Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111results about "Leasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

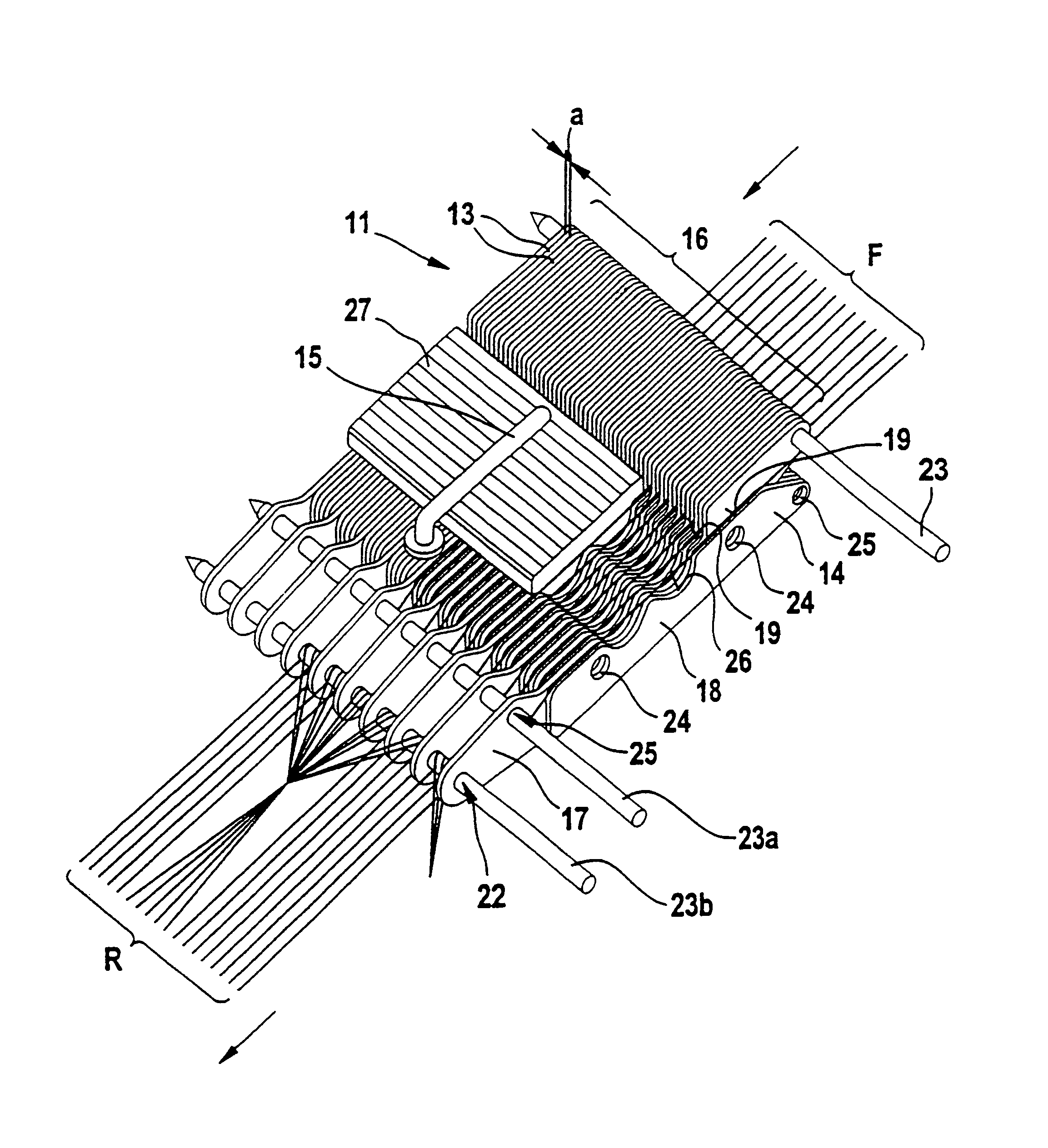

System and method for textile positioning

InactiveUS20110275266A1High fiber volumeEasy to createLayered productsLoomsEngineeringMechanical engineering

