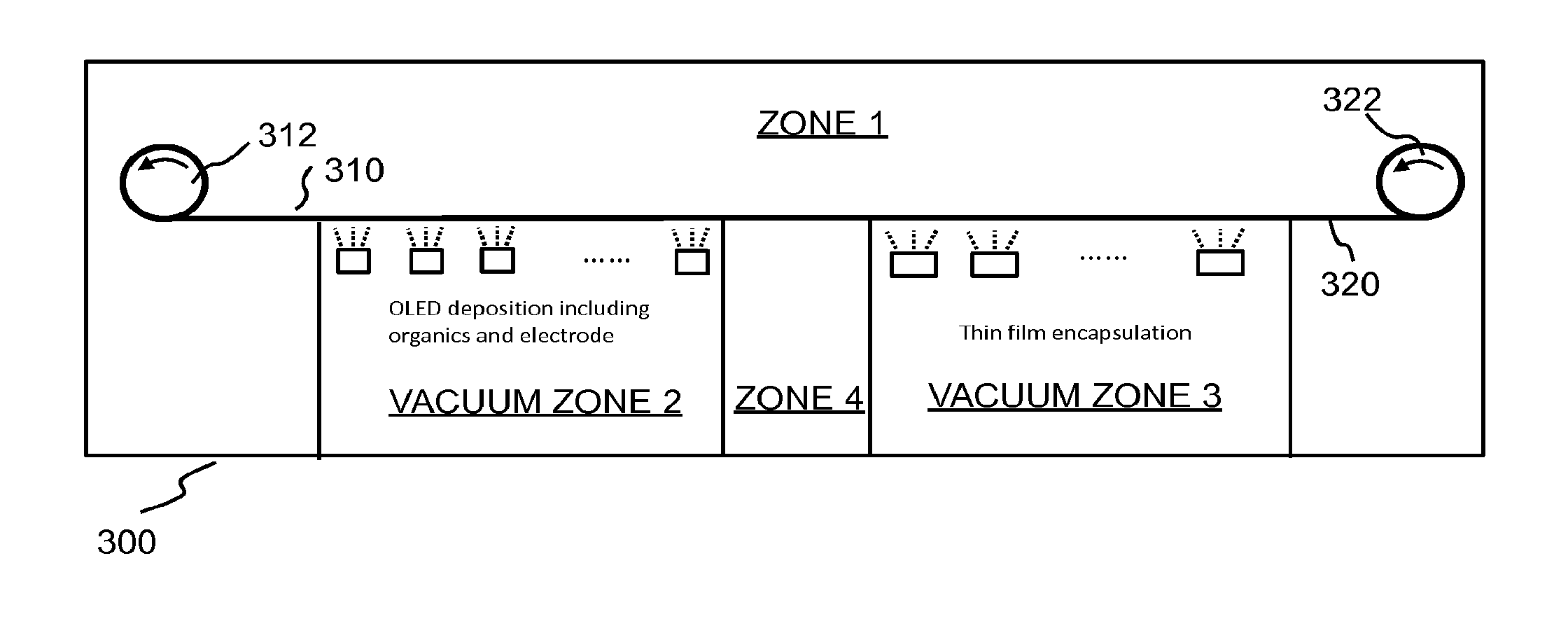

Manufacturing flexible organic electronic devices

InactiveUS20160133838A1OLED manufacture/treatment processesFinal product manufactureElectronic systemsOptoelectronics

A method of forming microelectronic systems on a flexible substrate includes depositing (typically sequentially) on a first side of the flexible substrate at least one organic thin film layer, at least one electrode and at least one thin film encapsulation layer over the at least one organic thin film layer and the at least one electrode, wherein depositing the at least one organic thin film layer, depositing the at least one electrode and depositing the at least one thin film encapsulation layer each occur under vacuum and wherein no physical contact of the at least one organic thin film layer or the at least one electrode with another solid material occurs prior to depositing the at least one thin film encapsulation layer.

