Method for manufacturing warp and conical warping device

A warping and warp technology, applied in the field of warp manufacturing, can solve problems such as damage to the pressing roller, damage to the handle, and inability to achieve, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

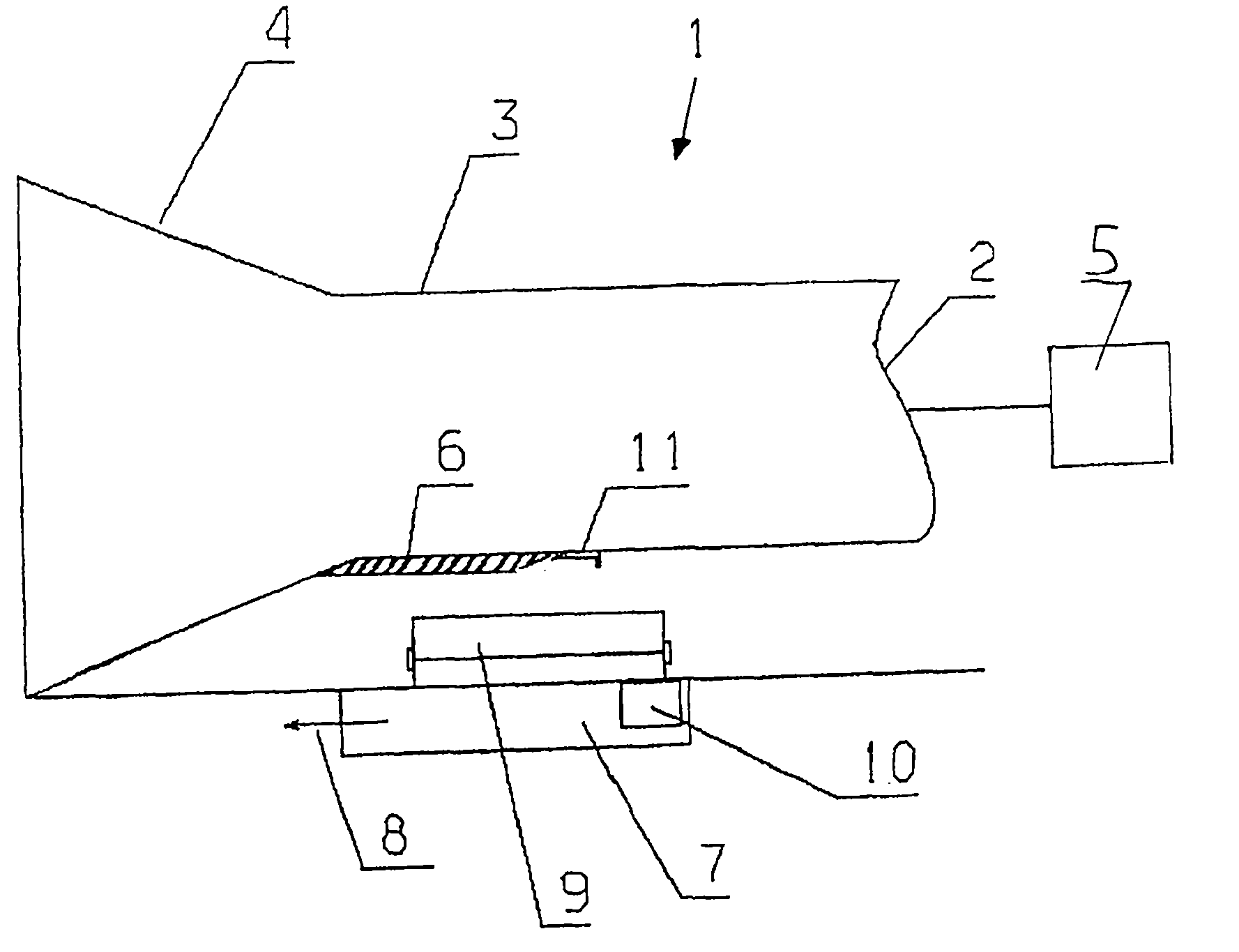

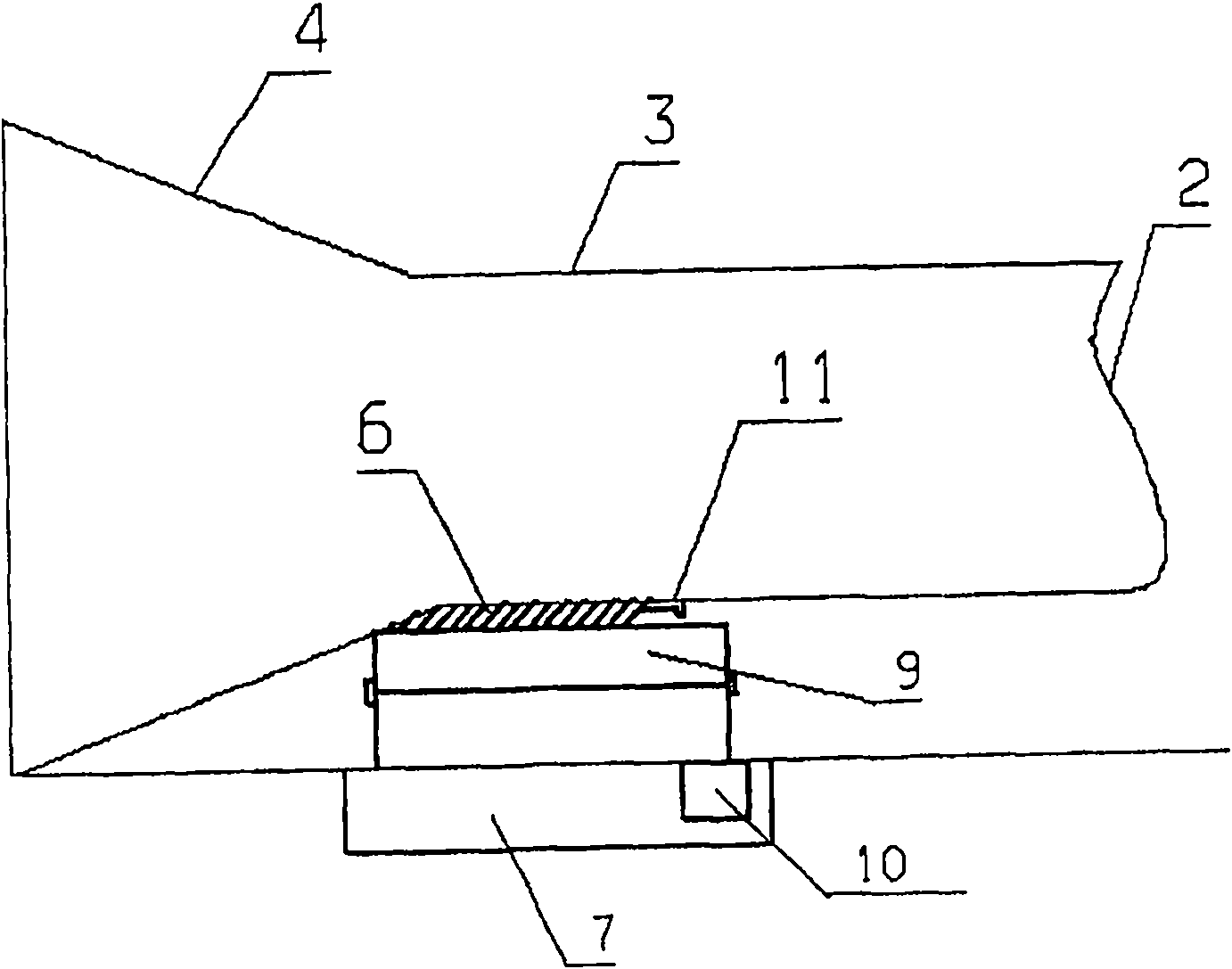

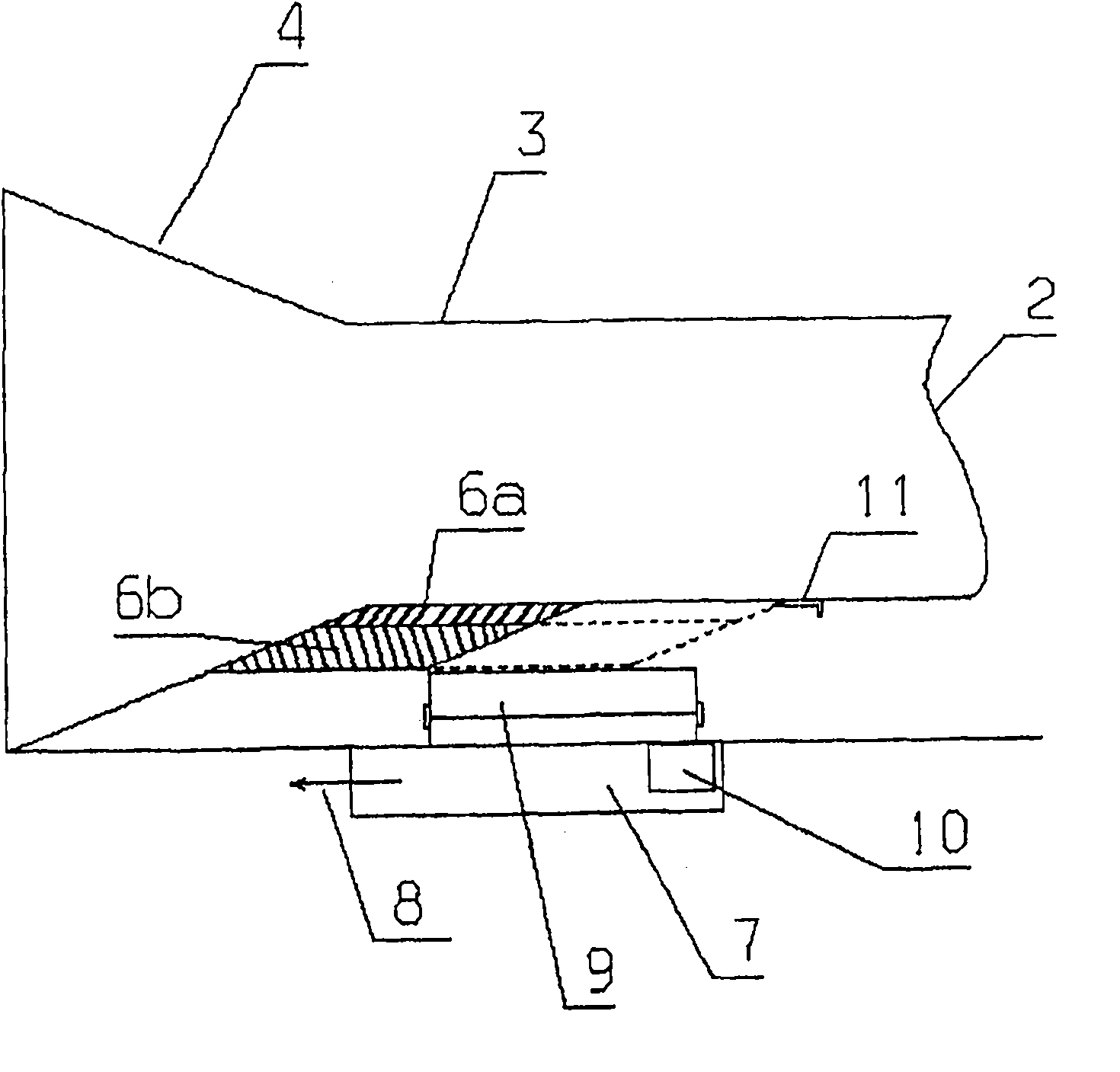

[0026] The conical warping machine 1 has a warping cylinder 2 with a cylindrical section 3 and a conical section 4 . The warping cylinders are rotated by a drive 5 which is only schematically shown.

[0027] A plurality of yarns are drawn parallel to one another from a creel, not shown in detail, in which a coil is arranged for each yarn. Sheets of yarns made up of yarns parallel to each other are also referred to as "stripes". When the warping cylinder 2 turns, such strips are drawn onto the circumference of the warping cylinder 2 and form the yarn reel 6 there.

[0028] For the sake of clarity, the reel 6 is shown here only on the lower edge of the warping cylinder 2 . Of course, the yarn reel 6 surrounds the warping cylinder 2 .

[0029] The lower layer of the strip is placed on the cylindrical section 3 . All other layers of the strip then move a short distance in the offset direction, that is, parallel to the axis of the warping cylinder 2 (to the left in the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com