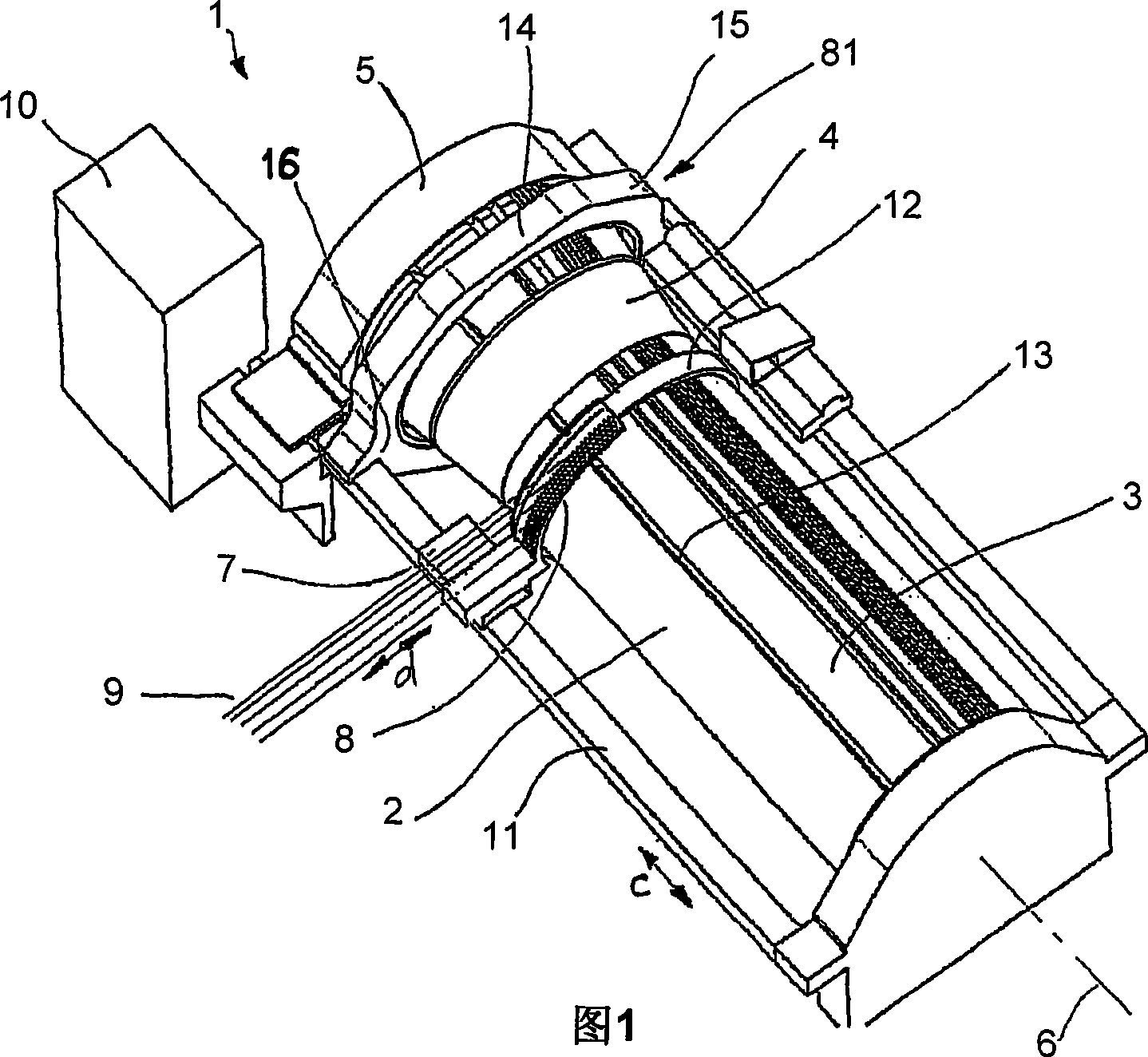

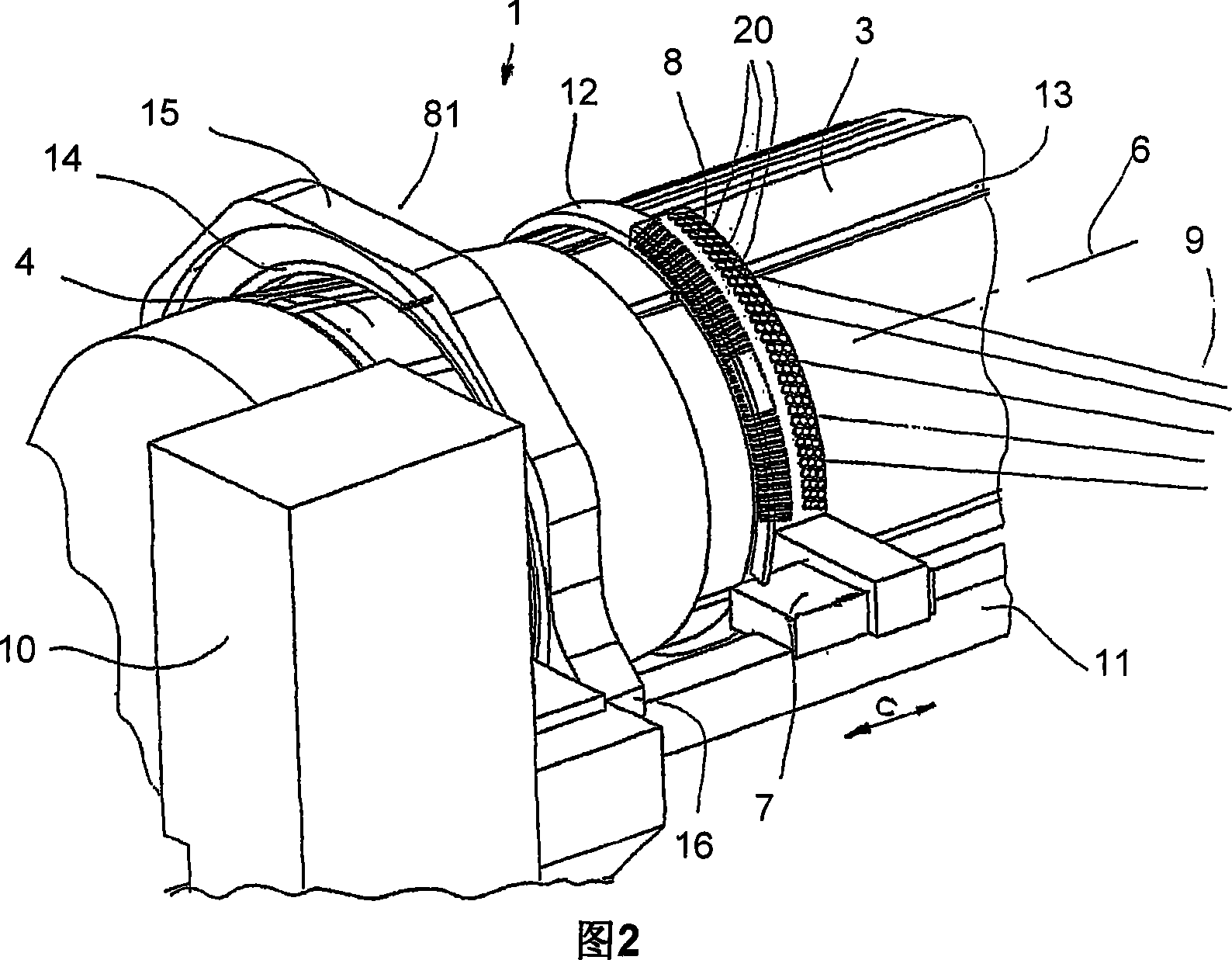

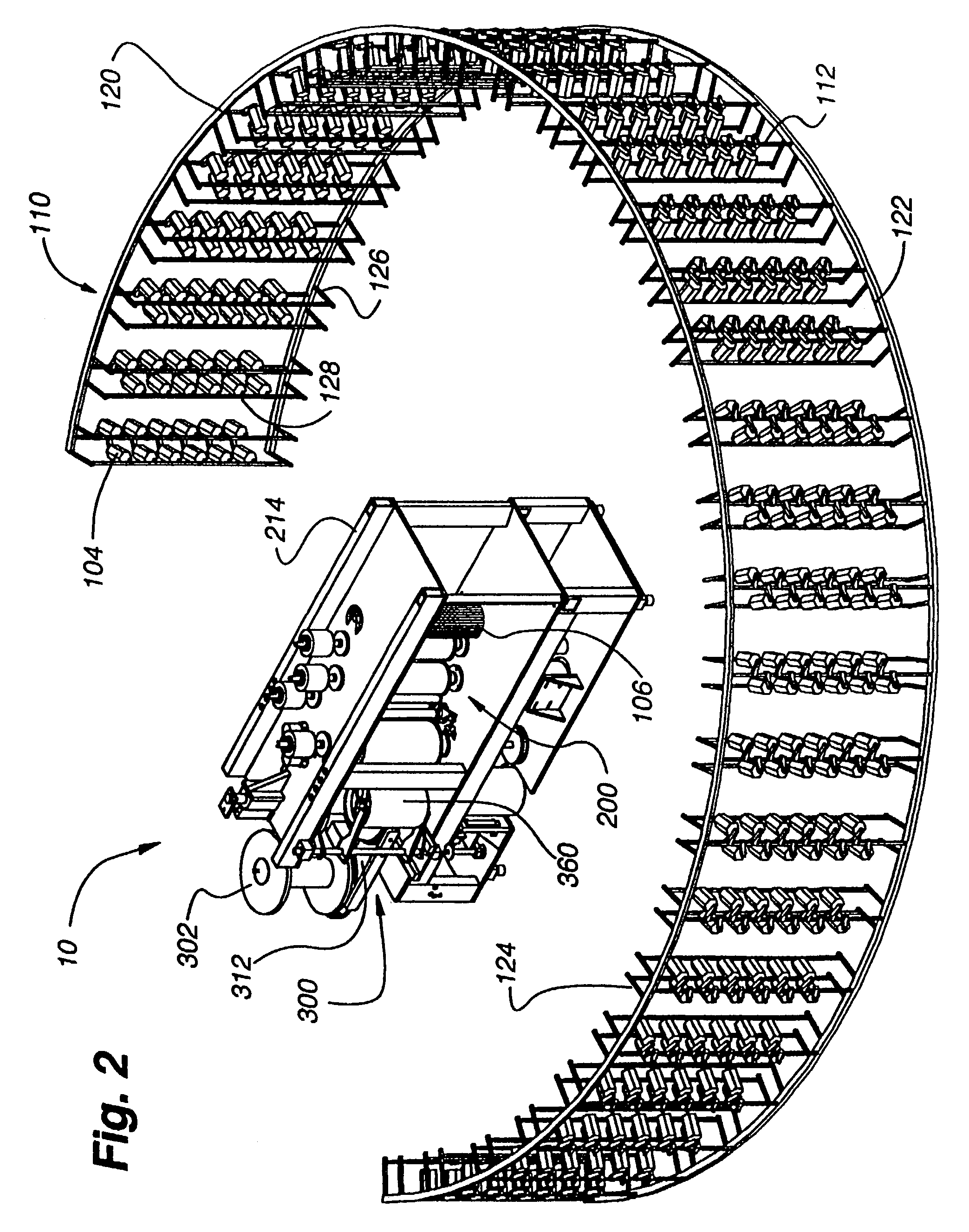

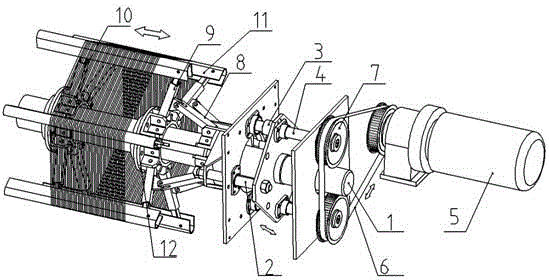

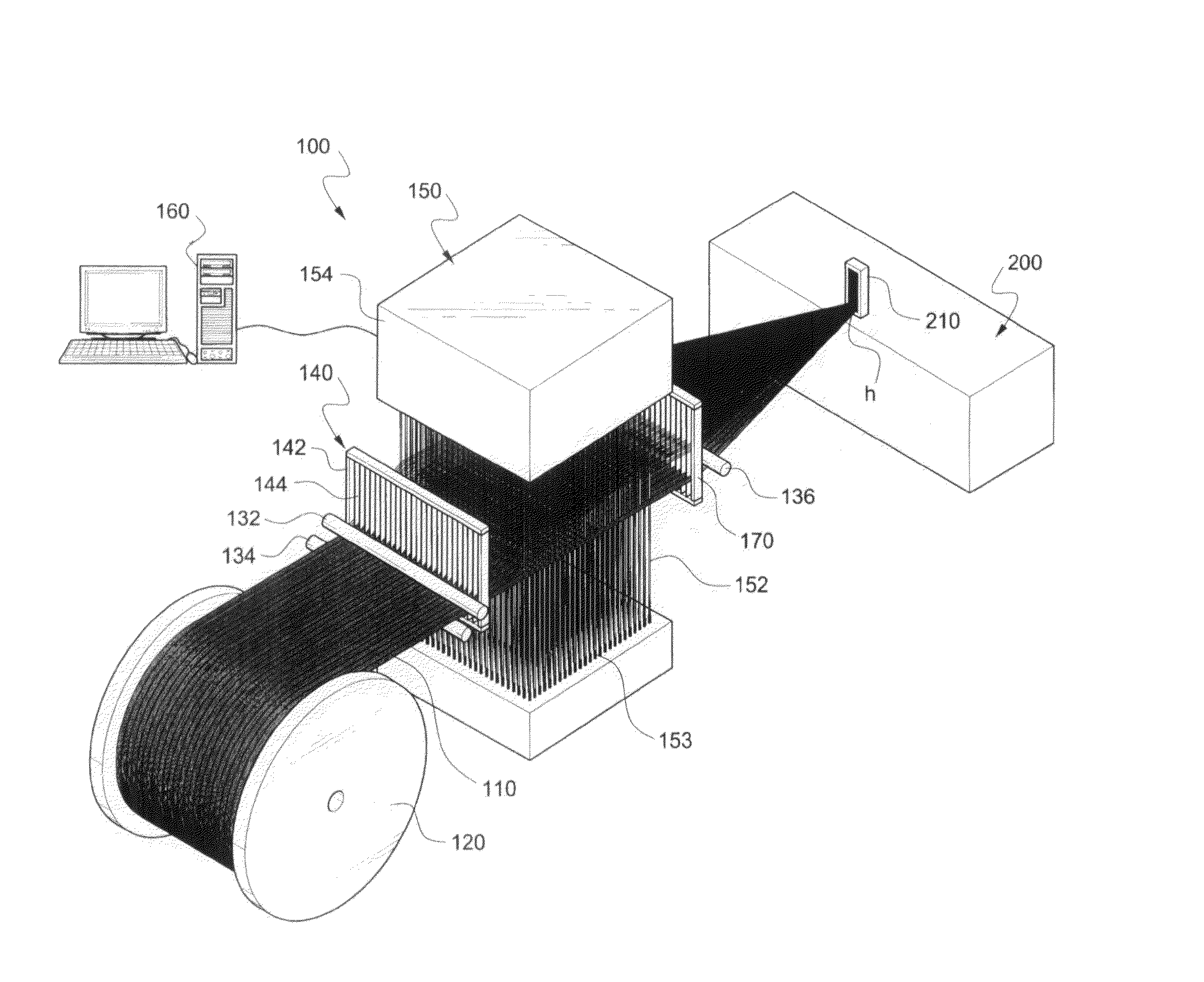

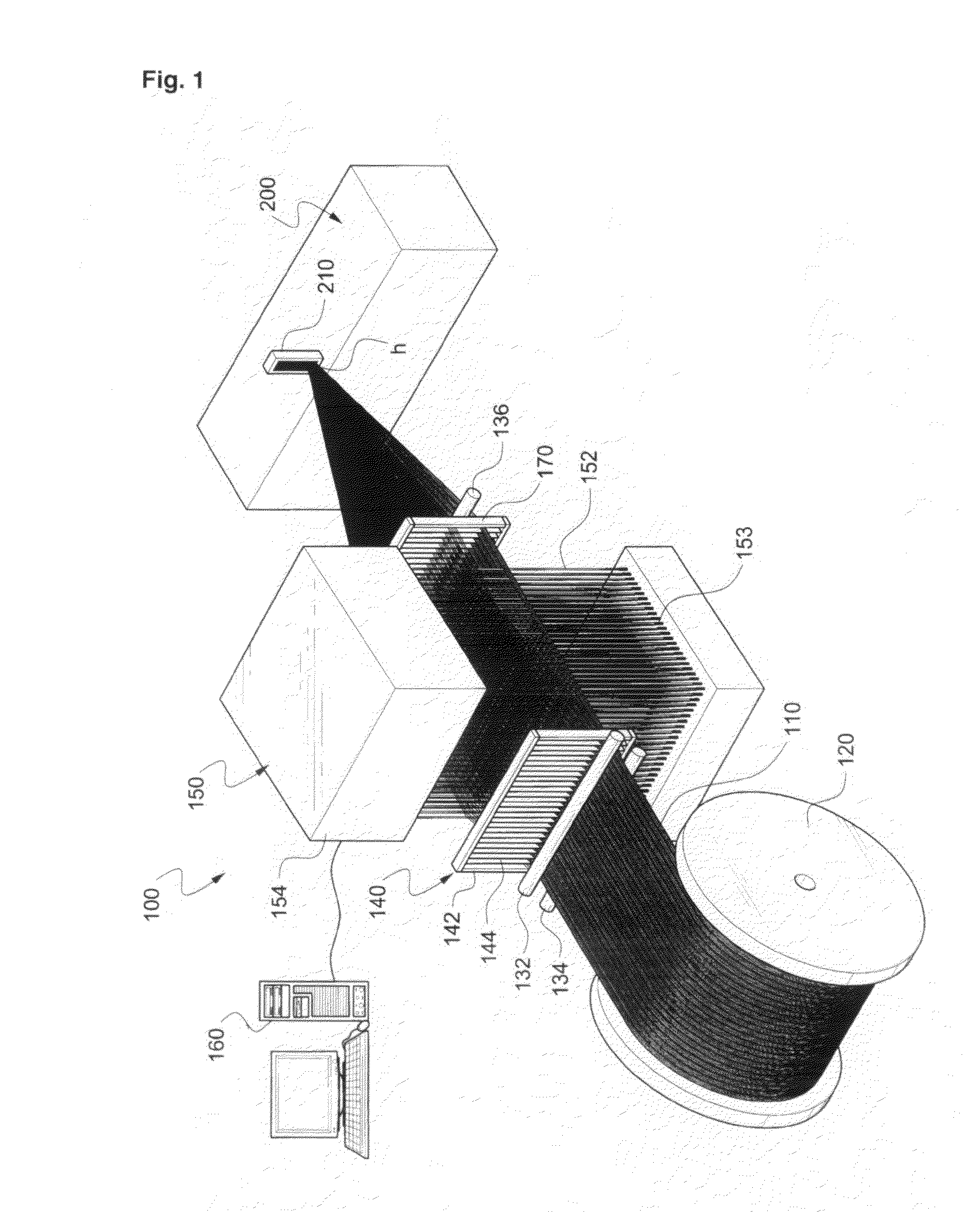

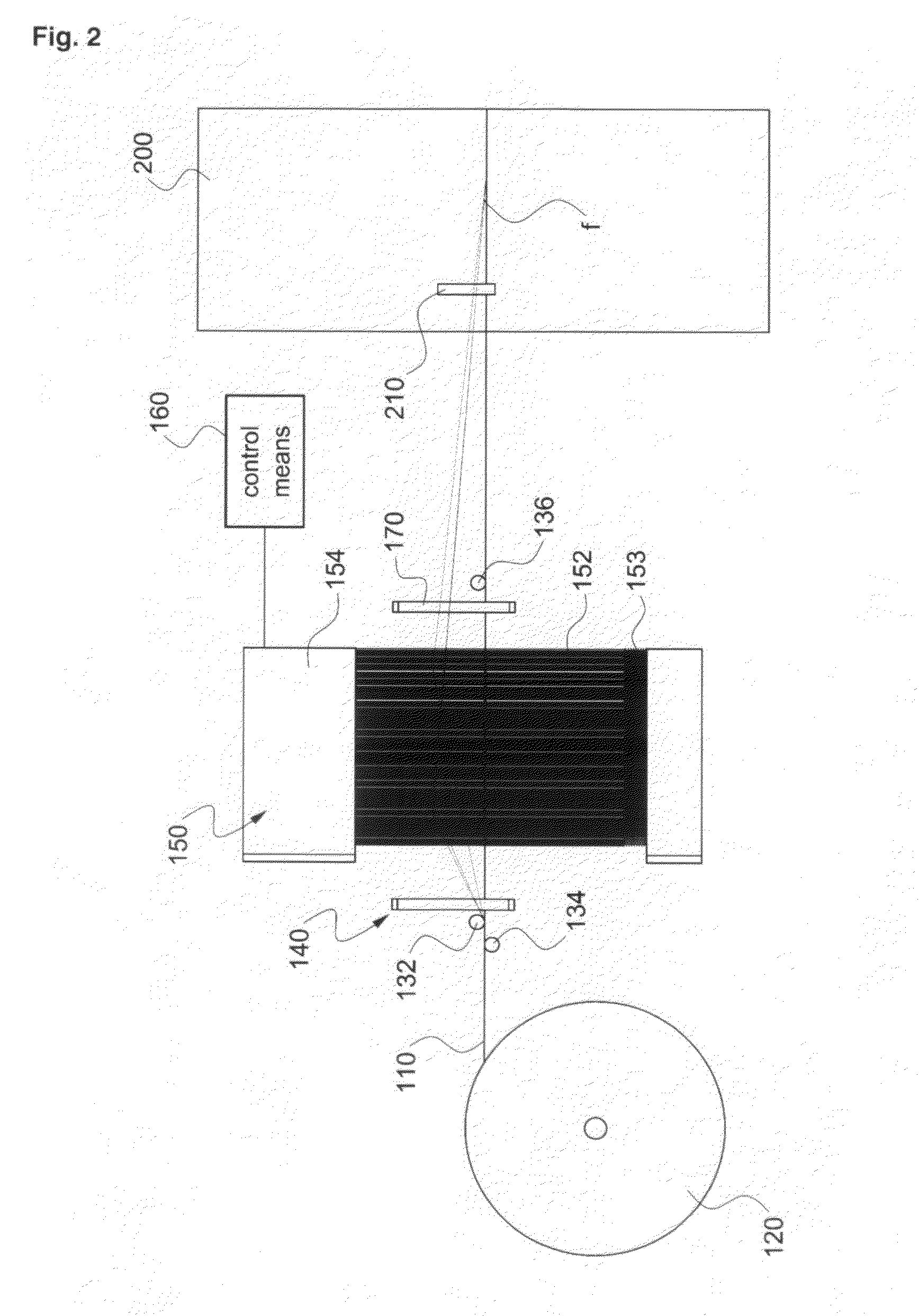

A circular needle loom comprises a stationary bed plate for receiving a spiral textile. Engagement members may be disposed next to the stationary bed plate, such that the engagement members interface with a positional structure of the spiral textile that is used to position and rotate the spiral textile around the stationary bed plate. A conical roller deploys the spiral textile on the stationary bed plate. The engagement members rotate the spiral textile around the stationary bed plate until a predetermined number of layers are deposited on the stationary bed plate.A spiral textile comprises a weft tow that extends from an inside diameter to an outside diameter, and a positional structure, such as a sacrificial edge and / or loop, is located next to and / or is attached to the weft tow. The positional structure facilitates positioning the spiral textile in a desired manner with respect to the circular needle loom in order to create a needled preform.

Owner:THE BF GOODRICH CO

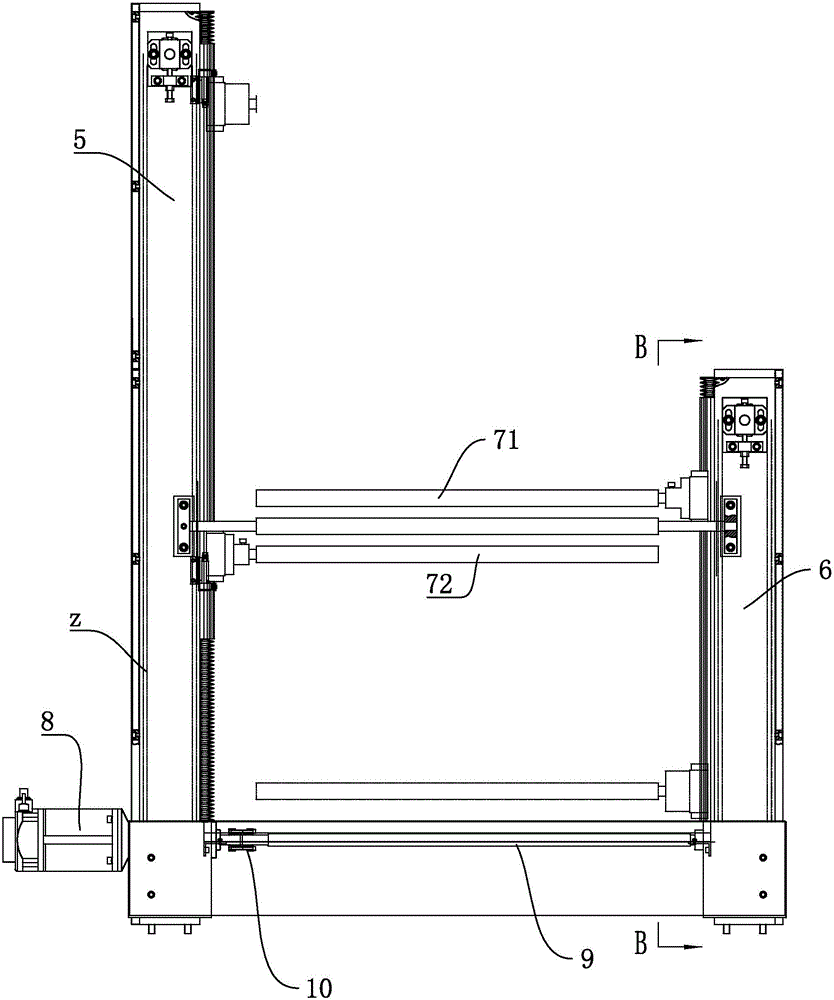

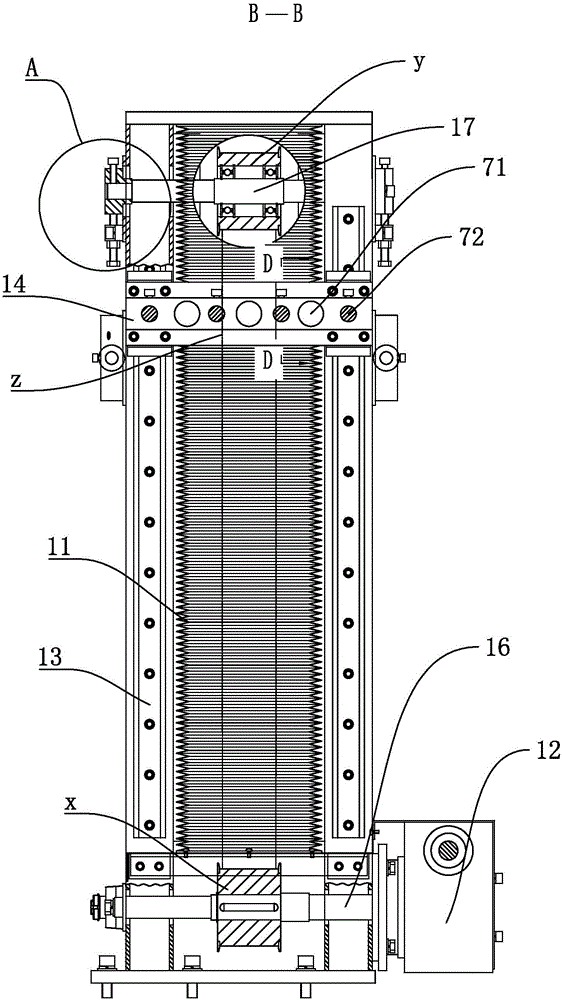

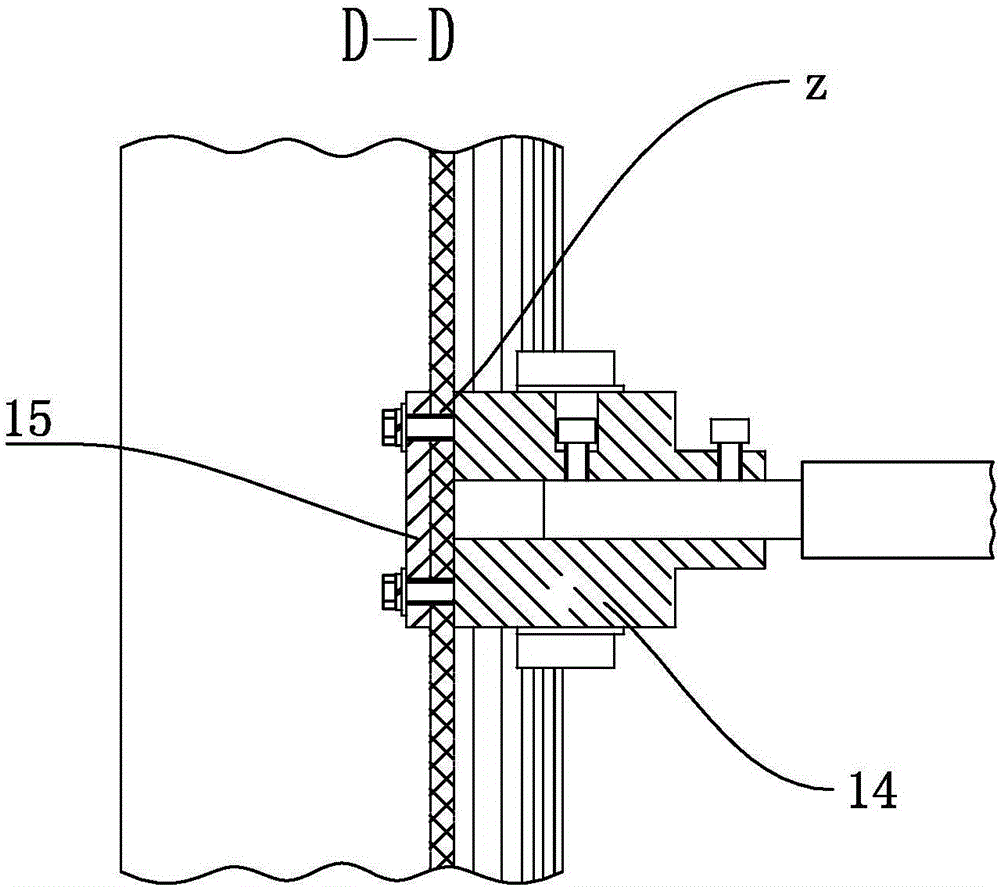

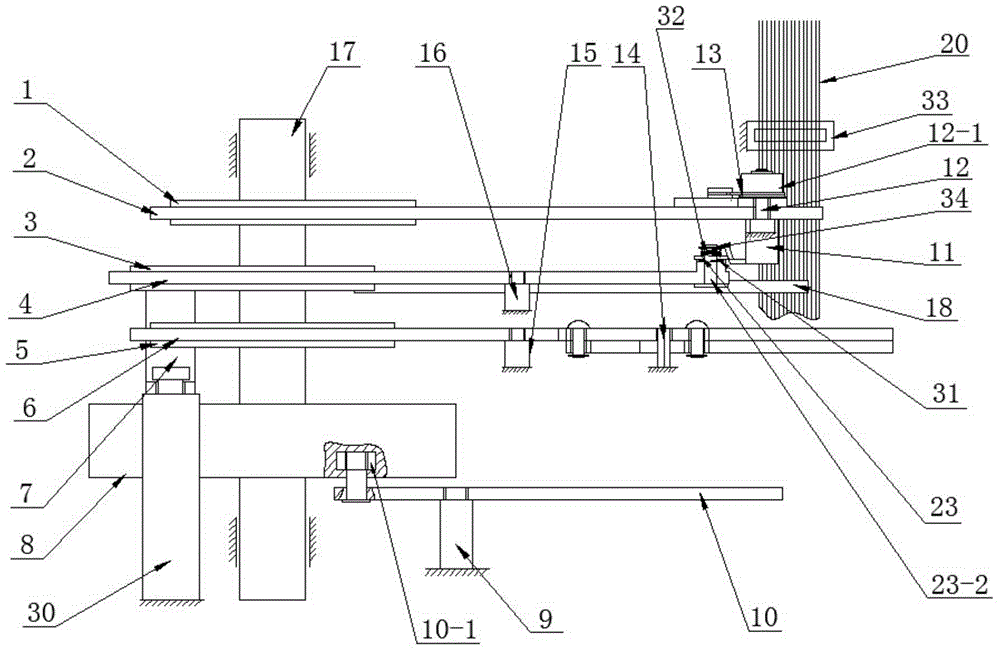

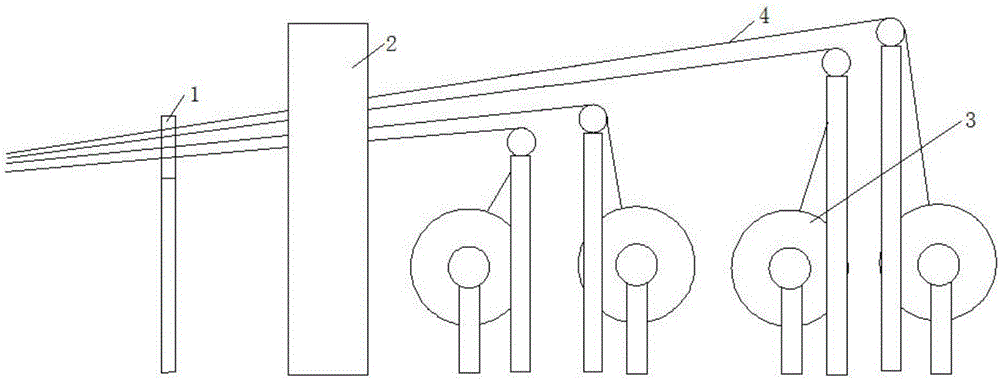

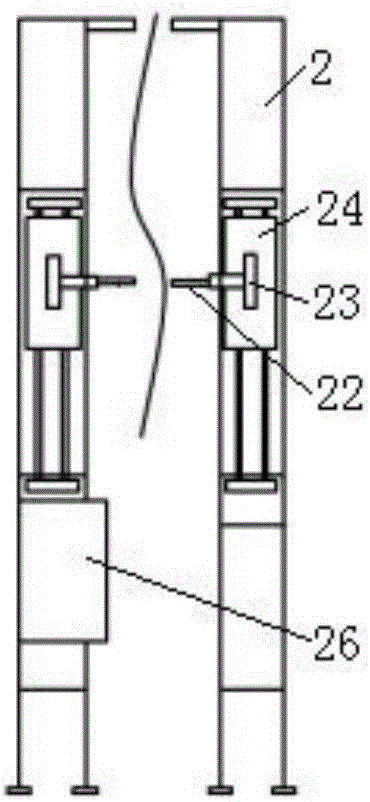

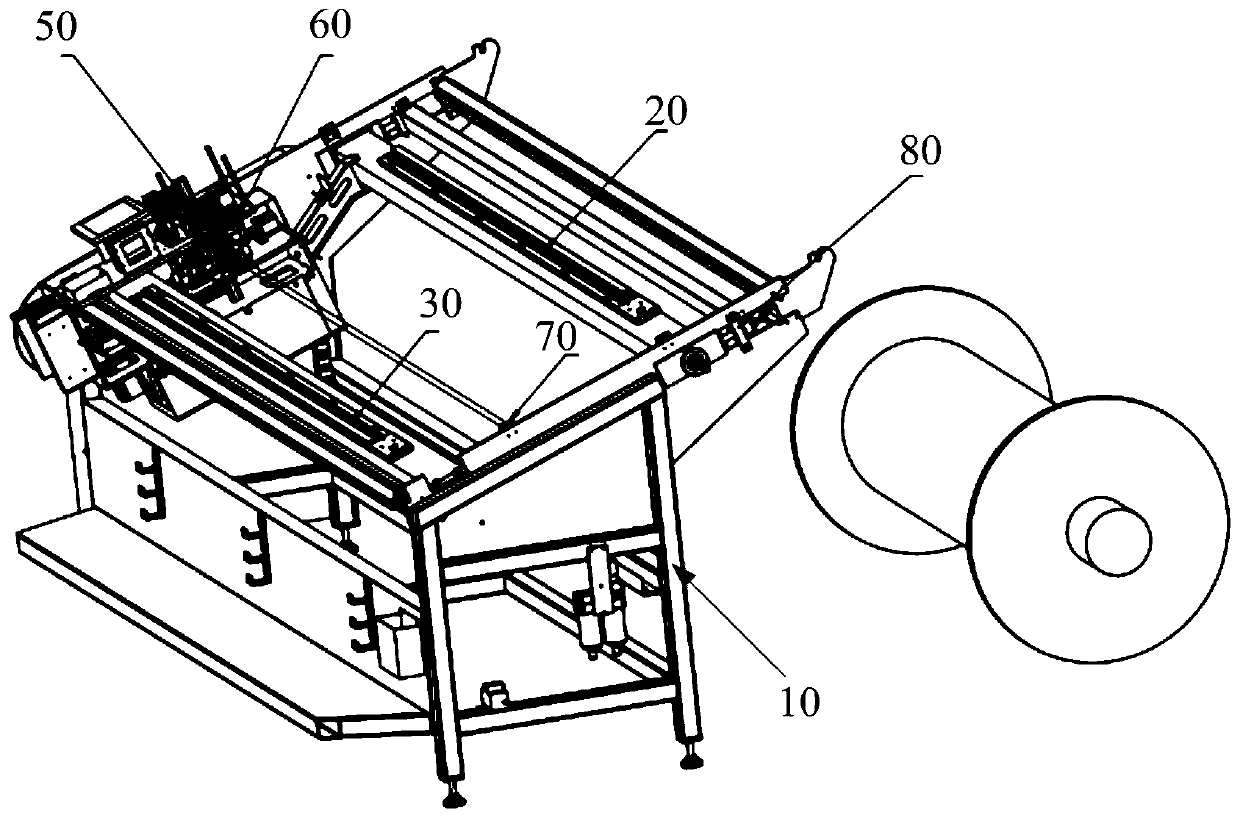

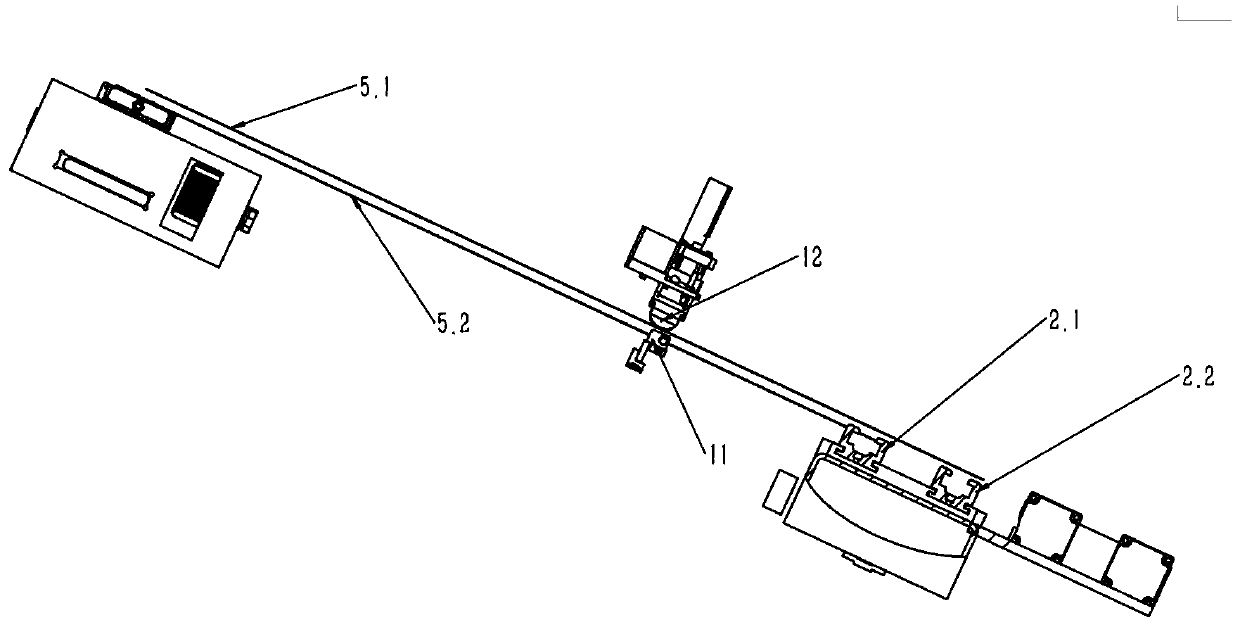

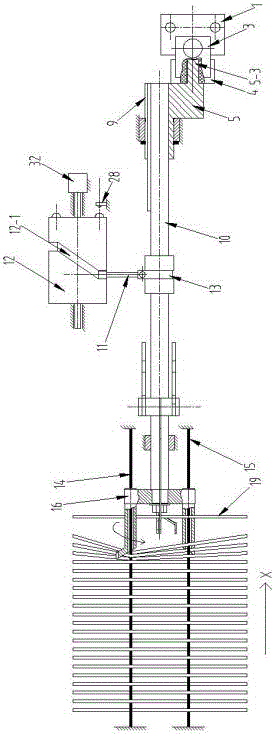

Sectional warping machine and yarn storing, yarn feeding and leasing system thereof