Owner:UNIVERSAL DISPLAY

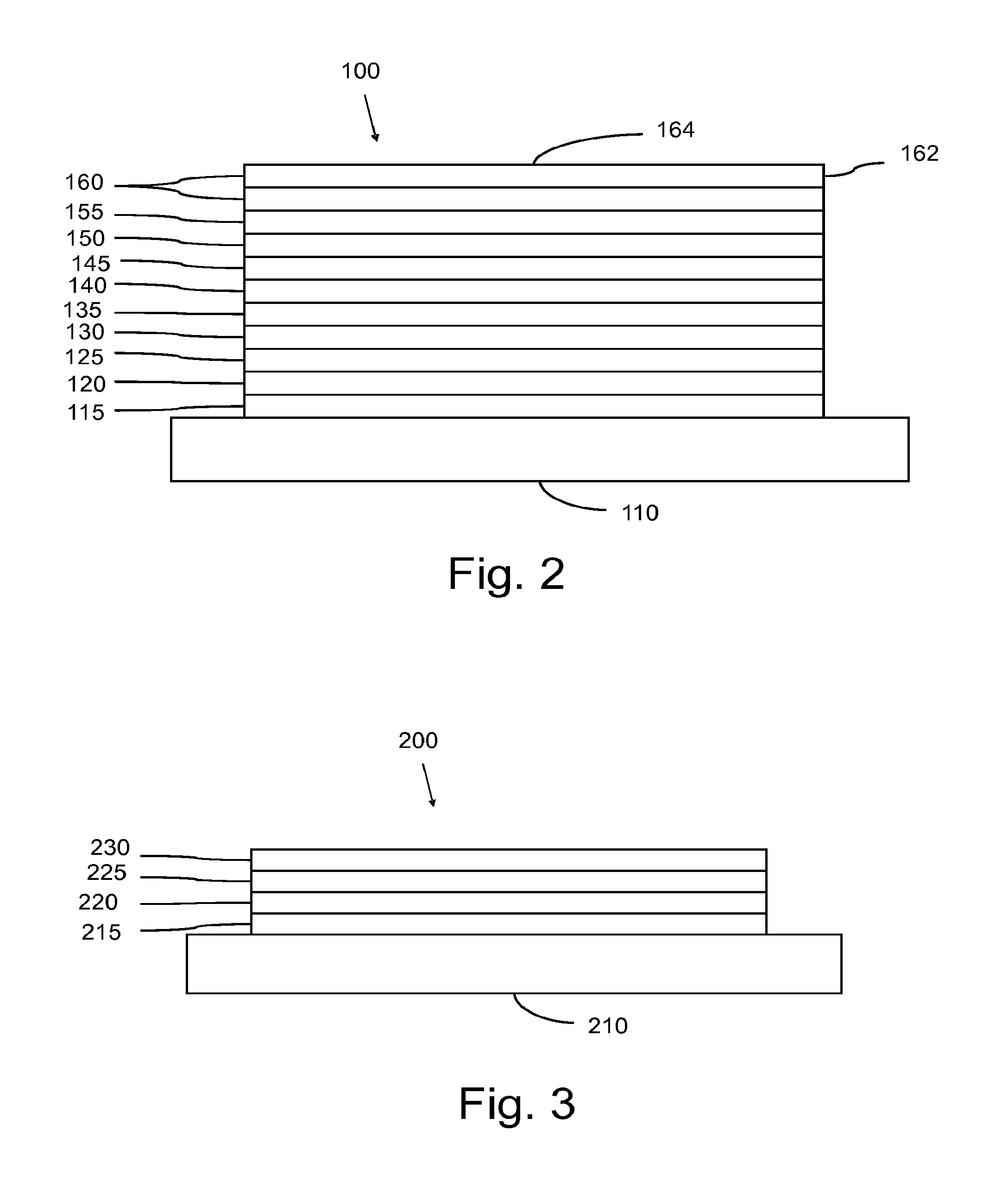

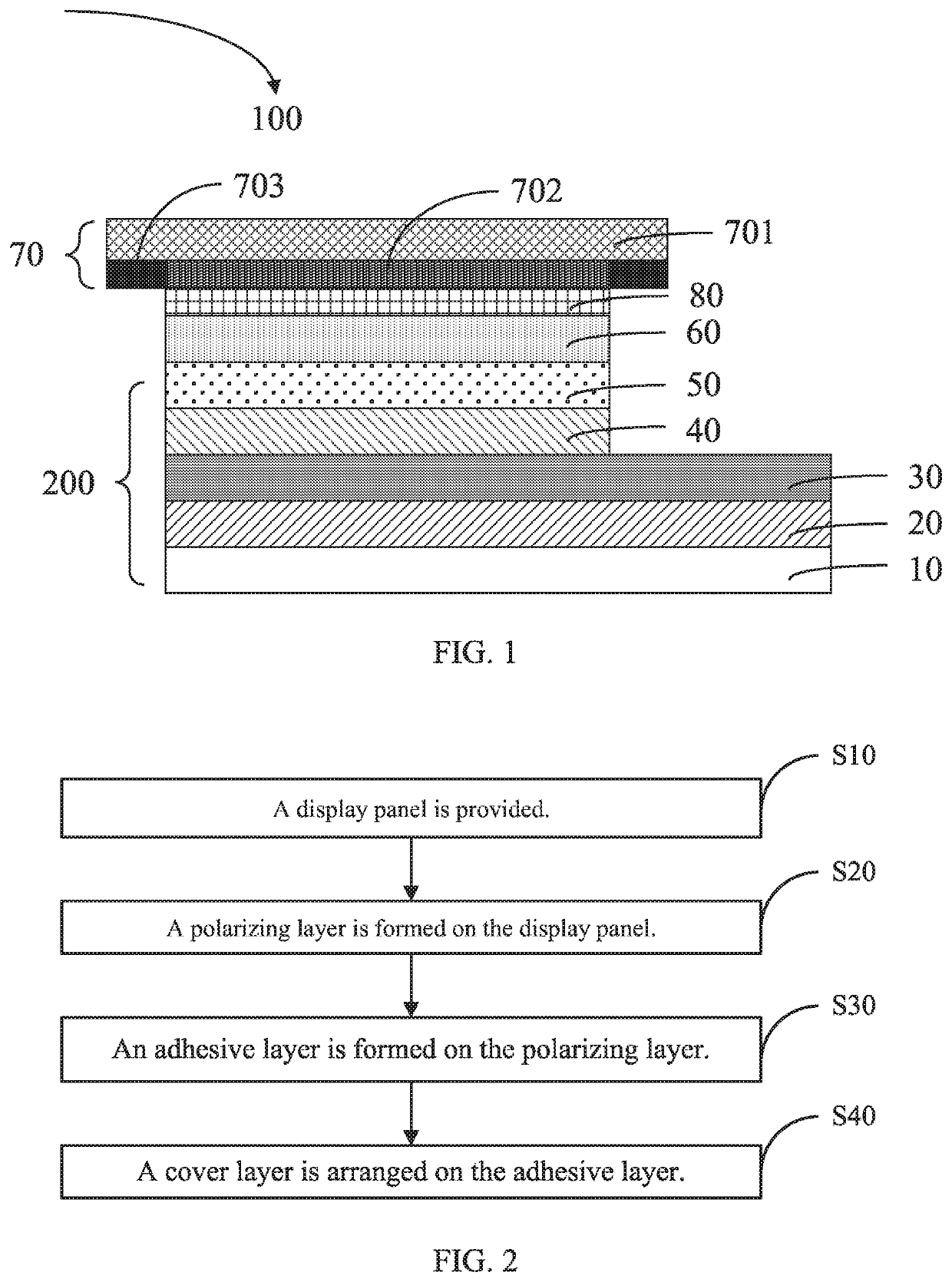

Display module, manufacturing method thereof and electronic device

ActiveUS10879499B2Easy to loseIncrease successOLED manufacture/treatment processesSolid-state devicesMechanical engineeringElectrical and Electronics engineering

The present disclosure proposes a display module, a manufacturing method, and an electronic device. The display module includes a display panel, a polarizing layer on the display panel, a cover layer on the polarizing layer, and an adhesive layer between the polarizing layer and the cover layer. The adhesive layer is a viscosity-releasing adhesive layer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Organic electroluminescent device and method for preparing same

InactiveCN104518109AImprove conductivityIncrease transfer rateOLED manufacture/treatment processesSolid-state devicesOrganic electroluminescenceEnergy level

Provided is an organic electroluminescent device, comprising an anode, a hole injection layer, a hole transport layer, a luminous layer, an electron transfer layer, an electron injection layer, and a cathode stacked in sequence. A cathode layer is formed by a first doping layer, and a second doping layer, and a third doping layer. The first doping layer contains a first metal material and an organic electron transport material doped in the first metal material. The second doping layer contains the first metal material and titanium dioxide doped in the first metal material. The third doping layer contains the first metal material and a second metal material doped in the first metal material. The work function of the first metal material is -2.0 eV to -3.5 eV. HOMO energy level of the organic electron transport material is -6.5 eV to -7.5 eV. Glass-transition temperature is 50 DEG C to 100 DEG C. The work function of the second metal material is -4.0 eV to -5.5 eV. The invention also provides a method for preparing the organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

