Hanked yarn integral beam-splitting method and beam-splitting device

A beam splitting and skeining technology, which is applied in the textile field, can solve problems such as unusable yarns and unclear knotting of yarns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

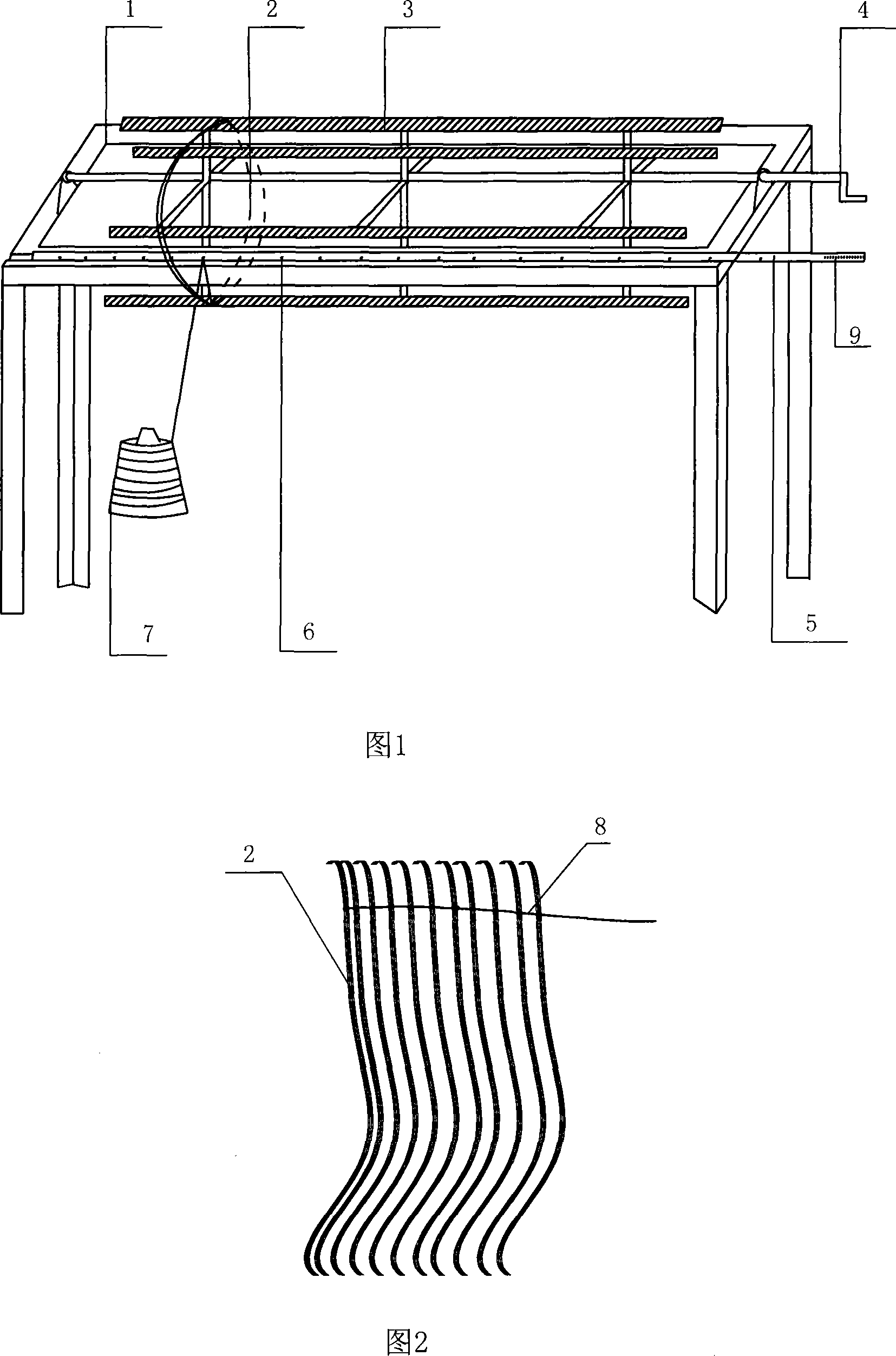

[0022] First, the acrylic skein purchased on the market is rewound into cheese 7 with a rewinding machine, and the cheese 7 is placed under the drum 3 of the beam splitting device, and the drum 3 is fixed on the support frame 1 through the rocking shaft 4 . Insert the end of the bobbin yarn into the introduction eye 6 on the control rod 5 and fix it on the roller 3, shake the rocker shaft 4 and drive the roller 3 fixed on it to roll, wind the yarn on the roller 3, and the roller 3 rolls once The circle of yarn is also wound once. After 10 rounds, push the control lever forward for a control scale of 9, and then continue to wind the yarn. After 10 rounds, push a control scale of 9, and wait until 35 control scales are used up. After the scale 9, stop winding, use a fixed line 8 to tie each wire bundle 2 into a relatively independent wire bundle, and then get off the machine to form a bundled wire bundle combined skein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com