ActiveCN105908314AImprove transmission stabilityHigh precisionWarping machinesLeasingYarn tensionLinear drive

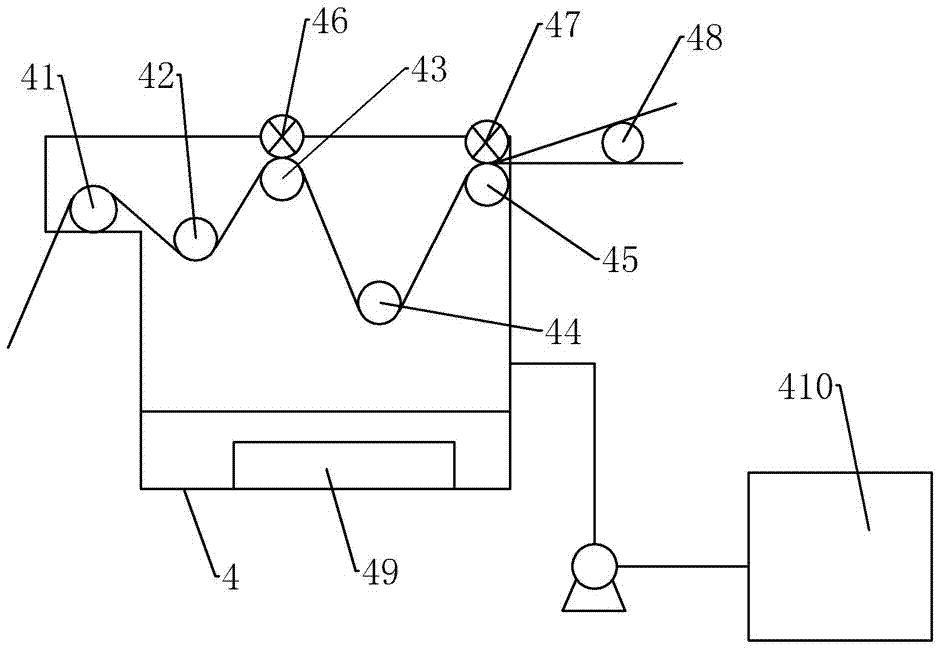

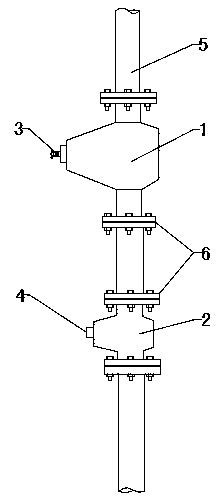

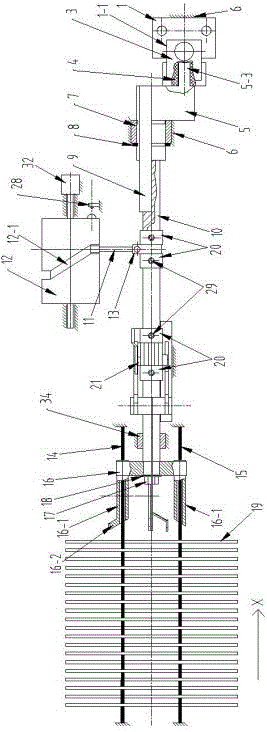

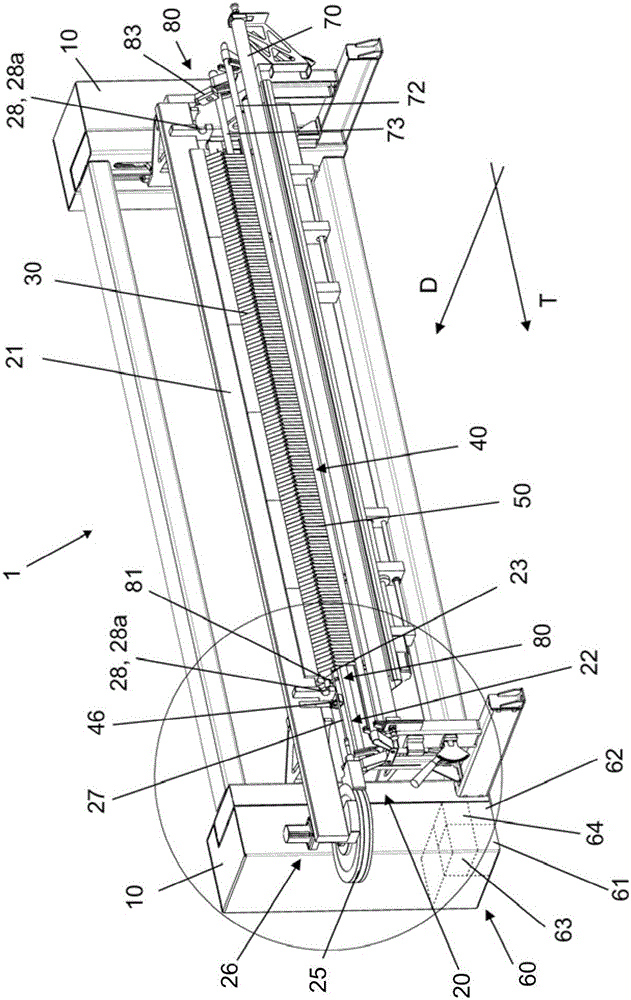

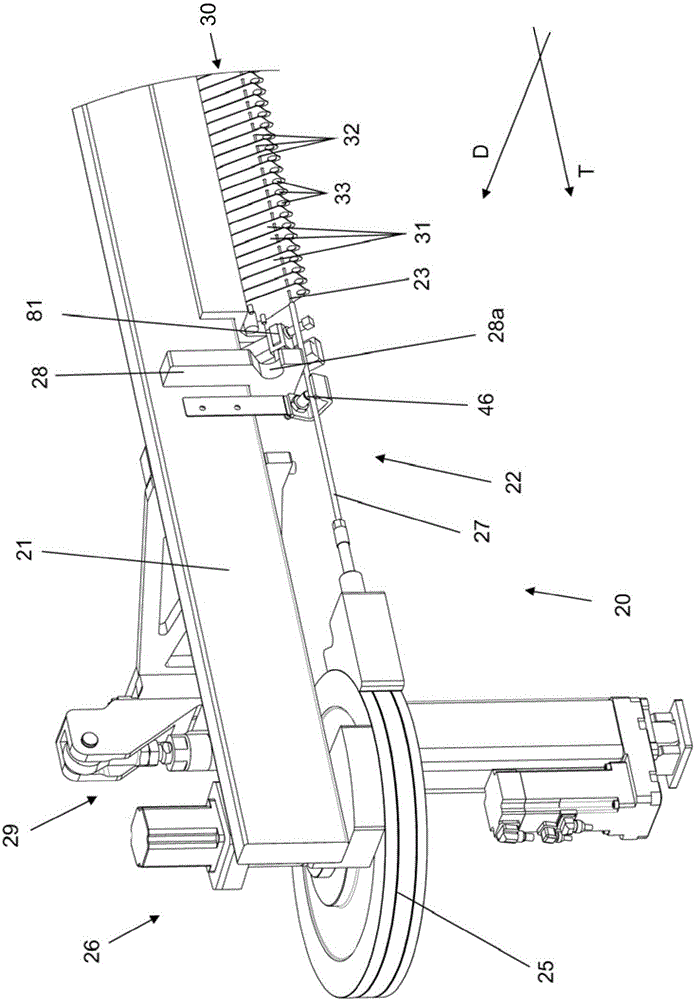

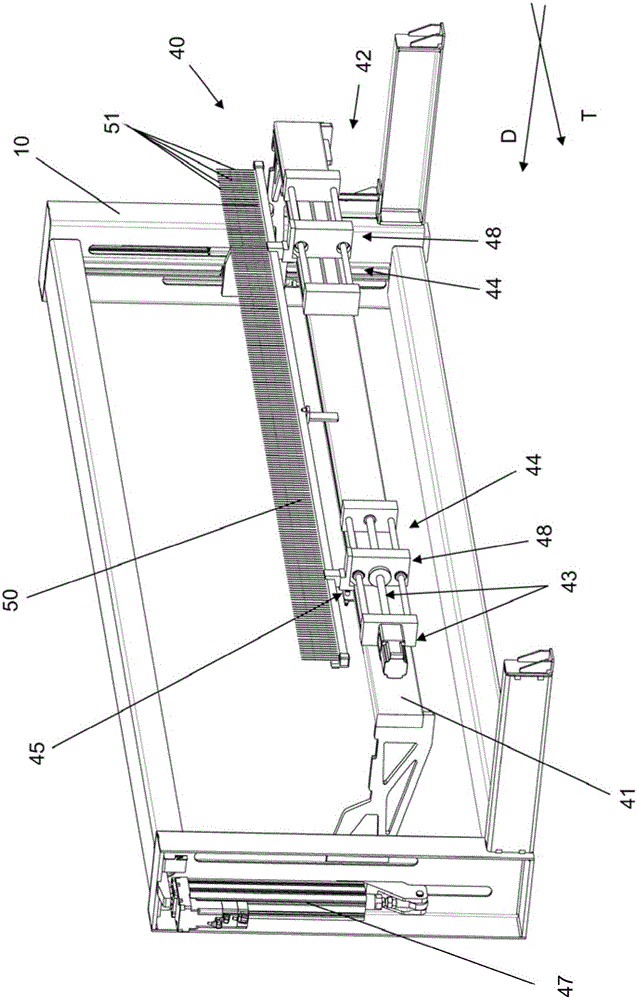

The invention discloses a yarn storing, yarn feeding and leasing system of a sectional warping machine. The system is characterized in that a yarn storing unit, a yarn feeding unit and a leasing unit which are sequentially arranged are included; the yarn storing unit comprises a long stand column, an upper yarn storing roller arranged on the long stand column, a short stand column, a lower yarn storing roller arranged on the short stand column and a linear driving device used for driving the upper yarn storing roller and the lower yarn storing roller to vertically rise and fall; the yarn feeding unit comprises a box, a yarn pressing rubber roller and a yarn guiding roller which are arranged on the box, a driving device d used for driving the yarn guiding roller to rotate and a reciprocating mechanism used for driving the yarn pressing rubber roller to abut against and be separated from the surface of the yarn guiding roller; the leasing unit comprises wallboards, linear guide rails, a leasing reed and a three-segment driving device used for driving the leasing reed to slide on the linear guide rails. Accordingly, the same length and equal tension among yarn and among strips during sectional warping are guaranteed through the yarn storing unit, the yarn feeding unit and the leasing unit, and the sheet yarn tension also can be strictly controlled when broken ends are processed.

Owner:江阴市四纺机新科技制造有限公司

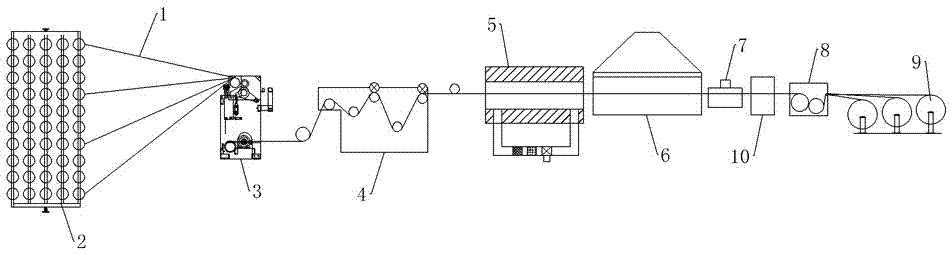

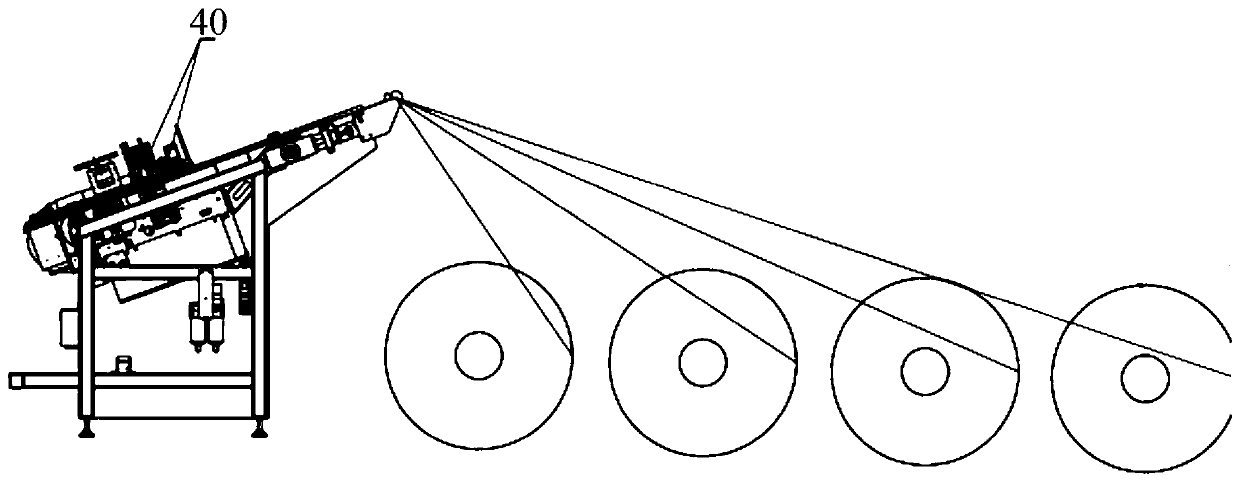

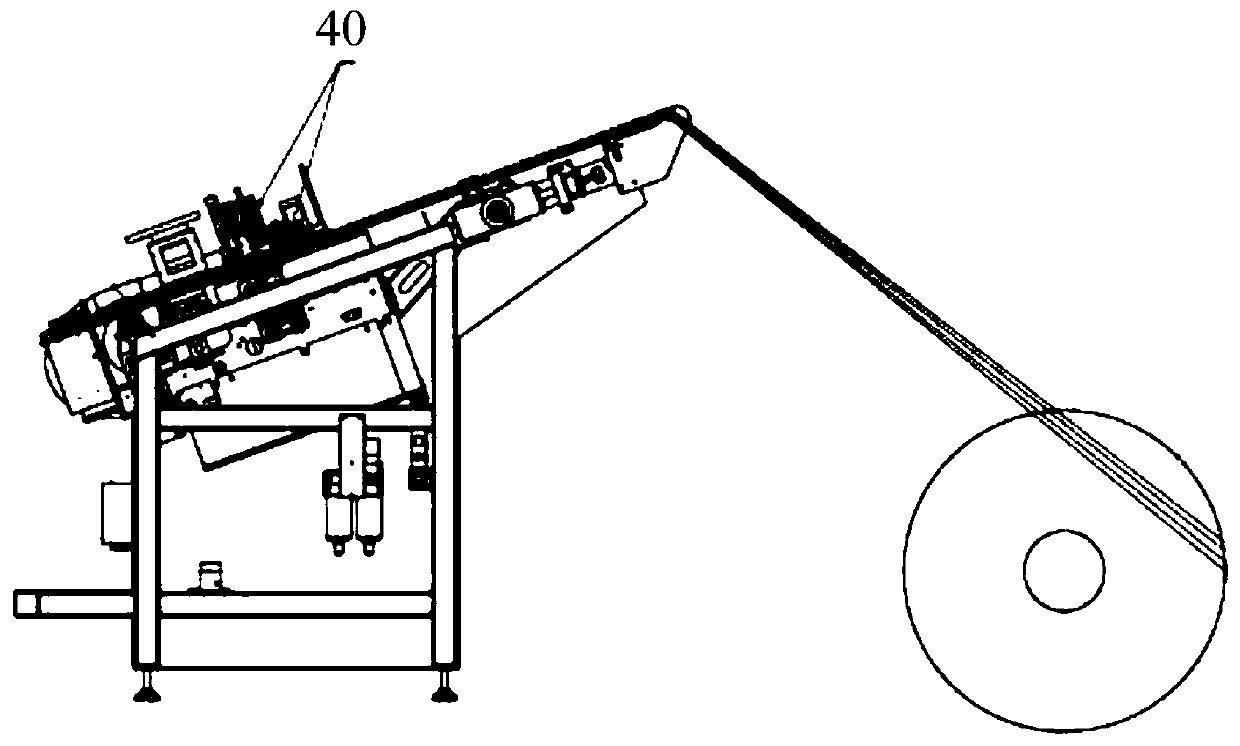

Aramid filament warping, sizing and drawing equipment

PendingCN107130381AAvoid markingsAvoid entanglementSucessive textile treatmentsCreelsBobbinStructural engineering

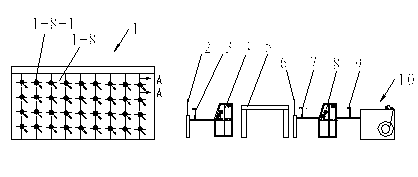

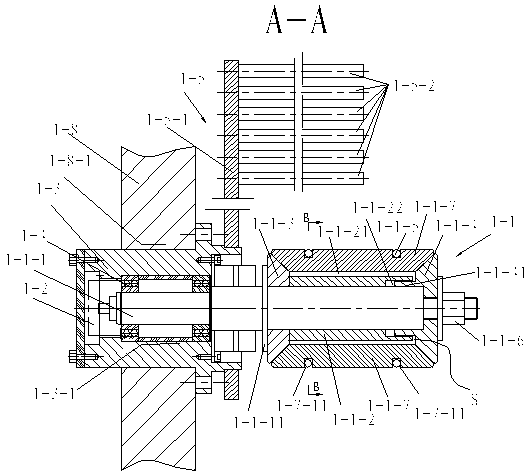

The invention discloses aramid filament warping, sizing and drawing equipment. The aramid filament warping, sizing and drawing equipment comprises a warping mechanism, a sizing mechanism and a re-beaming mechanism which are arranged along the advancing direction of aramid filaments sequentially, the warping mechanism comprises a bobbin creel, a destaticizing device and a tension frame, the sizing mechanism comprises a size box, a preheating oven, a drying room, a waxing device and a take-up device which are arranged along the advancing direction of the aramid filaments sequentially, a drawing roller is arranged on the inner side of a filament inlet of the size box, a first sizing roller, a second sizing roller, a third sizing roller and a fourth sizing roller are arranged in the size box along the advancing direction of the aramid filaments sequentially, a first squeezing roller is arranged at the top of the second sizing roller, and the re-beaming mechanism comprises a beam creel. The aramid filament warping, sizing and drawing equipment is applicable to processing the aramid filaments, is simple in structure, convenient to use and higher in working efficiency, and can achieve centralized control.