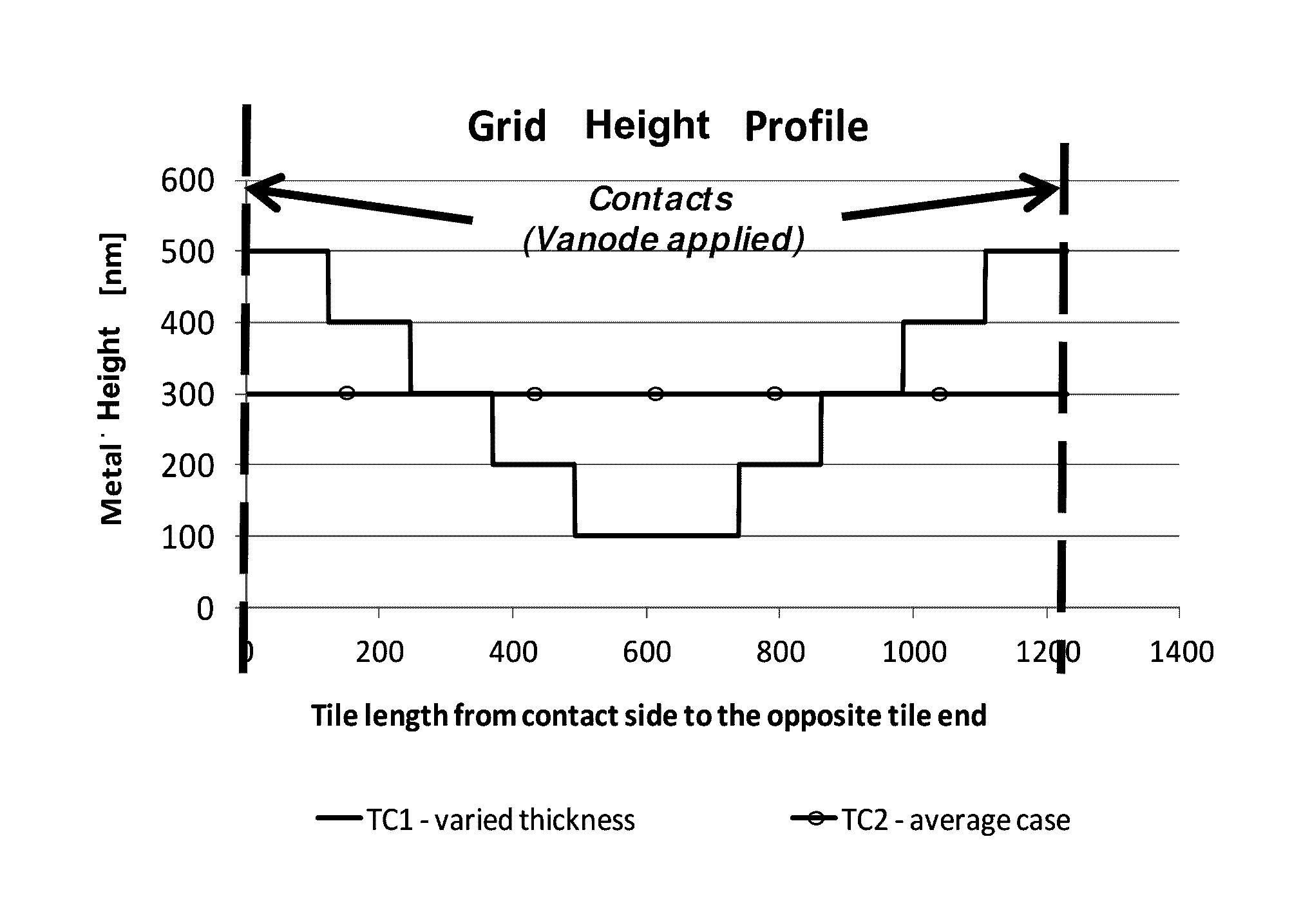

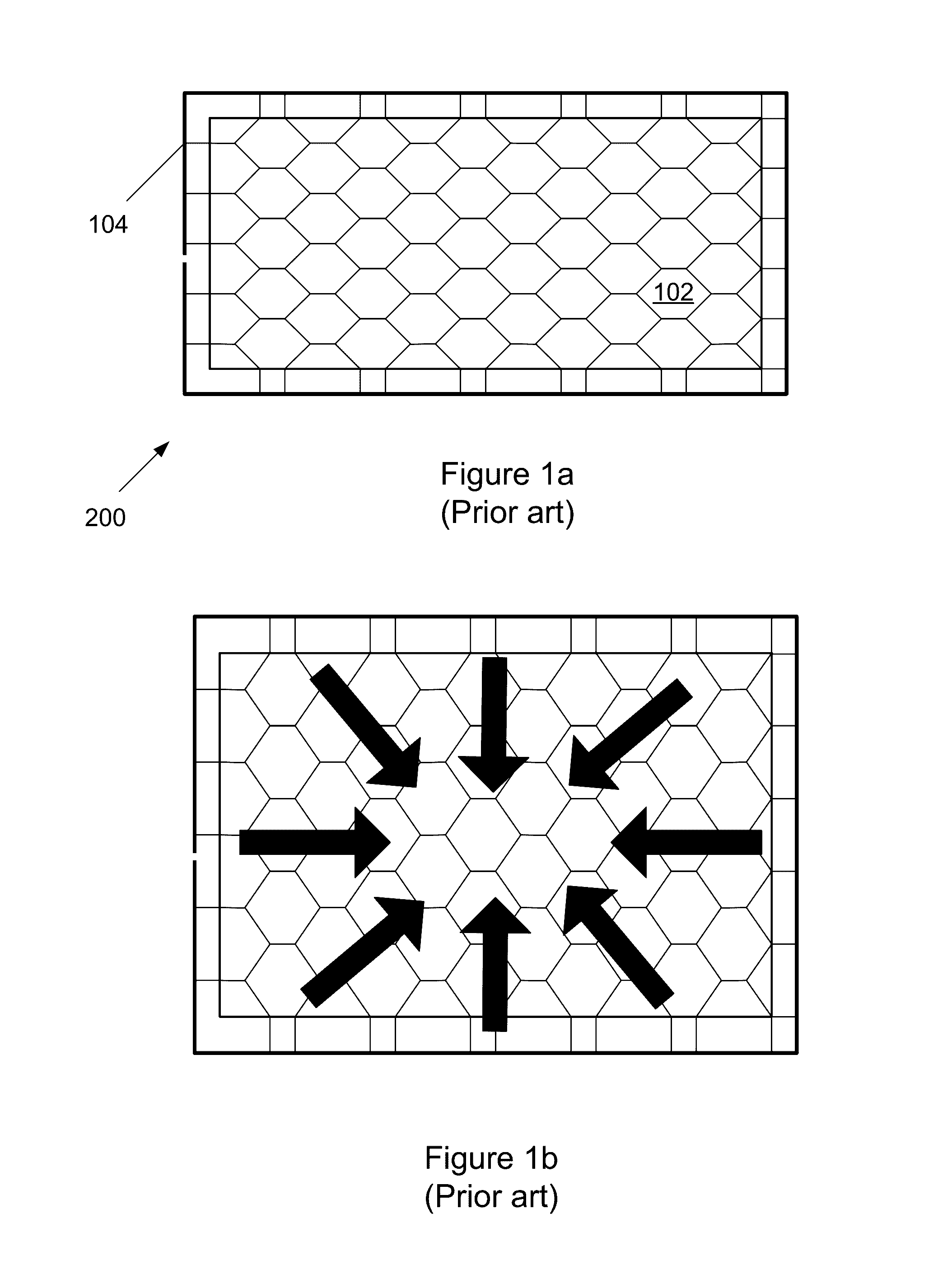

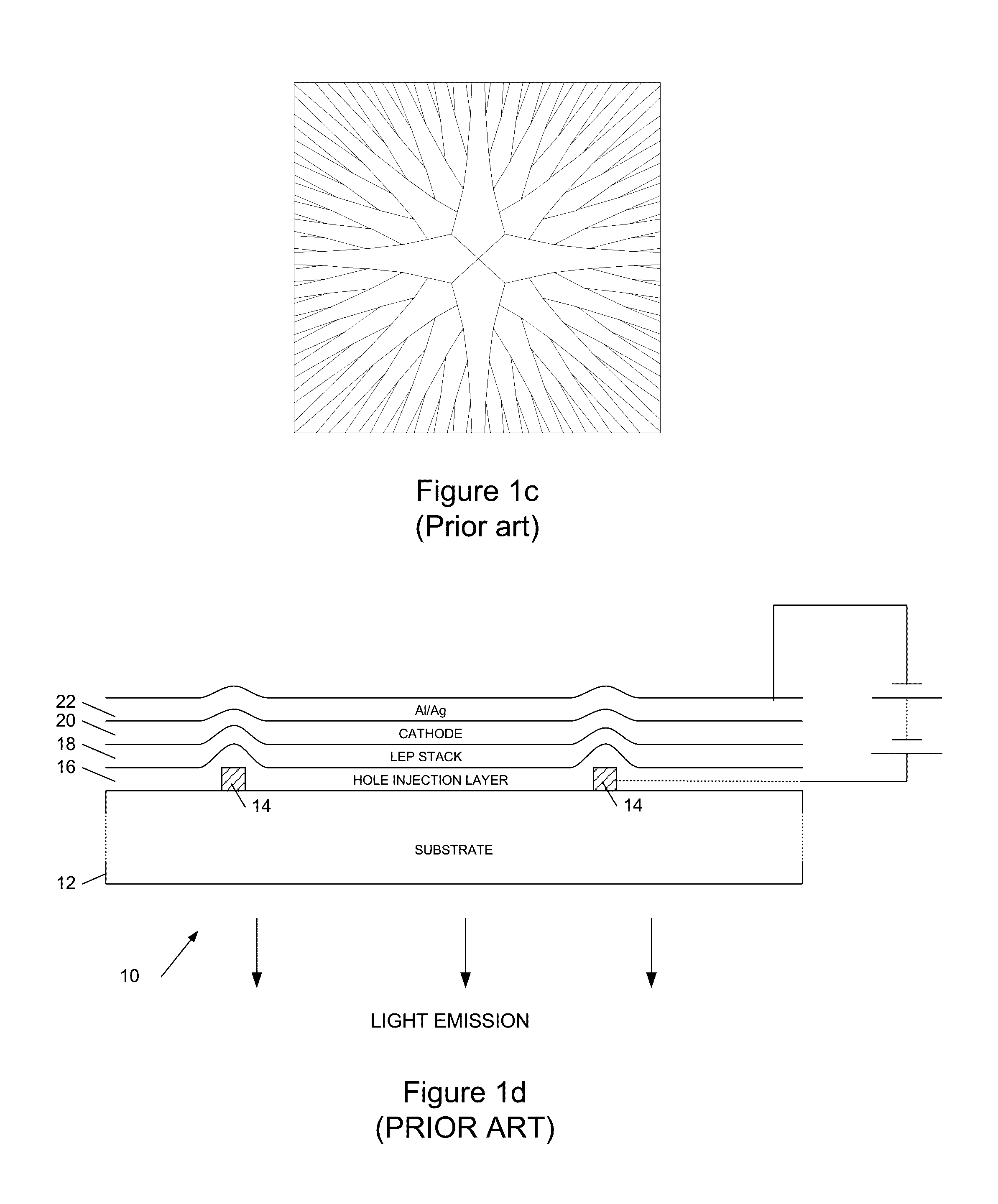

Lighting tiles

InactiveUS9487878B2Increase widthReduce resistanceOLED manufacture/treatment processesSolid-state devicesElectrical resistance and conductanceElectricity

We describe a lighting tile having a substrate bearing an electrode structure, the electrode structure comprising: a plurality of electrically conductive tracks disposed over said substrate; and an electrical connection region connecting to said plurality of tracks; wherein the height of said tracks tapers away from said connection region to compensate for a reduction in luminance from said lighting tile array from the electrical connection region which arises from a non-uniform voltage drop which appears along the tracks in use. Advantageously the tracks are fabricated by electroplating: then, as the rate of deposition is determined by the voltage drop along a track during plating, the height of the deposited tracks, and therefore their resistance, will match the profile required in operation to compensate for the reduction in luminance which would otherwise occur.

Owner:CAMBRIDGE DISPLAY TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com