Automatic skein braiding machine

An automatic, twisting technology, applied in the field of yarn twisting, can solve the problems of wasting time, low efficiency, high labor cost, etc., and achieve the effect of reducing the number of use, improving production efficiency, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

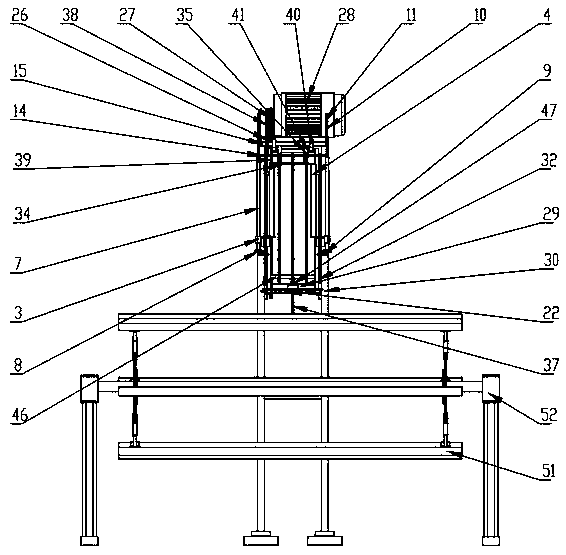

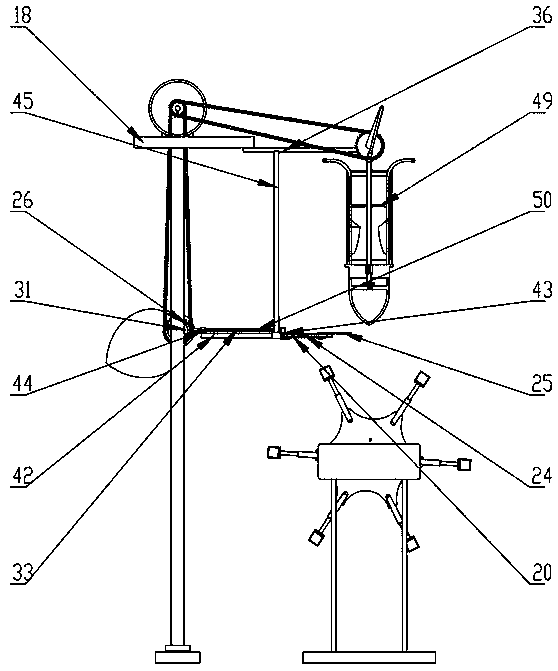

[0012] see figure 2 , image 3 , Figure 4 , an automatic braiding machine in the figure includes, beam 1 (17), longitudinal beam 1 (18), beam 2 (19), column 1 (30), column 2 (35), longitudinal beam (36), Side beam 1 (41), U-shaped frame (42), beam 3 (46), square steel guide rail (47), longitudinal beam 3 (48) are connected to form a frame structure; drive shaft 1 (15), motor (28), Rubber-coated pulley (22), sprocket 1 (26), sprocket 2 (27), shaft 1 (29), chain 1 (38), and chain 2 (39) form a transmission system; Thread hook 2 (2), hook thread claw 3 (5), hook thread claw 4 (6), hook thread claw 5 (12), hook thread claw 6 (13) two groups, use hook thread claw shaft 2 (9), spring 1 (49), etc. are connected, and are fixed in parallel by the spacing control rod (14), then the hook line claw shaft 2 (9) is connected with the hook line claw shaft 1 (8), and the mobile guide rod (7) , rod 2 (10), rod 1 (11) are sequentially connected to the drive shaft 1 (15) to communicate wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com