Owner:盐城市荣意来纺机有限公司

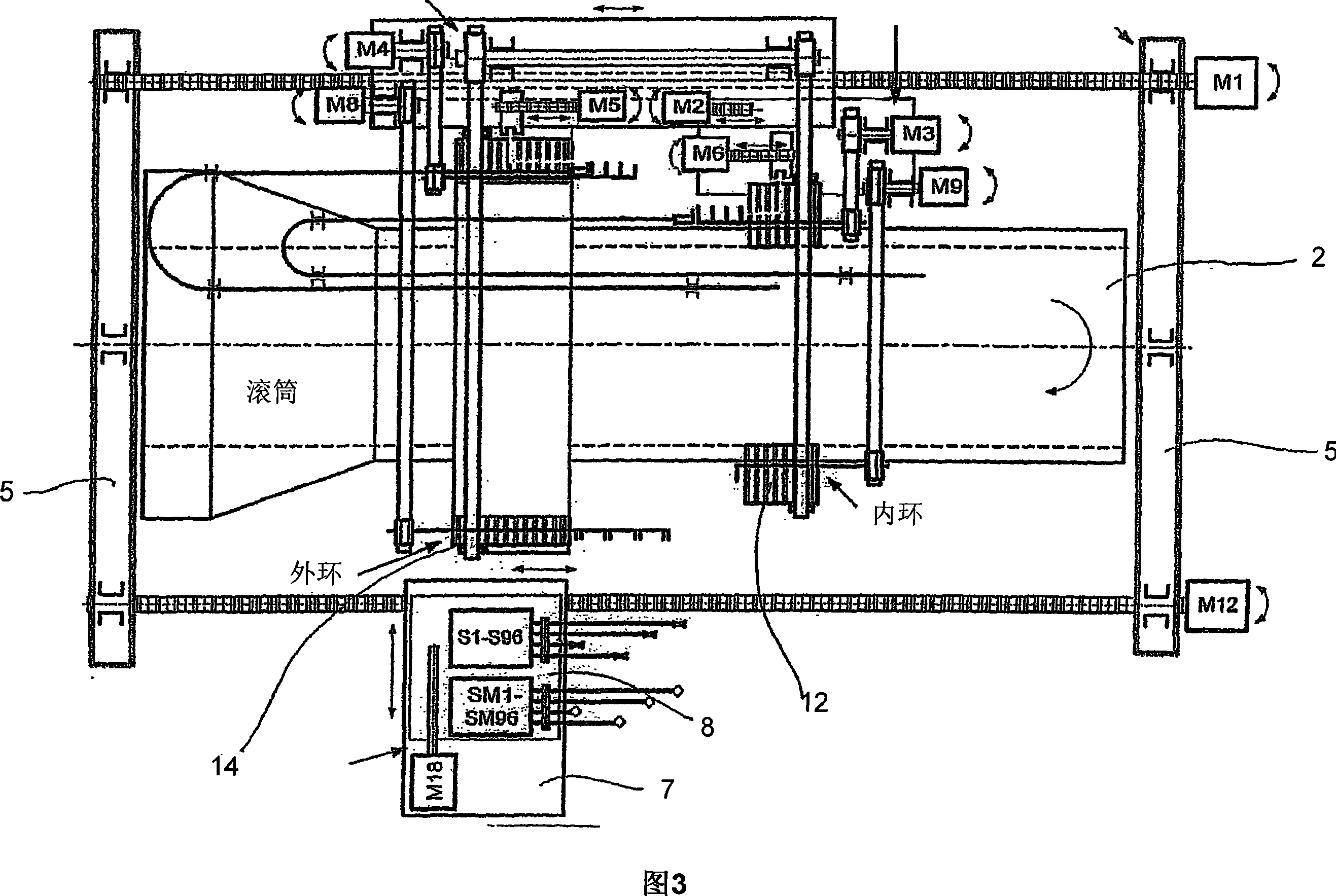

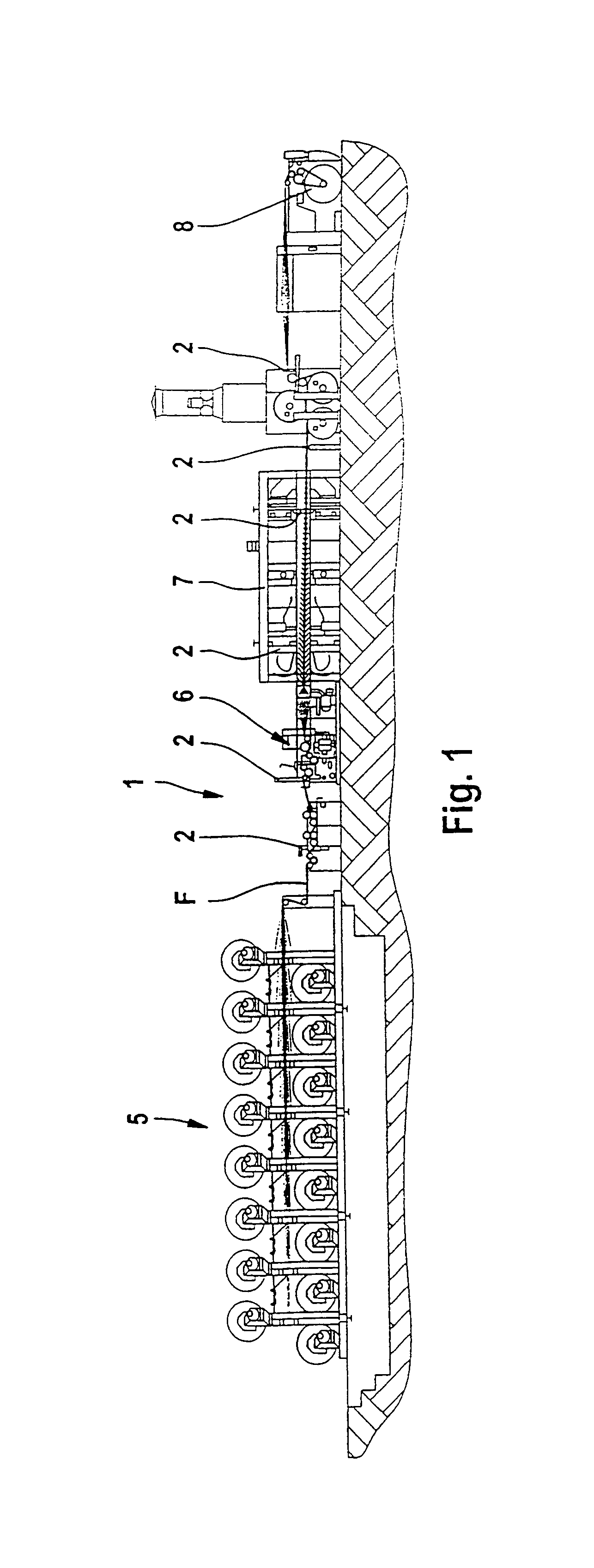

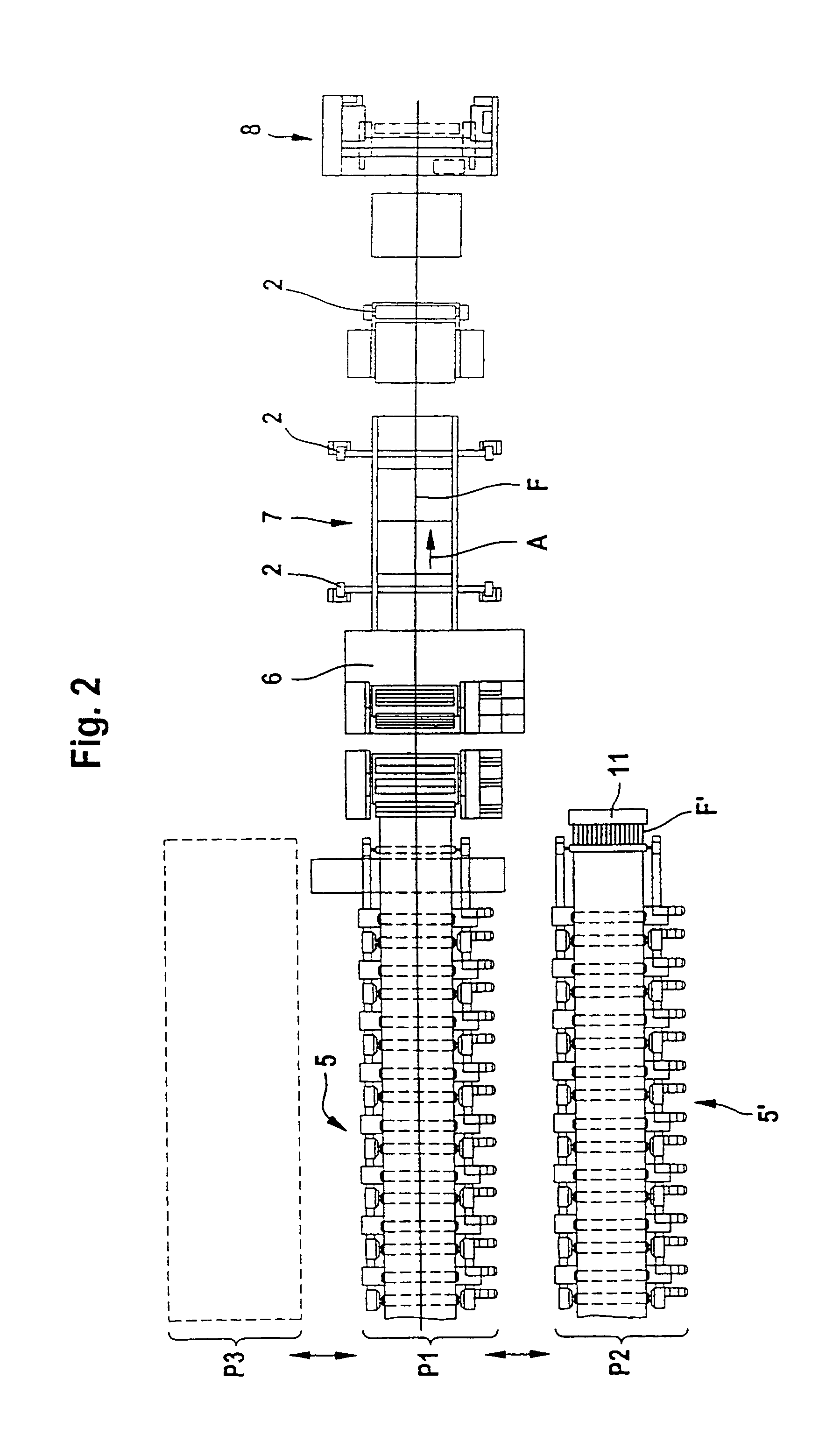

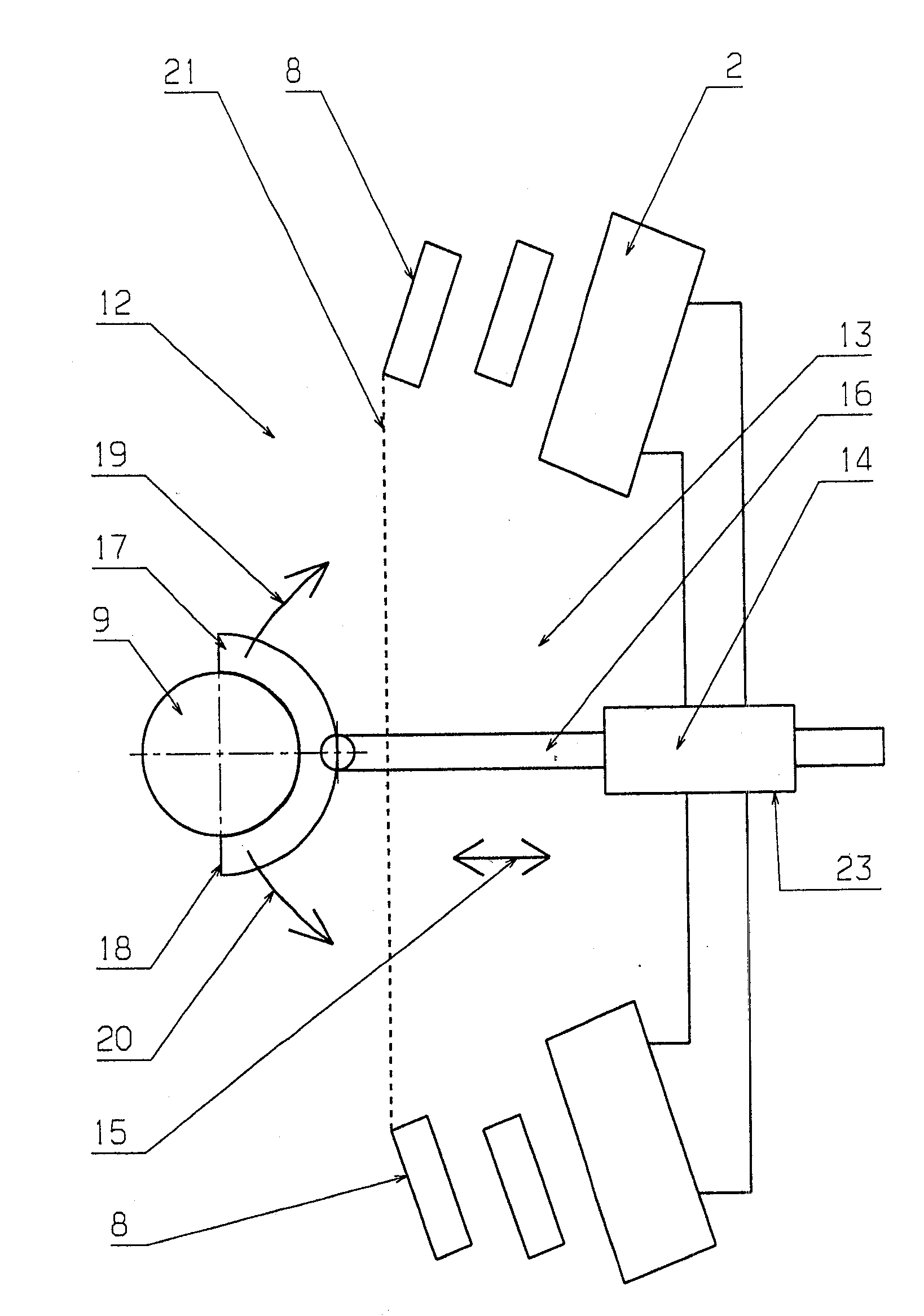

Method and device for thread distribution in a warping frame

The invention relates to a method for winding a strip (17) consisting of a plurality of parallel threads (18) onto a rotating warping drum (2), wherein the winding position of each individual thread is determined with the aid of a thread guide (21) which is associated with a thread selection device (8) and which is allocated to said thread. The thread guides (21) are displaced in the direction of the axis of rotation (6) of the warping drum (2) from a rest position into a working position and the individual threads (18) are seized successively by an internal thread carrier (30) associated with the warping drum (2).

Owner:KARL MAYER STOLL R&D GMBH

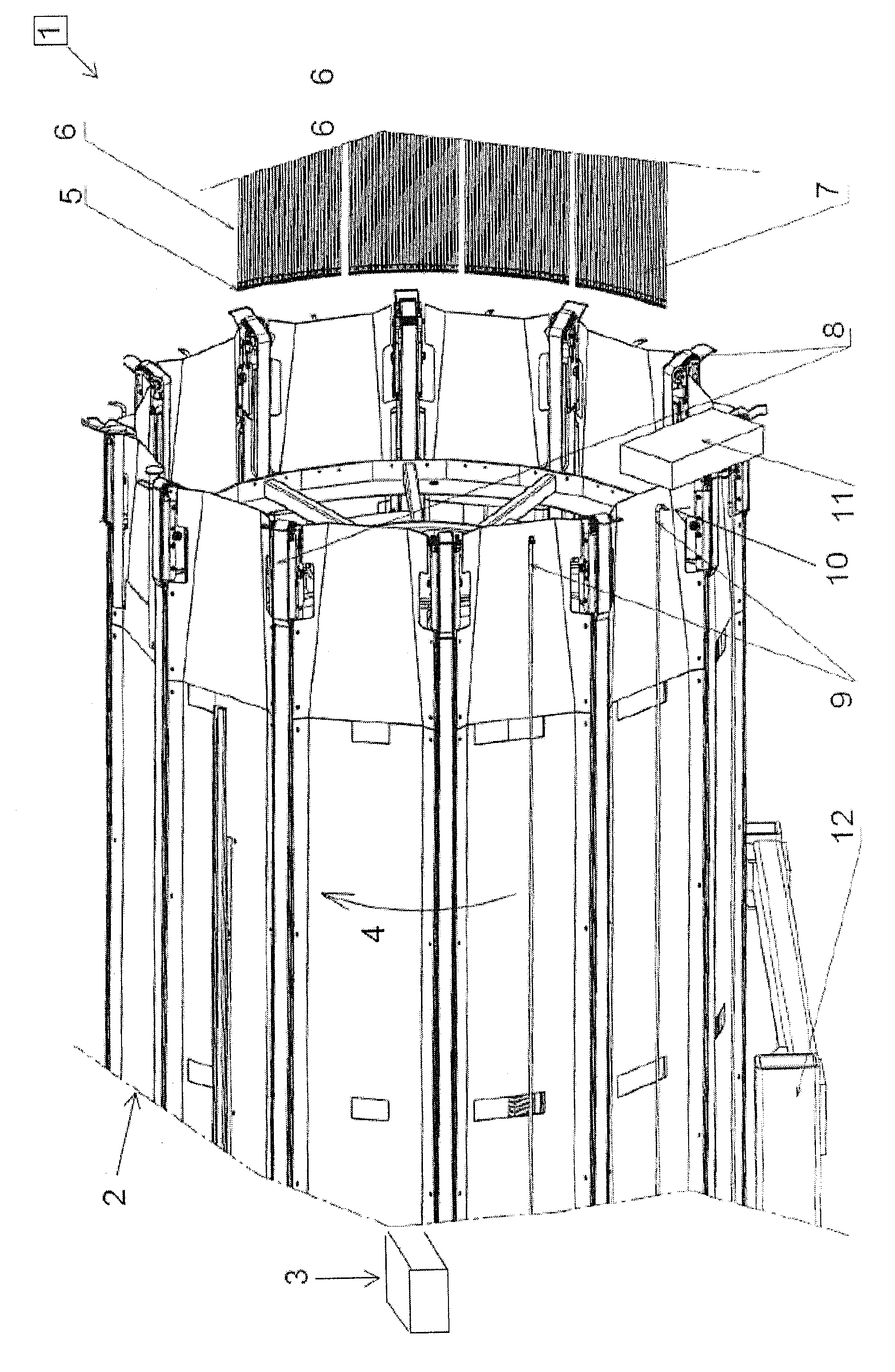

Sample warper

The sample warping machine (1) has a warping drum (2) that is connected with a winding drive (3). A yarn guide unit (6) is movably connected in parallel to the axis of the warping drum. Several attachment rods (9) are attached to the peripheral surface of the warping drum. A sensor arrangement (11) is arranged for detecting the positions of the attachment rods attached to the peripheral surface of the warping drum. The sensor arrangement is arranged opposite to the end surface of the warping drum.

