Threading mechanism for warping machine

A warping machine and threading technology, which is applied in the direction of textiles and papermaking, tool manufacturing, and stranding, etc. It can solve the problems of low threading efficiency, long time-consuming, and worker fatigue, and achieve fast and convenient threading, low cost, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

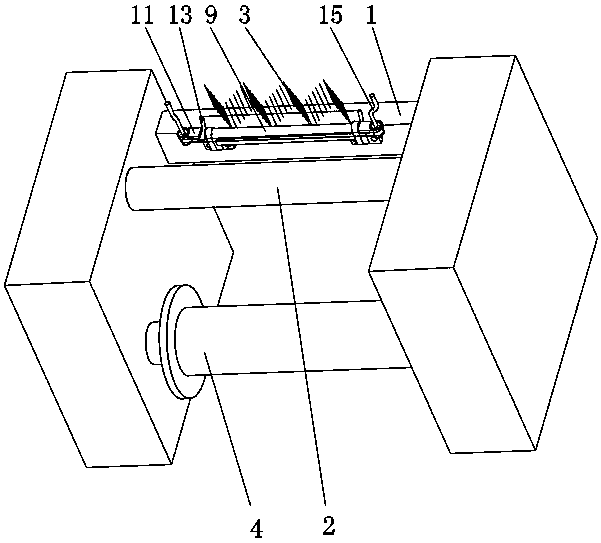

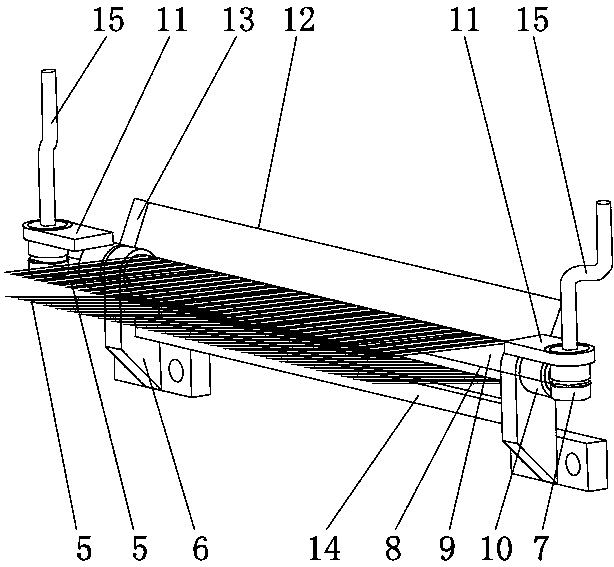

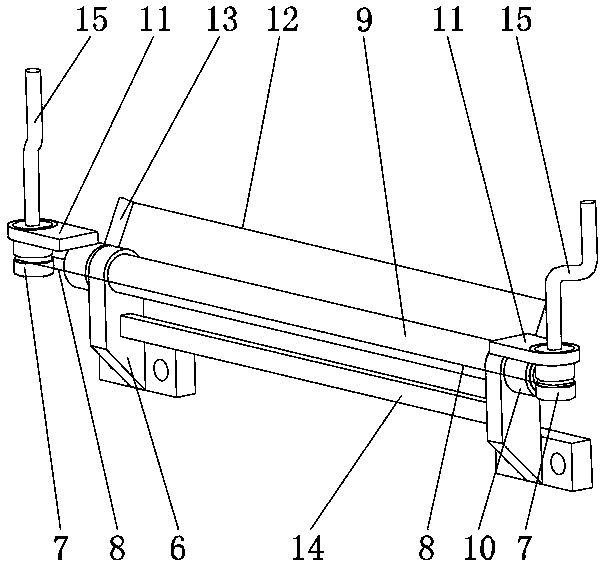

[0019] like Figures 1 to 3 As shown, it is used for the threading and splitting mechanism on the warping machine. The threading mechanism is fixedly arranged on the frame 1 of the warping machine, and is located between the guide roller 2 and the telescopic reed structure 3 of the warping machine. The threading mechanism includes a fixed The supports 6 arranged at the left and right ends of the frame 1 are horizontally rotated and provided with pulleys 7 of the same height, and a closed traction wire ring 8 is sleeved on the pulleys 7 at the left and right ends, and the traction wire ring 8 can be a steel wire Or a thin wire rope, which is specifically set as a thin wire rope here, and its two ends go around the outer end faces of the two pulleys 7 respectively, and the part of the traction wire ring 8 that is located in the middle of the two pulleys 7 is a two-section straight line section, and the two-section pulley The straight section is horizontal and at the same height....

Embodiment 2

[0024] like figure 2 and 3 As shown, on the basis of Embodiment 1, it also includes warp yarn limit iron wire 12, and the two ends of warp yarn limit iron wire 12 are fixedly connected with two supports 6 respectively, specifically, the two ends of warp yarn limit iron wire 12 pass through respectively The fixing nail 13 is fixedly connected with the collars 10 at both ends, and the warp yarn limiter wire 12 is lower than the apex of the telescopic reed structure 3, preventing the warp yarn 5 from accidentally jumping to other warp yarn 5 intervals of the telescopic reed structure 3, causing the warp yarn 5 to be entangled, and the warp yarn limit The end of the position iron wire 12 is fixedly connected with the support 6 through a tension spring (not shown in the figure), so that when the warp yarn 5 is in contact with the warp yarn limit iron wire 12, the warp yarn limit iron wire 12 has a certain elastic buffer to prevent the warp yarn 5 from breaking .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com