Reeling rack

A winch and skein technology, which is applied in the field of winch, can solve the problems that the yarn cannot be twisted well, the spinning process is not fine enough, and the spinning speed cannot be automatically adjusted, and the elastic tensioning mechanism can be achieved. The effect of tightness, ensuring spinning quality and improving tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

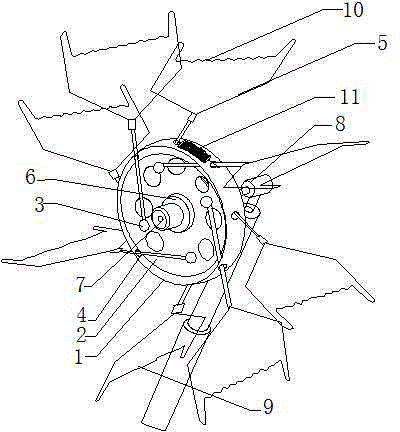

[0016] Such as picture A hank creel shown in 1 includes a sleeve 1; an isolation plate 2 is installed in the middle of the sleeve; studs 3 are respectively installed on the front side and the rear side of the isolation plate; A plurality of through-holes 4 are arranged at intervals on the sleeve wall; a skein arm 5 is installed on the inside of the through-hole 4; the inner side of the skein arm 5 is fixed on the stud 3; the middle part of the isolation plate 2 is installed with a bearing 6. A shaft 7 is installed inside the bearing 6; a rear bearing 8 is installed on the rear side of the shaft 7; a support shaft 9 is installed at the bottom of the rear bearing 8; four shafts are installed on the front and rear sides of the sleeve 1 respectively. The skein arms 5; elastic tensioning mechanisms 11 are installed between the adjacent skein arms 5.

Embodiment 2

[0018] Such as picture A hank creel shown in 1 includes a sleeve 1; an isolation plate 2 is installed in the middle of the sleeve; studs 3 are respectively installed on the front side and the rear side of the isolation plate; A plurality of through-holes 4 are arranged at intervals on the sleeve wall; a skein arm 5 is installed on the inside of the through-hole 4; the inner side of the skein arm 5 is fixed on the stud 3; the middle part of the isolation plate 2 is installed with a bearing 6; the inner side of the bearing 6 is equipped with a rotating shaft 7; the rear side of the rotating shaft 7 is equipped with a rear bearing 8; the bottom of the rear bearing 8 is installed with a support shaft 9; the rear side of the rear bearing 8 can also be installed with a power motor (not picture shown); the front side and the rear side of the sleeve 1 are respectively equipped with four skein arms 5; elastic tensioning mechanisms 11 are installed between the adjacent skein arms 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com