Owner:KARL MAYER STOLL R&D GMBH

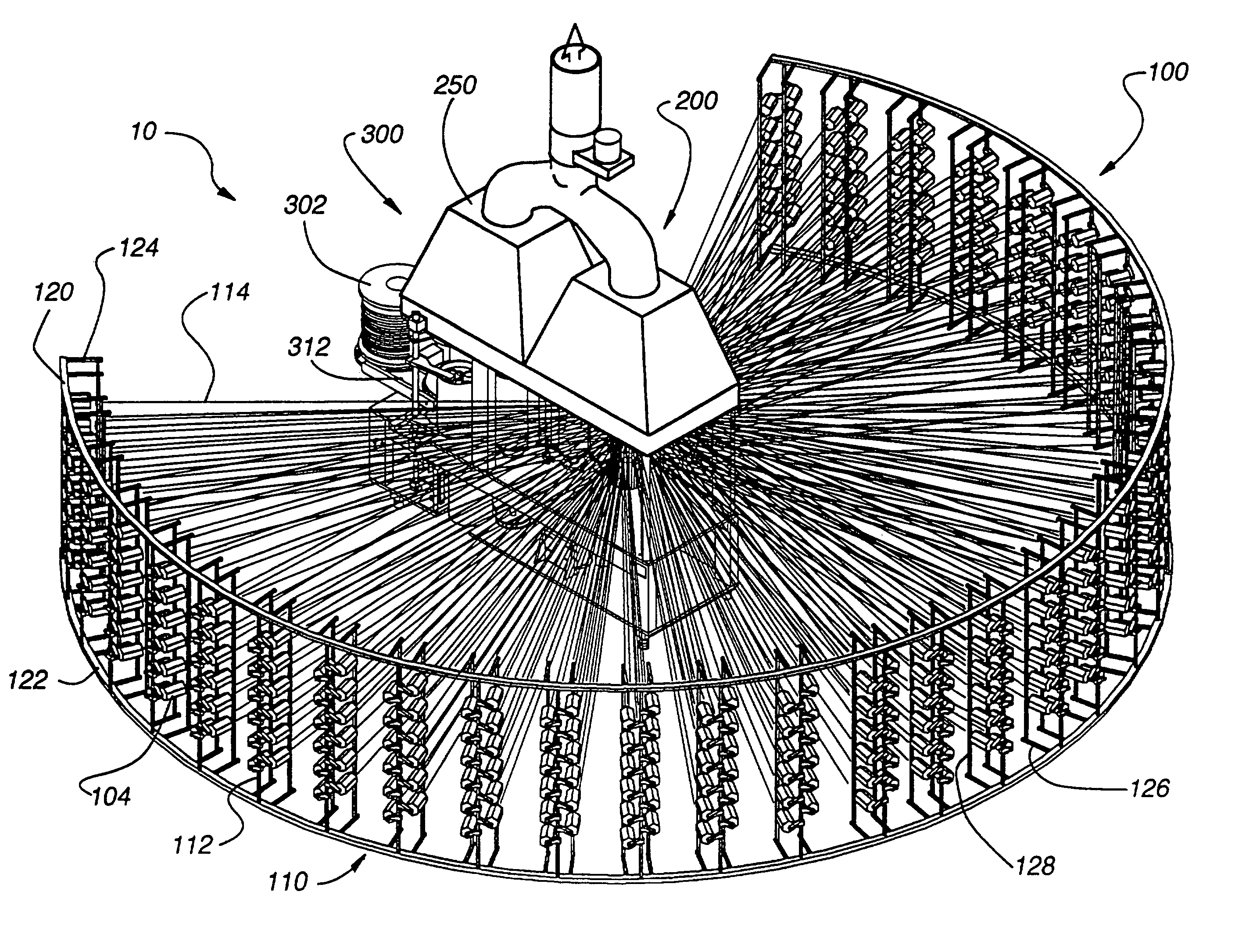

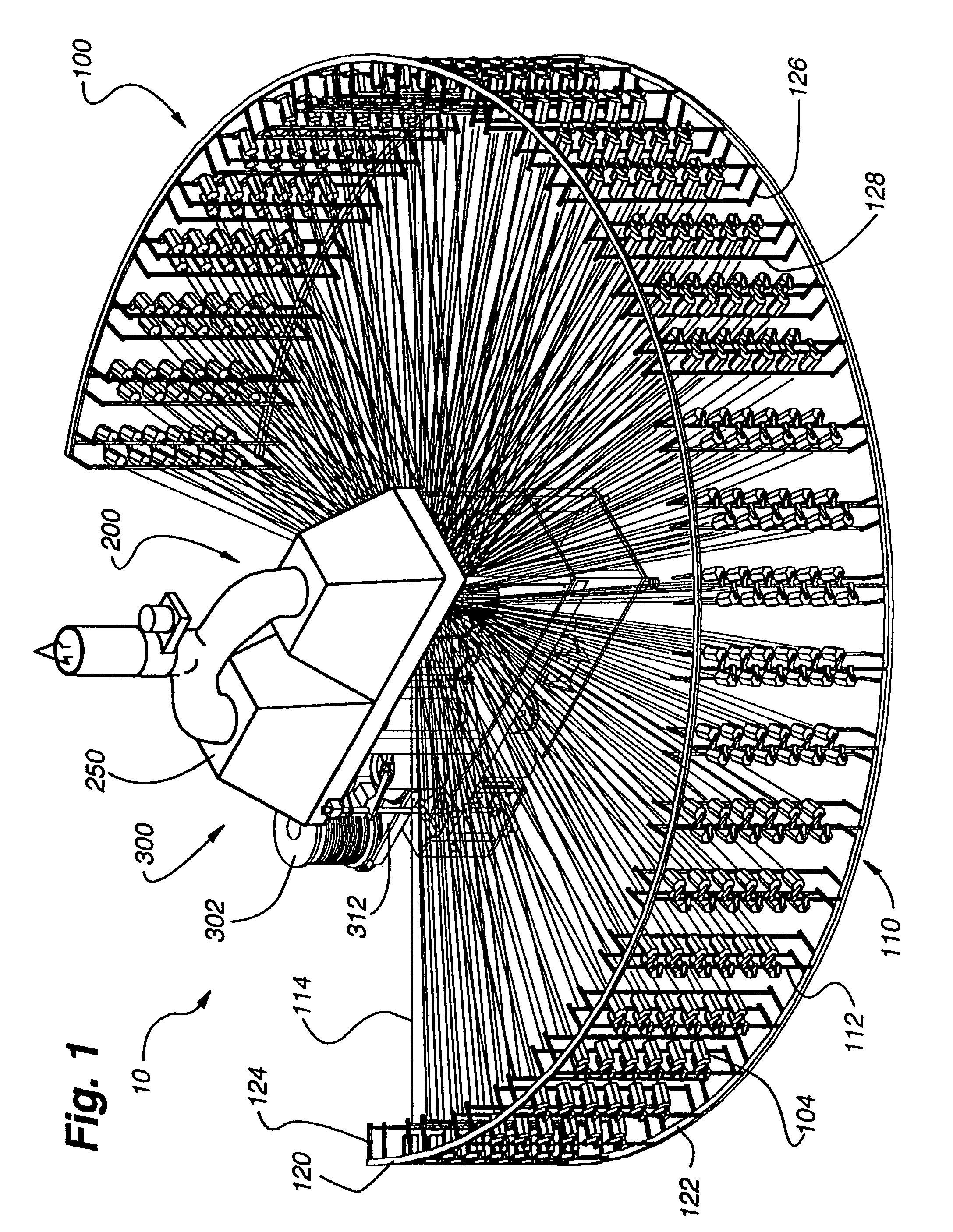

Beam winding apparatus

An apparatus and method for winding a sheet of aligned parallel yarns onto a beam is described. The beam winder utilizes a circularly arced yarn spool rack that feeds each yarn to an alignment comb through associated guide tubes. The distance between each spool of yarn and the alignment comb is substantially the same for all spools of yarn, thereby equalizing the force necessary to pull them to the comb. Next, the aligned sheet of material is preshrunk using heated rollers and wound onto a beam. Multiple speed controlled stepper motors are utilized to maintain a constant low level of tension in the sheet during the shrinking process. After shrinkage, the tension level of the yarn sheet is increased as it is wrapped onto the beam. A turntable that supports two or more beams is provided to facilitate the rapid switching of beams once one beam has become full.

Owner:HUNTER DOUGLAS INC

Sizing yarn technology utilizing short fiber sizing machine to produce DTY filament varieties

ActiveCN103835089ASolve twisted headSolve adhesionSucessive textile treatmentsTextile treatment machine arrangementsWaxAntistatic agent

The invention discloses a sizing yarn technology utilizing a short fiber sizing machine to produce DTY filament varieties and belongs to the technical field of textile filament preparation. The sizing yarn technology is characterized in that the speed of the short fiber sizing machine is adjusted to be reduced to be 20-25m / min, filament sizing agents with 4.5-5.5% solid content are used for sizing, filament oil is filled into a wax tank, antistatic agents are added in the filament sizing agents and the filament oil, the temperature of a baking barrel is maintained at 150-155 DEG C, the filament is dried after oiling, the filaments are evenly placed in a telescopic reed after dry leasing, the number of filaments of each radial shaft is controlled to be 680-760 pieces / shaft, and each filament is provided with a dent on each shaft. According to the sizing yarn technology, the short fiber sizing machine is used for realizing successful production of the DTY filament varieties, existing equipment does not need substantial improvements, investment is little, and filament varieties and short fiber varieties can all be produced normally. The sizing yarn technology makes up the blank that the short sizing machine cannot size filaments, and reduces waste of devices and raw materials through technological improvements.

Owner:ZIBO YINSHILAI TEXTILE

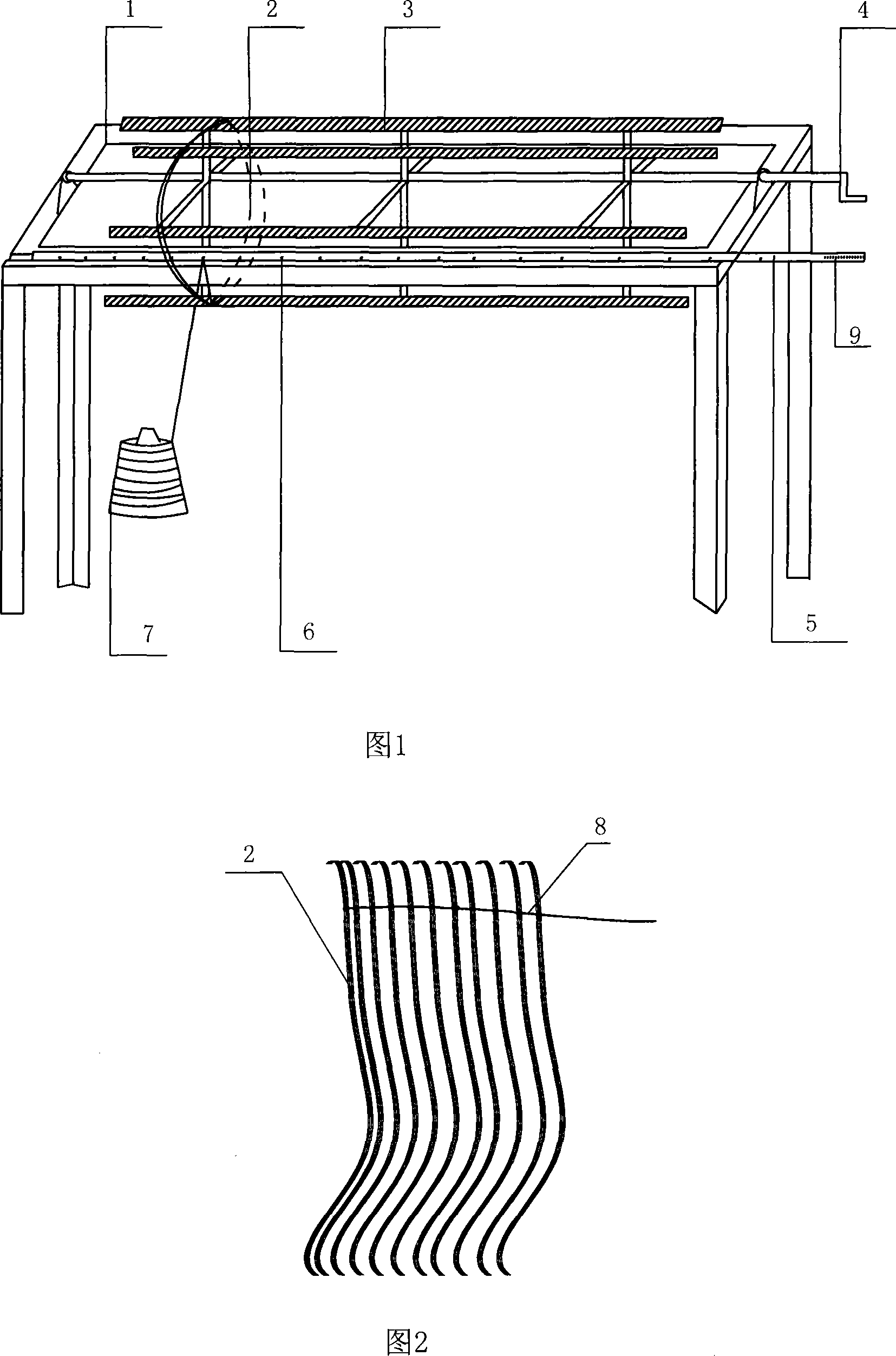

Silk separating and warping equipment

InactiveCN102995205APrevent radial movementTighten and firmCreelsWarping machinesYarnProcess engineering

The invention discloses silk separating and warping equipment. The silk separating and warping equipment comprises a drive yarn feeding creel and a warping machine. The silk separating and warping equipment is characterized in that the subsequent device of the drive yarn feeding creel further comprises a yarn collecting plate, a yarn needle collecting assembly, a first tension roller device, a silk separating frame, a silk separating plate, a silk separating needle assembly, a second tension roller device and a warping needle assembly which are sequentially connected, a plurality of yarn collecting holes are formed on the yarn collecting plate, and a plurality of silk separating holes are formed on the silk separating plate; the drive yarn feeding creel comprises a creel body, a tension device, a motor, an installation sleeve and an installation bearing; and the silk separating creel comprises a support, a plurality of silk separating rod assembly, a left silk separating rod seat and a right silk separating rod seat. Silk separating and warping processes can be realized through one equipment, so that cost and labor are saved; and moreover, drive unreeling is adopted during the silk separating process, so that the product quality is improved.

Owner:CHANGZHOU CHANGHAN MACHINERY

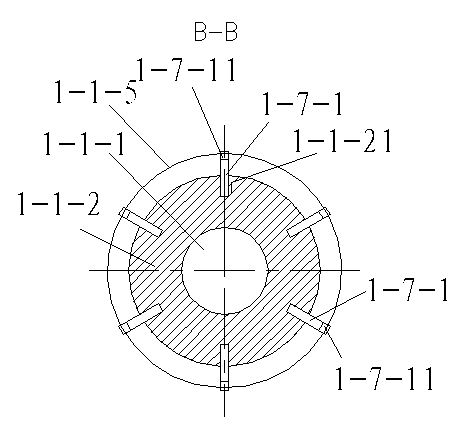

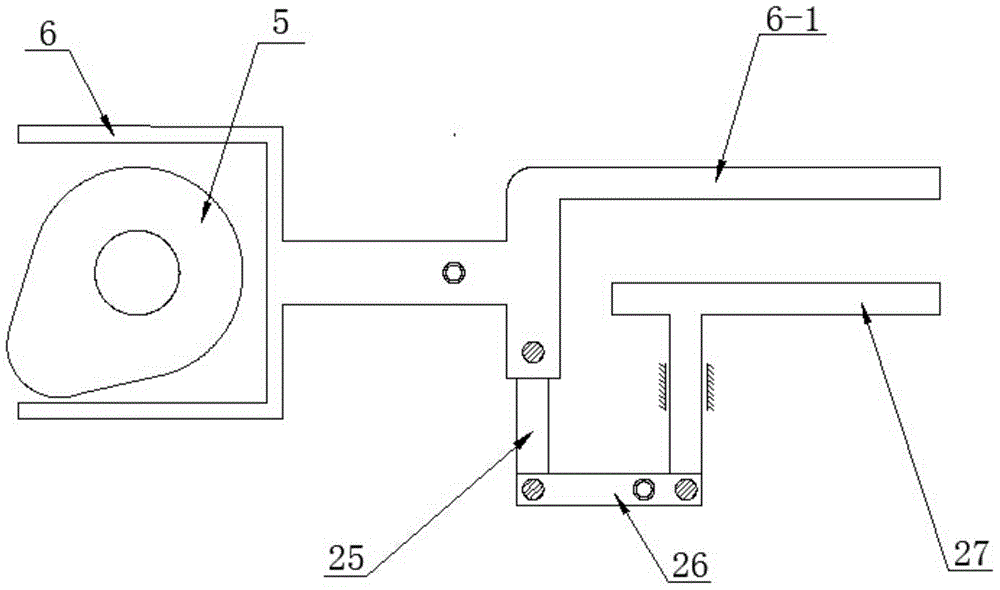

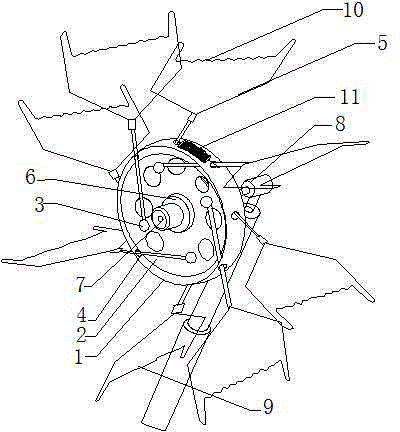

Open-close type reel for hank reeling machine

ActiveCN103696072ARealize opening and closingChange outer diameterLeasingOther manufacturing equipments/toolsEngineeringFlange

The invention discloses an open-close type reel for a hank reeling machine. The open-close type reel comprises a reel shaft, wherein the front end and the rear end of the reel shaft are inserted and sleeved with two shaft sleeves, the shaft sleeves are fixed on the reel shaft by screws, a plurality of hinge seats are fixed on the two shaft sleeves; connection rods are hinged on the hinge seats by pin shafts; a reel rod is fixedly connected between the two opposite connection rods at the front end and the rear end of the reel shaft, a support rod is fixedly connected between the two connection rods at the inner side of the reel rod, the reel shaft is inserted and sleeved with a flange disc, an arc-shaped waist-shaped slot is formed in the front end surface of the flange disc, and the support rod is inserted and sleeved in the waist-shaped slot of the flange disc; a groove penetrating through the outer wall of the flange disc is formed in the rear end surface of the flange disc, a boss is inserted and clamped in the groove of the flange disc, and the boss is fixed on the outer wall of the reel shaft. According to the open-close type reel disclosed by the invention, the rotations of the connection rods around hinge points are realized by the rotation of the flange disc, thus changing the outer diameter of the reel and realizing the opening and closing of the reel, in this way, the function of a belt is replaced, thus increasing the production efficiency of hank reeling.

Owner:苏州熙硕纺织有限公司

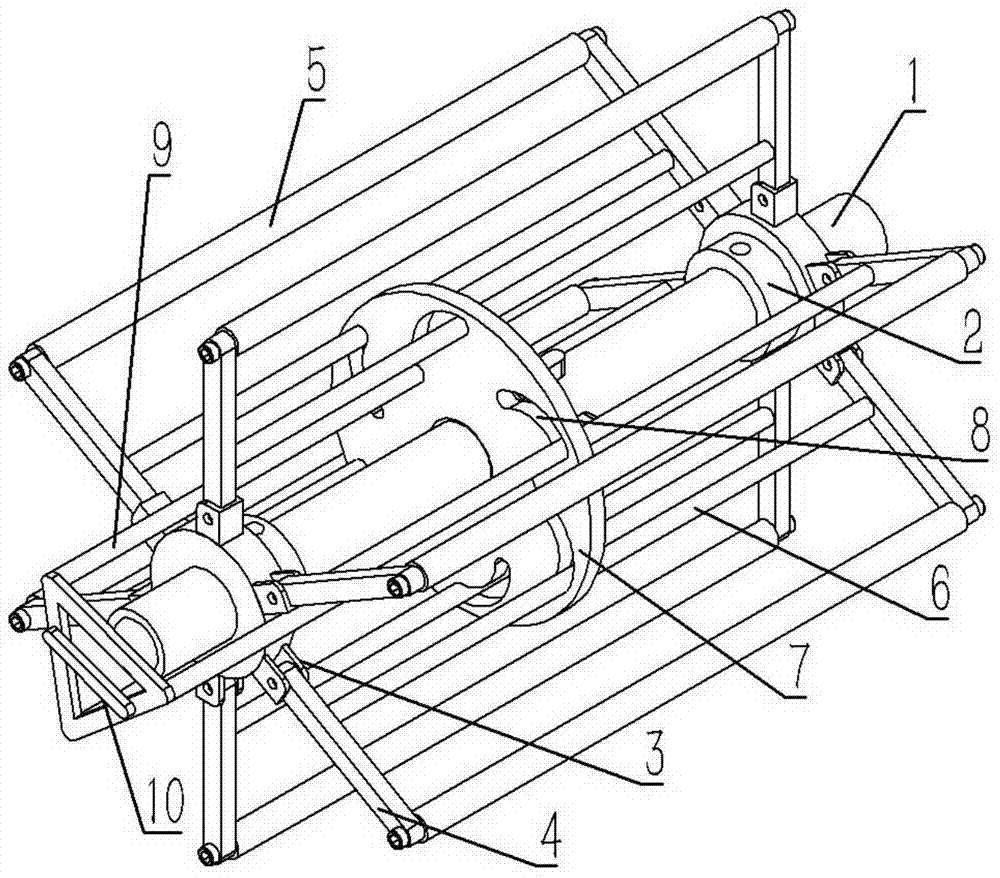

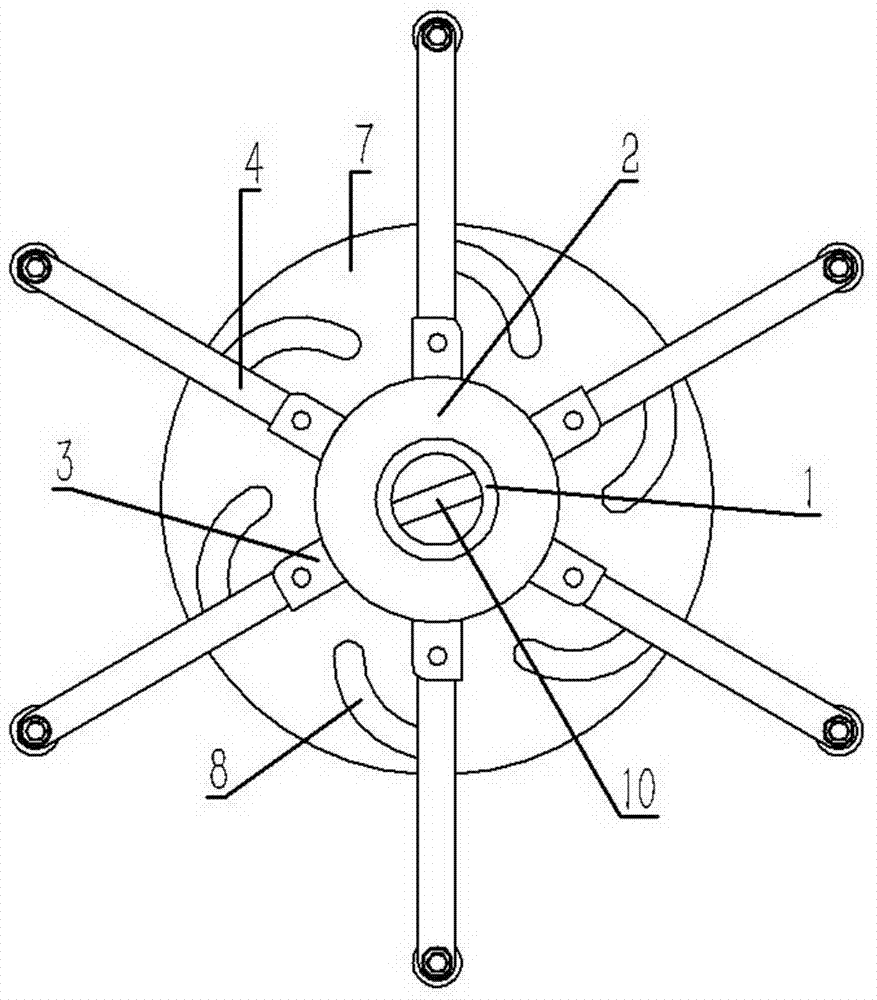

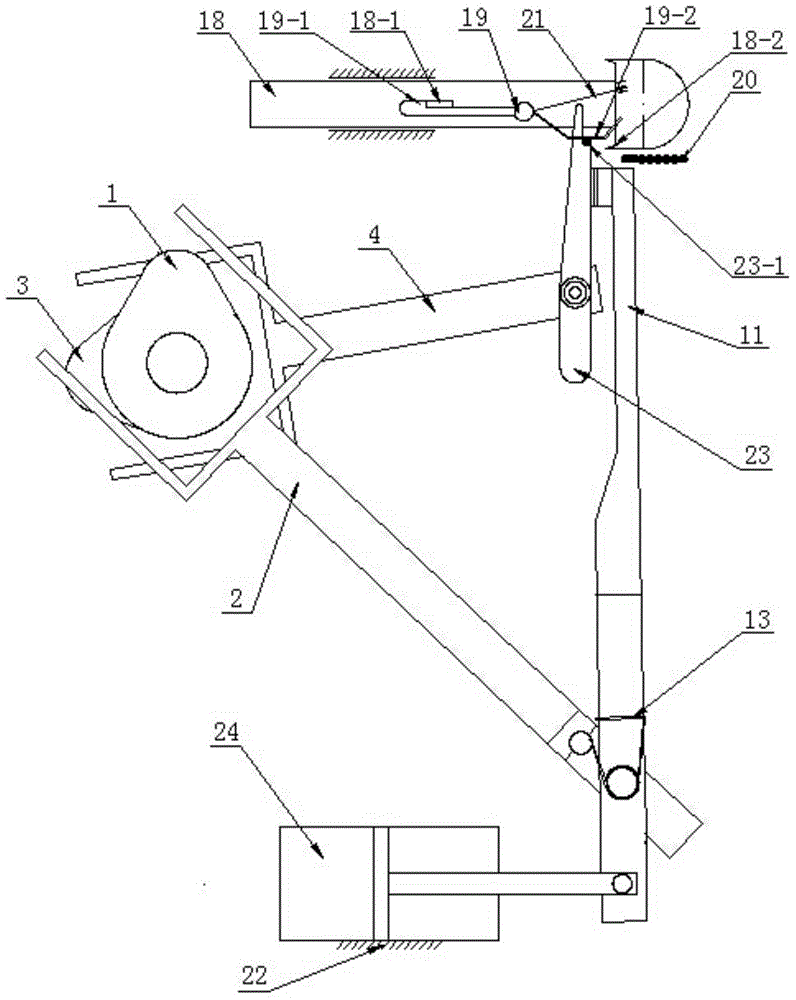

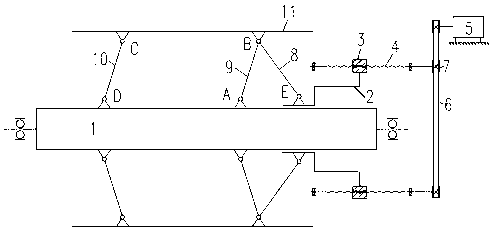

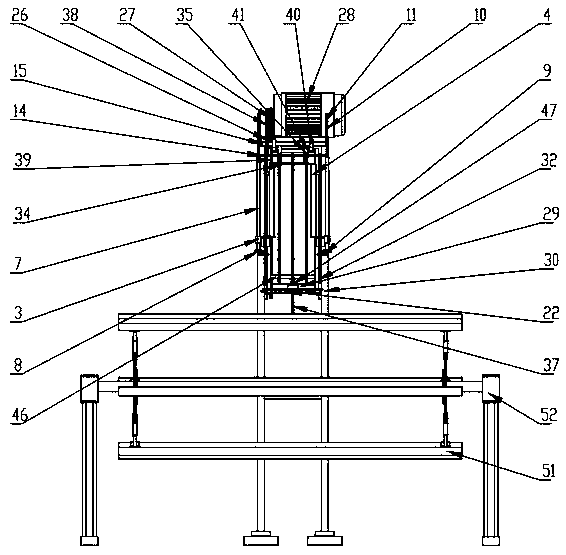

Automatic opening and closing device for hank reels of hank reeling machine

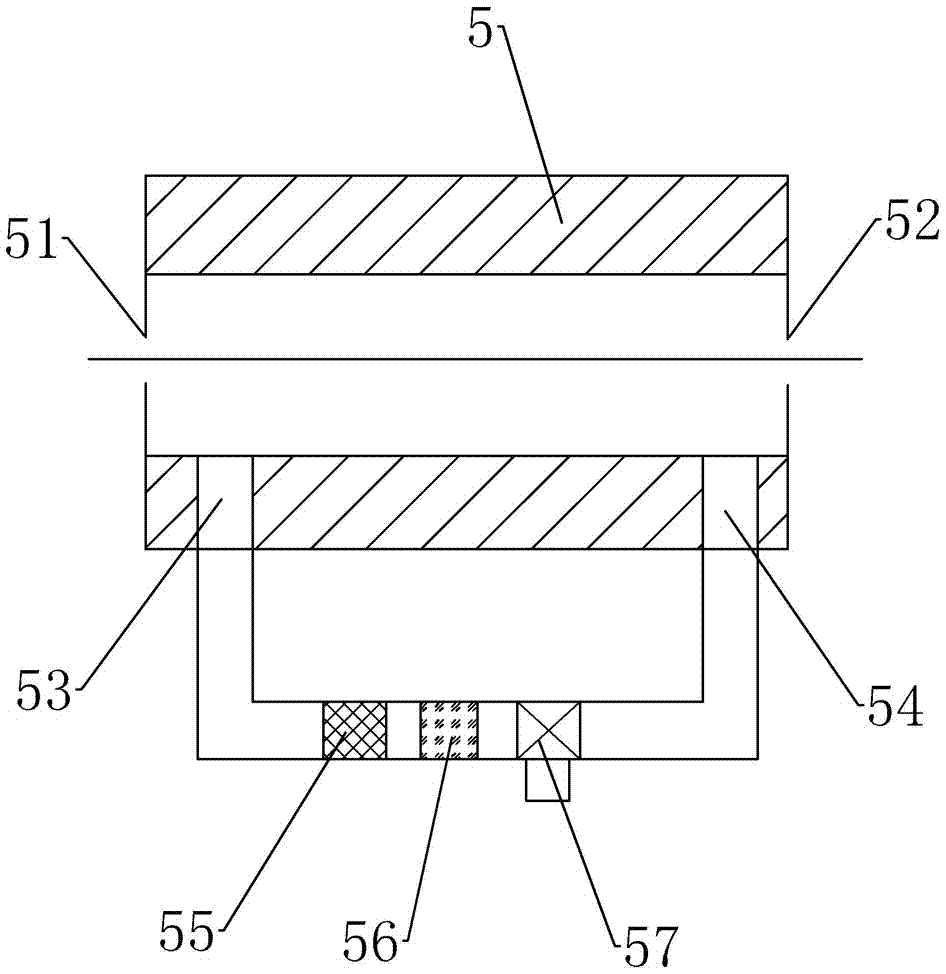

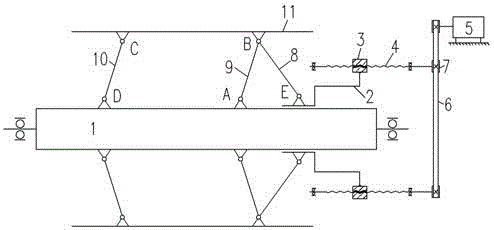

InactiveCN103290587BHigh degree of automationHigh positioning accuracyLeasingOther manufacturing equipments/toolsYarnMotor drive

The invention relates to an automatic opening and closing device for hank reels of a hank reeling machine. The hank reels are movably connected with a spindle through a parallelogram mechanism; an AB connecting rod in the parallelogram mechanism is connected with one push rod through a BE driving connecting rod; each push rod is fixedly connected with a nut which is connected with a belt pulley through a screw rod; and the belt wheels are synchronous toothed belt wheels. According to the automatic opening and closing device, rectilinear motion of a screw rod pair is used, the four-bar linkage hank reels are driven by the push rods, and expansion and reduction of the outer diameter of each reel are finished. The automatic opening and closing device has the advantages that the motor-driven degree of automation is high, the reel positioning accuracy is high, and the self-locking is reliable; the reels can be positioned in multiple appointed positions, so that requirements for different reel circumferences of various yarns in hank reeling can be met flexibly; and the device is simple in structure, convenient to mount and low in cost.

Owner:SHANGHAI CORAL TEXTILE MACHINERY

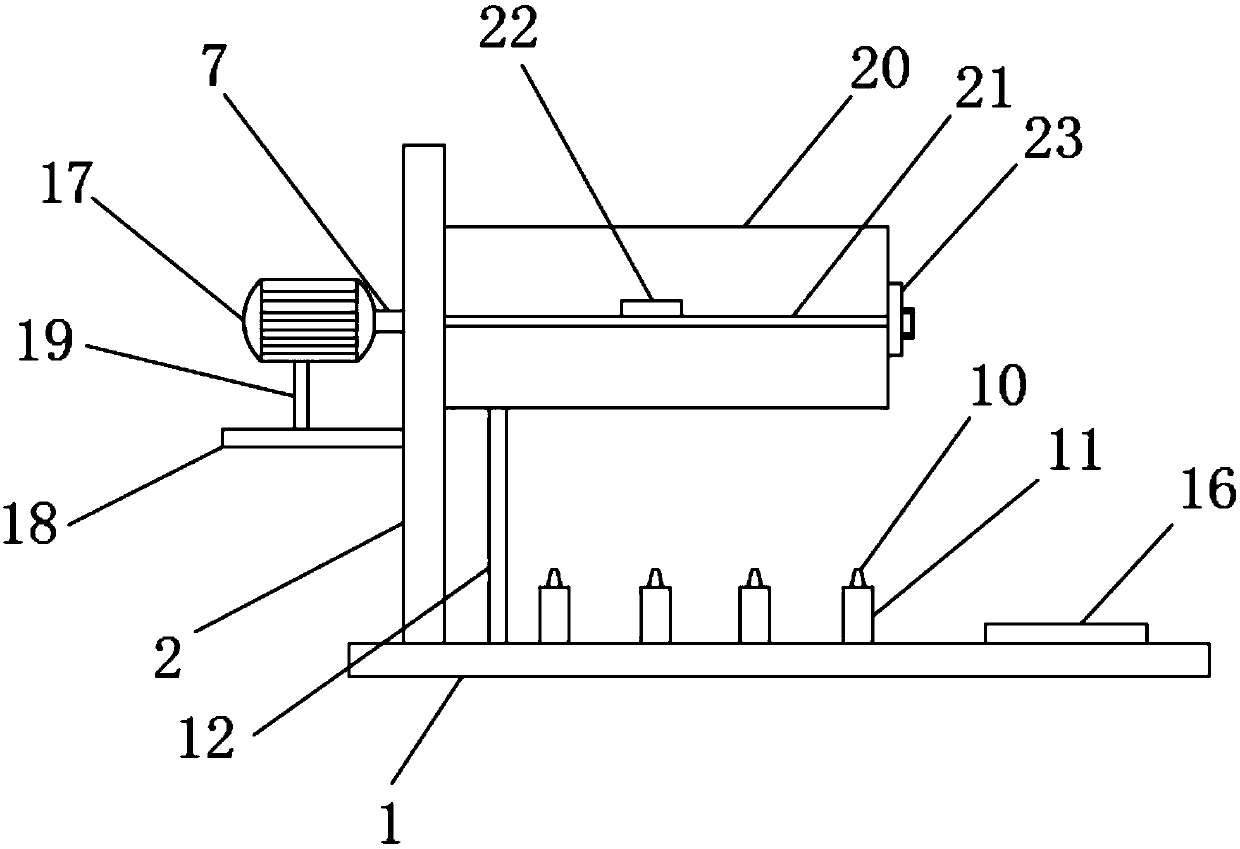

Auxiliary energy-saving type yarn reeler based on intelligent semi-worsted processing production line

ActiveCN109576855AWinding radius adjustmentPracticalLeasingOther manufacturing equipments/toolsYarnProduction line

The invention discloses an auxiliary energy-saving type yarn reeler based on an intelligent semi-worsted processing production line. The auxiliary energy-saving type yarn reeler comprises a working bottom plate and a side plate installed on one side of the upper end of the working bottom plate, rolling rings are installed on the outer surface of one side of the side plate, a rotating shaft is arranged between the two sets of rolling rings, and movable rods are distributed on the outer surfaces of the peripheries of the two sets of rolling rings respectively. According to the auxiliary energy-saving type yarn reeler based on the intelligent semi-worsted processing production line, the yarn winding radius of yarn frame rods can be adjusted, corresponding reamed yarn is obtained, practicability is high, dust in air can be prevented from adhering to the reamed yarn, product quality is ensured, meanwhile, wound yarn is prevented from popping outwards, a dust cover and a yarn winding guidingplate are convenient to open and close, the yarn frame rods can be controlled to stop automatically, friction generated by rotation of the rotating shaft can be effectively reduced to reduce the lossof the rotating shaft, meanwhile, the energy loss can be reduced, and the auxiliary energy-saving type yarn reeler has the advantages of being environmentally friendly and saving energy, can avoid interference among different batches, and reduces generation of flyings.

Owner:TONGXIANG YIDE TEXTILE

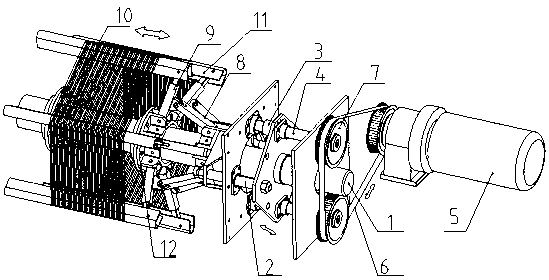

Automatic yarn separating machine

The invention discloses an automatic yarn separating machine which comprises a rack, a motor, a camshaft, an upper cam, a middle cam, a lower cam, an end face cam, a limiting mechanism, a yarn separating mechanism, a yarn clamping mechanism and a yarn feeding mechanism. The upper cam, the middle cam, the lower cam and the end face cam are sequentially fixed to the camshaft from top to bottom. The motor drives the camshaft to rotate. The limiting mechanism, the yarn separating mechanism, the yarn clamping mechanism and the yarn feeding mechanism are matched with the upper cam, the middle cam, the lower cam and the end face cam respectively. The limiting mechanism is used for limiting the position of the yarn separating mechanism. The yarn separating mechanism ejects out one piece of yarn located at the foremost end of a weaving shaft charka. The yarn clamping mechanism enables the yarn ejected out by the yarn separating mechanism to be tightened. The yarn feeding mechanism pushes the yarn ejected out by the yarn separating mechanism into a clamping opening. The warp yarn conveyed by the weaving shaft charka to be separated fast and automatically in sequence one by one and fed into the next warp yarn threading working procedure accurately, labor intensity is relieved, the labor cost is saved, and the production efficiency is improved.

Owner:YONGXUSHENG MACHINERY TECH CHANGZHOU CO LTD

Memory fabric manufacturing technique

The invention discloses a memory fabric manufacturing technique. PPT silk is used and serves as a raw material, the memory fabric manufacturing technique comprises the steps of beam warping, scaling, silk sizing, re-beaming, leasing, drafting, weaving and desizing, and memory fabric is obtained. The memory fabric manufacturing technique has the advantages that the memory fabric manufacturing technique is provided, and the complete no-iron effect is achieved.

Owner:NANTONG YUEDA KNITTING GARMENT

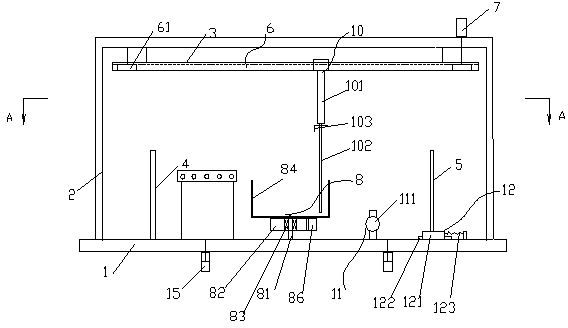

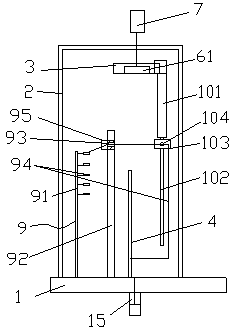

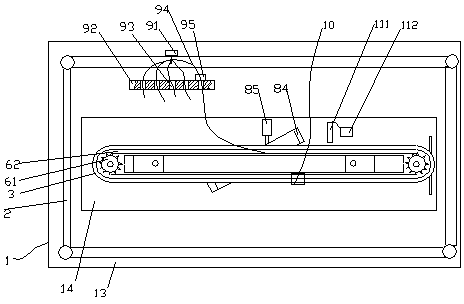

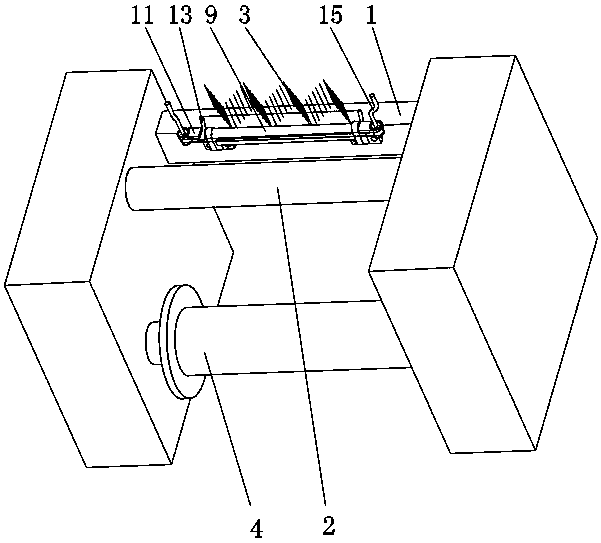

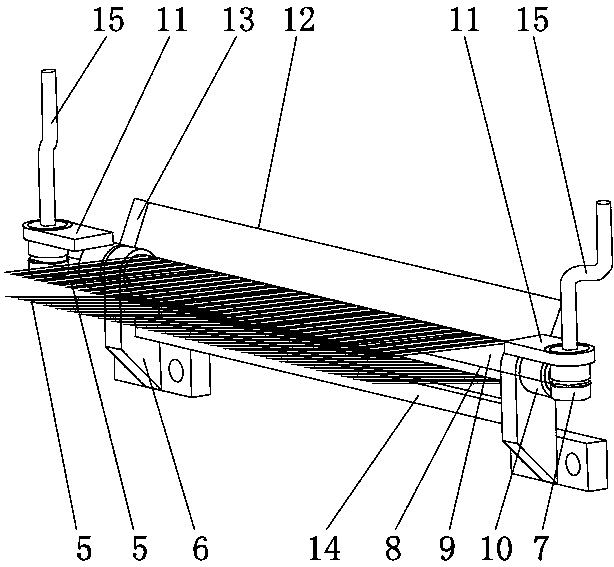

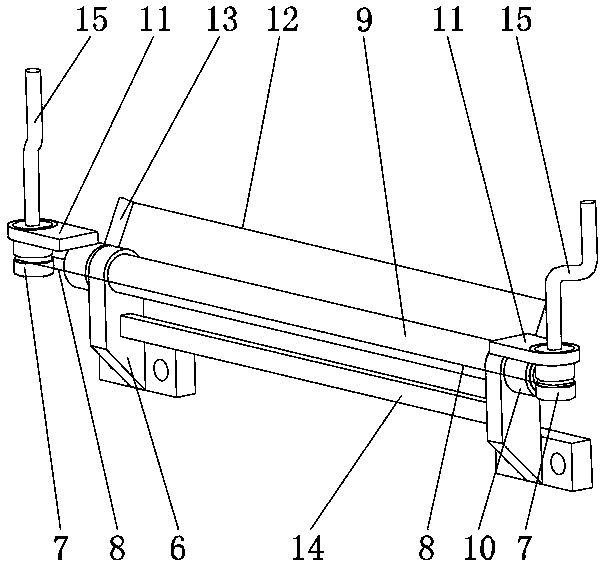

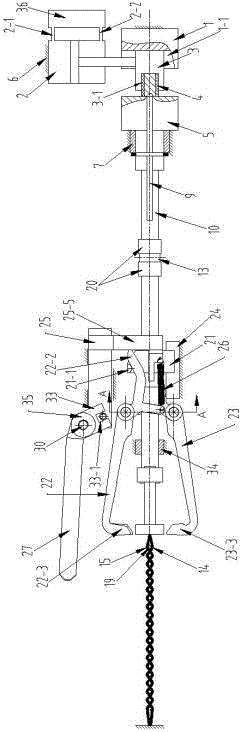

Warp beam yarn leasing device and leasing method thereof

ActiveCN106835422AShorten working timeRealization of Yarn PressingLeasingTextiles and paperYarnEngineering

The invention belongs to the field of textile machinery and discloses a warp beam yarn leasing device and a leasing method thereof. The warp beam yarn leasing device comprises a yarn pressing device and a straight reed carriage which are arranged front to back, and a straight reed is arranged on the straight reed carriage. The yarn pressing device comprises a mounting support, yarn pressing lifting devices, yarn pressing strips and yarn pressing strip connectors. The yarn pressing lifting devices in more than two pairs are fixed to two sides of the mounting support, and two ends of each yarn pressing strip are connected to the corresponding pair of yarn pressing lifting devices through the corresponding yarn pressing strip connectors. The warp beam yarn leasing device and the leasing method thereof have advantages that by adoption of the yarn pressing strips for replacement of traditional iron rods, operation time is saved; one person can control ascending and descending of the yarn pressing strips through a switch to realize yarn pressing, two-person operation is avoided, operator quantity is decreased, and one person can complete yarn pressing and leasing operations in ten minutes finally, so that production efficiency is greatly improved.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Production process of yarn-dyed double-mercerized knitted fabric

InactiveCN104762785AHigh color fastnessFeel goodMercerising of yarns/threads/filamentsSingeingYarnColour fastness

The invention discloses a production process of a yarn-dyed double-mercerized knitted fabric, relating to the processing field of garment materials. The yarn-dyed double-mercerized knitted fabric is produced by using all-cotton combing piled yarns as a raw material and adopting five steps of yarn singing, twisting, mercerizing, pulsating and dewatering and drying. According to the production method of the yarn-dyed double-mercerized knitted fabric, provided by the invention, the steps are simple, the operation is convenient, a knitted fabric product which has a real-silk like luster, a smooth and full hand feel, an extremely small shrinkage rate, an excellent color fastness, a drape effect and good gas permeability can be produced, and the demand of a consumer can be met.

Owner:ANHUI CHUANGRONG CLOTHING ACCESSORIES

Automatic opening and closing device for hank reels of hank reeling machine

InactiveCN103290587AHigh degree of automationHigh positioning accuracyLeasingOther manufacturing equipments/toolsYarnMotor drive

The invention relates to an automatic opening and closing device for hank reels of a hank reeling machine. The hank reels are movably connected with a spindle through a parallelogram mechanism; an AB connecting rod in the parallelogram mechanism is connected with one push rod through a BE driving connecting rod; each push rod is fixedly connected with a nut which is connected with a belt pulley through a screw rod; and the belt wheels are synchronous toothed belt wheels. According to the automatic opening and closing device, rectilinear motion of a screw rod pair is used, the four-bar linkage hank reels are driven by the push rods, and expansion and reduction of the outer diameter of each reel are finished. The automatic opening and closing device has the advantages that the motor-driven degree of automation is high, the reel positioning accuracy is high, and the self-locking is reliable; the reels can be positioned in multiple appointed positions, so that requirements for different reel circumferences of various yarns in hank reeling can be met flexibly; and the device is simple in structure, convenient to mount and low in cost.

Owner:SHANGHAI CORAL TEXTILE MACHINERY

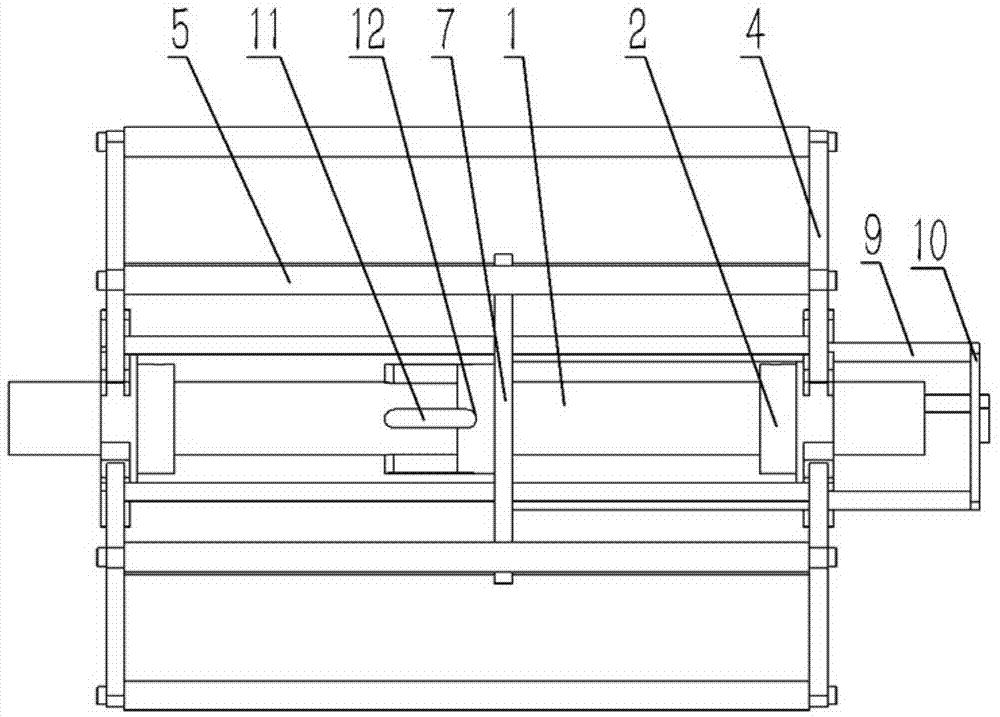

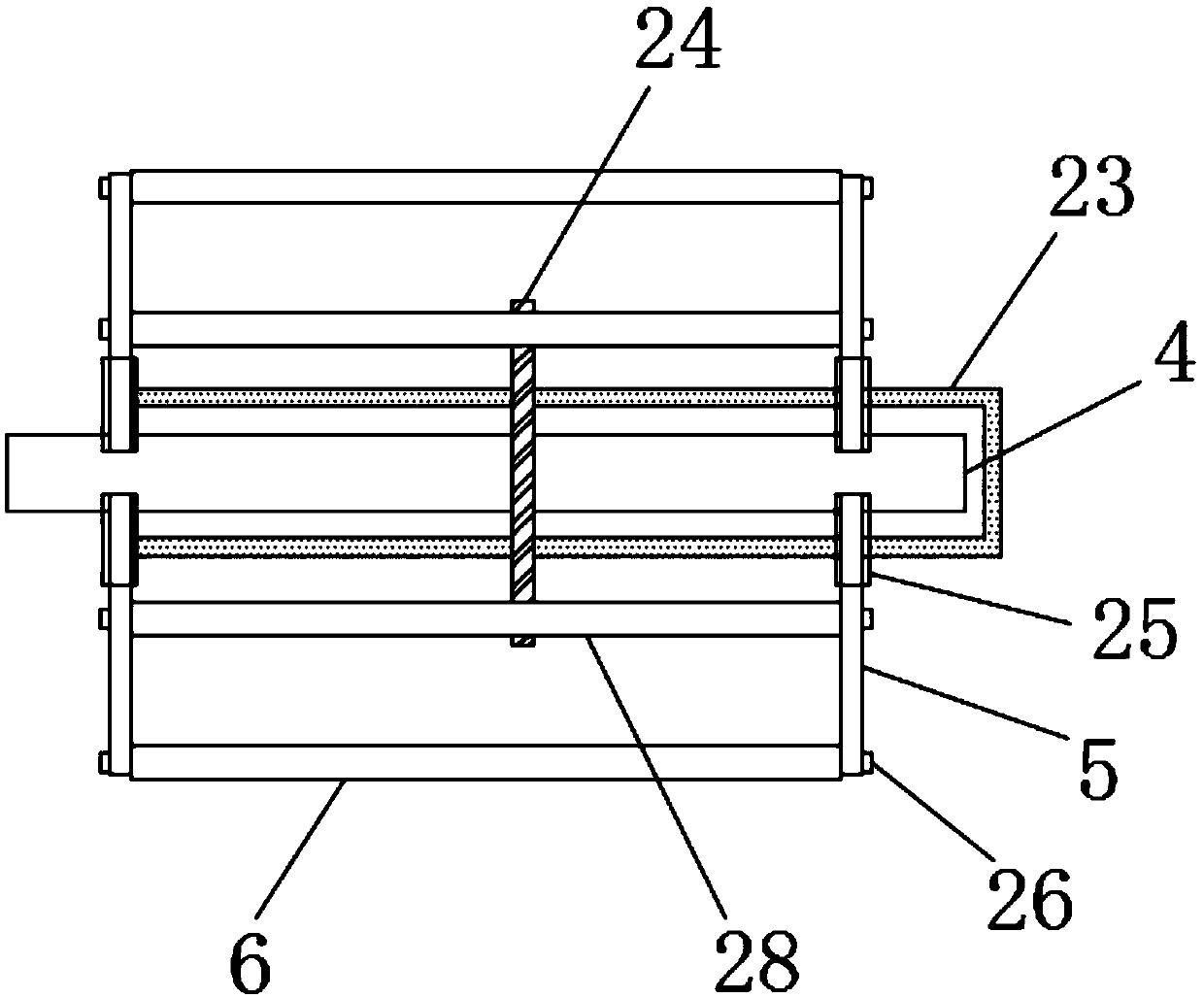

Multi-layer yarn leasing machine

ActiveCN109913999AGuaranteed validityImprove work efficiencyLeasingOther manufacturing equipments/toolsYarnReciprocating motion

The invention discloses a multi-layer yarn leasing machine. The multi-layer yarn leasing machine comprises a mounting frame, a supporting unit mounted on the mounting frame and a multi-layer leasing unit, wherein the supporting unit is used for clamping and tensioning multiple layers of yarn and supporting the multi-layer leasing unit to reciprocate on the supporting unit to complete selection, splitting and leasing of the yarn. Compared with the prior art, the multi-layer yarn leasing machine has the advantages that the function of simultaneous leasing of multiple disk heads on one leasing machine is achieved, leasing is carried out on multiple layers of yarn of multiple weaving beams or multiple layers of yarn of a single weaving beam, and the multiple layers of yarn are orderly combinedinto a same layer of yarn according to textile pattern needs and alternately leased so that one piece of cloth can have different kinds of yarn or different colors after weaving, a required number ofyarn layering mechanisms can be freely added according to the needs of field work, the effectiveness of the motion stroke of a shuttle selection mechanism is ensured, and the working efficiency of equipment is improved.

Owner:SHENZHEN HAYHON EQUIP TECH

Method and auxiliary device for leasing threads into guide elements of a handling device for handling threads and a handling device of this type

InactiveUS7000296B1Rapid and secure leasingSimple and rapid leasingFilament handlingWarping machinesEngineering

Owner:MENSING HEINRICH JOHANN

Adjustment mechanism and method for automatic adjustment of multilayer yarn screen edge layer difference

ActiveCN110629373AThe left and right position gap is reduced or eliminatedContinuously workingLeasingAuxillary apparatusYarnAutomatic control

The invention provides an adjustment mechanism and method for automatic adjustment of multilayer yarn screen edge layer difference. The adjustment mechanism comprises a controller, a yarn camera recognition mechanism, a first pressing mechanism and a second pressing mechanism. The yarn camera recognition mechanism is used for judging layer difference distance of different layers of yarn screen edges, the first pressing mechanism is used for fixing one end of multilayer yarn screens, and the second pressing mechanism is used for fixing the other end of the multilayer yarn screens. The first pressing mechanism comprises a fixed pressing box for fixing different layers of the yarn screens, and the second pressing mechanism comprises a supporting frame and a plurality of movable pressing boxeson the supporting frame. The invention further provides an adjustment method for automatic adjustment of multilayer yarn screen edge layer difference. The adjustment mechanism and the method have advantages that bilateral positional difference of different layers of yarn edges can be judged through the yarn camera recognition mechanism, the corresponding movable pressing boxes are automatically controlled to move bilaterally to reduce or eliminate the bilateral difference of the yarn edges of closer layers, and accordingly quick and continuous operation of automatic equipment can be realized.

Owner:SHENZHEN HAYHON EQUIP TECH

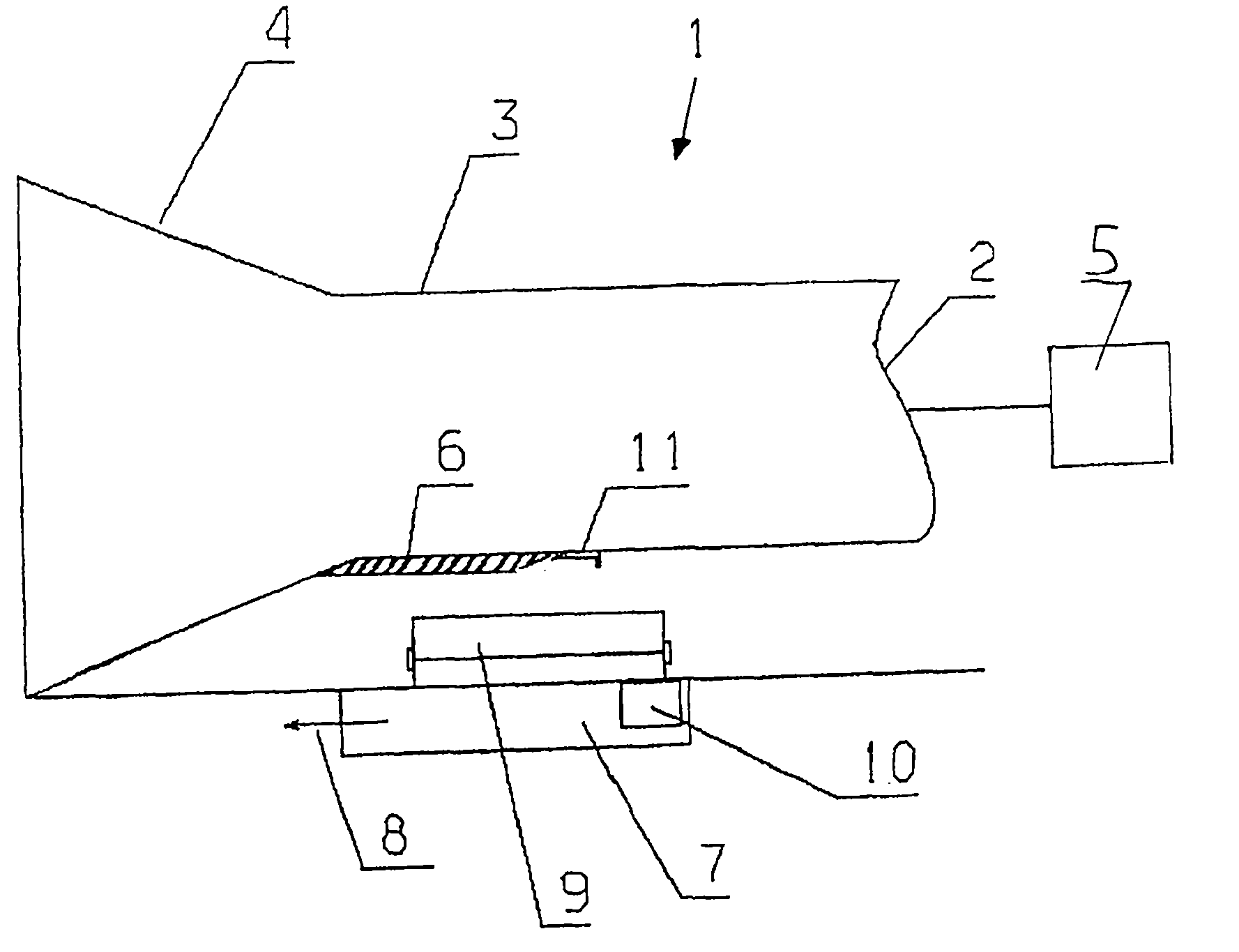

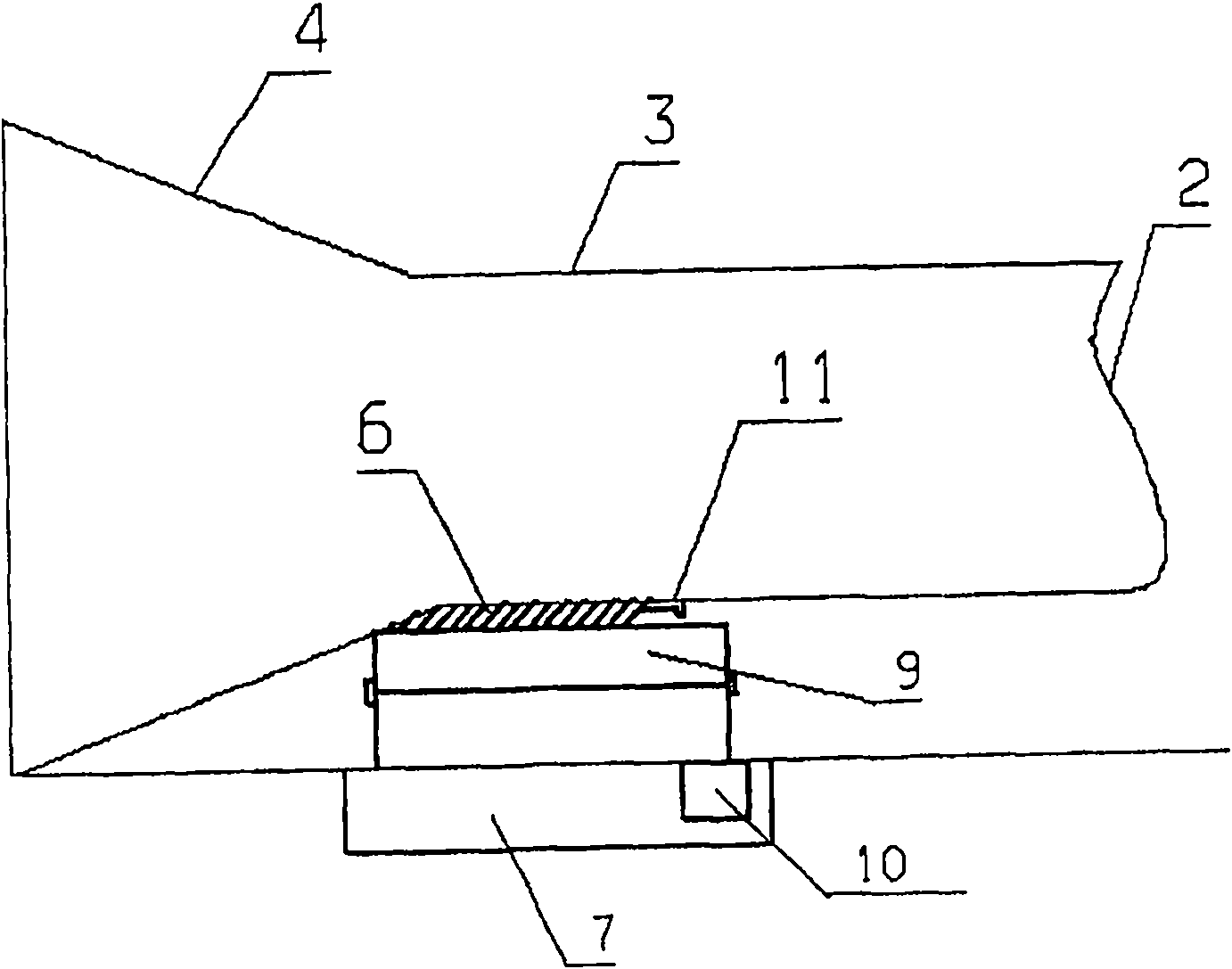

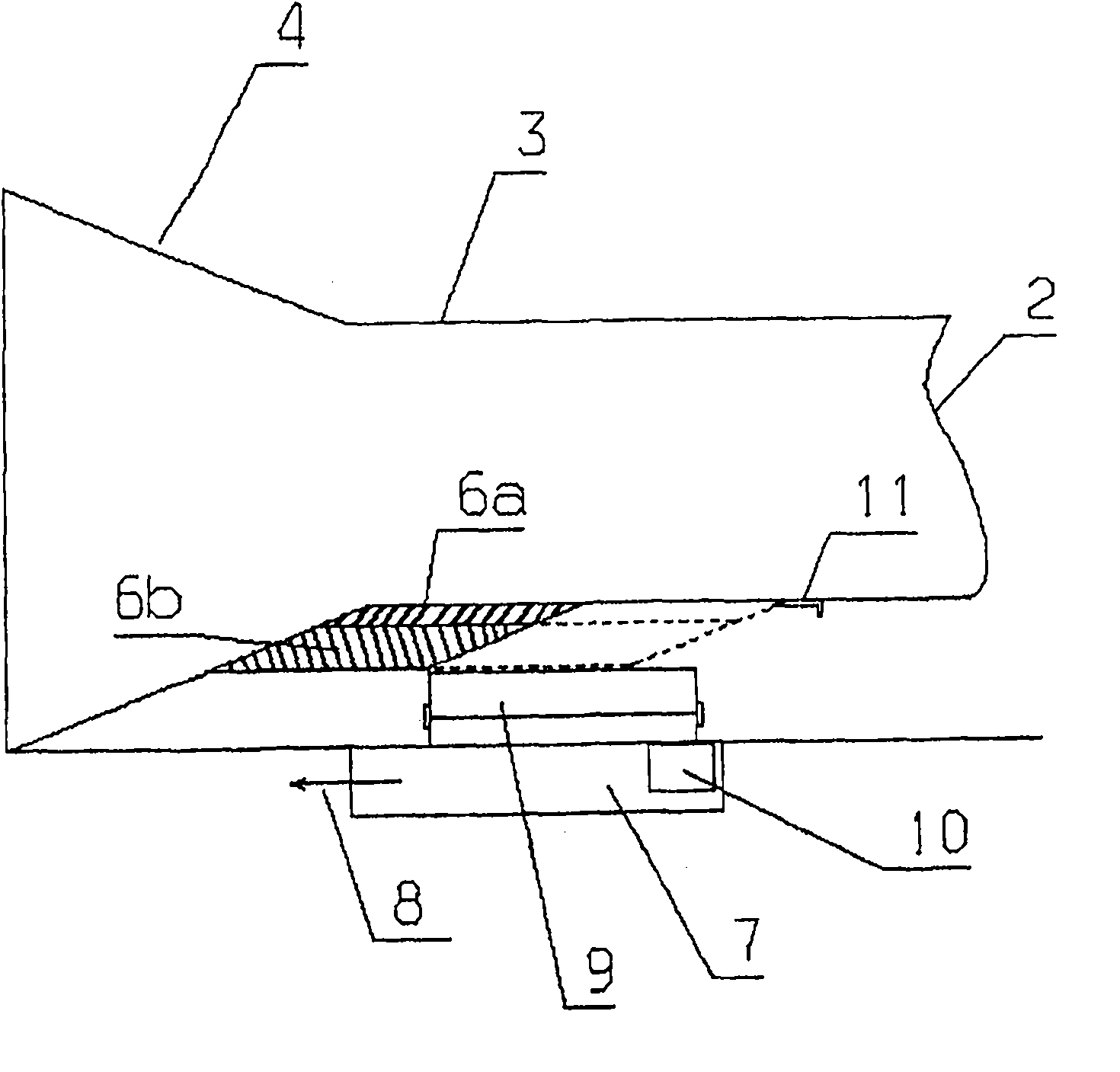

Method for manufacturing warp and conical warping device

The invention relates to a method for manufacturing warps and a conical warping device. According to the method, a warping roller (2) is rotated and at least one belt formed from yarn sheets is winded on the warping roller (2) so as to form a yarn roll (6), wherein at least one internal distributing device is used which is provided with a handle (11) at an end part protruding out of the yarn roll (6), and the handle has a predetermined radially-extending part. The purpose is to expand the possibility for influencing the yarn roll structure. Thus it is specified that when the yarn roll (6) reaches a radial thickness which at least corresponds to the radially-extending part of the handle (11), a pressure roller (9) is leaned against the yarn roll (6).

Owner:KARL MAYER STOLL R&D GMBH

Reeling rack

InactiveCN105780238AEasy to operateIncrease tightnessLeasingOther manufacturing equipments/toolsYarnSpinning

The invention discloses a reeling rack which comprises a sleeve, wherein a separation plate is installed in the middle of the sleeve; studs are installed on the front side and the rear side of the separation plate respectively; multiple through holes are formed in a crossed manner at intervals on the sleeve walls located on the front and rear sides of the separation plate; reeling arms are installed on the inner side of the through holes; the inner sides of the reeling arms are fixed on the studs; a bearing is installed on the middle part of the separation plate; a spindle is installed on the inner side of the bearing; a rear bearing is installed on the rear side of the spindle; and a supporting shaft is installed on the bottom of the rear bearing. The reeling rack disclosed by the invention is characterized in that operations are simple; through crossed disposition of the front and rear through holes, multiple sets of reeling arms can be disposed, so that the shape of the reeling arms can further approach a round shape, tightness of yarn winding is increased, and spinning quality is ensured; automatic adjustment and driving can be carried out by a power motor according to spinning speeds; the height of a yarn installation place can be adjusted by a telescopic rod; and yarns can be supplied uniformly by yarn grasping grains, and an elastic tensioning mechanism can become more compact.

Owner:TIANJIN HAOSHI CARPET

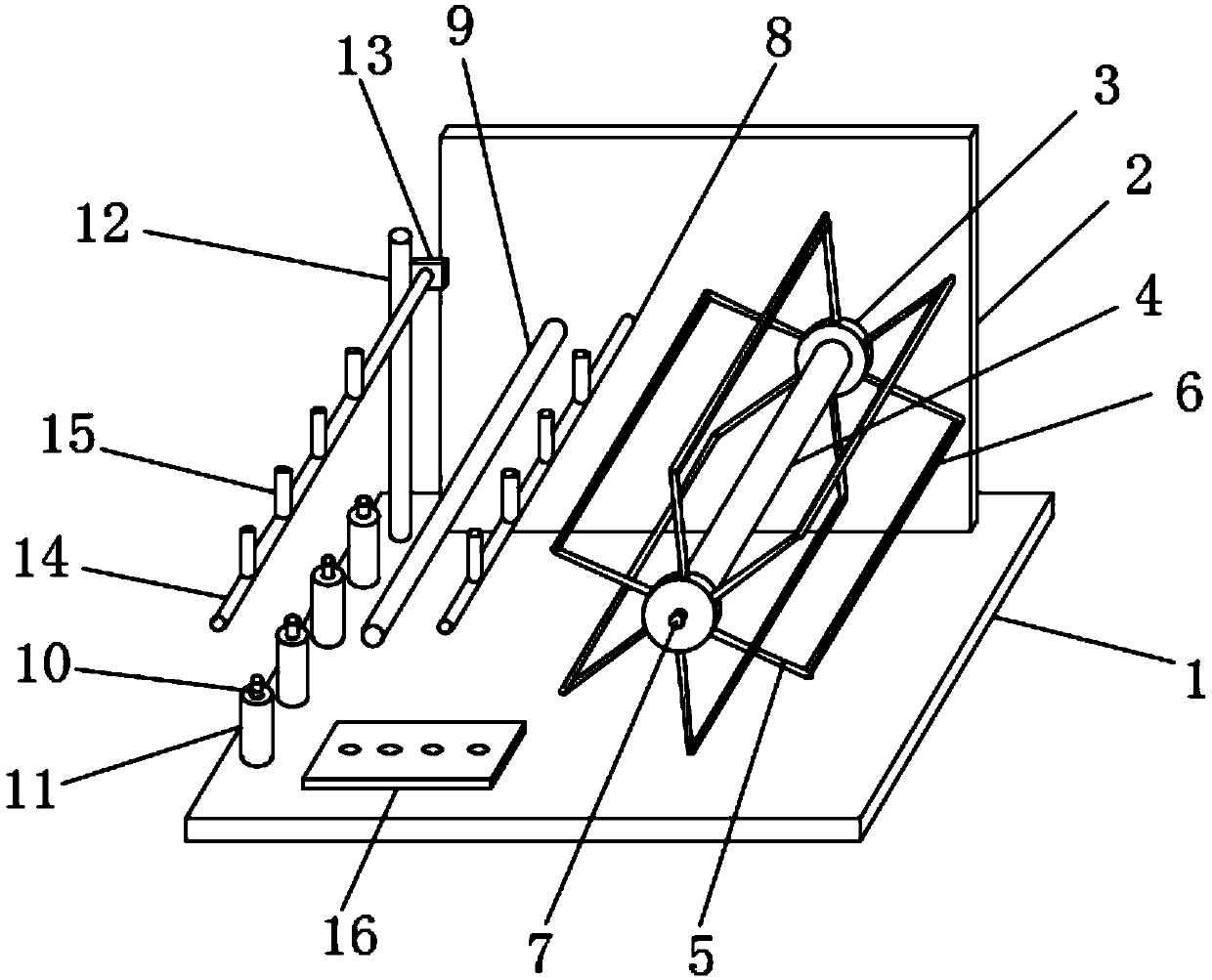

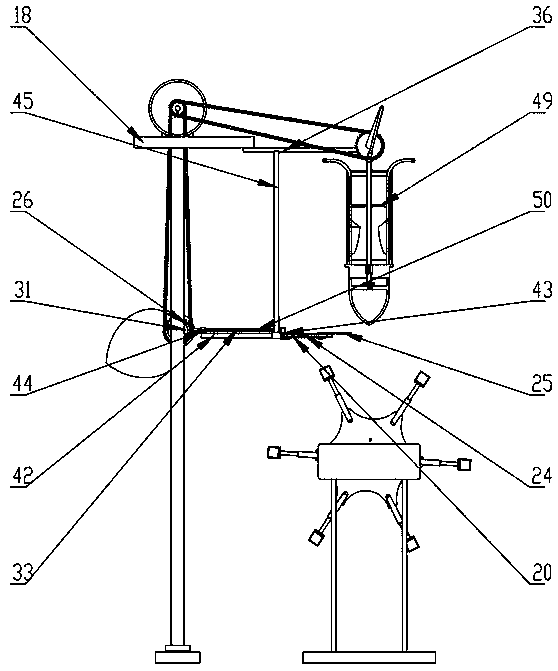

Multicolor warp sample hank reeling machine

InactiveCN104005136AAccurate CountingEasy to wrapLeasingOther manufacturing equipments/toolsYarnAuto encoders

The invention discloses a multicolor warp sample hank reeling machine. The multicolor warp sample hank reeling machine comprises a base, an upward rail and driving device, a yarn feeding and winding device, a U-shaped vertical rod splitting device, a tensioned yarn guide rack device, a yarn selecting bar device and a detecting and counting device. The multicolor warp sample hank reeling machine automatically count the number of turns of wound yarns through an automatic encoder and accordingly achieve precise counting of the number of turns of yarns of different colors; for achieving 8-shaped winding, the U-shaped vertical rod splitting device rotates intermittently rot control the yarns on the tensioned yarn guide rack device to penetrate the U-shaped vertical rod splitting device, and specifically, the intermittent movement of thee U-shaped rod splitting device comprises that a photoelectric sensor detects a yarn guide hook, and a control air cylinder drives gears and racks to work; by precisely counting the number of reciprocating movements of the yarn guide hook through the automatic encoder directly connected with the photoelectric sensor, the multicolor warp sample hank reeling machine achieves precise counting the number of turns of the yarns and accordingly facilitates precise winding of the various yarns of different colors.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

Hanked yarn integral beam-splitting method and beam-splitting device

A hank integrally tread splitting method and thread splitter belongs to the technical field of textile, in particular to a hank thread splitting method and thread splitter. The hank integrally thread splitting method is that the hank sold in bundles is wound into cone yarn by a rewinding machine; the cone yarn is splitter into necessary thread by the thread splitter; and then the split thread is fixed by a fixed thread; finally the split thread is run down and combined into hank. Wherein, the thread splitting device essentially consists of a support bracket, a roller, a rocking shaft and a control rod; the roller is fixed on the support bracket by the rocking shaft; the control rod is provided with a yarn lead-in eye; one end of the control rod is provided with thread quantity control calibration and is arranged in a control rod groove at the front part of the support bracket. When the consumers use the hank, they only need to pull and break the fixed thread to use one of the thread bundles, to prevent the thread bundles from mess; and the thread bundles can also be singly sold, which is very convenient.

Owner:罗维秀

Threading mechanism for warping machine

InactiveCN109837632AReduce labor intensitySimple structureLeasingTextiles and paperUltimate tensile strengthLine segment

The invention relates to the field of warping operation assisting equipment and discloses a lease thread threading mechanism for a warping machine. The threading mechanism is fixedly arranged on a warping machine frame and positioned between a yarn guide roller and an adjustable reed structure of the warping machine and comprises supporting seats on left and right ends of the frame, pulleys identical in height are horizontally and rotationally arranged on the supporting seats, a closed pull thread loop sleeves the pulleys at the left and right ends, two ends of the closed pull thread loop bypass outer end faces of the two pulleys respectively, and portions, between the two pulleys, of the pull thread loop are two linear sections in horizontal arrangement at the same height. When one of thepulley rotates, the linear sections of the pull thread loop are driven to move linearly while the other pulley is driven to rotate through the pull thread loop, the pull thread loop penetrates warpsof the warping machine, each warp bypasses the upper end or the lower end of the pull thread loop, and adjacent warps are positioned at different ends of the pull thread loop. The threading mechanismis structurally simple and practical and quick and convenient to thread, labor intensity is reduced, and operating efficiency is improved.

Owner:SICHUAN YUYANG TEXTILE

Thread feeding method, warp thread feeding method, thread feeder and weaving method

Owner:SHO JINSOO +1

Warp strand unbinding device

ActiveCN105671724AAccurate entryReduce manufacturing costLeasingAuxillary apparatusStructural engineeringMachine

The invention relates to a warp strand unbinding device. The device comprises a swing driving mechanism, a movement driving mechanism, an actuation mechanism and a warp isolation mechanism. The swing driving mechanism comprises a cylinder, a support, a sliding block connected with a piston rod of the cylinder and arranged in a support groove in a matched mode and an eccentric shaft. The eccentric end of the eccentric shaft is connected with a cushion block in a sliding block groove. One end of a deflector rod of the movement driving mechanism is arranged in a cylindrical surface cam spiral groove in a matched mode. The actuation mechanism comprises a rotary shaft rotationally connected to a drawing-in machine frame and a U-shaped fork arm fixed to one end of the rotary shaft. The other end of the rotary shaft is connected to the rotation center of the eccentric shaft in a matched mode. The other end of the deflector rod is connected with a lantern ring of the rotary shaft. An upper twisted rope and a lower twisted rope penetrate through two end arms of the fork arm respectively. Two lugs of the warp isolation mechanism make contact with the bevel edges of two arm holding levers. Two suspended edges of the two-arm support are connected with the two arm holding levers through tension springs respectively. Through the warp strand unbinding device, warp stranded by the two twisted ropes can be unbound piece by piece automatically and quickly, installation and debugging are convenient, manpower is saved, work efficiency is improved, and cost is low.

Owner:YONGXUSHENG MACHINERY TECH CHANGZHOU CO LTD

Automatic skein braiding machine

The invention discloses an automatic skein braiding machine, and belongs to the technical field of yarn skein twisting in textile machinery. In the yarn skein twisting process, according to a traditional spinning yarn skein twisting method, skein braiding yarns are manually and repeatedly connected in series and knotted to complete the skein bradding work, the labor cost of the process is high, and the efficiency is low. By aiming at the problem, the invention designs a skein braiding machine consisting of vertically moving yarn hooking claws and a transversely moving knotting device. The skein braiding machine is used for replacing manual work to perform serial connection and knotting action on skein braiding yarns, so that the skein braiding operation in the spinning yarn skein twistingprocess is completed. After the automatic skein braiding machine completes the skein braiding operation, the yarn distribution quantity is uniform, and the efficiency is greatly improved. Important practical significance is realized on the development of textile industry.

Owner:SICHUAN AGRI UNIV

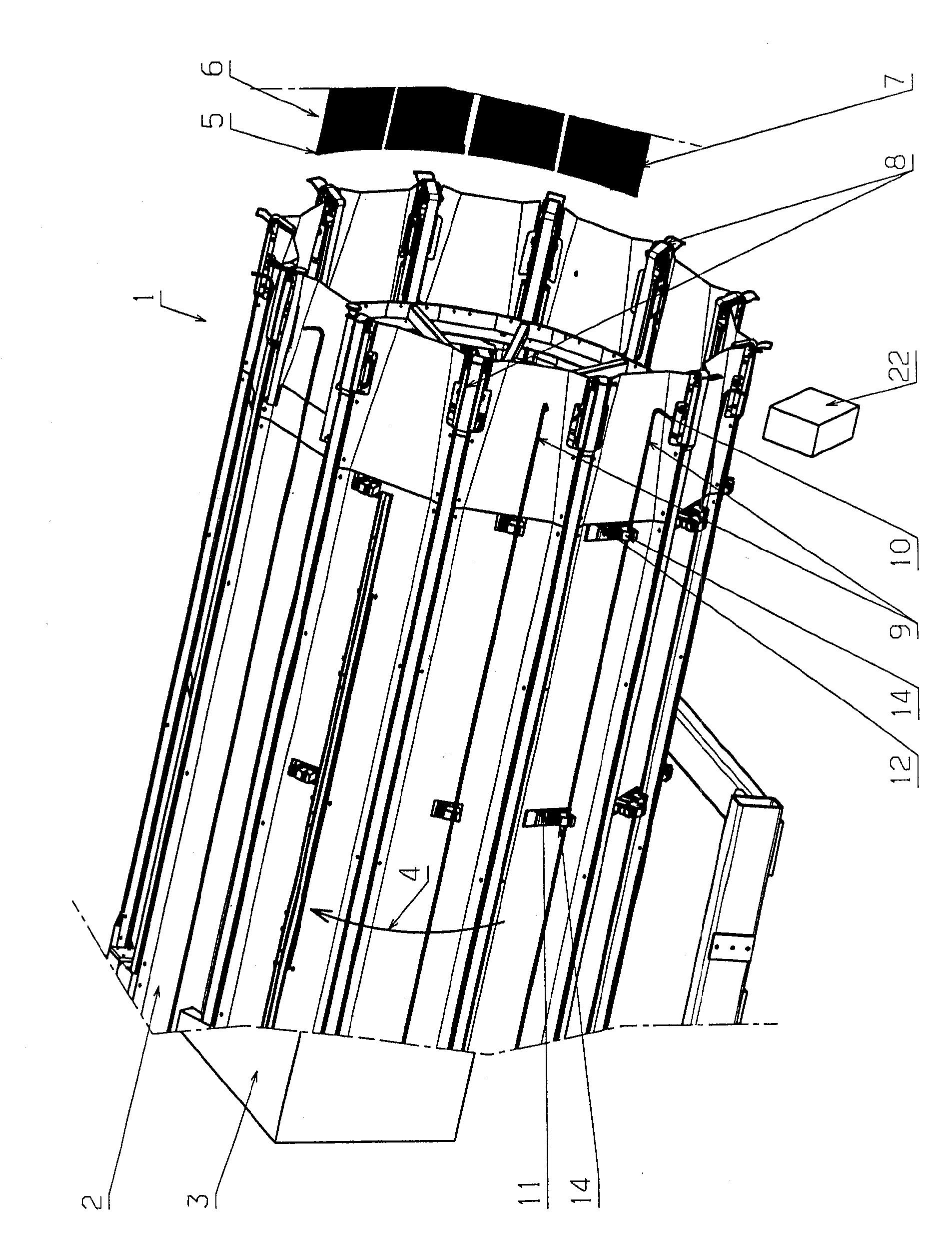

Yarn arranging machine

The invention relates to a yarn arranging machine for forming a warp with a desired yarn arrangement from a plurality of yarn layers, said yarn arranging machine comprising; an open collector comb for receiving the plurality of yarns according to the desired yarn arrangement; a yarn releasing device comprising at least one support member for supporting the yarns of a respective yarn layer selected from the plurality of yarn layers; releasing driving means configured to move the free end of the support member in the transverse direction relative to the selected yarn layer to free a passage for the supported yarns of the selected yarn layer toward the collector comb; collector driving means configured to cause a relative movement between the collector comb and the selected yarn layer at least in the transverse direction (T). Further, a controller unit is included. The invention further relates to a method for preparing a warp with a desired yarn arrangement from a plurality of separated yarn layers overlapping each other across the width of the plurality of yarn layers.

Owner:STAUBLI SARGANS AG

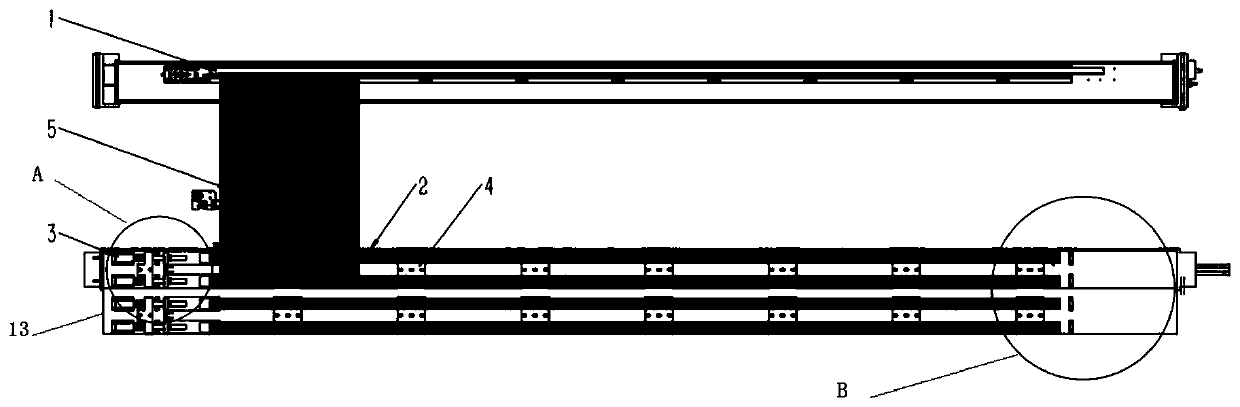

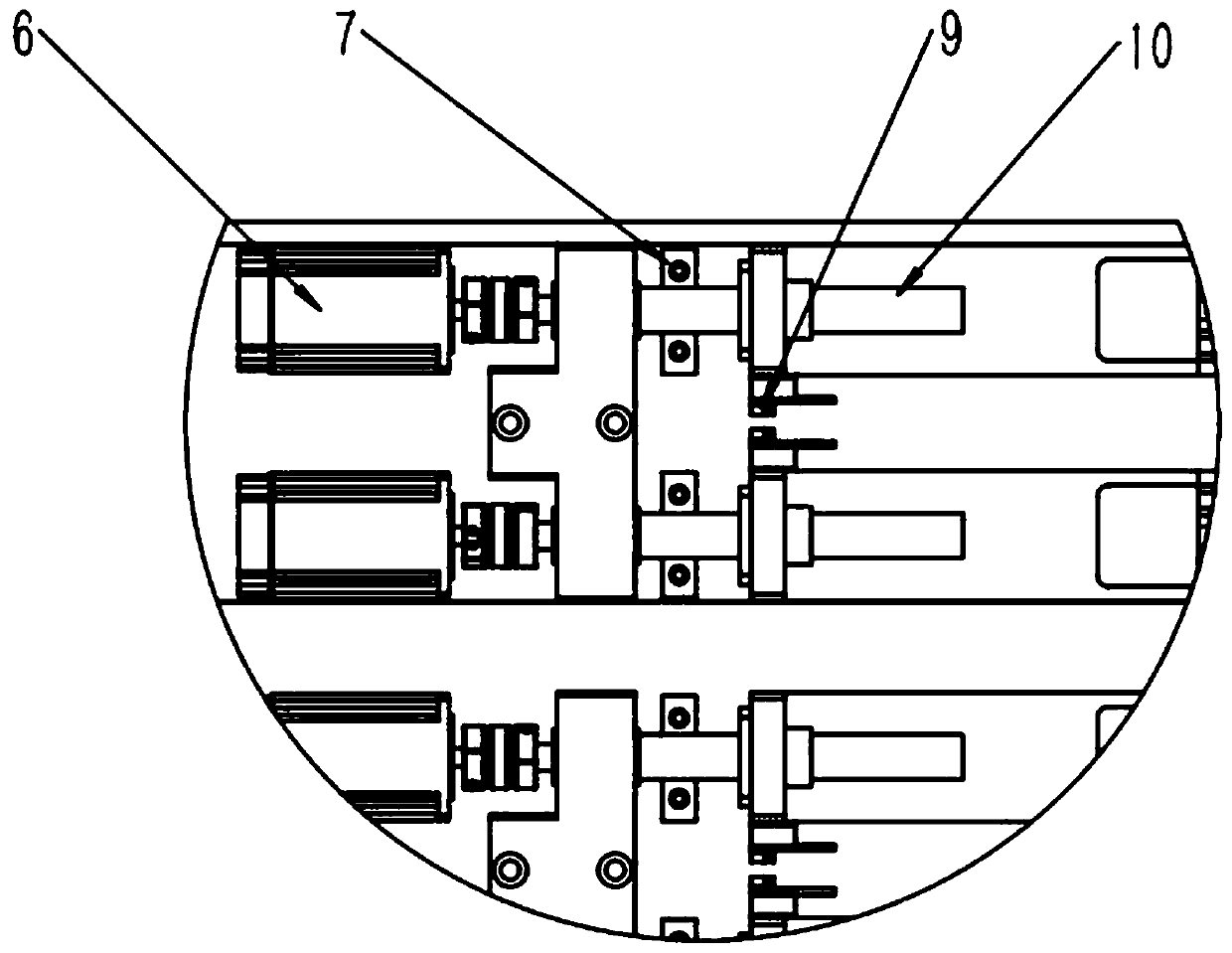

Sample warper

ActiveCN102851819AHigh warping speedEasy to removeWarping machinesLeasingSoftware engineeringMechanical engineering

The sample chain wrapping machine (1) has a warping drum (2), a thread guide assembly (7) with a thread guide (6), and multiple sub bars (9). The thread guide and the warping drum are movable relative to each other in a rotation direction around the axis of the warping drum. The sub bars are positioned in different radial positions relative to the axis of the warping drum. The sub bars distributed over their length are detachably connected with two positioning drives (14) and are displaceable by the positioning drives. A sensor arrangement (22) is connected with the positioning drives.

Owner:KARL MAYER STOLL R&D GMBH

Natural colored cotton slashing technology

InactiveCN101177854AReduce head breaksImprove permeabilityLeasingTextile treatment by pouringYarnEngineering

The invention provides a novel concept of natural colored cotton sizing and a method thereof. When the natural colored cotton is clear-starched, penetration of serous fluid to the yarn is improved; after the yarn enters a drying area, the holding and control of a serous film to the yarn is enhanced; unwinding tension is properly enhanced, and the coverage of serous material to the yarn is improved so as to lead the weaving efficiency of the yarn on a weaving machine to be greatly improved; few broken ends exist during the clear-starching process; sizing junk can meet requirement; clear-starching rate of the yarn is as high as 7.5 percent plus or minus 0.5 percent; sizing hairs adhesiveness and the strength of the yarn are improved obviously; the efficiency of the weaving machine is over 96.4 percent and the production value of the product is increased.

Owner:SHENGHONG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com